Page 1

FX50

Operator’s

Manual

CMW

®

Issue 1.0

053-2545

Page 2

FX50 Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Equipment Modification . . . . . . . . . . . . . . . . . . . . . 3

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operator Orientation. . . . . . . . . . . . . . . . . . . . . . . . . 6

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Bulleted Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Numbered Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CMW

Page 3

Overview - 2 FX50 Operator’s Manual

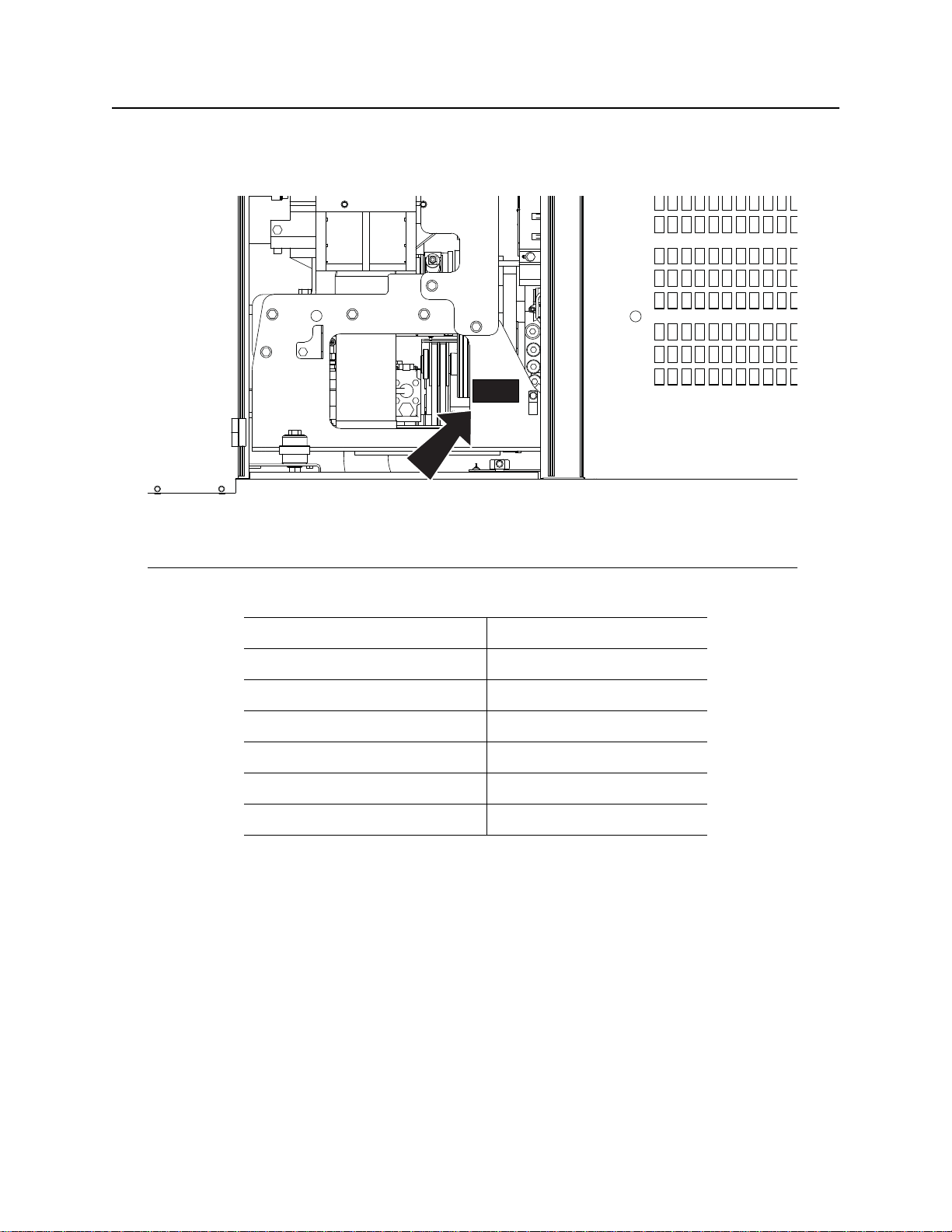

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in spaces provided. FX50 serial number is located as shown.

j36om071w.eps

Date of manufacture

Date of purchase

FX50 serial number (shown)

Engine serial number

Blower serial number

Water pump serial number

Trailer serial number

Intended Use

The FX50 is a self-contained vacuum excavation unit capable of vacuuming a wide variety of nonhazardous, non-flammable liquid and solid debris. It is designed to perform efficient soft excavation,

including exposing utilities for visual verification and/or potholing. The optional reverse flow system allows

for spoils transfer to another tank. The FX50 is intended for operation in ambient temperatures from 0° to

115°F (-18° to 46°C). Use in any other way is considered contrary to the intended use.

The FX50 should be operated, serviced, and repaired only by persons familiar with its particular

characteristics and acquainted with the relevant safety procedures.

CMW

Page 4

FX50 Operator’s Manual Overview - 3

j35om001h.eps

1

2

33445

6

7

8

10

9

11

12

Equipment Modification

Equipment Modification

This equipment was designed and built in accordance with applicable standards and regulations.

Modification of equipment could mean that it will no longer meet regulations and may not function properly

or in accordance with the operating instructions. Modification of equipment should only be made by

competent personnel possessing knowledge of applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

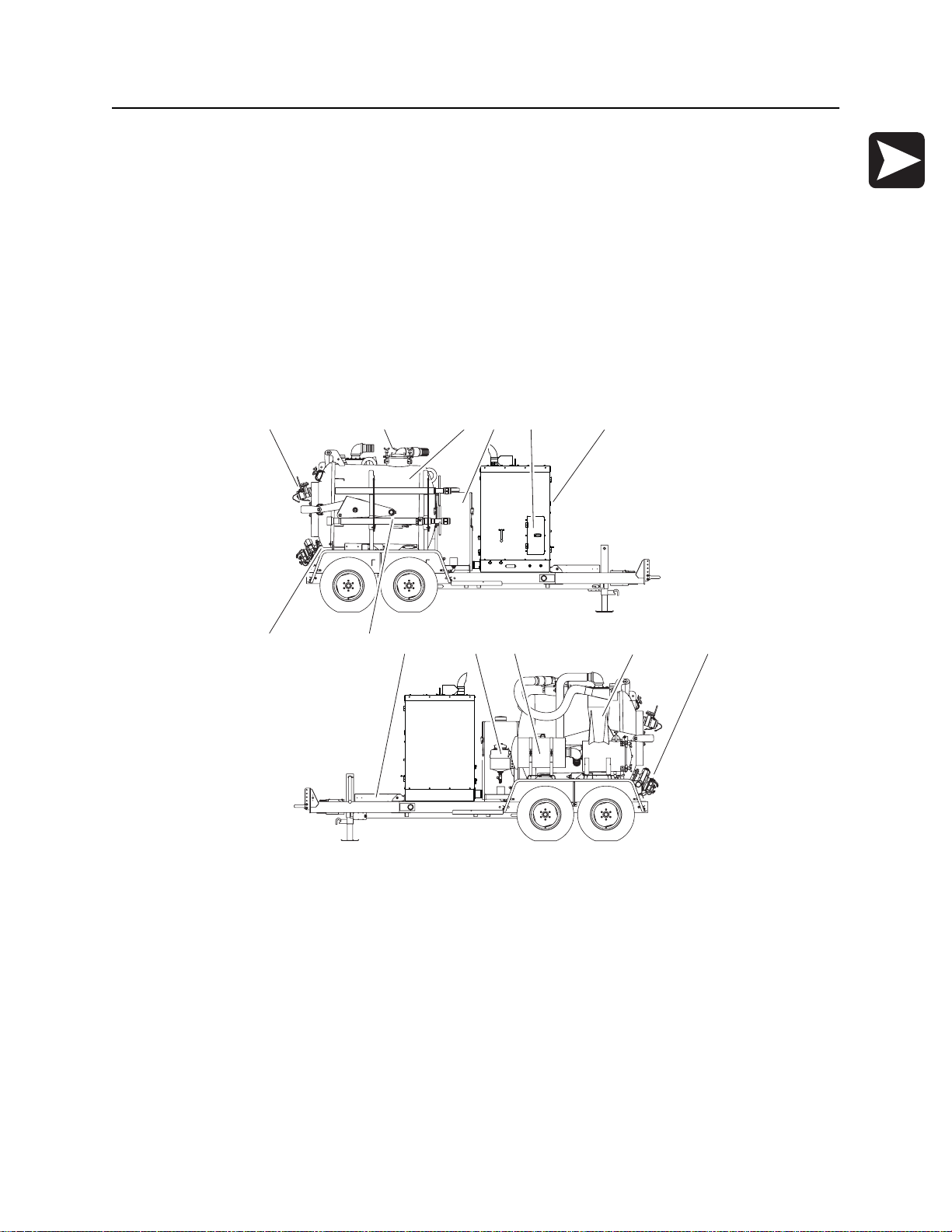

Unit Components

300-Gallon Tank

1

7

2

8

5

9

10

11

6

1312

j36om075w.eps

1. Inlet valve

2. Vacuum tank

3. Primary shut-off valve

4. Water tank

5. Operator’s station

6. Power unit

7. Hose reel

8. Potholing tools

9. Tool storage

10. Antifreeze tank

11. Vacuum filter

12. Cyclonic separator

13. Drain/outlet valve

CMW

Page 5

Overview - 4 FX50 Operator’s Manual

1

2

3

4

5

6

7

8

10

9

11

12

j

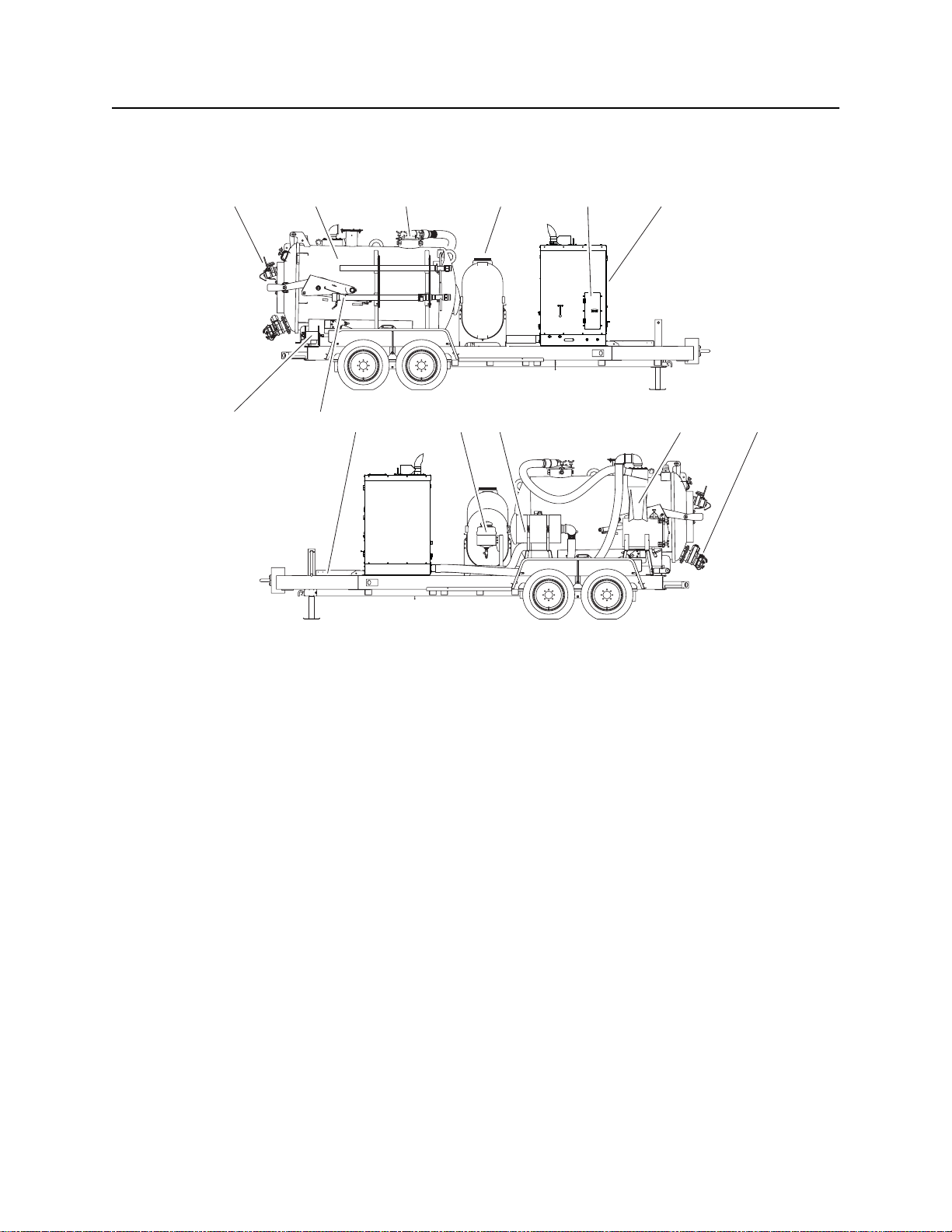

Unit Components

800-Gallon Tank

36om002w.eps

1

7

2

9

8

3

10

11

4

5

6

1312

1. Inlet valve

2. Vacuum tank

3. Primary shut-off valve

4. Water tank

5. Operator’s station

6. Power unit

7. Hose reel

8. Potholing tools

9. Tool storage

10. Antifreeze tank

11. Vacuum filter

12. Cyclonic separator

13. Drain/outlet valve

CMW

Page 6

FX50 Operator’s Manual Overview - 5

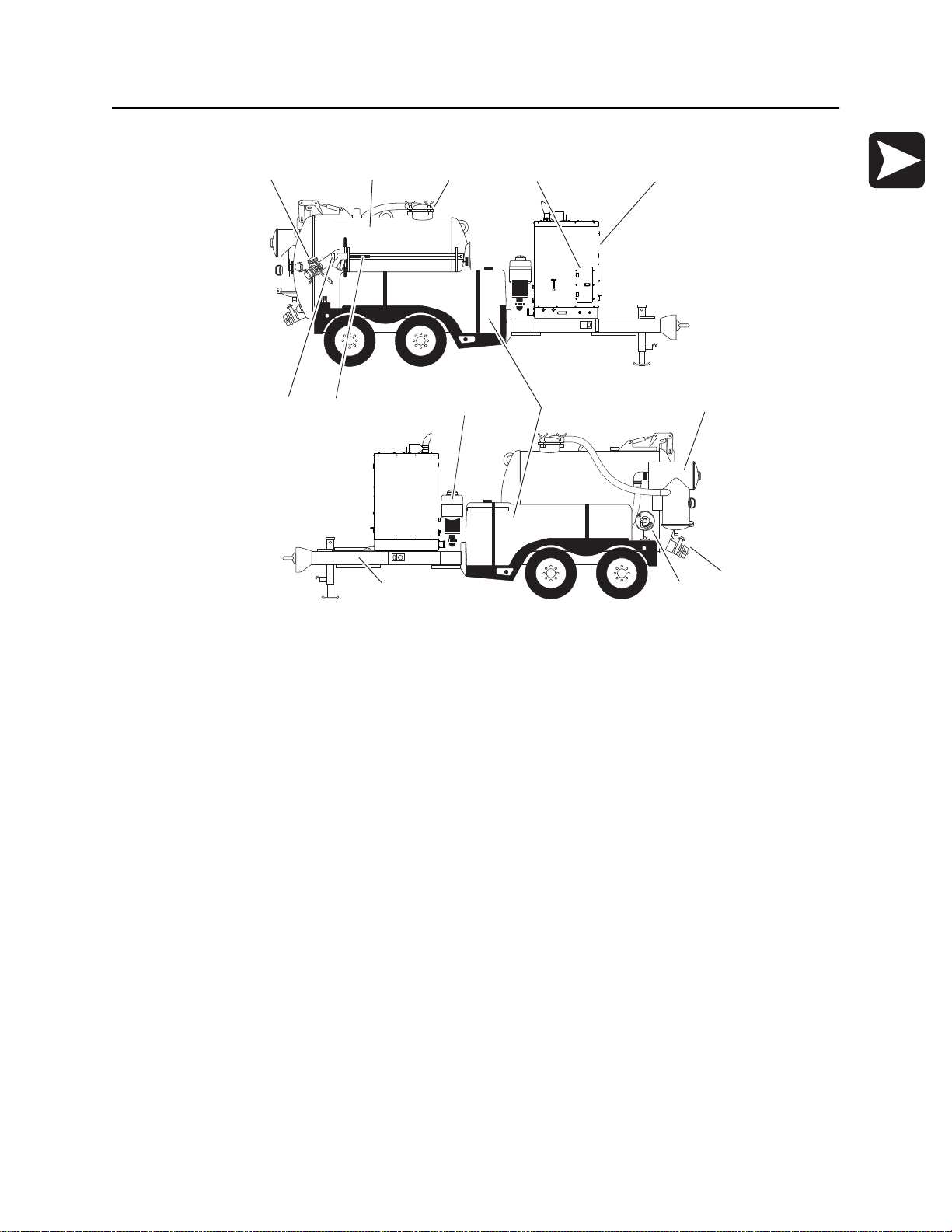

Unit Components

1200-Gal (4542-L)Tank

234 51

j36om077w.eps

1. Inlet valve

2. Vacuum tank

3. Primary shutoff valve

4. Operator’s station

5. Power unit

6. Potholing tools

7. Water lance

76

8 10

9

11

1213

8. Antifreeze tank

9. Water tanks

10. Vacuum filter/secondary shutoff valve

11. Drain/Outlet valve

12. Hose reel

13. Tool storage

CMW

Page 7

Overview - 6 FX50 Operator’s Manual

1

2

3

4

Operator Orientation

Operator Orientation

1. Front of unit

2. Right of unit

Right and left sides of machine are determined by

facing towing vehicle.

3. Rear of unit

4. Left of unit

4

j36om003w.eps

1

2

3

About This Manual

This manual contains information for the proper use of this machine. See Operation Overview for basic

operating procedures. Cross references such as “See page 50” will direct you to detailed procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

CMW

Page 8

FX50 Operator’s Manual Foreword - 7

Reporting Safety Defects

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipment at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was published. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

Reporting Safety Defects

If you believe that your vehicle has a defect which could cause a crash or could cause injury or death, you

should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to

notifying The Charles Machine Works, Inc, Attn: Product Safety Coordinator.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists

in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become

involved in any individual problems between you, your Ditch Witch dealer, or The Charles Machine Works,

Inc.

To contact NHTSA you may either call the Auto Safety Hotline toll-free at 1-800-424-9393 (366-0123 in

Washington, DC area) or write to:

NHTSA

U.S. Department of Transportation

400 7th Street SW (NSA-11)

Washington, DC 20590

You can also obtain other information about motor vehicle safety from the Hotline.

CMW

Page 9

Foreword - 8 FX50 Operator’s Manual

Works, Inc.

FX50

Operator’s Manual

Issue number 1.0/OM-9/12

Part number 053-2545

Copyright 2012

by The Charles Machine Works, Inc.

, Ditch Witch, and CMW are registered trademarks of The Charles Machine

U.S. patents pending.

CMW

Page 10

FX50 Operator’s Manual Contents - 9

Contents

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

Safety

machine safety alerts and emergency procedures

Controls

machine controls, gauges, and indicators and how to use them

Operation Overview

an overview for completing a job with this machine: planning, setting up, vacuuming,

potholing, and restoring the jobsite; with cross references to detailed procedures

Prepare

procedures for inspecting and classifying the jobsite, and preparing the jobsite for

work

Transport

procedures for lifting and hauling

1

7

11

21

37

41

47

Vacuum and Pothole

procedures for removing debris and potholing utility locations

Complete the Job

procedures for restoring the jobsite and rinsing and storing equipment

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

51

69

73

115

127

CMW

Page 11

Contents - 10 FX50 Operator’s Manual

Service Record

a record of major service performed on the machine

Appendix

Information regarding tire safety

131

133

CMW

Page 12

FX50 Operator’s Manual Safety - 11

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Alert Classifications . . . . . . . . . . . . . . . . . . 13

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 17

• Electric Strike Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CMW

Page 13

Safety - 12 FX50 Operator’s Manual

Guidelines

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service.

• Classify jobsite based on its hazards and use correct tools and machinery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment

use.

CMW

Page 14

FX50 Operator’s Manual Safety - 13

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates a hazardous situation that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme situations.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

IMPORTANT can help you do a better job or make your job easier in some way.

CMW

Page 15

Safety - 14 FX50 Operator’s Manual

Safety Alerts

Safety Alerts

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Confined space will cause suffocation. Use proper procedures for entering

or stay away.

Vacuum will suffocate. Maintain distance between face and vacuum inlets.

correct equipment and work methods. Use and maintain proper safety

equipment.

proper procedures and equipment or stay away.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

Jobsite hazards could cause death or serious injury. Use

Crushing weight could cause death or serious injury. Use

Moving parts could cut off hand or foot. Stay away.

CMW

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Page 16

FX50 Operator’s Manual Safety - 15

Safety Alerts

Improper control function could cause death or serious injury. If control does

not work as described in instructions, stop machine and have it serviced.

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Moving traffic - hazardous situation. Death or serious injury could result.

Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

CMW

Page 17

Safety - 16 FX50 Operator’s Manual

Safety Alerts

Hot pressurized cooling system fluid could cause serious burns. Allow to

cool before servicing.

Flying objects may cause injury. Wear hard hat and safety glasses.

Hot parts may cause burns. Do not touch until cool.

Exposure to high noise levels may cause hearing loss. Wear hearing

protection.

Fall possible. Slips or trips may result in injury. Keep area clean.

Battery acid may cause burns. Avoid contact.

Improper handling or use of chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels and in material safety data sheets

(MSDS).

Breathing crystalline silica dust may cause lung disease. Cutting, drilling, or

working materials such as concrete, sand, or rock containing quartz may result in exposure

to silica dust. Use dust control methods or appropriate breathing protection when exposed

to silica dust.

CMW

Page 18

FX50 Operator’s Manual Safety - 17

Emergency Procedures

Emergency Procedures

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Before operating any equipment, review emergency procedures and check that all safety precautions have

been taken.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote engine stop button (if

equipped).

Electric Strike Description

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

• smoke

• explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

CMW

Page 19

Safety - 18 FX50 Operator’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on truck or trailer, DO NOT MOVE.

Remain on truck or trailer and take the following actions. The order and degree of action will depend on the

situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Do not allow anyone into area until given permission by utility company.

• Do not allow anyone to touch equipment.

If you suspect an electric line has been damaged and you are off truck or trailer, DO NOT TOUCH

EQUIPMENT. Take the following actions. The order and degree of action will depend on the situation.

• LEAVE AREA. The ground surface may be electrified so take small shuffle steps with feet close

together to reduce the hazard of being shocked from one foot to the other.

• Contact utility company to shut off power.

• Do not return to area or allow anyone into area until given permission by utility company.

CMW

Page 20

FX50 Operator’s Manual Safety - 19

Emergency Procedures

If a Gas Line is Damaged

Fire or explosion possible. Fumes could ignite and cause burns. No

smoking, no flame, no spark.

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

CMW

Page 21

Safety - 20 FX50 Operator’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped and accessible) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

CMW

Page 22

FX50 Operator’s Manual Controls - 21

Controls

Chapter Contents

Power Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• Gauges and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

• Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• Tethered Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• Machine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Vacuum Boom (optional) . . . . . . . . . . . . . . . . . . . . 34

CMW

Page 23

Controls - 22 FX50 Operator’s Manual

Power Pack

Power Pack

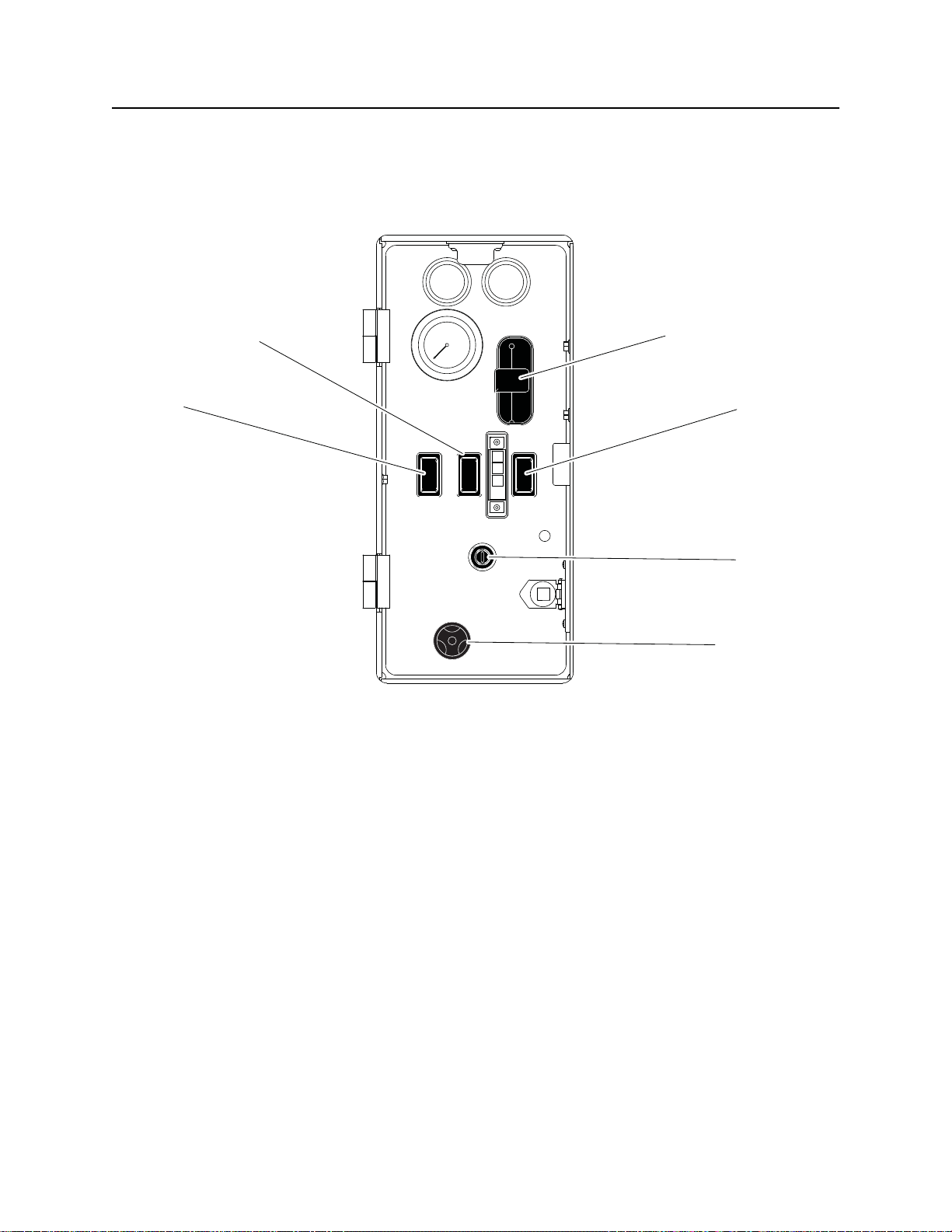

Controls and Connectors

23

1

j36om016w.eps

1. Hydraulic function switch

2. Auxiliary outlet switch

3. Throttle

4

5

6

4. Water pressure switch

5. Ignition switch

6. Water pressure control

CMW

Page 24

FX50 Operator’s Manual Controls - 23

Power Pack

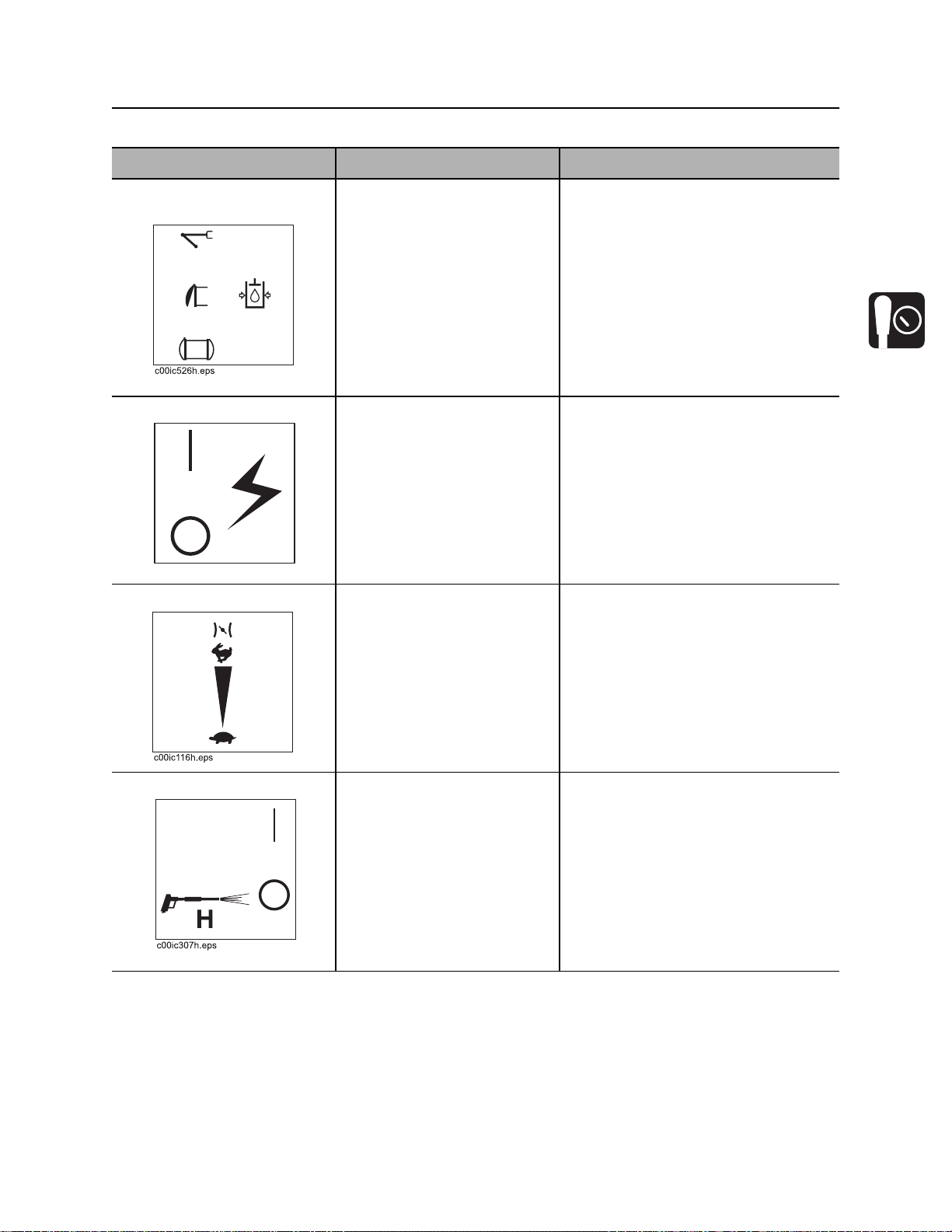

Item Description Notes

1. Hydraulic function

switch

2. Auxiliary outlet switch To turn on, press top.

c00ic061t.eps

3. Throttle To increase engine speed,

To direct hydraulic power to

the optional boom function,

press top.

To direct hydraulic power to

the door function, move to

center position.

To direct hydraulic power to

the tank tilt function, press

bottom.

To turn off, press bottom.

push up.

IMPORTANT: Keep switch in off

position unless in use.

To decrease engine speed,

pull down.

4. Water pressure switch To turn on water pump, press

top.

To turn off water pump, move

to center position.

To bypass low water

indication, press bottom.

Water pump will operate for

60 seconds.

Use bypass to feed antifreeze into

system when freshwater tank is

empty. See “Add Antifreeze” on

page 70.

CMW

Page 25

Controls - 24 FX50 Operator’s Manual

Power Pack

Item Description Notes

5. Ignition switch To start engine, insert key and

turn clockwise.

To stop engine, turn key

counterclockwise.

6. Water pressure control To increase water pressure,

turn clockwise.

To decrease water pressure,

turn counterclockwise.

IMPORTANT:

• When engine is on, blower

operates and vacuum is present

at tank inlet.

• All indicators should light briefly at

startup.

CMW

Page 26

FX50 Operator’s Manual Controls - 25

Power Pack

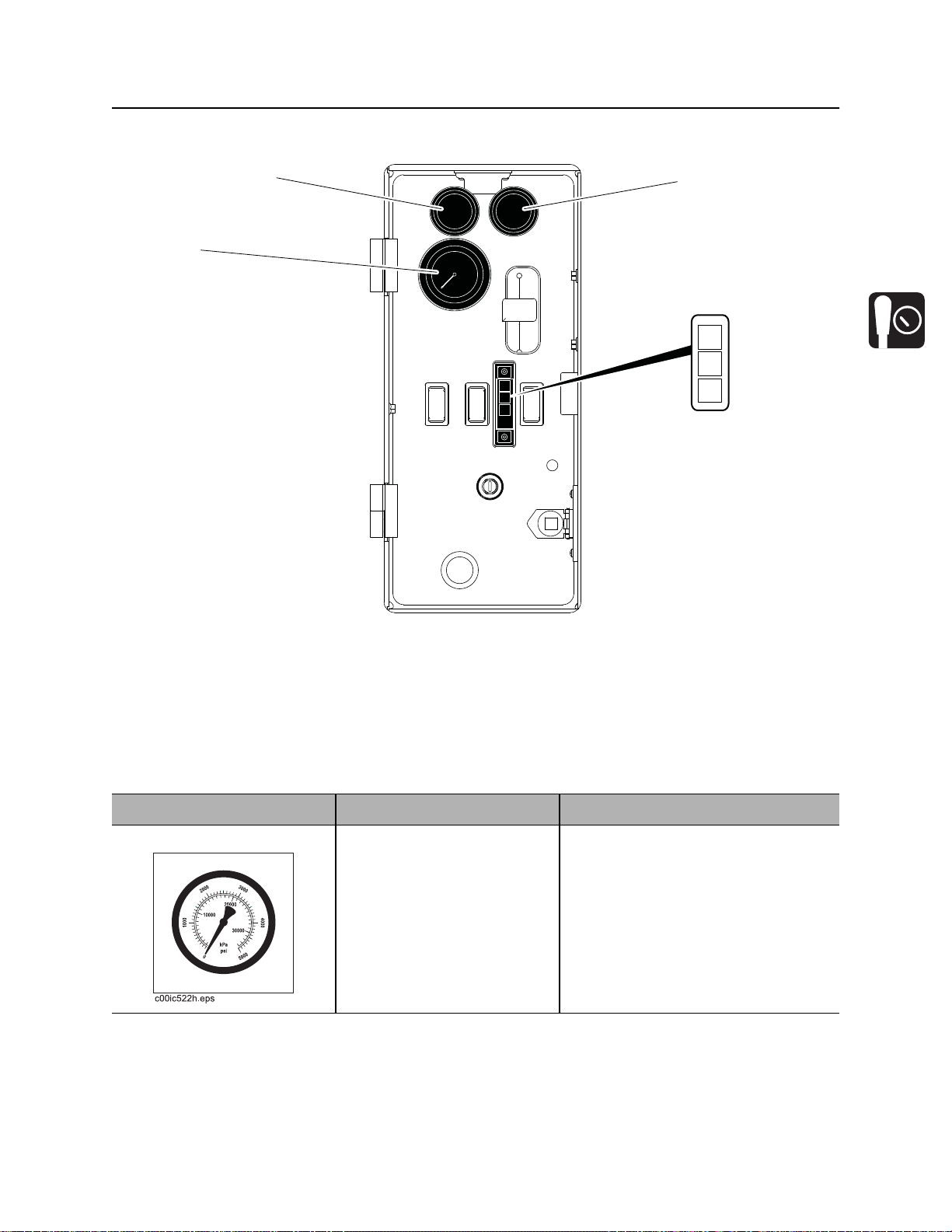

Gauges and Indicators

23

1

4

5

6

1. Water pressure gauge

2. Fuel gauge

3. Hourmeter

Item Description Notes

1. Water pressure gauge Displays water pressure

when water pressure switch

is on and water lance is in

use.

4. Engine oil pressure indicator

5. Engine oil temperature indicator

6. Cold start wait indicator

CMW

Page 27

Controls - 26 FX50 Operator’s Manual

Power Pack

Item Description Notes

2. Fuel gauge Displays fuel level in tank. NOTICE: Use low sulfur or ultra low

sulfur diesel fuel only.

In temperatures below 32° F

(0° C), use #1 diesel fuel.

Tank holds 19 gal (72 L).

3. Hourmeter Displays engine operating

time.

4. Engine oil pressure

indicator

Indicates engine oil pressure

is too low.

Also lights briefly when

engine is started.

4. Engine oil temperature

indicator

Indicates engine oil

temperature is too high.

Hourmeter runs when ignition switch

is on.

Use these times to schedule service.

Engine will stop.

1. Check oil level.

2. Check for leaks before starting

engine.

3. If pressure is still low, consult

engine manual.

Engine will stop.

1. Let engine cool.

CMW

2. Check fan belt tension.

3. Check engine oil level.

4. Check cooling fins for dirt and

debris.

c00ic120h.eps

Page 28

FX50 Operator’s Manual Controls - 27

Power Pack

Item Description Notes

5. Cold start wait indicator Indicates intake air preheater

is operating.

Wait until light goes off before

starting engine. See “Cold

Start Procedure” on page 57.

Explosion possible.

Serious injury or

equipment damage

could occur.

To help avoid injury: do not use

ether or starting fluid

CMW

Page 29

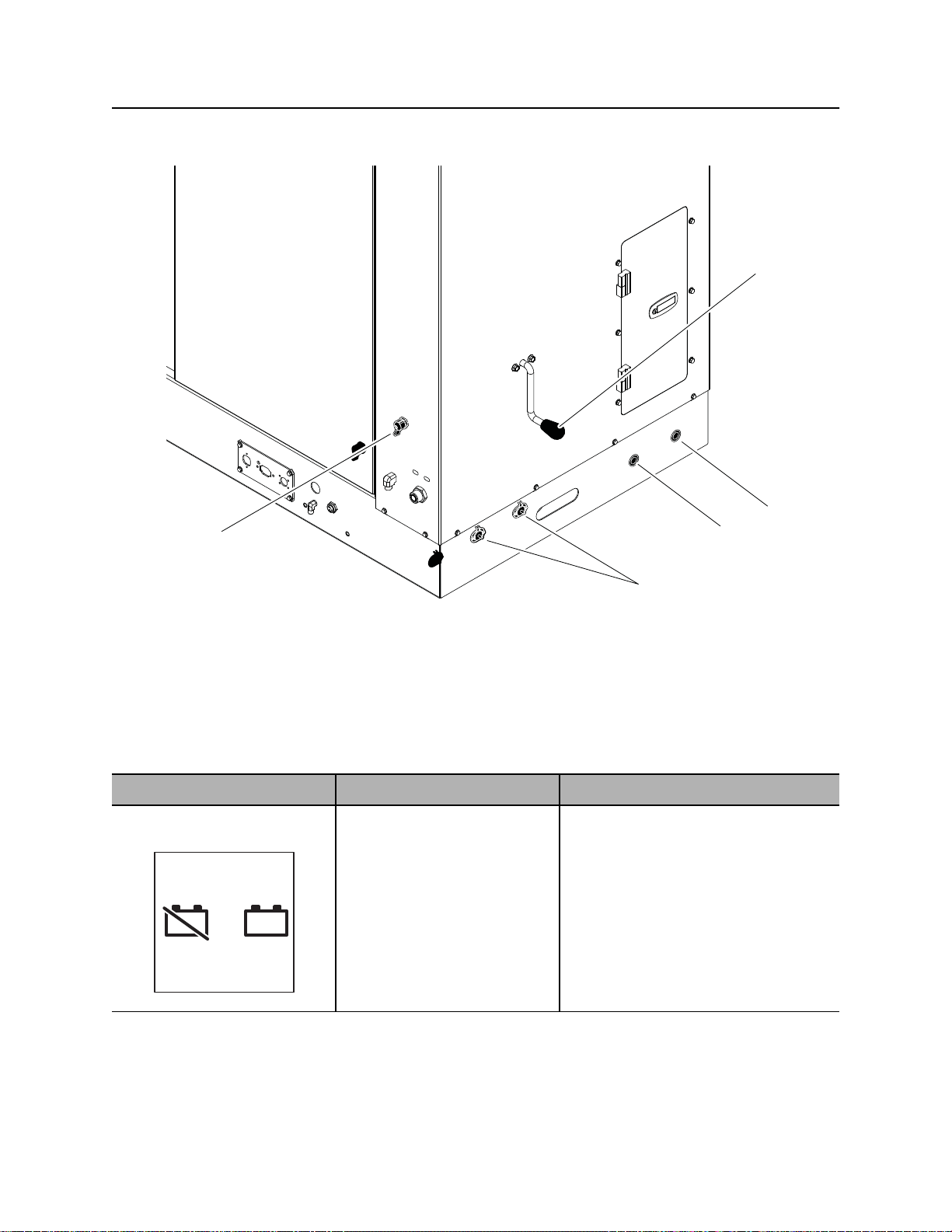

Controls - 28 FX50 Operator’s Manual

Power Pack

Miscellaneous

2

3

1

4

1. Battery disconnect

2. Flow direction control (optional)

3. Hydraulic fluid drain

Item Description Notes

1. Battery disconnect

switch

_

c00ic063t.eps

+

_

+

To connect, turn clockwise.

To disconnect, turn

counterclockwise.

4. Engine oil drain

5. Auxiliary outlets

IMPORTANT: Use battery disconnect

switch when servicing, welding, and

during long-term storage.

5

CMW

Page 30

FX50 Operator’s Manual Controls - 29

Power Pack

Item Description Notes

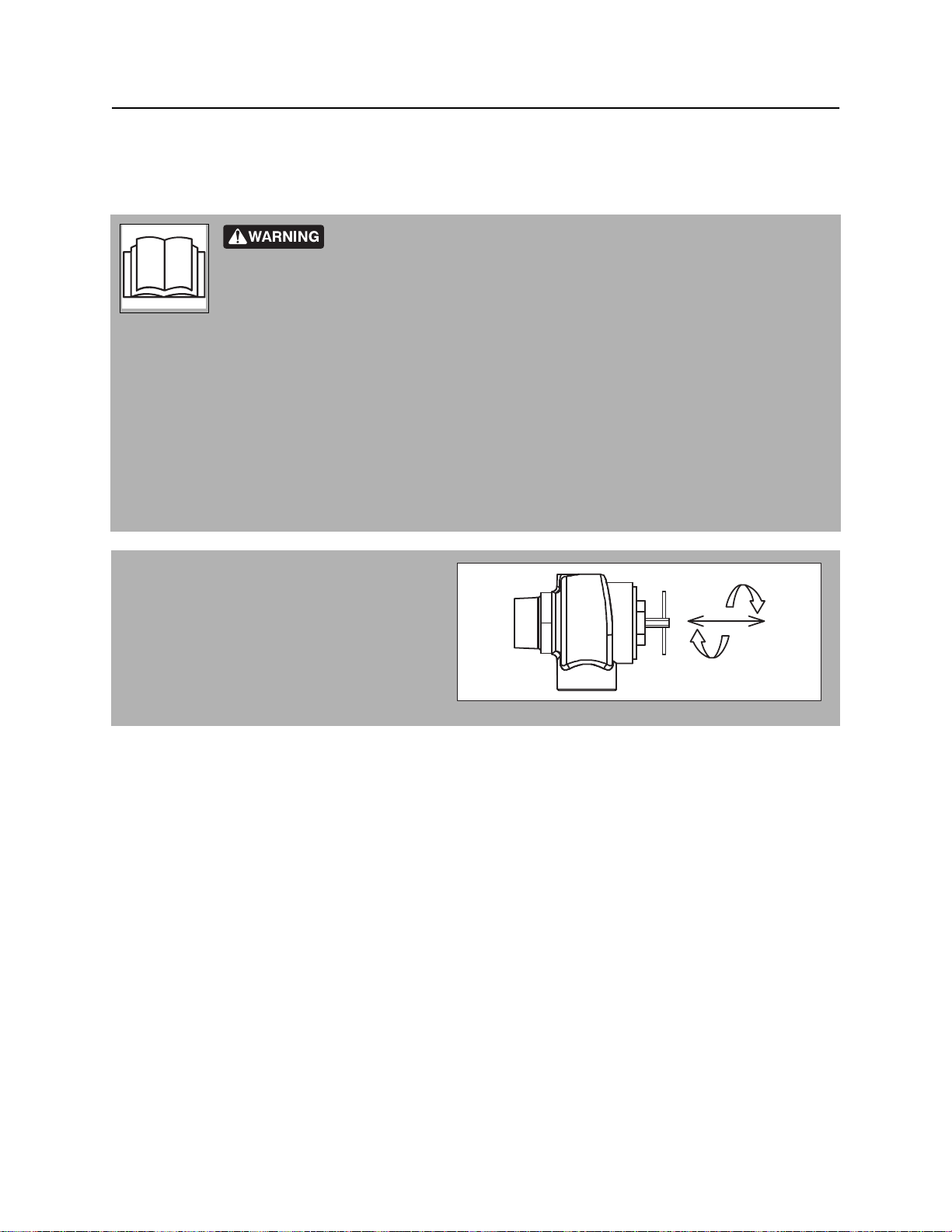

2. Flow direction control To operate in reverse flow

mode, turn counterclockwise.

To operate in vacuum mode,

turn clockwise.

c00ic605h.eps

3. Hydraulic fluid drain To drain:

• Remove plug.

• Replace plug when drain

pan is empty.

4. Engine oil drain To drain:

• Remove plug.

• Replace plug when drain

pan is empty.

5. Auxiliary outlets To operate work lights or

other 12V devices, plug into

outlet.

Use reverse flow to unload tank

contents to another tank. Operate in

reverse flow mode only when drain/

outlet valve is open.

Outlet has power only when ignition

switch is on.

Device can be turned on and

off with auxiliary power

switch.

CMW

Page 31

Controls - 30 FX50 Operator’s Manual

Tank

Tank

Tethered Controller

1

UP

DOWN

j36om018w.eps

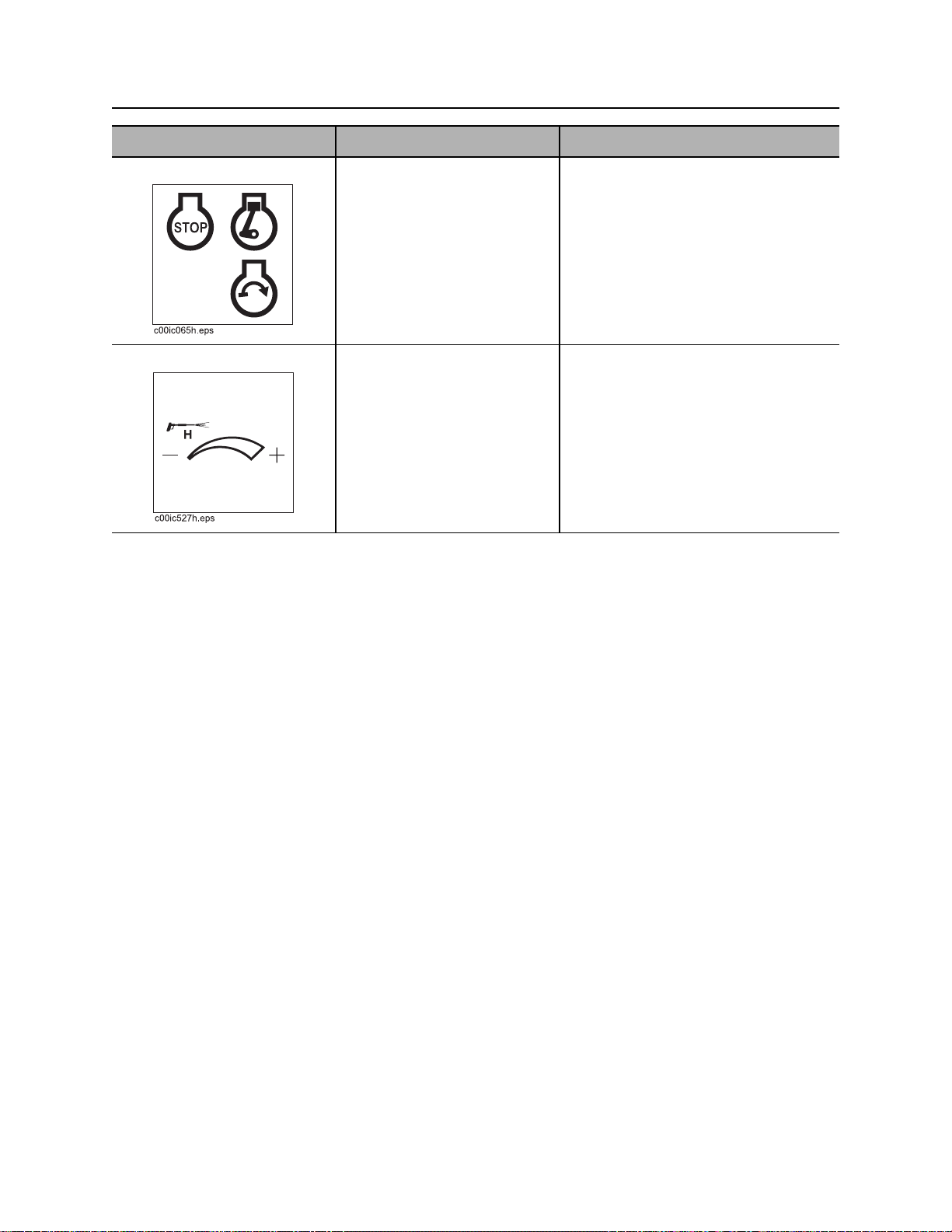

Item Description Notes

1. Up To raise tank, set hydraulic

function switch to the tank

position and press UP.

To open tank door, set

U P

c00ic064t.eps

hydraulic function switch to

the door position and press

UP.

Note: The vacuum boom uses a

different tethered controller. See

page 34.

2

2. Down To lower tank, set hydraulic

function switch to the tank

position and press DOWN.

To close tank door, set

DOWN

c00ic065t.eps

CMW

hydraulic function switch to

the door position and press

DOWN.

Page 32

FX50 Operator’s Manual Controls - 31

1

2

3

4

5

6

Tank

Machine Controls

j36om005w.eps

1

4

2

5

3

6

7

8

1. Inlet valve

2. Water tank drain

3. Water tank supply valve

4. Vacuum gauge

Item Description Notes

1. Inlet valve To close valve (stop suction),

rotate up.

To open valve (start suction),

rotate down.

5. Antifreeze tank supply valve

6. Flow direction control (optional)

7. Drain/Outlet valve

8. Reverse flow gauge (optional)

CMW

Page 33

Controls - 32 FX50 Operator’s Manual

Tank

Item Description Notes

2. Water tank drain To drain tank, open valve.

Close valve when tank is

empty.

c00ic604h.eps

3. Water tank supply valve To open valve (send water

from the water tank through

the pump and water lance),

rotate counterclockwise.

To close valve (stop water

flow), rotate clockwise.

c00ic603h.eps

4. Vacuum gauge Displays blower vacuum

reading in inches of mercury.

Vacuum relief valve opens

when vacuum reaches 16”

(406 mm).

5. Antifreeze tank supply

valve

To open valve (send

antifreeze through pump and

water lance), rotate

counterclockwise.

IMPORTANT: Water tank supply

valve or antifreeze supply valve must

be open when pump is running or

pump will be damaged.

IMPORTANT: Water tank supply

valve or antifreeze supply valve must

be open when pump is running or

pump will be damaged.

CMW

To close valve (stop

antifreeze flow), rotate

clockwise.

c00ic603h.eps

Page 34

FX50 Operator’s Manual Controls - 33

Tank

Item Description Notes

6. Flow direction control To operate in reverse flow

mode, turn counterclockwise.

To operate in vacuum mode,

turn clockwise.

c00ic605h.eps

7. Drain/Outlet valve To drain tank, rotate down.

To close drain, rotate up.

8. Reverse flow gauge Displays reverse flow

pressure.

Use reverse flow to unload tank

contents to another tank. Operate in

reverse flow mode only when drain/

outlet valve is open.

CMW

Page 35

Controls - 34 FX50 Operator’s Manual

j35om053h.eps

Vacuum Boom (optional)

Vacuum Boom (optional)

5

j35om053h.eps

1. Boom latch

2. Boom up

3. Boom down

Item Description Notes

1. Boom latch Pull cable to open latch and

3

4

2

4. Boom retract

5. Boom extend

release boom from saddle.

1

Push boom into latch to lock

boom into saddle.

CMW

Page 36

FX50 Operator’s Manual Controls - 35

Vacuum Boom (optional)

Item Description Notes

2. Boom up To raise boom, set hydraulic

function switch to the optional

boom position and press UP.

To stop movement, release.

3. Boom down To lower boom, set hydraulic

function switch to the optional

boom position and press UP.

To stop movement, release.

4. Boom retract To retract boom, set hydraulic

function switch to the optional

boom position and press IN.

To stop movement, release.

NOTICE: Do not use boom to raise or

lower objects.

NOTICE: Do not use boom to raise or

lower objects.

5. Boom extend To extend boom, set hydraulic

function switch to the optional

boom position and press

OUT.

To stop movement, release.

CMW

Page 37

Controls - 36 FX50 Operator’s Manual

Vacuum Boom (optional)

CMW

Page 38

FX50 Operator’s Manual Operation Overview - 37

Operation Overview

Chapter Contents

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting Up at Jobsite . . . . . . . . . . . . . . . . . . . . . . . 38

Vacuuming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Potholing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Leaving Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Storing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 39

CMW

Page 39

Operation Overview - 38 FX50 Operator’s Manual

Planning

Planning

1. Gather information about jobsite (page 42).

2. Inspect jobsite (page 43).

3. Check supplies and prepare equipment (page 45).

Setting Up at Jobsite

1. Prepare jobsite (page 44).

2. Position vacuum excavation unit.

3. Leave unit hitched to towing vehicle or properly stabilized.

4. Block trailer wheels.

Vacuuming

1. Connect hoses (page 52).

2. Start unit (page 56).

3. Position optional vacuum boom (page 58).

4. Remove debris (page 59).

5. Disconnect hoses (page 71).

6. Drain tank (page 62) or unload to another tank (page 64)

CMW

Page 40

FX50 Operator’s Manual Operation Overview - 39

Potholing

Potholing

1. Connect hoses (page 52).

2. Start unit (page 56).

3. Pothole (page 60).

4. Disconnect hoses (page 71).

5. Drain tank (page 62).

Leaving Jobsite

1. Rinse unit and tools (page 71).

2. Stow tools (page 72).

Storing Equipment

1. For cold weather storage, antifreeze vacuum excavation unit (page 70).

2. For long-term storage, disconnect battery disconnect switch (page 29).

CMW

Page 41

Operation Overview - 40 FX50 Operator’s Manual

Storing Equipment

CMW

Page 42

FX50 Operator’s Manual Prepare - 41

Prepare

Chapter Contents

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . 42

• Arrange for Traffic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

• Prepare for Working Near Existing Utilities . . . . . . . . . . . . . . . . . . . . . 42

• Plan for Emergency Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Inspect Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Prepare Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

• Prepare Excavation Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Check Supplies and Prepare Equipment . . . . . . . 45

• Assemble Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

• Check Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

• Prepare Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CMW

Page 43

Prepare - 42 FX50 Operator’s Manual

Gather Information

Gather Information

A successful job begins before the excavation. The first step in planning is reviewing information already

available about the job and jobsite.

Arrange for Traffic Control

If working near a road or other traffic area, contact local authorities about safety procedures and

regulations.

Prepare for Working Near Existing Utilities

If jobsite may contain electrical lines, wear protective boots and gloves meeting the following standards:

• Boots must have high tops and meet the electric hazard protection requirements of ASTM F2413 or

ASTM F1117, when tested at 14,000 volts. Tuck legs of pants completely inside boots.

• Gloves must have 17,000 AC maximum use voltage, according to ASTM specification D120.

If working around higher voltage, use gloves and boots with appropriately higher ratings.

Plan for Emergency Services

Have the telephone numbers for local emergency and medical facilities on hand. Check that you will have

access to a telephone.

CMW

Page 44

FX50 Operator’s Manual Prepare - 43

Inspect Jobsite

Inspect Jobsite

• Follow U.S. Department of Labor regulations on excavating and trenching (Part 1926, Subpart P) and

other similar regulations.

• Contact your local One-Call (811 in USA) or the One-Call referral number (888-258-0808 in USA and

Canada) to have underground utilities located before digging. Also contact any utilities that do not

participate in the One-Call service..

• Inspect jobsite and perimeter for evidence of underground hazards, such as:

– “Buried utility” notices

– Utility facilities without overhead lines

– Gas or water meters

– Junction boxes

– Drop boxes

– Light poles

– Manhole covers

– Sunken ground

• Mark location of all buried utilities and obstructions.

CMW

Page 45

Prepare - 44 FX50 Operator’s Manual

Prepare Jobsite

Prepare Jobsite

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

To help avoid injury:

• If jobsite classification is in question or if the possibility of unmarked electric utilities exists, classify

jobsite as electric.

• Expose lines by hand before digging. Cutting high voltage cable can cause electrocution.

• All vegetation near operator’s station must be removed. Contact with trees, shrubs, or weeds during

electrical strike could result in electrocution.

Prepare Excavation Point

• Clear the area to be excavated. Remove rocks or branches too large for vacuum hose.

• If excavating fluids while drill string is moving, clear area of trees, shrubs, and weeds.

• Select a solid area to stand on while excavating.

CMW

Page 46

FX50 Operator’s Manual Prepare - 45

Check Supplies and Prepare Equipment

Check Supplies and Prepare Equipment

Assemble Accessories

Fire Extinguisher

If required, mount a fire extinguisher near the power unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric fires. It should meet legal and regulatory

requirements.

Lighting Kit

If you will need additional light, plug lighting kit into provided outlet. Contact your Ditch Witch dealer for

further information.

Check Supplies

• water and additional hoses

• fuel

• keys

• spray lubricant

• personal protective equipment, such as hard hat and safety glasses

CMW

Page 47

Prepare - 46 FX50 Operator’s Manual

Check Supplies and Prepare Equipment

Prepare Equipment

Fluid Levels

• fuel

• hydraulic fluid

• engine coolant

• battery charge

• engine oil

• blower oil

Condition and Function

• filters (air, oil, hydraulic)

• belts

• hydraulic pump

• blower

• tires

• hoses and valves

• couplers and fittings

• water tanks

CMW

Page 48

FX50 Operator’s Manual Transport - 47

Transport

Chapter Contents

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

• Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Inspect Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

• Hitch Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

• Unhitch Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

CMW

Page 49

Transport - 48 FX50 Operator’s Manual

Lift

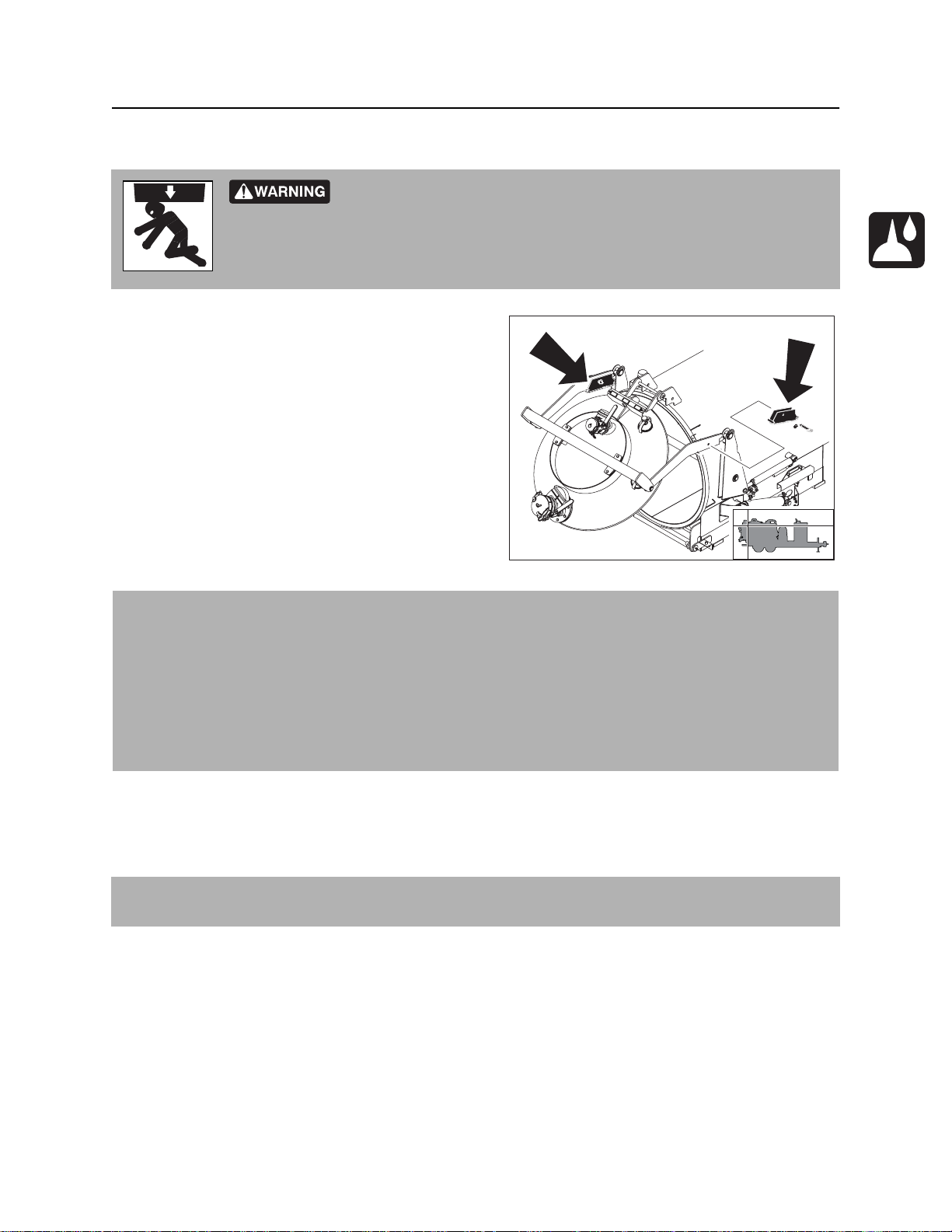

Lift

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

Points

Lifting points are identified by lifting decals. Lifting at other points is unsafe

and can damage machinery.

Procedure

Power Pack

Use a crane capable of supporting 3000 lb (1360 kg).

Use top lift point as shown.

Tank

Use crane capable of supporting 2500 lb (1134 kg). Use

top lift point (1) as shown. Use end lift point (2) to drain

tank if machine is disabled.

NOTICE:

• Relieve pressure in tank before storing or

transporting.

• Only lift empty water or spoils tanks.

• Do not lift tank by vacuum boom, if installed.

CMW

Page 50

FX50 Operator’s Manual Transport - 49

Haul

Haul

Crushing weight. If load falls or moves it could kill or crush you. Use

proper procedures and equipment or stay away.

To help avoid injury:

• Do not haul or move trailer unless tank is fully lowered and horizontal. Damage to machine or injury

to personnel could occur.

• Do not haul or move trailer unless optional vacuum boom is secured by boom latch. Damage to

machine or injury to personnel could occur.

Inspect Trailer

• Check hitch for wear and cracks. Lubricate if needed.

• Check battery for 12 volt charge.

• Inspect lights for cleanliness and correct operation. Inspect reflectors and replace if needed.

• Check tire pressure. Check lug nut torque with a torque wrench.

• Ensure trailer brakes are adjusted to come on in synchronization with tow vehicle brakes.

• Check ramps (if equipped) and trailer bed for cracks.

CMW

Page 51

Transport - 50 FX50 Operator’s Manual

TrailerHitchAdjust_T18.eps

Haul

Hitch Trailer

1. Back tow vehicle to trailer.

2. Put manual transmission into first or reverse gear or automatic transmission into park. Turn off ignition.

Set parking brake.

3. Connect trailer drawbar, lunette or coupler to

tow vehicle hitch and lock in place with lock

pin. If needed, adjust drawbar, lunette or

coupler height (shown) to level load.

4. Connect safety chains to tow vehicle chain

keepers (cross-shaped slots on bumper of

tow vehicle). Attach left chain to right side of

tow vehicle and vice versa to cradle hitch. Do

not connect to pintle hook or hitch ball.

5. Connect breakaway switch cable to tow

vehicle. Do not connect to pintle hook or hitch

ball.

6. Plug trailer electrical connector into tow

vehicle connector.

7. Use jack crank to raise jack base and stow.

TrailerHitchAdjust_T18.eps

8. Remove wheel blocks.

Unhitch Trailer

1. Stop tow vehicle and trailer on level ground.

2. Put manual transmission into first or reverse gear or automatic transmission into park. Turn off ignition.

Set parking brake.

3. Block trailer wheels.

4. To unhitch trailer from tow vehicle, reverse “Hitch Trailer“ steps.

CMW

Page 52

FX50 Operator’s Manual Vacuum and Pothole - 51

Vacuum and Pothole

Chapter Contents

Connect Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Determine Tank Fill Level . . . . . . . . . . . . . . . . . . . 53

• 300-gal Vacuum Tank on T9SE6 or T9SH6 Trailer . . . . . . . . . . . . . . . 53

• 800-gal Vacuum Tank on T18S Trailer . . . . . . . . . . . . . . . . . . . . . . . . 54

• 1200-gal Vacuum Tank on T26S Trailer . . . . . . . . . . . . . . . . . . . . . . . 55

Start Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

• Standard Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

• Cold Start Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Position Vacuum Boom . . . . . . . . . . . . . . . . . . . . . 58

Remove Debris . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Pothole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Drain Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Unload to Another Tank . . . . . . . . . . . . . . . . . . . . 64

Open/Close Tank Door . . . . . . . . . . . . . . . . . . . . . 66

CMW

Page 53

Vacuum and Pothole - 52 FX50 Operator’s Manual

Connect Hoses

Connect Hoses

1. Remove vacuum hoses from storage.

2. If potholing, remove 2-in-1 potholing tool or basic potholing tool from storage.

3. Connect hoses. Secure all locking clamps.

4. Ensure drain/outlet valve is closed.

5. If potholing, connect water pressure hose.

2-in-1 Tool Basic Tool

CMW

Page 54

FX50 Operator’s Manual Vacuum and Pothole - 53

Determine Tank Fill Level

Determine Tank Fill Level

Use these reference charts to help determine how full of various materials the vacuum tank can be without

overloading trailer. Exceeding the maximum fill level will overload the trailer.

Never exceed the trailer capacity. You can exceed the vacuum tank lifting capacity if you drain the tank

down to the lifting capacity before lifting tank.

To use these charts, first select the appropriate table based on trailer and vacuum tank size. Next find the

material being excavated. If the material being excavated is not listed, find a material with similar density.

Then, determine the maximum fill level based on the amount of water in the water tank.

IMPORTANT: For all materials, the vacuum tank should be no more than half full when lifting the tank.

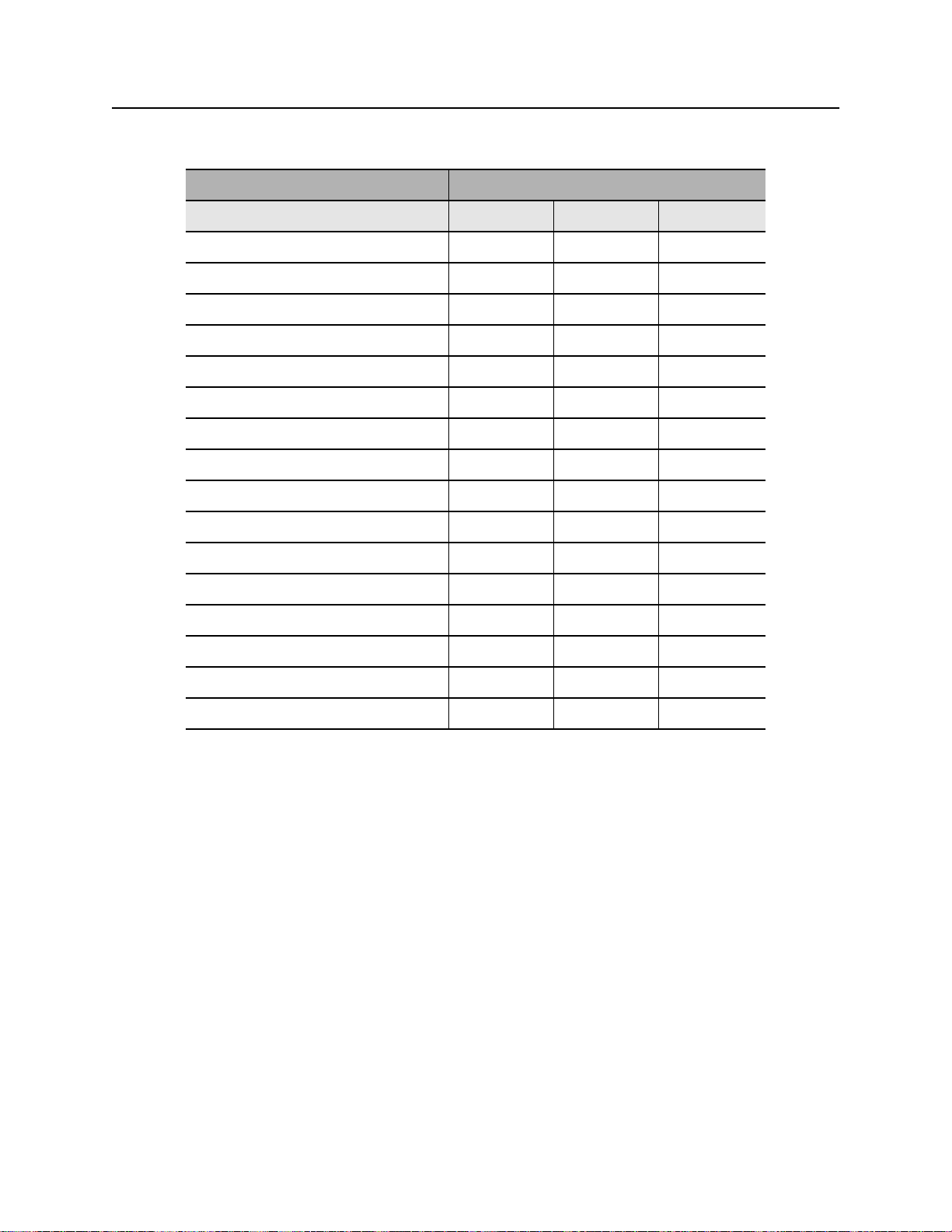

300-gal Vacuum Tank on T9S Trailer

Material Maximum Vacuum Tank

Fill Level

Water tank fill level full (80 gal) empty (0 gal)

wood chips (dry) 100% 100%

snow (dry) 100% 100%

water 76% 99%

light weight mud (8-10 lb/gal) 70% 92%

earth (dry, loose) 66% 86%

caliche 61% 79%

earth, loam 61% 79%

medium weight mud (10-12 lb/gal) 57% 75%

limestone (crushed) 49% 65%

asphalt 47% 62%

sand (dry) 47% 62%

earth (wet, excavated) 47% 62%

heavy weight mud (12-15 lb/gal) 47% 61%

gravel (dry) 46% 60%

shale, riprap 45% 59%

sand (wet) 36% 48%

CMW

Page 55

Vacuum and Pothole - 54 FX50 Operator’s Manual

Determine Tank Fill Level

800-gal Vacuum Tank on T18S Trailer

Material Maximum Vacuum Tank Fill Level

Water tank fill level full (200 gal) full (300 gal) empty (0 gal)

wood chips (dry) 100% 100% 100%

snow (dry) 100% 100% 100%

water 100% 93% 100%

light weight mud (8-10 lb/gal) 96% 86% 100%

earth (dry, loose) 90% 81% 100%

caliche 83% 74% 100%

earth, loam 83% 74% 100%

medium weight mud (10-12 lb/gal) 79% 70% 95%

limestone (crushed) 68% 61% 82%

asphalt 65% 58% 79%

sand (dry) 65% 58% 78%

earth (wet, excavated) 65% 58% 78%

heavy weight mud (12-15 lb/gal) 64% 57% 78%

gravel (dry) 63% 56% 76%

shale, riprap 62% 55% 75%

sand (wet) 50% 45% 61%

CMW

Page 56

FX50 Operator’s Manual Vacuum and Pothole - 55

Determine Tank Fill Level

1200-gal Vacuum Tank on BT26 Trailer

Material Maximum Vacuum Tank

Fill Level

Water tank fill level full (500 gal) empty (0 gal)

wood chips (dry) 100% 100%

snow (dry) 100% 100%

water 94% 100%

light weight mud (8-10 lb/gal) 87% 100%

earth (dry, loose) 82% 100%

caliche 75% 100%

earth, loam 75% 100%

medium weight mud (10-12 lb/gal) 71% 99%

limestone (crushed) 61% 85%

asphalt 59% 81%

sand (dry) 59% 81%

earth (wet, excavated) 59% 81%

heavy weight mud (12-15 lb/gal) 58% 81%

gravel (dry) 57% 79%

shale, riprap 56% 78%

sand (wet) 48% 63%

CMW

Page 57

Vacuum and Pothole - 56 FX50 Operator’s Manual

Start Unit

Start Unit

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

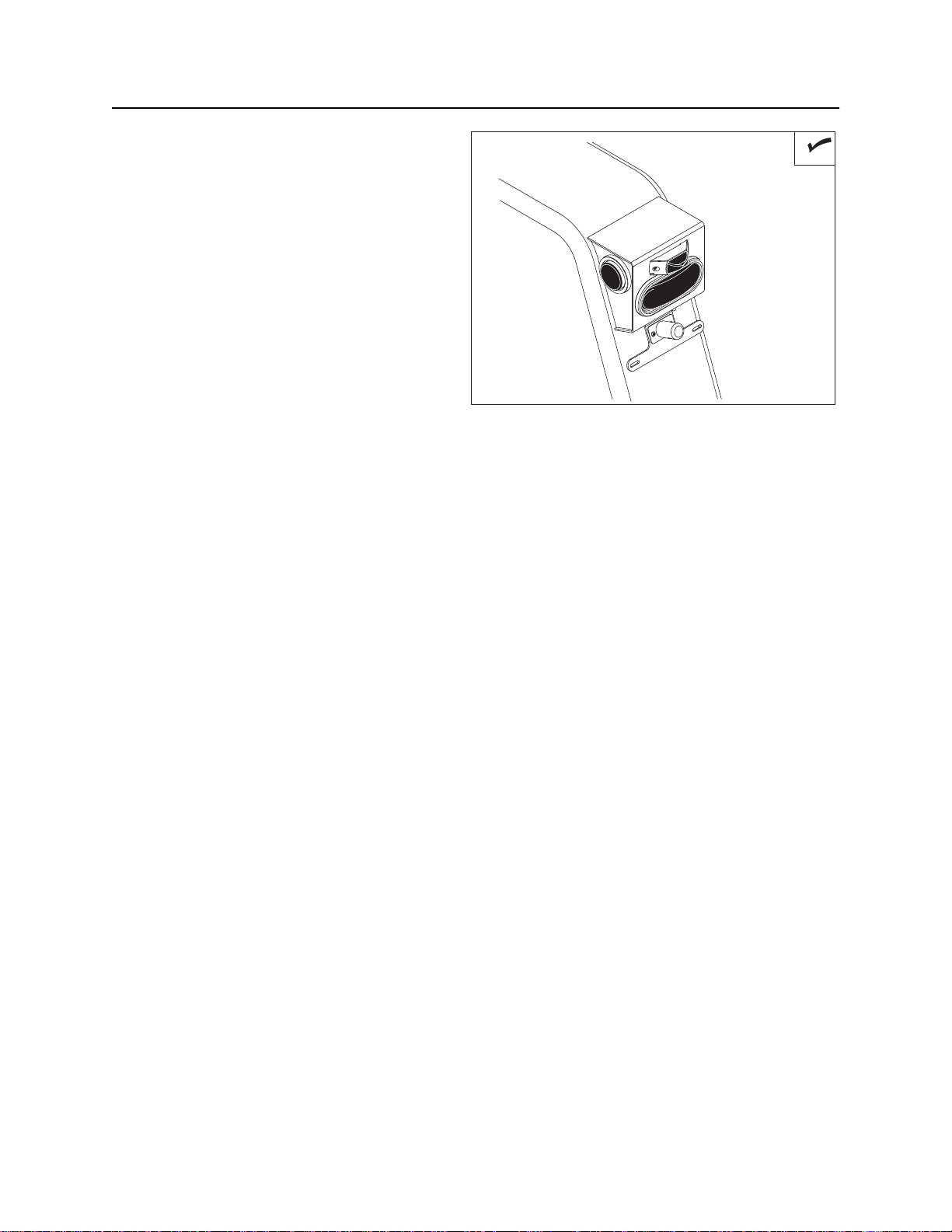

Standard Procedure

IMPORTANT: If power pack is not connected to external tank control

valves, connect a -04 hose with a minimum working pressure rating of

3000 psi (207 bar) from pressure (1) to power beyond (2) connections

on power pack.

j36om006w.eps

1. Open tank inlet valve.

NOTICE: Avoid idling engine with inlet valve closed.

2. If equipped with reverse flow, ensure vacuum is in “vacuum” mode before starting.

3. Insert key.

4. Turn key clockwise.See page 24 for more information.

NOTICE: If engine turns but does not start within 10 seconds, allow starter to cool before trying to

start engine again.

5. Run engine at low throttle for 5 minutes.

CMW

Page 58

FX50 Operator’s Manual Vacuum and Pothole - 57

Start Unit

Cold Start Procedure

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

To help avoid injury: do not use ether or starting fluid.

1. Open tank inlet valve.

NOTICE: Avoid idling engine with inlet valve closed.

2. If equipped with reverse flow, ensure vacuum is in “vacuum” mode before starting.

3. Insert key.

4. Turn key clockwise to “run” position (key on, engine off). See page 24 for more information. Cold start

wait indicator will light.

5. Wait for cold start wait indicator to go off.

6. Turn key all the way clockwise to start engine.

NOTICE: If engine turns but does not start within 10 seconds, allow starter to cool before trying to

start engine again.

7. Run engine at low throttle for 5 minutes.

CMW

Page 59

Vacuum and Pothole - 58 FX50 Operator’s Manual

Position Vacuum Boom

Position Vacuum Boom

The vacuum boom is optional equipment. Contact your Ditch Witch dealer to add this option.

Procedure

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

To help avoid injury:

• Latch boom before tilting tank.

• Do not unlatch boom when tank is tilted up.

• If unit is parked on a slope, control boom so it does not swing freely when released.

• Do not use boom to lift or move objects. Using boom in an inappropriate way may damage

equipment or injure personnel.

See “Controls” on page 21 to become familiar with the power pack controls and the tethered boom

controller.

1. Start engine.

2. Set hydraulic function switch to “boom” position.

3. Remove vacuum hoses from storage.

4. Pull boom latch cable to release boom.

5. Use tethered boom controller to:

• raise boom until it clears saddle.

• extend/retract boom to desired length.

• raise/lower boom to desired height.

6. Rotate boom by manually swinging it left or right.

CMW

Page 60

FX50 Operator’s Manual Vacuum and Pothole - 59

Remove Debris

Remove Debris

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

Procedure

1. Position vacuum hose in area to be excavated.

2. Start engine.

Vacuum will suffocate. Maintain distance between face and

vacuum inlets.

Fire or explosion possible. Do not vacuum flammable or

combustible substances.

3. Open inlet valve if necessary to begin excavation.

Incorrect procedures could result in death, injury, or property

damage. Learn to use equipment correctly.

To help avoid injury: Do not excavate hazardous or toxic materials. Unit is designed to

excavate only soil cuttings, drilling fluids, and other non-toxic waste.

4. Use sight glasses to monitor debris level in tank. Vacuum will shut off when tank is full but always heed

trailer and tank lifting capacities as indicated on page 53. Engine will remain running.

CMW

Page 61

Vacuum and Pothole - 60 FX50 Operator’s Manual

Pothole

Pothole

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

1. Start engine.

Vacuum will suffocate. Maintain distance between face and

vacuum inlets.

Fire or explosion possible. Do not vacuum flammable or

combustible substances.

2. Open water tank valve.

3. Move water pump switch to on.

4. Open inlet valve if necessary.

5. Position tool over area to be excavated and begin pothole.

Electric shock. Contacting electric lines will cause death or

serious injury. Know location of lines and stay away.

To help avoid injury: Do not direct water lance at overhead lines. Water conducts electricity.

2-in-1 Tool Basic Tool

• Squeeze water pressure lever to start

water pressure.

• Work pressurized water in a rocking or

circular motion to loosen and excavate

soil until hole is at the desired diameter

and depth.

• First use water lance to loosen soil.

• Work tool in a rocking or circular motion to

excavate soil.

• Use water lance and tool alternately until

hole is at the desired diameter and depth.

CMW

Page 62

FX50 Operator’s Manual Vacuum and Pothole - 61

Pothole

6. Adjust water pressure as needed to match soil conditions and/or material of utility being exposed.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

To help avoid injury: Test water pressure on a sample of the material to be located. Adjust

pressure until no damage occurs to the material. High pressure water can cut utility lines.

7. Ensure that water sprays from nozzle in a fan pattern. If it does not, nozzle may be clogged and pump

will not function properly. Clean or replace nozzle as necessary.

8. When freshwater tank is empty, stop operation and turn water pump switch to off.

NOTICE: Do not continue to operate with freshwater tank empty. Running water pump with no

water will damage pump.

CMW

Page 63

Vacuum and Pothole - 62 FX50 Operator’s Manual

Drain Tank

Drain Tank

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

1. Ensure that unit is hitched to vehicle. See “Hitch Trailer” on page 50.

2. Haul unit to approved dumping area.

Incorrect procedures could result in death, injury, or property

damage. Learn to use equipment correctly.

To help avoid injury:

• Do not unhitch unit from tow vehicle before or during dumping. A freestanding unit can

become unstable when tilting tank.

• Do not unlatch door with tank tilted up.

• Do not unlatch vacuum boom (optional) with tank tilted up.

Breathing crystalline silica dust may cause lung disease. Cutting,

drilling, or working materials such as concrete, sand, or rock containing quartz may

result in exposure to silica dust. Use dust control methods or appropriate breathing

protection when exposed to silica dust.

NOTICE: Do not drive with tank or door raised.

3. Open drain/outlet valve and inlet valve.

4. Allow tank to drain in the horizontal position until

tank is approximately half drained. Monitor sight

glasses.

5. When tank is half drained, start engine and run at

low idle.

6. Tilt tank up to help flush solids from tank.

7. Lower tank to the full horizontal position.

8. Close drain/outlet valve and inlet valve.

CMW

Page 64

FX50 Operator’s Manual Vacuum and Pothole - 63

Drain Tank

9. If further draining is necessary, open tank door. See “Open/Close Tank Door” on page 66.

Crushing weight could cause death or serious injury. Use proper

procedures and equipment or stay away.

To help avoid injury: Use tools (provided with unit) if unit must be serviced with

tank door up.

10. Tilt tank up. Allow tank to drain completely.

11. Connect water pressure hose to water lance.

12. Turn water pump switch on. Adjust water pressure.

13. Use water lance to thoroughly rinse inside of tank

and around door seal.

Confined space

will cause suffocation. Use

proper procedures for entering

or stay away.

To help avoid injury: Enter tank only if

necessary. Follow U.S. Department of Labor

guidelines for entering confined spaces.

14. Return tank to the fully lowered horizontal position.

15. Close tank door. See “Open/Close Tank Door” on page 66.

CMW

Page 65

Vacuum and Pothole - 64 FX50 Operator’s Manual

Unload to Another Tank

Unload to Another Tank

Optional reverse flow mode can be used to transfer vacuumed material to another tank or disposal site.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

To help avoid injury:

• Keep unit in “vacuum” mode unless pressure is needed.

• Restrain hose prior to pressurization. Unrestrained hose may cause property damage, injury or

death.

• Do not open fitting cams or valves when tank is pressurized. Flying debris, plugs and doors can

cause injury or death.

• Do not open tank door while tank is pressurized.

• Do not use pressure to clear clogs in vacuum hose.

IMPORTANT: Check relief valves as shown

before each use.

j33om059h.eps

1. Throttle down completely and turn off engine. Securely connect transfer hose to FX tank. Ensure drain/

outlet valve on FX tank is closed.

2. Securely connect other end of transfer hose to offboard tank. Ensure inlet valve on offboard tank is

closed and tank is vented.

3. Open FX tank drain/outlet valve. Material will flow into transfer hose.

4. Open offboard tank inlet valve.

CMW

Page 66

FX50 Operator’s Manual Vacuum and Pothole - 65

Unload to Another Tank

5. Move valve handle counterclockwise to engage “reverse flow” mode and start engine. Material will flow

into offboard tank.

6. Increase throttle as desired to transfer material.

7. When transfer is complete, throttle down completely and turn off engine. Close FX tank drain/outlet

valve.

8. Close offboard tank inlet valve and disconnect hose from offboard tank inlet valve.

9. Move handle clockwise to “vacuum” mode and turn on engine.

10. Open FX tank drain/outlet valve. Material will empty from transfer hose.

11. Close FX tank drain/outlet valve, throttle down and turn off engine.

12. Disconnect transfer hose from FX tank.

CMW

Page 67

Vacuum and Pothole - 66 FX50 Operator’s Manual

Open/Close Tank Door

Open/Close Tank Door

Crushing weight could cause death or serious injury. Use proper

procedures and equipment or stay away.

To help avoid injury: Use tools (provided with unit) if unit must be serviced with tank

door up.

To help avoid injury: Do not raise tank with door held closed only by vacuum. Door may suddenly

open and possibly injure someone.

NOTICE: Do not drive with tank or door raised.

IMPORTANT: Depressurize tank before emptying cyclonic canister, cleaning filter, clearing hoses or

opening any doors.

300 or 800 Tank:

Open

1. If tank is tilted, lower tank fully before opening door.

2. Open tank inlet valve.

3. Set hydraulic function switch to door position.

4. Press OPEN on tethered control.

Close

1. Press CLOSE on tethered control until the linkage on both sides of the tank is fully collapsed.

2. Close tank inlet valve.

CMW

Page 68

FX50 Operator’s Manual Vacuum and Pothole - 67

Open/Close Tank Door

1200 Tank:

Open

1. Push door seal control to SEAL.

2. Turn tank door lock counterclockwise.

3. Pull door seal control to RELEASE.

4. Turn door handle to DISENGAGE and pull out.

5. Push door lift control to OPEN.

6. Ensure door lift latch (1) engages properly.

Door lift latch (1) should be fully seated on pin

(2).

NOTICE: If door latch is not fully seated on

pin, door will close and possibly injure

someone.

Close

1. Fully open door to disengage door lift latch (1)

from pin (2). Latch cover (3) must be down for

tank door to close.

2. Pull door lift control to CLOSE.

3. Turn door handle to DISENGAGE, push in and

turn to ENGAGE.

4. Push door seal control to SEAL.

om0663h.eps

1

2

1

2

3

5. Turn tank door lock clockwise until it stops to

lock.

6. Pull door seal control to RELEASE.

om0664h.eps

CMW

Page 69

Vacuum and Pothole - 68 FX50 Operator’s Manual

Open/Close Tank Door

CMW

Page 70

FX50 Operator’s Manual Complete the Job - 69

Complete the Job

Chapter Contents

Antifreeze Fluid Excavation Unit . . . . . . . . . . . . . 70

• Add Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

• Reclaim Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rinse Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Stow Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

CMW

Page 71

Complete the Job - 70 FX50 Operator’s Manual

Antifreeze Fluid Excavation Unit

Antifreeze Fluid Excavation Unit

Add Antifreeze

Follow these steps for overnight or long-term storage of unit during cold weather.

1. Fill antifreeze tank with a propylene-glycol based antifreeze.

2. Ensure that water tank valve is closed.

3. Open antifreeze tank valve.

4. Connect water pressure hose to water lance.

5. Start engine.

6. Move water pump switch to on. If freshwater tank is empty, move to bypass.

7. Squeeze water lance handle and run until antifreeze runs through the water lance.

8. Move water pump switch to off.

9. Close antifreeze tank supply valve.

10. Turn ignition switch to off.

11. Drain water tank completely.

Reclaim Antifreeze

1. Turn water pressure down.

2. Move water pump switch to on.

3. Put end of water lance in antifreeze tank.

4. Squeeze water lance handle and run until water comes out of lance.

5. Move water pump switch to off.

CMW

Page 72

FX50 Operator’s Manual Complete the Job - 71

Rinse Equipment

Rinse Equipment

Spray water onto equipment to remove dirt and mud. Use water lance. Thoroughly rinse inside of tank and

around door seal.

Confined space will cause suffocation. Use proper procedures for

entering or stay away.

To help avoid injury: Enter tank only if necessary. Follow U.S. Department of Labor guidelines for

entering confined spaces.

NOTICE: Do not spray water onto operator’s console. Electrical components could be damaged. Wipe

down instead.

Disconnect

Disconnect and store the following hoses and cables (if used):

• vacuum hoses

• water pressure hose

CMW

Page 73

Complete the Job - 72 FX50 Operator’s Manual

Stow Tools

Stow Tools

Make sure optional vacuum boom, potholing tools, water lance, and other tools are properly stowed.

CMW

Page 74

FX50 Operator’s Manual Service - 73

Service

Chapter Contents

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Recommended Lubricants/Service Key . . . . . . . 76

Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

25 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

50 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

100 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

250 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

500 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

1000 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2000 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

As Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

200 Mile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

3000 Mile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

12,000 Mile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

CMW

Page 75

Service - 74 FX50 Operator’s Manual

FX_Tank_Raised.eps

Precautions

Precautions

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

To help avoid injury:

• Unless otherwise instructed, all service should be performed with engine off.

• Refer to engine manufacturer’s manual for engine maintenance instructions.

Working Under Raised Debris Tank

Crushing weight could cause death or serious injury. Use proper

procedures and equipment or stay away.

To help avoid injury: Use tools (provided with unit) if hydraulic system must be serviced

with tank tilted up.

1. Raise vacuum tank.

2. Remove cylinder lockout tool and place over

extended cylinder rod.

3. Lower vacuum tank until load is supported by

cylinder lockout tool.

FX_Tank_Raised.eps

CMW

Page 76

FX50 Operator’s Manual Service - 75

Precautions

Working Under Raised Tank Door

Crushing weight could cause death or serious injury. Use proper

procedures and equipment or stay away.

To help avoid injury: Use tools (provided with unit) if unit must be serviced with tank

door up.

1. Locate door lock tools in tool storage area and bring

to rear of tank.

2. Raise tank door completely.

3. Pin door lock tools into place as shown.

4. Lower tank lid until load is supported by door lock

tools.

Welding Precaution

NOTICE: Welding can damage electronics.

• Disconnect battery to prevent damage to battery. Do not turn off battery disconnect switch with

engine running, or alternator and other electronic devices may be damaged.

• Connect welder ground clamp close to welding point and make sure no electronic components are

in the ground path.

• Always disconnect the Engine Control Unit ground connection from the frame, harness connections

to the ECU, and other electronic components prior to welding on machine or attachments.

j36om019w.eps

Washing Precaution

NOTICE: Water can damage electronics. When cleaning equipment, do not spray electrical components

with water.

CMW

Page 77

Service - 76 FX50 Operator’s Manual

Recommended Lubricants/Service Key

Recommended Lubricants/Service Key

Item Description

DEO Diesel engine oil meeting or exceeding CH-4 per the API service classification or E5

per the European Automobile Manufacturer’s Association (ACEA) and SAE viscosity

recommended by engine manufacturer (SAE 15W40)

HTG NGLI #2 premium grade, petroleum-based grease with high temperature resistance

and good mechanical stability

NDO SAE30 non-detergent oil

SGL Synthetic gear oil, ISO 100, p/n 256-044. See blower manual for more information.

MPL Multipurpose gear oil meeting API service classification GL-5 (SAE 80W90)

THF Tractor hydraulic fluid, similar to Phillips 66 HG, Mobilfluid 423, Chevron Tractor

Hydraulic Fluid, Texaco TDH Oil, or equivalent

MPG Multipurpose grease meeting ASTM D217 and NLGI 5

DOT DOT 3 or 4 brake fluid

Check level of fluid or lubricant

Check condition

Filter

Change, replace, adjust, service or test

Proper lubrication and maintenance protects Ditch Witch equipment from damage and failure. Service

intervals listed are for minimum requirements. Use only recommended lubricants. Fill to capacities listed in

“Specifications” on page 115.

For more information on engine lubrication and maintenance, see your engine manual.

NOTICE:

• Use only genuine Ditch Witch parts, filters, approved lubricants, TJC, and approved coolants to

maintain warranty.

• Use the “Service Record” on page 131 to record all required service to your machine.

CMW

Page 78

FX50 Operator’s Manual Service - 77

Recommended Lubricants/Service Key

Engine Oil Temperature Chart

Temperature range anticipated before next oil change

See engine manual for more information about oil viscosity and operation in arctic conditions.

Approved Fuel

This engine is designed to run on diesel fuel. Use only high quality fuel meeting ASTM D975 No. 2D,

EN590, or equivalent. At temperatures below 32° F (0° C) winter fuel blends are acceptable. See the

engine operation manual for more information.

IMPORTANT: Fuel sulfur content should be less than 5000 ppm (0.5%). Worldwide, fuel sulfur

regulations vary widely. Fuel used should always comply with local regulations. If using lube oil meeting

API CJ-4, (or other low SAPS equivalent) and fuel with sulfur content above 15 ppm (0.0015%), ULSD

in the U.S.), reduce oil change interval to 250 hours.

Biodiesel blends up to 5% (B5) are approved for use in this unit. The fuel used must meet the

specifications for diesel fuel shown above. In certain markets, higher blends may be used if certain steps

are taken. Extra attention is needed when using biodiesel, especially when operating in cold weather or

storing fuel. Contact your Ditch Witch dealer or the engine manufacturer for more information.

CMW

Page 79

Service - 78 FX50 Operator’s Manual

Each Use

Each Use

Location Task Notes

Trailer Check torque of hitch bolts

Check hydraulic brake actuator bolts If equipped

Check hydraulic brake fluid level If equipped; DOT 3 or 4

Check trailer battery

Check tire pressure and lug nut torque

Check lights and reflectors

Trailer

Check Torque of Hitch Bolts

Check torque of hitch bolts. Torque varies by

trailer model. Refer to “Specifications” on

page 115.

Check Hydraulic Brake Actuator Bolts

Check hydraulic brake actuator bolts. Tighten if

loose.

j36om020w.eps

CMW

j36om021w.eps

Page 80

FX50 Operator’s Manual Service - 79

Each Use

Check Hydraulic Brake Fluid Level

Check hydraulic brake fluid level at master

cylinder each use. Fluid should be visible a top of

master cylinder. Add DOT 3 or DOT 4 brake fluid

and bleed brakes as needed. See page 107.

j36om022w.eps

Check Trailer Battery

Check battery connections for wear or corrosion.

Keep connections clean and tight. Batteries

supplied by factory are maintenance-free. Service

replacement batteries according to

manufacturer’s instructions.

Check Tire Pressure and Lug Nut

Torque

Check tire pressure (2) and lug nut (1) torque.

See below for correct pressure and torque.

Trailer Pressure Torque

T9S 80 psi (5.5 bar) 95 ft•lb (129 N•m)

T18S 125 psi (8.6 bar) 300 ft•lb (407 N•m)

T26S 110 psi (7.6 bar) 271 ft•lb (271 N•m)

j36om023w.eps

1

2

j36om051w.eps

CMW

Page 81

Service - 80 FX50 Operator’s Manual

j33om013h.eps

Each Use

Check Lights and Reflectors

Check lights and reflectors for correct operation

and cleanliness.

j33om013h.eps

CMW

Page 82

FX50 Operator’s Manual Service - 81

10 Hour

10 Hour

Location Task Notes

Vacuum

System

Debris Tank Check vacuum tank hoses

Check engine oil level

Inspect belts (water pump, blower and fan)

Check air filter service indicator

Check hydraulic fluid level THF

Check hydraulic hoses

Check blower oil level SGL

Check blower

Check water pump oil level NDO

Check water pump

Check water pump regulator

Clean water pump filter

Clean vacuum air filter

Check spray nozzle

Drain cyclonic separator canister

Check strobe light

Check vacuum tank door seals/fittings

Check tank deflector

CMW

Page 83

Service - 82 FX50 Operator’s Manual

10 Hour

Vacuum System

Check Engine Oil Level

Check engine oil at dipstick (2) before operation

and every 10 hours thereafter. Check with unit on

level surface and at least 15 minutes after

stopping engine. Add DEO at fill (1) as necessary

to keep oil level at highest line on dipstick.

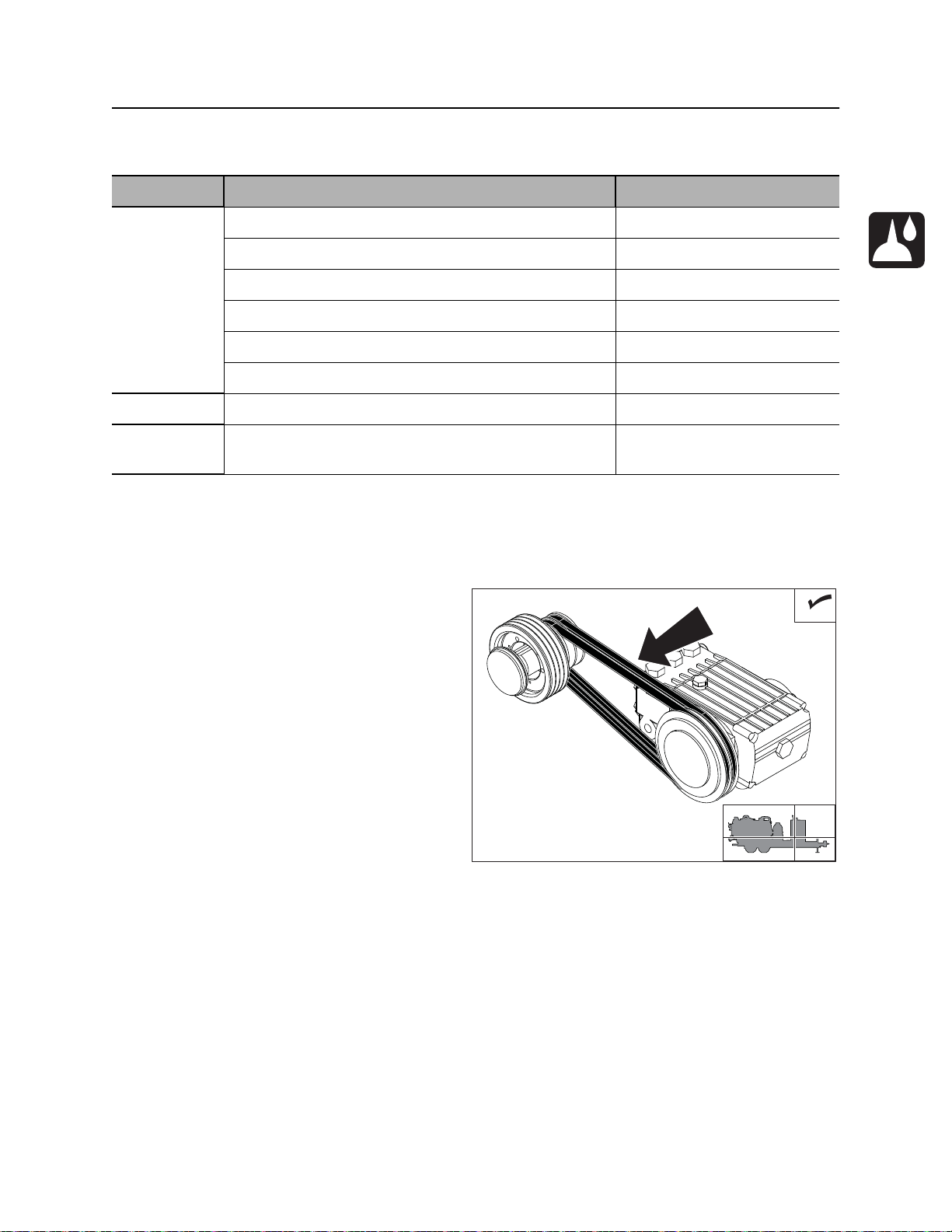

Inspect Belts

Check fan (2), blower (1), and water pump (3)

belts every 10 hours for damage or wear.

1

2

j36om009w.eps

1

2

CMW

3

j36om058w.eps

Page 84

FX50 Operator’s Manual Service - 83

10 Hour

Check Air Filter Indicator and Clean

Dust Trap

Check air filter indicator (2) and inspect dust trap

(1) for cracks every 10 hours. Change filter

elements when indicator reaches red zone.

NOTICE: Only open the air filter canister when

air restriction is indicated. Change the elements,

do not attempt to clean them.

• Compressed air or water may damage filter

elements.

12

• Tapping filter elements to loosen dirt may

damage filter seals.

Check Hydraulic Fluid Level

With frame level, check oil at indicator every 10

hours. Add THF at fill (1) as necessary. Clean dust

from cap by blowing with low-pressure air.

j36om007w.eps

1

j36om010w.eps

CMW

Page 85

Service - 84 FX50 Operator’s Manual

10 Hour

Check Hydraulic Hoses

Check hoses every 10 hours for wear or damage.

Replace as needed.

Fluid or air pressure could pierce skin and cause injury or

death. Stay away.

To help avoid injury:

• Before disconnecting a hydraulic line, turn engine off and operate all controls to relieve pressure.

Lower, block, or support any raised component with a hoist. Cover connection with heavy cloth and

loosen connector nut slightly to relieve residual pressure. Catch all fluid in a container.

• Before using system, check that all connections are tight and all lines are undamaged.

• Fluid leaks can be hard to detect. Use a piece of cardboard or wood, rather than hands, to search

for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a doctor familiar with this type of injury.

CMW

Page 86

FX50 Operator’s Manual Service - 85

10 Hour

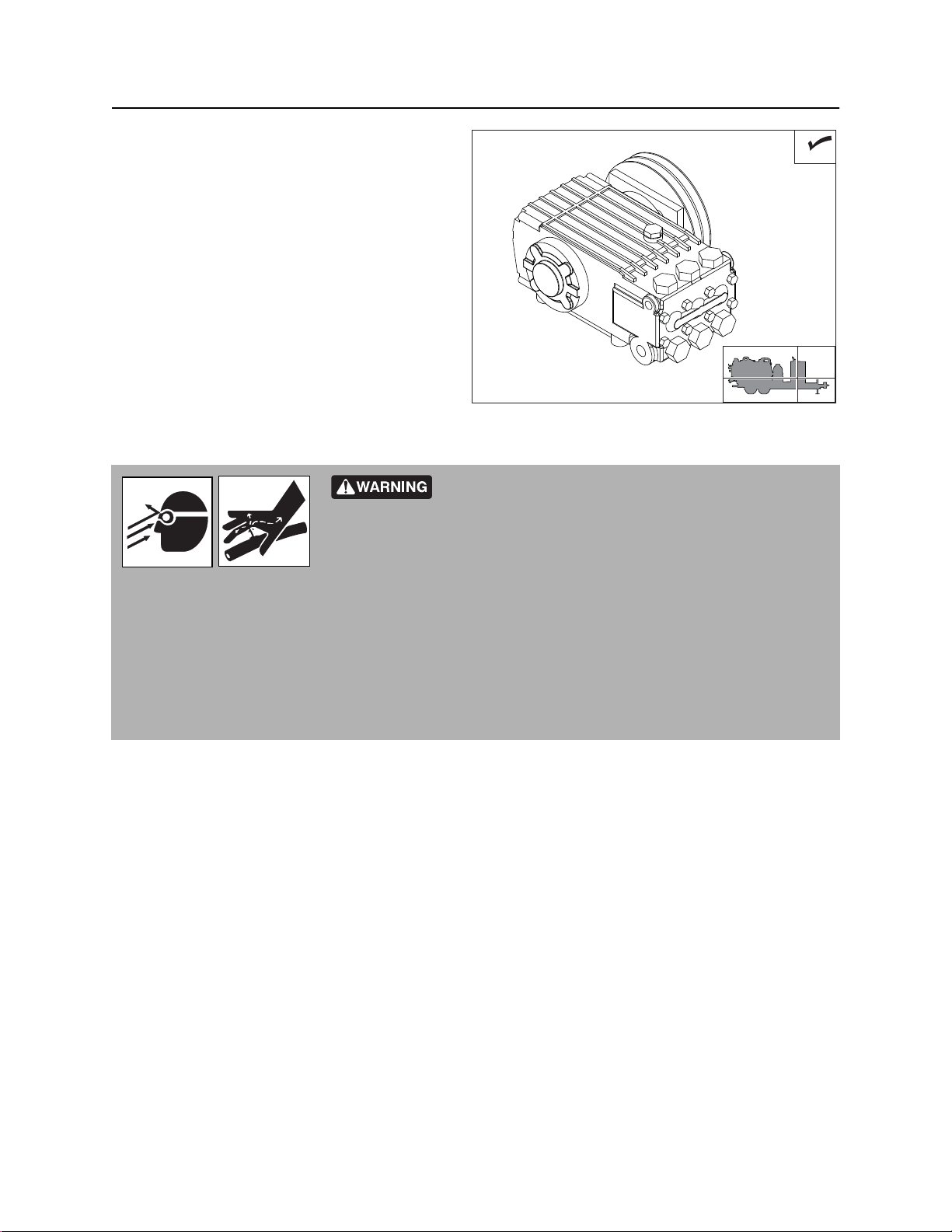

Check Blower Oil Level

1

With frame level, check blower oil at sight glass

(2) every 10 hours. Add SGL at breather (1) as

necessary to maintain oil level at halfway point on

sight glass (2). Do not overfill.

2

j36om011w.eps

Check Blower

Check blower every 10 hours for unusual noise or

vibration. If malfunction is detected:

1. Stop engine.

2. Consult blower repair manual.

Check Water Pump Oil Level

With frame level, check water pump oil at dipstick

every 10 hours. Oil should be [where?] on sight

glass (2). Add NDO at fill (1) as necessary to keep

oil at full mark on dipstick.

j36om024w.eps

1

2

j36om013w.eps

CMW

Page 87

Service - 86 FX50 Operator’s Manual

10 Hour

Check Water Pump

Check water pump unit every 10 hours for leaks,

loose fittings, unusual noise or vibration. Repair if

necessary.

j36om025w.eps

Fluid or air pressure could pierce skin and cause injury or

death. Stay away.

To help avoid injury:

• Before using system, check that all connections are tight and all lines are undamaged.

• Use a piece of cardboard or wood, rather than hands, to search for leaks. Fluid leaks can be hard to

detect.

• Wear protective clothing, including gloves and eye protection.

CMW

Page 88

FX50 Operator’s Manual Service - 87

10 Hour

Check Water Pump Regulator

Check for proper operation of regulator every 10

hours.

To check:

1. Start engine.

2. Connect water pressure hose to water lance.

3. Move water pressure switch to on.

4. Squeeze water lance handle. Water pump

should engage.

5. Release water lance handle. Water pump

should disengage.

If pump does not engage and disengage with movement of water lance handle, water pump control system

is not functioning properly. See water pump manual for more information.

j36om062w.eps

Clean Water Pump Filter

Clean water pump filter every 10 hours and

replace as needed.

1. Open filter housing.

2. Remove element and rinse housing

thoroughly with water.

3. Inspect element for signs of collapse and for

brittle or broken rubber seals on the ends of

the element. Replace as needed. See

page 103.

4. Replace element and close filter housing.

j36om026w.eps

CMW

Page 89

Service - 88 FX50 Operator’s Manual

10 Hour

Clean Vacuum Air Filter

Clean filter every 10 hours or as needed.

To clean filter:

1. Remove filter from canister.

2. Run low pressure water into inside of filter.

NOTICE: Do not use high pressure water

to clean filter. Filter will be damaged.

3. Allow filter to dry completely before returning

to canister.

j36om027w.eps

Check Spray Nozzle

Check spray nozzle every 10 hours. Ensure that

water sprays from nozzle in a fan pattern. Clean

or replace nozzle as necessary.

Drain Cyclonic Separator Canister

IMPORTANT: Depressurize tank before

emptying cyclonic canister, cleaning filter,

clearing hoses or opening any doors.

Drain canister at drain (2) every 10 hours or when

water is visible in sight glass (1).

CMW

j36om029w.eps

1

2

j36om028w.eps

Page 90

FX50 Operator’s Manual Service - 89

10 Hour

Debris Tank

Check Vacuum Tank Hoses

Check hoses every 10 hours for wear or damage.

Replace as needed.