FM13V - SERVICE 1

SERIAL NUMBER

SERVICE

SERIAL NUMBER

Record the serial numbers and date of purchase of your

equipment in the spaces below.

Date of manufacture:

Date of purchase:

Fluid mixing unit serial

number:

2 FM13V - SERVICE

SUPPORT PROCEDURE

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of your

uipment purchase. This information should be recorded and

eq

placed on file by the owner at the time of purchase.

Return damaged parts to dealer for inspection and Warranty

eration if in warranty time frame.

consid

Order genuine Ditch Witch replacement or repair parts from your

thorized Ditch Witch dealer. Use of another manufacturer's

au

parts may void warranty consideration.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications and videos

covering safety, operation, service, and repair of your equipment.

Ditch Witch Training Center

For information about on-site, individualized training, contact your

Ditch Witch dealer.

FM13V - FOREWORD 3

RESOURCES

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

uipment at all times for future reference. If you sell your

eq

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, conta

ct your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine W

orks, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to

ge. The Charles Machine Works, Inc. reserves the right to

chan

improve equipment. Some product improvements may have

taken place after this manual was published. For the latest

information on Ditch Witch equipment, see your Ditch Witch

dealer.

Thank you for buying and using

Ditch Witch equipment.

4 FM13V - FOREWORD

RESOURCES

Operator's Manual

13V

FM

Issue No. 1.0/OP-1/07

t Number 053-1125

Par

Copyright 2007

by The

Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, CMW, AutoCrowd,

Modularmatic, Jet Trac, Roto Witch, Subsite, Fluid Miser, PermaSoil, Power Pipe, Super Witch, Super Witch II, Pierce Airrow, The

Underground, and The Underground Authority Worldwide are

registered trademarks of The Charles Machine Works, Inc.

FM13V - CONTENTS 5

RESOURCES

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . . 19

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

LIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Check Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Select Drilling Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 FM13V - CONTENTS

RESOURCES

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mix Drilling Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pump Fluid to Drilling Unit . . . . . . . . . . . . . . . . . . . . . 33

LUBRICATION AND MAINTENANCE . . . . . . . . . . . . . . . 37

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

FM13V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Drilling Fluid Tanks. . . . . . . . . . . . . . . . . . . . . . . . . . . 45

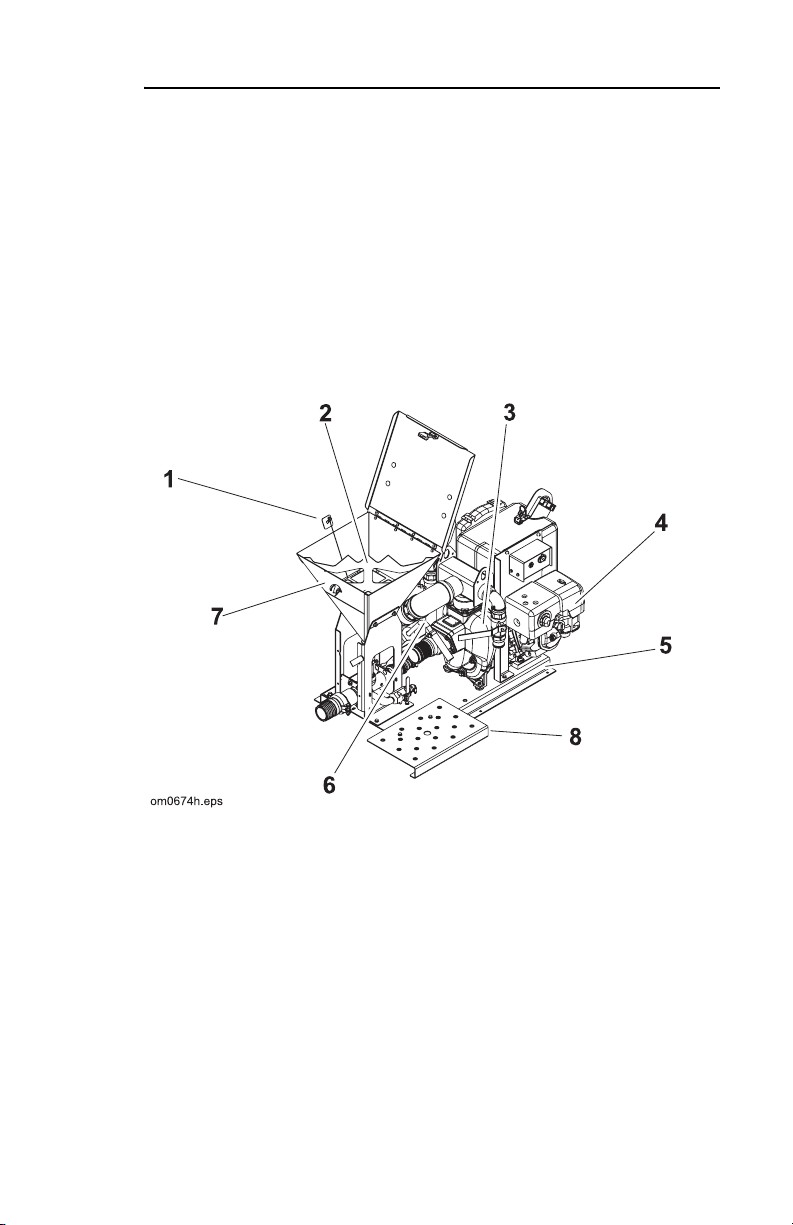

FM13V - OVERVIEW 7

RESOURCES

OVERVIEW

The FM13V is a platform mounted venturi mixing system which

mixes drilling fluid quickly and efficiently. It transfers drilling fluid

for use with directional drilling systems. The FM13V has two

available drilling fluid mixing tank sizes: 500 gal (1892 L) and

1000 gal (3785 L).

1. metering plate 5. base

2. bag ripper 6. suction wand

3. pump 7. dry chemical hopper

4. engine 8. platform

8 FM13V - OVERVIEW

RESOURCES

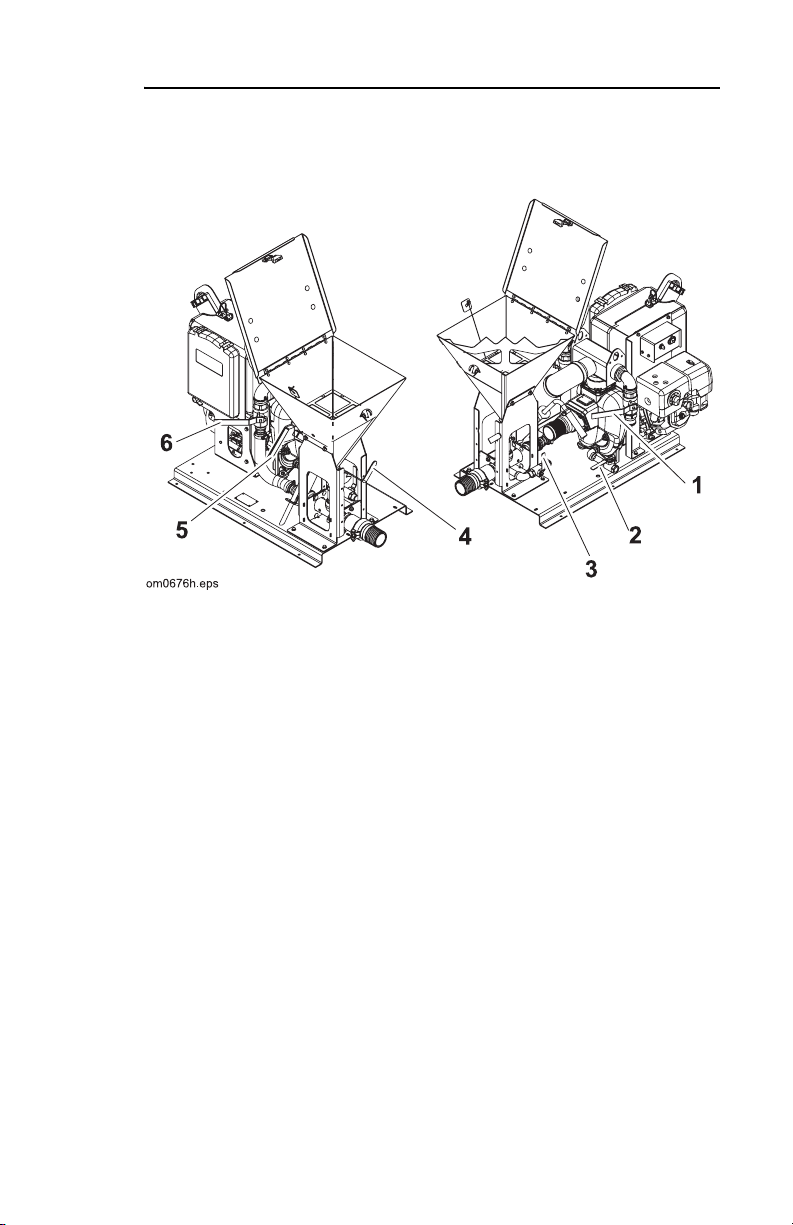

FM13V - CONTROLS 9

OVERVIEW

CONTROLS

OVERVIEW

Switches and Gauges

1. ignition switch 6. choke

2. auxiliary outlet (12VDC) 7. manual fuel shut-off valve

3. hourmeter 8. engine stop switch

4. throttle 9. battery disconnect

5. rope start

10 FM13V - CONTROLS

OVERVIEW

DESCRIPTIONS

Ignition Switch

This switch has three positions.

• Insert key and turn clockwise to the “ON” position.

• Turn switch all the way clockwise to the “Start” position.

• Release when engine starts. K

ey will return to on position.

• Turn counterclockwise to STOP to stop engine.

IMPORTANT Turn ignition s

witch to the STOP position any time

the engine stops running.

Auxiliary Outlet

This outlet provides auxiliary power

to electrical accessories. To

operate work lights or other 12V devices, plug into outlet.

Notice En

gine alternator is capable of delivering 3 Amps at 3600

RPM. Running engine at part throttle while using electrical

accessories, or using accessories that use more than 3 amps for

an extended time may discharge battery.

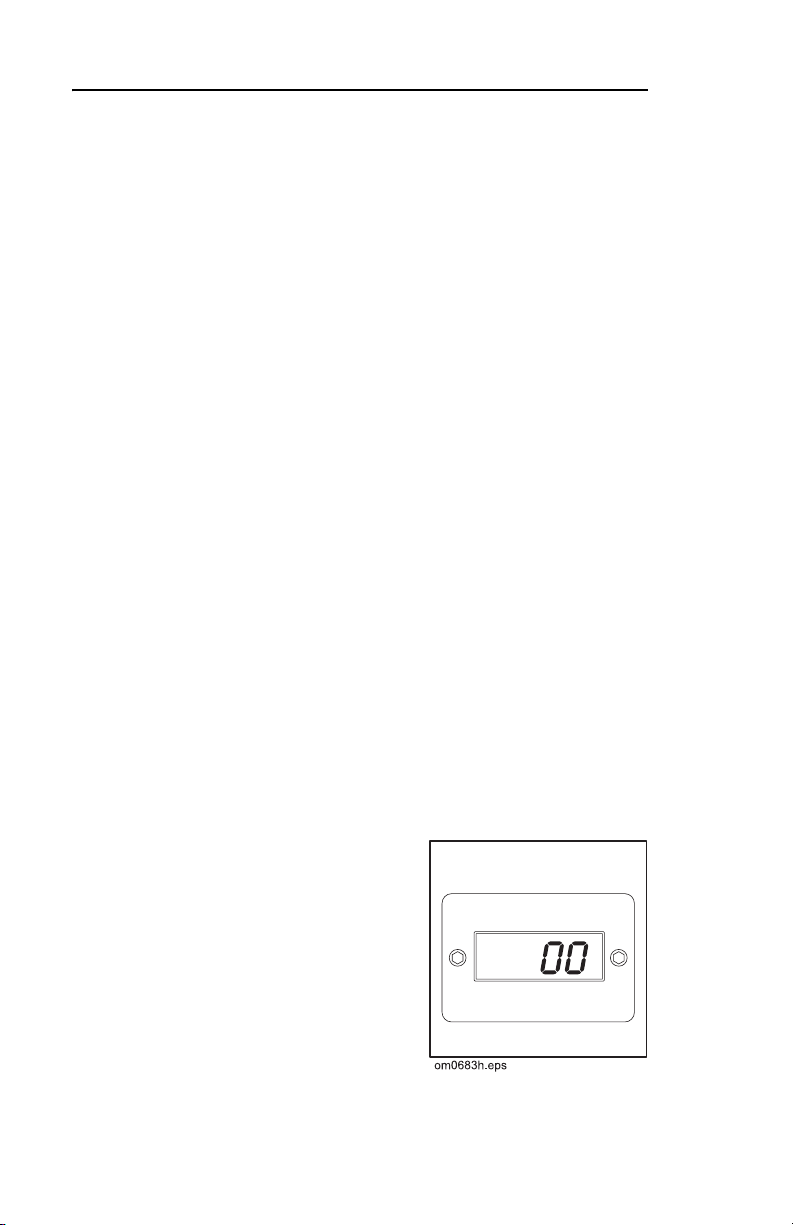

Tachometer/Hourmeter

This gauge records engine

operating time. Use these times

to schedule lubrication and

maintenance.

When engine is operating,

gine rpm is displayed.

en

When engine is not operating,

gine operating time is

en

FM13V - CONTROLS 11

OVERVIEW

displayed.

Throttle

This lever adjusts engine speed during mixing process.

• Move lever to the right to increase engine speed.

• Move lever to the left to decrease engine speed.

Rope Start

This rope is used as a backup method to start engine if electric

st

art fails. Pull rope to start engine.

Choke

This valve regulates air/fuel mixture. To help start cold engine,

close valve.

12 FM13V - CONTROLS

OVERVIEW

Manual Fuel Shut-off Valve

This valve stops the flow of fuel fro

m the fuel tank to the engine

when unit is transported or stored.

• To open valve, turn lever

to the right.

• To close valve, turn lever to the left.

Engine Stop Switch

This switch controls power to the ignition system.

• To turn power on, turn clockwise.

• To turn power off, turn counterclockwise.

Note The ig

nition switch is the preferred method of stopping

engine. For normal operation, leave this switch on all the time

and use ignition switch to stop and start unit. Turn key to the off

position when engine is not running.

Battery Disconnect

This switch connects/disconnects

power from battery during

service and long-term storage.

• To connect, move switch so that

indicator points left.

• To disconnect, move switch so that indicator point

s right.

FM13V - CONTROLS 13

DESCRIPTIONS

Valves

1. mixing jet valve 4. dry chemical hopper valve

2. pump drain valve 5. discharge valve

3. liquid chemical valve 6. mixing venturi valve

DESCRIPTIONS

Mixing Jet Valve

This valve controls the flow of fluid fr

tank.

• Turn valve handle counterclockwise 1/4 turn to open valve.

• Turn valve handle clockwise 1/4 turn to close valve.

om pump to the mixing jets in

14 FM13V - CONTROLS

DESCRIPTIONS

Pump Drain Valve

This valve drains fluid from pump and some fluid lines.

• Turn handle counterclockwise 1/4 turn to open.

• Turn clockwise 1/4 turn to close.

Liquid Chemical Hopper Valve

This valve controls the flow of poly

mers or wetting agents to the

mixing system.

• Turn handle counterclockwise 1/4 turn to open valve.

• Turn handle clockwise 1/4 turn to close valve.

Dry Chemical Hopper Valve

This valve controls flow of dry chem

icals into mixing venturi.

• Turn handle to left (counterclockwise) to open valve.

• Move handle to right (clockwise) to close valve.

IMPORTANT Do

not open valve unless pump is running and

mixing venturi valve is open. Fluid could flow back into hopper.

Discharge Valve

This valve controls the flow of drilling fluid from

mixing tank to

drilling unit.

• Turn handle counterclockwise 1/4 turn to open valve.

• Turn handle clockwise 1/4 turn to close valve.

FM13V - CONTROLS 15

DESCRIPTIONS

Mixing Venturi Valve

This valve controls flow of flu

id though mixing venturi at the

bottom of the dry hopper.

• Turn handle counterclockwise 1/4 turn to open.

• Turn handle clockwise 1/4 turn to close.

16 FM13V - CONTROLS

DESCRIPTIONS

FM13V - SAFETY 17

SAFETY

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before

sing equipment.

u

• Contact One-Call (888-258-0808) and any utility

which do not subscribe to One-Call. Have all underground

pipes and cables located and marked before operating

equipment. If you damage a utility, contact utility company.

• Classify jobsite based on its hazards and use correct tools

d machinery, safety equipment, and work methods for

an

jobsite.

• Mark jobsite clearly and keep

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures,

and indiv

begins. Safety videos are available from your Ditch Witch

dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate

an

• Do not operate unit where flammable gas is present.

• Contact your Ditch Witch dealer

about operation, maintenance, or equipment use.

idual responsibilities with all personnel before work

ything that does not look or feel right.

spectators away.

if you have any question

companies

18 FM13V - SAFETY

ACCESSORIES

ACCESSORIES

Fire Extinguisher

If required, a fire extinguisher should be mounted near the power

unit but away from possible points of ignition. The fire

extinguisher should always be classified for both oil and electric

fires. It should meet legal and regulatory requirements.

FM13V - SAFETY 19

SAFETY ALERT CLASSIFICATIONS

SAFETY ALERT CLASSIFICATIONS

These classifications and the icons defined on the following

pages work together to alert you to situations which could be

harmful to you, jobsite bystanders or your equipment. When you

see these words and icons in the book or on the machine,

carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safe

ty alert levels: DANGER, WARNING and

CAUTION. Learn what each level means.

indicates an imminently hazardous situation

which, if not avoided, will result in death or s

erious injury.

indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Watch for two other words: NOTIC

NOTICE

can keep you from doing something that might damage

E and IMPORTANT.

the machine or someone's property. It can also alert you against

unsafe practices.

IMPORTANT

can help you do a better job or make your job

easier in some way.

20 FM13V - SAFETY

SAFETY ALERTS

SAFETY ALERTS

Electric shock. Contacting electric

lines will cause death or serious injury. Know

location

presence of gas will cause sickness or death.

Pro

of lines and stay away.

Deadly gases. Lack of oxygen or

vide ventilation.

could cause death or serious injury.

correct equipment and work

Use

methods. Use and maintain proper

safety equipment.

Jobsite hazards

Crushing weight

could cause death or serious

ry. Use proper procedures and

inju

equipment or stay away.

FM13V - SAFETY 21

SAFETY ALERTS

Incorrect procedures could result

in death, injury, or property damage. Learn to use

uipment correctly.

eq

Fire or explosion possible. Fumes

could ignite and cause burn

s. No smoking, no

flame, no spark.

Moving traffic - hazardous

situation. Death or serious injury could result.

oid moving vehicles, wear high visibility clothing,

Av

post appropriate warning signs.

Improper control function could

cause death or serious injury. If control does not

as described in instructions, stop machine

work

and have it serviced.

Hot parts may cause burns. Do not

touch until cool.

22 FM13V - SAFETY

SAFETY ALERTS

Exposure to high noise levels may

cause hearing loss. Wear hearing protection.

Fall possible. Slips or trips may

result in injury. Keep area clean.

Improper handling or use of

chemicals may result in illness, injury, or

uipment damage. Follow instructions on labels

eq

and in material safety data sheets (MSDS).

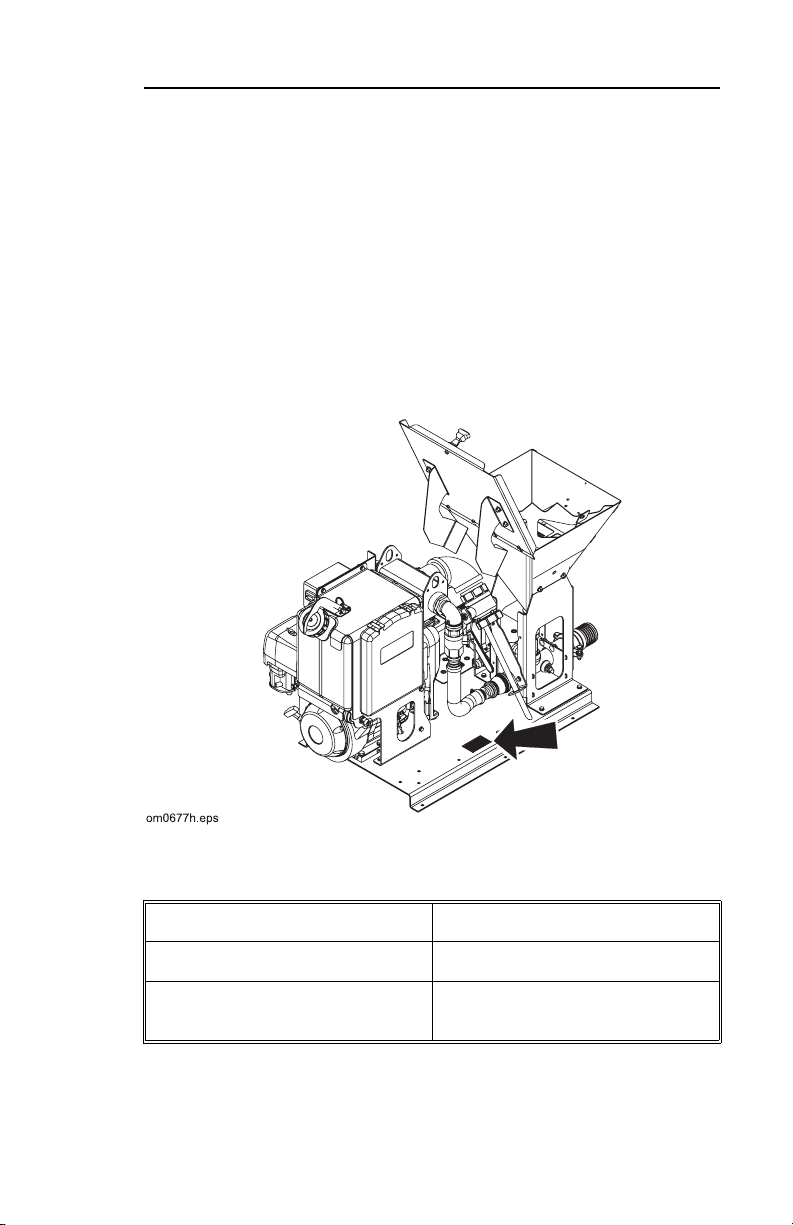

FM13V - LIFT 23

LIFT

LIFT

Crushing weight. If load falls or

moves it could kill or crush you. Use proper

ocedures and equipment or stay away.

pr

LIFT

Points

Lifting points are identified by lifting

decals. Lifting at other points is

unsafe and can damage machinery.

Mixing Unit

Lift mixing unit by attaching

chains to lift points on top of

pump.

Bolt base to truck or trailer bed

sing provided holes.

u

If mounting without a base,

ure pump coupler is covered.

ens

24 FM13V - LIFT

LIFT

Tank

Lift fluid tank by attaching sling to

lift points located on side of tank.

IMPORTANT: Em

lifting.

pty tank before

FM13V - PREPARATION 25

CHECK EQUIPMENT

PREPARATION

CHECK EQUIPMENT

Check the following before starting each day’s work. Refer to

LUBRICATION AND MAINTENANCE for additional information

and locations.

• General appearance of equipment

• Safety sign location and readability

• All guard and shield locations. Replace if missing or worn.

• Condition of all wear items such as

and clamps

• Drilling fluid hoses, and electric c

wear, or other damage.

• Engine crankcase oil level. Keep

dipstick. Do not overfill.

• Fuel level. Fuel tank should be filled

reduce condensation.

• All nuts and bolts. Tighten if necessary.

strainers, filters, hoses,

ables for signs of leakage,

oil level at the highest line on

at the end of the day to

26 FM13V - PREPARATION

SELECT DRILLING FLUID

SELECT DRILLING FLUID

For productive drilling and equipment protections, use these

®

recommended Baroid

Dealer.

• Quik-Gel™ dry powder bentonite (p/n 259-804)

• E-Z Mud™ liquid polymer (p/n 259-805)

• Liqui-Trol™ liquid polymer suspension (p/n 259-808)

• Quik-Trol™ dry powder polymer (p/n 259-809)

• Bore-Gel™ drilling fluid (p/n 259-807)

• Con-Det™ water-soluble cleaning solution (p/n 259-810)

Guidelines

Match drilling fluid to soil type. Although specific conditions at

each jobsite vary, use the following guidelines when selecting a

drilling fluid.

products, available from your Ditch Witch

If soil is... use...

Smooth, flowing sand Bentonite + medium chain

po

lymer

Coarse sand or light soil Bentonite

Heavy clay Long chain polymer

Swelling clay Long chain polymer

Rock Bore-Gel

For recommended mixture to reach desired

drilling fluid viscosity

or thickness, contact your Ditch Witch dealer.

FM13V - PREPARATION 27

SELECT DRILLING FLUID

Bentonite

Bentonite is a dry powder. When properly mixed with water, it

cakes on bore walls, lubricating the bore, keeping it open, and

holding fluid in the bore.

Some things to remember when mixing bentonite:

• Use clean water free of salt, calcium, or excessive chlorine.

• Use water with pH level between 7.5 and 10.

• Do not use bentonite containing sand.

• Mix bentonite thoroughly or

it will settle in tank.

• Do not mix bentonite to a funnel viscosity of over 50.

For information on measuring funnel viscosity, read “Measuring

Funnel Viscosity

” in OPERATION.

Polymer

This drilling fluid additive provides excellent lubrication and

increases viscosity in average soils and heavy clay. In swelling

clay, polymer can reduce swelling that traps pipe in the bore.

There are two types of polymer:

• Long chain such as Baroid EZ-Mud

• Medium chain such as Baroid

Quik-Trol

Mixtures

Bentonite does not mix well in water containing polymer. To use

both, mix bentonite first, then add polymer.

Bore-Gel

Use 15 lb/100 gal (6.8 kg/378.5 L) in normal drilling conditions, up

to 45 lb/100 gal (20.4/378.5 L) in sand or gravel and up to 50 lb/

100 gal (22.6/378.5 L) in rock.

contains premixed bentonite, polymer, and soda ash.

28 FM13V - PREPARATION

SELECT DRILLING FLUID

Planning Drilling Fluid Requirements

1. Determine drilling conditions and choose appropriate drilling fluid mix.

2. Estimate amount of supplies

needed and check availability.

• Drilling fluid

• Water supply. If more water than can be carried with the

unit will be needed, arrange to trans

port additional water.

• Bentonite and/or polymer

3. Check water quality.

• Visually perform pH test on water. If pH is below 5.0, add

.25 L) soda ash per tank. Test and repeat until pH

1 cup (

is between 7.5 and 10.

FM13V - OPERATION 29

SELECT DRILLING FLUID

OPERATION

This section covers basic operation. For questions about specific

situations, contact your Ditch Witch dealer.

Jobsite hazards

could cause death or serious injury.

Use cor

methods. Use and maintain proper

safety equipment.

NOTICES:

• Wear personal protective equipment including hard hat,

safety e

ye wear, and hearing protection.

• Do not wear jewelry or loose clothing.

rect equipment and work

30 FM13V - OPERATION

Mix Drilling Fluid

Mix Drilling Fluid

1. Ensure valve in suction line and at least one valve on the pressure side of the pump is open.

2. If necessary, choke cold engine.

3. Move throttle to half open.

4. Turn ignition switch to start position and release when engine

st

arts.

IMPORTANT If battery

is dead, turn key to ON and pull start

rope.

FM13V - OPERATION 31

Mix Drilling Fluid

5. Open choke after engine is warm.

EMERGENCY SHUTDOWN Turn ignition sw

itch to STOP.

NOTICES:

• If chemicals are added in the wrong order, they w

ill not mix

properly and will form clumps. See “Mixtures” in Preparation.

• If tank contains bentonite/polyme

r mix and more drilling fluid

is needed, completely empty tank and start with fresh water

before mixing another batch.

6. Open tank jet valve (3) and mixing venturi valve (6).

7. Start engine on mixing pump.

8. Partially open dry chemical hopper valve (4). Listen for a

n

oticeable “suction” sound.

IMPORTANT Ad

d polymers at a very slow rate.

9. For dry chemicals, open sack using bag ripper located inside

y chemical hopper and pour chemicals into hopper.

dr

NOTICE

Metering plate can be seated in bottom of dry chemical

hopper to allow dry chemicals to be added at a slower rate.

• Approximate feed rate with meter

ing plate, 50 lb : 1.5 minutes.

• Approximate feed rate without metering plate, 50 lb : 0.7

min

utes.

10. Open dry chemical valve (4) slowly.

11. For liquid polymer and other liquid chemicals, pour needed

am

ount of additive into a suitable container, insert wand into

container.

12. Open liquid chemical valve (3) slowly.

13. Open fillwell on top of tank and c

heck fluid in tank to ensure

that chemicals are mixed correctly.

14. If clumps of chemical or polymer can be seen in fluid tank,

re

duce the rate at which materials are added.

32 FM13V - OPERATION

Mix Drilling Fluid

Measuring Funnel Viscosity

Viscosity is the measure of internal resistance of a fluid to flow;

the greater the resistance, the higher the viscosity. Viscosity of

drilling fluids must be controlled.

To determine viscosity, you

will need a Marsh funnel and a

measuring cup, available from your Ditch Witch Dealer.

1. Take a fresh sample from the

drilling fluid tank. The sample

st be more than 1 qt

mu

(.95 L).

2. Hold funnel over 1 qt (.95 L) measuring cup and place a finger over outlet.

3. Pour test sample into top of

el through screen to

funn

ensure no large particles

enter the funnel that might

alter the measurement. Fill to screen.

4. Remove finger and time flow. Co

unt the number of seconds

necessary for 1 qt (.95 L) of fluid to pass through funnel. The

number of seconds is the viscosity.

5. Thoroughly rinse measuring cup and Marsh funnel with water.

FM13V - OPERATION 33

PUMP FLUID TO DRILLING UNIT

PUMP FLUID TO DRILLING UNIT

Electric shock. Contacting electric

lines will cause death or serious injury. Know

location

of lines and stay away.

NOTICE: If ele

ctrical strike occurs while fluid hose

is connected to drilling unit, fluid system will also

become electrified.

1. Connect mixing pump hose to drilling unit.

NOTICE To prevent damage

to the drilling fluid pump, make sure

y-strainer is used in-line between mixing unit and drilling unit.

2. Open discharge valve of mixing pump, adjust engine throttle

to purge all air from the line when starting drilling fluid

to full

pump on drilling unit. After flow is stable, adjust throttle to

give desired flow rate to drilling unit (approximately half

throttle).

IMPORTANT:

• To reduce agitation in tank when us

ing polymer-based drilling

fluids, partially close the tank jet valve.

• Overmixing of polymer-based

drilling fluids can reduce fluid

viscosity.

• Close venturi valve when dry chemical hopper is not in use.

34 FM13V - OPERATION

DRAIN SYSTEM

DRAIN SYSTEM

Drain system under the following circumstances:

• Temperature is expected to be 32°F (0°C) or below.

• System is not going to be used for several days.

• System is going to be used on a different job requiring

ent chemicals.

differ

1. Pump as much fluid as possible out of tanks.

2. Shut off pumps and open all valves (sho

wn). Disconnect tank

jet hose.

3. Lower suction wand to allow fluid to drain from hose and mixing venturi.

4. Allow fluid to drain into suitable containers.

5. Recycle or properly dispose of fluid.

6. If needed, drain any remaining fluid in tank by removing plug

o

n bottom of tank’s suction end.

FM13V - OPERATION 35

DRAIN SYSTEM

7. When finished, pull up the ground wire and grounding stake (if used). Store in secure place.

36 FM13V - OPERATION

DRAIN SYSTEM

FM13V - LUBRICATION AND MAINTENANCE 37

DRAIN SYSTEM

LUBRICATION AND

MAINTENANCE

Fluid under pressure can pierce

skin and cause injury or death. Stay away.

NOTICES:

• Before using system, check that a

all lines are undamaged.

• Fluid leaks can be hard to detect. Use a piece of cardboard or

wood

, rather than hands, to search for leaks.

• Wear protective clothin

• If you are injured, seek im

moves, death or serious injury can result. Use

oper procedures and equipment or stay away.

pr

NOTICE: Unless otherwis

should be performed with the engine(s) shut off.

g and eye protection.

mediate medical attention.

Crushing weight. If load falls or

e instructed, all service in this chapter

ll connections are tight and

38 FM13V - LUBRICATION AND MAINTENANCE

OVERVIEW

OVERVIEW

Interval Task Page no.

daily check engine oil 39

50 hours grease pump 40

100 hours change engine oil 39

change air filter element 40

Lubricant chart:

GEO Gasoline engine oil (see chart for

NLGI #1 Polyurea based NLGI #1

meeting API engine service classification SD

appropriate SAE viscosity rating)

FM13V - LUBRICATION AND MAINTENANCE 39

ENGINE OIL

ENGINE OIL

Check Oil

Check engine oil at dipstick before

h operation. Add GEO at fill

eac

neck as necessary to keep oil level

at highest line on dipstick.

Change

Oil

Change oil every 100 hours with

.

GEO

• Pull drain plug and drain

ase while oil is still

crankc

warm.

• Refill at fill neck with 2.3 pt

(1.1 L) of GEO.

40 FM13V - LUBRICATION AND MAINTENANCE

AIR FILTER

AIR FILTER

Change foam air filter element

every 100 hours. Do not allow dirt

to fall into carburetor.

PUMP

Lube grease fitting with

Lubra-plate -630-AA every 50

urs.

ho

Grease cavity is full when grease

es from grease cylinder

escap

relief valve.

FM13V - TROUBLESHOOTING 41

PUMP

TROUBLESHOOTING

The FM13V has a metering plate in the bottom of the dry

chemical hopper sized to match material flow to fluid volume

going through venturi. This plate helps each unit maintain the

approximate time required to feed 50 lb (22.7 kg) of material into

tank when engine is running at full speed. Changing material flow

rate by removing or resizing plate will affect mixing results.

Problem Possible solutions

Slow feed rate from

opper

h

Poor drilling fluid

m

ix characteristics

Clumps in drilling

fluid

tank

Run engine at full speed

Place control valves in recommended

mixing positions

.

Clear obstructions from metering plate

nd check that screen is in place.

a

Remove build-up from venturi chamber.

Clean plugged hoses and fittings. Repair

o

r replace damaged hoses and fittings.

See pump instructions for procedure on

chec

king flow.

Test water pH and treat if necessary (see

PREPARATION for instructions).

Check feed rate.

42 FM13V - TROUBLESHOOTING

PUMP

Problem Possible solutions

Low yield properties Check feed rate.

Make sure screen is in strainer.

Check water pH.

Try different brand of drilling fluid

a

dditive.

Add polymer to drilling fluid tank only

a

fter bentonite has been yielded out.

Hourmeter does not

work.

Replace hourmeter. Contact your local

Ditch

Witch dealership for replacement

parts.

• Mount with provided screws.

• Wrap pick-up wire around spark plug

e no more than four times. Ensure

wir

that pick-up wire does not come in

contact with spark plug and is not

near a heat source (i.e. muffler).

• Attach ground wire to an engine

lock bolt.

b

Important:

Ensure that hourmeter is

not placed too close to a sound

source other than the engine. Failure

to do so will result in inaccurate

readings.

FM13V - SPECIFICATIONS 43

FM13V

SPECIFICATIONS

FM13V

Dimensions U.S. Metric

Length 60 in 1.5 m

Height 43 in 1.1 m

Width 26 in 660 mm

Weight 450 lb 204 kg

Drilling fluid system U.S. Metric

Maximum flow rate at 26 viscosity 300 gpm 1135 L/m

Mixing hopper capacity 1.0 cu ft 28 L

Drilling fluid/mixing tank 500/1000 gal 1892/3785 L

Mixing time for 50 lb (22.7 kg) 0.7 min 0.7 min

Mixing time for 100 lb (45 kg) 1.5 min 1.5 min

Fluid capacities U.S. Metric

Fuel tank 6.0 gal 22.7 L

Engine oil 2.3 pt 1.1 L

44 FM13V - SPECIFICATIONS

FM13V

Engine U.S. Metric

Engine: Honda GX390

Fuel: gasoline

Cooling medium: air

Number of cylinders: one

Displacement 23.7 cu in 389 cu cm

Bore 3.53 in 90 mm

Stroke 2.52 in 64 mm

Gross power @ 3600 rpm 13 hp 9.7 kW

Noise Level:

Operator 92 dbA sound pressure per ISO 6394.

Exterior 105 dbA sound power per ISO 6393.

FM13V - SPECIFICATIONS 45

DRILLING FLUID TANKS

DRILLING FLUID TANKS

500 gal (1893 L) tank

Dimensions U.S. Metric

Length 93 in 2.36 m

Height (H1) 68 in 1.73 m

Height (H

) 75 in 1.91 m

2

Width 30 in 800 mm

Weight (empty) 550 lb 250 kg

Weight (full of water) 4720 lb 2141 kg

46 FM13V - SPECIFICATIONS

DRILLING FLUID TANKS

1000 gal (3786 L) tank

Dimensions U.S. Metric

Length 125 in 3.18 m

Height (H1) 72 in 1.83 m

Height (H

) 79 in 2.01 m

2

Width 42 in 1.07 m

Weight (empty) 1000 lb 454 kg

Weight (full of water) 9350 lb 4241 kg

Loading...

Loading...