JT5

Operator’s

Manual

CMW

®

Issue 1.0

Original Instruction

053-2380

JT5 Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Modification . . . . . . . . . . . . . . . . . . . . . . 3

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operator Orientation. . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Bulleted Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Numbered Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• “Continued” Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CMW

Overview - 2 JT5 Operator’s Manual

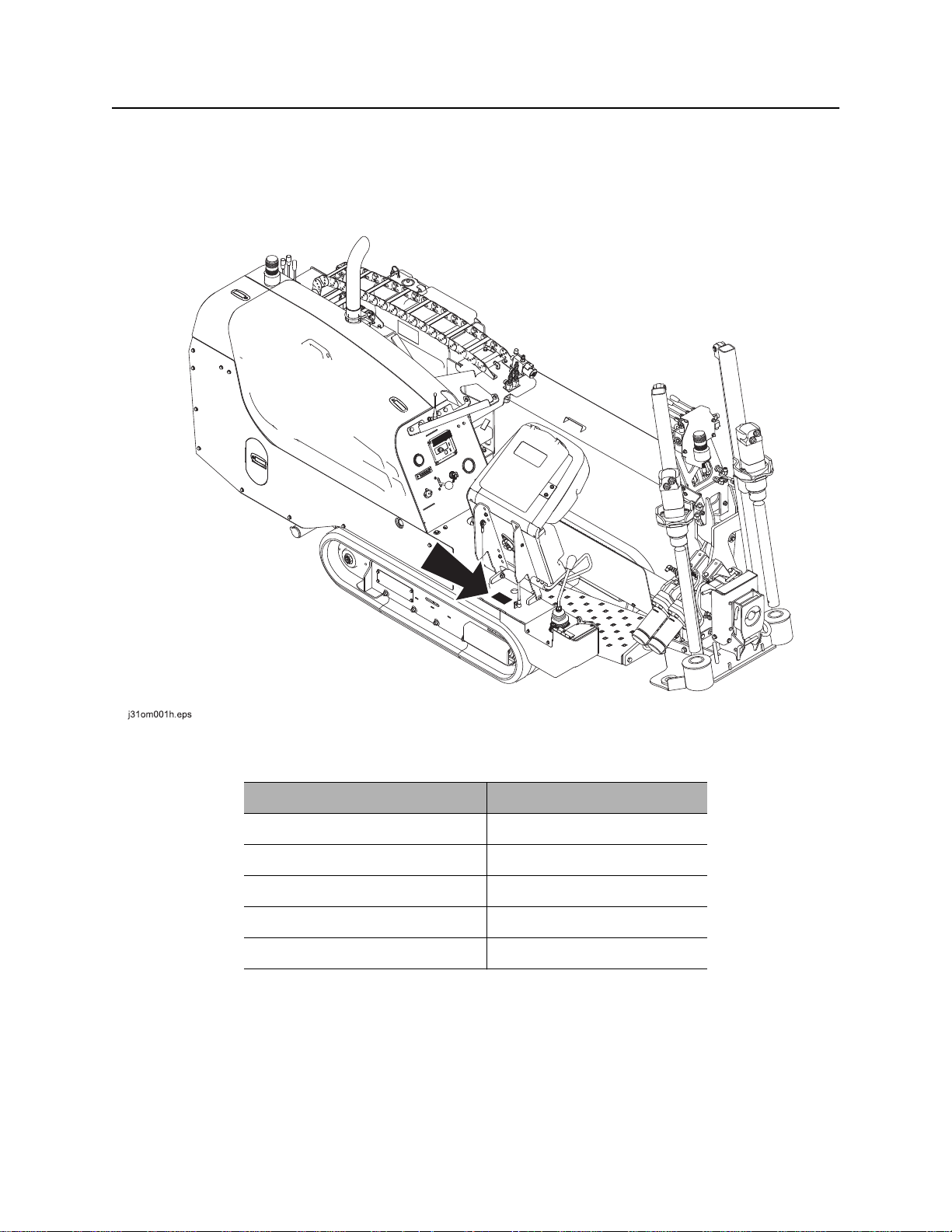

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. Drilling unit serial number is located as

shown.

CMW

Item

date of manufacture

date of purchase

drilling unit serial number

trailer serial number

engine serial number

JT5 Operator’s Manual Overview - 3

Intended Use

Intended Use

The JT5 is a self-contained horizontal directional drilling unit designed to install buried cable and pipe at

distances to 150’ (45.7 m) depending on soil conditions and is intended for operation in ambient

temperatures from 0° to 115°F (-18° to 46°C). Use in any other way is considered contrary to the intended

use.

The JT5 can be used with Ditch Witch drilling fluid units and Ditch Witch locating equipment. It should be

operated, serviced, and repaired only by persons familiar with its particular characteristics and acquainted

with the relevant safety procedures.

Equipment Modification

This equipment was designed and built in accordance with applicable standards and regulations.

Modification of equipment could mean that it will no longer meet regulations and may not function properly

or in accordance with the operating instructions. Modification of equipment should only be made by

competent personnel possessing knowledge of applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

CMW

Overview - 4 JT5 Operator’s Manual

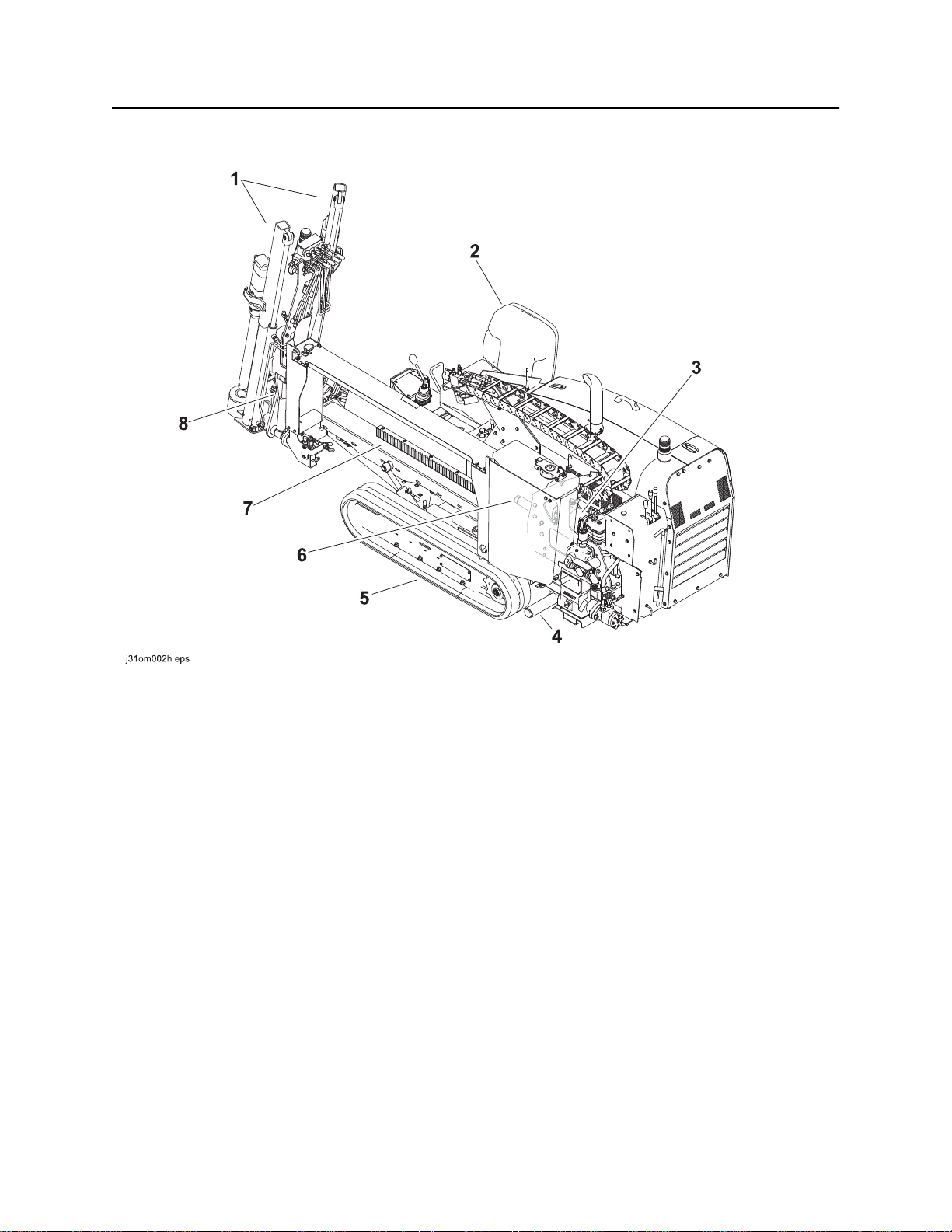

Unit Components

Unit Components

1. Anchoring system

2. Operator’s station

3. Carriage

4. Stabilizer

5. Tracks

6. Spindle

7. Drill frame

8. Wrench

CMW

JT5 Operator’s Manual Overview - 5

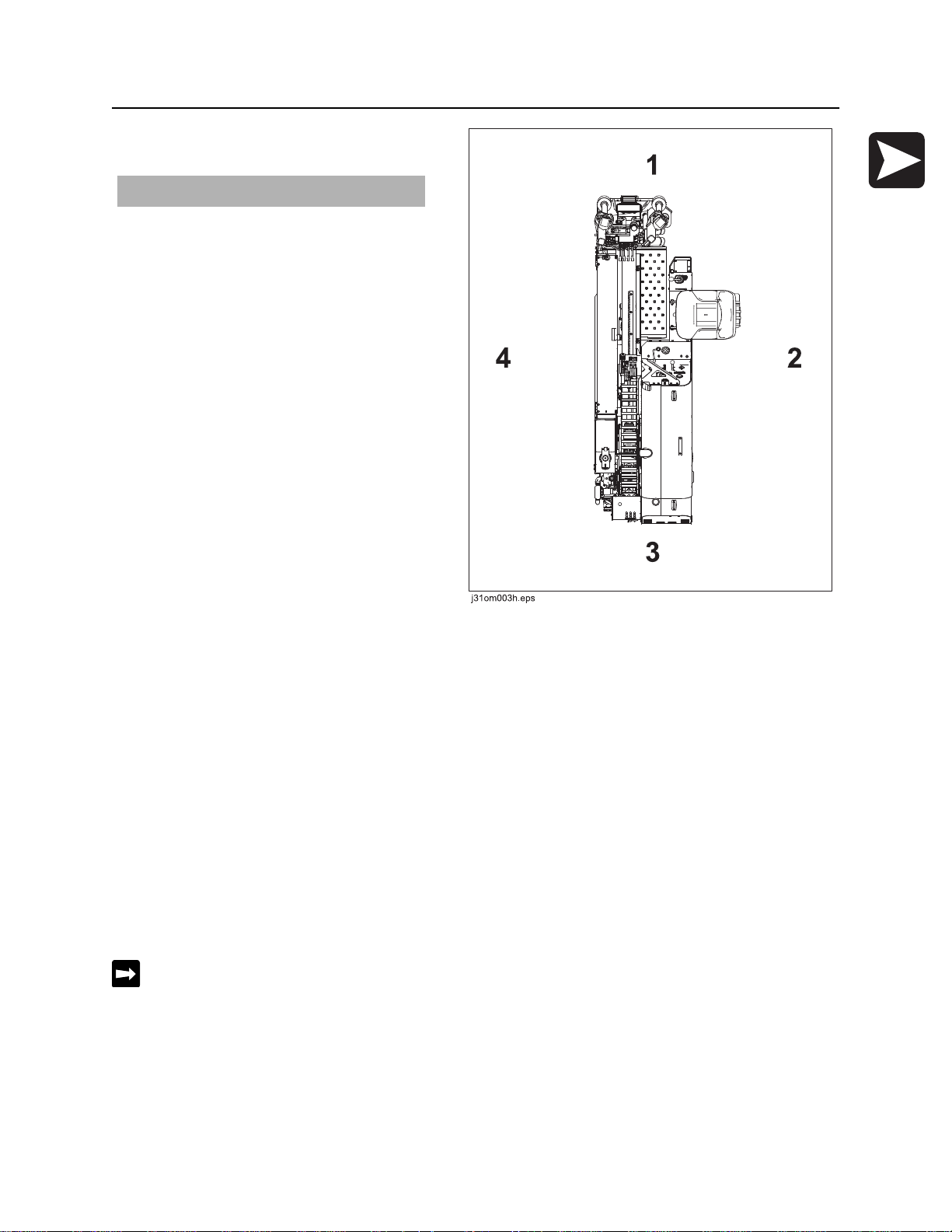

Operator Orientation

Operator Orientation

IMPORTANT: Top view of unit is shown.

1. Front of unit

2. Right side of unit

3. Rear of unit

4. Left side of unit

About This Manual

This manual contains information for the proper use of this machine. See the beige Operation Overview

pages for basic operating procedures. Cross references such as “See page 50” will direct you to detailed

procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

“Continued” Indicators

indicates that a procedure is continued on the next page.

CMW

Overview - 6 JT5 Operator’s Manual

CMW

JT5 Operator’s Manual Foreword - 7

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipment at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was published. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

CMW

Foreword - 8 JT5 Operator’s Manual

JT5

Operator’s Manual

Issue number 1.0/OM- 4/11

Part number 053-2380

Copyright 2011

by The Charles Machine Works, Inc.

, Ditch Witch, CMW, AutoCrowd, Jet Trac, Roto Witch, Subsite, Fluid Miser,

Power Pipe, Super Witch, Pierce Airrow, The Underground, The Underground Authority Worldwide, and

Zahn are registered trademarks of The Charles Machine Works, Inc.

This product is covered by one or more of the following patents:

U.S. B1 4,858,704; 4,953,638; 5,148,880; 5,242,026; 5,341,887; 5,490,569; 5,684,466; 5,713,423; 5,794,719; 5,880,680; 5,941,322;

6,085,852; 6,109,371; 6,179,065; 6,216,803; 6,250,403; 6,250,404; 6,290,606; 6,311,790; 6,411,094; 6,543,551; 6,550,547;

6,672,409; 6,739,413; 6,761,231; 6,776,246; 6,808,210; 6,827,158; 6,848,506; 6,871,712; RE37,450; RE37,923; RE37,975;

RE38,418; AU 689,533; 706,544; 718,034; 755,862; CA 2,156,398; 2,217,899; DE 694 17 019; 695 29 634; 297 01 406;

EP 0683845; 0674093; 0817901; 0846841; 0927892; FR 674,093; GB 2,309,239; 2,312,006; EP674,093; EP846,841; JP 3,458,247;

other U.S. and foreign patents pending.

CMW

JT520 Operator’s Manual Contents - 9

Contents

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls, gauges, and indicators and how to use them

Operation Overview

an overview for completing a job with this machine: planning, setting up, installing

product, and restoring the jobsite; with cross references to detailed procedures

Prepare

procedures for inspecting and classifying the jobsite, planning the installation path,

and preparing the jobsite for work

Drive

procedures for startup, cold start, driving, and shutdown

1

7

11

21

43

47

63

Transport

procedures for lifting, hauling, and towing

Conduct a Bore

procedures for drilling and backreaming

Systems and Equipment

downhole tools and drill pipe, anchor, electric strike, tracker control, and fluid

systems

Complete the Job

procedures for restoring the jobsite and rinsing and storing equipment

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

67

73

91

121

127

CMW

Contents - 10 JT520 Operator’s Manual

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

Service Record

a record of major service performed on the machine

151

155

159

CMW

JT2720 Mach 1/All Terrain Operator’s Manual Safety - 11

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 13

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 17

• Electric Strike Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CMW

Safety - 12 JT2720 Mach 1/All Terrain Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

• Classify jobsite based on its hazards and use correct tools and machinery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment

use.

CMW

JT2720 Mach 1/All Terrain Operator’s Manual Safety - 13

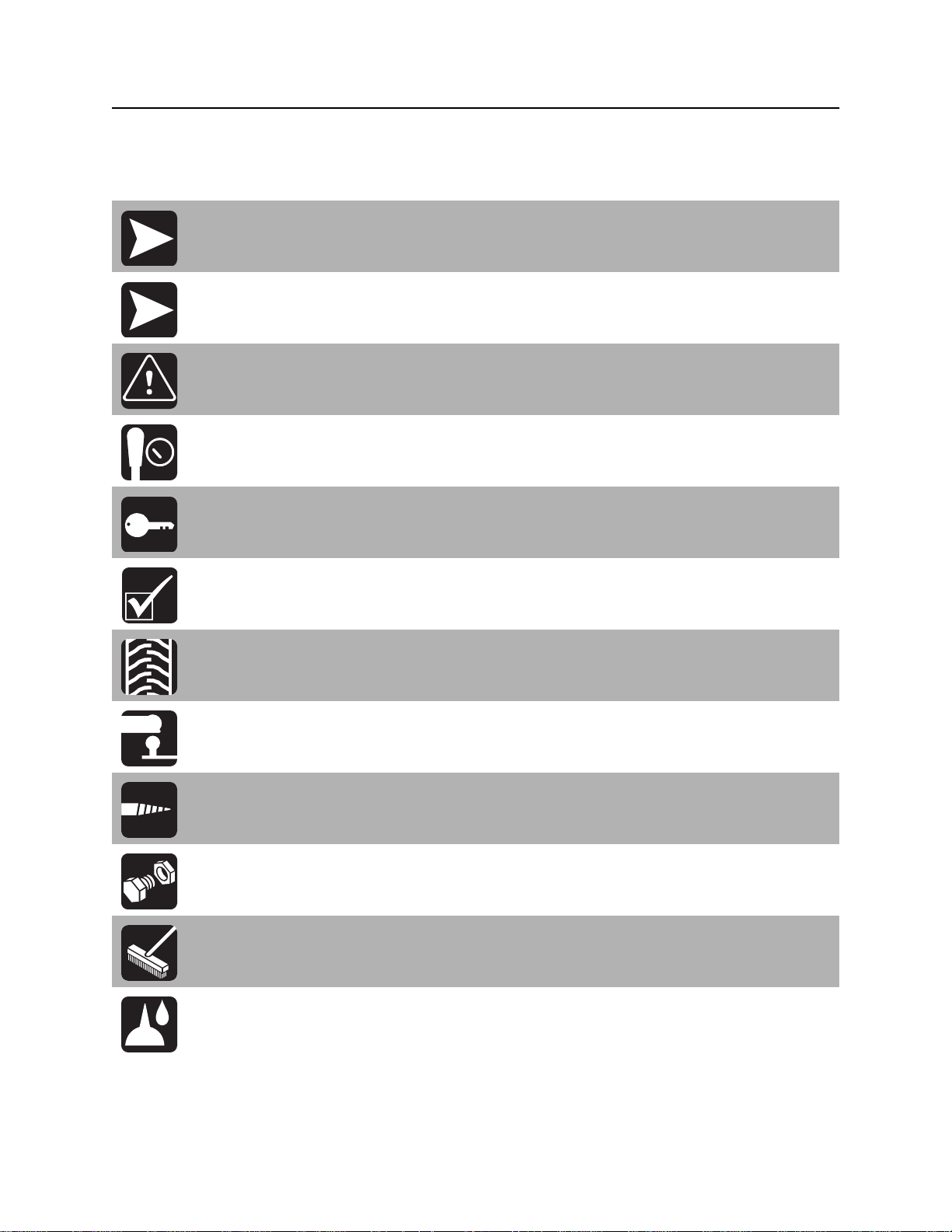

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE can keep you from doing something that might damage the machine or someone's property. It

can also alert you against unsafe practices.

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

Safety - 14 JT2720 Mach 1/All Terrain Operator’s Manual

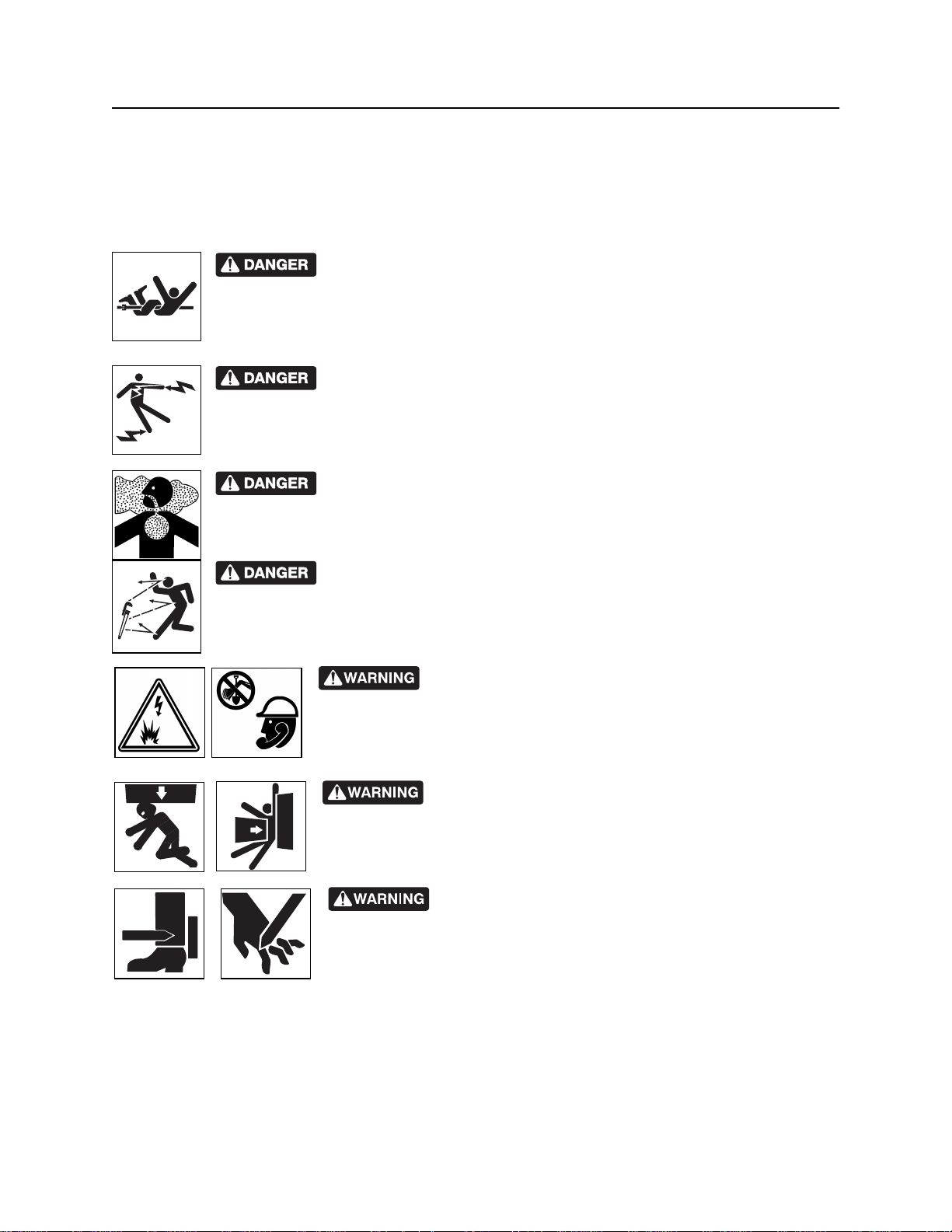

Safety Alerts

Safety Alerts

Turning shaft will kill you or crush arm or leg. Stay away.

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Deadly gases. Lack of oxygen or presence of gas will cause sickness or

death. Provide ventilation.

Moving tools will kill or injure. Shut off drill string power when anyone can be

struck by moving or thrown tools. Never use pipe wrenches on drill string.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Crushing weight could cause death or serious injury. Use

proper procedures and equipment or stay away.

Moving parts could cut off hand or foot. Stay away.

CMW

JT2720 Mach 1/All Terrain Operator’s Manual Safety - 15

Safety Alerts

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Improper control function could cause death or serious injury. If control does

not work as described in instructions, stop machine and have it serviced.

Looking into fiber optic cable could result in permanent vision damage. Do

not look into ends of fiber optic or unidentified cable.

Pressurized fluid or air could pierce skin and cause injury or

death. Stay away.

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Moving traffic - hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

CMW

Safety - 16 JT2720 Mach 1/All Terrain Operator’s Manual

Safety Alerts

Hot pressurized cooling system fluid could cause serious burns. Allow to

cool before servicing.

Flying objects may cause injury. Wear hard hat and safety glasses.

Hot parts may cause burns. Do not touch until cool.

Exposure to high noise levels may cause hearing loss. Wear hearing

protection.

Fall possible. Slips or trips may result in injury. Keep area clean.

Battery acid may cause burns. Avoid contact.

Improper handling or use of chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels and in material safety data sheets

(MSDS).

CMW

JT2720 Mach 1/All Terrain Operator’s Manual Safety - 17

Emergency Procedures

Emergency Procedures

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Before operating any equipment, review emergency procedures and check that all safety precautions have

been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote engine stop button (if

equipped).

Electric Strike Description

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

• smoke

• explosion

• popping noises

• arcing electricity

If any of these occur, or if strike alarm sounds or flashes, assume an electric strike has occurred.

CMW

Safety - 18 JT2720 Mach 1/All Terrain Operator’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on drilling unit or bonded equipment, DO

NOT MOVE. Remain on drilling machine or mats and take the following actions. The order and degree of

action will depend on the situation.

• Warn people nearby that an electric strike has occurred.

• Have someone contact electric company.

• Reverse drilling direction and try to break contact. Do not touch drill pipe with hands or hand-held

tools.

• Press electric strike system status button.

• If alarm sounds again, stay where you are and wait for electric company to shut off power.

• If alarm does not sound and there is no other indication of a strike, wait at least one full minute

before moving away from equipment. Utility might use automatic reclosers which will restart

current flow. If alarm sounds again while waiting, stay where you are until electric company shuts

off power.

• If alarm does not sound but all lights in strike indicator are on, assume strike is continuing and stay

where you are until electric company shuts off power.

• Do not resume drilling or allow anyone into area until given permission by electric company.

If you suspect an electric line has been damaged and you are off drilling unit or bonded equipment, DO

NOT TOUCH ANY EQUIPMENT connected to drilling unit. Take the following actions. The order and

degree of action will depend on the situation.

• Stay where you are unless you are wearing electric insulating boots. If you leave, do not return to area

or allow anyone into area until given permission by electric company.

CMW

JT2720 Mach 1/All Terrain Operator’s Manual Safety - 19

Emergency Procedures

If a Gas Line is Damaged

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

CMW

Safety - 20 JT2720 Mach 1/All Terrain Operator’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

CMW

JT5 Operator’s Manual Controls - 21

Controls

Chapter Contents

Set-Up Console . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Anchor Console . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operator’s Station . . . . . . . . . . . . . . . . . . . . . . . . . 26

• Gauges and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

• Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Engine Compartment . . . . . . . . . . . . . . . . . . . . . . . 32

ESID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

750/752 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

• Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

• Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CMW

Controls - 22 JT5 Operator’s Manual

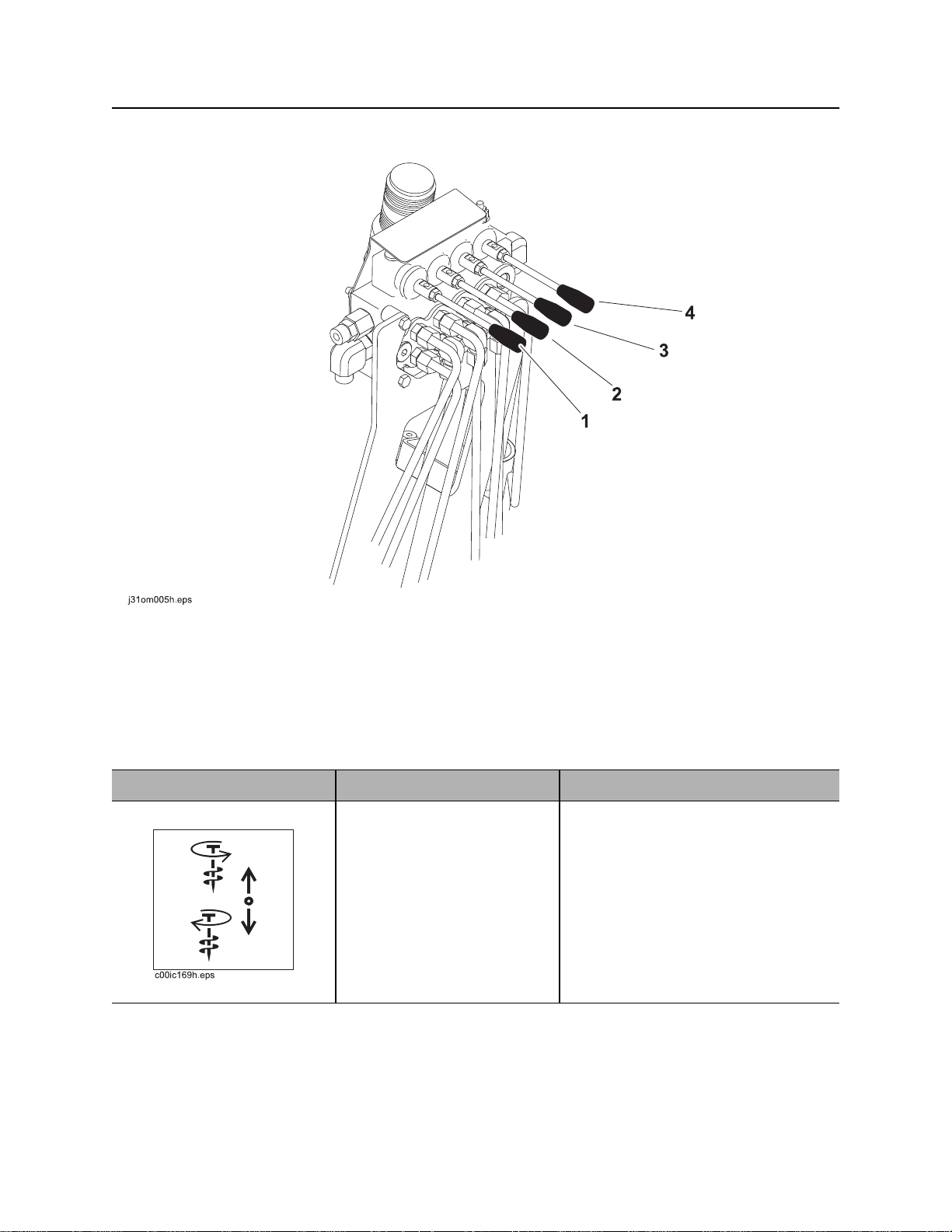

Set-up Console

Set-up Console

1. Engine stop button

2. Stabilizer and frame tilt control

Item Description Notes

1. Engine stop button To stop engine, press. IMPORTANT:

CMW

3. Left track control

4. Right track control

• If this switch is used to stop

drilling unit, turn ignition switch off

if machine will be left unattended

for long periods of time. Battery

discharge can occur.

• If wrenches are engaged when

engine stop button is pressed,

wrenches will remain engaged but

could gradually open.

JT5 Operator’s Manual Controls - 23

Set-up Console

Item Description Notes

2. Stabilizer and frame tilt

control

To raise stabilizer and

decrease frame tilt, pull.

To lower stabilizer and

increase frame tilt, push.

3. Left track control To move forward, push.

To move backward, pull.

To stop, move to center.

c00ic147h.eps

4. Right track control To move forward, push.

To move backward, pull.

Note: Stabilizer control lowers the

front of the drill frame along with the

stabilizer.

c00ic148h.eps

To stop, move to center.

CMW

Controls - 24 JT5 Operator’s Manual

Anchor Console

Anchor Console

1. Left rotation control

2. Left thrust control

Item Description Notes

1. Left rotation control To drive anchor, push down.

To remove anchor, pull up.

3. Right rotation control

4. Right thrust control

IMPORTANT: Stand on platform when

operating anchor controls.

CMW

JT5 Operator’s Manual Controls - 25

Anchor Console

Item Description Notes

2. Left thrust control To move anchor down, push

down.

To move anchor up, pull up.

3. Right rotation control To drive anchor, push down.

To remove anchor, pull up.

4. Right thrust control To move anchor down, push

down.

IMPORTANT: Stand on platform when

operating anchor controls.

IMPORTANT: Stand on platform when

operating anchor controls.

IMPORTANT: Stand on platform when

operating anchor controls.

To move anchor up, pull up.

CMW

Controls - 26 JT5 Operator’s Manual

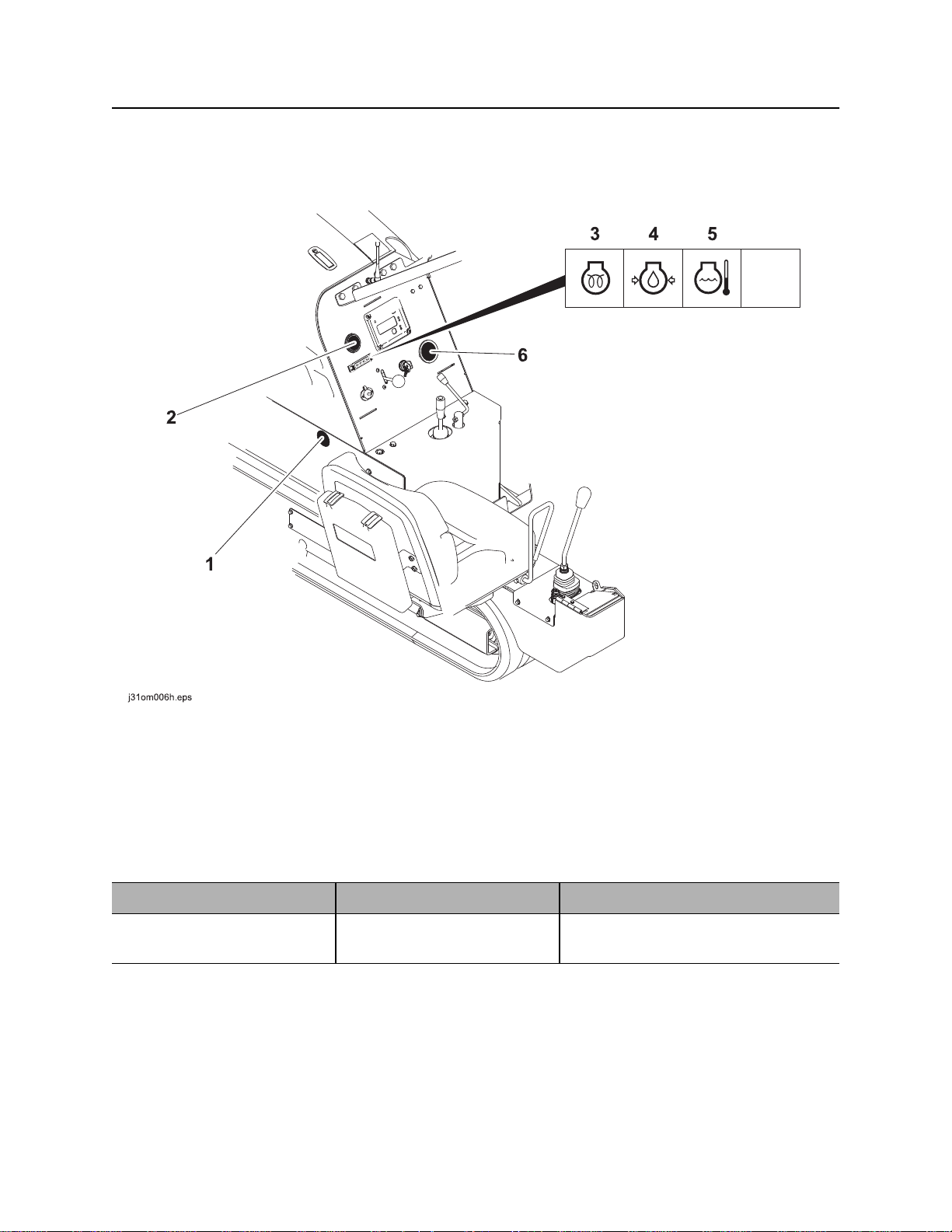

Operator’s Station

Operator’s Station

Gauges and Indicators

1. Hydraulic fluid sight glass

2. Hourmeter

3. Cold start wait (glow plug) indicator

Item Description Notes

1. Hydraulic fluid sight

glass

CMW

Displays level of hydraulic

fluid.

4. Engine oil pressure indicator

5. Engine temperature indicator

6. Drilling fluid pressure gauge

Maintain level in center of glass.

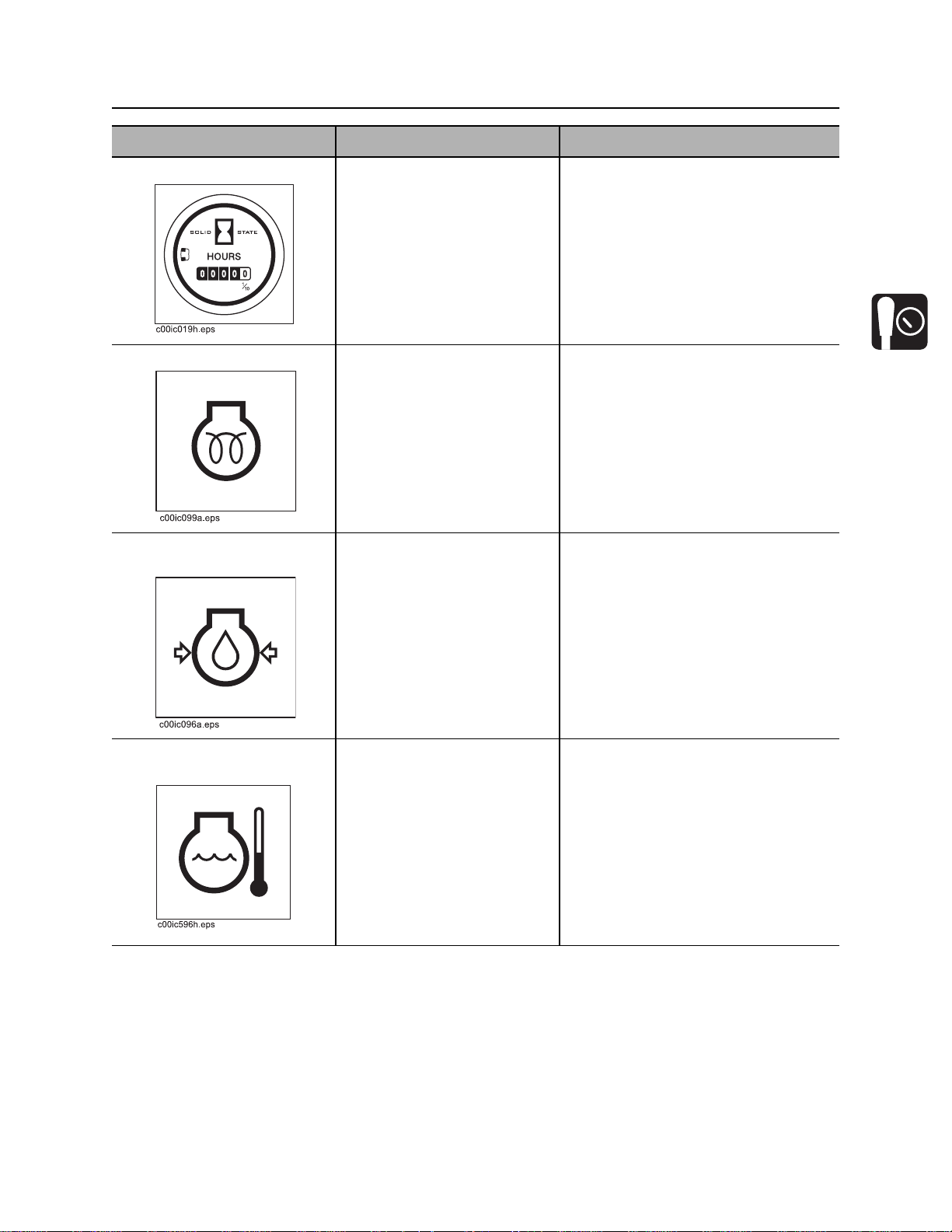

JT5 Operator’s Manual Controls - 27

Operator’s Station

Item Description Notes

2. Hourmeter Displays engine operating

time.

3. Cold start wait indicator Lights when intake air pre-

heater (glow plug) is

operating.

Wait until light goes off before

starting engine.

4. Engine oil pressure

indicator

Lights when oil pressure is

too low. Light will come on

briefly when engine is started.

Use engine operating times to

schedule service.

See “Start Unit” on page 64.

If light remains on:

• Stop engine.

• Check oil level.

5. Engine temperature

indicator

Lights when engine

temperature is too high.

• Check for leaks before starting

engine.

• If pressure is still low, consult

engine manual.

If light remains on:

• Stop engine and let it cool.

• Check fan belt tension.

• Check for low engine oil level.

• Check cooling fins for dirt and

debris.

CMW

Controls - 28 JT5 Operator’s Manual

Operator’s Station

Item Description Notes

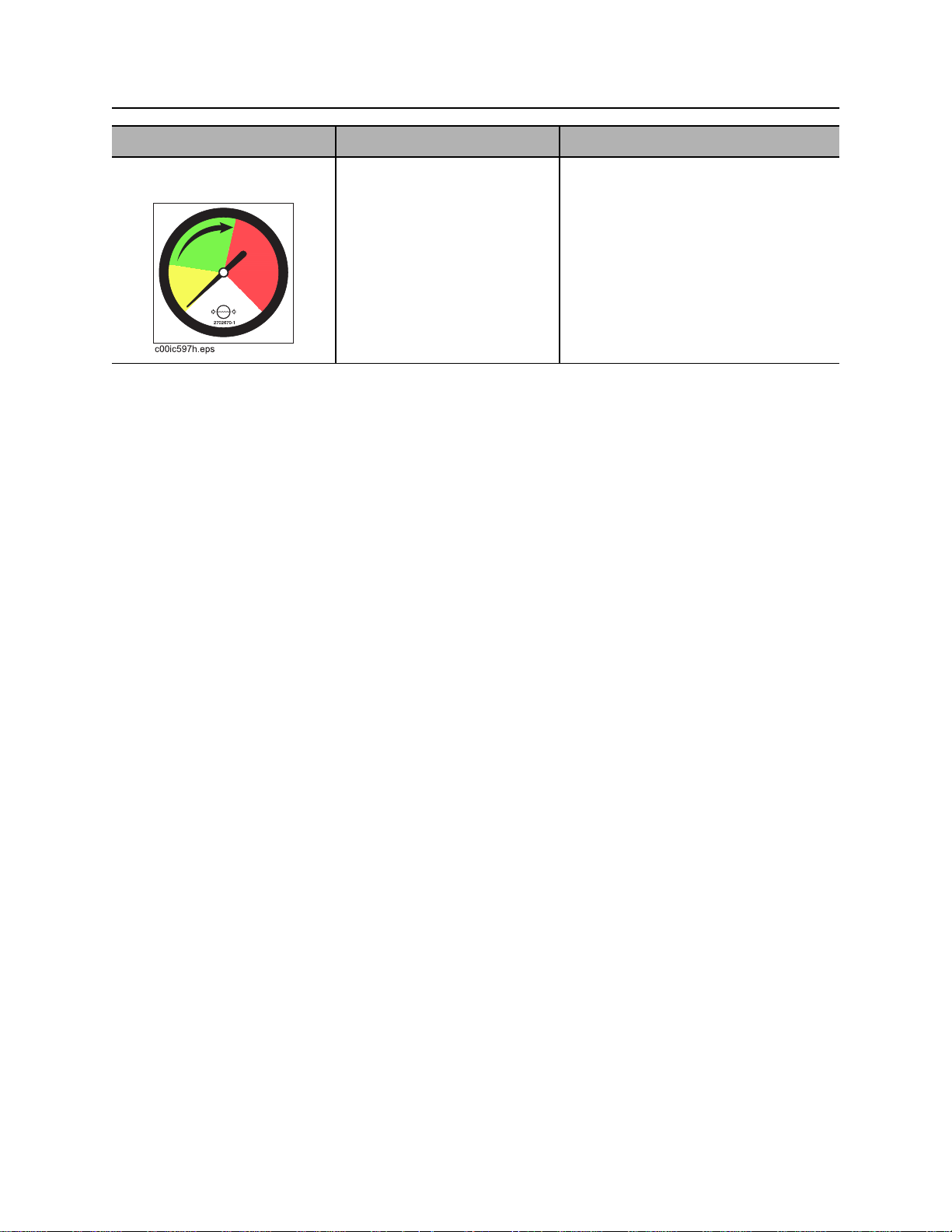

6. Drilling fluid pressure

gauge

Displays drilling fluid pressure

supplied by drilling fluid

pump.

• Yellow: low pressure

• Green: optimum pressure

• Red: high pressure

If pressure is too high, check if nozzle

is plugged.

CMW

JT5 Operator’s Manual Controls - 29

Operator’s Station

Controls

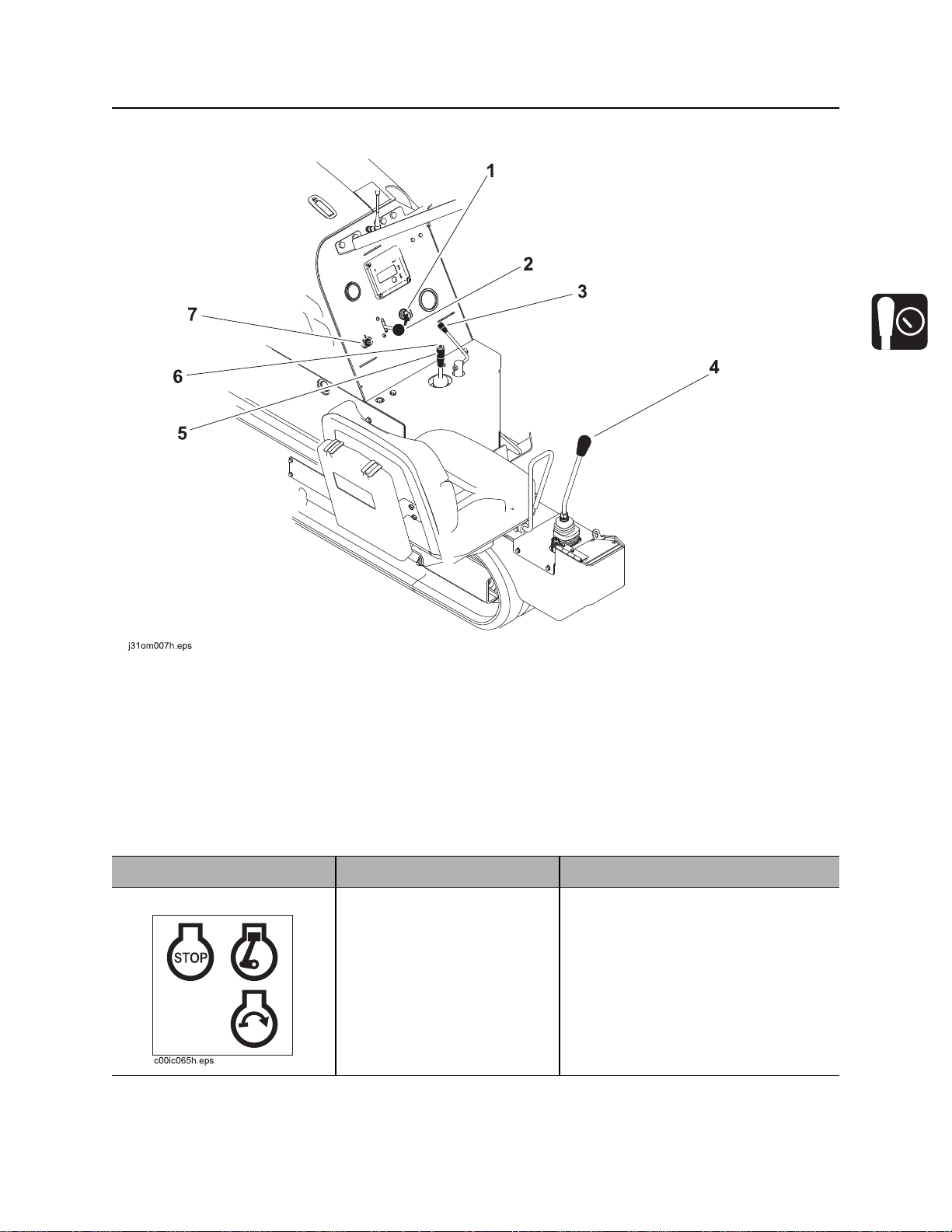

1. Ignition switch

2. Engine throttle control

3. Fluid flow control

4. Carriage control

Item Description Notes

1. Ignition switch To start engine, insert key and

turn clockwise.

To stop engine, turn key

counterclockwise.

5. Wrench control

6. Pipe lubricator control

7. Auxiliary outlet

CMW

Controls - 30 JT5 Operator’s Manual

Operator’s Station

Item Description Notes

2. Engine throttle control To increase engine speed,

push up.

To decrease engine speed,

pull down.

3. Fluid flow control To increase flow, turn

counterclockwise.

To decrease flow, turn

clockwise.

To stop flow, turn all the way

clockwise.

4. Carriage control To move carriage forward,

push.

To move carriage backward,

pull.

To rotate spindle

counterclockwise (breakout),

move right.

To rotate spindle clockwise

(makeup), move left.

5. Wrench control To clamp front wrench and

shut off drilling fluid, move

toward pipebox.

To unclamp front wrench,

move away from pipebox.

To clamp and rotate rear

(rotating) wrench, move

toward engine compartment.

To unclamp rear (rotating)

wrench, move toward seat.

6. Pipe lubricator control

(optional)

CMW

To apply joint compound at

front wrench, press button.

IMPORTANT: Manually apply joint

compound at carriage.

JT5 Operator’s Manual Controls - 31

Operator’s Station

Item Description Notes

7. Auxiliary outlet Provides power for other

equipment.

Power output is 12V, 5A.

CMW

Controls - 32 JT5 Operator’s Manual

Engine Compartment

Engine Compartment

1. Air filter service indicator

3. Battery disconnect switch

2. Tracker control switch

Item Description Notes

1. Air filter service

indicator

Indicates when to change air

filter.

Press button to reset indicator

after changing filter.

CMW

JT5 Operator’s Manual Controls - 33

Engine Compartment

Item Description Notes

2. Tracker control key To allow tracker operator to

stop thrust and rotation, move

key to enable position (up).

To override tracker control

mode, move key to disable

position (right).

1. Battery disconnect

switch

To connect, turn clockwise.

To disconnect, turn

counterclockwise.

IMPORTANT: Remove key and keep

in tracker operator’s possession.

CMW

Controls - 34 JT5 Operator’s Manual

ESID

ESID

23

1

4

5

6

7

8

j07om042h.eps

1. Alphanumeric display

2. Strike indicator

3. Alarm interrupt button

4. Voltage problem indicator

Item Description Notes

1. Alphanumeric display Display amount of current

and voltage being detected

as a percentage of strike

condition.

The line with the “V” shows

voltage reading and the line

with the “A” shows current

reading.

5. Current problem indicator

6. OK indicator

7. Electrical power supply indicator

8. Self test button

CMW

JT5 Operator’s Manual Controls - 35

ESID

Item Description Notes

2. Strike indicator Red lights come on as values

in display increase.

Light in triangle represents

strike warning condition and

will trigger alarm(s) and

strobe(s).

Remember that system can

go from one or two lights to

an electric strike immediately.

3. Alarm interrupt button To turn off strike alarm at

drilling unit, press.

4. Voltage problem

indicator

Blinking red light indicates a

voltage indicator problem.

NOTICE: The ESID does not indicate

proximity to electric lines. System will

activate only when voltage and/or

amperage detected at the drilling unit

are above threshold minimum limits.

See “ESID Diagnostic Codes” on

page 97.

5. Current problem

indicator

Blinking red light indicates a

current indicator problem.

See “ESID Diagnostic Codes” on

page 97.

CMW

Controls - 36 JT5 Operator’s Manual

ESID

Item Description Notes

6. OK indicator Green light means system

self test detected no

problems.

Strike system is ready to

operate.

7. Electrical power supply

indicator

8. Self test button To start manual self test,

Green light means control

box has sufficient electrical

power for operation.

Strike system is ready to

operate if OK indicator is also

on.

press.

To reset system after a strike

has been detected, press.

Checks all systems and circuits.

NOTICE: See “If an Electric Line is

Damaged” on page 18.

CMW

JT5 Operator’s Manual Controls - 37

750/752 Display

750/752 Display

Indicators

1. Beacon temperature display

2. Pitch/slope indicator and percentage indicator

3. Roll indicator

4. Target indentifier indicator

IMPORTANT: Some items operate differently depending where data is being saved. Internal refers to

pipe data being saved to 750/752 Display memory. External refers to pipe data being sent to a properly

connected laptop computer running a version of Trac Management System software.

Item Description Notes

1. Beacon temperature

display

Shows beacon temperature

readings in degrees Farenheit

and degrees Centigrade.

5. Depth estimate

6. Display battery status indicator

7. Beacon battery status indicator

8. Beacon temperature indicator

CMW

Controls - 38 JT5 Operator’s Manual

750/752 Display

Item Description Notes

2. Pitch/slope indicator

and percentage

indicator

3. Roll indicator Indicates beacon roll angle.

4. Target identifier

indicator

Indicates pitch beacon

percent of grade.

Indicates approximate

beacon location.

Internal: shows pipe label and stored

pitch.

External: shows desired pitch.

Only one set of arrows is active at a

time.

5. Depth estimate Indicates beacon depth

estimate.

CMW

Internal: shows job number and

stored depth.

External: shows desired depth.

JT5 Operator’s Manual Controls - 39

750/752 Display

Item Description Notes

6. Display battery status

indicator

7. Beacon battery status

indicator

8. Beacon temperature

indicator

Indicates display power from

drilling unit.

Indicates beacon battery

status.

Indicates beacon

temperature.

If all five bars are not showing, check

display power connections.

See beacon instruction sheet.

See beacon instruction sheet.

CMW

Controls - 40 JT5 Operator’s Manual

750/752 Display

Controls

1. Delete button

2. On/Off button

3. Channel select button

IMPORTANT: Some items operate differently depending where data is being saved. Internal refers to

pipe data being saved to 750/752 Display memory. External refers to pipe data being sent to a properly

connected laptop computer running a version of Trac Management System software.

Item Description Notes

1. Delete button To delete current pipe, press.

Second function:

To delete all jobs in internal

logging memory, press with

Recall button.

2. On/Off button To turn on, press.

4. Roll stop button

5. Recall button

6. Store button

Previous pipe number will appear in

numeric display when data is deleted.

CMW

To turn off, press again.

JT5 Operator’s Manual Controls - 41

750/752 Display

Item Description Notes

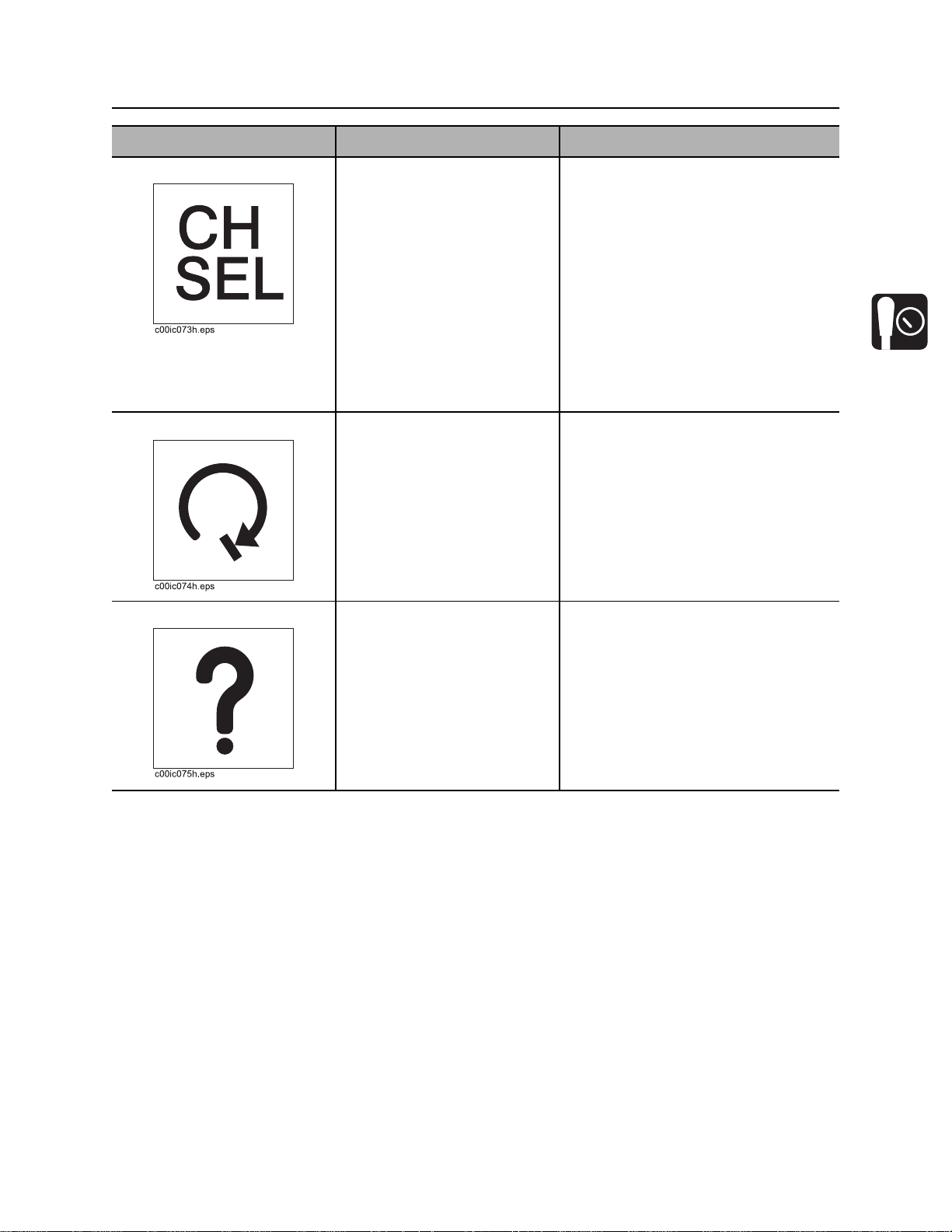

3. Channel select button To display current channel,

press and release.

To switch channels, press

and hold.

Second function:

To start a new job, press with

Recall button.

“Init” and job number will be

displayed.

4. Roll stop button This feature is not yet

available.

5. Recall button To see data about pipe, press

and release.

Unit defaults to last channel used

each time unit is turned on.

IMPORTANT: Make sure display and

tracker are set to the same channel.

Internal: shows data about previous

pipe.

Second function:

To access second functions,

press with other buttons.

External: shows data about next pipe.

CMW

Controls - 42 JT5 Operator’s Manual

750/752 Display

Item Description Notes

6. Store button To display serial number,

press and hold while pressing

on/off button.

To store current pipe data,

press.

Second function:

To download all jobs stored in

internal logging memory:

• Press with Recall button

• Connect display to PC

running Trac

Management System

software.

Pipe number will appear in numeric

display when data is stored.

IMPORTANT: Pipe data cannot be

stored without a valid depth estimate.

CMW

JT5 Operator’s Manual Operation Overview - 43

Operation Overview

Chapter Contents

Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Setting Up at Jobsite . . . . . . . . . . . . . . . . . . . . . . . 44

Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Backreaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Leaving Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Storing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 46

CMW

Operation Overview - 44 JT5 Operator’s Manual

Planning

Planning

1. Gather information about jobsite. See page 49.

2. Inspect jobsite. See page 50.

3. Classify jobsite. See page 52.

4. Plan bore path. See page 55.

5. Check supplies and prepare equipment. See page 61.

6. Load equipment. Seepage 68.

Setting Up at Jobsite

1. Prepare jobsite. See page 60.

2. Unload drilling unit from trailer. See page 70.

3. Assemble drill string. See page 79.

4. Position drilling unit and frame. See page 75.

5. Assemble strike system. See page 95.

6. Anchor drilling unit. See page 93.

7. Calibrate tracker with beacon that will be installed in beacon housing. See tracker operator’s manual.

CMW

JT5 Operator’s Manual Operation Overview - 45

Drilling

Drilling

1. Start system. See page 75.

2. Prime drilling fluid pump. See page 76.

3. Engage tracker control if desired. See page 107.

4. Drill first pipe. See page 81.

5. Record bore path. See page 84.

6. Add pipe. See page 82.

7. Drill remaining pipes in pipe box and correct direction (page 80) as necessary.

8. Surface drill head. See page 85.

Backreaming

1. Assemble backream string. See page 86.

2. Start drilling unit and adjust throttle.

3. Set drilling fluid flow. Check that fluid flows through all nozzles. See page 102.

4. Remove pipe from bore. See page 88.

5. Remove pullback device. See page 89.

Backreaming Tips

• Plan backreaming job before drilling. Plan bore path as straight as possible. Check bend limits of

pullback material. Check that appropriate pullback devices are on hand.

• Keep all bends as gradual as possible.

• Drilling fluid quality is a key factor in backreaming success. Contact your Ditch Witch dealer for

information on testing water, selecting additives, and mixing drilling fluid.

• Backreaming requires more fluid than drilling. Make sure enough fluid is used.

CMW

Operation Overview - 46 JT5 Operator’s Manual

Leaving Jobsite

Leaving Jobsite

1. Remove downhole tools. See page 89.

2. Remove anchors. See page 94.

3. Rinse unit and downhole tools. See page 124.

4. Disassemble strike system and disconnect from fluid system. See page 125.

5. Stow tools. See page 125.

6. Load unit onto trailer. See page 68.

Storing Equipment

1. For cold weather storage, antifreeze drilling unit. See page 122.

2. For long-term storage, disconnect battery disconnect switch.

CMW

JT5 Operator’s Manual Prepare - 47

Prepare

Chapter Contents

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Review Job Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Notify One-Call Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Examine Pullback Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Arrange for Traffic Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Plan for Emergency Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Inspect Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

• Identify Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

• Select Start and End Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Classify Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

• Inspect Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

• Select a Classification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

• Apply Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Plan Bore Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

• Recommended Bend Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

• Entry Pitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• Minimum Setback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

• Minimum Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

• Bore Path Calculator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

CMW

Prepare - 48 JT5 Operator’s Manual

Prepare Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

• Mark Bore Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

• Prepare Entry Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Check Supplies and Prepare Equipment . . . . . . . 61

• Check Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

• Prepare Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• Assemble Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CMW

JT5 Operator’s Manual Prepare - 49

Gather Information

Gather Information

A successful job begins before the bore. The first step in planning is reviewing information already

available about the job and jobsite.

Review Job Plan

Review blueprints or other plans and make sure you have taken bore enlargement during backreaming

and pullback into account. Check for information about existing or planned structures, elevations, or

proposed work that may be taking place at the same time.

Notify One-Call Services

Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

Examine Pullback Material

Ask for a sample of the material you will be pulling back. Check its weight and stiffness. Contact the

manufacturer for bend radius information. Check that you have appropriate pullback devices.

Arrange for Traffic Control

If working near a road or other traffic area, contact local authorities about safety procedures and

regulations.

Plan for Emergency Services

Have the telephone numbers for local emergency and medical facilities on hand. Check that you will have

access to a telephone.

CMW

Prepare - 50 JT5 Operator’s Manual

Inspect Site

Inspect Site

Inspect jobsite before transporting equipment. Check for the following:

• overall grade or slope

• changes in elevation such as hills or open trenches

• obstacles such as buildings, railroad crossings, or streams

• signs of utilities (See “Inspect Jobsite” on page 52.)

• traffic

• access

• soil type and condition

• water supply

• sources of locator interference (rebar, railroad tracks, etc.)

Take soil samples from several locations along bore path to determine best bit and backreamer

combinations.

Identify Hazards

Identify safety hazards and classify jobsite. See “Classify Jobsite” on page 52.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

NOTICE:

• Wear personal protective equipment including hard hat, safety eye wear, and hearing protection.

• Do not wear jewelry or loose clothing.

• Notify One-Call and companies which do not subscribe to One-Call.

• Comply with all utility notification regulations before digging or drilling.

• Verify location of previously marked underground hazards.

• Mark jobsite clearly and keep spectators away.

Remember, jobsite is classified by hazards in place -- not by line being installed.

CMW

JT5 Operator’s Manual Prepare - 51

Inspect Site

Select Start and End Points

Select one end to use as a starting point. Consider the following when selecting a starting point:

Slope

Fluid system should be parked on a level site. Consider how slope will affect drilling unit setup, bending

pipe, and fluid flow out of hole.

Traffic

Vehicle and pedestrian traffic must be a safe distance from drilling equipment. Allow at least 10’ (3 m)

buffer zone around equipment.

Space

Check that starting and ending points allow enough space for gradual pipe bending. See “Minimum

Setback” on page 58.

Check that there is enough space to work and to set up electric strike system.

Comfort

Consider shade, wind, fumes, and other site features.

Drill downhill when possible so fluid will flow away from drilling unit.

CMW

Prepare - 52 JT5 Operator’s Manual

Classify Jobsite

Classify Jobsite

Inspect Jobsite

• Follow U.S. Department of Labor regulations on excavating and trenching (Part 1926, Subpart P) and

other similar regulations.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

• Inspect jobsite and perimeter for evidence of underground hazards, such as:

– “buried utility” notices

– utility facilities without overhead lines

– gas or water meters

– junction boxes

– drop boxes

– light poles

– manhole covers

– sunken ground

• Have an experienced locating equipment operator sweep area within 20’ (6 m) to each side of bore

path. Verify previously marked line and cable locations.

• Mark location of all buried utilities and obstructions.

• Classify jobsite.

Select a Classification

Jobsites are classified according to underground hazards present.

If working . . . then classify jobsite as . . .

within 10’ (3 m) of a buried electric line electric

within 10’ (3 m) of a natural gas line natural gas

in concrete, sand or granite which is capable of producing

crystalline silica (quartz) dust

within 10’ (3 m) of any other hazard other

NOTICE: If you have any doubt about jobsite classification, or if jobsite might contain unmarked

hazards, take steps outlined previously to identify hazards and classify jobsite before working.

crystalline silica (quartz) dust

CMW

JT5 Operator’s Manual Prepare - 53

Classify Jobsite

Apply Precautions

Once classified, precautions appropriate for jobsite must be taken.

Electric Jobsite Precautions

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

In addition to using a directional drilling system with an electric strike system, use one or both of these

methods.

• Expose line by careful hand digging or soft excavation. Use beacon to track bore path.

• Have service shut down while work is in progress. Have electric company test lines before returning

them to service.

Natural Gas Jobsite Precautions

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

In addition to using a directional drilling system and positioning equipment upwind from gas lines, use one

or both of these methods.

• Expose lines by careful hand digging or soft excavation. Use beacon to track bore path. Have

someone observe clearance between drill head and backreamer when crossing a line.

• Have gas shut off while work is in progress. Have gas company test lines before returning them to

service.

CMW

Prepare - 54 JT5 Operator’s Manual

Classify Jobsite

Crystalline Silica (Quartz) Dust Precautions

Jobsite hazards could cause death or serious injury. Use correct

equipment and work methods. Use and maintain proper safety equipment.

NOTICE: Cutting, drilling, or working materials such as concrete, sand, or rock containing quartz may

result in exposure to silica dust. Use water spray or other means to control dust. If workers are exposed

to dust they must wear appropriate breathing protection. Silica dust may cause lung disease and is

known to the State of California to cause cancer.

Follow OSHA or other guidelines for exposure to crystalline silica when trenching, sawing or drilling

through material that might produce dust containing crystalline silica (quartz).

Other Jobsite Precautions

You may need to use different methods to safely avoid other underground hazards. Talk with those

knowledgeable about hazards present at each site to determine which precautions should be taken or if

job should be attempted.

CMW

JT5 Operator’s Manual Prepare - 55

Plan Bore Path

Plan Bore Path

Plan the bore path, from entry to end, before drilling begins. The Ditch Witch Trac Management System

Plus is available for planning your bore path. This special software can be run in the field using a laptop

computer equipped with Windows

If not using Trac Management System Plus, mark the bore path on the ground with spray paint or flags, or

record it on paper for operator reference.

For complicated bores, consult an engineer. Have the jobsite surveyed and bore path calculated. Be sure

the engineer knows minimum entry pitch, bend limits of drill pipe, bend and tension limits of pullback

material, pipe lengths, and location of all underground utilities.

For less complicated bores, plan the bore based on four measurements:

• recommended bend limit

• entry pitch

• minimum setback

• minimum depth

®

95 or higher operating system. See your Ditch Witch dealer for details.

IMPORTANT: See the following pages for more information about these measurements. If not using

Trac Management System Plus, see “Bore Path Calculator” on page 59 and use these measurements to

help plan your bore.

CMW

Prepare - 56 JT5 Operator’s Manual

Plan Bore Path

Recommended Bend Limits

Ditch Witch drill pipes are designed to bend slightly during operation. Slight bending allows for steering and

correcting direction. Bending beyond recommended limits will cause damage that might not be visible. This

damage adds up and will later lead to sudden drill pipe failure.

IMPORTANT: Consider recommended bend limits during any bend, not just during bore entry.

Pipe Pitch

Ditch Witch drill pipe is tested to bend at a maximum

percent pitch. For JT5 drill pipe, make sure pitch (A)

changes no more than 7% over the full length of each

pipe.

NOTICE: Bending drill pipe more sharply than

recommended will damage pipe and cause failure

over time. Changes in pitch must be equally

distributed over the length of a pipe. Maximum

changes in pitch within 1-2’ (300-600 mm) of pipe

create sharp bends that will damage pipe.

Monitor the pitch of each pipe with the 750/752 Display

on the operator’s console. See page 49.

Bend Radius

JT5 drill pipes have a tested minimum bend radius of

70’ (21.3 m). This means that a 90-degree bend in the

bore path:

• has a radius (A) of 70’ (21.3 m)

• requires approximately 110’ (33.5 m) of drill

pipe (B).

NOTICE: Bending drill pipe more sharply than

recommended will damage the pipe and cause

failure over time.

• If bend radius is reduced, drill pipe life is

reduced.

• If bend radius is increased, drill pipe life is

increased.

IMPORTANT: Use the charts on the next page to keep bends within safe limits.

CMW

JT5 Operator’s Manual Prepare - 57

Plan Bore Path

Pipe-By-Pipe Bend Limits

Pipe

(C)

1 4’ 11" (1.5 m) 0’ 2" (.05 m) 13 55’ 5" (16.9 m) 27’ 3" (8.3 m)

2 9’ 10" (3.0 m) 0’ 8" (.2 m) 14 58’ 4" (17.8 m) 31’ 3" (9.5 m)

3 14’ 8" (4.5 m) 1’ 7" (.5 m) 15 60’ 11" (18.6 m) 35’ 5" (10.8 m)

4 19’ 5" (5.9 m) 2’ 9" (.8 m) 16 63’ 2" (19.3 m) 39’ 8" (12.1 m)

5 24’ 1" (7.4 m) 4’ 3" (1.3 m) 17 65’ 1" (19.9 m) 44’ 4" (13.5 m)

6 28’ 8" (8.7 m) 6’ 2" (1.9 m) 18 66’ 9" (20.4 m) 48’ 11" (14.9 m)

7 33’ 1" (10.1 m) 8’ 4" (2.5 m) 19 68’ 1" (20.8 m) 53’ 8" (16.4 m)

8 37’ 4" (11.4 m) 10’ 9" (3.3 m) 20 69’ 1" (21.1 m) 58’ 6" (17.8 m)

9 41’ 5" (12.6 m) 13’ 7" (4.1 m) 21 69’ 8" (21.2 m) 63’ 4" (19.3 m)

10 45’ 3" (13.8 m) 16’ 7" (5.1 m) 22 69’ 11" (21.3 m) 68’ 4" (20.8 m)

11 48’ 11" (14.9 m) 19’ 11" (6.1 m) 23 70’ 0” (21.4 m) 70’ 0” (21.3 m)

12 52’ 4" (15.9 m) 23’ 6" (7.2 m)

Forward (B) Deflection (A) Pipe

(C)

Forward (B) Deflection (A)

Pipe 13 is illustrated.

CMW

Prepare - 58 JT5 Operator’s Manual

Plan Bore Path

Entry Pitch

Entry pitch is the slope of the drill frame compared with the slope of the ground. Determine entry pitch one

of two ways:

1. With Pitch Beacon

• Lay pitch beacon on the ground and read

pitch.

• Lay pitch beacon on drill frame and read pitch.

• Subtract ground pitch from drilling unit pitch.

2. With Measurements

• Measure from the ground to front end of drill

frame (H1).

• Measure from the ground to back end of frame

(H2).

• Subtract (H1) from (H2). Record this number.

• Measure the distance between front and back

points (C).

• Divide (H2-H1) by (C), then multiply by 100.

This is your pitch.

IMPORTANT: A shallow entry pitch (A1) allows you

to reach horizontal sooner and with less bending.

Increasing entry pitch (A2) makes bore path longer

and deeper.

Minimum Setback

Setback is the distance from the entry point to where

pipe becomes horizontal (B1).

NOTICE: If setback is too small (B2), you will

exceed bend limits and damage the pipe.

CMW

JT5 Operator’s Manual Prepare - 59

Plan Bore Path

Minimum Depth

Because you must bend pipe gradually, entry pitch and

bend limits determine how deep the pipe will be when

it becomes horizontal. This is called the minimum

depth.

• To reduce minimum depth (D1), reduce entry

pitch. This also decreases setback.

• To increase minimum depth (D2), increase entry

pitch. This also increases setback.

Bore Path Calculator

Entry pitch, setback, and minimum depth work together with bend limits to determine the bore path. To find

the setback (B) and entry pitch (A) that will take you to the desired minimum depth (D), use the chart

below.

Minimum depth (D) Entry pitch (A) Setback (B) Depth to begin steering (S)

2’ 0" (0.6 m) -18% 17’ 4" (5.3 m) 0’ 11" (0.28 m)

2’ 4" (0.7 m) -20% 18’ 8" (5.7 m) 1’ 0" (0.30 m)

2’ 9" (0.8 m) -22% 19’ 11" (6.1 m) 1’ 1" (0.33 m)

3’ 1" (0.9 m) -24% 21’ 2" (6.5 m) 1’ 2" (0.36 m)

3’ 6" (1.1 m) -26 22’ 5" (6.8 m) 1’ 3" (0.38 m)

3’ 11" (1.2 m) -28 23’ 8" (7.2 m) 1’ 4" (0.41 m)

4’ 5" (1.4 m) -30 24’ 11" (7.6 m) 1’ 5" (0.43 m)

IMPORTANT: Numbers in table based on 70’ (21.3 m) minimum bend radius, beacon housing, EZ-

Connect, connector, transition sub, and 1/3 of first drill pipe (L, totaling 5’ [1.5 m]) in the ground before

steering.

CMW

Prepare - 60 JT5 Operator’s Manual

Prepare Jobsite

Prepare Jobsite

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

NOTICE:

• If jobsite classification is in question or if the possibility of unmarked electric utilities exists, classify

jobsite as electric.

• Cutting high voltage cable can cause electrocution. Expose lines by hand before digging.

• All vegetation near operator’s station must be removed. Contact with trees, shrubs, or weeds during

electrical strike could result in electrocution.

Mark Bore Path

Mark your planned bore path and all located utility lines with flags or paint.

Prepare Entry Point

For bore to be successful, first pipe must be straight as

it enters the ground.

To help ensure that the first pipe does not bend, dig a

small starting hole so that the first pipe is drilled into a

vertical surface.

To prevent bending or straining pipe, position drilling

unit for straight entry.

CMW

JT5 Operator’s Manual Prepare - 61

Check Supplies and Prepare Equipment

Check Supplies and Prepare Equipment

Check Supplies

• receiver/transmitter or tracker with spare batteries

• beacons with new and spare batteries

• two-way radios with new and spare batteries

• quick wrench (see page 115)

• transition sub

• anchoring equipment and accessories

• bits, screens, nozzles (see page 110)

• adapters, pipe, beacon housings

• marking flags or paint

• water and additional hoses

• fuel (Use low sulfur or ultra low sulfur fuel only.)

• drilling fluid additives (see page 102)

• spare fuses

• keys

• backreamers, swivels, pulling devices (see page 110)

• wash down hose and spray gun

• duct tape

• spray lubricant

• tool joint compound (see page 130)

• electrically insulating boots and gloves

• personal protective equipment, such as hard hat and safety glasses

• notepad and pencil

CMW

Prepare - 62 JT5 Operator’s Manual

Check Supplies and Prepare Equipment

Prepare Equipment

Fluid Levels

• fuel (Use low sulfur or ultra low sulfur fuel only.)

• hydraulic fluid

• engine coolant

• battery charge

• engine oil

Condition and Function

• filters (air, oil, hydraulic)

• fluid pump

• couplers

• tires and tracks

• pumps and motors

• drilling fluid mixer

• hoses and valves

• water tanks

Assemble Accessories

Fire Extinguisher

If required, mount a fire extinguisher near the power unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric fires. It should meet legal and regulatory

requirements.

CMW

JT5 Operator’s Manual Drive - 63

Drive

Chapter Contents

Start Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Steer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Shut Down Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

CMW

Drive - 64 JT5 Operator’s Manual

Start Unit

Start Unit

1. Insert key.

2. Turn key clockwise. When the ambient temperature is below 32°F (0°C), use the cold start procedure

to activate glow plugs.

• Turn key to ON position. Glow plugs will activate.

• Wait for cold start wait indicator to turn off. (See page 26.)

• Turn key to START position.

3. Run engine at low throttle for 5 minutes.

Steer Unit

To steer drilling unit, follow instructions for type of steering desired. See page 22 for more information.

To steer while moving forward, move one control slightly more than the other to turn in the desired

direction. Drilling unit will gradually turn to left or right.

To steer while moving backward, move one control slightly more than the other to turn in the desired

direction. Drilling unit will gradually turn to left or right.

For tight steering at low speed, one control to reverse and one control to forward to turn in the desired

direction. Tracks will counter-rotate and turn drilling unit in a tight circle.

Tips to Reduce Track Wear

Rubber tracks are best suited for soil-based job sites with minimal rock and debris. Sharp objects such as

gravel, steel shards, and broken concrete will damage rubber tracks and undercarriage components.

Excessive operation on concrete or asphalt will shorten track life. When storing your machine, keep tracks

away from rain and direct sunlight.

Wash tracks daily to remove foreign objects and abrasive soil from sprockets and idler rollers. Drive slowly

and make wide turns when possible. Regularly check undercarriage components (sprocket, rollers, idler)

for wear and damage. Maintain proper track tension. (See “Check Track Tension and Condition” on

page 148.)

To prevent premature wear, avoid the following:

• Spinning tracks under heavy load.

• Turning on sharp objects such as stones, stumps and debris.

• Quick turns or “spin” turns on asphalt or concrete.

• Driving over curbs, ledges, and sharp objects.

• Driving with sidewall edges pressed against hard walls, curbs or other objects.

• Driving on slopes.

• Operating on corrosive materials such as salt or fertilizer. Wash immediately.

CMW

JT5 Operator’s Manual Drive - 65

Shut Down Unit

Shut Down Unit

1. Stop track movement.

2. Lower drill frame and stabilizer to the ground.

IMPORTANT: If frame and stabilizer cannot be lowered, use cylinder locks or other suitable

material to block the tracks. Remove cylinder locks or chocks before driving unit.

3. Run engine at low throttle for 3 minutes to cool.

4. Turn key to STOP.

5. Remove key.

CMW

Drive - 66 JT5 Operator’s Manual

Shut Down Unit

CMW

JT5 Operator’s Manual Transport - 67

Transport

Chapter Contents

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

• Unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Tow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

CMW

Transport - 68 JT5 Operator’s Manual

Lift

Lift

This machine is not configured for lifting. If the machine must be lifted, load machine into a container or

onto a platform appropriate for lifting. See “Specifications” on page 151 for weight of machine.

Haul

Load

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

NOTICE:

• Load and unload trailer on level ground.

• Verify that trailer wheels are blocked.

• Incorrect loading can cause trailer swaying.

• Attach trailer to vehicle before loading or unloading.

• Ten to fifteen percent of total vehicle weight (equipment plus trailer) must be on tongue to help

prevent trailer sway.

1. Start drilling unit engine.

2. Move drilling unit to rear of trailer and align with ramps.

3. Slow engine to low throttle and slowly drive unit onto trailer.

4. Lower drill frame and stabilizer to trailer floor. Keep tracks fully on trailer floor.

5. Stop engine when unit is safely positioned on trailer bed.

6. Attach tiedowns to drilling unit where indicated on page 69.

CMW

JT5 Operator’s Manual Transport - 69

Haul

Tie Down

Points

Tiedown points are identified by tiedown decals. Securing to trailer at other

points is unsafe and can damage machinery.

Procedure

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Do not use tiedown points for towing or lifting.

Loop tiedowns around rear tiedown points. Use D-rings or pin to trailer using hole in anchor plate. Make

sure tiedowns are tight before transporting.

CMW

Transport - 70 JT5 Operator’s Manual

Haul

Unload

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

NOTICE:

• Load and unload trailer on level ground.

• Ensure trailer wheels are blocked.

• Attach trailer to vehicle before loading or unloading.

1. Lower ramps.

2. Remove tiedowns.

3. Start drilling unit engine.

4. Raise stabilizer and drill frame.

5. Slow engine to low throttle and slowly back unit down trailer or ramps.

CMW

JT5 Operator’s Manual Transport - 71

Tow

Tow

Under normal conditions, drilling unit should not be towed. If unit breaks down and towing is necessary:

• Attach chains to indicated tow points facing towing vehicle.

• Disengage track hydraulics.

• Tow for short distances at less than 1 mph (1.6 km/h).

• Use maximum towing force of 1.5 times unit weight.

To disengage track hydraulics:

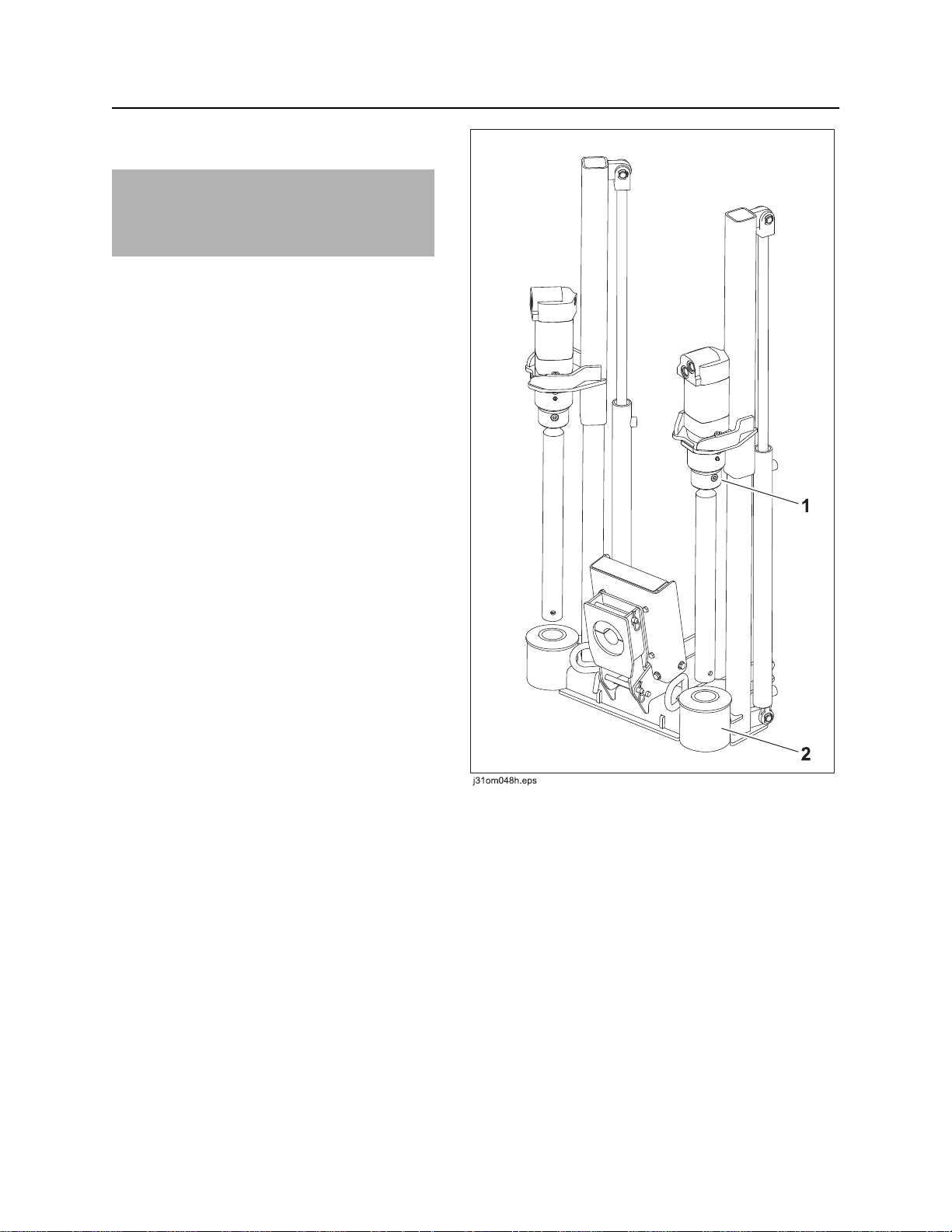

1. Loosen locknut (2).

2. Turn screw (1) on each counterbalance valve

clockwise until it stops.

IMPORTANT: Be sure to count number of

turns.

3. Repeat on other track.

To engage track hydraulics:

1. Turn screw (1) on counterbalance valve

exactly the same number of turns

counterclockwise.

2. Tighten locknut (2).

3. Repeat on other track.

CMW

Transport - 72 JT5 Operator’s Manual

Tow

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Do not use tiedown points (D-rings) for towing or lifting.

Loop chain through tow points on left and right side of unit (shown) and pull straight forward.

CMW

JT5 Operator’s Manual Conduct a Bore - 73

Conduct a Bore

Chapter Contents

Position Equipment . . . . . . . . . . . . . . . . . . . . . . . . 75

Connect Fluid System . . . . . . . . . . . . . . . . . . . . . . 75

Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Prime Drilling Fluid Pump . . . . . . . . . . . . . . . . . . . 76

Operate Carriage Control . . . . . . . . . . . . . . . . . . . 77

Assemble Drill String . . . . . . . . . . . . . . . . . . . . . . . 79

• Prepare Beacon Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

• Attach EZ-Connect to Drill Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

• Attach Transition Sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

• Connect Drill Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

• Engage EZ-Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drill First Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Add Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Correct Direction . . . . . . . . . . . . . . . . . . . . . . . . . . 83

• Basic Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

• Drill Head Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

CMW

Conduct a Bore - 74 JT5 Operator’s Manual

Record Bore Path . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Surface Drill Head . . . . . . . . . . . . . . . . . . . . . . . . . 85

Assemble Backream String . . . . . . . . . . . . . . . . . 86

Remove Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Remove Pullback Device . . . . . . . . . . . . . . . . . . . . 89

CMW

JT5 Operator’s Manual Conduct a Bore - 75

Position Equipment

Position Equipment

1. Review bore plan and select drilling unit position and fluid unit position. See “Select Start and End

Points” on page 47.

2. Move equipment into selected positions.

Connect Fluid System

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

NOTICE: If an electrical strike occurs while drilling unit is connected to a fluid system, the

fluid system will also become electrified. Do not connect drilling unit to a public or private

(business or home) water supply.

1. Connect fluid hose from mixing system to

drilling fluid pump. A 1.5” (38 mm) or larger,

non-collapsible hose is required.

2. Install y-strainer between mixing unit and

drilling fluid pump. Position strainer so that

drilling fluid flows in the direction of the arrow.

In most cases, positioning strainer at outlet of

mixing unit gives best results.

IMPORTANT: Clean y-strainer regularly.

Start System

1. Start drilling unit and remote fluid unit. Allow both engines to warm up.

IMPORTANT: Ensure that mixture of drilling fluid matches drilling conditions.

2. Enable tracker control mode. See “Tracker Control” on page 107.

3. Move drilling unit throttle control until engine is at full throttle.

4. Move fluid control to desired setting to fill pipe with fluid.

CMW

Conduct a Bore - 76 JT5 Operator’s Manual

Prime Drilling Fluid Pump

Prime Drilling Fluid Pump

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

NOTICE: Failure to prime the drilling fluid pump will cause flow fluctuations, which will

make it difficult to control the washwand.

Pressurized fluid or air could pierce skin and cause injury

or death. Stay away.

Prime drilling fluid pump each time tank is changed. To prime the pump:

1. Fill drilling fluid hose and connect hose to unit.

2. Operate mixing/transfer pump at full speed for 1 - 3 minutes to discharge air from system.

3. Return mixing/transfer pump to normal operating speed and continue the bore.

4. If drilling fluid pressure surges are observed, repeat step 2.

CMW

JT5 Operator’s Manual Conduct a Bore - 77

Operate Carriage Control

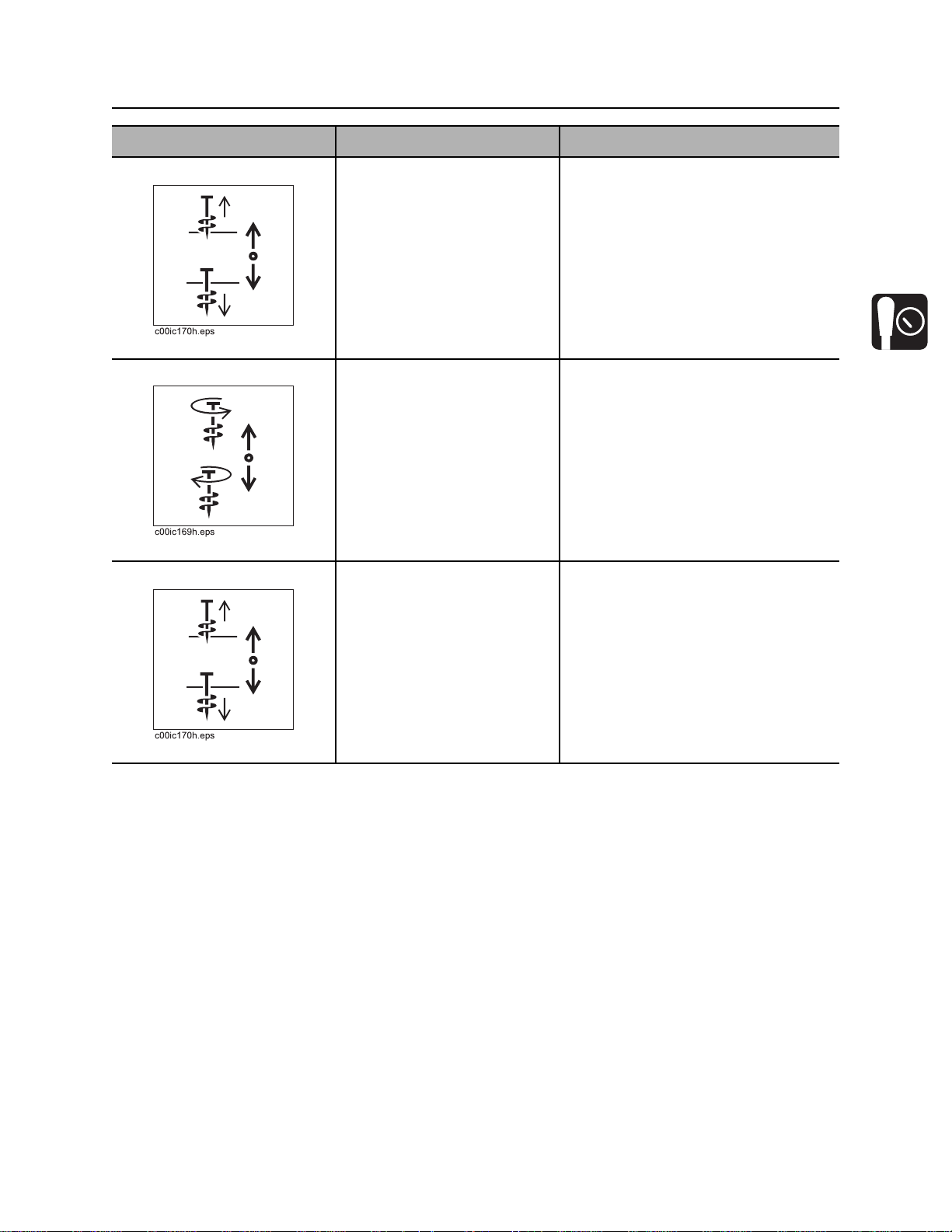

Operate Carriage Control

The thrust/rotation control has eight positions which allow the four basic

functions to be combined. The chart below summarizes functions that occur

when control is put at a combined position. Operator must be in seat for

control to function.

Carriage Movement Rotation Direction

forward clockwise (makeup)

reverse counterclockwise (breakout)

CMW

Conduct a Bore - 78 JT5 Operator’s Manual

Clamp Pipe

Clamp Pipe

Turning shaft can kill you or crush arm or leg. Stay away.

NOTICE: Clamping anywhere else on the pipe will weaken the pipe. Pipe can later break,

even when operating under normal loads.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

NOTICE: Wrenches can open after engine shutdown. Ensure that any downhole tool or pipe in tool joint

vises is attached to spindle or removed before transport.

Clamp on pipe when joint is centered between

wrenches (1 and 2). Always clamp on the larger

diameter areas on either side of the tool joint face.

CMW

JT5 Operator’s Manual Conduct a Bore - 79

Assemble Drill String

Assemble Drill String

Moving tools will kill or injure. Shut off drill string power when anyone can

be struck by moving or thrown tools. Never use pipe wrenches on drill string.

Prepare Beacon Housing

1. Select nozzles and bit.

IMPORTANT: A variety of nozzles and bits are available to suit your particular job conditions. See

“Downhole Tools” on page 110 for more information, or contact your Ditch Witch dealer.

2. Insert nozzle (2) into beacon housing.

3. Attach bit (3) to beacon housing (1).

4. Install beacon, following beacon instructions

for:

• battery replacement

• beacon positioning

5. Install beacon housing lid. See “Beacon

Housings” on page 111.

6. Follow beacon instructions to check beacon

operation.

7. Follow tracker instructions to calibrate

beacon.

Attach EZ-Connect to Drill Head

1. Apply tool joint compound to shoulders and threads and hand tighten EZ-Connect adapter (4) to

beacon housing (1).

2. Use quick wrench to fully tighten joint.

CMW

Conduct a Bore - 80 JT5 Operator’s Manual

Assemble Drill String

Attach Transition Sub

Use either machine torque or quick wrench to

attach transition sub.

• Attach transition sub (6) directly to beacon

housing (1), or

• Attach transition sub (5) to EZ-Connect

adaptor (4).

Machine Torque

1. Apply tool joint compound to shoulders and

threads and thread transition sub onto saver

sub.

2. Align drill pipe flats of EZ-Connect box or

beacon housing with front wrench of drill

frame.

3. Start drilling unit engine.

4. Use machine power to slowly rotate spindle and transition sub onto EZ-Connect box or beacon

housing.

5. Tighten to full machine torque.

Quick Wrench

1. Lube joints with TJC.

2. Attach quick wrench to the joint in the join position and tighten joint. See “Quick Wrench” on page 115.

Connect Drill Pipe

1. Start drilling unit engine.

2. Align transition sub in front wrench.

3. Load pipe into wrench cradle.

4. Lubricate shoulders and threads.

5. Remove hands from pipe area.

6. Move carriage forward until saver sub nears male pipe thread.

7. Slowly rotate spindle clockwise. Carriage will move forward as threads screw together.

8. Slowly move carriage forward until pipe end touches end of transition sub.

9. To thread pipes together and fully torque joint, slowly rotate drill pipe until spindle stops turning.

10. Open front wrench and move carriage back.

CMW

JT5 Operator’s Manual Conduct a Bore - 81

Drill First Pipe

Drill First Pipe

Turning shaft can kill you or crush arm or leg. Stay away.

NOTICE:

• Keep everyone at least 10’ (3 m) away from turning drill string.

• Push rod or pipe slowly. Forcing can bend string. Do not use bent rod or pipe.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

1. Turn on drilling fluid.

2. Visually check for drilling fluid flow.

3. Turn drill bit to starting position. See “Prepare Entry Point” on page 60.

4. Slowly move carriage forward. See “Prepare Entry Point” on page 60. Take care to steer to drill straight

in line with drilling unit. Drill in downhole tools and 1/3 of first pipe before steering.

5. Monitor gauges.

CMW

Conduct a Bore - 82 JT5 Operator’s Manual

Add Pipe

Add Pipe

1. Set engine throttle to full speed.

2. Clamp pipe joint. See “Clamp Pipe” on page 78.

3. Locate drill head.

4. Engage front wrench until pipe is clamped and pressure develops.

5. Slowly rotate spindle counterclockwise. Move carriage back as threads unscrew.

6. After threads are fully unscrewed, stop rotation and move carriage to back of frame, slowing down as

carriage approaches rear end.

7. Connect Pipe. See “Connect Drill Pipe” on page 80.

8. Ensure that pipe fills and fluid pressure begins to rise.

9. Rotate spindle.

10. Slowly move carriage forward. Adjust rotation speed control according to bit size and soil conditions.

11. Monitor gauges.

12. Locate drill head with tracker at least every half-length of pipe.

CMW

JT5 Operator’s Manual Conduct a Bore - 83

Correct Direction

Correct Direction

Correcting direction is a skill operators gain with experience and knowledge of equipment and soil

conditions. These instructions cover only basic procedures. For information about specific equipment or

jobsites, contact your Ditch Witch dealer.

To track progress and make corrections, one crew member locates the drill head and sends instructions to

the operator. Corrections are made by tracking the drill head, comparing current position to bore plan, and

steering drill head as needed.

Basic Rules

• Steering ability depends on soil condition; bit, drill head, and nozzle used; roll of drill head; and

distance pushed without outer rotation.

• All corrections should be made as gradually as possible. See “Recommended Bend Limits” on

page 56.

• Over correcting will cause “snaking.” This can damage pipe and will make drilling and pullback more

difficult. Begin to straighten out of each correction as early as possible.

• Do not push an entire piece of drill pipe into ground without rotation. This can exceed bend radius and

cause pipe failure.

Procedure

1. When drilling has stopped/paused, locate drill head. Take readings available with your beacon and

locating equipment such as:

• depth

• pitch

• left/right information

• temperature

• beacon roll

2. Compare position to bore plan. Determine direction drilling should go.

3. Position drill head.

4. Push in drill pipe as needed to change direction.

5. Rotate in remaining length of drill pipe.

CMW

Conduct a Bore - 84 JT5 Operator’s Manual

Record Bore Path

Drill Head Position

The drill head position is determined by reading

beacon roll. Roll is displayed as a clock face

position.

1. Read beacon roll.

2. Slowly rotate pipe until locator displays desired

beacon roll.

To change direction:

1. Rotate pipe to clock position you intend to travel.

2. Push pipe into ground.

To move forward without changing direction:

Rotate pipe into ground.

Record Bore Path

Locate drill head every length of pipe. As the job is completed, record the actual data for each drill pipe.

List pitch and depth of each joint and a brief description of the procedure. In addition, draw a simple sketch

of the site and record depth and rough location of pullback.

The Trac Management System Plus is also available for plotting and tracking your bore path. It utilizes the

750/752 Tracker, 750/752 Display, a tracking beacon, and special software. The display can store jobs in

its memory or the system can be run in the field using a laptop computer equipped with the Windows® 95

or higher operating system. See your Ditch Witch dealer for details.

CMW

JT5 Operator’s Manual Conduct a Bore - 85

Surface Drill Head

Surface Drill Head

Moving tools will injure or kill. Shut off drill string power when anyone can

be struck by moving or thrown tools. Never use pipe wrenches on drill string.

Turning shaft will kill you or crush arm or leg. Stay away.

NOTICE:

• Tracker operator and drill operator should maintain two-way communication.

• Keep everyone clear of the exposed drill string.

• No one should enter pit until clear communication is given by the drill operator that the drill unit is