Page 1

© 2005

Instruction Manual

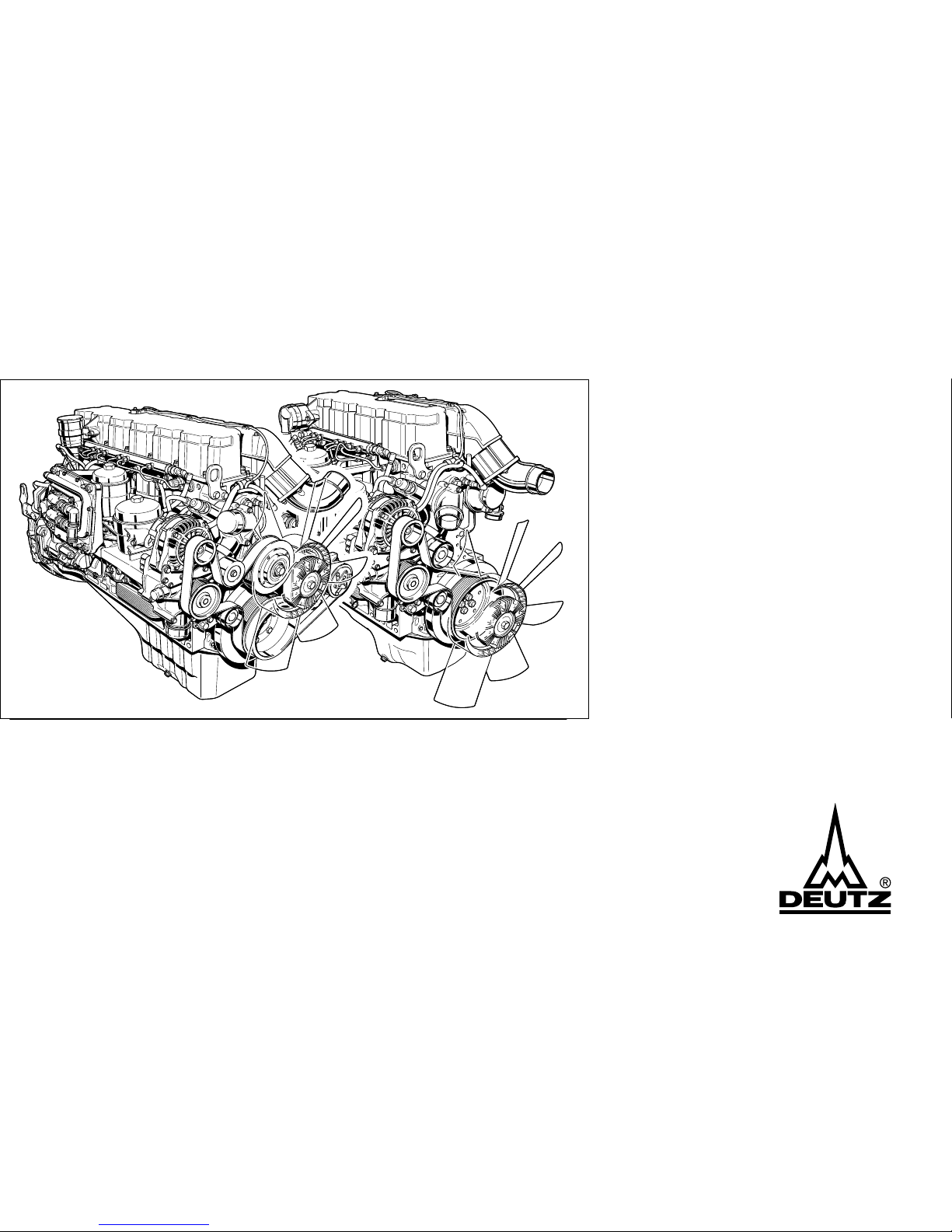

TCD 2012 L04/06 4V

TCD 2013 L04/06 4V

Page 2

© 2005

Read and observe the information in this

instruction manual. You will avoid accidents,

retain the manufacturer’s warranty and have

a fully functional, ready to use engine at your

disposal.

z This engine is exclusively for the purpose

according to the scope of delivery - defined

and built by the equipment manufacturer (use

for the intended purpose) Any use above and

beyond this is considered improper use. The

manufacturer will not be liable for damages

resulting from this. The user will bear the sole

risk in this case.

z Use for the intended purpose also includes

observance of the operating, maintenance

and repair instructions specified by the

manufacturer. The engine may only be used,

maintained and repaired by persons who are

familiar with it and instructed in the dangers.

z Maintenance/cleaning work on the engine

may only be carried out when the engine is not

running and has cooled down.

When doing this, make sure that the electrical

system is switched off (remove ignition key).

The specifications for accident prevention

with electrical systems (e.g. VDE-0100/-0101/

-0104/-0105 Electrical protective measures

against dangerous touch voltages) must be

observed.

Cover all electrical components tightly when

cleaning with liquids.

z Do not work on the fuel system while the

engine is running - Danger to life.

- Wait (1 minute) for the engine to come to a

standstill (pressure release), as system is

under high pressure: there is a - Danger to

life.

During the first trial run do not stand in the

danger area of the engine (danger due to high

pressure of leaks) - Danger to life.

- In case of leaks immediately contact the

workshop.

- When working on the fuel system

ensure that the engine is not unintentionally

started during repairs. Danger to life.

z The pertinent rules for the prevention of

accidents and other generally recognised

safety and industrial medicine rules must be

observed.

z When the engine is running there is a danger

of injury caused by:

- rotating / hot components

- engines with extraneous ignition

- ignition systems (high electrical voltage)

Contact must be avoided!

z The manufacturer will not be liable for damages

resulting from unauthorised modification to the

engine.

Equally, manipulations to the injection and control

system can affect the engine’s performance

and the exhaust characteristics. Compliance

with environmental regulations will no longer

be guaranteed in this case.

z Do not alter, obstruct or block the area of the

cool air supply to the fan.

The manufacturer will accept no liability for

damages resulting from this.

z Only DEUTZ original parts may be used when

carrying out maintenance/repair work on the

engine. These have been designed especially

for your engine and ensure a trouble-free

operation.

Failure to observe this will lead to voiding of the

warranty!

Page 3

© 2005

Instruction Manual

TCD 2012 L04/06 4V

TCD 2013 L04/06 4V

0312 2443 en

Engine number:

Please enter the engine number here. This

will simplify the handling of customer service,

repair and spare parts queries (see Section

2.1).

Illustrations and data in this instruction manual

are subject to technical changes in the course

of improvements to the engines. Reprinting

and reproductions of any kind, even in part,

require our written permission.

Page 4

© 2005

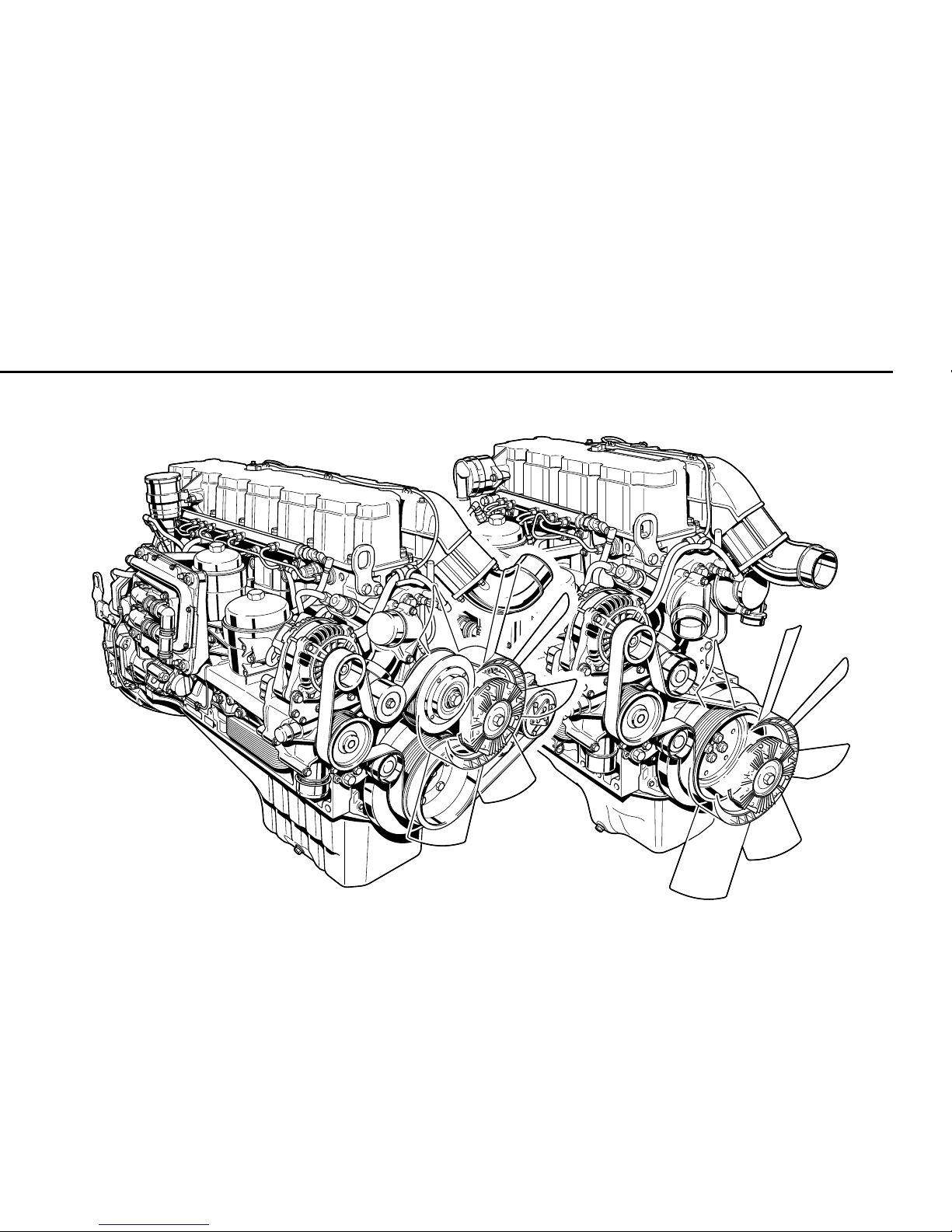

Foreword

Dear customer,

The liquid-cooled engines made by DEUTZ are

developed for a wide variety of applications.

An extensive range of variants ensures that

the respective special requirements are met.

Your engine is equipped according to the

installation, i.e. not all the parts and

components described in this instruction

manual are installed on your engine.

We have done our best to clearly identify the

differences, so that you can easily find the

operating, maintenance and repair

instructions relevant to your engine.

Please read these instructions before you

start your engine and observe the operating

and maintenance instructions.

We are at your service for any questions you

may have in this matter.

Your

DEUTZ AG

Page 5

© 2005

Contents

1. General

2. Engine description

2.1 Engine type

2.1.1 Company plate

2.1.2 Location of company plate

2.1.3 Engine number

2.1.4 Cylinder numbering

2.2.1 Operation side

TDC 2012 L04 4V

2.2 Engine diagrams

2.2.2 Starter side

TDC 2012 L04 4V

2.2.3 Operation side

TDC 2012 L06 4V

2.2.4 Starter side

TDC 2012 L06 4V

2.2.5 Operation side

TDC 2013 L06 4V

2.2.6 Starter side

TDC 2013 L06 4V

2.2.7 Operation side

Agri Power

2.2.8 Starter side

Agri Power

2.2 Engine diagrams

2.3.1 Lube oil diagram

TCD 2013 L06 4V (example)

2.4 Fuel circuit

2.4.1 Fuel diagram

2.5 Coolant circuit

2.5.1 Coolant diagram

2.5.2 Exhaust gas recirculation diagram

2.6 Electrics

2.6.1 Electrical cable connections for

monitoring

3. Operation

3.1 Initial commisioning

3.1.1 Filling engine oil

3.1.2 Filling fuel

3.1.3 Filling / bleeding cooling system

3.1.4 Other preparations

3.2 Starting

3.2.1 Electrical starting

3.3 Operation monitoring

3.3.1 Engine oil pressure

3.3.2 Coolant temperature

3.3.3 Coolant level

3.3.4 Lube oil level

3.4 Shutting down

3.4.1 Electrical shutdown

3.5 Operating conditions

3.5.1 Winter operation

3.5.2 High ambient temperature,

high altitude

4. Operating substances

4.1 Lube oil

4.1.1 Quality

4.1.2 Viscosity

4.2 Fuel

4.2.1 Quality

4.2.2 Winter fuel

4.3 Coolant

4.3.1 Water quality for coolant

4.3.2 Coolant preparation

4.3.3 Cooling system preservative

5. Maintenance

5.1 Maintenance schedule

5.2 Maintenance diagram

5.3 Maintenance work carried out

6. Care and maintenance

work

6.1 Lubrication system

6.1.1 Oil change intervals

6.1.2 Checking oil level, changing engine oil

6.1.3 Changing oil filter insert

6.1.4 Cleaning / changing oil filter (cup) fehlt

6.2 Fuel system

6.2.1 Changing fuel filter

6.2.2 Cleaning / changing fuel filter (cup)

6.2.3 Changing / bleeding fuel pre-filter, filter

insert

6.3 Cooling system

6.3.1 Cleaning intervals

6.3.2 Cleaning cooling system

6.3.3

Emptying / filling / bleeding cooling

isystem

6.4 Combustion air filter

6.4.1 Cleaning intervals

6.4.2 Emptying cyclone pre-separator

6.4.3 Dry air filter

6.5 Belt drive

6.5.1 Checking V-rib belt

6.5.2 Changing V-rib belt

6.5.3 Checking wear limit of v-rib belt fehlt

6.6 Setting work

6.6.1 Checking valve clearance, setting if

necessary

6.6.2 Checking control piston clearance at

engine brake, setting if necessary

6.7 Add-on parts

6.7.1 Battery

6.7.2 Three-phase current generator

6.7.3 Transportation suspension

Page 6

© 2005

7. Faults, causes and remedies

7.1 Fault table

7.2 Engine management

7.2.1 Engine protection function of the

electronic engine controller EMR3

7.2.2 Using the diagnosis button

7.2.3 Table of fault blink codes

8. Engine corrosion protection

8.1 Corrosion protection

9. Technical data

9.1 Engine and setting data

9.2 Screw tightening torques

9.3 Tools

10. Service

Contents

Page 7

© 2005

Page 8

1

© 2005

General

DEUTZ engines Maintenance and care

This symbol is used for all safety

instructions which, if not

observed, present a direct

danger to life and limb for the

person involved. Observe these

carefully. Also pass on the

safety instructions to your operating

personnel. Furthermore, the legislation for

„general regulations for safety and the

prevention of accidents“ must be observed.

Service

Please consult one of our service

representatives responsible for operating

faults and spare parts questions. Our trained

specialist personnel ensures fast,

professional repairs using original parts in

the event of damage.

The Technical Circulars listed in this operating

manual are obtainable from your DEUTZ

partner.

Please turn to the end of this manual for

further service information.

Take care when the engine is

running

Only carry out maintenance work or repairs

with the engine switched off. Ensure that the

engine cannot be started unintentionally danger of accidents!

Re-install any removed protective equipment

upon completion of the work.

Observe industrial safety regulations when

operating the engine in enclosed spaces or

underground.

When working on the running engine, work

clothing must be close fitting.

Only re-fuel with the engine switched off.

are decisive for whether the engine

satisfactorily meets the demands put on it.

Compliance with the prescribed maintenance

times and the careful execution of

maintenance and care work are therefore

essential. Difficult operating conditions

deviating from normal operation must be

observed especially.

Warning

Danger for component/engine.

Failure to comply can lead to

destruction of the component/

engine. Must be observed.

Danger

are the product of years of research and

development. The profound know-how

gained in connection with high quality

requirements is the guarantee for

manufacturing of engines with a long life,

high reliability and low fuel consumption.

Naturally the high requirements for protection

of the environment are also met.

Page 9

2

Engine description

© 2005

2.1 Engine type

2.2 Engine diagrams

2.3 Lube oil circuit

2.4 Fuel circuit

2.5 Coolant circuit

2.6 Electrics

Page 10

2

Engine description

© 2005

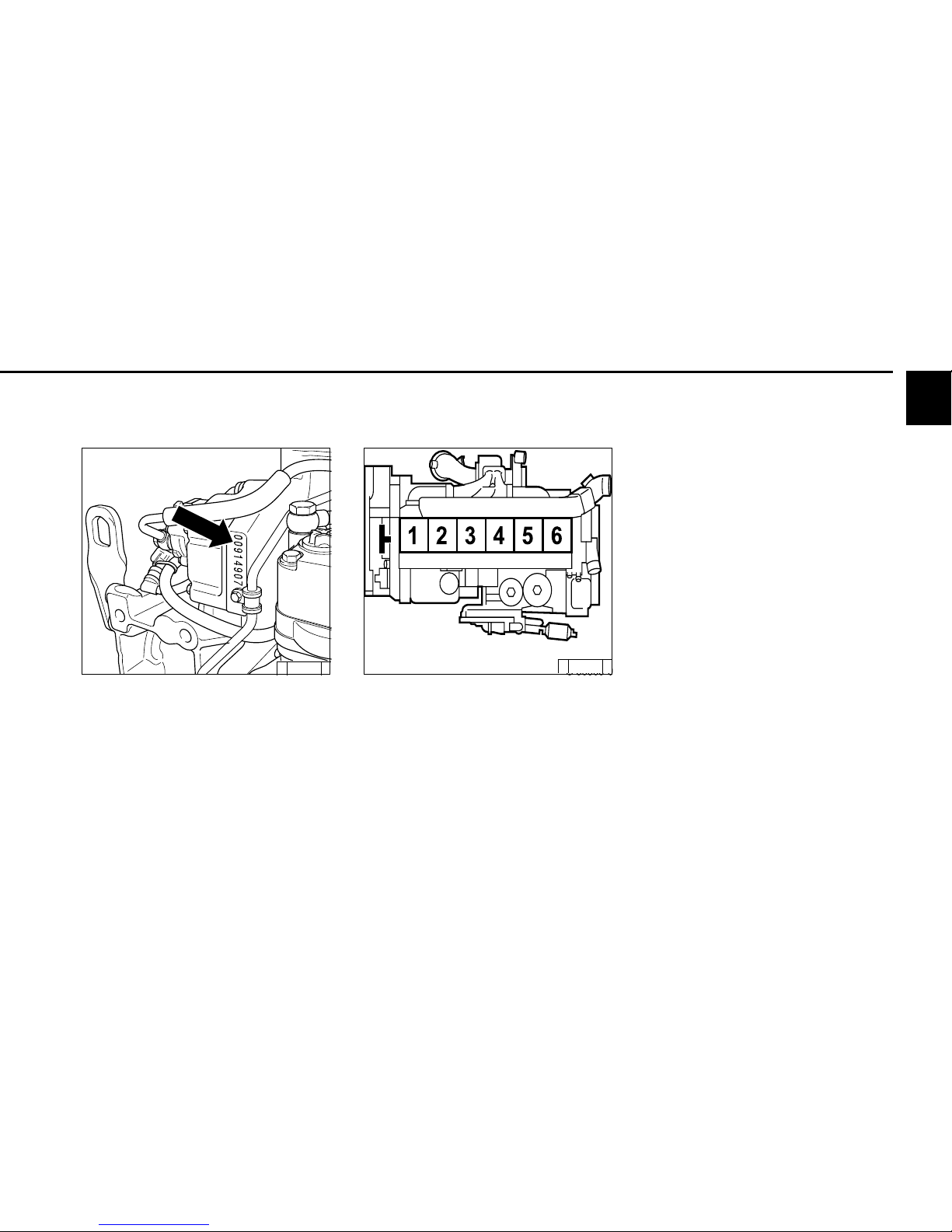

© 35 985 0

© 38 986 0

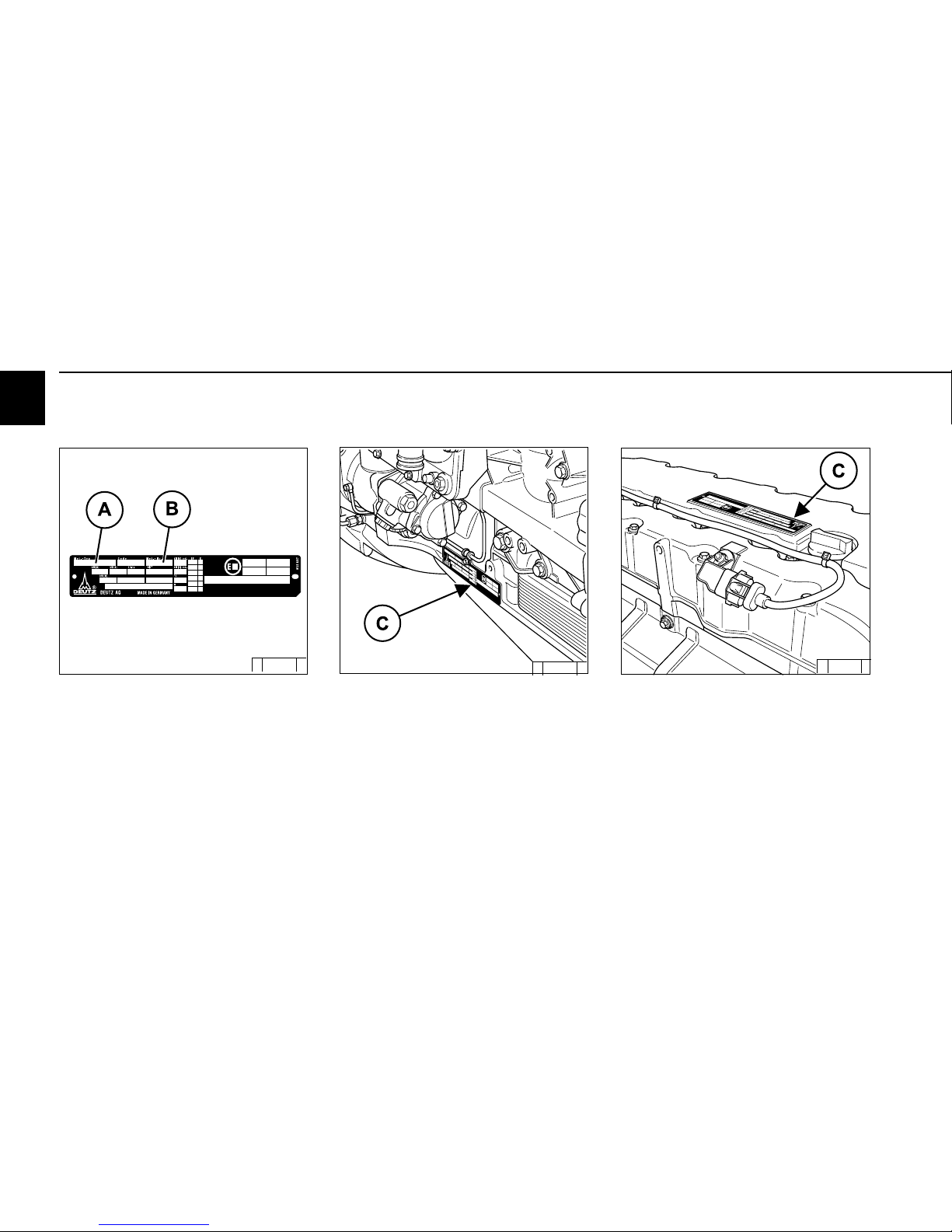

2.1 Engine type

2.1.1 Company plate

The engine type A, engine numberB and the

power data are stamped on the company plate.

The engine type and number must be stated

when purchasing spare parts.

2.1.2 Location of company plate

The company plate C is fixed on the crankcase.

© 38 987 0

Or company plate C is fixed on the cylinder head

cover.

Or both plates are attached.

Page 11

2

Engine description

© 2005

© 38 988 0

© 38989 0

2.1 Engine type

2.1.4 Cylinder numbering

The cylinders are counted consecutively, starting

from the flywheel.

2.1.3 Engine number

The engine number is stamped on the crankcase

(arrow) and on the company plate.

Page 12

2

Engine description

© 2005

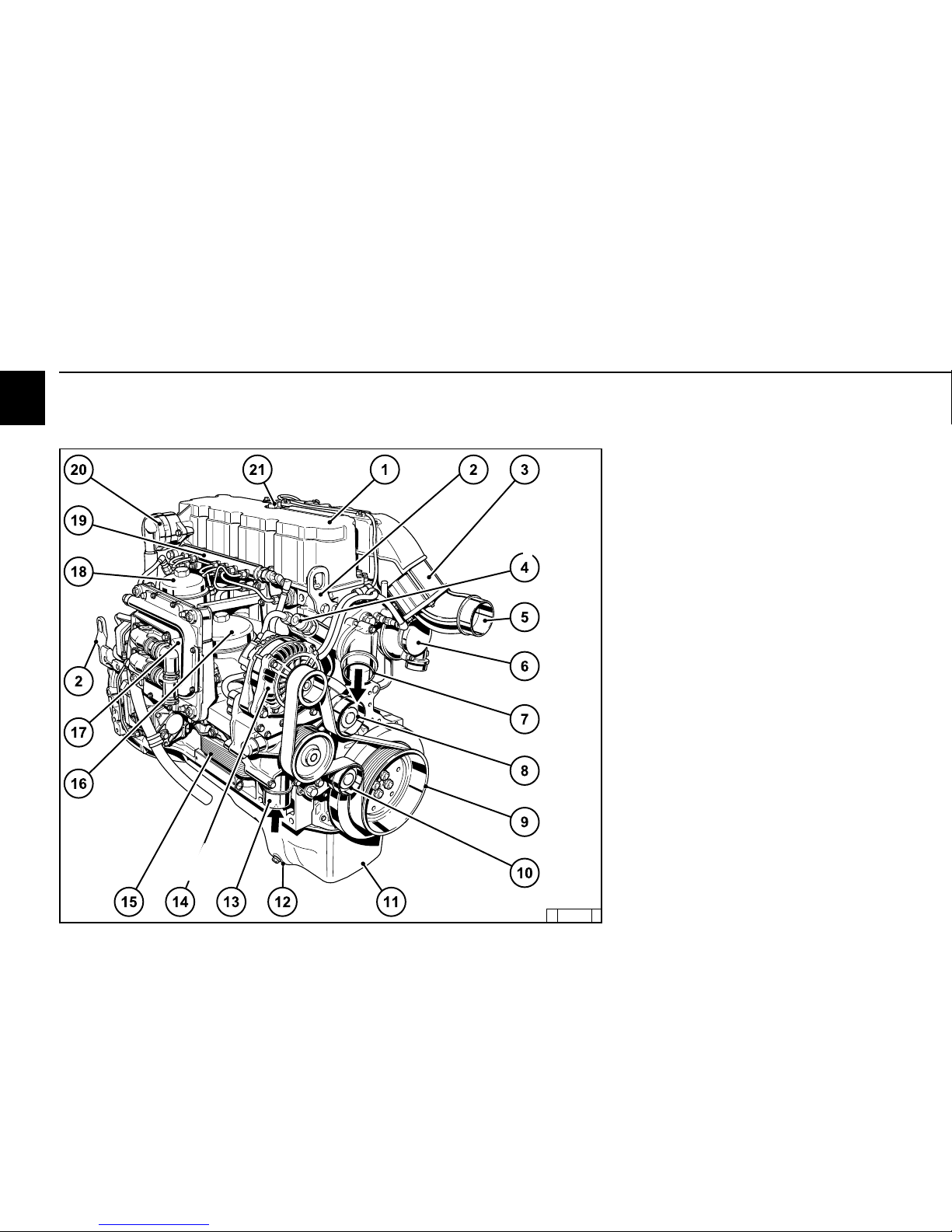

© 38 980 1

2.2 Engine diagrams

2.2.1 Operation side

TCD 2013 L04 4V

1 Cylinder head cover

2 Transportation eyelets

3 Heating flange

4 Cabin heater connection

5 Intake elbow to charge air cooler

6 Connection to air filter

7 Coolant outlet adapter

8 Deflection pulley

9 Belt pulley on crankshaft

10 Tension pulley

11 Oil tray

12 Oil drain screw

13 Coolant inlet adapter

14 Generator

15 Oil cooler

16 Exchangeable lube oil filter

17 Engine control unit

18 Exchangeable fuel filter

19 Rail with pressure reducing valve and pressure

sensor

20 Crankcase ventilation (open system)

21 Oil filler neck

Page 13

2

Engine description

© 2005

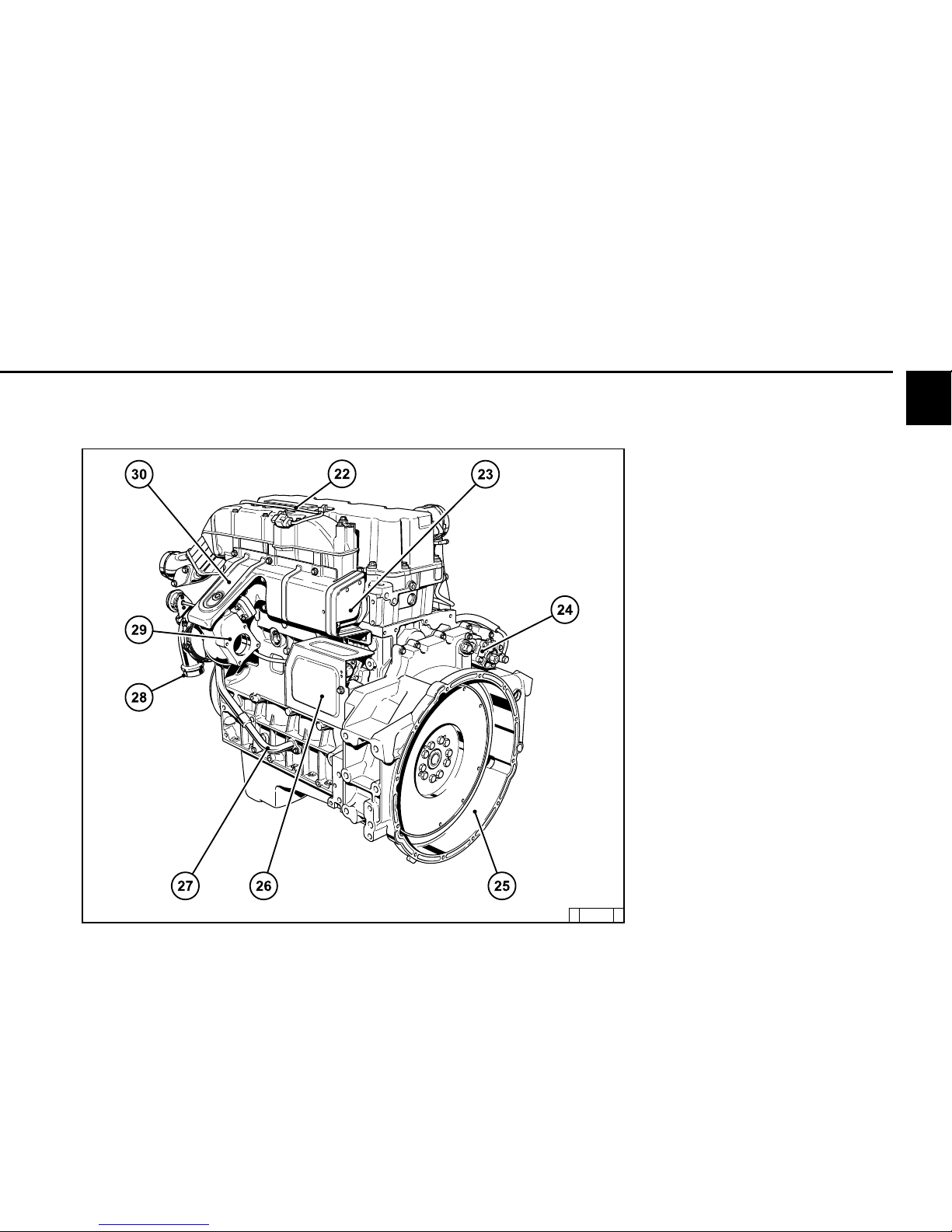

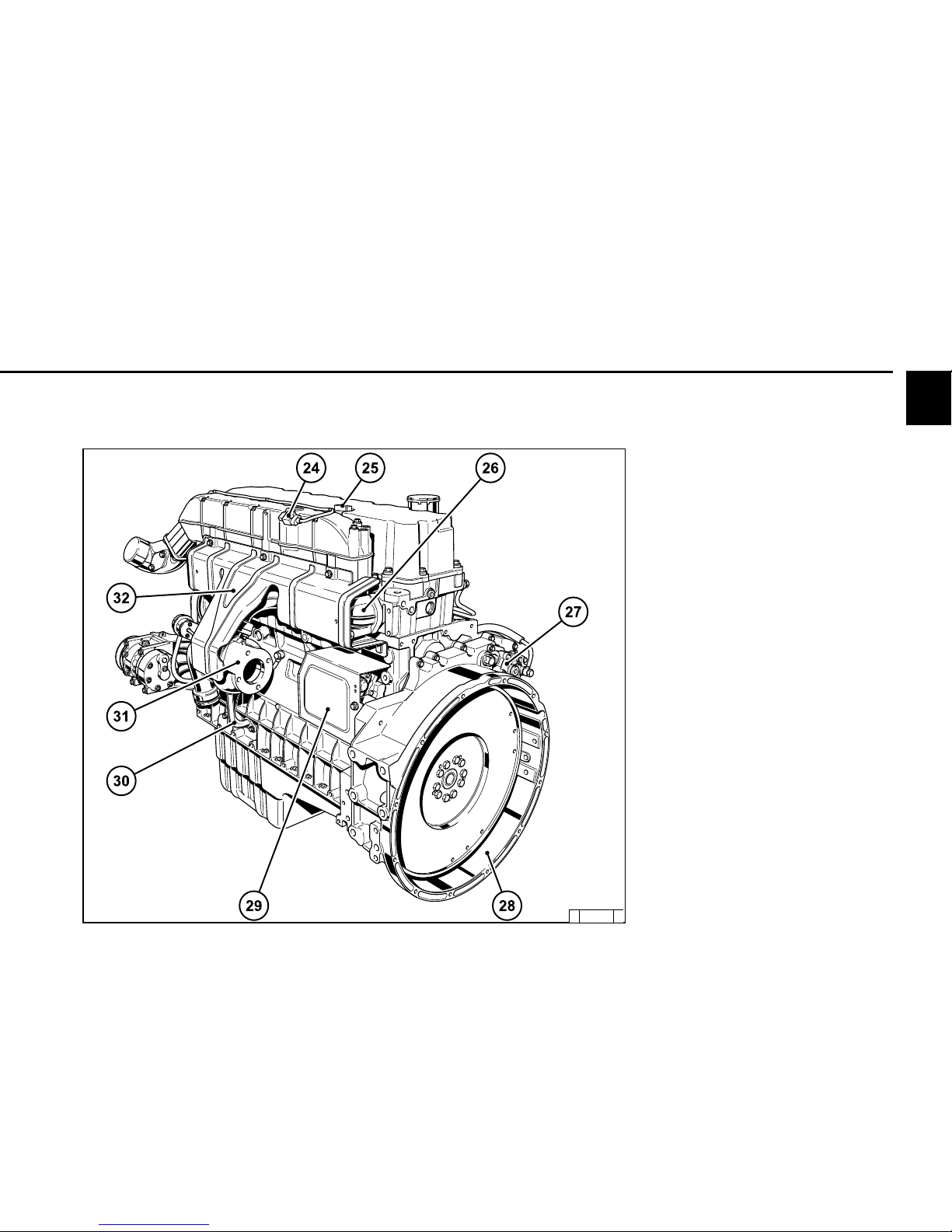

© 38 981 1

2.2 Engine diagrams

2.2.6 Starter side

TCD 2013 L04 4V

22 Charge air temperature line to transmitter

23 Exhaust manifold

24 Compressor (optional)

25 SAE housing

26 Starter cover

27 Oil return line from turbocharger

28 Inlet combustion air turbocharger

29 Turbocharger exhaust gas outlet

30 Screening plate (thermal protection)

Page 14

2

Engine description

© 2005

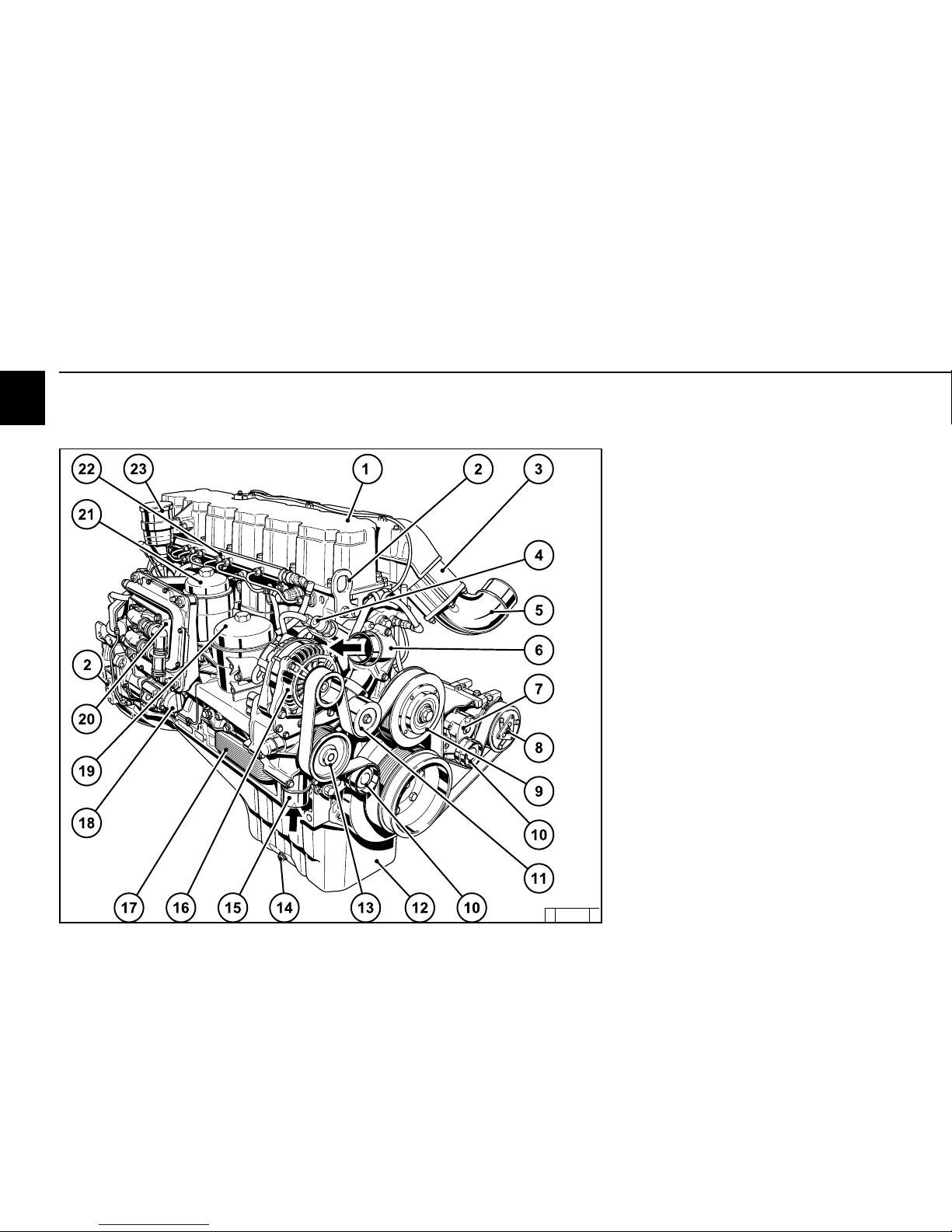

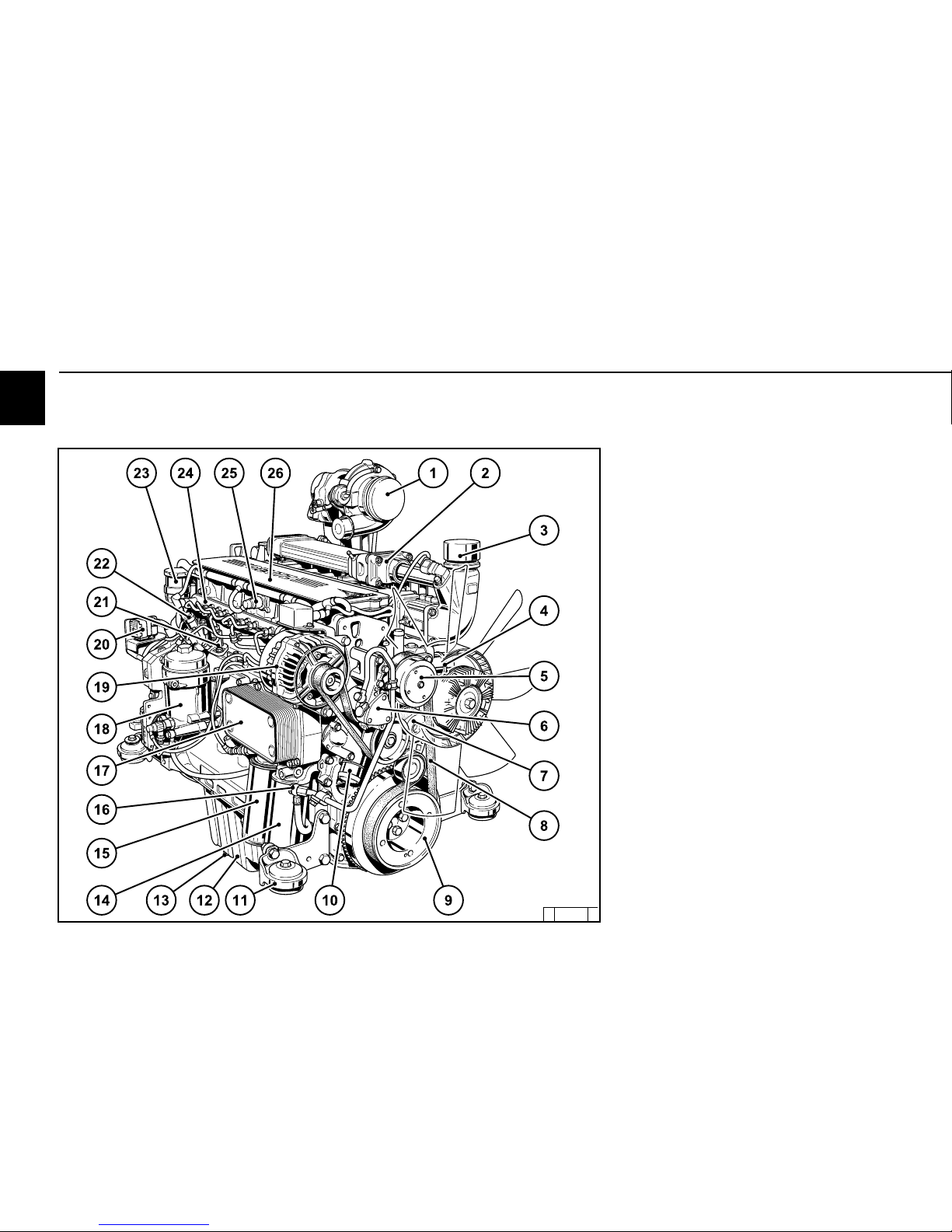

© 38 982 0

2.2 Engine diagrams

1 Cylinder head cover

2 Transportation eyelets

3 Heating flange

4 Cabin heater connection

5 Intake elbow from charge air cooler

6 Thermostat housing (coolant outlet)

7 Spring-loaded tension pulley

8 Compressor (optional)

9 Belt pulley for fan attachment

10 Tension pulley (s)

11 Deflection pulley

12 Oil tray

13 Belt pulley coolant pump

14 Oil drain screw

15 Coolant inlet adapter

16 Generator

17 Oil cooler

18 Hydraulic pump or compressor installation

(optional)

19 Exchangeable lube oil filter

20 Engine control unit with fuel cooling

21 Exchangeable fuel filter

22 Rail with pressure reducing valve and pressure

sensor

23 Crankcase ventilation (open system)

2.2.3 Operation side

TCD 2013 L06 4V

Page 15

2

Engine description

© 2005

© 38 983 0

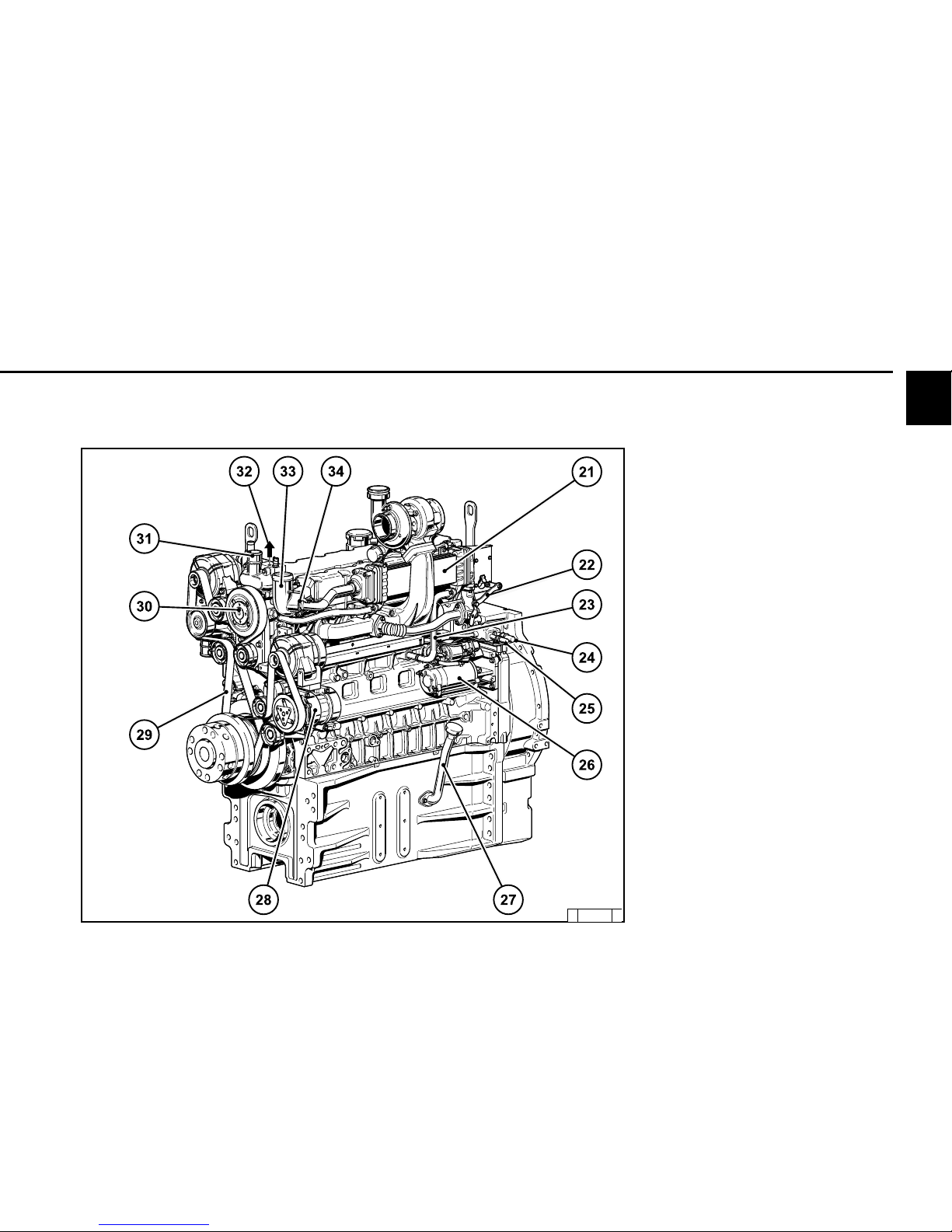

2.2 Engine diagrams

2.2.4 Starter side

TDC 2013 L06 4V

2 4 P r e s s u r e a n d t e m p e r a t u r e t r a n s m i t t e r, c h a r g e a i r

25 Oil filler neck

26 Exhaust manifold

27 Compressor (optional)

28 SAE housing

29 Starter cover

30 Oil return line from turbocharger

31 Exhaust turbocharger

32 Screening plate (thermal protection).

Page 16

2

Engine description

© 2005

© 43 895 0

2.2 Engine diagrams

2.2.5 Operation side Agri Power

TCD 2012 L04 4V

1 Exhaust turbocharger

2 EGR exhaust gas recirculation

3 Intake elbow from charge air cooler

4 Coolant return from cooler

5 Coolant pump

6 Fuel supply pump

7 Spring-loaded tension pulley

8 V-rib belt

9 Belt pulley for drive

10 Coolant inlet adapter from cooler

11 Mounting foot (engine suspension)

12 Oil tray

13 Oil drain screw

14 Fuel filter

15 Lube oil filter

16 Fuel connection from tank

17 Lube oil cooler

18 Fuel pre-filter

19 Generator

20 Central connector

21 ECU ElectronicControl Unit

22 High-pressure pump

23 Crankcase ventilation

24 Rail with pressure reducing valve

25 Charge air sensor

26 Cylinder head cover

Page 17

2

Engine description

© 2005

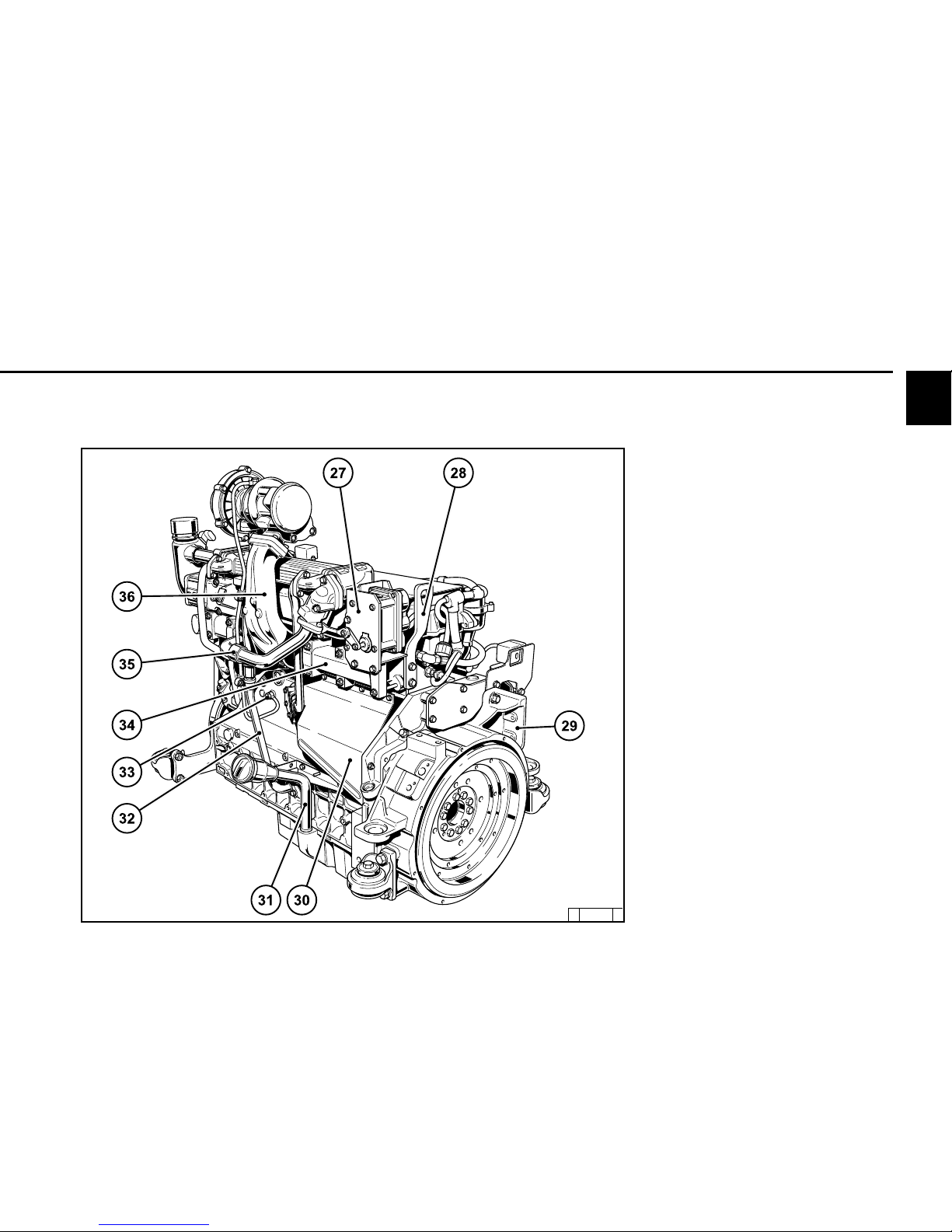

2.2 Engine diagrams

27 EGR exhaustgasRecirculation

Throttle lever for exhaustgasrecirculation

28 Transportation eyelets

29 SAE housing

30 Starter with cover

31 Lube oil filler neck

32 Lube oil return from turbocharger

33 Oil pressure pipe to turbocharger

34 Exhaust manifold

35 Cooling line to exhaust gas recirculation

system

36 Exhaust manifold

2.2.6 Operation side Agri Power

TCD 2012 L04 4V

© 43 896 0

Page 18

2

Engine description

© 2005

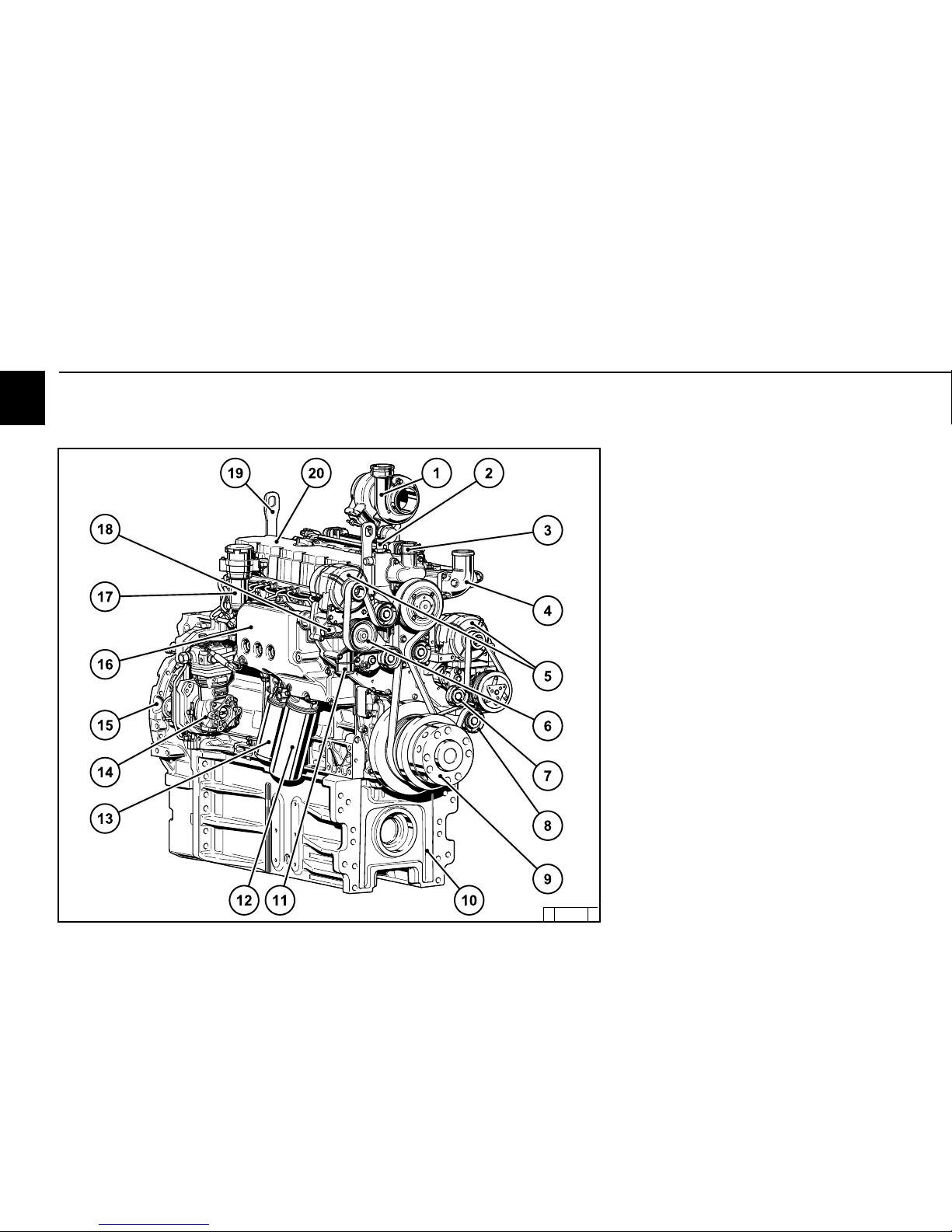

© 43 826 0

2.2 Engine diagrams

2.2.7 Operation side

TCD 2013 L06 4V Agri Power

1 Exhaust turbocharger

2 Coolant return from heater

3 Coolant outlet to cooler

4 Intake elbow from charge air cooler

5 Generator

6 Coolant pump

7 Spring-loaded tension pulley

8 Deflection pulley

9 Front power takeoff

10 Oil tray

11 Coolant inlet adapter from cooler

12 Lube oil filter

13 Fuel filter

14 Compressor (optional)

15 SAE housing

16 Lube oil cooler

17 Crankcase ventilation socket

18 Coolant outlet adapter to heater

19 Engine suspension

20 Cylinder head cover

Page 19

2

Engine description

© 2005

© 43 827 0

2.2 Engine diagrams

21 EGR exhaustgasrecirculation system

22 Throttle lever for exhaustgasrecirculation

23 Cooling line to exhaust gas recirculation

system

24 Fuel inlet to engine

25 Fuel outlet to fuel container

26 Starter

27 Lube oil filler neck

28 Compressor

29 V-rib belt

30 Fan bearing /coolant pump

31 Thermostat housing coolant outlet

to cooler

32 Ventilation line to cooler

33 Charge air supply to charge air cooler

34 Coolant return from EGR

2.2.8 Starter side

TCD 2013 L06 4V Agri Power

Page 20

2

Engine description

© 2005

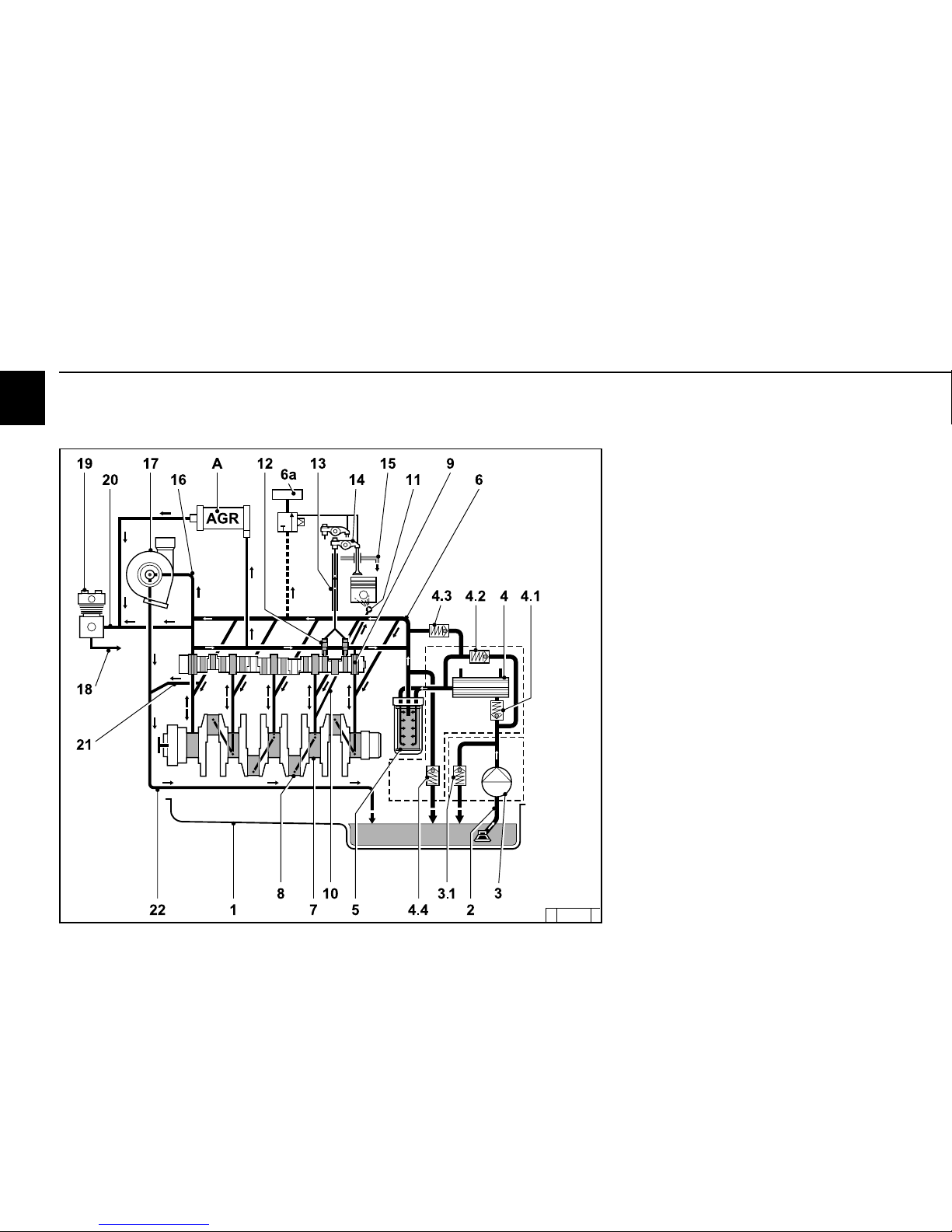

© 39 012 3

2.3 Lube oil circuit

2.3.1 Lube oil diagram

TCD 2013 L06 4V (example)

1 Oil tray

2 Intake pipe

3 Lube oil pump

3.1 Safety valve

4 Lube oil cooler

4.1 Reverse lock valve

4.2 By-pass valve

4.3 By-pass valve

4.4 Control valve

5 Exchangeable lube oil filter

6 Main oil pipe

6a Engine brake lubrication

A Exhaustgasrecirculation (EGR) lubrication

7 Crankshaft bearing

8 Con rod bearing

9 Camshaft bearing

10 Line to injection nozzle

11 Injection nozzle for piston cooling

12 Tappet with rocker arm pulse lubrication

13 Stop rod, oil supply for rocker arm

lubrication

14 Rocker arm

15 Return line to oil tray

16 Oil line to exhaust turbocharger

17 Exhaust turbocharger

18 Oil line to compressor or hydraulic pump

19 Compressor or hydraulic pump

20 Return line from compressor

21 Return line from cylinder head

22 Exhaust turbocharger return to crankcase

Page 21

2

Engine description

© 2005

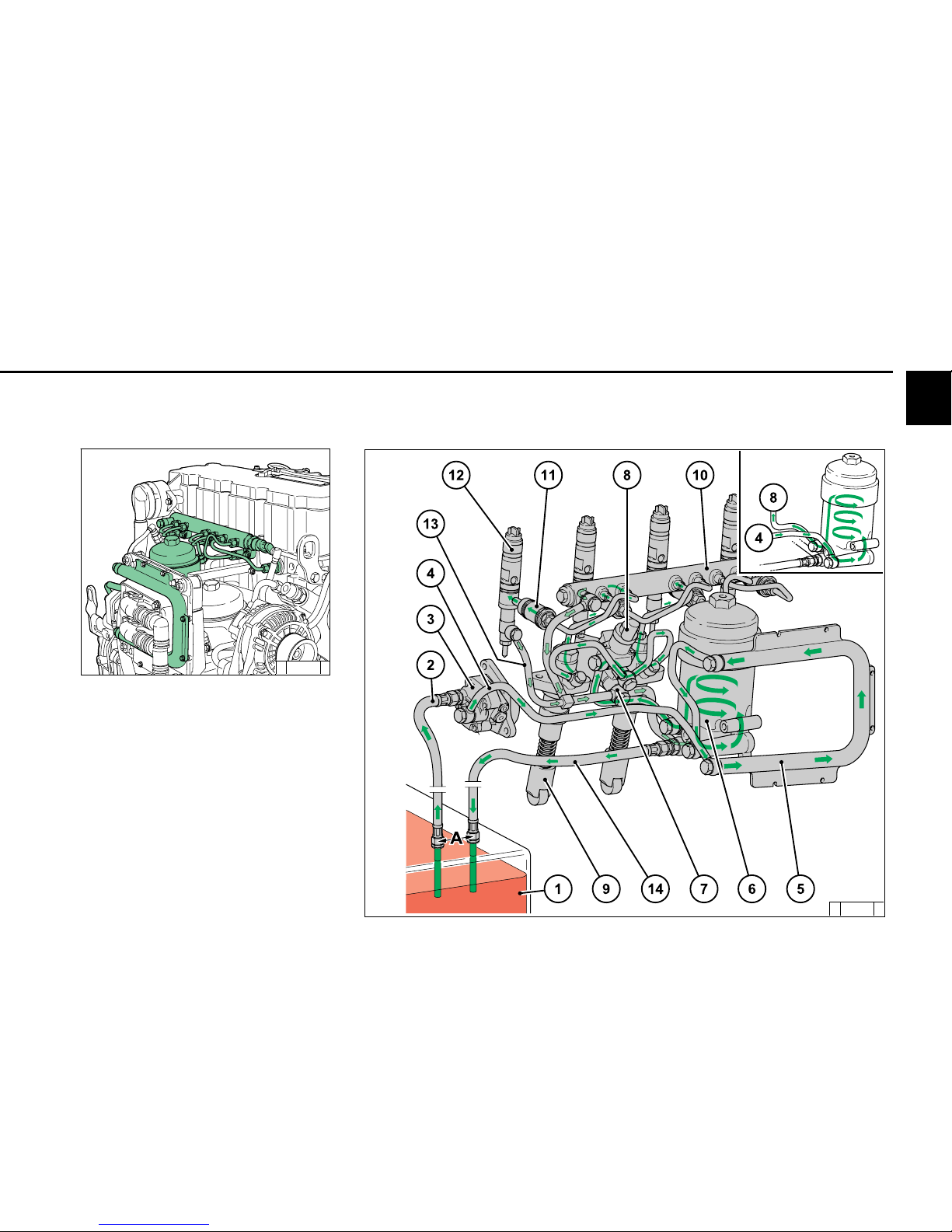

© 38 991 0

© 38 992 2

2.4 Fuel circuit

2.4.1 Fuel diagram

1 Fuel container

2 Line to fuel pump

3 Fuel pump

4 Line to fuel filter

5 Fuel cooling for engine control unit

(without cooler, upper right in diagram)

6 Fuel filter

7 Line to injection pumps

8 Fuel to control unit

9 Tappet rollers on camshaft

10 DCR Rail

11 Injection line to injection valve

12 Injectors

13 Fuel leak oil line

14 Return line to container

A Keep distance as large as possible

Page 22

2

Engine description

© 2005

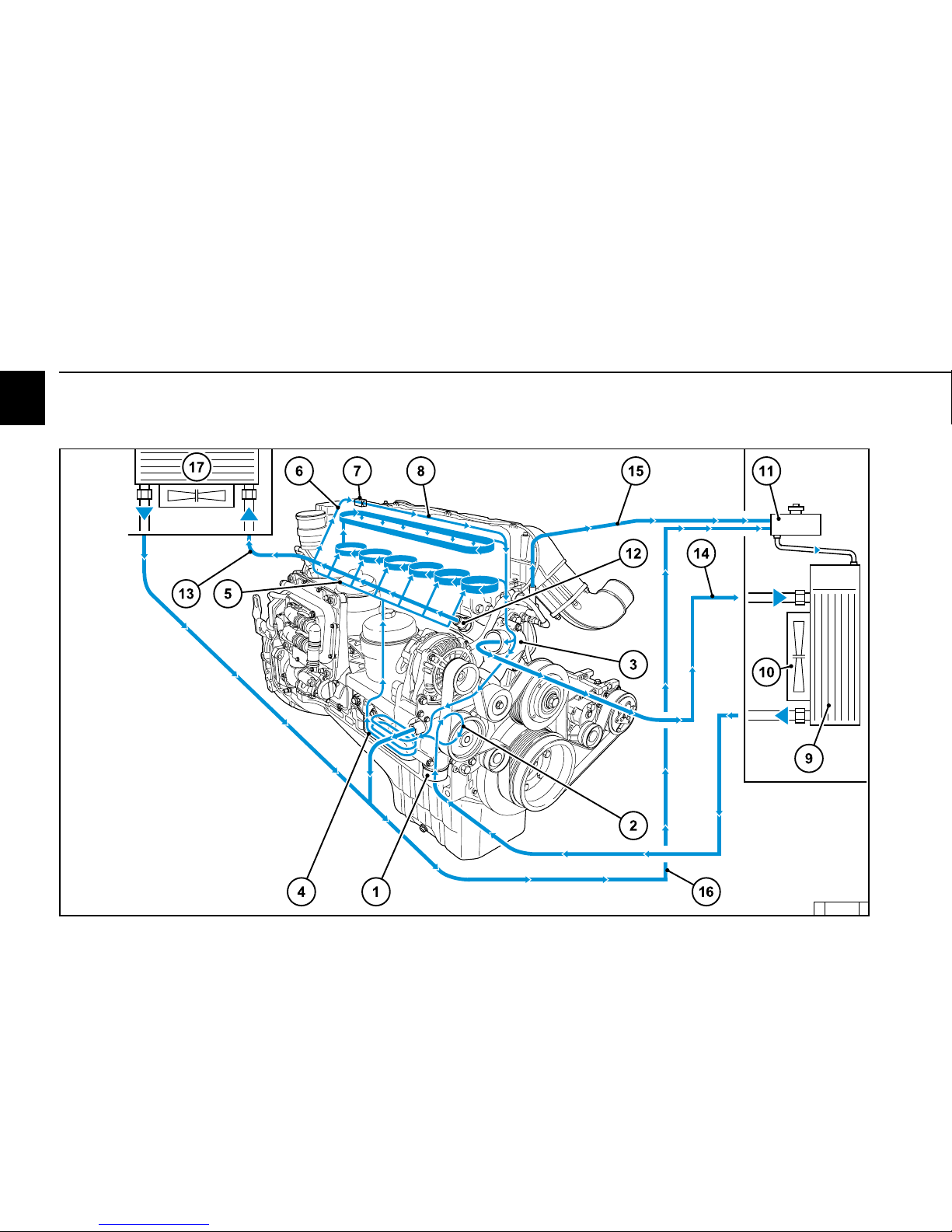

© 39 982 3

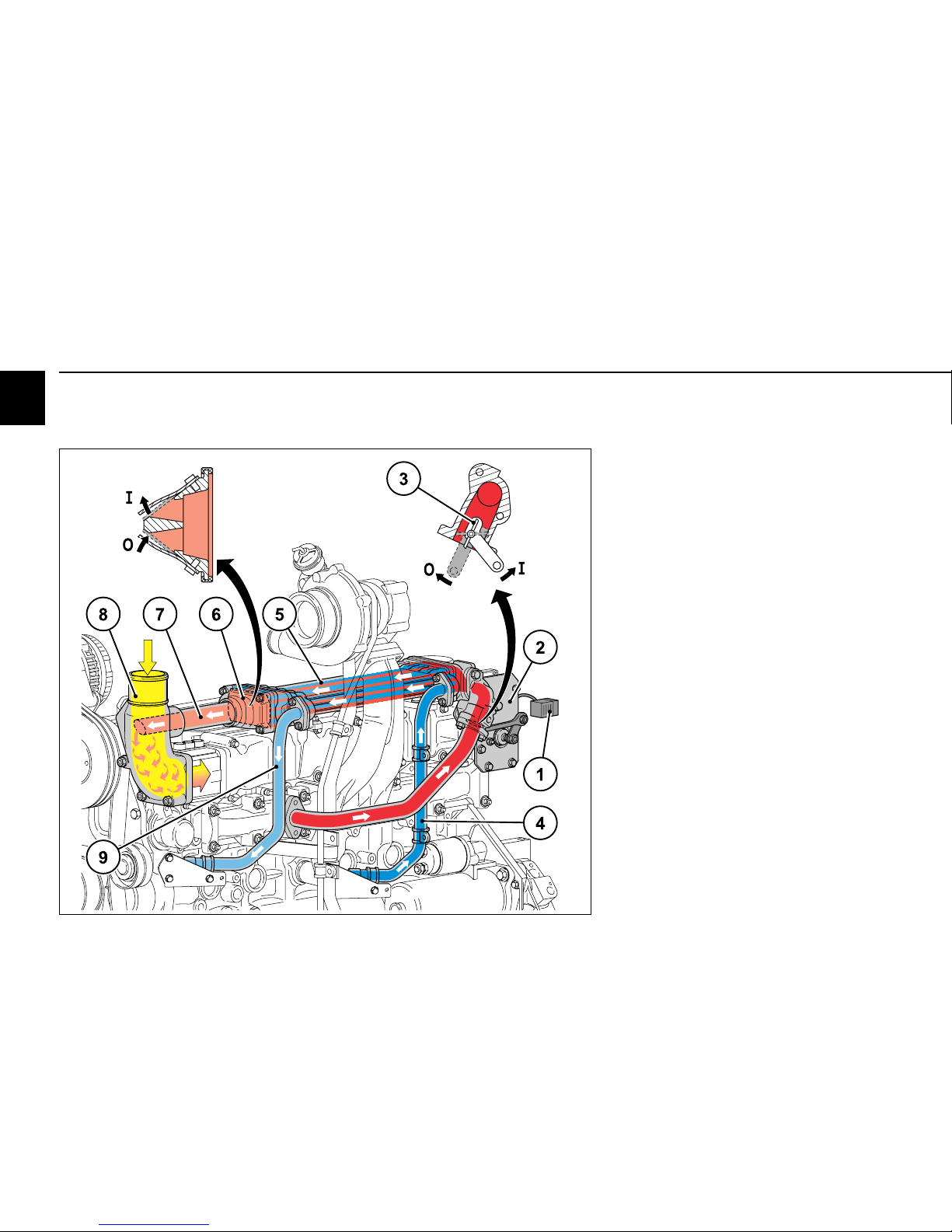

2.5 Coolant circuit

Page 23

2

Engine description

© 2005

2.5 Coolant circuit

1 Coolant inlet to engine

2 Coolant pump

3 Thermostat housing

4 Lube oil cooler (plate cooling)

5 Cylinder head cooling and EGR cooling

6 Coolant supply to engine brake

7 Engine brake cooling

8 Return line to thermostat

9 Heat exchanger (customer)

10 Fan (customer)

11 Compensation tank (customer)

12 Heating connection

13 Compensation tank return line

to heater connection

14 Thermostat compensation tank return

15 Engine ventilation to compensation tank

16 Return line from engine heat exchanger

Page 24

2

Engine description

© 2005

2.5 Coolant circuit

1 Coolant inlet to engine

2 Coolant pump

3 Thermostat housing

4 Lube oil cooler (plate cooling)

5 Cylinder head cooling and EGR cooling

6 Coolant supply to engine brake

7 Engine brake cooling

8 Return line to thermostat

9 Heat exchanger (customer)

10 Fan (customer)

11 Compensation tank (customer)

12 Heating connection

13 Compensation tank return line

to heater connection

14 Thermostat compensation tank return

15 Engine ventilation to compensation tank

16 Return line from engine heat exchanger

2.6.1 Exhaust gas recirculation

diagram

Page 25

2

Engine description

© 2005

© 39 010 0

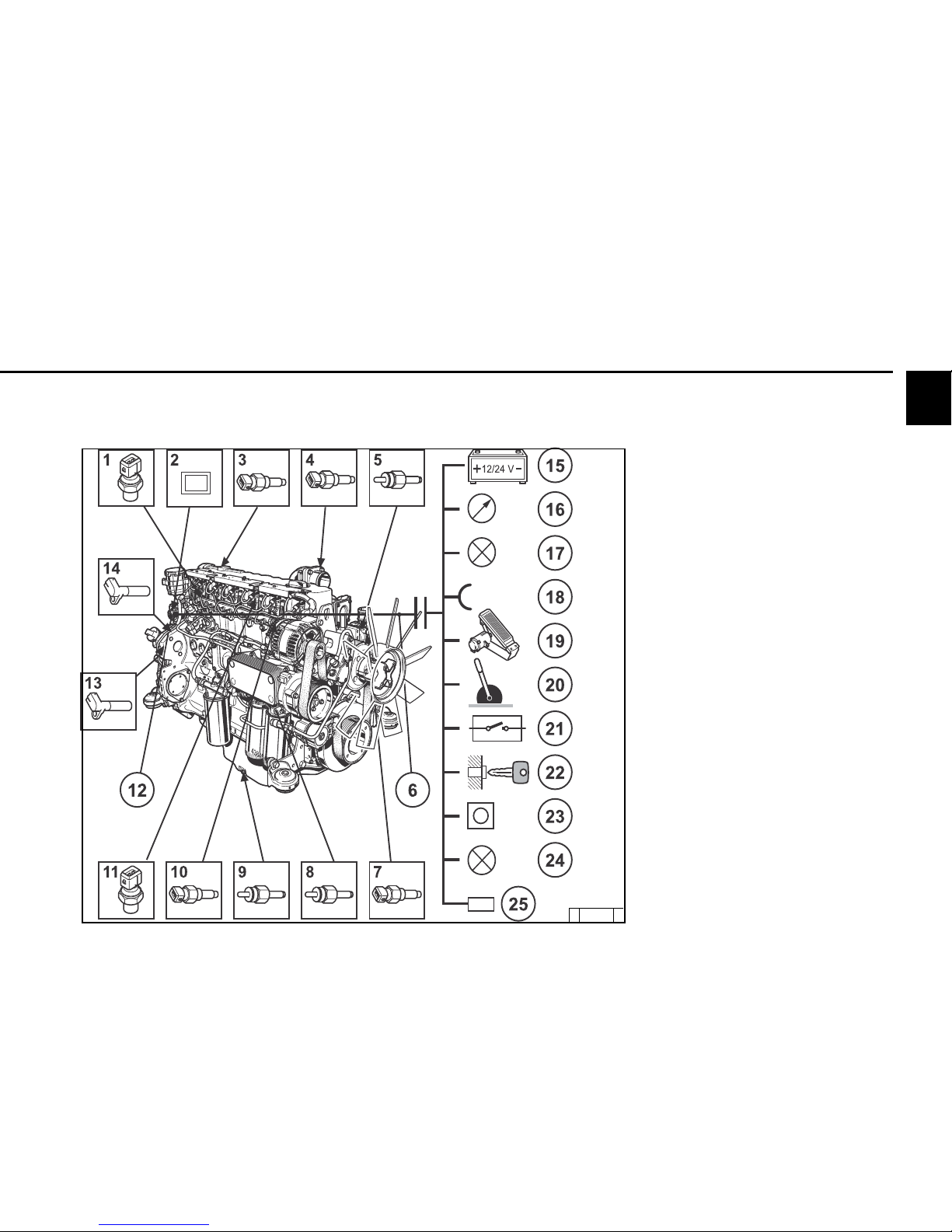

2.6 Electrics

2.6.1 Electrical cable connections

for monitoring (example)

1 Fuel pressure

2 Shutdown magnet (solenoid valve) example

3 Charge air pressure/temperature sensor

4 Coolant temperature

5 Cold start aid

6 Rail pressure (fuel pressure)

8 Oil temperature transmitter engine pre-heating

heating

7 Oil pressure transmitter

9 Oil level transmitter

10 Oil pressure sensor

11 Injectors engine brake (optional)

1 2 E.M.S II

13 Pick-up on SAE housing

14 Speed sensor

15 Energy supply

16 Multifunction displays

17 Outputs (configurable)

18 Inputs (configurable)

(PWM/digital/analogue)

19 Accelerator pedal

20 Hand throttle (optional)

21 Switch functions

22 Key switch

Start/stop

23 Diagnosis button

24 Fault light with blink code

25 Diagnosis interface/

CAN-Bus

Page 26

© 2005

Operation

3

3.1 Initial commissioning

3.2 Starting

3.3 Operation monitoring

3.4 Shutting down

3.5 Operating conditions

Page 27

3

© 2005

Operation

3.1 Initial commissioning

3.1.3 Filling / bleeding cooling

system

zz

zz

z Connect the coolant outlet 2 and coolant inlet

1 to the cooling system. Connect the lead line

from the compensation tank to the water pump

or to coolant inlet pipe 1.

z Connect vent lines from the engine and if

necessary from the cooler to the compensation

tank.

z Fill the cooling system through the

compensation tank

z Close the compensation tank with the valve.

z Start the engine and warm up until the

thermostat opens (line 2 heats up).

z Run engine run with open thermostat for

2 –3 minutes.

© 39 8 50 0

© 26 397 0

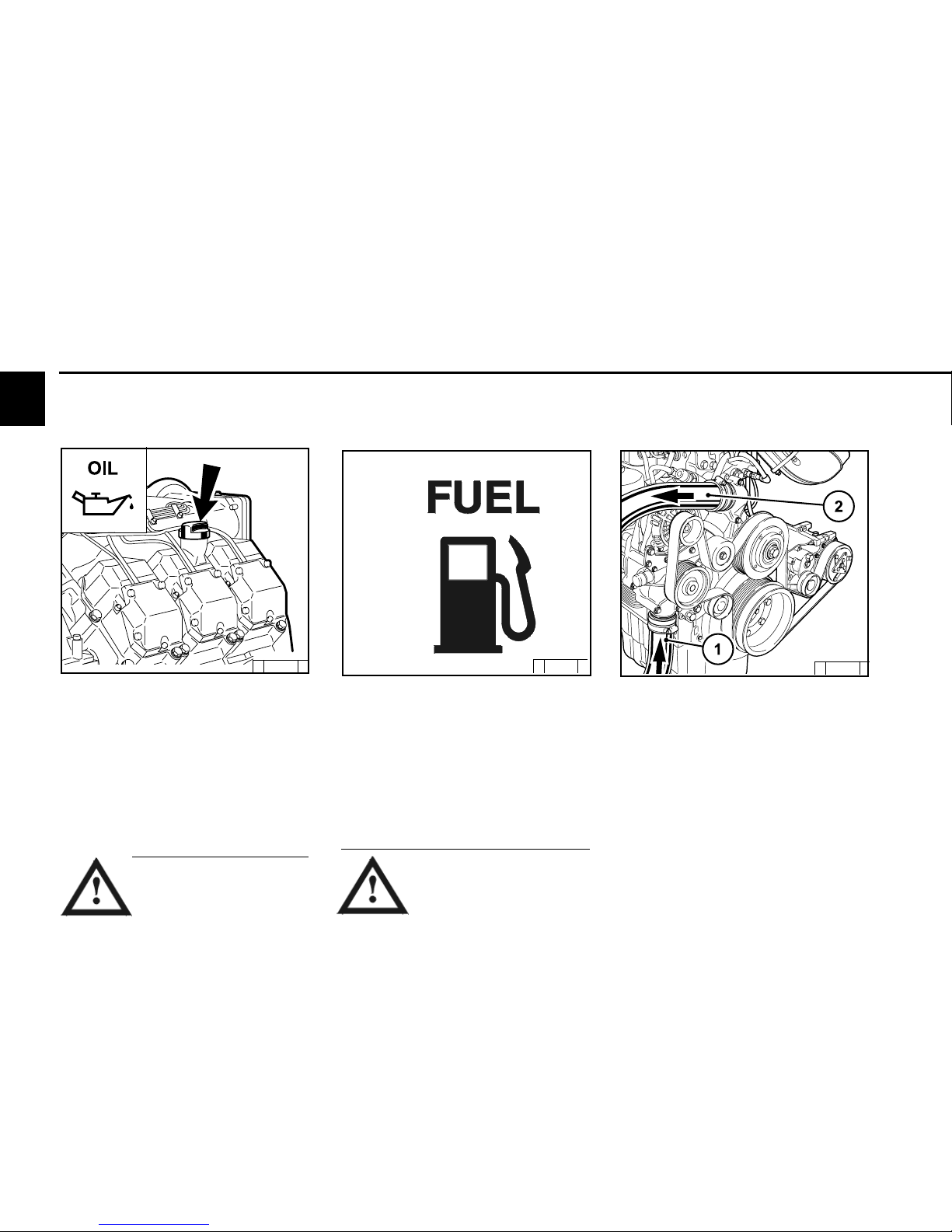

3.1.1 Filling engine oil

The engines are generally supplied without

oil filling.

Fill engine with lube oil through the oil filler (1)

on the cylinder head cover. Alternatively, you

can fill on the wheel box (2) or on the side of

the crankcase.

For oil filling amount see 9.1.

For quality and viscosity of oil see 4.1.

3.1.2 Filling fuel

Oil may not be filled into the

dust collecting tank of the

pre-separator, if this is

present.

Only use clean, standard, branded diesel fuel.

For fuel quality see 4.2.

Depending on the outdoor temperature, use

either summer or winter diesel fuel.

Only re-fuel when the engine is

not running!

Pay attention to cleanliness!

Do not spill any fuel!

© 26 398 0

Page 28

© 2005

Operation

3

3.1 Initial commissioning

3.1.4 Other preparations

z Check battery and cable connections, see

6.7.1.

z Trial run

- After preparations carry out a short

trial run of approx. 10 min. Do not fully load the

engine.

During and after the trial run

- Check engine for tightness.

With engine not running

- Check oil level, re-fill oil if necessary, see

6.1.2.

- Re-tighten V-belts, see 6.5.

z Running-in

It is recommended to check the oil level twice

a day during the running-in phase.

After the running-in phase, checking once a

day is sufficient.

z Check the coolant level in the compensation

tank and top up the coolant if necessary.

z Repeat the process with engine start if

necessary.

Never operate the engine without

coolant (not even briefly).

Page 29

3

© 2005

Operation

3.2 Starting

Start the engine for a maximum of 20 seconds

uninterrupted. If the engine does not start up,

wait for one minute and then repeat the starting

process. If the engine does not start up after

two starting processes, determine the cause

as per fault table (see 7.1).

If the engine does not start and the diagnostic lamp

flashes, the EMR3 system has activated the start

lock to protect the engine.

The start lock is released by switching off the

system with the ignition key for about 30 seconds.

3.2.1 Electrical starting

without cold start aid

Before starting make sure that

there is nobody in the engine/

work machine danger area.

After repairs: Check that all

protective equipment is

mounted and all tools have been removed

from the engine.

When starting with heating plugs/heating

flange, do not use additional start aids (e.g.

injection with start pilot)! Danger of accidents!

z Engine is electronically controlled by

Example: EMR3 (electronic engine control)

- engine is programmed and supplied with

the necessary function configurations.

z As far as possible separate engine from

driven devices by disconnecting.

z Engine connector plug must be connected

by the customer (e.g in driver’s cab/

device) to at least:

- Supply voltage

- Torque output

- Speed output.

z Warm up the engine for approx. 30 seconds

at a low idling speed.

z Do not run up the engine immediately to

high idling speed / full load operation from

cold.

If the starter is connected by a relay on the

EMR3,

- the maximum starting time is limited by

the EMR3.

- the pause between two start attempts

is given by the EMR3.

© 26 411 0

z Insert key

- Step 0 = no operating voltage.

z Turn key to the right

- Step 1 = operating voltage,

- Warning lights light up.

z Turn the key further to the right against the

spring load.

- Step 2 = start

z Release key as soon as the engine starts up.

- Warning lights go out.

- If the touch start function is programmed, a

short start command with the ignition key

suffices in position 2 or, if available, by a start

button.

The start is then continued automatically by the

EMR3.

- For special applications, the EMR3 can be

programmed by data record so that the control

unit performs other automatic start attempts if

the engine fails to start.

Start uninterruptedly for max. 20 s. If the engine

does not start, repeat the start procedure after

a 1 minute pause. If the engine has not started

after two attempts, find the cause in the fault

table (see 7.1).

Page 30

© 2005

Operation

3

3.3 Operation monitoring

with cold start aid

Heating plug/heating flange

© 26 411 0

z Insert key.

- Step 0 = no operating voltage.

z Turn key to the right.

- Step 1 = operating voltage,

- Warning lights 1+2+3 light up.

- Pre-heat until heating indicator goes out. If the

pre-heating indicator flashes, there is an

error, e.g. pre-heating relay sticking which

can fully discharge the battery at standstill.

- Engine is ready for operation.

z Turn the key further to the right against the

spring load to

- Step 2 = start

z Release key as soon as the engine starts up.

- Warning lights go out.

Caution: Engine must start within 30 seconds,

if not, repeat the starting process.

Page 31

3

© 2005

Operation

3.3 Operation monitoring

© 25 752 1

© 25 754 0

3.3.1 Engine oil pressure

Oil pressure light

z The oil pressure light comes on for about 2s

after switching on the system.

z The oil pressure light must be off when the

engine is running.

Oil pressure gauge

z Needle of oil pressure measuring instrument

must show the minimum oil pressure (see 9.1).

The EMR3 system monitors the engine condition

and itself.

The states are indicated by the diagnostic

lamp.

Lamp test:

z The diagnostic lamp lights for about 2s after

ignition (ignition lock stage 1).

Steady light:

z There is an error in the system or a variable of

the engine (temperature, pressure, etc.) is in

the warning area. Depending on the error, the

performance of the engine may be reduced by

the EMR3 to protect the engine so that it is not

in danger.

Fast flashing:

z Attention, the engine is in danger and

must be switched off.

z Depending on the application, the

control unit switches the engine off

automatically.

z The control unit may also specify an idle speed

to cool the engine before shutting down.

z There may be a start lock after stopping the

engine.

z Additional control lamps e.g. for oil pressure or

oil temperature may be on.

z The override key can bypass the reduction in

performance to avoid critical situations, as

well as delay the automatic shutdown or

bypass a start lock. This overwriting of the

engine protection functions is logged in the

control unit.

z The start lock is released by switching off the

system with the ignition key for about 30

seconds.

Page 32

© 2005

Operation

3

3.4 Shutting down

min

3.3.3 Coolant level

z Light on coolant level display comes on (contact

is via float switch/ level probe if coolant level

is at minimum):

Switch off the engine and determine the cause

as per fault table (see 7.1).

z Function check of coolant level:

Key in step 1 or 2

(Float switch or level probe)

Warning light comes on for approx. 2 seconds

- Coolant level OK:

Light goes out

- Coolant level not OK:

Light comes on again.

3.3.4 Lube oil level

z Light on lube oil level display comes on (contact

is via float switch / level proble if lube oil level

is at minimum):

Switch off the engine and determine the cause

as per fault table (see 7.1).

z Function check of lube oil level :

Key in step 1 or 2

(Float switch or level probe)

Warning light comes on for approx. 2 seconds

- Lube oil level OK :

Light extinguished.

- Lube oil level not OK :

Light comes on again.

© 26 278 1

© 26 291 1

© 26 246 0

3.3.2 Coolant temperature

z The needle of the temperature display should

always be in the green area, and only as an

exception in the yellow/green area. If the

needle rises into the orange area the engine is

getting too hot. Switch off the engine and

determine the cause as per fault table (see

7.1).

Page 33

3

© 2005

Operation

3.5 Operating conditions

P

1

2

0

+–

1

2

3

3.4.1 Electrical shutdown

© 26 411 0

z Turn the key to the left (to step 0) and

remove. Warning lights go out.

Note:

The control unit remains active for about another

40 seconds to save the system data (lag) and

then switches itself off.

Avoid shutting down from full

load operation if possible (coking/

blockage of the remaining oil in

the turbocharger bearing

housing).

Lube oil is no longer supplied to the

turbocharger!

Run the engine after relieving the load for about

one minute at low idling speed.

Page 34

© 2005

Operation

3

3.5 Operating conditions

z Cold start aids

- When there is a frost, start with heating

flange if if necessary (see 3.2.1).

The heating flange not only lowers the

starting limit temperature, but also

simplifies starting at temperatures which

don’t actually require a starting aid.

z Battery

- A well-charged battery is a

prerequisite for a good cold start,

see 6.7.1.

- Heating the battery to approx. 20 °C

(dismantle and store in a warm room) lowers

the starting limit temperatureby 4-5 °C.

3.5.1 Winter operation

z Lube oil viscosity

- Select the viscosity (SAE class)

according to the ambient temperature

before starting the engine, see 4.1.2.

- Observe shorter oil change times when

operating below -10 °C, see 6.1.1.

z Diesel fuel

- Below 0 °C use winter fuel,see 4.2.2.

z Coolant

- Mixing ratio anti-freeze / water for lowest

temperature (max. - 35 °C), see 4.3.1.

z Additional maintenance work

- Check the fuel container weekly for

contamination, clean if necessary.

- If necessary, adjust the oil filling of the oil

bath air filter (as engine oil) according to

the outside temperature.

© 26 248 0

Page 35

3

© 2005

Operation

3.5.2 High ambient temperature,

high altitude

z When the altitude or ambient temperature

increases, the air density decreases.

This impairs the maximum engine performance,

exhaust quality, temperature level and, in extreme cases, the starting performance.

For transient operation, usage up to

1000 m altitude and a temperature of 30°C is

permissible.

z In case of doubt regarding engine usage, ask

your engine or device supplier whether

necessary fuel stop reduction has been carried

out in the interest of operational safety, service

life and exhaust quality (smoke), or contact

your service representative.

© 25 901 1

Page 36

4

© 2005

Operating substances

4.1 Lube oil

4.2 Fuel

4.3 Coolant

Page 37

4

© 2005

only with engine pre-heating

30 298 1

Operating substances 4.1 Lube oil

4.1.1 Quality

Lube oils are classified by DEUTZ into quality

classes according to their performance

capability. Oils according to other comparable

specifications can be used.

Permissible oils:

Deutz DQC I-02 DQC II-05 DQC III *+DQC IV

#

ACEA E2-96 E3-96/E5-02/ E4- 99/

E7-04 E6-04

API CF/CF-4 CH-4/CG-4 DHD - DHD-1 -

DQC III-05 * Annex 1

DQC IV-05

#

only fully synthetic

The exact assignment of permissible oil quality

and oil change intervals to the engines is

listed in chapter 6.1.1.

In case of doubt, please ask your service

representative.

*For oil change intervals see 6.1.1

For oil filling amounts see 9.1

4.1.2 Viscosity

Since lube oil changes its viscosity (viscidity)

depending on temperature, the ambient

temperature of the location of engine operation

is decisive for the selection of viscosity class

(SAE class). Refer to the oil viscosity diagram

on the right to achieve optimal operating

performance.

Falling below the temperature limits

occasionally can impair the cold start ability,

but will not lead to engine damages. In order

to minimise wear, the operating limits should

not be exceeded over a long period of time.

Oil changes determined by the time of year

can be avoided by using multi-viscosity oils.

Multi-viscosity oils, in particular smooth running

oils, also have the effect of reducing fuel

consumption.

Page 38

4

© 2005

4.1 Lube oil Operating substances

DEUTZ lube oil quality level DQC III Annex 1

Manufacturer Lube oil type SAE class Availability

DEUTZ DEUTZ ÖlTLX-10W40 FE 10W-40 Europe

ADDINOL ADDINOL SuperTruck MD 1048 10W-40 Europe, Asia

ADDINOL Ultra TruckMD 0538 5W-30 Europe, Asia

AGIP Agip SigmaUltra TFE 10W-40 worldwide

Autol Valve UltraFE 10W-40 Germany

ARAL Aral MegaTurboral 10W-40 worldwide

Aral SuperTurboral 5W-30 worldwide

AVIA TURBOSYNTHHT-E 10W-40 Germany

BAYWA BayWa SuperTruck 1040 MC 10W-40 Southern Germany

BayW a Turbo4000 10W-40 Southern Germany

BP OIL International BP Vanellus E7 Plus 10W-40 Europe

BP Vanellus E7Supreme 5W-40 Europe

Castrol CastrolSYNTRUCK 5W-40 Europe, North America, Brazil, Argentina, Australia, South Africa

Castrol Castrol DYNAMAX 7.5W-40 Europe, North America, Brazil, Argentina, Australia, South Africa

CEPSA EUROTRANSSHPD 10W-40 Spain, Portugal

CHEVRON Chevron Delo400 Synthtic 5W-40 North America

DEA DEA CronosSynth 5W-30 Germany, Europe

DEA Cronos PremiumLD 10W-40 Germany, Europe

DEA Cronos PremiumLD 10W-40 Europe

ESSO EssolubeXTS 501 10W-40 Europe

FUCHS EUROPE Fuchs Titan Cargo MC 10W-40 worldwide

Fuchs Titan UnicPlus MC 10W-40 worldwide

MOBIL OIL Mobil Delvac 1 SHC 5W-40 Europe, SE Asia, Africa

Mobil De lva c 15W-40 worldwide

Mobil Delvac XHP Extra 10W-40 Europe, SE Asia

Lube oil refinery Wintershall TFG 10W-40 Europe, Salzbergen

Shell International ShellMyrina TX / 5W-30 Europe, code

Shell Rimula Ultra country specific, varies

Shell MyrinaTX / 10W-40 Europe, code

Shell Rimula Ultra country specific, varies

Texaco Ursa Super TDX 10W-40 10W-40 Europe

Ursa Premium FE 5W-30 5W-30 Europe

TOTALFINA ELF TOTAL RUBIA TIR 8600 10W-40 worldwide

ELF PERFORMANCE 10W-40 worldwide

EXPERTY MX 1010

ELF PERFORMANCE 10W-40 Germany, Benelux,

EXPERTY MX 1012 Scandinavia, Austria

FINA KAPPA FIRST 5W-30 Europe

FINA KAPPA ULTRA 10W-40 Europe

This table will be extended if necessary.

Page 39

4

© 2005

Operating substances 4.2 Fuel

4.2.1 Quality

Use standard diesel fuels with a sulphur content

of less than 0.5 %. If the sulphur content is higher,

the oil change intervals must be reduced (see

6.1.1).

The following fuel specifications are

permitted:

zz

zz

z Diesel fuels

- DIN EN 590

zz

zz

z JIS K 2204 grade 1 and 2 *

zz

zz

z ASTM D 975-88; 1-D and 2-D *

* as long as the lubrication properties

correspond to diesel fuel EN 590 (positive

test results are necessary)

(see TR 0199-99-3005)

If other fuels are used which do not meet the

requirements of the technical circular, the

warranty will be voided.

Technical circular is obtainable from the DEUTZ

Service Organisation.

The certification measurements for the

observance of legal emission limits are carried

out with the test fuels defined by legislation.

These correspond to the diesel fuels

described in section 1 in accordance with EN

590 and ASTM D 975. Emission values cannot

be guaranteed with the other fuels described

in this circular.

4.2.2 Winter fuel

At low ambient temperatures paraffin

discharges can lead to blockages in the fuel

system and cause operating faults. Use winter

fuel at outside temperatures below 0 °C (to

-20 °C) (generally offered by petrol stations

in good time before the cold season begins).

z Paraffin should be added at temperatures

below -20 °C. The mixing ratios required

are as per the diagram on the right.

z Special diesel fuels can be used for arctic

climates to -44 °C.

Íf it is necessary to use summer diesel fuel

under 0 °C, paraffin can also be added by up

to 30% as per the diagram on the right.

Only carry out mixing in the tank!

First pour in the necessary

amount of paraffin, then the

diesel fuel.

Diagram key:

I Summer diesel fuel

I I Winter diesel fuel

A Outside temperature

B Paraffin mixing proportion

© 43 923 0

For the engines TCD 2013 4V

and fuel according to ASTM D

975 1-D/2-D, adding paraffin

is not permissible.

Generally, sufficient resistance to cold can

also be achieved by adding a flow ameliorant.

For questions regarding this please contact

your DEUTZ partner.

Page 40

4

© 2005

.

4.3 Coolant Operating substances

Contact your local waterworks for information

regarding the water quality.

4.3.2 Coolant preparation

Particular attention should be paid to preparing

and inspecting the coolant in liquid-cooled

engines, as otherwise corrosion, cavitation

and freezing damages can occur on the

engine.

Preparation of the coolant involves mixing a

cooling system preservative to the cooling

water.

The cooling system must be monitored

regularly, see 5.1. This includes checking the

concentration of the cooling system

preservative, as well as inspecting the coolant

level.

The inspection of the concentration of cooling

system preservative can be carried out with

standard testing devices. (Example: gefo

glycomat R ).

Mixing cooling system

preservatives of a nitrite

base with substances of an

amine basis forms harmful

nitrosamines.

4.3.3 Cooling system preservative

Using the cooling system preservative, order

no. 01011490/ 01016416/12211500 (nitrite,

amine and phosphate free, available in 5/ 20/

210 litre containers), provides effective

protection against corrosion, cavitation and

freezing.

The cooling system preservative in the coolant

must not fall below or exceed the following

concentrations:

Cooling system Water Cold protection

preservative proportion to

proportion

min. 35 % 65% -22 °C

40 % 60% -28 °C

max. 45 % 55% -35 °C

For filling amounts see the table overleaf in

combination with the information in chapter

9.1.

The use of other cooling system

preservatives, e.g. chemical corrosion

preservatives, is possible in exceptional

cases, consult DEUTZ Service.

Order the cooling system preservative from:

DEUTZ AG

4.3.1 Water quality for coolant

The following values may not be exceeded or

fallen short of.

A test case can be requested from DEUTZ

Service under the order no. 1213 0382 for

checking your water quality.

Analysis values min. max.

ph value at 20 °C 6.5 8.5

Chloride ion content[mg/dm3] - 100

Sulphate ion content[mg/dm3] - 100

Total hardness [°dGH] 3 20

* Carbonate hardness proportion of total

hardness min 3 dGH

Cooling system preservatives

must be disposed of in an

environmentally friendly manner.

Page 41

© 2005

5

Maintenance

5.1 Maintenance schedule

5.2 Maintenance diagram

5.3 Maintenance work carried out

Page 42

© 2005

5

Activity

Maintenance 5.1 Maintenance schedule

check= z set= clean=L renew=

Industrial engines

The engine maintenance times given are maximum permissible job

times. Depending on the usage circumstances, shorter maintenance

times may be necessary. Observe the instruction manual of the

equipment manufacturer.

# Maintenance only to be carried out by authorised service personnel

Section

⇓ check 2x daily before or during the 1st trial run, during the running-in phase or

when commissioning new and overhauled engines.

⇓ every 10 oh or daily

in operating hours (oh) every year(s)

E10 E20 E30 E40 E45 E50 E60 E70

500 1,000 1,500 3,000 6,000 12,000 1 2

EGR* exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

zz

z

z

1)

zz

zzz

zz

zz L

L

z

L

z

z

zz

zz

z

zz

zz

zz

Lube oil level, if necessary re-fill 6.1.2

Lube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

6.1.1/ 6.1.2

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

#

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

(if available, maintenance as per maintenance display)

6.4.3 /6.4.4

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR (option) Check cap and adjustment mechanism for clearance, renew if necessary.

Cooler EGR(option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system 3.3

#

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1/6.5.3

Crankcase pressure bleed valve (option)

#

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

General overhaul

#

Page 43

© 2005

5

Activity

5.1 Maintenance schedule Maintenance

check= z set= clean= L renew=

max. permissible job times in operating hours (oh) every

⇓

check 2x daily before or during the 1st trial run, during the running-in phase or

when commissioning new and overhauled engines.

⇓ every 10 oh or daily

in operating hours (oh) every

E10 E30 E40 E70

500 6.000 12.000 1 2

Enhancements or modifications for engines with

EPA acceptance

The engine maintenance times given are maximum

permissible job times. Depending on the usage

circumstances, shorter maintenance times may be

necessary. Observe the instruction manual of the

equipment manufacturer. # Maintenance only to be

carried out by authorised service personnel

Section

Charge air cooler (drain lube oil/condensation)

#

Charge air cooler inlet surface (clean if necessary) #

Crankcase pressure bleed valve (option)

#

z L

z L

L

Page 44

Maintenance 5.1 Maintenance schedule

Lube oil level, if necessary re-fill 6.1.2

Lube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

6.1.1/ 6.1.2

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

#

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

(if available, maintenance as per maintenance display)

6.4.3 /6.4.4

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR (option) Check cap and adjustment mechanism for clearance, renew if necessary.

Cooler EGR(option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system & 3.3

#

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1/6.5.3

Crankcase pressure bleed valve (option)

#

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

General overhaul

#

Service Yearly op. Average

group performance

Drive

speed

km

approx.km/h

I <30 000 20

II >30 to 100 000 40

III >100 000 60

Vehicle engines

Service group I <30 000km 20

approx.km/h

The engine maintenance times given are maximum permissible

job times. Depending on the usage circumstances, shorter

maintenance times may be necessary. Observe the instruction

manual of the equipment manufacturer.

#

Maintenance only

to be carried out by authorised service personnel

Section

EGR* Exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

⇓ check 2x daily before or during the 1st trial run, during the running in phase or when commissioning new and overhauled engines.

⇓ every 200 km or daily

OPERATIONAL PERFORMANCE IN (km) ye a r(s)

E10 E20 E30 E40 E45 E50 E60 E70

Activity

check= z set= clean= L renew=

5,000

10.000

20.000

30.000

120..000

240.0 0 0

1

2

zz

z

z

1)

zz

zz z

zz

zz L

L

z

L

z

z

zz

zz

z

zz

zz

zz

5

Page 45

5.1 Maintenance schedule Maintenance

Lube oil level, if necessary re-fill 6.1.2

L

ube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

6.1.1/ 6.1.2

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

#

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

(if available, maintenance as per maintenance display)

6.4.3 /6.4.4

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR (option) Check cap and adjustment mechanism for clearance, renew if necessary.

Cooler EGR(option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system & 3.3

#

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1/6.5.3

Crankcase pressure bleed valve (option)

#

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

General overhaul

#

check= zset= clean= L renew=

Vehicle engines

Service group Il 100 000km 40approx.km/h

The engine maintenance times given are maximum permissible

job times. Depending on the usage circumstances, shorter

maintenance times may be necessary. Observe the instruction

manual of the equipment manufacturer. # Maintenance only to be

carried out by authorised service personnel

Section

Activity

EGR* Exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

20,000

40,000

50,000

240,000

480,000

1

2

⇓ check 2x daily before or during the 1st trial run, during the runningin phase or when commissioning new and overhauled engines.

⇓ every 200 km or daily

OPERATIONAL PERFORMANCE IN (km) ye a r(s)

E10 E20 E30 E40 E40 E50 E60 E70

Service Yearly op. Average

gro up performance

Drive

speed

km

approx.km/h

I <30 000 20

II >30 to 100 000 40

III >100 000 60

zz

z

z

1)

zz

zz z

zz

zz L

L

z

L

z

z

zz

zz

z

zz

zz

zz

5

Page 46

© 2005

5

Maintenance

5.1 Maintenance schedule

check= zset= clean= L renew=

ServiceYearly op. Average

gro up performance

Drive

speed

km

approx.km/h

I <30 000 20

II >30 to 100 000 40

III >100 000 60

Vehicle engines

Service group Ill >100 000 km 60approx.km/h

The engine maintenance times given are maximum

permissible job times. Depending on the usage circumstances,

shorter maintenance times may be necessary. Observe the

instruction manual of the equipment manufacturer.

# Maintenance only to be carried out by authorised service personnel

Section

30.000

60.000

90.000

120.000

360.000

1000.000

1

2

EGR* Exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

Activity

⇓

check 2x daily before or during the 1st trial run, during the running-in phase

or when commissioning new and overhauled engines

⇓ every 200 km or daily

OPERATIONAL PERFORMANCE IN (km) every

Service group III year(s)

E10 E20 E30 E40 E45 E50 E60 E70

zz

z

z

1)

zz

zz z

zz

zz L

L

z

L

z

z

zz

zz

z

zz

zz

zz

Lube oil level, if necessary re-fill 6.1.2

L

ube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

6.1.1/ 6.1.2

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

#

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

(if available, maintenance as per maintenance display)

6.4.3/6.4.4

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR (option) Check cap and adjustment mechanism for clearance, renew if necessary.

Cooler EGR(option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system & 3.3

#

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1

Crankcase pressure bleed valve (option)

#

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

General overhaul

#

Page 47

5

© 2005

Maintenance 5.1 Maintenance schedule

5.1.1 Standard maintenance schedule

Intervals Deutz maintenance and Activity Execution by:

at/after service schedules

50 oh E 10 after commissioning and E 50-E 70 autho rised specialists

daily E 20 daily inspection round the user / authorised specialists

500 o h E 30 inspection authorised specialists

1000 oh E 40 intermediate overhaul authorised specialists

1500 oh E 45 extended intermediate overhaul authorised specialists

3 000 oh E 60 partial overhaul authorised specialists

6000 oh E 60 partial overhaul authorised specialists

10 000 oh (2012) E 70 overhaul authorised specialists

13 000 oh (2013) E 70 overhaul authorised specialists

*) approximate value, depends on the type of engine application and/or regular engine maintenance.

Please contact your responsible DEUTZ Service partner.

Page 48

5

© 2005

All maintenance work should

only be carried out when the

engine is not running.

The maintenance diagram shown on this

page is supplied with every engine in selfadhesive form. It should be stuck onto a well

visible location on the engine or equipment.

Check that this is the case!

If not, request a replacement from your engine

or equipment supplier!

The maintenance schedule is decisive for

standard maintenance, see 5.1.

5.2 Maintenance diagram Maintenance

Page 49

Date

Op. hrs.

Signature / stamp Op. hrs. Date

Signature / stamp

5

© 2005

-

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

50-150

*

125

375

625

875

1125

1375

1625

1875

2115

2375

* after commissioning new and overhauled engines

The maintenance work carried out methodically can be recorded in the table and confirmed.

5.3 Maintenance work carried out Maintenance

Page 50

Op. hrs.

Date

Date Signature / stamp

Op. hrs. Signature / stamp

5

© 2005

Maintenance 5.3 Maintenance work carried out

2875

3125

3375

3625

3875

4125

4375

4625

4875

5125

5375

5625

The maintenance work carried out methodically can be recorded in the table and confirmed.

3000

3250

3500

3750

4000

4250

4500

4750

5000

5250

5500

5750

Page 51

Date

Op. hrs.

Signature / stamp Op. hrs. Date

Signature / stamp

5

© 2005

The maintenance work carried out methodically can be recorded in the table and confirmed.

5875

6125

6375

6625

6875

7125

7375

7625

7825

8125

8375

8625

6000

6250

6500

6750

7000

7250

7500

7750

8000

8250

8500

8750

5.3 Maintenance work carried out Maintenance

Page 52

Op. hrs.

Date

Date Signature / stamp

Op. hrs. Signature / stamp

5

© 2005

Maintenance 5.3 Maintenance work carried out

8875

9125

9375

9625

9875

10125

10375

10625

10875

10125

10375

10625

9000

9250

9500

9750

10000

10250

10500

10750

10000

10250

10500

10750

The maintenance work carried out methodically can be recorded in the table and confirmed.

Page 53

6

© 2005

Care and maintenance work

6.1 Lubrication system

6.2Fuel system

6.3Cooling system

6.4Combustion air filter

6.5 Belt drive

6.6Setting work

6.7Add-on parts

Page 54

6

© 2005

Care and maintenance work 6.1Lubrication system

6.1.1 Oil change intervals

z The oil change times depend on the engine

application and the quality of the lube oil.

z If the oil change times are not reached

within a year, the oil change should be

carried out at least 1x yearly.

z The following conditions apply for the table

– Sulphur content max. 0.5 % of weight for

diesel fuel.

– Constant ambient temperature ³ -10 °C

(+14 °F)

z For fuels

– with sulphur content > 0.5 to 1%

or

– Constant ambient temperatures < -10 °C

(+14 °F)

or

– with bio-diesel fuels according to DIN

51606- FAME the oil change times

should be halved.

z For fuels with a sulphur content higher

than 1% ask your responsible

service representative.

Carry out oil changes on warm engine when the

engine is not running (lube oil temperature < 80 °C).

z If the lube oil change intervals are planned

in terms of operating hours, the lube oil

change intervals for installed engines

6.1.1.1 apply.

Page 55

6

© 2005

6.1 Lubrication system Care and maintenance work

6.1.1.1 Lube oil change intervals for installed engines

Lube oil quality

Deutz lube oil quality class DQC I-02 DQC II-05 DQC III-05 DQC iV-05

ACEA specificat ion E2-96 E3-96/E5-02/E07-04 E4-99/E6-04 E4-99/E6-04

see 6.1.1.3 only fully synthetic

API specification CF/CF-4 CG-4/CH-4/ CI-4 - worldwide specification - DHD-1 - special DEUTZ release list - - see chap. 4.1.2.1 Standard lubricant code designation EO... EO...C - for building machines and building vehicles EO...A, EO...B

Engine Engine version Lube oil change intervals in oh

series

TCD All engines with:

2012 Crankcase ventilation:

L04/06 4V open - 500 500 500

closed - - 500 500

2013 Crankcase ventilation:

L04/06 4V open - 500 500 500

closed - - 500 500

Page 56

6

© 2005

average driving speed km/h

Care and maintenance work 6.1 Lubrication system

6.1.1.2 Lube oil change intervals for vehicle engines

Lube oil quality

Deutz lube oil quality class DQC I-02 DQC II-05 DQC III-05 DQC iV-05

ACEA specificat ion E2-96 E3-96/E5-02/E07-04 E4-99/E6-04 E4-99/E6-04

see 6.1.1.3 only fully

synthetic

API specification CF/CF-4 CG-4/CH-4/ CI-4 - worldwide specification - DHD-1 - special DEUTZ release list - - see chap. 4.1.2.1 -

Application

Engine version Crankcase

TCD 2012/2013 L04/ 06 4V ventilation Lube oil change intervals in km

Building site

TCD

2012 4V open - 20 000 20 000 20 000

closed - - 20 000 20 000

vehicles /

TCD 2013 L06 4V

city buses/ Coach bus closed - 30 000 50 000 50 000

25 Inter city bus closed - 20 000 30 000 30 000

City busbus closed - 15 000 20 000 20 000

City TCD 2013 L04 4V closed - 25 000 45 000 45 000

transport TCD 2013 L06 4V closed - 30 000 50 000 50 000

TCD

2012 4V open - 30 000 30 000 30 000

closed - - 30 000 30 000

Local transport 4 0 TCD 2013 L04 4V closed - 40 000 60 000 60 000

TCD 2013 L06 4V closed - 50 000 75 000 75 000

TCD

2012 4V open - 40 000 40 000 40 000

Long distance

60 closed - - 40 000 40 000

transport

TCD 2013 L04 4V closed - 60 000 80 000 80 000

TCD 2013 L06 4V closed - 75 000 100 000 100 000

Page 57

6

© 2005

© 25 729 0

© 26 02 2 0

© 26 02 3 0

6.1 Lubrication system Care and maintenance work

6.1.2 Checking oil level / changing

engine oil

6.1.2.1Checking oil level

z Position the engine or vehicle so as to be level.

z – Engine warm:

Switch off the engine, wait for 5 minutes and

check oil level.

z – Engine cold:

Check oil level.

z Extract oil dipstick.

z Wipe with a fibre-free, clean cloth.

z Insert until it stops and extract again.

z Check oil level and re-fill to „MAX“ if necessary.

– If the oil level lies just above the „MIN“-

line marking, re-filling is necessary.

6.1.2.2 Changing engine oil

z Warm up engine.

z Position the engine or vehicle so as to be level.

– Lube oil temperature approx. 80 °C.

z Switch off engine.

z Position oil drip cup under the engine.

z Unscrew oil drain screw.

z Drain off oil.

z Screw in oil drain screw with new sealing ring

and tighten. (For tightening torque

see 9.2).

z Pour in lube oil.

– For quality / viscosity data see 4.1.

– For filling quantities, see 9.1.

z Check oil level, see 6.1.2.1.

Caution when draining

hot oil: danger of scalding!

Collect the used oil, do not allow to

seep into floor!

Dispose of according to instructions!

The oil level may not fall short of the „MIN“ line

marking.

Page 58

6

© 2005

© 25 882 0

© 25 881 0

© 25 880 0

Care and maintenance work 6.1 Lubrication system

6.1.3 Changing oil filter insert

z When anti-rotation lock is installed:

Loosen clamping screws and remove tightening clamps from below.

z Loosen lube oil filter cartridge with stan-

dard tool and unscrew.

z Collect any oil which may run out.

z Clean the sealing surface of the filter sup-

port for any possible dirt.

z Lightly oil the rubber seal of the new lube

oil cartridge.

z Screw on the cartridge by hand until the

seal makes contact.

Careful with hot oil:

danger of scalding!

z Tighten lube oil filter cartridge three quarters

of a turn (approx. 10 Nm).

z If there is an anti-rotation lock:

Position the tightening clamps and tighten

with clamping screws.

z Check oil level, see 6.1.2.

z Check oil pressure, see 3.3.1.

z Check the seal of the lube oil filter cartridge

for tightness.

Page 59

6

© 2005

6.1 Lubrication system Care and maintenance work

6.1.4 Cleaning / changing oil filter

(cup)

© 30 0 74 1

z Switch off engine.

z Loosen lube oil filter cover 1 with two or three

turns and wait for 30 seconds.

z Unscrew lube oil filter cover 1 with paper filter

cartridge 5 in anti-clockwise direction.

z Carefully loosen paper filter cartridge 5 from

the guide 4, which is inserted in the housing 3,

from above.

z Collect any lube oil which may run out.

z Crease the paper filter cartridge 5 in the

collection vessel slightly at the side until the

cartridge is released from the clip 6.

z Clean the sealing surface of the filter support

and the lube oil filter cover 1 as well as the guide

4 of any dirt there may be

Careful with hot oil:

Danger of scalding

Dispose of used oil in an

environmentally friendly way.

© 43 937 0 © 300 74 0

z Change the round sealing ring 2 and lightly oil.

z Press new paper filter cartridge 5 into the clip

6 and insert carefully in the guide 4 together.

z Screw the lube oil filter cover 1 tight in clock-

wise direction (25 Nm).

z Start the engine.

z Check lube oil filter assembly for leaks.

z Check engine oil level and top up if necessary.

Page 60

6

© 2005

© 25 882 0

© 25 880 0

© 25 881 0

Care and maintenance work 6.2 Fuel system

6.2.1 Changing fuel filter

z Screw on the cartridge by hand until the seal

makes contact.

z Tighten the fuel filter cartridge with one more

half turn.

z Open fuel stopcock.

z Check for tightness.

Only work on the fuel system

when the engine is switched off.

Wait at least 30 seconds. No open

fire! Do not smoke!

Pay attention to cleanliness as the

fuel system (Rail) is very sensitive!!!

It is necessary to bleed the fuel

system.

z Close fuel stopcock.

z Loosen fuel filter cartridge with standard tool

and unscrew.

z Collect any fuel which may run out.

z Clean the sealing surface of the filter support

for any dirt there may be.

z Lightly oil the rubber seal of the new DEUTZ

original fuel filter cartridge or wet with diesel

fuel.

Page 61

6

© 2005

6.2 Fuel system Care and maintenance work

© 300 74 0

Only work on the fuel system

when the engine is switched off

(at least 30 seconds).

No open fire! Do not smoke!

Dispose of used fuel in an

environmentally friendly

manner.

6.2.2 Cleaning / changing fuel filter

(cup)

z Change the rubber seal 2 and lightly oil.

z Carefully place new paper filter cartridge 3 in

the guide 4.

z Tighten the fuel filter cover 1 in clockwise

direction (25 Nm).

z Start engine.

z Check fuel filter attachment for tightness.

z Switch off engine

z Loosen fuel filter cover 1 and unscrew in anti-

clockwise direction.

z Carefully loosen paper filter cartridge 3 from

the guide 4 from above.

z Collect any fuel which may run out.

z Change paper filter cartridge 3.

z Clean the sealing surface of the filter support

and the fuel filter cover 1 as well as the guide4

of any dirt there may be.

Page 62

6

© 2005

© 43 848 1

6.2.3 Changing / bleeding

fuel pre-filter, filter insert

z Clean any dirt from the sealing surface of the

new filter cartridge (5) and the reverse side

of the filter head

z Wet the sealing surfaces of the filter cartridge

(5) slightly with fuel and screw back onto the

filter head in clockwise direction (17-18 Nm)

z Open the fuel stopcock and bleed the system

(see „Bleeding fuel system“).

z Dispose of collected fuel and old filter cartridge

(5) properly.

Bleeding fuel system:

z Unlock the bayonet plug of the fuel hand

pump (3) by pressing and turning

anti-clockwise at the same time. The pump

plunger is now pushed out through the spring.

Turn the shutdown lever of the thermostat valve (4) by approx. 45° in

clockwise direction until it is felt to

engage.

z Pump until a very strong resistance is felt and

pumping becomes very slow.

z Now pump a few more times.

(The return line must be filled).

z Turn the shutdown lever of the thermostat

valve (4) by approx. 45° in anti-clockwise

direction until it is felt to engage.

z Lock the bayonet plug of the fuel hand pump

(3) by pressing and turning clockwise at the

same time.

Filter change:

z Close fuel stopcock (for high tanks).

z Position fuel collecting vessel beneath fuel pre-filter.

z Loosen drain cock (7) and drain water + fuel

completely.

z Unscrew filter cartridge (5) together with

water collecting vessel (8) in anti-clockwise

direction and remove.

z Loosen water collecting vessel (8) from old

filter cartridge (5) in anti-clockwise direction

and remove.

z Empty remaining fuel into the fuel collecting

vessel and clean water collecting vessel (8).

z Screw water collecting vessel (8) onto the

new filter cartridge (5) in clockwise direction.

1 Fuel supply to pump

2 Fuel return from control block FCU

(

Fuel Control Unit)

3 Fuel hand pump with bayonet plug for

locking and unlocking

4 Thermostat valve with shutdown lever

5 Filter cartridge

6 Connection facility for electrical

water level sensor

7 Drain cock

8 Water collecting vessel (bowl)

9 Fuel inlet from fuel tank

10 Fuel return to fuel tank

Care and maintenance work 6.2 Fuel system

Only work on the fuel system

when the engine is switched off.

No open fire! Do not smoke!

Dispose of used fuel in an

environmentally friendly manner.

Page 63

6

© 2005

6.3 Cooling system Care and maintenance work

6.3.1 Cleaning intervals

z The cooling system soiling depends on the

type of engine application.

z The risk of soiling is increased by oil and fuel

residues on the engine. Therefore pay particular

attention to tightness when operating under

high dust exposure.

z Increased soiling occurs, for example, during:

- Building site application from high dust content

of air.

- Harvesting application from high proportion of

chaff and chopped straw, for example, in the

area of the work machine.

z Due to the various application conditions, the

cleaning intervals must be defined according

to each case. Therefore, the cleaning intervals

given in the table below can be used as

guidelines.

Checking or cleaning intervals

Guideline oh

Engine application

2000 Ships, electronic units in

enclosed spaces, pumps.

1000 Vehicles on paved

roads

500 Tractors, fork lift trucks, drivable

electronic units.

250 Vehicles on building sites and

unpaved roads, building

machines, compressors, mining

equipment.

125 Agricultural machinery, tractors

with harvesting application.

Page 64

6

© 2005

Care and maintenance work 6.3 Cooling system

6.3.2 Cleaning cooling system

Cleaning with compressed air

- Blast out the engine wih compressed air. Do not

damage any components.

- Rinse out the loosened dirt with a water jet.

Cleaning with cold cleaner

- Spray the engine with standard cold cleaner

and leave to work for approx. 10 minutes.

- Spray the engine clean with an acute water jet

(do not spray the water jet directly at sensitive

engine parts, e.g. generator, cabling, electronic

components, fan drive).

©39 001 0

© 39 002 0

© 38 999 0

Page 65

6

© 2005

Caution when draining hot coolant:

danger of scalding! Collect coolant

when draining off.

Dispose of according to

instructions!

6.3.3 Emptying / filling / bleeding

cooling system

© 39 851 0

Emptying cooling system:

z Position collecting dish underneath locking

screw 5 and coolant supply 4.

z Remove locking screw 5 on the crankcase

and pull off hose on 4.

z Loosen bleed screw 2.

z Drain off coolant.

z Re-tighten locking screw 5 and hose on 4 and

bleed screw 2.

z If locking screw 3 is not accessible,

emptying may be carried out on the engine

oil cooler (coolant channel).

Filling / bleeding cooling system:

z Open cooler cover.

z Loosen bleed screw item 2.

z Pour in coolant until the maximum mark or the filling

limit (system heating valve must be open, if

present).

z Tighten bleed screw item 2 + locking screw

item 5.

zClose cooler cover.

zStart engine and warm up until the thermostat opens.

zSwitch off engine.

zCheck the coolant level with the engine cold and

re-fill if necessary.

zClose cooler cover item 1.

Bleeding

zThe cooling system, which was built according

to our installation guides, is bled automatically

after filling.

6.3 Cooling system Care and maintenance work

Page 66

6

© 2005

© 25 885 1

Care and maintenance work 6.4Combustion air filter

6.4.1 Cleaning intervals

z The soiling of the combustion air filter

depends on the dust content of the air and

the selected filter size. If a high dust

exposure is to be expected, a cyclone

separator can be connected to the

combustion air filter.

z The cleaning intervals cannot be generally

defined. They must be defined depending

on each case.

z If dry air filters are used, cleaning should only

be carried out according to the maintenance

display or maintenance switch.

z Filter maintenance is required when on the:

- Maintenance display

the red service field 1 is fully

visible when the engine is not running.

- Maintenance switch

the yellow warning light comes on when

the engine is running.

z After completion of the maintenance work

push the reset button on the maintenance

display. The maintenance display is ready

for operation again.

Page 67

6

© 2005

© 25 886 0

6.4 Combustion air filter Care and maintenance work

6.4.2 Emptying cyclone preseparator

z Loosen wing nut 1 and lift housing cover 2.

z Remove the dust container 3 from the base of

the cyclone 4 and empty. Clean foliage, straw

and the like from the cylone base.

z Place the dust container 3 on the base 4 and

tighten the housing cover 2 with wing nut 1.

Never fill the dust container with oil, replace

damaged containers!

Page 68

6

© 2005

© 25 888 2

© 25 889 1

6.4.3 Dry air filter

Dust discharge valve

Filter cartridge

Care and maintenance work 6.4 Combustion air filter

z Empty the dust discharge valve 1 by squeezing

the discharge slot in the direction of the arrow.

z Clean the discharge slot occasionally.

z Remove any stuck on dust residues by

squeezing the upper area of the valve.

Never clean filter cartridge with

petrol or hot liquids!

z Open clamping bracket 1.

z Remove filter hood 2 and pull out filter cartridge 3.

z Clean filter cartridge, renew after a year at the latest.

z Clean filter cartridge 3.

- Blast out from the inside out with dry

compressed air (max. 5 bar), or

- beat out (only in extreme cases). Do not

damage the cartridge, or

- Wash according to manufacturer’s

specifications.

z Check filter cartridge for damage to the filter

paper (shine light through) and check seals.

Exchange if necessary.

z Renew the safety cartridge 4 after 5 filter

maintenances, after 2 years at the latest

(never clean!).

To do t h is :

- Loosen the hexagonal nut 5 and pull out

the cartridge 4.

- Insert new cartridge, re-mount hexagonal

nut and tighten.

z Insert filter cartridge 3, close hood 2 and

secure clamping bracket 1.

Page 69

6

© 2005

© 39 004 0

© 39 005 0

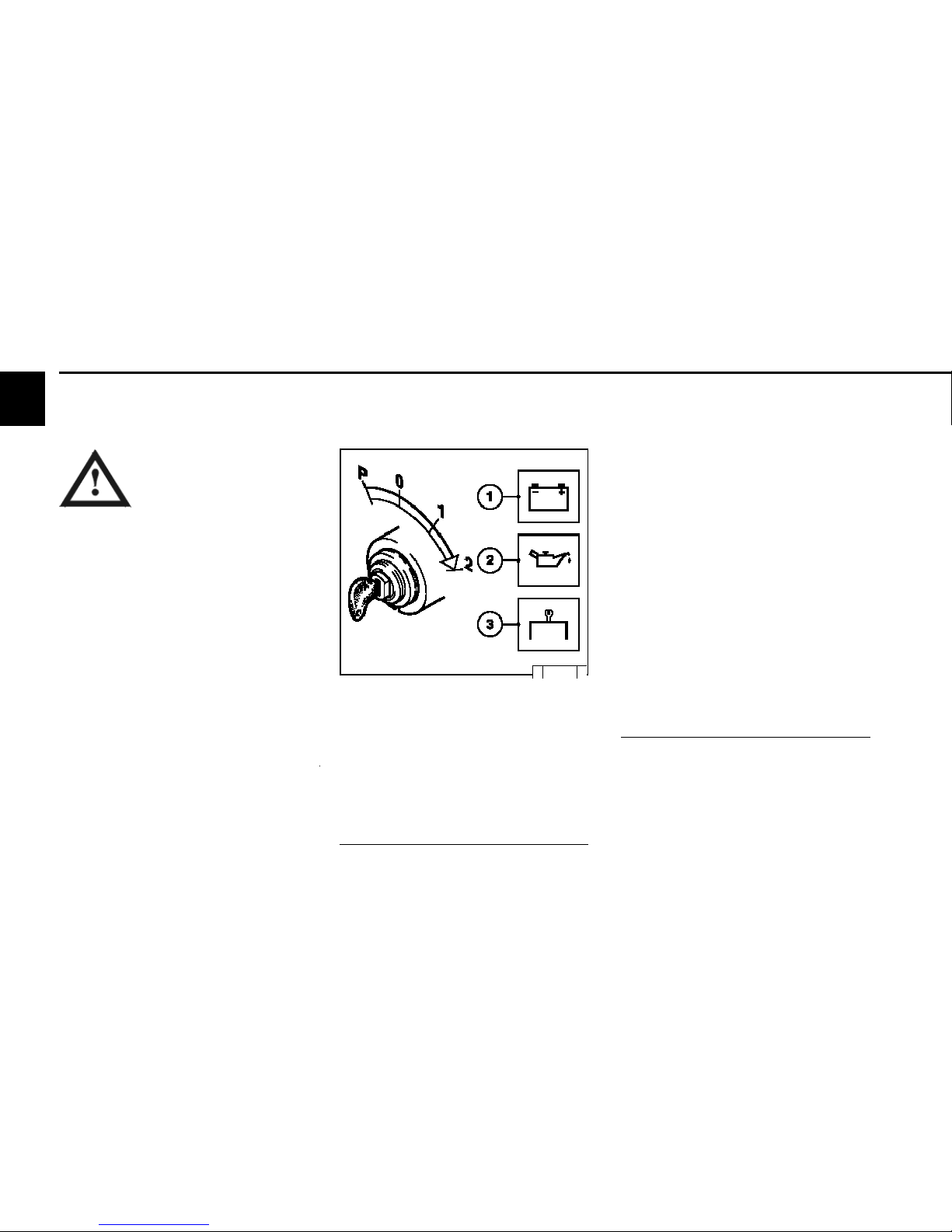

6.5.1 Changing V-belt

V-rib belt

6.5.2 Changing V-belt

V-rib belt

6.5 Belt drive Care and Maintenance work

z Push tension pulley in the direction of the arrow

until V-rib belt is free.

z First remove the V-rib belt from the smallest