Page 1

GE

Sensing

DPI 320/325

Series

The DPI 320/325 Series are Druck

products. Druck has joined other

GE high-technology sensing

businesses under a new name

—

GE Industrial, Sensing.

g

• High accuracy 0.025% full scale (FS)

• Generates pneumatic pressures to 3000 psi (200 bar)

• Dual channel readout: pressure and electrical

• Self contained rechargeable gas cylinder

• RS232 interface and documenting versions

• Coarse/fine adjust selection

Features

Druck Portable High

Pressure Pneumatic

Calibrators

For over twenty years, GE Druck has led the world in

portable pressure calibrator technology and function. The

DPI 320/325 Series of high pressure pneumatic

calibrators are the latest additions to a comprehensive

range of compact and rugged instruments. This range of

portable calibrators is designed to make testing and

calibration of high pressure instruments and systems

both quick and simple. Two versions are available: the

DPI 320, which is the standard model, and the DPI 325,

which has full documenting capability. These

self-contained portable calibrators from GE Druck provide

unparalleled accuracy and control performance. A built-in

gas cylinder provides source pressures up to 3000 psi

(200 bar), a precision pressure regulator and fine volume

adjuster ensures optimum control, and a digitally

characterized sensor measures pressure to better than

0.025% of FS.

Fast and Convenient Solution for

Pressure Calibration

Page 2

Field and Workshop Operation

The DPI 320/325 Series pressure calibrators are designed

for use in the workshop, in the plant or out in the field.

The large capacity gas cylinder ensures maximum

productivity between refills. In addition, the calibrators

can be operated directly from an external pressure

source connected to the charging port.

Dual Channel Display

The DPI 320/325 Series are dual channel instruments,

able to display both the input and output values

simultaneously. The calibrators are capable of providing

current and voltage excitation to the unit under test (UUT),

and can measure DC voltage, DC current and ambient

temperature. Electrical terminations are made by

industry standard 4 mm sockets, and the large backlit

display provides a clear readout of the process

parameters.

Application Specific Task Menu

A dedicated task key provides instant access to the task

menu, permitting the calibrator to be configured for

specific applications. For example, the P-I task configures

the calibrator to source pressure and measure current at

24 VDC. Loop-power is also available to allow complete

pressure transmitter calibration. Running the pressure

switch task captures the open and closed switch values

and calculates switch hysteresis. The contact resistance

of the switch under test can also be monitored.

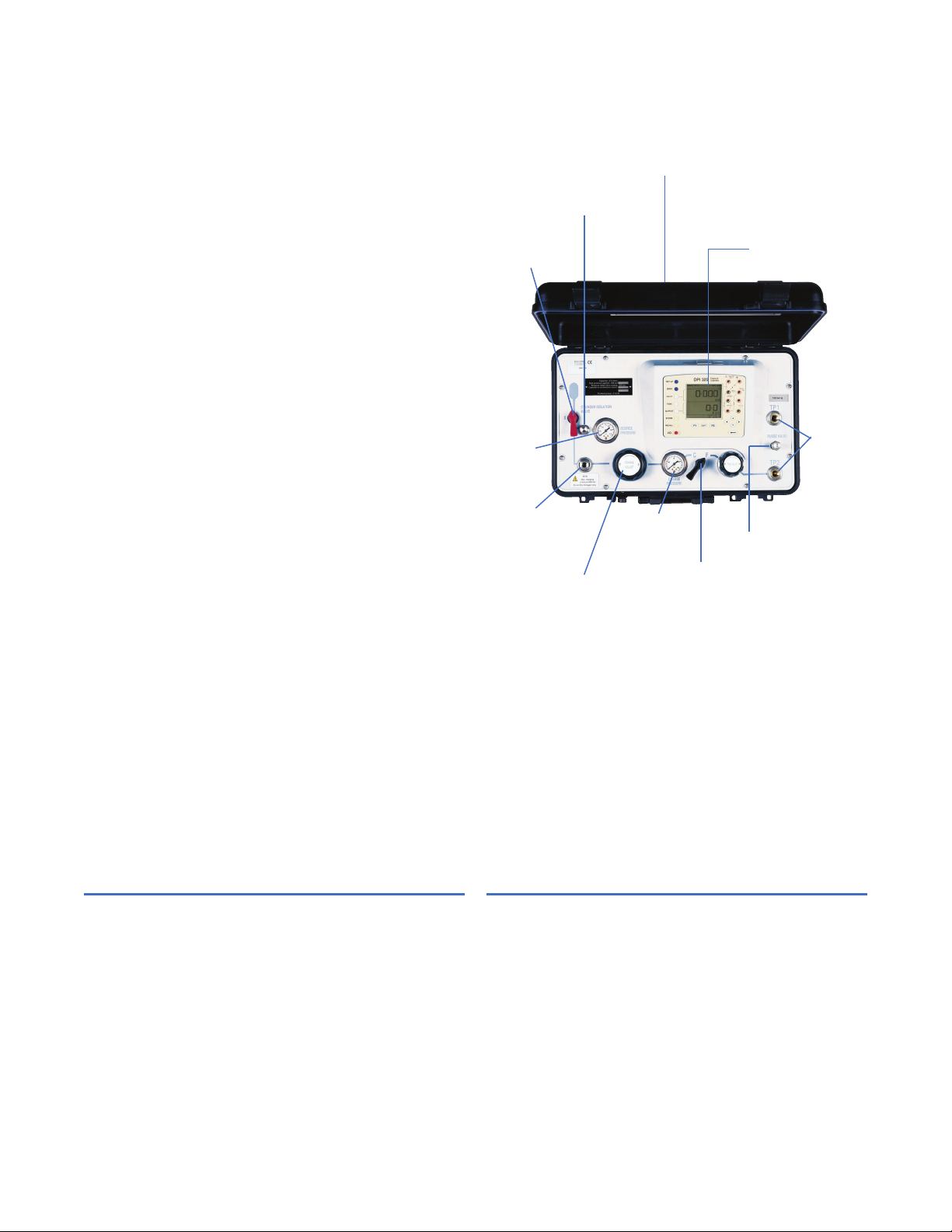

High contrast, menu

driven, dual function

display

GE

Sensing

Built-in rugged

transit case

Charge overpressure

vent port

Purge valve

1/4 in NPT

test ports

Volume adjustor for

fine pressure control

Regulator

output pressure

indicaor

Pressure regulator for

coarse pressure control

AN4 or G 1/8 in

female charging

port

Gas bottle

isolation valve

Charge

pressure

indicator

Reduce Process Downtime

The DPI 325 version enables calibration criteria to be

easily entered via the keypad, allowing fast diagnosis of

field instruments and automatic reporting of errors with a

Pass or Fail status. When used in conjunction with Intecal

for Industry (i4i) calibration management software, it will

be possible to download test procedures from a PC to the

DPI 325. The calibrator will prompt the technician during

the calibration routine, and the results will be recordered

electronically, reducing downtime and eliminating human

errors.

Page 3

GE

Sensing

DPI 320/325

Specifications

Pressure

The DPI 320 and 325 include a built-in pressure sensor

and matched pressure regulator. The pressure range

should be selected from the table below.

Pressure Range Accuracy* (% FS) Maximum Overpressu Type**

500 psi (35 bar) 0.025% 1000 psi (70 bar) G or A

1000 psi (70 bar) 0.025% 2000 psi (140 bar) G or A

1500 psi (100 bar) 0.025% 3000 psi (200 bar) G or A

2000 psi (135 bar) 0.025% 4000 psi (220 bar) G or A

3000 psi (200 bar) 0.025% 6000 psi (220 bar) G or A

*Combined non-linearity, hysteresis and repeatability

**G = Gage, A = Absolute (pressure reference)

Temperature Effects (averaged and w.r.t. 20°C ±0.004% of reading/°C

Pressure Source

• Built-in Nitrogen/Air cylinder; maximum refill pressure

3000 psi (200 bar).

• Storage volume: 122 cubic inches (2 liters).

• Recommended media: Oxygen Free Nitrogen (OFN)

• Remote pressure sensors: Please consult factory for

list.

Electrical

In addition to pressure, the dual display can

simultaneously monitor mA, V, switch continuity and

ambient temperature. Also, 10 VDC and 24 VDC power

supplies are available for the device under test.

Input Range Accuracy Resolution Remarks

Voltage* ±50 VDC. 0.05% reading 100 Autoranging

0.004% FS maximum >10 S

Current* ±55 mA 0.05% Reading 0.001 mA 10 Ω , 50 V

0.004% FS maximum

Temperature 15°F to 105°F ±2°F (±0.1°C) 0.1°F (0.1°C) Case

(-10°C to 40°C) ambient

Switch Open/Closed 5 mA

whetting

Features

Pressure Units

25 scale units plus one user defined

mA Source

Auto 10-sec. step cycle and programmable ramp

(60 seconds end-to-end)

Process Functions

Filter, maximum/minimum, tare, flow, and % span

Power Management

Auto power off, auto backlight off, battery status

indicator

Display

2.36 in x 2.36 in (60 mm x 60 mm) graphic LCD with

backlight, +/-99999 readout, two readings per second

Data Storage

92 kbytes memory

Environmental

Temperature

• Operating range: 15°F to 120°F (-10°C to 50°C)

• Calibrated: 15° to 105°F (-10°C to 40°C)

Humidity

0 to 90%, non-condensing

Sealing

Type 12/IP54 in operation (IP65 when closed)

Conformity

EN 61010, EN 61326 Class A, CE marked

Physical

• Weight: 28 lb (12.8 kg)

• Approximate size (w x l x d): 16.9 in x 10 in x 6.5 in

(429 mm x 254 mm x 165 mm)

Power supply

Battery powered 6 x 1.5 V NiCad cells_20 hours nominal

use at 68°F (20°C). The unit will operate from an AC power

supply, 85 to 265 V, 45 to 400 Hz, and allow the battery

pack to recharge. A low battery condition is indicated on

the display.

Output Range Accuracy Resolution Remarks

Voltage 10 VDC. 0.1% 100 microV Maximum

maximum load 10 mA

Voltage 24 VDC 5% 0.001 mA Maximum

load 26 mA

Current* 0 to 24 mA 0.05% Reading 0.001 mA

*Temperature coefficient 0.004% reading/°F (0.0075% reading/°C) w.r.t. 20°C

Page 4

The fully documenting DPI 325 also provides the

following additional features:

• Calibration mode, showing on-line error analysis

indicating pass/fail status. Storage of as-found and

as-left results.

• Graphical analysis of results, showing pass/fail

tolerance. Two-way PC interface for transferring test

procedures and results.

• Compatible with Intecal for Industry (i4i) calibration

management software.

Confirm availability with your GE representative.

GE

Sensing

DPI 320/325

Specifications

Options

Remote Pressure Sensors

The calibrators have a second pressure channel which

can be configured with up to 10 remote sensors (one at a

time). The sensors are supplied with an electrical

connector and 1/4 in NPT female or G 1/4 female

pressure ports. A mating cable is required.

Mating Cable for Remote Sensor

A six foot mating cable for connecting remote sensors to

the calibrator. At least one should be ordered when

ordering a remote pressure sensor.

Intecal for Industry Calibration Management Software

For a fully-functional free copy of Intecal for Industry,

please visit ge-intecal.com.

The complimentary version is limited to a data base with

25 tags.

Carrying Case

A backpack style carrying case with padded shoulder

straps and adjustable chest band, providing a stable and

comfortable carrying system for the DPI 320 Series. Also

features a large pocket designed to carry the DPI 320

Series accessories and options.

Accessories

The DPI 320/325 Series is supplied with a battery charger,

test leads, RS232 cable, user manual, pressure test

certificate, calibration certificate and accessory bag as

standard.

The Nitrogen cylinder will be supplied empty, for filling

on site.

Calibration Standards

Instruments manufactured by GE Druck are calibrated

against precision calibration equipment traceable to

International Standards, including NIST.

Ordering Information

Please state the following (where applicable):

1. DPI 320 or DPI 325 type number.

2. Internal pressure range required.

3. Options, (if required) including range for remote sensor.

Remote pressure sensor and cable should be ordered as

separate line items.

g

©2005 GE All rights reserved.

920-207A

All specifications are subject to change for product improvement without notice.

GE

®

is a registered trademark of General Electric Co. Other company or product

names mentioned in this document may be trademarks or registered trademarks

of their respective companies, which are not affiliated with GE.

www.gesensing.com

Loading...

Loading...