Page 1

FT5 - SERVICE

SERIAL NUMBER

SERVICE

SERIAL NUMBER

Record the serial numbers and date of purchase of your

equipment in the spaces below.

1

Date of Manufacture:

Serial Number:

Date of Purchase:

Page 2

2

FT5 - SERVICE

SUPPORT PROCEDURE

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of your

equipment purchase. This information should be recorded and

placed on file by the owner at the time of purchase.

Return damaged parts to dealer for inspection and warranty

consideration if in warranty time frame.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's

parts may void warranty consideration.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications covering the

operation, service, and repair of your equipment.

Ditch Witch Training

For information about on-site, individualized training, contact your

Ditch Witch dealer.

Page 3

FT5 - FOREWO RD

RESOURCES

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future ref erence. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com

or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

3

The descriptions and specifications in this manual are subject to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improv ements may hav e t aken

place after this manual was published. For the latest information

on Ditch Witch equipment, see your Ditch Witch dealer.

Thank you for buy ing and using Ditch Witch equipment .

Page 4

4

FT5 - FOREWORD

RESOURCES

Operator's Manual

FT5

Issue No.1.0/OP-3/99

Part Number 054-058

Copyright 1999

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, Jet Trac, Pro Tech, Fluid Miser, Perma-Soil,

Modularmatic, Roto Witch, AutoCrowd, and Subsite are

registered trademarks of The Charles Machine Works, Inc.

Pierce Airrow is a registered trademark of Oklahoma Airrow, Inc.

Page 5

FT5 - CONTENTS

RESOURCES

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . .12

5

Safety Alerts and Notices . . . . . . . . . . . . . . . . . . . . . .13

LIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Check Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Select Drilling Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Plan Drilling Fluid Requ ire m e nts. . . . . . . . . . . . . . . . .20

Page 6

6

FT5 - CONTENTS

RESOURCES

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mix Drilling Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pump Fluid to Boring Unit. . . . . . . . . . . . . . . . . . . . . . 23

Operate in Cold Weather . . . . . . . . . . . . . . . . . . . . . . 2 4

LUBRICATION AND MAINTENANCE . . . . . . . . . . . . . . . 25

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 6

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Page 7

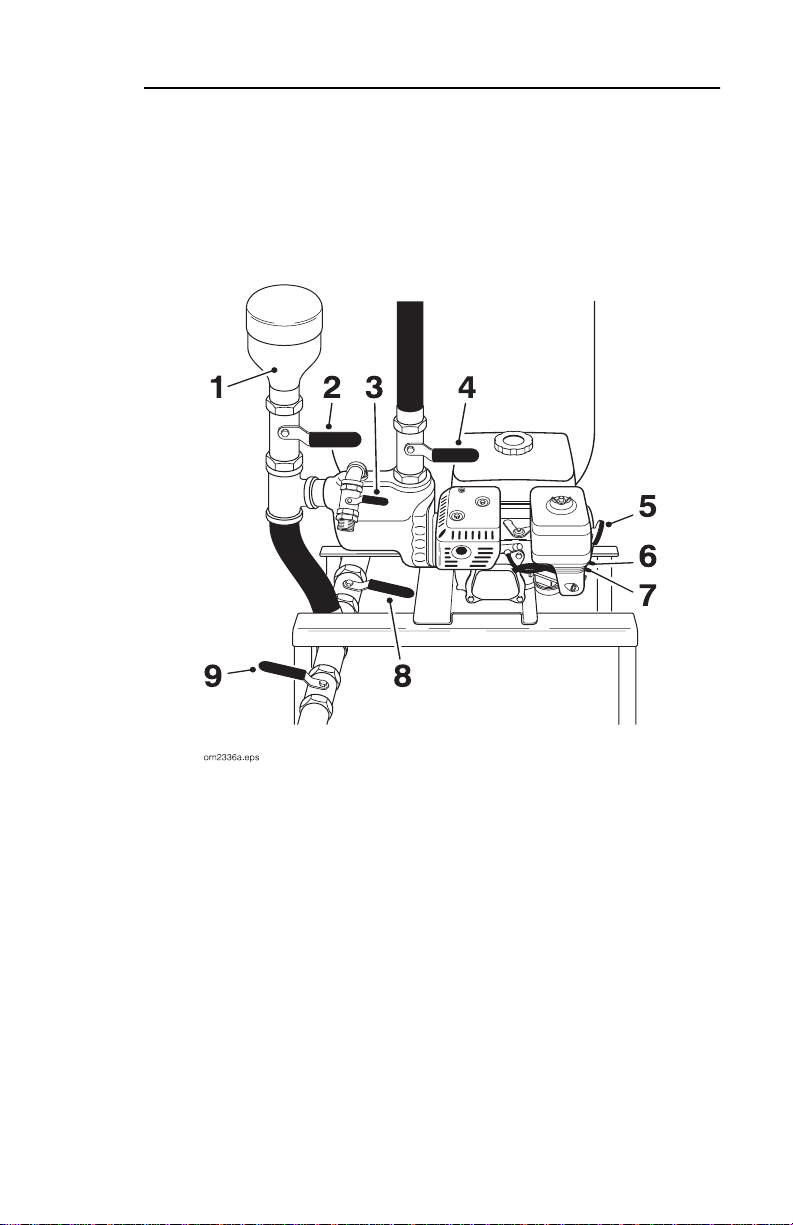

FT5 - CONTROLS

OVERVIEW

OVERVIEW

7

CONTROLS

1. Filler neck

2. Mixing valve

3. Discharge valve

4. Circulation valve

5. Rope start

6. Throttle

7. Choke

8. Tank discharge valve

9. Drain valve

Page 8

8

FT5 - CONTROLS

DESCRIPTIONS

DESCRIPTIONS

Filler Neck

Remove cap to add additives t o drilling fluid mixture. Replace cap

when finished.

Mixing Valve

Controls flow from filler neck to pump. Open only when pouring

additives into filler neck for mixing. Close when finished.

IMPORTANT:

Do not open valve unless pump is running.

Discharge Valve

Controls flow from FT5 to fluid pump on boring unit.

Circulation Valve

Controls flow from pump to tank. Open to circulate fluid between

pump and tank while mixing.

Page 9

FT5 - CONTROLS

Rope Start

Cranks engine for starting. Pull to start engine.

Throttle

Controls engine speed. Increasing engine speed also increases

pump flow.

Choke

Regulates air/fuel mixture in engine.

Tank Discharge Valve

This valve must be open while unit is running.

Open this valve and the drain valve to drain fluid from tank. If

drawing water into tank from an external source, open the drain

valv e and close this valve.

9

Drain Valve

Open this valve and tank discharge valve to drain fluid from tank.

If drawing water into tank from an external source, open this valve

and close tank discharge valve.

Page 10

10

FT5 - CONTROLS

Page 11

FT5 - SAFETY

11

SAFETY

For additional precautions and guidelines, consult boring unit

operator’ s manual before beginning bore. In addition, follow these

guidelines before operating any jobsite equipment:

• Do not operate any equipment unless you have completed

proper training and read the operator’ s manual.

• Wear personal protective equipment.

• Replace missing or damaged safety shields and safety signs.

• Do not operate unit where flammable gas is present.

• Use equipment carefully. Stop operation and invest igate

anything that does not look or feel right.

• Contact your Ditch Witch dealer if you have any question

about operation, maintenance, or equipment use.

Page 12

12

SAFETY ALERT CLASSIFICATIONS

FT5 - SAFETY

SAFETY ALERT CLASSIFICATIONS

These classifications and the icons defined on the following

pages work together to alert you to situations which could be

harmful to you, jobsite bystanders or your equipment. When you

see these words and icons in the book or on the machine,

carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels:

CAUTION

. Learn what each level means.

DANGER, WARNING

and

indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Watch for two other words:

NOTICE

can keep you from doing something that might damage

NOTICE

and

IMPORTANT

.

the machine or someone's property. It can also alert you against

unsafe practices.

IMPORT ANT

can help you do a better job or make your job

easier in s ome way.

Page 13

FT5 - SAFETY

SAFETY ALERTS AND NOTICES

SAFETY ALERTS AND NOTICES

Electric shock. Contacting electric

lines will cause death or serious injury. Know

location of lines and stay away.

Deadly gases. Lack of oxygen or

presence of gas will cause sickness or death.

Provide ventilation.

13

Fire or explosion possible. Fumes

could ignite and cause burns. No smoking, no

flame, no spark.

Page 14

14

FT5 - SAFETY

Improper handling or use of

chemicals may result in illness, injury, or

equipment damage. Follow instructions on labels

and in material safety data sheets (MSDS).

Fall possible. Slips or trips may

result in injury. Keep area clean.

Hot parts may cause burns. Do not

touch until cool.

Page 15

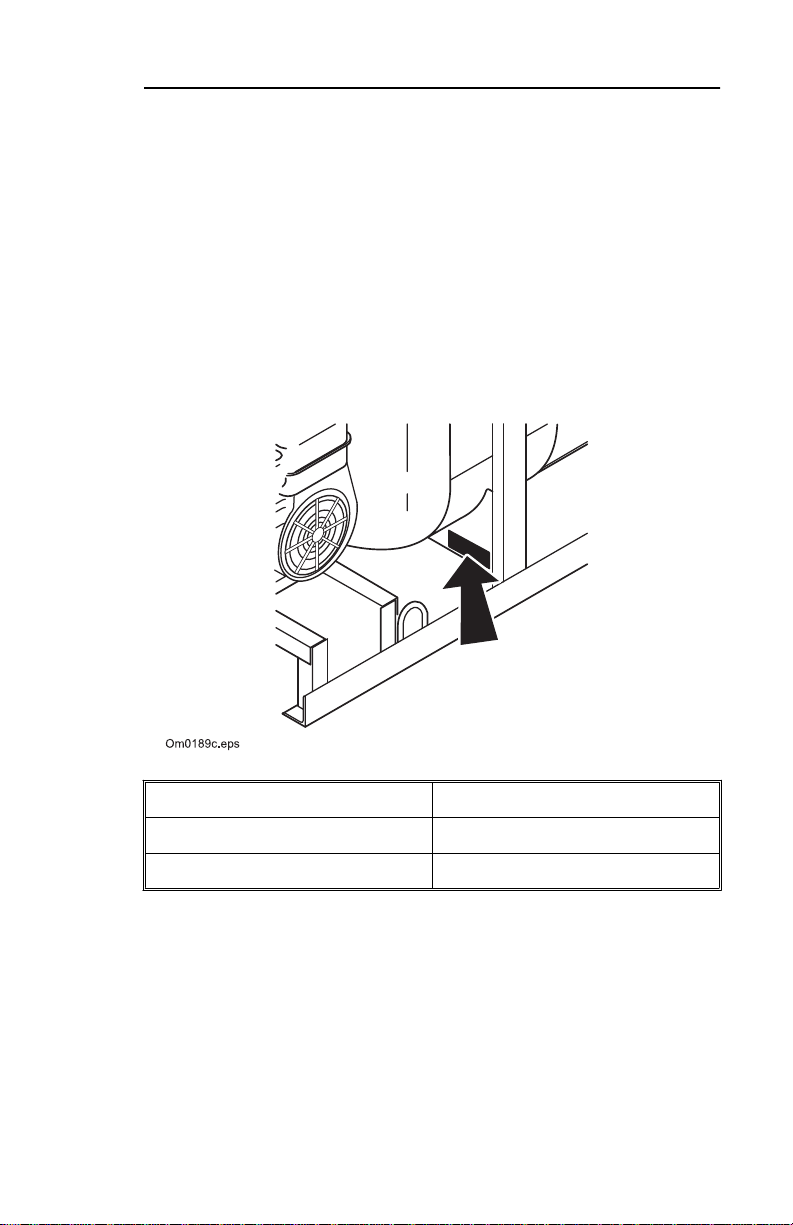

FT5 - LIFT

POINTS

Crushing weight could cause

death or serious injury. Use proper procedures

and equipment or stay away.

POINTS

Lifting Po int s

Lifting points are identified by lifting

decals. Lifting at any other point is

unsafe and can damage machinery.

15

LIFT

PROCEDURE

Lifting Skid

Lift skid by attaching chains to

designated lift points on sides of

skid.

IMPORTANT:

lifting.

Empty tank before

Page 16

16

FT5 - LIFT

PROCEDURE

Page 17

FT5 - SETUP

CHECK EQUIPMENT

17

SETUP

CHECK EQUIPMENT

Check the following before each day ’s work. Refer to

LUBRICATION AND MAINTENANCE

and locations.

• General appearance of equipment.

• Safety sign location and readability.

• All guard and shield locations. Replace if missing or worn.

• Condition of all wear items such as filters, hoses, and clamps.

• Drilling fluid hose s and electric cables for signs of leakage,

wear, or other damage.

• Engine crankcase oil level. Keep oil lev el at the highest line on

dipstick. Do not overf ill.

for additional information

• Fuel level. Fuel tank should be filled at the end of the day to

reduce condensation.

• All nuts and bolts. Tighten if necessary.

Page 18

18

FT5 - SETUP

SELECT DRILLING FLUID

SELECT DRILLING FLUID

For productive boring and equipment protection, use these

recommended Baroid

dealer.

®

products, available from your Ditch Witch

•Quik-Gel

•E-Z Mud

• Liqui-Trol

• Quik-Trol

• Bore-Gel

• Con-Det

•Poly-Bore

TM

dry powder bentonite (P/N 259-804)

TM

liquid polymer (P/N 259-805)

TM

liquid polymer suspension (P/N 259-808)

TM

dry powder polymer (P/N 259-809)

TM

drilling fluid (P/N 259-807)

TM

water-soluble cleaning solution (P/N 259-810)

TM

borehole stabilizing agent (P/N 259-820)

Guidelines

Match drillin g fluid to soil type. Although s pecif ic conditions at

each jobsite vary, use the following guidelines when selecting a

drilling fluid.

If soil is . . . use . . .

smooth, flowing sand bentonite + medium-chain polymer

coarse sand or light soil bentonite

heavy clay long-chain polymer

swelling c lay long-chain polymer

For recommended mixture to reach desired drilling fluid viscosity

or thickness, contact your Ditch Witch dealer.

Baroid and all Baroid products mentioned on this page are trademarks of Dresser Industries, Inc.

Page 19

FT5 - SETUP

SELECT DRILLING FLUID

Bentonite

19

IMPORTANT:

Before adding bentonite to drilling fluid, be sure

boring unit is equipped to use a bentonite mixture.

Bentonite is a dry powder. When properly mixed with water, it

cakes on bore walls, lubricating the bore, keeping it open, and

holding fluid in the bore.

Some things to remember when mixing bentonite:

• Use clean water free of salt, calcium, or excess ive chlorine.

• Use water with a pH level between 7.5 and 10.

• Do not use bentonite containing sand.

• Mix bentonite thoroughly or it will settle in tank.

• Do not mix bentonite to a funnel viscosity of over 50.

For information on measuring funnel viscosity, read “Measuring

Funnel Viscosity” in

OPERATION

.

Polymer

This drilling fluid additive provides excellent lubrication and

increase s vi sco s ity. In swelling clay, polymer c a n reduce swelling

that traps pipe in the bore.

There are two types of polymer:

• long-chain such as Baroid E-Z Mud.

• medium-chain such as Baroid Quik Trol.

Page 20

20

PLAN DRILLING FLUID REQUIREMENTS

FT5 - SETUP

Mixtures

Bentonite does not mix well in water containing polymer. To use

both, mix bentonite first, then add polymer.

Bore-Gel contains premixed bentonite, polymer, and soda ash.

Use 15 lb/100 gal (6.8 kg/378.5 L) in normal boring conditions

and up to 45 lb/100 gal (20.4 kg/378.5 L) in sand or gravel.

PLAN DRILLING FLUID REQUIREMENTS

1. Determine boring co nditions and choos e appropriate drilling

fluid mix.

2. Estimate amounts of supplies needed and check availability:

• drilling fluid

• water supply. If more water than can be carried with the

unit will be needed, arrange to transport additional water.

• bentonite and/or polymer

3. Check water quality.

• Using litmus paper, perform a pH test on water.

• If pH is below 5.0, add 1 cup (.25 L) soda ash per tank.

• Test and repeat until pH is between 7.5 and 10.

Page 21

FT5 - OPERATION

MIX DRILLING FLUID

21

OPERATION

Jobsite hazards

could cause death or serious injur y.

Use correct equipment and work

methods. Use and maintain proper

safety equipment.

NOTICES:

• Wear personal protective equipment including hard hat, safety

eye wear, and hearing protection.

• Do not wear jewelry or loose clothing.

MIX DRILLING FLUID

1. Fill fluid tank with water. Allow room for additives.

2. Open circulation valve and tank discharge valve.

3. Start engine and run at half throttle or higher.

4. Open mixing valve.

5. Remove filler neck cap and pour bentonite, polymer and other

additives into filler neck.

IMPORTANT:

sure boring unit is equipped to use a bentonite mixture.

6. Close mixing valve and replace filler nec k cap.

7. Mix well.

Before adding bentonite to drilling fluid, be

Page 22

22

FT5 - OPERATION

Measuring Funnel Viscosity

Fluid thickness is called viscosity. The higher the viscosity, the

harder the fluid is to push through the system.

To determine viscosit y, you will need a viscosity funnel and a

measuring cup, available from your Ditch Witch dealer.

1. Take a fresh sample from

the drilling fluid tank. The

sample must be more than 1

qt (.95 L).

2. Hold funnel over 1-qt (.95-L)

measuring cup and place a

finger over the outlet.

3. Pour test sample into top of

funnel. Fill to screen.

4. Remove finger and time

flow. Count the number of seconds it takes for 1 qt (.95 L) of

liquid to pass through the funnel. The number of seconds is

the viscosity.

See your Ditch Witch dealer for i nformation on matching viscosity

to soil type.

Page 23

FT5 - OPERATION

PUMP FLUID TO BORING UNIT

PUMP FLUID TO BORING UNIT

Electric shock. Contacting electric

lines will cause death or serious injury. Know

location of lines and stay away.

23

NOTICE:

If electrical strike occurs while fluid hose is connected

to boring unit, fluid system also will become electrif ied.

1. Connect hose from mixing pump to boring unit.

2. Open discharge valve and adjust engine throttle to give

desired flow rate to boring unit (approximately half throttle).

IMPORTANT:

If using bentonite in fluid mixture, leave

circulation valve approximately half open to allow continuous

mixing while boring.

A higher throttle setting is necessary if recirculating fluid

through the pump.

Page 24

24

FT5 - OPERATION

OPERATE IN COLD WEATHER

OPERATE IN COLD WEATHER

For successful operation in cold weather, follow these

procedures.

• Use pump to keep drilling fluid circulating at all times, ev en

when traveling to and from the jobsite.

• If possible, use all drilling fluid in tank before transporting the

unit away from the jobsite.

• To prepare unit for storage in cold weather, open all valves

and drain tank. Open drain valve on pump and drain pump.

Page 25

FT5 - LUBRICATION AND MAINTENANCE

LUBRICATION

LUBRICATION AND

MAINTENANCE

LUBRICATION

Check oil level in engine daily. Fill as needed with SAE 10 W40

engine oil. See manufact urer’s manual for lubrication schedule.

MAINTENANCE

Check filler neck daily. Filler neck should be clean and free of

obstructions.

25

Page 26

26

FT5 - LUBRICATION AND MAINTENANCE

TROUBLESHOOTING

Problem Possible solutions

TROUBLESHOOTING

poor drilling fluid mix

characteristics

Test water pH and treat if necessary (see

OPERATION

Residual polymer may be present in

tank. Drain tank and remix fluid, adding

bentonite first.

low yield properties Test water pH.

Try a different brand of drilling fluid

additive.

Add polymer to drilling fluid tank only

after bentonite has been yielded out.

for instructions).

Page 27

FT5 - SPECIFICATIONS

TROUBLESHOOTING

SPECIFICATIONS

Dimens ions U.S. Metric

L1, length (without hose and valve) 73 in 1.85 m

L2, leng th (with hose and valve) 84 in 2.13 m

W, width 32 in 0.81 m

H, height 53.5 i n 1.36 m

Weight with e mpty fluid tank 402 lb 182 kg

Weight with full fluid tank 2071 lb 939 kg

Fluid System U.S. Metric

Fluid t ank 200 gal 757 L

Fluid Capacities U.S. Metric

Fuel tank 1 gal 3.6 L

Engine oil with filter 0.63 qt 0.6 L

Engine U.S. Metric

Honda GX160, gasoline

Flywheel power @ 3600 rpm 5.4 hp 4 .0 kW

27

Page 28

28

FT5 - SPECIFICATIONS

Loading...

Loading...