EFD 781S INSTALLATION GUIDE

®

A NORDSON COMPANY

781S Series Spray Valve

INSTALLATION GUIDE

Electronic pdf files of EFD® manuals are also available at

www.efd-inc.com/manuals.html.

USA: 800-556-3484 or +1-401-434-1680 Europe: 0800 585733 or +44 (0) 1582 666334 Asia: +86 (21) 5854 2345 technical@efd-inc.com www.efd-inc.com

Introduction

The 781S Series precision low volume low pressure (LVLP) liquid spray valves are designed for high transfer efficiency without overspray or airborne mist and provide consistent coating of low to medium viscosity fluids.

781S Series valves are simple to use and will operate many millions of cycles without maintenance. Spray valve cleaning is accomplished by purging with the appropriate solvent.

The 781S air cylinder body and fluid body are hard-coated aluminum. The 781S-SS valve model uses stainless steel throughout.

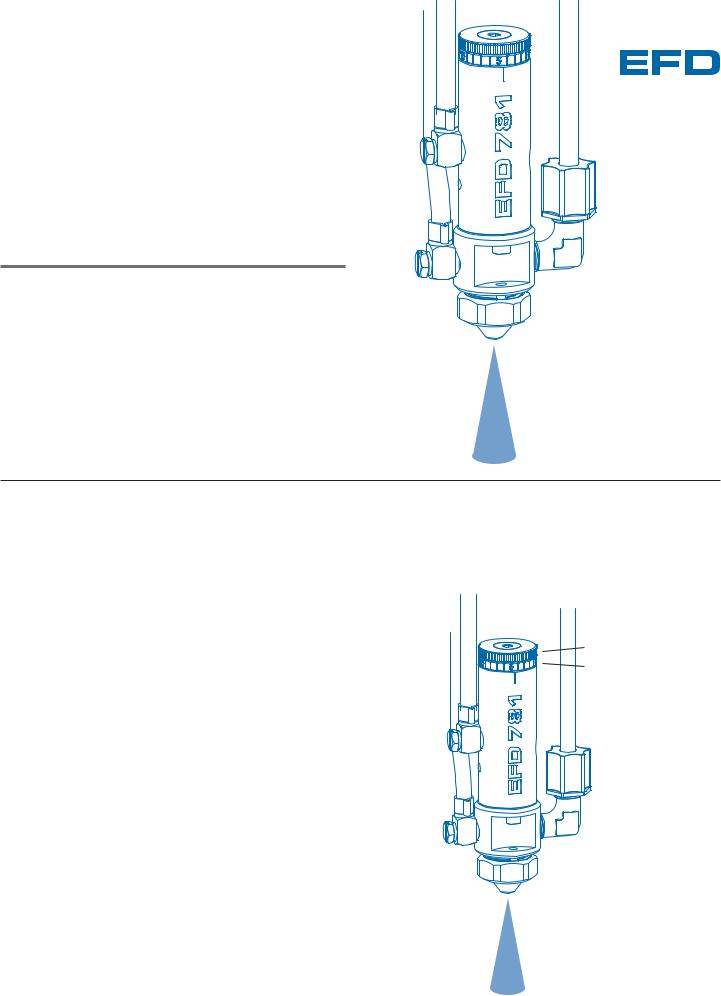

Valve control

air hose Fluid

supply line

Nozzle

air hose

Needle stroke control knob

Stroke reference ring

Inlet fitting

LVLP spray valve

Installation

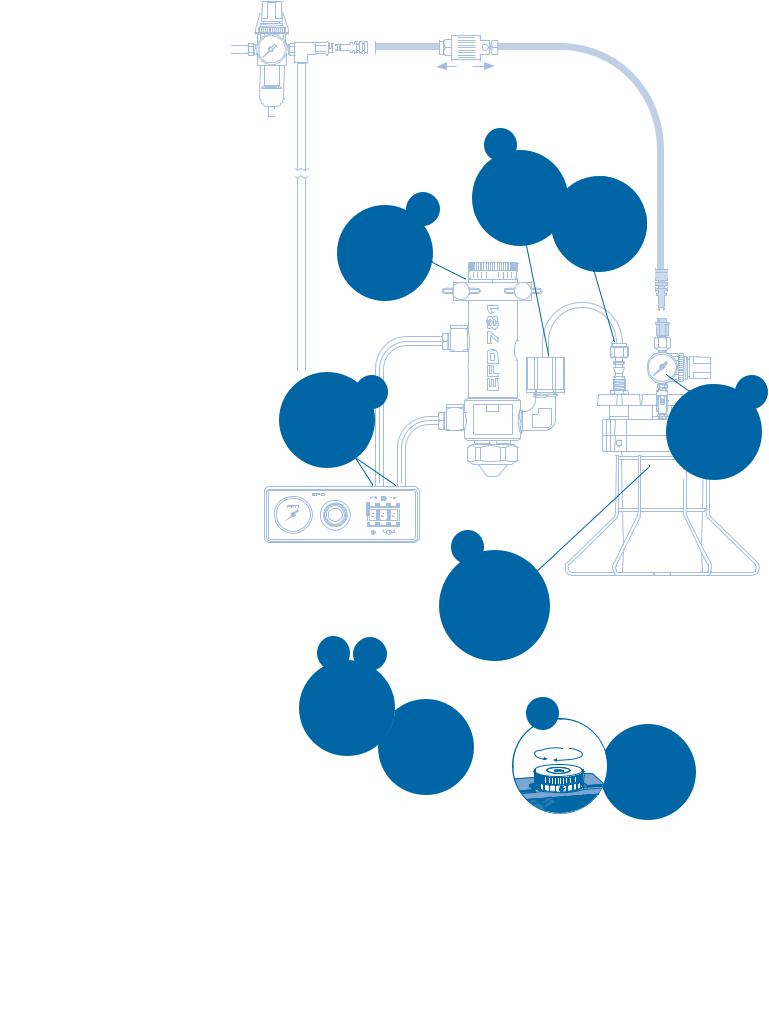

Prior to installing this valve, please read the associated reservoir and valve controller operating instructions to become familiar

operation of all dispensing system.

1.Mount valve with an EFD universal valve mount (#7002VM) or other fixture.

2.Connect the fluid supply line to the fluid inlet port and to the reservoir.

3.Connect the control air hose (labeled “A”) and the nozzle air hose (labeled “B”) to corresponding outputs on ValveMate™ controller (or other pneumatic switch).

4.Fill reservoir by pouring fluid directly into tank liner or manufacturer’s bottle placed inside reservoir. Secure cover prior to setting pressure.

5.Set reservoir pressure to low for thin fluids and higher for thick

6.Turn off nozzle air at the controller regulator. Open the needle stroke control one full turn. Place a cup under the nozzle and actuate valve until fluid lines are free of

7.Using the needle stroke control knob on the 781S valve, set the fluid flow rate to one or two drops per second. Check flow rate by actuating the controller in the time override mode. Make valve stroke adjustments when the controller is off.

8.Set the nozzle air pressure on the ValveMate 7040 controller to 10 psi (.7 bar) and actuate the controller.

The valve will produce a fine spray.

To change fluid flow, use the needle stroke control knob and/or reservoir pressure.

To change nozzle air, use the nozzle air pressure regulator. Higher pressures will provide finer spray.

To exhaust |

To pressurize |

2

Output A 3 |

5 |

Output B |

|

VALVEMATE |

|

7040 |

|

6 8

VALVEMATE

7040

Close

Note: The area of spray |

by the distance |

between the spray valve |

work surface. Refer to the |

charts on the back page |

distance. |

|

|

Loading...

Loading...