MV800

Operator’s

Manual

CMW

®

Issue 1.0

053-2767

MV800 Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Equipment Modification . . . . . . . . . . . . . . . . . . . . . 3

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operator Orientation. . . . . . . . . . . . . . . . . . . . . . . . . 4

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 4

• Bulleted Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

• Numbered Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

CMW

®

Overview - 2 MV800 Operator’s Manual

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. MV800 serial number is located as

shown.

Date of manufacture

Date of purchase

MV800 serial number (shown)

Engine serial number

Blower serial number

Water pump serial number

Trailer serial number

Intended Use

The MV800 is a self-contained vacuum excavation unit designed to remove used drilling fluid from the

jobsite and to expose existing buried utilities. The optional reverse flow system allows for spoils transfer to

another tank. The MV800 is intended for operation in ambient temperatures from 0° to 115°F (-18° to

46°C). Use in any other way is considered contrary to the intended use.

The MV800 should be operated, serviced, and repaired only by persons familiar with its particular

characteristics and acquainted with the relevant safety procedures.

CMW

®

MV800 Operator’s Manual Overview - 3

Equipment Modification

Equipment Modification

This equipment was designed and built in accordance with applicable standards and regulations.

Modification of equipment could mean that it will no longer meet regulations and may not function properly

or in accordance with the operating instructions. Modification of equipment should only be made by

competent personnel possessing knowledge of applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

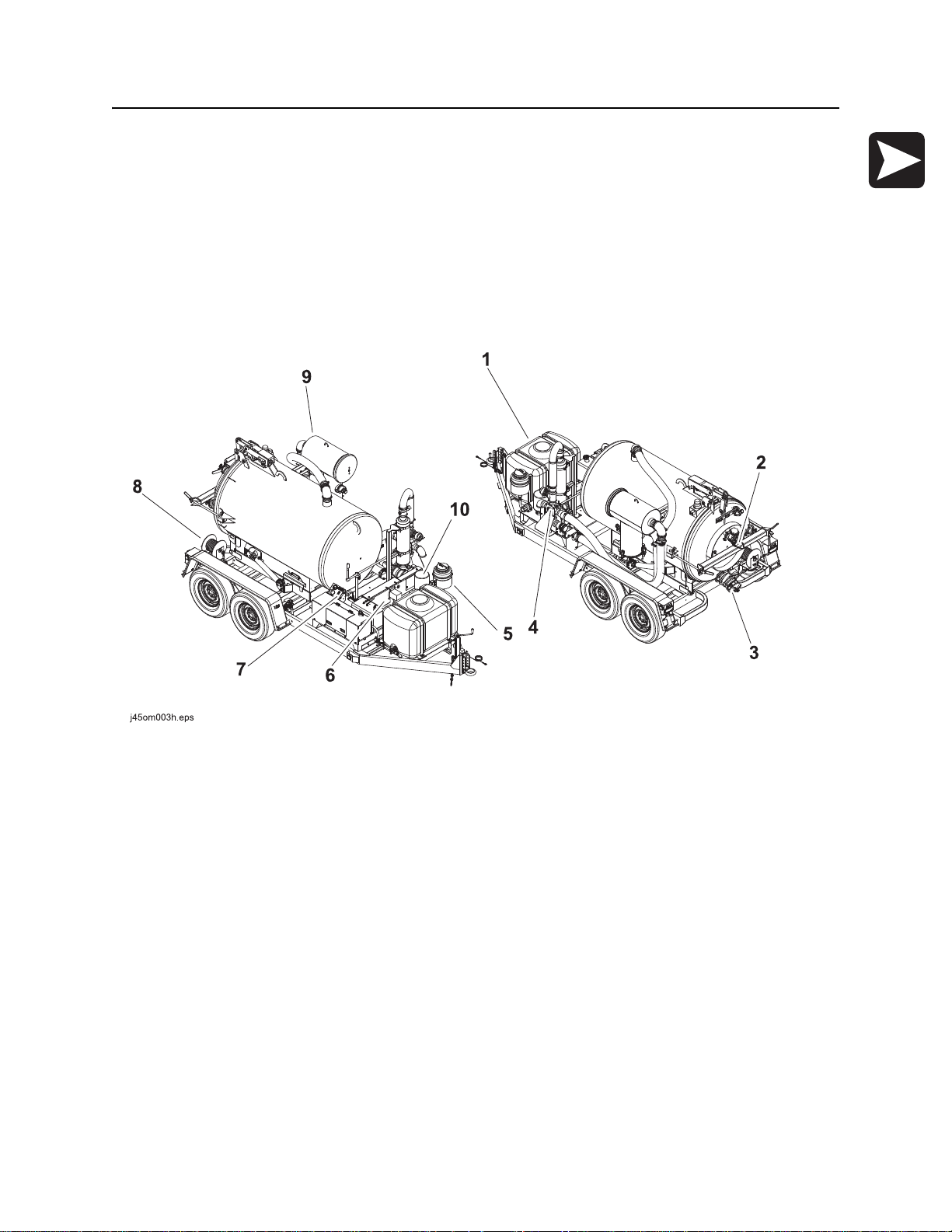

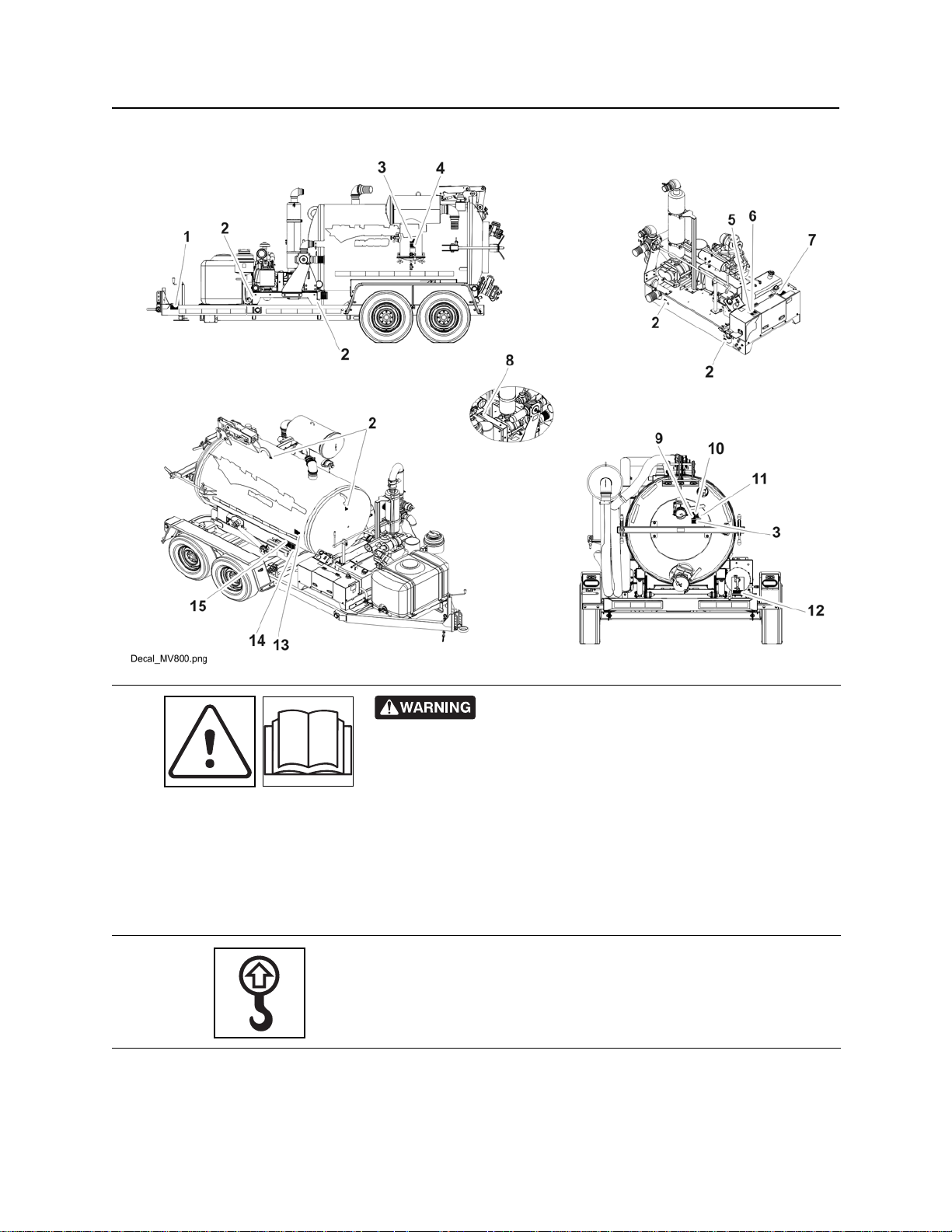

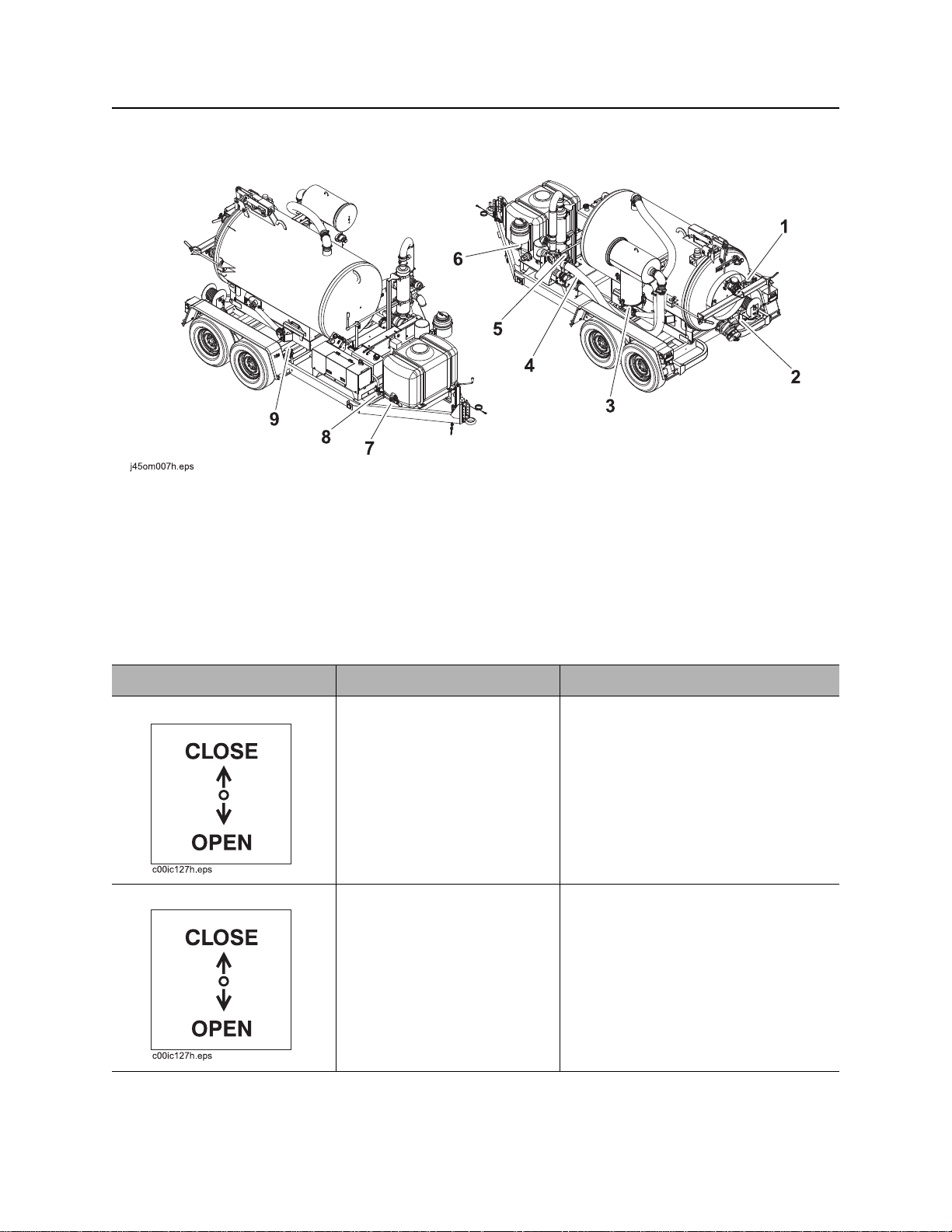

Unit Components

1. Water tank

2. Inlet valve

3. Drain/Outlet valve

4. Reverse flow valve

5. Antifreeze tank

6. Power pack

7. Operator’s station

8. Hose reel

9. Vacuum filter

10. Blower relief air filter

CMW

®

Overview - 4 MV800 Operator’s Manual

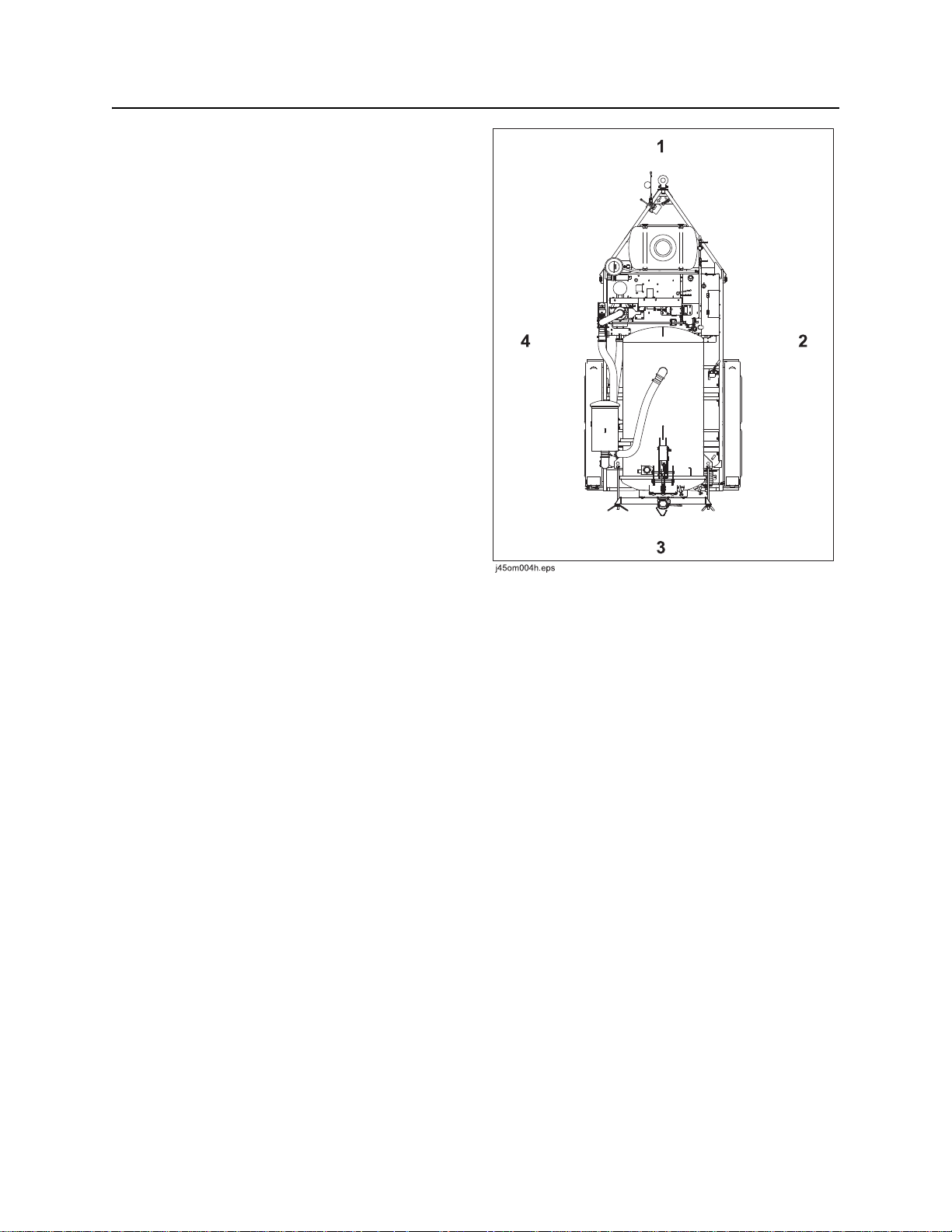

Operator Orientation

Operator Orientation

1. Front of unit

2. Right of unit

Right and left sides of machine are determined by

facing towing vehicle.

3. Rear of unit

4. Left of unit

About This Manual

This manual contains information for the proper use of this machine. See Operation Overview for basic

operating procedures. Cross references such as “See page 50” will direct you to detailed procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

CMW

®

MV800 Operator’s Manual Foreword - 5

Reporting Safety Defects

Foreword

This manual is an important part of your equipment. It provides safety information and operation

®

instructions to help you use and maintain your Ditch Witch

Read this manual before using your equipment. Keep it with the equipmen t at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was publishe d. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

equipment.

Thank you for buying and using Ditch Witch equipment.

Reporting Safety Defects

If you believe that your vehicle has a defect which could cau se a cr ash o r co uld ca use injury or death, you

should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to

notifying the Product Safety Coordinator at The Charles Machine Works, Inc.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists

in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become

involved in any individual problems between you, your Ditch Witch dealer, or The Charles Machine Works,

Inc.

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-888-327-4236 (TTY: 1-800424-9153), go to http://www.safercar.gov, or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle safety from http://www.safe rcar.gov.

CMW

®

Foreword - 6 MV800 Operator’s Manual

Works, Inc.

MV800

Operator’s Manual

Issue number 1.0/OM-9/14

Part number 053-2767

Copyright 2014

by The Charles Machine Works, Inc.

, Ditch Witch, and CMW are registered trademarks of The Charles Machine

U.S. patents pending.

®

CMW

MV800 Operator’s Manual Contents - 7

Content s

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls, gauges, and indicators and how to use them

Operation Overview

an overview for completing a job with this machine: planning, setting up, vacuuming,

potholing, and restoring the jobsite; with cross references to detailed procedures

Prepare

procedures for inspecting and classifying the jobsite, and preparing the jobsite for

work

Transport

procedures for lifting and hauling

1

5

9

19

27

31

37

Vacuum and Pothole

procedures for removing debris and potholing utility locations

Complete the Job

procedures for restoring the jobsite and rinsing and storing equipment

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

41

55

59

93

97

CMW

®

Contents - 8 MV800 Operator’s Manual

Service Record

a record of major service performed on the machine

Appendix

additional information about Ditch Witch® equipment

101

103

CMW

®

MV800 Operator’s Manual Safety - 9

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 11

• Electric Strike Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 15

Machine Safety Alerts . . . . . . . . . . . . . . . . . . . . . . 16

CMW

®

Safety - 10 MV800 Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service. Mark proposed p ath with white paint prior to cont acting One- Call or

utilities.

• Classify jobsite based on its hazards and use cor rect tools and machin ery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch

ditchwitch.com/resources/safety .

• Replace missing or damaged safety shields and safety signs.

®

dealer or at

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about operation, ma intenance, or equipment

use.

• Complete the equipment checklist located at www.ditchwitch.com/resources/safety.

CMW

®

MV800 Operator’s Manual Safety - 11

Emergency Procedures

Emergency Procedures

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Before operating any equipment, review emergency proc edures and check that all safety precau tions have

been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote e ngine stop button ( if

equipped).

Electric Strike Description

or serious injury. Know location of lines and stay away.

274-050

Electric shock. Contacting electric lines will cause death

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

•smoke

•explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

CMW

®

Safety - 12 MV800 Operator’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on truck or trailer, DO NOT MOVE.

Remain on truck or trailer and take the following actions. The order and degree of action will depend on the

situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Do not allow anyone into area until given permission by utility company.

• Do not allow anyone to touch equipment.

If you suspect an electric line has been damaged and you are off truck or trailer, DO NOT TOUCH

EQUIPMENT. Take the following actions. The order and degree of action will depend on the situation.

• LEAVE AREA. The ground surface may be electrified so take small shuffle steps with feet close

together to reduce the hazard of being shocked from one foot to the other.

• Contact utility company to shut off power.

• Do not return to area or allow anyone into area until given permission by utility company.

CMW

®

MV800 Operator’s Manual Safety - 13

Emergency Procedures

If a Gas Line is Damaged

Fire or explosion possible. Fumes could ignite and cause

burns. No smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

275-419 (2P)

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

CMW

®

Safety - 14 MV800 Operator’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur. Contact utility

company.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped and accessible) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

CMW

®

MV800 Operator’s Manual Safety - 15

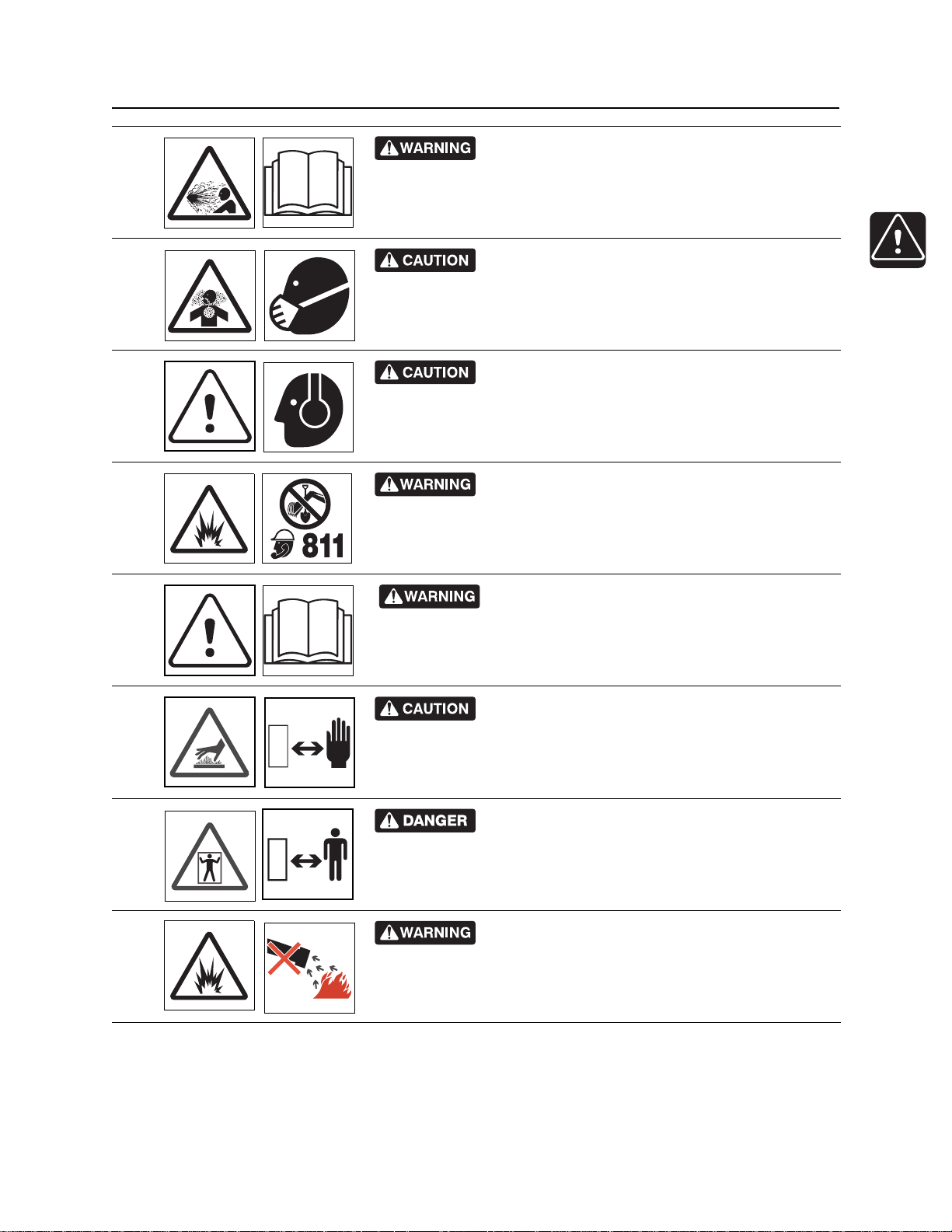

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates a hazardous situation that, if not avoided, will result in death or serious injury. This

signal word is to be limited to the most extreme situations.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

®

Safety - 16 MV800 Operator’s Manual

Machine Safety Alerts

Machine Safety Alerts

275-146

• Secure equipment and accessories with chain and binder.

• Check brakes and lights prior to use.

1

2

• Use proper size coupler.

• Maintain adequate distan ce for stopping and passing vehicles.

• Block wheels when parked.

• Check tire condition and inflation frequently.

• Failure to follow these rules may result in personal injury.

Lift point. See Tra nsport chapter for more information.

274-442

CMW

®

MV800 Operator’s Manual Safety - 17

Machine Safety Alerts

Contents under pressure. Relieve pressure b efore

3

opening. Death or injury could occur.

Use breathing protection when exposed to silica

dust.

4

270-4952

Exposure to high noise levels may cause hearing

5

loss. Wear hearing protection.

Jobsite hazards could cause death or serious

6

injury. Use correct equipment and work methods. Use and maintain

proper safety equipment.

274-050; 274-724 (2P)

270-2732

700-009 (2-P)

7

8

9

10

Read operator’s manual. Know how to use all

controls. Your safety is at stake.

273-475

Hot parts may cause burns. Do not touch until cool

or wear gloves.

275-355 (2-P), 273-423 (2-P)

Confined space will cause suffocation. Use proper

procedures for entering or stay away.

273-200

Fire or explosion possible. Do not vacuum

flammable or combustible substances.

273-483

CMW

®

Safety - 18 MV800 Operator’s Manual

Machine Safety Alerts

Vacuum can suffocate. Keep hose end away from

face.

11

12

13

14

273-205

Pressurized fluid or air could pierce skin and cause

severe injury. Refer to operator’s manual for proper use.

Crushing weight could cause

death or serious injury. Stay away.

275-326

Moving parts could cut off hand or foot. Stay away.

275-184

270-6035

15

Crushing weight. Place cylinder lock on extended

cylinder and secure.

273-231, 273-413

CMW

®

MV800 Operator’s Manual Controls - 19

Controls

Chapter Contents

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operator’s Station . . . . . . . . . . . . . . . . . . . . . . . . . 21

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CMW

®

Controls - 20 MV800 Operator’s Manual

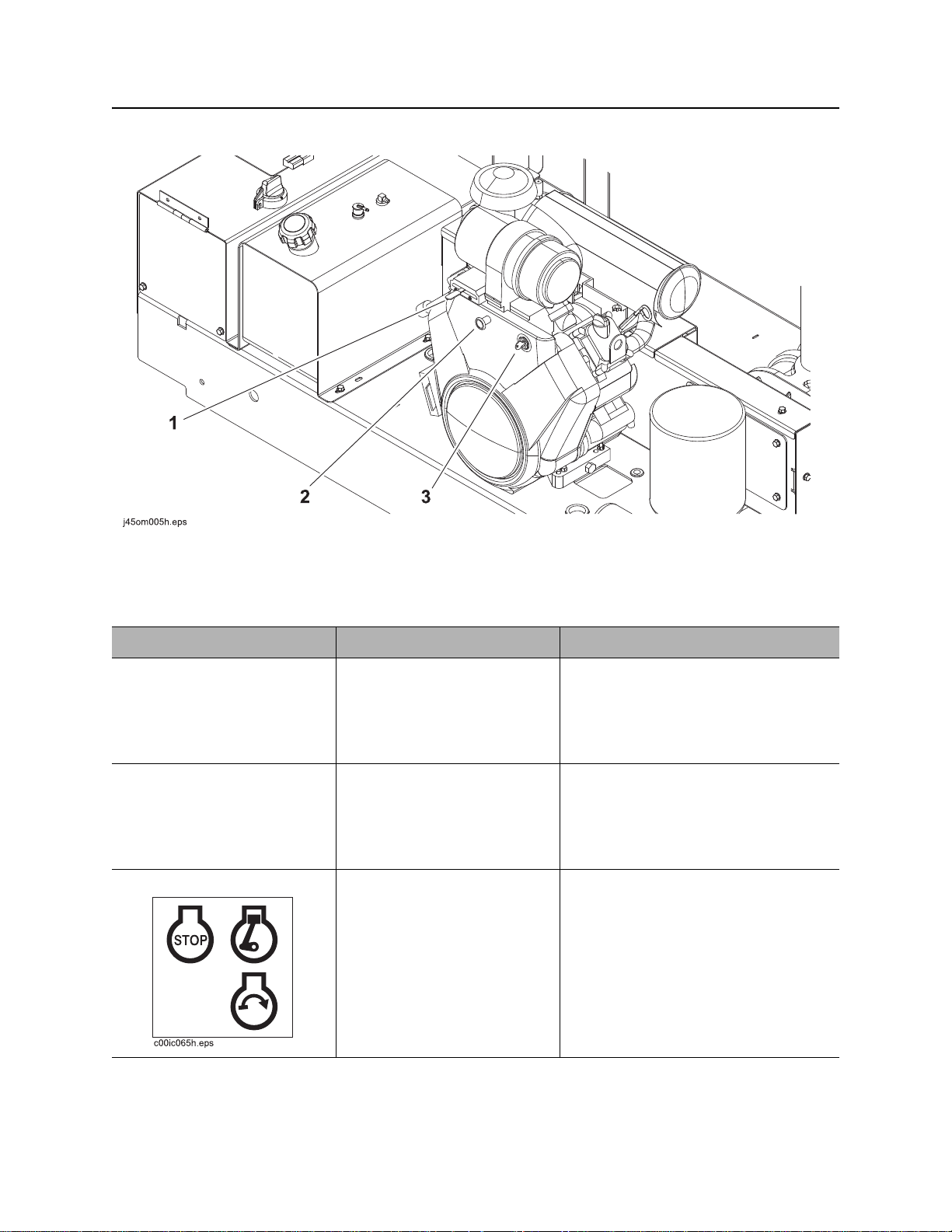

Engine

Engine

1. Throttle

2. Choke

Item Description Notes

1. Throttle To increase engine speed,

move to right.

To decrease engine speed,

move to left.

2. Choke To help start cold engine, pull

knob.

When engine has warmed,

push in completely.

3. Ignition switch T o star t engine, insert key and

turn clockwise.

To stop engine, turn key

counterclockwise.

3. Ignition switch

IMPORTANT: Run engine at full

throttle during operation.

IMPORTANT:

• When engine is on, blower

operates and vacuum is present

at tank inlet.

• All indicators should light briefly at

startup.

CMW

®

MV800 Operator’s Manual Controls - 21

c00ic114t.eps

Operator Station

Operator Station

1. Water pressure switch

2. Water pressure control

3. Water pressure gauge

4. Auxiliary outlet

Item Description Notes

1. Water pressure switch To turn on water pump, press

top.

To turn off water pump, move

to center position.

To bypass low water

indication, press bottom.

Water pump will operate for

60 seconds.

5. Hourmeter

6. Flow direction control (optional)

7. Battery disconnect switch

8. Tethered tank control outlet

Use bypass to feed antifreeze into

system when freshwater tank is

empty. See “Add Antifreeze” on

page 56.

CMW

®

Controls - 22 MV800 Operator’s Manual

c00ic113t.eps

c00ic112t.eps

Operator Station

Item Description Notes

2. Water pressure control To increase water pressure,

turn clockwise.

To decrease water pressure,

turn counterclockwise.

3. Water pressure gauge Displays water pressure

when water pressure switch

is on and spray wand is in

use.

4. Auxiliary outlet To operate work lights or

other 12V devices, plug into

outlet.

5. Hourmeter Displays engine operating

time.

6. Flow direction control To operate in reverse flow

mode, turn counterclockwise.

To operate in vacuum mode,

turn clockwise.

Outlet has power only when ignition

switch is on.

Hourmeter runs when engine is

running.

Use these times to schedule service.

Use optional reverse flow to unload

tank contents to another tank.

Operate in reverse flow mode only

when drain/outlet valve is open.

CMW

®

MV800 Operator’s Manual Controls - 23

c00ic063t.eps

+

_

+

_

c00ic065t.eps

DOWN

c00ic064t.eps

U P

Operator Station

Item Description Notes

7. Battery disconnect

switch

8. Tethered tank control

outlet

Tethered tank control To lift and lower tank, set

To connect, turn clockwise.

To disconnect, turn

counterclockwise.

Connection for tethered tank

control.

hydraulic function switch to

the tank position, then

• To lift tank, press UP.

• To lower tank, press

DOWN.

To open and close tank door,

set hydraulic function switch

to the door position, then

IMPORTANT: Use battery disconnect

switch when servicing, welding, and

during long-term storage.

NOTICE: When opening and closing

door, stand in a position with a full

view of the door.

• To open door, press UP.

• To close door, press

DOWN.

CMW

®

Controls - 24 MV800 Operator’s Manual

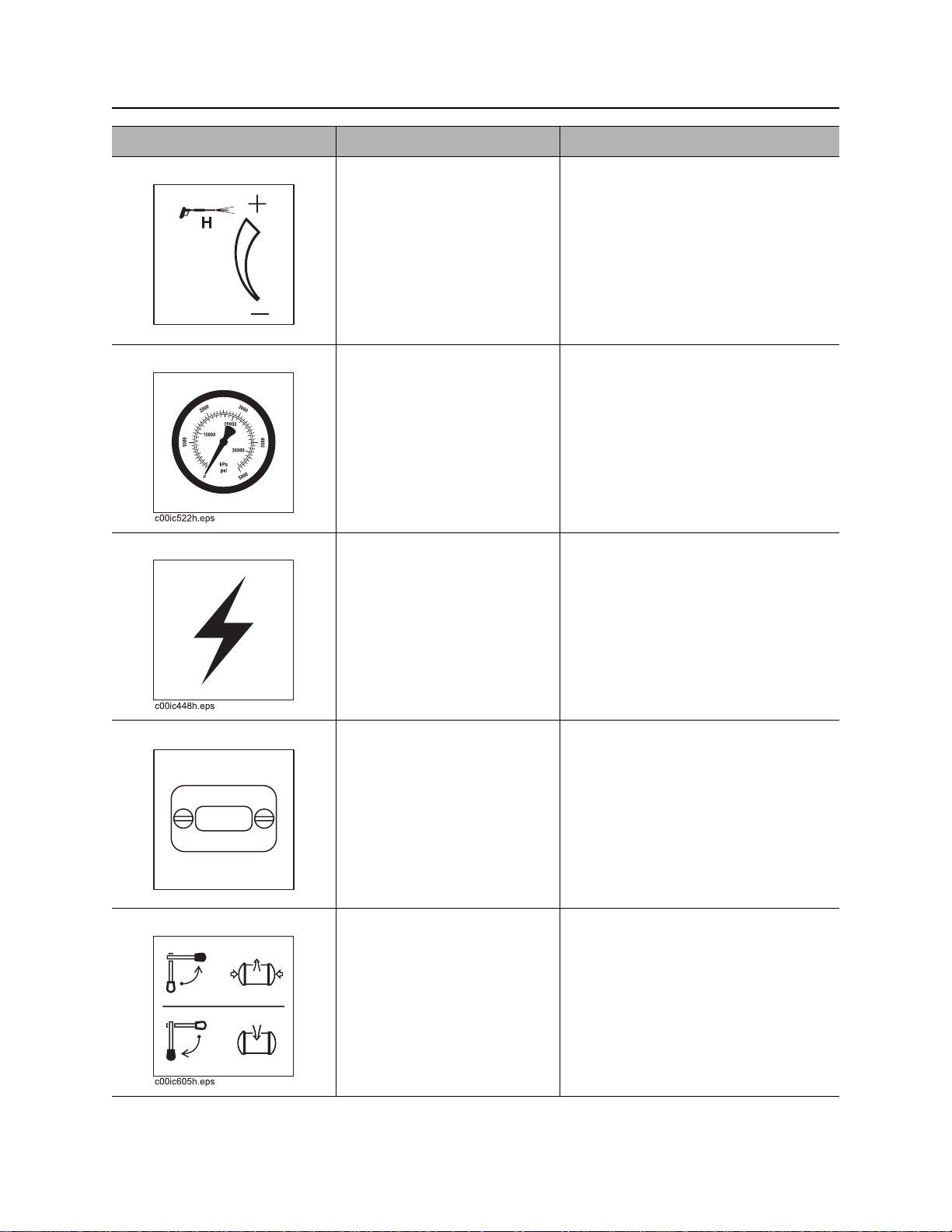

Machine

Machine

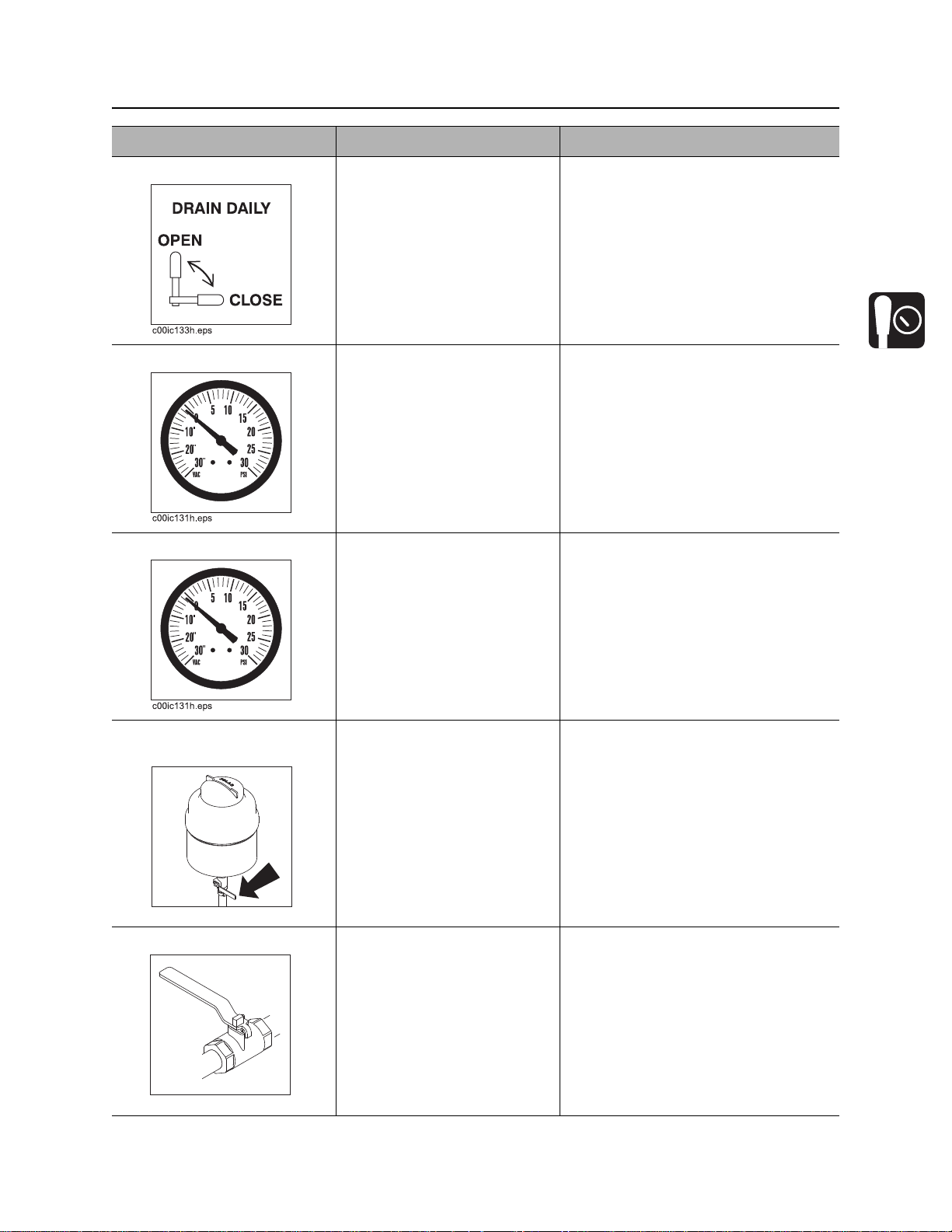

1. Inlet valve

2. Drain/Outlet valve

3. Vacuum filter drain

4. Vacuum gauge

5. Reverse flow gauge (optional)

Item Description Notes

1. Inlet valve To close valve (stop suction),

rotate up.

To open valve (start suction),

rotate down.

2. Drain/Outlet valve To drain tank, rotate down.

To close drain, rotate up.

6. Antifreeze tank supply valve (optional)

7. Water tank drain (optional)

8. Water tank supply valve (optional)

9. Hydraulic function switch (optional)

NOTICE: Do not idle engine with inlet

valve closed.

CMW

®

MV800 Operator’s Manual Controls - 25

c00ic602h.eps

c00ic604h.eps

Machine

Item Description Notes

3. Vacuum filter drain To drain vacuum filter

canister, rotate up.

To close drain, rotate down.

4. Vacuum gauge Displays blower vacuum

reading in inches of mercury.

Vacuum relief valve opens

when vacuum reaches 15”

(381 mm).

5. Reverse flow gauge Displays reverse flow

pressure.

6. Antifreeze tank supply

valve

To open valve (send

antifreeze through pump and

water lance), rotate

counterclockwise.

To close valve (stop

antifreeze flow), rotate

clockwise.

7. Water tank drain To drain tank, open valve.

Close valve when tank is

empty.

IMPORTANT: Water tank supply

valve or antifreeze supply valve must

be open when pump is running or

pump will be damaged.

CMW

®

Controls - 26 MV800 Operator’s Manual

c00ic603h.eps

Machine

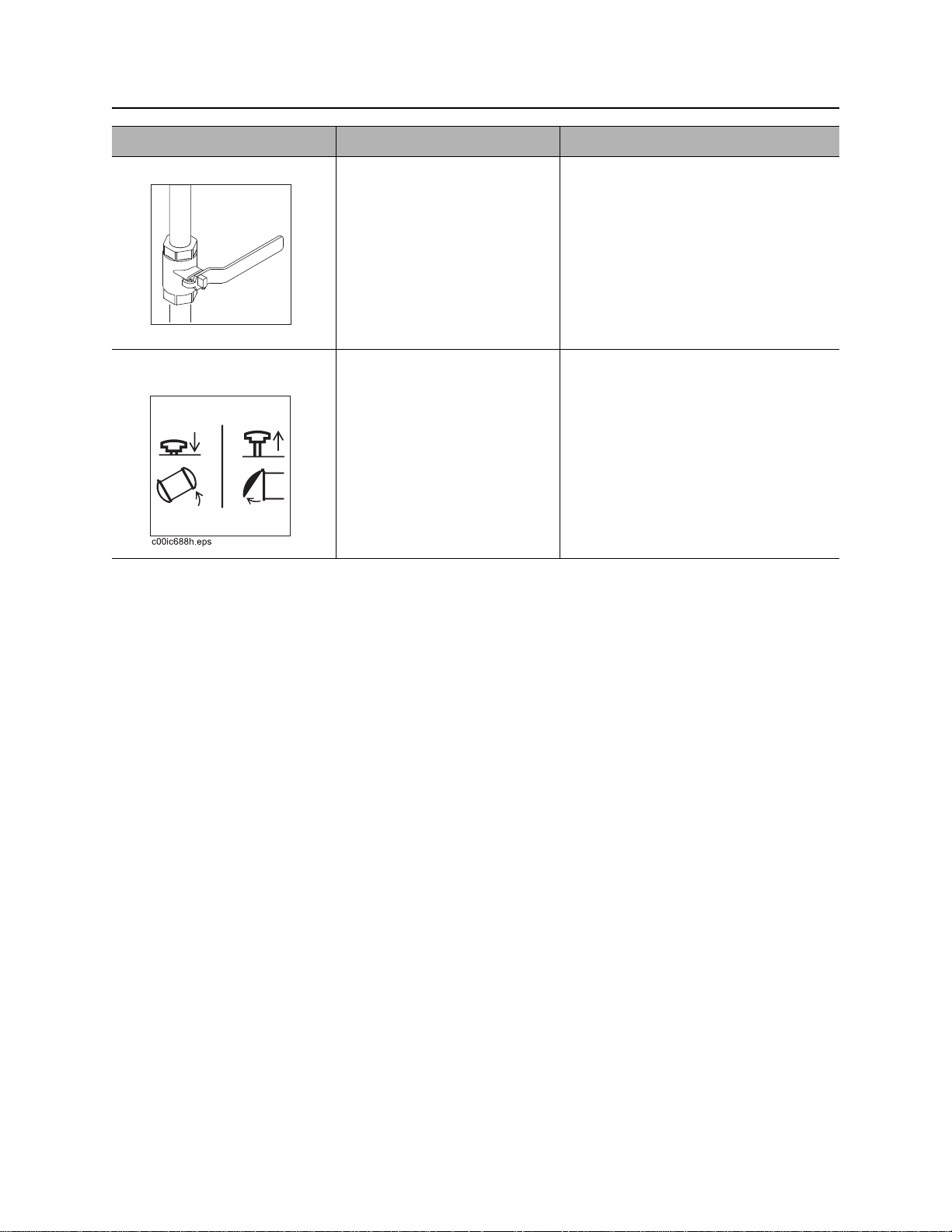

Item Description Notes

8. Water t ank supply valve To open valve (send water

from the water tank through

the pump and water lance),

rotate counterclockwise.

To close valve (stop water

flow), rotate clockwise.

9. Hydraulic function

switch

To lift and lower tank, push

down.

To open and close door, pull

up.

IMPORTANT: Water tank supply

valve or antifreeze supply valve must

be open when pump is running or

pump will be damaged.

Only with hydraulic door option.

CMW

®

MV800 Operator’s Manual Operation Overview - 27

Operation Overview

Chapter Contents

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setting Up at Jobsite . . . . . . . . . . . . . . . . . . . . . . . 28

Vacuuming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Potholing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Leaving Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Storing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 29

CMW

®

Operation Overview - 28 MV800 Operator’s Manual

Planning

Planning

1. Gather information about jobsite (page 32).

2. Inspect jobsite (page 33).

3. Check supplies and prepare equipment (page 35).

Setting Up at Jobsite

1. Prepare jobsite (page 34).

2. Leave unit hitched to towing vehicle or properly stabilized if trailer-mounted unit.

3. Block trailer wheels if trailer-mounted unit.

Vacuuming

1. Connect hoses (page 42).

2. Start unit (page 44).

3. Remove debris (page 45).

4. Disconnect hoses.

5. Drain tank (page 48) or unload to another tank (page 50).

CMW

®

MV800 Operator’s Manual Operation Overview - 29

Potholing

Potholing

1. Connect hoses (page 42).

2. Start unit (page 42).

3. Pothole (page 46).

4. Disconnect hoses.

5. Drain tank (page 48).

Leaving Jobsite

1. Rinse unit and tools (page 57).

2. Stow tools (page 57).

Storing Equipment

1. For cold weather storage, antifreeze vacuum excavation unit (page 56).

2. For long-term storage, disconnect battery disconnect switch (page 22).

CMW

®

Operation Overview - 30 MV800 Operator’s Manual

Storing Equipment

CMW

®

MV800 Operator’s Manual Prepare - 31

Prep are

Chapter Contents

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . 32

• Arrange for Traffic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

• Prepare for Working Near Existing Utilities . . . . . . . . . . . . . . . . . . . . . .32

• Plan for Emergency Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Inspect Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Prepare Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

• Prepare Excavation Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Check Supplies and Prepare Equipment . . . . . . . 35

• Assemble Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

• Check Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

• Prepare Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CMW

®

Prepare - 32 MV800 Operator’s Manual

Gather Information

Gather Information

A successful job begins before the excavation. The first step in planning is reviewing information already

available about the job and jobsite.

Arrange for Traffic Control

If working near a road or other traffic area, contact local authorities about safety procedures and

regulations.

Prepare for Working Near Existing Utilities

If jobsite may contain electrical lines, wear protective boots and gloves meeting the following standards:

• Boots must have high tops and meet th e electric hazard protection requirements of ASTM F2413 or

ASTM F1117, when tested at 14,000 volts. Tuck legs of pants completely inside boots.

• Gloves must have 17,000 AC maximum use voltage, according to ASTM spec ifica tio n D12 0.

If working around higher voltage, use gloves and boots with appropriately higher ratings.

Plan for Emergency Services

Have the telephone numbers for local emergency and medical facilities on hand. Check that you will have

access to a telephone.

CMW

®

MV800 Operator’s Manual Prepare - 33

Inspect Jobsite

Inspect Jobsite

• Follow U.S. Department of Labor regulations on excavating and trenching (Part 1926, Subpar t P) and

other similar regulations.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before working. Also contact any utilities that do not

participate in the One-Call service.

• Inspect jobsite and perimeter for evidence of underground hazards, such as:

– “Buried utility” notices

– Utility facilities without overhead lines

– Gas or water meters

– Junction boxes

– Drop boxes

– Light poles

– Manhole covers

– Sunken ground

• Mark location of all buried utilities and obstructions.

CMW

®

Prepare - 34 MV800 Operator’s Manual

Prepare Jobsite

Prepare Jobsite

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

To help avoid injury:

• Classify jobsite as electric if jobsite classification is in question or if the possibility of unmarked

electric utilities exists.

• Expose lines by hand before digging.Cutting high voltage cable can cause electrocution.

• All vegetation near operator’s station must be removed. Conta ct with trees, shrubs, or weeds during

electrical strike could result in electrocution.

Prepare Excavation Point

274-050

• Clear the area to be excavated. Remove rocks or branches too large for vacuum hose.

• If excavating fluids while drill string is moving, clear area of trees, shrubs, and weeds.

• Select a solid area to stand on while excavating.

CMW

®

MV800 Operator’s Manual Prepare - 35

Check Supplies and Prepare Equipment

Check Supplies and Prepare Equipment

Assemble Accessories

Fire Extinguisher

If required, mount a fire extinguisher near the power unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric fires. It should meet legal and regulatory

requirements.

Lighting Kit

If you will need additional light, plug lighting kit into provided outlet. Contact your Ditch Witch® dealer for

further information.

Check Supplies

• water and additional hoses

•fuel

•keys

• spray lubricant

• personal protective equipment, such as hard hat and safety glasses

CMW

®

Prepare - 36 MV800 Operator’s Manual

Check Supplies and Prepare Equipment

Prepare Equipment

Fluid Levels

•fuel

•battery

• engine oil

• blower oil

Condition and Function

• filters (air, oil)

•belts

• blower

•tires

• hoses and valves

• couplers and fittings

• water tank

CMW

®

MV800 Operator’s Manual Transport - 37

Transport

Chapter Contents

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

• Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

• Inspect Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

• Hitch Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

• Unhitch Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

CMW

®

Transport - 38 MV800 Operator’s Manual

Lift

Lift

Crushing weight could cause death or serious injury. Stay

away.

Points

Lifting points are identified by lifting decals. Lifting at other points is unsafe

and can damage machinery.

Procedure

275-326

Power Pack

Use a crane capable of supporting 1500 lb (680

kg). Attach lifting device to corners and lift as

shown.

CMW

®

MV800 Operator’s Manual Transport - 39

j04omo33t.eps

2

1

Haul

Tank

Use crane capable of supporting the 2000 lb (907 kg).

Use top lift point (1) as shown. Use end lift point (2) to

drain tank if machine is disabled.

NOTICE:

• Relieve pressure in tank before storing or

transporting.

• Only lift empty water or spoils tanks.

Haul

Crushing weight could cause death or serious injury. Stay

away.

275-326

T o help avoid injury: Do not haul or move trailer unless ta nk is fully lowered and h orizontal. Damage to

machine or injury to personnel could occur.

Inspect Trailer

• Check hitch for wear and cracks. Lubricate if needed.

• Inspect lights for cleanliness and correct operation. Inspect reflectors and replace if needed.

• Check tire pressure. Check lug nut torque with a torque wrench.

• Ensure trailer brakes are adjusted to come on in synchronization with tow vehicle brakes.

CMW

®

Transport - 40 MV800 Operator’s Manual

TrailerHitchAdjust_T9.epsTrailerHitchAdjust_T9.eps

Haul

Hitch Trailer

1. Back tow vehicle to trailer.

2. Put manual transmission into first or reverse gear or automatic transmission into park. Turn off ignition.

Set parking brake.

3. Connect trailer drawbar, lunette or coupler to

tow vehicle hitch and lock in place with lock

pin. If needed, adjust drawbar, lunette or

coupler height (shown) to level load.

4. Connect safety chains to tow vehicle chain

keepers (cross-shaped slots on bumper of

tow vehicle). Attach left chain to right side of

tow vehicle and vice versa to cradle hitch. Do

not connect to pintle hook or hitch ball.

5. Connect breakaway switch cable to tow

vehicle. Do not connect to pintle hook or hitch

ball.

6. Plug trailer electrical connector into tow

vehicle connector.

7. Use jack crank to raise jack base and stow.

8. Remove wheel blocks.

Unhitch Trailer

1. Stop tow vehicle and trailer on level ground.

2. Put manual transmission into first or reverse gear or automatic transmission into park. Turn off ignition.

Set parking brake.

3. Block trailer wheels.

4. To unhitch trailer from tow vehicle, reverse “Hitch Trailer“ steps.

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 41

Vacuum and Pothole

Chapter Contents

Connect Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Determine Tank Fill Level . . . . . . . . . . . . . . . . . . . 43

• 800-gal Vacuum Tank on T14MV Trailer . . . . . . . . . . . . . . . . . . . . . . . .43

Start Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

• Standard Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Remove Debris . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Pothole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Drain Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Unload to Another Tank . . . . . . . . . . . . . . . . . . . . 50

Open/Close Tank Door . . . . . . . . . . . . . . . . . . . . . 52

• Standard Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

• Hydraulic Door (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

CMW

®

Vacuum and Pothole - 42 MV800 Operator’s Manual

Connect Hoses

Connect Hoses

1. Remove vacuum hoses from storage.

2. If potholing, remove 2-in-1 potholing tool or basic potholing tool from storage.

3. Connect hoses. Secure all locking clamps.

4. Ensure drain/outlet valve is closed.

5. If potholing, connect water pressure hose.

2-in-1 Tool Basic Tool

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 43

Determine Tank Fill Level

Determine Tank Fill Level

Use these reference charts to help determine how full of various ma terials the va cuum t ank ca n be without

overloading trailer. Exceeding the maximum fill level will overload the trailer.

Never exceed the trailer capacity. You can exceed the vacuum tank lifting capacity if you drain the tank

down to the lifting capacity before lifting tank.

To use these charts, first select the appropriate table based on trailer and vacuum tank size. Next find the

material being excavated. If the material being excavated is not listed, find a material with similar density.

Then, determine the maximum fill level based on the amount of water in the water tank.

IMPORTANT: For all materials, the vacuum tank should be no more than half full when lifting the tank.

800-gal Vacuum Tank on T14MV Trailer

Material Maximum Vacuum Tank Fill

Level

Water tank fill level full (100 gal) empty (0 gal)

wood chips (dry) 100% 100%

snow (dry) 100% 100%

water 100% 100%

light weight mud (8-10 lb/gal) 100% 100%

earth (dry, loose) 100% 100%

caliche 93% 100%

earth, loam 93% 100%

medium weight mud (10-12 lb/gal) 88% 98%

limestone (crushed) 76% 84%

asphalt 72% 80%

sand (dry) 72% 80%

earth (wet, excavated) 72% 80%

heavy weight mud (12-15 lb/gal) 72% 79%

gravel (dry) 70% 78%

shale, riprap 69% 76%

sand (wet) 56% 62%

CMW

®

Vacuum and Pothole - 44 MV800 Operator’s Manual

Start Unit

Start Unit

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

Standard Procedure

1. Open tank inlet valve.

NOTICE: Avoid idling engine with inlet valve closed.

2. If equipped with reverse flow, ensure vacuum is in “vacuum” mode before starting.

3. Insert key.

4. Turn key clockwise. See page 20 for more information.

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 45

Remove Debris

Remove Debris

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

Procedure

1. Position vacuum hose in area to be excavated.

2. Start engine.

Vacuum can suffocate. Keep hose end away from

face.

273-205

Fire or explosion possible. Do not vacuum

flammable or combustible substances.

273-483

Read operator’s manual. Know how to use all

controls. Your safety is at stake.

To help avoid injury: Do not excavate hazardous or toxic materials. Unit is designed to excavate

only soil cuttings, drilling fluids, and other non-toxic waste.

3. Open inlet valve.

NOTICE: Avoid idling engine with inlet valve closed.

4. Use sight glasses to monitor debris level in tank. V acuum will shut off when tank is full but always heed

trailer and tank lifting capacities as indicated on page 43. Engine will remain running.

273-475

CMW

®

Vacuum and Pothole - 46 MV800 Operator’s Manual

Pothole

Pothole

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

1. Start engine.

Vacuum can suffocate. Keep hose end away from

face.

273-205

Fire or explosion possible. Do not vacuum

flammable or combustible substances.

273-483

2. Open inlet valve.

NOTICE: Avoid idling engine with inlet valve closed.

3. Open water tank valve.

4. Move water pump switch to on.

5. Position tool over area to be excavated and begin pothole.

Jobsite hazards could cause death or serious

injury. Use correct equipment and work methods. Use and maintain

proper safety equipment.

274-050

To help avoid injury: Do not direct water lance at overhead lines. Water conducts electricity.

2-in-1 Tool Basic Tool

• Squeeze water pressure lever to start

water pressure.

• Work pressurized water in a rocking or

circular motion to loosen and excavate soil

until hole is at the desired diameter and

depth.

• First use water lance to loosen soil.

• Work tool in a rocking or circular motion to

excavate soil.

• Use water lance and tool alternately until

hole is at the desired diameter and depth.

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 47

Pothole

6. Adjust water pressure as needed to match soil conditions and/or material of utility being exposed.

Jobsite hazards could cause death or serious injury.

Use correct equipment and work methods. Use and maintain proper

safety equipment.

To help avoid injury: Test water pressure on a sample of the utility line material to be exposed.

Adjust pressure until no damage occurs to the material. High pressure water can cut utility lines.

severe injury. Refer to operator’s manual for proper use.

Ensure that water sprays from nozzle in a fan pattern. If it does not, nozzle may be clogged and pump

will not function properly. Clean or replace nozzle as necessary .

274-050

Pressurized fluid or air could pierce skin and cause

270-6035

7. When freshwater tank is empty, stop operation and turn water pump switch to off.

NOTICE: Do not continue to operate with freshwater tank empty. Running water pump with no

water will damage pump.

CMW

®

Vacuum and Pothole - 48 MV800 Operator’s Manual

Drain Tank

Drain Tank

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

1. Ensure that unit is hitched to vehicle. See “Hitch Trailer” on page 40.

2. Haul unit to approved dumping area

Read operator’s manual. Know how to use all

controls. Your safety is at stake.

To help avoid injury:

•Do not unhitch unit from tow vehicle before or during dumping. A freestanding unit can

become unstable when tilting tank.

• Do not unlatch door with tank tilted up.

273-475

Use breathing protection when exposed to silica

dust.

270-4952

NOTICE: Do not drive with tank or door raised.

3. Open drain/outlet valve and inlet valve.

4. Allow tank to drain in the horizontal position until

tank is approximately half drained. Monitor sight

glasses.

5. When tank is half drained, start engine and run at

low idle.

6. Tilt tank up to help flush solids from tank.

7. Lower tank to the full horizontal position.

8. Close drain/outlet valve and inlet valve.

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 49

Drain Tank

9. If further draining is necessary, open tank door. See “Open/Close Tank Door” on page 52.

Crushing weight could cause death or serious

injury. Stay away.

To help avoid injury: Use tools (provided with unit) if unit must be

serviced with tank door up.

10. Tilt tank up fully. Allow tank to drain completely.

11. Connect water pressure hose to water lance.

12. Turn water pump switch on. Adjust water pressure.

13. Use water lance to thoroughly rinse inside of tank

and around door seal.

273-200

275-326

Confined space will cause suffocation. Use

proper procedures for entering or stay away.

To help avoid injury: Enter tank only if

necessary. Follow U.S. Department of Labor

guidelines for entering confined spaces.

14. Return tank to the fully lowered horizontal position.

15. Close tank door. See “Open/Close Tank Door” on page 52.

CMW

®

Vacuum and Pothole - 50 MV800 Operator’s Manual

j33om059h.eps

Unload to Another Tank

Unload to Another Tank

Optional reverse flow mode can be used to transfer vacuumed material to another tank or disposal site.

Read operator’s manual. Know how to use all controls.

Your safety is at stake.

To help avoid injury:

• Keep unit in “vacuum” mode unless pressure is needed.

• Restrain hose prior to pressurization. Unrestrained hose may cause property damage, injury or

death.

• Do not open fitting cams or valves when tank is pressurized. Fl ying debris, plugs and doors can

cause injury or death.

• Do not open tank door while tank is pressurized.

273-475

• Do not use pressure to clear clogs in vacuum hose.

IMPORTANT: Check relief valve as shown

before each use.

1. Throttle down completely and turn off engine. Securely connect transfer hose to vac tank. Ensure

drain/outlet valve on vac tank is closed.

2. Securely connect other end of transfer hose to offboard tank. Ensure inlet valve on offboard tank is

closed and tank is vented.

3. Open vac tank drain/outlet valve. Material will flow into transfer hose.

4. Open offboard tank inlet valve.

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 51

Unload to Another Tank

5. Move valve handle counterclockwise to engage “reverse flow” mode and start engine. Material will flow

into offboard tank.

6. Increase throttle as desired to transfer material.

7. When transfer is complete, throttle down completely and turn off engine. Close vac tank drain/outlet

valve.

8. Close offboard tank inlet valve and disconnect hose from offboard tank inlet valve.

9. Move handle clockwise to “vacuum” mode and turn on engine.

10. Open vac tank drain/outlet valve. Material will empty from transfer hose.

11. Close vac tank drain/outlet valve, throttle down and turn off engine.

12. Disconnect transfer hose from vac tank.

CMW

®

Vacuum and Pothole - 52 MV800 Operator’s Manual

Open/Close Tank Door

Open/Close Tank Door

Standard Door

Open

Crushing weight could cause death or serious injury. Stay

away.

To help avoid injury: Do not raise tank with door held closed only by vacuum. Door may suddenly

open and possibly injure someone.

NOTICE: Do not drive with tank or door raised.

IMPORTANT: Depressurize tank before emptying vacuum air filter canister, cleaning filter, clearing

hoses or opening any doors.

275-326

1. If using optional reverse flow mode, turn off

engine and ensure handle is down (in

“vacuum” mode).

2. If tank is tilted, lower tank fully before opening

door.

3. Open tank inlet valve.

4. Turn handles (1) coun terclockwise until door

latches are free. Rotate latches away from

tank.

Close

1. Close door.

2. Close tank inlet valve.

3. Pull stop pin (2) up and rotate door latches toward tank.

4. Turn handles (1) clockwise until door touches seal on both sides.

5. Repeat tightening until both door latches are tight.

CMW

®

MV800 Operator’s Manual Vacuum and Pothole - 53

Open/Close Tank Door

Hydraulic Door (Optional)

Open

Crushing weight could cause death or serious injury. Stay

away.

To help avoid injury: Do not raise tank with door held closed only by vacuum. Door may suddenly

open and possibly injure someone.

NOTICE: Do not drive with tank or door raised.

IMPORTANT: Depressurize tank before emptying vacuum air filter canister, cleaning filter, clearing

hoses or opening any doors.

1. If using optional reverse flow mode, turn off

engine and ensure handle is down (in

“vacuum” mode).

275-326

2. If tank is tilted, lower tank fully before opening

door.

3. Open tank inlet valve.

4. Turn handles (1) coun terclockwise until door

latches are free. Rotate latches away from

tank.

5. Set hydraulic function valve to door position.

6. Push top button on tethered control to open

door.

7. Ensure door lift latch (1) engages properly.

Door lift latch should be fully seated on pin (2).

CMW

®

Vacuum and Pothole - 54 MV800 Operator’s Manual

Open/Close Tank Door

Close

1. Fully open door to disengage optional door lift

latch (1) from pin (2). Latch cover (3) must be

down for tank door to close.

2. Close door.

3. Close tank inlet valve.

4. Pull stop pin (2) up and rotate door latches

toward tank.

5. Turn handles (1) clockwise until door tou ches

seal on both sides.

6. Repeat tightening until both door latches are

tight.

CMW

®

MV800 Operator’s Manual Complete the Job - 55

Complete the Job

Chapter Contents

Antifreeze Fluid Excavation Unit . . . . . . . . . . . . . 56

• Add Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

• Reclaim Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Rinse Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Stow Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

CMW

®

Complete the Job - 56 MV800 Operator’s Manual

Antifreeze Fluid Excavation Unit

Antifreeze Fluid Excavation Unit

Add Antifreeze

Follow these steps for overnight or long-term storage of unit during cold weather.

1. Fill antifreeze tank with a propylene-glycol based antifreeze.

2. Ensure that water tank valve is closed.

3. Open antifreeze tank valve.

4. Connect water pressure hose to water lance.

5. Start engine.

6. Move water pump switch to on. If freshwater tank is empty, move to bypass.

7. Squeeze water lance handle and run until antifreeze runs through the water lance.

8. Move water pump switch to off.

9. Close antifreeze tank supply valve.

10. Turn ignition switch to off.

11. Drain water tank completely.

Reclaim Antifreeze

1. Turn wate r pressure down.

2. Move water pump switch to on.

3. Put end of water lance in antifreeze tank.

4. Squeeze water lance handle and run until water comes out of lance.

5. Move water pump switch to off.

CMW

®

MV800 Operator’s Manual Complete the Job - 57

Rinse Equipment

Rinse Equipment

Pressurized fluid or air could pierce skin and cause

severe injury. Refer to operator’s manual for proper use.

Spray wate r onto equipmen t to remove d irt and mud. Us e water lance . Thoroughly rins e inside of tank and

around door seal

Confined space will cause suffocation. Use proper

procedures for entering or stay away.

To help avoid injury: Enter tank only if necessary. Follow U.S. Department of Labor guidelines for

entering confined spaces.

273-200

270-6035

NOTICE: Do not spray water onto operator’s console. Electrical components could be damaged. Wipe

down instead.

Disconnect

Disconnect and store the following hoses and cables (if used):

• vacuum hoses

• water pressure hose

Stow Tools

Make sure potholing tools, water lance, and other tools ar e properly stowed.

CMW

®

Complete the Job - 58 MV800 Operator’s Manual

Stow Tools

CMW

®

MV800 Operator’s Manual Service - 59

Service

Chapter Contents

Service Precautions . . . . . . . . . . . . . . . . . . . . . . . . 60

Recommended Lubricants/Service Key . . . . . . . . 62

Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

50 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

100 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1000 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2000 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

As Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

200 Mile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3,000 Mile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12,000 Mile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

CMW

®

Service - 60 MV800 Operator’s Manual

FX_Tank_Raised.epsFX_Tank_Raised.eps

Service Precautions

Service Precautions

Read operator’s manual. Know how to use all controls.

Your safety is at stake.

To help avoid injury:

• Unless otherwise instructed, all service should be performed with engine off.

• Refer to engine manufacturer’s manual for engine maintenance instructions.

Working Under Raised Debris Tank

Crushing weight. Place cylinder lock on extended cylinder

and secure.

273-231

273-475

1. Raise vacuum tank.

2. Remove cylinder lockout tools.

3. Place channel of lock around extended cylinders

and secure.

4. Lower vacuum tank until load is supported by

cylinder lockout tools.

CMW

®

MV800 Operator’s Manual Service - 61

Service Precautions

Working Under Raised Tank Door

Crushing weight could cause death or serious injury. Stay

away.

275-326

Standard Door

Do not work under raised tank door.

Hydraulic Door (Optional)

1. Raise tank door.

2. Ensure latch engages fully.

Welding Precaution

NOTICE: Welding can damage electronics.

• Disconnect battery to prevent damage to battery. Do not turn off battery disconnect switch with

engine running, or alternator and other electronic devices may be damaged.

• Connect welder ground clamp close to welding point and make sure no electronic components are

in the ground path.

• Always disconnect the Engine Control Unit ground connection from the frame, harness conne ctions

to the ECU, and other electronic components prior to welding on machine or attachments.

Washing Precaution

NOTICE: W ater can damage electronics. When clean ing equipment, do not spray electrical component s

with water.

CMW

®

Service - 62 MV800 Operator’s Manual

Recommended Lubricants/Service Key

Recommended Lubricants/Service Key

Item Description

GEO Gasoline engine oil meeting API service classification CF-4 or E1-96 and SAE viscosity

recommended by engine manufacturer (SAE 15W40)

SGL Synthetic gear oil (ISO 100), cmw p/n 256-044

MPG Multipurpose grease meeting ASTM D217 and NLGI 5

HTG High temperature, NLGI #2 premium grade, petroleum-based grease with high

temperature resistance and good mechanical stability

NDO 30W non-detergent oil

THF

DOT DOT 3 or 4 brake fluid

Proper lubrication and maintenance protects Ditch Witch® equipment from damage and failure. Service

intervals listed are for minimum requirements. In ex treme conditions, service machine more frequently.

Use only recommended lubricants. Fill to capacities listed in “Specifications” on page 93.

For more information on engine lubrication and maintenance, see your engine manual.

NOTICE:

• Use only genuine Ditch Witch parts, filters, approved lubricants, TJC, and approved coolants to

maintain warranty.

• Use the “Service Record” on page 101 to record all required service to your machine.

Tractor hydraulic fluid, similar to Phillips 66

®

Hydraulic Fluid, Texaco

Check level of fluid or lubricant Check condition

Filter Change, replace, adjust, service or

TDH Oil, or equivalent.

®

HG, Mobilfluid® 423, Chevron® Tractor

test

CMW

®

MV800 Operator’s Manual Service - 63

-20

20

40

60

80 100

0

F

C

-30 -20

10 0 10 20 30 40

SAE 10W-30

SAE 5W-30

Synthetic SAE 5W-30

SAE 30

j32om079t.eps

Temperature range anticipated before next oil change

Recommended Lubricants/Service Key

Engine Oil Temperature Chart

IMPORTANT: If temperature is below 40°F (4°C), using SAE 30 will result in hard starting. If

temperature is above 80°F (27°C), using 10W-30 can cause increased oil consumption. Check oil level

more frequently.

CMW

®

Service - 64 MV800 Operator’s Manual

Each Use

Each Use

Location Task Notes

Trailer Check torque of hitch bolts and verify proper hitch

height

Check tire pressure and lug nut torque 80 psi (5.5 bar);

Check lights and reflectors

Trailer

Check Hitch Bolts and Verify Proper

Hitch Height

Check that trailer hitch bolts are properly

tightened. Tighten bolts to 160 ft•lb (217 N•m).

Verify that hitch is at the proper height to avoid

adding excess load on axle and wheels.

160 ft•lb (217 N•m)

90-120 ft•lb (122-163 N•m)

Check Trailer Tire Pressure and

Lug Nut Torque

Check tire pressure (2) and lug nut (1) torque.

See below for correct pressure and torque.

Pressure Torque

80 psi (5.5 bar) 90-120 ft•lb (122-163 N•m)

®

CMW

MV800 Operator’s Manual Service - 65

Each Use

Check Trailer Lights and Reflectors

Check lights and reflectors for correct operation

and cleanliness.

CMW

®

Service - 66 MV800 Operator’s Manual

10 Hour

10 Hour

Location Task Notes

VACUUM

SYSTEM

DEBRIS

TANK

Check engine air filter service indicator

Check engine oil level GEO

Check hydraulic hoses

Check hydraulic fluid level THF

Check blower oil level SGL

Check blower belt tension

Check water pump oil level NDO

Clean water pump filter

Check tension of water pump belts

Clean vacuum air filter

Check spray nozzle

Drain vacuum air filter canister

Check strobe light

Check vacuum tank door seals/fittings

Check tank deflector

CMW

®

MV800 Operator’s Manual Service - 67

10 Hour

Vacuum System

Check Engine Air Filter

Check air filter every 10 hours. Press dust ejector

valve to release dust. Change air filter elements

when air filter restriction indicator (1) reache s the

red zone.

NOTICE: Only open the air filter canister when

air restriction is indicated. Change the elements,

do not attempt to clean them.

• Compressed air or water may damage filter

element.

• Tapping filter elements to loosen dirt may

damage the element.

.To change:

1. Remove air filter cover and remove element.

2. Wipe inside of housing and wash cover.

3. Insert new element.

4. Replace cover.

Check Engine Oil Level

While engine oil is warm, check oil level at dipstick

(2) every 10 hours. Add GEO at fill (1) as necessary

to keep oil level at highest line on dipstick.

CMW

®

Service - 68 MV800 Operator’s Manual

10 Hour

Check Hydraulic Hoses

Pressurized fluid or air could pierce skin and cause severe

injury. Refer to operator’s manual for proper use.

To help avoid injury:

• Before disconnecting a hydraulic line, turn engine off and operate all controls to relieve pressure.

Lower, block, or support any raised component with a hoist. Cover connection with heavy cloth and

loosen connector nut slightly to relieve residual pressure. Catch all fluid in a container.

• Before using system, check that all connections are tight and all lines are undamaged.

• Use a piece of cardboard or wood, rather than hands, to search for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a doctor familiar with this type of injury.

270-6035

Check hydraulic hoses for leaks every 10 hours.

CMW

®

MV800 Operator’s Manual Service - 69

10 Hour

Check Hydraulic Fluid Level

Check hydraulic fluid level every 10 hours. Maintain

fluid level at 3/4 tank when engine is off and fluid is

cool. Add THF at hydraulic fluid fill (shown) as

necessary.

Check Blower Oil Level

With frame level, check blower oil at sight glass

(3) every 10 hours. Add SGL at fill (2) as

necessary to maintain oil level at halfway point on

sight glass (3). Do not overfill.

Check Blower Belt Tension

Check belt every 10 hours for correct tension,

damage or wear. Idler pulley tensioner should be

set to 70 lb of force. Verify that the indication

marks on tensioner are in the same position as

initially set, or apply 10 lb of force to the belt and

check that deflection is .25-.375” (6-10 mm).

CMW

®

Service - 70 MV800 Operator’s Manual

10 Hour

Check Water Pump Oil Level

With frame level, check water pump oil at sight

glass (2) every 10 hours. Add NDO at fill (1) as

necessary to keep oil at halfway mark on sight

glass.

Clean Water Pump Filter

Clean water pump filter every 10 hours and

replace as needed.

1. Open filter housing.

2. Remove element and rinse housing

thoroughly with water.

3. Inspect element for signs of collapse and for

brittle or broken rubber seals on the ends of

the element. Replace as needed. See

page 83.

4. Replace element and close filter housing.

Check Water Pump Belt Tension

Check belt every 10 hours for correct tension,

®

damage or wear. Contact your Ditch Witch

dealer for adjustment or belt replacement.

To check

1. Turn ignition to STOP and remove key.

2. Apply moderate thumb pressure to belt

between pulleys.

3. Belt is properly tensioned when deflection is

.125-.25” (3-6 mm).

CMW

®

MV800 Operator’s Manual Service - 71

10 Hour

Clean Vacuum Air Filter

Use breathing

protection when

exposed to silica

dust.

270-4952

Clean filter every 10 hours or as needed.

To clean filter:

1. Remove filter from canister.

2. Run low pressure water into inside of filter.

NOTICE: Do not use high pressure water to clean filter. Filter will be damaged.

3. Allow filter to dry completely before returning to canister.

Check Spray Nozzle

Check spray nozzle every 10 hours. Ensure that

water sprays from nozzle in a fan pattern. Clean

or replace nozzle as necessary.

CMW

®

Service - 72 MV800 Operator’s Manual

10 Hour

Drain Vacuum Air Filter Canister

IMPORTANT: Depressurize tank before

emptying vacuum air filter canister, cleaning

filter, clearing hoses or opening any doors.

Drain canister at drain (2) every 10 hours or when

water is visible in sight glass (1).

Debris Tank

Check Strobe Light

Check strobe light for proper function every 10

hours. When ignition is on, strobe light should be

flashing. Repair if necessary.

CMW

®

MV800 Operator’s Manual Service - 73

10 Hour

Check Vacuum Tank Door Seals and

Fittings

Check door seal every 10 hours for wear or

damage. Repair if necessary. Check for leaks

and loose fittings every 10 hours. Repair or

replace if necessary.

Check Tank Deflector

Check tank deflector every 10 hours for buildup,

wear, or damage. Clean or replace as needed.

CMW

®

Service - 74 MV800 Operator’s Manual

50 Hour

50 Hour

Location Task Notes

VACUUM

SYSTEM

DEBRIS

TANK

Change engine oil and filter Initial service, GEO

Change fuel filters Initial service

Check battery

Check water pressure hoses

Check vacuum relief valve

Lube blower bearings

Change water pump oil Initial service, NDO

Lube tank pivot pins

CMW

®

MV800 Operator’s Manual Service - 75

50 Hour

Vacuum System

Change Engine Oil and Filter

(Initial Service)

Change engine oil and filter after 50 hours, and

every 100 hours thereafter. Drain oil (4), change

filter (3), and add 2.5 qt (2.3 L) of GEO at fill (2).

IMPORTANT: Use oil spec ified in temperature

chart found in “Recommended Lubricants/

Service Key” on page 62.

Change Fuel Filter (Initial)

Replace filter after the first 50 hours of operation,

and every 100 hours thereafter.

1. Remove filter.

2. Install new filter. Apply fuel oil thinly over the

gasket and hand-tighten.

CMW

®

Service - 76 MV800 Operator’s Manual

50 Hour

Check Battery

Keep battery clean and free of corrosion. Apply

coat of grease to cable clamps after cleaning.

In cold weather, battery loses some starting ability.

Closely watch voltmeter for signs of battery

discharge.

If battery will not hold charge, see your Ditch

®

Witch

dealer for replacement battery.

IMPORTANT: Use battery disconnect switch

when servicing, welding, and during long-term

storage.

Check Water Pressure Hoses

Check hoses every 50 hours for wear or damage.

Replace as necessary.

Check Vacuum Relief Valve

Check relief valve for proper operation every 50

hours. To check:

1. Ensure that vacuum inlet valve and drain

valve are both closed.

2. Start engine. Vacuum will start to build.

3. When vacuum goes over relief, check for

suction at the bottom of the relief air filter.

4. If suction is not present, stop engine and

change relief valve.

®

CMW

MV800 Operator’s Manual Service - 77

50 Hour

Lube Blower Bearings

Wipe two zerks clean and lube every 50 hours

with HTG. Inject grease into zerk until clean

grease comes out of relief fittings.

NOTICE: Do not inject grease too quickly.

Drive shaft seal damage could occur.

Change Water Pump Oil

Change oil after the first 50 hours of operation

and every 100 hours thereafter. Change oil more

frequently if working in dusty conditions.

• Drain at drain plug (3) while oil is warm.

• Add NDO at fill (1) until oil is at halfway mark

on sight glass (2).

Debris Tank

Lube Tank Pivot Pins

Lube two pins every 50 hours with MPG.

CMW

®

Service - 78 MV800 Operator’s Manual

100 Hour

100 Hour

Location Task Notes

VACUUM

SYSTEM

Change engine oil and filter GEO

Change fuel filters

Change blower oil initial service, SGL

Change hydraulic fluid DC unit initial service, THF

Change water pump oil NDO

Vacuum System

Change Engine Oil and Filter

(Regular Service)

Change engine oil and filter every 100 ho urs. Dr ain

oil (4), change filter (3), and add 2.5 qt (2.3 L) of

GEO at fill (2).

IMPORTANT: Use oil spec ified in temperature

chart found in “Recommended Lubricants/

Service Key” on page 62.

CMW

®

MV800 Operator’s Manual Service - 79

100 Hour

Change Fuel Filter

Replace filter every 100 hours.

1. Remove filter.

2. Install new filter. Apply fuel oil thinly over the

gasket and hand-tighten.

Change Blower Oil

Change oil after the first 100 hours of operation,

and every 1000 hours thereafter. Change oil more

frequently if working in dusty conditions.

• Drain at drain plug (4) while oil is warm.

• Add SGL at fill (2) until oil is at halfway point

on sight glass (3).

CMW

®

Service - 80 MV800 Operator’s Manual

100 Hour

Change Hydraulic Fluid

Change hydraulic fluid after the first 100 hours, and

every 1000 hours thereafter. Drain hydraulic fluid

(2), add THF at hydraulic fluid fill (1) and check

level.

Change Water Pump Oil

Change oil after the first 25 hours of operation

and every 100 hours thereafter. Change oil more

frequently if working in dusty conditions.

• Drain at drain plug (3) while oil is warm.

• Add NDO at fill (1) until oil is at halfway mark

on sight glass (2).

CMW

®

MV800 Operator’s Manual Service - 81

1000 Hour

1000 Hour

Location Task Notes

VACUUM

SYSTEM

Change blower oil SGL

Change hydraulic fluid THF

Vacuum System

Change Blower Oil

Change oil every 1000 hours. Change oil more

frequently if working in dusty conditions.

• Drain at drain plug (4) while oil is warm.

• Add SGL at fill (2) until oil is at halfway point

on sight glass (3).

Change Hydraulic Fluid

Change hydraulic fluid every 1000 hours. Drain

hydraulic fluid (2), add THF at hydraulic fluid fill (1)

and check level.

CMW

®

Service - 82 MV800 Operator’s Manual

2000 Hour

2000 Hour

Location Task Notes

VACUUM

SYSTEM

Replace water pump belts

Replace blower belt

Vacuum System

Replace Water Pump Belts

Replace belt every 2000 hours.

Replace Blower Belt

Replace belt every 2000 hours.

CMW

®

MV800 Operator’s Manual Service - 83

As Needed

As Needed

Location Task Notes

VACUUM

SYSTEM

DEBRIS

TANK

Change water pump filter

Lube blower for longterm storage

Change blower relief air filter

Check battery

Clean primary shutoff valve

Vacuum System

Change Water Pump Filter

1. Open filter housing.

2. Remove element and rinse housing

thoroughly with clean water.

3. Install new element and close filter housing.

Lube Blower for Long-term Storage

Lubricate blower before long-term storage to help

prevent rust and seizing.

1. Remove filter.

2. Start engine.

3. Spray light oil into port and ru n unit for 1-2

minutes.

4. Turn off engine.

CMW

®

Service - 84 MV800 Operator’s Manual

As Needed

Change Blower Relief Air Filter

Check air filter whenever vacuum gauge goes

over 16” (406 mm) of mercury. Change as

needed.

NOTICE: Operating system above 16” (406

mm) of mercury may result in blower damage.

1. Remove clamp.

2. Remove filter and discard.

3. Install new filter .

4. Replace clamp.

Lube Reverse Flow 4-Way Valve

Lube reverse flow 4-way valve at zerk (shown)

with MPG as needed. Also open left access panel

of power unit and lube zerk on other side of valve.

CMW

®

MV800 Operator’s Manual Service - 85

As Needed

Check Battery

Check battery as needed. Keep battery clean and

terminals free of corrosion.

To clean:

1. Turn battery disconnect switch, if equipped, to

the off position.

2. Ensure that no ignition sources are near

batteries.

3. Loosen and remove battery cable clamps

carefully, negative (-) cable first.

4. Clean cable clamps and terminals to remove

dull glaze.

5. Check for signs of internal corrosion in cables.

6. Apply MPG to terminals after cleaning to reduce corrosion.

7. Connect battery cable clamps, positive (+) cable first.

8. Tighten any loose connections.

9. Ensure that battery tiedowns are secure.

10. Turn battery disconnect switch to the on position.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully .

To help avoid injury: Do not create sparks and do not short across battery terminals for

any reason.

CMW

®

Service - 86 MV800 Operator’s Manual

As Needed

Charge Battery

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

To help avoid injury:

• Use a single 12V maximum source for charging. Do not connect to rapid chargers or dual batteries.

• Use caution and wear personal protective equipment such as safety eyewear, when charging or

cleaning battery.

• Keep sparks, flames, and any ignition source away from batteries at all times. Internal contents are

extremely hazardous. Leaking fluid is corrosive. Battery may be explosive at higher temperatures.

• NEVER lean over battery when making connections.

• Do not allow vehicles to touch when charging.

• Do not attempt to charge a battery that is leaking, bulging, heavily corroded, frozen, or otherwise

damaged.

• NEVER short-circuit battery terminals for any reason or strike battery posts or cable terminals.

• Refer to MSDS for additional information regarding this battery.

Before You Start

Electronic components can be easily damaged by electrical surges. Jump starting can dam age electronics

and electrical systems, and is not recommended. Try to charge the battery instead. Use quality large

diameter jumper cables capable of carrying hig h currents ( 400 amps or more). Cheap ca bles may not allow

enough current flow to charge a dead/discharged battery.

Read all steps thoroughly and review illustration before performing procedure.

CMW

®

MV800 Operator’s Manual Service - 87

As Needed

Charging Procedure (Engine Off)

1. Park service vehicle close to disabled equipment but do not allow vehicles to touch. Engage parking

brake in both vehicles.

2. Turn the igni tion switch to the OFF position in both ve hicles, and turn off all electrical loads. Disconnect

the machine controller.

3. Inspect battery in disabled vehicle (B) for signs of cracking, bulging, leaking, or other damage.

Connect red positive (+) jumper cable clamp to positive (+) post (2) o f batter y in disab led vehicle fir st.

IMPORTANT: Some equipment may have a positive jumper cable terminal (1) located externally.

If so equipped, connect red positive (+) jumper cable clamp to terminal.

4. Connect the other red positive (+) jumper cable clamp to positive (+) post of battery (A) in the service

vehicle.

5. Connect black negative (-) cable clamp to negative (-) post of battery (A) in service vehicle.

6. Connect the other black negative (-) cable clamp to the engine or frame ground on the disabled

vehicle, at least 12” (305 mm) from the failed battery, as shown.

7. Operate service vehicle engine at 1500-2000 rpm for a few minutes to build an electrical charge in the

failed battery.

8. Stop engine in service vehicle.

9. Remove jumper cables from the service vehicle, black negative (-) clamp first. Do not allow clamps to

touch.

10. Remove black negative (-) cable clamp from the disabled engine or frame ground first.

11. Remove red positive (+) cable clamp from the disabled vehicle positive (+) battery post last.

12. Reconnect machine controller and try to start disabled vehicle.

If the disabled vehicle did not start, check for loose or corroded battery cable connectio ns. Poor

connections will prevent current from charging the failed battery. Clean terminals and posts if necessary

and repeat steps above.

CMW

®

Service - 88 MV800 Operator’s Manual

As Needed

Debris Tank

Clean Primary Shut-off Valve

Clean primary shut-off valve as needed. Replace

primary shut-off valve as needed.

To clean:

1. Open tank door. See “Drain T ank” on p age 48.

2. Spray valve housing inside vacuum tank with

high-pressure water.

3. Store water pressure hose.

4. Close tank door. See “Drain Tank” on

page 48.

To remove:

1. Remove nuts and bolts (1).

2. Remove cover (2).

3. Remove ball (3).

4. Clean ball and housing with high-pressure water.

5. Replace ball and housing.

6. Install cover and secure with nuts and bolts.

CMW

®

MV800 Operator’s Manual Service - 89

200 Mile

200 Mile

Trailer

Adjust Electric Brakes (Initial)

Adjust brakes after 200 miles (320 km).

1. Place adequate jack stands under frame rails

and remove wheels.

2. Remove cover from adjusting slot on bottom

of backing plate.

3. Rotate adjuster starwheel with screwdriver or

brake spoon to expand brake shoes. Adjust

until drum is very difficult to turn by hand.

4. Rotate starwheel the other direction until drum

turns with slight drag.

5. Replace adjusting slot cover and replace

wheel.

6. Repeat procedure for all remaining brakes.

7. Remove jack stands and lower wheels to ground.

CMW

®

Service - 90 MV800 Operator’s Manual

3000 Mile

3000 Mile

Trailer

Adjust Electric Brakes

Adjust brakes every 3000 miles (5000 km).

1. Place adequate jack stands under frame rails

and remove wheels.