Ditch Witch FX25 User Manual

FX25

Operator’s

Manual

CMW

®

Issue 2.1

053-2379

FX25 Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Equipment Modification . . . . . . . . . . . . . . . . . . . . . 3

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operator Orientation. . . . . . . . . . . . . . . . . . . . . . . . . 4

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Bulleted Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Numbered Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CMW

Overview - 2 FX25 Operator’s Manual

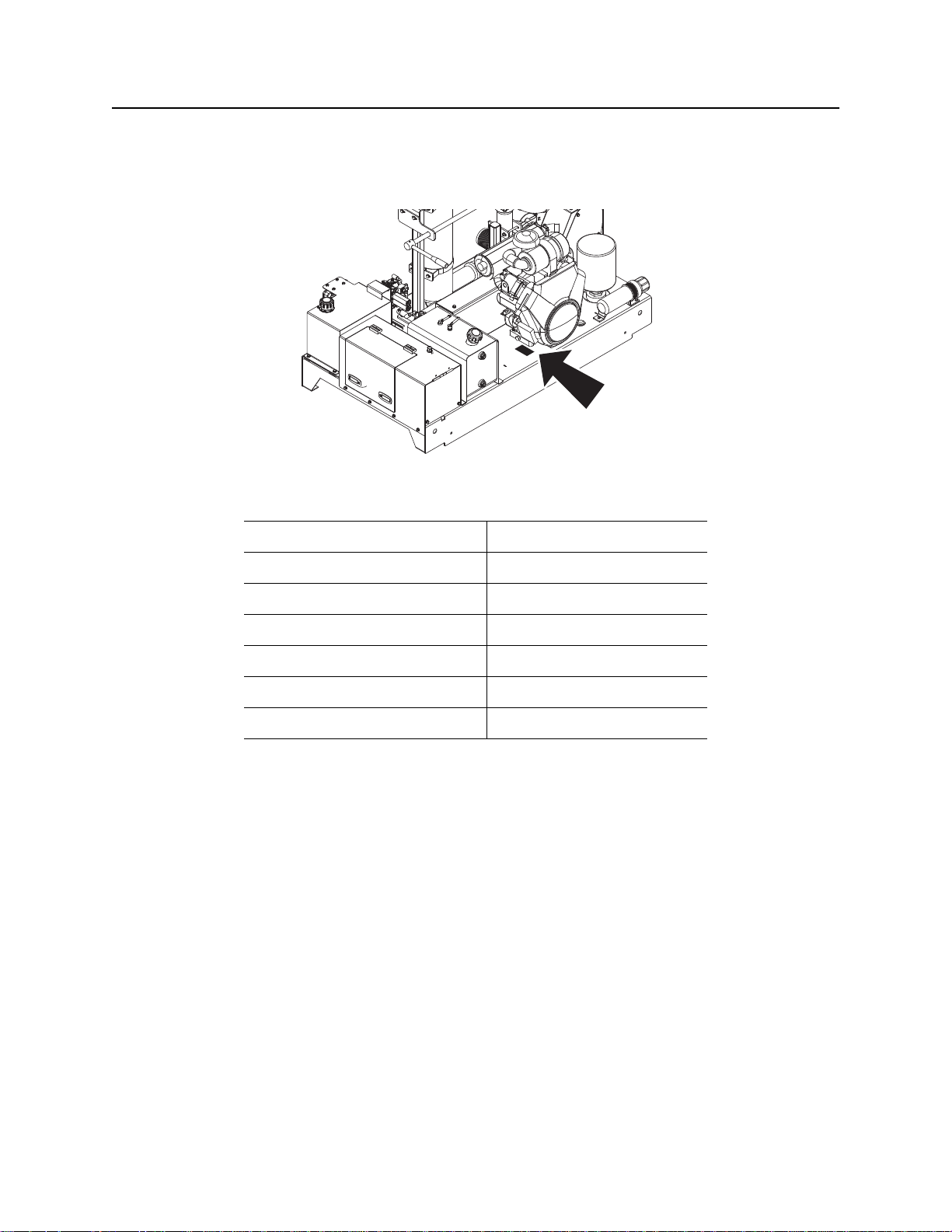

j32om001h.jpg

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. FX25 serial number is located as shown.

j32om001h.jpg

Date of manufacture

Date of purchase

FX25 serial number (shown)

Engine serial number

Blower serial number

Water pump serial number

Trailer serial number

Intended Use

The FX25 is a self-contained vacuum excavation unit capable of vacuuming a wide variety of nonhazardous, non-flammable liquid and solid debris. It is designed to perform efficient soft excavation,

including exposing utilities for visual verification and/or potholing. The optional reverse flow system allows

for spoils transfer to another tank. The FX25 is intended for operation in ambient temperatures from 0° to

115°F (-18° to 46°C). Use in any other way is considered contrary to the intended use.

The FX25 should be operated, serviced, and repaired only by persons familiar with its particular

characteristics and acquainted with the relevant safety procedures.

CMW

FX25 Operator’s Manual Overview - 3

1

2

33445

6

7

8

10

9

11

12

j32om002h.eps

Equipment Modification

Equipment Modification

This equipment was designed and built in accordance with applicable standards and regulations.

Modification of equipment could mean that it will no longer meet regulations and may not function properly

or in accordance with the operating instructions. Modification of equipment should only be made by

competent personnel possessing knowledge of applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

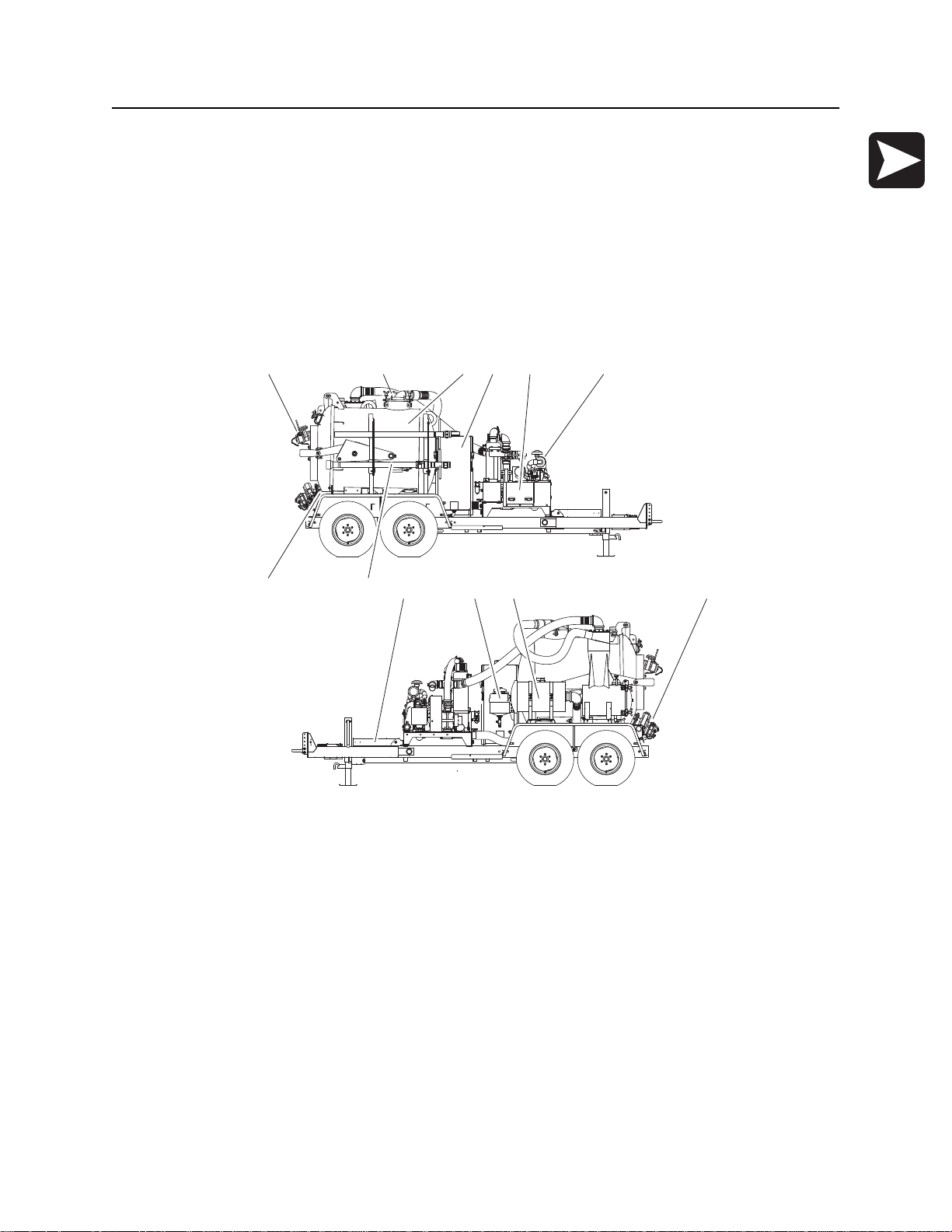

Unit Components

j32om002h.eps

1

7

2

9

8

10

5

11

6

12

1. Inlet valve

2. Primary shut-off valve

3. Vacuum tank

4. Water tank

5. Operator’s station

6. Power pack

7. Hose reel

8. Potholing tools

9. Tool storage

10. Antifreeze tank

11. Vacuum filter

12. Drain/Outlet valve

CMW

Overview - 4 FX25 Operator’s Manual

1

2

3

4

j33om003h.eps

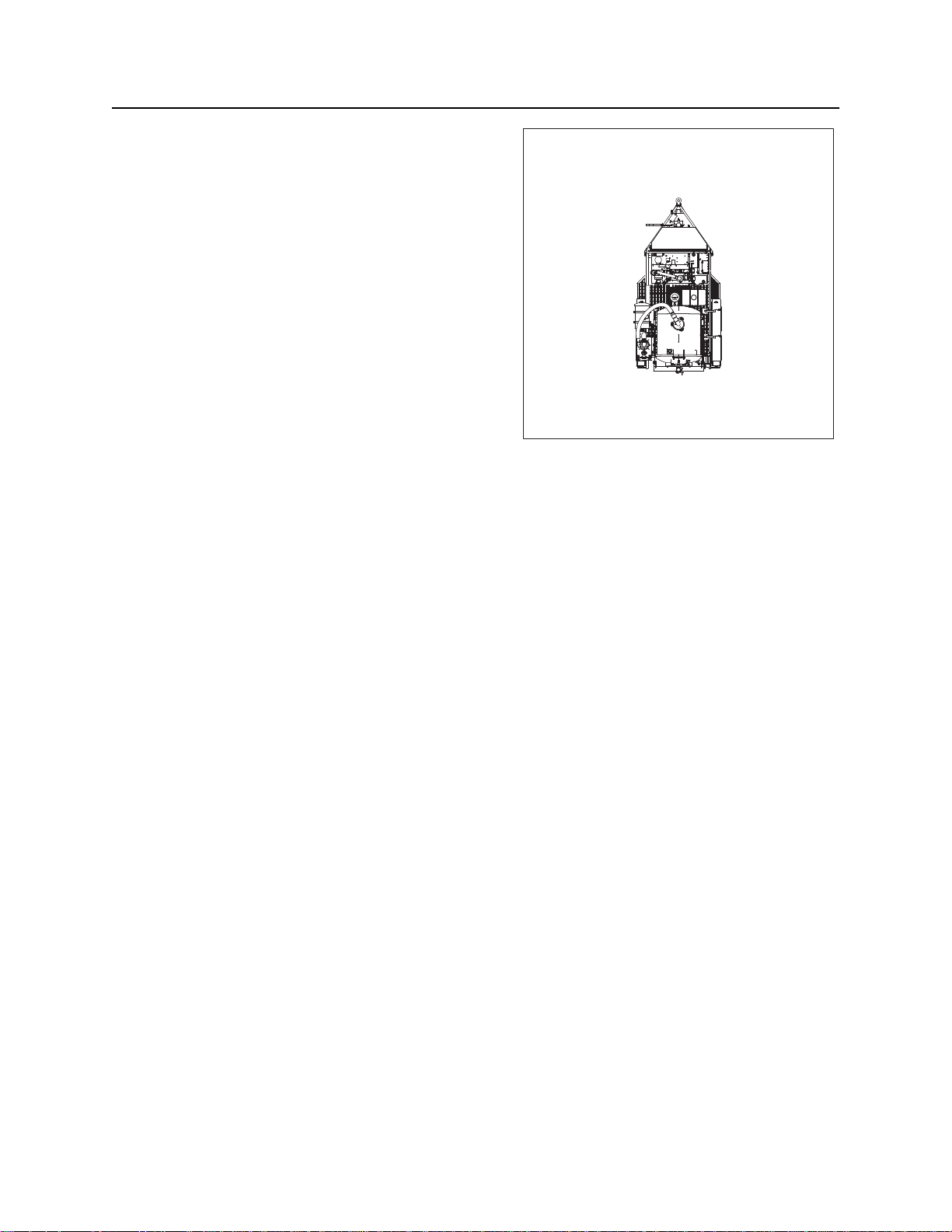

Operator Orientation

Operator Orientation

1. Front of unit

2. Right of unit

Right and left sides of machine are determined by

facing towing vehicle.

3. Rear of unit

4. Left of unit

4

j33om003h.eps

1

2

3

About This Manual

This manual contains information for the proper use of this machine. See Operation Overview for basic

operating procedures. Cross references such as “See page 50” will direct you to detailed procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

CMW

FX25 Operator’s Manual Foreword - 5

Reporting Safety Defects

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipment at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was published. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

Reporting Safety Defects

If you believe that your vehicle has a defect which could cause a crash or could cause injury or death, you

should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to

notifying the Product Safety Coordinator at The Charles Machine Works, Inc.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists

in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become

involved in any individual problems between you, your Ditch Witch dealer, or The Charles Machine Works,

Inc.

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-888-327-4236 (TTY: 1-800424-9153), go to http://www.safercar.gov, or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle safety from http://www.safercar.gov.

CMW

Foreword - 6 FX25 Operator’s Manual

Works, Inc.

FX25

Operator’s Manual

Issue number 2.1/OM-4/13

Part number 053-2379

Copyright 2011, 2012, 2013

by The Charles Machine Works, Inc.

, Ditch Witch, and CMW are registered trademarks of The Charles Machine

U.S. patents pending.

CMW

FX25 Operator’s Manual Contents - 7

Contents

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls, gauges, and indicators and how to use them

Operation Overview

an overview for completing a job with this machine: planning, setting up, vacuuming,

potholing, and restoring the jobsite; with cross references to detailed procedures

Prepare

procedures for inspecting and classifying the jobsite, and preparing the jobsite for

work

Transport

procedures for lifting and hauling

1

5

9

19

29

33

39

Vacuum and Pothole

procedures for removing debris and potholing utility locations

Complete the Job

procedures for restoring the jobsite and rinsing and storing equipment

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

43

57

61

99

105

CMW

Contents - 8 FX25 Operator’s Manual

Service Record

a record of major service performed on the machine

Appendix

additional information about Ditch Witch equipment

109

111

CMW

FX25 Operator’s Manual Safety - 9

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 11

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 15

• Electric Strike Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CMW

Safety - 10 FX25 Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service. Mark proposed path with white paint prior to contacting One-Call or

utilities.

• Classify jobsite based on its hazards and use correct tools and machinery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment

use.

CMW

FX25 Operator’s Manual Safety - 11

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates a hazardous situation that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme situations.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

Safety - 12 FX25 Operator’s Manual

Safety Alerts

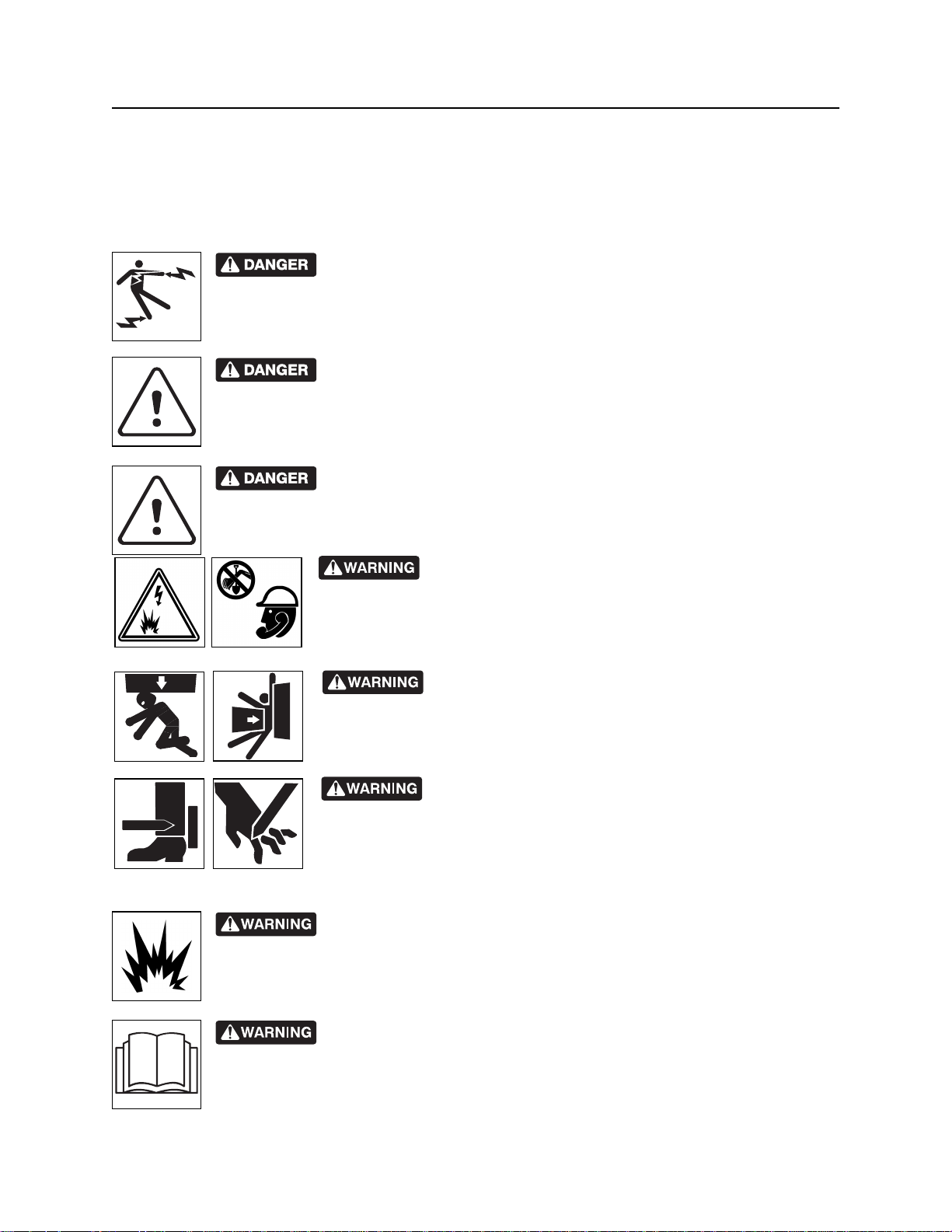

Safety Alerts

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Confined space will cause suffocation. Use proper procedures for entering

or stay away.

Vacuum will suffocate. Maintain distance between face and vacuum inlets.

correct equipment and work methods. Use and maintain proper safety

equipment.

proper procedures and equipment or stay away.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

Jobsite hazards could cause death or serious injury. Use

Crushing weight could cause death or serious injury. Use

Moving parts could cut off hand or foot. Stay away.

CMW

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

FX25 Operator’s Manual Safety - 13

Safety Alerts

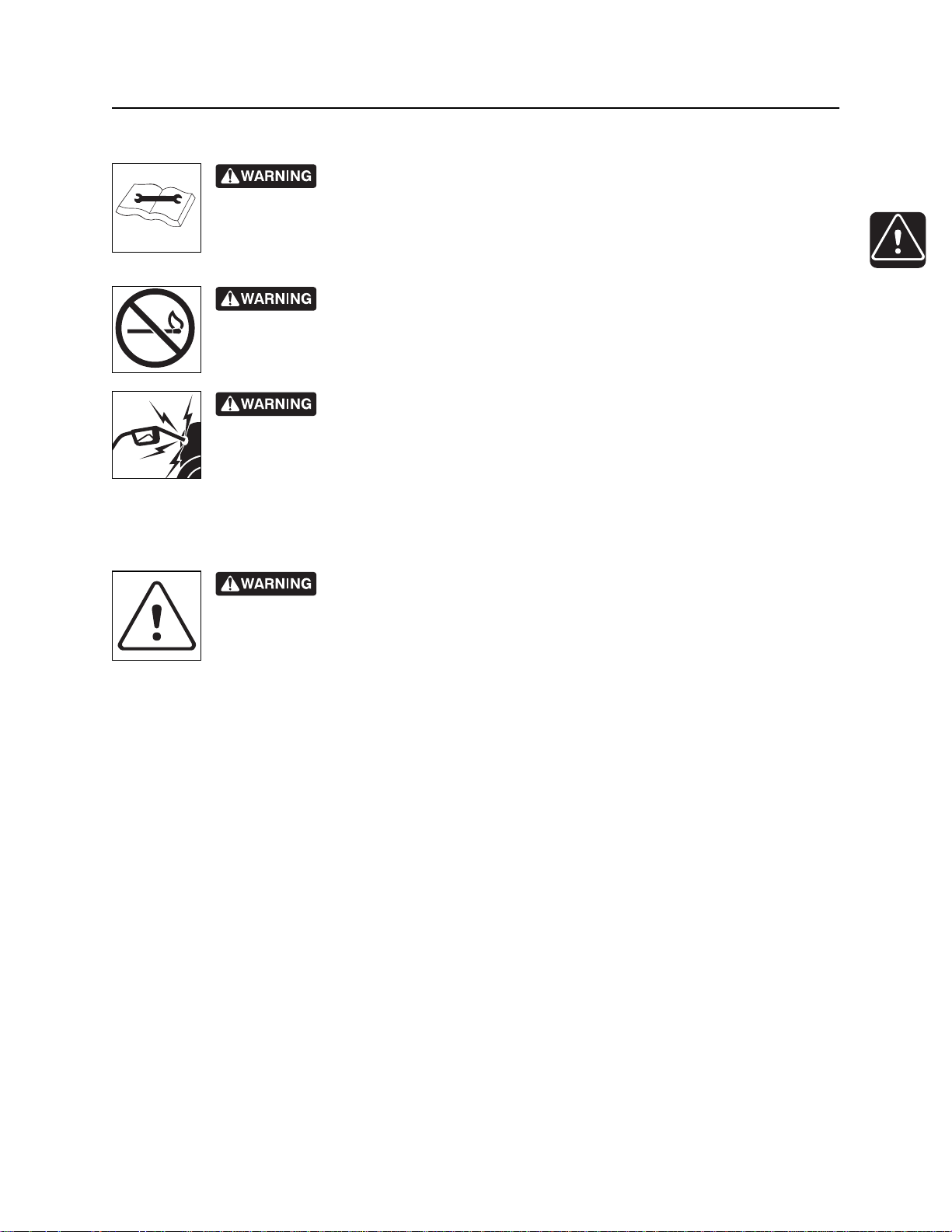

Improper control function could cause death or serious injury. If control does

not work as described in instructions, stop machine and have it serviced.

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Avoid static electricity when fueling. Ultra Low Sulfur Diesel (ULSD) poses a

greater static ignition hazard than earlier diesel formulations. Avoid death or serious injury

from fire or explosion. Consult with your fuel system supplier to ensure the delivery system

is in compliance with fueling standards for proper grounding and bonding practices.

Moving traffic - hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

CMW

Safety - 14 FX25 Operator’s Manual

Safety Alerts

Hot pressurized cooling system fluid could cause serious burns. Allow to

cool before servicing.

Flying objects may cause injury. Wear hard hat and safety glasses.

Hot parts may cause burns. Do not touch until cool.

Exposure to high noise levels may cause hearing loss. Wear hearing

protection.

Fall possible. Slips or trips may result in injury. Keep area clean.

Battery acid may cause burns. Avoid contact.

Improper handling or use of chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels and in material safety data sheets

(MSDS).

Breathing crystalline silica dust may cause lung disease. Cutting, drilling, or

working materials such as concrete, sand, or rock containing quartz may result in exposure

to silica dust. Use dust control methods or appropriate breathing protection when exposed

to silica dust.

CMW

FX25 Operator’s Manual Safety - 15

Emergency Procedures

Emergency Procedures

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Before operating any equipment, review emergency procedures and check that all safety precautions have

been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote engine stop button (if

equipped).

Electric Strike Description

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

• smoke

• explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

CMW

Safety - 16 FX25 Operator’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on truck or trailer, DO NOT MOVE.

Remain on truck or trailer and take the following actions. The order and degree of action will depend on the

situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Do not allow anyone into area until given permission by utility company.

• Do not allow anyone to touch equipment.

If you suspect an electric line has been damaged and you are off truck or trailer, DO NOT TOUCH

EQUIPMENT. Take the following actions. The order and degree of action will depend on the situation.

• LEAVE AREA. The ground surface may be electrified so take small shuffle steps with feet close

together to reduce the hazard of being shocked from one foot to the other.

• Contact utility company to shut off power.

• Do not return to area or allow anyone into area until given permission by utility company.

CMW

FX25 Operator’s Manual Safety - 17

Emergency Procedures

If a Gas Line is Damaged

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

CMW

Safety - 18 FX25 Operator’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped and accessible) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

CMW

FX25 Operator’s Manual Controls - 19

Controls

Chapter Contents

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operator’s Station . . . . . . . . . . . . . . . . . . . . . . . . . 21

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CMW

Controls - 20 FX25 Operator’s Manual

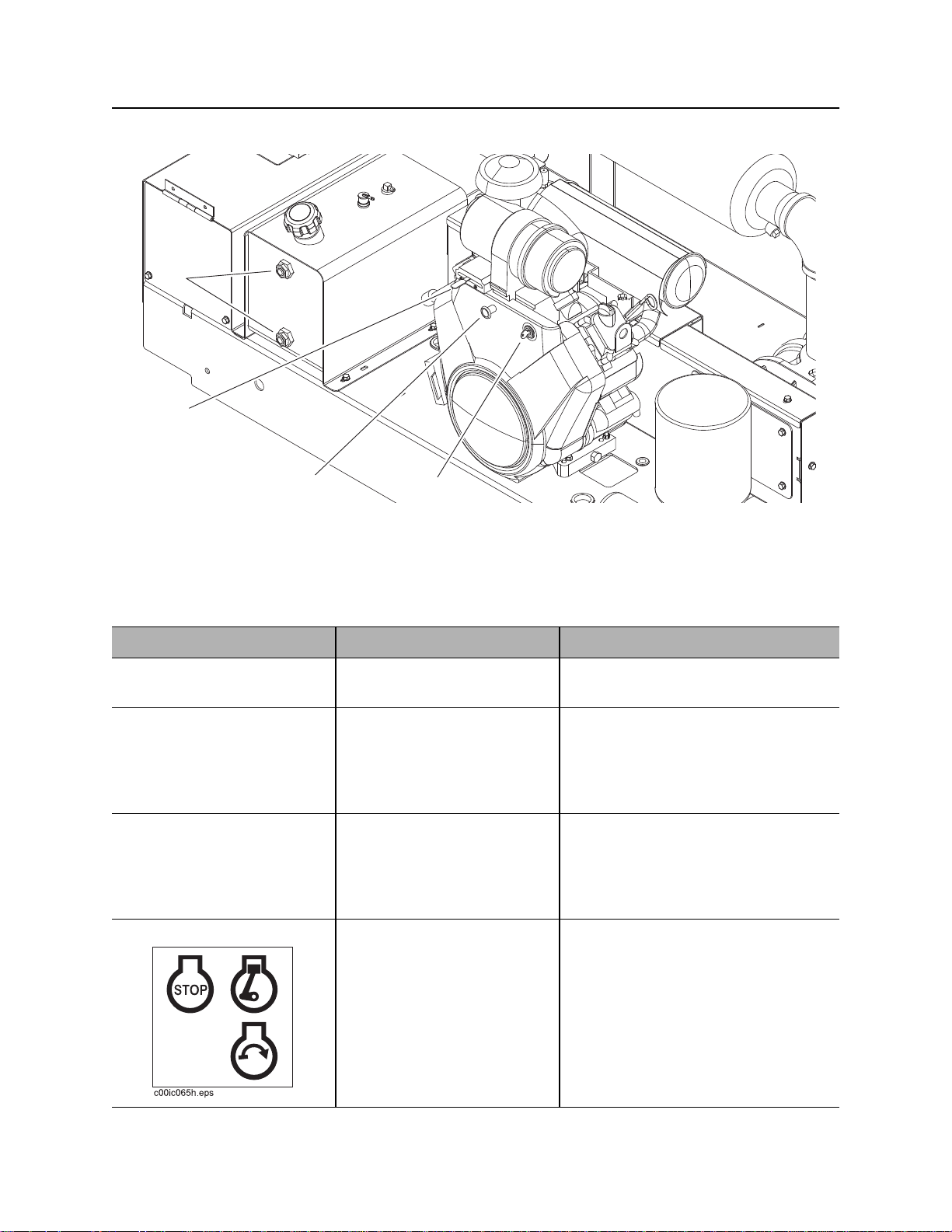

Engine

Engine

1

2

3

j32om005t.eps

1. Fuel level sight glasses

2. Throttle

Item Description Notes

1. Fuel level sight glasses Monitor sight glasses to

determine fuel level.

2. Throttle To increase engine speed,

move to right.

To decrease engine speed,

move to left.

3. Choke To help start cold engine, pull

knob.

When engine has warmed,

push in completely.

4. Ignition switch To start engine, insert key and

turn clockwise.

To stop engine, turn key

counterclockwise.

4

3. Choke

4. Ignition switch

IMPORTANT: Run engine at full

throttle during operation.

IMPORTANT:

• When engine is on, blower

operates and vacuum is present

at tank inlet.

CMW

• All indicators should light briefly at

startup.

FX25 Operator’s Manual Controls - 21

2

3

4

5

6

7

8

9

1

j32om004h.eps

Operator Station

Operator Station

1

5

4

3

j32om004h.eps

1. Flow direction control (optional)

2. Water pressure gauge

3. Auxiliary outlet

4. Hourmeter

5. Battery disconnect switch

2

6

7

9

6. Hydraulic function switch

7. Water pressure switch

8. Water pressure control

9. Tethered tank control outlet

8

Item Description Notes

1. Flow direction control To operate in reverse flow

c00ic605h.eps

mode, turn counterclockwise.

To operate in vacuum mode,

turn clockwise.

Use optional reverse flow to unload

tank contents to another tank.

Operate in reverse flow mode only

when drain/outlet valve is open.

CMW

Controls - 22 FX25 Operator’s Manual

Operator Station

Item Description Notes

2. Water pressure gauge Displays water pressure

when water pressure switch

is on and spray wand is in

use.

3. Auxiliary outlet To operate work lights or

other 12V devices, plug into

outlet.

4. Hourmeter Displays engine operating

time.

c00ic112t.eps

5. Battery disconnect

To connect, turn clockwise.

switch

To disconnect, turn

counterclockwise.

Outlet has power only when ignition

switch is on.

Hourmeter runs when engine is

running.

Use these times to schedule service.

IMPORTANT: Use battery disconnect

switch when servicing, welding, and

during long-term storage.

CMW

_

c00ic063t.eps

+

_

+

FX25 Operator’s Manual Controls - 23

Operator Station

Item Description Notes

6. Hydraulic function

switch

To operate the vacuum boom

option, press top.

To operate hydraulic door lift,

move to center position.

To operate hydraulic tank tilt,

press bottom.

7. Water pressure control To increase water pressure,

turn clockwise.

To decrease water pressure,

turn counterclockwise.

c00ic113t.eps

8. Water pressure switch To turn on water pump, press

top.

To turn off water pump, move

to center position.

c00ic114t.eps

9. Tethered tank control

outlet

To bypass low water

indication, press bottom.

Water pump will operate for

60 seconds.

Connection for tethered tank

control.

Use bypass to feed antifreeze into

system when freshwater tank is

empty. See “Add Antifreeze” on

page 58.

CMW

Controls - 24 FX25 Operator’s Manual

Operator Station

Item Description Notes

Tethered tank control To lift and lower tank, set

hydraulic function switch to

the tank position, then

• To lift tank, press UP.

U P

c00ic064t.eps

DOWN

c00ic065t.eps

• To lower tank, press

DOWN.

To open and close tank door,

set hydraulic function switch

to the door position, then

• To open door, press UP.

• To close door, press

DOWN.

NOTICE: When opening and closing

door, stand in a position with a full

view of the door.

CMW

FX25 Operator’s Manual Controls - 25

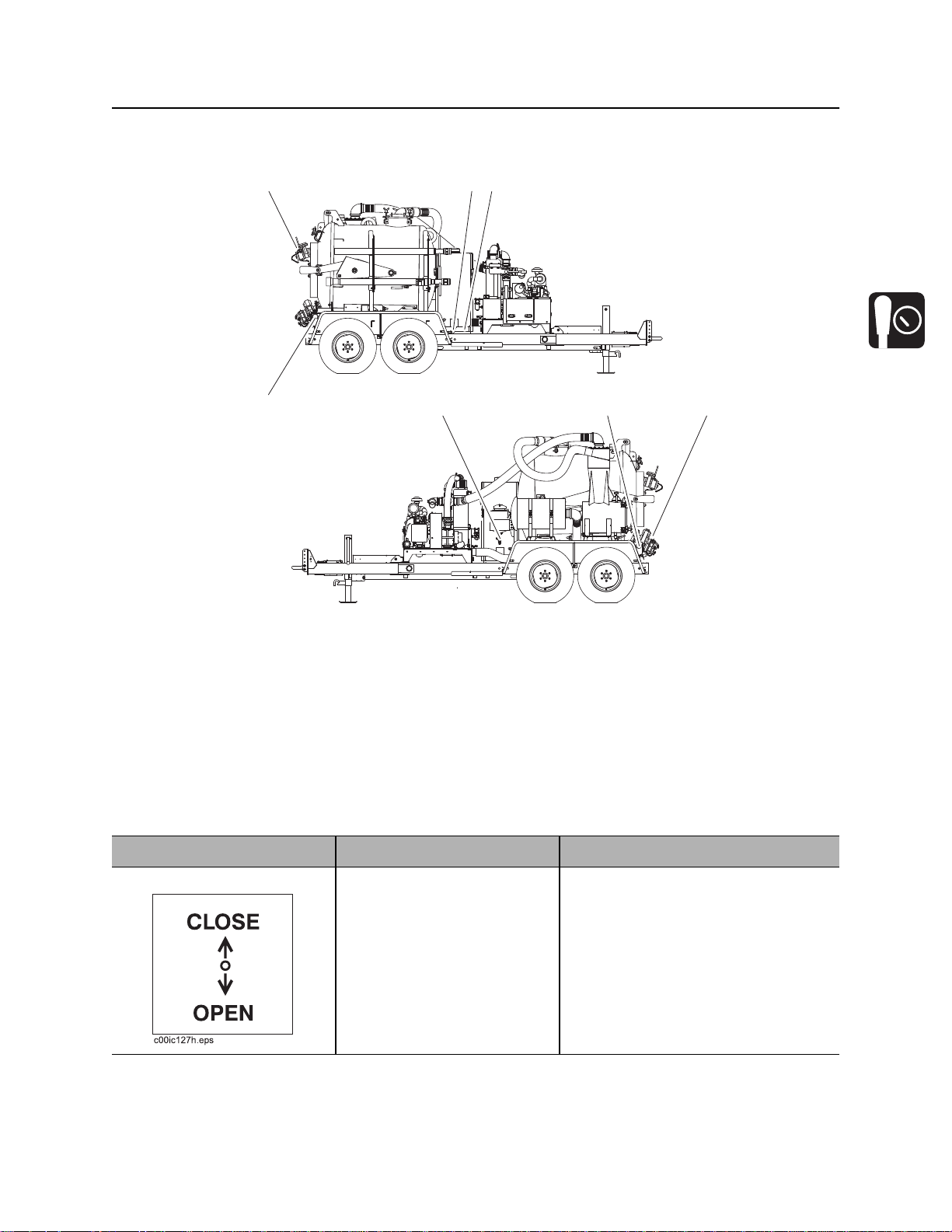

1

2

7

4

3

6

5

j32om005h.eps

Machine

Machine

j32om005h.eps

1

7

2

3

6

5

4

1. Inlet valve

2. Water tank supply valve

3. Water tank drain

4. Drain/Outlet valve

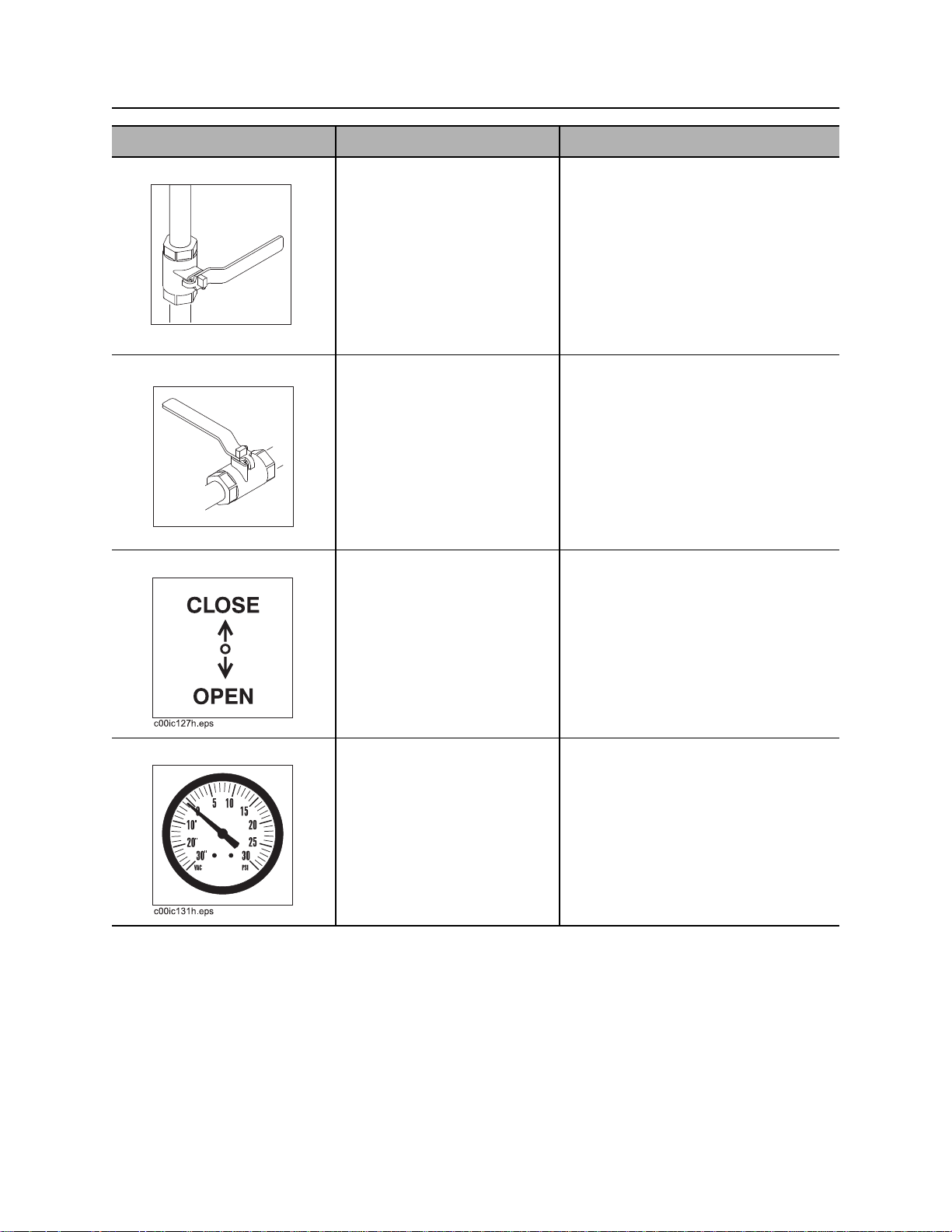

Item Description Notes

1. Inlet valve To close valve (stop suction),

rotate up.

To open valve (start suction),

rotate down.

5. Reverse flow gauge (optional)

6. Antifreeze tank supply valve

7. Vacuum gauge

NOTICE: Do not idle engine with inlet

valve closed.

CMW

Controls - 26 FX25 Operator’s Manual

Machine

Item Description Notes

2. Water tank supply valve To open valve (send water

from the water tank through

the pump and water lance),

rotate counterclockwise.

To close valve (stop water

flow), rotate clockwise.

c00ic603h.eps

3. Water tank drain To drain tank, open valve.

Close valve when tank is

empty.

c00ic604h.eps

4. Drain/Outlet valve To drain tank, rotate down.

To close drain, rotate up.

IMPORTANT: Water tank supply

valve or antifreeze supply valve must

be open when pump is running or

pump will be damaged.

5. Reverse flow gauge Displays reverse flow

pressure.

CMW

FX25 Operator’s Manual Controls - 27

Machine

Item Description Notes

6. Antifreeze tank supply

valve

c00ic602h.eps

7. Vacuum gauge Displays blower vacuum

To open valve (send

antifreeze through pump and

water lance), rotate

counterclockwise.

To close valve (stop

antifreeze flow), rotate

clockwise.

reading in inches of mercury.

Vacuum relief valve opens

when vacuum reaches 15”

(381 mm).

IMPORTANT: Water tank supply

valve or antifreeze supply valve must

be open when pump is running or

pump will be damaged.

CMW

Controls - 28 FX25 Operator’s Manual

Machine

CMW

FX25 Operator’s Manual Operation Overview - 29

Operation Overview

Chapter Contents

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting Up at Jobsite . . . . . . . . . . . . . . . . . . . . . . . 30

Vacuuming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Potholing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Leaving Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Storing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 31

CMW

Loading...

Loading...