Page 1

GE

Sensing

Druck Portable High

Pressure Hydraulic

Calibrators

g

• High accuracy 0.025% full scale (FS)

• Generates pressures up to 10,000 psi (700 bar)

• Dual pressure and electrical readout

• Thermal compensator for high speed stable control

• Unique vacuum priming of hydraulic system

• RS232 interface and documenting versions

The DPI 330/335 Series is designed to make the

calibration of hydraulic systems and instrumentation

quick and simple. Two versions are available, the DPI 330

and the DPI 335. The DPI 330 is the standard model with

RS232 interface and the DPI 335 has full documenting

capability.

These self-contained portable calibrators provide

unparalleled accuracy and performance. Hydraulic

pressures up to 10,000 psi (700 bar) can be generated

quickly and easily with excellent setpoint control.

Features

DPI 330/335 Series is a Druck

product. Druck has joined other GE

high-technology sensing

businesses under a new name–

GE Industrial, Sensing.

DPI 330/335 Series

Page 2

Unique Priming System

The DPI 330/335 uses a unique priming system to

conveniently fill the hydraulic system under test . The

pressure/vacuum selector valve, combined with the

priming pump, first evacuates the system and then fills

the system with fluid from the reservoir and generates

the initial pressure. Once the system is primed, any

desired pressure can be easily set using the pressure

pump and volume adjuster.

Excellent Control Stability

The thermal compensator eliminates adiabatic thermal

effects which are generated by pressure changes within

the hydraulic system. This innovative feature holds the

generated pressure steady while a nudge facility allows

the exact pressure to be set. Overall test/calibration time

and precision is significantly improved.

Dual Channel Display

The DPI 330/335 are dual channel instruments able to

display the input and output values simultaneously. The

calibrators are capable of providing current and voltage

excitation to the device under test and can measure DC.

voltage, DC current and ambient temperature. Electrical

terminations are made via industry standard 4 mm

sockets and the large backlit display provides a clear

readout of the process parameters.

Application Specific Task Menu

A dedicated task key provides instant access to the task

menu permitting the calibrator to be configured for

specific applications. For example, the P-I task configures

the calibrator to source pressure and measure current.

24 VDC loop power is also available to allow complete

pressure transmitter calibration. Running the Pressure

Switch task captures the open and closed switch values

and calculates switch hysteresis. The contact resistance

of the switch can also be monitored.

Reduced Process Downtime

The DPI 335 version enables calibration criteria to be

easily entered via the keypad allowing fast diagnosis of

field instruments and automatic reporting of errors with a

Pass or Fail status. When used in conjunction with i4i

(Intecal for Industry) calibration management software,

test procedures can be downloaded to the DPI 335 from

a PC. The calibrator will prompt the technician during the

calibration routine and the results will be recorded

electronically, reducing plant downtime and human

errors.

GE

Sensing

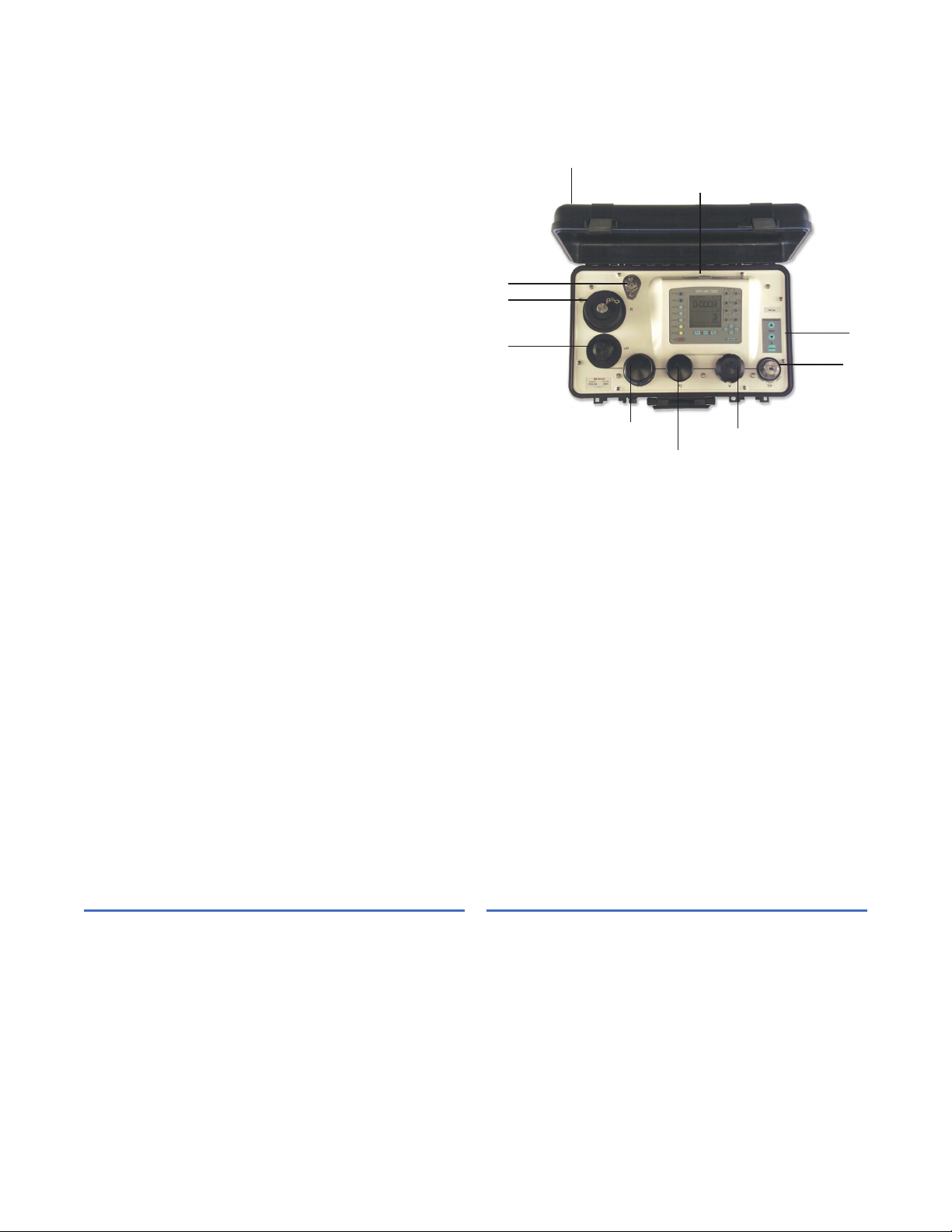

Rugged transit case

High contrast,

menu-driven dual

function display

Thermal

compensator

control panel

1/8 NPT or BSP

test port

Volume adjuster

Pressure pump

Priming pump

Pressure/

vacuum

selector valve

Reservoir

Remote

sensor

connection

Page 3

General

Pressure

The DPI 330/335 series include an internal pressure

sensor. The pressure range should be selected below.

DPI 330/335

Specification

Temperature Effects

(Averaged and w.r.t. 20°C) w.r.t. ±0.004% reading/°C

Pressure Source

Internal hydraulic reservoir (volume 300 cubic inches)

with volume adjuster high pressure pump and pre-prime

pump.

Recommended Media

Mineral oil or distilled water

External Pressure Sensor

Up to 10 remote-sensors (option B) may also be ordered

per calibrator and connected to the instrument via the

1/4 in test port. Consult factory for available ranges.

Test Port Connections

1/8 NPT or BSP female

Input Range Accuracy Resolution Remarks

Voltage* ±50 VDC 0.05% Rdg 0.004% 100 :Vmax Autoranging

FS >100 MW

Current* ±55 mA 0.05% Rdg 0.004% 0.001 mA 10 W, 50 V

FS maximum

Temp 15°F to 105°F 2°F (-16°C) 0.1°F (-17°C) Case ambient

(-10°C to 40°C)

Switch Open/Closed 5 mA whetting

Output Range Accuracy Resolution Remarks

Voltage 10 VDC 0.01% Maximum load

10 mA

Voltage 24 VDC. 5% Maximum load

26 mA

Current* 0 to 24 mA 0.05% Rdg. 0.01% FS0.001 mA

*Temperature coefficient 0.0075% reading/°C w.r.t. 20°C

GE

Sensing

Pressure Accuracy* Maximum Type**

Range (% FS) Overpressure

1000 psi (70 bar) 0.025% 2000 psi (140 bar) G or A

2000 psi (140 bar) 0.025% 4000 psi (275 bar) G or A

3000 psi (200 bar) 0.025% 6000 psi (400 bar) G or A

5000 psi (350 bar) 0.025% 10,000 psi (700 bar) G or A

10,000 psi (700 bar) 0.025% 12,000 psi (825 bar) G or A

*Combined non-linearity, hysteresis and repeatability.

**G = Gage, A = Absolute (pressure reference).

Electrical

In addition to pressure, the dual display can

simultaneously monitor mA, V, switch, continuity and

ambient temperature. Also, 10 VDC and 24 VDC power

supplies are available for the device under test (DUT).

Features

Pressure Units

25 scale units plus one user defined.

mA Source

Auto 10 second step cycle and programmable

(60 second end-to-end) ramp

Process Functions

Filter, maximum/minimum, tare, flow, and % span.

Power Management

Auto power off, auto backlight off, battery status

indicator.

Display

2.36 in x 2.36 in (60 mm x 60 mm) graphic LCD with

backlight. ±99999 readout, 2 readings per second.

Data Storage

92 KB memory

Environmental

Temperature

• Operating range: 15°F to 120°F (-10°C to 50°C)

• Calibrated range: 15°F to 105°F (-10°C to 40°C)

Humidity

0 to 90% non-condensing.

Sealing

Type 12/IP54

Page 4

DPI 330/335

Specification

GE

Sensing

Conformity

• EN61010

• EN61326 Class A

• CE marked

Physical

23 lb (10.4 kg)

Dimensions

16.9 in x 10 in x 6.5 in (429 mm x 254 mm x 165 mm)

Power Supply

Battery powered 7.2 V NiMH cell. In addition, the unit will

operate from AC power supply 85 V to 265 V,

45 to 400 Hz which also allows the battery pack to

recharge. Display indicates a low battery condition.

DPI 335 Additional Specifications

The fully documenting DPI 335 also provides the

following features:

Error analysis with Pass/Fail status and graphs. Storage

of As Found and As Left results. Two-way PC interface for

transferring test procedures and results. Compatible with

Intecal for Industry software.

Options

(A) Intecal for Industry

Developed to help meet the growing demand on

industry to comply with quality systems and

calibration documentation. Test procedures are

created on screen in a Windows based utility and

devices due for calibration are reported and grouped

into work orders for transfer to the DPI 605, DPI 615,

DPI 325 and DPI 335, TRX II and the MCX II.

Calibration results, including files from the DPI 615,

are uploaded to the PC via the RS232 interface or

g

©2006 GE All rights reserved.

920-106A

All specifications are subject to change for product improvement without notice.

GE

®

is a registered trademark of General Electric Co. Other company or product

names mentioned in this document may be trademarks or registered trademarks

of their respective companies, which are not affiliated with GE.

www.gesensing.com

PCMCIA card for analysis and or printing calibration

certificates. Visit www.ge-intecal.com for Intecal for

Industry demonstration.

External Pressure Sensor

(B1) The DPI 330/335 Series has a second pressure

channel which can be configured with up to 10

remote pressure sensors (one at a time). For ease of

use the sensors are fitted with an electrical

connector and 1/4 in pressure ports.

At least one mating cable is required per DPI 330/335

when ordering remote pressure sensors.

(B2) A 3 ft (1 m) mating cable for connecting remote

sensors to the DPI 330/335.

(C) 1 quart ST 55 mineral oil (P/N PPA9152) if operation

with oil is desired.

Supplied as Standard

The DPI 330 and DPI 335 are supplied with a

rechargeable cell, battery charger, test lead, user guide

and calibration certificate as standard.

Calibration Standards

Instruments manufactured are calibrated against

precision calibration equipment traceable to International

Standards.

Related Products

• Portable field calibrators

• Laboratory and workshop instruments

• Pressure transducers and transmitters

Ordering Information

Please state the following (where applicable):

1. DPI 330 or DPI 335 type number, indicate 1/8 NPT or

BSP test port adaptors

2. Internal pressure range

3. Options (if required) including external pressure sensor

range

Loading...

Loading...