750 Tracker - SUPPORT

1

SERIAL NUMBER RECORD

750 Tracker - SUPPORT

1

SERIAL NUMBER RECORD

SUPPORT

SERIAL NUMBER RECORD

Record the serial numbers and date of purchase of your Subsite

components in the spaces below.

Date of purchase:

Tracker serial number:

2

750 Tracker -

SERVICE PROCEDURE

2

750 Tracker -

SERVICE PROCEDURE

SERVICE PROCEDURE

Notify Subsite immediately of any malfunction of Subsite

equipment.

Always give model, serial number, and approximate date of

purchase. This information should be recorded and placed on file

by owner at time of purchase. Give detailed explanation of

malfunction.

Return damaged parts to Subsite for inspection and warranty

consideration.

Order genuine Subsite replacement or repair parts from your

Subsite dealer. Use of another manufacturer’s parts may void

warranty.

750 Tracker - FOREWORD

3

SERVICE PROCEDURE

750 Tracker - FOREWORD

3

SERVICE PROCEDURE

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Subsite Electronics equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Subsite Electronics

dealer.

The descriptions and speci fi ca tio ns in thi s manual ar e subj ect to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have taken

place after this manual was published.

Thank you for buying and using Subsite Electronics equipment.

4

750 Tracker - FOREWORD

SERVICE PROCEDURE

4

750 Tracker - FOREWORD

SERVICE PROCEDURE

Operator's Manual

750 Tracker

Issue No.2.2/OP-4/01

Part Number 754-050

Copyright 1999, 2000, 2001

by The Charles Machine Works, Inc.,

Perry, Oklahoma

Subsite is a registered trademark of The Charles Machine Works,

Inc.

U.S. Patent No. 5,065,098; 4,881,083. Other U.S. and foreign patents

pending.

750 Tracker - CONTENTS

5

SERVICE PROCEDURE

750 Tracker - CONTENTS

5

SERVICE PROCEDURE

CONTENTS

SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Serial Number Record . . . . . . . . . . . . . . . . . . . . . . . . .1

Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Beacon Tracking Modes . . . . . . . . . . . . . . . . . . . . . . . 21

Line Locating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

General Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6

750 Tracker - CONTENTS

SERVICE PROCEDURE

6

750 Tracker - CONTENTS

SERVICE PROCEDURE

750 Tracker - CONTROLS

7

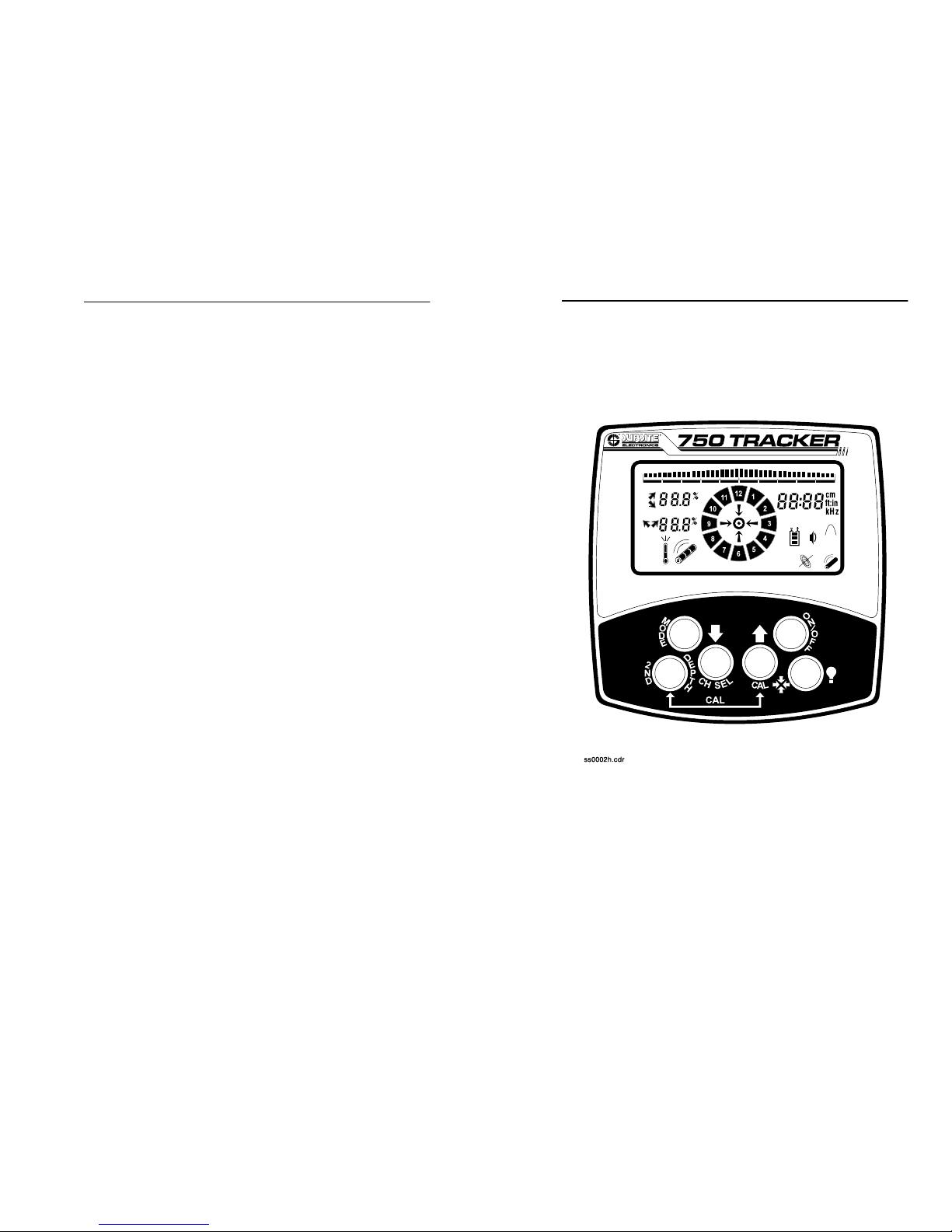

OVERVIEW

750 Tracker - CONTROLS

7

OVERVIEW

CONTROLS

OVERVIEW

The 750 Tracker performs well with a variety of beacons and can

track shallow or deep bores. It can send beacon information to a

display mounted on the drilling unit operator’s station. The 750

Tracker can also locate lines and cables. Available modes are 8

kHz active (when used with transmitter) and 60 or 50 Hz passive

(for locating power cables).

A brief description of the buttons and display on the 750 Tracker

follows.

8

750 Tracker - CONTROLS

CONTROLS

8

750 Tracker - CONTROLS

CONTROLS

CONTROLS

On/Off

Pressing this button turns unit on and off.

Fore/Aft/Left/Right

Pressing this button while in walkover tracking

mode switches from fore/aft to left/right arrows.

Only one set of arrows will show at a time. See

OPERATION

for further information.

Up

Pressing this button raises gain (increases

signal).

Down

Pressing this button reduces gain (decreases

signal).

Depth

This button estimates depth of properly located signal source

when pressed. See

OPERATION

for information on locating

signals.

Mode

Pressing this button changes location mode and operating

frequency .

750 Tracker - CONTROLS

9

CONTROLS

750 Tracker - CONTROLS

9

CONTROLS

Depth + On/Off

Pressing these b utt ons when t rac ker is on cycles v olu me from lo w

to high to off. Pressing and holding depth button before turning

tracker on changes signal strength display. See “Signal Strength”

section later in this chapter for more information.

Depth + Fore/Aft/Left/Right

Pressing these buttons switches LCD backlight off and on.

Depth + Up

Pressing these buttons enters tracker into calibration mode. See

OPERATION

for further information.

Depth + Down

Pressing these buttons selects radio channel. “CH-1” or “CH-2” or

“OFF” will appear in display.

Depth + Mode

Pressing these buttons changes depth units from default setting

of feet:inches to inches, centimeters, or meters.

On + Up

Holding up button and pressing on button switches left/right

arrows off and on.

On + Down

Holding down button and pressing on button switches all

guidance arrows off and on. NOTE: If all arrows are disabled,

remote guidance will not work.

10

750 Tracker - CONTROLS

CONTROLS

10

750 Tracker - CONTROLS

CONTROLS

Fore/Aft/Left/Right + Mode

Pressing these buttons starts tracker control code transmission

(see

OPERATION

).

Fore/Aft/Left/Right + On/Off

Pressing these buttons advances first two digits of tracker control

code (see

OPERATION

).

Fore/Aft/Left/Right + Depth

Pressing these buttons lowers first two digits of tracker control

code (see

OPERATION

).

Fore/Aft/Left/Right + Up

Pressing these buttons advances last two digits of tracker control

code (see

OPERATION

).

Fore/Aft/Left/Right + Down

Pressing these buttons lowers last two digits of tracker control

code (see

OPERATION

).

750 Tracker - CONTROLS

11

SETUP

750 Tracker - CONTROLS

11

SETUP

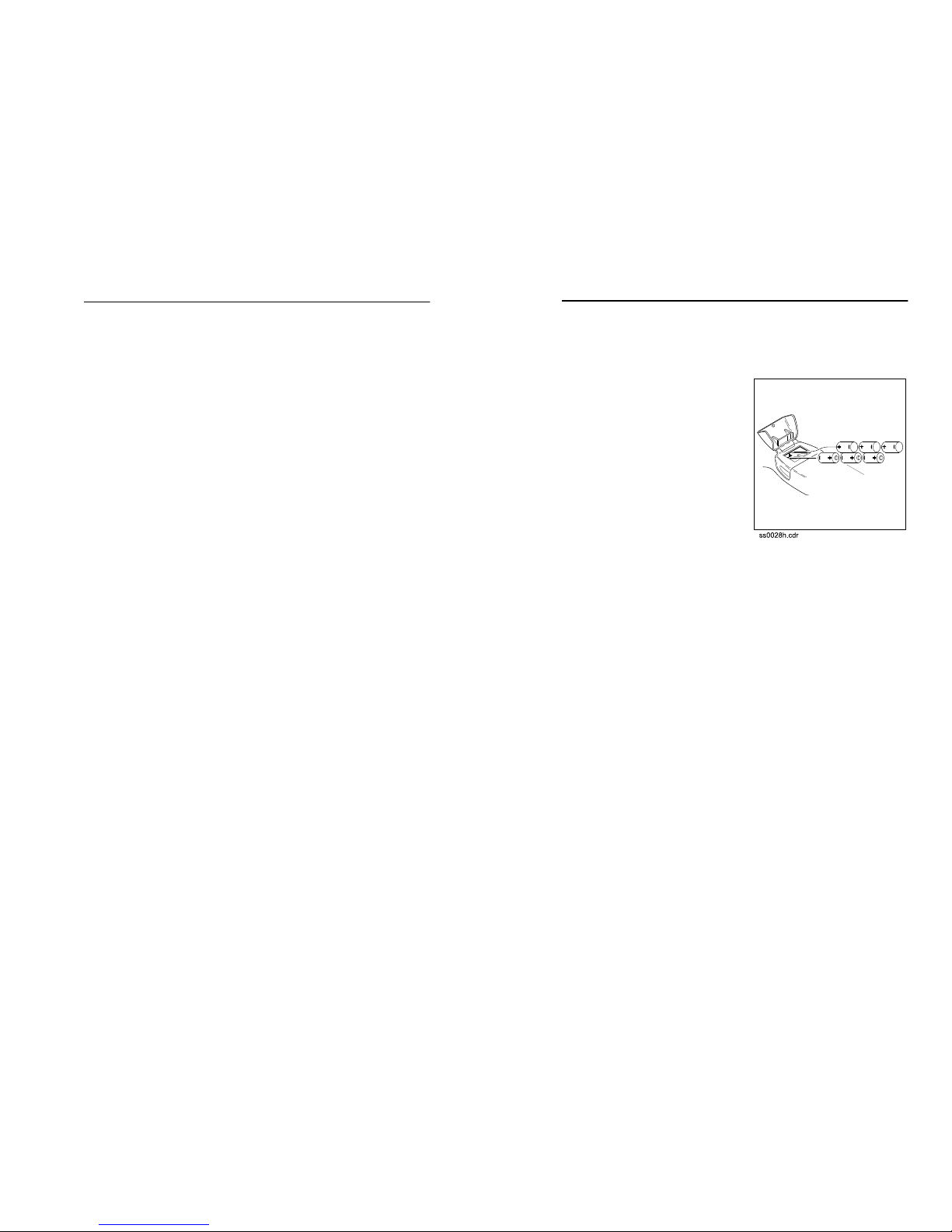

SETUP

Install batteries

Use 6 C-cell alkaline batteries in

tracker. To install:

• unscrew battery cover

• insert batter ie s as ind icate d

• close cover and tighten screw

• check operation

Check Operation

Always check that tracker operates before leaving for jobsite and

after every battery change. To check operation:

• turn on tracker

• entire display will light briefly

• battery level will be shown graphically

• unit defaults to 29 kHz mode

12

750 Tracker - CONTROLS

DISPLAY

12

750 Tracker - CONTROLS

DISPLAY

DISPLAY

Mode

Tracker can track beacons and locate lines. Switch between

modes by pressing mode button.

Beacon Mode Indicator

Line Mode Indicator

750 Tracker - CONTROLS

13

DISPLAY

750 Tracker - CONTROLS

13

DISPLAY

Tracker Information

A variety of tracker information can be monitored in the display

window. Additionally, several tracker display settings can be

changed.

Battery Level

Tracker battery level is shown graphically.

Display shows battery status in 33% steps.

When tracker battery drops below 10%, tracker

battery symbol outlin e flashes. Replac e

batteries immediately.

Volume Level

Speaker volume can be adjusted by pressing

the depth and on/off buttons. Available settings

are low, high and off.

Depth Units

Depth estimates can be displayed in four ways:

feet:inches, inches, centimeters, or meters. To

change depth units, press depth and mode

buttons.

Loading...

Loading...