Page 1

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 1 of 11

Foreword

This guide is an important part of your attachment. It

provides safety, operation, parts, and maintenance

information to help you use and maintain your Ditch

Witch equipment.

Read this manual and the unit operator’s manual before

using your attachment. Keep it with the equipment at all

times for future reference. If you sell your equipment, be

sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch

dealer. If you need assistance in locating a dealer, visit

our website at www.ditchwitch.com or write to the

following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are

subject to change without notice. The Charles Machine

Works, Inc. reserves the right to improve equipment.

Some product improvements may have taken place after

this manual was published. For the latest information on

Ditch Witch equipment, see your Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

Safety

• Read and follow all safety precautions.

• Contact One-Call (888-258-0808) or your local utility company.

Have all underground lines and cable located and marked before

operating equipment. Know appropriate actions to take in case

you damage a utility. If you damage a utility, contact utility

company.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment. Do not wear jewelry or loose

clothing that can catch on controls.

• Use equipment carefully. Stop operation and investigate anything

that does not look or feel right.

• Contact your Ditch Witch dealer if you have any question about

operation, maintenance, or equipment use.

Jobsite hazards could cause death or

serious injury. Use correct equipment and work

methods. Use and maintain proper safety

equipment.

Improper control function could cause death or

serious injury. If control does not work as described in

instructions, stop machine and have it serviced.

Incorrect procedures could result in death, injury,

or property damage. Learn to use equipment correctly.

Moving parts could cut off hand or foot.

Stay away.

All Terrain Air Hammer Attachment

Operation and Parts Manual

Issue number 2.0 OM-1/12

Part number ID0273478

Copyright 2011, 2012

by The Charles Machine Works, Inc.

Ditch Witch, CMW, and Jet Trac are registered

trademarks of The Charles Machine Works,

Inc.

cause death or serious injury. Know location of lines and

Electrical shock. Contacting electrical lines will

stay away.

Crushing weight could cause death or

serious injury. Use proper procedures and

equipment or stay away.

Flying objects may cause injury. Wear hard hat

and safety glasses.

Exposure to high noise levels may cause hearing

loss. Wear hearing protection.

Pressurized fluid or air could pierce

skin and cause injury or death. Stay away.

Hot parts may cause burns. Do not touch until

cool.

Moving tools will kill or injure. Shut off drill string

power when anyone can be struck by moving or thrown

tools. Never use pipe wrenches on drill string.

CMW

®

Page 2

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 2 of 11

Improper handling or use of chemicals may

result in illness, injury, or equipment damage. Follow

instructions on labels and in material safety data sheets

(MSDS).

Overview

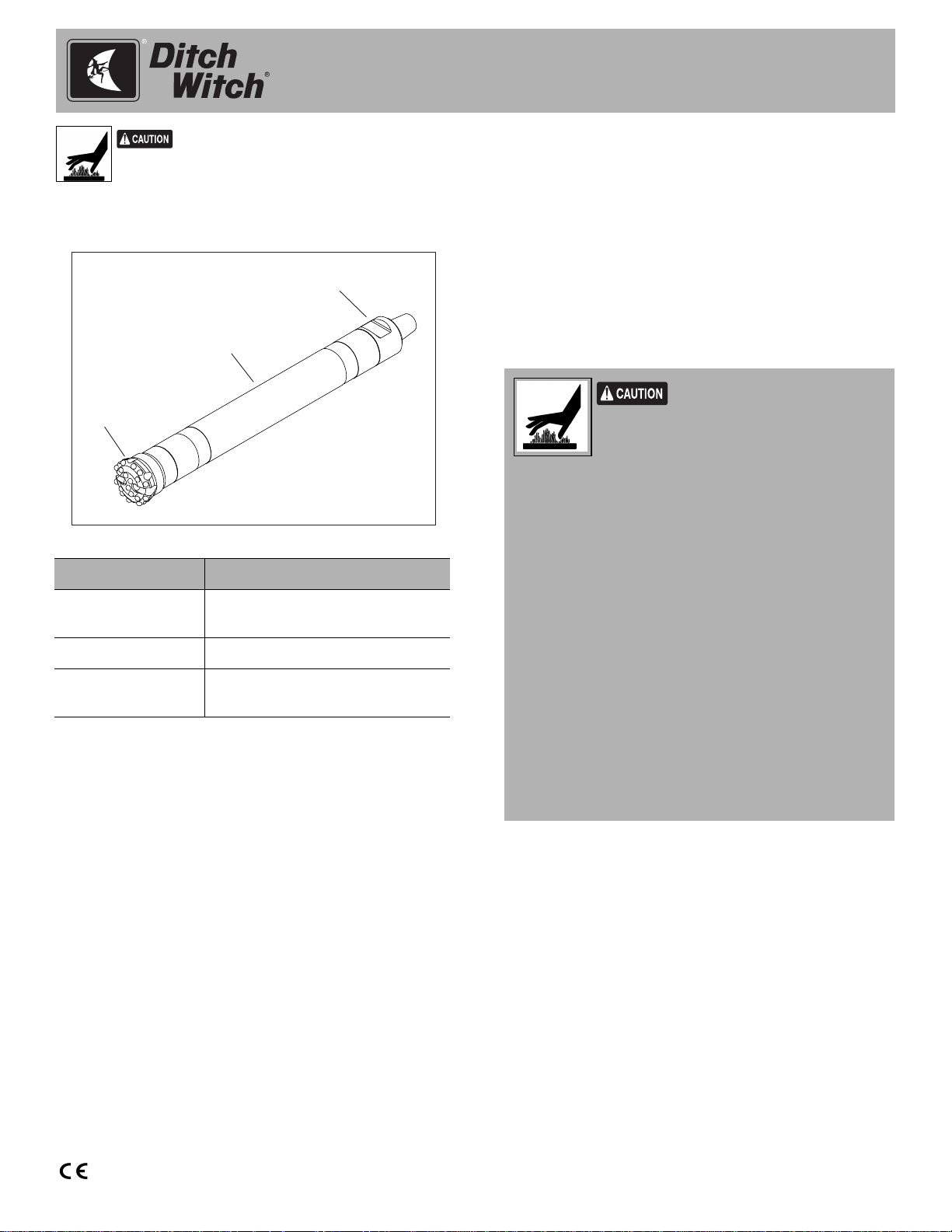

3

2

1

a38om001t.eps

Component Description

1. Bit holds cutting teeth that chip rock

at impact

2. Hammer houses the percussion piston

3. Hydrocyclone separates pressurized air from

water in foam mix

The All Terrain Air Hammer is designed for use on

directional drills in hard rock applications. The air

hammer uses air pressure to create percussive force,

which drives cutting inserts into rock. After the “drive” air

has produced impact, it is expelled as “return” air that

removes cuttings. Foam mix injected into the bore

through the drill string is used to suppress dust and clean

the bore.

Prepare Foam Mix

The manufacturer recommends the use of Baroid QuikFoam® foaming agent (p/n 255-1023) to improve holecleaning capability of the airstream and reduce dust

during drilling.

As a general guideline, use 0.25-1 gal (0.9-3.8 L) of foam

agent for each 100 gal (379 L) of water.

For more information, see the instructions for foam

drilling system mixtures included with the foaming agent

or contact your Ditch Witch dealer.

Improper handling or use of

chemicals may result in illness, injury, or

equipment damage. Follow instructions

on labels and in material safety data

sheets (MSDS).

To help avoid injury:

• Flammable.

• Do not allow QuikFoam to enter sewer, water way,

or low area. Contain all product and dispose

properly.

• Quik-Foam may cause eye, skin, and respiratory

irritation. May cause headache, dizziness, and

other central nervous system affects. May be

absorbed through the skin. May be harmful if

swallowed. Repeated overexposure may cause

liver and kidney effects.

• Use appropriate protective equipment.

• See Quik-Foam MSDS (available on

www.ditchwitch.com) for more information.

CMW

®

Page 3

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 3 of 11

Prepare Entry Point

Flying objects may cause injury. Wear hard

hat and safety glasses.

a38om005t.eps

1. Dig an entry pit approximately 10-15 ft (3-4.5 m) in

front of the drilling unit to collect spoils and foam

blowback. The pit should be approximately 6 ft (1.8

m) long, 3 ft (0.9 m) wide, and deep enough to

expose the drill string.

2. Drill into the ground, through the entry pit, and

continue bore.

IMPORTANT: It may be necessary to cover the

entry pit with a sheet of plywood or other

durable material to contain blowback material.

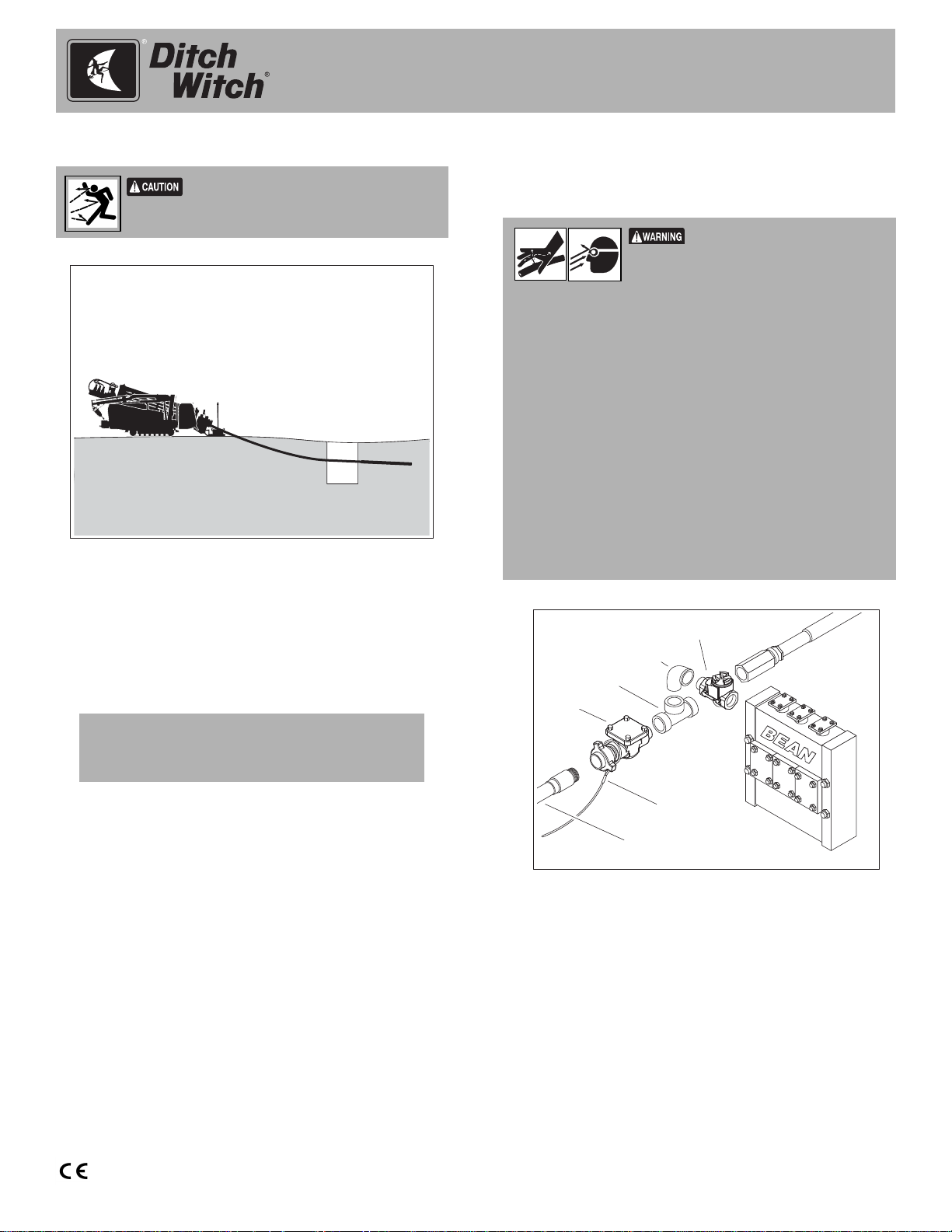

Connect Air Adaptor

To operate the air hammer, modify the drilling fluid pump

onboard the drilling unit to provide air flow to the hammer.

Pressurized fluid or air could pierce

skin and cause injury or death. Stay away.

To help avoid injury:

• Escaping pressurized fluid or air can cause injury or pierce skin

and poison.

• Before disconnecting a hydraulic line or pressurized air line,

turn engine off and operate all controls to relieve pressure.

Lower, block, or support any raised component with a hoist.

Cover connection with heavy cloth and loosen connector nut

slightly to relieve residual pressure.

• Before using system, check that all connections are tight and

all lines are undamaged.

• Fluid and air leaks can be hard to detect. Use a piece of

cardboard or wood, rather than hands, to search for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a

doctor familiar with this type of injury.

4

3

2

1

6

5

a38om003t.eps

Note: See parts pages for a complete list of parts.

1. Disconnect washwand from drilling fluid pump inlet.

2. Install check valve (4) in drilling fluid pump inlet.

3. Connect elbow and T-fitting (3, 2) to check valve.

4. Connect air adaptor (1) to rear of T-fitting.

5. Connect whip check cable (6) and air compressor

hose (5) to air adaptor.

CMW

®

Page 4

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 4 of 11

Connect Air Hammer

IMPORTANT: The procedures below require the use of

a Hydratong wrench to tighten connections. See “Use

Hydratong Wrenches” on page 4.

Install Bit

1. Lubricate bit splines and chuck threads with copper

or zinc based tool joint compound.

2. Slide chuck over bit splines and secure with retaining

rings.

3. Thread bit/chuck assembly into hammer housing.

4. Use appropriate bit ring and chrome pins included

with air hammer with Hydratong wrench. Place chain

tongs no less than 6.5” (152 mm) and no more than

17” (432 mm) from chuck.

NOTICE: Using wrench tongs to grip the

hammer casing in the wrong location can

damage threads or distort the casing.

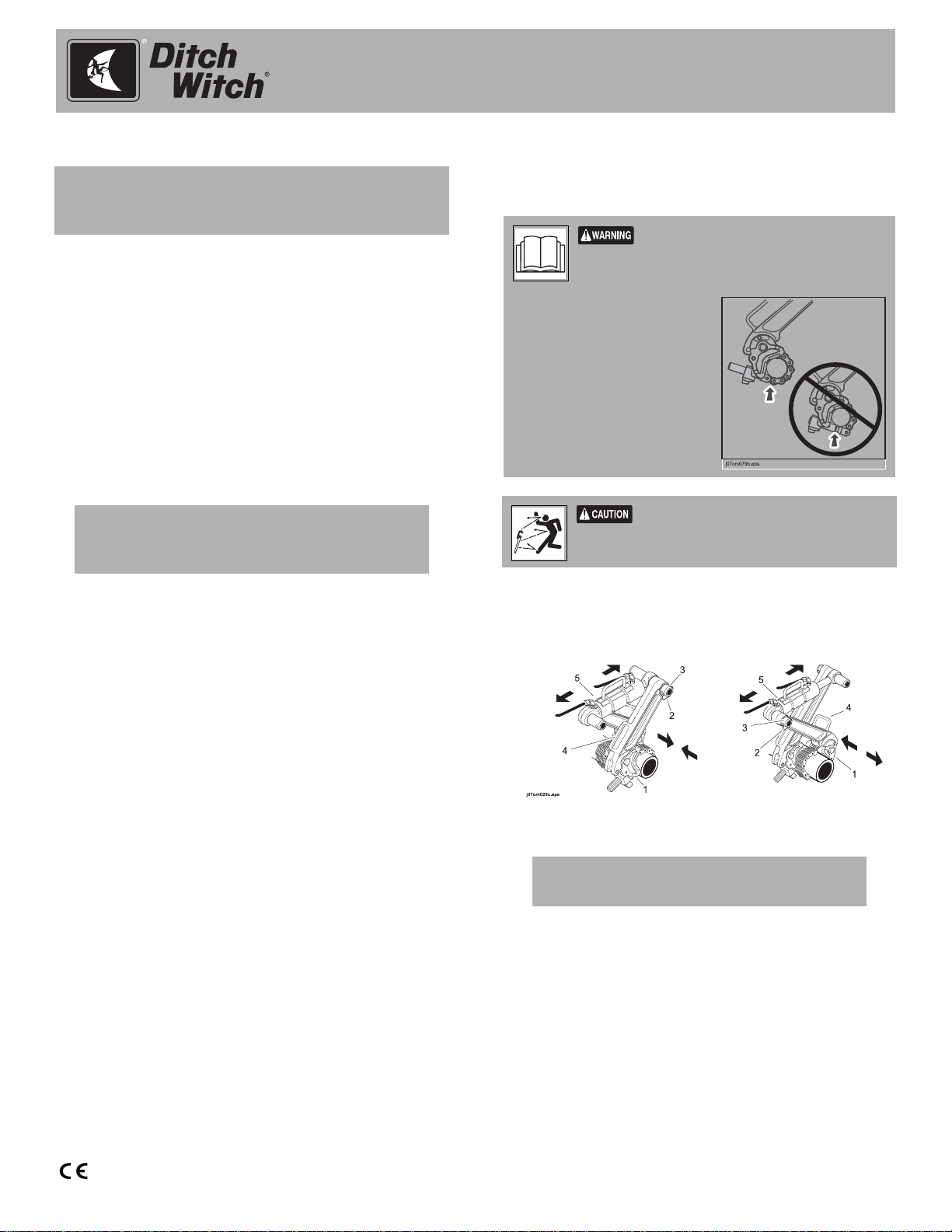

Use Hydratong Wrenches

To attach or remove downhole tools, use the Hydratong

wrenches to join or break the joint.

Incorrect procedures could result in death,

injury, or property damage. Learn to use equipment

correctly.

To help avoid injury:

• Ensure only chain tongs and

chain are in contact with pipe

(shown) and that chain is

correctly wrapped. Do not

use Hydratong with chain

bushing pin touching pipe

(shown).

• Stand away from the

Hydratong when using it.

Moving tools will kill or injure. Shut off drill

string power when anyone can be struck by moving or

thrown tools. Never use pipe wrenches on drill string.

5. Tighten to 6000 ft•lb (8135 N•m).

Assemble Drill String

1. Connect air hammer to Rockmaster beacon housing

using Hydratong wrench and air hammer wrench

insert.

2. Follow the instructions in your drilling unit operator’s

manual to prepare and calibrate the beacon before

drilling.

3. Connect air hammer/beacon assembly to drill string.

1. To join, apply tool joint compound to threads and

hand tighten joint.

2. Attach Hydratong in either the join or break position.

Join Break

IMPORTANT: Ensure arms are crossed

before using wrench.

• Attach chain tongs (1) to both sides of joint.

Place tongs as close to joint as possible.

• Remove snapper pins (2) from slide pins (3), and

insert slide pins into wrench handles (4).

• Attach each end of hydraulic cylinder (5) to slide

pins and insert snapper pins.

3. Remove all slack from wrench and joint.

CMW

®

Page 5

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 5 of 11

4. To join, scribe

straight line across

joint on both sides

of separating line

(A).

5. To join, scribe

second line (B) on

A

B

A

B

AA

moveable side of

joint in the opposite

direction of

tightening action.

j07om071h.eps

Refer to table for

correct dimension.

6. Connect Hydratong

power pack.

• Attach hoses

from power

pack to

cylinder.

• Attach leads (4)

to 12V battery.

7. To tighten or loosen

joint, move shuttle valve handle (2) toward gauge (3)

and press power switch (1).

8. To reposition chain tongs and continue tightening or

loosening joint, move handle away from gauge, then

back toward gauge, and then press power switch.

9. Monitor gauge and refer to decal to achieve

approximately 4000 ft•lb (5420 N•m) of torque. Then

tighten joint until second line (B) meets first (A).

Operate Air Hammer

Wear hearing and eye

protection when operating air

hammer.

To start hammering, turn on the drill fluid pump. Air will

enter the drill string.

IMPORTANT: The air hammer requires resistance to

fire. If the bit is not next to hard rock air will simply flow

through the hammer without triggering percussion.

Monitor Gauges

Drill Fluid

Maintain drill fluid flow at 2-10 gpm (7.5-38 L/min)

depending on the hole size, rate of penetration, and type

of material being drilled. The ideal drill fluid flow produces

a thin foam that allows cuttings to be cleared from the

hole without sticking to drill pipe.

Rotation

The correct rotation speed produces the best penetration

rate, the longest drill bit life, and smooth operation.

1. For a 6.5” (165 mm) bit with spherical inserts, begin

with inner rotation of 25 rpm.

2. Adjust rotation until penetration is approximately

3/8-5/8” (9.5-116 mm) per revolution.

IMPORTANT: Gauge gives an estimate of

torque. Use scribe line to get exact torque.

10. Move handle to center (neutral) position to relieve

pressure.

11. Disconnect hoses and remove Hydratong

components.

Thrust

Maintain thrust at about 3200 lbf (14 kN) when operating

at maximum power. This is theoretically 600-800 psi (4055 bar) as measured by the thrust pressure gauge on the

drilling unit.

Note: Some operators increase thrust until rotation

pressure begins to pulse, then reduce thrust slightly until

rotation is smooth.

CMW

®

Page 6

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 6 of 11

Monitor Cuttings

Monitor spoils leaving the bore at the entry pit. If cuttings

are not clearing the hole, a different drill fluid mixture

might be needed to seal the bore.

Set Cruise Control

Once bore is established, set cruise control. (See drilling

unit operator’s manual for instructions.)

Add Pipe

Pressurized fluid or air could

pierce skin and cause injury or death.

Stay away.

Drill string contains pressurized air and water. Before

breaking joints to add pipe, stop drilling fluid flow and wait

for the reading on the drill fluid pressure gauge to drop.

Storage

If the air hammer will not be used for 48 hours after

drilling, coat the inside of the hammer with oil.

To add oil, choose one of the methods below:

• If the hammer is connected to the drill string, turn off

drilling fluid supply to the drilling unit. Operate

hammer to push remaining fluid out of hammer.

Break joint and pour 1 pint (0.5 L) of oil into the last

drill pipe. Operate hammer to blow oil through the

hammer components.

• If the hammer is not connected to the drill string,

remove bit and pour oil into the hammer housing.

Rotate hammer housing so that oil coats the inside.

Store air hammer in a clean, dry place. Cover air hammer

to keep it clean. For long-term storage, place tool

vertically.

Service

Each Use

Inspect Hydrocyclone

Inspect hydrocyclone after each bore to ensure that

backhead ports are passing air.

10-Hour

Grease Rockmaster Beacon Housing

Install zerk and pump multi-purpose grease into lube

point at the beginning of each bore and every 10 hours of

operation.

Every 15, 000 ft (4575 m)

Check Air Hammer

Disassemble air hammer and inspect inner components

every 15, 000 ft (4575 m) of use. Replace components as

needed and reassemble tool.

CMW

®

Page 7

Disassemble

16

2

a38om006t.eps

1. Break joint at bit (2). Do not remove bit and chuck.

2. Break backhead joint and remove backhead (16).

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 7 of 11

a38om008t.eps

5. Remove valve cap/valve/distributor/air cylinder

assembly (shown).

15

14

13

a38om007t.eps

3. Remove dart valve (15) and spring (14) assembly.

4. Remove make-up spacer (13).

8

a38om023t.eps

6. Remove bit/chuck assembly from casing (8).

8

4

3

2

1

a38om021t.eps

7. Disassemble bit (1) from chuck (2) by removing oring (4) from around bit lock (3).

CMW

®

Page 8

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 8 of 11

or serious injury. Use proper procedures and

equipment or stay away.

To help avoid injury:

• Use proper lifting equipment and lifting procedures.

• Use team lifting when necessary.

Crushing weight could cause death

7

6

5

a38om010t.eps

5. bit bearing

6. lock ring

7. piston

a38om012t.eps

10. Slam remaining parts of valve/distributor/cylinder

assembly on piston (7) until valve and distributor

8

separate from the inner air cylinder.

Assemble

8. Remove bit bearing/lock ring/piston assembly by

slamming casing (8) on a block of wood.

Disassemble parts as shown.

a38om011t.eps

9. Using a pry bar or screwdriver, pry up on the valve

cap where shown on both sides to remove.

12

11

a38om013t.eps

1. Press valve (11) firmly into valve cap (12).

10

9

a38om014t.eps

2. Press distributor (10) firmly into inner air cylinder (9).

CMW

®

Page 9

a38om015t.eps

3. Press valve assembly firmly into distributor/cylinder

assembly.

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 9 of 11

8

6

5

a38om019t.eps

5. Click lock ring (6) into place and then install bit

bearing (5) into casing (8). Use a bar to tap bearing

until it is seated. Use bit lock as spacing guide.

a38om016t.eps

Verify valve has approximately 0.05 in (1.3 mm) of

free movement, as shown.

8

7

a38om018t.eps

4. Insert piston assembly (7) into casing (8).

8

a38om017t.eps

6. Slide valve assembly into opposite end of casing (8).

7. Install make-up spacer, spring, and dart valve.

16

8

a38om020t.eps

8. Install backhead (16) into casing (8).

9. Install bit. “Change Air Hammer Bits” on page 10

CMW

®

Page 10

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 10 of 11

As Needed

Change Air Hammer Bits

8

4

3

2

1

a38om021t.eps

Change air hammer bits whenever inserts are worn.

To remove:

1. Break joint at chuck and remove bit/chuck assembly.

2. Remove o-ring (4) from bit lock (3).

3. Remove bit (1) from chuck (2).

To install:

Specifications

L3

D

L2

L

a38om004t.eps

General U.S. Metric

Standard drill pipe connection 3.5 in API Reg Pin

Shank style QL 60

D Outside diameter 5.4 in 138,2 mm

L1 Length without bit shoulder to

shoulder

L2 Length with bit extended 49.5 in 1256,3 mm

L3 Length with bit retracted 48.1 in 1220,7 mm

44.6 in 1131,8 mm

1. Slide bit (1) into chuck (2).

2. Assemble bit lock (3) over end of bit and secure with

o-ring (4).

3. Install bit/chuck assembly into casing (8) and tighten

to 6000 ft•lb (8124 N•m).

Weight without bit 200 lb 90,9 kg

Backhead across flats 2x4 AF

Recommended air pressure 350 psi 24,1 bar

Make-up torque 6000 ft•lb 8124,0 N•m

Recommended fluid flow 3-4 gpm

Air volume 973 cfm 458 L/sec

Blows per minute 1770 1770

CMW

®

Page 11

All Terrain Air Hammer

Attachment Operator’s Manual

Publication number: ID0273478; page 11 of 11

Support

Procedure

Notify your dealer immediately of any malfunction or

failure of Ditch Witch equipment.

Always give model, serial number, and approximate date

of your equipment purchase. This information should be

recorded and placed on file by the owner at the time of

purchase.

Return damaged parts to dealer for inspection and

warranty consideration if in warranty time frame.

Order genuine Ditch Witch replacement or repair parts

from your authorized Ditch Witch dealer. Use of another

manufacturer's parts may void warranty consideration.

Resources

Publications

Contact your Ditch Witch dealer for publications and

videos covering safety, operation, service, and repair of

your equipment.

Ditch Witch Training

For information about on-site, individualized training,

contact your Ditch Witch dealer.

Warranty

Ditch Witch Equipment and Replacement Parts

Limited Warranty Policy

Subject to the limitation and exclusions herein, free replacement parts

will be provided at any authorized Ditch Witch dealership for any Ditch

Witch equipment or parts manufactured by The Charles Machine

Works, Inc. (CMW) that fail due to a defect in material or workmanship

within one (1) year of first commercial use (Exception: 2 years for all SK

attachments). Free labor will be provided at any authorized Ditch Witch

dealership for installation of parts under this warranty during the first

year following “initial commercial” use of the serial-numbered Ditch

Witch equipment on which it is installed. The customer is responsible

for transporting their equipment to an authorized Ditch Witch dealership

for all warranty work.

Exclusions from Product Warranty

• All incidental or consequential damages.

• All defects, damages, or injuries caused by misuse, abuse,

improper installation, alteration, neglect, or uses other than those

for which products were intended.

• All defects, damages, or injuries caused by improper training,

operation, or servicing of products in a manner inconsistent with

manufacturer’s recommendations.

• All engines and engine accessories (these are covered by original

manufacturer’s warranty).

• Tires, belts, and other parts which may be subject to another

manufacturer’s warranty (such warranty will be available to

purchaser).

• ALL IMPLIED WARRANTIES NOT EXPRESSLY STATED

HEREIN, INCLUDING ANY WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY.

IF THE PRODUCTS ARE PURCHASED FOR COMMERCIAL

PURPOSES, AS DEFINED BY THE UNIFORM COMMERCIAL CODE,

THEN THERE ARE NO WARRANTIES WHICH EXTEND BEYOND

THE FACE HEREOF AND THERE ARE NO IMPLIED WARRANTIES

OF ANY KIND WHICH EXTEND TO A COMMERCIAL BUYER. ALL

OTHER PROVISIONS OF THIS LIMITED WARRANTY APPLY

INCLUDING THE DUTIES IMPOSED.

Ditch Witch products have been tested to deliver acceptable

performance in most conditions. This does not imply they will deliver

acceptable performance in all conditions. Therefore, to assure

suitability, products should be operated under anticipated working

conditions prior to purchase.

Defects will be determined by an inspection within thirty (30) days of the

date of failure of the product or part by CMW or its authorized dealer.

CMW will provide the location of its inspection facilities or its nearest

authorized dealer upon inquiry. CMW reserves the right to supply

remanufactured replacements parts under this warranty as it deems

appropriate.

Extended warranties are available upon request from your local Ditch

Witch dealer or CMW.

Some states do not allow exclusion or limitation of incidental or

consequential damages, so above limitation of exclusion may not apply.

Further, some states do not allow exclusion of or limitation of how long

an implied warranty lasts, so the above limitation may not apply. This

limited warranty gives product owner specific legal rights and the

product owner may also have other rights which vary from state to

state.

For information regarding this limited warranty, contact CMW’s Product

Support department, P.O. Box 66, Perry, OK 73077-0066, or contact

your local Ditch Witch dealer.

First version: 1/91; Latest version: 7/05

CMW

®

Loading...

Loading...