Electrolux Professional ECOE61T3L0 Service Manual

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

SERVICE MANUAL

ELECTRONIC BOARDS

SKYLINE OVEN 6-10-20GN

MAGISTAR OVEN 6-10-20GN

Document made by Product Care – Technical Training & Service – Vallenoncello PN/Italy

All the images and information of this document are property of ©Electrolux Professional Spa. This document

and all of its contents cannot be copied or used, in part or entirely without the written authorization of Electrolux

Professional Spa.

©Electrolux Professional Spa.

Doc. N. 595404A00

Edition 4 – 01 / 2020

2

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

REVISIONS UPDATE:

Foreword

The service manual (here in after Manual) provides the engineer with information necessary for correct

and safe use of the machine (or “appliance“).

The following must not be considered a long and exacting list of warnings, but rather a set of instructions

suitable for improving machine performance in every respect and, above all, preventing injury to persons and

animals and damage to property due to improper operating procedures.

All persons involved in machine transport, installation, commissioning, use and maintenance, repair and disassembly must consult and carefully read this manual before carrying out the various operations, in order to

avoid wrong and improper actions that could compromise the machine's integrity or endanger people.

If, after reading this manual, there are still doubts regarding machine use, do not hesitate to contact the Manufacturer or the Customer Care to receive prompt and precise assistance for better operation and maximum

efficiency of the machine. During all stages of machine assessment, always respect the current regulations on

safety, work hygiene and environmental protection. It is the user's responsibility to make sure the machine is

started and operated only in optimum conditions of safety for people, animals and property.

IMPORTANT

• The manufacturer declines any liability for operations carried out on the appliance without respect-

ing the instructions given in this manual.

• The manufacturer reserves the right to modify the appliances presented in this publication without

notice.

• No part of this manual may be reproduced without the consent of the manufacturer.

• This manual is available in digital format by:

o contacting the dealer or reference customer care;

EDITION

SERVICE

MANUAL

DESCRIPTION

DATE

1.00

First edition of service manual relative to SETTINGS & SOFTWARE ,

TOUCH / DIGIT electronic boards

Nov. 2019

1.01

Update of the S.M for new software version 4.3.7 on TOUCH ovens; Some

updates to Digit too. Updates in §:

2.1.1.3 ACCESSORIES, ENABLE (TOUCH)

2.1.1.5.9 BOILER MAINTENANCE (TOUCH)

2.1.2 SOFTWARE UPDATE LEVEL T,K (TOUCH)

2.1.2.5 PROGRAMMING PARAMETERS (TOUCH)

2.1.2.6 PNC & SER - JSON FILE (TOUCH)

2.2.5 BOILER MAINTENANCE (DIGIT)

4.1 ALLARMS - Eotd 70°C→ 100°C / Htd 90°C→ 115°C.

Dic. 2019

1.02

Update of the S.M for new chapters:

4.2 EH2O, LEVEL T,K, (TOUCH) – CLEANING ABORT

4.3 EH2O, LEVEL, B,C (DIGIT) – CLEANING ABORT

Dic. 2019

2

Update of the S.M for new software version 1.0.18 on DIGIT ovens.

Update of chapter § 4.3 EH2O, LEVEL, B,C (DIGIT) – CLEANING ABORT.

New chapters § 2.1 / 4.3.1 & 4.3.2

Jan. 2020

3

Update of the S.M for new software version 1.1.0 on DIGIT ovens.

Update of chapter §2.1.2 / 2.2.1.5.5 / 2.2.1.5.9 / 2.3.1.2.1 / 2.3.1.4 /

2.3.1.8 / 2.3.2 / 2.3.3 / 2.3.4 / 2.3.5 / 2.4 / 4.1

New chapters § 2.3.1.4 / 2.3.6 / 2.5 / 4.3 / 4.3.1 / 4.3.2 / 4.3.3

Jan. 2020

4

Update edition of the S.M for new software version 1.1.2 on DIGIT ovens,

update of software (bugs) no changes in S.M ed3.

Jan. 2020

3

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

o downloading the latest and up to date manual/technical bulletin(s) on the web site;:

www.electrolux.com/professional.

The manual must always be part of the documentation available when servicing the machine.

THIS MANUAL IS FOR THE ELECTRONIC BOARD TOUCH / DIGIT OF OVENS, IN SPECIFIC, THE MODELS

COVERED BY THE SERVICE MANUAL ARE:

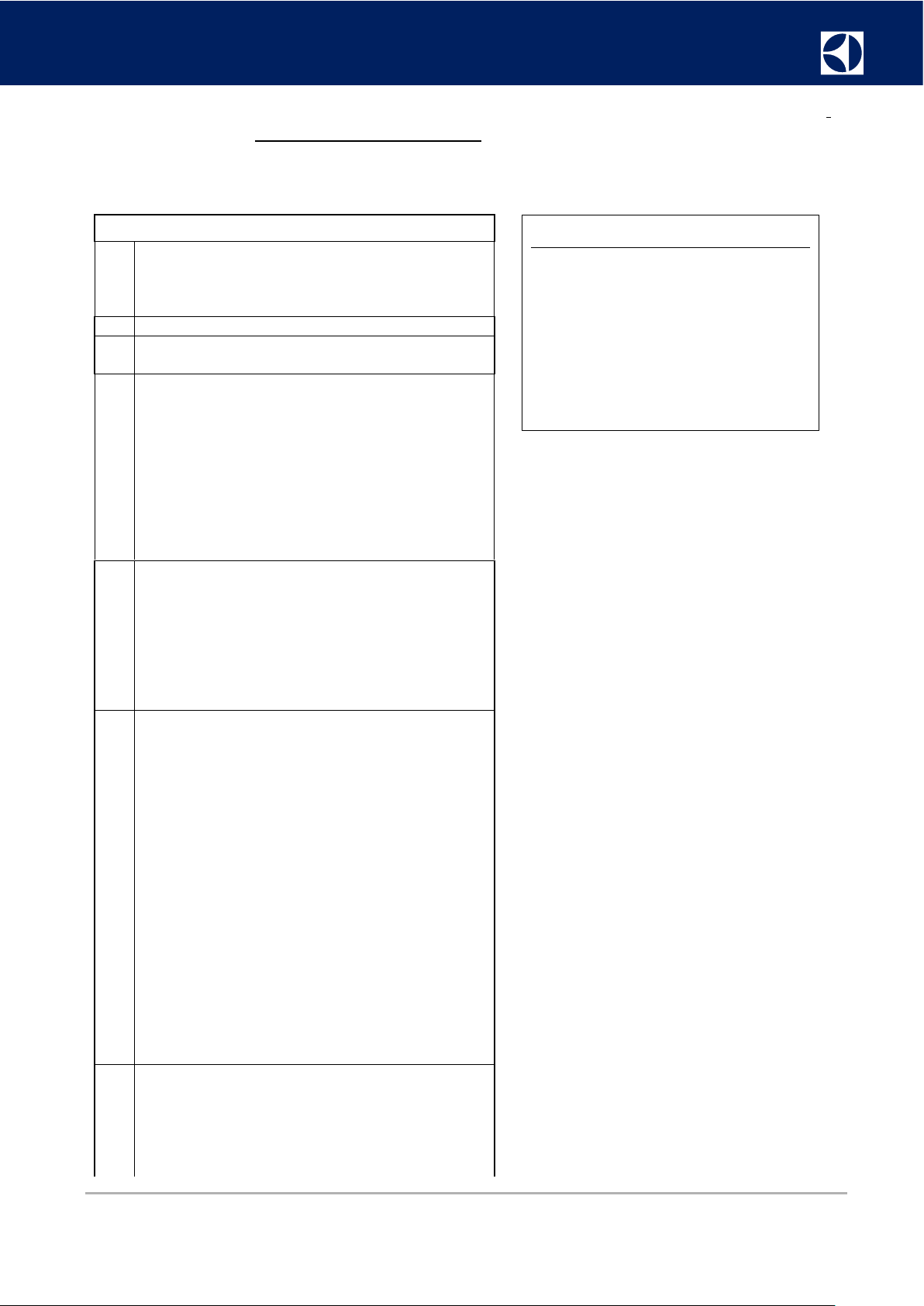

MODEL LEGEND

Z

Model for Zanussi LW

T

Model for Alpeninox/Multibrand LW

D

Model for Horecaland (Diamond)

E

Model for Electrolux LW

CO

Combi

E

Electric

G

Gas

61

6 GRIDS 1/1

62

6 GRIDS 2/1

101

10 GRIDS 1/1

102

10 GRIDS 2/1

201

20 GRIDS 1/1

202

20 GRIDS 2/1

661

6 GRIDS 1/1 on 6 GRIDS 1/1

662

6 GRIDS 2/1 on 6 GRIDS 2/1

611

6 GRIDS 1/1 on 10 GRIDS 1/1

612

6 GRIDS 2/1 on 10 GRIDS 2/1

T2

boiler touch / 2-GLASS

T3

boiler touch / 3 GLASS

K2

boilerless touch / 2 GLASS

K3

boilerless touch / 3 GLASS

B2

boiler digital / 2 GLASS

B3

boiler digital / 3 GLASS

C2

boilerless digital / 2 GLASS

C3

boilerless digital / 3 GLASS

A

STD el. (380-415 3N 50/60Hz)

B

Greene King (400 3N 50/60Hz)

C

Norway (230 3 50/60Hz) e HORECALAND

D

Marine (440 3 60Hz)

E

Marine (400 3 50Hz)

F

Marine (480 3 60Hz)

G

STD gas (230 1 50/60Hz)

H

LPG gas (230 1 50/60Hz)

I

Usa el (480 3 60Hz)

L

USA el. (208 3 60Hz)

M

USA el. (240 3 60Hz)

N

USA gas (208 2 60Hz)

O

USA gas (120 1N 60Hz)

P

JAPAN el. (200 3 50/60Hz)

Q

Japan gas (100 50/60Hz)

K

Japan lpg (100 50/60Hz)

S

Australia (el. 415-440)

T

Coop

U

Australia (gas 220-240)

0

NO VARIANTS

1

BOILER 316L

2

P84-P85 NORDIC

S

SMOKER

K

kit GPL

L

LEFT HINGED DOOR

EXAMPLE:

THIS MANUAL CAN BE FOUND ATTACHET TO:

PNC : 217782

FACTORY MODEL :

ECOG101T2G0

4

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

B

BAKERY (40X60)

V

VARIANTS (WASH, PROBE, SHELVES)

W

WASHING

Refer also to § DATA PLATE (IDENTIFICATION STICKER)

5

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

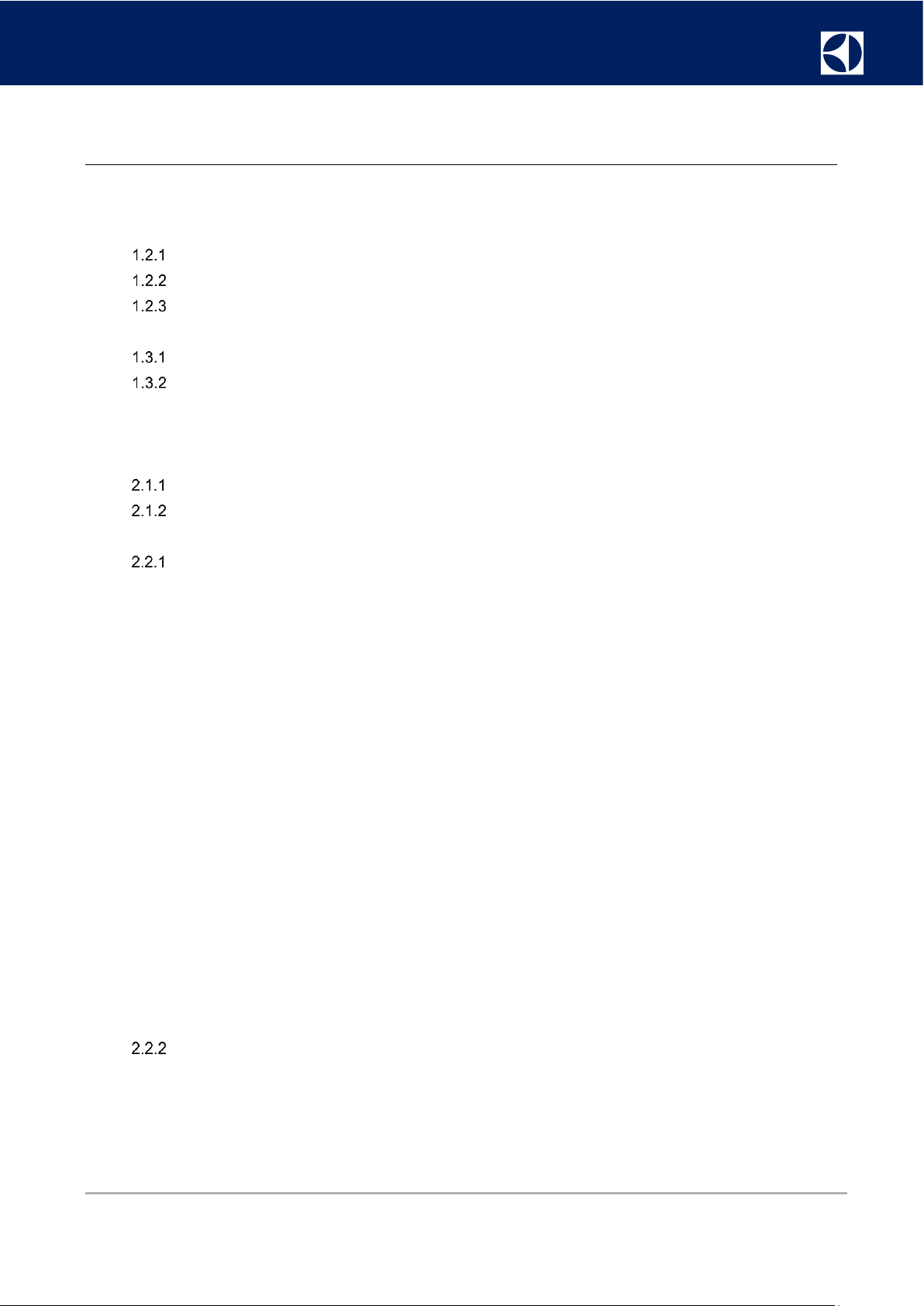

INDEX

1 GENERAL INFORMATION .......................................................................................................................... 7

1.1 GENERAL INFORMATION ................................................................................................................. 7

1.2 SAFETY INFORMATION/PRECAUTIONS ........................................................................................... 8

PERSONAL PROTECTION EQUIPMENT ................................................................................... 8

GENERAL INFORMATION ........................................................................................................... 9

RESIDUAL RISKS ........................................................................................................................ 9

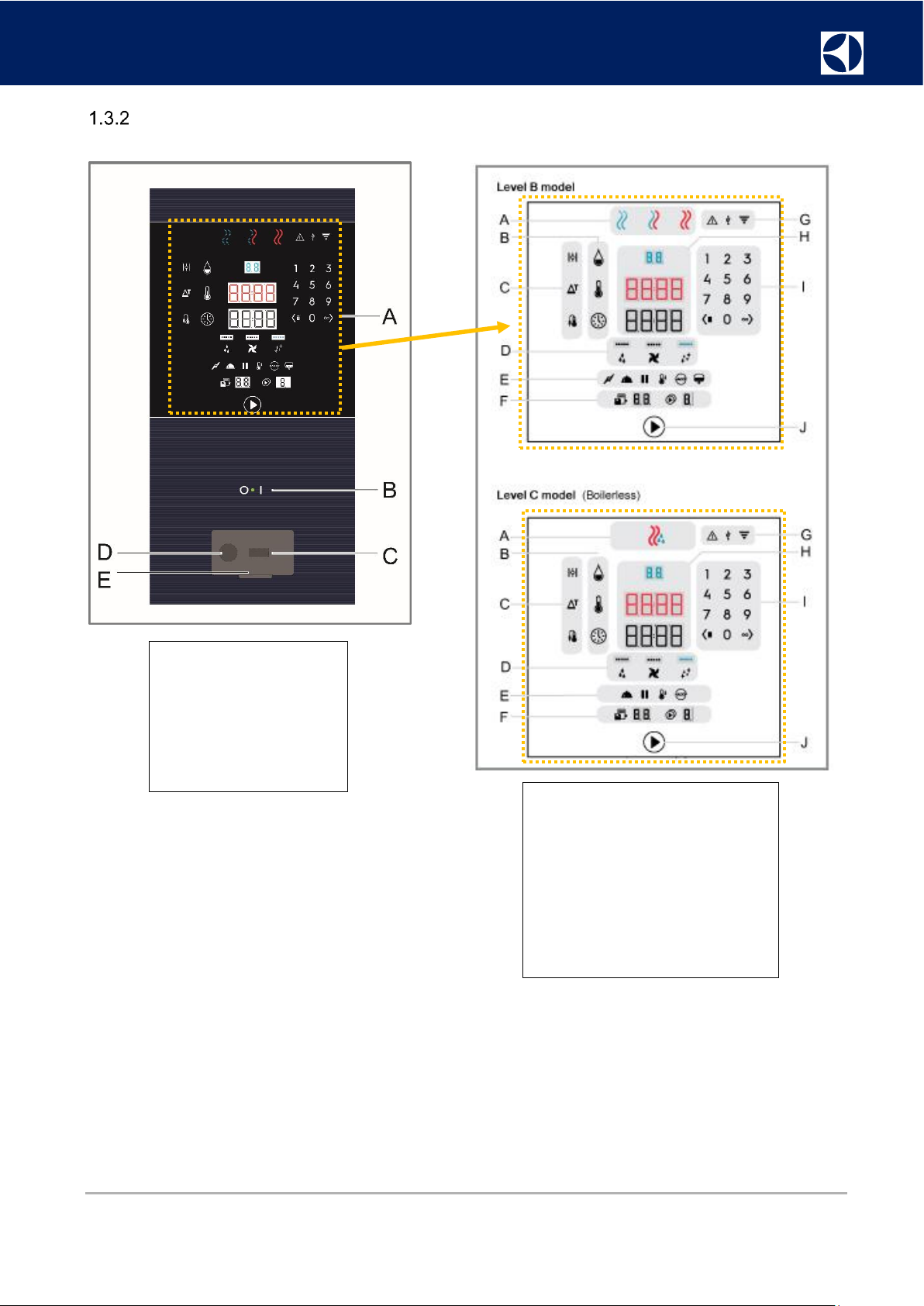

1.3 CONTROL PANEL INTERFACES ...................................................................................................... 11

TOUCH SCREEN INTERFACE (LEVEL T,K) ............................................................................. 11

DIGIT DISPLAY (LEVEL B, C) .................................................................................................... 12

1.4 ELECTRONIC BOARD INTERACTIONS ........................................................................................... 13

2 SETTINGS ELECTRONIC BOARDS ........................................................................................................ 14

2.1 SOFTWARE EDITIONS...................................................................................................................... 14

LEVEL “T,K” TOUCH .................................................................................................................. 14

LEVEL “B,C” DIGIT ..................................................................................................................... 14

2.2 LEVEL T, K (TOUCH SCREEN) ........................................................................................................ 15

SETTINGS AND SERVICE AREA .............................................................................................. 15

2.2.1.1 DISPLAY / TOUCHSCREEN CALIBRATION..................................................................... 16

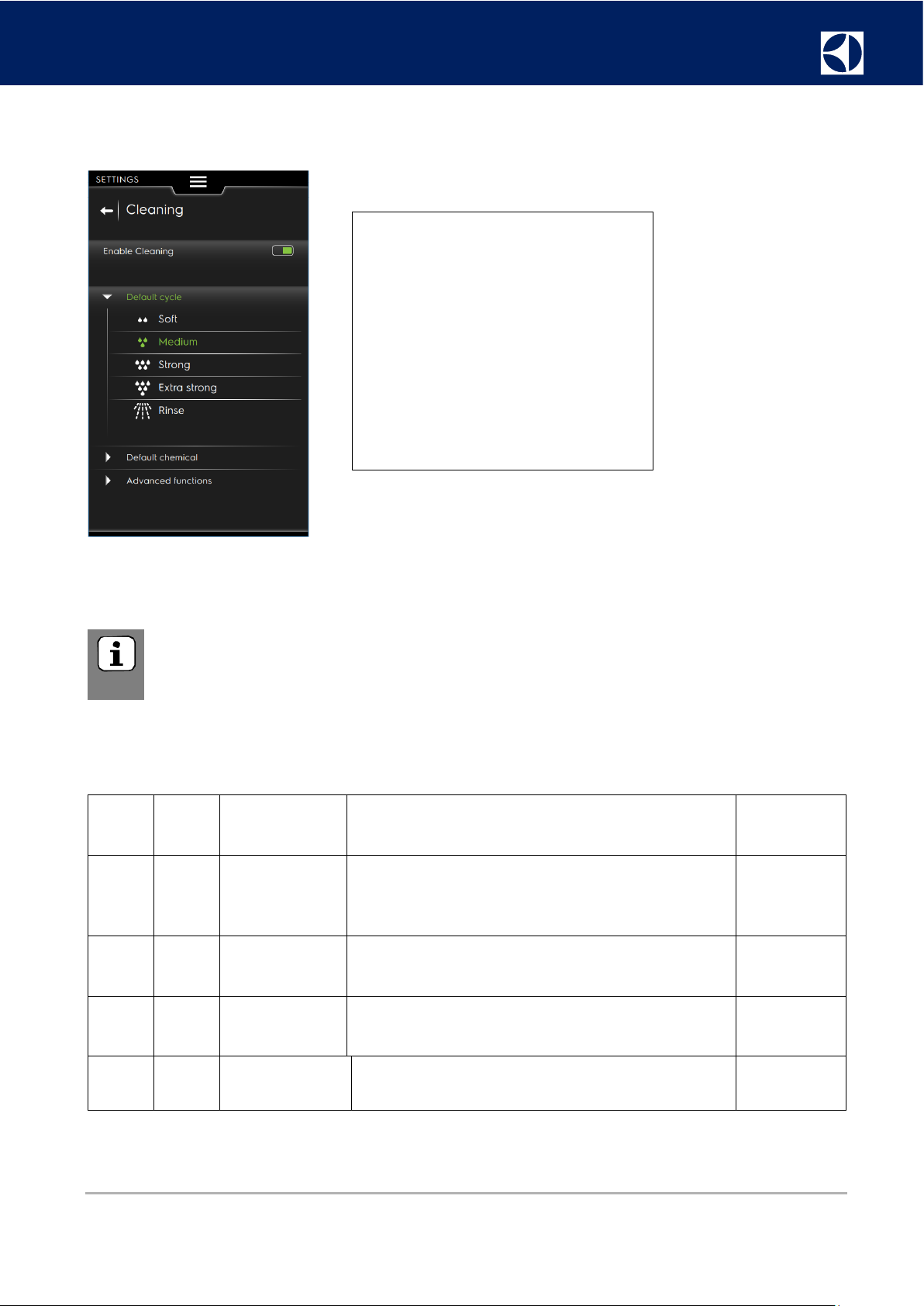

2.2.1.2 CLEANING ......................................................................................................................... 17

2.2.1.3 ACCESSORIES, ENABLE IN SOFTWARE ....................................................................... 17

2.2.1.4 OVEN IDENTITY CARD ..................................................................................................... 18

2.2.1.5 SERVICE ............................................................................................................................ 20

2.2.1.5.1 ENVIRONMENTS ........................................................................................................... 21

2.2.1.5.2 ALARM LOGS ................................................................................................................. 21

2.2.1.5.3 TECHNICAL SERVICE ID .............................................................................................. 21

2.2.1.5.4 APPLIANCE PARAMETERS T, K (TOUCH SCREEN) / LIST ...................................... 22

2.2.1.5.5 COUNTERS .................................................................................................................... 23

2.2.1.5.6 LAMBDA PROBE CALIBRATION ................................................................................... 25

2.2.1.5.7 RESTORE AUTOMATIC MODE ..................................................................................... 26

2.2.1.5.8 CLEAR PROGRAM MODE, MULTI TIMER DATA ......................................................... 26

2.2.1.5.9 BOILER MANTENANCE / DESCALE ............................................................................. 27

2.2.1.6 BY-PASS ENVIRONMENT................................................................................................. 28

2.2.1.7 USB TRANSFER AMBIENT ( SERVICE FUNCTIONS) .................................................... 29

2.2.1.8 RECOVERY MODE ............................................................................................................ 31

SOFTWARE UPDATE LEVEL T,K ( TOUCH SCREEN) ............................................................ 32

2.2.2.1 AGELUX WEB SITE - EXAMPLE ILLUSTRATION ............................................................ 33

2.2.2.2 PRIDE WEB SITE - EXAMPLE ILLUSTRATION ............................................................... 34

2.2.2.3 UNZIPPING ........................................................................................................................ 35

2.2.2.3.1 - PRIDE/ FIREFOX UNZIPPING ..................................................................................... 35

2.2.2.3.2 - PRIDE/ INTERNET EXPLORER UNZIPPING.............................................................. 38

6

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2.2.2.4 PROGRAMMING FILE UPLOAD ....................................................................................... 39

2.2.2.5 PROGRAMMING PARAMETERS UPLOAD ...................................................................... 40

2.2.2.6 PNC & SER (pncSerial.json) UPLOAD .............................................................................. 42

UTILITIES ACTIVATED WITH OVEN ON .................................................................................. 47

2.2.3.1 CAVITY TEMPERATURE / HUMIDITY .............................................................................. 47

2.3 LEVEL B, C (DIGIT) ........................................................................................................................... 48

SERVICE AREA .......................................................................................................................... 48

2.3.1.1 APPLIANCE PARAMETERS (APPL PAr) .......................................................................... 49

2.3.1.2 COUNTERS (COUntErS) ................................................................................................... 50

2.3.1.2.1 COUNTER LIST DETAIL ................................................................................................ 51

2.3.1.3 GAS TABLE ADJUSTMENTS (GAS tAbL)......................................................................... 52

2.3.1.4 CLEAN TABLE (CLN tAbL) ................................................................................................ 53

2.3.1.5 HACCP LOG (HACP LOG)................................................................................................. 54

2.3.1.6 PROGRAMS, CHEF RECIPES (PrOG) ............................................................................. 55

2.3.1.7 ALARM LOG (ALrM LOG) .................................................................................................. 56

2.3.1.8 NIU (WIFI MANAGEMENT) ................................................................................................ 57

2.3.1.9 IDENTITY CARD (APPL dAtA) ........................................................................................... 58

SOFTWARE UPDATE B,C ( DIGIT) ........................................................................................... 59

2.3.2.1 AGELUX WEB SITE - EXAMPLE ILLUSTRATION ............................................................ 59

2.3.2.2 PRIDE WEB SITE - EXAMPLE ILLUSTRATION ............................................................... 60

2.3.2.3 UNZIPPING ........................................................................................................................ 61

2.3.2.3.1 - PRIDE/ FIREFOX UNZIPPING ..................................................................................... 61

2.3.2.3.2 - PRIDE/ INTERNET EXPLORER UNZIPPING.............................................................. 64

UPLOAD PROGRAMMING FILE & PROGRAMMING PARAMETERS ..................................... 65

BOILER ORDINARY MAINTENANCE / DESCALE .................................................................... 66

BOILER EXTRAORDINARY DESCALE CYCLE ........................................................................ 67

ACCESSORIES, ENABLE IN PARAMETERS ........................................................................... 68

2.4 - PARAMETERS LIST CHART FOR ALL LEVEL (T,K ; B,C) ............................................................ 69

2.5 WASH CYCLES / DETERGENTS / DESCALE .................................................................................. 73

3 USER INTERFACE (UI) TOUCH/DIGIT & ACU DESCRIPTION .............................................................. 74

3.1 U.I LEVEL T,K (TOUCHSCREEN) ..................................................................................................... 74

3.2 U.I LEVEL B,C (DIGIT) ....................................................................................................................... 76

3.3 A.C.U LEVEL T,K,B,C (POWER BOARD).......................................................................................... 77

4 TROUBLESHOOTING ............................................................................................................................... 79

4.1 ALARMS & WARNINGS ..................................................................................................................... 79

4.2 EH2O, LEVEL T,K, (TOUCH) – CLEANING ABORT ........................................................................ 92

PRIDE EH2O “KILL_CLEAN” SOFTWARE DOWNLOAD .......................................................... 92

AGELUX EH20 “KILL_CLEAN” SOFTWARE DOWNLOAD ....................................................... 93

4.3 EH2O, LEVEL, B,C (DIGIT) – CLEANING ABORT ............................................................................ 94

SOFTWARE FROM 1.1.0 ........................................................................................................... 94

SOFTWARE FROM 1.0.18 ......................................................................................................... 94

7

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

SOFTWARE UP TO 1.0.11 ......................................................................................................... 94

5 ELECTRICAL WIRING DIAGRAM ............................................................................................................ 96

5.1 GAS APPLIANCE ............................................................................................................................... 96

5.2 ELECTRIC APPLIANCE ................................................................................................................... 100

1 GENERAL IN FORMATION

1.1 GENERAL INFORMATION

To ensure safe use of the machine and a proper understanding of the manual it is necessary to be familiar

with the terms and typographical conventions used in the documentation. The following symbols are used in

the manual to indicate and identify the various types of hazards:

WARNING

Danger for the health and safety of operators.

WARNING

Danger of electrocution - dangerous voltage.

CAUTION

Risk of damage to the machine or the product.

WARNING

Danger of magnetic fields.

IMPORTANT

Important instructions or information on the product

Read the instructions before using the appliance

Clarifications and explanations

• Only specialised personnel are authorised to operate on the machine.

• This appliance must not be used by minors and adults with limited physical, sensory or mental

abilities or without adequate experience and knowledge regarding its use.

– Do not let children play with the

appliance.

– Keep all packaging and detergents away from children.

– Cleaning and user maintenance shall not be made by children without supervision.

• Do not store explosive substances, such as pressurized containers with flammable propellant, in

this appliance or close to the appliance

• Do not remove, tamper with or make the machine “CE“ marking illegible.

• Refer to the data given on the machine’s data plate “CE“ marking for relations with the Manufacturer

(e.g. when ordering spare parts, etc.).

• When scrapping the machine, the “CE“ marking must be destroyed.

8

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

1.2 SAFETY INFORMATION/PRECAUTIONS

- Risks mainly of a mechanical, thermal and electrical nature exist in the machine. Where possible the

risks have been neutralised:

- directly, by means of adequate design solutions.

- indirectly by using guards, protection and safety devices.

- During maintenance several risks remain, as these could not be eliminated, and must be neutralised

by adopting specific measures and precautions.

- Do not carry out any checking, cleaning, epair or maintenance operationson moving parts. Workers

must be informed of this prohibition by means of clearly visible signs.

- To guarantee machine efficiency and correct operation, periodical maintenance must be carried out

according to the instructions given in this manual.

- Make sure to periodically check correct operation of all the safety devices and the insulation of electrical cables, which must be replaced if damaged.

- Extraordinary machine maintenance operations must only be carried out by specialized Technicians

provided with all the appropriate personal protection equipment (safety shoes, gloves, glasses,

overalls, etc.), tools, utensils and ancillary means.

- Never operate the machine, removing, modifying or tampering with the guards, protection or safety

devices.

- Before carrying out any operation on the machine, always consult the manual which gives the correct

procedures and contains important information on safety.

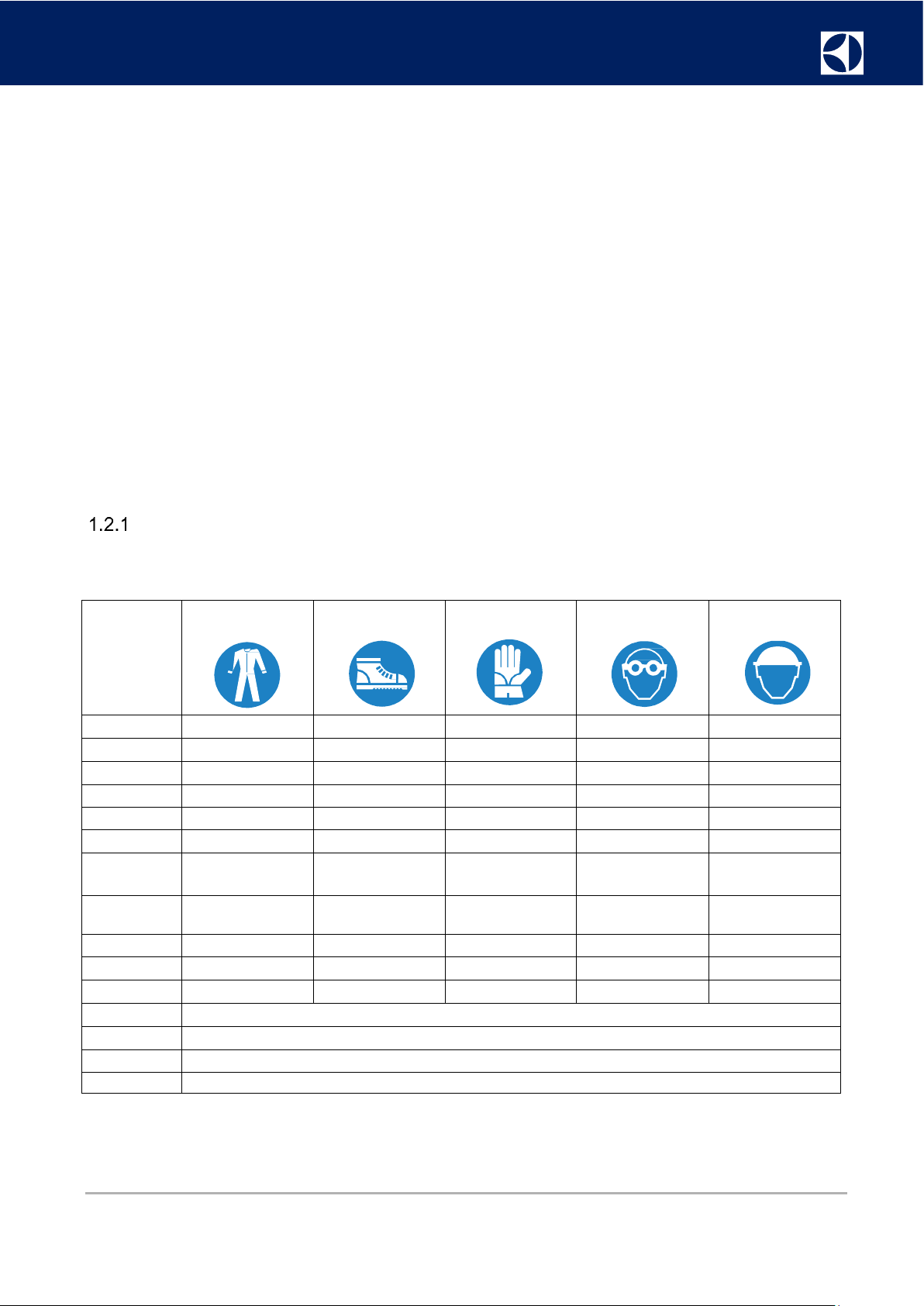

PERSONAL PROTECTION EQUIPMENT

Summary table of the Personal Protection Equipment (PPE) to be used during the various stages of the machine's service life.

1.

During Normal use, gloves must be heatproof to protect hands from contact with hot food or

hot parts of the appliance and/or when removing hot items from

it.

Failure to use the personal

protection equipment by operators, specialised personnel or users can involve exposure to

chemical risk and possible damage

to

health (depending on the

model).

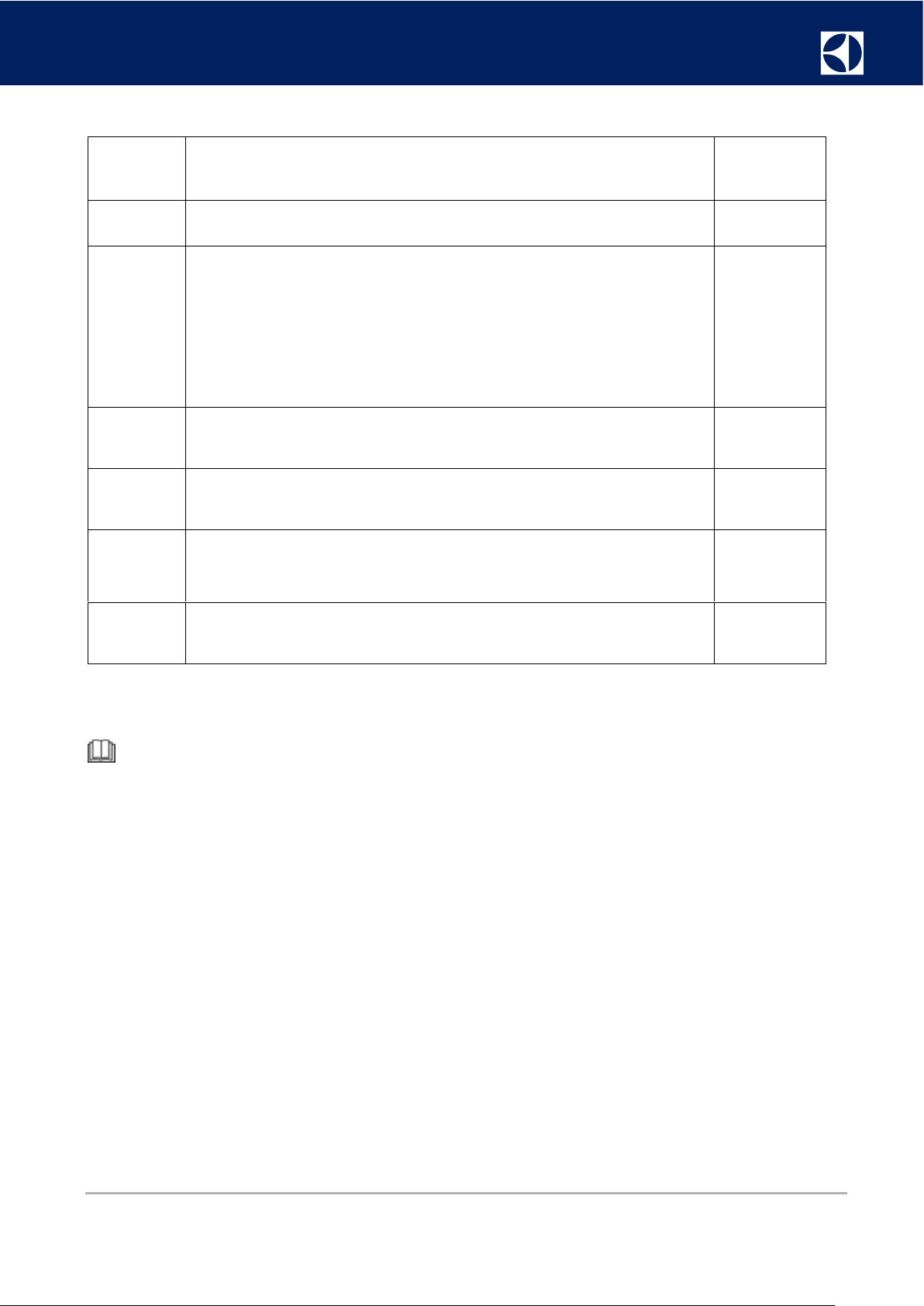

Stage

Protective

garments

Safety footwear

Gloves

Glasses

Safety helmet

Transport

—

● ○

—

○

Handling

—

● ○

— —

Unpacking

—

● ●

— —

Installation

—

● ●

2

●

—

Normal use

● ● ●

1

○

—

Adjustments

○ ●

○ ○

—

Routine cleaning

○ ● ●

1 or 2

○

—

Extraordinary

cleaning

○ ●

●

1 or 2

○

—

Maintenance

○ ● ○

○

—

Dismantling

○ ● ○ ○

—

Scrapping

●

● ● ●

—

Key:

●

PPE REQUIRED

○

PPE AVAILABLE OR TO BE USED IF NECESSARY

—

PPE NOT REQUIRED

9

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2. During these operations, the worn gloves must be cut-resistant.

Failure to use the personal

protection equipment by operators, specialized personnel or users can involve exposure to

damage to health (depending on the model)

GENERAL INFORMATION

• The machines are provided with electric and/or mechanical safety devices for protecting workers

and the machine itself. Therefore the user must not remove or tamper with such devices. The Manufacturer

declines any liability for damage due to tampering or their non-use.

• Never operate the machine, removing, modifying or tampering with the guards, protection or safety de-

vices.

• Do not make any modifications to the parts supplied with the appliance.

• Several illustrations in the manual show the machine, or parts of it, without guards or with guards

removed. This is purely for explanatory purposes. Do not use the machine without the guards or with the

protection devices deactivated.

• Do not remove, tamper with or make illegible the safety, danger and instruction signs and labels on

the machine.

• Air recirculation must take into account the air necessary for combustion, 2 m³/h/kW of

gas power, and also the "well-being" of persons working in the kitchen.

• Inadequate ventilation causes asphyxia. Do not obstruct the ventilation system in the place where this

appliance is installed. Do not obstruct the vents or ducts of this or other appliances.

• Place emergency telephone numbers in a visible position.

• The measured sound level emitted “A“ does not exceed 70 dB (“A“).

• Turn the appliance off in case of fault or poor operation.

• Do not use products (even if diluted) containing chlorine (sodium hypochlorite, hydrochloric or

muriatic acid, etc.) to clean the appliance or the floor under it.

• Do not use metal tools to clean steel parts (wire brushes or Scotch Brite type scouring pads).

• Do not allow oil or grease to come into contact with plastic parts. Do not allow dirt, fat, food or other residu-

als to form deposits on the appliance.

• Do not spray water or use steam to clean the equipment.

• Do not store or use gasoline or other flammable vapours, liquids or items in the vicinity of this or any

other appliance.

• Do not spray aerosols in the vicinity of this appliance while it is in operation.

• Never check for leaks with an open flame.

RESIDUAL RISKS

• The machine has several risks that were not completely eliminated from a design standpoint or with

the installation of adequate protection devices. Nevertheless, through this manual the Manufacturer has taken

steps to inform operators of such risks, carefully indicating the

personal protection equipment to be used by them. Sufficient spaces are provided for during the machine

installation stages in order to limit these risks.

To preserve these conditions, the areas around the machine must always be:

– kept free of obstacles (e.g. ladders, tools, containers, boxes, etc.);

– clean and dry;

– well lit.

For the Customer's complete information, the residual risks remaining on the machine are indicated below:

such actions are deemed improper and therefore strictly forbidden.

Residual risk

Description of hazardous situation

Slipping or falling

The operator can slip due to water or dirt on the floor

Burns/abrasions (e.g. heating elements)

The operator deliberately or unintentionally touches some components inside the machine without using protective gloves

Electrocution

Contact with live parts during maintenance operations carried out

with the electrical panel powered

10

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

Sudden closing of the lid/ door/oven door (if present, depending on

the

appliance type)

The operator for normal machine use could suddenly and deliberately close the lid/door/oven door (if present, depending on the appliance type)

Tipping of loads

When handling the machine or the packing containing it, using unsuitable lifting systems or accessories or with the load unbalanced

Mechanical safety characteristics, hazards

• The appliance does not have sharp edges or protruding parts. The guards for the moving and live

parts are fixed to the cabinet with screws, to prevent accidental access.

Protection devices installed on the machine

• The guards on the machine are:

– fixed guards

(e.

g. casings, covers, side panels, etc.), fixed to the machine and/or frame with screws

or quick-release connectors that can only be removed or opened with tools

Safety signs to be placed near the machine area

Prohibition

Meaning

do not remove the safety devices

do not use water to extinguish fires (placed on electrical parts)

Keep the area around the appliance clear and free

from combustible materials. Do not keep flammable

materials in the vicinity of the appliance

Install the appliance in a well-ventilated place to avoid

the creation of dangerous mixtures of unburnt gases

in the same room

Danger

Meaning

danger of burns

danger of electrocution (shown on electrical parts with

indication of voltage)

risk of electromagnetic fields

Access forbidden to wearers of electrical stimulator

(pacemakers)

End of use: When the appliance is no longer to be used, make it unusable by removing the mains power

supply wiring.

11

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

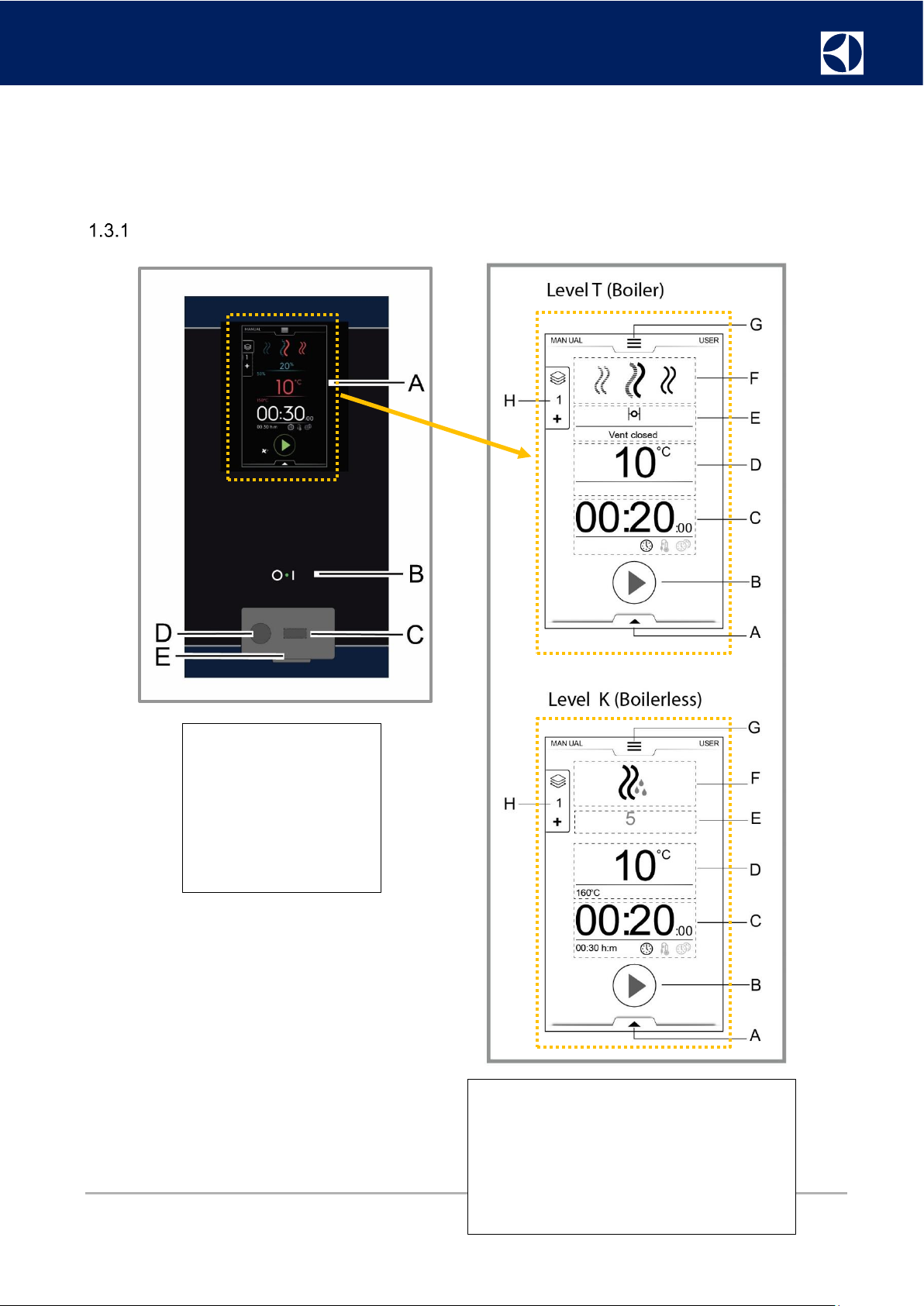

1.3 CONTROL PANEL INTERFACES

There are two type of user interfaces (U.I) :

- Level B,C are DIGIT (buttons)

- Level T, K are TOUCH (touch screen)

TOUCH SCREEN INTERFACE (LEVEL T,K)

A. Utilities drawer (lower drop down menu)

B. start button

C. Time / food probe area

D. Cavity temperature

E. Cavity humidification

F. Cooking cycles

G. Main menu (drop down menu)

H. Multiphase drop down menu

A.Control panel screen

B.ON/OFF button

C.USB key in/out

D.Print out

E.Openable flap

12

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

DIGIT DISPLAY (LEVEL B, C)

Level B ( with boiler) & C (appliance without boiler / boilerless)

A.Cooking cycles

B.Cooking parameters

C.Cooking option

D.Special functions

E.Utilities

F.Programs and Multi phase

G.Indicator Lights

H.Digits display

I.Key pad

J.Start button cycle

A.Control panel screen

B.ON/OFF button

C.USB key in/out

D.Print out

E.Openable flap

13

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

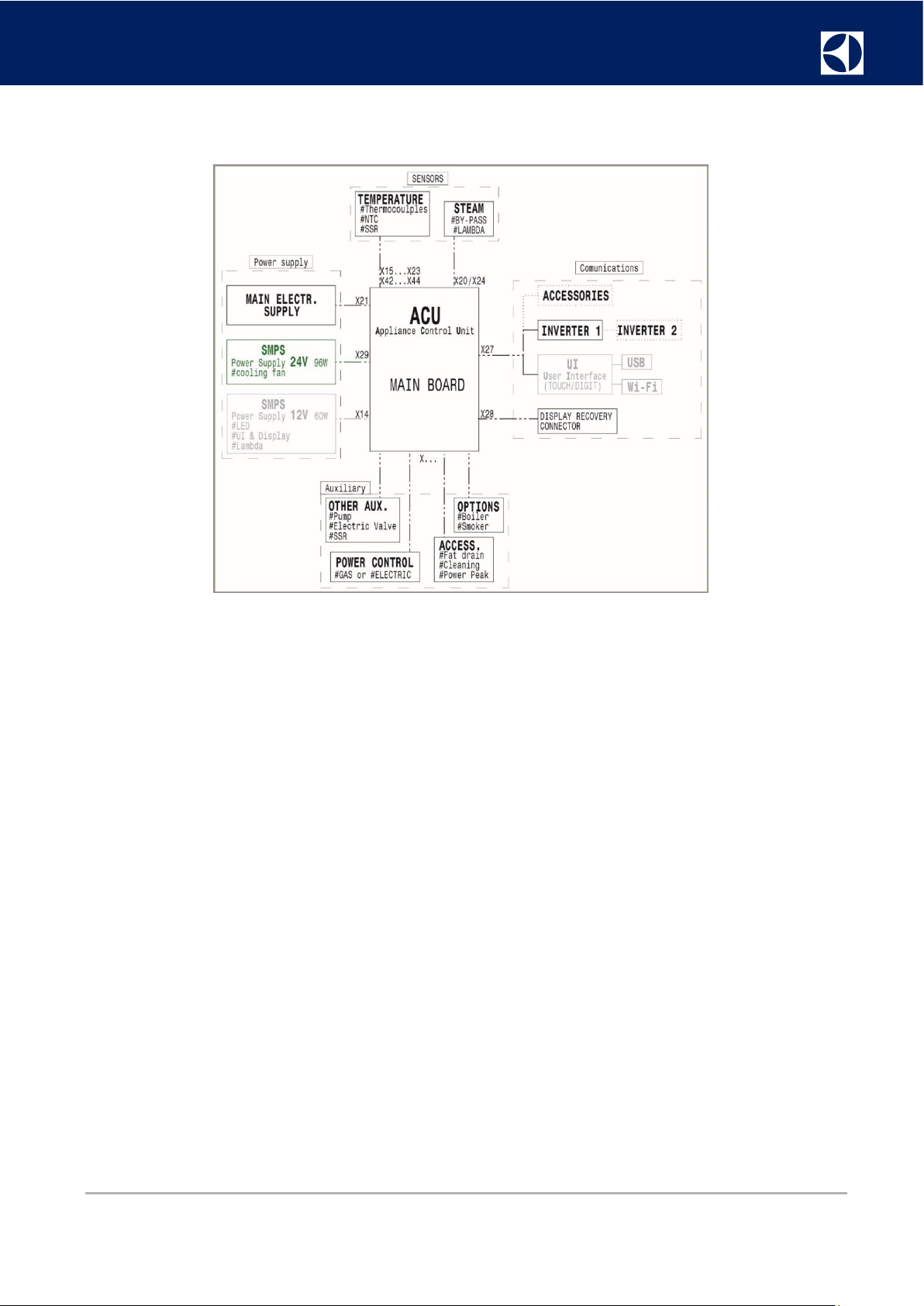

1.4 ELECTRONIC BOARD INTERACTIONS

14

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2 SETTINGS ELECTRONIC BOARDS

The following chapters are intended only for authorized technicians / engineers.

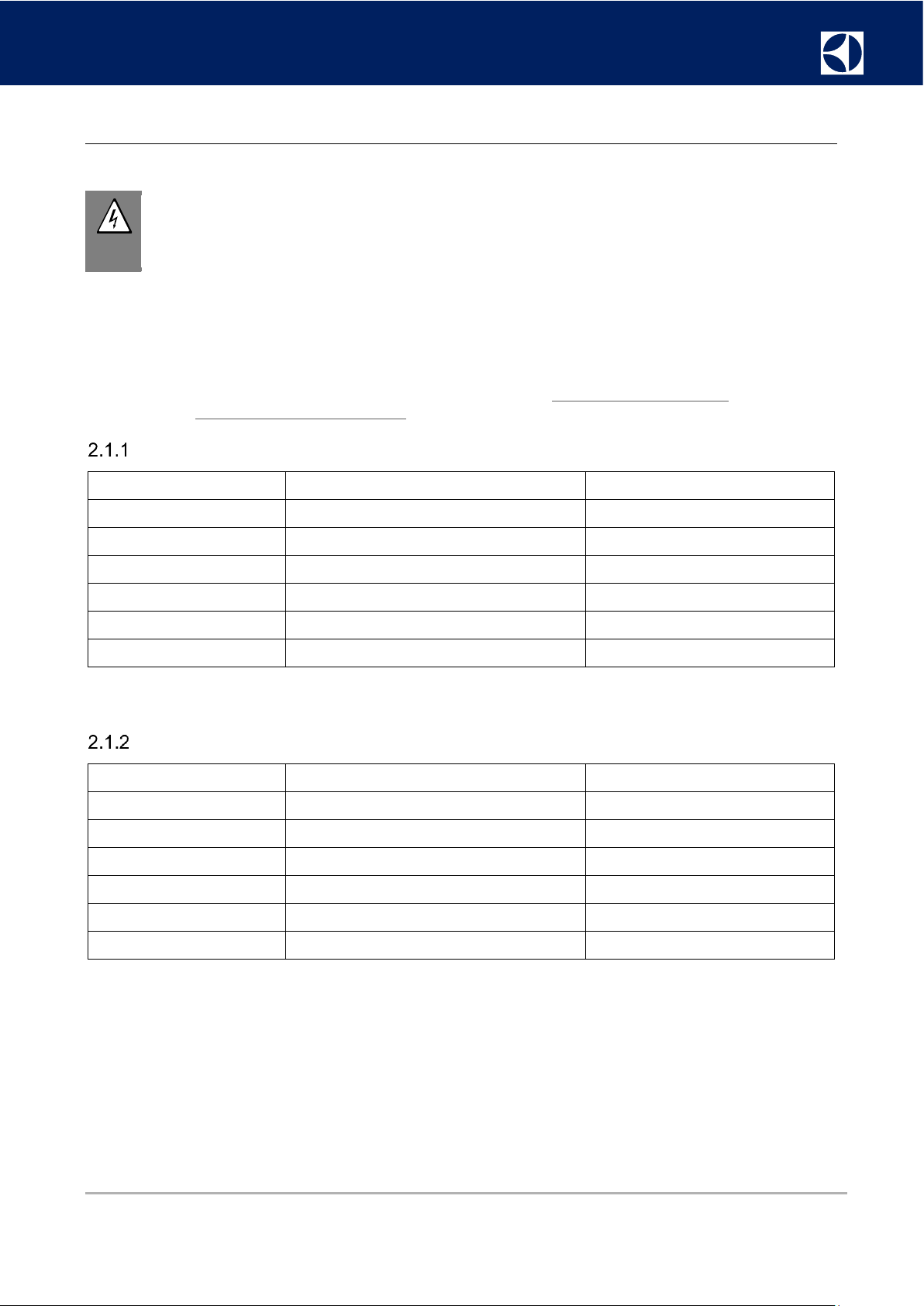

2.1 SOFTWARE EDITIONS

In the following chapters/tables are listed the software editions released from the factory and therefore available “in the market”.

The software edition of the electronic board can be found in OVEN IDENTITY CARD (for level T,K

Touchscreen) ; IDENTITY CARD (APPL dAtA) (for level B,C Digit).

LEVEL “T,K” TOUCH

LEVEL “B,C” DIGIT

WARNING !

Take GREAT CARE when connecting / testing anything with live current, if you are unsure what you

are doing and how to use your equipment safely, then DON'T DO IT.

SOFTWARE EDITION

DESCRIPTION

DATE PRODUCTION

4.0.4

LEVEL “T,K” TOUCH electronic boards

July 2019

4.2.2

LEVEL “T,K” TOUCH electronic boards

Nov. 2019

4.2.4

LEVEL “T,K” TOUCH electronic boards

Nov. 2019

4.3.5

LEVEL “T,K” TOUCH electronic boards

Nov. 2019

4.3.7

LEVEL “T,K” TOUCH electronic boards

Dic. 2019

SOFTWARE EDITION

DESCRIPTION

DATE PRODUCTION

1.0.07

LEVEL “B,C” DIGIT electronic boards

May. 2019

1.0.11

LEVEL “B,C” DIGIT electronic boards

Nov. 2019

1.0.18

LEVEL “B,C” DIGIT electronic boards

Dic. 2019

1.1.0

LEVEL “B,C” DIGIT electronic boards

Jan. 2020

1.1.2

LEVEL “B,C” DIGIT electronic boards

Jan. 2020

15

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2.2 LEVEL T, K (TOUCH SCREEN)

A complete list of all the available software editions released in the markert can be found at § SOFTWARE

EDITIONS

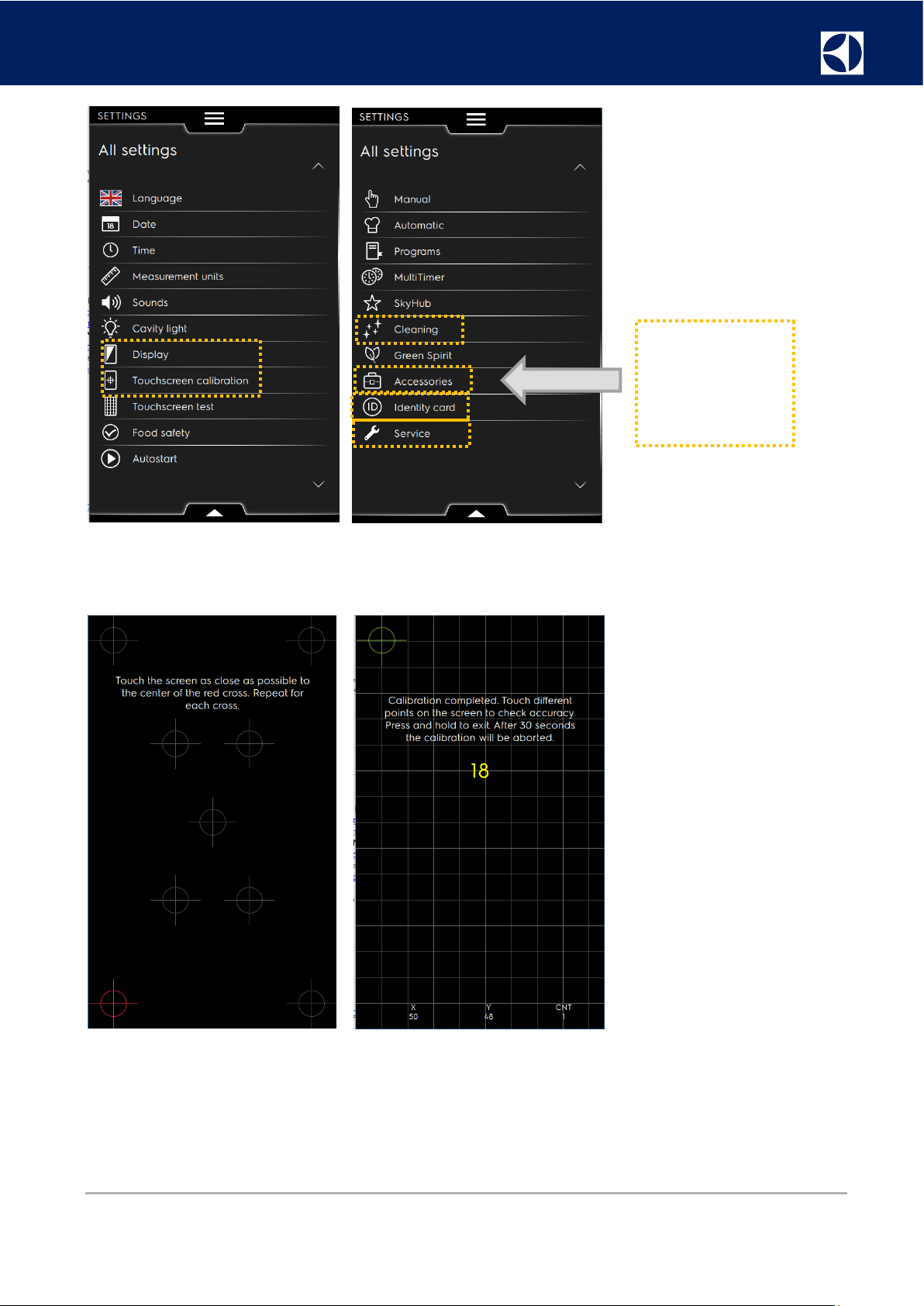

SETTINGS AND SERVICE AREA

The SETTING AREA is accessible in the main screen view by pressing the menu drop down menu.

The access of this area does not require a password.

In the SETTING AREA are located some features that are usefull for technicians, these features have been

highlighted in the next two pictures and will be discussed in separate chapters.

IMPORTANT !

The following instructions/illustrations are relative to software 4.3.7. on-

wards. Previous software editions could differ to what is reported in this

manual edition.

16

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2.2.1.1 DISPLAY / TOUCHSCREEN CALIBRATION

Highlighted

chapters useful

for technician

settings

17

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2.2.1.2 CLEANING

Before starting any washing cycle the appliance will check the inner cavity temperature, if the inner temperature

is too hot the appliance will proceed to a "Forced cooling"

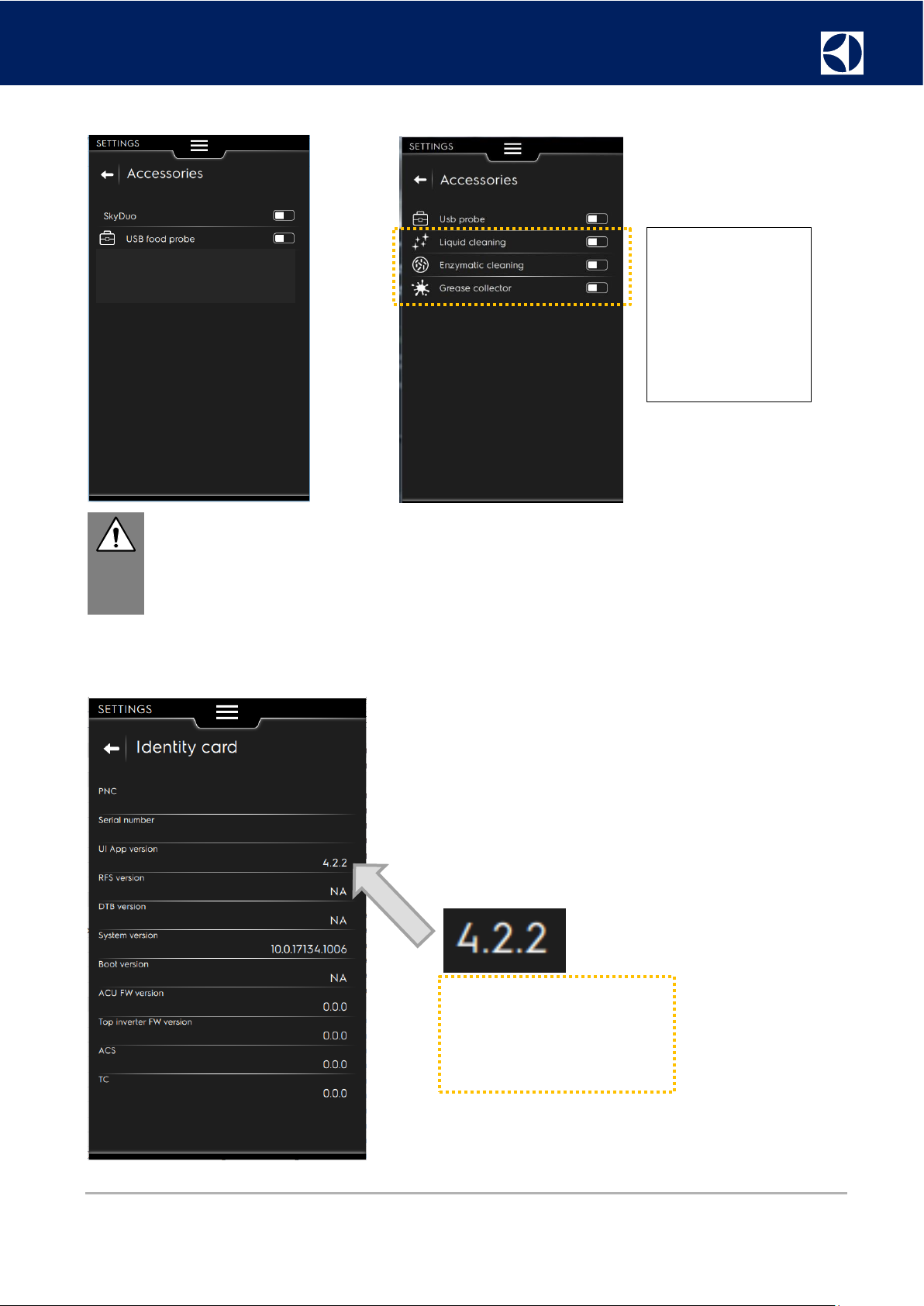

2.2.1.3 ACCESSORIES, ENABLE IN SOFTWARE

If any accessories is added to an oven, it may be necessary to enable the item:

First it will be necessary to enter into the parameter list and “add in/enable” the parameter, EXAMPLE:

Lets say we need to add the accessory liquid detergent kit 922618, enter in service/parameters and enable/disable and/or adjust par 45,47,55, 416.

Param-

eter ID

Mne-

monic

Short Descrip-

tion

Long Description

Table

45

CLnC

Cleaning cycle

chemicals

Byte type parameter user settable that sets which kind of detergent and rinse aid must be used during the cleaning cycle.

The allowable values for this parameter are dependent on

the value of parameters 46/47/55/56

{0, "Solid"}

{1, "Enzymatic"}

{2, "Liquid"}

{3, "Powder"}

47

FCLL

Cleaning – liquid

(factory settings)

Bit type parameter factory settable which enables/disables

the use of liquid chemicals during the cleaning cycle

{0, "Disabled"}

{1, "Enabled"}

55

FCLS

Cleaning – solid

(factory settings)

Bit type parameter factory settable which enables/disables

the use of solid chemicals during the cleaning cycle

{0, "Disabled"}

{1, "Enabled"}

416

FCLP

Cleaning – powder (factory set-

tings)

Bit type parameter factory settable which enables/disables the use of powder chemicals during the cleaning

cycle

{0, "Disabled"}

{1, "Enabled"}

Once that the accessory has been added in the parameter list, you will have to enter in the user accessories

area and abilitate it.

NOTE !

IN THE ACCESSORY PACKAGING BOX IS CONTAINED A DEDICATED MANUAL WITH DETAILED EXPLANATION

Cycle stop Keep hold to stop the cy-

cle;The Stop button will be available

when the function can be performed. After the selection the display will show the

remaining time for the rinsing of the cavity and of the boiler.

Forced rinse if you have stopped a running cleaning cycle, the appliance mayproceed to perform a forced rinse to

washout all the chemicals from the cavity. During this count down the door cannot be opened.

18

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

EXAMPLE ONE EXAMPLE TWO

2.2.1.4 OVEN IDENTITY CARD

Oven identity card EXAMPLES

IMPORTANT !

In case you update the oven software or the parameters, the accessories

list will be reset; you will have to enable again the item in the parameter

list and then enabled it in the Accessories menu’.

EXAMPLE: “U.I App

version” 4.2.2, is to be

considered the “software “ of the oven.

EXAMPLE TWO:

after adding in the

accessory / parameter 45/47/55

etc in the Accessories menu the new

items will be available to enable.

19

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

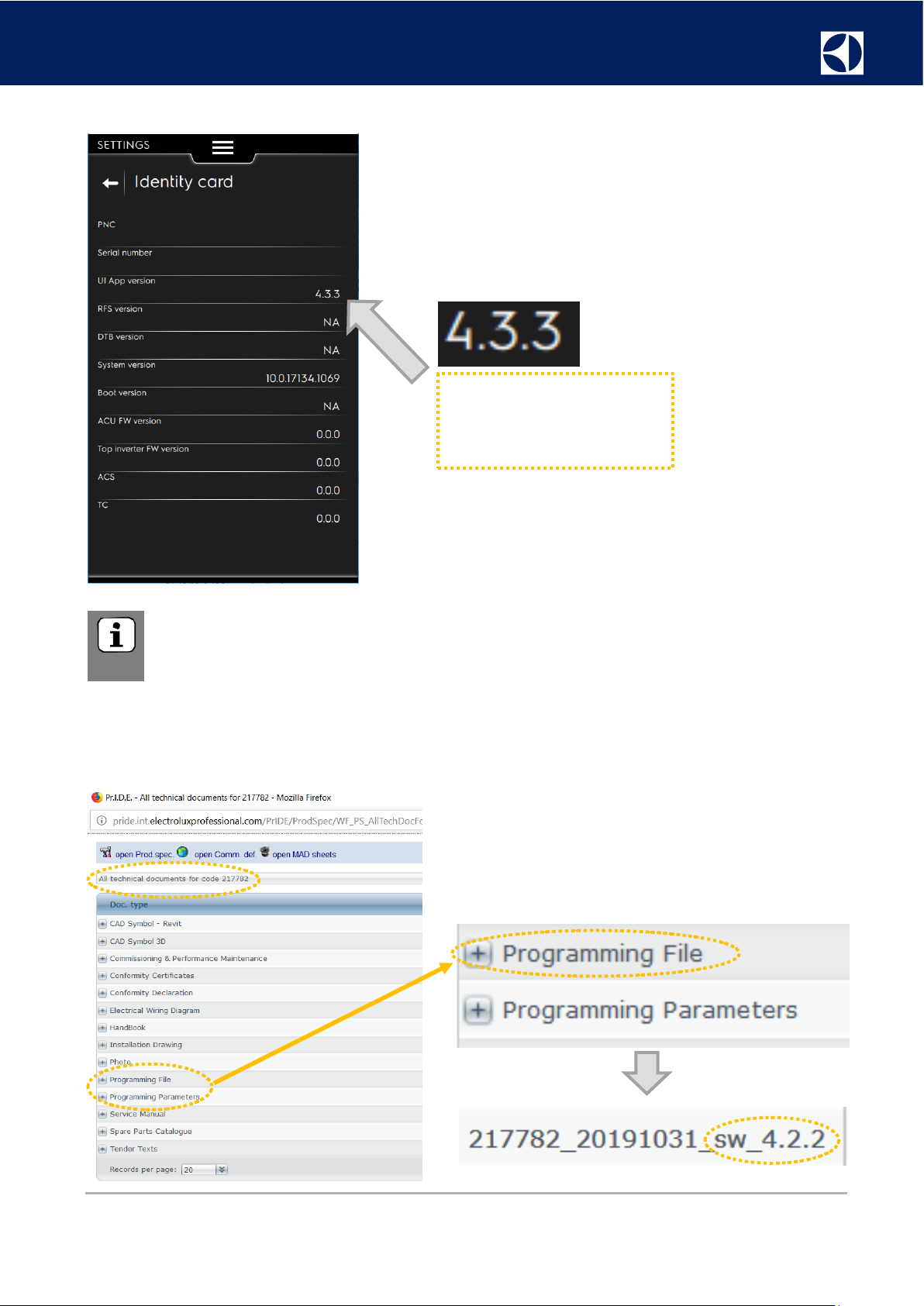

Oven identity card EXAMPLES

Refer to the latest edition name of the software (programming file) edition or date publication from the official

TechDoc web pages.

- Programming File

- Programming Parameters

NOTE !

IN THE WEB SITE YOU WILL ALWAYS FIND THE LATEST EDITIONS OF SOFTWARE

AVAILABLE

U.I App version 4.3.3, is

to be considered the

“software “ of the oven.

20

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

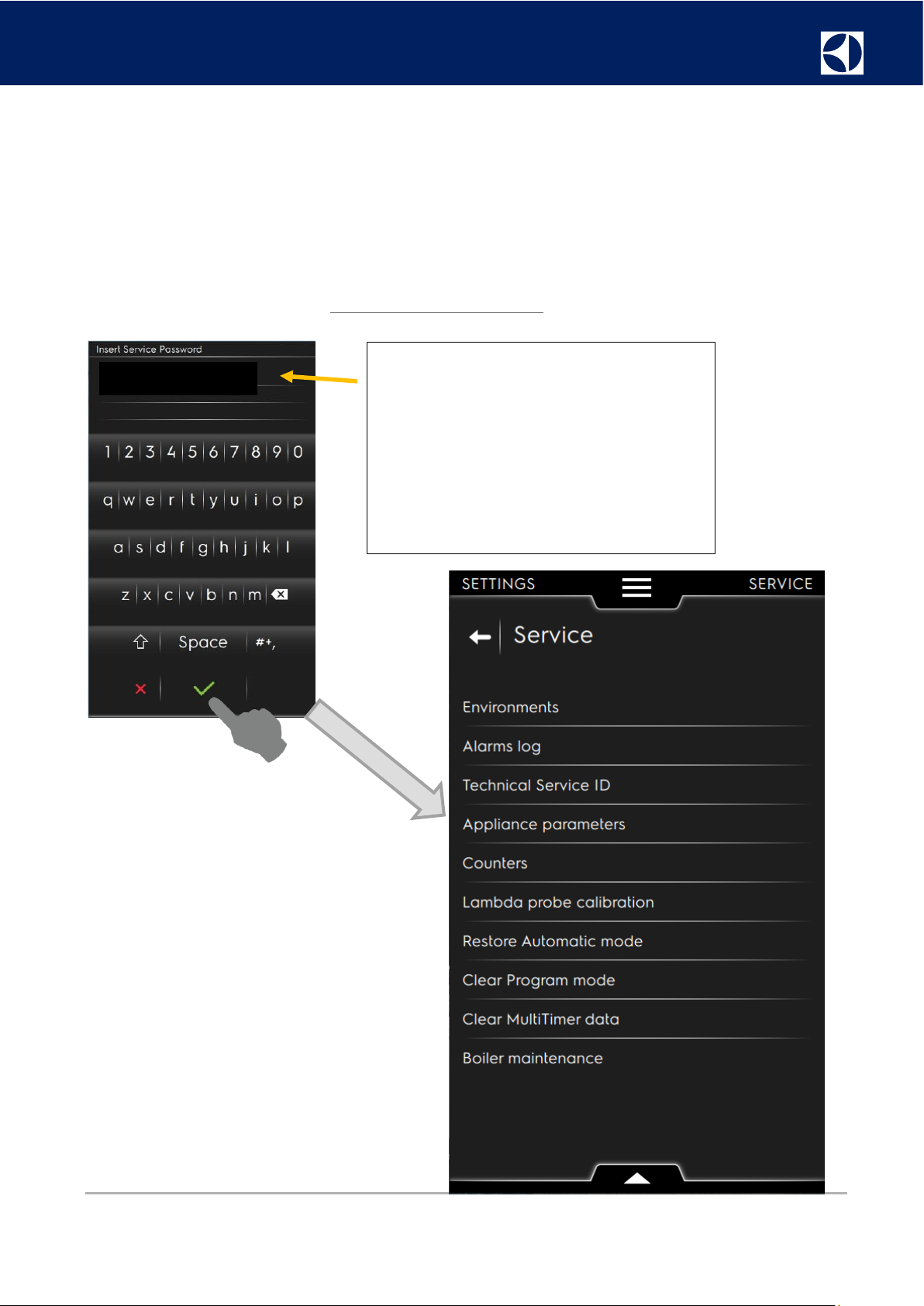

2.2.1.5 SERVICE

“Service” will be accessed through password in Settings->Service. Once the password is correctly entered the

“Service” credentials will be active for 15 minutes while navigating the interface. The 15 minutes timeout is

continually reset while the appliance is in running state and every time the interface detects a touch.

With “Service” credentials correctly inserted (password) the user interaction will be abilitated for all menu in

the "service /setting" area as well as in the USB (service functions).

Remember to EXIT the “Service credentials" at the end of your operations by turning the appliane OFF, or by

waiting time out (15 minutes / without touching the display).

The USB area , only when correctly accessed, has complete upload/download options for the technician. For

the USB technician area, refer to § USB ( SERVICE FUNCTIONS)

PASSWORD : 1 1 2 3 5 8 13

First character = 1

1+0= 1

1+1= 2

2+1= 3

3+2= 5

5+3= 8

8+5= 13

1 1 2 3 5 8 13

21

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

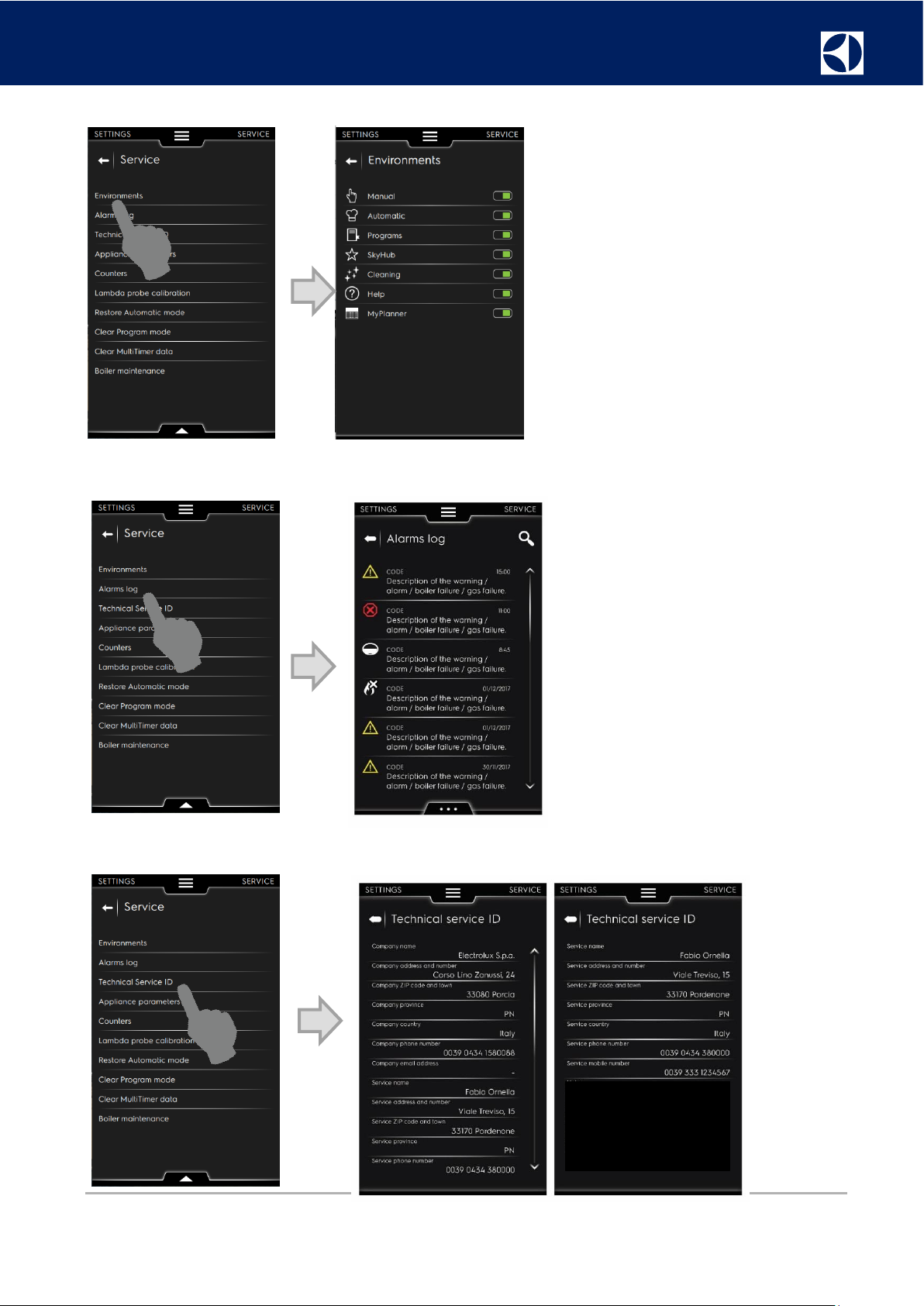

2.2.1.5.1 ENVIRONMENTS

2.2.1.5.2 ALARM LOGS

2.2.1.5.3 TECHNICAL SERVICE ID

22

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

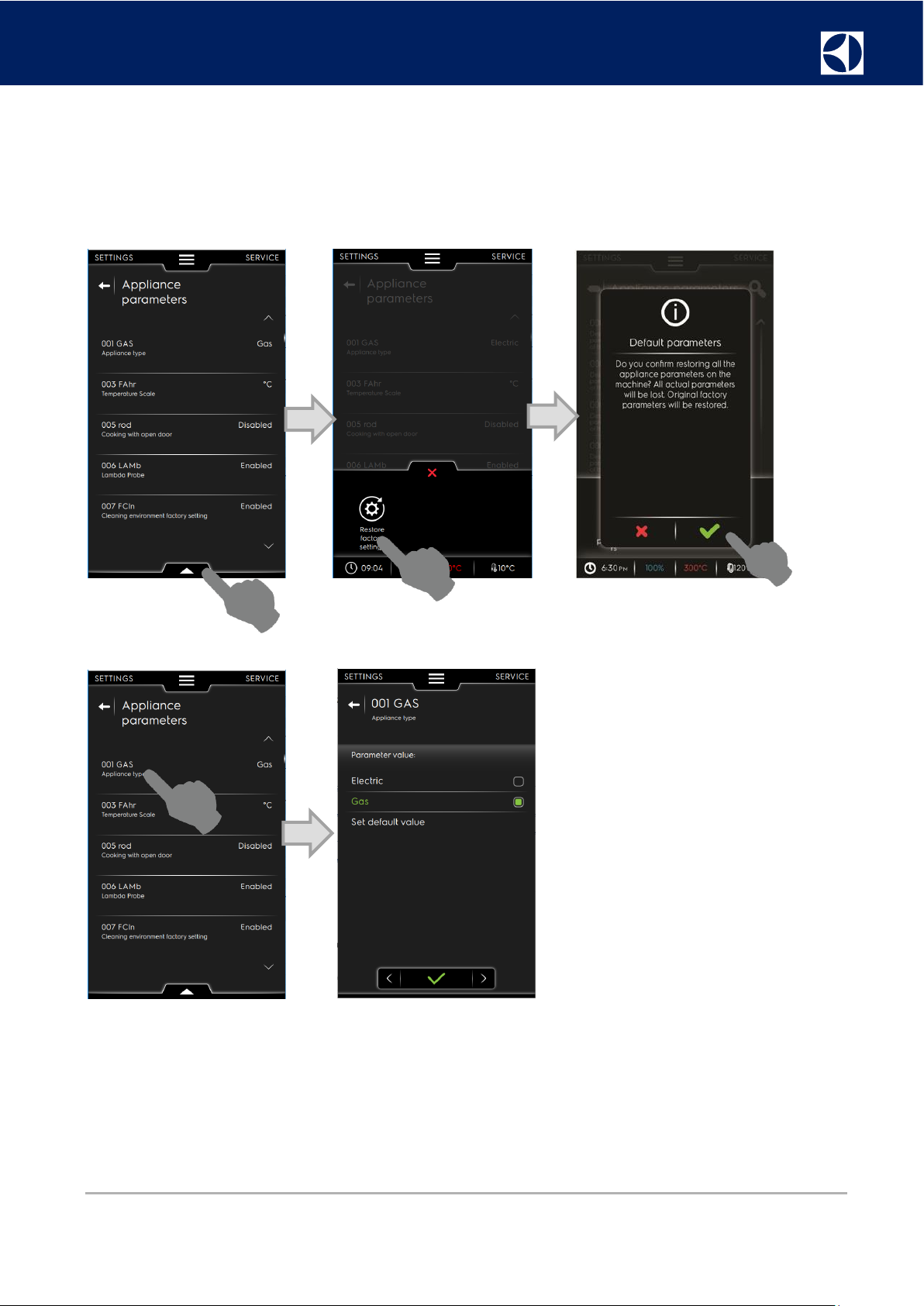

2.2.1.5.4 APPLIANCE PARAMETERS T, K (TOUCH SCREEN) / LIST

The parameter lists are available in a separate document for authorized technicians on the web sites (PRIDESERVICE PORTAL- AGELUX etc..) In case of any doubt, refer to your local country customer care.

Identification of parameter and value to set or change.

23

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

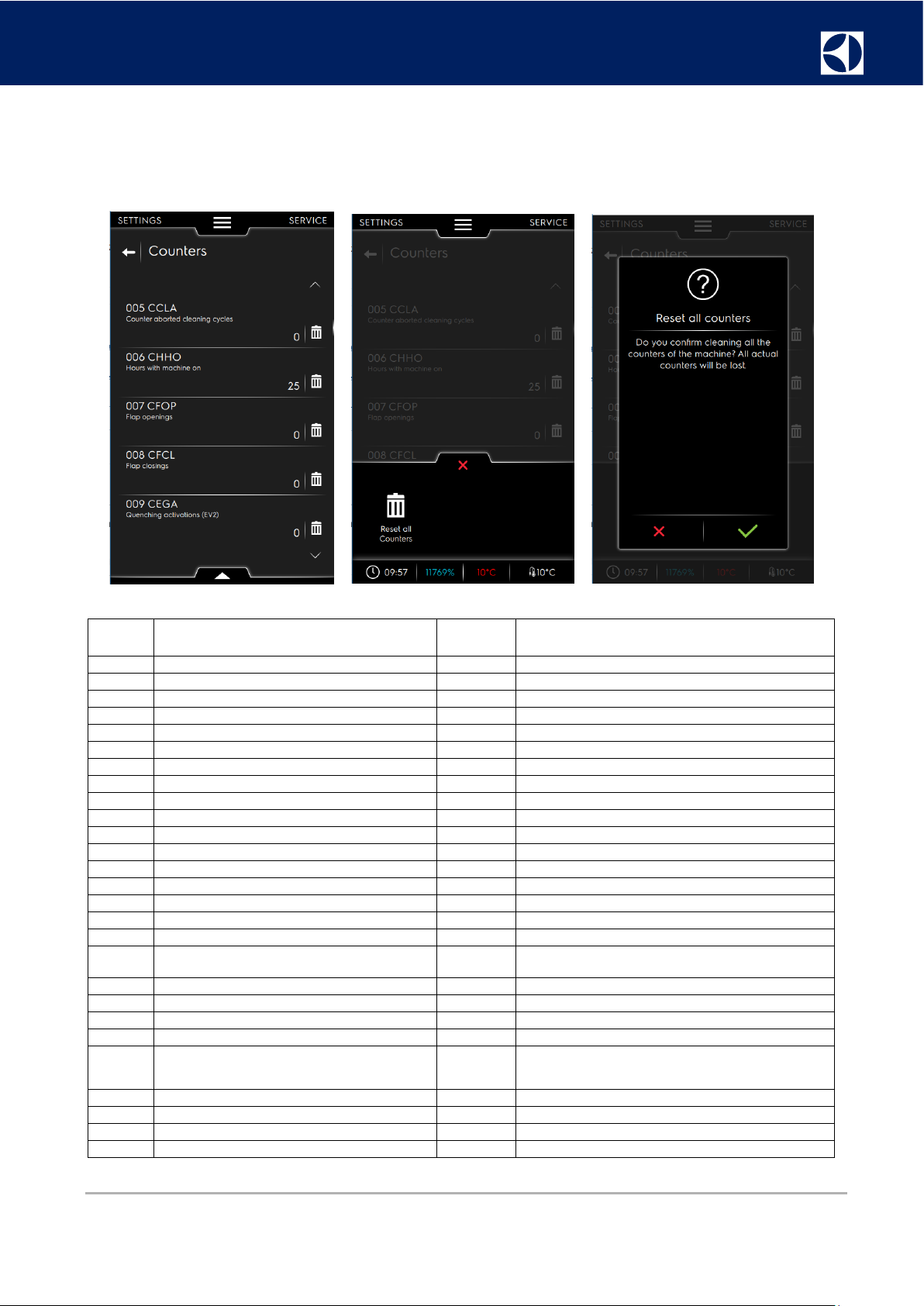

2.2.1.5.5 COUNTERS

Here it is possible check the time and cycle used in the units, as:

-How many cycle used

-How many hours used

-Reset all counter

COUNTERS ED3 DRAFT, in attesa info da Luca G.

Counter

id

COUNTER NAME

Mnemonic

Description

0

CNT_CLN_XS

CCL4

Counter for extra strong type cleaning cycle concluded

1

CNT_CLN_S

CCL3

Counter for strong type cleaning cycle concluded

2

CNT_CLN_M

CCL2

Counter for medium type cleaning cycle concluded

3

CNT_CLN_SF

CCL1

Counter for soft type cleaning cycle concluded

4

CNT_CLN_R

CCL0

Counter for rinse cleaning cycle concluded

5

CNT_CLN_ABORTED

CCLA

Counter for aborted cleaning cycle concluded

6

CNT_HH_ON

CHHO

Number of hours with machine on

7

CNT_FLAP_OPENING

CFOP

Flap openings 8 CNT_FLAP_CLOSING

CFCL

Flap closings

9

CNT_QUENCHING_ACTIVATIONS

CEGA

Quenching activations

10

CNT_HH_QUENCHING_ON

CHoA

Quenching active time

11

CNT_BURNER_TOP_ACTIVATIONS

CbtA

Gas burner top cavity activations

12

CNT_BURNER_BOTTOM_ACTIVATIONS

CbbA

Gas burner bottom cavity activations

13

CNT_BURNER_BOILER1_ACTIVATIONS

Cb1A

Gas burner boiler 1 activations

14

CNT_BURNER_BOILER2_ACTIVATIONS

Cb2A

Gas burner boiler 2 activations

15

CNT_BOILER_FILL_ACTIVATIONS

CbFA

Boiler filling valve activations

16

CNT_BOILER_FILL_ACTIVE

CHbF

Boiler filling valve on time (EV5)

17

CNT_HH_COOKING

CHCO

Conts hours during cooking process (manual cooldown

not included)

18

CNT_HH_STEAM

CHSt

Counts hours during steam cycles

19

CNT_HH_COMBI

CHCI

Counts hours during combi cycles

20

CNT_HH_CONVECTION

CHCn

Counts hours during convection cycles

21

CNT_HH_OVER40DEG

CH40

Hours with cavity above 40°C

22

CNT_HH_GASKET_LIFE

CHEL

Counts equivalent hours of gasket life based on a function that depends on cavity temperature and humidity

(TBD)

23

CNT_ISG_ACTIVATIONS

CISA

ISG activations (EV1)

24

CNT_HH_ISG_ACTIVATE

CHIS

ISG active time (EV1)

27

CNT_INLET_WATER_ACTIVATIONS

CInA

inlet water cleaning valve activations (EV7)

28

CNT_HH_INLET_WATER_ACTIVE

CHIA

inlet water cleaning valve active time (EV7)

24

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

Counter

id

COUNTER NAME

Mnemonic

Description

29

CNT_DRAWER_LOADING_ACTIVATIONS

CdLA

drawer loading valve activations (EV11)

30

CNT_HH_DRAWER_LOADING_ACTIVE

CHdL

drawer loading valve active time (EV11)

31

CNT_DRAWER_DRAIN_ACTIVATIONS

CddA

drawer drain valve activations (EV12)

32

CNT_HH_DRAWER_DRAIN_ACTIVE

CHdd

drawer drain valve active time (EV12)

33

CNT_RECIRC_PUMP_ACTIVATIONS

CrPA

recirculating pump activations (M8)

34

CNT_HH_RECIRC_PUMP_ACTIVE

CHrP

recirculating pump active time (M8)

35

CNT_BOILER_DRAIN_OPENINGS

CbdO

boiler drain openings (BV6)

36

CNT_BOILER_DRAIN_CLOSINGS

CbdC

boiler drain closings (BV6)

37

CNT_CAVITY_DRAIN_OPENINGS

CcdO

cavity drain openings (BV3)

38

CNT_CAVITY_DRAIN_CLOSINGS

CcdC

cavity drain closings (BV3)

39

CNT_LIQUID_DETERGENT_ACTIVATIONS

CLdA

Liquid detergent activations (P1)

40

CNT_LIQUID_DETERGENT_ACTIVE

CHLd

Liquid detergent active time (P1)

41

CNT_LIQUID_RINSE_ACTIVATIONS

CLrA

Liquid rinse aid activations (P2)

42

CNT_LIQUID_RINSE_ACTIVE

CHLr

Liquid rinse aid active time (P2)

43

CNT_HH_SMOKER_AROMATIZER_ACTIVE

CHSA

Count the hours while the aromatizer's or the smoker's

heater is on, based on which accessory is installed

44

CNT_PREHEATING_SKIPPED

CPrS

Counts how many times the preheat is skipped

45

CNT_CYCLES_STOPPED_USER

CCSU

Counts how many times the user stops a cycle

46

CNT_CYCLES_STOPPED_ALARM

CCSA

Counts how many times a cycle was stopped by an

alarm

47

CNT_AUTOMATIC_CYCLES

CACL

Counts how many automatic cycles are launched

48

CNT_MANUAL_CYCLES

CMAn

Counts how many manual cycles are launched

49

CNT_PROGRAM_CYCLES

Cpro

Counts how many programs are launched

50

CNT_SORT_AND_SAVE

CSAS

Counts how many times the Sort & Save functionality is

used

51

CNT_AGENDA_FEATURE_LAUNCHED

CAFL

Counts how many times a feature is launched through

the agenda feature

52

CNT_SKYDUO_REQUESTED

CSdr

Counts how many skyduo cycle requestes are sent to a

blast chiller

53

CNT_SKYDUO_ACCEPTED

CSdA

Counts how many skyduo cycle requestes by blast

chiller are accepted

54

CNT_OPEN_DOOR

CdOP

Counts how many times the door is opened

55

CNT_OPEN_DOOR_COOKING

CdOC

Counts how many times the door is opened while a

cooking cycle is running

56

CNT_OPEN_DOOR_CLEANING

CdCL

Counts how many times the door is opnened while a

cleaning cycle is running

57

CNT_POWER_ON

CPOn

Counts how many times the machine has been powered on

58

CNT_POWER_FAIL

CPFA

Counts how many times a power fail occurred

59

CNT_CLN_DESCALE

CCdE

Unsigned word type parameter that counts the number

of descaling phases concluded

60 CCdn

61

CNT_DRAWER_INSERTIONS

CdIn

Countts how many times the cleaning drawer is inserted

62

CNT_CYC_POW

CEPo

Last cycle power counter

63

CNT_CYC_WATER

CH2o

Last cycle water consumption

64 CEPo

65

CNT_CYC_WATER

CH2o

Last cycle water consumption

66

CNT_HH_BOILER_ON

CHOO

Counts the hours with the boiler thermoregulation of

boiler water or cavity temperature or humidity activated

25

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

Counters available/shown only if accessory is enabled/present.

Counter

id

COUNTER NAME

Mnemonic

Description

71

CNT_HH_BOILER_ON_FROM_DRAIN

CHbd

As CNT_HH_BOILER_ON, but from the last time the

safety boiler probe has not detected water

73

CNT_CLN_GF2

CCG2

Counter cleaning cycles with green feature 2 active

74

CNT_CLN_GF3

CCG3

Counter cleaning cycles with green feature 3 active

75

CNT_HOOD_LAMP1_CLEAN

CHL1

Hood's lamp 1 working since last cleaned

76

CNT_HOOD_LAMP2_CLEAN

CHL2

Hood's lamp 2 working since last cleaned

77

CNT_HOOD_LAMPS_SUBS

CHLS

Hood's lamps working

78

CNT_HOOD_COND_CLEAN_POST

HSCP

Hood's condensation sink cleaning postponed

79

CNT_HOOD_DEMIST_CLEAN_POST

HDFP

Hood's demister and filter cleaning postponed

80

CNT_HOOD_LAMP1_CLEAN_POST

HL1P

Hood's lamp 1 cleaning postponed

81

CNT_HOOD_LAMP2_CLEAN_POST

HL2P

Hood's lamp 2 cleaning postponed

82

CNT_HOOD_LAMPS_SUBS_POST

HLSP

Hood's lamps substitution postponed

83

CNT_HOOD_OZONE_POST

CHOP

Hood's ozone generator substitution postponed

84

CNT_HOOD_COND_CLEAN_DONE

HSCd

Hood's condensation sink cleaning done

85

CNT_HOOD_DEMIST_CLEAN_DONE

HDFd

Hood's demister and filter cleaning done

86

CNT_HOOD_LAMP1_CLEAN_DONE

HL1d

Hood's lamp 1 cleaning done

87

CNT_HOOD_LAMP2_CLEAN_DONE

HL2d

Hood's lamp 2 cleaning done

88

CNT_HOOD_LAMPS_SUBS_DONE

HLSd

Hood's lamps substitution done

89

CNT_HOOD_OZONE_DONE

CHOd

Hood's ozone generator substitution done

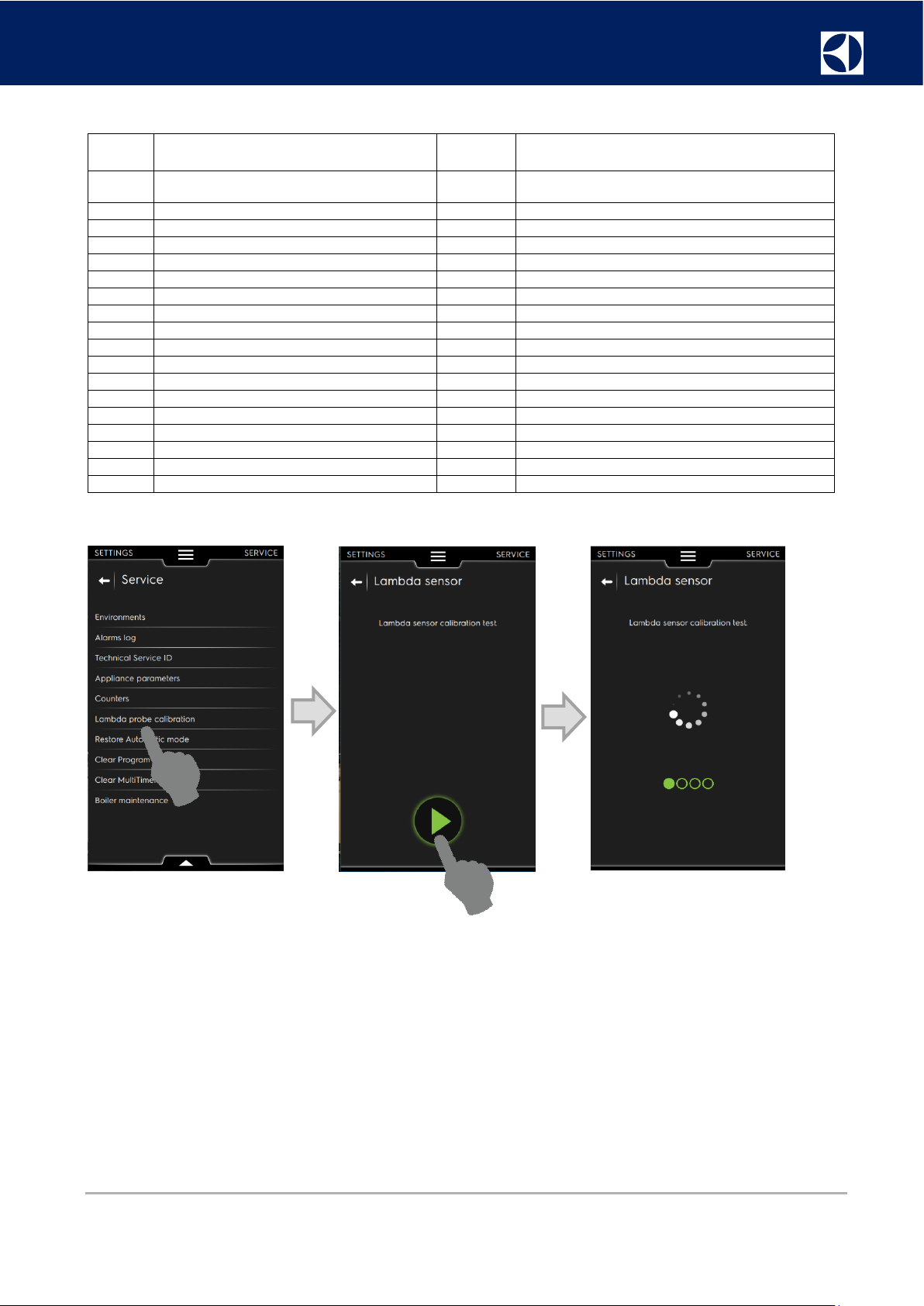

2.2.1.5.6 LAMBDA PROBE CALIBRATION

26

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

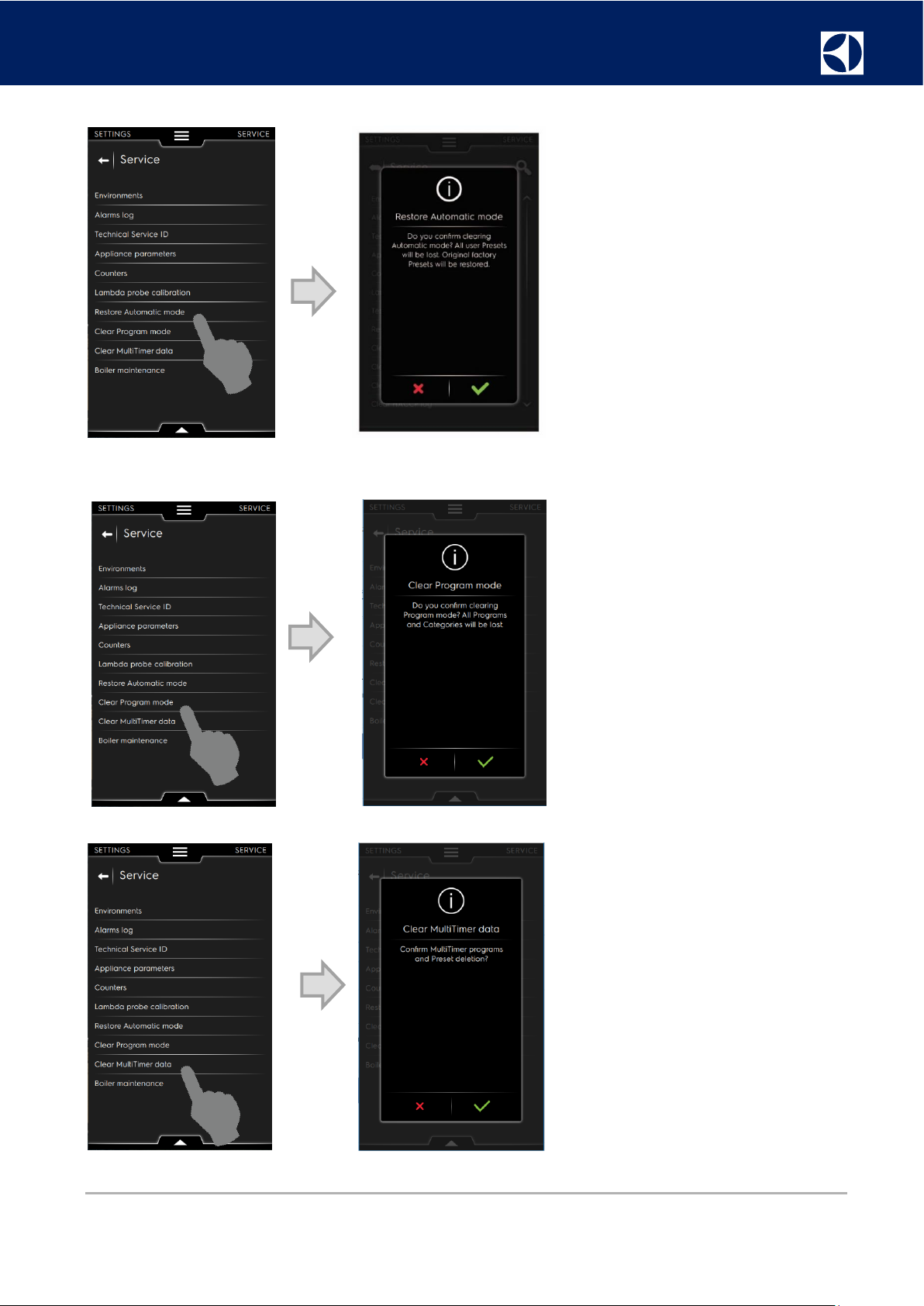

2.2.1.5.7 RESTORE AUTOMATIC MODE

2.2.1.5.8 CLEAR PROGRAM MODE, MULTI TIMER DATA

27

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

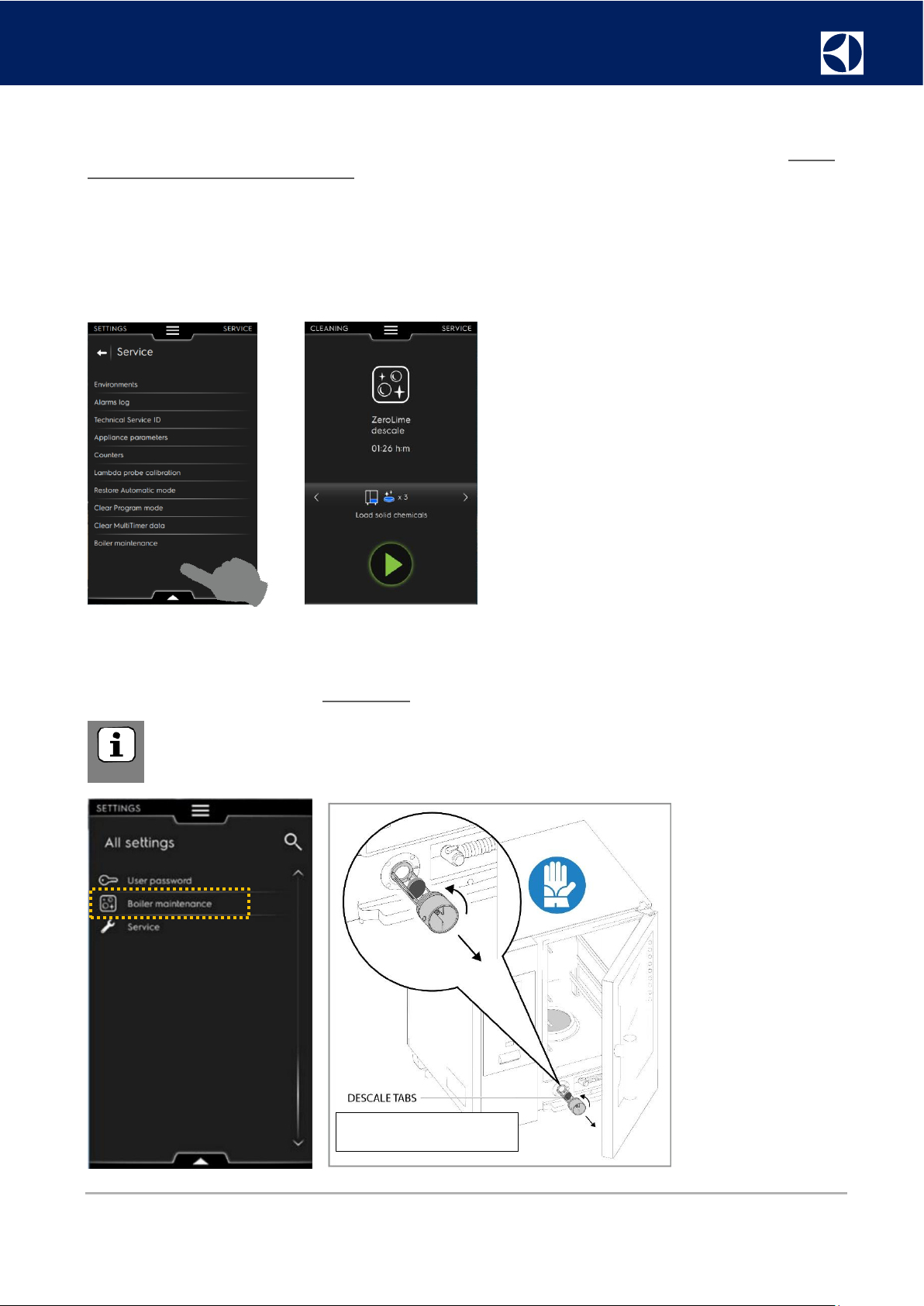

2.2.1.5.9 BOILER MANTENANCE / DESCALE

During the routine washing cycles carried out with the suggested chemicals (rinse & descale tablets) the boiler

is maintained scale free (refer to the amount and type of detergent/rinse aid to use as indicated at §WASH

CYCLES / DETERGENTS / DESCALE).

In case of excessive scale in the boiler the display may show a message with “dESC“ error code; this is not a

blocking error code message, it’s a notification “I am heating up/presence of scale in boiler” in this case the

technician can carry out an user descale cycle. dESC" will be shown on the display if the temperature of the

boiler will exceed the setted value of parameter called "bSct" (Boiler Scale build up threshold) set at 115C°

(HIDDEN PARAMETER).

“dESC“ error code can be skipped, it will appear now and again to remind the user about this condition and

descale cycle to be carried out. "

Insert the descaling tablets C25 in the front drawer and execute the "Boiler maintenance" cycle. If the end of

the descaling cycle of the boiler the display shows the error code "dESC" again, the boiler and the level probes

must be checked. water etc. / repeat the procedure

If the cycle is completed without interruptions, the special "descaling counter" (descale counter) is increased

by one unit (+1). Also refer to the COUNTERS section.

NOTE !

The boiler descale operation cannot be carried out “manually”; the boiler is not equipped with an

external access like in previous models.

TABS C25 (3 PCS.)

28

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

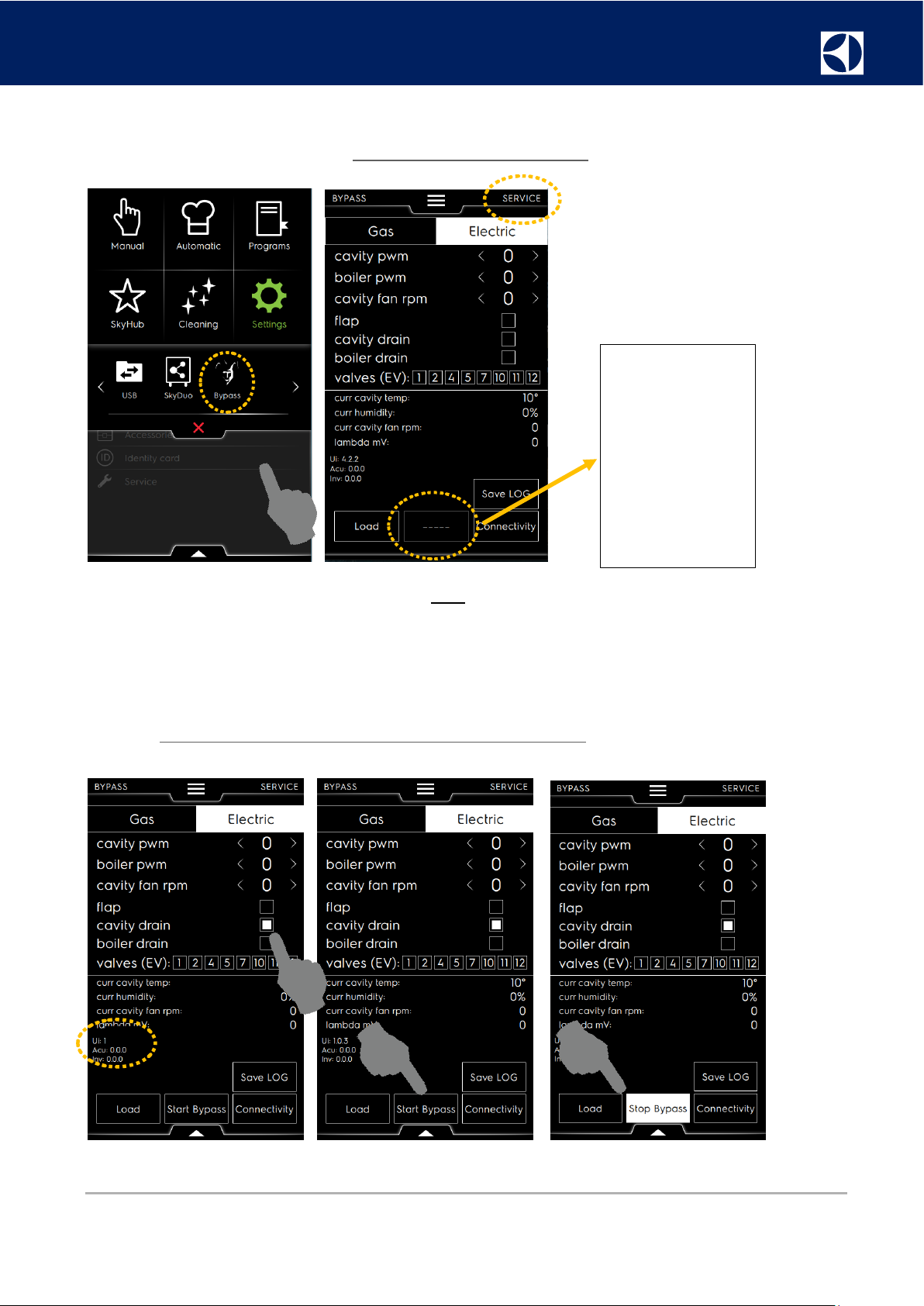

2.2.1.6 BY-PASS ENVIRONMENT

Once you are logged as SERVICE § SETTINGS AND SERVICE AREA the By-Pass environment is automatically available in the secondary menu of the home page.

From this environment it is possible to do two things:

1-Manually activate the following devices:

Cavity flap venting valve VV1 (cavity air intake)

• Cavity drain valve (BV3)

• Bolier drain valve (BV6)

• The valves EV1-EV2-EV4-EV5-EV7-EV10-EV11-EV12

Refer to § COMPONENTS TECHNICAL DESCRIPTION/FUNCTIONING

Below the example on how to START and STOP the cavity drain valve with software 4.2.2 :

4.22

Note: In case that

the “START BYPASS” button is not

active, the PARAMETER 219

needs to be set at 1

(enable) to permit

to start the bypass

cycle = UPDATE

PARAMETER

FILE OF APPLIANCE

29

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

2-Manually load PNC & SERIAL file:

“Load” into the U.I the § PNC & SER UPLOAD (pncSerial.json) U.I. SPARE PART different type of files

2.2.1.7 USB TRANSFER AMBIENT ( SERVICE FUNCTIONS)

The USB Transfer ambient is used to manage data transfer between UI and a USB key. It contains four functionalities:

- Download all: Used to copy all data (parameters, recipes,…) from UI to USB key;

- Upload all: Used to copy all data from USB key to UI;

- Download selection: Used to select, from a single category (parameters, recipes,…), which items to copy

from UI to USB key;

- Upload selection: Used to select, from a single category, which items to copy from USB key to UI.

The usb ambient can be accessed in two ways: SERVICE credentials - USER credentials; the service credentials has more advanced upload/download options while the user credentials is mainly upload/download

generic user files.

The navigation in this ambient will be the same for the "Service User" and the "generic User", but the effects

on the download/upload operations will be different

USER credentials:

The customer/chef can log in without password directly from home page.

USB transfer area

Home

Use the left/right scroll

buttons to locate the USB

transfer area with older

software version

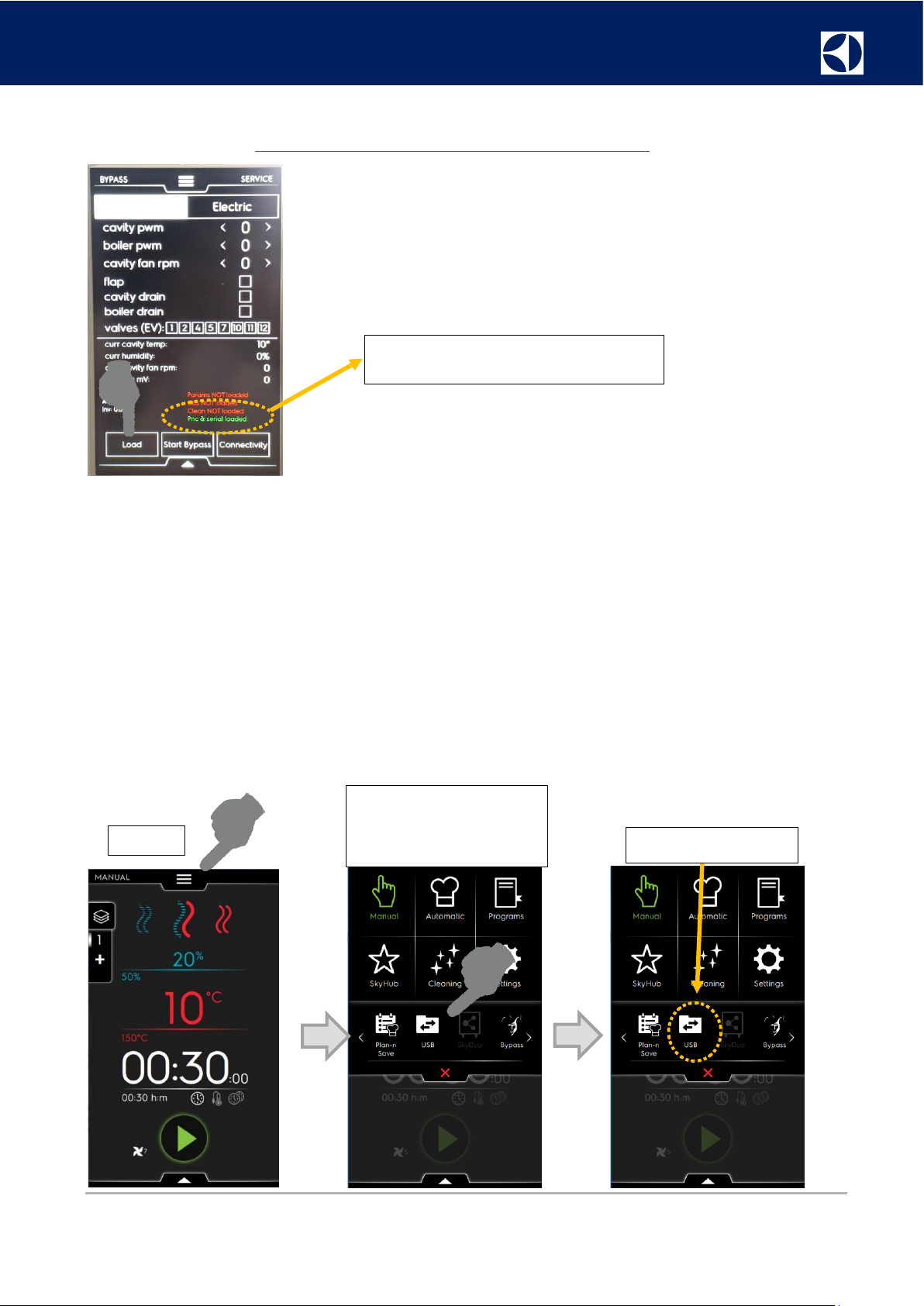

Press “load” the “Pnc & Serrial loaded”

should display.

30

ELECTRONIC BOARDS SKYLINE – MAGISTAR OVEN 6-10-20GN

SERVICE credentials:.To obtain the complete service functions of the usb transfer ambient it will first be

necessary to log into the service area like described in § SETTINGS AND SERVICE AREA / SERVICE

Once that you have logged into the service area press the "back arrow" , DO NOT PRESS THE DROP DOWN

MENU, or you will loose the " rights " to then see all the service functions in the USB transfer area.

SERVICE VIEW OF USB AREA:

The “SERVICE credentials” are used also to update the parameter list into an appliance but for further info

please refer to chapter § PROGRAMMING PARAMETERS. It will be possible to DOWNLOAD or UPLOAD

files INTO / FROM your USB key.

The presence of the "SERVICE" icon means that you are

logged in with

" SERVICE credentials ". If “User credentials” are active, the space will be left blank.

“Service” credentials will be active for 15 minutes while navigating the

interface. The 15 minutes timeout is continually reset while the appliance

is in running state and every time the interface detects a touch. Remember to EXIT the “Service credentials" at the end of your operations by

turning the appliane OFF, or by waiting time out (15 minutes / without

touching the display).

With “SERVICE credentials” the user interaction will differ from "USER

credentials” for the following points:

- The download/upload functionalities will include Service parameters,

and other characteristics related to the machine model.

- The download functionalities for logs will include additional logs for debugging or "post-mortem" analysis purposes.

- In running state the service user will have access to the top drawer.

Only the data monitor button will be active.

- The service user will have full access to Service parameters setting and

data monitor.

Loading...

Loading...