Page 1

RT115Q

Operator’s

Manual

CMW

®

Issue 4.1

Original Translation

053-2255

Page 2

RT115Q Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Modification . . . . . . . . . . . . . . . . . . . . . . 3

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operator Orientation. . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Bulleted Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Numbered Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CMW

Page 3

Overview - 2 RT115Q Operator’s Manual

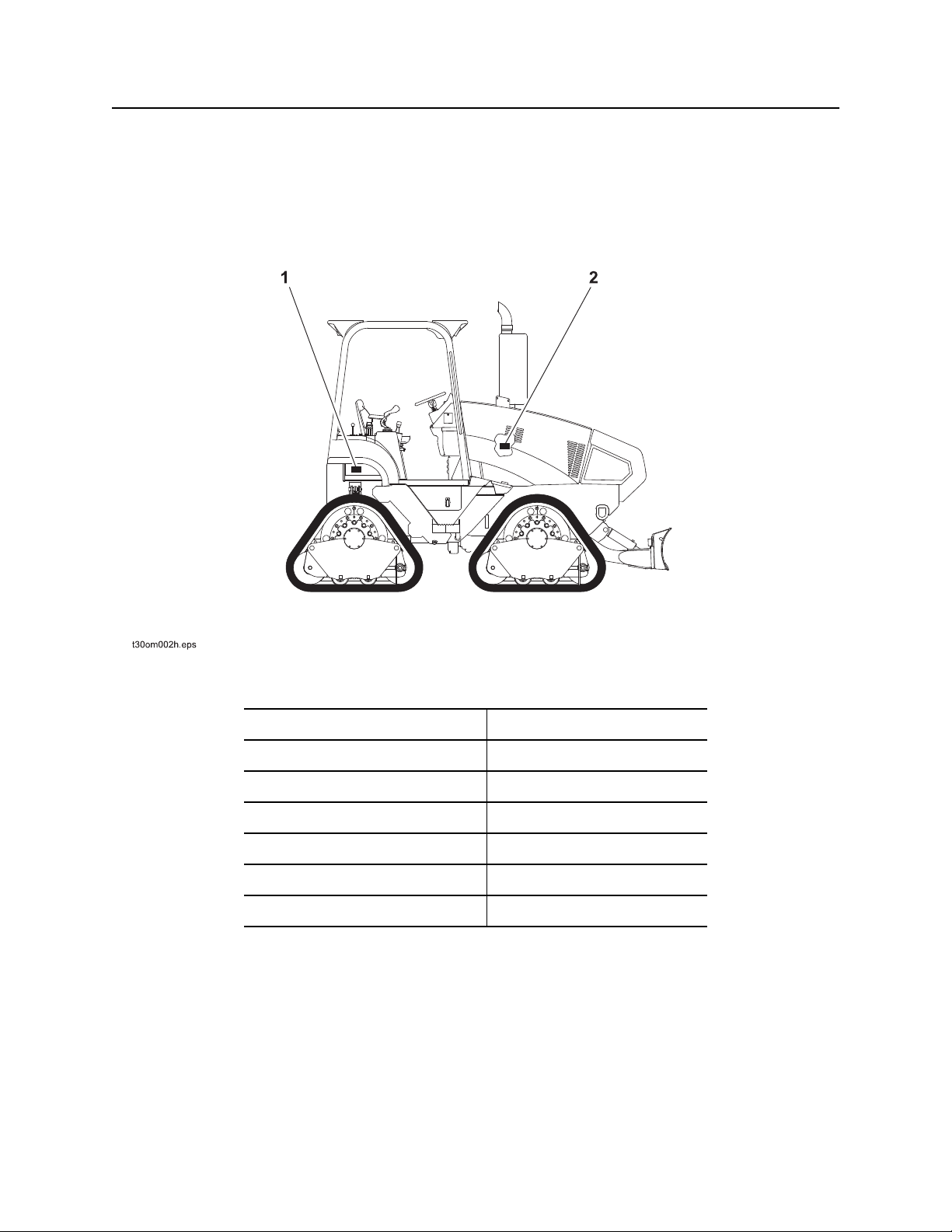

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. RT115Q (1) and engine serial numbers

(2) are located as shown.

CMW

Date of manufacture

Date of purchase

RT115Q serial number

Front attachment serial number

Rear attachment serial number

Trailer serial number

Engine serial number

Page 4

RT115Q Operator’s Manual Overview - 3

Intended Use

Intended Use

The RT115Q is a riding trencher designed to install buried service lines of various sizes using a variety of

Ditch Witch attachments.

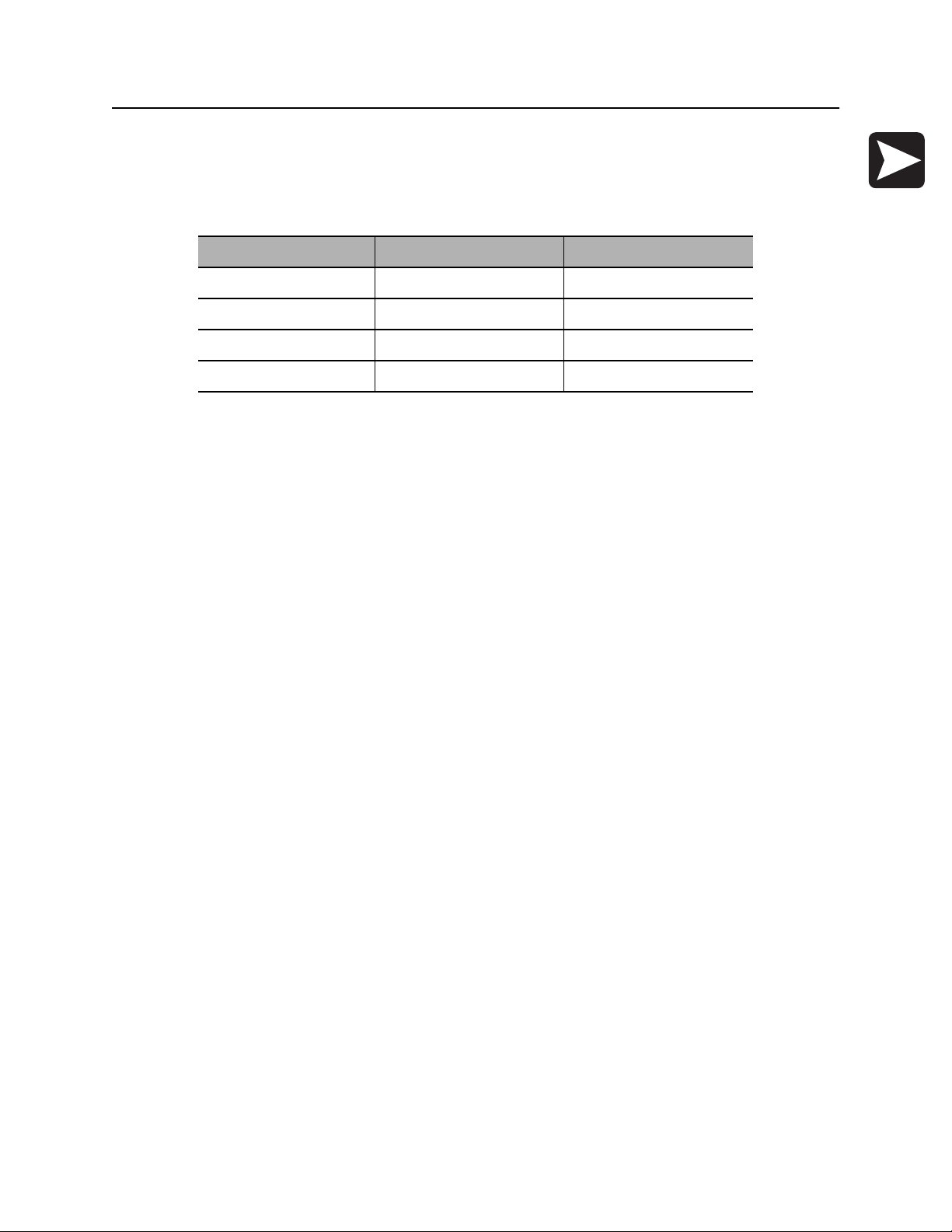

Attachment Max. width/diameter Max. depth

H910 trencher 24” (610 mm) 96” (2.4 m)

H911 trencher 24” (610 mm) 92” (2.3 m)

H1032 plow 3” (80 mm) 42” (1.07 m)

A920 backhoe 24” (610 mm) 105” (2.7 m)

This unit is designed for operation in temperatures typically experienced in earth moving and construction

work environments. Provisions may be required to operate in extreme temperatures. Contact your Ditch

Witch dealer.

The RT115Q should be used with genuine Ditch Witch chain, teeth, and sprockets. It should be operated,

serviced, and repaired only by persons familiar with their particular characteristics and acquainted with the

relevant safety procedures.

Use in any other way is considered contrary to the intended use.

Equipment Modification

This equipment was designed and built in accordance with applicable standards and regulations.

Modification of equipment could mean that it will no longer meet regulations and may not function properly

or in accordance with the operating instructions. Modification of equipment should only be made by

competent personnel possessing knowledge of applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

The protection offered by the Rollover Protective System (ROPS) will be imp ar i ed if it has been subjected

to any modification, structural damage, or has been involved in an overturn accident. The ROPS must be

replaced after a roll-over.

CMW

Page 5

Overview - 4 RT115Q Operator’s Manual

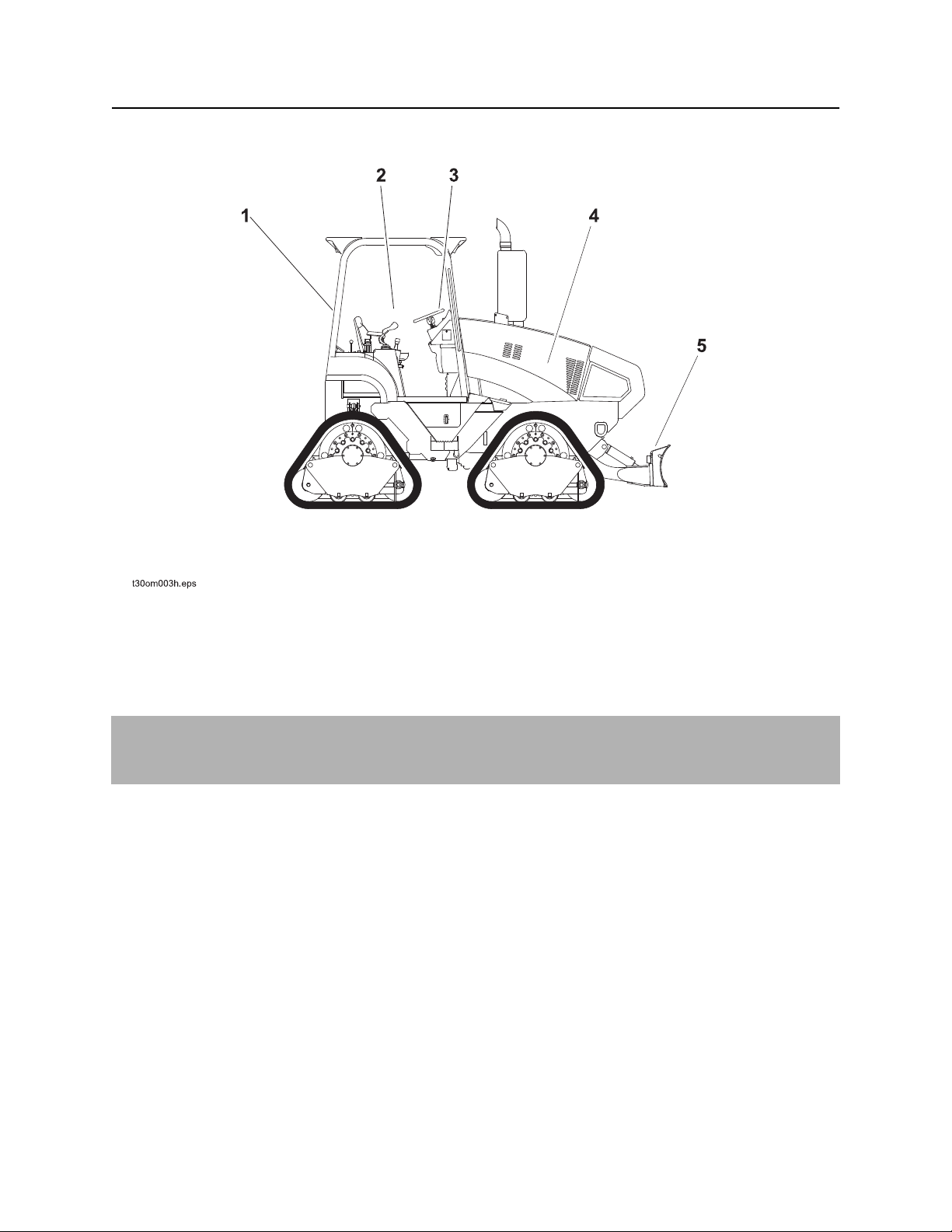

Unit Components

Unit Components

1. Rollover Protective Structure (ROPS)

2. Operator station

3. Control console

NOTICE: The protection offered by the Rollover Protective System (ROPS) will be impaired if it has

been subjected to any modification, structural damage, or has been involved in an overturn accident.

The ROPS must be replaced after a roll-over.

4. Engine compartment

5. Backfill blade (optional)

CMW

Page 6

RT115Q Operator’s Manual Overview - 5

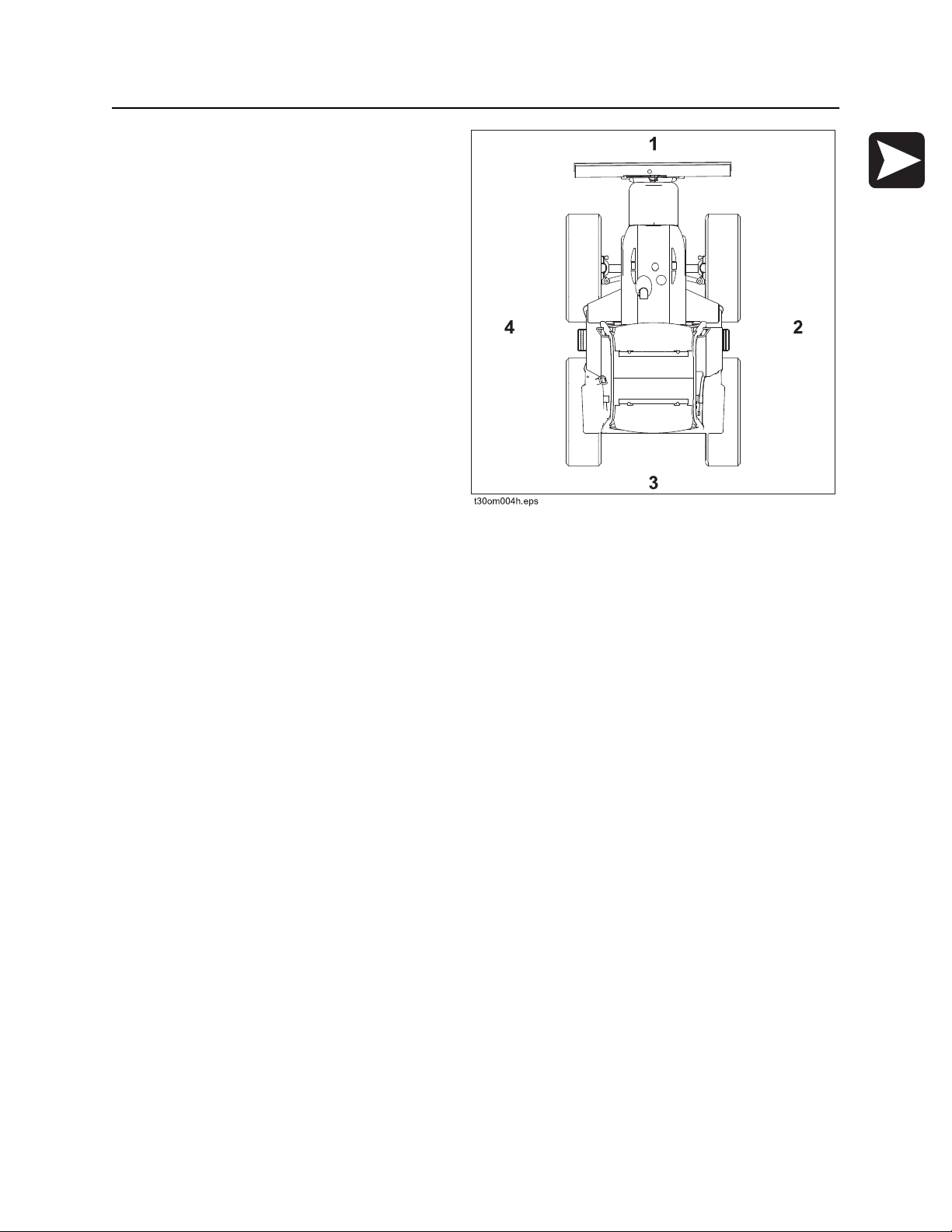

Operator Orientation

Operator Orientation

1. Front of unit

2. Right of unit

Right and left sides of machine are determined by

facing front of unit while seated at the controls.

3. Rear of unit

4. Left of unit

About This Manual

This manual contains information for the proper use of this machine. See Operation Overview for basic

operating procedures. Cross references such as “See page 50” will direct you to detailed procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

CMW

Page 7

Overview - 6 RT115Q Operator’s Manual

About This Manual

CMW

Page 8

RT115Q Operator’s Manual Foreword - 7

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipment at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was published. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

CMW

Page 9

Foreword - 8 RT115Q Operator’s Manual

RT115 Quad-Track

Operator’s Manual

Machine Works, Inc.

Issue number DRAFT 4.1/OM-7/2014

Part number 053-2255

Copyright 2010, 2011, 2012, 2014

by The Charles Machine Works, Inc.

, Ditch Witch, CMW, and Roto Witch are registered trademarks of The Charles

CMW

Page 10

RT115Q Hydrostat Operator’s Manual Contents - 9

Contents

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls, gauges, and indicators and how to use them

Operation Overview

an overview for completing a job with this machine: planning, setting up, installing

product, and restoring the jobsite; with cross references to detailed procedures

Prepare

procedures for inspecting and classifying the jobsite, planning the installation path,

and preparing the jobsite for work

Drive

procedures for startup, cold start, driving, and shutdown

1

7

11

21

53

57

63

Transport

procedures for lifting, hauling, and towing

Trench

procedures for trenching

Plow

procedures for plowing

Reel Winder

procedures for using reel winder

Backhoe

procedures for digging with backhoe

69

81

89

99

103

CMW

Page 11

Contents - 10 RT115Q Hydrostat Operator’s Manual

Drill

procedures for drilling

Systems and Equipment

chain, teeth, sprockets, and optional equipment

Complete the Job

procedures for backfilling and restoring the jobsite and rinsing and storing

equipment

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

Service Record

a record of major service performed on the machine

109

117

123

187

169

189

187

CMW

Page 12

RT115Q Operator’s Manual Safety - 11

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 13

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 17

• Electric Strike Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CMW

Page 13

Safety - 12 RT115Q Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

• Classify jobsite based on its hazards and use correct tools and machinery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment

use.

CMW

Page 14

RT115Q Operator’s Manual Safety - 13

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates a hazardous situation that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme situations.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

Page 15

Safety - 14 RT115Q Operator’s Manual

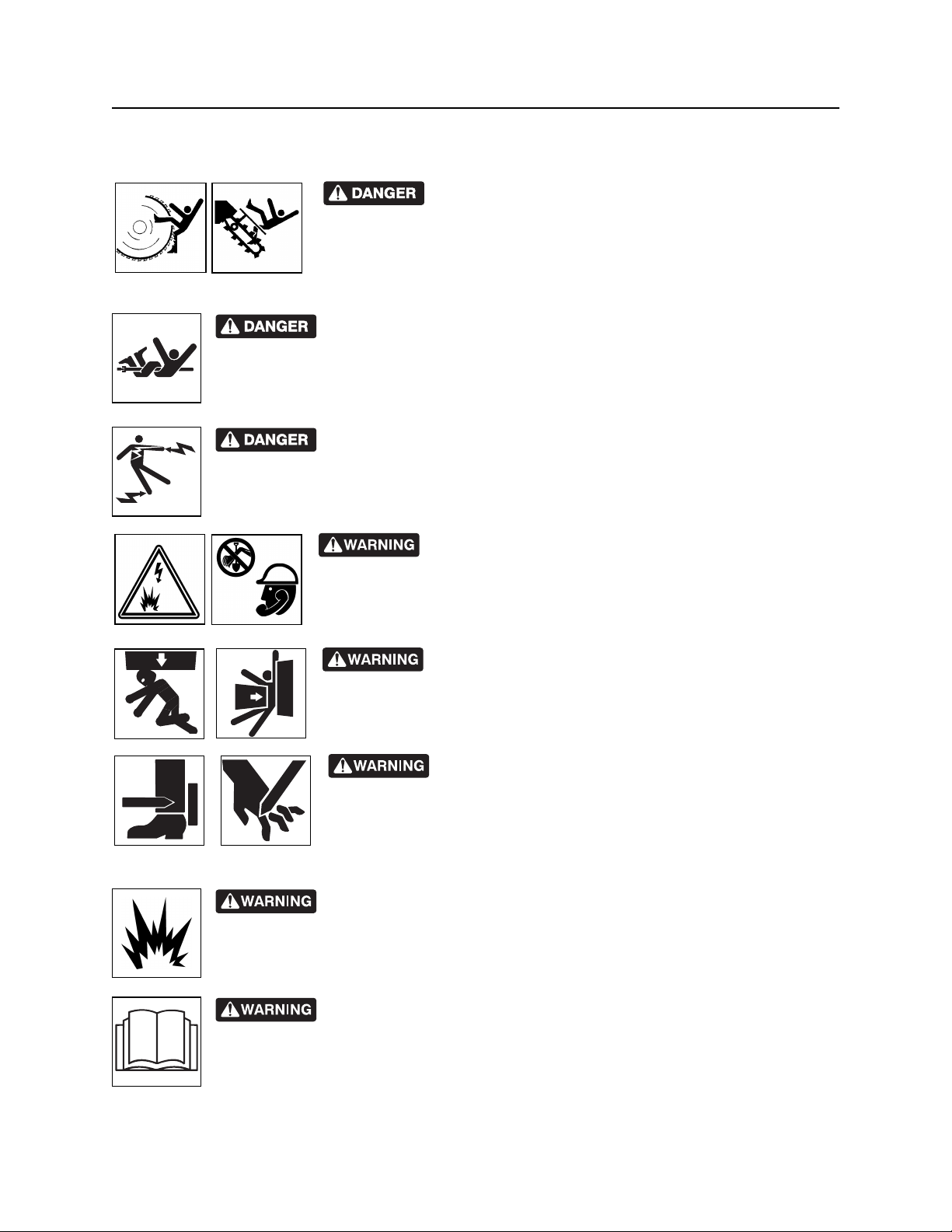

Safety Alerts

Safety Alerts

Moving digging teeth will kill you or cut off arm or leg. Stay

away.

Turning shaft will kill you or crush arm or leg. Stay away.

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

correct equipment and work methods. Use and maintain proper safety

equipment.

proper procedures and equipment or stay away.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

Jobsite hazards could cause death or serious injury. Use

Crushing weight could cause death or serious injury. Use

Moving parts could cut off hand or foot. Stay away.

CMW

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Page 16

RT115Q Operator’s Manual Safety - 15

Safety Alerts

Fall possible. Riders can fall from machine and be injured or killed. Only

operator is allowed on machine.

Rollover possible. If machine rolls over, you could be thrown from seat and

killed or crushed. Wear seat belt.

Improper control function could cause death or serious injury. If control does

not work as described in instructions, stop machine and have it serviced.

Looking into fiber optic cable could result in permanent vision damage. Do

not look into ends of fiber optic or unidentified cable.

Pressurized fluid or air could pierce skin and cause injury or

death. Stay away.

Runaway possible. Machine could run over you or others. Learn how to use

all controls. Start and operate only from operator’s position.

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

CMW

Page 17

Safety - 16 RT115Q Operator’s Manual

Safety Alerts

Moving traffic - hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

Hot pressurized cooling system fluid could cause serious burns. Allow to

cool before servicing.

Flying objects may cause injury. Wear hard hat and safety glasses.

Hot parts may cause burns. Do not touch until cool.

Exposure to high noise levels may cause hearing loss. Wear hearing

protection.

Fall possible. Slips or trips may result in injury. Keep area clean.

Battery acid may cause burns. Avoid contact.

Improper handling or use of chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels and in material safety data sheets

(MSDS).

Breathing crystalline silica dust may cause lung disease. Cutting, drilling, or

working materials such as concrete, sand, or rock containing quartz may result in exposure

to silica dust. Use dust control methods or appropriate breathing protection when exposed

to silica dust.

CMW

Page 18

RT115Q Operator’s Manual Safety - 17

Emergency Procedures

Emergency Procedures

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Before operating any equipment, review emergency procedures and check that all safety precautions have

been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote engine stop button (if

equipped).

Electric Strike Description

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

• smoke

• explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

CMW

Page 19

Safety - 18 RT115Q Operator’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on tractor, DO NOT MOVE. Remain on

tractor and take the following actions. The order and degree of action will depend upon the situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Raise attachments and drive from immediate area.

• Contact utility company to shut off power.

• Do not return to jobsite or allow anyone into area until given permission by utility company.

If you suspect an electric line has been damaged and you are off tractor, DO NOT TOUCH TRACTOR.

Take the following actions. The order and degree of action will depend upon the situation.

• LEAVE AREA. The ground surface may be electrified, so take small steps with feet close together to

reduce the hazard of being shocked from one foot to the other. For more information, contact your

Ditch Witch dealer.

• Contact utility company to shut off power.

• Do not return to jobsite or allow anyone into area until given permission by utility company.

CMW

Page 20

RT115Q Operator’s Manual Safety - 19

Emergency Procedures

If a Gas Line is Damaged

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

CMW

Page 21

Safety - 20 RT115Q Operator’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped and accessible) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

CMW

Page 22

RT115Q Operator’s Manual Controls - 21

Controls

Chapter Contents

Center Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

• Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Right Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Seat Deck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rear Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

• Optional Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

• Trencher Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

• Plow Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

• Combo Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backhoe Console . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CMW

Page 23

Controls - 22 RT115Q Operator’s Manual

Center Console

Center Console

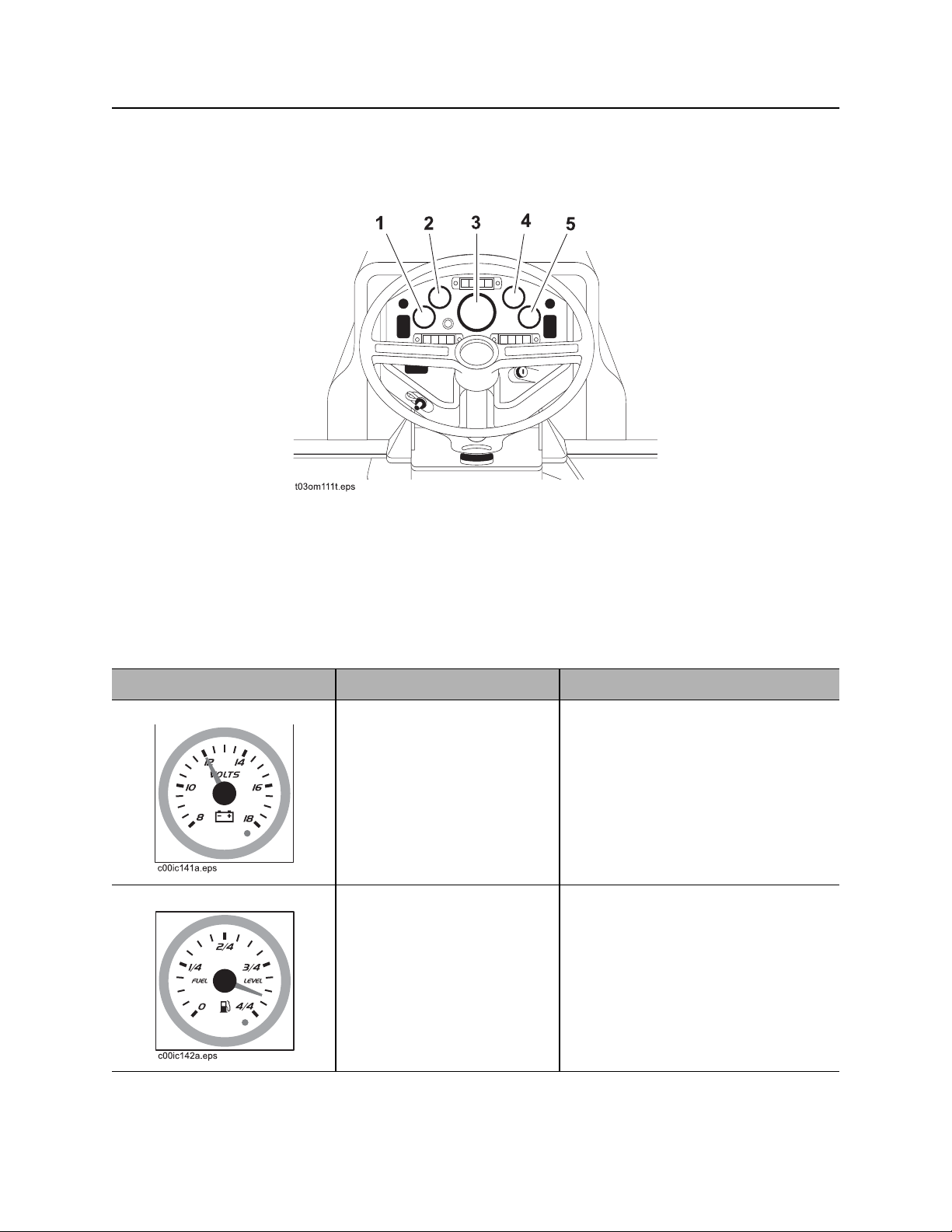

Gauges

1. Voltmeter

2. Fuel gauge

3. Tachometer/Hourmeter

Item Description Notes

1. Voltmeter Displays system voltage. Should show 12-14V with engine

2. Fuel gauge Displays fuel level in tank. RT115Q fuel tank holds 38 gal (144

4. Engine oil pressure gauge

5. Engine temperature gauge

running.

L).

CMW

Page 24

RT115Q Operator’s Manual Controls - 23

Center Console

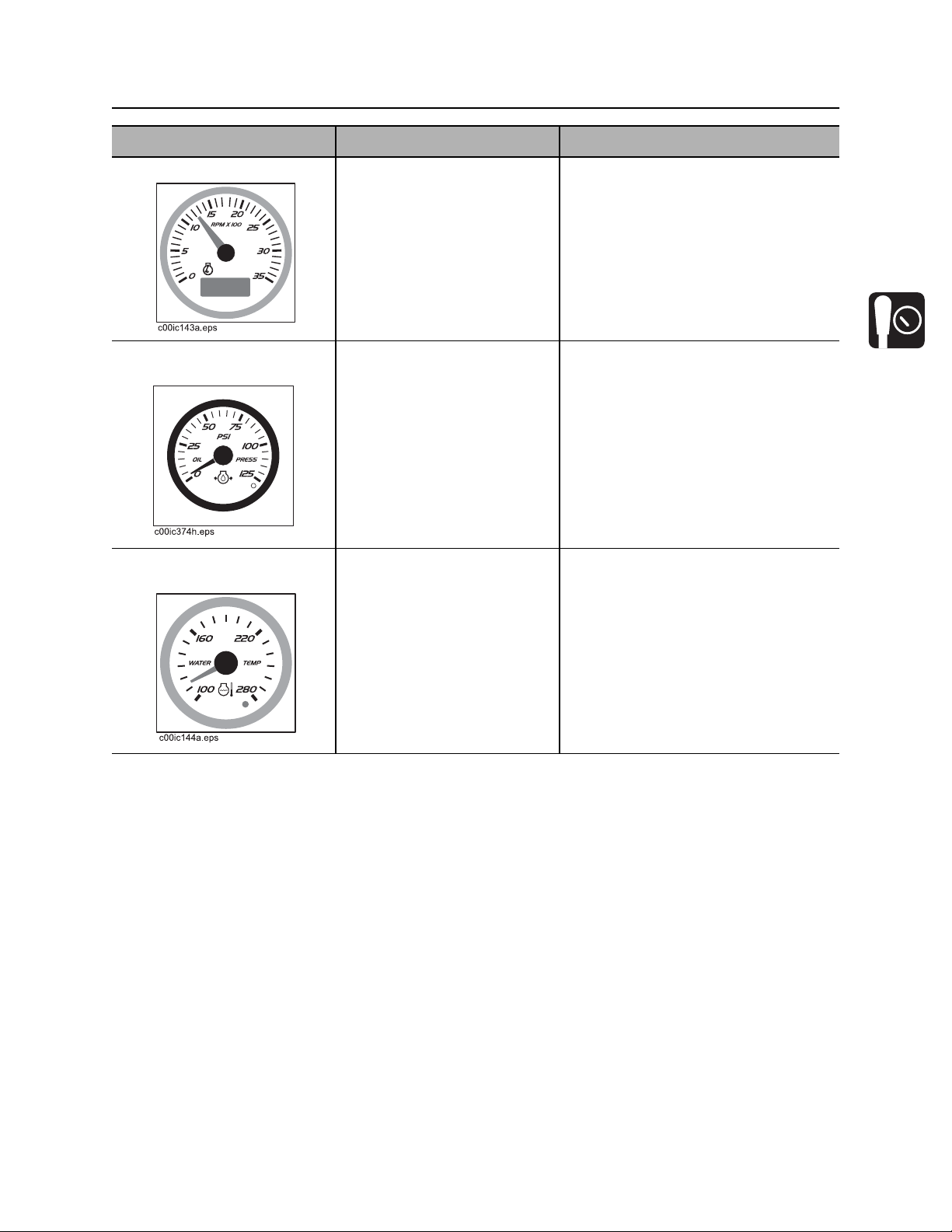

Item Description Notes

3. Tachometer/Hourmeter Displays engine speed and

records engine operating

time.

4. Engine oil pressure

gauge

5. Engine coolant

temperature gauge

Displays engine oil pressure.

Indicator will light and alarm

will sound if pressure is too

low.

Displays engine coolant

temperature.

Engine temperature indicator

will light and alarm will sound

if temperature is too high.

Use engine operating times to

schedule service.

Normal operating pressure is 15-50

psi (1.03 - 3.45 bar).

If pressure is low:

• Check oil level.

• If pressure is still low, consult

engine manual.

Normal temperature is 180°-220° F

(82°-104° C).

If temperature is high:

• Turn off engine and let it cool.

• Check cooling system for low fluid

level, seal damage, or leaks.

CMW

Page 25

Controls - 24 RT115Q Operator’s Manual

Center Console

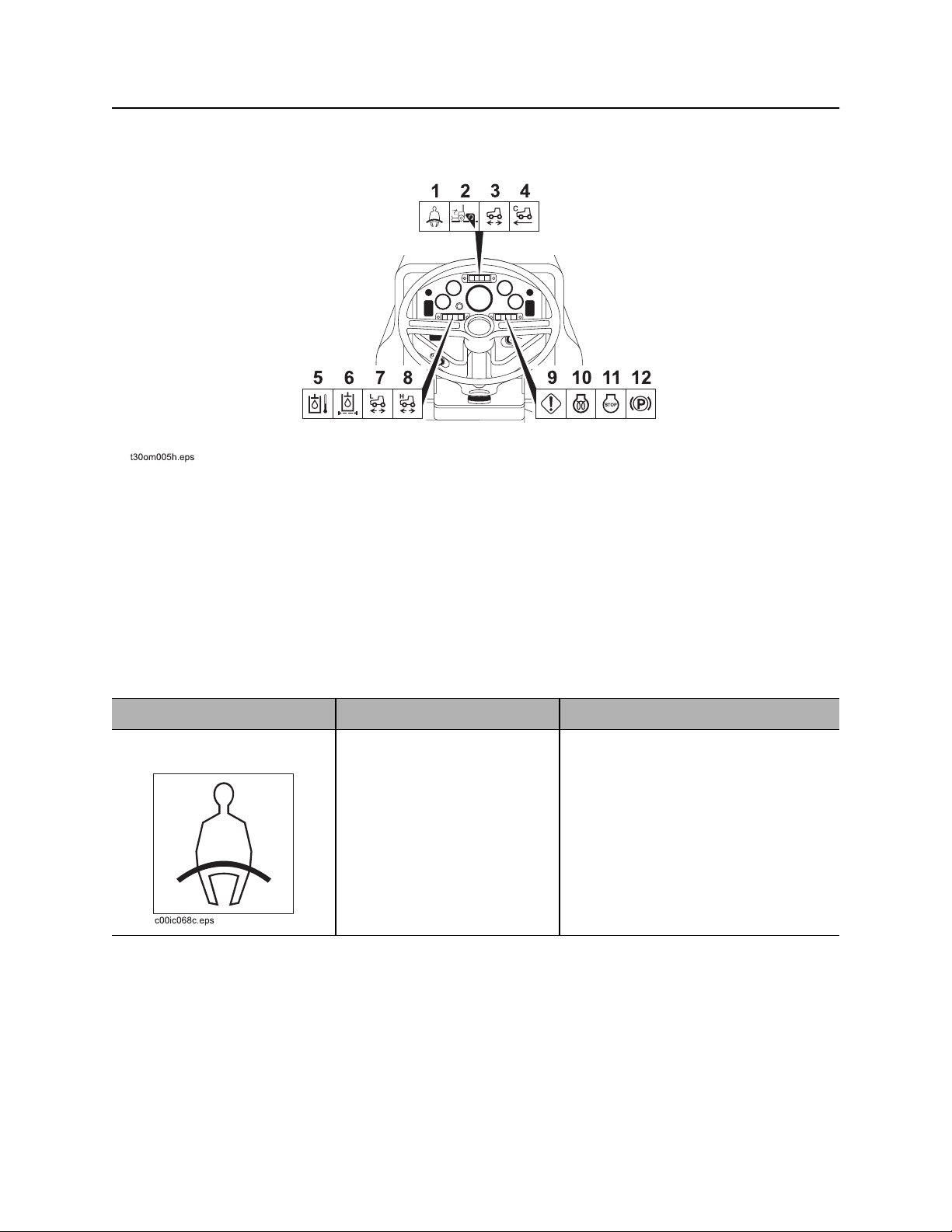

Indicators

1. Operator presence indicator

2. Attachment speed/direction indicator

3. Ground drive indicator

4. Cruise control indicator

5. Hydraulic fluid temperature indicator

6. Hydraulic filter restriction indicator

Item Description Notes

1. Operator presence

indicator

Lights when operator is in

seat.

7. Low speed indicator

8. High speed indicator

9. Operator alert indicator

10. Cold start wait indicator

11. Engine shutdown indicator

12. Parking brake indicator

Part of the start interlock system. to

start engine:

• operator must be in seat,

• attachment drive control must be

in neutral, and

• ground drive control must be in

neutral.

CMW

Page 26

RT115Q Operator’s Manual Controls - 25

Center Console

Item Description Notes

2. Attachment speed/

direction indicator

3. Ground drive indicator Lights when ground drive

4. Cruise control indicator Lights when cruise control is

Lights when attachment

speed/direction control is in

neutral.

hand or foot control is in

neutral.

enabled.

Part of the start interlock system. to

start engine:

• operator must be in seat,

• attachment drive control must be

in neutral, and

• ground drive control must be in

neutral.

Part of the start interlock system. to

start engine:

• operator must be in seat,

• attachment drive control must be

in neutral, and

• ground drive control must be in

neutral.

Contact your Ditch Witch dealer if a

fault condition is detected.

c00ic030t.eps

5. Hydraulic fluid

temperature indicator

Flashes when a controller

fault condition is detected.

Lights and alarm sounds if

hydraulic fluid overheats.

See “Cruise Control” on page 118.

If light remains on:

• Check that engine fan is turning

when engine is running.

• Turn off engine and let it cool.

• Check hydraulic fluid level.

• Check front of hydraulic fluid

cooler for debris.

CMW

Page 27

Controls - 26 RT115Q Operator’s Manual

Center Console

Item Description Notes

6. Hydraulic filter

restriction indicator

7. Low speed indicator Lights when ground drive

8. High speed indicator Lights when ground drive

Lights when hydraulic filter is

restricted.

May also light in when fluid is

extremely cold.

motor is in low.

Flashes when a controller

fault condition is detected.

motor is in high.

When indicator lights, change filter.

Run tractor at low engine speed until

hydraulic fluid warms. Indicator may

turn off after hydraulic fluid warms.

If neither the high or low speed

indicator is lighted, the ground drive

motor is in medium.

Contact your Ditch Witch dealer if a

fault condition is detected.

If neither the high or low speed

indicator is lighted, the ground drive

motor is in medium.

9. Operator alert indicator Lights when a non-critical

engine fault occurs.

CMW

A fault code will be stored in the

diagnostic gauge.

See “Tier 3 Engine” on page 164.

Page 28

RT115Q Operator’s Manual Controls - 27

Center Console

Item Description Notes

10. Cold start wait indicator Lights when intake air pre-

heater is operating.

Wait until light goes off before

starting engine.

11. Engine shutdown

indicator

12. Parking brake indicator Lights when parking brake is

Lights when engine shutdown

sequence is activated.

engaged.

See page 65 for more information.

Ground drive is disabled when brake

is engaged.

CMW

Page 29

Controls - 28 RT115Q Operator’s Manual

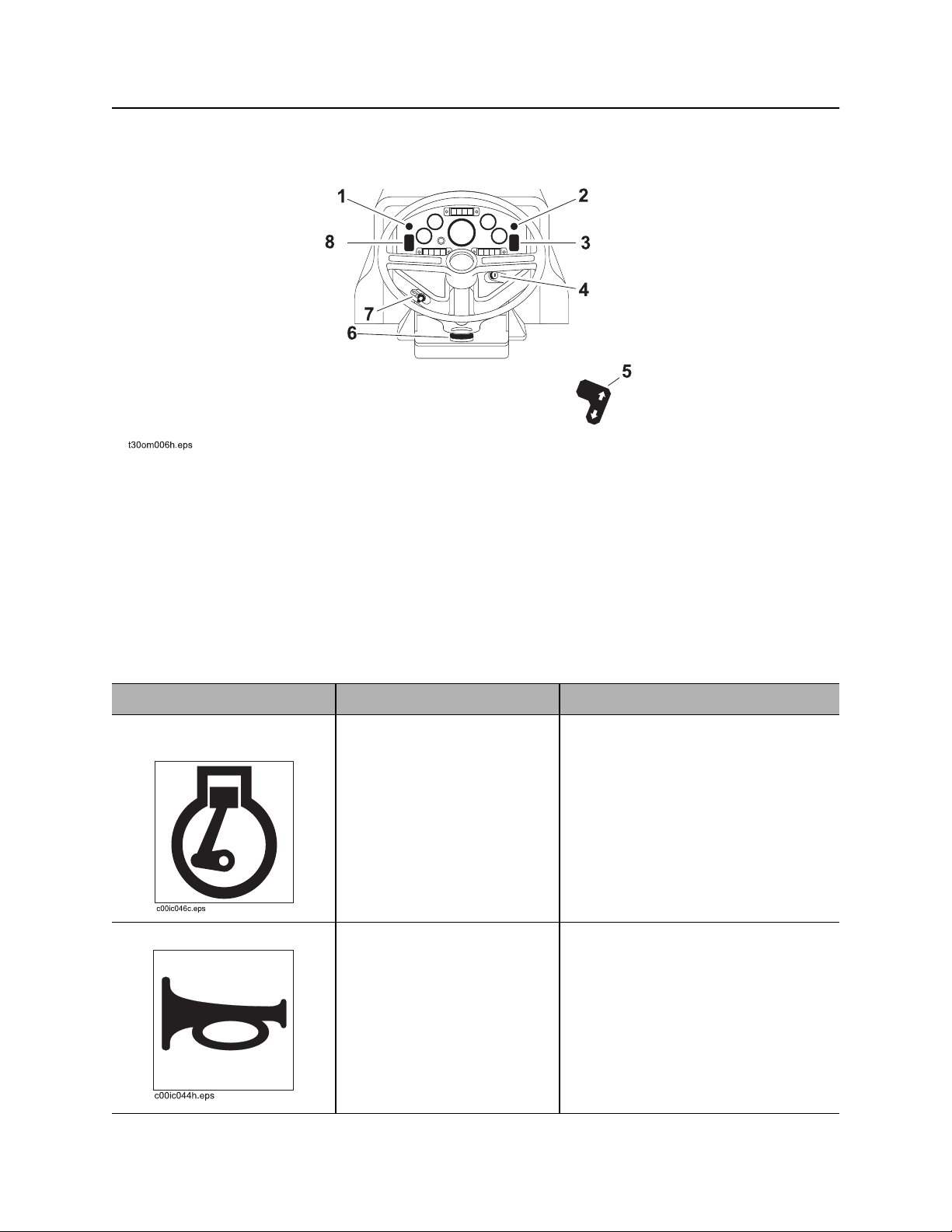

Center Console

Controls

1. Engine shutdown override button

2. Horn

3. Drilling attachment control*

4. Ignition switch

5. Ground drive foot control

Item Description Notes

1. Engine shutdown

override button

2. Horn To sound horn, press.

Press to delay engine

shutdown for 30 seconds

after cycling ignition switch to

OFF.

After 30 seconds, engine will

again shut down unless fault

condition has been cleared

on the diagnostic gauge.

6. Steering column tilt control

7. Auxiliary outlet

8. Reel carrier control*

*optional

See engine manufacturer’s manual

for more information.

CMW

Page 30

RT115Q Operator’s Manual Controls - 29

Center Console

Item Description Notes

3. Drilling attachment

control

To rotate clockwise, press

top.

To rotate counterclockwise,

press bottom.

Switch returns to neutral

when released.

c00ic218h.eps

4. Ignition switch To start engine, insert key and

turn clockwise.

To stop engine, turn

counterclockwise.

c00ic217h.eps

5. Ground drive foot

control

To move tractor forward, push

top of pedal.

NOTICE: Always rotate clockwise

during drilling and backreaming.

Rotate counterclockwise only to

dislodge a dry bore bit or reamer that

has seized in the bore hole.

For more information about drilling

attachment, see page 109.

If engine does not start on first

attempt, check that all interlock

requirements have been met, return

switch to STOP, and try again.

Pedal should automatically return to

neutral when released.

6. Steering column tilt

control

To move tractor backward,

push bottom of pedal.

To increase speed in either

direction, push pedal farther

from center.

To reduce speed in either

direction, release pedal.

To adjust tilt, pull.

To secure steering column in

position, release.

For more information, see page 66.

CMW

Page 31

Controls - 30 RT115Q Operator’s Manual

Center Console

Item Description Notes

7. Auxiliary outlet Provides power for other

equipment.

c00ic179h.eps

8. Reel carrier control To raise, press top.

To lower, press bottom.

c00ic205h.eps

Power output is 12V, 5A.

Optional.

CMW

Page 32

RT115Q Operator’s Manual Controls - 31

Right Console

Right Console

1. Backfill blade/reel winder* control

2. Reel winder selector switch*

3. Frame tilt switch

4. Throttle lever

5. Ground drive motor speed switch

6. Auxiliary circuit pressure gauge

7. Axle lock switch

8. Manual rear steer switch

9. Rear steer auto/center/manual switch

*optional

CMW

Page 33

Controls - 32 RT115Q Operator’s Manual

Right Console

Item Description Notes

1. Backfill blade/reel

winder control

c00ic207h.eps

Backfill blade mode:

• To lower, move forward.

• To float, move forward to

end.

• To raise, move backward.

• To tilt right side down,

move right.

• To tilt left side down,

move left.

• To angle left, twist left.

• To angle right, twist right.

Reel winder mode:

• To unwind, move forward.

• To wind, move backward.

• To lower reel winder arm,

move right.

• To raise reel winder arm,

move left.

NOTICE: Ensure that intended

function is selected before operating.

IMPORTANT: Control works in this

mode when reel winder selector

switch is in backfill blade position.

NOTICE:

• Ensure that intended function is

selected before operating.

• Do not continue to push lift control

after track makes contact with

reel.

IMPORTANT: Control works in this

mode when reel winder selector

switch is in reel winder position. For

more information on reel winder

operation, see page 99.

2. Reel winder selector

switch

c00ic206h.eps

CMW

For reel winder function,

press right.

For backfill blade function,

press left.

NOTICE: Ensure that intended

function is selected before operating.

IMPORTANT:

• Backfill blade control converts to

reel winder function when reel

winder is selected.

• For more information on reel

winder operation see page 99.

Page 34

RT115Q Operator’s Manual Controls - 33

Right Console

Item Description Notes

3. Frame tilt switch To tilt right, press top.

To tilt left, press bottom.

4. Ground drive motor

switch

5. Throttle lever To increase speed, move left.

To select high speed, press 3.

High speed indicator will light.

To select medium speed, set

to position 2.

To select low speed, press 1.

Low speed indicator will light.

To decrease speed, move

right.

6. Auxiliary circuit

pressure gauge

c00ic191h.eps

Displays auxiliary circuit

pressure.

Maximum operating pressure is 3200

psi (221 bar).

CMW

Page 35

Controls - 34 RT115Q Operator’s Manual

Right Console

Item Description Notes

7. Axle lock switch To lock rear axle, press top.

To unlock rear axle, press

bottom.

8. Rear steer switch To move rear tracks left,

press left.

To move rear tracks right,

press right.

9. Rear steer manual/auto

switch

To center tracks, press right.

To manually steer rear tracks,

press left.

IMPORTANT: After pressing switch to

unlock axle, It may be necessary to

move tractor 6’ (2 m) in reverse to

fully unlock.

NOTICE:

• Tracks move when you press the

switch. To stop movement,

release switch.

• Visually verify track position

Use manual mode and the manual

rear steer switch to bypass auto

mode.

CMW

Page 36

RT115Q Operator’s Manual Controls - 35

Left Console Controls

Left Console Controls

1. Parking brake

Item Description Notes

1. Parking Brake To set brake, pull handle up.

To release brake, push button

and lower handle.

Ground drive will not engage if

parking brake is set.

CMW

Page 37

Controls - 36 RT115Q Operator’s Manual

Seat Deck

Seat Deck

1. Ground drive hand control 2. Attachment speed/direction control

Item Description Notes

1. Ground drive hand

control

To go forward, push.

To go backward, pull.

To go faster in either

direction, move farther from

neutral.

To stop, return to center.

Lever does not automatically return to

neutral when released.

For more information, see page 66.

CMW

Page 38

RT115Q Operator’s Manual Controls - 37

Seat Deck

Item Description Notes

2. Attachment speed/

direction control

To rotate attachment forward

or to start plow vibrator box,

push.

To rotate attachment

backward, pull.

To go faster in either

direction, move farther from

center.

To stop attachment rotation or

plow vibrator box, move to

neutral.

In plow mode, controller will not allow

attachment to operate in reverse.

CMW

Page 39

Controls - 38 RT115Q Operator’s Manual

Seat

Seat

1. Seat belt

2. Armrest adjustment control

3. Seat slide control

Item Description Notes

1. Seat belt To fasten, insert latch into

buckle. Adjust until seat belt

is low and tight.

To release, lift top of buckle.

2. Armrest adjustment

control

To raise or lower armrests:

• Remove knob.

• Adjust armrest to desired

position.

• Replace knob.

4. Seat pivot control

5. Seat height adjustment lock

CMW

Page 40

RT115Q Operator’s Manual Controls - 39

Seat

Item Description Notes

3. Seat slide control To slide seat forward or

backward, pull, then adjust

seat.

To lock seat in place, release.

4. Seat pivot control To pivot seat to the right, pull.

To lock seat in position,

release.

To return seat to front-facing

position, swing seat left.

5. Seat height adjustment

lock

To lock seat height, turn

clockwise.

To unlock seat height, turn

counterclockwise.

Seat pivots only to the right and can

be locked in any position from 0-90°.

Drive tractor with operator’s seat

facing front. If desired, operate rear

attachments with seat pivoted.

CMW

Page 41

Controls - 40 RT115Q Operator’s Manual

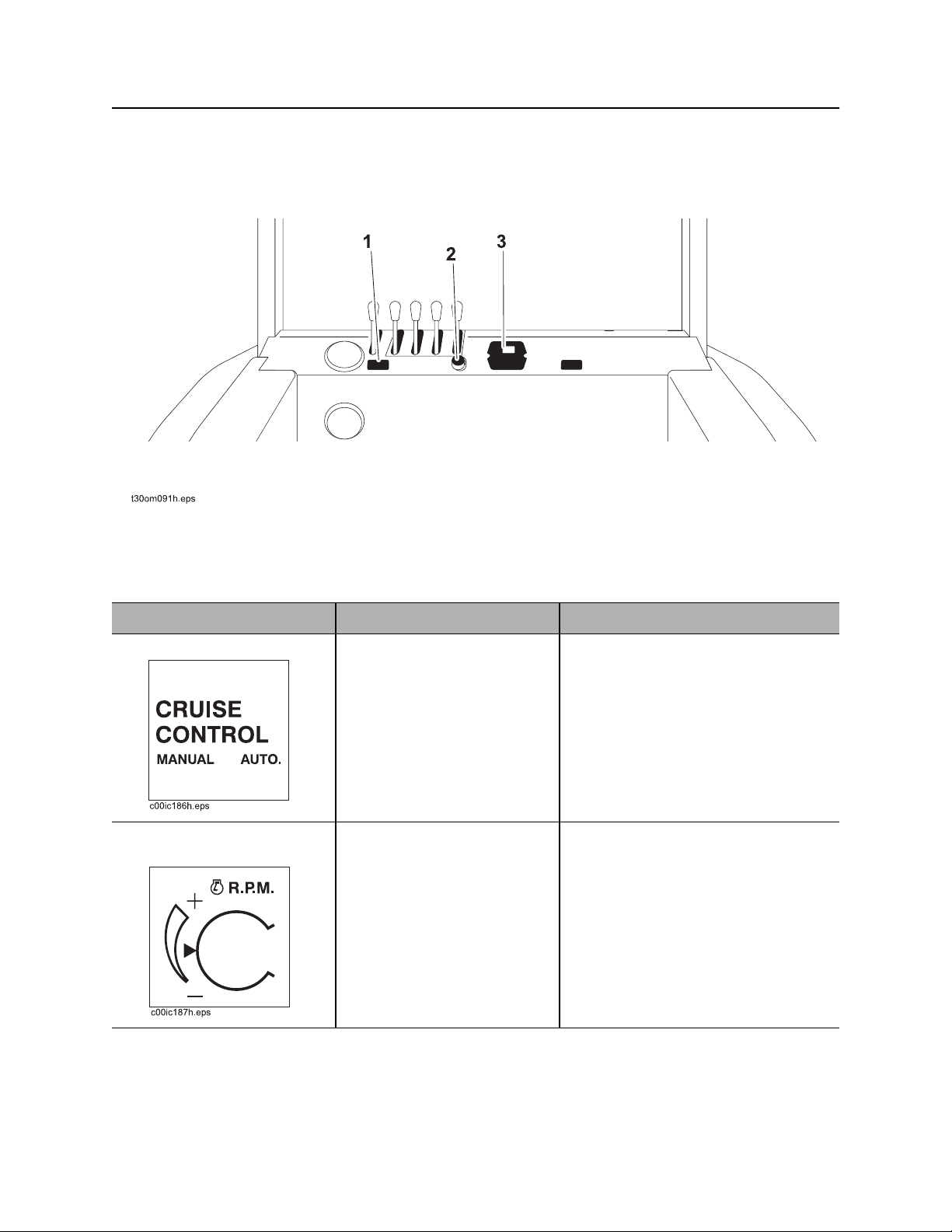

Rear Console

Rear Console

Optional Controls

1. Cruise control selector

2. Cruise control RPM control

Item Description Notes

1. Cruise control selector To turn on, press once.

To turn off, press again.

2. Cruise control RPM

control

To increase engine speed

while using cruise control,

turn clockwise.

To decrease engine speed

while using cruise control,

turn counterclockwise.

3. Trench Depth Meter

Turn on cruise control only when:

• ground drive motor control is in 1 /

low

• ground drive is in neutral

For more information about cruise

control, see page 118.

This typically decreases ground drive

speed temporarily.

This typically increases ground drive

speed temporarily.

For more information about cruise

control, see page 118.

CMW

Page 42

RT115Q Operator’s Manual Controls - 41

Rear Console

Item Description Notes

3. Trench Depth Meter Measures and records trench

depth.

c00ic201h.eps

For more information, see page 120.

CMW

Page 43

Controls - 42 RT115Q Operator’s Manual

Rear Console

Trencher Controls

1. Trencher slide control*

2. Trench cleaner lift control*

3. Boom lift control

*optional

Item Description Notes

1. Trencher slide control To slide trencher right, push.

To slide trencher left, pull.

If slide sticks:

• Lower trencher to ground.

• Operate trencher slide until

trencher moves slightly.

• Raise trencher and slide it into

position.

c00ic198h.eps

2. Trench cleaner lift

To lower, push.

control

To raise, pull.

CMW

Page 44

RT115Q Operator’s Manual Controls - 43

Rear Console

Item Description Notes

3. Boom lift control To lower, push.

To raise, pull.

CMW

Page 45

Controls - 44 RT115Q Operator’s Manual

Rear Console

Plow Controls

1. Plow swing control

2. Blade steer control

3. Plow lift control

4. Stow lock control

Item Description Notes

1. Plow swing control To swing left, pull.

To swing right, push.

NOTICE:

• If soil conditions allow, operate in

float position.

To float, push to end.

• Lower plow into ground before

moving control to float position.

• Do not raise plow with control in

c00ic202h.eps

float position.

2. Blade steer control To steer right, push.

To steer left, pull.

CMW

c00ic203h.eps

Page 46

RT115Q Operator’s Manual Controls - 45

Rear Console

Item Description Notes

3. Plow lift control To raise, pull.

To lower, push.

To float, push to end.

c00ic204h.eps

4. Stow lock control To lock:

• Raise plow fully.

• Pull stow lock handle.

• Lower plow slightly to

engage lock.

To unlock:

• Raise plow slightly.

• Push stow lock handle to

release lock.

NOTICE:

• If soil conditions allow, operate in

float position.

• Lower plow into ground before

moving control to float position.

Use this control to lock plow in the up

position.

CMW

Page 47

Controls - 46 RT115Q Operator’s Manual

Rear Console

Combo Controls

1. Plow swing control

2. Blade steer control

3. Plow lift control

4. Boom lift control

5. Plow stow lock control

6. Trench / Plow switch

Item Description Notes

1. Plow swing control To swing left, pull.

To swing right, push.

NOTICE:

• If soil conditions allow, operate in

float position.

To float, push to end.

• Lower plow into ground before

moving control to float position.

• Do not raise plow with control in

c00ic202h.eps

float position.

2. Blade steer control To steer right, push.

To steer left, pull.

CMW

c00ic203h.eps

Page 48

RT115Q Operator’s Manual Controls - 47

Rear Console

Item Description Notes

3. Plow lift control To raise, pull.

To lower, push.

To float, push to end.

c00ic204h.eps

4. Boom lift control To lower, push.

To raise, pull.

5. Plow stow lock control To lock:

• Raise plow fully.

• Pull stow lock handle.

NOTICE:

• If soil conditions allow, operate in

float position.

• Lower plow into ground before

moving control to float position.

Use this control to lock plow in the up

position.

• Lower plow slightly to

engage lock.

To unlock:

• Raise plow slightly.

• Push stow lock handle to

release lock.

6. Trench / Plow switch To trench, set switch to trench

position.

To plow, set switch to plow

position.

CMW

Page 49

Controls - 48 RT115Q Operator’s Manual

Backhoe Console

Backhoe Console

1. Remote backfill blade* control

2. Left stabilizer control

3. Boom/Swing control

4. Remote throttle

5. optional

6. Work light switch*

7. Swing lock pin

8. Ground drive switch

9. Remote engine stop switch

10. Bucket/dipper control

11. Stow lock control

12. Right stabilizer control

*optional

CMW

Page 50

RT115Q Operator’s Manual Controls - 49

Backhoe Console

Item Description Notes

1. Remote backfill blade

control

2. Left stabilizer control To lower, push out.

3. Boom/Swing control To swing boom left, move left.

To lower, push.

To raise, pull.

To raise, pull in.

To swing boom right, move

right.

Control can perform more than one

action at a time. By “feathering” the

control, operator can combine

backhoe operations.

To raise boom, pull.

To lower boom, push.

4. Remote throttle To increase engine speed,

turn counterclockwise.

To decrease engine speed,

turn clockwise.

To lock, push button, pull up,

then release button.

To unlock, push button, then

push down.

5. Optional

NOTICE: Do not operate with

backhoe in the stowed (upright)

position.

CMW

Page 51

Controls - 50 RT115Q Operator’s Manual

Backhoe Console

Item Description Notes

6. Work light switch To turn on, press right.

To turn off, press left.

7. Swing lock pin To lock:

• Engage stow lock.

• Insert swing lock pin into

hole (1).

To release:

• Remove pin and store in

hole (2).

• Release stow lock.

8. Remote ground drive

control

To move tractor forward,

push.

To move tractor backward,

pull.

c00ic216h.eps

This pin locks boom from swinging

during transport.

NOTICE: Do not store pin in holes

marked with an “X.” Backhoe could

swing and destroy pin.

NOTICE:

• This control is disabled if tractor

seat is occupied.

• Ensure that backfill blade, if

equipped, and stabilizers are

raised before operating this

control.

• Do not move more than 30’ (10

m) at a time.

9. Remote engine stop

switch

CMW

Stops engine immediately. For normal engine shutdown, use

ignition switch.

Page 52

RT115Q Operator’s Manual Controls - 51

Backhoe Console

Item Description Notes

10. Bucket/dipper control To open bucket, move right.

To close bucket, move left.

To move dipper in, pull.

To move dipper out, push.

11. Stow lock control To lock:

• Raise boom fully.

• Pull stow lock handle.

• Lower boom slightly to

engage lock.

• Insert swing lock pin.

To unlock:

• Remove swing lock pin.

• Raise boom slightly.

Control can perform more than one

action at a time. By “feathering” the

control, operator can combine

backhoe operations.

Use this control to lock boom in the up

position.

NOTICE: Always use stow lock and

install swing lock pin during transport.

When unlocked, store swing lock pin

in holder located on left stabilizer

support.

• Push stow lock handle to

release lock.

12. Right stabilizer control To lower, push out.

To raise, pull in.

CMW

Page 53

Controls - 52 RT115Q Operator’s Manual

Battery

Battery

1. Battery disconnect switch

Item Description Notes

1. Battery disconnect

switch

To connect, move right.

To disconnect, move left.

CMW

Page 54

RT115Q Operator’s Manual Operation Overview - 53

Operation Overview

Chapter Contents

Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Trenching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Plowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Digging with Backhoe . . . . . . . . . . . . . . . . . . . . . . 55

Leaving Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

CMW

Page 55

Operation Overview - 54 RT115Q Operator’s Manual

Planning

Planning

1. Gather information about jobsite. See page 58.

2. Inspect jobsite. See page 59.

3. Classify jobsite. See page 60.

4. Select chain and teeth to match your soil type, if necessary. See page 120.

5. Check supplies and prepare equipment. See page 62.

6. Haul equipment to jobsite. See page 76.

Trenching

1. Start unit. See page 64.

2. Position tractor and controls. See page 83.

3. Begin trenching. See page 83.

4. Engage cruise control if desired. See page 118.

5. Engage optional Trench Depth Meter if desired. See page 120.

6. Complete the installation. See page 87.

7. Shut down tractor. See page 67.

Plowing

1. Start unit. See page 64.

2. Position tractor and controls. See page 91.

• offset plowing - page 97

• coordinated plowing - page 97

• crabbing - page 97

3. Attach product. See page 91.

4. Begin plowing. See page 94.

5. Engage cruise control if desired. See page 118.

6. Complete the installation. See page 123.

7. Shut down tractor. See page 67.

CMW

Page 56

RT115Q Operator’s Manual Operation Overview - 55

Drilling

Drilling

1. Start unit. See page 64.

2. Dig approach trench and target trench. See page 111.

3. Assemble drill string and position tractor. See page 111.

4. Begin drilling. See page 113.

5. Use drill string guide as needed. See page 114.

6. Add rod. See page 115.

7. Backream. See page 115.

8. Shut down tractor. See page 67.

9. Disassemble joints. See page 116.

Digging with Backhoe

1. Start unit. See page 64.

2. Set stabilizers and unstow backhoe. See page 104.

3. Excavate. See page 105.

4. Stow backhoe properly. See page 106.

5. Shut down tractor. See page 67.

Leaving Jobsite

1. Backfill if necessary. See page 124.

2. Rinse equipment. See page 124.

3. Stow tools. See page 124.

4. Haul equipment from jobsite. See page 76.

CMW

Page 57

Operation Overview - 56 RT115Q Operator’s Manual

Leaving Jobsite

CMW

Page 58

RT115Q Operator’s Manual Prepare - 57

Prepare

Chapter Contents

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . 58

• Review Job Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• Notify One-Call Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• Arrange for Traffic Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• Plan for Emergency Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Inspect Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

• Identify Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Classify Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

• Inspect Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

• Select a Classification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

• Apply Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Check Supplies and Prepare Equipment . . . . . . . 62

• Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• Fluid Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• Condition and Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CMW

Page 59

Prepare - 58 RT115Q Operator’s Manual

Gather Information

Gather Information

A successful job begins before you dig. The first step in planning is reviewing information already available

about the job and jobsite.

Review Job Plan

Review blueprints or other plans. Check for information about existing or planned structures, elevations, or

proposed work that may be taking place at the same time.

Notify One-Call Services

Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

Arrange for Traffic Control

If working near a road or other traffic area, contact local authorities about safety procedures and

regulations.

Plan for Emergency Services

Have the telephone numbers for local emergency and medical facilities on hand. Check that you will have

access to a telephone.

CMW

Page 60

RT115Q Operator’s Manual Prepare - 59

Inspect Site

Inspect Site

Inspect jobsite before transporting equipment. Check for the following:

• changes in elevation such as hills or other open trenches

• obstacles such as buildings, railroad crossings, or streams

• signs of utilities (See “Inspect Jobsite” on page 60.)

• traffic

• access

• soil type and condition

Identify Hazards

Identify safety hazards and classify jobsite. See “Classify Jobsite” on page 60.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

NOTICE:

• Wear personal protective equipment including hard hat, safety eye wear, and hearing protection.

• Do not wear jewelry or loose clothing.

• Notify One-Call and companies which do not subscribe to One-Call.

• Comply with all utility notification regulations before digging or drilling.

• Verify location of previously marked underground hazards.

• Mark jobsite clearly and keep spectators away.

Remember, jobsite is classified by hazards in place -- not by line being installed.

CMW

Page 61

Prepare - 60 RT115Q Operator’s Manual

Classify Jobsite

Classify Jobsite

Inspect Jobsite

• Follow U.S. Department of Labor regulations on excavating and trenching (Part 1926, Subpart P) and

other similar regulations.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

• Inspect jobsite and perimeter for evidence of underground hazards, such as:

– “buried utility” notices

– utility facilities without overhead lines

– gas or water meters

– junction boxes

– drop boxes

– light poles

– manhole covers

– sunken ground

• Have an experienced locating equipment operator sweep area within 20’ (6 m) to each side of trench

path. Verify previously marked line and cable locations.

• Mark location of all buried utilities and obstructions.

• Classify jobsite.

Select a Classification

Jobsites are classified according to underground hazards present.

If working . . . then classify jobsite as . . .

within 10’ (3 m) of a buried electric line electric

within 10’ (3 m) of a natural gas line natural gas

in sand, granite, or concrete which is capable of producing

crystalline silica (quartz) dust

within 10’ (3 m) of any other hazard other

NOTICE: If you have any doubt about jobsite classification, or if jobsite might contain unmarked

hazards, take steps outlined previously to identify hazards and classify jobsite before working.

crystalline silica (quartz) dust

CMW

Page 62

RT115Q Operator’s Manual Prepare - 61

Classify Jobsite

Apply Precautions

Once classified, precautions appropriate for jobsite must be taken.

Electric Jobsite Precautions

Use one or both of these methods.

• Expose line by careful hand digging or soft excavation.

• Have service shut down while work is in progress. Have electric company test lines before returning

them to service.

Natural Gas Jobsite Precautions

In addition to positioning equipment upwind from gas lines, use one or both of these methods.

• Expose lines by careful hand digging or soft excavation.

• Have gas shut off while work is in progress. Have gas company test lines before returning them to

service.

Crystalline Silica (Quartz) Dust Precautions

Crystalline silica dust is a naturally occurring substance found in soil, sand, concrete, granite, and quartz.

Breathing silica dust particles while cutting, drilling, or working materials may cause lung disease or

cancer. To reduce exposure:

• Use water spray or other means to control dust.

• Refer to U.S. Department of Labor Occupational Safety and Health Administration guidelines to learn

more about appropriate breathing protection and permissible exposure limits.

Other Jobsite Precautions

You may need to use different methods to safely avoid other underground hazards. Talk with those

knowledgeable about hazards present at each site to determine which precautions should be taken or if

job should be attempted.

CMW

Page 63

Prepare - 62 RT115Q Operator’s Manual

Check Supplies and Prepare Equipment

Check Supplies and Prepare Equipment

Supplies

• fuel

• keys

• personal protective equipment, such as hard hat and safety glasses

Fluid Levels

• fuel

• hydraulic fluid

• battery charge

• engine oil

Condition and Function

• digging chain and teeth

• brake pads and disc

• fan belts

• light bulbs

• filters (air, oil, hydraulic)

• tracks

• pumps and motors

• hoses and valves

• signs, guards, and shields

Accessories

Fire Extinguisher

If required, mount a fire extinguisher near the power unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric fires. It should meet legal and regulatory

requirements.

CMW

Page 64

RT115Q Operator’s Manual Drive - 63

Drive

Chapter Contents

Start Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

CMW

Page 65

Drive - 64 RT115Q Operator’s Manual

Start Unit

Start Unit

Before operating tractor, read engine manufacturer’s starting and operating instructions. Follow

instructions for new engine break-in.

Runaway possible. Machine could run over you or others. Learn how to

use all controls. Start and operate only from operator’s position.

Rollover possible. If machine rolls over, you could be thrown from seat

and killed or crushed. Wear seat belt.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

To help avoid injury:

• Read operator’s manual before operating equipment. Follow instructions carefully. Contact Ditch

Witch dealership for operation information or demonstration.

• Wear hard hat, safety glasses, and other protective equipment required by job. Do not wear jewelry

or loose clothing that can catch on controls.

CMW

Page 66

RT115Q Operator’s Manual Drive - 65

Start Unit

1. Fasten and adjust seat belt.

2. Check that ground drive control and attachment speed/direction control are in neutral.

3. Move throttle to idle.

4. Check that parking brake is engaged.

5. If starting in weather where temperature is below 32° F (0° C):

• Turn key to on position, but do not start engine.

• Press button for up to 30 seconds.

• Continue pressing cold start button and start engine.

6. Turn ignition switch to start tractor. Warning alarm will sound. Indicators will light.

Improper control function could cause death or serious injury. If

control does not work as described in instructions, stop machine and have it

serviced.

To help avoid injury: Stop machine and have it serviced if control does not work as described

in instructions.

NOTICE: If engine turns but does not start within 10 seconds, allow starter to cool before trying

to start again.

IMPORTANT: Machine will not start if start interlock requirements are not met. See page 24 for

start interlock information.

7. Run engine at half-throttle or less for five minutes before operating tractor. During warm-up, check that

all controls work properly.

CMW

Page 67

Drive - 66 RT115Q Operator’s Manual

Drive

Drive

General Operation

Moving traffic – hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

To help avoid injury:

• Drive carefully in congested areas. Know machine’s clearance and turning radius.

• Keep attachments low when operating on slope. Drive slowly and cautiously.

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

The ground drive foot pedal and ground drive speed/direction hand control perform the same function and

override each other. This override feature is intended to be used while digging. While driving or backfilling,

use only the foot pedal to control speed. While digging, use the hand control to set travel speed. Use the

foot pedal to temporarily adjust travel speed if digging conditions change for a short distance. For example,

if soil becomes sticky or tight, press the reverse foot pedal to slow travel speed. When optimal soil

condition returns, release foot pedal to return to original speed.

1. Fasten and adjust seat belt.

2. Turn on lights and warning flasher as needed.

3. Raise backfill blade, if equipped, and all attachments.

4. Release parking brake and verify parking brake indicator is off.

NOTE: Machine will not move if parking brake indicator is on.

5. Move gearbox motor switch to high.

6. Adjust throttle.

7. Move ground drive control to forward or reverse.

CMW

Page 68

RT115Q Operator’s Manual Drive - 67

Drive

Safe Slope Operation

Tipover possible. Machine can tip over and crush you.

To help avoid injury:

• Always operate with heavy end uphill.

• Drive cautiously at all times.

• Never jerk control levers. Use a steady even motion.

• Do not park unit on slope without lowering digging attachment to the

ground, returning all controls to neutral position, shutting down unit, and applying parking brake.

Operating safely on a slope depends upon many factors including:

• Distribution of machine weight, including front loading and absence of load

• Height of load

• Even or rough ground conditions

• Potential for ground giving way causing unplanned tilt forward, reverse or sideways

• Nearness of ditches, ruts, stumps or other obstructions and sudden changes in slope

• Speed

• Turning

• Braking performance

• Operator skill

These varying factors make it impractical to specify a maximum safe operating angle in this manual. It is

therefore important for the operator to be aware of these conditions and adjust operation accordingly.

Maximum engine angle and braking performance are two absolute limits which must never be exceeded.

These maximums are stated below since they are design limits. These design limits usually exceed the

operating limits and must never be used alone to establish safe operating angle for variable conditions.

Maximum engine lubrication angle – 30°

Maximum service brake retarding force – equal to traction of both tracks.

Maximum secondary brake retarding force – equal to traction of one track.

Maximum park brake holding force – equal to traction of both tracks.

CMW

Page 69

Drive - 68 RT115Q Operator’s Manual

Shut Down

Shut Down

1. When job is complete, move ground drive control to neutral.

2. Engage parking brake and verify parking brake indicator is on.

3. Lower all attachments to ground and let machine idle for three minutes to cool.

4. Turn ignition switch to STOP. If leaving machine unattended, remove key.

5. For maintenance or long-term storage, turn battery disconnect switch to disconnect position.

CMW

Page 70

RT115Q Operator’s Manual Transport - 69

Transport

Chapter Contents

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

• Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

• Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

CMW

Page 71

Transport - 70 RT115Q Operator’s Manual

Lift

Lift

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Points

Lifting points are identified by lifting decals. Lifting at other points is unsafe

and can damage machinery.

Procedure

Tractor

This machine is not configured for lifting. If the machine must be lifted, load machine into a container or

onto a platform appropriate for lifting. See “Specifications” on page 179 for size and weight of machine.

CMW

Page 72

RT115Q Operator’s Manual Transport - 71

Lift

Centerline Trencher

Use crane capable of supporting the

equipment's size and weight. See page 183 or

measure and weigh equipment before lifting.

Traversing Trencher

Use crane capable of supporting the

equipment's size and weight. See page 185 or

measure and weigh equipment before lifting.

Combo

Use crane capable of supporting the equipment’s

size and weight. See page 179 or measure and

weigh equipment before lifting.

CMW

Page 73

Transport - 72 RT115Q Operator’s Manual

Lift

Plow

Use crane capable of supporting the

equipment's size and weight. See page 187 or

measure and weigh equipment before lifting.

Reel Carrier

Use crane capable of supporting the

equipment's size and weight. See page 199 or

measure and weigh equipment before lifting.

CMW

Page 74

RT115Q Operator’s Manual Transport - 73

Tie Down

Tie Down

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Points

Tiedown points are identified by tiedown decals. Securing to trailer at other

points is unsafe and can damage machinery.

Procedure

Tractor

Attach chains at front and rear tiedown points.

Make sure chains are tight before transporting

unit.

Centerline Trencher

Lower trencher to trailer deck and chain at

attachment frame and through boom. Make

sure chains are tight before transporting.

IMPORTANT: If trencher is equipped with

a trench cleaner, ensure that trench

cleaner shoe is fully up and extra bolt

(found in operator’s manual compartment)

is installed in appropriate hole for

additional support.

CMW

Page 75

Transport - 74 RT115Q Operator’s Manual

Tie Down

Traversing Trencher

Lower trencher to trailer deck and chain at

attachment frame and through boom. Make

sure chains are tight before transporting.

IMPORTANT: If trencher is equipped with

a trench cleaner, ensure that trench

cleaner shoe is fully up and extra bolt

(found in operator’s manual compartment)

is installed in appropriate hole for

additional support.

Combo

Lower attachment to trailer deck and chain at

attachment frame and vibrator box. Make sure

chains are tight before transporting.

NOTICE:

• Engage attachment stow lock and swing

lock devices in addition to securing at

tiedowns.

• Unsecured plow can swing outside the

trailer and become a traffic hazard. Lower

plow and chain to trailer deck before

hauling.

• If trencher is equipped with a trench

cleaner, ensure that trench cleaner shoe

is fully up and extra bolt (found in

operator’s manual compartment) is

installed in appropriate hole for additional

support.

CMW

Page 76

RT115Q Operator’s Manual Transport - 75

Tie Down

Plow

Lower plow to trailer deck and chain at

attachment frame and vibrator box. Make sure

chains are tight before transporting.

NOTICE:

• Engage attachment stow lock and

swing lock devices in addition to

securing at tiedowns.

• Unsecured plow can swing outside

the trailer and become a traffic

hazard. Lower plow and chain to

trailer deck before hauling.

Reel Carrier

Lower reel carrier to lowest position and tie down

at attachment arms. Make sure chains are tight

before transporting.

CMW

Page 77

Transport - 76 RT115Q Operator’s Manual

Haul

Haul

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

To help avoid injury:

• Read trailer operator’s manual before loading or transporting your machine. Incorrectly loaded

machine can slip or cause trailer sway.

• Ensure that tow vehicle has proper tow capacity rating.

• Attach trailer to tow vehicle before loading or unloading.

• Park, load, and unload trailer on level ground.

• Check that unit and trailer do not exceed size or weight regulations.

• Load trailer correctly to avoid trailer sway. Ten to fifteen percent of total vehicle weight (equipment

plus trailer) must be on tongue to help prevent trailer sway.

• Connect safety chains to tow vehicle. Attach left chain to right side of tow vehicle and vice versa to

cradle hitch. Do not connect to pintle hook or hitch ball.

• Connect breakaway switch cable to tow vehicle. Do not connect to pintle hook or hitch ball.

Procedure

Inspect Trailer

1. Check hitch for wear and cracks. Lubricate if needed.

2. Check battery for 12V charge.

3. Inspect lights for cleanliness and correct operation. Inspect reflectors and replace if needed.

4. Check trailer tire pressure. Check lug nut torque with a torque wrench. Adjust if needed.

5. Ensure trailer brakes are adjusted to come on in synchronization with tow vehicle brakes.

6. Check ramps and trailer bed for cracks.

CMW

Page 78

RT115Q Operator’s Manual Transport - 77

Haul

Load

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

To help avoid injury:

• Attach trailer to tow vehicle before loading or unloading.

• Load and unload trailer on level ground.

• Block trailer wheels.

• Put ground drive control into park. Turn off ignition. Set parking brake.

Rollover possible. If machine rolls over, you could be thrown from seat

and killed or crushed. Wear seat belt.

1. Fasten and adjust seat belt.

2. Tilt steering column down.

3. Start tractor. See page 66 for proper start-up procedures.

4. Raise attachments, but keep them low and centered. Check that they are not in float.

5. Release parking brake and verify that parking brake indicator is off.

6. Move ground drive switch to low.

7. Slow engine to low throttle and slowly drive tractor onto trailer.

8. Position tractor on trailer deck for proper weight distribution.

9. Engage parking brake and verify that parking brake indicator is on.

10. Lower attachments to trailer bed and turn tractor off. See page 66 for proper shutdown procedures.

11. Attach chains to tractor and attachments where tiedown decals are located. See page 73.

CMW

Page 79

Transport - 78 RT115Q Operator’s Manual

Haul

Unload

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

NOTICE:

• Attach trailer to tow vehicle before loading or unloading.

• Load and unload trailer on level ground.

• Block trailer wheels.

Rollover possible. If machine rolls over, you could be thrown from seat

and killed or crushed. Wear seat belt.

1. Lower trailer or ramps.

2. Check that parking brake is engaged and verify that parking brake indicator is on.

3. Check that ground drive controls are in neutral.

4. Remove chains from tiedowns.

5. Fasten and adjust seat belt.

6. Tilt steering column down.

7. Start tractor. See page 66 for proper start-up procedures.

8. Raise attachments, but keep them low and centered. Check that they are not in float.

9. Release parking brake and verify that parking brake indicator is off.

10. Slow engine to low throttle and slowly back unit down trailer or ramps.

CMW

Page 80

RT115Q Operator’s Manual Transport - 79

Tow

Tow

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Under normal conditions, tractor should not be towed. If tractor becomes disabled and towing is

necessary:

• Do not tow for more than 200 yd (180 m).

• Tow at less than 1 mph (1.6 km/h).

• Steering will be very difficult.

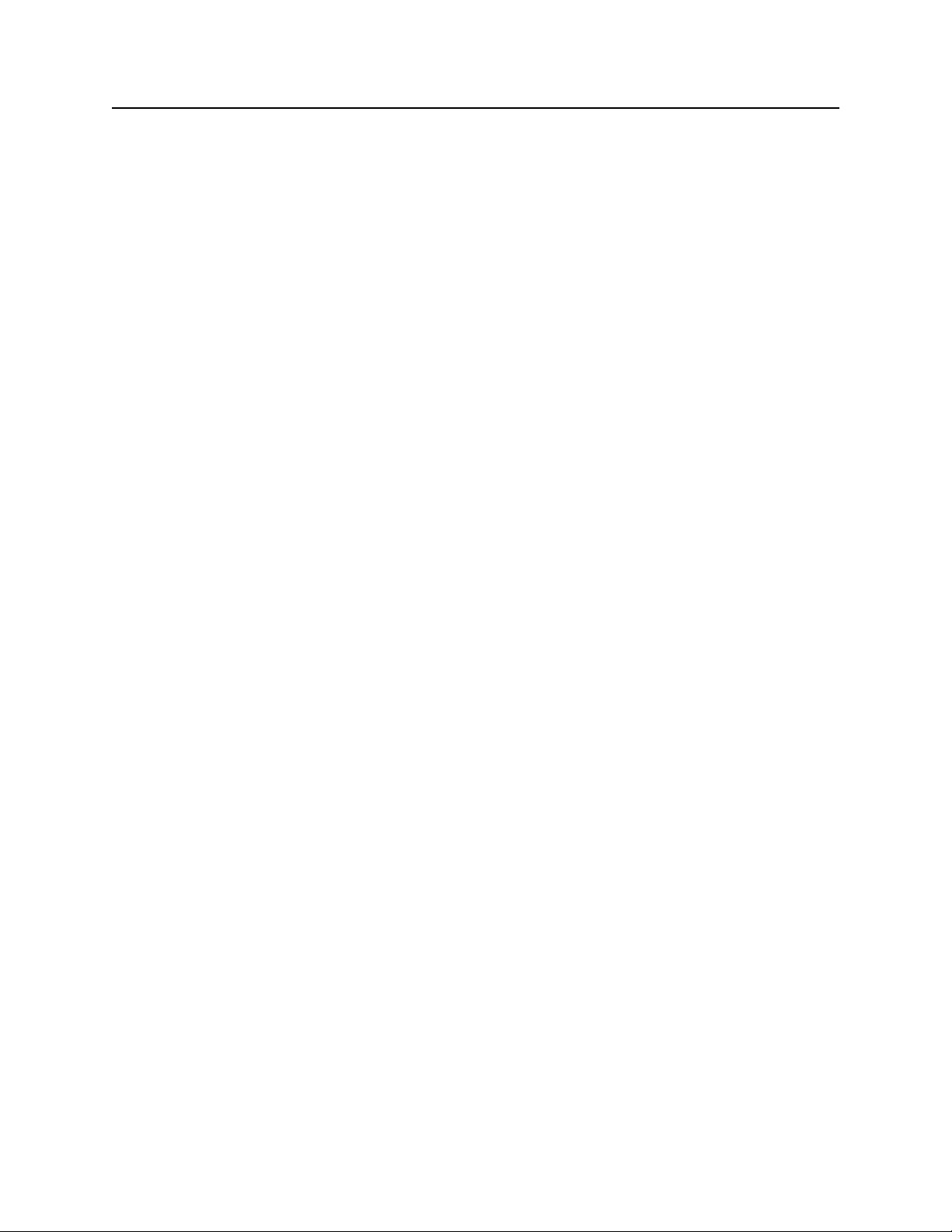

Procedure

1. Engage parking brake.

2. Block front and rear tracks to prevent unit

from rolling.

3. Attach tow line to all available tie-down

points facing towing vehicle.

4. Activate the tow valve (shown).

• Remove floor plate.

• Locate two hex-shaped relief valves.

• Turn each valve (whole hex)

counterclockwise three complete

revolutions.

NOTICE: Do not turn tow valve

more than three revolutions.

• Replace floor plate.

5. Remove blocks.

6. Fasten seat belt and adjust seat belt.

7. Disengage parking brake.

8. After towing, turn tow valve clockwise three complete revolutions.

CMW

Page 81

Transport - 80 RT115Q Operator’s Manual

Tow

CMW

Page 82

RT115Q Operator’s Manual Trench - 81

Trench

Chapter Contents

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

CMW

Page 83

Trench - 82 RT115Q Operator’s Manual

Setup

Setup

EMERGENCY SHUTDOWN - Turn ignition switch to STOP.

Crushing weight could cause death or serious injury. Use proper

procedures and equipment or stay away.

To help avoid injury: Use attachments or counterweights to make front and rear loads balance when all

attachments are raised. Contact your Ditch Witch dealer about counterweighting for your equipment.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

To help avoid injury: Comply with all utility notification regulations before digging or drilling.

Incorrect procedures can result in death, injury, or property damage.

Learn to use equipment correctly.

NOTICE: The RT115Q is programmed to operate with the original attachment (trencher or plow)

configuration. If you change attachments, contact your Ditch Witch dealer to make sure the electronic

programming is updated. If you change attachments without updating the electronic programming, your

attachment may not function correctly.

CMW

Page 84

RT115Q Operator’s Manual Trench - 83

Setup

1. If using optional trench cleaner, remove bolt installed for transport.

2. Fasten and adjust seat belt.

3. Start tractor. See page 64 for start-up procedures.

4. Drive to starting point. Move in line with planned trench. See page 66 for driving procedures.

5. Engage parking brake and verify parking brake indicator is on.

6. Move ground drive switch to low.

7. Turn seat to the desired position.

8. Engage axle lock.

9. Lower boom to just above ground.

10. Engage optional Trench Depth Meter, if equipped. See page 120.

11. Check that attachment speed/direction control is in neutral.

12. Check that boom is in line with planned trench.

CMW

Page 85

Trench - 84 RT115Q Operator’s Manual

Operation

Operation

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

To help avoid injury:

• Comply with all utility notification regulations before digging or drilling.

• Notify companies that do not subscribe to One-Call.

Breathing crystalline silica dust may cause lung disease. Cutting, drilling,

or working materials such as concrete, sand, or rock containing quarts may result in

exposure to silica dust. Use dust control methods or appropriate breathing protection

when exposed to silica dust.

Electrical shock. Contacting electrical lines will cause death or serious

injury. Know location of lines and stay away.

To help avoid injury: Expose lines by hand before digging. Cutting high voltage cable can

cause electrocution.

Flying objects thrown by machine may strike people. Wear hard hat and

safety glasses.

CMW

Page 86

RT115Q Operator’s Manual Trench - 85

Operation

Start Trench

1. Lower backfill blade, if equipped, to reduce shock when trenching begins.

2. Set Trench / Plow switch to the trench position.

3. Move attachment speed/direction control to desired speed. DIGGING CHAIN WILL MOVE.

Moving digging teeth will cause death or serious injury. Stay away.

To help avoid injury:

• Machine might jerk when digging starts. Allow 3’ (1 m) between digging teeth and obstacle.

• Keep everyone at least 6’ (2 m) from machine, attachments, and their range of movement.

4. Set throttle to full engine speed.

5. Lift trench cleaner, if equipped.

6. Slowly lower digging boom to desired trench depth.

CMW

Page 87

Trench - 86 RT115Q Operator’s Manual

Operation

Move Forward

1. Raise backfill blade, if equipped.

2. Release parking brake, if set, and verify parking brake indicator is off.

3. If using trench cleaner:

• Use ground drive foot control to move forward about 1 foot (30 cm), or until there is enough room

for trench cleaner to enter trench.

• Return ground drive control to neutral to stop forward movement.

• Raise boom slightly, then fully lower trench cleaner to lock it in place.

• Lower boom to desired trench depth.

NOTICE:

• Do not have trench cleaner in working position when starting a trench.

• Do not back up with trench cleaner in working position.

• Do not use trench cleaner in working position in conditions where large rocks can get

between chain and cleaner.

4. Move ground drive hand control to desired speed. Always start trenching with ground drive speed set

at low. Increase ground drive speed only as soil conditions permit.

IMPORTANT:

• Ground drive speed/direction can be controlled with foot pedal or hand lever. When

trenching, set ground drive speed with hand lever. Use foot pedal to temporarily adjust

speed if digging conditions change for a short distance.

• For cruise control operation, see page 118.

5. Operate engine at full throttle when working.

NOTICE:

• Do not make sharp turns. Lower boom to full depth when turning.

• If an object becomes lodged in chain, move attachment speed/direction control to neutral