EFD 750 INSTALLATION GUIDE

750 Series

Dispense Valve

INSTALLATION GUIDE

®

A NORDSON COMPANY

Electronic pdf files of EFD® manuals are also available at www.efd-inc.com/manuals.html.

USA: 800-556-3484 or +1-401-434-1680 Europe: 0800 585733 or +44 (0) 1582 666334 Asia: +86 (21) 5854 2345 technical@efd-inc.com www.efd-inc.com

Introduction

The 750 Series fluid dispense valves are simple to use and will operate many millions of cycles without maintenance. The 750 Series incorporates a variety of compact, precise, adjustable diaphragm valves for dispensing low to medium viscosity fluids. These include the 750V, 750V-SS, 751V, 752V, 752V-SS,

752V-UH, 752V-UHSS, 752V-DVD and 752V-UHDVD models.

All 750 Series valves use the same actuating assembly. But fluid body styles and diaphragms differ according to the model. The 752V Series fluid bodys are constructed with the outlet at the end of the fluid body. The 750V and 751V fluid bodys are constructed with the outlet on the side of the fluid body.

Each valve is shipped with a dispensing tip adapter, fluid inlet fitting and 5-foot actuating air hose installed.

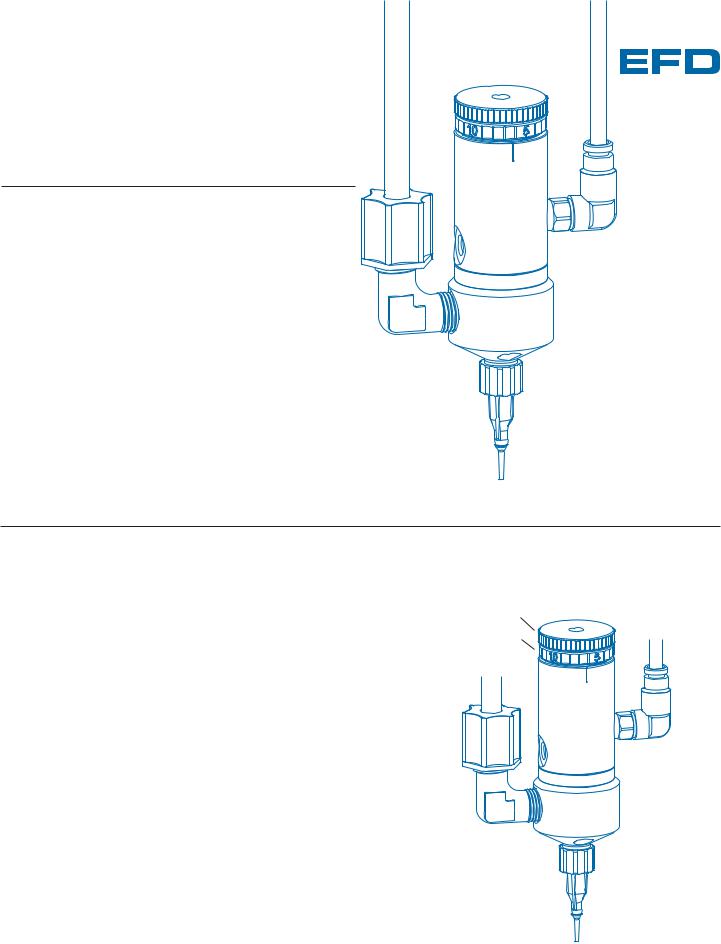

Stroke control knob |

Control |

Stroke reference ring |

air hose |

|

|

Fluid supply line |

|

Inlet fitting |

Fluid body |

|

Dispensing tip

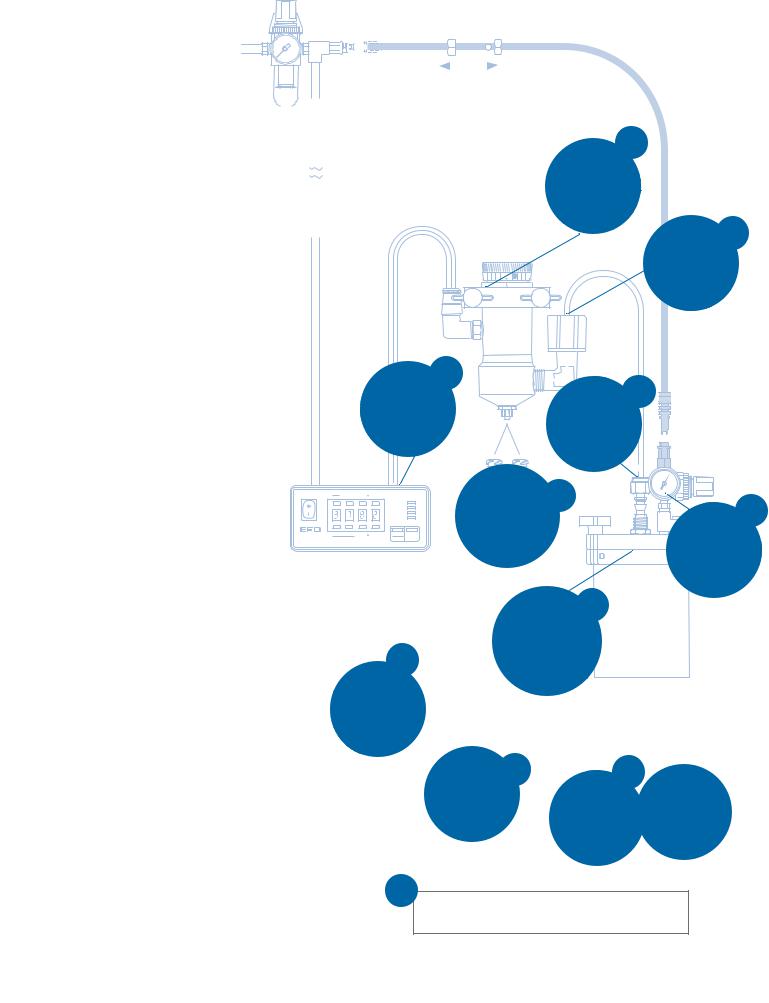

Installation

Prior to read the

valve controller operating instructions to become familiar with the operation of all components of the dispensing system.

1.Mount valve with an EFD universal valve mount (#7002VM) or other fixture.

2.Connect fluid supply line to valve. If 3/8” OD tubing is used, change to fitting #7610BP supplied.

3.Connect the fluid supply line to reservoir. The reservoir can accept either OD or 1/4” OD or 3/8” OD tubing using #62518PT supplied.

4.Connect valve control air hose to ValveMate™ controller (or other pneumatic switch) used to control valve open time.

5.Choose a dispensing tip—small tips

(20 gauge) for low-viscosity fluids and larger (14 gauge) for higher viscosities.

6.Fill reservoir by pouring fluid directly into tank liner or manufacturer’s bottle placed inside reservoir. Secure cover prior to setting pressure.

7.Set reservoir pressure to low for thin fluids and higher for thick fluids.

8.Set the diaphragm stroke starting no more than 1/2 turn open.*

9.Place a cup under the dispensing tip and actuate the valve until fluid lines,

valve and dispensing tip are free of air.

10. Set desired flow rate by adjusting fluid reservoir pressure or changing dispensing tip.

*Do not overtighten the stroke adjustment knob or open it more than two full turns. If open more than

two turns, pressurized liquid could force open the diaphragm seal, resulting in continuous liquid flow.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To pressurize |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To exhaust |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1

2

4

r |

Air Output |

3 |

ut |

|

|

Exhaust

Open

Close

11

time. Refer to valve controller operating manual.

Loading...

Loading...