MR90

Operator’s

Manual

CMW

68

®

Issue 1.0

053-2768

MR90 Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Modification . . . . . . . . . . . . . . . . . . . . . . 2

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operator Orientation. . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Bulleted Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

• Numbered Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CMW

®

Overview - 2 MR90 Operator’s Manual

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. Fluid unit serial number is located as

shown.

Item

date of manufacture

date of purchase

fluid unit serial number

engine serial number

CMW

®

MR90 Operator’s Manual Overview - 3

Intended Use

Intended Use

The MR90 is a self-contained fluid handling unit capable of mixing and recycling drilling fluid and

transferring fluid under pressure to the drilling unit. It is intended for operation in ambient temperatures

from 32° to 115°F (0° to 46°C). Use in any other way is considered contrary to the intended use.

The MR90 can be used with Ditch Witch

by persons familiar with its particular characteristics and acquainted with the relevant safety procedures.

®

drilling units. It should be operated, serviced, and repaired only

Equipment Modification

This equipment was designed and built in accordance with applicable standards and regulations.

Modification of equipment could mean that it will no longer meet regulations and may not function properly

or in accordance with the operating instructions. Modification of equipment should only be made by

competent personnel possessing knowledge of applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

CMW

®

Overview - 4 MR90 Operator’s Manual

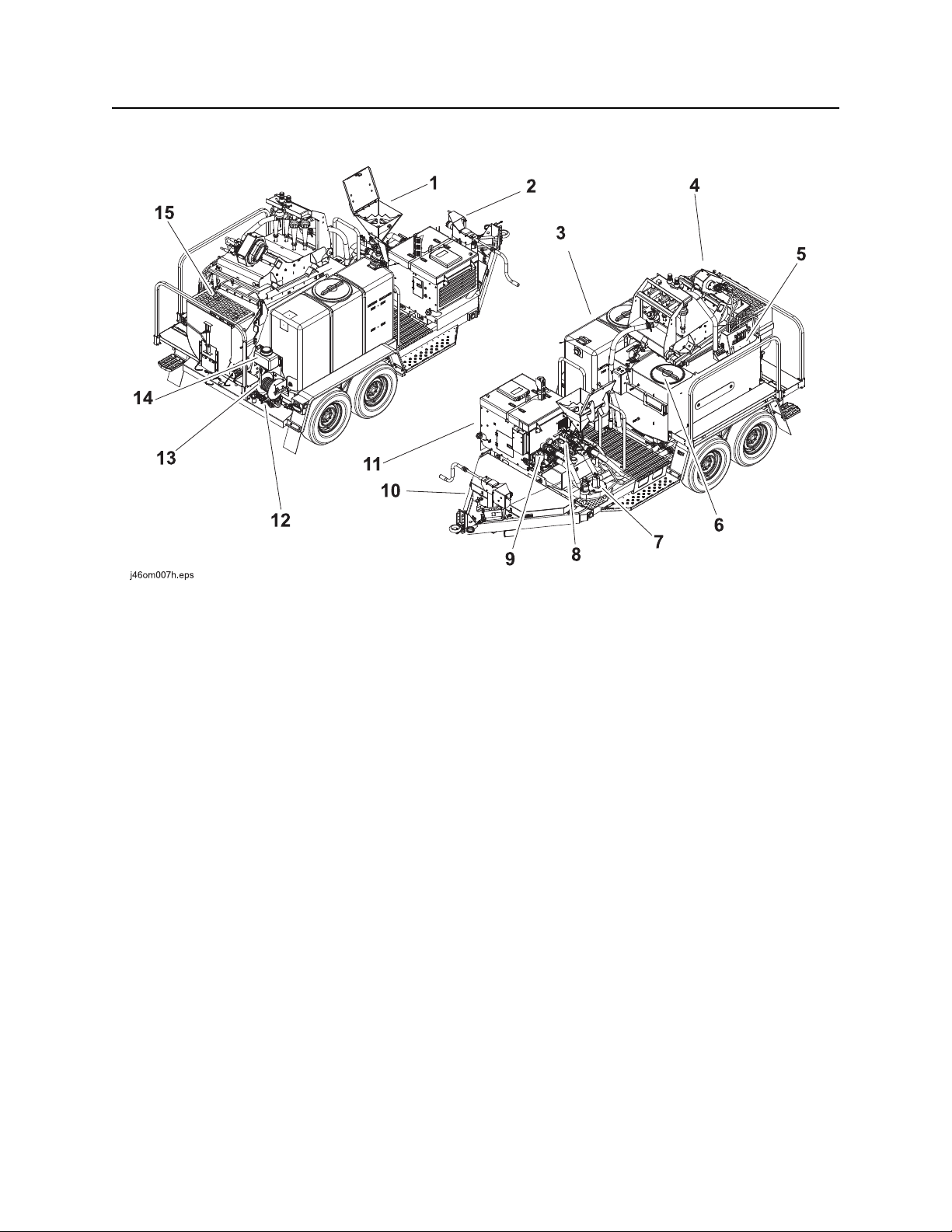

Unit Components

Unit Components

1. Mixing hopper

2. Hydraulic jack

3. Fresh water tank (300 gallon)

4. Shaker

5. Operator station

6. MR90 tank

7. Pit pump

8. Mix/supply pump

9. Cleaning pump

10. T14 trailer

11. FM25h power unit

12. Water pump

13. Hose reel

14. Antifreeze tank

15. Spoils hopper*

*optional

CMW

®

MR90 Operator’s Manual Overview - 5

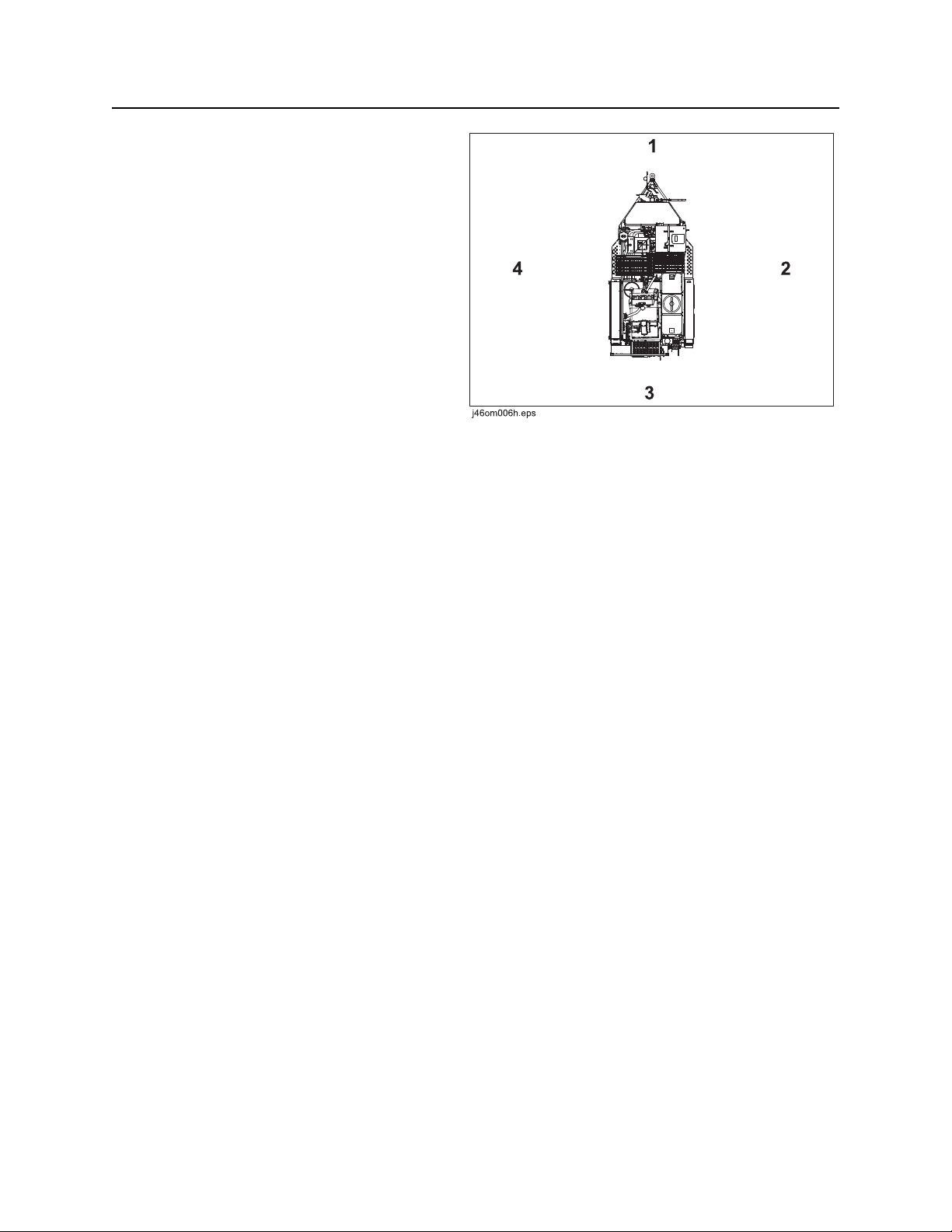

Operator Orientation

Operator Orientation

1. Front of unit

2. Right of unit

Right and left sides of machine are determined

by facing towing vehicle.

3. Rear of unit

4. Left of unit

About This Manual

This manual contains information for the proper use of this machine. See the beige Operation Overview

pages for basic operating procedures. Cross references such as “See page 50” will direct you to detailed

procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

CMW

®

Overview - 6 MR90 Operator’s Manual

About This Manual

CMW

®

MR90 Operator’s Manual Foreword - 7

Reporting Safety Defects

Foreword

This manual is an important part of your equipment. It provides safety information and operation

®

instructions to help you use and maintain your Ditch Witch

Read this manual before using your equipment. Keep it with the equipmen t at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was publishe d. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

equipment.

Thank you for buying and using Ditch Witch equipment.

Reporting Safety Defects

If you believe that your vehicle has a defect which could cau se a cr ash o r co uld ca use injury or death, you

should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to

notifying the Product Safety Coordinator at The Charles Machine Works, Inc.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists

in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become

involved in any individual problems between you, your Ditch Witch dealer, or The Charles Machine Works,

Inc.

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-888-327-4236 (TT Y: 1-800424-9153), go to http://www.safercar.gov, or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor vehicle safety from http://www.safercar.gov.

CMW

®

Foreword - 8 MR90 Operator’s Manual

Works, Inc.

MR90

Operator’s Manual

Issue number 1.0/OM-10/14

Part number 053-2768

Copyright 2014

by The Charles Machine Works, Inc.

, Ditch Witch, and CMW are registered trademarks of The Charles Machine

U.S. patents pending.

®

CMW

MR90 Operator’s Manual Contents - 9

Content s

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls, gauges, and indicators and how to use them

Prepare

procedures for inspecting the jobsite and preparing the jobsite fo r work

Transport

procedures for lifting and hauling

Handle Fluid

procedures for mixing, recycling, and transferring fluid

1

5

9

17

29

33

37

Systems and Equipment

procedures for selecting fluid additives, determining fluid requirements and fluid

measurements, and screens

Complete the Job

procedures for rinsing and storing equipment

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

Service Record

a record of major service performed on the machine

43

43

45

57

107

111

CMW

®

Contents - 10 MR90 Operator’s Manual

Appendix

additional information about your equipment

113

CMW

®

MR90 Operator’s Manual Safety - 11

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 13

• Electric Strike Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 17

Machine Safety Alerts. . . . . . . . . . . . . . . . . . . . . . . 18

CMW

®

Safety - 12 MR90 Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service. Mark proposed p ath with white paint prior to cont acting One- Call or

utilities.

• Classify jobsite based on its hazards and use cor rect tools and machin ery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch

ditchwitch.com/resources/safety .

• Replace missing or damaged safety shields and safety signs.

®

dealer or at

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about operation, ma intenance, or equipment

use.

• Complete the equipment checklist located at www.ditchwitch.com/resources/safety.

CMW

®

MR90 Operator’s Manual Safety - 13

Emergency Procedures

Emergency Procedures

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Before operating any equipment, review emergency proc edures and check that all safety precau tions have

been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote e ngine stop button ( if

equipped).

Electric Strike Description

or serious injury. Know location of lines and stay away.

274-050

Electric shock. Contacting electric lines will cause death

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

•smoke

•explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

CMW

®

Safety - 14 MR90 Operator ’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on truck or trailer, DO NOT MOVE.

Remain on truck or trailer and take the following actions. The order and degree of action will depend on the

situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Do not allow anyone into area until given permission by utility company.

• Do not allow anyone to touch equipment.

If you suspect an electric line has been damaged and you are off truck or trailer, DO NOT TOUCH

EQUIPMENT. Take the following actions. The order and degree of action will depend on the situation.

• LEAVE AREA. The ground surface may be electrified so take small shuffle steps with feet close

together to reduce the hazard of being shocked from one foot to the other.

• Contact utility company to shut off power.

• Do not return to area or allow anyone into area until given permission by utility company.

CMW

®

MR90 Operator’s Manual Safety - 15

Emergency Procedures

If a Gas Line is Damaged

Fire or explosion possible. Fumes could ignite and cause

burns. No smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

275-419 (2P)

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

CMW

®

Safety - 16 MR90 Operator ’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur. Contact utility

company.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped and accessible) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

CMW

®

MR90 Operator’s Manual Safety - 17

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates a hazardous situation that, if not avoided, will result in death or serious injury. This

signal word is to be limited to the most extreme situations.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or mo derate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

®

Safety - 18 MR90 Operator ’s Manual

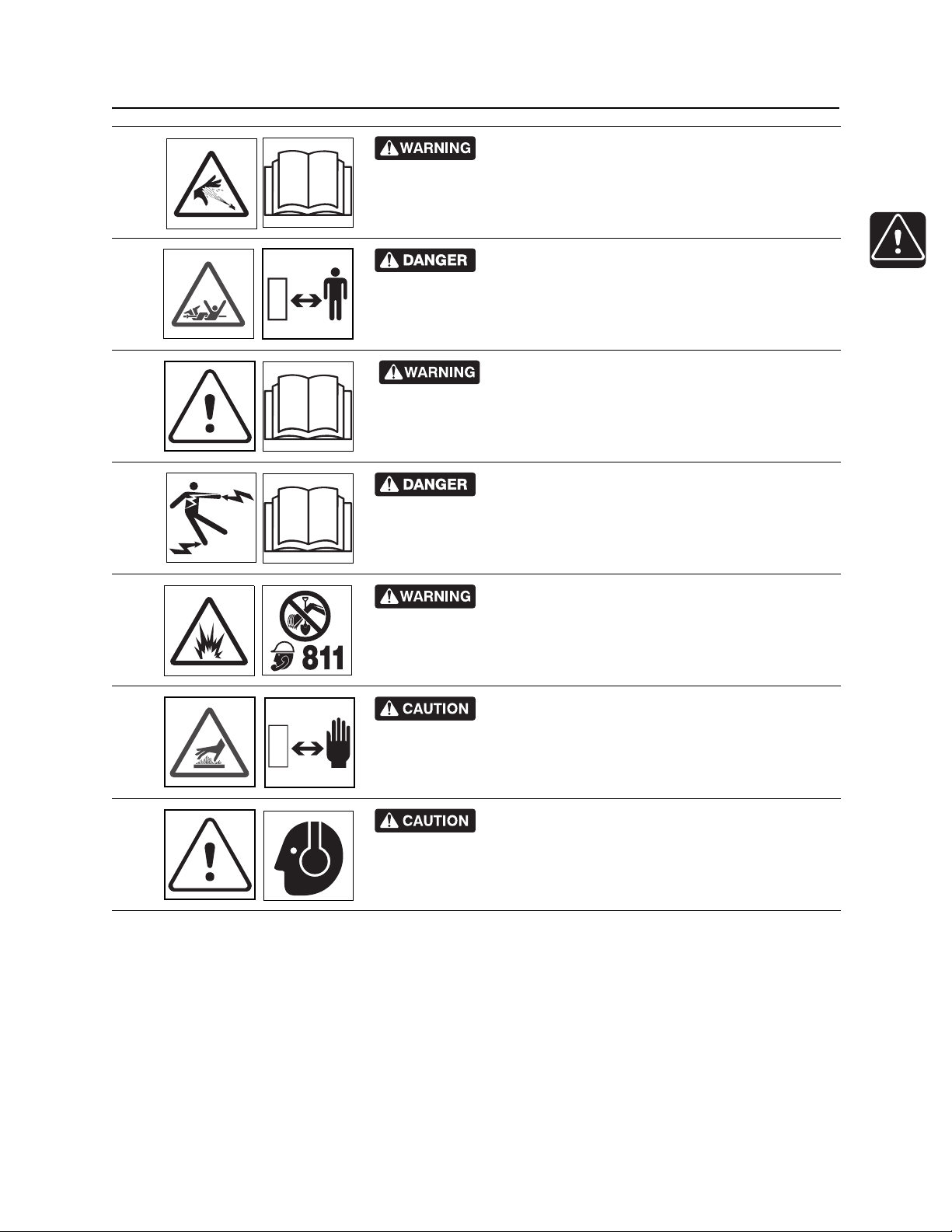

Machine Safety Alerts

Machine Safety Alerts

Moving parts could cut off hand o r foot. S tay away.

1

275-184, 273-437, 273-546

Tiedown location. See Transport chapter for more information.

274-318

2

Lift point. See Tra nsport chapter for more information.

274-442

3

CMW

®

MR90 Operator’s Manual Safety - 19

Machine Safety Alerts

Pressurized fluid or air could pierce skin and cause

4

severe injury. Refer to operator’s manual for proper use.

Rotating shaft will cause death or serious injury.

5

Stay away.

270-1506

Read operator’s manual. Know how to use all

6

controls. Your safety is at stake.

273-475

Electric shock will cause death or serious injury.

7

Fluid system could become electrified while connected to drilling

unit. Read operator’s manual and know emergency procedures.

273-265

270-6035

8

9

10

Jobsite hazards could cause death or serious

injury. Use correct equipment and work methods. Use and maintain

proper safety equipment.

274-050; 274-724 (2P)

Hot parts may cause burns. Do not touch until cool

or wear gloves.

275-355 (2-P), 273-423 (2-P)

Exposure to high noise levels may cause hearing

loss. Wear hearing protection.

700-009 (2-P)

CMW

®

Safety - 20 MR90 Operator ’s Manual

Machine Safety Alerts

CMW

®

MR90 Operator’s Manual Controls - 21

Controls

Chapter Contents

Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mixing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Recycling Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CMW

®

Controls - 22 MR90 Operator’s Manual

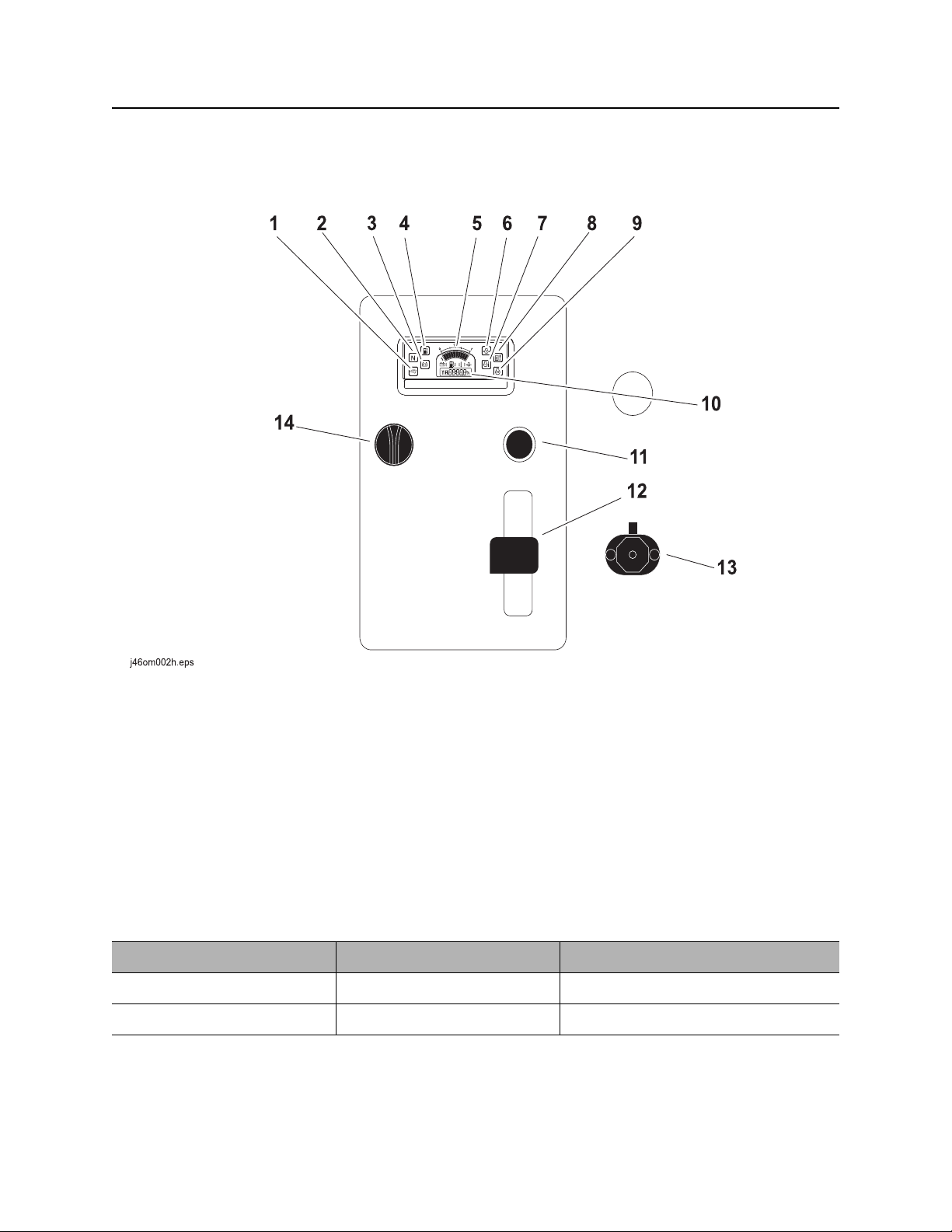

Power Unit

Power Unit

Controls and Indicators

1. Not used

2. Not used

3. Battery indicator

4. Low fuel indicator

5. Fuel gauge

6. Engine oil pressure indicator

7. Coolant temperature indicator

Item Description Notes

1. Not used

2. Not used

8. Hydraulic fluid temperature indicator

9. Glow plug indicator

10. Hourmeter

11. Cold start button

12. Throttle

13. Auxiliary outlet

14. Ignition switch

CMW

®

MR90 Operator’s Manual Controls - 23

c00ic008w.eps

Power Unit

Item Description Notes

3. Battery indicator Indicates low battery voltage.

4. Low fuel indicator Displays fuel level near

empty.

5. Fuel gauge Displays fuel level in tank. Fuel tank holds 15 gal (56.85 L).

NOTICE: Notice: Use ultra low sulfur

fuel only.

6. Engine oil pressure

indicator

Lights when engine oil

pressure falls below 8-12 psi

(.6-.8 bar).

Also lights briefly when

engine is started.

If light remains on:

• Turn off engine.

• Check oil level.

• If pressure is still low, consult

engine manual.

CMW

®

Controls - 24 MR90 Operator’s Manual

c00ic232h.eps

Power Unit

Item Description Notes

7. Coolant temperature

indicator

Lights when engine coolant

temperature is over 275°F

(135°C).

Also, lights briefly when

engine is started.

8. Hydraulic fluid

temperature indicator

Lights and alarm sounds

when hydraulic fluid is

overheating.

9. Glow plug indicator Lights when cold start button

is pressed.

If light remains on:

• Turn off engine and let unit cool.

• Check fan belt tension.

• Check for low coolant level.

• Check cooling fins for dirt and

debris.

Check hydraulic fluid level.

Reduce load.

Ensure oil cooler is clean.

10. Hourmeter Displays engine operating

time.

®

CMW

Hourmeter runs when ignition switch

is on.

Use these times to schedule service.

MR90 Operator’s Manual Controls - 25

c00ic179h.eps

Power Unit

Item Description Notes

11. Cold start button To help start cold engine, turn

ignition switch to first position.

Press cold start button as

directed in notes.

Release button, then turn

ignition switch clockwise to

start.

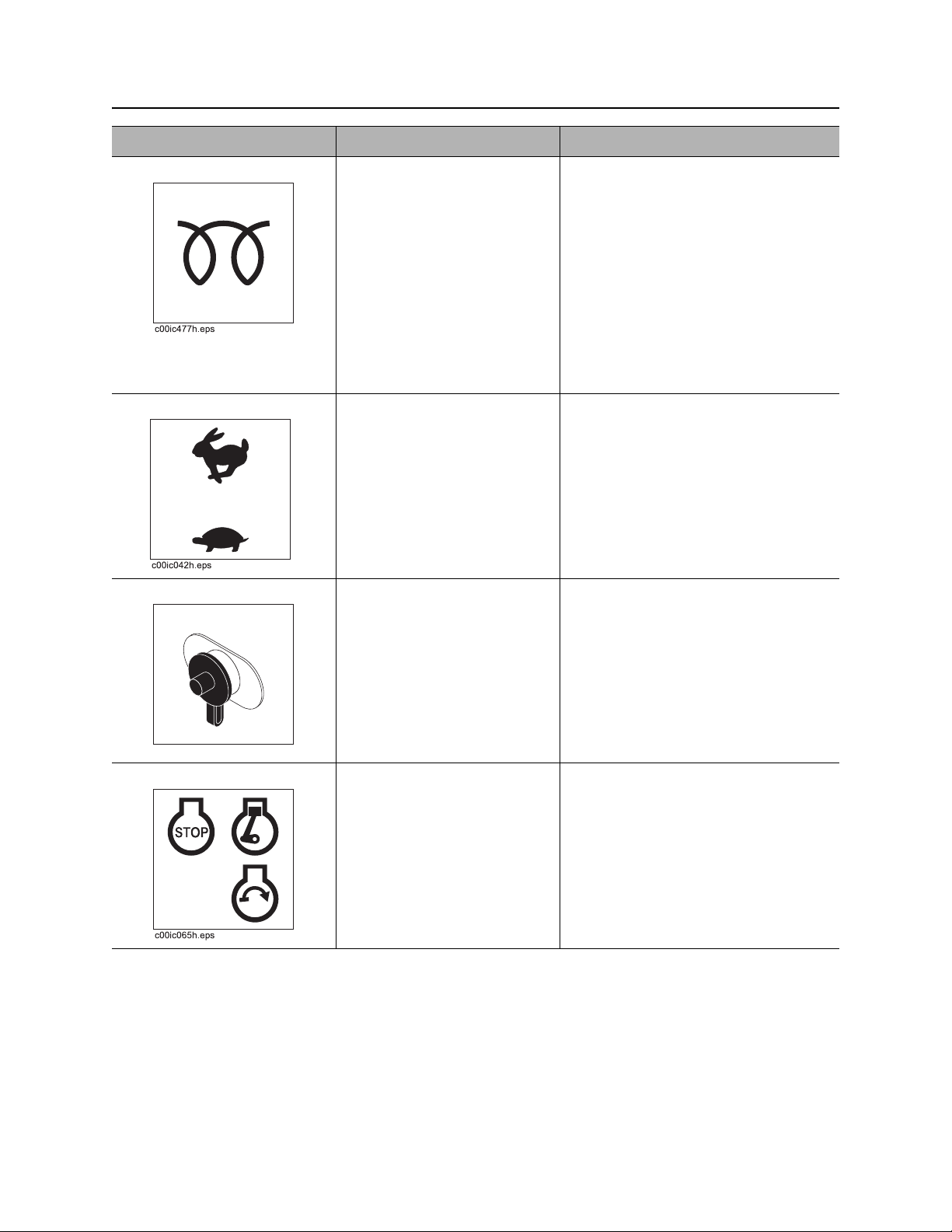

12. Throttle To increase engine speed,

move up.

To decrease engine speed,

move down.

13. Auxiliary outlet To operate work lights or

other 12V devices, plug into

outlet.

IMPORTANT: Press cold start button

according to temperatures below.

• If ambient temperature is below

40°F (4°C), press and hold button

for five seconds.

• If ambient temperature is below

20°F (-7°C), press and hold

button for ten seconds.

• Do not press for more than 20

seconds continuously.

Outlet has power only when ignition

switch is on.

14. Ig n iti o n sw itch T o star t engine, insert key and

turn clockwise.

To stop engine, turn key

counterclockwise.

CMW

®

Controls - 26 MR90 Operator’s Manual

Power Unit

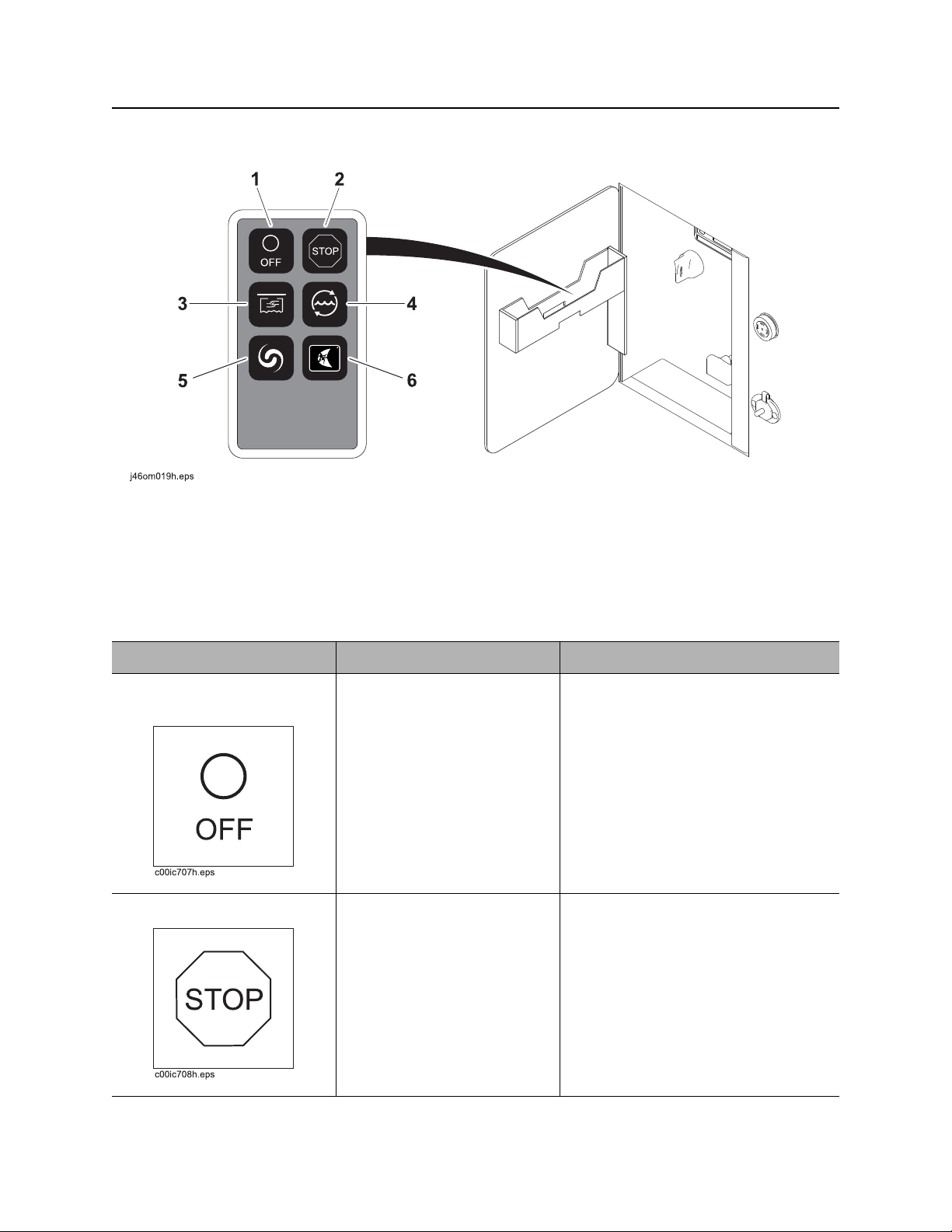

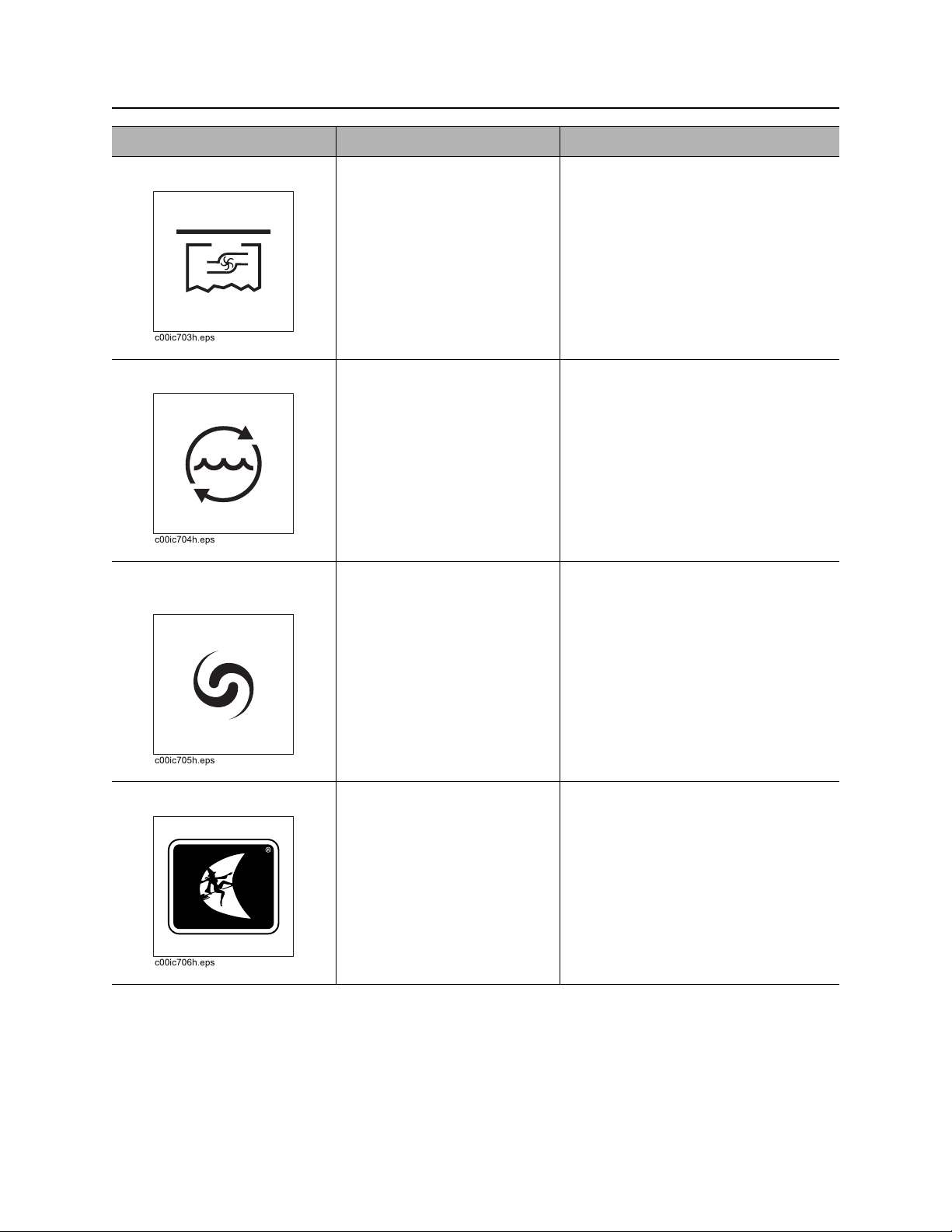

Remote Control (optional)

1. Remote control power button

2. Remote stop button

3. Pit pump button

Item Description Notes

1. Remote control power

button

2. Remote stop button To stop the engine, press.

T o turn r emote control module

off, press.

4. Cleaning pump button

5. Mix/supply pump button

6. Not used

IMPORTANT:

• Pressing any button will turn the

remote on.

• Turning the remote off does not

shut off pumps.

CMW

®

MR90 Operator’s Manual Controls - 27

Power Unit

Item Description Notes

3. Pit pump button To turn pit pump on and off,

press.

4. Cleaning pump button To turn cleaning pump on and

off, press.

5. Mix/supply pump

button

To turn mix/supply pump on

and off, press.

Pit pump control must be engaged for

the remote function to work. See “Pit

pump/pressure wash pump selector”

on page 35.

Switch at control panel must be on for

remote function to work. See

“Cleaning pump switch” on page 34.

Switch at control panel must be on for

remote function to work. See “Mix/

supply pump switch” on page 34.

6. Not used

CMW

®

Controls - 28 MR90 Operator’s Manual

Power Unit

Indicators

1. Fluid low warning light 2. Fluid full warning light

Item Description Notes

1. Fluid low warning light Amber light will flash when

volume of fluid in MR90 tank

is too low.

2. Fluid full warning light Green light will flash when

volume of fluid in dirty side of

MR90 tank is full.

IMPORTANT: This light is magnetic

and can be moved to ensure better

visibility.

IMPORTANT: This light is magnetic

and can be moved to ensure better

visibility.

CMW

®

MR90 Operator’s Manual Controls - 29

c00ic654w.eps

Power Unit

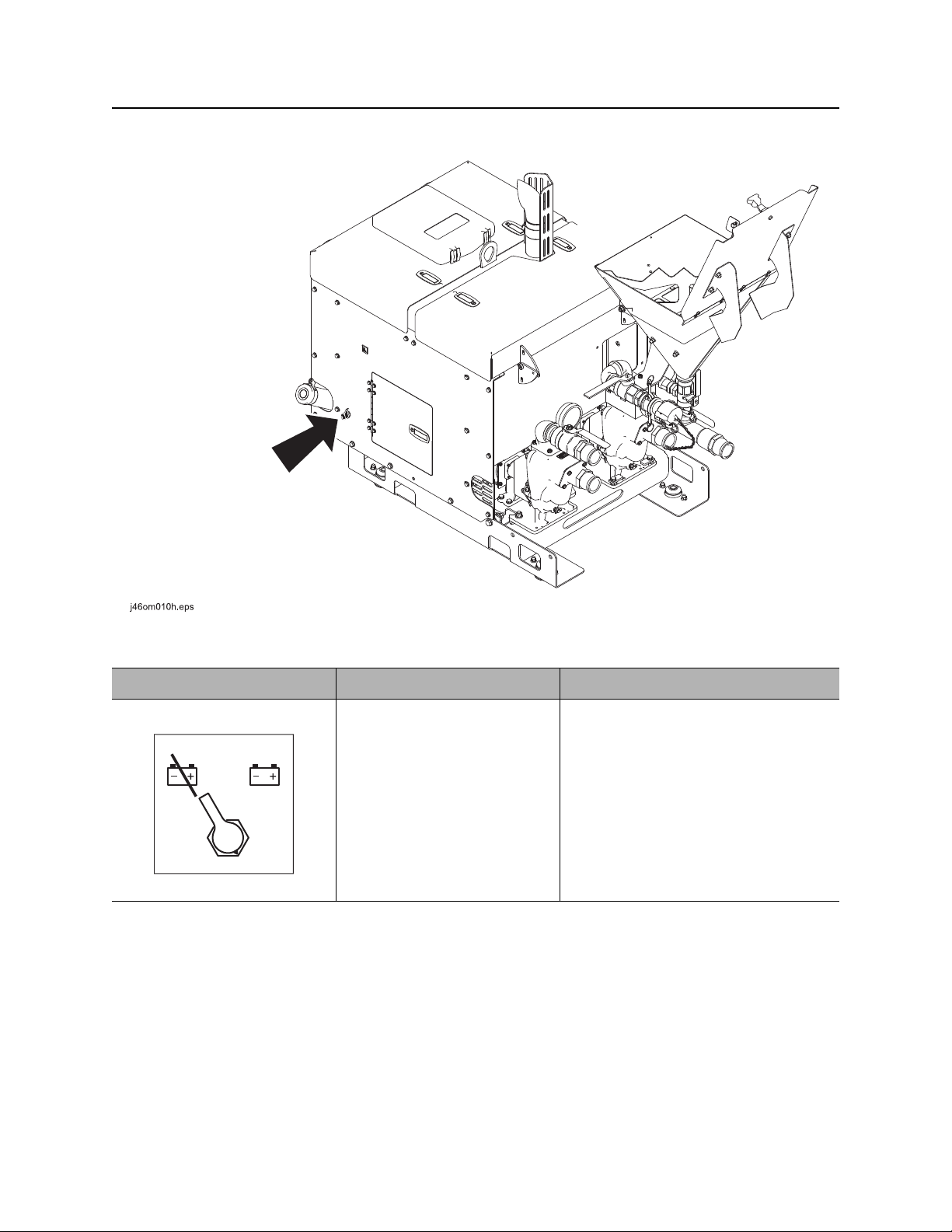

Miscellaneous

Item Description Notes

Battery disconnect switch To connect, move clockwise.

To disconnect, move

counterclockwise.

CMW

®

Controls - 30 MR90 Operator’s Manual

Mixing Unit

Mixing Unit

Gauges

Hydrocyclone pressure gauge

Item Description Notes

Hydrocyclone pressure

gauge

Indicates the pressure of fluid

moving through the

hydrocyclones.

Gauge should read 30-35 psi

(2.06-2.41 bar).

IMPORTANT:

• If gauge reads lower than 30-35

• If gauge reads higher than 30-35

psi (2.06-2.41 bar), check

hydrocyclones. See “Clean

Hydrocyclones” on page 94.

psi (2.06-2.41 bar) check the Ystrainer. See“Clean Y -S trainer” on

page 79.

CMW

®

MR90 Operator’s Manual Controls - 31

Mixing Unit

Valves

1. Fluid sample valve

2. Circulating jet valve

3. Mix hopper valve

Item Description Notes

1. Fluid sample valve To obtain a sample of drilling

fluid for testing, open valve.

2. Circulating jet valve T o circulate fluid while mixing,

open valve.

To stop circulation, close

valve.

3. Mixing hopper valve To add drilling additives to

hopper, open valve.

To stop flow of drilling

additives, close valve.

4. Venturi jet valve

5. Hydrocyclone valve

6. Drill supply valve

CMW

®

Controls - 32 MR90 Operator’s Manual

Mixing Unit

Item Description Notes

4. Venturi jet valve To allow flow from hopper to

mixing venturi, open valve.

To stop flow from hopper to

mixing venturi, close valve.

5. Hydrocyclone valve To allow air flow to operate

hydrocyclones, open valve.

To stop air flow from

hydrocyclones, close valve.

6. Drill supply valve To supply fluid to drill, open

valve.

To stop supply of fluid to drill,

close valve.

IMPORTANT:

• Open valve only when pouring

additives into hopper for mixing.

Close valve when finished.

• Do not open valve unless pump is

running and venturi jet valve is

open. Fluid could flow back into

hopper.

CMW

®

MR90 Operator’s Manual Controls - 33

Recycling Unit

Recycling Unit

Controls

1. Cleaning pump switch

2. Mix/supply pump switch

3. Pit pump auto control switch

4. Shaker control

5. Pit pump/pressure wash pump selector

6. Screen forward/rear tilt control

7. Screen left/right tilt control

8. Spoils hopper mixer control*

9. Spoils hopper door control*

10. Shaker speed control

11. Pit pump speed adjustment control

*optional

CMW

®

Controls - 34 MR90 Operator’s Manual

Recycling Unit

Item Description Notes

1. Cleaning pump switch To turn cleaning pump on,

press top.

To turn pump off, press

bottom.

2. Mix/supply pump

switch

3. Pit pump auto control

switch

4. Shaker control T o start shaker , push leve r up.

To turn mix/supply pump on,

press top.

To turn pump off, press

bottom.

To turn pit pump auto control

on, press top.

To allow manual control,

press bottom.

IMPORTANT: Leave pit pump auto

control on to reduce possibility of

over-filling dirty side of MR90 tank.

CMW

To stop shaker, pull lever

back.

®

MR90 Operator’s Manual Controls - 35

Recycling Unit

Item Description Notes

5. Pit pump/pressure

wash pump selector

6. Screen front/rear tilt

control

7. Screen left/right tilt

control

To turn pit pump on, push

lever up.

To turn pressure washer

pump on, pull lever back.

To turn pumps off, center

lever.

To raise front of screens,

push lever up.

To lower front of screens, pull

lever back.

To tilt screens to the right,

push lever up.

IMPORTANT:

• Pit pump lever must be engaged

for remote to function.

• Do not leave lever pulled back

when not using wash wand.

Damage may occur.

8. Spoils hopper mixer

control (optional)

To tilt screens to the left, pull

lever back.

To turn spoils hopper mixer

counterclockwise, push lever

up.

To turn spoils mixer

clockwise, pull lever back.

To turn spoils hopper mixer

off, center lever.

CMW

®

Controls - 36 MR90 Operator’s Manual

Recycling Unit

Item Description Notes

9. Spoils hopper door

control (optional)

10. Shaker speed control To increase shaker speed,

11. Pit pump speed

adjustment control

To raise door on back of

spoils hopper, push lever up.

To lower door on back of

spoils hopper, pull lever back.

turn counterclockwise.

To decrease shaker speed,

turn clockwise.

To increase pit pump flow,

turn clockwise.

To decrease pit pump flow,

turn counterclockwise.

CMW

®

MR90 Operator’s Manual Controls - 37

Recycling Unit

Auxiliary Controls

1. Fresh water transfer pump switch

2. Auxiliary outlet switch

Item Description Notes

1. Fresh water transfer

pump switch

To turn fresh water transfer

pump on, press top.

To turn pump off, press

bottom.

3. Auxiliary outlet

Transfers water from 300 gal tank to

the MR90 tank.

CMW

®

Controls - 38 MR90 Operator’s Manual

c00ic179h.eps

Recycling Unit

Item Description Notes

2. Auxiliary outlet switch To turn auxiliary outlet on,

press top.

To turn auxiliary outlet off,

press bottom.

3. Auxiliary outlet To operate work lights or

other 12V devices, plug into

outlet.

Outlet has power only when ignition

switch is on.

CMW

®

MR90 Operator’s Manual Controls - 39

Recycling Unit

Valves

1. Spoils hopper drain valve*

2. Antifreeze valve

3. Water drain valve

4. Dirty side tank drain valve

Item Description Notes

1. Spoils hopper drain

valve (optional)

2. Antifreeze valve To mix antifreeze into the

3. Water drain valve To drain water from fresh

4. Dirty side tank drain

valve

5. Clean side tank drain

valve

To drain spoils hopper, open

valve.

fresh water pump, open

valve.

water tank, open valve.

To drain dirty side tank, open

valve.

T o drain clea n side tank, open

valve.

5. Clean side tank drain valve

6. Fresh water control valve

7. Mud flow control valve

*Optional

CMW

®

Controls - 40 MR90 Operator’s Manual

Recycling Unit

Item Description Notes

6. Fresh water control

valve

7. Mud flow control valve To increase mud flow onto

T o transfer water from 300 gal

tank to MR90 tank, open

valve.

screens, move valve toward

open.

To decrease mud flow onto

screens, move valve toward

close.

IMPORTANT:

• Turn on with fresh water transfer

pump to transfer water to MR90

tank.

• Shut off when MR90 tank is full to

avoid overflow from dirty side tank

into fresh water tank.

CMW

®

MR90 Operator’s Manual Controls - 41

Recycling Unit

Trailer Controls

1. Hydraulic trailer jack control 2. Manual trailer jack handle

Item Description Notes

1. Hydraulic trailer jack

control

2. Manual trailer jack

handle

Push lever down to lower

front of trailer.

Pull lever up to raise front of

trailer.

Turn handle clockwise to

lower front of trailer.

Turn handle counterclockwise

to raise front of trailer.

IMPORTANT: Ensure manual trailer

jack control is disengaged.

IMPORTANT:

• Only use if hydraulic trailer jack

control will not work.

• Handle is stowed in toolbox.

CMW

®

Controls - 42 MR90 Operator’s Manual

Recycling Unit

CMW

®

MR90 Operator’s Manual Prepare - 43

Prep are

Chapter Contents

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . 44

• Arrange for Traffic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

• Prepare for Working Near Existing Utilities . . . . . . . . . . . . . . . . . . . . . .44

• Plan for Emergency Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Inspect Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Prepare Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Check Supplies and Prepare Equipment . . . . . . . 46

• Assemble Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

• Check Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

• Prepare Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

CMW

®

Prepare - 44 MR90 Operator’s Manual

Gather Information

Gather Information

A successful job begins before the excavation. The first step in planning is reviewing information already

available about the job and jobsite.

Arrange for Traffic Control

If working near a road or other traffic area, contact local authorities about safety procedures and

regulations.

Prepare for Working Near Existing Utilities

If jobsite may contain electrical lines, wear protective boots and gloves meeting the following standards:

• Boots must have high tops and meet th e electric hazard protection requirements of ASTM F2413 or

ASTM 1117, when tested at 14,000 volts. Tuck legs of pants completely inside boots.

• Gloves must have 17,000 AC maximum use voltage, according to ASTM spec ifica tio n D12 0.

If working around higher voltage, use gloves and boots with appropriately higher ratings.

Plan for Emergency Services

Have the telephone numbers for local emergency and medical facilities on hand. Check that you will have

access to a telephone.

CMW

®

MR90 Operator’s Manual Prepare - 45

Inspect Jobsite

Inspect Jobsite

• Follow U.S. Department of Labor regulations on excavating and trenching (Part 1926, Subpar t P) and

other similar regulations.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

• Inspect jobsite and perimeter for evidence of underground hazards, such as:

– “Buried utility” notices

– Utility facilities without overhead lines

– Gas or water meters

– Junction boxes

– Drop boxes

– Light poles

– Manhole covers

– Sunken ground

• Mark location of all buried utilities and obstructions.

Prepare Jobsite

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

NOTICE:

• If jobsite classification is in question or if the possibility of unmarked electric utilities exists, classify

jobsite as electric.

• Cutting high voltage cable can cause electrocution. Expose lines by hand before digging.

• All vegetation near operator’s station must be removed. Conta ct with trees, shrubs, or weeds during

electrical strike could result in electrocution.

CMW

®

Prepare - 46 MR90 Operator’s Manual

Check Supplies and Prepare Equipment

Check Supplies and Prepare Equipment

Assemble Accessories

Fire Extinguisher

If required, mount a fire extinguisher near the power unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric fires. It should meet legal and regulatory

requirements.

Check Supplies

• water and additional hoses

•fuel

• drilling fluid additives, such as bentonite and polymer

• drilling fluid measurement kit

Prepare Equipment

Fluid Levels

•fuel

• engine oil

Condition and Function

• filters (air, oil)

•tires

• hoses and valves

• couplers and fittings

• water tank

• screens

CMW

®

MR90 Operator’s Manual Transport - 47

Transport

Chapter Contents

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

• Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

CMW

®

Transport - 48 MR90 Operator’s Manual

Lift

Lift

Crushing weight. If load falls or moves it could kill or crush

you. Use proper procedures and equipment or stay away.

Points

Lifting points are identified by lifting decals. Lifting at other points is unsafe

and can damage machinery.

Procedure

Tank

Use crane capable of supporting the equipment's

size and weight. See “Specifications” on page 103

or measure and weigh equipment before lifting. Lif t

mixing tank by attaching lif ting de vices at lift points

and joining at a common lift points.

IMPORTANT: Empty tank before lifting.

Power Unit

Use crane capable of supporting the equipment's

size and weight. See “Specifications” on page 103

or measure and weigh equipment before lifting. Lif t

power unit by attaching lifting device at lift point.

CMW

®

MR90 Operator’s Manual Transport - 49

Lift

Recycling Unit

Use crane capable of supporting the equipment's

size and weight. See “Specifications” on page 103

or measure and weigh equipment before lifting. Lif t

recycling unit by attaching lifting device at lift point.

IMPORTANT: Empty before lifting.

CMW

®

Transport - 50 MR90 Operator’s Manual

TrailerHitchAdjust_T9.epsTrailerHitchAdjust_T9.eps

Lift

Haul

Inspect Trailer

• Check hitch for wear and cracks. Lubricate if needed.

• Check battery for 12V charge.

• Inspect lights for cleanliness and correct operation. Inspect reflectors and replace if needed.

• Check tire pressure. Check lug nut torque with a torque wrench.

• Ensure trailer brakes are adjusted to come on in synchronization with tow vehicle brakes.

• Check ramps (if equipped) and trailer bed for cracks.

Hitch Trailer

1. Back tow vehicle to trailer.

2. Put manual transmission into first or reverse gear or automatic transmission into park. Turn off ignition.

Set parking brake.

3. Connect trailer drawbar, lunette or coupler to

tow vehicle hitch and lock in place with lock

pin. If needed, adjust drawbar, lunette or

coupler height (shown) to level load.

4. Connect safety chains to tow vehicle chain

keepers (cross-shaped slots on bumper of

tow vehicle). Attach left chain to right side of

tow vehicle and vice versa to cradle hitch. Do

not connect to pintle hook or hitch ball.

5. Connect breakaway switch cable to tow

vehicle. Do not connect to pintle hook or hitch

ball.

6. Plug trailer electrical connector into tow

vehicle connector.

7. Use jack crank to raise jack base and stow.

8. Remove wheel blocks.

Unhitch Trailer

1. Stop tow vehicle and trailer on level ground.

2. Put manual transmission into first or reverse gear or automatic transmission into park. Turn off ignition.

Set parking brake.

3. Block trailer wheels.

4. To unhitch trailer from tow vehicle, reverse “Hitch Trailer” steps

CMW

®

MR90 Operator’s Manual Handle Fluid - 51

Handle Fluid

Chapter Contents

Mix Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

• Set Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

• Mixing Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

• Transferring Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Recycle Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

• Set Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

• Recycling Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

• Transferring Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Operate in Cold Weather . . . . . . . . . . . . . . . . . . . . 57

CMW

®

Handle Fluid - 52 MR90 Operator’s Manual

Mix Fluid

Mix Fluid

Set Up

1. Position fluid unit and connect to drilling unit. See drilling unit operator’s manual.

IMPORTANT: Leave unit hitched to towing vehicle or properly stabilized.

2. Block trailer wheels.

Mixing Fluid

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

To help avoid injury:

• Wear personal protective equipment including hard hat, safety eye wear, and hearing protection.

• Do not wear jewelry or loose clothing.

Improper handling or use of chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels and in material safety data sheets

(MSDS).

1. Verify that hopper throat is not plugged before mixing.

2. Fill MR90 tank with water. Allow room for additives.

3. Open circulation valve and tank discharge valve.

4. Start engine and run at full throttle.

5. Turn mix/supply pump on.

6. Open mixing hopper valve.

IMPORTANT: Do not open valve unless pump is running and venturi jet valve is open. Fluid

could flow back into hopper.

7. Open hopper lid and pour in bentonite. See page 61.

IMPORTANT: Before adding bentonite to drilling fluid, be sure drilling unit is equipped to use a

bentonite mixture.

®

CMW

MR90 Operator’s Manual Handle Fluid - 53

Mix Fluid

8. Close hopper valve and close hopper lid.

9. Mix well.

10. Add liquid additives directly to MR90 tank.

IMPORTANT: Pumps must be circulating when adding liquid additives.

Transferring Fluid

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

To help avoid injury: Keep in mind, if electrical strike occurs while fluid hose is connected to drilling

unit, fluid system will also become electrified.

1. Connect hose from mixing pump to drilling unit.

2. Open venturi jet valve and drill supply valve.

IMPORTANT: If drilling fluid contains bentonite, leave jet valve open to allow continuous mixing

while drilling.

3. Run engine at full throttle.

CMW

®

Handle Fluid - 54 MR90 Operator’s Manual

Recycle Fluid

Recycle Fluid

Set Up

1. Position fluid unit and connect to drilling unit. See drilling unit operator’s manual.

IMPORTANT: Leave unit hitched to towing vehicle or properly stabilized.

2. Block trailer wheels.

Connect Pit Pump

1. Connect hose at 1B and secure other end at

1A.

2. Connect hose at 2B and secure other end at

2A.

CMW

®

MR90 Operator’s Manual Handle Fluid - 55

Recycle Fluid

3. Ensure pit pump is not directly on bottom of

pit by suspending it in the pit or digging a

shelf for it to sit on (shown).

CMW

®

Handle Fluid - 56 MR90 Operator’s Manual

Recycle Fluid

Recycling Fluid

1. Level screens left to right. See “Screen left/right tilt control” on page 35.

2. Turn shaker on.

3. Turn on cleaning pump and check that hydrocyclones are operating at 30 psi (2.06 bar).

IMPORTANT: MR90 tank should be at least half full before turning on cleaning pump.

4. Turn on pit pump to supply used mud to shaker screens.

IMPORTANT: Use auto mode for pit pump to avoid overflowing MR90 tank. See “Pit pump auto

control switch” on page 34.

5. Routinely check mud weight and sand content to prevent damage to drill. See page 66.

6. Level screens front to rear. See “Screen front/rear tilt control” on page 35.

IMPORTANT:

• If front of shaker is too high, large amounts of water will exit the shaker with the spoils.

• Monitor and adjust front/rear screen tilt as soil conditions change.

Transferring Fluid

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

To help avoid injury: Keep in mind, if electrical strike occurs while fluid hose is connected to drilling

unit, fluid system will also become electrified.

1. Connect hose from mixing pump to drilling unit.

2. Open venturi jet valve and drill supply valve.

IMPORTANT: If drilling fluid contains bentonite, leave jet valve open to allow continuous mixing

while drilling.

3. Run engine at full throttle.

CMW

®

MR90 Operator’s Manual Handle Fluid - 57

Operating in Cold Weather

Operating in Cold Weather

For successful operation in cold weather, follow these procedures.

• Use mix/supply pump to keep drilling fluid circulating at all times, even during transport to and from the

jobsite.

• Use antifreeze wash pump to mix antifreeze into system.

• If possible, use all drilling fluid in MR90 tank before transporting unit.

CMW

®

Handle Fluid - 58 MR90 Operator’s Manual

Operating in Cold Weather

CMW

®

MR90 Operator’s Manual Systems and Equipment - 59

Systems and Equipment

Chapter Contents

Recommended Products . . . . . . . . . . . . . . . . . . . . 60

• Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

• Polymer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

• Bentonite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

• Mixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Drilling Fluid Requirements. . . . . . . . . . . . . . . . . . 64

Drilling Fluid Measurements . . . . . . . . . . . . . . . . . 65

• Funnel Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

• Mud Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

• Sand Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

CMW

®

Systems and Equipment - 60 MR90 Operator’s Manual

Recommended Products

Recommended Products

Improper handling or use of chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels and in material safety data sheets

(MSDS).

Use breathing protection when exposed to silica dust.

270-4952

For productive drilling and equipment protection, use these recommended Baroid® products, available

®

from your Ditch Witch

• Soda ash

• Quik-Gel

®

dry powder bentonite (p/n 259-804)

dealer.

• Liqui-Trol™ liquid polymer suspension (p/n 259-808)

•Quik-Trol

• Bore-Gel

• E-Z Mud™ Gold dry powder polymer (p/n 255-1012)

®

dry powder polymer (p/n 259-809)

®

drilling fluid (p/n 259-807)

Guidelines

Match drilling fluid to soil type. This chart is meant as a guideline only . See your local Ditch Witch dealer for

soil conditions and drilling fluid recommendations for your area. Also see our interactive Drilling Fluid

Formulator at www.ditchwitch.com.

Soil type Drilling fluid recommendation

smooth, flowing sand bentonite or Bore-Gel + medium chain polymer

coarse sand or light soil bentonite or Bore-Gel

heavy clay medium chain polymer

swelling clay medium chain polymer

rock Bore-Gel

CMW

®

MR90 Operator’s Manual Systems and Equipment - 61

Recommended Products

Polymer

This drilling fluid additive provides excellent lubrication and increases viscosity in average soils and heavy

clay. In swelling clay, polymer can reduce swelling that traps pipe in the bore.

There are two types of polymer:

• long chain such as Baroid

NOTICE: Long chain polymer is not recommended for this unit.

• medium chain such as Baroid Quik-Trol

®

EZ-Mud Gold

Bentonite

Bentonite is a dry powder. When properly mixed with water, it forms a thin cake on bore walls, lubricating

the bore, keeping it open, and holding fluid in the bore.

Some things to remember when mixing bentonite:

• Use clean water free of salt, calcium, or excessive chlorine.

• Use water with pH level between 9 and 10.

• Use water with hardness of less than 120 ppm.

• Do not use bentonite containing sand.

• Mix bentonite thoroughly or it will settle in tank.

• Do not mix bentonite to a funnel viscosity of over 50.

For information on measuring funnel viscosity, see “Drilling Fluid Measurements” on page 65.

CMW

®

Systems and Equipment - 62 MR90 Operator’s Manual

Recommended Products

Mixtures

NOTICE: Bentonite does not mix well in water containing polymer. To use both, mix bentonite first, then

add polymer.

• If chemicals are added in the wrong order, they will not mix properly and will form clumps.

• If tank contains bentonite/polymer mix and more drilling fluid is needed, completely empty tank and

start with fresh water before mixing another batch.

General mixing order

1. Soda ash

2. Bentonite

3. Polymer

Bore-Gel

drilling fluid viscosity for expected drilling conditions.

®

contains premixed bentonite, polymer, and soda ash. Follow guidelines below to ensure proper

Conditions Amount to Use

normal drilling 15 lb/100 gal 7 kg/380 L

sand or gravel up to 45 lb/100 gal up to 21 kg/380 L

rock up to 50 lb/100 gal up to 23 kg/380

Basic Fluid Recipes

Soil type Mixture/100 gal (378 L) of water Notes

fine sand 35 lb (16 kg) Bore-Gel

coarse sand 35 lb (16 kg) Bore-Gel

.5 lb (225 g) No-Sag

fine sand below water

table

coarse sand below

water table

40 lb (18 kg) Bore-Gel

.75 lb (340 g) Quik-Trol

40 lb (18 kg) Bore-Gel

.75 lb (340 g) Quik-Trol

.75 lb (340 g) No-Sag

Add .5 lb (225 g) of Quik-Trol for

additional filtrate control

Add .5 - 1 gal (2-4 L) of Dinomul in high

torque situations

Add .5 - 1 gal (2-4 L) of Dinomul in high

torque situations

gravel 50 lb (23 kg) Bore-Gel

.75 lb (340 g) Quik-Trol

.75 lb (340 g) No-Sag

cobble 50 lb (23 kg) Bore-Gel

.75 lb (340 g) Quik-Trol

.75 lb (340 g) No-Sag

®

CMW

Add .5 lb (225 g) of Barolift to reduce loss

of returns

Add .5 lb (225 g) of Barolift to reduce loss

of returns

MR90 Operator’s Manual Systems and Equipment - 63

Recommended Products

Soil type Mixture/100 gal (378 L) of water Notes

sand, gravel, clay or

shale

clay .5 lb (225 g) Poly Bore Flow rate should be 3-5 parts fluid to 1

swelling/sticky clay .75 - 1 lb (340-450 g) EZ-Mud

solid rock (shale) 40 lb (18 kg) Bore-Gel Use .5 pt (235 mL) of No Sag for large

solid rock (other than

shale)

rock/clay mixture 40 - 50 lb (18-23 kg) Bore-Gel

rock/sand mixture 40 - 50 lb (18-23 kg) Bore-Gel Use .5 pt (235 mL) of No Sag for large

fractured rock 50 lb (23 kg) Bore-Gel

35 - 40 lb (16-18 kg) Bore-Gel

.5lb (227 g) EZ-Mud Gold

Gold

40 - 50 lb (18-23 kg) Bore-Gel Use .5 pt (235 mL) of EZ-Mud in reactive

.5 lb (227 g) EZ-Mud Gold

.5 - 1lb (225-450 g) No-Sag

Vary mixture according to percentage of

sand and clay

part soil.

Flow rate should be 3-5 parts fluid to 1

part soil.

diameter or longer bores

shales

diameter or longer bores

Use .5 lb (225 g) of Barolift to reduce fluid

loss to formation

CMW

®

Systems and Equipment - 64 MR90 Operator’s Manual

Drilling Fluid Requirements

Drilling Fluid Requirements

1. Determine drilling conditions and choose appropriate drilling fluid mix.

2. Estimate amount of supplies needed and check availability.

• Drilling fluid

• Water supply. If more water than can be carried with the unit will be needed, arrange to transport

additional water.

• Bentonite and/or polymer

3. Check water quality.

• Use meter or pH test strips to test pH of water. If pH is below 9.0, add 1 lb (454 g) soda ash per

tank. Test and repeat until pH is between 9 and 10.

• Check water hardness using hardness test strips. Treat with soda ash if hardness exceeds 125

ppm.

CMW

®

MR90 Operator’s Manual Systems and Equipment - 65

Drilling Fluid Measurements

Drilling Fluid Measurements

Fluid measurements are important in ensuring the drilling system functions correctly. The viscosity, mud

weight, and sand content of drilling fluids must be controlled and can be measured using the drilling fluid

test kit (p/n 191-158), available from your Ditch Witch

Funnel Viscosity

Viscosity is the measure of internal resistance of a fluid to flow; the greater the resistance, the higher the

viscosity.

To determine viscosity, you will need the Marsh funnel and measuring cup in your drilling fluid test kit.

IMPORTANT: Make sure Marsh funnel is clean and free of obstruction and that you have a stopwatch

available for timing the viscosity.

1. Using wash hose and a clean container, take a fresh

sample of drilling fluid. The sample must be at least

1.5 qt (1.4 L).

®

dealer.

2. With finger over bottom of funnel, fill with fluid from

the container through the screen until fluid reaches

the bottom of the screen.

3. Move funnel over 1 qt (.95 L) container.

4. Remove finger from bottom of funnel and use the

stopwatch to count the number of seconds it t akes for

1 qt (.95 L) of fluid to pass through the funnel. The

number of seconds is the viscosity.

5. Thoroughly rinse measuring cup and Marsh funnel.

CMW

®

Systems and Equipment - 66 MR90 Operator’s Manual

Drilling Fluid Measurements

Mud Weight

The density of a given liquid is the mud weight.

To determine mud weight, you will need the mud balance and scale in your drilling fluid test kit (p/n 191-

158), available from your Ditch Witch

IMPORTANT: Make sure all pieces of mud weight kit are clean and free of obstruction before measuring

drilling fluid.

1. Place mud balance base on level surface.

2. Fill the cup to the top with mud sample to be weighed. See “Fluid sample valve” on page 31.

3. Secure the lid on the cup.

IMPORTANT: Mud should be expelled through the hole in the lid to ensure cup is full and any trapped a ir

is freed from the cup.

4. Cover the hole in the cap with a finger and wash all mud from outside of the cup.

®

dealer.

5. Place balance on the scale and slide rider along the arm until the level bubble indicates the scale is

level. The mud weight of the drilling fluid is the number indicated by the scale.

6. Thoroughly rinse mud weight cup and scale.

Sand Content

Sand content is measured by determining the volume percent of sand-sized particles present in the drilling

fluid.

To determine sand content, you will need the sand content tube, wash bottle, screen, and funnel in your

drilling fluid test kit.

IMPORTANT: Make sure sand content kit components are clean and free of obstruction before

measuring drilling fluid.

1. Fill sand content tube to the indicated mark with mud sample. See “Fluid sample valve” on page 31.

2. Use wash bottle to add water to the next mark.

3. Close tube and shake vigorously.

4. Pour mixture onto clean screen. Discard liquid passing through the screen.

5. Repeat steps 2-4 until all drilling fluid has been washed out of the tube.

6. Place funnel upside down over top of screen.

7. Slowly invert the assembly and insert the tip of the funnel into the mouth of the measuring tube.

8. Wash sand into measuring tube with wash bottle and allow sand to settle. The volume percen t of sand

is measured using the scale on the side of the measuring tube.

9. Thoroughly rinse all components of the sand content kit.

®

CMW

MR90 Operator’s Manual Systems and Equipment - 67

Screens

Screens

Use the chart below to determine which set of screens will work best for the soil type at the jobsite.

A. Clay B. Silt C. Sand D. Loam

Description P/N Micron

fine screen set 301-7191 165

301-7192 70

medium screen set 301-7189 225

301-7190 88

overlap area, both fine and medium screens can be used

coarse or very fine screens, contact Ditch Witch® dealer

CMW

®

Systems and Equipment - 68 MR90 Operator’s Manual

Screens

CMW

®

MR90 Operator’s Manual Complete the Job - 69

Complete the Job

Chapter Contents

Dispose of Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rinse Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Stow Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

CMW

®

Complete the Job - 70 MR90 Operator’s Manual

Dispose of Fluid

Dispose of Fluid

Moving parts could cut off hand or foot. Stay away.

275-184

To help avoid injury: Never place hands through spoils door unless

engine is off and battery is disconnected.

Rotating shaft will cause death or serious injury. Stay

away.

270-1506

To help avoid injury: Leave cover on spoils hopper.

Dispose of unneeded fluid and waste products

using one of the methods described below.

1. Hook vacuum unit directly to MR90

connectors.

• Connect at 1 to drain clean side tank.

• Connect at 2 to drain dirty side tank.

• Connect at 3 to drain optional spoils

hopper.

2. Open optional spoils hopper door to dump

waste products. See “Spoils hopper door

control (optional)” on page 36.

IMPORTANT:

• Some areas may have regulations regarding

the disposal of waste products. Consult local

regulations.

• If a gelling agent is required, Baroid

428 is recommended.

®

IDP-

CMW

®

MR90 Operator’s Manual Complete the Job - 71

Rinse Equipment

Rinse Equipment

Pressurized fluid or air could pierce skin and cause

severe injury. Refer to operator’s manual for proper use.

Spray water onto equipment to remove dirt and

mud. Hose reel is equipped with a handle restraint

(shown).

• Pull latch forward and lift handle up to release.

• Pull latch forward and push handle down to

secure.

270-6035

CMW

®

Complete the Job - 72 MR90 Operator’s Manual

Disconnect

Disconnect

Disconnect and store hoses and cables.

Stow Tools

Make sure hoses, drilling fluid measurement kit,

and other tools are properly stowed.

Stow pit pump as shown.

Storage

Drain tank and ensure all fluid system valves are

open. Also open drain valve on pump.

CMW

®

MR90 Operator’s Manual Service - 73

Service

Chapter Contents

Service Precautions . . . . . . . . . . . . . . . . . . . . . . . . 74

• Welding Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

• Washing Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Recommended Lubricants/Service Key . . . . . . . . 75

• Engine Oil Temp er a tur e Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

• Approved Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

• Approved Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

10 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

50 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

150 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

300 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

450 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

900 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

1800 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

As Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

200 Mile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3000 Mile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

12,000 Mile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

CMW

®

Service - 74 MR90 Operator’s Manual

Service Precautions

Service Precautions

Incorrect procedures could result in death, injury, or

property damage. Learn to use equipment correctly.

To help avoid injury:

• Unless otherwise instructed, all service should be performed with engine off.

• Refer to engine manufacturer’s manual for engine maintenance instructions.

Welding Precaution

NOTICE: Welding can damage electronics.

• Welding currents can damage electronic components. Connect welder ground close to welding

point and make sure no electronic comp on en ts are in the gro u nd path. .

• Disconnect battery at battery disconnect switch before welding to prevent damage to battery.

• Do not turn off battery disconnect switch with engine running, or alternator and other electronic

devices may be damaged.

Washing Precaution

NOTICE: W ater can damage electronics. When clean ing equipment, do not spray electrical component s

with water.

CMW

®

MR90 Operator’s Manual Service - 75

Recommended Lubricants/Service Key

Recommended Lubricants/Service Key

Item Description

DEO Diesel engine oil meeting or exceeding CH-4 per th e API service classification or E5 per

the European Automobile Manufacturer’s Association (ACEA) and SAE viscosity

recommended by engine manufacturer (SAE 10W30)

MPG Multipurpose grease meeting ASTM D217 and NLGI 1

THF

DEAC Diesel engine antifreeze/coolant meeting ASTM D5345 (prediluted) or D4985

NDO 30W non-detergent oil

MPL Multipurpose gear oil meeting API service classification GL-5 (SAE 80W90)

Proper lubrication and maintenance protects Ditch Witch® equipment from damage and failure. Service

intervals listed are for minimum requirements. In ex treme conditions, service machine more frequently.

Use only genuine Ditch Witch parts, filters, approved lubricants, TJC, and approved coolants to maintain

warranty. Fill to capacities listed in “Specifications” on page 121.

For more information on engine lubrication and maintenance, see your engine manual.

Tractor hydraulic fluid, similar to Phillips 66

Hydraulic Fluid, Texaco

(concentrate)

Check level of fluid or lubricant Check condition

Filter Change, replace, adjust, service or

®

TDH Oil, or equivalent

®

HG, Mobilfluid® 423, Chevron® Tractor

test

IMPORTANT: Use the “Service Record” on page 111 to record all required service to your machine.

CMW

®

Service - 76 MR90 Operator’s Manual

Temperature range anticipated before next oil change

Recommended Lubricants/Service Key

Engine Oil Temperature Chart

Approved Coolant

This unit was filled with John Deere® Cool-Gard® coolant before shipment from factory. Add only CoolGard (p/n 255-006) or any fully-formulated, ethylene glycol based, low-silicate, heavy-duty diesel engine

coolant meeting ASTM specification D5345 (prediluted) or D4985 (concentrate). Before using any other

kind of coolant, completely flush radiator.

NOTICE: Do not mix heavy-duty diesel engine coolant and automotive-type coolant. This will lead to

coolant breakdown and engine damage.

CMW

®

MR90 Operator’s Manual Service - 77

Recommended Lubricants/Service Key

Approved Fuel

Avoid static electricity when fueling. Ultra Low Sulfur Diesel (ULSD)

poses a greater static ignition hazard than earlier diesel formulations. Avoid death or

serious injury from fire or explosion. Consult with your fuel system supplier to ensure the

delivery system is in compliance with fueling standards for proper grounding and bonding

practices.

The engine is this unit is designed to run on diesel fuel. Use o nly high-quality fuel meeting ASTM D975 No.

2D, EN590, or equivalent. At temperatures below 32°F (0°C), winter fuel blends are acceptable. See

engine operation manual for more information.

IMPORTANT: Fuel sulfur content should be less than 5000 ppm (0.5%). Worldwide, fuel sulfur

regulations vary widely. Fuel used should always comply with local regulations. Do not use lube oil

meeting API CJ-4 (or other low SAPS equivalent) if fuel sulfur content is above 500 ppm (0.05%, low

sulfur diesel in the U.S.).

Biodiesel blends up to 5% (B5) are approved for use in this unit. The fuel used must meet the

specifications for diesel fuel shown above. Extra attention is needed when using biodiesel, especially when

operating in cold weather or storing fuel. Contact your Ditch Witch

more information.

®

dealer or the engine manufacturer for

CMW

®

Service - 78 MR90 Operator’s Manual

10 Hour

10 Hour

Location Task Notes

Recycling

Unit

Trailer Check tire pressure and lug nut torque 80 psi (5.5 bar)/90-120 ft•lb

Clean screens

Clean Y-strainer

Clean pit pump

Check coolant level DEAC

Check engine oil level DEO

Check water pump oil level NDO

Clean water pump filter

Check radiator

Check hydraulic hoses

(122-163 N•m)

Check tail lights and reflectors

Check hitch bolts

Recycling Unit

Clean Screens

Clean screens every 10 hours, after each use, and

as needed.

1. Pin access flaps (3) back to expose screens.

2. Spray screens (1 ,2) with wash wand to ensure

they are free from dirt and debris.

IMPORTANT: Placing wash wand directly on

screen will damage it.

CMW

®

MR90 Operator’s Manual Service - 79

10 Hour

Clean Y-Strainer

Remove Y-strainer and clean every 10 hours.

Clean Pit Pump

Spray pit pump with wash wand every 10 hours or

after each use.

Check Coolant Level

Check coolant level every 10 hours. Add coolant at

cap (shown) as needed to maintain level between

LOW and FULL on overflow tank.

CMW

®

Service - 80 MR90 Operator’s Manual

10 Hour

Check Engine Oil Level

Check engine oil level at dipstick (1) every 10

hours. Add DEO at fill (2) as needed to maintain oil

level at highest line on dipstick. See “Approved

Coolant” on page 76.

Check Water Pump Oil Level

With frame level, check water pump oil at sight

glass (2) every 10 hours. Add NDO at fill (1) as

necessary to keep oil at halfway mark on sight

glass.

CMW

®

MR90 Operator’s Manual Service - 81

10 Hour

Clean Water Pump Filter

Clean water pump filter every 10 hours and

replace as needed.

1. Open filter housing.

2. Remove element and rinse housing thoroughly

with water.

3. Inspect element for signs of collapse and for

brittle or broken rubber seals on the ends of

the element. Replace as needed.

4. Replace element and close filter housing.

Check Radiator

Check radiator for dirt, grass, and other foreign

matter every 10 hours. Clean out with compressed

air or spray wash if required. Be careful not to

damage fins with high-pressure air or water . Check

more often if operating in dusty or grassy

conditions.

CMW

®

Service - 82 MR90 Operator’s Manual

10 Hour

Check Hydraulic Hoses

Pressurized fluid or air could pierce skin and cause severe

injury. Refer to operator’s manual for proper use.

To help avoid injury:

• Before disconnecting a hydraulic line, turn engine off and operate all controls to relieve pressure.

Lower, block, or support any raised component with a hoist. Cover connection with heavy cloth and

loosen connector nut slightly to relieve residual pressure. Catch all fluid in a container.

• Before using system, check that all connections are tight and all lines are undamaged.

• Use a piece of cardboard or wood, rather than hands, to search for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a doctor familiar with this type of injury.

270-6035

Check hydraulic hoses for leaks at startup and

every 10 hours.

CMW

®

MR90 Operator’s Manual Service - 83

j33om013h.epsj33om013h.eps

TrailerHitchAdjust_T9.epsTrailerHitchAdjust_T9.eps

10 Hour

Trailer

Check Trailer Tire Pressure and

Lug Nut Torque

Check tire pressure (2) and lug nut (1) torque

every ten hours. See below for correct pressure

and torque. To verify trailer model, see the

certification plate located on the trailer tongue.

Trailer Pressure Torque

T14R 80 psi

(5.5 bar)

90-120 ft•lb

(122-163 N•m)

Check Trailer Lights and Reflectors

Check lights and reflectors for correct operation

and cleanliness every 10 hours.

Check Hitch Bolts

Check torque of trailer hitch bolts every 10 hours.

Bolts should be torqued to 260 ft•lb (352 N•m).

CMW

®

Service - 84 MR90 Operator’s Manual

50 Hour

50 Hour

Location Task Notes

Recycling

Unit

Change water pump oil NDO, initial

Check air filter

Change engine oil and filter Initial, DEO

Lube pump

Change shaker gearbox oil MPL

Change hydraulic fluid filter initial

Recycling Unit

Change Water Pump Oil

Change oil after the first 50 hours of operation

initially , and every 45 0 hours thereaf ter. Change oil

more frequently if working in dusty conditions.

1. Drain at plug (3) while oil is warm.

2. Add approximately 1 qt (.95 L) NDO at fill (1)

until oil is at halfway mark on sight glass (2).

Check Air Filter

Check air filter every 50 hours. Replace as

needed.

®

CMW

MR90 Operator’s Manual Service - 85

50 Hour

Change Engine Oil and Filter (Initial)

Change engine oil after the first 50 hours and

every 150 hours thereafter, while oil is warm and

with unit parked on level ground.

1. Open drain (3).

2. Replace filter (4).

3. Close drain.

4. Add approximately 4.2 qt (4 L) DEO at fill (2)

until oil level is at highest line on dipstick (1).

Lube Pump

Lube zerk (2) with MPG every 50 hours. Grease

cavity is full when grease escapes from grease

cylinder relief valve (1).

Change Shaker Gearbox Oil

Change shaker gearbox oil after the first 50 hours

and every 450 hours thereafter.

To change:

1. Remove drain plug (2).

2. Drain oil and replace plug.

3. Add MPL at fill (1) until cold oil is halfway up

sight glass (3).

NOTICE:

• Fill capacity is 2.4 pt (1L). Do not overfill.

• Do not drain oil from gearbox when hot. Let

gearbox cool before removing drain plug.

CMW

®

Service - 86 MR90 Operator’s Manual

50 Hour

Change Hydraulic Fluid Filter

Replace hydraulic fluid filter (shown) after the first

50 hours, and every 900 hours thereafter.

CMW

®

MR90 Operator’s Manual Service - 87

150 Hour

150 Hour

Location Task Notes

Recycling

Unit

Change fuel filters

Check fan belt tension

Change engine oil and filter

Recycling Unit

Change Fuel Filters

Change fuel filter (1) and in-line fuel filter (2) every

150 hours.

1. Remove filters.

2. Fill new filter with clean fuel.

3. Apply fuel oil over the gasket and hand-tighten.

Check Fan Belt Tension

Check fan belt tension every 150 hours.

1. Turn off engine and remove key.

2. Apply moderate thumb pressure to top of belt.

Belt is properly tensioned when deflection (A)

is 1/4-1/2” (5-13 mm). To adjust, see page 93.

CMW

®

Service - 88 MR90 Operator’s Manual

150 Hour

Change Engine Oil and Filter

Change engine oil every 150 hours while oil is

warm and with unit parked on level ground.

1. Open drain (3).

2. Drain crankcase while oil is warm.

3. Replace filter (4).

4. Close drain.

5. Add approximately 4.2 qt (4 L) DEO at fill (2)

until oil level is at highest line on dipstick (1).

CMW

®

MR90 Operator’s Manual Service - 89

300 Hour

300 Hour

Location Task Notes

Recycling

Unit

Change air filter

Recyling Unit

Change Air Filter

Change air filter every 300 hours.

1. Open air filter housing at latches (1).

2. Remove primary (3) and secondary (2)

elements.

3. Wipe inside of housing and wash end cap.

4. Insert new primary and secondary elements.

5. Close air filter case.

CMW

®

Service - 90 MR90 Operator’s Manual

450 Hour

450 Hour

Location Task Notes

Recycling

Unit

Replace fan belt

Replace pump drive belt

Change water pump oil NDO

Change shaker gearbox oil MPL

Recycling Unit

Replace Fan Belt

Replace fan belt (shown) every 450 hours.

To replace

1. Loosen bolts (1, 2) and remove belt.

2. Install new belt and adjust properly. See

page 93.

Replace Pump Drive Belt

Replace pump drive belt (shown) every 450 hours.

To replace

1. Loosen bolts (1, 2) and remove belt.

2. Install new belt and adjust properly. See

page 93.

CMW

®

MR90 Operator’s Manual Service - 91

450 Hour

Change Water Pump Oil

Change oil every 450 hours. Change oil more

frequently if working in dusty conditions.

1. Drain at plug (3) while oil is warm.

2. Add approximately 1 qt (.95 L) NDO at fill (1)

until oil is at halfway mark on sight glass (2).

Change Shaker Gearbox Oil

Change shaker gearbox oil every 450 hours.

To change:

1. Remove drain plug (2).

2. Drain oil and replace plug.

3. Add MPL at fill (1) until cold oil is halfway up

sight glass (3).

NOTICE:

• Fill capacity is 2.4 pt (1L). Do not overfill.

• Do not drain oil from gearbox when hot. Let

gearbox cool before removing drain plug.

CMW

®

Service - 92 MR90 Operator’s Manual

900 Hour

900 Hour

Recycling Unit

Change Hydraulic Fluid and Filter

Change hydraulic fluid and filter yearly or every

900 hours.

1. Drain hydraulic fluid (3), add THF at hydraulic

fluid fill (1) until level is midway at sight glass

(4).

2. Replace filter (2).

1800 Hour

Recycling Unit

Change Engine Coolant

Drain cooling system at drain (2). Add approved

coolant at fill (1) every two years or 1800 hours.

NOTICE:

• The use of non-approved coolant may lead

to engine damage or premature engine

failure and will void engine warranty.

• See “Approved Coolant” on page 76. for list

of approved coolants.

CMW

®

MR90 Operator’s Manual Service - 93

As Needed

As Needed

Location Task Notes

Recycling

Unit

Adjust fan belt

Adjust pump drive belt

Clean hydrocyclones

Change remote batteries

Change screens

Check battery

Recycling Unit

Adjust Fan Belt

Adjust fan belt as needed.

1. Turn off engine and remove key.

2. Apply moderate thumb pressure to belt

between pulleys where shown.

Belt is properly tensioned when deflection is

about 1/4-3/8” (6-10 mm).

3. If needed, loosen alternator bolts (1,2) and pull

alternator out until correct tension is reached.

Adjust Pump Drive Belt

Adjust pump drive belt as needed.

1. Loosen two bolts (1,2) until pump slides freely.

2. Adjust bolt (3) to increase or decrease tension.

When washer is aligned with cutout and

dimension A (shown) is 3/4” (19 mm), tension

is correct.

3. Once tension is set, tighten bolts.

CMW

®

Service - 94 MR90 Operator’s Manual

As Needed

Clean Hydrocyclones