Page 1

Ver. 1

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E2C E1K EUT

DN-HC5000

33

Serato ITCHTM for Mobile Entertainers

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

X0458V01DM/DG0910

Copyright 2009 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

CAUTION

Heed the cautions!

◎

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the cautions

indicated in the handling instructions.

Caution concerning electric shock!

◎

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

Caution concerning disassembly and

◎

Please heed the points listed below during servicing and inspection.

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

RQWKHHGJHVRISDUWVZKLFKFRXOGFDXVHLQMXU\LI¿QJHUV

are moved across them. Use gloves to protect your hands.

Only use designated parts!

◎

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement parts,

be sure to use parts which have the same poroperties. In

particular, for the important safety parts that are marked

on wiring diagrams and parts lists, be sure to use the

z

designated parts.

Be sure to mount parts and arrange the wires

◎

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high voltage

parts, so be sure to set everything back as it was originally.

Inspect for safety after servicing!

◎

Check that all screws, parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area that

has been serviced have been negatively affected, conduct

an inslation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

0ȍ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the zmark.

(2) Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, ¿Ues

or other dangerous situations.

2

Page 3

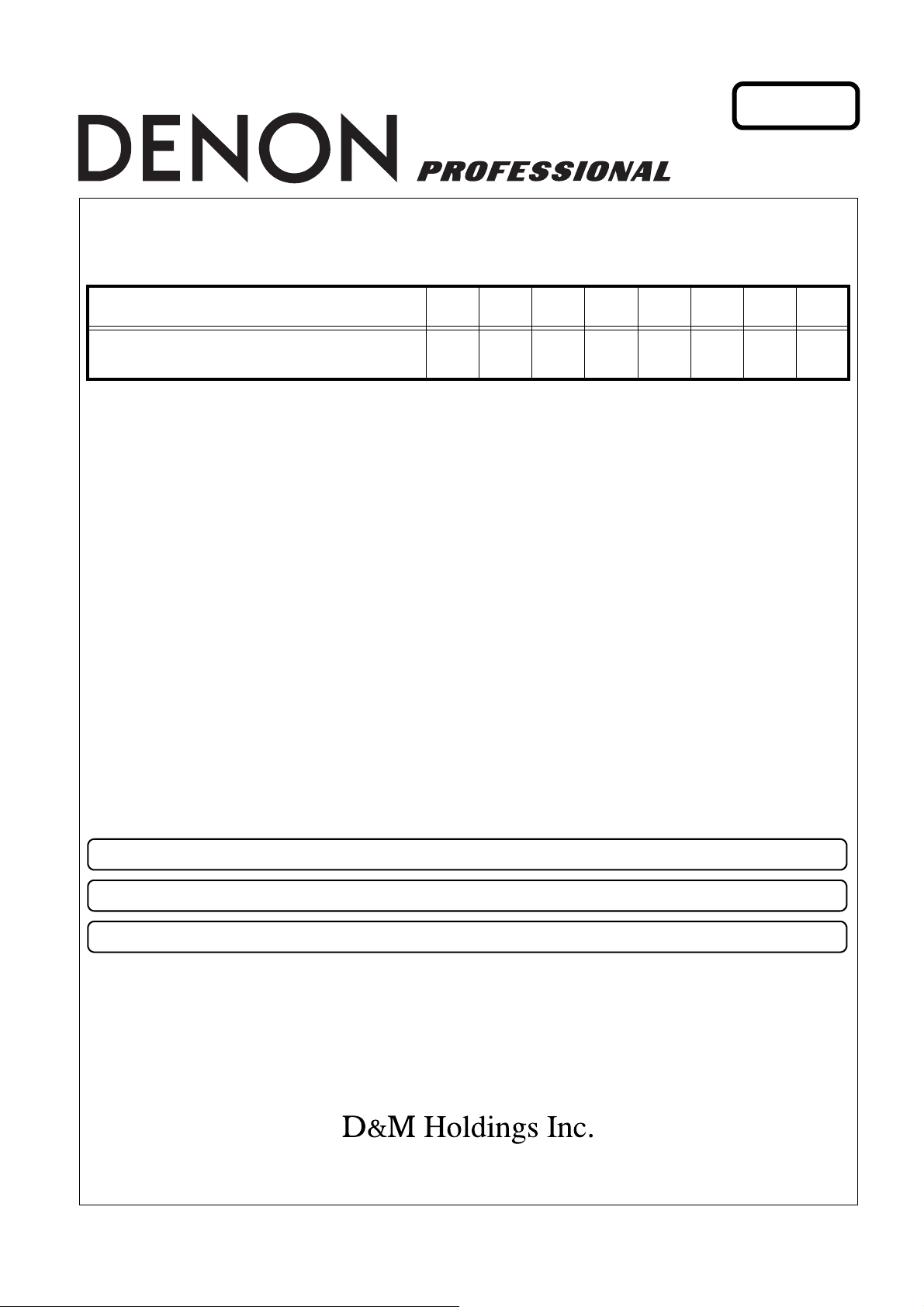

DIMENSION

-*/&065

-*/&065

0/0''

108&3

"$*/

-

3

䇭%&/0/

䇭%/%

䇭#6POMZ

㪩㪠㪪㪢㩷㪦㪝㩷㪜㪣㪜㪚㪫㪩㪠㪚㩷㪪㪟㪦㪚㪢

㪚㪘㪬㪫㪠㪦㪥

㪛㪦㩷㪥㪦㪫㩷㪦㪧㪜㪥

'PSVTFXJUI

%3*7&

64##

9$0/530-

'"%&3

'"%&3

3

Page 4

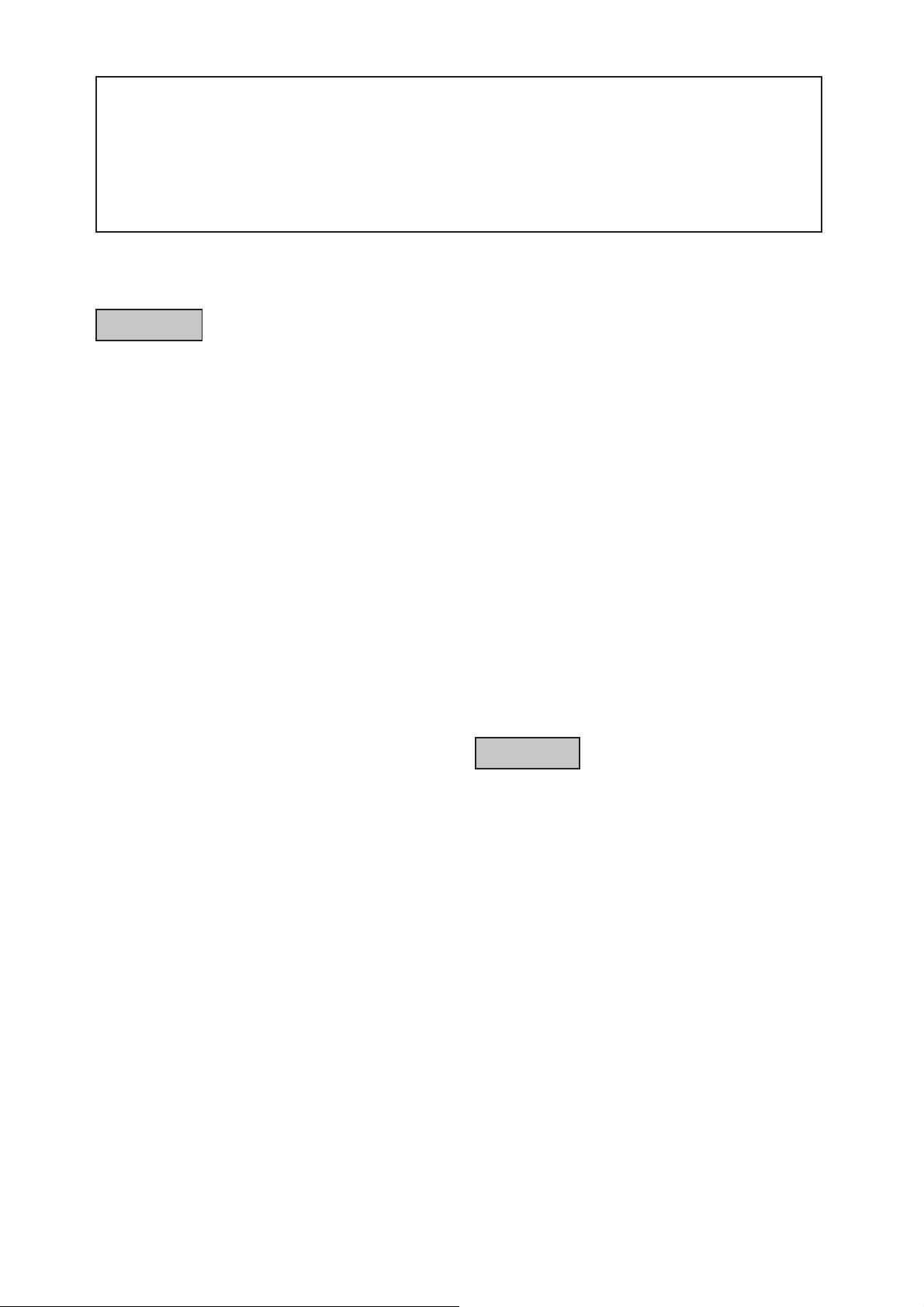

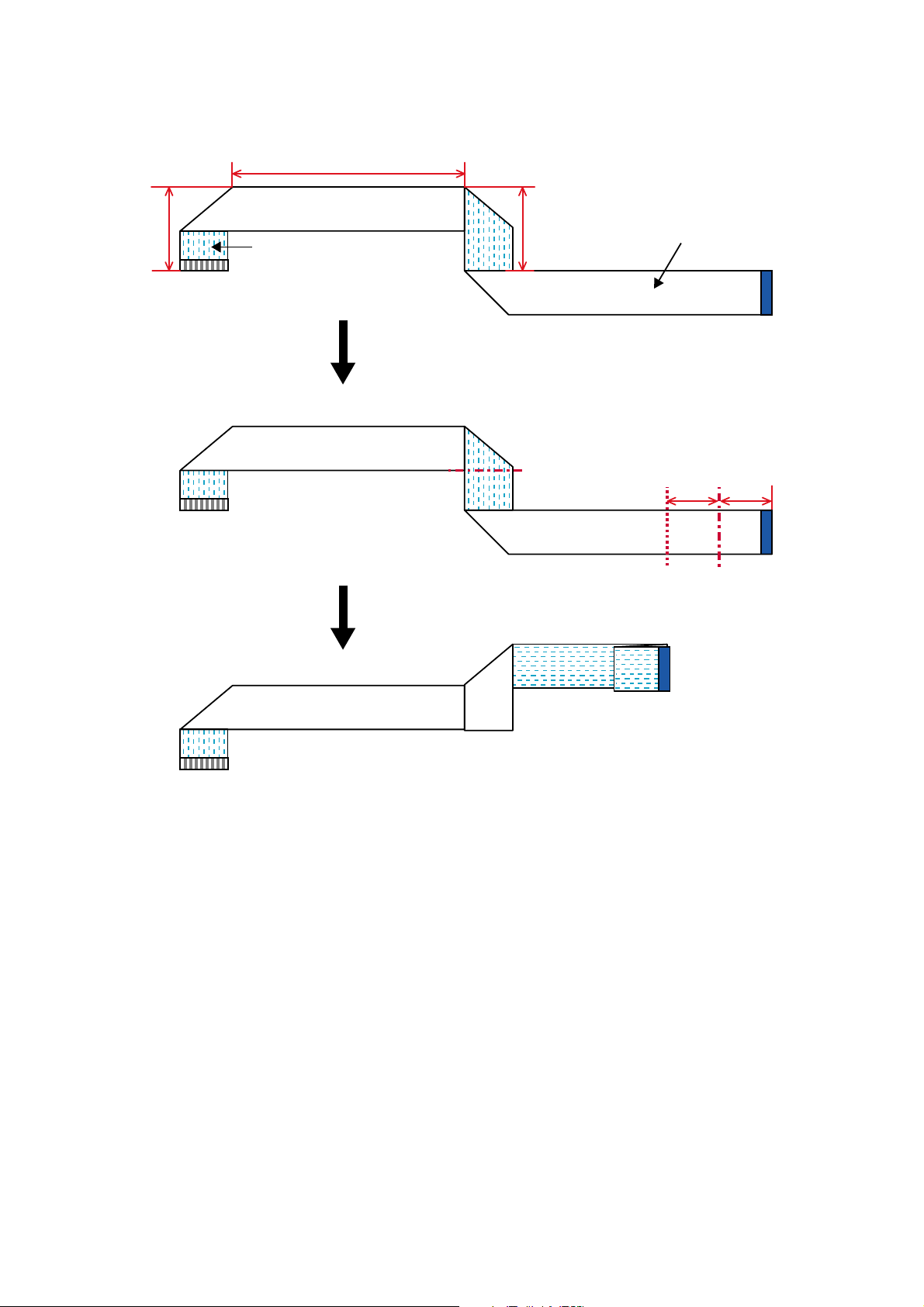

WIRE ARRANGEMENT

CX111

CX061

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise

generation.

※Refer to 6~8 page for folding the FFC.

(1) The cord holder folds as shown on the diagram.

(2) Fasten the FFC to externals of figure with a cord holder.

(3) Fasten the 6P connector with a cord holder.

4

Page 5

(4) Fasten the two 4P connectors with a cord holder.

CX042

CX272

CX271

CX041

•Fasten the cord not to touch the trans.

(5) It coverd with TOP PANEL SUB ASSY.

NOTE:The wire gets caught in TOP PANEL SUB ASSY.

5

Page 6

Folding the FFC

Printed surface

Fold as shown on the diagram.

45mm

160mm

55mm

White surface

35mm 35mm

Fold as shown on the diagram.

Fold inward

Fold inward

Fold outward

(1) 8U-110066-1 PANEL1 UNIT (00D0090290040 : 27P FFC(1.0) L=400)

6

Page 7

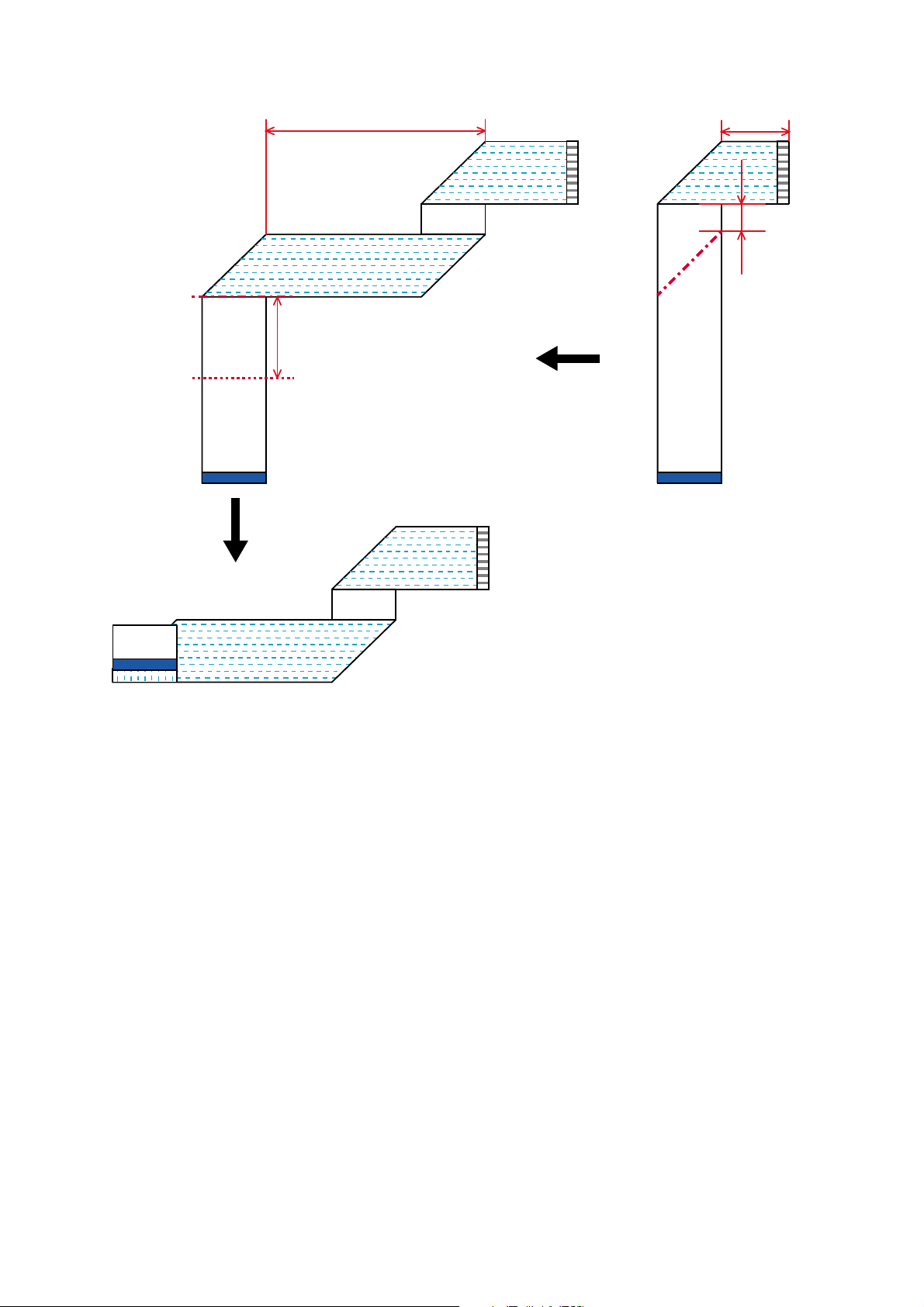

(2) 8U-110066-2 PANEL2 UNIT (00D0090290053 : 27P FFC(1.0) L=200 )

Fold inward

Fold inward

Fold outward

Fold outward

Fold outward

45mm

5mm

Fold as shown on the diagram.

Fold as shown on the diagram.

25mm

65mm

7

Page 8

(3) 8U-110066-5 DISC1 UNIT / 8U-110066-6 DISC2 UNIT

㪘㩷㫊㫀㪻㪼

㪘㩷㫊㫀㪻㪼

㪘㩷㫊㫀㪻㪼

㪘㩷㫊㫀㪻㪼

16mm

㪘㩷㫊㫀㪻㪼

㪙㩷㫊㫀㪻㪼

㪙㩷㫊㫀㪻㪼

㪙㩷㫊㫀㪻㪼

㪙㩷㫊㫀㪻㪼

16mm

㪙㩷㫊㫀㪻㪼

Fold as shown on the diagram.

Fold inward

Fold inward

Fold outward

Place fold against the A side.

(00D0090290037 : 11P FFC(1.0) L=60)

8

Page 9

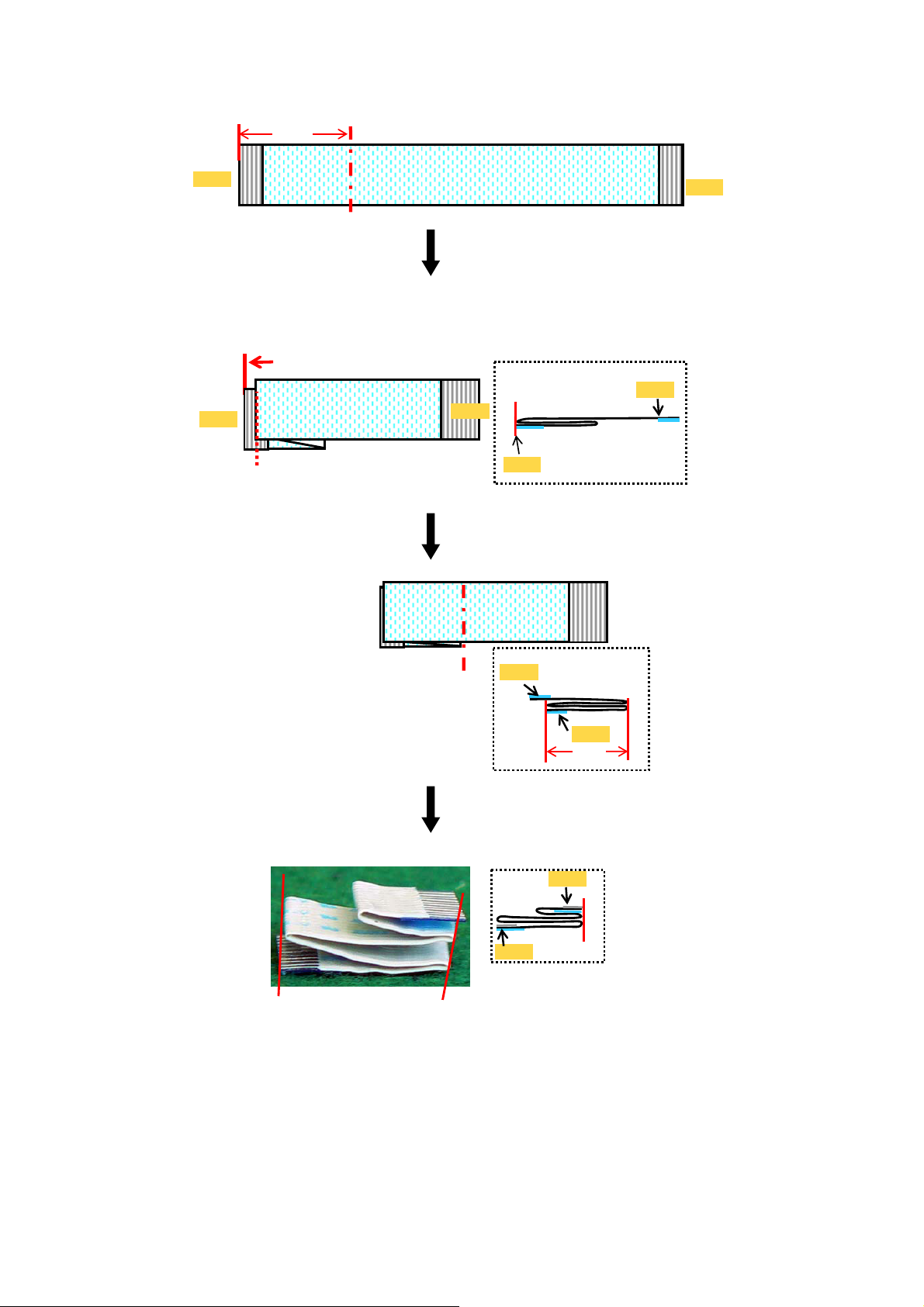

DISASSEMBLY

(Follow the procedure below in reverse order when

reassembling.)

1. Top Panel Unit

(1) Remove 10 side screws with washer and pull up the Top Panel Unit.

Notes: Do not pull out aslant to prevent FFC cable damage.

Do not fail to pull AC cord from wall outlet before disconnect the FFC cable and wire.

If AC cord is remained plugged into wall outlet, power is kept supplied in the unit, which may cause damage.

9

Page 10

ASSEMBLY NOTE

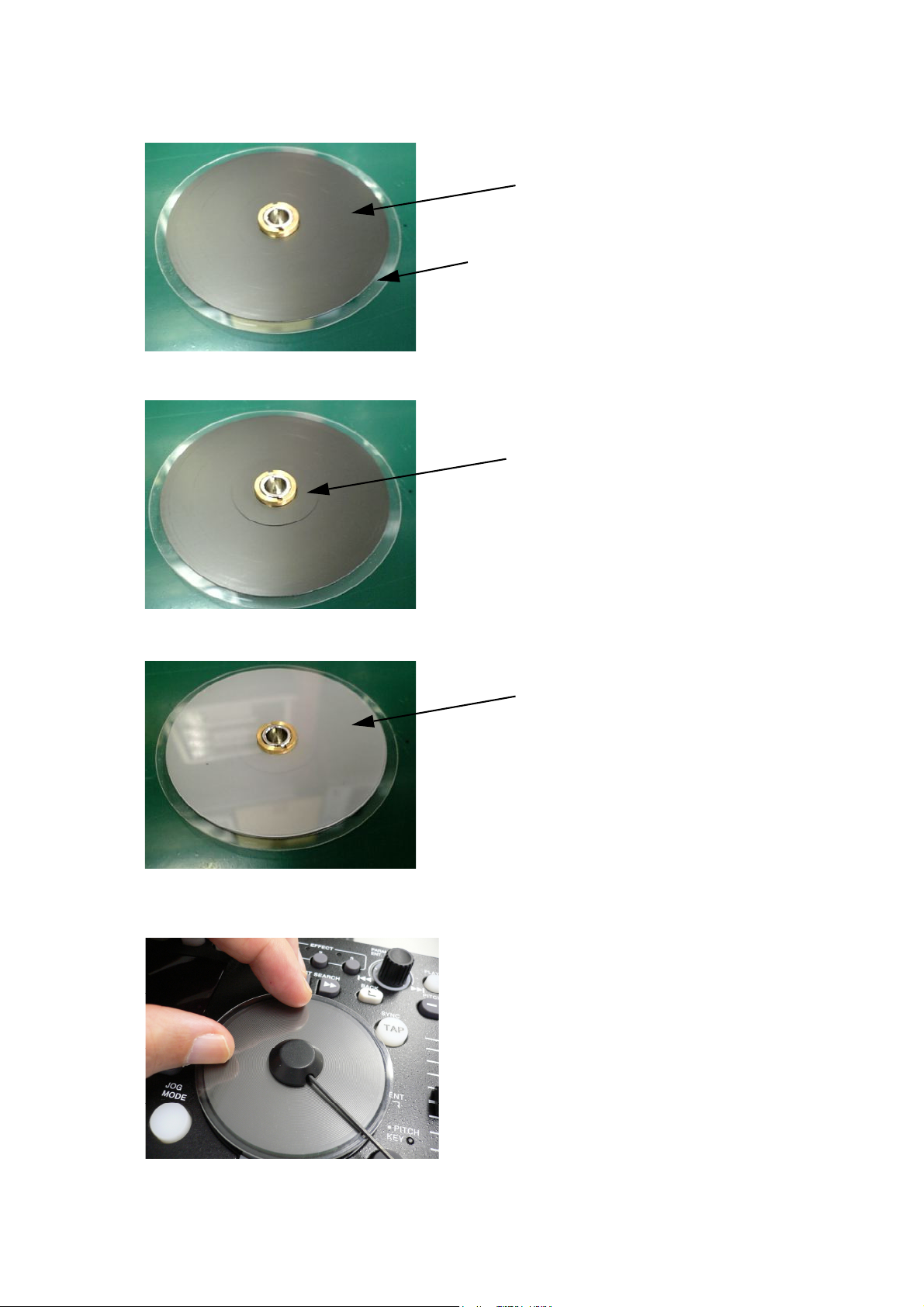

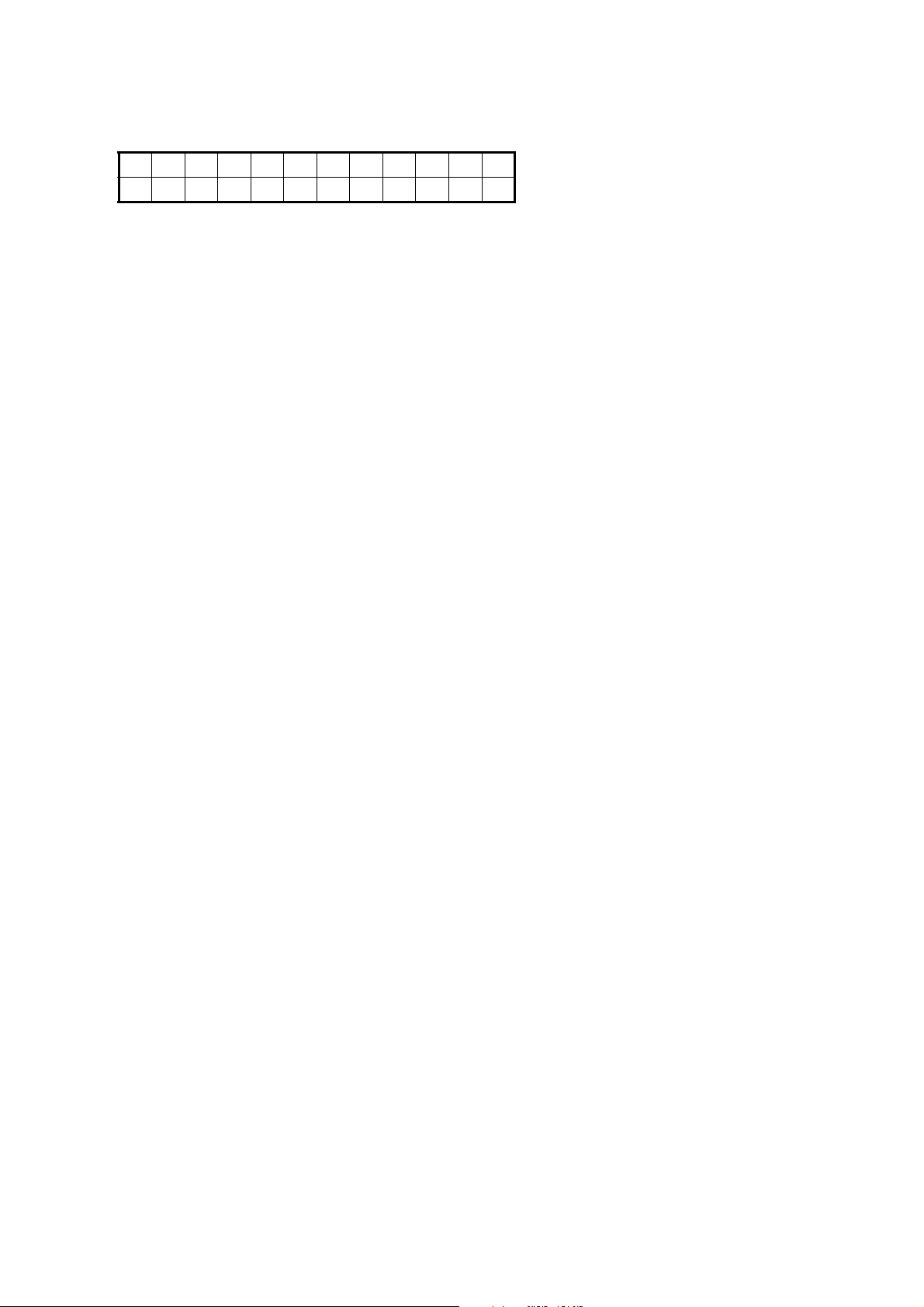

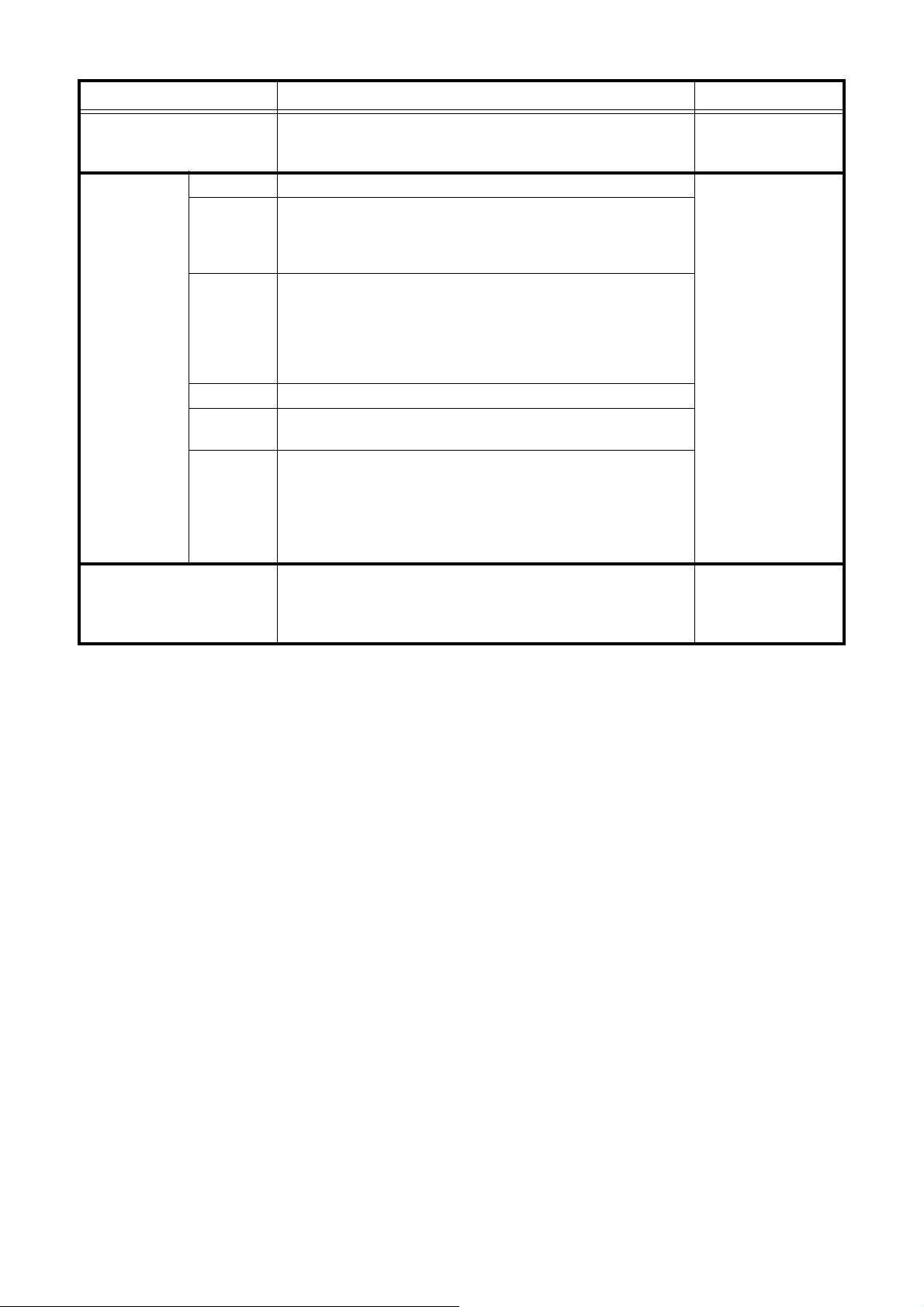

Mounting the JOG DISC

(1) Mount SLIP MAT (B) on the JOG WHEEL SUB ASSY.

(2) Next mount SLIP MAT.

SLIP MAT (B) : Ref No. 34

(The slip mat has no specific front or rear side.)

JOG WHEEL SUB ASSY : Ref No. 38

SLIP MAT : Ref No. 35

(The slip mat has no specific front or rear side.)

(3) Next mount SLIP MAT.

SLIP MAT : Ref No. 36

(luster surface)

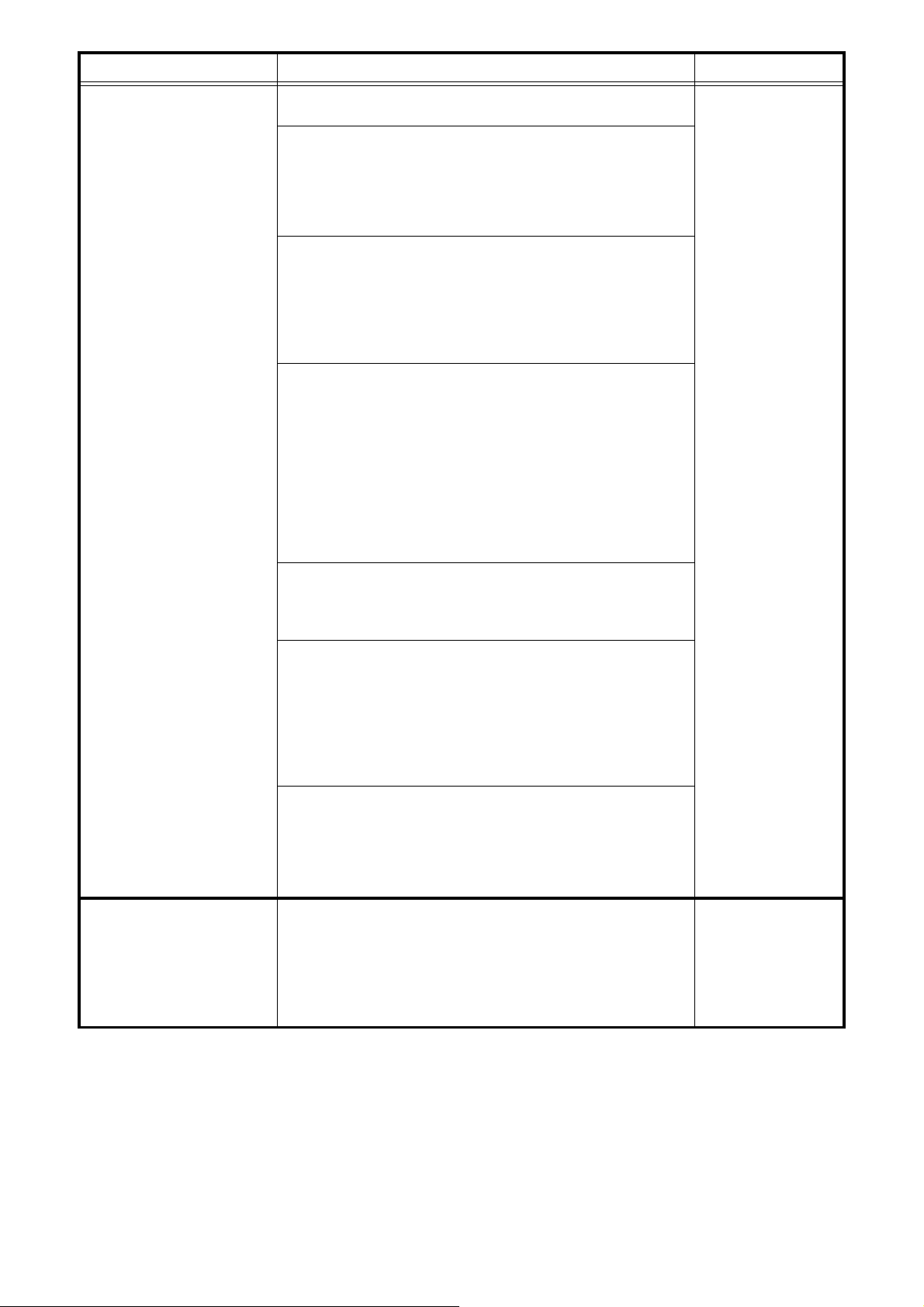

(4) Turn over, being careful that the piled slip mats do not fall, and set on the main unit. Hold the JOG WHEEL SAB ASSY,

then tighten the screw using a hexagonal wrench (2.6 x 3 BSS).

10

Page 11

SERVICE MODE

1. Turning on the power in the service mode

(1) Turn on the power while pressing the PARAMETERS knob and the NEXT button (Deck 1 or Deck 2) simultaneously.

The following appears on the VFD segment display section:

Service Mode

Function CHK

(2) When the PARAMETERS knob is turned clockwise, the display on the lower tier of the VFD segment display section

switches in the following order: "Function CHK" → "SW Check" → "Panel CHK" → "Touch MEAS".

The display switches in the opposite order when the PARAMETERS knob is turned counterclockwise.

(3) The displayed mode can be selected by pressing the PARAMETERS knob.

※ The service mode switches simultaneously for Deck 1 and Deck 2. When the operations for selecting and executing the

different check modes are performed for one deck, they are automatically performed for the other deck as well.

For some items, however, the selection and execution operation must be performed individually for Deck 1 and Deck 2.

(“SW CHECK”, “Panel CHK”, “Touch MEAS”)

2. Function summary

※ Refer to [3. Service mode function table] for details.

(1) Checking the operation of the function (Function CHK)

When the item to be checked is selected from the TOP menu, the device performs the check and settings and the results

are displayed on the VFD segment display section.

• Equipped function

① Setting initialization

② Drive Terminal check

③ Audio signal output

④ Audio Mute check

⑤ Touch initialization

⑥ USB-HIDI command transmission

(2) Checking the operation of the switches(SW Check)

Once all the switches on the panel surface have been pressed, the switch check mode ends automatically.

(3) Checking the operation of the panel(Panel CHK)

• Checking the operation of the various control elements on the panel surface

① PARAMETERS knob

② JOG disc

③ FADERIN

④ X-Control level

⑤ FADER level

• The functions shown below are always available while in the panel check mode.

⑥ All LEDs lit /LED DIM lit/All LEDs off

(4) Touch measurement(Touch MEAS)

Measurement of the count value when the touch sensor section is not being touched, and measurement and judgment

of the amount of change of the count value when the touch sensor section is being touched.

11

Page 12

3. Service mode function table

Mode Summary Remark

Service Mode TOP

(Service Mode)

Function

check mode

(Function CHK)

Switch check mode

(SW Check)

Turn on the power while pressing the PARAMETERS knob and the

NEXT button (Deck 1 or Deck 2) simultaneously.

→ Service mode starts

HC5000 Int, The various parameters are set to the factory defaults.

When executed with the drive terminal's Tx and Rx pins connected

Drive Check

Audio OUT

Mute Check Switches the hardware's muting circuit on and off.

Touch Init.

USB-HIDI

externally, the loop-back test is performed.

The device checks whether the transferred and received contents

are the same and the results are displayed.

The device's built-in 24 bit/44.1 kHz sampling frequency 1 kHz/0dB

audio signal is played.

Turn the PARAMETERS knob to select whether the output is on or

off, then press the PARAMETERS knob to execute.

During playback, the letters "OUT" on the VFD segment display

section flash.

Sets the contents of the EPROM built into the touch sensor IC to

the factory defaults.

Sends the HIDI/MIDI command corresponding to the function

selected on the VFD segment display section.

Turn the PARAMETERS knob clockwise to select the function in

the order shown below.

"CUE" → "PLAY" → "A1" → "A2" → "HOT1"

※ Refer to [3.3. MIDI Ccommands table] for details.

Initially, the VFD is all off, and when a switch is pressed, the corresponding VFD characters lit. → Once all the switches are pressed,

"Complete" is displayed on the VFD segment display section.

※ Refer to [3.1. Switch check mode] for details.

To cancel the service

mode, turn the power

off.

Press the BACK button

to return to the top

level of the Function

check mode.

Press the PARAMETERS knob to return to

the top level of the

Switch check mode.

12

Page 13

Mode Summary Remark

Panel check mode

(Panel CHK)

Touch measurement mode

(Touch MEAS)

※ Display of the status and results of the various control elements

on the panel surface and external input from the side panel

• PARAMETERS knob

The segment on the right side of the "P" column at the upper left

of the VFD segment display section toggles between white and

black each time the PARAMETERS knob is pressed.

When the PARAMETERS knob is turned, -> (clockwise) or <(counterclockwise) is displayed.

• JOG disc

When a touch is detected: The center of the scratch marker at

the bottom right of the VFD display section lights.

The left and right display sections of the scratch marker light

according to the direction of rotation.

The jog rev count detection result is displayed on the frame count

display section.

• PITCH slider

The pitch signal's AD conversion value is displayed on the pitch

display section.

The center tap value is displayed in three digits on the track number display section.

<Spec>

Central tap display value : CENTER = 512 ± 77

Pitch signal display value

• MAX value : 1018 or more

• Central click position : PITCH = CENTER ± 25

• MIN value : 6 or less

• FADERIN

The segment display sections at the sides of FC and FP on the

VFD segment display section are displayed as ■ while the CUE

and PLAY fade-in signals are being detected, respectively.

• X-Control

The AD conversion values of the X-Fade and CH signals are displayed at the sides of XF and XC on the VFD segment display

section.

• XF display value

• MAX value : 1010 or more

• MIN value : 10 or less

• XC display value : 0 fixation → Future

• LED/VFD light/off

When the TAP button is pressed, the display toggles in the fol-

lowing order: All LEDs lit + VFD all lit → LED DIM lit + VFD off →

LED off + normal VFD display

※This function is always available while in the "Panel CHK"

mode.

The count value detected by the touch sensor IC is displayed on

the VFD.

OK if the difference between the count value when not being

touched and the count value when touched is 50 or greater.

OK if the count value when not being touched is between the

range of 100 and 300.

※ Refer to [3.2. Touch measurement mode] for details.

Press the BACK button

to return to the top

level of the panel

check mode.

Press the BACK button

to return to the top

level of the Touch measurement mode.

13

Page 14

3.1. Switch check mode (SW Check)

AC

PPHFC

CAFL+ B BR

S

-

(1) All the VFD characters are turned off.

The following characters are assigned to the 12 places of the VFD segment display section:

(2) When each switch is pushed

IN1 → Turn on the pertinent figure in the third place of the track number.

IN2 → Turn on the pertinent figure in the second place of the track number.

IN3 → Turn on the pertinent figure in the first place of the track number.

OUT1 → Turn on the second place of the minutes display counter.

OUT2 → Turn on the first place of the minutes display counter.

OUT3 → Turn on the second place of the seconds display counter.

AUTO TEMPO → Turn on the "A" in the first place of first row.

PITCH BEND- → Turn on the "-" in the fourth place of first row.

PITCH BEND+ → Turn on the "+" in the fifth place of first row.

TIME → Turn on the "REMAIN" .

TITLE → Turn on the "CONT".

AUTO LOOP → Turn on the "CD".

8 → Turn on the " ( " of A1.

9 → Turn on the " ) " of A1.

6 → Turn on the " ( " of A2.

7 → Turn on the " ) " of A2.

JOG MODE → Turn on the "MP3".

KEY ADJ → Turn on the "KEY ADJ".

TAP → Turn on the "BPM".

1/2 → Turn on the second place of BPM.

*2 → Turn on the first place of BPM.

ITCH/CD → Turn on the "PC".

CENSOR → Turn on the "C" in the second place of first row.

LOAD A/B → Turn on the "L" in the third place of first row.

BACK → Turn on the "B" in the eighth place of first row. (DECK 1,2 is displayed simultaneously)

CRATES → Turn on the "C" in the ninth place of first row. (DECK 1,2 is displayed simultaneously)

FILES → Turn on the "F" in the tenth place of first row. (DECK 1,2 is displayed simultaneously)

BROWSE → Turn on the "B" in the eleventh place of first row. (DECK 1,2 is displayed simultaneously)

RELAY → Turn on the "R" in the twelfth place of first row. (DECK 1,2 is displayed simultaneously)

CUE → Turn on the "C" in the first place of second row.

PLAY →

FWD → Turn on the "F" in the seventh place of second row. (DECK 1,2 is displayed simultaneously)

ADD → Turn on the "A" in the ninth place of second row. (DECK 1,2 is displayed simultaneously)

PREPARE → Turn on the "P" in the tenth place of second row. (DECK 1,2 is displayed simultaneously)

HISTORY → Turn on the "H" in the eleventh place of second row. (DECK 1,2 is displayed simultaneously)

SHIFT → Turn on the "S" in the twelfth place of second row. (DECK 1,2 is displayed simultaneously)

Turn on the "P" in the second place of second row.

(3) Once all the switches have been pressed, "Complete" is displayed on the second row of the VFD segment display

section.(both decks)

For both decks, press any switch while "Complete" is displayed to return to the top level of the switch check mode.

14

Page 15

3.2. Touch measurement mode(Touch MEAS)

(1) All the VFD characters are turned off.

The following appears on the VFD segment display section:(Count value display mode)

TP_***RT_***

BM_***LT_***

*** : Current touch count value is displayed.

(TP : TOP, BM : BOTTOM, RT : RIGHT, LT : LEFT)

The average of the count values acquired for the first four times measurements are made after this mode is set is

calculated and used as the reference value.

(2) Turn the PARAMETERS knob one click to switch the display on the VFD segment display section as shown below.

(Difference display mode)

TP

BM

*** : (Standard value) - (Current touch count value) is displayed.

Now, turn the PARAMETERS knob one click to switch to the count display mode in (1).

(3) The center of the scratch mark lights if the difference of the count value calculated with any one of the four sensors

above, below and to the sides of the disc during the touch measurement mode is 50 or greater.

(4) When the PARAMETERS knob is pressed, the average of the count value acquired for the first four times measure-

ments are made after the PARAMETERS knob is pressed is held on the display.

(5) Press the PARAMETERS knob again to return to the count display mode in (1).

(6) Press the BACK and PLAYLIST buttons to return to the top level of the Touch measurement mode.

***RT

▲

***LT

▲

***

▲

***

▲

15

Page 16

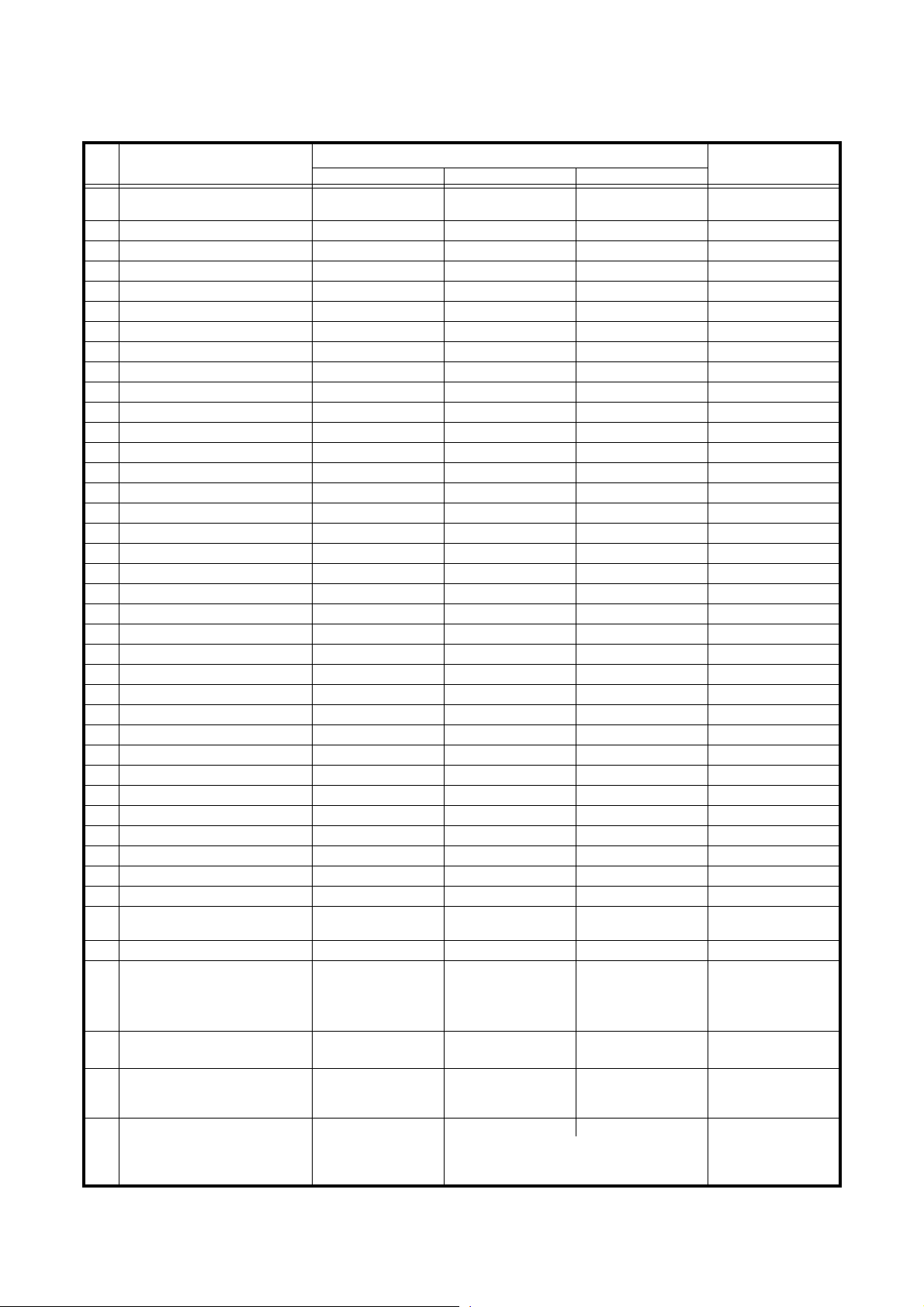

3.3. MIDI COMMANDS

(1) Data transmission

The panel operation data is transmitted by MIDI command, as per the table below.

● Send command to PC

items

1Playlist

2 JOG mode

3 Pitch/KEY

4TAP

5 Pitch Bend+

6 Pitch Bend-

7 Fast search+

8 Fast search-

9EFX1/ECHO/LOOP

10 EFX2/FLANGER

11 EFX3/FILTER

12 HOT1

13 HOT2

14 HOT3

15 HOT4

16 HOT5

17 TIME/TOTAL

18 MEMO/PRESET

19 TITLE

20 CONT./SINGLE

21 Parameters KNOB SW

22 BACK

23 SOURCE mode

24 FLIP

25 A1

26 A2

27 B

28 EXIT/Reloop

29 Cue

30 Play

31 JOG UP

32 JOG DOWN

33 JOG LEFT

34 JOG RIGHT

35 Jogwheel touch

36 Preset Mode

37 D4500 Cont. mode

38 Jogwheel fwd/rev 0xBn 0x51

Command Number Value

SW ON : 0x9n

SW OFF : 0x8n

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

SW ON : 0x9n

SW OFF : 0x8n

↑

MIDI command

0x02

0x04

0x05

0x07

0x08

0x09

0x10

0x11

0x12

0x13

0x14

0x17

0x18

0x19

0x20

0x21

0x23

0x24

0x25

0x26

0x28

0x30

0x31

0x36

0x37

0x38

0x39

0x40

0x42

0x43

0x47

0x48

0x49

0x50

0x51

0x52

0x53

SW ON : 0x40

SW OFF : 0x00

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

SW ON : 0x40

SW OFF : 0x00

↑↑

Reverse 0x3F ~ 0x01

Foward 0x41 ~ 0x7F

slow

→ fast

Message type

Note ON/OFF

Note ON/OFF

Control change

※ relative data

39 X-Control fader

Parameters KNOB

40

Increment/Decrement

41 Pitch Slider 0xEn 0xllh (LSB) 0xmmh (MSB) Pitch bend change

↑

↑

0x53

0x54

-100% : 0x7F7F (MSB/LSB)

0% : 0x4000 (MSB/LSB)

+100% : 0x0000 (MSB/LSB)

0x00 (min) → 0x7F

(max)

"Increment : 0x00

Decrement : 0x7F"

↑

↑

n = MIDI CH

16

Page 17

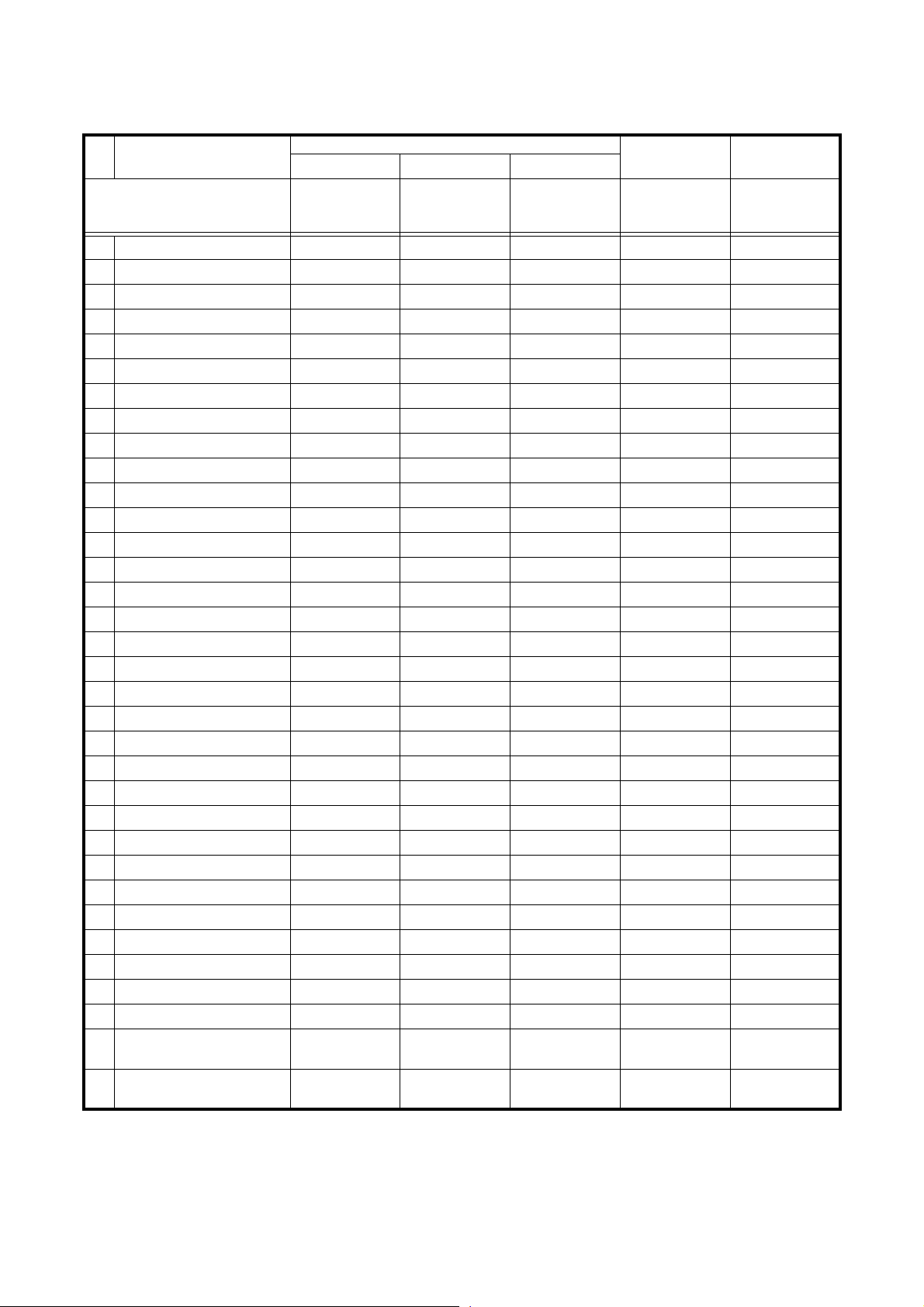

(2) Data reception

LED data reception

The panel operation data is transmitted by MIDI command, as per the table below.

● Receive command for LED

items

LED 0xBn

1 Playlist 0x02

2 Pitch match LED 0x04

3 JOG mode Green 0x05

4 JOG mode Orange 0x06

5 Pitch/KEY Green 0x07

6 Pitch/KEY Orange 0x08

7 TAP Green 0x09

8 TAP Orange 0x0A

9 EFX1/ECHO/LOOP RED 0x0B

10 EFX1 Green 0x0C

11 EFX2/FLANGER RED 0x0D

12 EFX2 Green 0x0E

13 EFX3/FILTER RED 0x0F

14 EFX3 Green 0x10

15 HOT1 0x11

16 HOT1 Dimmer 0x12

17 HOT2 0x13

18 HOT2 Dimmer 0x14

19 HOT3 0x15

20 HOT3 Dimmer 0x16

21 HOT4 0x17

22 HOT4 Dimmer 0x18

23 HOT5 0x19

24 HOT5 Dimmer 0x1A

25 Parameter KNOB 0x1E

26 A1 0x24

27 A1 Dimmer 0x3C

28 A2 0x25

29 A2 Dimmer 0x3D

30 Cue 0x26

31 Play 0x27

32 Jogwheel 0x3B

33 Pitch slider request

34 X-Control fader request

Command Number Value

MIDI command

ON TRG : 0x4A

OFF TRG : 0x4B

Blink ON TRG : 0x4C

only Use 0x4A

(request TRG)

only Use 0x4A

(request TRG)

↓

0x3C

0x3D

Message type Notes

Control Change

DN-HC5000 return

pitch slider position

DN-HC5000 return

XControl fader position

n = MIDI CH

17

Page 18

VFD symbol data reception

The Various Vfd Symbols Can Be Set To On, Off Or Blinking, As Per The Table Below.

● Receive command for VFD Symbol

items

Command Number Value

VFD Symbol 0xBn

1T.

2 REMAIN

3 ELAPSED

4CONT.

5SINGLE

6 BPM

7m

8s

9f

10 Pitch dot Right

11 Pitch dot center

12 Pitch dot left

13 MP3

14 WAV

15 KB

16 KEY ADJ.

17 MEMO

18 ( : A1 side

19 ( : A2 side

20 ) : A1 side

21 ) : A2 side

22 A1

23 A2

24 B : A1 side

25 B : A2 side

26 Scratch Ring out side

27 Scratch Ring in side

28 Touch dot

29 Track Position Blink only Use 0x4F/0x4E

30 Scratch Position 1 (Top right) only Use 0x4D/0x4E

31 Scratch Position 2 only Use 0x4D/0x4E

32 Scratch Position 3 only Use 0x4D/0x4E

33 Scratch Position 4 only Use 0x4D/0x4E

34 Scratch Position 5 only Use 0x4D/0x4E

35 Scratch Position 6 only Use 0x4D/0x4E

36 Scratch Position 7 only Use 0x4D/0x4E

37 Scratch Position 8 only Use 0x4D/0x4E

38 Scratch Position 9 only Use 0x4D/0x4E

39 Scratch Position 10 only Use 0x4D/0x4E

MIDI command

ON TRG : 0x4D

OFF TRG : 0x4E

Blink ON TRG : 0x4F

↓

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x09

0x0A

0x0B

0x0C

0x10

0x11

0x13

0x14

0x15

0x16

0x17

0x18

0x19

0x1A

0x1B

0x1C

0x1D

0x1E

0x1F

0x20

0x21

0x22

0x23

0x24

0x25

0x26

0x27

0x28

0x29

0x2A

0x2B

Message type

Control Change

18

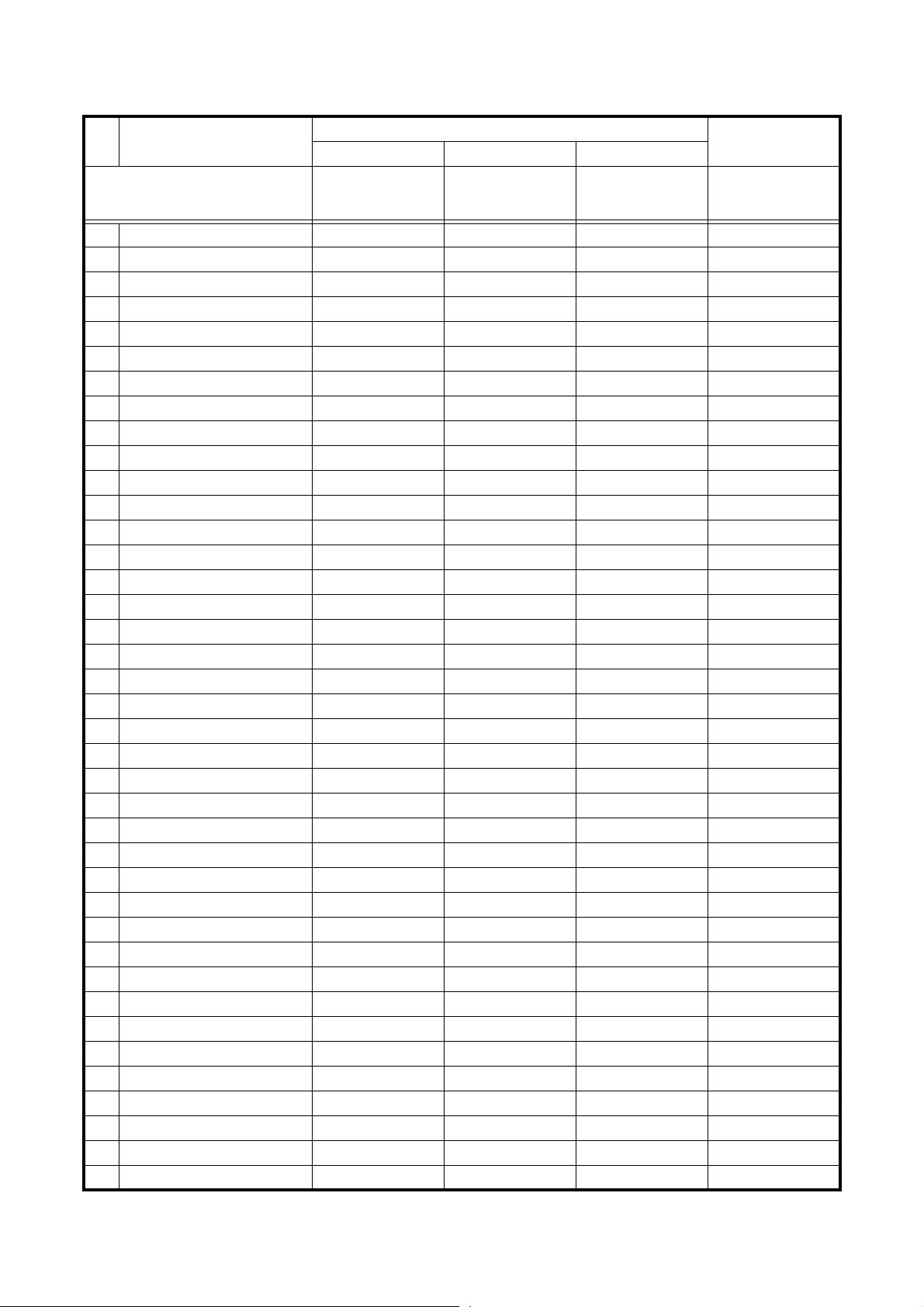

Page 19

items

VFD Symbol 0xBn

40 Scratch Position 11 only Use 0x4D/0x4E

41 Scratch Position 12 only Use 0x4D/0x4E

42 Scratch Position 13 only Use 0x4D/0x4E

43 Scratch Position 14 only Use 0x4D/0x4E

44 Scratch Position 15 only Use 0x4D/0x4E

45 Scratch Position 16 (Bottom) only Use 0x4D/0x4E

46 Scratch Position 17 only Use 0x4D/0x4E

47 Scratch Position 18 only Use 0x4D/0x4E

48 Scratch Position 19 only Use 0x4D/0x4E

49 Scratch Position 20 only Use 0x4D/0x4E

50 Scratch Position 21 only Use 0x4D/0x4E

51 Scratch Position 22 only Use 0x4D/0x4E

52 Scratch Position 23 only Use 0x4D/0x4E

53 Scratch Position 24 only Use 0x4D/0x4E

54 Scratch Position 25 only Use 0x4D/0x4E

55 Scratch Position 26 only Use 0x4D/0x4E

56 Scratch Position 27 only Use 0x4D/0x4E

57 Scratch Position 28 only Use 0x4D/0x4E

58 Scratch Position 29 only Use 0x4D/0x4E

59 Scratch Position 30 only Use 0x4D/0x4E

60 Scratch Position 31 only Use 0x4D/0x4E

61 Scratch Position 32 (Top) only Use 0x4D/0x4E

Command Number Value

MIDI command

ON TRG : 0x4D

OFF TRG : 0x4E

Blink ON TRG : 0x4F

↓

0x2C

0x2D

0x2E

0x2F

0x30

0x31

0x32

0x33

0x34

0x35

0x36

0x37

0x38

0x39

0x3A

0x3B

0x3C

0x3D

0x3E

0x3F

0x40

0x41

Message type

Control Change

n = MIDI CH

※ Track Position Blink” sets blinking of the entire track position display segment on or off.

19

Page 20

VFD parameter data reception

The time-related display and segment display can be set by MIDI command, as per the table below.

● Receive command for VFD Parameter

Items

VFD Parameter

1 Tr number MSB 0xBn 0x40

2 Tr number LSB

3 Time mini

4Time sec

5 Time frame

6Pitch POL

7Pitch MSB

8Pitch LSB

9 Track Position

10 Segment 1-1 MSB

11 Segment 1-2 MSB

12 Segment 1-3 MSB

13 Segment 1-4 MSB

14 Segment 1-5 MSB

15 Segment 1-6 MSB

16 Segment 1-7 MSB

17 Segment 1-8 MSB

18 Segment 1-9 MSB

19 Segment 1-10 MSB

20 Segment 1-11 MSB

21 Segment 1-12 MSB

22 Segment 1-1 LSB

23 Segment 1-2 LSB

24 Segment 1-3 LSB

25 Segment 1-4 LSB

26 Segment 1-5 LSB

27 Segment 1-6 LSB

28 Segment 1-7 LSB

29 Segment 1-8 LSB

30 Segment 1-9 LSB

31 Segment 1-10 LSB

32 Segment 1-11 LSB

33 Segment 1-12 LSB 0xBn 0x2D 0x00 ~ 0x0F Control Change

34 Segment 2-1 MSB

35 Segment 2-2 MSB

36 Segment 2-3 MSB

37 Segment 2-4 MSB

Command Number Value

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑↑

↑↑

↑↑

↑↑

MIDI command

100-109 : “-0” to”-9”

110 : “-”, 111 : “ "

0x41

0x42

0x43

0x44

0x45

0x46

0x47

0x48 normal

0x49 reverse

0x01 0x00 ~ 0x0F

0x02

0x03

0x04

0x05

0x07

0x08

0x09

0x0A

0x0B

0x0C

0x0D

0x21

0x22

0x23

0x24

0x25

0x27

0x28

0x29

0x2A

0x2B

0x2C

Message Type

0-99

Control Change

↑↑

↑↑

↑↑

↑↑

" “ 0x00

“+” 0x01

“-” 0x02"

↑

↑↑

↑↑

0-100%

↑

↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

0x0E

0x0F

0x10

0x11

↑

↑

↑

↑

20

Page 21

38 Segment 2-5 MSB

39 Segment 2-6 MSB

40 Segment 2-7 MSB

41 Segment 2-8 MSB

42 Segment 2-9 MSB

43 Segment 2-10 MSB

44 Segment 2-11 MSB

45 Segment 2-12 MSB

46 Segment 2-1 LSB

47 Segment 2-2 LSB

48 Segment 2-3 LSB

49 Segment 2-4 LSB

50 Segment 2-5 LSB

51 Segment 2-6 LSB

52 Segment 2-7 LSB

53 Segment 2-8 LSB

54 Segment 2-9 LSB

55 Segment 2-10 LSB

56 Segment 2-11 LSB

57 Segment 2-12 LSB

n = MIDI CH

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

↑↑

0x12

0x13

0x14

0x15

0x16

0x17

0x18

0x19

0x2E

0x2F

0x30

0x31

0x32

0x33

0x34

0x35

0x36

0x37

0x38

0x39

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

21

Page 22

VFD segment data reception

The various segments are set by 2-byte data, as per the following font code.

(0x00/0x00 to 0x00/0x07 cannot be used.)

● Font codes for segments

※ For the Reflex function operations corresponding to the above MIDI commands, refer to the Reflex manual.

22

Page 23

CAUTION IN SERVICING

When replacing the MAIN P.W.B. UNIT

When replacing the MAIN P.W.B. UNIT, be sure to perform update to latest firmware after replacement.

VERSION UPGRADE PROCEDURE OF FIRMWARE

※ When replacing the MAIN P.W.B. UNIT, how to enter version up modes is different.

Refer to 1.2.procedure [When replacing the MAIN P.W.B.] (1).

1.1. preparation

(1) Connect the computer by USB cable.

1.2. procedure

※ Turn on the device’s power in the update mode.

(1) Turn on the power while pressing the OUT3 and BACK buttons simultaneously on Deck1 or Deck2.

[When replacing the MAIN P.W.B.]

(1) Turn on the power while pressing the PARAMETERS knob and the OUT3 button (Deck 1 or Deck 2) simultaneously.

The following appears on the VFD segment display section:

Update Mode

Ver****

on Deck1

The version informationis displayed.

PC Linked

Don t Touch!

on Deck2

If the device is not yet connected, the following appears on the VFD segment display section:

PC Disconn..

on Deck2

(2) Launch the DN-HC5000 update program.

The screen shown below appears on thecomputer.

Current version information

The identified device name is displayed.

23

Page 24

(3) If the device is not connected or not in the update mode at this time, the screen shown below is displayed.

If the update file has not been loaded, “Fileis not ready.” is displayed.

The device is not in the update mode.

(4) Drag and drop the update file to the ”DENON DJ Upgrade program” screen.

The Load button can now be selected.

24

Page 25

(5) Press the Load button to transfer the update file.

(6) The following appears on the VFD segment display section:

During file transfer:on Deck1

Update Mode

Loading

Once file transfer is finished;

Update Mode

**** >> ****

(Left side: Old version, Right side: New version)

Once file transfer is finished, press the OK button. The Execute button is now enabled (can be pressed).

25

Page 26

(7) Press the Execute button to begin updating the version.

Once version updating is completed, “Version up was completed.” is displayed.

The following appears on the VFD segment display section during version updating:

On Deck1:

Update Mode

Updating

Once version updating is completed:

Update Mode

Completed

If version updating has failed, “Version up was not completed.” is displayed and the screen returns to as it was before

the Execute button was pressed. Press the Execute button again.

(8) Press the OK button to finish.

The following appears on the VFD segment display section:

On Deck2:

PC Linked

Power Off!!

Quit the updating program and turn off the DN-HC5000’s power.

26

Page 27

NOTE:

• Do not turn off the set’s power or disconnect the cable connecting it to the computer during loading or version updating.

Also, do not press any buttons on the set or any keys on the computer’s keyboard.

• If an error message appears during loading or version updating, repeat from step 1.

Other error messages are as follows:

“File is invalid”

When the loaded update file was invalid.

“Load failed. Check the connection, and retry”

When a transfer error has occurred during transfer of the update file to the device.

“Loaded data is invalid. Check the file.”

When a SUM check error has occurred after transfer of the update file to the device.

“Version up was not completed.”

When version updating was not completed normally.

27

Page 28

TROUBLE SHOOTING

FLOW CHART NO.1

The power cannot be turned on.

Is the fuse normal?

Yes

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

Yes

Is the +5VD line voltage normal?

Yes

Check each rectifying circuit of the secondary circuit

and replace it if defective.

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and replace it if defective.

After servicing, replace the fuse.

FLOW CHART NO.3

+5VD is not outputted.

Is the voltage of 9V or more supplied to 1pin(Vcc)

of IC901?

Yes

Check IC901, D910, L902 and the periphery circuit,

and replace it if defective.

No

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and replace it if defective.

(C903, C912, C913, C914, L901, BR901, T901)

Check the presence that the rectifying diode or

circuit is shorted in each rectifying circuit of

secondary side, and replace it if defective.

Check D914~D917 and the periphery circuit,

and replace it if defective.

FLOW CHART NO.4

+3.3V is not outputted.

Is 5V voltage supplied to 2pin(IN) of IC902?

Yes

Check IC902 and the periphery circuit,

and replace it if defective.

FLOW CHART NO.5

+1.2V is not outputted.

Is 5V voltage supplied to 2pin(Vcc) of IC401?

Yes

Check IC402 and the periphery circuit,

and replace it if defective.

FLOW CHART NO.6

+8V is not outputted.

Is the voltage of 10V or more supplied to

INPUTpin of IC904?

Yes

Check IC904 and the periphery circuit,

and replace it if defective.

No

No

No

Refer to FLOW CHART NO.3 [+5VD is not outputted.]

Check FB401, CX601 and the periphery circuit,

and replace it if defective.

Check D907, D908 and the periphery circuit,

and replace it if defective.

28

Page 29

FLOW CHART NO.7

-8V is not outputted.

Is the voltage of -10V or less supplied to INPUTpin

of IC905?

Yes

Check IC905 and the periphery circuit,

and replace it if defective.

FLOW CHART NO.8

+5VA is not outputted.

Is 8V voltage supplied to INPUTpin of IC801?

Yes

Check IC801 and the periphery circuit,

and replace it if defective.

FLOW CHART NO.9

HV is not outputted.

Is the voltage of 30V or more supplied to

collector terminalof TR904?

Yes

Check TR904 and the periphery circuit,

and replace it if defective.

FLOW CHART NO.10

F1/F2 is not outputted.

No

No

No

Check D903, D904 and the periphery circuit,

and replace it if defective.

Refer to FLOW CHART NO.6 [+8V is not outputted.]

Check D901, D902, D509, D906 and the

periphery circuit, and replace it if defective.

Is the regulated voltage(±15%) supplied to T901?

Yes

Is the regulated voltage(AC2.7V~AC3.3V) supplied

for T901?

Yes

Check if there is any leak or short-circuiting on the

primary circuit component, and replace it if defective.

FLOW CHART NO.11

The fluorescent display tube(FL701, FL801)

does not light up.

Is 3.3V voltage supplied to 36pins(VDD)

of FL701(FL801)?

Yes

Is 34V voltage supplied to 37pins(HV)

of FL701(FL801)?

Yes

Are the filament voltage supplied between 1, 2, 3pins

and 42, 43, 44pins of the fluorescent display tube

(FL701, FL801)? And the +5V voltage applied between

these pins and GND?

Yes

Replace the fluorescent display tube(FL701, FL801).

No

No

No

No

No

Refer to FLOW CHART NO.1

[The power cannot be turned on.]

Check T901, ZD903 and the periphery circuit,

and replace it if defective.

Check the +3.3V line and service it if defective.

Check the HV(+34V) line and service it if defective.

Check the F1/F2 line and service it if defective.

29

Page 30

FLOW CHART NO.12

The key operation is not functioning.

Are the contact point and the installation state of the

key switches (S701~734, S801~830) normal?

Yes

Does LED(LD701~739, LD801~829) light correctly ?

Yes

When pressing each switches, do the voltage of

each pin of IC702(IC802) (shown below) increase?

S704,709,713,715,719,702,730 : IC702 14pin

S717,721,725,727,718,729,701,706 : IC702 3pin

S703,708,712,716,731,724,733,726 : IC702 4pin

S707,711,734,720 : IC702 5pin

S710,714,723,722,728 : IC702 6pin

S802,806,810,812,816,820 : IC802 13pin

S823,824,825,815,817 : IC802 14pin

S821,826,827,828,819 : IC802 3pin

S801,805,809,811,829 : IC802 4pin

S803,807,830,813 : IC802 5pin

S804,808,818,814,822 : IC802 6pin

Yes

Replace IC702(IC802).

FLOW CHART NO.13

Both functions of picture and sound do not operate normally.

Start the service mode, and with both Deck the mode

of Function CHK→Audio OUT→1kHz All L&R is

sequentially selected.

Are the audio signals outputted to 14pin(Rch) and

15pin(Lch) of IC802(Deck1)and IC803(Deck2)?

Yes

Are the audio signals outputted to 7pin(Lch) and

1pin(Rch) of IC804(Deck1)and IC805(Deck2)?

Yes

Is 11pin of CY111 (MUTE control signal)H, and has

been the TR803 collector (MUTE drive signal) L(-8V)?

Yes

No

No

No

No

No

No

Check periphery circuit from 7pin and 1pin to

replace

JK801 of IC804 and IC805, and

it if

defective.

Re-install the switches (S701~734, S801~830)

correctly or replace the poor switch.

Check the TR701~708(TR807~814)and

their periphery, and service it if detective.

Check the switches (S701~734, S801~830) and

their periphery, and service it if detective.

Check the input signal from CY111 to IC802, IC803

and their periphery, and service it if detective.When the

input signal is correct, IC802 or IC803 is replaced.

Check periphery circuit from 14pin and 15pin to

IC804 and IC805 of IC802 and IC803, and service

it if defective. When the periphery circuit is correct,

IC804 or IC805 is replaced.

Check TR803 and the periphery circuit, and service it if

defective.

30

Page 31

LEVEL DIAGRAM

-10

-20

-30

-40

-50

-60

+6

OUTPUT

PC

CPU

SH7263

Audio

DAC

PCM178

LPF

+6.0dBV

0

0dBFS

GAIN=2.78dB

+2.78dBV

GAIN=3.22dB

16bit:SNR=98dB

24bit:SNR=106dB

-70

-80

-90

-100

-120

-130

-140

-150

16bit:SNR=98dB

㪉㪋㪹㫀㫋㪑㪪㪥㪩㪔㪈㪋㪍㪻㪙

PCM1781:SNR=106dB(typ)

-92dBV

-95.22dBV

-100dBV

-103.22dBV

31

Page 32

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

1. IC’s

R5S72630P200FP (IC104)

.

32

Page 33

R5S72630P200FP Block Diagram

33

Page 34

R5S72630P200FP Terminal Function

Pin No. Pin Name Symbol I/O Function

1 PC10/-RASU /MUTE O General-purpose port Not used: OPEN

2 -CASL SHCAS O %CASL% SDRAM /CAS

3 -RASL SHRAS O %RASL% SDRAM /RAS

4 VCC V1SH Power supply for in Digital +1.2V

5 DQMUU - O DQMUU Not used: OPEN

6 VSS DGND Digital GND

7 PVSS DGND GND for I/O Digital GND

8 DQMUL - O DQMUL Not used: OPEN

9 PVCC V3SH Power supply for I/O

10 DQMLU DQMLU O DQMLU SDRAM DQMU

11 -CS0 CS0 O CS0 :FLASH ROM FLASH /E

12 -RD SHRD O %RD% FLASH /G

13 DQMLL DQMLL O DQMLL SDRAM DQML

14 PC3/-CS3 CS3 O CS3 SDRAM /CS

15 PC2/-CS2 - O General-purpose port Not used: OPEN

16 VCC V1SH Power supply for in Digital +1.2V

17 PC0/A0/-CS7 - O General-purpose port Not used: OPEN

18 VSS DGND Digital GND

19 PVSS DGND GND for I/O Digital GND

20 PC1/A1 SHA1 O A1 SDRAM/FLASH A0

21 PVCC V3SH Power supply for I/O Digital +3.3V

22 A2 SHA2 O A2 Same A1

23 A3 SHA3 O A3 Same A2

24 A4 SHA4 O A4 Same A3

25 A5 SHA5 O A5 Same A4

26 A6 SHA6 O A6 Same A5

27 A7 SHA7 O A7 Same A6

28 A8 SHA8 O A8 Same A7

29 PVCC V3SH Power supply for I/O Digital +3.3V

30 A9 SHA9 O A9 Same A8

31 PVSS DGND GND for I/O Digital GND

32 VSS DGND Digital GND

33 A10 SHA10 O A10 Same A9

34 VCC V1SH Power supply for in Digital +1.2V

35 A11 SHA11 O A11 Same A10

36 A12 SHA12 O A12 Same A11

37 A13 SHA13 O A13 FLASH A12

38 A14 SHA14 O A14 FLASH A13

39 A15 SHA15 O A15 FLASH A14

40 A16 SHA16 O A16 FLASH A15

41 PVSS DGND GND for I/O Digital GND

42 A17 SHA17 O A17 FLASH A16

43 PVCC V3SH Power supply for I/O Digital +3.3V

44 A18 SHA18 O A18 FLASH A17

45 A19 - O A19 Not used: OPEN

46 A20 - O A20 Not used: OPEN

47 PE2 - O General-purpose port

48 PE3 - O General-purpose port

49 -BS/-ADTRG - O General-purpose port Not used: OPEN

50 CKIO CKIO O CKIO SDRAM CLK

51 VCC V1SH Power supply for in Digital +1.2V

52 VSS DGND Digital GND

53 PVSS DGND GND for I/O Digital GND

54 PVCC V3SH Power supply for I/O Digital +3.3V

55 XTAL - O Oscillation output Not used: OPEN

56 EXTAL EXTAL I EXTAL 16.9344MHz input

57 NMI NMI I NMI Unused: 3.3k pull-up

58 PLLVSS DGND Digital GND

59 -RES -RES I -RES CPU RST is connected

60 PLLVCC PLLVCC 1.2V after LC

61 -ASEMD -ASEMD I Emulator function ON/OFF JTAG I/F connectoráBB pin

62 PE8/IRQ4 - O General-purpose port Not used: OPEN

34

Page 35

Pin No. Pin Name Symbol I/O Function

63 -CS4 - O CS4 Not used: OPEN

64 PE4/DREQ0 - O General-purpose port Not used: OPEN

65 PVSS DGND GND for I/O Digital GND

66 PE5/DACK0 DRVDET I DRVDET input Terminal Drive connection detection signal

67 PVCC V3SH Power supply for I/O Digital +3.3V

68 PE6/RXD2 RX I Rx Terminal Drive

69 PE7/TXD2 TX O Tx Terminal Drive

70 PE9/-CS5 - O CS5 Not used: OPEN

71 PE10 - O General-purpose port Not used: OPEN

72 PE11/-CS6 - O General-purpose port Not used: OPEN

73 PE12/RXD3 - O General-purpose port Not used: OPEN

74 VCC V1SH Power supply for in Digital +1.2V

75 -WAIT - O Not used: OPEN

76 VSS DGND Digital GND

77 PVSS DGND GND for I/O Digital GND

78 RTC_X1 DGND I Empty pin processing GND when not used

79 RTC_X2 - O Empty pin processing OPEN when not used

80 PVCC V3SH Power supply for I/O Digital +3.3V

81 PE13/TXD3 - O General-purpose port Not used: OPEN

82 -CS1 - O CS1 Not used: OPEN

83 PE15 - O General-purpose port Not used: OPEN

84 PVSS DGND GND for I/O Digital GND

85 PB8 - O General-purpose port Not used: OPEN

86 PB9 - O General-purpose port Not used: OPEN

87 PB10 - O General-purpose port Not used: OPEN

88 PB11 - O General-purpose port Not used: OPEN

89 VCC V1SH Power supply for in Digital +1.2V

90 MD - I Mode setting(1:32bit/0:16bit) Pull-down in GND

91 VSS DGND Digital GND

92 PVSS DGND GND for I/O Digital GND

93 USB_X1 USB_X1 Clock generation for USB 12MHz X 'tal connection

94 USB_X2 USB_X2

95 PVCC V3SH Power supply for I/O Digital +3.3V

96 MD_CLK1 DGND I Clock selection setting

97 MD_CLK0 DGND I

98 USBDPVSS DGND Digital GND for drive Digital GND

99 USBDPVCC USBDPVCC

100 DM DM I/O D-terminal USB connector connection

101 DP DP I/O D + terminal

102 VBUS VBUS I VBUS detection terminal

103 USBAVCC USBAVCC Analog power supply for in

104 USBAVSS DGND Analog GND for in driver Analog GND

105 REFRIN REFRIN I Reference resistance con-

106 USBAPVSS DGND Analog GND for driver Analog GND

107 USBAPVCC USBAPVCC Analog power supply for

108 USBDVCC USBDVCC Digital power supply for in

109 USBDVSS DGND Digital GND for in driver Digital GND

110 AN0 PITCH1 I ADC input Deck1 Pitch input

111 AN1 CENT1 I ADC input Deck1 Center input

112 AN2 PITCH2 I ADC input Deck2 Pitch input

113 AN3 CENT2 I ADC input Deck2 Center input

114 AVCC AVCC Power supply for ADC/DAC After LC, +3.3V is supplied

115 AN4 CH I ADC input X-Control X-fade input

116 AVREF AVCC I Conversion standard voltage 114pin and connection

117 AN5 XFADE I ADC input X-Control CH input

118 AN6/DA0 AN6/DA0 O DAC output VCXO CONT (16.9344MHz)

119 AN7/DA1 AN7/DA1 O DAC output VCXO CONT (24.576MHz)

120 AVSS DGND Power supply for ADC/DAC Analog GND

121 PVSS DGND GND for I/O Digital GND

122 -WDTOVF - O WDT output(L active) Drives with DTA LED

↑↑

↑

Digital power supply for driver

driver

nection

driver

driver

Digital +3.3V

↑

Terminal VBUS connecting directly through 56

Analogue +1.2V

Connects it GND by 5.6kΩ±1% resistance

Analogue +3.3V

Digital +1.2V

Ω

35

Page 36

Pin No. Pin Name Symbol I/O Function

123 PVCC V3SH Power supply for I/O Digital +3.3V

124 SSIDATA3 DATA_A O Audio data For Deck1

125 SSIWS3 LRCK O Audio word clock For Deck1

126 SSISCK3 BCK O Audio BCK For Deck1

127 VCC V1SH Power supply for in Digital +1.2V

128 AUDIO_CLK AUDIO_CLK I Master clock for audio

129 VSS DGND Digital GND

130 PVSS DGND GND for I/O Digital GND

131 AUDIO_X1 DGND I Not used GND

132 AUDIO_X2 - O Not used OPEN

133 PVCC V3SH Power supply for I/O Digital +3.3V

134 SSIDATA2 DATA_B O Audio data For Deck2

135 SSIW2 LRCK O Audio word clock For Deck2

136 SSISCK2 BCK O Audio BCK For Deck2

137 PF18/LCD_CL2 B6SCK1 I/O SCK1 Deck1 B6TS BCK/3CH detection

138 PF19/

LCD_M_DISP

139 PF20/LCD_FLM CHG2 I CHG2 Deck2 B6TS 1CH detection

140 PF21/SSISCLK1 -SCS2 I/O SCS2 Deck2 B6TS CS/2CH detection

141 VCC V1SH Power supply for in Digital +1.2V

142 PF22/SSIWS1 B6SCK2 I/O SCK2 Deck2 B6TS BCK/3CH detection

143 VSS DGND Digital GND

144 PVSS DGND GND for I/O Digital GND

145 PF23/SSIDATA1 SD2 I/O SD2 Deck2 B6TS DATA/4CH detection

146 PVCC V3SH Power supply for I/O Digital +3.3V

147 PF17/LCD_CL1 -SCS1 I/O SCS1 Deck1 B6TS CS/2CH detection

148 PF16/LCD_DON CHG1 I CHG1 Deck1 B6TS 1CH detection

149 PF15/SD_CD 48KON O 48kON 24.576MHz ON:H, OFF:L

150 PF14/SD_WP 48/44.1 O 48/44.1 Audio CLK Sel(48:H, 44.1:L)

151 PF13/SD_D1 FL/RST O FL/RST FL reset signal output

152 PF12/SD_D0 CUE2 I CUE2 Fader IN input

153 PF11/SD_SCLK PLAY2 I PLAY2 Fader IN input

154 VCC V1SH Power supply for in Digital +1.4V

155 PF10/SD_CMD CUE1 I CUE1 Fader IN input

156 VSS DGND Digital GND

157 PVSS DGND GND for I/O Digital GND

158 PF9/SD_D3 PLAY1 I Fader IN input

159 PVCC V3SH Power supply for I/O Digital +3.3V

160 PF8/SD_D2 - O General-purpose port Not used: OPEN

161 PF7/-SCS1 FL-SCS2 O FLSCS2 Deck2 FL cereal chip selection

162 SSO1 DA2 O DA2 Deck2 FL DATA

163 PF5/SSI1 - O General-purpose port Not used: OPEN

164 SSCK1 CP2 O CP2 Deck2 FL SCK

165 PF3/-SCS0 FL-SCS1 O FLSCS1 Deck1 FL cereal chip selection

166 SSO0 DA1 O DA1 Deck1 FL DATA

167 PF1/SSI0 - O General-purpose port Not used: OPEN

168 VCC V1SH Power supply for in Digital +1.2V

169 SSCK0 CP1 O CP1 Deck1 FL SCK

170 VSS DGND Digital GND

171 PVSS DGND GND for I/O Digital GND

172 TMS TMS I Test mode selection

173 PVCC V3SH Power supply for I/O Digital +3.3V

174 TDI TDI I Test data input

175 -ASEBRKAK -ASEBRKAK I/O Emulator hit I/O

176 -TRST -TRST I Test reset input

177 TDO TDO O Test data output

178 TCK TCK I Test clock input

179 PB0/IRQ0 - I General-purpose port Not used: 3.3k pull-up

180 PB1/IRQ1 - I General-purpose port Not used: 3.3k pull-up

181 PB2/IRQ2 - I General-purpose port Not used: 3.3k pull-up

182 PB3/IRQ3 - I General-purpose port Not used: 3.3k pull-up

183 PVCC V3SH Power supply for I/O Digital +3.3V

184 PVCC V3SH Power supply for I/O Digital +3.3V

SD1 I/O SD1 Deck1 B6TS DATA/4CH detection

Change input of 16.9344MHz/24.576MHz on the outside

JTAG I/F connector ⑨ pin

JTAG I/F connector ⑪ pin

JTAG I/F connector ⑦ pin

JTAG I/F connector ③ pin

JTAG I/F connector ⑤ pin

JTAG I/F connector ① pin

36

Page 37

Pin No. Pin Name Symbol I/O Function

185 PB4/SCL2 - I General-purpose port Not used: 3.3k pull-up

186 PB5/SDA2 - I General-purpose port Not used: 3.3k pull-up

187 PVSS DGND GND for I/O Digital GND

188 VSS DGND Digital GND

189 PB6/SCL3 KEYDAT2 I KEYDAT2 Deck2 SW/ENC data input

190 PB7/SDA3 KEYDAT1 I KEYDAT1 Deck1 SW/ENC data input

191 VCC V1SH Power supply for in Digital +1.2V

192 PD15/D31 LEDDAT2 O LEDDAT2 Deck2 LED data output

193 PD14/D30 LEDDAT1 O LEDDAT1 Deck1 LED data output

194 D29/TIOC4B JOG2 I Deck2 ExOR input Input for pulse width capture

195 D28/TIOC4A JOGA2 I Deck2 A aspect input Input for pulse width measurement

196 PVSS DGND GND for I/O Digital GND

197 PD11/D27 SCK2 O SCK2 Deck2 cereal clock output

198 PVCC V3SH Power supply for I/O Digital +3.3V

199 PD10/D26 SCK1 O SCK1 Deck1 cereal clock output

200 D25/TIOC3B JOG1 I Deck1 ExOR input Input for pulse width capture

201 D24/TIOC3A JOGA1 I Deck1 A aspect input Input for pulse width measurement

202 D23/TCLKD JOGB2 I Deck2 B aspect input Input for pulse number count

203 D22/TCLKC JOGA2 I Deck2 A aspect input Input for pulse number count

204 VCC V1SH Power supply for in Digital +1.2V

205 D21/TCLKB JOGB1 I Deck1 B aspect input Input for pulse number count

206 VSS DGND Digital GND

207 PVSS DGND GND for I/O Digital GND

208 D20/TCLKA JOGA1 I Deck1 A aspect input Input for pulse number count

209 PVCC V3SH Power supply for I/O Digital +3.3V

210 PD3/D19 SC2 O SC2 Clock output of three Deck1/2 common aspects

211 PD2/D18 SC1 O SC1 Clock output of three Deck1/2 common aspects

212 D17/TIOC0B SC0 O SC0 Clock output of three Deck1/2 common aspects

213 D16/TIOC0A BLINK O BLINK signal output

214 D15 SHDB16 O D15

215 D14 SHDB14 O D14

216 PVSS DGND GND for I/O Digital GND

217 D13 SHDB13 O D13

218 PVCC V3SH Power supply for I/O Digital +3.3V

219 D12 SHDB12 O D12

22 0 D11 SH DB11 O D11

221 D10 SHDB10 O D10

222 D9 SHDB9 O D9

223 D8 SHDB8 O D8

224 VCC V1SH Power supply for in Digital +1.2V

225 D7 SHDB7 O D7

226 VSS DGND Digital GND

227 PVSS DGND GND for I/O Digital GND

228 D6 SHDB6 O D6

229 PVCC V3SH Power supply for I/O Digital +3.3V

230 D5 SHDB5 O D5

231 D4 SHDB4 O D4

232 D3 SHDB3 O D3

233 D2 SHDB2 O D2

234 D1 SHDB1 O D1

235 D0 SHDB0 O D0

236 PVSS DGND GND for I/O Digital GND

237 PVCC V3SH Power supply for I/O Digital +3.3V

238 RD/-WR SHRW O RD/WR SDRAM /WE

239 CKE CKE O Clock is enable SDRAM CKE

240 -CASU/-BREQ MEAS O MEAS

37

Page 38

W981616BH-7 (IC102)

CS

BA

1

CC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

A0

22

A1

23

A2

A3

24

CC

25

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

V

DQ0

DQ1

VQ

SS

DQ2

DQ3

VQ

CC

DQ4

DQ5

VQ

SS

DQ6

DQ7

VQ

CC

LDQM

WE

CAS

RAS

A10

V

V

SS

DQ15

DQ14

VQ

SS

DQ13

DQ12

VQ

CC

DQ11

DQ10

VQ

SS

DQ9

DQ8

VQ

CC

NC

UDQM

CLK

CKE

NC

A9

A8

A7

A6

A5

A4

V

SS

PIN DESCRIPTION

PIN NUMBER PIN NAME FUNCTION DESCRIPTION

20- 24,

27- 32

A0- A10

19 BA Bank Select Select bank to activate during row address latch time,

2, 3, 5, 6, 8, 9,

11, 12, 39, 40,

DQ0- DQ15

42, 43, 45, 46,

48, 49

18

17

16

15

CS

RAS

CAS

WE

36, 14 UDQM/

LDQM

35 CLK Clock Inputs System clock used to sample inputs on the rising

34 CKE Clock Enable CKE controls the clock activation and deactivation.

1, 25 VCC Power (+3.3V) Power for input buffers and logic circuit inside DRAM.

26, 50 VSS Ground Ground for input buffers and logic circuit inside

7, 13, 38, 44, VCCQ Power (+3.3V)

4, 10, 41, 47 VSSQ Ground for I/O

33, 37 NC No Connection No connection

Address Multiplexed pins for row and column address.

Row address: A0- A10. Column address: A0- A7.

or bank to read/write during column address latch

time.

Data Input/

Multiplexed pins for data input and output.

Output

Chip Select Disable or enable the command decoder. When

command decoder is disabled, new command is

ignored and previous operation continues.

Row Address

Strobe

Command input. When sampled at the rising edge of

the clock,

RAS , CAS and WE define the operation

to be executed.

Column

Address Strobe

Write Enable

Input/Output

Mask

Referred to

Referred to

The output buffer is placed at Hi-Z (with latency of 2)

when DQM is sampled high in read cycle. In write

RAS

RAS

cycle, sampling DQM high will block the write

operation with zero latency.

edge of clock.

When CKE is low, Power Down mode, Suspend

mode, or Self Refresh mode is entered.

DRAM.

Separated power from VCC, used for output buffers to

for I/O buffer

improve noise immunity.

Separated ground from VSS, used for output buffers

buffer

to improve noise immunity.

M29W400DT55N6E (IC103)

A15

1

A14

A13

A12

A11

A10 DQ14

A9

A8

NC

NC

W

RP

12

M29W400DT

NC

M29W400DB

13

NC

RB

NC

A17

A7

A6

A5

A4

A3

A2

24 25

A1

Note: 1. NC = Not Connected

48

37

36

AI06854

A16

BYTE

V

SS

DQ15A–1

DQ7

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

E

A0

Diagram

A0-A17

W

E

G

RP

18

V

CC

M29W400DT

M29W400DB

V

SS

15

DQ0-DQ14

DQ15A–1

BYTE

RB

AI06853

Signal Names

A0-A17 Address Inputs

DQ0-DQ7 Data Inputs/Outputs

DQ8-DQ14 Data Inputs/Outputs

DQ15A–1 Data Input/Output or Address Input

E

G

W

RP

RB

BYTE

V

CC

V

SS

NC Not Connected Internally

Chip Enable

Output Enab le

Write Enable

Reset/Block Temporary Unprotect

Ready/Busy Output

Byte/Word Organization Select

Supply Voltage

Ground

38

Page 39

B6TS-04LT (IC706, 803) TB62777FNG (IC704, 805) PCM1781 (IC802, 803)

1 FMT

2 DEMP0

3 DEMP1

4 MUTE

5 SCK

6DATA

7 BCK

8 LRCK

ZEROA

V

OUT

L

V

OUT

R

V

COM

AGND

V

CC

NC

TEST 9

10

11

13

12

14

15

16

OUT2/SCK

OUT3/SD

RESET

TEST1

VSS

MEAS

VDD

TEST2

SETUP

CH3B

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

OUT1/SCS

OUT0/CHG

CH0A

CH0B

VDD

CH1A

CH1B

CH2A

CH2B

CH3A

GND

SERIAL-IN

CLOCK

LATCH

OUT0

OUT1

OUT2

OUT3

VDD

R-EXT

SERIAL-OUT

ENABLE

OUT7

OUT6

OUT5

OUT4

BD9110NV (IC401) GP1A038RBK (IC703, 801)

1

2

3

4

5

6

7

8

1. ADJ

2. Vcc

3. ITH

4. GND

5. PGND

6. SW

7. PVcc

8. EN

1

2

1

3

6

2

54

PD

PD2

PD3

PD1

4

10kΩ

10kΩ

Vcc=2.7 to 5.5V

6

5

4

3

1 Anode

Cathode

2

GND

3

B

Vo

4

5

VoA

6

Vcc

BD9703T-V5 (IC901)

39

Page 40

2. VFD MODULE

17-BT-30GINK

CGROM code table

40

Page 41

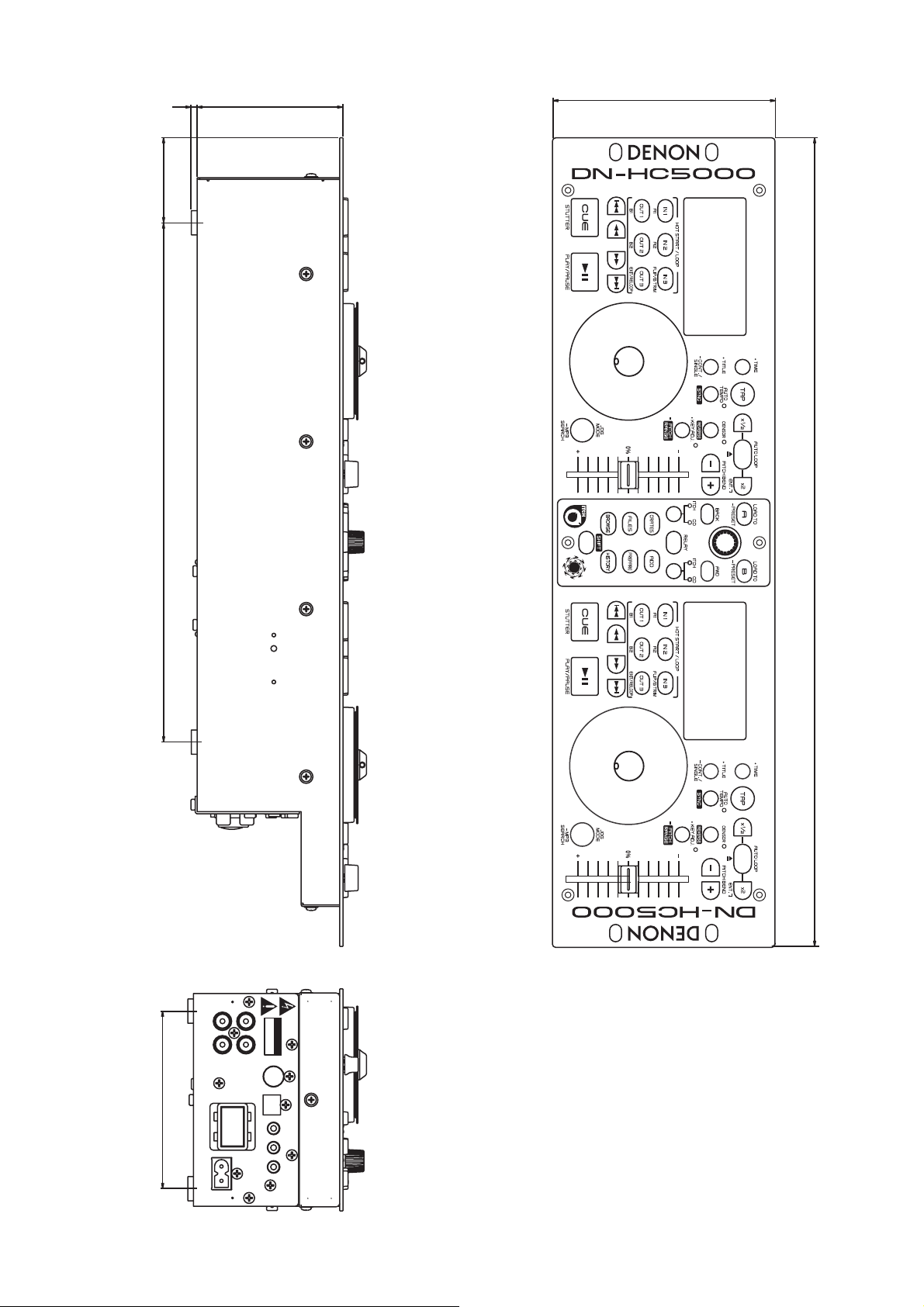

BLOCK DIAGRAM

DN-HC5000 block Diagram

DND REMOTE

8PMINI

DIN

䖃䖃䖃䖃

DFG

USB

B

Main

Main

+5V

CX141

14pin

+3.3V

+1.2V

CPU

SH7263

䞉䞉䞉䞉USB Device

(MIDI/HID/Speaker)

䞉䞉䞉䞉Operation cont

䞉䞉䞉䞉DAC OUT

䞉䞉䞉䞉D4500 cont

䡖

䡖

䡖

䡖

16.9344MH

䞉䞉䞉䞉Data䠖䠖䠖䠖32bit

䞉䞉䞉䞉ADD 䠖䠖䠖䠖1-12

2MBx16bit

䖃䖃䖃䖃

RST

SDRAM

䞉䞉䞉䞉Data䠖䠖䠖䠖16bit

䞉䞉䞉䞉ADD 䠖䠖䠖䠖1-18

IC

512KB Flash

M29W400DB

ADD1-18 16bit BUS

䖃䖃䖃䖃

䞉䞉䞉䞉Data䠖䠖䠖䠖32bit

䞉䞉䞉䞉ADD 䠖䠖䠖䠖1-17

16bit/66MHz

+1.2V +5V

16.9344MHz

/25.476MHz

Audio MCLK

25.476MH䡖䡖䡖䡖

16.9344MH䡖䡖䡖䡖

X(tal

X(tal

PCM data

+1.2V

DC-DC

2-1

Selector

x2

16.9344MHz

/25.476MHz

CY081

CX181

Power

Power

CW081

6pinPH

6pinPH

+5V

DC-DC

+3.3V

Reg

㼼㼼㼼㼼8V

Reg

㼼㼼㼼㼼15V

F1/F2

AC Sel

Jumper

TRANS

+36V

Reg

GND0

AC SW

AC Inlet AC IN

䖃䖃䖃䖃

䖃䖃䖃䖃

5V Reg

A+5V

Audio

DAC

PCM

1781

CY181

A+5V

Audio

DAC

PCM

11pinFFC

11pinFFC

1781

㼼㼼㼼㼼15V

LPF&

LPF&

㼼㼼㼼㼼15V

LPF&

LPF&

AFG

RCA

RCA

RCA

RCA

Audio

OUTB L

Audio

OUTB R

Audio

OUTB L

Audio

OUTB R

䖃䖃䖃䖃

FG7

FG3

Panel 1

Panel 1

Panel1 x31

Panel2 x29

䖃䖃䖃䖃

CX231

CY231

S/P Driver

TB62777FNG

/5

LED

Tr

/3/3

SW

Panel1 x32

Panel2 x30

+5V

P/S buff

74LV165

/4

ENC x1

Panel1 only

FADER IN

SC0/1/2

LED DRV I/F

SW SIR DATA

FL SIR I/F

JOG DATA

B6TS SIR I/F

FADER DATA

27pinFFC 27pinFFC

27pinFFC

LV14

/2/6/1/1

4-1 Select

74LV4052

/2

/2

+5V +3.3V

B6TS-04

FL

Display

䖃䖃䖃䖃

FG8

CW042 CY042

4pinPH

CX071 CY071

11pinFFC

4pinPH

4pinPH

11pinFFC

Sensor1

TOUCH1

CX232

CY232

䖃䖃䖃䖃

FG11

Panel2

Panel2

27pinFFC

Same as Panel1

䖃䖃䖃䖃

MINI

DIN

MINI

DIN

MINI

DIN

FG1

X-Control IN

FADER A IN

FADER B IN

䖃䖃䖃䖃

FG4

䖃䖃䖃䖃

FG12

CW043

4pinPH11pinFFC

CX072 CY072

4pinPH

CY043

4pinPH

11pinFFC

Sensor2

TOUCH2

4pinPH 4pinPH

VFD POWER

VFD POWER

䖃䖃䖃䖃

FG2

䖃䖃䖃䖃

FG9

3-8 DEC

SN74LV138

Faderx1

Faderx1

䖃䖃䖃䖃

FG10

䖃䖃䖃䖃

FG13

䖃䖃䖃䖃

FG14

41

Page 42

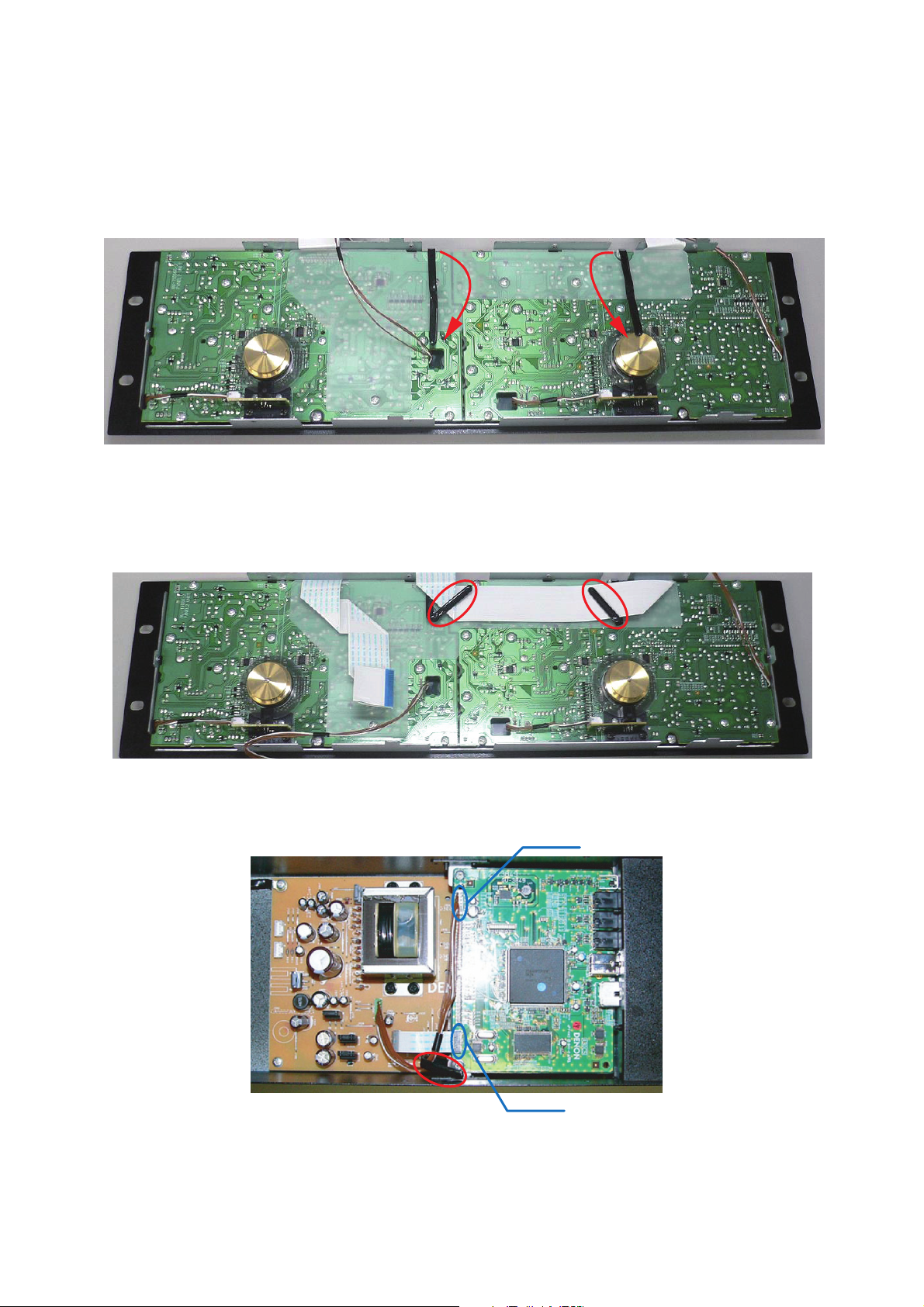

PRINTED WIRING BOARDS

GU-3849 MAIN P.W.B. UNIT

COMPONENT SIDE

FOIL SIDE

42

Page 43

GU-3850A POWER P.W.B. UNIT

COMPONENT SIDE

43

FOIL SIDE

Page 44

8U-110066 PANEL P.W.B. UNIT (1/2)

44

COMPONENT SIDE

Page 45

8U-110066 PANEL P.W.B. UNIT (2/2)

45

FOIL SIDE

Page 46

WIRING DIAGRAM

㪛㪠㪪㪚㪈㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪌

㫆㫉

㪛㪠㪪㪚㪉㩷㪬㪥㪠㪫

㪞㪬㪄㪊㪏㪋㪏㪄㪍

㪪㪜㪥㪪㪦㪩㪈㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪊

㫆㫉

㪪㪜㪥㪪㪦㪩㪉㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪋

CW041

CX041 or CX042

VH41VH

1F321F

2F232F

DNGP14DNGP

CY112 or CY113

CX112 CY271 CX271

CH3 DOWN 11 1 CH3A SC0 1 1 SC0

CH2 RIGHT 9 3 CH2A SC2 3 3 SC2 DGND 11 1 DGND

KLCM201KLCM1KCS441KCS48

DNGD39DNGDDNGD55DNGD57

DGND_5 6 6 DGND BLINK 6 6 BLINK DATA1 8 4 DATA1

D

NGD66DNGD1TADYEK881TADYEK84

CH1 UP 3 9 CH1A +5V 9 9 +5V BCK 5 7 BCK

DNGD84DNGD3V3+01013V3+012

CH0 LEFT 1 11 CH0A DGND 11 11 DGND LRCK 3 9 LRCK

PITCH1 12 12 PITCH1 DGND 2 10 DGND

CENT1 13 13 CENT1 /MUTE 1 11 /MUTE

DGND 14 14 DGND

CY043 or CY044

CW043 JOGA1 15 15 JOGA1

+5VD 1 1 +5VD JOGB1 16 16 JOGB1

DGND 2 2 DGND DGND 17 17 DGND

JOGB1 3 3 JOGB1 MEAS 18 18 MEAS

JOGA1 4 4 JOGA1 0-CHG1 19 19 0-CHG1

1-/SCS1 20 20 1-/SCS1 CY061 CW061

2-B6SCK1 21 21 2-B6SCK1 +5VD 6 1 +5VD

3-SD1 22 22 3-SD1 +5VD 5 2 +5VD

DGND 23 23 DGND DGND 4 3 DGND

FL/RST 24 24 FL/RST +3.3V 3 4 +3.3V

DA1 25 25 DA1 DGND 2 5 DGND

㪧㪘㪥㪜㪣㪈㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪈

CP1 26 26 CP1 +1.2V_CTL 1 6 +1.2V_CTL

FL/SCS1 27 27 FL/SCS1

111YC111XC1CS221CS201

2ATAD572ATAD1TADDEL771TADDEL75

㪛㪠㪪㪚㪈㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪌

㫆㫉

㪛㪠㪪㪚㪉㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪍

㪪㪜㪥㪪㪦㪩㪈㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪊

㫆㫉

㪪㪜㪥㪪㪦㪩㪉㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪋

CY112 or CY113

CX113 CY272 CX272 CX101

CH3 DOWN 11 1 CH3A SC0 1 1 SC0 RC_RXD 1

DGND_5 6 6 DGND BLINK 6 6 BLINK -HB 6

TADYEK882TADYEK84

CH1 UP 3 9 CH1A +5V 9 9 +5V DFG 9

CH0 LEFT 1 11 CH0A DGND 11 11 DGND

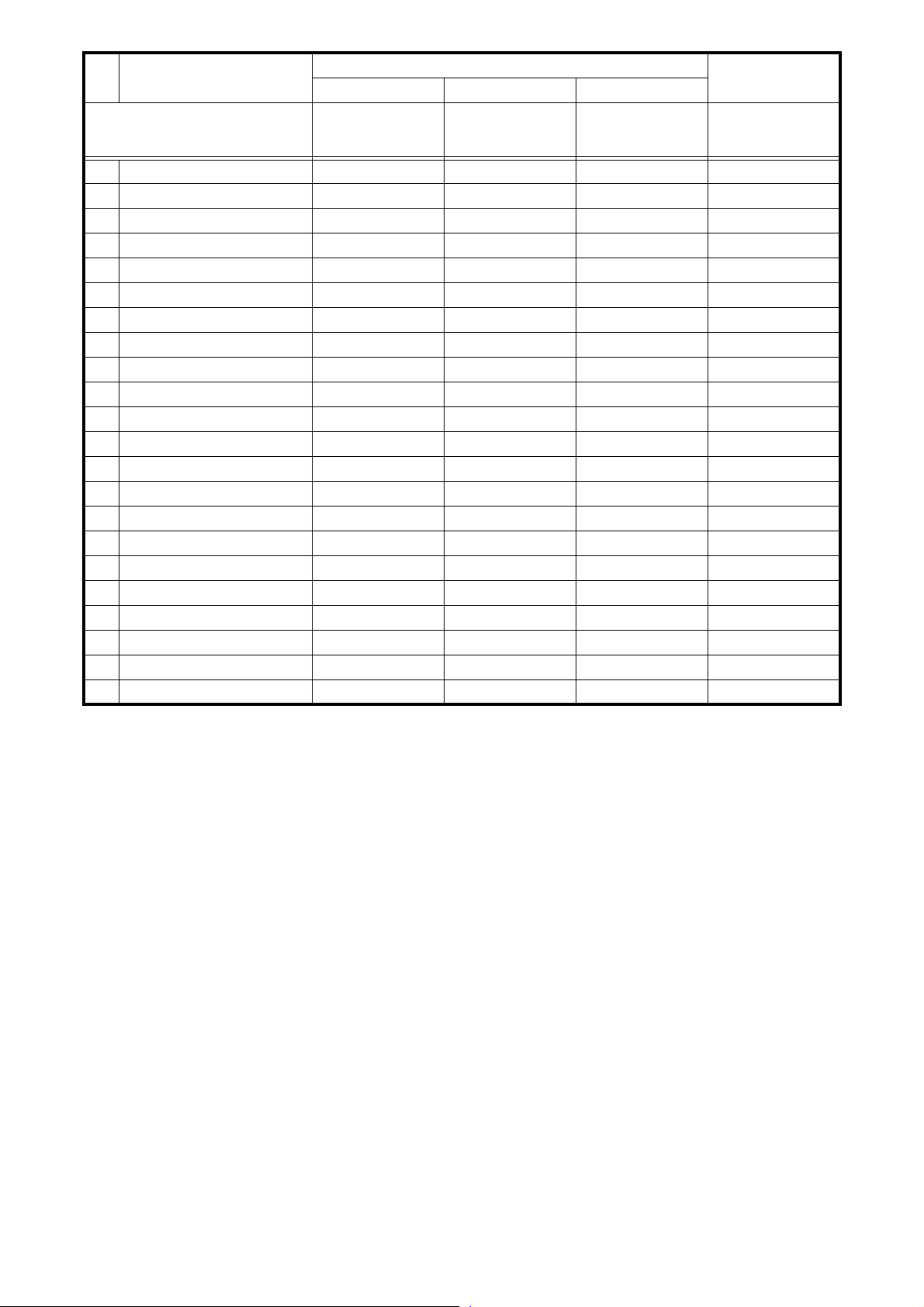

PITCH2 12 12 PITCH2

CENT2 13 13 CENT2

DGND 14 14 DGND

CY043 or CY044

CW044 JOGA2 15 15 JOGA2

+5VD 1 1 +5VD JOGB2 16 16 JOGB2

DGND 2 2 DGND DGND 17 17 DGND CX045

JOGB1 3 3 JOGB1 MEAS 18 18 MEAS VBUS 1

JOGA1 4 4 JOGA1 0-CHG2 19 19 0-CHG2 DM 2

1-/SCS2 20 20 1-/SCS2 DP 3

2-B6SCK2 21 21 2-B6SCK2 GND 4

3-SD2 22 22 3-SD2

DGND 23 23 DGND

FL/RST 24 24 FL/RST

DA2 25 25 DA2

CP2 26 26 CP2

FL/SCS2 27 27 FL/SCS2

㪤㪘㪠㪥㩷㪬㪥㪠㪫

㪞㪬㪄㪊㪏㪋㪐

2DXT_CR1CS221CS201

32CS332CSA2HC39THGIR2HC

41F1KCS441KCS48

5DNGDNGD55DNGD57

㩷㪛㪩㪠㪭㪜

72F2TADDEL772TADDEL75

8V8+2

01GFD3V3+01013V3+012

㪬㪪㪙

㪧㪘㪥㪜㪣㪉㩷㪬㪥㪠㪫

㪏㪬㪄㪈㪈㪇㪇㪍㪍㪄㪉

CW042

CX041 or CX042

VH41VH

1F321F

2F232F

DNGP14DNGP

46

㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫

㪞㪬㪄㪊㪏㪌㪇㪘

Page 47

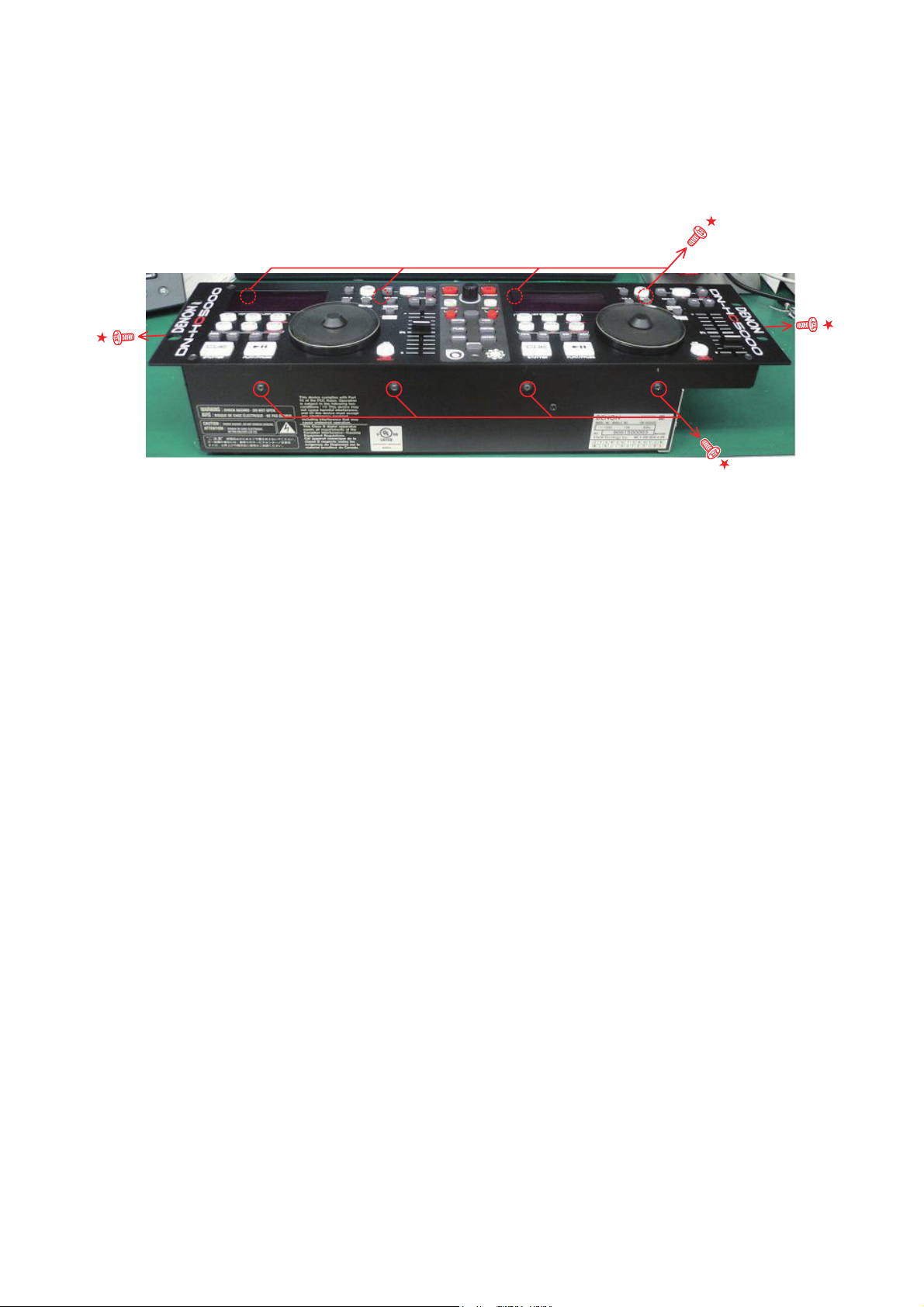

NOTE FOR PARTS LIST

1.

Parts for which "nsp" is indicated on this table cannot be supplied.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

2.

Ordering part without stating its part number can not be supplied.

3.

Part indicated with the mark "★" is not illustrated in the exploded view.

4.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

5.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

WARNING:

Parts marked with this symbol z have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

● Resistors

Ex.: RN

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

* Resistance

2

14K

Shape

and performance

Indicates number of zeros after effective number.

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm18

182

Resistance

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

FR

Others

: Units: ohm

● Capacitors

Ex.: CE

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

* Capacity (electrolyte only)

2

・ Units:μF.

1.2ohm1R 2

1-digit effective number.

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

Indicates number of zeros after effective number.

2-digit effective number.

2200μF22

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

3R2

CapacityMAllowable

error

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

Z:±80%

: - 20%

P : +100%

C:±0.25pF

D:±0.5pF

= : Others

Others

BP

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

2.2μF2R

1-digit effective number.

2-digit effective number, decimal point indicated by R

* Capacity (except electrolyte)

2

・ Units:pF

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

2200pF=0.0022μF22

Indicates number of zeros after efective number.

(More than 2)

2-digit effective number.

1

・ Units:pF

Indicates number of zeros after effective numver.

(0 or 1)

2-digit effective number.

47

220pF22

Page 48

PARTS LIST OF P.W.B. UNIT

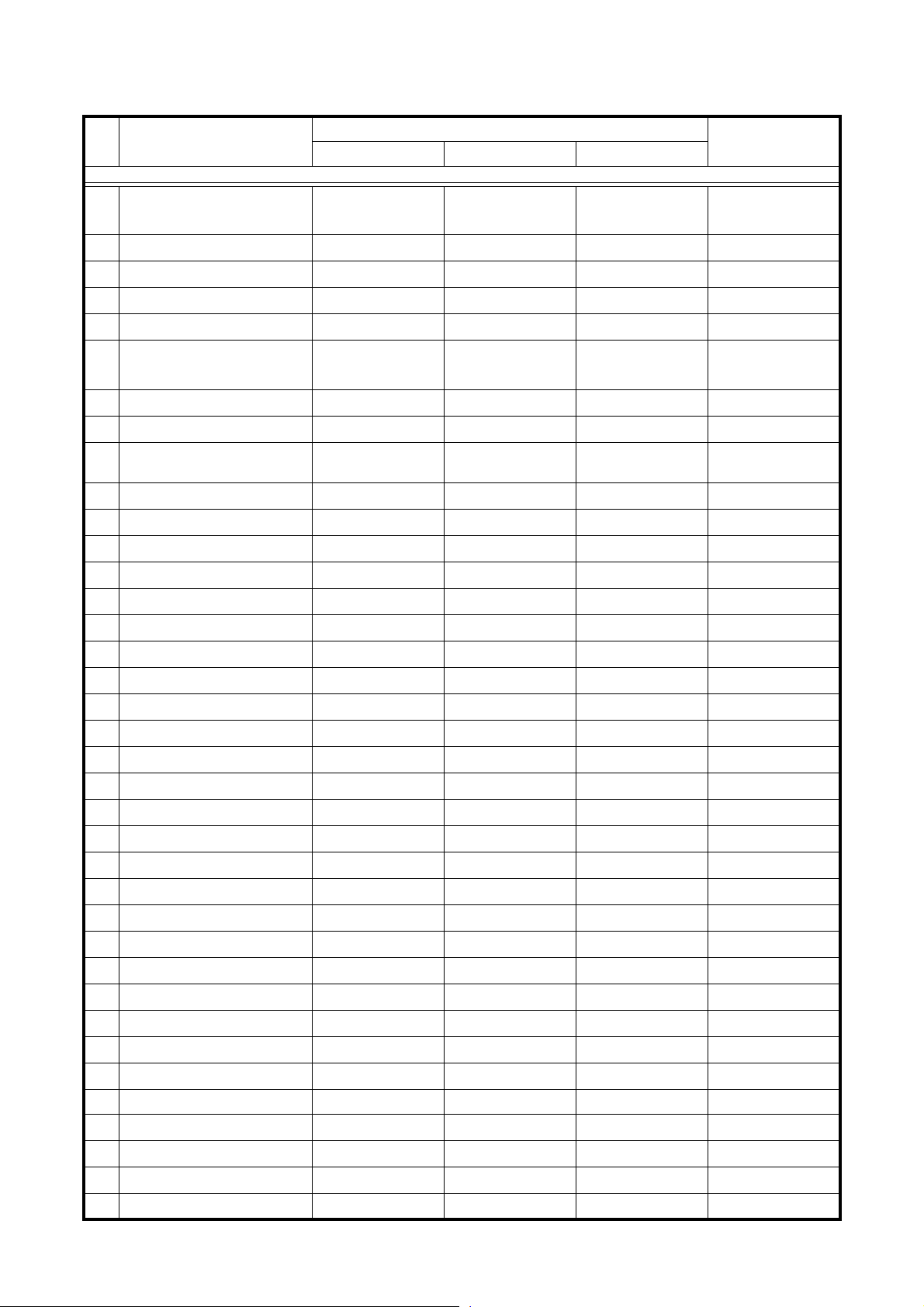

* Parts for which "nsp" is indicated on this table cannot be supplied.

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3 : U.S.A. & Canadamodel E2 : Europe model

GU-3849 MAIN UNIT P.W.B. ASSY

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC101 00D2622813903 SN74AHCT08PW-EL2 +C

IC102 246810028605S W9816G61H-7

IC103 00DGEN8704

IC104 00D2623764006 R5S72630P200FP

IC105 00D2622948904 SN74LV86APW +REF

IC106 00D2622572901 SN74LVU04APW-EL2 +REF

IC107 00D2622669908 SN74LV157APW +C

IC401 00D2623689903 BD9110NV

IC402 00D2622557900 SN74LV14APW-EL2 +REF

IC403 00D2630989900 NJM2904M-TE1 +C

TR101 00D2690083901 DTA114EKT96 +C

TR102 00D2690082902 DTC114EKT96 +C

TR103,104 00D2690238905 DTA123EKA

TR106 00D2690082902 DTC114EKT96 +C

TR107 00D2690083901 DTA114EKT96 +C

TR108 00D2690055900 DTA144EKT96 +C

TR401 00D2690237906 DTC123JKA

TR402 00D2690082902 DTC114EKT96 +C

TR403 00D2690238905 DTA123EKA

TR404 00D2690086908 DTA114TKT96 +C

TR405,406 00D2690238905 DTA123EKA

DNHC4500 ROM ASSY

(M29W400DT55N6E)

NOTE :

When update Firmware, please

confirm a last version in SDI.

Use the service board after

updating it.

D101,102 00D2760559909 DAP202KT146 +C

D103 00D2760560901 DAN202KT146 +C

D104 00D2760717903 1SS355 TE-17 +C

D105 00D2760559909 DAP202KT146 +C

D106 00D2760560901 DAN202KT146 +C

D107 00D2760559909 DAP202KT146 +C

D108 00D2760560901 DAN202KT146 +C

D109 00D2760858901 HZM6.2Z4MWA

D401,402 00D2760559909 DAP202KT146 +C

D403,404 00D2760560901 DAN202KT146 +C

D405 00D2760559909 DAP202KT146 +C

D406 00D2760560901 DAN202KT146 +C

ZD101 00D2760683943 UDZS3.6B-TE17

LD101-103 00MHI10101210 SML-310LT

RESISTORS GROUP

R153 00D2472029905 RM73B--562FT

R280 nsp CK73F1H103ZT +1608

R292 nsp CK73F1H103ZT +1005

R402 nsp RM73B--103FT +1608

R403 00D2472029905 RM73B--562FT

48

Page 49

Ref. No. Part No. Part Name Remarks Q'ty New

CAPACITORS GROUP

C101 nsp CK73F1E104ZT +1608

C102 nsp CK73B1H103KT (1608) +1608

C103 nsp CK73B1E104KT +1608

C104 nsp CC73CH1H470JT +1608

C105 nsp CK73B1E104KT +1608

C106 nsp CK73B1H103KT (1608) +1608

C107 nsp CK73F1E104ZT +1608

C108,109 nsp CK73B1E104KT +1608

C110,111 nsp CK73B1H103KT (1608) +1608

C112 nsp CK73F1E104ZT +1608

C113 nsp CK73B1A105KT +1608

C114-117 nsp CK73F1C104ZT +1005

C118 00D2544464951 CE67C0J220MT(MV-B) +REF

C119,120 nsp CK73F1C104ZT +1005

C121 00D2760870905 HVC375B

C122 nsp CC73CH1H220JT +1608

C123 00D2760870918 HVC376B

C124 nsp CK73B1E104KT +1608

C125 nsp CC73CH1H7R0DT +1608

C126 nsp CK73B1E104KT +1608

C127 nsp CC73CH1H8R0DT +1608

C128 00D2544464951 CE67C0J220MT(MV-B) +REF

C129 nsp CC73CH1H8R0DT +1608

C130 nsp CK73B1E104KT +1608

C131 nsp CK73F1E104ZT +1608

C132,133 nsp CK73F1C104ZT +1005

C134 nsp CK73B1H103KT (1608) +1608

C135,136 nsp CK73F1C104ZT +1005

C137 00D2544464951 CE67C0J220MT(MV-B) +REF

C138 nsp CK73F1C104ZT +1005

C139 nsp CK73B1H332KT +1608

C140-142 nsp CK73F1C104ZT +1005

C143 nsp CK73B1H332KT +1608

C144,145 nsp CK73F1C104ZT +1005

C146 nsp CK73B1H332KT +1608

C147,148 nsp CK73F1C104ZT +1005

C149 nsp CK73B1H332KT +1608

C150,151 nsp CK73F1C104ZT +1005

C152 nsp CK73B1H332KT +1608

C153 nsp CK73F1C104ZT +1005

C154 nsp CK73B1H332KT +1608

C155,156 nsp CK73F1C104ZT +1005

C157 00MDK2647601Y GRM32EB31C476KE15L

C158-171 nsp CK73F1C104ZT +1005

C172 00D2544464951 CE67C0J220MT(MV-B) +REF

C173-208 nsp CC73CH1H470JT +1608

C209,210 00D2574018908 CE67C1A100MT(PXA)

C211-213 nsp CK73F1C104ZT +1005

C214 nsp CK73F1E104ZT +1608

C215 nsp CK73B1H103KT (1608) +1608

C216 nsp CK73B1E104KT +1608

C401 nsp CK73F1E104ZT +1608

C402 nsp CK73F1H103ZT +1608

C403 nsp CK73F1E104ZT +1608

C404 nsp CK73F1H103ZT +1608

49

Page 50

Ref. No. Part No. Part Name Remarks Q'ty New

C405 nsp CK73B1E104KT +1608

C406 00D2544655906 CE67C0J220MT (RV2) +REF

C407 nsp CK73B1E104KT +1608

C408 00D2544656934 CE67C1A470MT (RV2)

C409 nsp CK73B1H103KT (1608) +1608

C410-412 00D2570038908 CK73B1A106KT +2125

C413 nsp CK73B1A474KT

C414 nsp CK73F1E104ZT +1608

C415 nsp CK73B1E223KT +1608

C418-423 nsp CK73F1E104ZT +1608

C424 nsp CK73B1E104KT +1608

C425-432 nsp CK73B1H103KT (1608) +1608

C433 nsp CK73B1E104KT +1608

OTHERS PARTS GROUP

AS101 nsp IC SOCKET (TSOP48)

CX045 00D2051295105 USB(B)CON. FLANGE

CX061 nsp 6P CONN.BASE(KR-PH)

CX101 nsp 8P MD BASE (F-S)

CX111 nsp 11P FFC BASE(9610SB)

CX141 nsp BM14B-SRSS-TB

CX271,272 nsp 27P FFC BASE (P=1)

FB101-103 00D2350158901 CHIP BEADS(18PG121) +1608

FB104,105 00D2350130903 CHIP EMIFIL(11A121) +1608

FB106-110 00D2350158901 CHIP BEADS(18PG121) +1608

FB401,402 00D2350158901 CHIP BEADS(18PG121) +1608

JK401-403 00D2048416007 MINI JACK

L401 00D2350183905 INDUCTOR 2.2UH(7E06N

W101 nsp M3 SCREW TERMINAL

X101 00D3991051903 X-TAL(16.9344/HC-49)

X102 00D3991127905 FCX-03(48MHz)

X103 00D3991030908 HC-49/U03C24.576MHZ

50

Page 51

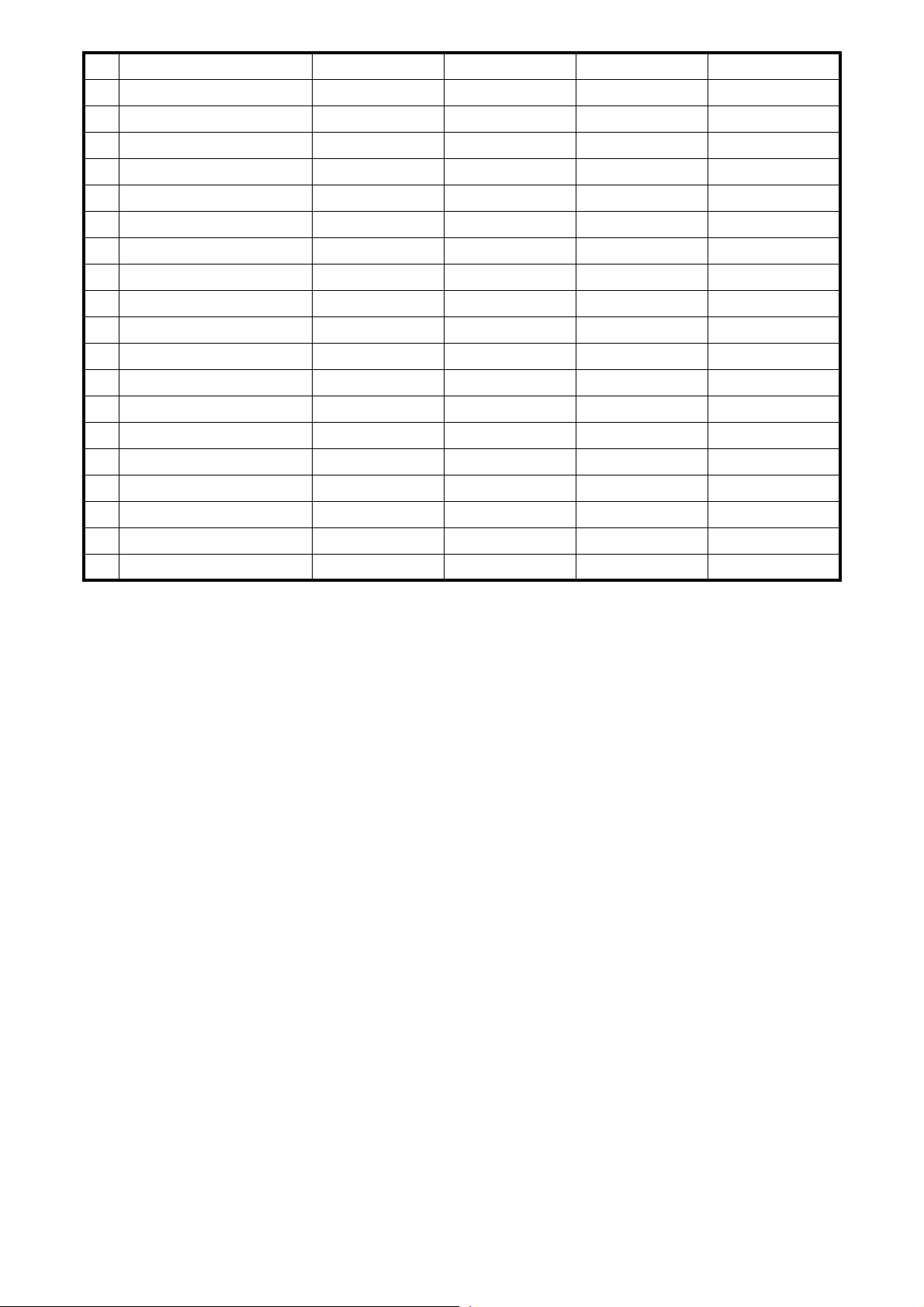

GU-3850AE3 POWER UNIT P.W.B. ASSY(E3 model)

GU-3850AE2 POWER UNIT P.W.B. ASSY(E2 model)

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC801 00D2630809006 NJM7805FA(S)

IC802,803 00D2623692903 PCM1781

IC804,805 00D2630896909 NJM2068MD-TE1 +C

IC901 00D2623765005 BD9703T-V5

IC902 00D2623698004 BA33BC0WT-V5

IC903 00D2630454901 M51957BFP(TP1)

IC904 00D2630810008 NJM7808FA(S)

IC905 00D2630503001 NJM7908FA

TR801 00D2690082902 DTC114EKT96 +C

TR802 00D2690083901 DTA114EKT96 +C

TR803 00D2690082902 DTC114EKT96 +C

TR808 00D2690083901 DTA114EKT96 +C

TR809-812 00D2730460905 KTC2875-B-RTK/P

TR903 00D2690238905 DTA123EKA

TR904 00D2740158003 2SD1763A(D)

TR905,906 00D2690088906 DTC114TKT96 +C

TR907 00D2690082902 DTC114EKT96 +C

D801,802 00D2760717903 1SS355 TE-17 +C

D901-908 00D2760704903 1SR35-400A(T93X)

D909 00D2760717903 1SS355 TE-17 +C

D910 00D2760684900 RB051L-40TE25 +C

D912,913 00D2760796908 1SR139-400T-31

D914-917 00D2760704903 1SR35-400A(T93X)

ZD801 00D2760683901 UDZS5.6B-TE17 +C

ZD901 00D2760760976 MTZJ6.8B T77

ZD903 00D2760760947 MTZJ5.1B T77

ZD904 00D2760762945 MTZJ36B T77

RESISTORS GROUP

R902 00D2472029918 RM73B--622FT

R903 00D2472035915 RM73B--152DT(1608)

R908 00D2472029905 RM73B--562FT

R909 00D2472045963 RM73B--222FT_1608

CAPACITORS GROUP