EN Original operating instructions

Cordless Paint Sprayer

SP Manual de instrucciones original

Rociadora de pintura inalámbrica

FR Traduction du mode d’emploi

d’origine

Pistolet à peinture sans cordon

TC-SY 18/60 Li

7

Art.-Nr.: 4260027 I.-Nr.: 21011

Anl_TC_SY_18_60_Li_SPK7_USA.indb 1Anl_TC_SY_18_60_Li_SPK7_USA.indb 1 25.08.2021 15:05:5225.08.2021 15:05:52

1

9

1

14

2

3

12

15

16

5

6

4

8

17 18

2

Anl_TC_SY_18_60_Li_SPK7_USA.indb 2Anl_TC_SY_18_60_Li_SPK7_USA.indb 2 25.08.2021 15:05:5325.08.2021 15:05:53

14 15

7

4

3

6

5

- 2 -

4

10

11

5

8

12

7

4

7

A

B

C

9

+

6

-

6

11

11

8

4

- 3 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 3Anl_TC_SY_18_60_Li_SPK7_USA.indb 3 25.08.2021 15:05:5725.08.2021 15:05:57

10

2-6 in./plg/po.

(5-15 cm)

11

12 13

2

1

3

3

2

13

3

14 15

15

18 13

16

- 4 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 4Anl_TC_SY_18_60_Li_SPK7_USA.indb 4 25.08.2021 15:06:0025.08.2021 15:06:00

16

20

17

21

19

12 3

4

56 7

- 5 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 5Anl_TC_SY_18_60_Li_SPK7_USA.indb 5 25.08.2021 15:06:0425.08.2021 15:06:04

EN

Table of contents

1. Safety information

2. Layout and items supplied

3. Intended use

4. Technical data

5. Before starting the equipment

6. Operation

7. Cleaning, maintenance and ordering spare parts

8. Disposal and recycling

9. Storage

10. Viscosity Table

11. Troubleshooting Guide

Einhell USA LLC · 305 Veterans Blvd · Carlstadt · NJ 07072 · USA

- 6 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 6Anl_TC_SY_18_60_Li_SPK7_USA.indb 6 25.08.2021 15:06:0525.08.2021 15:06:05

EN

DANGER!

When using the equipment, a number of safety

precautions must be observed to avoid injuries

and damage. Please read the complete operating

instructions and safety information with due care.

Keep these operating instructions in a safe place

so that the information is available at all times. If

you give the equipment to any other person, hand

over these operating instructions and the safety

information as well. We cannot accept any liability

for damage or accidents which arise due to

failure to follow these instructions and the safety

information.

1. Safety information

DANGER!

Read all the safety information and

instructions. Failure to adhere to the safety

information and instructions set out below

may result in electric shock, fi re and/or serious

injury. Keep all the safety information and

instructions in a safe place for future use.

General safety information for power tools

The term „power tool“ used in the safety

regulations refers to power tools operated from

the mains power supply (with a power cable) and

to battery operated power tools (without a power

cable).

1) Work area safety

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodifi ed plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f) If operating a power tools in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the infl uence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off -position before

connecting to power source and/or

BATTERY pack, picking up or carrying the

tool. Carrying power tools with your fi nger on

the switch or energising power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

- 7 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 7Anl_TC_SY_18_60_Li_SPK7_USA.indb 7 25.08.2021 15:06:0525.08.2021 15:06:05

EN

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust

related hazards.

h) Do not let familiarity gained from frequent

use of tools allow you to become

complacent and ignore tool safety

principles. A careless action can cause

severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch

does not turn it on and off . Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or remove the battery pack,

if detachable, from the power tool before

making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools and accessories.

Check for misalignment or binding of

moving parts, breakage of parts and

any other condition that may aff ect the

power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with

these instructions and in the manner

intended for the particular type of power

tool, taking into account the working

conditions and the work to be performed.

Use of the power tool for operations diff erent

from intended could result in a hazardous

situation.

h) Keep handles and grasping surfaces

dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do

not allow for safe handling and control of the

tool in unexpected situations.

5) Battery tool use and care

a) Recharge only with the charger specifi ed

by the manufacturer. A charger that is

suitable for one type of battery pack may

create a risk of fi re when used with another

battery pack.

b) Use power tools only with specifi cally

designated battery packs. Use of any other

battery packs may create a risk of injury and

fi re.

c) When battery pack is not in use, keep it

away from other metal objects, like paper

clips, coins, keys, nails, screws or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

cause burns or a fi re.

d) Under abusive conditions, liquid may be

ejected from the battery; avoid contact.

If contact accidentally occurs, fl ush with

water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the

battery may cause irritation or burns.

e) Do not use a BATTERY pack or tool that

is damaged or modifi ed. Damaged or

modifi ed batteries may exhibit unpredictable

behaviour resulting in fi re, EXPLOSION or

risk of injury.

f) Do not expose a BATTERY pack or tool to

fi re or excessive temperature. Exposure to

fi re or temperature above 266°F (130°C) may

cause explosion.

g) Follow all charging instructions and do

not charge the BATTERY pack or tool

outside the temperature range specifi ed

in the instructions. Charging improperly or

at temperatures outside the specifi ed range

may damage the BATTERY and increase the

risk of fi re.

6) Service

a) Have your power tool serviced by a

qualifi ed repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

b) Never service damaged BATTERY packs.

Service of BATTERY packs should only be

- 8 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 8Anl_TC_SY_18_60_Li_SPK7_USA.indb 8 25.08.2021 15:06:0525.08.2021 15:06:05

EN

performed by the manufacturer or authorized

service providers.

Additional safety instructions

We pay a great deal of attention to the design

of every battery pack to ensure that we supply

you with batteries which feature maximum

power density, durability and safety. The battery

cells have a wide range of safety devices.

Each individual cell is initially formatted and its

electrical characteristic curves are recorded.

These data are then used exclusively to be able

to assemble the best possible battery packs.

Despite all the safety precautions, caution

must always be exercised when handling

batteries. The following points must be

obeyed at all times to ensure safe use.

Safe use can only be guaranteed if

undamaged cells are used. Incorrect

handling can cause cell damage.

Caution! Analyses confi rm that incorrect use and

poor care are the main causes of the damage

caused by high performance batteries.

Information about the battery

1. The battery pack supplied with your cordless

tool is not charged. The battery pack has to

be charged before you use the tool for the fi rst

time.

2. For optimum battery performance avoid low

discharge cycles. Charge the battery pack

frequently.

3. Store the battery pack in a cool place, ideally

at 59°F (15°C) and charged to at least 40%.

4. Lithium-ion batteries are subject to a natural

ageing process. The battery pack must be

replaced at the latest when its capacity

falls to just 80% of its capacity when new.

Weakened cells in an aged battery pack are

no longer capable of meeting the high power

requirements and therefore pose a safety risk.

5. Do not throw battery packs into an open fi re.

There is a risk of explosion!

6. Do not ignite the battery pack or expose it to

fi re.

7. Do not exhaustively discharge batteries.

Exhaustive discharge will damage the battery

cells. The most common cause of deep

discharge is lengthy storage or non-use of

partly discharged batteries. Stop working as

soon as the performance of the battery falls

noticeably or the electronic protection system

triggers. Place the battery pack in storage

only after it has been fully charged.

8. Protect batteries and the tool from

overloads. Overloads will quickly result

in overheating and cell damage inside the

battery housing without this overheating

actually being apparent externally.

9. Avoid damage and shocks. Replace

batteries which have been dropped from

a height of more than one meter or which

have been exposed to violent shocks without

delay, even if the housing of the battery pack

appears to be undamaged. The battery cells

inside the battery may have suff ered serious

damage. In this respect, please also read the

waste disposal information.

10. If the battery pack suff ers overloading and

overheating, the integrated protective cutoff will switch off the equipment for safety

reasons. Caution! Do not press the ON/OFF

switch any more if the protective cut-off has

actuated. This may damage the battery.

11. Use only original battery packs. The use

of other batteries may result in injuries,

explosion and a fi re risk.

12. Protect your rechargeable battery against

moisture, rain and high humidity. Moisture,

rain and high humidity can cause dangerous

cell damage. Never charge or work with

batteries which have been exposed to

moisture, rain or high humidity – replace them

immediately.

13. If your equipment is fi tted with a detachable

battery, remove the battery for safety reasons

after you have fi nished your work

Information on chargers and the charging

process

1. Please check the data marked on the rating

plate of the battery charger. Be sure to

connect the battery charger to a power supply

with the voltage marked on the rating plate.

Never connect it to a diff erent mains voltage.

2. Protect the battery charger and its cable from

damage and sharp edges. Have damaged

cables repaired without delay by a qualifi ed

electrician.

3. Keep the battery charger, batteries and the

cordless tool out of children‘s reach.

4. Do not use damaged battery chargers.

5. Do not use the supplied battery charger to

charge other cordless tools.

6. In heavy use the battery pack will become

warm. Allow the battery pack to cool to room

temperature before commencing with the

charging.

7. Do not over-charge batteries. Do not

- 9 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 9Anl_TC_SY_18_60_Li_SPK7_USA.indb 9 25.08.2021 15:06:0525.08.2021 15:06:05

EN

exceed the maximum charging times. These

charging times apply only to discharged

batteries. Frequent insertion of a charged

or partly charged battery pack will result in

over-charging and cell damage. Do not leave

batteries in the charger for days on end.

8. Never use or charge batteries if you

suspect that the last time they were

charged was more than 12 months

previously. There is a high probability

that the battery pack has already suff ered

dangerous damage (exhaustive discharge).

9. Charging batteries at a temperature below

50°F (10°C) will cause chemical damage to

the cell and may cause a fi re.

10. Do not use batteries which have heated

during the charging process, as the battery

cells may have suff ered dangerous damage.

11. Do not use batteries which have suff ered

curvature or deformation during the charging

process or which show other non-typical

symptoms (gassing, hissing, cracking,…)

12. Never fully discharge the battery pack

(recommended depth of discharge max.

80%) A complete discharge of the battery

pack will lead to premature ageing of the

battery cells.

13. Never charge the batteries unsupervised.

Protection from environmental infl uences

1. Wear suitable work clothes. Wear safety

goggles.

2. Protect your cordless tool and the battery

charger from moisture and rain. Moisture

and rain can cause dangerous cell damage.

3. Do not use the cordless tool or the battery

charger near vapors and infl ammable liquids.

4. Use the battery charger and cordless tools

only in dry conditions and an ambient

temperature of 50°F to 104°F (10°C to 40°C).

5. Do not keep the battery charger in places

where the temperature is liable to reach over

104°F (40°C). In particular, do not leave the

battery charger in a car that is parked in the

sunshine.

6. Protect batteries from overheating.

Overloads, over-charging and exposure to

direct sunlight will result in overheating and

cell damage. Never charge or work with

batteries which have been overheated –

replace them immediately if possible.

7. Storage of batteries, battery chargers

and cordless tools. Store the charger and

your cordless tool only in dry places with an

ambient temperature of 50°F to 104°F (10°C

to 40°C). Store the lithium-ion rechargeable

battery in a cool and dry place at 50°F to 68°F

(10°C to 20°C). Protect them from humidity

and direct sunlight! Place only fully charged

batteries in storage (charged at least 40%).

8. Prevent the lithium-ion battery pack from

freezing. Battery packs which were stored

below 32°F (0°C) for more than 60 minutes

must be disposed of.

9. When handling batteries beware of

electrostatic charge: Electrostatic discharges

cause damage of the electronic protection

system and the battery cells. Avoid

electrostatic charging and never touch the

battery poles.

Battery Caution + Disposal

Disposal

Should your appliance need replacement after

extended use, do not dispose of it with the

household refuse, but in an environmentally safe

way.

Waste produced by electrical machine

items should not be handled like normal

household rubbish. Please recycle where

recycle facilities exist. Check with your local

authority or retailer for recycling advice.

Always dispose of your battery pack according

to federal, state, and local regulations. Contact

a recycling agency in your area for recycling

locations.

CAUTION! Even discharged battery packs

contain some energy. Before disposing, use

electrical tape to cover the terminals to prevent

the battery pack from shorting, which could cause

a fi re or explosion.

WARNING! To reduce the risk of injury or

explosion, never burn or incinerate a battery

pack even if it is damaged, dead, or completely

discharged. When burned, toxic fumes and

materials are emitted into the surrounding

atmosphere.

1. Batteries vary according to device. Consult

your manual for specifi c information.

2. Install only new batteries of the same type in

your product (where applicable).

3. Failure to insert batteries in the correct

polarity, as indicated in the battery

compartment or manual, may shorten the life

of the batteries or cause batteries to leak.

4. Do not mix old and new batteries.

5. Do not mix Alkaline, Standard (Carbon-Zinc),

or Rechargeable (Nickel Cadmium, Nickel

- 10 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 10Anl_TC_SY_18_60_Li_SPK7_USA.indb 10 25.08.2021 15:06:0525.08.2021 15:06:05

EN

Metal Hydride, or Lithium-Ion) batteries.

6. Do not dispose of batteries in fi re.

7. Batteries should be recycled or disposed of

as per state and local guidelines.

When shipping or disposing of batteries and

cordless tools, always ensure that they are

packed individually in plastic bags to prevent

short circuits and fi res.

Special safety information

Always remove the battery before doing any

•

work on the paint spray gun.

You may only spray materials such as paint,

•

lacquer, varnish, etc. which have a flash

point above 131°F (55°C), without additional

heating. (Hazard Class A II or A III, refer to

material tin)

Be aware of the hazards associated with the

•

material you are spraying. Read the hazard

information on the tin or the information

provided by the manufacturer.

Follow the manufacturer‘s safety precautions

•

when working with the material you are

spraying.

Do not spray any materials if you do not know

•

how hazardous they are.

Use personal protective equipment (face

•

mask) which filters the air to avoid inhalation

of spray mist.

Wear gloves and protective clothing to avoid

•

skin contact with the paint.

Wear suitable eye protection (goggles).

•

The work area must exceed 1060 cu ft

•

(30 m3), and sufficient ventilation must be

ensured during spraying and drying.

Be aware that paint and lacquer can be

•

highly inflammable and potentially explosive.

There must be no ignition sources such as

fireplaces, open flames, buring cigarettes or

machines that generate sparks.

The paint spray gun may not be used in

•

premises were the explosion protection

directive applies.

When you are spraying, there must be no

•

ignition sources nearby such as open flames,

cigarette smoking, sparks, hot glowing wires,

hot surfaces, etc.

The paint spray gun must not be used to

•

spray flammable substances.

Flammable solvents must not be used to

•

clean the paint spray gun.

INJURY RISK! Never point the paint spray

•

gun at yourself, other people or animals.

Properly dispose of residual paint and

•

cleaning agents in accordance with local laws

and regulations.

Residual paint must be taken to a suitable

•

collection point. If you are not sure, ask the

local council where the nearest collection

point is.

When you are working with the paint spray

•

gun indoors or outdoors, the gun must not

suck in any solvent fumes.

When you are working outdoors, pay

•

attention to the wind direction. The wind can

distribute the material over long distances

and cause damage.

Do not allow children to handle the gun.

•

Never open the gun to carry out electrical

•

repairs.

Spraying into the skin can introduce toxins

•

into the body. Call a doctor immediately if the

jet causes a skin injury or penetrates the skin.

Children are not allowed to use this

•

equipment. Children should be supervised

so that they do not play with the equipment.

Children are not allowed to carry out cleaning

or maintenance.

This equipment must not be used by persons

•

with reduced physical, sensory or mental

capacities or those with a lack of experience

and knowledge.

SAVE THESE INSTRUCTIONS

Explanation of the symbols used (see Fig. 17)

1. Danger! - Read the operating instructions to

reduce the risk of injury.

2. Caution! Wear ear-muff s. The impact of

noise can cause damage to hearing.

3. Caution! Wear a breathing mask. Dust

which is injurious to health can be generated

when working on wood and other materials.

Never use the device to work on any

materials containing asbestos!

4. Caution! Wear safety goggles. Sparks

generated during working or splinters, chips

and dust emitted by the device can cause

loss of sight.

5. Caution! Wear gloves.

6. Note! Disassemble and clean the equipment

immediately after each use. This is the only

way to keep the wetted parts clean and

prevent clogging. Parts that are not cleaned

can become clogged, causing an equipment

fault.

- 11 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 11Anl_TC_SY_18_60_Li_SPK7_USA.indb 11 25.08.2021 15:06:0525.08.2021 15:06:05

EN

7. Store the batteries only in dry rooms with

an ambient temperature of +10°C to +40°C.

Place only fully charged batteries in storage

(charged at least 40%).

2. Layout and items supplied

2.1 Layout

1. Air cap retaining ring

2. Air cap

3. Nozzle

4. Locking lever

5. Trigger

6. Max. paint volume control

7. Pistol mounting

8. Viscosity cup

9. Wall storage hook

10. Material tube connection

11. Material tube

12. Container

13. Fluid needle

14. Trigger unit

15. Drive unit

16. Filter cap with fi lter

17. Cleaning needle

18. Adapter for fl uid needle

19. Pushlock button

20. Battery capacity indicator

21. Battery capacity indicator button

2.2 Items supplied

Please check that the article is complete as

specifi ed in the scope of delivery. If parts are

missing, please contact our service center or the

store where you made your purchase at the latest

within 5 work days after purchasing the article and

upon presentation of a valid bill of purchase.

Open the packaging and take out the

•

equipment with care.

Remove the packaging material and any

•

packaging and/or transportation braces (if

present).

Check to see if all the items are supplied.

•

Inspect the equipment and accessories for

•

transport damage.

If possible, keep the packaging until the end

•

of the guarantee period.

Container

•

Cleaning brush (not shown)

•

Cleaning needle

•

Viscosity cup

•

Cap

•

2.5 mm nozzle, mounted on the pistol

•

(black)

Replacement nozzle, 2 mm (red)

•

Original operating instruction with safety

•

information

Separately available accessories

18V 1.5Ah P-X-C lithium-ion battery

18V 2.0Ah P-X-C lithium-ion battery

18V 2.5Ah P-X-C lithium-ion battery

18V 3.0Ah P-X-C lithium-ion battery

18V 4.0Ah P-X-C lithium-ion battery

18V 5.2Ah P-X-C Plus lithium-ion battery

18V 4.0Ah/6.0Ah P-X-C Plus lithium-ion battery

18V P-X-C Dual Port Fast Charger

18V P-X-C Fast Charger

Explore battery + charger options at

einhellUSA.com

3. Intended use

The machine is suitable for spraying solventborne and water-borne paint, varnish, primers,

transparent lacquer, vehicle basecoats and

clearcoats, stains and wood preservatives.

It must not be used for alkaline solutions,

acidic solutions, particle-containing spraying

substances, latex paints, and paints containing

spray or drip inhibitors.

The equipment is allowed to be used only for its

prescribed purpose. Any other use is deemed to

be a case of misuse. The user/operator and not

the manufacturer will be liable for any damage or

injuries of any kind resulting from such misuse.

Please note that our equipment has not been

designed for use in commercial, trade or

industrial applications. Our warranty will be voided

if the equipment is used in commercial, trade or

industrial businesses or for equivalent purposes.

Danger!

The equipment and packaging material are

not toys. Do not let children play with plastic

bags, plastic sheets and small parts. There is

a risk of choking and suff ocating!

- 12 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 12Anl_TC_SY_18_60_Li_SPK7_USA.indb 12 25.08.2021 15:06:0525.08.2021 15:06:05

EN

4. Technical data

Motor power supply: ............................18 V

Max fl ow per minute: .............22 fl . oz. (0.65 l/min)

Nozzle size: ............................... 2.0 mm / 2.5 mm

Max viscosity: ....................................... 60 DIN-s

Paint container capacity: ............... 27 fl . oz. (0.8 l)

Weight (Paint sprayer alone): .....2.65 lbs (1.2 kg)

Wear ear-muff s.

The impact of noise can cause damage to

hearing.

Reduce noise generation and vibration to a

minimum!

Use only equipment that is in perfect

•

condition.

Maintain and clean the equipment regularly.

•

Adapt your way of working to the equipment.

•

Do not overload the equipment.

•

Have the equipment checked if necessary.

•

Switch off the equipment when not in use.

•

Wear gloves.

•

CAUTION!

Residual risks

Even if you use this electric power tool in

accordance with the instructions, certain

residual risks cannot be eliminated. The

following hazards may arise in connection

with the equipment‘s construction and

layout:

1. Lung damage if no suitable protective dust

mask is used.

2. Damage to hearing if no suitable ear

protection is applied.

3. Health damage caused by hand-arm

vibrations if the equipment is used over a

longer period or is not properly guided and

maintained.

5. Before starting the equipment

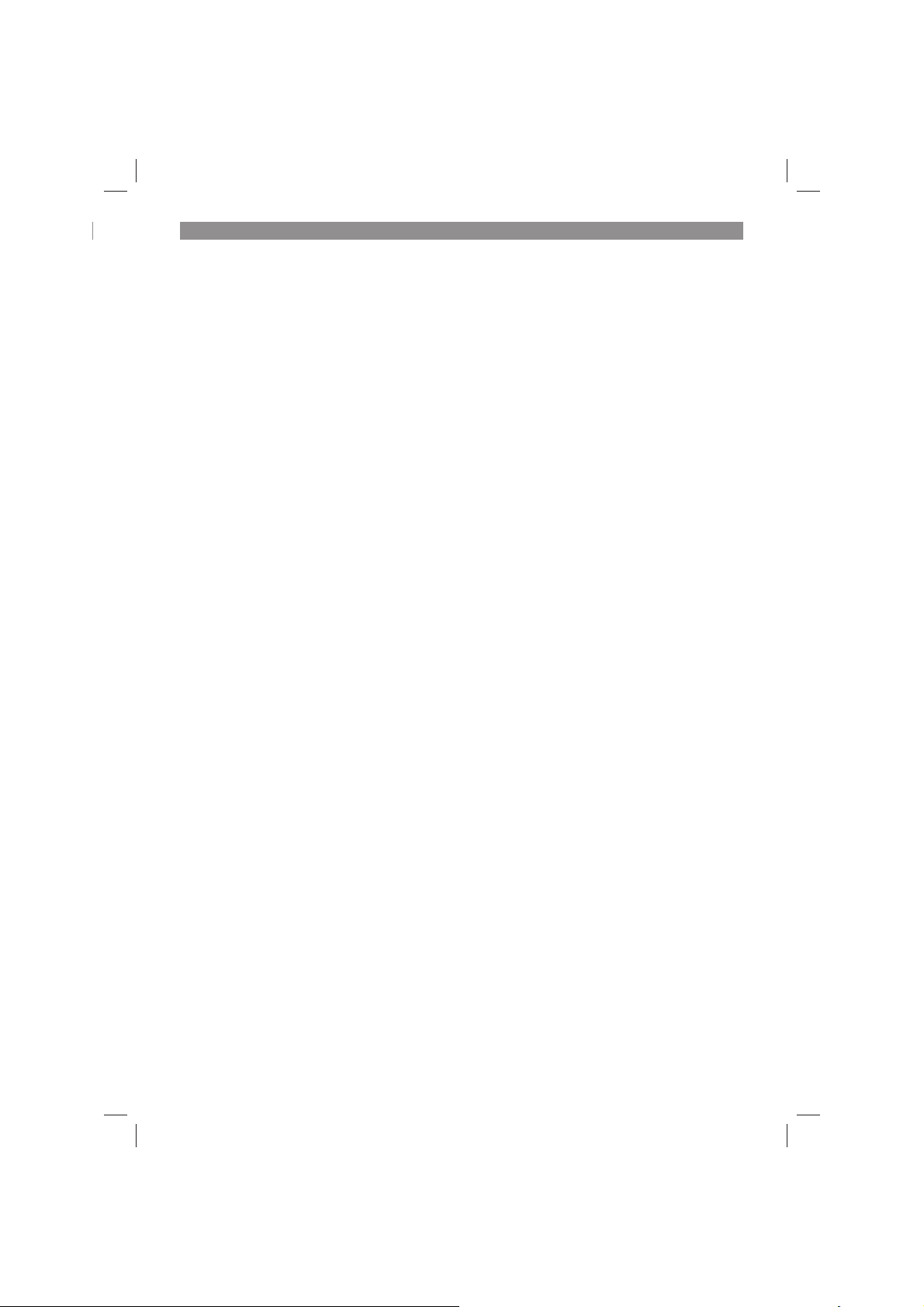

5.1 Spray gun assembly (Fig. 2/3/4)

The trigger unit (14) is attached to the drive

•

unit (15) by a bayonet connector on the gun

mounting (7).

Open the locking lever (4).

•

Insert the trigger unit (14) into the gun

•

mounting (7) with a twist.

Close the locking lever.

•

Insert the material tube (11) into the material

•

tube connection (10)

Screw the container into the trigger unit.

•

5.2 Charging the Li battery pack

The corresponding instructions can be found

in the original operating instructions for your

charger.

5.3 Battery capacity indicator (Fig. 16 / item

20)

Press the battery capacity indicator button (21).

The battery capacity indicator (20) shows the

charge status of the battery using 3 LEDs.

All 3 LEDs lit:

The battery is fully charged.

2 or 1 LED(s) lit:

The battery has an adequate remaining charge.

1 LED fl ashing:

The battery is empty, recharge the battery.

All LEDs fl ashing:

The battery pack has been deep-discharged and

is defective. Do not re-use or charge a defective

battery pack.

6. Operation

Warning!

Follow the safety precautions provided by the

manufacturer of the material you want to spray.

Use suitable face masks, gloves and protective

clothing.

6.1 Material preparation

The paint usually has to be thinned before it can

be used in the spray gun. Instructions on how to

thin the paint for spraying are not always printed

on the paint tin. You should use the viscosity table

as a guide (viscosity = consistency of the paint).

6.1.1 Measuring the viscosity (Fig. 5)

1. Mix the material thoroughly before measuring.

2. Completely immerse the viscosity cup (8) into

the material.

3. Then lift the viscosity cup (8) out of the mixture

and use a stopwatch to measure the time it

takes for all of the material to fl ow through the

cup. As soon as the continuous fl ow out of the

bottom is interrupted, stop the timer. Repeat

until you have the viscosity you need.

- 13 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 13Anl_TC_SY_18_60_Li_SPK7_USA.indb 13 25.08.2021 15:06:0525.08.2021 15:06:05

EN

This is the „Draining time in seconds“. (See 10.

Viscosity Table)

6.1.2 Nozzle diameter

The size of the nozzle and fl uid needle to be

used depends on the viscosity of the material.

Depending on the viscosity, use the 2.0 mm

dia. nozzle (colour: red, for lower viscosity) or

the 2.5 mm dia. nozzle (colour: black, for higher

viscosity). The fl uid needle in the gun is suitable

for both nozzle diameters.

6.2 Working with the paint spray gun (Fig. 6)

Important! Cover all surfaces which must be

protected from the spray, even areas which

are further away from the place where you are

working. A fi ne mist from the spray gun can

spread to areas in the wider surroundings indoors

and outdoors, and the material will be deposited

on surfaces there.

Unscrew the container (12) from the paint

•

spray gun.

Align the material tube (11) for the object you

•

are working on.

Spaying on horizontal objects: Rotate the

•

material tube (11) towards the front.

Spaying on raised objects: Rotate the

•

material tube (11) towards the rear.

Never continue spraying until the container

•

is completely empty. If the material tube no

longer reaches the spray material, the spray

flow will be interrupted and the coverage on

the surface will be uneven.

Once you have performed the viscosity

•

measurement as described in 6.1.1, place

the container (12) on some paper, pour in the

material you have prepared and tightly screw

the container (12) back into the paint spray

gun.

The paint spray gun is allowed to be placed

•

only on a clean, even surface. Otherwise it

might tip over.

After each cleaning (see 7.1) or change of fan

•

pattern (see 6.3), tighten the air cap retaining

ring (1) to prevent material from leaking out

between the air cap retaining ring and the air

cap (2).

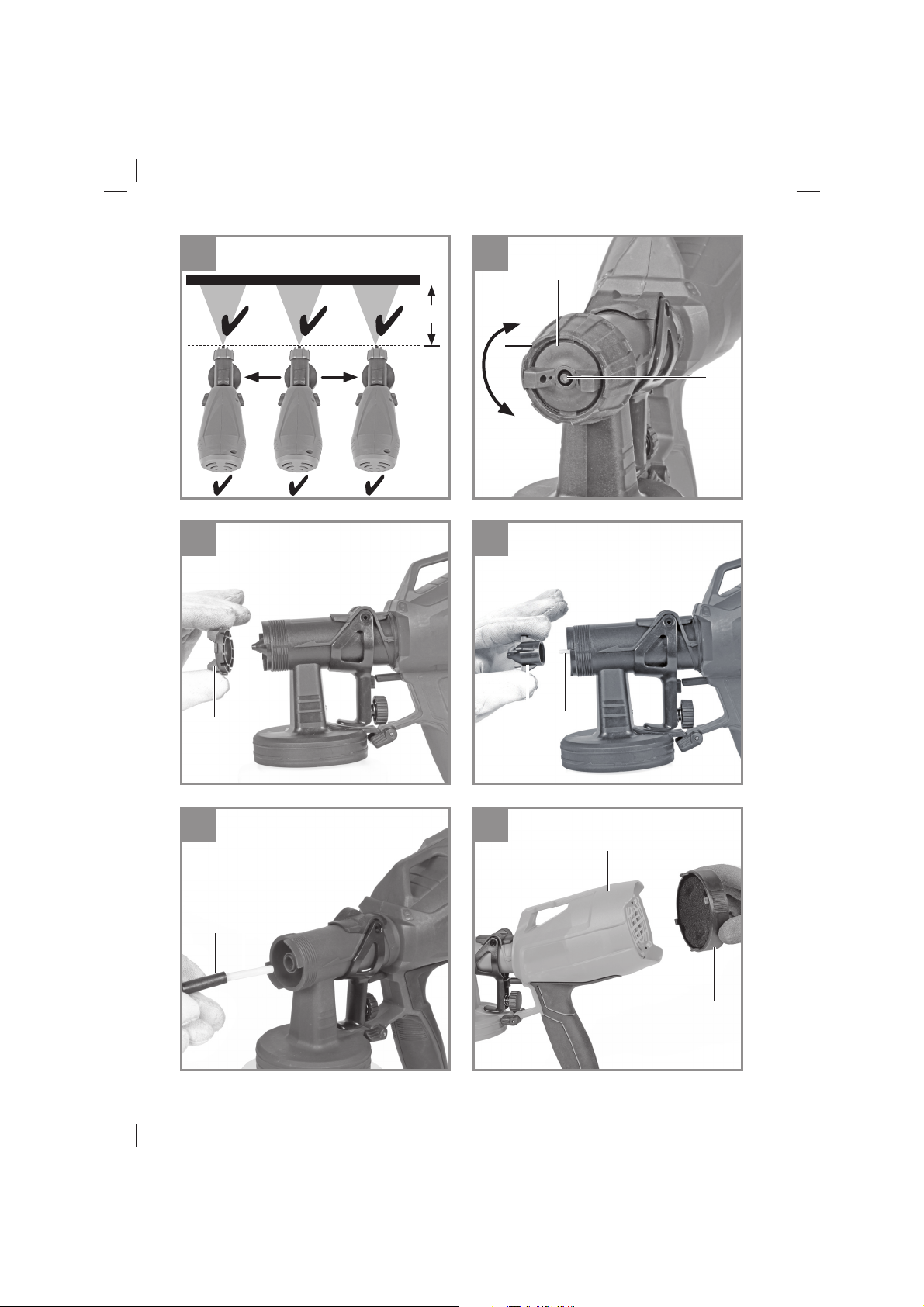

6.3 Adjusting the fan pattern (Fig. 7)

You can set the paint spray gun to produce three

diff erent fan patterns to suit your needs.

Loosen the air cap retaining ring (1) and rotate

the air cap (2) to the desired position. Re-tighten

the air cap retaining ring.

Selecting the fan pattern:

A: vertical fan

-> for horizontal surfaces

B: horizontal fan

-> for vertical surfaces

C: Round cone

-> for corners, edges and surfaces that are

diffi cult to access

Risk of injury!

Never press the trigger while you are adjusting

the jet.

6.4 Adjusting the material fl ow (Fig. 8)

You can rotate the max. paint volume control (6)

to regulate the material fl ow.

- direction -> lower material fl ow

+ direction -> higher material fl ow

6.5 Spraying techniques

The results you get depend on how smooth

•

and clean the surface is. The surface must be

carefully prepared and free of dust.

Surfaces, threads, etc. which should not be

•

sprayed must be covered.

Always set the spray gun down on cardboard

•

or something similar. You can use the

cardboard as a target to properly adjust the

spray gun.

Important:

Always begin spraying outside of the area to be

sprayed and avoid interrupting spraying inside the

area to be sprayed.

Wrong (Fig. 9): If you only rotate the spray

•

gun from side to side, the gun will produce a

heavy mist and the coverage will be uneven.

Right (Fig. 10): Always hold the spray gun at

•

the same distance (about 5-15 cm) from the

surface you are working on.

Move the spray gun uniformly laterally or up

•

and down depending on the fan pattern.

Uniform motion of the spray gun produces

•

uniform finish quality.

If material residue remains on the nozzle

•

(3) and the air cap (2), clean both parts with

solvent or water.

- 14 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 14Anl_TC_SY_18_60_Li_SPK7_USA.indb 14 25.08.2021 15:06:0525.08.2021 15:06:05

EN

6.6 Disconnecting and cleaning the gun (Fig.

1-2, 11-15)

Danger!

Always pull out the battery pack before starting

any cleaning work.

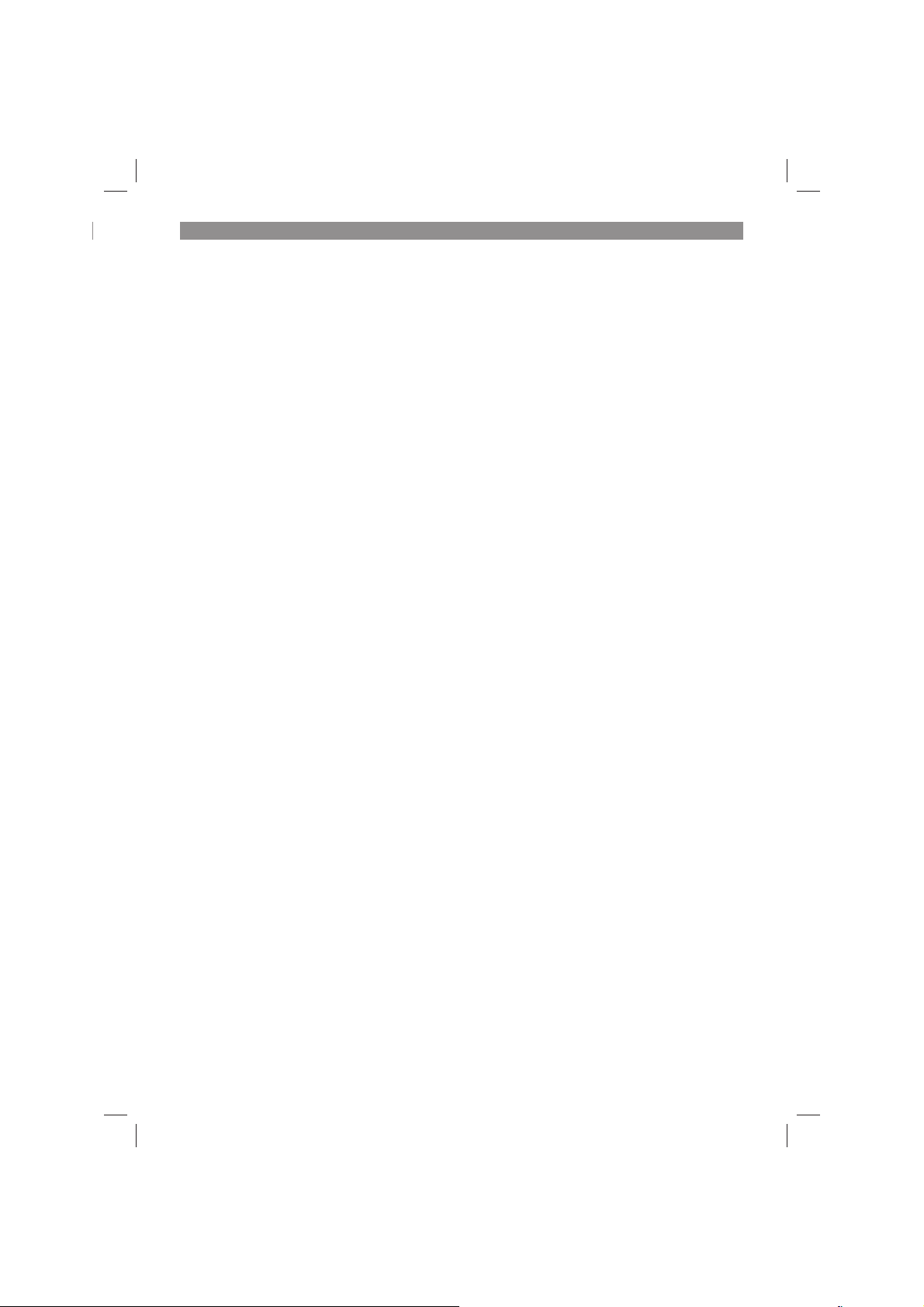

1. Press the trigger (5), so that the residual

material fl ows back into the container (12).

2. Unscrew the container (12) and empty the

residual material back into the material tin.

3. Clean the container (12) and the material

tube (11) with a bristle brush.

4. Pour solvent or water into the container.

Screw the container back on. Solvents with

a fl ash point above 131° F (55°C) are not

allowed to be used.

5. Reinsert the battery and turn on the paint

spray gun. Set the max. paint volume control

(6) to the maximum fl ow setting. Spray the

solvent or water into a container or rag, but

never into the surroundings.

6. Repeat the procedure above until the clear

solvent or water exits from the nozzle (3).

7. Then switch off the paint spray gun and

remove the battery.

8. Completely empty the container (12). Always

keep the container (12) free of residue and

check it for damage.

9. Use a rag soaked in solvent or water to clean

the outside of the paint spray gun and the

container (12).

10. Unscrew the air cap retaining ring (1) and

then remove the air cap (2). Remove the

nozzle (3). Push the fl uid needle adapter (18)

onto the fl uid needle (13). Twist and pull to

remove the fl uid needle. Clean the air cap

retaining ring, the air cap, the nozzle and the

fl uid needle with a bristle brush and solvent or

water.

11. Remove the fi lter cap (16) to clean the air inlet

fi lter. Remove the fi lter and clean it by blowing

out with air. Then reinsert the fi lter and screw

the fi lter cap onto the gun. Do not operate the

gun without the fi lter.

12. Reinsert the fl uid needle. Pull the trigger and

insert the nozzle on the fl uid needle. While

inserting, ensure that the pins on the sides of

the fl uid needle point up/down and not right/

left. Pull the trigger while placing the air cap

on the nozzle and fastening the air cap with

the air cap retaining ring.

13. Ensure that the paint spray gun is completely

dry before storing it.

14. Properly dispose of residual paint and

cleaning agents in accordance with local laws

and regulations. Residual paint and solvents

must be taken to a suitable collection point. If

you are not sure, ask the local council where

the nearest collection point is.

Warning!

Never immerse the paint spray gun in water

or other liquids. Clean the housing only with a

dampened rag.

Note: If you use 2-component paint, you must

clean the gun immediately. Otherwise the paint

might dry inside the gun, causing an equipment

fault.

7. Cleaning, maintenance and

ordering spare parts

HAZARD!

Always take the battery out of the equipment

before starting any cleaning work.

7.1 Cleaning

Keep all safety devices, air vents and the

•

motor housing free of dirt and dust as far as

possible. Wipe the equipment with a clean

cloth or blow it down with compressed air at

low pressure.

We recommend cleaning the equipment

•

immediately each time after use.

Clean the equipment regularly with a damp

•

cloth and some soft soap. Do not use

cleaning agents or solvents; these may

be aggressive to the plastic parts in the

equipment. Ensure that no water can get into

the interior of the equipment. The ingress of

water into an electric power tool increases the

risk of an electric shock.

7.2 Maintenance

There are no other parts inside the equipment

which require maintenance.

7.3 Ordering replacement parts:

Service

1. If your power tool requires service,

contact an authorized Einhell USA dealer

or call the Einhell USA customer service

center at 1-866-EINHELL

(1-866-346-4355). Only identical

replacement parts should be utilized for

repairs. This will ensure that the safety of the

power tool is maintained.

- 15 -

Anl_TC_SY_18_60_Li_SPK7_USA.indb 15Anl_TC_SY_18_60_Li_SPK7_USA.indb 15 25.08.2021 15:06:0525.08.2021 15:06:05

Loading...

Loading...