Page 1

D&M Holdings lnc.

e

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 5

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E1C E1K EUT

DRA-F107

DRA-F107DAB

AM-FM STEREO RECEIVER

3

3

S0089-1V05DM/DG1007

Page 2

Please heed the points listed below during servicing and inspection.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

CAUTION

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

DRA-F107 / DRA-F107DAB

2

Page 3

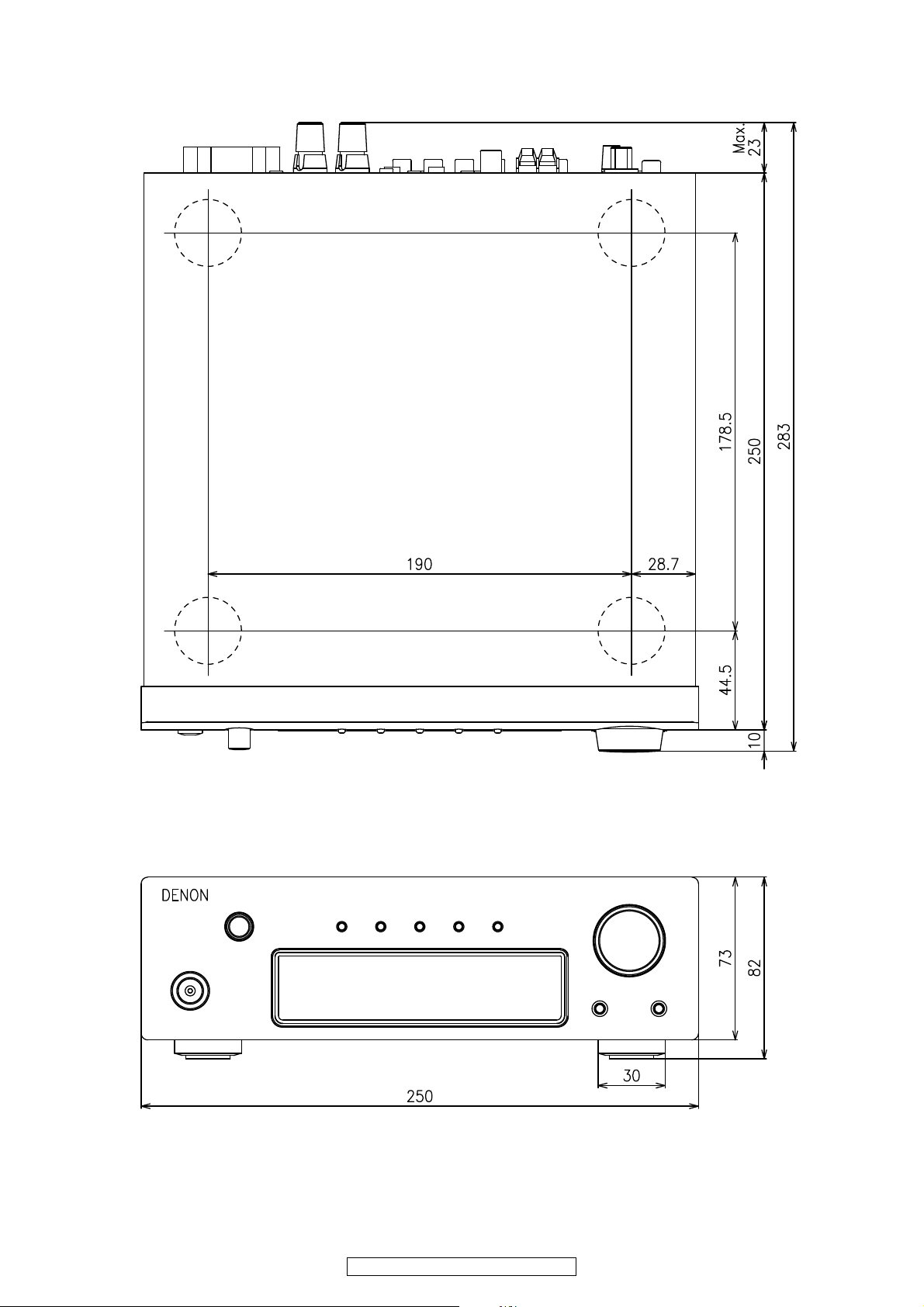

DIMENSION

3

DRA-F107 / DRA-F107DAB

Page 4

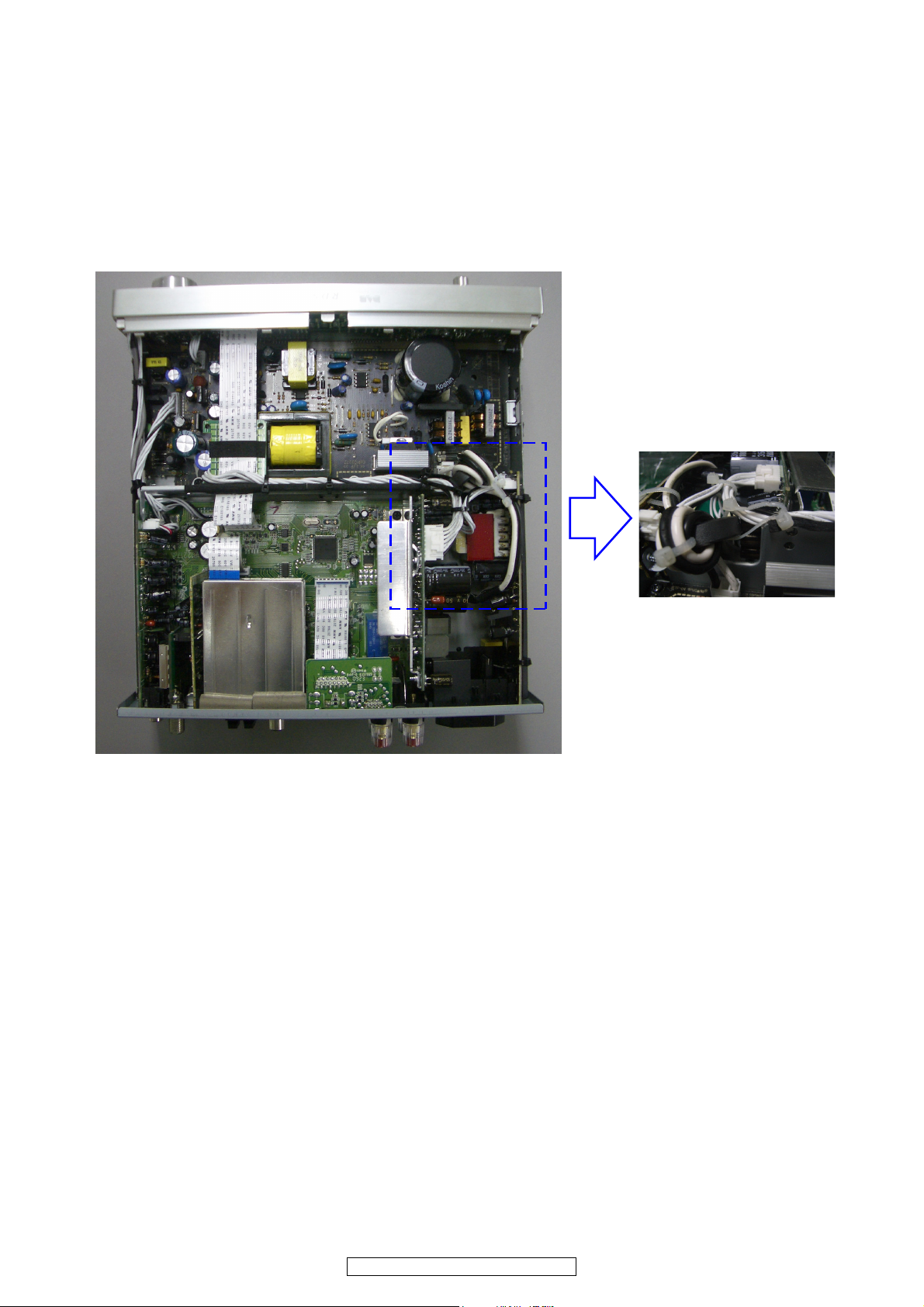

WIRE ARRANGEMENT

Front Panel side

Back Panel side

If wire bundles are untied or moved to perform adjustment or parts replacement etc.,be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

4

DRA-F107 / DRA-F107DAB

Page 5

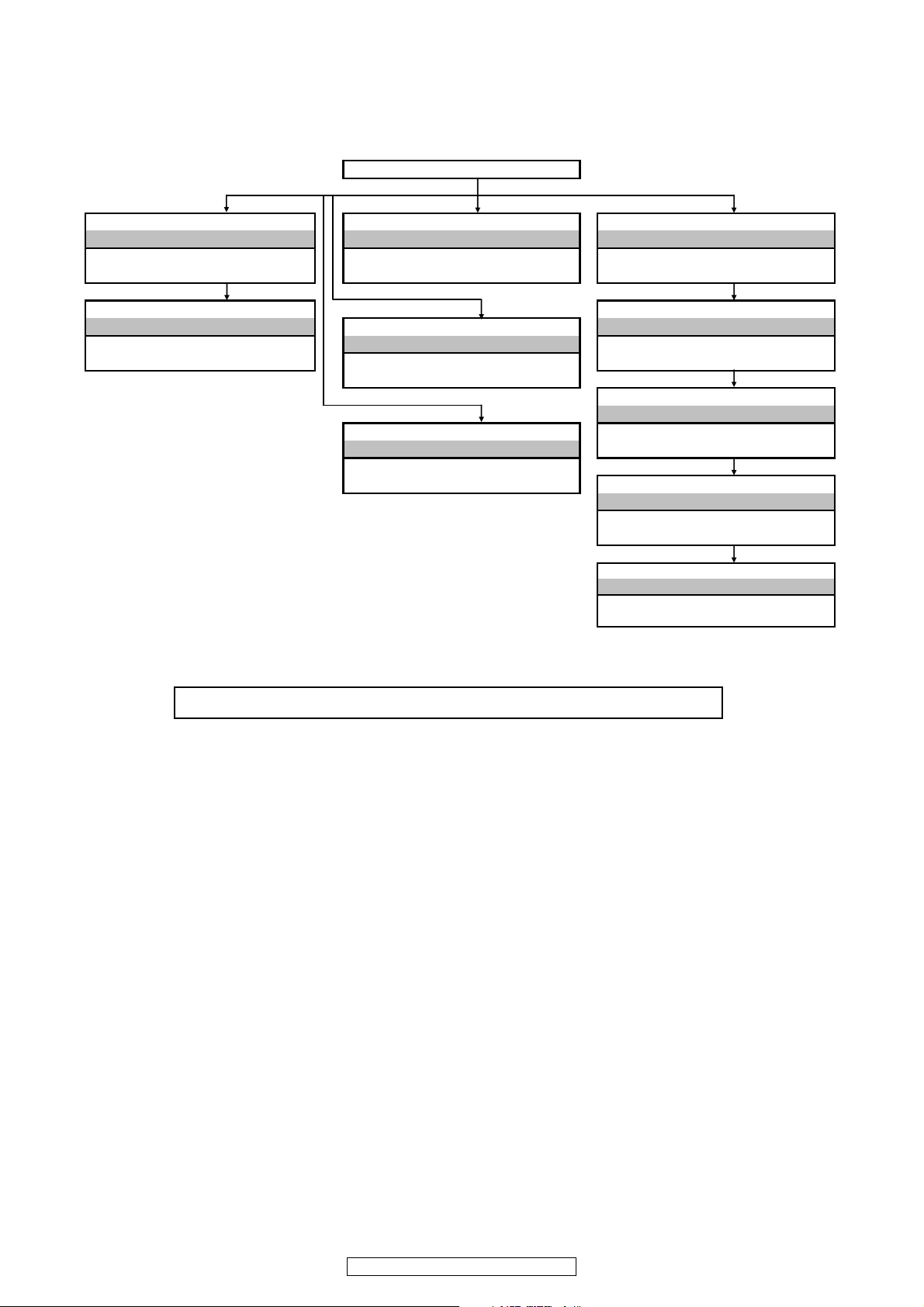

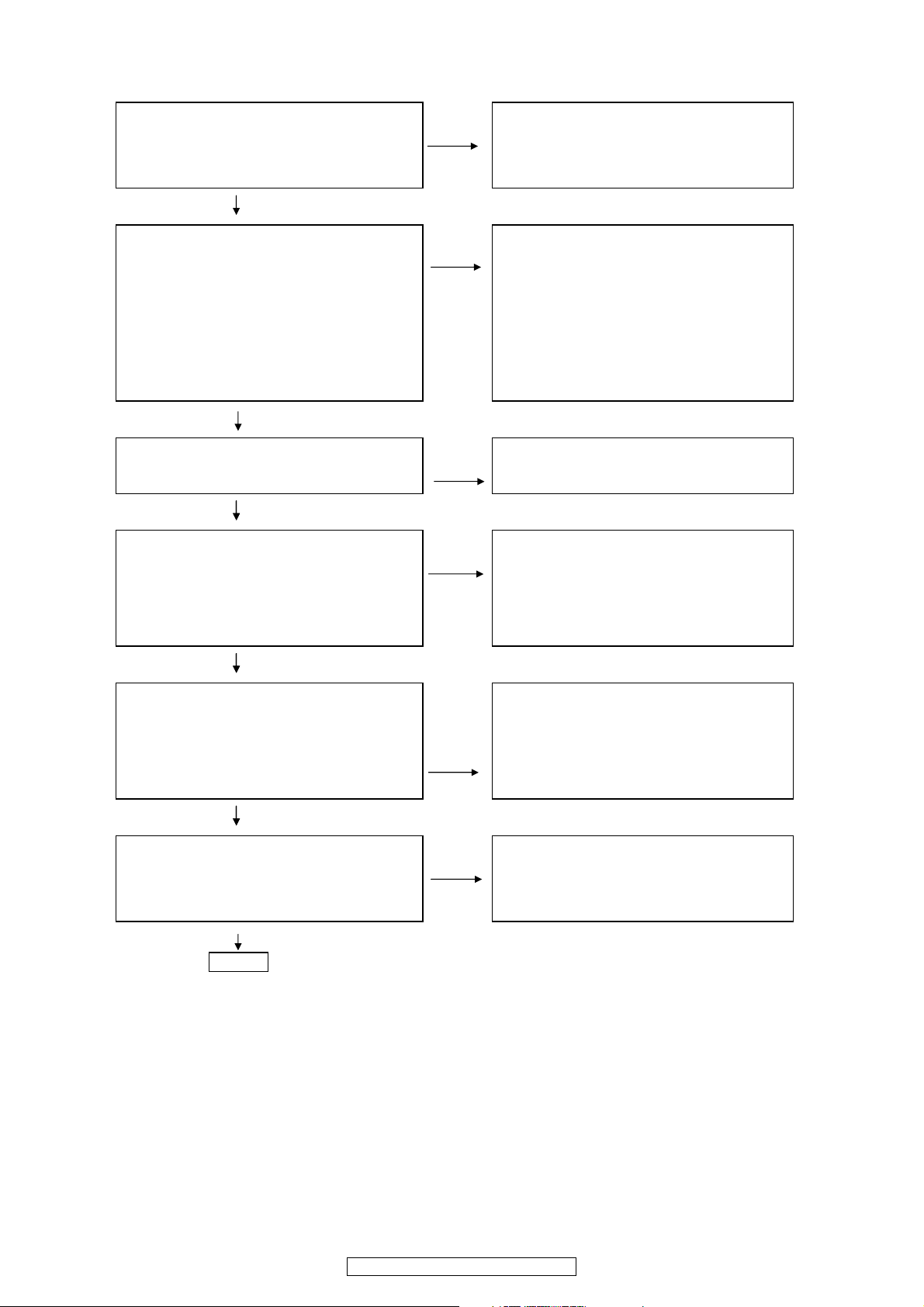

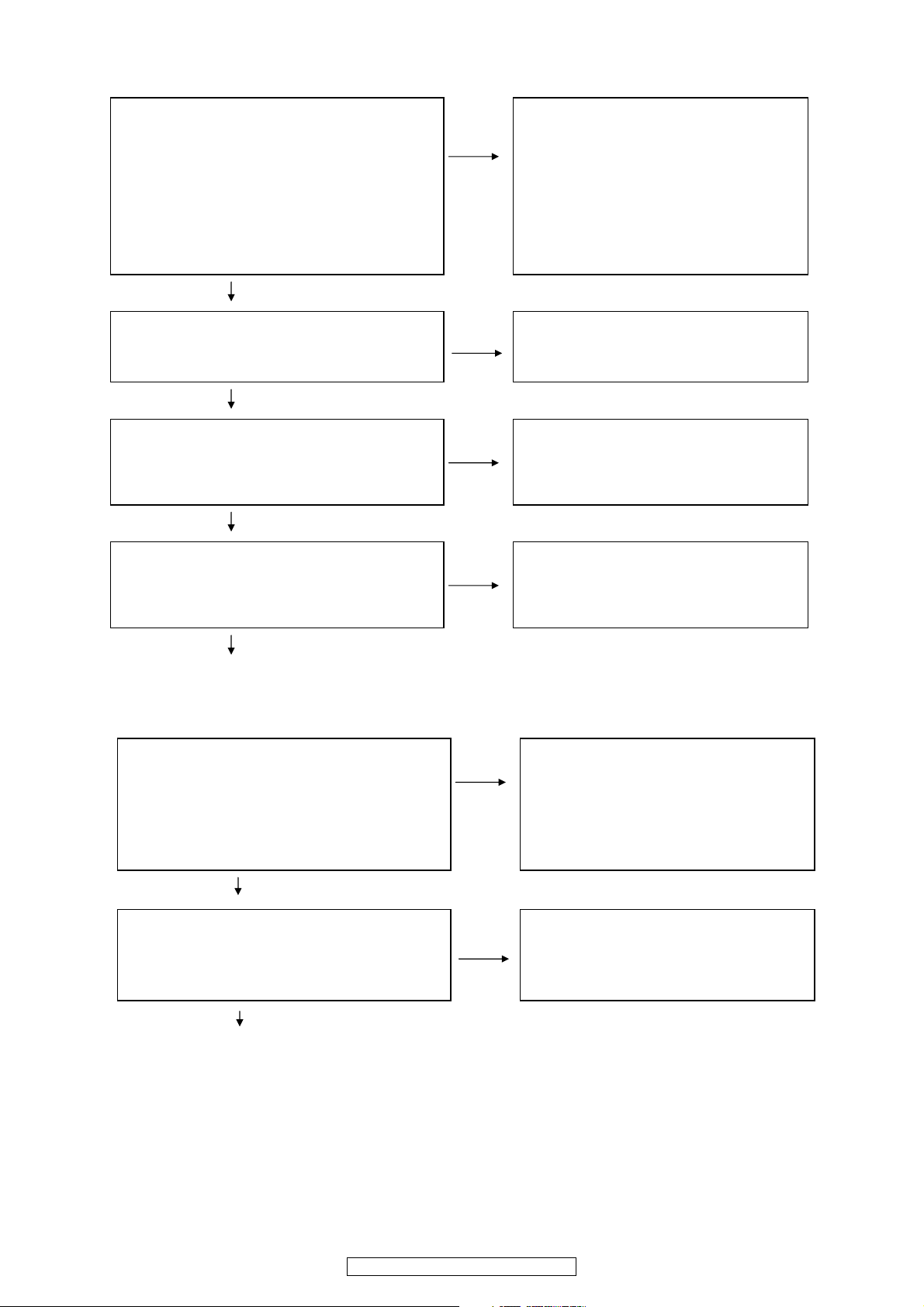

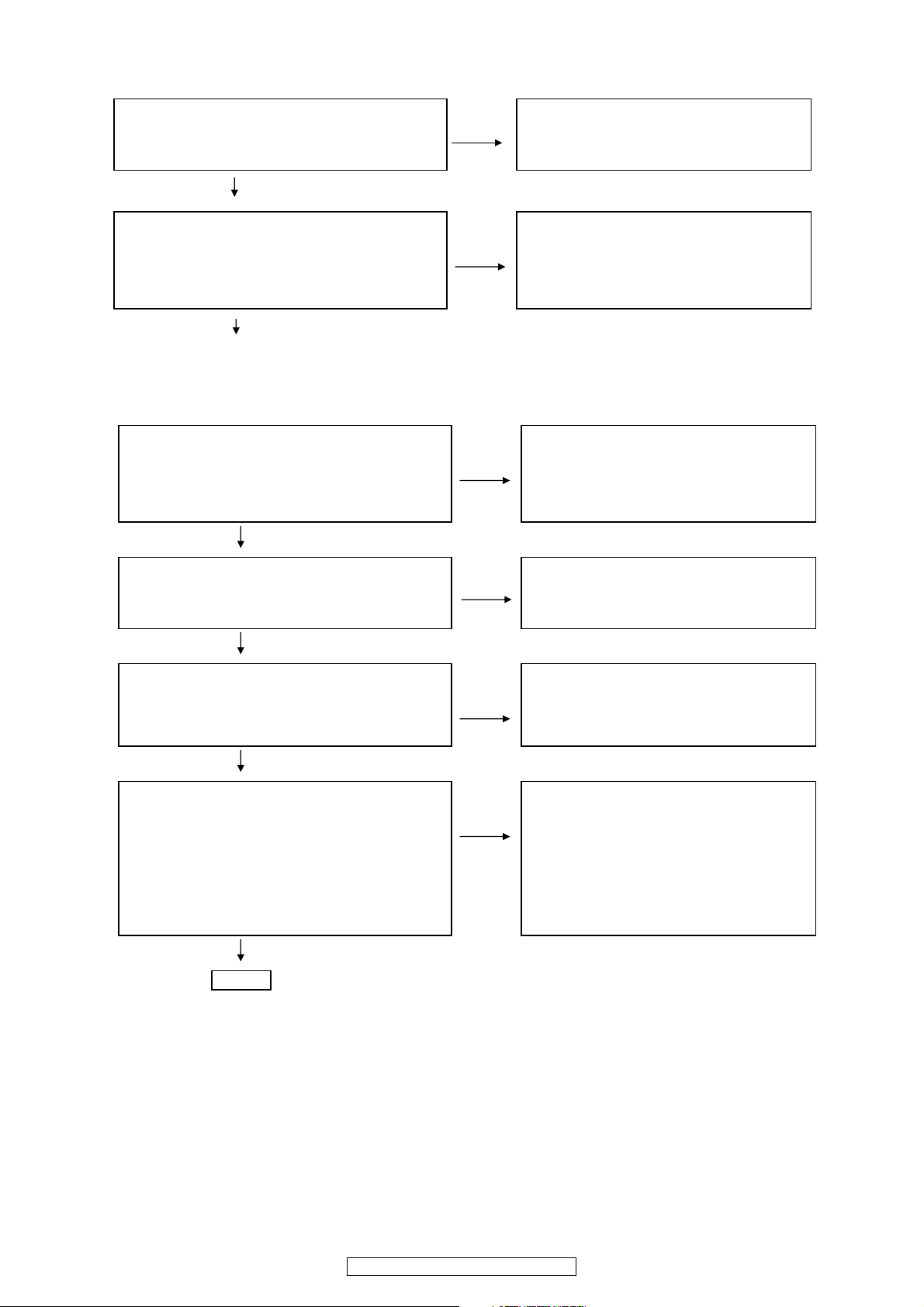

DISASSEMBLY

TOP COVER

FRONT PANEL ASSY AMP PCB REAR PANEL

Refer to "EXPLODED VIEW" Refer to "EXPLODED VIEW" Refer to "EXPLODED VIEW"

FRONT PCB AMP PCB REAR PANEL

(Ref. No. of EXPLODED VIEW : C2) (Ref. No. of EXPLODED VIEW : C7) (Ref. No. of EXPLODED VIEW : M14)

SMPS PCB MAIN PCB

Refer to "EXPLODED VIEW" UPDATE PCB Refer to "EXPLODED VIEW"

SMPS PCB Refer to "EXPLODED VIEW" MAIN PCB

(Ref. No. of EXPLODED VIEW : C3) UPDATE PCB (Ref. No. of EXPLODED VIEW : C8)

(Ref. No. of EXPLODED VIEW : C13)

POWER PCB

Refer to "EXPLODED VIEW"

TUNER PACK POWER PCB

Refer to "EXPLODED VIEW" (Ref. No. of EXPLODED VIEW : C6)

TUNER PACK

(Ref. No. of EXPLODED VIEW : C12)

PHONO PCB

Refer to "EXPLODED VIEW"

PHONO PCB

(Ref. No. of EXPLODED VIEW : C11)

DAB PCB

Refer to "EXPLODED VIEW"

DAB PCB

(Ref. No. of EXPLODED VIEW : C9

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB.

• Disassemble in order of the arrow of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

5

DRA-F107 / DRA-F107DAB

Page 6

CAUTION IN SERVICING

Note:・ All user settings will be lost and this factory setting will be recovered when this initialization mode.

So make sure to m+emorize your setting for restoring after the initialization.

Initializing DRA-F107/DRA-F107DAB

DRA-F107/DRA-F107DAB initialization should be performed when the μcom, and peripheral parts of μcom are replaced.

1. Switch off the unit and remove the AC cord from the wall outlet.

2. Hold the following the 0 button and the AUTO PRESET button, and plug the AC cord into the outlet. d

6

DRA-F107 / DRA-F107DAB

Page 7

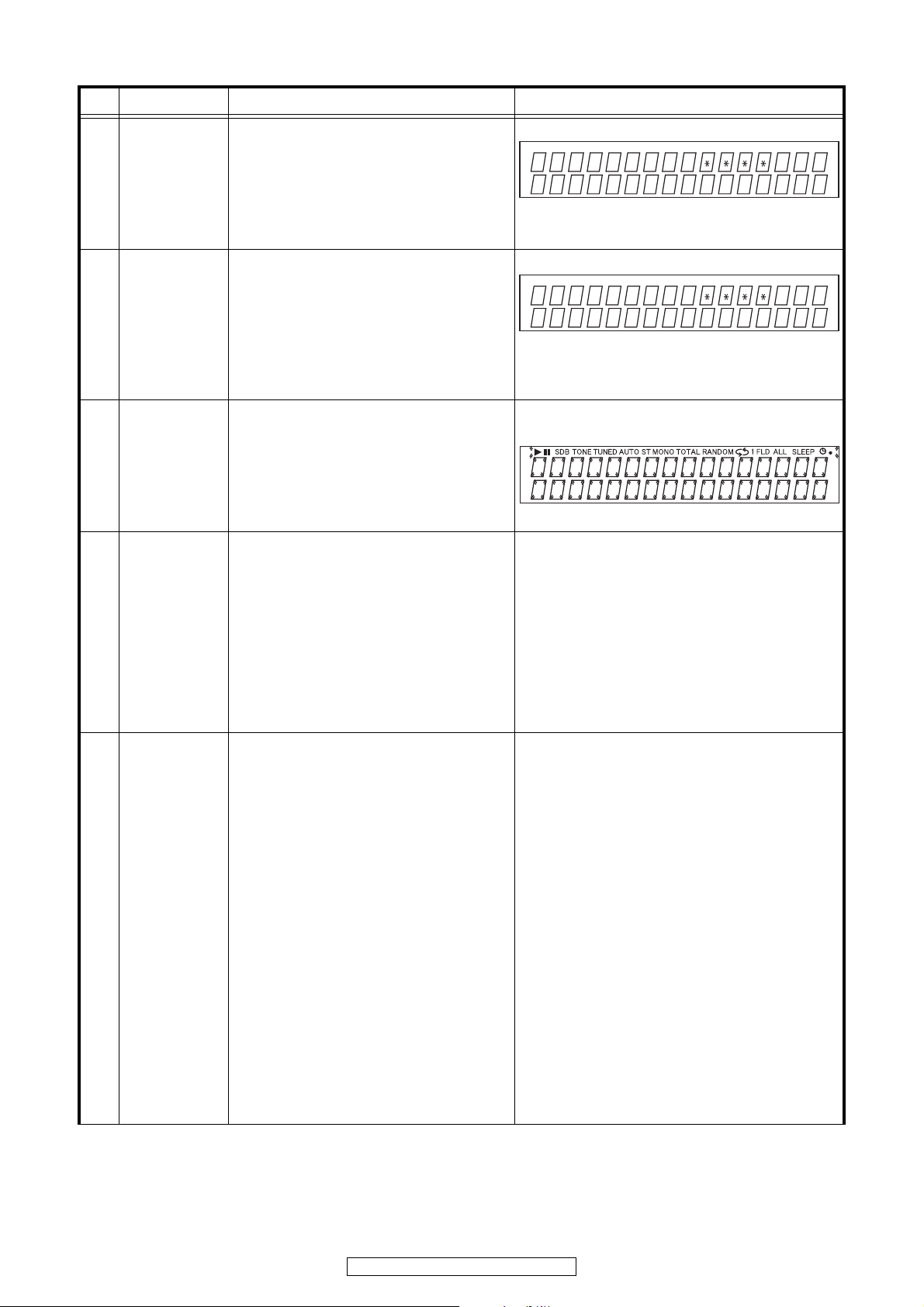

SPECIAL MODECD TEST MODE

DRA VER

D

DOCK

RA VER

VER + +++

No Button name Function Display

S1.1

・

Plug AC cord into power outlet while pressing

the ON/STANDBY button and the SDB/

TONE button same time on Main Unit.

・The Version number of MPU is displayed.

・MUTING ON

・

Unplug AC cord to clear this mode.

S1.2

※ When the iPod Dock is connected

・ Plug AC cord into power outlet while pressing

the ON/STANDBY button and the SDB/

TONE button same time on Main Unit.

・The Version number of MPU is displayed.

・MUTING ON

・

Unplug AC cord to clear this mode.

・ Plug AC cord into power outlet while pressing

the ON/STANDBY button and the AUTO

PRESET button same time on Main Unit.

・All segment of FLD is turning on and off every

one second .

・MUTING ON.

・Unplug AC cord to clear this mode.

***** :The version number of Main MPU

***** :The version number of MPU

++++ :The version number of iPod Dock

・All segment turn on and off.

S1

S1

S2

Versi on No.

Display Mode

Versi on No.

Display Mode

VFD checking

mode

EEPROM

S3

testing Mode

Cold start mode

S4

(Initialization)

・Plug AC cord into power outlet while pressing

the ON/STANDBY button and the TUNER

button same time on Main Unit.

・ON / STANDBY LED lighted ORANGE (The

test is started).

・MUTING ON.

・When power LED lighted Green, this

EEPROM test was OK.

・When power LED lighted RED, this EEPROM

test was NG.

・Unplug AC cord to clear this mode.

・Plug AC cord into power outlet while pressing

the AUTO PRESET button and the

same time on Main Unit.

・The system is reset.

- source : CD/USB

- SDB : OFF

- BASS : 0

- TREBLE : 0

- BALANCE : CENTER

- DIMMER : 100%

- VOLUME : 0

- Preset Frequency of TUNER:

All 0

- Main Unit

- CLOCK : 00:00(Flashing)

- TIMER(EVERYDAY/ONCE):

Timer Function : CD

Timer start time : 0:00 (AM12:00 : E3)

Timer stop time : 0:00 (AM12:00 : E3)

・The system is reset, and once this is com-

pleted the unit is set to the normal mode.

0/1 button:

:

-/+ button for PRESET

AM12:00(Flashing)(E3)

0 button

7

DRA-F107 / DRA-F107DAB

Page 8

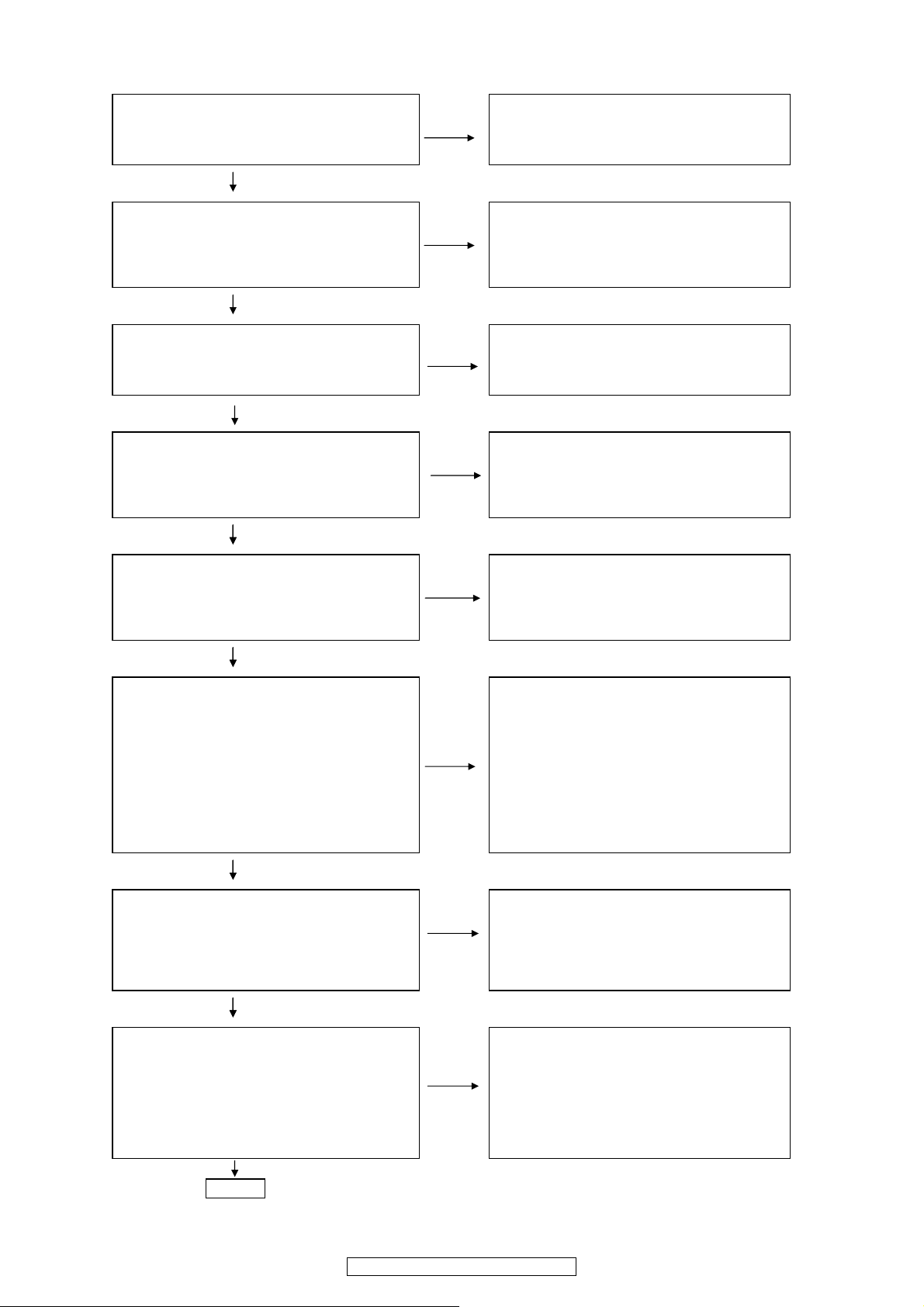

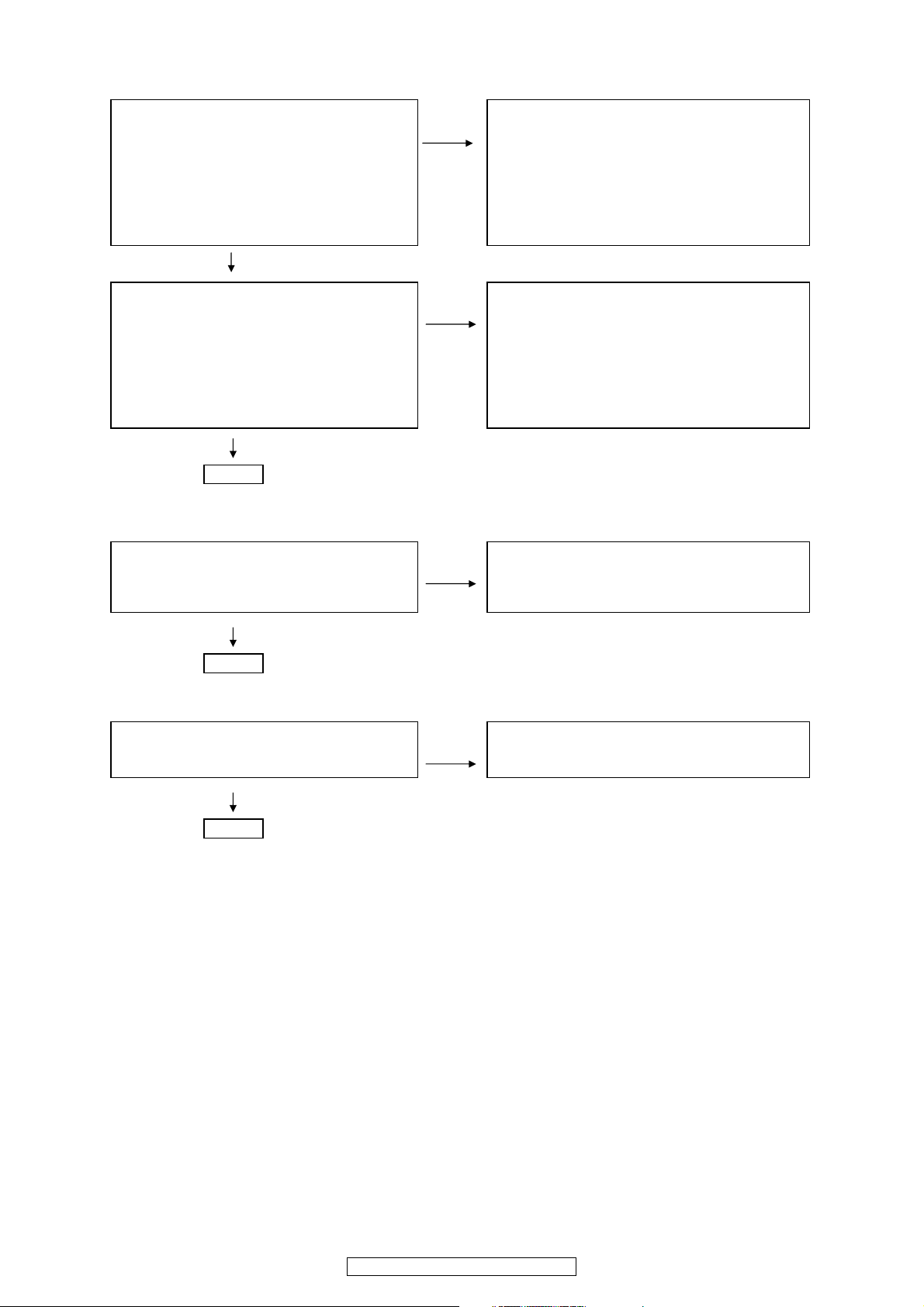

TROUBLE SHOOTING

1. FLD dosen't light

Check Fuse Check if there is any leak or short-circuiting

SMPS B'D N.G on rectifier circuit of SMPS B'D

䊶 F901 OK? Check Parts

䊶 Q903,IC93,IC92,DB91 on SMPS B'D

O.K.

Check Power Supply Voltages for System uCOM.

MAIN B'D MCU,Function Bloc䌫 N.G Check Soldering.

䊶 [BN96]:1pin ST+6V 䊶 [BN96]:1䌰䌩䌮

䊶 [D607]:Cathode 䊶 SUB TRANS B'D

䊶 [IC65]:3pin +3.3V

O.K.

Check Reset signal for System uCOM.

MAIN B'D MCU,Function Bloc䌫 N.G Check Soldering.

䊶 [IC62]:10pin RESET 䊶 IC66 on MAIN B'D

"H"level O.K.? (>2.8V)

O.K.

Check Oscillation waveform.

MAIN B'D MCU,Function Bloc䌫 N.G Check Soldering.

䊶 [IC62]:11pin 䊶 X202 on Main B'D

14.7456MHz OK?

O.K.

Check Power 50/60 Signal

MAIN B'D MCU,Function Bloc䌫 N.G Check Soldering.

䊶 [IC62]:19pin 50/60 䊶 [BN96]: 2pin

Pulse OK? 䊶 SUB TRANS B'D

O.K.

Check Power Supply Voltages for FLD Check Soldering.

FRONT B'D 䊶 FRONT B'D [BN83]:3pin +VKK

䊶 [FL81]:38pin VH (42V) 䊶 FRONT B'D [BN83]:4pin ,5pin F_AC

䊶 [FL81]:37pin VDD (3.3V) 䊶 FRONT B'D [WF81]:1pin SW+3.3V

䊶 [FL81]: 1pin F1,43pin F2 (AC3.3V) N.G 䊶 SMPS B'

D

CN93 3pin VKK

䊶 SMPS B'

D

,CN93 4pin FL+- 5pin FL-

䊶 MAIN B'

D

WN81 1pin SW+3.3V

Check Parts

䊶 SMPS B'D

Q933,Q934, IC97,D945, D935

IC94, D950 ,D933

O.K.

Check Reset Signal for FLD Check Soldering.

FRONT B'D N.G 䊶 FRONT B'D [WF81]:5pin VFD_RST1

䊶 [FL81]:35pin /RST 䊶 MAIN B'D [WN81]:5pin VFD_RST1

Hlevel O.K.? (3.3V) 䊶 [IC62]:2pin FL_RST on MAIN B'D

O.K.

Check FLD Dirive Signal for FLD Check Soldering.

FRONT B'D N.G 䊶 [WF81]: 2,3,4pin on FRONT B'D

䊶 [FL81]:32,33,34pin DA,CP,CS VFD_DI,VFD_CLK,VFD_CE

䊶 [WN81]: 2,3,4pin on MAIN B'D

VFD_DI,VFD_CLK,VFD_CE

䊶 IC62 on MAIN B'D

END

8

DRA-F107 / DRA-F107DAB

Page 9

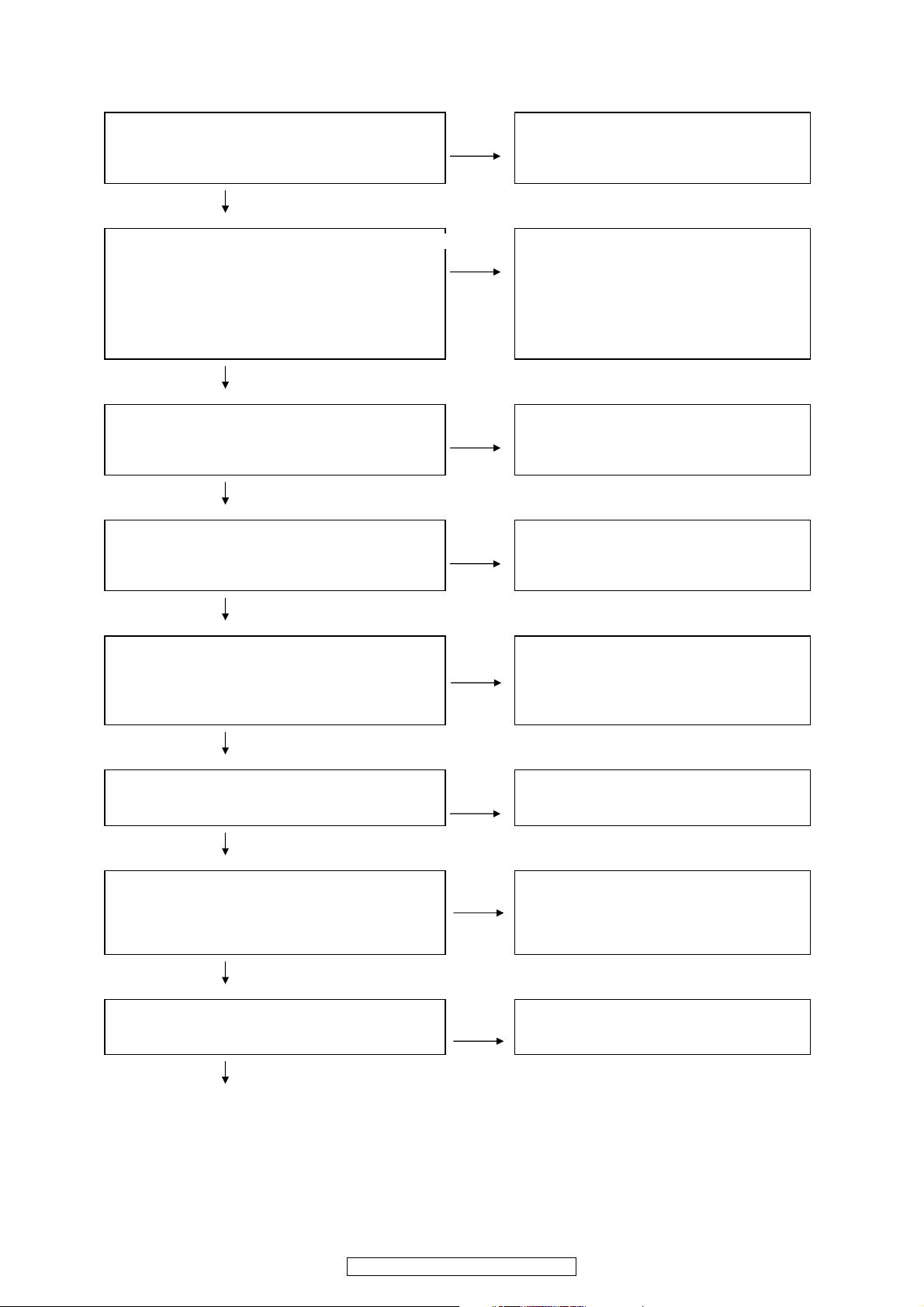

2. POWER OFF with Blinking POWER LED

Check Power Supply Voltages for Analog Block Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G 䊶 IC22,23 on MAIN B'D

䊶䈀IC21䈁:31pin AVCC+7V 䊶䈀BN61䈁:1pin,2pin ±12V on MAIN B'D

67pin AVCC-7V 䊶䈀CN92䈁1pin,2pin ±12V on SMPS B'D

䊶 SMPS B'D IC97,IC98,D945,D931

O.K.

Check Power Supply Voltages for Digital Block Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G MAIN B'D MCU,Function Bloc䌫

䊶䈀IC64䈁:3pin 䋫3.3V 䊶 IC64

䊶䈀WC52䈁:3pin HB+ 䊶䈀BN61䈁:4pin SW5.6V

䊶䈀WC52䈁:3pin 27VA

D.POWER AMP B'D

䈀WP52䈁:3pin 27VA

䈀CN91䈁:1,2,3,7pin 27VA

SMPS B'D

䈀BN91䈁:1,2,3,7pin 27VA

D931

O.K.

Check Protect Signal for System uCOM. Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G MAIN B'D MCU,Function Bloc䌫

䊶 [IC62]:71pin PROT_2 High Level OK? 䊶 D371,D373,D374

O.K.

Check Protect Signal for D.Power Amp Check Soldering.

D.POWER AMP B'D N.G D.POWER AMP B'D

䊶䈀IC53䈁:3pin 12V 䊶 IC54

䊶䈀IC54䈁:17pin SD,18pin OTW,19 pin READY 䊶 IC53

High Level OK? ㇱຠ⏕

䊶 IC54,IC53

䊶 D.Power Amp Heat Sink

O.K.

Check Control Singal for DC Protect Check Soldering.

䊶 Q573_B Low Level OK? MAIN B'D MCU

䊶 Q571,572,573,574

䊶 D571,572

N.G Check Parts

䊶 Q571,572,573,574

䊶 D571,572

O.K.

Check Protect Signal for System uCOM. Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G MAIN B'D MCU

䊶 [IC62]:74pin PROT_1 High Level OK? 䊶 D570

D.POWER AMP B'D

䊶 D504,D505,D506

END

9

DRA-F107 / DRA-F107DAB

Page 10

3. System Connector(DENON BUS) don't work

Check Power Supply Voltages for DENON BUS Check Soldering.

INPUT B'D DENON BUS BLOCK N.G INPUT B'D DENON BUS BLOCK

䊶 [WF31䈁:13pin ST5V 䊶 [WF31䈁:13pin ST5V

MAIN B'D

䊶 [WN31䈁:13pin ST5V

䊶 Q613

䊶䈀BN96䈁:1pin ST6V

䊶 D607

䊶 SUB TRANS B'D

O.K.

Check Control Signal for DENON BUS Check Soldering.

INPUT B'D DENON BUS BLOCK N.G INPUT B'D DENON BUS BLOCK

䊶 [WF31䈁:9pin BUS CLK,10pin BUS RXD_O 䊶 JK31

11pin BUS TXD_O OK? 䊶 Q301,Q302

䊶 [WF31] 9,10,11pin

MAIN B'D

[WN31] 9,10,11pin

IC31

[IC21]:26,27,28 pin

O.K.

END

4. The Key Operation don't work

Check Signal for KEY Check Soldering.

MAIN B'D N.G 䊶 WF81,S801 䌾S809,VR81,VR82 on FRONT B'D

䊶 [IC62]3,5pin F_JOG±,21,22 VJOG± 䊶 WN81,IC62 in MAIN B'D

䇭17pin PWR_KEY,93,95pin Key 0/1 OK?

O.K.

END

5. The Remote Control Operation don't work

Check Signal for Remote Control Check Soldering.

䊶䌛IC62䌝:73pin REMOTE on MAIN B'D N.G 䊶 WF81on FRONT B'D

䊶䌛RC81䌝:3pin Vcc 3.3V OK? 䊶 WN81,IC62 in MAIN B'D

O.K.

END

10

DRA-F107 / DRA-F107DAB

Page 11

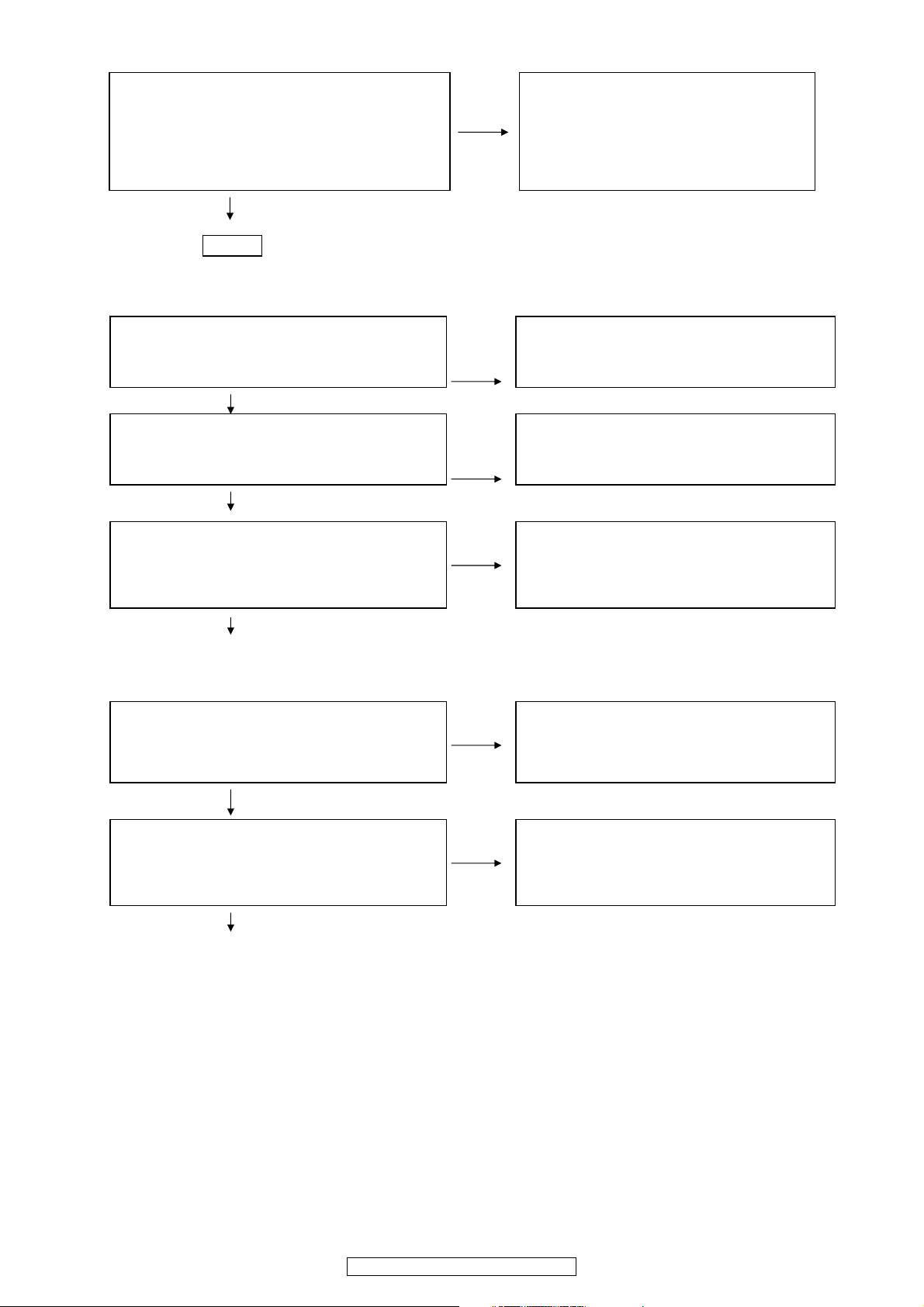

6. No Sound,Noise generated

(1)CD/USB PLAY in

Check Analog Audio Data input for FUNCTION IC

MAIN B'D MCU,Function Bloc䌫 N.G Check Soldering.

䊶 [IC21] input 78,79pin 䊶 [IC21] on MAIN B'D

CD_L,CD_R 䊶 JK21

O.K.

Check Power Supply Voltages for PREAMP & POWER AMP. Check Soldering.

MAIN B'D MCU,Function Block N.G 䊶 [BN61]:1,2pin +12V,-12V,

䊶 [BN61]:1,2,4pin+12V,-12V , SW+5.6V 4pin SW+5.6V on MAIN B'D

䃨 D.POWER AMP B'D 䊶 [CN91]:1,2,3,7pin +27Von D.AMP BLOCK

䊶 [WP51]:5pin +12V 䊶䈀WP51䈁:5pin +12V

䊶 [CN91] : 1,2,3,7pin +27V 䊶 SMPS B'D IC97,IC98,D945,D931

䊶 [IC53]: 3pin +12V 䊶 SMPS B'D IC91,D951

䊶 D.POWER AMP B'D IC53

O.K.

Check Power Supply Voltages for FUNCTION IC Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G 䊶 IC22,IC23 on MAIN B'D

䊶 [IC21]:30pin VDD (3.3V) 䊶 IC64 on MAIN B'D

31pin AVCC+7V,67pin AVCC-7V

O.K.

Check Control Signal for FUNCTION IC Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G 䊶 IC62 on MAIN B'D

䊶 [IC21]:27,28,29pin

CLK,DATA,LATCH

O.K.

Check Analog Audio Data output from FUNCTION & Check Soldering.

PRE AMP N.G 䊶 IC21 on MAIN B'D

MAIN B'D MCU,Function Bloc䌫䊶IC24 on MAIN B'D

䊶 [IC21]:44, 39pin Lout,Rout

䊶 [IC24]:1,7 pin

O.K.

Check Audio function Mute Signal. Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G 䊶 Q603,604, on MAIN B'D

[Q103,104]:"L"level O.K.? (-12V) 䊶 IC62 on MAIN B'D

O.K.

Check Analog Audio Data input for POWER AMP Check Soldering.

D.AMP B'D N.G 䊶 [WC51] 1,3pin on MAIN B'D,

䊶 [IC54]: 6,7pin IN_A,IN_B VOL_L_OUT,VOL_R_OUT

12,13pin IN_C, IN_D 䊶䈀WP51䈁:1,3pin on D.Power B'D

䊶 IC51,IC52 on D.AMP B'D

O.K.

Check SPEAKER RELAY control Signal Check Soldering.

MAIN B'D N.G 䊶

Q570,Q575 on MAIN B'D

䊶 [D573]:ANODE "L"level O.K.? (-12V) 䊶 [IC62] 77pin RL_MUTE on MAIN B'D

O.K.

11

DRA-F107 / DRA-F107DAB

Page 12

Check Analog Audio Data output for POWER AMP Check Soldering.

to SPEAKER. 䊶 WP52 on D.AMP BLOCK

D.POWER AMP BLOCK N.G 䊶 IC54 on D.AMP BLOCK

䊶 [IC54]:39,40pin OUT_A , 36pin OUT_B 䊶 WC52 on MAIN B'D

31pin OUT_C , 27,28pin OUT_D

MAIN B'D SP OUT BLOCK

䊶 JK51

O.K.

END

(2) AM/FM TUNER-in

Check Power Supply Voltages for AM/FM TUNER. Check Soldering.

MAIN B'D N.G 䊶 D931 on SMPS B'D

䊶 Q813, 611 on MAIN B'D

䊶䈀IC62䈁:59pin TU_PWR

O.K.

Check Control Signal for AM/FM TUNER. Check Soldering.

MAIN B'D N.G MAIN B'D

䊶 [WN21]: 7pin PLL_CE,8pin R/F_DATA 䊶 IC61,62,WN21

9pin RF_CLK,10pinPLL_DI OK?

O.K.

Check Analog Audio Data output from TUNER PACK Check Soldering.

MAIN B'D N.G 䊶 WN21 1,3 pin TU_L,TU_R on MAIN B'D

䊶 TUNER PACK output

䊶 [WN 21]:1,3pin TU_L, TU_R

䊶 [IC21]:68,69pin䇭TU_L,TU_R

O.K.

to CD/USB in 䃨Mark

(3) Portable-in(Front-in)

Check Analog Audio Data output from Prtable-in

FRONT B'D N.G Check Soldering.

䊶 Portable-in output 䊶 JK82,on FRONT B'D

䊶 BN82 1,3pin POR_L.POR_R 䊶 BN82 on FRONT B'D

O.K.

Check Analog Audio Data input for FUNCTION IC Check Soldering.

MAIN B'D MCU,Function Bloc䌫 N.G 䊶 [CN82]:1,3pin PORT_L<PORT_R on MAIN B'D

䊶 [IC21] input 2,3pin 䊶 [WP11]:10,12pin on MAIN B'D

POR_L.POR_R 䊶 [WC11]:10,12pin on MAIN B'D

䊶 [IC21]:2,3pin PORT_L,PORT_R

O.K.

to CD/USB in 䃨Mark

12

DRA-F107 / DRA-F107DAB

Page 13

(4) DAB TUNER-in

Check Power Supply Voltages for DAB TUNER UNIT. Check Soldering.

INPUT B'D DAB BLOCK N.G 䊶䈀WP82䈁:1pin DAB_PWR

䊶䈀WP82䈁:5pin 5VDD 5pin SW+5V on INPUT B'D

䊶䈀CN71䈁:2pin 3.3V 䊶 IC71,72 on INPUT B'D

䊶䈀CN71䈁:1pin 1.5V 䊶䈀WC61䈁:1pin DAB_PWR

5pin 5VDD on MAIN B'D

䊶䈀BN61䈁:5pin 5VDD on MAIN B'D

䊶 D931 on POWER B'D

䊶䈀IC62䈁:53pin DAB_PWR

Check Parts

䊶 IC71,72 on INPUT B'D

O.K.

Check Controll Signal for DAB TUNER. Check Soldering.

INPUT B'D DAB BLOCK N.G 䊶 WP82 33,34pin on DAB B'D

䊶 CN71 15,16pin DIN,DOUT 䊶 IC62

O.K.

Check Analogl Audio Data output from DAB TUNER

INPUT B'D DAB BLOCK N.G Check Soldering.

䊶 [DAB TUNER] output 䊶 [CN71]:29,30pin on DAB B'D

[CN71]: 29,30pin LOUT,ROUT

O.K.

Check Analog Audio Data input for FUNCTION IC

MAIN B'D N.G Check Soldering.

䊶 [IC21]:72,73pin DAB_L,BAD_R 䊶䈀WP82䈁:6pin,8pin on INPUT B'D

䈀WC61䈁:6pin,8pin on MAIN B'D

O.K.

to CD/USB in 䃨Mark

(5) iPod PLAY

Check Control Signal for iPod Dock Check Soldering.

MAIN B'D N.G INPUT B'D

䊶 JK32 䊶 JK32

㩷䈀WF31䈁:4,12pin IPOD_TX,IPOD_RX 䊶 [WF31]: 4,12pin IPOD_TX,IPOD_RX

㪤㪘㪠㪥㩷㪙㩾㪛

䊶 [WN31]: 4,12pin IPOD_TX,IPOD_RX

䊶 [ IC62]:29,30pin

䊶 IC61

O.K.

Check Analog signal output from iPod Dock Check Soldering.

MAIN B'D N.G 䊶 JK21 on MAIN B'D

䊶 JK21 AUXi in L,R

䊶 [IC21]:71,71pin AUX1_L,AUX1_R

O.K.

to CD/USB in 䃨Mark

13

DRA-F107 / DRA-F107DAB

Page 14

(6) PHONO PLA

Y

Check Power Supply Voltages for PHONO Check Soldering.

INPUT B'D PHONO BLOCK N.G 䊶䈀WP11䈁:4pin-7V,5pin +7V

䊶䈀WP11䈁:4pin-7V,5pin +7V 䊶䈀WC11䈁:4pin-7V,5pin +7V on Main B'D

O.K.

Check Soldering.

Check Analog signal input for FUNCTION IC 䊶 [IC21]:80,1pin PHONO_L,PHONO_R

MAIN B'D N.G 䊶

䈀

㪮㪚㪈㪈䈁㪑㪈㪃㪊㫇㫀㫅

䊶 [IC21]:49,50pin LOUT,ROUT 䊶

䈀

㪮㪧㪈㪈䈁㪑㪈㪃㪊㫇㫀㫅

䊶 IC11

䊶 JK11

O.K.

to CD/USB in 䃨Mark

(7) Head Phone OUT

Check Analog signal output forom FUNCTION IC Check Soldering.

MAIN B'D N.G MAIN B'D

䊶 [IC21]:54pin LOUT,47pin ROUT 䊶 [IC21]:54pin LOUT,47pin ROUT

㪫㪦㩷㩿㪈㪀㪚㪛ౣ

↢

O.K.

Check Power Supply Voltages for Head Phone Amp Check Soldering.

INPUT B'D H/P AMP BLOCK N.G 䊶 䈀㪮㪧㪈㪈䈁㪑㪋㫇㫀㫅㩷㪄㪎㪭㪃㩷㪌㫇㫀㫅㩷㪂㪎㪭㩷㫆㫅㩷㪠㪥㪧㪬㪫㩷㪙㩾㪛

䊶 䈀㪮㪧㪈㪈䈁㪑㪋㫇㫀㫅㩷㪄㪎㪭㪃㩷㪌㫇㫀㫅㩷㪂㪎㪭 䊶 䈀㪮㪚㪈㪈䈁㪑㪋㫇㫀㫅㩷㪄㪎㪭㪃㩷㪌㫇㫀㫅㩷㪂㪎㪭㩷㫆㫅㩷㪤㪘㪠㪥㩷㪙㩾㪛

O.K.

Check Soldering.

Check Mute Control signal for Head Phone INPUT B'D H/P BLOCK

INPUT B'D H/P BLOCK N.G 䊶

䈀

WP11䈁:13pin HP_MUTE

䊶

䈀

WP11䈁:13pin HP_MUTE Low Level OK?(-7V) MAIN B'D

䈀

WC11䈁:13pin HP_MUTE

O.K.

Check Soldering.

Check Analog signal output from Head Phone Amp 䊶

䈀

㪮㪚㪈㪈䈁㪎㫇㫀㫅㩷㪟㪧㪶㪣㪠㪥㪃㪏㫇㫀㫅㩷㪟㪧㪶㪩㪠㪥㩷㫆㫅㩷㪤㪘㪠㪥㩷㪙㩾㪛

INPUT B'D H/P BLOCK N.G INPUT B'D H/P BLOCK

䊶 [IC13]:1pin LOUT,7pin ROUT 䊶

䈀

㪮㪧㪈㪈䈁㪎㫇㫀㫅㩷㪟㪧㪶㪣㪠㪥㪃㪏㫇㫀㫅㩷㪟㪧㪶㪩㪠㪥㩷㫆㫅㩷㪤㪘㪠㪥㩷㪙㩾㪛

㪝㫉㫆㫅㫋㩷㪙㩾㪛 䊶 IC13

䊶

䈀

㪙㪥㪏㪉䈁㪑㪌㫇㫀㫅㩷㪟㪧㪶㪣㪦㪃㪍㫇㫀㫅㩷㪟㪧㪶㪩㪦 䊶䈀㪚㪥㪏㪉䈁㪑㪌㫇㫀㫅㩷㪟㪧㪶㪣㪦㪃㪍㫇㫀㫅㩷㪟㪧㪶㪩㪦

㪝㫉㫆㫅㫋㩷㪙㩾㪛

䊶

䈀

㪙㪥㪏㪉䈁㪑㪌㫇㫀㫅㩷㪟㪧㪶㪣㪦㪃㪍㫇㫀㫅㩷㪟㪧㪶㪩㪦

㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊

Q105,Q106,Q107,Q108

O.K.

END

14

DRA-F107 / DRA-F107DAB

Page 15

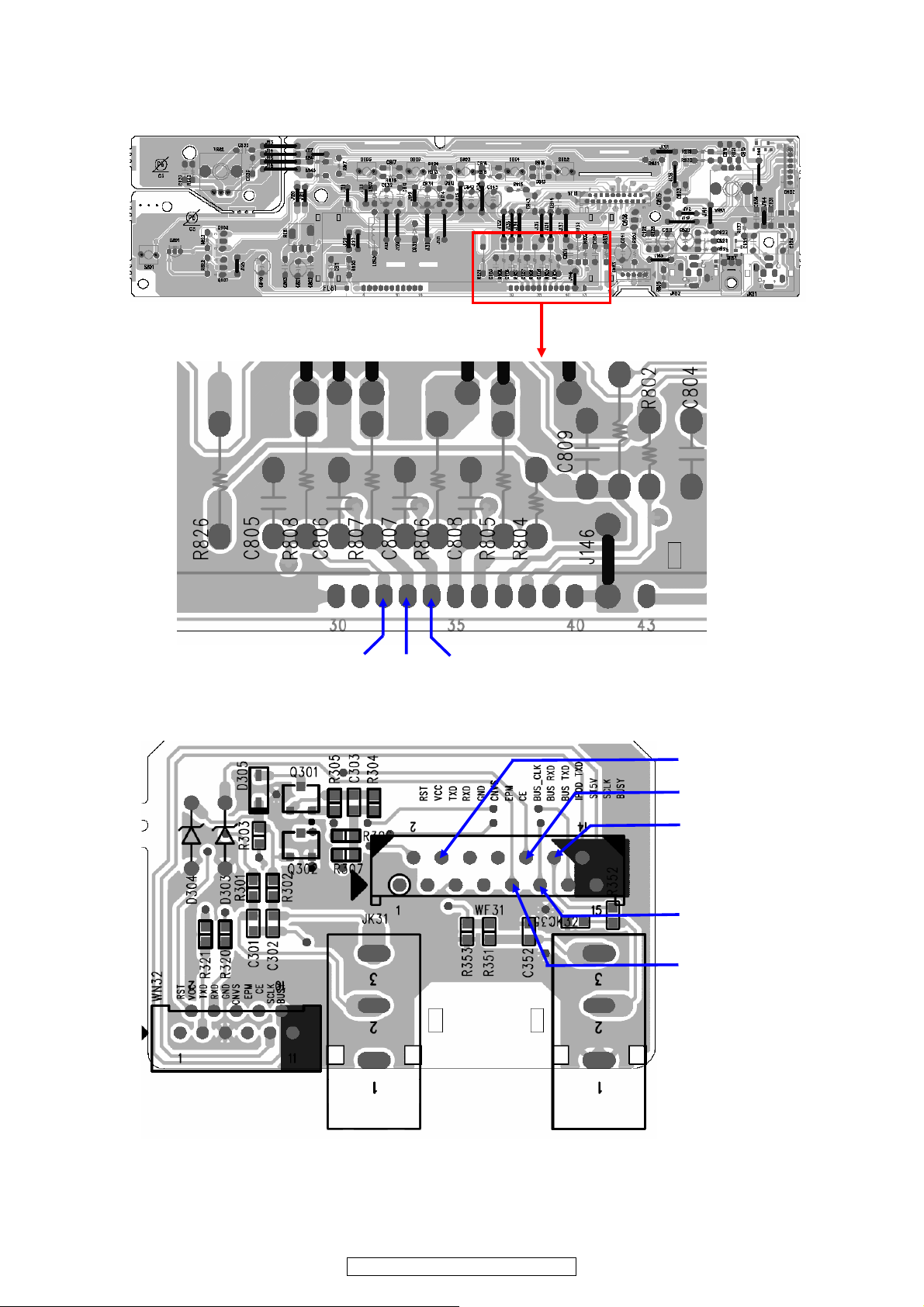

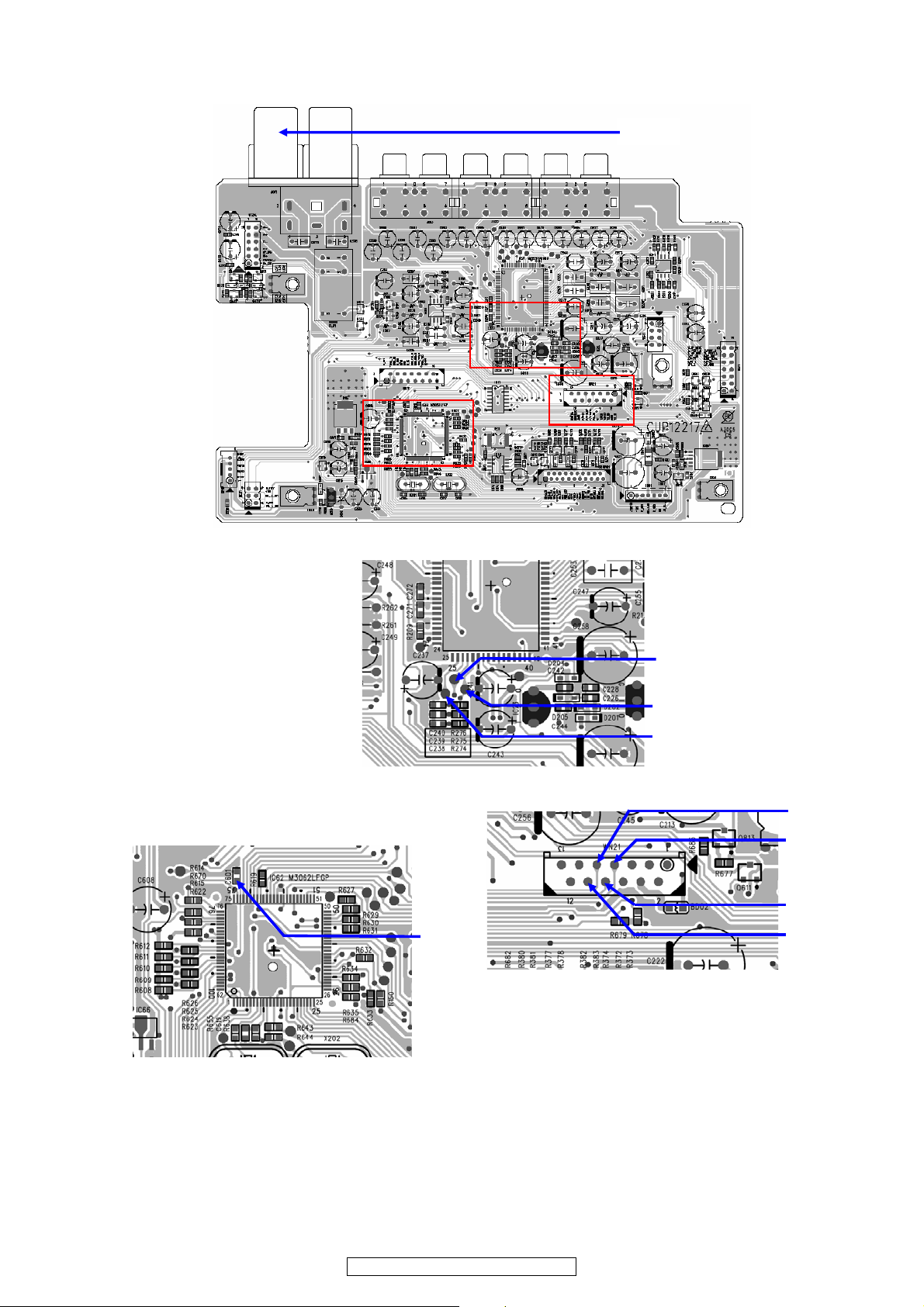

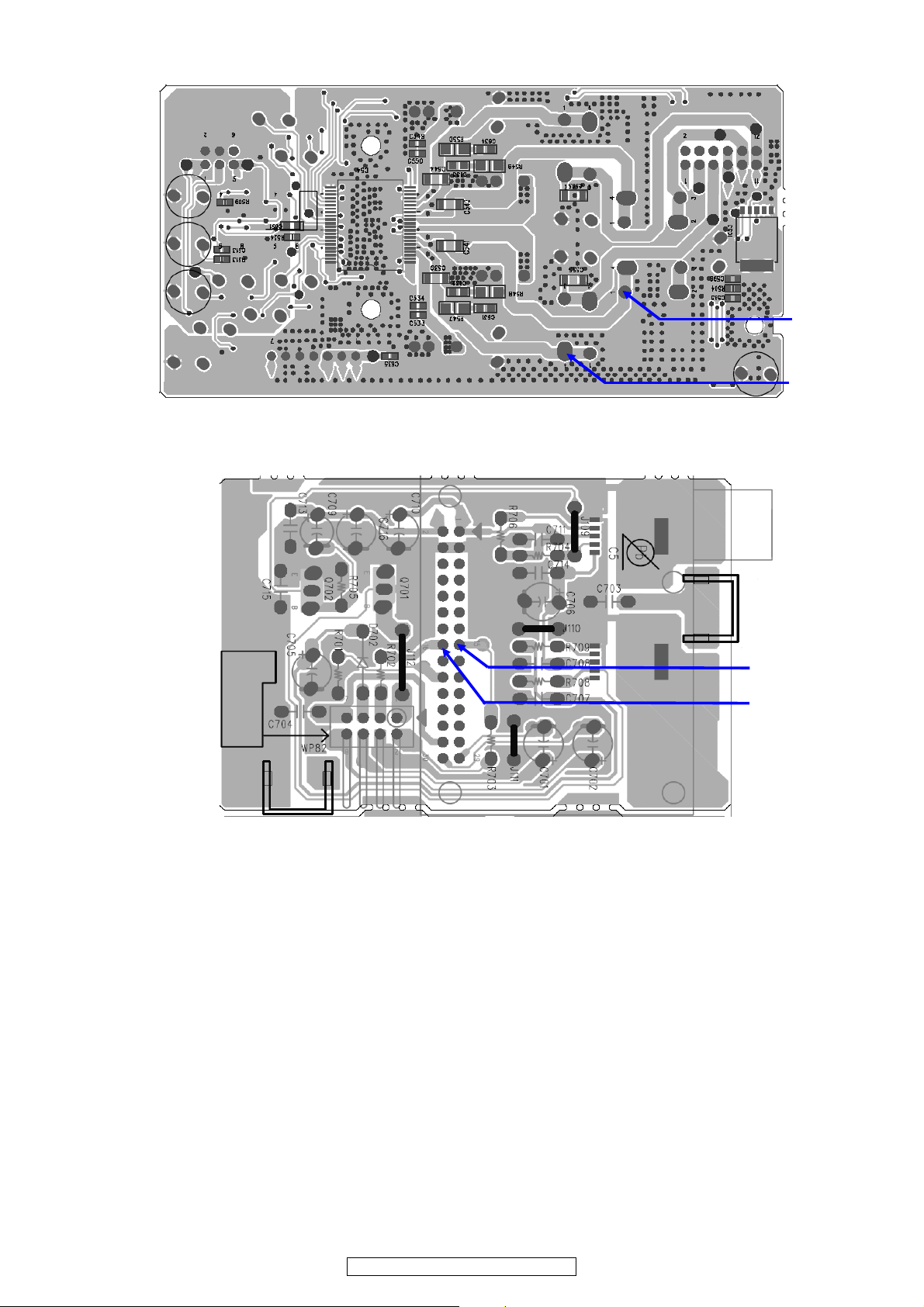

MEASURING POINT AND WAVEFORMS

Detail A

e

w

A

q

㩷

r

y

t

W2

W1

MEASURING POINT

FRONT PCB

UPDATE PCB

15

DRA-F107 / DRA-F107DAB

Page 16

MAIN PCB

㪛㪼㫋㪸㫀㫃㩷㪚

㪛㪼㫋㪸㫀㫃㩷㪛

㪛㪼㫋㪸㫀㫃㩷㪙

Q7

o

㪙

㪚

㪛

,

Q3 Q4

Q0

Q1

u

Q5

Q6

Q8

16

DRA-F107 / DRA-F107DAB

Page 17

POWER AMP

Q2

Q1

Q9

W0

DAB PCB

17

DRA-F107 / DRA-F107DAB

Page 18

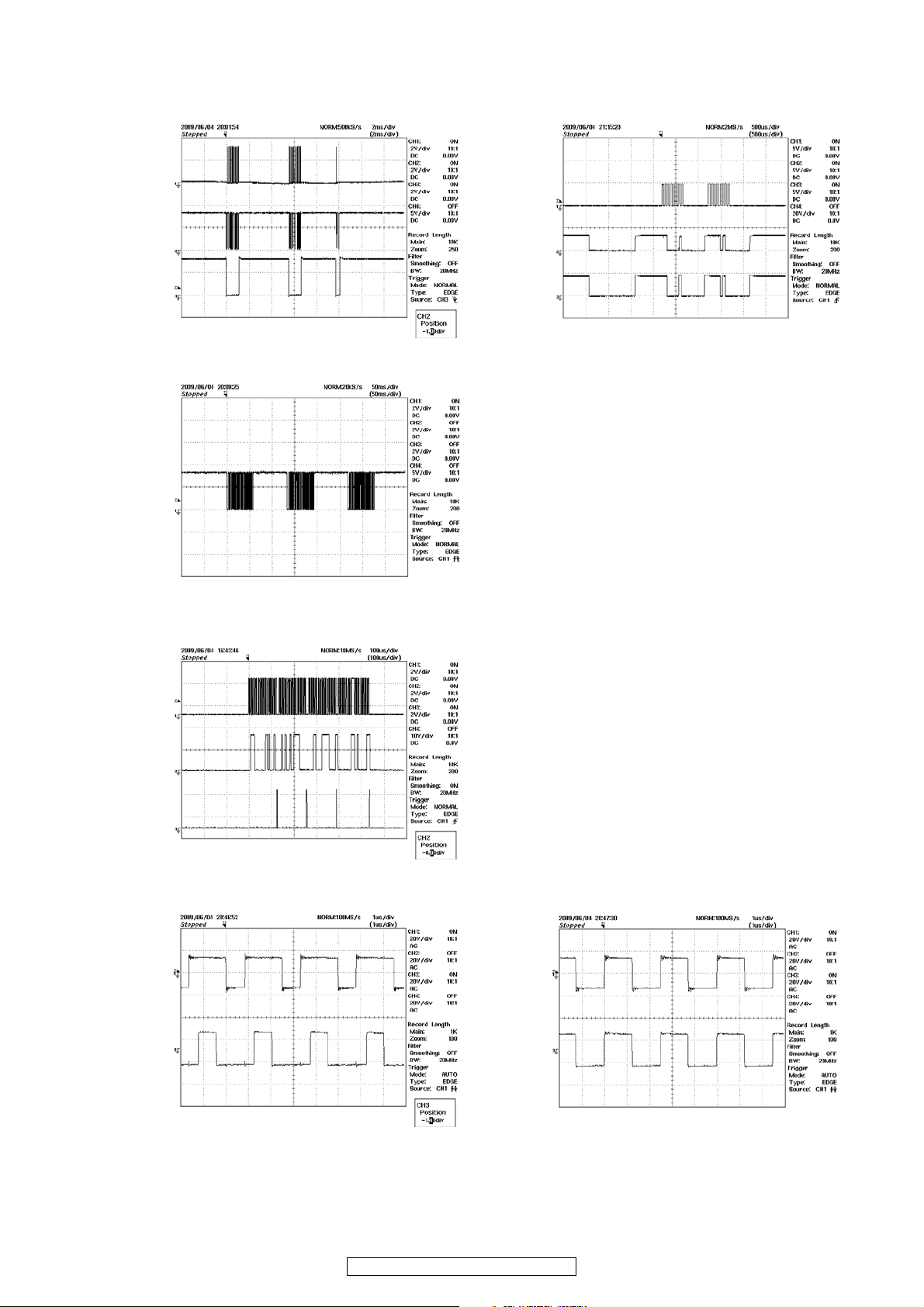

WAVEFORMS

FLD Drive Signal DENON BUS

䊶Mode:Fanction Selec

t

䊶Mode:Push Remote Control "CD Pla

y"

qFL_D

A

rBUS_CL

K

wFL_CP

tBUS

RXD

eFL

CS

yBUS

TXD

Remote Control

䊶Mode:Push Remote Control "SOURCE"

uREMOTE

CD/USB INPUT

䊶Mode:Fanction Selec

t

iCL

K

oDAT

A

Q0LATCH

CD/USB Play

䊶Mode: CD INPUT=200mVrms,1kHz S

p

eaker=4ohm 䊶Mode: CD INPUT=Open䇮Speaker=4ohm

Q1OUTA Q1OUTA

Q2OUTB Q2OUTB

_

_

_

18

DRA-F107 / DRA-F107DAB

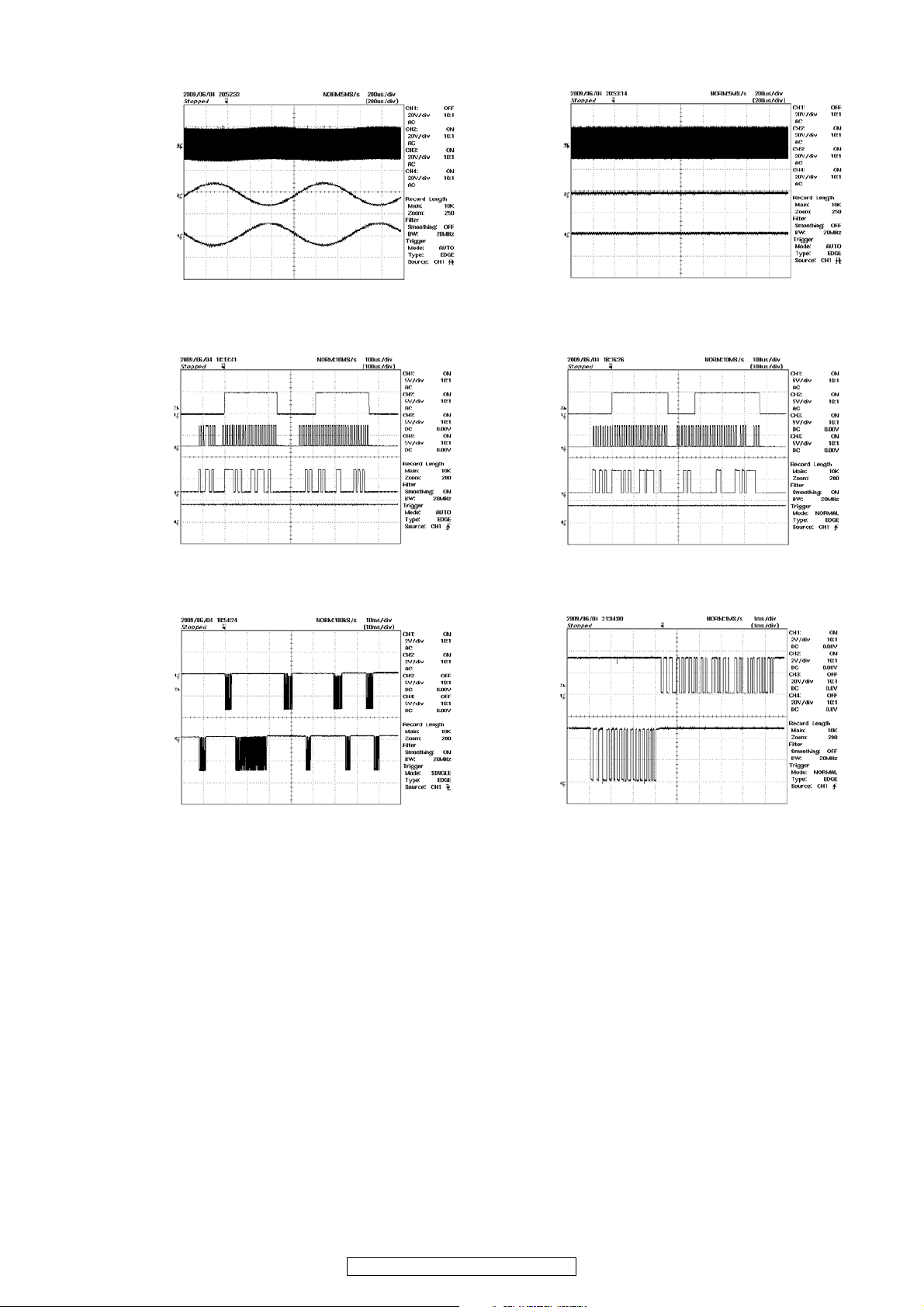

Page 19

䊶Mode: CD INPUT=200mVrms,1kHz Speaker=4ohm 䊶Mode: CD INPUT=Open䇮Speaker=4ohm

Q1OUTA Q1OUTA

Q3SPEAKE

R

Q3SPEAKE

R

OUT FL+ OUT FL+

Q4SPEAKE

R

Q4SPEAKE

R

OUT FL- OUT FL-

AM/FM TUNER INPUT

䊶Mode:Function CD㸢Tuner FM 䊶Mode:Tuner Band FM㸢

A

M

Q5PLL

CE Q5PLL_CE

Q6R/F

DAT

A

Q6R/F_DAT

A

Q7R/F_CL

K

Q7R/F_CL

K

Q8PLL_DI Q8PLL_DI

DAB TUNER INPUT iPod Play

䊶Mode:Tuner Band AM㸢DAB 䊶Mode:iPod Connec

t

W1IPOD_TX

Q9DIN

W2IPOD

RX

W0DOUT

_

_

_

19

DRA-F107 / DRA-F107DAB

Page 20

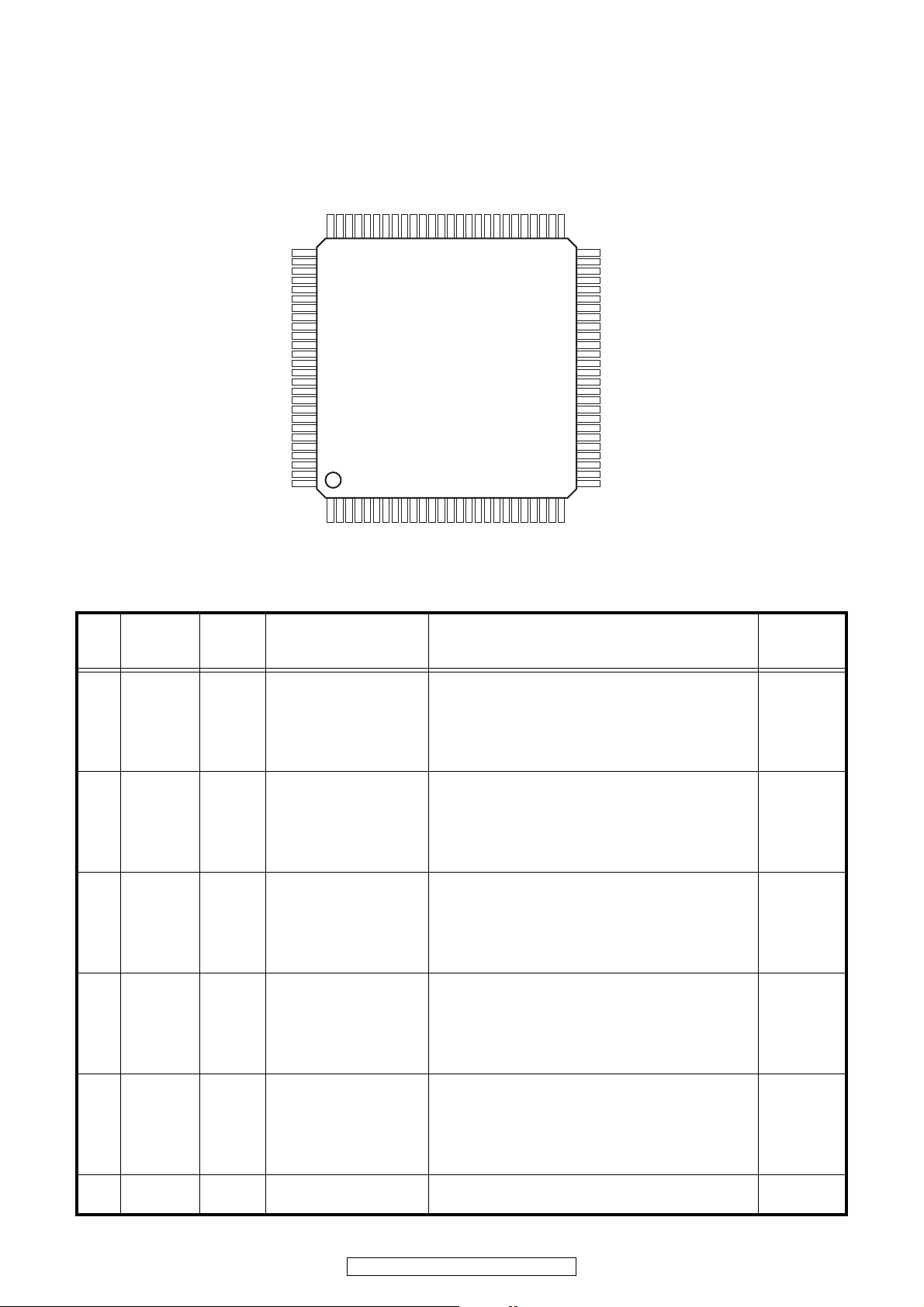

SEMICONDUCTORS

75

76

1

100

51

50

26

25

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

M3062LFGPGP (IC62)

M3062LFGPGP Terminal Function

Pin

No.

1 P94 O [LED_RL] [STANDBY Red LED output. ON:High] L

2 P93 O FL RESET Reset output to FLD L

3 TB2IN I FUNC_JOGB FUNCTION encoder Pulse-B input HI-Z

4 P91 O Not Used:N.C. L

5 TB0IN I FUNC_JOGA FUNCTION encoder Pulse-A input HI-Z

6 BYTE (VSS) GND -

7 CNVSS I FLASH CNVss Select input of Flash rom write mode HI-Z

8 P87 O Not Used:N.C. L

9 P86 O Not Used:N.C. L

10 RESET I RESET Reset input HI-Z

11 XOUT XTAL(16MHz) Xtal output -

12 VSS (VSS) GND -

13 XIN XTAL(16MHz) Xtal input -

14 VCC (VCC) Positive power -

15 NMI I (PullUp) Pull up HI-Z

16 P84 O Not Used:N.C. L

17 INT1 INT POWER KEY Power button input (interrupt input) HI-Z

18 INT0 INT /DBRXD DENON BUS Data input (interrupt input) HI-Z

19 P81 I 50/60 50Hz/60Hz AC Input HI-Z

20 P80 I H/P SW HEAD PHONE insert detect signal input HI-Z

21 TA3IN I VOL JOGB VOL encoder Pulse-B input HI-Z

22 TA3OUT I VOL JOGA VOL encoder Pulse-A input HI-Z

23 P75 O FLCS Chip Select output to FLD L

24 P74 O LED G POWER/SANDBY Green LED output. ON:High L

25 P73 O LED R POWER/SANDBY Red LED output. ON:High L

26 CLK2 O /DBCLK(DENON BUS) Serial Clock output for DENON BUS H

27 RXD2 I /DBRXD(DENON BUS) Serial Data input for DENON BUS HI-Z

Port

Function

Port

setting

Port Name Explaanation

Output of

Standby &

Default

20

DRA-F107 / DRA-F107DAB

Page 21

Pin

No.

28 TXD2 O /DBTXD(DENON BUS) Serial Data output for DENON BUS H

29 TXD3 SO IPOD_TX Serial Data output for IPOD DOCK L

30 RXD3 SI IPOD_RX Serial Data input for IPOD DOCK HI-Z

31 CLK1 I (PULLDOWN) Pull down L

32 P64 O Not Used:N.C. L

33 P63 SO S1_DIN Serial Data output to DAB Module L

34 P62 SI SI_DOUT Serial Data input from DAB Module L

35 P61 O Not Used:N.C. L

36 P60 O Not Used:N.C. L

37 P57 O.D Not Used:N.C. L

38 P56 O Not Used:N.C. L

39 P55 I (FLASH EPM) Not Used:N.C. HI-Z

40 P54 SO E2P CLK Serial Clock output to EEPROM L

41 P53 SI E2P DO Serial Data input from EEPROM HI-Z

42 P52 SO E2P DI Serial Data output to EEPROM L

43 P51 O E2P CS Chip Enable output to EEPROM L

44 P50 O (FLASH CE) Not Used:N.C. H

45 P47 O Not Used:N.C. L

46 P46 I PWB check Pull down HI-Z

47 P45 I PWB check Pull down HI-Z

48 P44 I PWB check Pull down HI-Z

49 P43 I PWB check Pull down HI-Z

50 P42 O Not Used:N.C. L

51 P41 O Not Used:N.C. L

52 P40 O Not Used:N.C. L

53 P37 O /FMAM TUNER Select to DAB or AM/FM . DAB:High AM/FM:Low L

54 P36 O TU/PHO

55 P35 O Not Used:N.C. L

56 P34 O Not Used:N.C. L

57 P33 O SW MUTE MUTE output for SW OUTPUT H

58 P32 O Not Used:N.C. L

59 P31 O TP.ON/OFF (TPOWER) AM/FM TUNER Power ON/OFF Switching output L

60 (VCC) Positive power -

61 P30 O Not Used:N.C. L

62 (VSS) GND -

63 P27 O Not Used:N.C. L

64 P26 I STEREO "STEREO" indicator input from FM/AM TUNER pack HI-Z

65 P25 I TUNED "TUNED" detect input from FM/AM TUNER pack HI-Z

66 P24 O T.MUTE MUTE output for FM/AM TUNER pack L

67 P23 O SANYO CE Chip Enable output to PLL/RDS IC L

68 P22 O SANYO DI Serial Data input to PLL/RDS IC L

69 P21 O SANYO CLK Serial Clock output to PLL/RDS IC L

70 P20 I SANYO DO Serial Data output to PLL/RDS IC HI-Z

71 P17 I PROTECT2 Protect Signal input 2 HI-Z

72 P16 O /SYR Reset output to RDS IC L

73 INT3 INT REMOTE Remote Control signal input HI-Z

74 P14 I PROTECT1/SP

75 P13 O /BUF_EN Enable signal output fot BUS BUFFER IC H

76 P12 O VR MUTE MUTE output for POWER AMP H

77 P11 O RL(RMUTE) SPEAKER RELAY ON/OFF output L

78 P10 O AP.ON/OFF (APOWER)

79 P07 O H/P MUTE MUTE output for HEAD PHONE output L

80 P06 O P.ON/OFF (POWER) MAIN POWER ON/STANDBY Switching output ON:High L

81 P05 O Not Used:N.C. L

Port

Function

Port

setting

Port Name Explaanation

REC.OUTPUT level Select to TU/PHO or Others . TU/PHO:High

Protect Signal input 1 HI-Z

PROTECTION

± 15V POWER ON/OFF Switching output ON:Hight

Output of

Standby &

Default

L

L

21

DRA-F107 / DRA-F107DAB

Page 22

Pin

No.

82 P04 O [RECOUT MUTE] [MUTE output for REC.OUTPUT] L

83 P03 O M61531_DATA Serial Data output to M61531 L

84 P02 O M61531_CLK Serial Clock output to M61531 L

85 P01 O M61531_LATCH Latch output to M61531 L

86 P00 I PORT.IN_SW PORTABL INPUT insert detect signal input HI-Z

87 P107 I Pull up HI-Z

88 P106 I USA Initial Setting input HI-Z

89 P105 I EURO Initial Setting input HI-Z

90 P104 I Pull up L

91 AN3 AD FREQ Initial Setting input HI-Z

92 AN2 AD RDS Initial Setting input HI-Z

93 AN1 AD KEY 0 Unit Operation Button input 0 HI-Z

94 (VSS) GND -

95 AN0 AD KEY 1 Unit Operation Button input 1 HI-Z

96 VREF (VCC) Positive power -

97 AVCC (VCC) Positive power -

98 P96 O Not Used:N.C. L

99 P97 SO FLDA Serial Data output to FLD L

100 P95 SO FLCK Serial Clock output to FLD L

Port

Function

Port

setting

Port Name Explaanation

Output of

Standby &

Default

22

DRA-F107 / DRA-F107DAB

Page 23

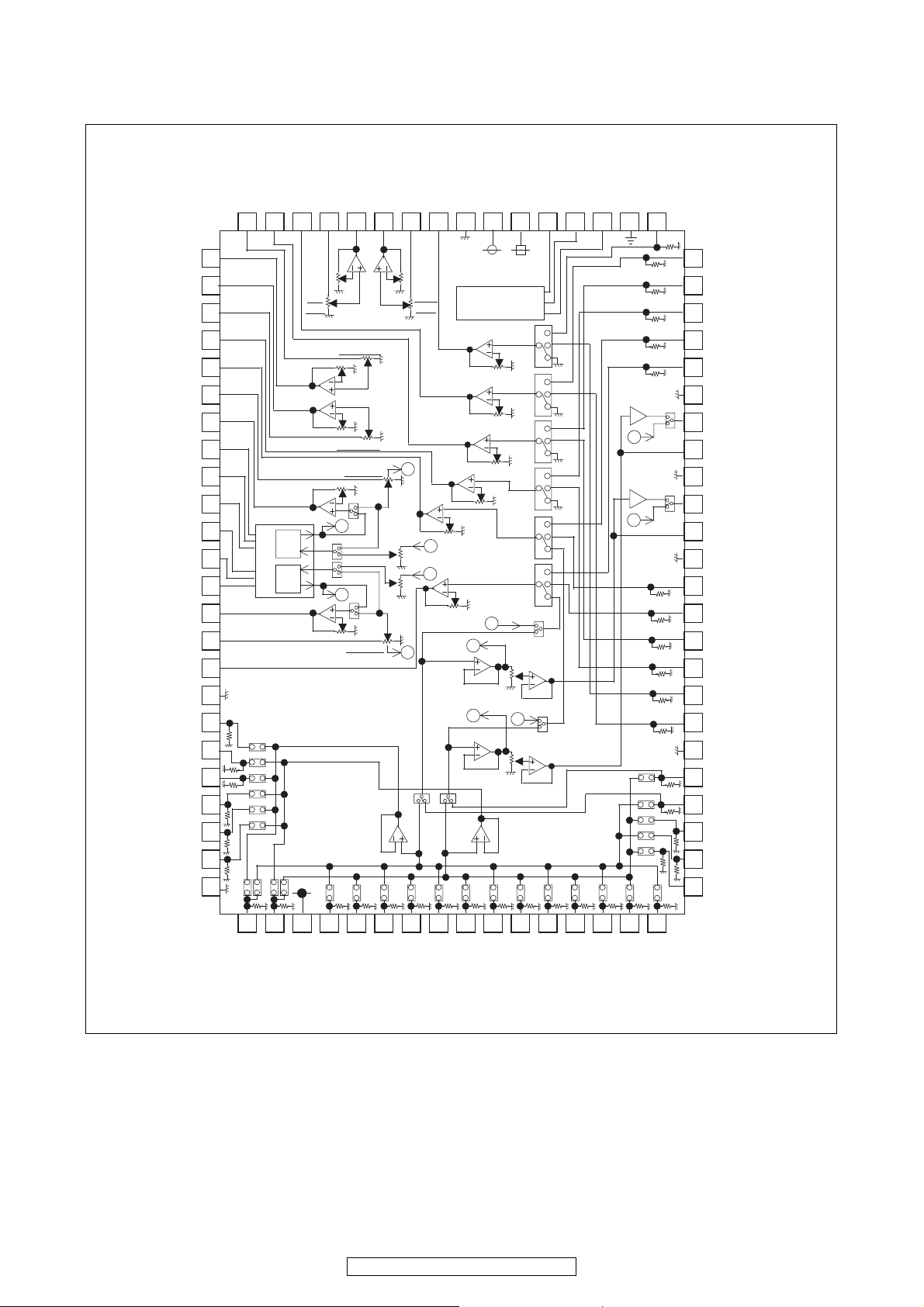

M61531FP (IC21)

Block Diagram and Pin Configuration (Top View)

CIN2

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

1

2

3

4

5

6

7

8

9

10

11

64

63

62

61

60

59

58

57

56

55

54

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

11

12

13

14

15

16

17

18

19

20

21

22

23

GND

INL3

INL10/RECL4

SWIN2

SLVIN

SLSELOUT

CSELOUT

CVIN

COUT

SWOUT

SWVIN

SWSELOUT

GND

AVCC

DVDD

LATCH

DATA

CLOCK

DGND

INR10/RECR4

AVEE

INL9

INR9

INL8

INR8

INL7

INR7

INL6

INR6

INL5

INR5

INL4

INR4

SLOUT

SROUT

SRVIN

SRSELOUT

RSELOUT

RVIN

ROUT

TRE R

BASS R2

BASS R1

BASS L1

BASS L2

TRE L

LOUT

LVIN

LSELOUT

GND

RECL1

RECR1

RECL2

RECR2

RECL3

RECR3

INR3

INR2

INL2

INL1/EXT INL

INR1/EXT INR

GND

CIN1

SWIN1

SRIN1

SLIN1

LIN1

RIN1

BALANCE L/+

BALANCE R/+

LOUD R

/BALANCE R/−

LOUD L

/BALANCE L/−

GND

GND

GND

LIN2

RIN2

SRIN2

SLIN2

24

53

52

51

50

49

48

47

46

45

44

43

42

41

Input

Gain

Control

Input

Gain

Control

Input

Gain

Control

Input

Gain

Control

Input

Gain

Control

Input

Gain

Control

Output

Gain

Control

Rch

Lch

SLch

SRch

SWch

Cch

Output

Gain

Control

Output

Gain

Control

Output

Gain

Control

Output

Gain

Control

MCU I/F

CLK

DATA

LATCH

Lch VOL

Output

Gain

Control

Rch VOL

SRch VOL

SLch VOL

Cch

VOL

SWch

VOL

Input ATT

Input ATT

Lch

Rch

GND

GND

DVDDAVCC

AVEE

SWch

Cch

SLch

SRch

Rch

Lch

Rch

Lch

Rch

GND

GND

Lch

GND

GND

L/R VOL

Input

L/R VOL

Input

Multi

Input Selector

Multi

Input Select or

Multi

Input Selector

Multi

Input Selector

GND

Tone(Bass,Treble)

Lch

Rch

R1

L1

R1

L1

-1

-1

R2

L2

R2

L2

Loudness tap

Loudness tap

Loudness tap

Loudness tap

Bypass/Tone

Bypass/Tone

Bypass/Tone

Bypass/Tone

Tone Block Position

Tone Block Position

Loud

/Balance

Loud

/Balance

R3

L3

L3

R3

Tone

Input

ATT

Tone

Input

ATT

Bypass

Selector

23

DRA-F107 / DRA-F107DAB

Page 24

Pin Description

Pin No. Pin Name Function

3, 1, 79, 77, 75, 73, 71, 69 INR2, 3, 4, 5, 6, 7, 8, 9 Input pin of R channel (Input Selector)

2, 80, 78, 76, 74, 72, 70, 68 INL2, 3, 4, 5, 6, 7, 8, 9 Input pin of L channel (Input Selector)

4 INL1/EXT INL

Input pin of L channel (Input Selector)/External Input pin(Lch)

5 INR1/EXT INR

Input pin of L channel (Input Selector)/External Input pin(Rch)

6, 13, 16, 19, 32, 57, 64 GND Analog Ground

7, 24 CIN1/CIN2 Input pin of C channel (2 Input Selector)

8, 25 SWIN1/SWIN2 Input pin of SW channel (2 Input Selector)

9, 22 SRIN1/SRIN2 Input pin of SR channel (2 Input Selector)

10, 23 SLIN1/SLIN2 Input pin of SL channel (2 Input Selector)

11, 20 LIN1/LIN2 Input pin of L channel (2 Input Selector)

12, 21 RIN1/RIN2 Input pin of R channel (2 Input Selector)

14, 17 BALANCE L/+, R/+ Output pin of L/R channel Balance Output(+)

15, 18 LOUD L/BALANCE L/–,

LOUD R/BALANCE R/–

Frequency characteristic setting pin of Loudness

/Output pin of L/R channel Balance Output(–)

26 DGND Ground of internal logic circuit

27, 28, 29 CLOCK, DATA, LATCH Input pin of control clock /data/ trigger

30 DVDD Power supply to internal logic circuit

31 AVCC Positive power supply to internal analog circuit

33 SWSELOUT Output pin of SW channel volume input selector

34 SWVIN Input pin of SW channel volume

35 SWOUT Output pin of SW channel

36 COUT Output pin of C channel

37 CVIN Input pin of C channel volume

38 CSELOUT Output pin of C channel volume input selector

39 SLSELOUT Output pin of SL channel volume input selector

40 SLVIN Input pin of SL channel volume

41 SLOUT Output pin of SL channel

42 SROUT Output pin of SR channel

43 SRVIN Input pin of SR channel volume

44 SRSELOUT Output pin of SR channel volume input selector

45 RSELOUT Output pin of R channel volume input selector

46 RVIN Input pin of R channel volume

47 ROUT Output pin of R channel

51, 52, 50, 49 BASS L1, L2/BASS R1, R2

Frequency characteristic setting pin of tone control (BASS)

53, 48 TRE L/TRE R

Frequency characteristic setting pin of tone control (TREBLE)

54 LOUT Output pin of L channel

55 LVIN Input pin of L channel volume

56 LSELOUT Output pin of L channel volume input selector

58, 60, 62/59, 61, 63 REC L1, L2, L3

/REC R1, R2, R3

Output pin of REC (Lch and Rch)

65 INL10/REC L4

Input pin of L channel (Input Selector)/Output pin of REC (Lch)

66 INR10/REC R4

Input pin of R channel (Input Selector)/Output pin of REC (Rch)

67 AVEE Negative power supply to internal analog circuit

DRA-F107 / DRA-F107DAB

24

Page 25

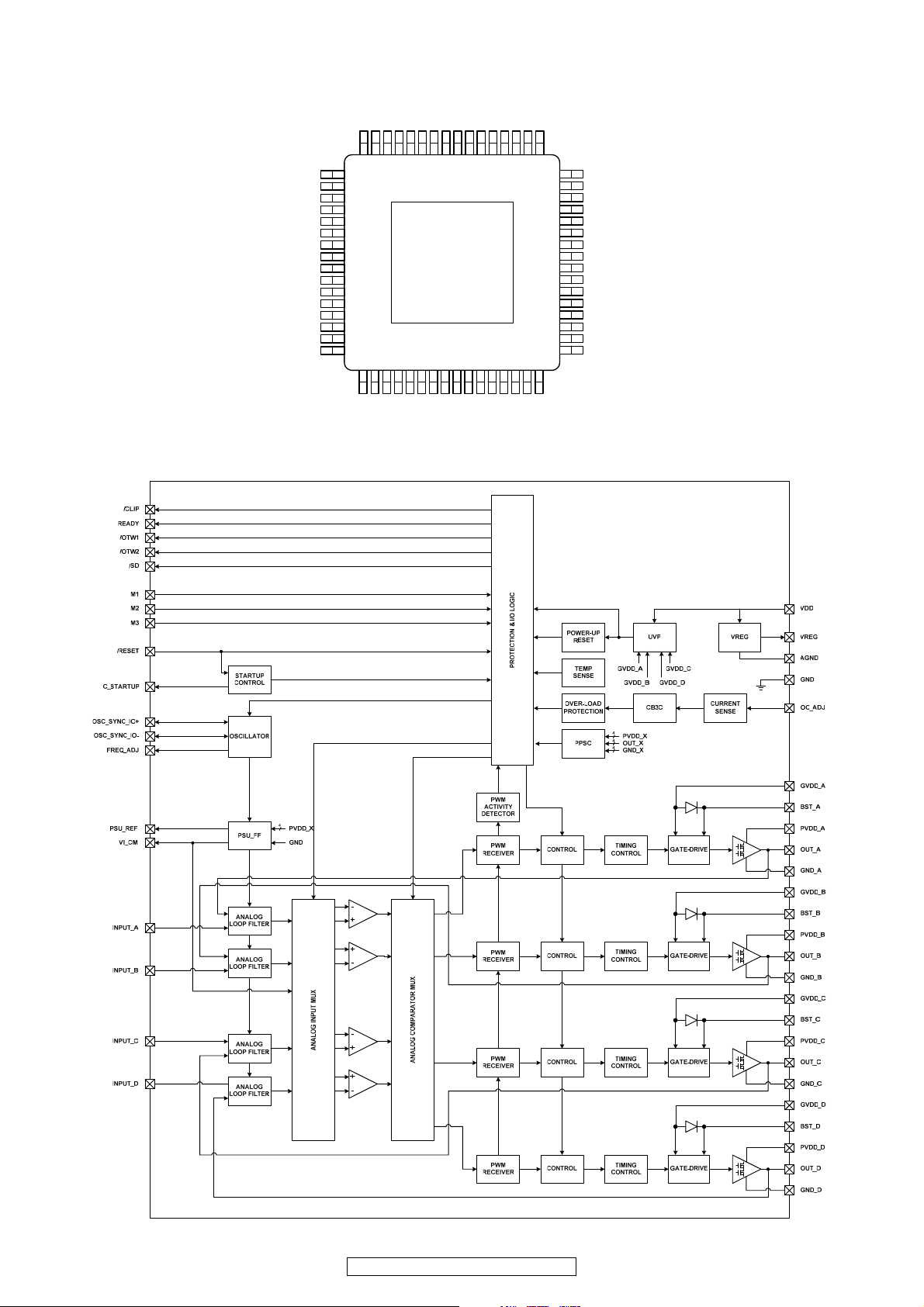

TAS5630DKD (IC54)

26

16

15

OC_ADJ

14

/RESET

13

C_STARTUP

12

INPUT_A

11

INPUT_B

10

VI_CM

9

GND

8

AGND

7

VREG

6

INPUT_C

5

INPUT_D

4

FREQ_ADJ

3

OSC_IO+

2

OSC_IO-

1

/SD

64-pins QFP package

32

GND_D

31

PVDD_D

30

PVDD_D

29

OUT_D

28

OUT_D

27

BST_D

GVDD_D

25

GVDD_C

24

GND

23

GND

22NC21

NC

20NC19

NC

18

PSU_REF

17

VDD

33

GND_D

34

GND_C

35

GND_C

36

OUT_C

37

OUT_C

38

PVDD_C

39

PVDD_C

40

BST_C

41

BST_B

42

PVDD_B

43

OUT_B

44

GND_B

45

GND_A

46

47

48

55

49

/OTW2

50

/CLIP

51

READY

52M153M254

M3

GND

56

GND

57

GVDD_B58GVDD_A

59

BST_A

60

OUT_A

61

OUT_A

62

PVDD_A

63

PVDD_A

64

GND_A

/OTW1

PVDD_B

OUT_B

GND_B

TAS5630DKD Block Diagram

25

DRA-F107 / DRA-F107DAB

Page 26

TAS5630DKD Terminal Function

TERMINAL

NAME PHD NO.

DKD NO.

FUNCTION

(1)

DESCRIPTION

AGND 8 10

P Analog ground

BST_A 54 43

P HS bootstrap supply (BST), external 0.033 uF capacitor to OUT_A required.

BST_B 41 34

P HS bootstrap supply (BST), external 0.033 uF capacitor to OUT_B required.

BST_C 40 33

P HS bootstrap supply (BST), external 0.033 uF capacitor to OUT_C required.

BST_D 27 24

P HS bootstrap supply (BST), external 0.033 uF capacitor to OUT_D required.

/CLIP 18 -

O Clipping warning; open drain; active low

C_STARTUP 3 5

O Startup ramp requires a charging capacitor of 4.7 nF to AGND in BTL mode.

FREQ_ADJ 12 14

I PWM frame rate programming pin requires resistor to AGND

GND 7,23,24,57,58 9

P Ground

GND_A 48, 49 38

P Power ground for half-bridge A

GND_B 46, 47 37

P Power ground for half-bridge B

GND_C 34, 35 30

P Power ground for half-bridge C

GND_D 32, 33 29

P Power ground for half-bridge D

GVDD_A 55 -

P Gate drive voltage supply requires 0.1 uF capacitor to GND_A

GVDD_B 56 -

P Gate drive voltage supply requires 0.1 uF capacitor to GND_B

GVDD_C 25 -

P Gate drive voltage supply requires 0.1 uF capacitor to GND_C

GVDD_D 26 -

P Gate drive voltage supply requires 0.1 uF capacitor to GND_D

GVDD_AB - 44

P Gate drive voltage supply requires 0.22 uF capacitor to GND_A/GND_B

GVDD_CD - 23

P Gate drive voltage supply requires 0.22 uF capacitor to GND_C/GND_D

INPUT_A 4 6

I Input signal for half bridge A

INPUT_B 5 7

I Input signal for half bridge B

INPUT_C 10 12

I Input signal for half bridge C

INPUT_D 11 13

I Input signal for half bridge D

M1 20 20

I Mode selection

M2 21 21

I Mode selection

M3 22 22

I Mode selection

NC 59-62 -

- No connect, pins may be grounded.

OC_ADJ 1 3

O Analog over current programming pin requires resistor to ground.

OSC_IO+ 13 15

I/O Oscillaotor master/slave output/input.

OSC_IO- 14 16

I/O Oscillaotor master/slave output/input.

/OTW - 18

O Overtemperature warning signal, open drain, active low.

/OTW1 16 -

O Overtemperature warning signal, open drain, active low.

/OTW2 17 -

O Overtemperature warning signal, open drain, active low.

OUT_A 52, 53 39, 40

O Output, half bridge A

OUT_B 44, 45 36

O Output, half bridge B

OUT_C 36, 37 31

O Output, half bridge C

OUT_D 28, 29 27, 28

O Output, half bridge D

PSU_REF 63 1

P PSU Reference requires close decoupling of 330 pF to AGND

PVDD_A 50, 51 41, 42

P

Power supply input for half bridges A requires close decoupling of 2.2-uF capacitor

to GND_A

PVDD_B 42, 43 35

P

Power supply input for half bridges B requires close decoupling of 2.2-uF capacitor

to GND_B

PVDD_C 38, 39 32

P

Power supply input for half bridges C requires close decoupling of 2.2-uF capacitor

to GND_C

PVDD_D 30, 31 25, 26

P

Power supply input for half bridges D requires close decoupling of 2.2-uF capacitor

to GND_D

READY 19 19

O Normal operation; open drain; active high

/RESET 2 4

I Device reset Input; active low, requires 47kOhm pull up resistor to VREG.

/SD 15 17

O Shutdown signal, open drain, active low

VDD 64 2

P

Power supply for internal voltage regulator requires a 10-uF capacitor in parallel

with a 0.1-uF capacitor to GND for decoupling.

VI_CM 6 8

O

Analog comparator reference node requires close decoupling of

1 nF to AGND

VREG 9 11

P Internal regulator supply filter pin requires 0.1-uF capacitor to AGND

(1) I = input, O = output, P = power

26

DRA-F107 / DRA-F107DAB

Page 27

ICE2QS01 (IC93)

Pin Symbol Function

1 ZC Zero Crossing

2 REG Regulation

3 CS Primary Current Sensing

4, 5 HV High Voltage input

6 OUT gate driver out put

7 VCC IC supply voltage

8 GND Common ground

1

6

7

8

4

3

2

5

GNDZC

REG

CS

VCC

OUT

HV

HV

Blockdigram

GND

8

CS

3

REG

2

OUT

6

ZC

1

controller

V

os

OLP

VCC

OVP

VCC

UVP

output

OVP

current limitation /

foldback correction

V

V

V

V

auto

restart

latch

off

current measurement

V

SWP

V

REF

R

ZCT2

VCCOVP

vccuvp

OPOVP

csSW

v1

power management

Reg

Vcsth

on/off FF

gate driver

PWM generator

Zero-crossing

counter

up/down

counter

HV

4, 5

VCC

7

power cell

V

OLP

active burst

control

ringing

suppression

time control

V

ZCT1

27

DRA-F107 / DRA-F107DAB

Page 28

ICE2QS01 Functional description

Functional Description

3 Functional Description

3.1 VCC Pre-Charging and Typical

VCC Voltage During Start-up

In the controller ICE2QS01, a power cell is integrated.

As shown in Figure 2, the power cell consists of a high

voltage device and a controller, whereby the high

voltage device is controlled by the controller. The

power cell provides a pre-charging of the VCC

capacitor till VCC voltage reaches the VCC turned-on

threshold V

VCCon

and the IC begins to operate, while it

may keep the VCC voltage at a constant value during

burst mode operation when the output voltage is pulled

down or the power from the auxiliary winding is not

enough, or when the IC is latched off in certain

protection mode.

Once the mains input voltage is applied, a rectified

voltage shows across the capacitor C

bus

. The high

voltage device provides a current to charge the VCC

capacitor C

vcc

. Before the VCC voltage reaches a

certain value, the amplitude of the current through the

high voltage device is only determined by its channel

resistance and can be as high as several mA. After the

VCC voltage is high enough, the controller controls the

high voltage device so that a constant current around

1mA is provided to charge the VCC capacitor further,

until the VCC voltage exceeds the turned-on threshold

V

VCCon

. As shown as the time phase I in Figure 3, the

VCC voltage increase near linearly.

Figure 3 VCC voltage at start up

The time taking for the VCC pre-charging can then be

approximately calculated as:

[1]

where I

VCCcharge2

is the charging current from the power

cell which is 1.05mA, typically.

Exceeds the VCC voltage the turned-on threshold

V

VCCon

of at time t1, the power cell is switched off, and

the IC begins to operate with a soft-start. Due to power

consumption of the IC and the fact that still no energy

from the auxiliary winding to charge the VCC capacitor

before the output voltage is built up, the VCC voltage

drops (Phase II). Once the output voltage is high

enough, the VCC capacitor receives then energy from

the auxiliary winding from the time point t

2

on. The VCC

then will reach a constant value depending on output

load.

Since there is a VCC undervoltage protection, the

capacitance of the VCC capacitor should be selected to

be high enough to ensure that enough energy is stored

in the VCC capacitor so that the VCC voltage will never

touch the VCC under voltage protection threshold

V

VCCUVP

before the output voltage is built up. Therefore,

the capacitance should fulfill the following requirement:

[2]

with I

VCCop

the operating current of the controller.

3.2 Soft-start

At the time t1, the IC begins to operate with a soft-start.

By this soft-start the switching stresses for the switch,

diode and transformer are minimised. The soft-start

implemented in the ICE2QS01 is a digital time-based

function. The preset soft-start time is 24ms with 8

steps. The internal reference for the regulation voltage

begins at 1.35V and with an increment of 0.35V for

each following step.

3.3 Normal Operation

The PWM section of the IC can be divided into two

main portions: PWM controller for normal operation

and PWM controller for burst mode operation. The

PWM controller for normal operation will be described

in the following paragraphs, while the PWM controller

for burst mode operation will be discussed in the next

section.

The PWM controller for normal operation consists of

digital signal processing circuit including an up/down

counter, a zero-crossing counter (ZC-counter) and a

comparator, and analog circuit including a current

measurement unit and a comparator. The switch-on

and -off time point is determined by the digital circuit

and the analog circuit, respectively. As input

information for the switch-on determination, the zerocrossing input signal and the value of the up/down

counter are needed, while the feedback signal v

REG

and the current sensing signal vCS are necessary for

the switch-off determination. Details about the

operation of the PWM controller in normal operation

are illustrated in the following paragraphs.

3.3.1 Switch-on Determination

As mentioned above, the digital signal processing

circuit consists of an up/down counter, a zero-crossing

counter and a comparator. A ringing suppression time

V

VCCon

VCC

V

VCCUVP

t1

t

t2

iiiiii

t

1

V

VCConCvcc

I

VCCch e2arg

--------------------------------- -=

C

vcc

I

VCCopt2t1

–

V

VCConVVCCUVP

–

------------------------------------------------t

DRA-F107 / DRA-F107DAB

28

Page 29

Functional Description

controller is implemented to avoid mistriggering by the

ring after MOSFET is turned off. Functionality of these

parts is described as in the following.

3.3.1.1 Up/down Counter

The up/down counter stores the number of zero

crossing to be ignored before the main power switch is

switched on after demagnetisation of the transformer.

This value is a function of the regulation voltage, which

contains information about the output power.

Generally, a high output power results in a high

regulation voltage. According to this information, the

value in the up/down counter is changed to a low value

in case of high regulation voltage, and to a high value

in case of low regulation voltage. In ICE2QS01, the

lowest value of the counter is 1 and the highest 7.

Following text explains how the up/down counter value

changes in responding to the regulation voltage v

REG

.

The regulation voltage v

REG

is internally compared with

three thresholds V

RL

, VRH and VRM. According to the

results, the value in the up/down counter is changed,

which is summarised in Table 1 and Figure 4

respectively.

Table 1 Operation of the up/down counter

Figure 4 Up/down counter operation

According to the comparison results the up/down

counter counts upwards, keeps unchanged or counts

downwards. However, the value in up/down counter is

limited between 1 and 7. If the counter tends to count

beyond this range, the attempt is ignored.

In normal case, the up/down counter can only be

changed by one each time at the clock period of 48ms.

However, to ensure a fast response to sudden load

increase, the counter is set to 1 in the following

switching period after the regulation voltage v

REG

exceeds the threshold VRM.

3.3.1.2 Zero-Crossing Counter and Ringing

Suppression Time Controller

In the system, the voltage from the auxiliary winding is

applied to the zero-crossing pin through a RC network,

which provides a time delay to the voltage from the

auxiliary winding. Internally, this pin is connected to a

clamping network, a zero-crossing detector, an output

overvoltage (OP OVP) detector and a ringing

suppression time controller.

During on-state of the power switch a negative voltage

applies to the ZC pin. Through the internal clamping

network, the voltage at the pin is clamped to certain

level. However, it is highly recommended that a fastrecovery diode D

zc

is added to block the negative

voltage when the power switch is on. This is because

the device in MOS technology is sensitive to negative

voltage.

The voltage at the ZC pin v

ZC

is compared with the

threshold V

ZCT1

. Once the voltage vZC crosses the

threshold at its falling edge, a pulse is generated which

is fed to the zero-crossing counter and the counter

value increases by 1.

After MOSFET is turned on, there will be some

oscillation on V

DS

, which will also appear on the voltage

on ZC pin. To avoid the MOSFET is turned on

mistriggerred by such oscillation, a ringing suppression

timer is implemented. The time is dependent on the

voltage v

ZC

. When the voltage v

ZC

is lower than the

threshold V

ZCT2

, a longer preset time applies, while a

shorter time is set when the voltage v

ZC

is higher than

the threshold.

The voltage v

ZC

is used for the output overvoltage

protection, as well. Once the voltage at this pin is

higher than the threshold V

OPOVP

during off-time of the

main switch, the IC is latched off after a fixed blanking

time.

To achieve the switch-on at voltage valley, the voltage

from the auxiliary winding is fed to a time delay network

(the RC network consists of D

zc

, R

zc1

, R

zc2

and Czcas

shown in typical application circuit) before it is applied

to the zero-crossing detector through the ZC pin. The

needed time delay to the main oscillation signal 't

should be approximately one fourth of the oscillation

period (by transformer primary inductor and drainsource capacitor) minus the propagation delay from the

v

REG

up/down counter

action

Always lower than V

RL

Count upwards till

7

Once higher than V

RL

, but

always lower than V

RH

Stop counting, no

value changing

Once higher than V

RH

, but

always lower than V

RM

Count downwards

till 1

Once higher than V

RM

Set up/down

counter to 1

1Case 3

Case 2

Case 1

n

n+1

n+2

n+2

n+2

n+2

n+1nn-1

4 5 6 6 6 6 5 4 311

2 3 4 4 4 4 3 2 1

7 7 7 7 7 7 6 5 4

t

t

V

FB

V

RM

V

RH

V

RL

clock T=48ms

1

29

DRA-F107 / DRA-F107DAB

Page 30

Functional Description

detected zero-crossing to the switch-on of the main

switch t

delay

, theoretically:

[3]

This time delay should be matched by adjusting the

time constant of the RC network which is calculated as:

[4]

3.3.1.3 Switch-on Determination

In the system, turn-on of the power switch depends on

the value of the up/down counter, the value of the zerocrossing counter and the voltage at the ZC pin v

ZC

.

Turn-on happens only when the value in the both

counters are the same and the voltage at the ZC is

lower than the threshold V

ZCT1

. For comparison of the

values from both counters, a digital comparator is used.

Once these counters have the same value, the

comparator generates a signal which sets the on/off

flip-flop, only when the voltage v

ZC

is lower than the

threshold V

ZCT1

.

Another signal which may trigger the digital comparator

is the output of a T

sMax

clock signal, which limits the

maximum off time to avoid the low-frequency

operation.

During active burst mode operation, the digital

comparator is disabled and no pulse will be generated.

3.3.2 Switch-off Determination

In the converter system, the primary current is sensed

by an external shunt resistor, which is connected

between low-side terminal of the main power switch

and the common ground. The sensed voltage across

the shunt resistor v

CS

is applied to an internal current

measurement unit, and its output voltage v

1

is

compared with the regulation voltage v

reg

. Once the

voltage v

1

exceeds the voltage v

REG

, the output flip-flop

is reset. As a result, the main power switch is switched

off. The relationship between the v

1

and the vcs is

described by:

[5]

To avoid mistriggering caused by the voltage spike

across the shunt resistor after switch-on of the main

power switch, a 330ns leading edge blanking time

applies to output of the comparator.

3.3.3 Foldback Point Correction

In addition to the cycle-by-cylce primary current

limitation, the IC incorporats a foldback point

correction. The current limit on CS pin voltage is now a

time dependent one. If the mains input voltage is high,

the MOSFET on time will be short and the current limit

will be low. In such a way, the maximum output power

for the SMPS designed with ICE2QS01 will be nearly

constant against the variations of mains input voltage.

The current sense voltage limit versus the MOSFET

maximum on time is shown in Figure 5.

't

T

osc

4

--------- -t

delay

–=

W

td

C

zc

R

zc1Rzc2

R

zc1Rzc2

+

--------------------------- -=

v

1

3.3 vCS 0.7+=

Figure 5 Maximum current limit versus MOSFET maximum on time

0

0.2

0.4

0.6

0.8

1

0 5 10 15 20 25 30

Ton(us)

Vcs-max(V)

DRA-F107 / DRA-F107DAB

30

Page 31

Functional Description

3.4 Active Burst Mode Operation

At very low load condition, the IC enters active burst

mode operation to minimize the input power. Details

about active burst mode operation are explained in the

following paragraphs.

3.4.1 Entering Active Burst Mode Operation

For determination of entering active burst mode

operation, three conditions apply:

the regulation voltage is lower than the threshold of

V

EB

(1.1V). Accordingly, the peak voltage across the

shunt resistor is 0.11V;

the up/down counter has its maximal value of 7; and

a certain blanking time (24ms).

Once all of these conditions are fulfilled, the active

burst mode flip-flop is set and the controller enters

burst mode operation. This multi-conditional

determination for entering active burst mode operation

prevents mistriggering of entering active burst mode

operation, so that the controller enters active burst

mode operation only when the output power is really

low during the preset blanking time.

3.4.2 During Active Burst Mode Operation

After entering the Active Burst Mode the regulation

voltage rises as V

OUT

starts to decrease due to the

inactive PWM section. One comparator observes the

regulation signal if the voltage level V

BH

(3.6V) is

exceeded. In that case the internal circuit is again

activated by the internal bias to start with swtiching.

Turn-on of the power MOSFET is triggered by the

timer. The PWM generator for burst mode operation

composes of a timer with a fixed frequency of 80kHz,

typically, and an analog comparator. Turn-off is

resulted by comparison of the voltage signal v

1

with an

internal threshold, by which the voltage across the

shunt resistor V

csB

is 0.25V, accordingly. A turn-off can

also be triggered by the maximal duty ratio controller

which sets the maximal duty ratio to 50%. In operation,

the output flip-flop will be reset by one of these signals

which come first.

If the output load is still low, the regulation signal

decreases as the PWM section is operating. When

regulation signal reaches the low threshold V

BL

(3.0V),

the internal bias is reset again and the PWM section is

disabled until next time regultaion siganl increases

beyond the V

BH

threshold. If working in active burst

mode the regulation signal is changing like a saw tooth

between 3.0V and 3.6V shown in Figure 6.

3.4.3 Leaving Active Burst Mode

The regulation voltage immediately increases if there is

a high load jump. This is observed by one comparator.

As the current limit is 25% during active burst mode a

certain load is needed so that regulation voltage can

exceed V

LB

(4.5V). After leaving active busrt mode,

maximum current can now be provided to stabilize V

O

.

In addition, the up/down counter will be set to 1

immediately after leaving active burst mode. This is

helpful to decrease the output voltage undershoot.

3.4.4 IC Power Supply During Active Burst

Mode

During active burst mode operation, the power cell is

activated again. Once the power from the auxiliary

winding is not high enough to keep the VCC voltage

above the preset value of V

VCCBL

, the power cell keeps

the VCC voltage at the preset value V

VCCBL

. Otherwise,

if the VCC voltage is still above this value, no current

flows through the power cell though it is activated.

Figure 6 Signals in active burst mode

1.1V

3.6V

4.4V

V

REG

t

0.25V

1.0V

V

CS

12.5V

V

VCC

t

t

V

O

t

3.0V

Max. Ripple < 1%

Blanking Window (24ms)

Current limit level

during Active Burst

Mode

Leaving

Active Burst

Mode

Entering

Active Burst

Mode

31

DRA-F107 / DRA-F107DAB

Page 32

Functional Description

3.5 Protection Functions

The IC provides full protection functions. The following

table summarizes these protection functions.

Table 2 Protection features

During operation, the VCC voltage is continuously

monitored. In case of an under- or an over-voltage, the

IC is reset and the main power switch is then kept off.

After the VCC voltage falls below the threshold

V

VCCUVP

, the power cell is activated. The VCC capacitor

is then charged up. Once the voltage exceeds the

threshold V

VCCon

, the IC begins to operate with a new

soft-start.

In case of open control loop or output over load, the

regulation voltage will be pulled up . After a blanking

time of 24ms, the IC enters auto-restart mode. The

blanking time here enables the converter to provide a

high power in case the increase in V

REG

is due to a

sudden load increase. During off-time of the power

switch, the voltage at the zero-crossing pin is

monitored for output over-voltage detection. If the

voltage is higher than the preset threshold v

OPOVP

, the

IC is latched off after the preset blanking time.

If the voltage at the current sensing pin is higher than

the preset threshold v

csSW

during on-time of the power

switch, the IC is latched off. This is short-winding

protection.

During latch-off protection mode, the power cell is

activated and it keeps the VCC voltage at the level of

V

VCCBL.

VCC Overvoltage Auto Restart Mode

VCC Undervoltage Auto Restart Mode

Overload/Open Loop Auto Restart Mode

Output Overvoltage Latched Off Mode

Short Winding Latched Off Mode

32

DRA-F107 / DRA-F107DAB

Page 33

Electrical Characteristics

4 Electrical Characteristics

Note: All voltages are measured with respect to ground (Pin 8). The voltage levels are valid if other ratings are

not violated.

4.1 Absolute Maximum Ratings

Note: Absolute maximum ratings are defined as ratings, which when being exceeded may lead to destruction

of the integrated circuit. For the same reason make sure, that any capacitor that will be connected to pin 7

(VCC) is discharged before assembling the application circuit.

4.2 Operating Range

Note: Within the operating range the IC operates as described in the functional description.

Parameter Symbol Limit Values Unit Remarks

min. max.

HV Voltage V

HV

-500V

VCC Supply Voltage V

VCC

-0.3 27 V

REG Voltage V

REG

-0.3 5.0 V

ZC Voltage V

ZC

-0.3 5.0 V

CS Voltage V

CS

-0.3 5.0 V

OUT Voltage V

OUT

-0.3 27 V

Junction Temperature T

j

-40 125 qC

Storage Temperature T

S

-55 150 qC

Thermal Resistance

Junction-Ambient

R

thJA

- 90 K/W PG-DIP-8

ESD Capability V

ESD

- 2 kV Human body model

1)

1)

According to EIA/JESD22-A114-B (discharging a 100pF capacitor through a 1.5k: series resistor)

Parameter Symbol Limit Values Unit Remarks

min. max.

VCC Supply Voltage V

VCC

V

VCCUVPVVCCOVP

V

Junction Temperature T

jCon

-25 125 °C

DRA-F107 / DRA-F107DAB

33

Page 34

Electrical Characteristics

4.3 Characteristics

4.3.1 Supply Section

Note: The electrical characteristics involve the spread of values guaranteed within the specified supply voltage

and junction temperature range T

J

from – 25 oC to 125oC. Typical values represent the median values,

which are related to 25°C. If not otherwise stated, a supply voltage of V

CC

= 18 V is assumed.

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Start-Up Current I

VCCstart

- 300 550 PAV

VCC

= 21V

VCC Charge Current I

VCCcharge1

5.0 mA V

VCC

= 0V

I

VCCcharge2

0.55 1.05 1.60 mA V

VCC

= 1V

I

VCCcharge3

-0.88-mAV

VCC

= 21V

Leakage Current of

Power Cell

I

StartLeak

-0.250PAV

HV

= 610V

at T

j

= 100°C

Supply Current in normal

operation

I

VCCop

- 2.5 3.6 mA Output low

Supply Current in

Auto Restart Mode

with Inactive Gate

I

VCCrestart

-300-PA

Supply Current in

Latch-off Mode

I

VCClatch

-300-PA

Supply Current in Burst Mode

with Inactive Gate

I

VCCburst

- 500 950 PAV

REG

= 2.5V

Supply Voltage with no power

from auxiliary winding in burst

mode or in latch-off mode

V

VCCBL

-12.5-VV

HV

= 100V

VCC Turn-On Threshold V

VCCon

21.2 22.0 22.8 V

Internal Reference Voltage V

REF

4.8 5.0 5.2 V measured at pin REG,

I

REG

= 0

34

DRA-F107 / DRA-F107DAB

Page 35

Electrical Characteristics

4.3.2 PWM Section

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Regulation Pull-Up Resistor R

REG

14 23 33 k:

PWM-OP Gain A

V

3.18 3.3 - -

Offset for Voltage Ramp V

OS

0.63 0.7 - V

Soft-Start time t

SOFTS

18 21 38 ms

Zero crossing threshold voltage V

ZCT1

20 50 110 mV

Ringing suppression threshold V

ZCT2

0.7 V

Minimum ringing suppression

time

t

ZCRST1

2.2 4.2 5.5 PsV

ZC

> V

ZCT2

Maximum ringing suppression

time

t

ZCRST2

-42-PsV

ZC

< V

ZCT2

Threshold to set Up/Down

Counter to one

V

RM

3.9 V

Threshold for downward

counting

V

RH

3.2 V

Threshold for upward counting V

RL

2.5 V

Counter time

1)

t

COUNT

48 ms

Maximum restart time in normal

operation

t

sMax

33 42 60 PsV

ZC<VZCT1

Leading Edge Blanking t

LEB

200 330 460 ns

Peak current limitation in normal

operation

V

csth

0.95 1.0 1.05 V

Regulation voltage for entering

Burst Mode

V

EB

1.1 V

Regulation voltage for leaving

Burst Mode

V

LB

4.5 V

Regulation voltage for burst-on V

BH

3.6 V

Regulation voltage for burst-off V

BL

3.0 V

Fixed Switching Frequency in

Burst Mode

f

sB

64 80 96 kHz

Max. Duty Cycle in Burst Mode D

maxB

0.5

Peak Current Limitation in Burst

Mode

V

csB

0.22 0.25 0.3 V

1) The parameter is not subject to production test - verified by design/characterization

35

DRA-F107 / DRA-F107DAB

Page 36

Electrical Characteristics

4.3.3 Protection

Note: The trend of all the voltage levels in the Control Unit is the same regarding the deviation except V

VCCOVP

4.3.4 Gate Driver

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

VCC overvoltage threshold V

VCCOVP

24 25.0 26 V

VCC undervoltage threshold V

VCCUVP

10.3 11.0 11.7 V

Over Load or Open Loop

Detection threshold for OLP

protection at REG pin

V

OLP

4.5 V

Over Load or Open Loop

Protection Blanking Time

T

OLP-B

16 24 35 ms

Output Overvoltage detection

threshold at the ZC pin

V

OPOVP

4.5 V

Threshold for short winding

protection

V

csSW

1.68 V

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Output voltage at logic low V

GATElow

0.7 V I

OUT

= 20mA

Output voltage at logic high V

GATEhigh

10.0 V I

OUT

= -20mA

Output voltage active shut down V

GATEasd

1.0 V

V

V

VCC

= 7V

I

OUT

= 20mA

Rise Time t

rise

-100-nsC

OUT

= 4.7nF

Fall Time t

fall

-25-nsC

OUT

= 4.7nF

36

DRA-F107 / DRA-F107DAB

Page 37

ICE2B265 (IC92)

Blockdiagram

Thermal Shutdown

T

j

>140°C

Internal Bias

Voltage

Reference

6.5V

4.8V

Leading Edge

Blanking

220ns

Undervoltage

Lockout

Oscillator

Duty Cycle

max

Current-Limit

Comparator

x3.65

Soft-Start

Comparator

Current Limiting

PWM OP

Improved Current Mode

Soft Start

13.5V

8.5V

6.5V

C2

C1

16.5V

4.0V

R

FB

6.5V

Protection Unit

Power-Down

Reset

Power-Up

Reset

Power Management

C

Soft-Start

C

VCC

R

Start-up

85 ... 270 VAC

C

Line

VCC

GND

+

-

Converter

DC Output

V

OUT

f

standby

-f

norm

CoolSET™-F2

Optocoupler

Snubber

Spike

Blanking

5s

PWM

Comparator

R

SQ

Q

Error-Latch

C4

5.3V

C3

4.8V

R

Soft-Start

Gate

Driver

G3

G2

G1

G4

SoftS

5.3V

T1

V

csth

Propagation-Delay

Compensation

R

S

Q

Q

PWM-Latch

0.72

Clock

U

FB

f

osc

f

norm

f

standby

Standby Unit

FB

4.0V

R

Sense

Drain

Isense

0.8V

C5

0.3V

10k

D1

5.6V

CoolMOS™

ICE2Axxxx

ICE2Bxxxx

f

norm

f

standby

100kHz

21.5kHz

67kHz

20kHz

Duty Cycle Max

Pin Symbol Function

1 SoftS Soft-Start

2FB Feedback

3 Isense Controller Current Sense Input,

CoolMOS™ Source Output

4 Drain

650V

1)

/800V2)CoolMOS™ Drain

1)

at Tj= 110°C

5 Drain

650V

1)

/800V2)CoolMOS™ Drain

2)

at Tj=25°C

6 N.C Not connected

7 VCC Controller Supply Voltage

8 GND Controller Ground

1

6

7

8

4

3

2

5

VCCFB

Is ens e

Dr ain

Sof tS

N. C

GND

Dr ain

37

DRA-F107 / DRA-F107DAB

Page 38

Functional Description

3 Functional Description

3.1 Power Management

Figure 6 Power Management

The Undervoltage Lockout monitors the external

supply voltage V

VCC

. In case the IC is inactive the

current consumption is max. 55μA. When the SMPS is

plugged to the main line the current through R

Start-up

charges the external Capacitor C

VCC

. When V

VCC

exceeds the on-threshold V

CCon

=13.5V the internal bias

circuit and the voltage reference are switched on. After

that the internal bandgap generates a reference

voltage V

REF

=6.5V to supply the internal circuits. To

avoid uncontrolled ringing at switch-on a hysteresis is

implemented which means that switch-off is only after

active mode when Vcc falls below 8.5V.

In case of switch-on a Power Up Reset is done by

resetting the internal error-latch in the protection unit.

When V

VCC

falls below the off-threshold V

CCoff

=8.5V the

internal reference is switched off and the Power Down

reset let T1 discharging the soft-start capacitor C

Soft-Start

at pin SoftS. Thus it is ensured that at every switch-on

the voltage ramp at pin SoftS starts at zero.

3.2 Improved Current Mode

Figure 7 Current Mode

Current Mode means that the duty cycle is controlled

by the slope of the primary current. This is done by

comparison the FB signal with the amplified current

sense signal.

Figure 8 Pulse Width Modulation

In case the amplified current sense signal exceeds the

FB signal the on-time T

on

of the driver is finished by

resetting the PWM-Latch (see Figure 8).

The primary current is sensed by the external series

resistor R

Sense

inserted in the source of the integrated

CoolMOS™. By means of Current Mode regulation, the

Internal

Bias

Voltage

Reference

6.5V

4.8V

Undervoltage

Lockout

13.5V

8.5V

Power-Down

Reset

Power-Up

Reset

Power Management

5.3V

4.0V

T1

PWM-Latch

RSQ

Q

Error-Latch

SoftS

6.5V

Error-Detection

VCC

Main Line (100V-380V)

Primary Winding

Soft-Start Comparator

C

VCC

R

Soft-Start

R

Start-Up

C

Soft-Start

x3.65

PWM OP

Improved

Current Mode

0.8V

PWM Comparator

PWM-Latch

Isense

FB

RSQ

Q

Driver

Soft-Start Comparator

t

FB

Amplified Current Signal

T

on

t

0.8V

Driver

DRA-F107 / DRA-F107DAB

38

Page 39

Functional Description

secondary output voltage is insensitive on line

variations. Line variation changes the current

waveform slope which controls the duty cycle.

The external R

Sense

allows an individual adjustment of

the maximum source current of the integrated

CoolMOS™.

Figure 9 Improved Current Mode

To improve the Current Mode during light load

conditions the amplified current ramp of the PWM-OP

is superimposed on a voltage ramp, which is built by

the switch T

2

, the voltage source V1 and the 1st order

low pass filter composed of R

1

and C1(see Figure 9,

Figure 10). Every time the oscillator shuts down for

max. duty cycle limitation the switch T2 is closed by

V

OSC

. When the oscillator triggers the Gate Driver T2 is

opened so that the voltage ramp can start.

In case of light load the amplified current ramp is to

small to ensure a stable regulation. In that case the

Voltage Ramp is a well defined signal for the

comparison with the FB-signal. The duty cycle is then

controlled by the slope of the Voltage Ramp.

By means of the Comparator C5, the Gate Driver is

switched-off until the voltage ramp exceeds 0.3V. It

allows the duty cycle to be reduced continuously till 0%

by decreasing V

FB

below that threshold.

Figure 10 Light Load Conditions

3.2.1 PWM-OP

The input of the PWM-OP is applied over the internal

leading edge blanking to the external sense resistor

R

Sense

connected to pin Isense. R

Sense

converts the

source current into a sense voltage. The sense voltage

is amplified with a gain of 3.65 by PWM OP. The output

of the PWM-OP is connected to the voltage source V1.

The voltage ramp with the superimposed amplified

current signal is fed into the positive inputs of the PWMComparator, C5 and the Soft-Start-Comparator.

3.2.2 PWM-Comparator

The PWM-Comparator compares the sensed current

signal of the integrated CoolMOS

TM

with the feedback

signal V

FB

(see Figure 11). VFB is created by an

external optocoupler or external transistor in

combination with the internal pull-up resistor R

FB

and

provides the load information of the feedback circuitry.

When the amplified current signal of the integrated

CoolMOS™ exceeds the signal V

FB

the PWM-

Comparator switches off the Gate Driver.

x3.65

PWM OP

0.8V

10k

:

Oscillator

PWM Comparator

20pF

T

2

R

1

C

1

FB

PWM-Latch

V

1

C5

0.3V

Gate Driver

Voltage Ramp

V

OSC

Soft-Start Comparator

t

t

V

OSC

0.8V

FB

t

max .

Dut y Cy cle

0.3V

Gate Driver

Voltage Ramp

39

DRA-F107 / DRA-F107DAB

Page 40

Functional Description

Figure 11 PWM Controlling

3.3 Soft-Start

Figure 12 Soft-Start Phase

The Soft-Start is realized by the internal pull-up resistor

R

Soft-Start