Page 1

Service Manual

Fuller Mid Range Transmissions

TRSM4106

October 2007

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Page 4

Eaton 6-Speed Synchromesh Transmission

Truck Components Operations Europe

PO Box 11 Worsley

Manchester M28 5GJ

England

Service Manual

(4106 / 5206)

Page 5

Section 1 General

1/1 Letter and Model Designation

1/2 Technical Data

1/3 Lubrication

1/4 Recommended Lubricants

1/5 Torque Tightening Recommendations

1/7 Disassembly Precautions and Inspection of Expendable Parts

1/9 Reassembly Precautions

1/10 Gear End Floats

1/11 Special Tools

1/14 Locally Made Tools

Section 2 General Discription

2/1 Features

2/2 Gear Change Pattern

2/2 Power Flow Diagrams

Section 3 Shifting Controls

3/2 Remote Control - Exploded View

3/3 Remote Control Disassembly

3/4 Remote Control Reassembly

3/7 Direct Control - Exploded View

3/8 Direct Control Disassembly

3/9 Direct Control Reassembly

Section 4 Transmission Overhaul

4/2 Transmission Case - Exploded View

4/3 Transmission Case Disassembly

4/9 Layshaft Disassembly

4/10 Layshaft Reassembly

4/11 Synchroniser Flange Removal / Fitment

4/12 Maninshaft Disassembly (New Type)

4/13 Maninshaft Reassembly (New Type)

4/17 Mainshaft Assembly - Exploded View (NewType)

4/31 Mainshaft Disassembly (Old Type)

4/32 Mainshaft Assembly - Exploded View (Old Type)

4/35 Mainshaft Reassembly (Old Type)

4/41 Selector Shaft Disassembly

4/42 Selector Shaft Reassembly

4/44 Transmission Case Reassembly

5/01

Page 6

Section 2 General

5/01

Page 7

General

Model Designation

Example: FSO-4106A

FS Standard prefix

O Overdrive

4 Nominal torque in 00 lbs ft

1 Series 1

06 Number of forward gears

A Standard ratio set

B, C Alternative ratio sets

Transmission Identification

All transmissions are fitted with an identification plate on the left hand side of the front case showing

1. Transmission serial number.

2. Transmission model.

3. Manufacturing data code.

4. Transmission specification number.

The transmission specification number is unique to each customer and gives precise details of the transmission design level. This number must be quoted when ordering replacement parts.

There are currently two design levels of the 4106 transmission. Each level is identified by the specification number.

Y 0400

Y 04100

The middle digit denotes the design level.

1/1

5/01

Page 8

General

Technical Data

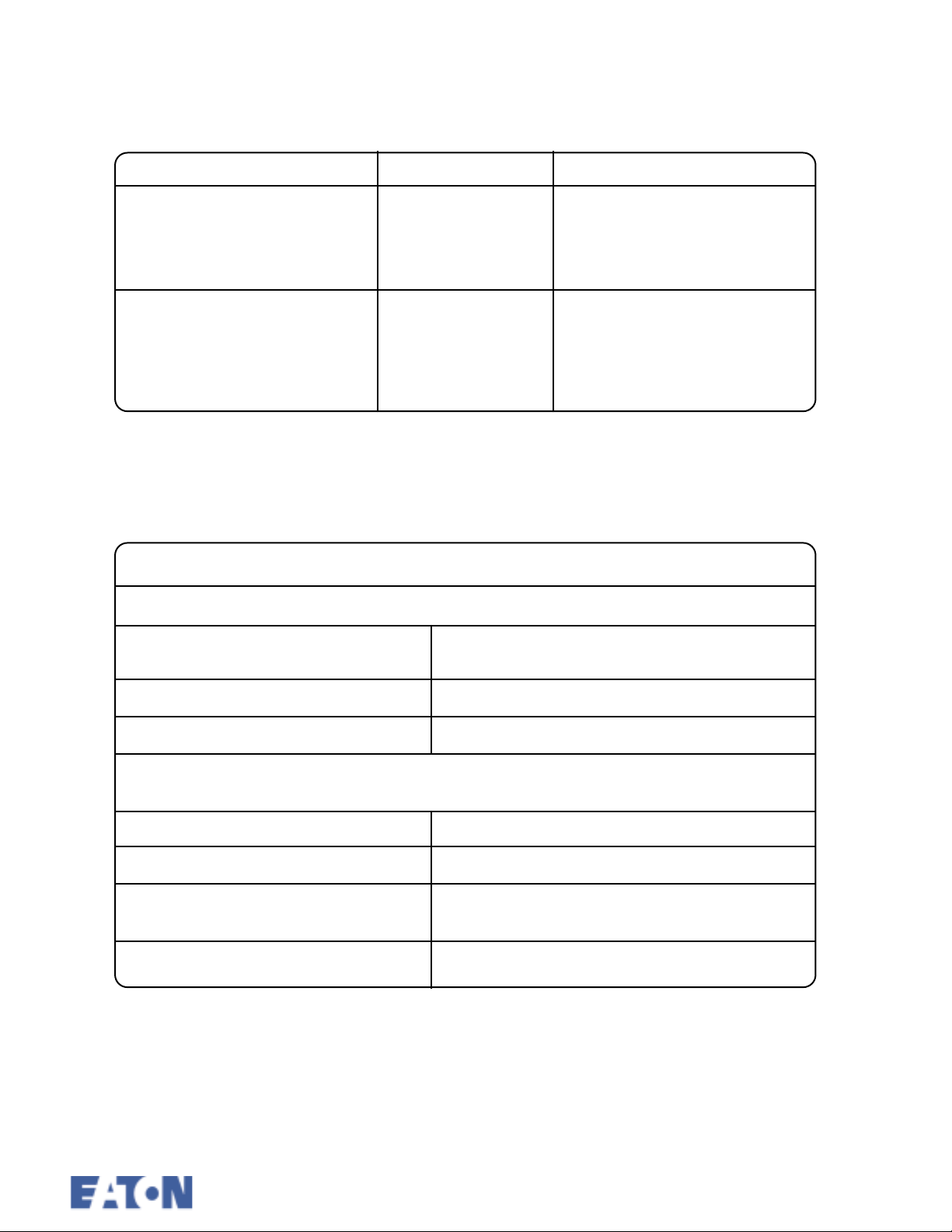

Models FS-4106A, FS-4106B, FS-5206A, FS(O)-5206B

Nominal Input Torque

FS-4106A

FS-4106B

FS-5206A

FS(O)-5206B

640 Nm

650 Nm

700 Nm

700 Nm

Weight 1)

Length 2)

Oil capacity

Vertical

Horizontal

Clutch Housing

Power Take-off Openings

PTO Drive Gears 3)

driven from the reverse idler gear at:

FS-4106A, FS-5206A

FS-4106B, FS-5206B

FS-4106B, FS(O)-5206B

driven from layshaft front gear at:

FS-4106A, FS-5206A

FS-4106B, FS-5206B

FS-4106B, FS(O)-5206B

115 kg

520 mm

7,5 lit

6,5 lit

SAE Standard

Left side (vertical installation), bottom right

(horizontal installation): 2 SAE 6 bolt facings

plus extended layshaft for Eaton PTO

Rotation to Engine

engine speed x

0,226 Same

0,271

0,336

engine speed x

0,434 Opposite

0,519

0,644

Gear

6

5

4

3

2

1

Reverse

1) including output coupling, low remote control; less clutch housing

2) front face of transmission case to rear face of output flange

3) recommended backlash is from 0.15 to 0.25mm.

FS-4106A

FS-5206A

1.00

__

1.38

__

2.00

__

3.10

__

5.25

__

9.03

__

8.07

%

Step

38

45

55

69

72

FS-4106B

FS-5206B

1.00

__

1.29

__

1.86

__

2.80

__

4.38

__

7.54

__

6.74

%

Step

26

43

50

57

72

FS(O)-4106B

FS(O)-5206B

1.00

__

1.37

__

2.12

__

3.56

__

6.08

__

9.03

__

5.43

%

Step

26

37

55

69

72

5/011/2

Page 9

General

Lubrication

Proper Oil Level

Before checking the oil level or refilling, vehicle should

be on level ground.

Make sure that the oil is level with the filler opening.

Draining Oil

Drain transmission while oil is warn. To drain oil remove

the drain plug at the bottom if case. Clean the drain plug

before re-installing.

Refilling

Clean area round filler plug.

Fill transmission to the level of the filler opening.

The exact amount of oil depends on the

transmission inclination. In every instance, fill to the

level of the filler opening. Do not overfill this causes

oil to be forced out of the case past the mainshaft and

input shaft seals.

Adding Oil

It is recommended that different types and brands of oil

are not intermixed because of possible incompatibility.

Operating Temprature

It is important that the transmission operating temperature does not exceed 120¡C (250¡F) for an extended

period of time. Operating temperatures above 120¡C

(250¡F) cause breakdown of the oil and shorten transmission life.

The following conditions in any combination can cause

operating temperatures of over 120¡C (250¡F):

1. Operating consistently at road speeds

under 32 km/h (20m.p.h.)

2. High engine RPM

3. High ambient temperature

4. Restricted air flow around transmission

5. Exhaust system too close to transmission

6. High horsepower, over-drive operation

7. High power PTO operation for

extensive periods while stationary

High operating temperatures may require more frequent

oil change.

Towing

When towing the vehicle, the propeller shaft between the

axle and transmission must be disconnected.

1/3

5/01

Page 10

General

Recommended Lubricants

Only use recommended lubricants to ensure smooth running.

Models Temprature RangeGrade

Mild EP Gear Oil

to Specification

MIL-L-2105 or

API-GL-4

Heavy Duty Engine Oil

to Specification

MIL-L-2104C or

MIL-L-46152 or

API-CD

DO NOT use oil additives, friction modifiers or synthetic lubricants.

SAE 80 W

SAE 90 W

SAE 80 W/90

SAE 50

SAE 40

SAE 30

Service Intervals

Lubrication Change and Inspection

Highway Use

First 5000 to 8000 km (3000 to

5000 miles)

Change transmission oil on new units

-26¡C to 21¡C

-12¡C to 37¡C

-26¡C to 38¡C

above -12¡C

above -12¡C

below -12¡C

Every 16000 km (10000 miles)*

Every 80000 km (50000 miles)+

Off Highway

First 30 hours

Every 40 hours *

Every 500 hours

Every 1000 hours +

Remove and clean oil strainer at each oil change.

Transmissions fitted with an oil cooler may additionally be fitted with a filter in the cooler line,

Renew the filter at every oil change.

* Or 2 months, whichever occurs first.

+ Or 12 months, whichever occurs first.

Inspect oil level. Check for leaks

Change transmission oil

Change transmission oil on new units

Inspect oil level. Check for leaks

Change transmission oil when severe dirt conditions exist

Change transmission oil (normal off- highway use)

5/011/4

Page 11

General

Torque Tightening Recommedations

Screws and Nuts

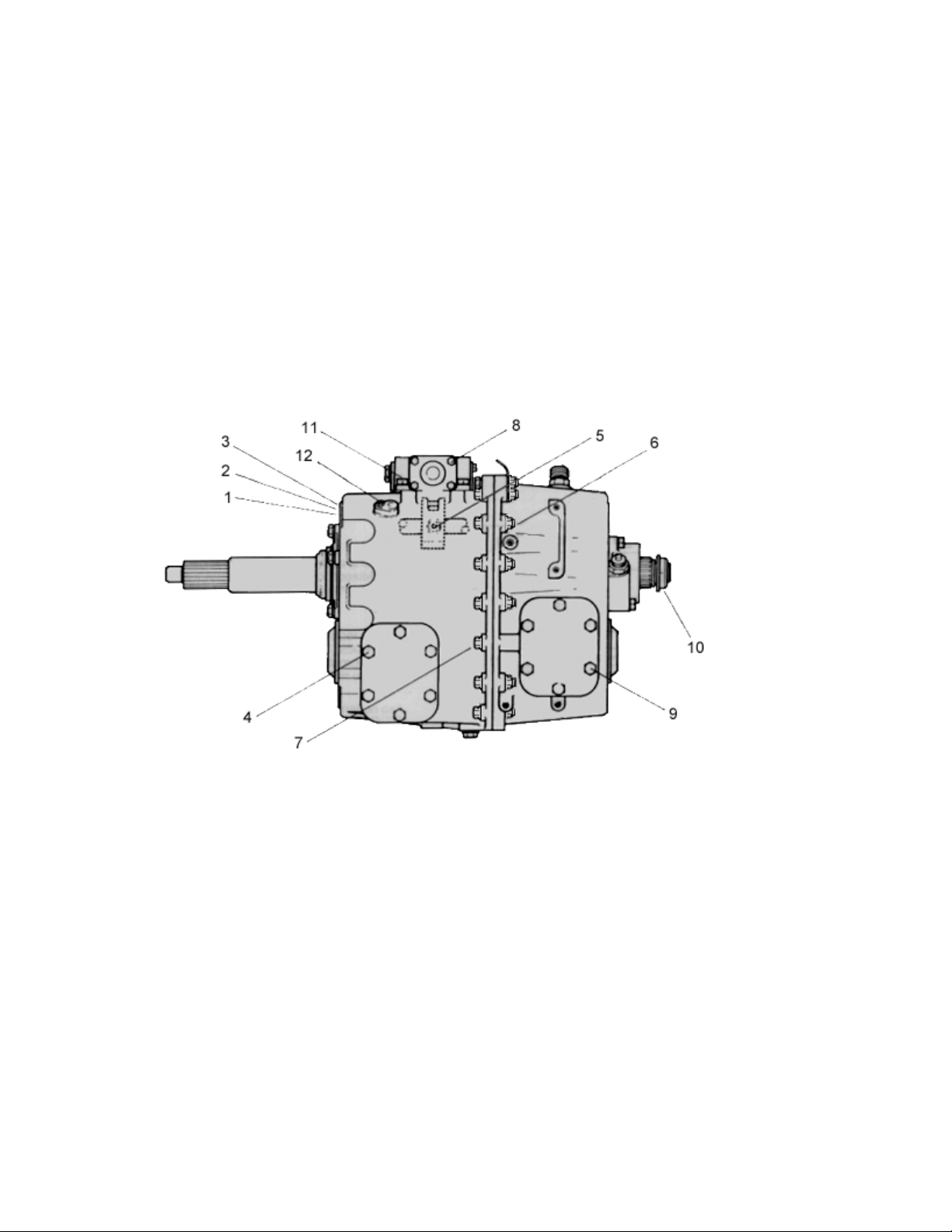

1. Clutch Housing

12 Studs M12 Thread 59 Nm (43 lbs ft) minimum. Installed with Loctite 242.

2. Clutch Housing

12 Nuts M12 Thread 69 to 78 Nm (51 to 58 lbs ft). With Plain Washers and Spring Lockwashers.

3. Clutch Housing

12 Capscrews M12 Thread 69 to 78 Nm (51 to 58 lbs ft). With Plain Washers and Spring

ockwashers.

4. Front P.T.O. Cover

6 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft).

5. Selector Block Tapered Lockscrew

1 Lockscrew M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Patchlock or Thread coated with Loctite 270.

6. Main Casing Halves

15 Capscrews with Plain Nuts M10 Thread 51 to 58 Nm (38 to 43 lbs ft). With Plain Washers

under Capscrews and Nuts.

15 Flange headed screws and Nuts M10 Thread 45 to 55 Nm.

7. Main Casing Halves

3 Capscrews M10 Thread 51 to 58 Nm (38 to 43 lbs ft). Plain Washers.

3 Flange headed screws M10 Thread 30 to 40 Nm.

8. Remote Control Housing End Cover

4 Capscrews M8 Thread 20 to 24 Nm (15 to 18 lbs ft). Spring Lockwashers.

9. P.T.O./Reverse Idler Gear Cover

6 Capscrews M10 Thread - 35 to 39 Nm (25 to 29 lbs ft).

10. Output Shaft

Locknut M33 Thread 490 to 588 Nm (362 to 434 lbs ft). With Nylon Locking Insert.

11. Remote Control Housing

4/6/8 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Plain Washers and Spring Lockwashers.

12. Overdrive Selector fork Pivots

2 Capscrews M8 Thread (with lockwashers) 20 to 24 Nm (15 to 18 lbs ft).

1/5

5/01

Page 12

General

Torque Tightening Recommedations (continued)

Screws and Nuts

1. Remote Control Shaft Lever

1 Capscrew and Nut M10 Thread 35 to 39 Nm (25 to 29 lbs ft). With Spring Lockwasher.

2. Selector shaft Detent Cover

2 Capscrews M8 Thread 20 to 24 Nm (15 to 18 lbs ft). Spring Lockwashers.

3. Oil Filler Plug

M24 Thread 32 to 37 Nm (24 to 27 lbs ft).

4. Layshaft Front Bearing Cover

4 Capscrews M12 Thread 69 to 78 Nm (51 to 58 lbs ft). Spring Lockwashers.

5. Input Shaft Front Bearing Cover

5 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Spring Lockwashers.

6. Remote Control Housing Detent Cover

2 Capscrews M8 Thread 20 to 24 Nm (15 to 18 lbs ft). Lockwashers.

7. Oil Drain Plug (Magnetic)

M24 Thread 32 to 37 Nm (24 to 27 lbs ft).

8. Speedo Pinion Adaptor

M22 Thread 20 to 27 Nm (15 to 20 lbs ft). Copper Washer.

9. Speedometer Housing

4 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Plain Washers and Spring Lockwashers.

10. Layshaft Rear Bearing Cover (Rear P.T.O.)

4 Capscrews M12 Thread 69 to 78 Nm (51 to 58 lbs ft). Spring Lockwashers.

11. Reverse Lamp Switch

M16 Thread 16 to 22 Nm (12 to 17 lbs ft).

5/011/6

Page 13

General

Disassembly Precautions

It is assumed in the detailed disassembly instructions

that the lubricant has been drained and the necessary

linkage and air lines (if fitted) have been removed from

the chassis.

Removal of the gear shift remote control housing

assembly is included in the detailed instructions; however, this assembly may also be removed from the transmission before removing unit from vehicle.

Follow each procedure closely in each section, making

use of both the text and the pictures.

1. Bearings Carefully wash and relubricate all

bearings as removed and protectively wrap until ready

for use. Remove bearings with pullers designed for this

purpose.

2. Assemblies When disassembling the various

assemblies, such as the mainshaft, layshaft and remote

control housing, lay all parts on a clean bench in the

same sequence as removed. This procedure will simplify reassembly and reduce the possibility of losing parts.

When pulling off synchroniser hubs follow the procedures detailed in Disassembly using a suitable puller of

adequate capacity. Failure to adhere to the recommended procedures may cause irreparable damage.

3. Snap rings Remove snap rings with pliers

designed for this purpose. New selective fit snap rings

must be fitted as specified in Reassembly .

4. Cleanliness Provide a clean place to work.

It is important that no dirt or foreign material enters the

unit during repairs. The outside of the unit should be

carefully cleaned before starting the disassembly. Dirt is

abrasive and can damage bearings.

5. When Pressing Apply force to shafts, housings etc. with restraint. Movement of some parts is

restricted. Do not apply force after the part being driven

stops solidly. Use soft hammers for all disassembly

work.

Do not use pry bars or chisels to separate casing halves

and housings or irreparable damage may be caused.

Inspection of Expendable

Before reassembling the transmission, the individual

parts should be carefully checked to eliminate those

damaged. They should be renewed. This inspection

procedure should be carefully followed to ensure the

maximum wear life from the rebuilt unit.

The cost of a new part is generally a small fraction of

the total cost of downtime and labour, should the use of

a questionable part make additional repairs necessary

before the next regularly scheduled overhaul.

Recommended inspection procedures are set forth in

the following check list.

A. Bearings

1. Wash all bearings in clean solvent. Check rollers

and races for pits and spalled areas. Renew damaged

bearings.

2. Lubricate undamaged bearings and check for axial

and radial clearances. Renew bearings with excessive

clearances.

3. Check fits of bearings in housing bores. If outer

races turn too freely in the bores, the housing should be

renewed. Check housing bores for signs of wear prior

to taking this action. Only replace housing if wear is

seen as a result of bearing spin.

B. Gears

1. Check gear teeth for pitting of the tooth faces.

Gears with pitted teeth should be renewed. Check the

reverse gear dog engagement teeth for freedom from

damage.

2. Check the internal bearing surfaces for wear of the

effects of overheating.

3. Check axial clearances of gears. Where excessive

clearance is found, check gear and hub for excessive

wear.

Maintain the specified axial clearance on mainshaft forward gears.

C. Bearing Sleeve Mainshaft

1. Sleeves with groove formation, pits or which have

either been overheated or worn out must be renewed.

1/7

5/01

Page 14

General

Inspection of Expendable Parts

D. Synchroniser Assemblies

1. Check to ensure all splines are free from excessive

wear.

2. Check that the engagement dog teeth on the sliding

sleeves, synchroniser rings are free from chipping and

burring.

3. Check that the synchroniser ring cones are not

excessively worn or showing the effects of overheating.

Check the clearance between the synchroniser ring and

the synchroniser flange is between 1.9 mm maximum

and 0.5 mm minimum.

4. Renew the springs, plungers and rollers.

E. Splines

1. Check splines on all shafts for wear. If synchroniser

hubs, output drive flange or clutch hub have worn into

the sides of the splines, the shafts in this condition must

be renewed.

F. Thrust Washers

4. Check condition and fit of selector key and inter-

lock key in shift shaft. Worn or damaged keys must be

renewed.

J. Gear Shift Remove Control

1. Check spring tension on cross shaft. Renew ten-

sion springs if shaft moves too freely.

2. If housing is dismantled, check cross shaft and

inner lever and the bearing bushes for wear. Renew

worn parts.

3. Check all seals and locating journals. Renew worn

parts.

K. Bearing Covers

1. Check covers for wear from thrust. Renew covers

worn or grooved from thrust of bearing outer race.

2. Check bores of covers for wear. Renew those worn

oversize.

L. Oil Return Threads and Seals

1. Check surfaces of all thrust washers. Washers

scored or reduced in thickness should be renewed.

G. Reverse Idler Gear

1. Check bearings and shaft for wear from action of

roller bearings.

H. Clutch Release Parts

1. Check clutch release parts, yokes and bearing car-

rier. Check pedal shafts. Renew worn shafts and bearings.

I. Gear Selector Shaft Assembly

1. Check forks and keys for wear at contact points.

Renew worn parts.

2. Check forks for excessive and uneven wear, renew

worn forks.

3. Check lockscrew in selector block. A lockscrew with

worn taper must be renewed.

1. Check oil seal in front bearing cover for damage and

wear, renew if necessary.

2. Check oil seal in speedometer housing for damage or

wear, renew if necessary. Renew grit shield if worn or

loose on flange.

3. Check oil seal journals for wear and renew if worn or

grooved.

M. O-Rings

1. Renew all O-rings.

5/011/8

Page 15

General

Reassembly Precautions

Make sure that interiors of all housings are clean. It is

important that dirt be kept out of transmission during

reassembly. Dirt is abrasive and can damage polished

surfaces of bearings and washers. Use certain precautions, as listed below, during reassembly.

1. Gaskets Use new gaskets where detailed only

(neutral detent cover and remote control housing covers). All other locations ensure mating faces are clean

and undamaged and apply a continuous bead of Loctite

518 Flange Sealant to one face only. Do not apply

excessive sealant or allow it to penetrate into the bearings.

2. Capscrews Use thread sealant (Loctite 641) on

all capscrews. The corresponding torque ratings are to

be found in Torque Recommendations for Screws and

Nuts .

3. O Rings Lubricate all O rings lightly with silicone lubricant.

4. Initial Lubrication Lubricate bearings with

gearbox oil during reassembly.

9. Layshaft The layshaft gears are a shrink and

press fit on the layshaft body. The gears must be heated to 150¡C (300¡F) before assembly.

10. Prior to fitting a flange (or yoke) ensure that the

seal track is not grooved, scored or pitted. If in doubt, it

must be replaced.

11. All synchroniser flanges are now loctited to the

gears. It is recommended that this is carried out before

reassembly commences to allow sufficient time for the

Loctite to cure.

5. Axial Clearances Maintain the end float of

mainshaft gears as detailed in the chart on the following

page.

6. Bearings Use of flange-end bearing drivers is

recommended for the installation of bearings. These

drivers apply equal force to both races of the bearing,

preventing damage to balls and races and maintaining

correct bearing alignment with shaft and bore. A tubular

type driver, if used, will apply force only to the inner

race. Heating the bearing inner tracks will aid installation.

7. Output Shaft Drive Flange Tighten the nut to

the correct torque.

8. Synchroniser Hubs All synchroniser hubs are

an interference fit on the mainshaft splines and must be

heated to approximately 85¡C (180¡F) before installation.

1/9

5/01

Page 16

General

Gear End Floats All dimensions in mm

Gear

Low Limit

High Limit

Tolerance

0,31

0,53

0,22

4th5th (o,d. 6th)

0,35

0,48

0,13

3rd

0,35

0,48

0,13

2nd

0,35

0,48

0,13

1st

0,40

0,57

0,17

Reverse

Sliding

Gear

5/011/10

Page 17

General

Special Tools

Some illustrations show the use of specialised tools. These tools are recommended for disassembly

and reassembly of the transmission. They make repair easier, faster and prevent damage.

The following tools are available from SPX UK (Ltd) Tel : +44 (0)1327 704461

LC 105A Bearing remover.

E 105-4 Countershaft bearing remover.

E 108 Driver.

E 109 Driver.

E 109-5 Selector control seal and bush installer.

Use with E 109.

E 109-6 Countershaft bearing cup installer adaptor.

Use with E 109.

E 108-5 Replacer adaptor for auxiliary countershaft

bearing and input bearing.

Use with E 108.

E 108-6 Mainshaft rear seal replacer adaptor.

E 109-7 Input shaft seal installer adaptor.

E 109-8 Selector shaft bush installer adaptor.

Use with E 109.

1/11

5/01

Page 18

General

Special Tools (continued)

E 109-9 Selector shaft plug installer adaptor.

Use with E 109.

E 109-10 Driver extension.

Use with E 109.

E 109-11 Countershaft bearing cone installer.

Use with E 109.

E 116-2 Adaptor gear assembly lifting fixture.

Use with E 116A.

LC 113A Flange holding wrench.

MS 284 Slide hammer.

E 114 Rear mainshaft bearing pilot.

E 115 Flange holding adaptor plate

E 116A Gear assembly lifting fixture.

E 117 Reverse idler shaft retaining pin installer.

MS 284-1 Extractor set - bearing/bush.

5/011/12

Page 19

General

Special Tools (continued)

The following general purpose pullers are available from Sykes-Pickavant Ltd., or through their

Dealers.

Three Legged Puller - Series 1500 with Hydraulic

Ram

Locally Made Tools

The following illustration shows a suitable cradle

which can be used to stand the transmission ’on

end’ during ’Disassembly’ and ’Reassembly’. The

thickness of the block has been calculated to lift

the mainshaft the required distance during removal

and installation of the layshaft. If the height of the

cradle is increasing, the thickness of the block

should be increased by the same amount.

Puller Kit - Series 1500 with Hydraulic Ram

All dimensions in mm.

Mounting Plates - 2 off.

1/13

5/01

Page 20

General

Special Tools (continued)

Locally made tools

1. 1 off hole 1.5 inches diameter 16 threads per

inch Whitworth form to suit Sykes Picavant

hydraulic ram No 150 000.

2. 8 holes 11 mm diameter.

Tool for 4 point ball bearing removal.

5/011/14

Page 21

2

General

Special Tools for United States

Eaton 4106/5206

SPX # NEW UK # Description

J-45895 LC 105A Bearing Remover

J-45896 E 105-4 Countershaft bearing remover

J-45902 E 108 Driver

Replacer adaptor for auxiliary countershaft bearing and input

J-45897 E 108-5

J 39588 E 108-6 Mainshaft real seal replacer adaptor

J-8092 E 109 Driver

J 39592-1&

J-39587 E 109-6

J-39589 E 109-7 Input shaft seal installer adaptor

J-39585-2 E 109-8

J-39585-1 E 109-9 Selector shaft plug installer adaptor. Use with E109

J-21465-13 E 109-10 Driver extension

J-39586 E 109-11 Countershaft bearing cone installer. Use with E109

J-39590 E 114 Rear mainshaft bearing pilot

J-45899 E 115 Flange holding adaptor plate

J-39584 E 116A Gear assembly lifting fixture

J-39584 E 116-2 Adaptor gear assembly lifting fixture. Use with E116A

J-45898 LC 113A Flange holding wrench

MS284 MS 284 Slide hammer

J-39591 E 117 Reverse idler shaft retaining pin installer

J-45901 MS 284-1 Extractor set - bearing/bush

E 109-5

bearing

Selector control seal and bush installer. Use with E109

Countershaft bearing cup installer adaptor. Use with E109

Selector shaft bush installer adaptor. Use with E109

1/15 5/01

Page 22

Section 2 General

Description

5/01

Page 23

General Description

Features

The Eaton six-speed transmissions have six forward speeds and are part of a family of synchromesh

transmissions. They have a simple shift pattern using a unique single rail selector mechanism.

The transmissions may be mounted vertically or horizontally and in both positions the gear change

remote control may be to the right or the left.

1. Left-Hand Horizontal 3. Right-Hand Vertical

2. Left-Hand Vertical 4. Right-Hand Horizontal

The synchroniser assemblies are of the baulk ring type with the gear ring cones manufactured separately

from the gears. This allows the synchroniser rings and flanges to be renewed without the need to renew

the gears themselves. Reverse gear is engaged by sliding the reverse gear on the mainshaft into mesh

with a dog clutch ring splined to the mainshaft.

2/1

5/01

Page 24

General Description

Gear Change Pattern

Simple shift pattern with the mechanism biased

in neutral between 3rd and 4th gears.

1 2

3 4

5 6

R

Power Flow in the Gears - Direct Drive Top Gear Version

5/012/2

Page 25

Section 3 Shifting

Controls

6 Speed MK.4

3/1

5/01

Page 26

Shifting Controls

Remote Control - Exploded View

1. Grooved pin

2. Inner striking lever

3. Cross shaft

4. Plug or Neutral switch

5. Pin

6. Washer

7. Breather

8. Housing

9. Plug

10. Gasket

11. End cover

12. Spring washer M8

13. Screw M8

14. Bolt M10 x 50

15. Outer lever

16. Washer

17. Nut M10

18. Boot

19. Oil Seal

20. Bush

21. Reverse plunger

22. Reverse detent spring

23. Detent cover gasket

24. Detent cover

25. Spring washer M8

26. Screw M8

27. Bush

28. Circlip

29. Spring retainer

30. Spring

31. Spring (LH only)

32. Spring retainer

33. Circlip

5/013/2

Page 27

Remote Control Disassembly

1. Ensure neutral is selected and remove the control assembly from the transmission.

2. Remove the outer shift lever and rubber boot.

Remove the neutral switch and pin (if fitted).

Note: The position of the lever is marked on the

shaft. Check before removal.

4. Remove the four separate capscrews and lift off

the end cover.

5. Remove the circlip from the shaft and remove

the spring retainer.

3. Remove the reverse detent cover and pull out

the spring and plunger.

6. Withdraw the booster spring, bias, spring inner

retainer and circlip.

3/3

5/01

Page 28

Remote Control Reassembly

7. Invert the housing and carefully drift out the

expansion plug.

8. Invert the housing, align the grooved pin in the

lever with the expansion plug hole.

1. If necessary renew the bearing bushes in the

housing using the special tool. The new bushes

are prefinished to the correct size.

2. If necessary renew the oil seal.

9. Drift out the pin. Remove the shaft and inner

lever.

3. Install the inner lever, long plain groove toward

the front of the housing.

5/013/4

Page 29

4. Install the shaft from the right hand side of the

housing.

7. Insert the springs and outer retainer.

Note: right hand drive units use a large

retainer: left hand drive units use one large (outer)

and one small (inner).

5. Align the inner lever on the shaft and install a

new grooved pin.

Note: Inner lever should be supported whilst driving pin to prevent damage to bushes.

6. Fit the inner circlip onto the shaft. Install the

smaller spring retainer.

8. Fit the outer circlip onto the shaft.

9. Fit a new gasket and secure the end cover to

the housing. Tighten to correct torque (20 to 24

Nm).

Note: The word Top has been cast into the cover

to identify correct positioning.

3/5

5/01

Page 30

10. Install the reverse detent plunger and spring

and fit the cover using a new gasket. Tighten the

capscrews to the correct torque (20 to 24 Nm).

11. Fit the rubber boot onto the housing. Align the

outer lever with the timing mark on the shaft. Fit

the pinch bolt and tighten to 35 to 39 Nm.

13. Apply Loctite 5900 sealant.

Fit control assembly to the transmission housing.

12. Fit the breather. Install the pin and neutral

switch (15 to 22 Nm). Apply sealant and install a

new blanking plug.

5/013/6

Page 31

Shifting Controls

Direct Control - Exploded View

Item

01 Housing

02 Bush

03 End cap

04 Spring washer

05 Screw

06 Breather

07 Plunger

08 Spring compression

09 Spring compression

10 Cover

11 Spring washer

12 Screw

13 Plunger

14 Spring

15 Cover

Item

16 Spring washer

17 Screw

18 Gaiter

19 Pin

20 Washer

21 Plug

22 End cap

23 Spring washer

24 Screw

25 Bush

29 Seating

30 Gear lever

31 Seating

32 Spring

33 Spring

34 Yoke

3/7

5/01

Page 32

Disassembly

1. Remove the rubber gaiter and breather.

2. Remove the screws, washers, detent cover

plate, spring and plunger.

4. Remove the screws, washers and end covers

from both sides of the housing.

5. If necessary the bushes in the end covers can

be replaced.

3. Remove the screws, washers, detent cover

plate, spring(s) and plunger.

6. Invert the housing and withdraw the yoke.

3/8

5/01

Page 33

Assembly

7. Remove the Circlip and spring.

8. Remove the seat and selector shaft.

1. Clean all joint faces. Fit the seat ensuring that

the slot aligns with the hole in the housing for the

pin.

2. Apply grease to the seat and then fit the pin.

9. Remove the pin and seat.

3. Apply a coating of grease to the Selector shaft

and then, ensuring that the slot in the selector shaft

aligns with the pin in the housing, fit the selector

shaft.

3/9

5/01

Page 34

4. Fit the seat ensuring that the slot in the seat

locates onto the pin and into the bore of the housing.

7. Apply a light coating of grease to the bushes in

the end covers. Apply Loctite 5900 to the joint

faces. Fit the end caps, screws and washers.

Torque screws to 20 to 24 Nm.

5. Ensuring that the smaller diameter of the spring

sits against the seat refit the spring and retaining

Circlip.

6. Install the yoke into the housing.

8. Refit the plunger, spring(s), end cover (apply

Loctite 5900 to the joint faces), screws and washers. Torque screws to 20 to 24Nm.

9. Refit the plunger, spring, detent cover (apply a

coating of Loctite 5900), screws and washers.

Torque screws to 20 to 24 Nm.

3/10

5/01

Page 35

10. Refit the rubber gaiter and breather.

3/11

5/01

Page 36

Section 4 Transmission

Overhaul

5/014/1

Page 37

Transmission Case

Exploded View

1. Screw M12

2. Washer M12

3. Cover

4. Washer

5. Screw M8

6. Rotation pins, overdrive

7. Front casing

8. Washer

9. Oil filler plug

10. Core plug

11. Neutral detent assembly

12. Screw

13. Spring washer

14. Cover

15. Gasket

16. Detent spring

17. Neutral detent plunger

18. Screw

19. Spring washer

20. Washer

21. Dowel

22. Bolt M10

23. Washer M10

24. Nut M10

25. Bushing

26. Oil trough

27. Hammer drive screw

28. Oil trough

29. Hammer drive screw

30. Dowel

31. Bushing

32. Reverse light switch or plug

33. Core plug

34. Rear casing

35. Screw M12

36. Spring washer M12

37. Cover

38. Cup plug

39. Cover

40. Spring washer

41. Screw M10

42. Gasket

43. Washer M10

44. Screw M10

45. Cover

46. Washer M10

47. Screw M10

48. Gasket

49. Magnetic drain plug

50. Washer

51. O ring

5/014/2

Page 38

Disassembly of Transmission Case

Caution: Drain gear oil from the transmission and

clean and refit the drain and filler plugs.

Note: The transmission illustrated in this section is

a standard ratio horizontally installed unit. The procedure is the same for all transmissions but the

physical size and number of teeth on some of the

gears will vary from those illustrated on overdrive

and alternative ratio models.

Horizontally installed units have the remote control

on the side of the transmission and alternative filler

and drain plug positions.

1. Secure the adaptor plates to the transmission

case rear mounting flanges.

Note: This may be a 4-hole square pattern on

early models.

2. Raise the transmission on a hoist and install the

unit onto the stand

4. Remove the reverse lamp switch.

5. Using a flange/yoke holding wrench remove the

output drive flange/yoke retaining nut.

3. Remove the speedometer pinion and adaptor or

electronic sender unit.

6. Remove the output drive flange/yoke, using a

suitable puller if necessary. Do not use a hammer

or the flange/yoke may be damaged.

4/3

5/01

Page 39

7. Ensure neutral is engaged and remove the

remote control housing bolts. Use a soft faced mallet to separate the housing from the transmission.

10 Position the transmission forward end uppermost on the stand or wooden cradle and remove

the detent spring cover plate, spring and plunger

as above or detent assembly (see below).

32mm

8. Measure the diameter of the core plug as shown.

If the diameter is 32mm then the retaining pin must

be removed as explained below. If the core plug

diameter is 37mm then a retaining pin is not fitted

therefore the following procedure can be missed

37mm

11.

9. Remove the rear PTO cover. Using the special

tool or an 8 mm punch, drive the reverse idler shaft

grooved pin INWARDS until the end is approximately 12 mm below the face of the hole. Do not

allow the pin to ’bottom’ against the shaft bore.

5/014/4

Page 40

12. Rotate the gear selector shaft to the left (vertically mounted) or right (horizontally mounted) so

that the case will not foul the selector block on

removal.

15. Remove the capscrews securing the input shaft

cover and remove the cover.

13. On overdrive models, remove the capscrews

retaining the two overdrive fork pivot pins and

remove the pins.

14. Remove the half case flange capscrews and

nuts. Note the position of the shorter capscrews

threaded into the case.

16. Remove the outer circlip from the input shaft

bearing.

17. Remove the spacer and bearing thrust washer.

4/5

5/01

Page 41

18. Using a soft face mallet break the seal and separate the front case from the rear case. DO NOT USE

PRY BARS OR CHISELS. Lift off the front case, leaving the input shaft and bearing in place.

20. Using a suitable long drift drive out the reverse

idler shaft and expansion plug from the case.

19. On overdrive models disengage and remove

the overdrive fork and pads.

1. Thrust washer

2. Needle roller bearing

3. Spacer

4. Reverse idler gear

5. Thrust washer

6. Reverse idler shaft - old design

7. Pin

8. ’O’ ring

9. Reverse idler shaft - new design

21. Remove the reverse idler gear and the thrust

washers. Remove the bearings and spacer from

the gear and the ’O’ ring from the reverse idler

shaft (old design).

22. Assemble the special lifting tool to the mainshaft under the 5th/6th synchroniser. Raise the

shaft by approximately 20 mm. This allows the

layshaft to lift clear.

5/014/6

Page 42

23. Lift out the layshaft

24. Lift off the input shaft with 6th gear flange.

Remove the 6th gear synchroniser ring.

26. Invert the rear case on the stand and remove

the capscrews securing the speedometer housing.

Note the positions of the different length capscrews. Remove the housing. If necessary drift out

the oil seal.

27. Remove the speedometer drive gear or tachograph rotor and the bearing spacer from the rear

case half.

25. Raise the hoist and lift out the mainshaft and

selector shaft and forks as an assembly. Carefully

lower on to a clean bench and remove the special

tool. Separate the selector shaft and forks from the

mainshaft.

28. Invert the casing on the stand and using the

special tool drift out the mainshaft rear bearing. Do

not allow the bearing to fall to the floor.

4/7

5/01

Page 43

29. Invert the casing on the stand and remove the

layshaft rear bearing cover and bearing spacer.

32. Drift out the layshaft front bearing cup using the

special tool. Remove the input shaft bearing using

the special tool.

30. Drift out the layshaft rear bearing outer cup

using the special tool.

31. Remove the layshaft front bearing retaining

plate and graded spacer from the front case.

33. If necessary, to renew the selector shaft bushes, drive the selector shaft expamsion plugs outwards from the case halves.

34. Invert the case halves and using the special

tool or a suitable (25mm diameter) mandrel drive

the selector shaft bushes out of the cases.

5/014/8

Page 44

Layshaft Disassembly

1. Support the shaft assembly and remove the

graded circlip retaining the front taper roller bearing.

2. Using the special tool remove the bearing cone

and roller assembly.

1. Countershaft assembly

2. Taper roller bearing

3. Distance piece

4. Taper roller bearing

5. Circlip

6. Shim

7. Spacer

3. Invert the shaft and remove the rear taper roller

bearing.

Layshaft Assembly

5/014/9

Page 45

Layshaft Reassembly

1. Heat the layshaft taper roller bearing inner races

to 85¡¡C (180¡F). Support the shaft assembly forward end uppermost and place the heated inner

cone and roller assembly onto the shaft. Use a

suitable mandrel to make sure bearing is fully

home.

2. From the range of graded fit circlips, select the

circlip which fits into the groove with the minimum

free play.

3. Fit the circlip using circlip pliers.

4. Invert the layshaft assembly and fit the heated

rear taper roller bearing inner race onto the shaft.

Make sure the bearing is fully home using a suitable mandrel.

Circlips are available in the following sizes and Part

Numbers.

Part No. Thickness (mm)

8870370 2,12

8870371 2,07

8870372 2,02

8871536 1,97

8871537 1,92

8871538 1,87

8871539 1,82

8871540 1,77

4/10

5/01

Page 46

Synchroniser Flange Removal / Fitment

Disassembly Assembly

1. Heat the gear and flange assembly to 80¡C to

deactiveate the Loctite. Using a suitable press or

puller, remove the flange from the gear.

Note: This also applies to the 6th gear flange on

the input shaft.

1. Using a suitable solvent ensure that both parts

are clean and free from oil.

2. Apply a thin bead of Loctite 648 to the spine

teeth of the gear. Press on the synchroniser flange

ensure the flange is fully home. Wipe off any

excess.

3. Allow the parts to cure for a minimum of two

hours.

Note: If the flange does not seat squarely, the procedure should be repeated.

5/014/11

Page 47

Mainshaft Assembly

Mainshaft Disassembly

Eaton have recently introduced a new design of

mainshaft assembly. As both designs are currently

in use strip and rebuid procedures for both are

included in this manual

Note: All snap rings and circlips on the mainshaft

are graded for selective fit. Take care not to score

the bearing surfaces of the mainshaft when removing or fitting the snap rings or circlips.

Note: The end float of the gears on the mainshaft

is established in manufacture by machining the

components to fine tolerances. Before disassembly

of the mainshaft the end floats should be checked

to ascertain whether they are within

the recommended limits.

Where end float is found to be excessive it is necessary to check the gears, mainshaft, synchroniser

hubs and bearing sleeve for wear.

See Inspection of expendable parts and renew

where necessary.

End float check

Refer to picture above:

if the profile of the 1st/2nd gear synchroniser

sleeve is as shown above then the following procedure should be followed(new design).

Where the old design mainshaft is fitted refer to the

procedure from page 4/31 onwards.

1. End float may be checked with the mainshaft

assembled by using a dial gauge, as shown, or

feeler gauges. Mount the mainshaft assembly on a

suitable stand. Locate the dial gauge on the gear

and zero the gauge. Raise the gear and record the

reading.

Gear FS-5th 4th 3rd 2nd 1st

FSO-6th

Minimum 0,31 0,35 0,35 0,35 0,40

Maximum 0,53 0,48 0,48 0,48 0,57

Tolerance 0,22 0,13 0,13 0,13 0,17

All dimensions in mm.

Note: Reverse gear is a sliding gear.

4/12

5/01

Page 48

Exploded View

1. Mainshaft.

2. 3rd gear needle roller bearing.

3. 3rd speed gear.

4. 3rd gear synchroniser ring.

4a. 3rd gear synchroniser flange

5. Roller.

6. Plunger

7. Spring

8. 3rd/4th speed synchroniser hub

9. 3rd/4th speed synchroniser sleeve

10. 4th gear synchroniser flange

10a. 4th gear synchroniser ring

11. 4th gear

12. 4th gear needle roller bearing

13. 4th gear sleeve

14. Snap ring

15. 5th gear needle roller bearing (FS)

6th gear needle roller bearing (FSO)

16. 5th speed gear (FS)

6th speed gear (FSO)

17. 5th gear synchroniser ring (FS)

6th gear synchroniser ring (FSO)

17a. 5th gear synchroniser flange (FS)

6th gear synchroniser flange (FSO)

18. Roller

19. Plunger

20. Spring

21. 5th/6th gear synchroniser hub

22. 5th/6th gear synchroniser sleeve

5th gear synchroniser ring (FSO)

24. Circlip

25. 6th gear needle roller bearing (FS)

5th gear needle roller bearing (FSO)

26. 2nd gear needle roller bearing

27. 2nd gear

28. Synchroniser flange

29. Synchroniser inner ring

30. Synchroniser friction ring

31. Synchroniser ring

32. 1st/2nd gear synchroniser hub

33. Retainer

34. Spring

35. Ball

36. Detent poppet

37. 1st/2nd speed synchroniser sleeve

38. Circlip

39. 1st speed gear

40. 1st gear needle roller bearing

41. Reverse gear hub

42. Snap ring

43. Reverse gear needle roller bearing

44. Reverse gear

45. Mainshaft bearing

46. Tachograph

47. Dust shield

48. Coupling flange

49. Nut

4/13

5/01

Page 49

Disassembly

1. Mount the mainshaft assembly, plain end uppermost, in a soft jawed vice. Remove the synchroniser ring. Carefully slide the 5th/6th synchroniser

sleeve upwards until the three rollers are clear of

the groove in the synchroniser sleeve. Remove the

three rollers, the synchroniser sleeve, the three

plungers and three springs from the synchroniser

hub.

3. Invert the mainshaft assembly. Using a press or

suitable puller remove the mainshaft bearing inner,

reverse gear and reverse gear needle roller bearing.

2. Remove the 5th/6th-gear synchroniser hub

retaining Circlip.

4. Remove the reverse gear fixed hub retaining

snap ring.

5. Using a press or suitable puller remove the

reverse gear fixed hub and 1st speed gear.

4/14

5/01

Page 50

6. Remove the 1st speed gear needle roller bearing.

9. Using a press or suitable tool remove the synchroniser assembly and 2nd speed gear. Remove

the needle roller bearing.

7. Remove the synchroniser assembly retaining

Circlip.

8. To prevent the synchroniser assembly from separating during removal fit the retaining tool. The

tool fits onto the mainshaft, boss down, with the

three retainers located underneath 2nd speed gear.

Adjust the retainers so that there is no free play

between 2nd speed gear and synchroniser assembly.

Note: Should the synchroniser separate then refer

to the relevant section for assembly instructions.

10. Carefully remove the retaining tool and then

place the synchroniser assembly and 2nd speed

gear onto a suitable work surface. Remove 2nd

speed gear.

11. Invert the mainshaft. As the 5th /6th -gear synchroniser hub is not symmetrical identify its orientation. Using a press, or suitable puller, remove the

5th /6th -gear synchroniser hub, synchroniser ring

and 5th speed gear assembly. Note: Care must be

taken to ensure that damage to the teeth on the

synchroniser flange does not occur. (On an overdrive transmission it may be necessary to engage

the press/puller also over the gear).

5/014/15

Page 51

12. Remove the 5th gear needle roller bearing. (On

overdrive transmissions this will be 6th gear).

13. Carefully remove the 4th gear-bearing sleeve

retaining snap ring.

15. Place the assembly on to a suitable work surface, 4th speed gear, uppermost. Remove the

bearing sleeve, needle roller bearing and 4th gear

assembly

14. Using a suitable press or puller support the

mainshaft assembly underneath 3rd speed gear.

Note: It is imperative that the flange, which is part

of the mainshaft, does not foul the press or puller

legs as this may result in damage to the mainshaft.

Press or pull the 4th speed gear bearing sleeve,

4th speed needle roller bearing, 4th speed gear

assembly, 3rd /4th -speed synchroniser assembly

and 3rd speed gear assembly off. Remove the 3rd

speed gear needle roller bearing from the mainshaft.

16. Dismantle the 3rd /4th -speed synchroniser

assembly as previously described in paragraph

one.

17. Lift off the synchroniser hub and synchroniser

ring.

4/16

5/01

Page 52

Mainshaft Reassembly

Before assembling the synchroniser assemblies on to the mainshaft, check the fit of each

synchroniser ring to the relevant synchroniser

flange.

Procedure for 3rd , 4th , 5th and 6th speed

synchronisers.

Procedure for 1st and 2nd speed

Synchronisers

Note: The synchroniser flanges, apart from those

fitted to the 1st and 2nd speed gears, must be loctited to the gears.

a) Stand the synchroniser assembly on to a flat

surface (Either way up)

Place the synchroniser ring to the relevant flange

and while holding the two parts firmly together,

measure the clearance between the two component parts using feeler gauges at several points

around the circumference as shown. The clearance

should be between 0,5 and 1,9 mm. Renew both

parts if the measurement is not within the specified

limits. Retain the synchroniser rings and flanges in

their respective pairs for assembly in the same relative position.

b) Remove the synchroniser flange.

c) Place the synchroniser flange, spigot uppermost

onto the bench.

4/17

5/01

Page 53

d) Remove the synchroniser inner ring.

e) Fit the synchroniser inner ring, tangs uppermost,

on to the synchroniser flange.

g) Fit the synchroniser friction ring on to the synchroniser flange ensuring that the tabs on the synchroniser friction ring locate into the slots on the

synchroniser flange.

h) Remove the synchroniser ring.

f) Remove the synchroniser friction ring.

i) Fit the synchroniser ring onto the assembly.

4/18

5/01

Page 54

j) While holding the parts firmly together, measure

the clearance between the synchroniser ring and

synchroniser flange using feeler gauges at several

points around the circumference as shown. The

clearance should be between 0,5 and 1,9 mm. If

the measured dimension is outside these tolerances then the synchroniser assembly must be

changed.

Reassembly

Note: The synchroniser flanges, apart from those

fitted to the 1st and 2nd speed gears, must be loctited to the gears.

1. Place the retaining tool, boss uppermost, on to a

suitable surface.

k) Refer to paragraphs twelve to fifteen of the

assembly procedure in the section 1st /2nd speed

synchroniser assembly .

l) Invert the synchroniser assembly and repeat the

process.

2. Place the 1st /2nd speed synchroniser assembly

onto the retaining tool ensuring that the chamfer on

the synchroniser sleeve is uppermost.

3. Heat the assembly to 85¡ Centigrade and then

place the retaining tool and synchroniser assembly

onto the press table.

4/19

5/01

Page 55

4. Fit the 2nd speed gear to the synchroniser

assembly ensuring that the splines on the gear

engage into the splines on the synchroniser

assembly. Fit and lubricate the needle roller bearing.

6. To prevent the synchroniser assembly separating the retainers should be used. Adjust the retainers so that there is no free play between 2nd

speed gear and the synchroniser assembly.

5. Fit the mainshaft, plain end uppermost, into the

2nd speed gear and synchroniser assembly ensuring that the splines on the mainshaft engage into

the splines of the synchroniser assembly. Press the

mainshaft into the synchroniser assembly.

7. Lubricate and install the 3rd gear needle roller

bearing and 3rd gear assembly.

5/014/20

Page 56

8. Lubricate the 3rd gear synchroniser flange and

then fit the synchroniser ring.

9. Heat the 3rd /4th -gear synchroniser hub to 85¡

Centigrade. Fit the synchroniser hub over the

splines on the mainshaft ensuring that the large

slots in the synchroniser hub align with the large

shoulders on the synchroniser ring. Press the synchroniser fully home.

11. Assemble the three springs and plungers into

the synchroniser hub. Place the synchroniser

sleeve over the synchroniser hub and support it

with the internal groove just above the synchroniser hub. Position the three rollers as shown, resting

on the heads of the plungers, and press downward

on the synchroniser sleeve. This compress the

springs allowing the synchroniser sleeve to centralise in the neutral position.

12. Place the 4th gear synchroniser ring onto the

synchroniser assembly ensuring that the shoulders

on the synchroniser ring locate into the slots of the

synchroniser hub. Lubricate the synchroniser ring.

10. Check that the 3rd gear end float is within the

tolerance stated in the chart.

13. Fit the 4th speed gear assembly. Lubricate the

needle roller bearing and then install it into the

gear.

4/21

5/01

Page 57

14. Heat the 4th speed gear-bearing sleeve to 85¡

Centigrade and locate it onto the mainshaft and

inside the needle roller bearing. Press the bearing

sleeve into position.

15. Fit a new snap ring into the mainshaft groove

taking care not to damage the mainshaft-bearing

surface.

17. Fit the 5th speed gear assembly. Lubricate the

needle roller bearing and then install it into the

gear.

18. Lubricate the 5th gear synchroniser flange. Fit

the synchroniser ring.

16. Check that the 4th gear end float is within the

tolerance stated in the chart.

19. Heat the 5th /6th -speed synchroniser hub to

85¡ Centigrade and then install it, boss downwards,

onto the mainshaft. Ensure that the large slots on

the synchroniser hub align with the large shoulders

on the synchroniser ring. Press the synchroniser

hub until it is fully seated.

5/014/22

Page 58

20. From the range of graded circlips select the

one which fits into the mainshaft groove with the

least amount of free play. Fit the Circlip into the

groove.

21. Using feeler gauges check that the 5th gear

end float is within the tolerance stated in the chart.

22. Invert the mainshaft and then remove the

retaining tool.

23. Install the Circlip into the groove of the mainshaft. Take care not to damage the mainshaft bearing surface.

4/23

5/01

Page 59

24. Check that the 2nd speed gear end float is

within the tolerances stated in the chart.

25. Fit and lubricate the needle roller bearing. Fit

the 1st speed gear ensuring that the splines on the

1st speed gear engage into the splines of the synchroniser flange.

27. From the range of graded circlips select the

one which fits into the mainshaft groove with the

least amount of free play. Fit the Circlip into the

groove taking care not to damage the mainshaft

needle roller bearing surface.

28. Check that the 1st speed gear is within the

specified tolerance stated in the chart.

26. Heat the reverse gear hub to 85¡ Centigrade

and then, with the boss uppermost, fit it onto the

splines of the mainshaft. Press the reverse gear

hub until it is fully seated.

29. Fit the reverse gear needle roller bearing.

Lubricate the bearing and then fit the reverse gear,

boss down, onto the mainshaft.

4/24

5/01

Page 60

30. Heat the mainshaft bearing inner to 85¡

Centigrade and then fit it, shoulder down, onto the

mainshaft. Use a press, if necessary, to ensure that

the bearing is fully home against the shoulder.

1st /2nd speed Synchroniser

assembly.

Note: The synchroniser is supplied as an assem-

bly. Parts that are used to make the complete

assembly are not available separately.

1. Stand the synchroniser assembly on a flat surface with the spigot of the synchroniser sleeve

uppermost.

31. Invert the mainshaft. Assemble the three

springs and plungers into the synchroniser hub and

then install the synchroniser sleeve and rollers as

described in paragraph eleven.

32. Fit the synchroniser ring ensuring that the three

bosses on the synchroniser ring locate into the

three slots on the synchroniser hub. Lubricate the

synchroniser ring.

2. Push the synchroniser sleeve downwards.

3. Remove the synchroniser flange.

5/014/25

Page 61

4. Remove the synchroniser inner ring.

7. Remove the three retainers.

5. Remove the synchroniser friction ring.

6. Remove the synchroniser ring.

8. Taking care not to lose the balls or springs lift

the detent poppets to release the balls. Once the

balls have been removed it is possible to remove

the detent poppets and springs.

9. Remove the synchroniser sleeve.

4/26

5/01

Page 62

10. If not already removed at step eight remove the

detent poppets and springs.

13. Remove the synchroniser friction ring.

11. Remove the synchroniser hub.

12. Remove the synchroniser ring.

14. Remove the synchroniser inner ring.

5/014/27

Page 63

Assembly

1. Place the synchroniser flange, spigot uppermost

onto the bench.

4. Fit the synchroniser ring ensuring that the undercuts (1) line up with the tabs (2) of the synchroniser inner ring and that bosses (3) of the synchroniser ring are to the left hand side of tabs (2) of the

synchroniser inner ring as shown.

2. Fit the synchroniser inner ring, tangs uppermost,

on to the synchroniser flange.

3. Lubricate all surfaces of the synchroniser friction

ring. Fit the synchroniser friction ring ensuring that

the tabs locate in to the slots of the synchroniser

flange.

5. With the holes in the synchroniser hub uppermost.

6. Fit the synchroniser hub ensuring that the narrow slots are in line with the bosses of the synchroniser ring.

4/28

5/01

Page 64

7. Place the three retainers in the large recesses of

the synchroniser hub so that the legs of the blocks

engage with the tabs of the synchroniser inner ring

and the undercuts of the synchroniser ring.

8. Take the synchroniser sliding sleeve, stepped

side uppermost, and fit it on to the synchroniser

hub ensuring that the three internal bosses of the

synchroniser sleeve locate in the slots of the synchroniser hub.

10. Place the detent ball onto the spring and then

using a suitable tool push against the detent ball to

compress the spring.

11. Whilst the spring is compressed push the

detent poppet downwards into the synchroniser

hub until the ball engages with the annular groove

of the sleeve. Fit the remaining detent springs,

balls and plungers into position.

9. Place the detent poppets and springs into the

holes of the synchroniser hub.

12. Place the synchroniser ring on to the synchroniser hub so that the three bosses engage with the

three narrow slots on the synchroniser hub.

5/014/29

Page 65

13. Lubricate all surfaces of the synchroniser friction ring. Place the synchroniser friction ring, tabs

uppermost, on to the synchroniser hub.

14. Place the synchroniser inner ring in to position

ensuring that the three tabs align with the legs of

the blocks.

16. Hold the synchroniser assembly down against

the bench and at the same time lift the synchroniser sleeve upwards to engage the neutral position.

15. Place the synchroniser flange in to position

ensuring that the slots of the synchroniser flange

align with the tabs of the synchroniser friction ring.

4/30

5/01

Page 66

Old Design

Mainshaft Disassembly

Note: All snap rings and circlips on the mainshaft

are graded for selective fit. Take care not to score

the bearing surfaces of the mainshaft when removing or fitting the snap rings or circlips.

Note: The end float of the gears on the mainshaft

is established in manufacture by machining the

components to fine tolerances. Before disassembly

of the mainshaft the end floats should be checked

to ascertain whether they are within the recommended limits.

Where end float is found to be excessive it is necessary to check the gears, mainshaft, synchroniser

hubs and bearing sleeve for wear. See ’Inspection

of Expendable Parts’ and renew where necessary.

End Float Check

End float may be checked with the shaft assembled by using a dial gauge as shown.

Disassembly

1. Mount the mainshaft assembly, plain end uppermost, in a soft jawed vice. Remove the synchroniser ring. Carefully slide the 5th/6th synchroniser

sleeve upwards until the three rollers are clear of

the groove in the synchroniser sleeve. Remove the

three rollers, the synchroniser sleeve, the three

plungers and three springs from the synchroniser

hub.

1. End float may be checked with the mainshaft

assembled by using a dial gauge, as shown, or

feeler gauges. Mount the mainshaft assembly on a

suitable stand. Locate the dial gauge on the gear

and zero the gauge. Raise the gear and record the

reading.

Gear 5th 4th 3rd 2nd 1st

(o.d. 6th)

Low Limit 0,31 0,35 0,35 0,35 0,40

High Limit 0,53 0,48 0,48 0,48 0,57

Range 0,22 0,13 0,13 0,13 0,17

All dimensions in mm.

Note: Reverse gear is a sliding gear.

2. Remove the 5th/6th-gear synchroniser hub

retaining Circlip.

4/31

5/01

Page 67

Exploded View

1. Needle roller bearing

2. Circlip

3. Synchro ring

4. Sliding sleeve

5. Fixed hub

6. Roller

7. Plunger

8. Synchro spring

9. Synchro flange

10. Mainshaft gear 5th or Overdrive

11. Needle roller bearing

12. Circlip 2,00 mm

13. Mainshaft bearing sleeve - 4th

14. Needle roller bearing

15. Mainshaft gear 4th

16. Synchro flange

17. Synchro ring

18. Sliding sleeve

19. Fixed hub

20. Synchro flange

21. Mainshaft gear 3rd.

22. Needle roller bearing

23. Mainshaft

24. Needle roller bearing

25. Gear 2nd.

26. Synchro flange

27. Synchro ring

28. Fixed hub

29. 4,00 mm graded circlip pack

30. Sliding Sleeve 1st.

31. Synchro flange

32. Gear, Mainshaft 1st.

33. Needle roller bearing

34. Fixed hub, reverse

35. Circlip 2,00/2,05/2,10

36. Needle roller bearing

37. Mainshaft gear, reverse

38. Spacer

39. Roller bearing

40. Speedo drive gear

41. Grit shield

42. Coupling flange

43. Nyloc nut M33

5/014/32

Page 68

3. Assemble the puller over the 5th/6th gear synchroniser hub and the 5th gear synchroniser ring,

taking care not to damage the teeth of the latter.

Pull off the hub, cone and ring.

(On an overdrive transmission it may be necessary

to engage the puller over 6th gear also.)

4. Lift off the 5th gear and 5th gear needle roller

bearing. (On overdrive transmissions this will be

6th gear.)

6. Invert the shaft assembly and using a suitable

puller under the reverse gear remove the gear,

thrust washer and bearing track. Remove the

reverse gear needle roller bearing.

7. Remove the reverse gear fixed hub retaining

snap ring.

5. Carefully remove the 4th gear bearing sleeve

retaining snap ring.

8. Using a press of suitable puller, pull off 1st gear

assembly and the reverse gear fixed gear hub.

4/33

5/01

Page 69

9. Lift off the steel cage bearing, 1st gear synchroniser ring.

10. Slide the 1st/2nd gear synchroniser sleeve

carefully rearwards until the three rollers are clear

of the groove in the sleeve. Remove the rollers, the

sleeve and the three plungers and springs from the

synchroniser hub.

12. Assemble the puller over the 2nd gear and pull

off 2nd gear, 2nd gear synchroniser ring and flange

the 1st/2nd gear synchroniser hub and the bearing.

13. Support the shaft on the press under 3rd gear.

Note: It is imperative that 3rd gear is supported

and that the flange on the shaft does not foul the

supporting blocks or press bed when the shaft is

being pressed through.

Press or pull the shaft through 3rd gear, 3rd/4th

gear synchroniser hub and 4th gear bearing

sleeve.

11. Remove the 1st/2nd synchroniser hub retaining

snap ring.

14. Dismantle the 3rd/4th gear synchroniser hub as

previously described in sub operation

5/014/34

Page 70

Mainshaft Reassembly

Note: The following parts must be heated to the

temperatures recommended prior to assembly.

Place the parts on a hotplate or in a temperature

controlled oven for not less than 30 minutes to

make sure they are thoroughly heated before placing them in position. Once fitted and cooled the

parts will shrink to an interference fit.

Refer to drawing Item No.

4th gear bearing sleeve 13

Reverse fixed hub 34

Mainshaft rear bearing

inner track 39

Synchroniser hubs (3 off) 5

19

28

Recommended Temperature 85¡C

2. Support the mainshaft rear end uppermost. Fit

the 2nd gear bearing.

1. Before assembling the synchroniser assemblies

on the mainshaft, check the fit of each synchroniser ring onto its synchroniser flange. Place the synchroniser ring on its mating flange and while holding the two parts firmly together, measure the

clearance between the two rings using feeler

gauges at several points around the circumference

as shown. The clearance should be between 0,5

and 1,9mm. Renew both parts if the measurement

is not within the specified limits. Retain the synchroniser rings and flanges in their respective pairs

for assembly in the same relative positions.

The synchroniser flanges must be loctited to the

gears.

The gears and flange are then treated as one

assembly.

3. Lubricate the bearing with clean gear oil and fit

the 2nd gear over the bearing.

4. Fit the 2nd gear assembly. Then fit the synchroniser ring.

4/35

5/01

Page 71

5. Take the heated 1st/2nd gear synchroniser hub

and place it over the spines on the mainshaft

ensuring that the large slots in the hub align with

the large shoulders on the synchroniser ring. Use a

soft drift or flange driver to ensure the hub is fully

home after cooling for 4/5 minutes. Use special

tool.

6. From the range of graded snap rings select the

thickest one which fits into the groove with the minimum free play.

8. Check that the gear end float is within the tolerances stated in the chart.

9. Assemble the three springs and plungers into

the synchroniser hub. Place the synchroniser

sleeve over the hub and support it with the internal

annular groove just above the hub. Position the

three rollers as shown, resting the on the heads of

the plungers, and press downward on the sleeve.

This compresses the springs allowing the sleeve to

centralise in the neutral position.

7. Install the snap ring in the groove taking care

not to damage the mainshaft bearing surfaces.

10. Assemble the 1st gear synchroniser ring onto

the synchroniser hub assembly.

5/014/36

Page 72

11. Lubricate 1st gear bearing and install the steel

cage bearing into the gear. Place the gear assembly and bearing onto the shaft and into the synchroniser ring.

14. From the range of graded snap rings, carefully

install the thickest one which will fit into the groove

with the minimum free play taking care not to damage the mainshaft bearing surface.

12. Take the heated reverse gear fixed hub and fit

it over the splines, boss uppermost, onto the mainshaft.

13. Use a soft drift or suitable flange driver if necessary, to ensure the hub is fully home against the

shoulder.

15. Check the gear end float is within the tolerances stated in the chart.

16. Lubricate the reverse gear bearing and install

the bearing and reverse gear onto the shaft.

4/37

5/01

Page 73

17. Fit the spacer on the standard cylindrical roller

or 4 point ball bearing. If integral spacer bearing is

fitted the spacer is part of the bearing inner race.

20. Install the 3rd gear synchroniser ring over the

flange.

18. Take the heated inner track of the mainshaft

rear bearing and fit it over the shaft, flange innermost against the spacer. Use a soft drift or flanged

driver if necessary to ensure that the bearing is

fully home against the shoulder.

Note: When cooled, the bearing track should be

sufficiently tight on the shaft to retain the reverse

gear on the shaft.

21. Take the heated 3rd/4th gear synchroniser hub

and fit it over the splines on the shaft ensuring that

the large slots in the hub align with the large shoulders on the synchroniser ring. Use a soft drift or

flanged driver if necessary to ensure the hub is

fully home. Recheck that the shoulders are in the

correct slots

19. Invert the shaft in the vice. Lubricate and install

the 3rd bearing and 3rd gear assembly.

22. Check that the gear end float is within the tolerance stated in the chart.

5/014/38

Page 74

23. Assemble the three springs and plungers into

the hub and install the synchroniser sleeve and

rollers as described in sub operation 9.

24. Place the 4th gear synchroniser ring onto the

synchroniser hub assembly

26. Take the heated 4th gear bearing sleeve and

locate it inside the bearing and over the shaft. Use

a soft drift or flanged driver if necessary, to ensure

the sleeve is firmly home against the synchroniser

hub.

27. Fit a new snap ring into the groove taking care

not to damage the mainshaft bearing surface.

25. Lubricate the 4th gear and bearing and position

the gear into the synchroniser ring and the bearing

into the gear

Note: If a smear of petroleum jelly is applied to the

outer edge of the bearing, this will support the

bearing to stand proud of the gear and ease the

procedure of aligning the bearing sleeve in the next

operation.

28. Check that the gear end float is within the tolerances stated in the chart.

4/39

5/01

Page 75

29. Lubricate the 5th gear bearing and install the

bearing and 5th gear assembly onto the shaft.

30. Position the 5th gear synchroniser ring onto the

synchroniser flange of 5th gear.

Caution: Ensure that when fitting the synchroniser

flange to the 5th gear, the correct flange is used.

On overdrive transmission it is possible to fit the

overdrive flange to the 5th gear

32. From the range of graded circlips select the

thickest one which fits into the groove with the minimum free play.

33. Fit the circlip into the groove in the mainshaft.

31. Take the heated 5th/6th gear synchroniser hub

and install it, boss side downwards onto the shaft.

Ensure that the large slots in the hub align with the

large shoulders on the synchroniser ring. Use a

soft drift or flanged driver, if necessary, to ensure

the hub is fully home against the shoulder.

Recheck that the shoulders are in the correct slots.

34. Check the gear end float using feeler gauges.

5/014/40

Page 76

35. Assemble the three springs and plungers into

the hub and install the synchroniser sleeve and

rollers as described in sub operation 9.

Selector Shaft Disassembly

Selector Shaft Disassembly

Note: Tapered capscrew fitted on opposite side

on horizontal unit.

1. Place selector assembly on bench with the

selector block to the left. Mark the front of the shaft

and keys to aid reassembly

2. Hold the assembly by the selector block and

withdraw the interlock key from the rear.

3. Remove the selector forks from the shaft.

4/41

5/01

Page 77

4. Remove the capscrew from the selector block

and slide the block off the shaft.

Selector Shaft - Reassembly

1. Overdrive shift pad

2. Overdrive fork

3. Overdrive selector

4. Selector keys

5. Selector shaft

6. Interlock key

7. Shift fork 5th/6th

Selector Shaft Assembly (Vertically mounted unit)

8. Selector block

9. Set screw

10. Pin

11. Shift fork 3rd/4th

12. Shift fork 1st/2nd

13. Shift fork-reverse

4/42

5/01

Page 78

1. Place selector key into slot on the selector shaft

with the three small lugs to the front.

4. Support the selector shaft and slide in the interlock key from the rear.

2. Put the selector block onto the shaft and tighten

the capscrew to 35 to 39 Nm.

Note: If reusing the screw apply Loctite 270 to the

threads before fitting.

3. Place the forks in their respective positions on

the selector shaft.

5. On overdrive units the 5th/6th fork is replaced by

a selector. Check the fit of the selector before

assembling the transmission.

5/014/43

Page 79

Transmission Case - Reassembly

Note: Before reassembling the transmission case

ensure that each half case and covers are clean

and that all gaskets and joining/sealing materials

are cleaned from the mating faces. When reusing

patch lock bolts or fitting capscrews to through

holes apply the recommended threadlock or

sealant to the threads (Loctite: 641).

4. Install the layshaft front bearing outer cup into

the front case until approximately 5mm below the

face of the case.

2. If removed apply Loctite 518 sealant and install

new selector shaft expansion plugs, dished side

facing inwards into the cases from the inside.

3. Using the special tool install the selector shaft

bushes into the cases. Drive in until fully home.

5. Using the special tool install the layshaft rear

bearing cup into the rear case, drive in until just

below the rear face of the case.

6. Place the spacer on the bearing cup, making

sure it is protruding above the case.

4/44

5/01

Page 80

7. Apply Loctite 5900 to the housing, install the

layshaft rear bearing cover to the case. Tighten the

capscrews evenly to the correct torque (69 to

78Nm) making sure that the bearing cup is pressed

into the case.

10. Locate the selector shaft assembly to the mainshaft. Support the mainshaft using the special tool

and hoist and lower the assembly into the case

making sure the selector shaft enters the rear

bush. Support the mainshaft and selectors approximately 20mm above the fully installed position.

8. Install the mainshaft rear bearing outer track and

roller assembly, snap ring groove outermost, into

the case. Temporarily install the speedo housing

with two or three capscrews.

9. Fit the special guide sleeve over the mainshaft.

11. Lubricate and install the spigot bearing on the

mainshaft. Fit the synchroniser ring and install the

input shaft assembly.

12. Locate the layshaft into mesh with the mainshaft.

5/014/45

Page 81

13. Lower the hoist to allow the mainshaft, layshaft

and selector shaft to seat into their respective

bearings or bushes. Remove the special tool.

Ensure the selector block is positioned so it does

not foul the front case.

16. On overdrive transmissions, using a suitable

probe as illustrated, align the pivot pins with the

holes in the case. Apply sealer (Loctite 518) to the

pivot pin flange and install the pins.

14. On overdrive transmissions, install the fork

pads into the 5th/6th overdrive selector fork.

Engage the fork and pads into the synchroniser

sleeve.

15. Apply Loctite 5900 sealant to the mating flange

on the rear case and install the front case. Install

the capscrews and nuts.

17. When aligning the right hand pin, use a screwdriver and lift the selector through the remote control aperture. Tighten the capscrews to the correct

torque (20 to 40Nm).

18. Fit the input shaft bearing ensuring oil feed

hole is kept clear.

4/46

5/01

Page 82

19. Fit bearing thrust washer. Place the original

spacer against the bearing and check that the snap

ring will fit into its groove without free play. Check

at several places around the diameter of the shaft.

If there is free play, or the snap ring will not fit into

the groove, a new thicker or thinner spacer respectively will be required in place of the original.

Graded spacers are available in the following six

thicknesses, marked with part number indicated in

the table,

Part No. Thickness (mm)

8872484 3,70

8872485 3,75

8874486 3,80

8872487 3,85

8872488 3,90

8872489 3,95

When the correct thickness spacer has been

selected and fitted, fit the new snap ring.

21. Lubricate the shaft seal surface and apply

Loctite 5900 sealant to the mating face of the front

cover. Install the front cover and tighten the capscrews to the correct torque (35 to 39Nm).

22. Select a shim pack and place it against the

layshift bearing cup. Place the spacer on top of the

shim.

Note: The shim pack must stand proud of the front

face of the case when the bearing cup is fully seated against the bearing cone and roller assembly.

Shims are available in the following thicknesses.