Page 1

PLC

PLC

Page 2

DVP-PLC Application Manual

【Programming】

Table of Contents

Chapter 1 Basic Principles of PLC Ladder Diagram

Foreword: Background and Functions of PLC.......................................................... 1-1

1.1 The Working Principles of Ladder Diagram........................................................ 1-1

1.2 Differences Between Traditional Ladder Diagram and PLC Ladder Diagram ........ 1-2

1.3 Edition Explanation of Ladder Diagram ............................................................. 1-3

1.4 How to Edit Ladder Diagram ............................................................................. 1-8

1.5 The Conversion of PLC Command and Each Diagram Structure......................... 1-12

1.6 Simplified Ladder Diagram ............................................................................... 1-15

1.7 Basic Program Designing Examples.................................................................. 1-17

Chapter 2 Functions of Devices in DVP-PLC

2.1 All Devices in DVP-PLC....................................................................................2-1

2.2 Values, Constants [K] / [H] ............................................................................... 2-6

2.3 Numbering and Functions of External Input/Output Contacts [X] / [Y].................. 2-8

2.4 Numbering and Functions of Auxiliary Relays [M] .............................................. 2-11

2.5 Numbering and Functions of Step Relays [S] ..................................................... 2-11

2.6 Numbering and Functions of Timers [T]............................................................. 2-12

2.7 Numbering and Functions of Counters [C]......................................................... 2-14

2.8 Numbering and Functions of Registers [D], [E], [F]............................................ 2-28

2.8.1 Data register [D]........................................................................................ 2-28

2.8.2 Index Register [E], [F]................................................................................ 2-29

2.8.3 Functions and Features of File Registers.................................................... 2-30

2.9 Pointer [N], Pointer [P], Interruption Pointer [I].................................................. 2-30

2.10 Special Auxiliary Relays and Special Data Registers........................................ 2-33

2.11 Functions of Special Auxiliary Relays and Special Registers............................. 2-69

2.12 Error Codes................................................................................................... 2-125

Chapter 3 Basic Instructions

3.1 Basic Instructions and Step Ladder Instructions ................................................ 3-1

3.2 Explanations on Basic Instructions ................................................................... 3-3

Page 3

Chapter 4 Step Ladder Instructions

4.1 Step Ladder Instructions [STL], [RET] ............................................................... 4-1

4.2 Sequential Function Chart (SFC) ...................................................................... 4-2

4.3 How does a Step Ladder Instruction Work? ....................................................... 4-3

4.4 Things to Note for Designing a Step Ladder Program......................................... 4-7

4.5 Types of Sequences......................................................................................... 4-9

4.6 IST Instruction................................................................................................. 4-17

Chapter 5 Categories & Use of Application Instructions

5.1 List of Instructions ........................................................................................... 5-1

5.2 Composition of Application Instruction .............................................................. 5-6

5.3 Handling of Numeric Values.............................................................................. 5-11

5.4 E, F Index Register Modification....................................................................... 5-14

5.5 Instruction Index.............................................................................................. 5-16

Chapter 6 Application Instructions API 00-49

● (API00~ 09)Loop Control .......................................................................... 6-1

● (API10~ 19)Transmission Comparison....................................................... 6-18

● (API20~ 29)Four Arithmetic Operation....................................................... 6-32

● (API30~ 39)Rotation & Displacement......................................................... 6-46

● (API40~ 49)Data Processing..................................................................... 6-57

Chapter 7 Application Instructions API 50-99

● (API50~ 59)High Speed Processing........................................................... 7-1

● (API60~ 69)Handy Instructions.................................................................. 7-39

● (API70~ 79)Display of External Settings .................................................... 7-59

● (API80~ 88)Serial I/O ............................................................................... 7-80

Chapter 8 Application Instructions API 100-149

● (API100~ 109)Communication ................................................................... 8-1

● (API110~119) Floating Point Operation...................................................... 8-23

● (API120~ 129)Floating Point Operation ..................................................... 8-31

● (API130~ 139)Floating Point Operatio .......................................................8-43

● (API140~ 149)Others ................................................................................ 8-55

Chapter 9 Application Instructions API 150-199

● (API150~ 154)Others ................................................................................ 9-1

● (API155~ 159)Position Control.................................................................. 9-14

Page 4

● (API160~ 169)Real Time Calendar ............................................................9-39

● (API170~ 171)Gray Code Conversion........................................................ 9-49

● (API172~ 175)Floating Point Operation ..................................................... 9-51

● (API180~ 190)Matrix................................................................................. 9-59

● (API191~ 199)Positioning Instruction ........................................................ 9-76

Chapter 10 Application Instructions API 215-246

● (API202~ 203)Others. ............................................................................... 10-1

● (API215~ 223)Contact Type Logic Operation Instruction. ............................ 10-7

● (API224~ 246)Contact Type Compare Instruction....................................... 10-10

Page 5

1 Basic Principles of PLC Ladder Diagram

Foreword: Background and Functions of PLC

PLC (Programmable Logic Controller) is an electronic device, previously called “sequence controller”. In 1978,

NEMA (National Electrical Manufacture Association) in the United States officially named it as “programmable logic

controller”. PLC reads the status of the external input devices, e.g. keypad, sensor, switch and pulses, and execute by

the microprocessor logic, sequential, timing, counting and arithmetic operations according the status of the input

signals as well as the pre-written program stored in the PLC. The generated output signals are sent to output devices

as the switch of a relay, electromagnetic valve, motor drive, control of a machine or operation of a procedure for the

purpose of machine automation or processing procedure. The peripheral devices (e.g. personal computer/handheld

programming panel) can easily edit or modify the program and monitor the device and conduct on-site program

maintenance and adjustment. The widely used language in designing a PLC program is the ladder diagram.

With the development of the electronic technology and wider applications of PLC in the industry, for example in

position control and the network function of PLC, the input/output signals of PLC include DI (digital input), AI (analog

input), PI (pulse input), NI (numeric input), DO (digital output), AO (analog output), and PO (pulse output). Therefore,

PLC will still stand important in the industrial automation field in the future.

1.1 The Working Principles of Ladder Diagram

The ladder diagram was a diagram language for automation developed in the WWII period, which is the oldest

and most widely adopted language in automation. In the initial stage, there were only A (normally open) contact, B

(normally closed) contact, output coil, timer and counter…the sort of basic devices on the ladder diagram (see the

power panel that is still used today). After the invention of PLC, the devices displayable on the ladder diagram are

added with differential contact, latched coil and the application commands which were not in a traditional power panel,

for example the addition, subtraction, multiplication and division operations.

The working principles of the traditional ladder diagram and PLC ladder diagram are basically the same. The

only difference is that the symbols on the traditional ladder diagram are more similar to its original form, and PLC

ladder diagram adopts the symbols that are easy to recognize and shown on computer or data sheets. In terms of the

logic of the ladder diagram, there are combination logic and sequential logic.

1. Combination Logic

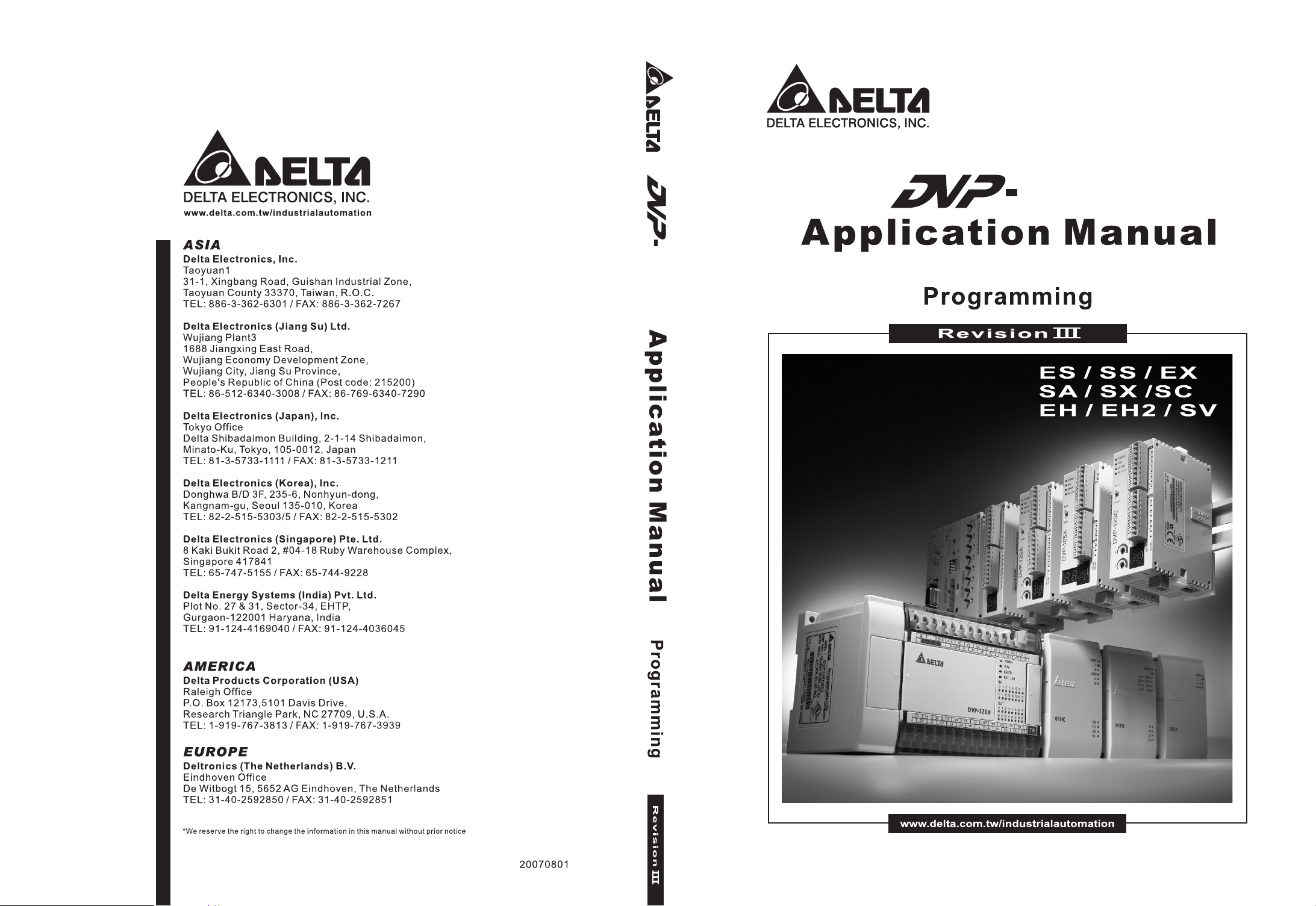

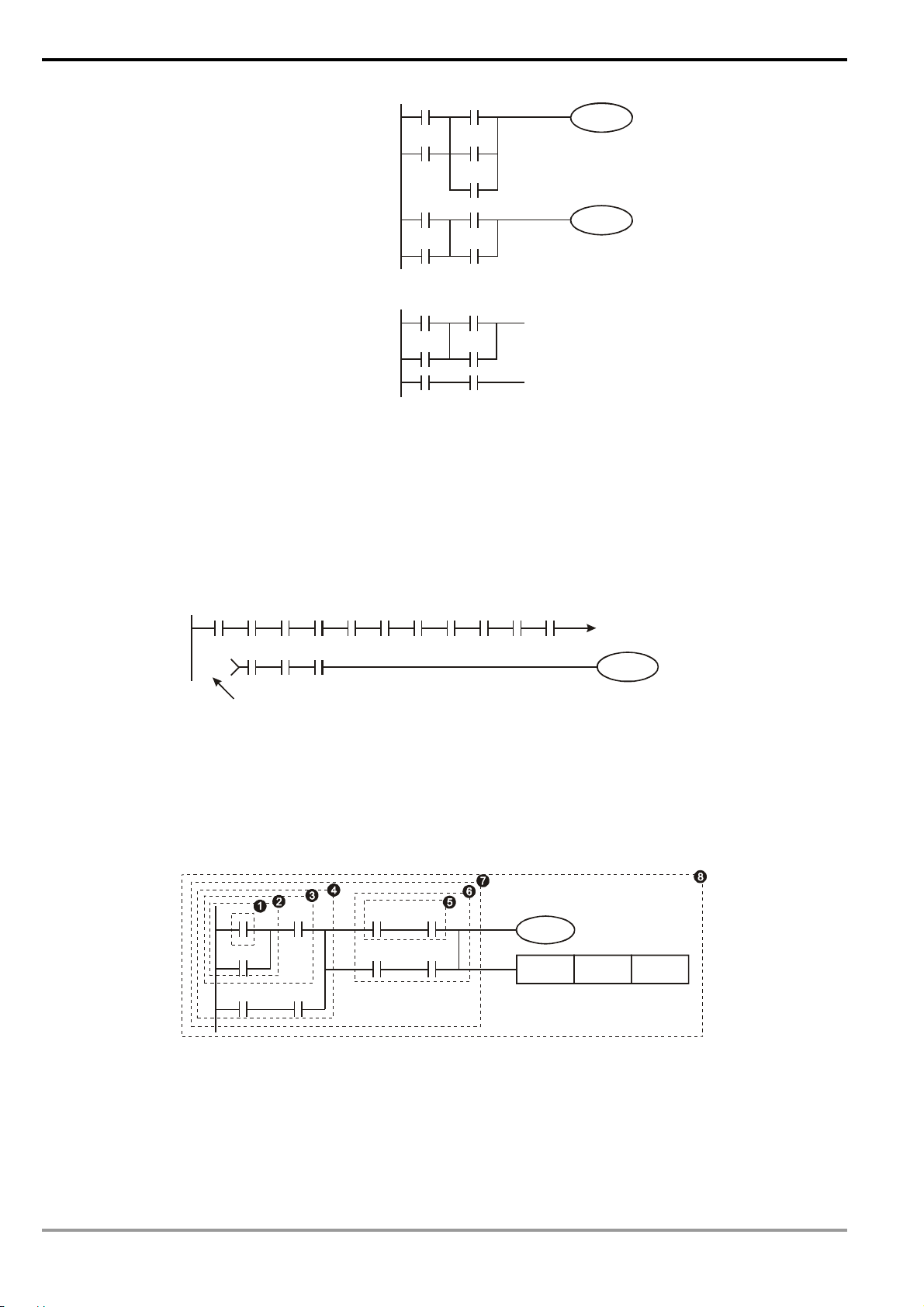

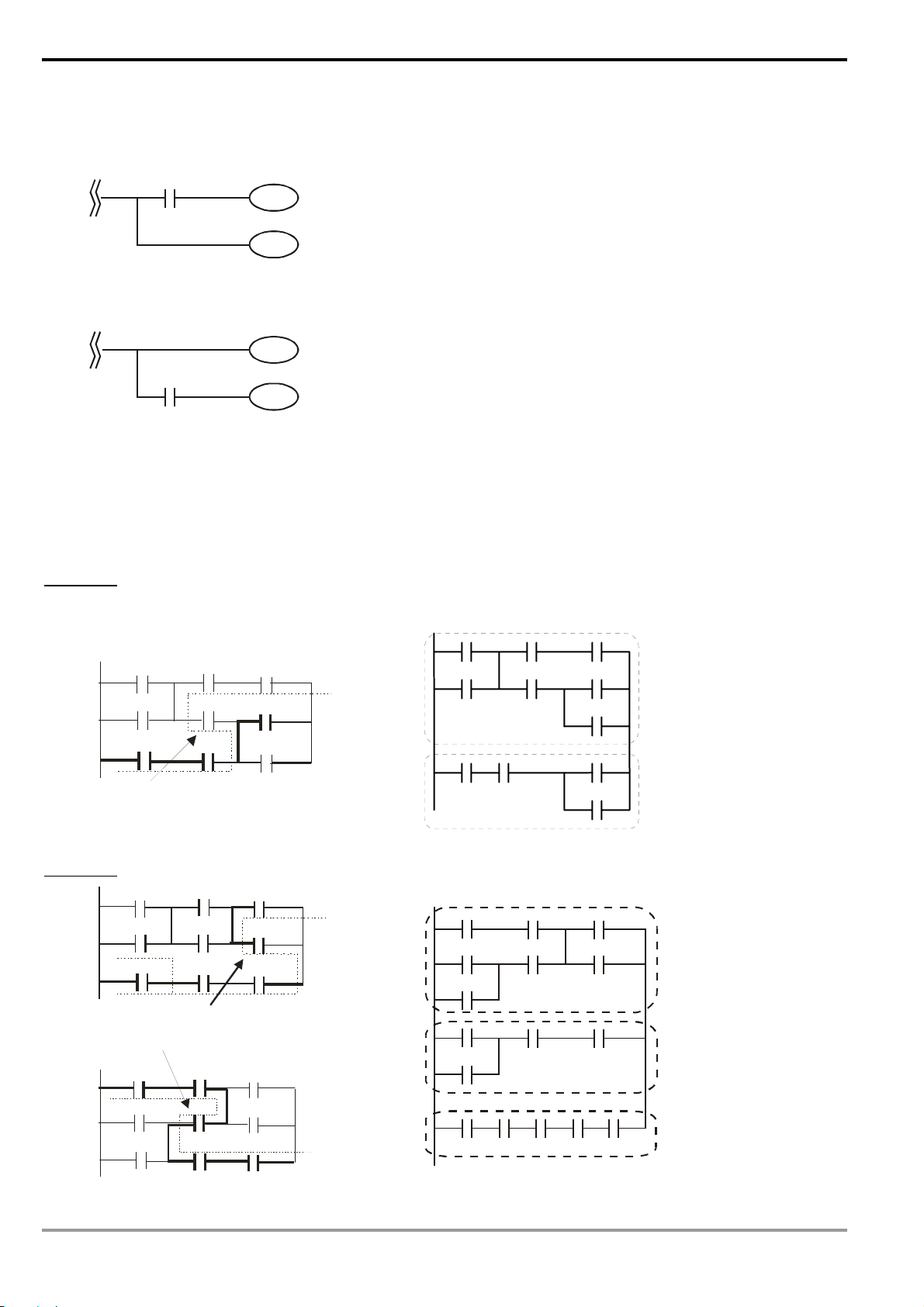

Examples of traditional ladder diagram and PLC ladder diagram for combination logic:

Traditional Ladder Diagram PLC Ladder Diagram

X0

X1

X2

X3

X4

Y0

Y1

Y2

X0

Y0

X1

X2

X3

X4

Y1

Y2

Row 1: Using a normally open (NO) switch X0 (“A” switch or “A" contact). When X0 is not pressed, the contact

will be open loop (Off), so Y0 will be Off. When X0 is pressed, the contact will be On, so Y0 will be On.

DVP-PLC Application Manual

1-1

Page 6

1 Basic Principles of PLC Ladder Diagram

Row 2: Using a normally closed (NC) switch X1 (“B” switch or “B” contact). When X1 is not pressed, the contact

will be On, so Y1 will be On. When X1 is pressed, the contact will be open loop (Off), so Y1 will be Off.

Row 3: The combination logic of more than one input devices. Output Y2 will be On when X2 is not pressed or

X3 and X4 are pressed.

2. Sequential Logic

Sequential logic is a circuit with "draw back” structure, i.e. the output result of the circuit will be drawn back as an

input criterion. Therefore, under the same input criteria, different previous status or action sequence will follow by

different output results.

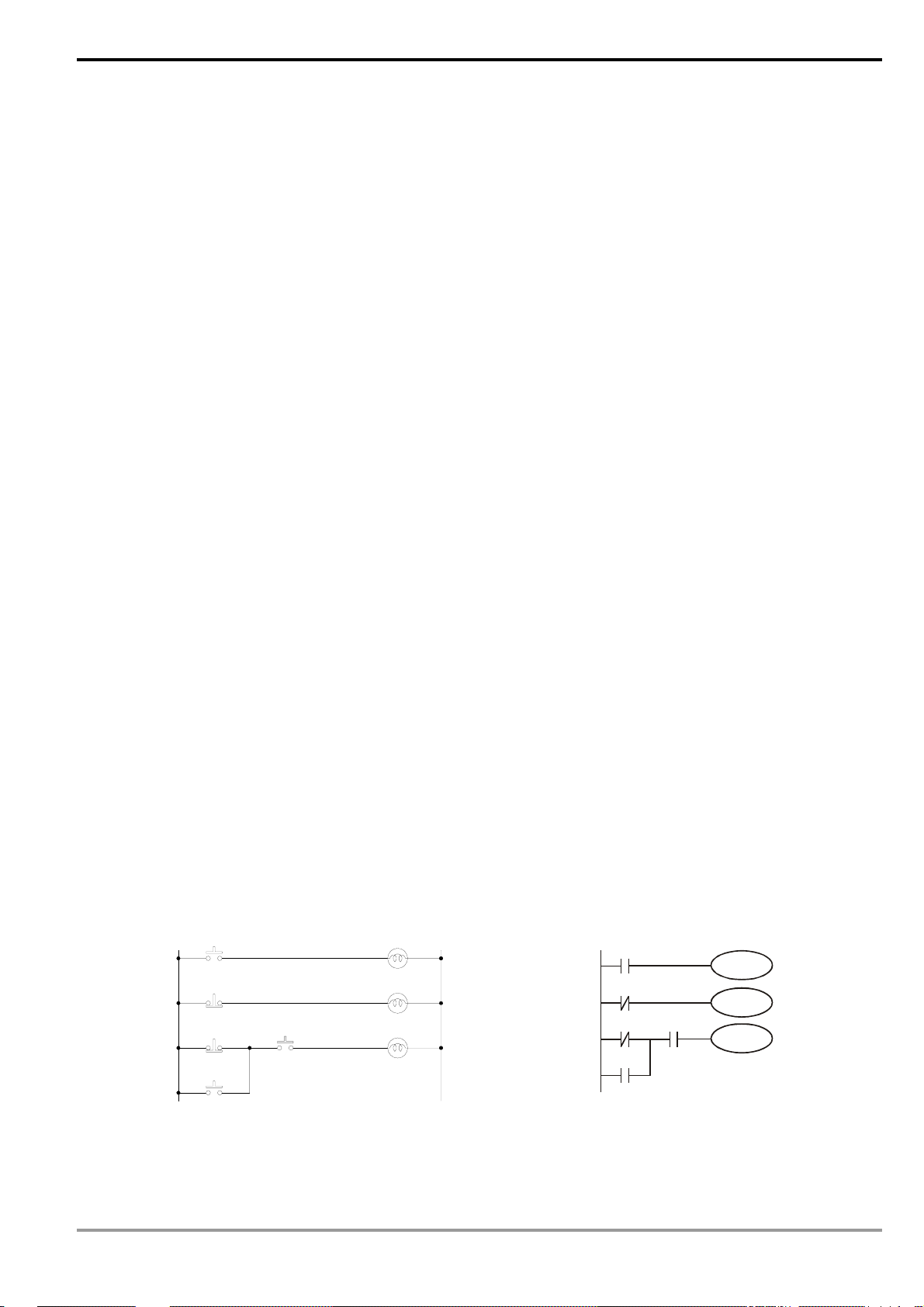

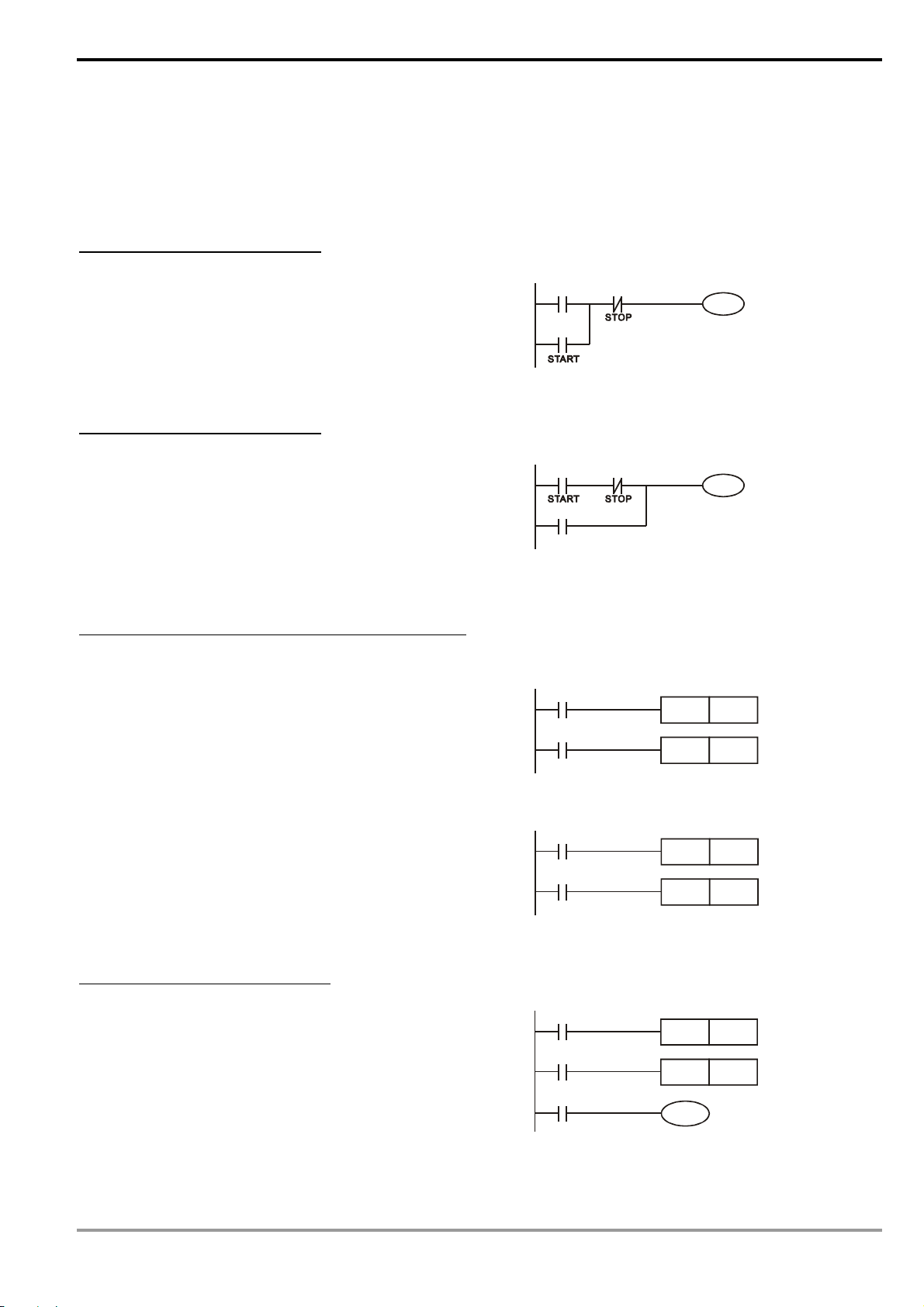

Examples of traditional ladder diagram and PLC ladder diagram for sequential logic:

Traditional Ladder Diagram PLC Ladder Diagram

X5

Y3

X6

Y3

X5

Y3

X6

Y3

When the circuit is first connected to the power, though X6 is On, X5 is Off, so Y3 will be Off. After X5 is pressed,

Y3 will be On. Once Y3 is On, even X5 is released (Off), Y3 can still keep its action because of the draw back (i.e.

the self-retained circuit). The actions are illustrated in the table below.

Device status

Action sequence

X5

X6 Y3

1 No action No action Off

2 Action No action On

3 No action No action On

4 No action Action Off

5 No action No action Off

From the table above, we can see that in different sequence, the same input status can result in different output

results. For example, switch X5 and X6 of action sequence 1 and 3 do not act, but Y3 is Off in sequence 1 and

On in sequence 3. Y3 output status will then be drawn back as input (the so-called “draw back”), making the

circuit being able to perform sequential control, which is the main feature of the ladder diagram circuit. Here we

only explain contact A, contact B and the output coil. Other devices are applicable to the same method. See

Chapter 3 “Basic instructions” for more details.

1.2 Differences Between Traditional Ladder Diagram and PLC Ladder Diagram

Though the principles of traditional ladder diagram and PLC ladder diagram are the same, in fact, PLC adopts

microcomputer to simulate the motions of the traditional ladder diagram, i.e. scan-check status of all the input devices

and output coil and calculate to generate the same output results as those from the traditional ladder diagram based

on the logics of the ladder diagram. Due to that there is only one microcomputer, we can only check the program of

the ladder diagram one by one and calculate the output results according to the program and the I/O status before the

cyclic process of sending the results to the output interface Æ re-reading of the input status Æ calculation Æ output.

The time spent in the cyclic process is called the “scan time” and the time can be longer with the expansion of the

program. The scan time can cause delay from the input detection to output response of the PLC. The longer the delay,

1-2

DVP-PLC Application Manual

Page 7

1 Basic Principles of PLC Ladder Diagram

the bigger the error is to the control. The control may even be out of control. In this case, you have to choose a PLC

with faster scan speed. Therefore, the scan speed is an important specification requirement in a PLC. Owing to the

advancement in microcomputer and ASIC (IC for special purpose), there has been great improvement in the scan

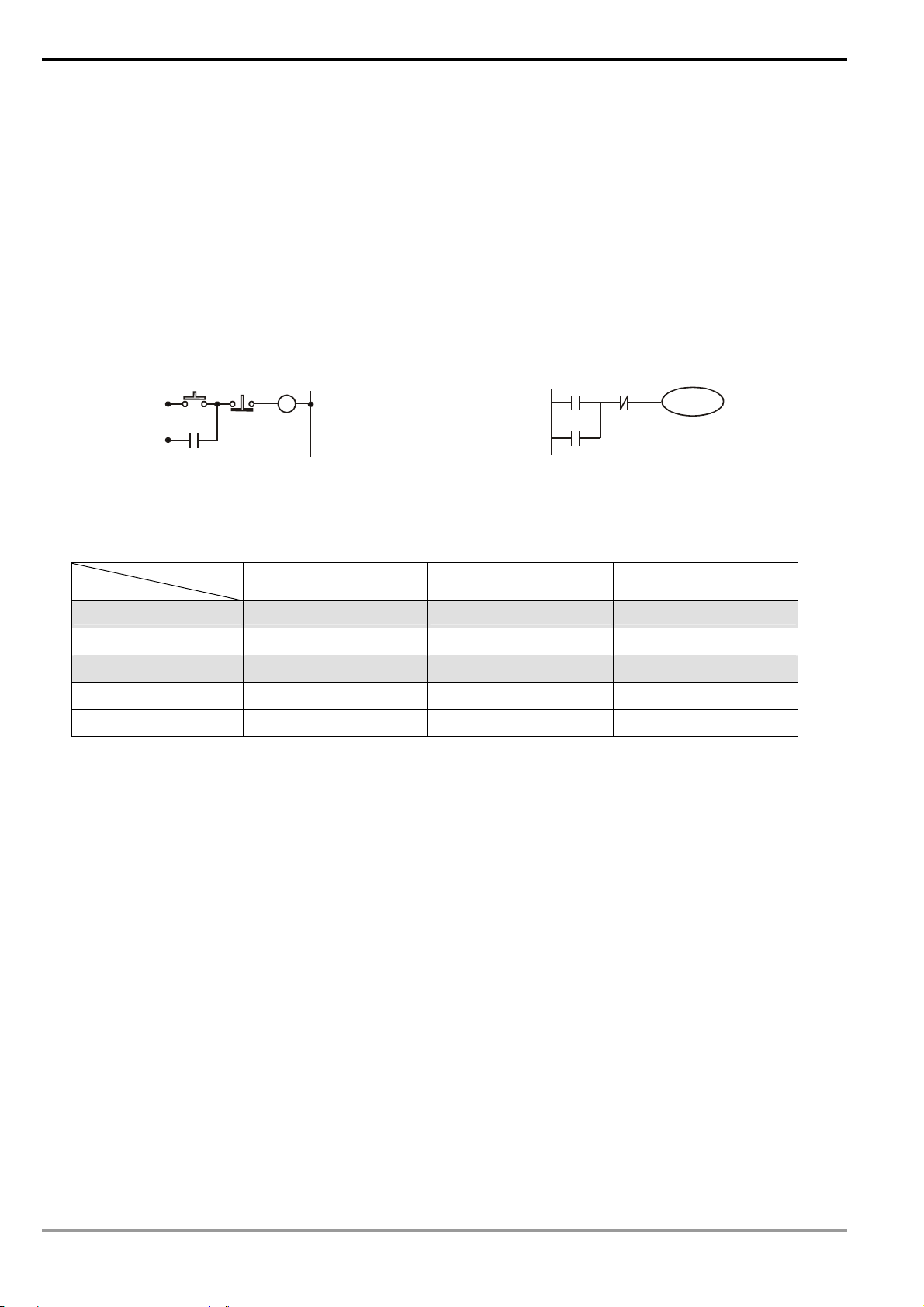

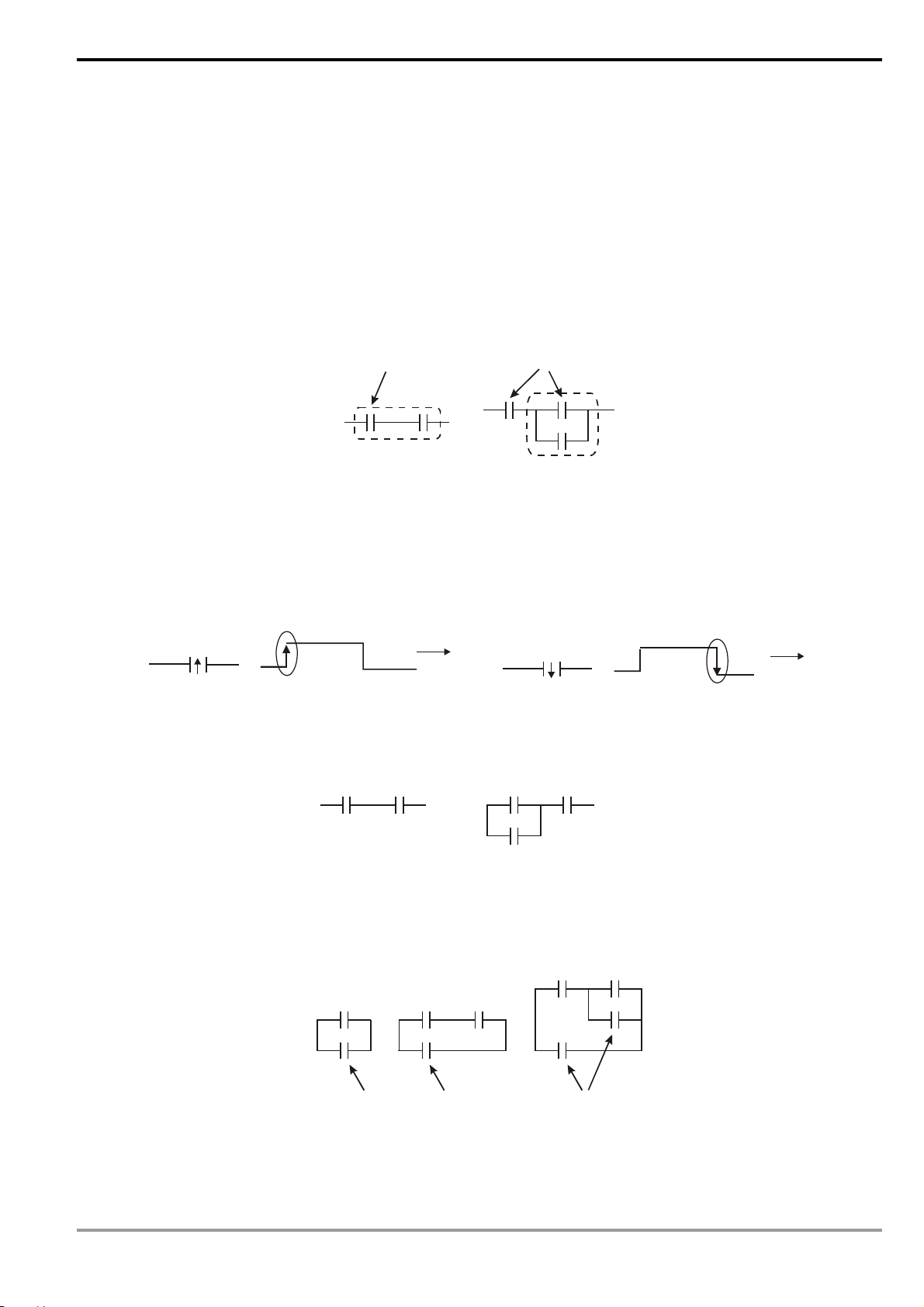

speed of PLC nowadays. See the figure below for the scan of the PLC ladder diagram program.

Read input status from outside

X0 X1

The output result is calculated

based on the ladder diagram.

(The result has not yet sent to the

external output point, but the

internal device will perform an

immediate output.)

Start

Y0

X3

M100

:

:

X100 M505

X10

Y0

Executing in cycles

Y1

Y126

End

Send the result to the output point

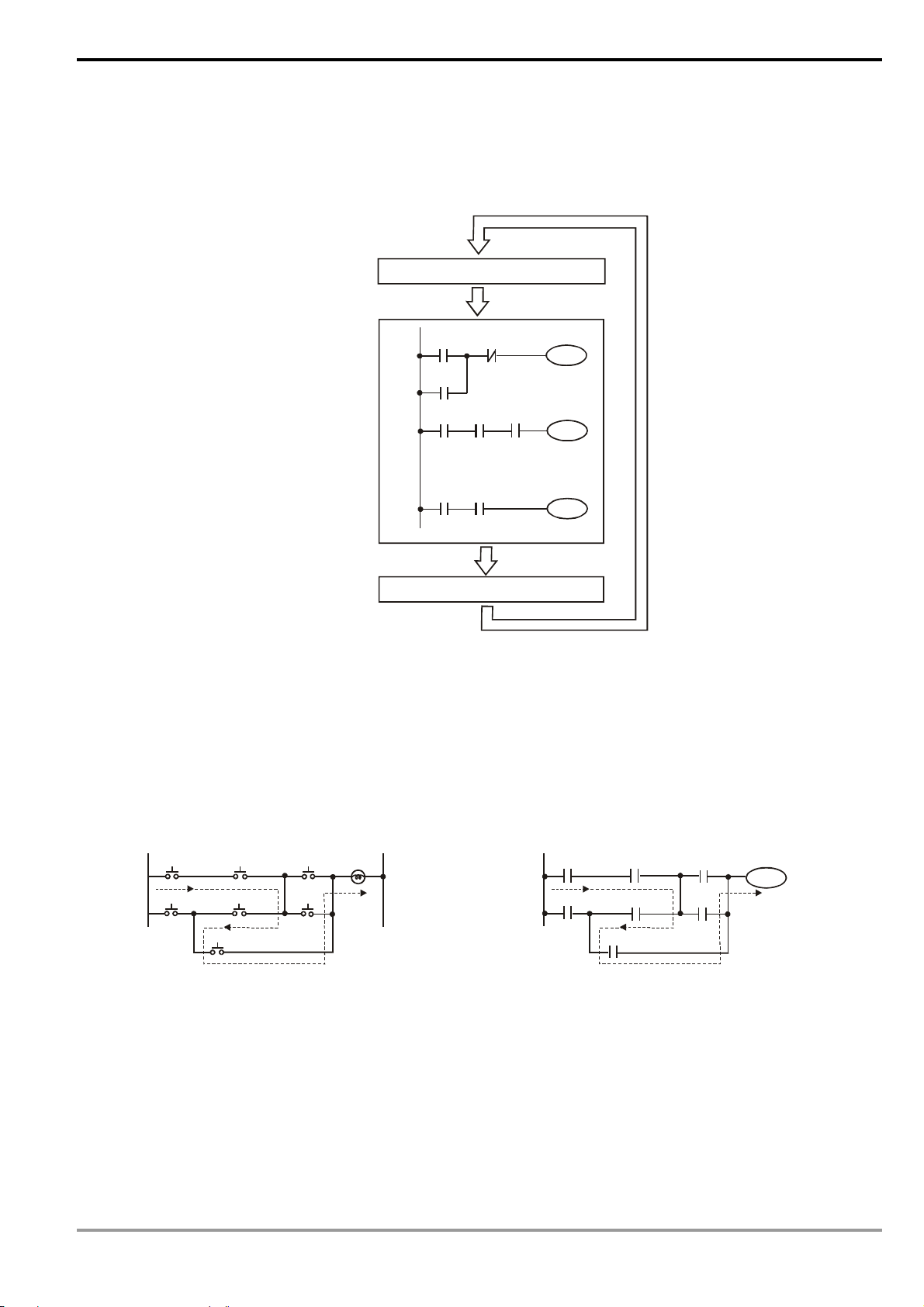

Besides the difference in the scan time, PLC ladder and traditional ladder diagram also differ in “reverse current”.

For example, in the traditional ladder diagram illustrated below, when X0, X1, X4 and X6 are On and others are Off,

Y0 output on the circuit will be On as the dotted line goes. However, the PLC ladder diagram program is scanned from

up to down and left to right. Under the same input circumstances, the PLC ladder diagram editing tool WPLSoft will be

able to detect the errors occurring in the ladder diagram.

Reverse current of traditional ladder diagram

X0

X3

a

X6

X1 X2

X4

X5

b

Y0

Error detected in the third row

Reverse current of PLC ladder diagram

X0

X3

a

X6

X1

X4 X5

b

X2

Y0

Y0

1.3 How to Edit Ladder Diagram

Ladder diagram is a diagram language frequently applied in automation. The ladder diagram is composed of the

symbols of electric control circuit. The completion of the ladder diagram by the ladder diagram editor is the completion

of the PLC program design. The control flow illustrated by diagram makes the flow more straightforward and

acceptable for the technicians of who are familiar with the electric control circuit. Many basic symbols and actions in

DVP-PLC Application Manual

1-3

Page 8

1 Basic Principles of PLC Ladder Diagram

the ladder diagram come from the frequently-seen electromechanical devices, e.g. buttons, switches, relay, timer and

counter, etc. in the traditional power panel for automation control.

Internal devices in the PLC: The types and quantity of the devices in the PLC vary in different brand names.

Though the internal devices in the PLC adopts the names, e.g. transistor, coil, contact and so on, in the traditional

electric control circuit, these physical devices do not actually exist inside the PLC. There are only the corresponding

basic units (1 bit) inside the memory of the PLC. When the bit is “1”, the coil will be On, and when the bit is “0”, the coil

will be Off. The normally open contact (NO or contact A) directly reads the value of the corresponding bit. The

normally close contact (NC or contact B) reads the opposite state of the value of the corresponding bit. Many relays

will occupy many bits. 8 bits equal a “byte”. 2 bytes construct a “word” and 2 words combined is “double word”. Byte,

word or double words are used when many relays are processed (e.g. addition/subtraction, displacement) at the

same time. The other two devices, timer and counter, in the PLC have coil, timer value and counter value and they

have to process some values in byte, word or double word.

All kinds of internal devices in the value storage area in the PLC occupy their fixed amount of storage units.

When you use these devices, you are actually read the contents stored in the form of bit, byte or word.

Introductions on the basic internal devices in the PLC (See Ch 2. Functions of Devices in DVP-PLC for more details.)

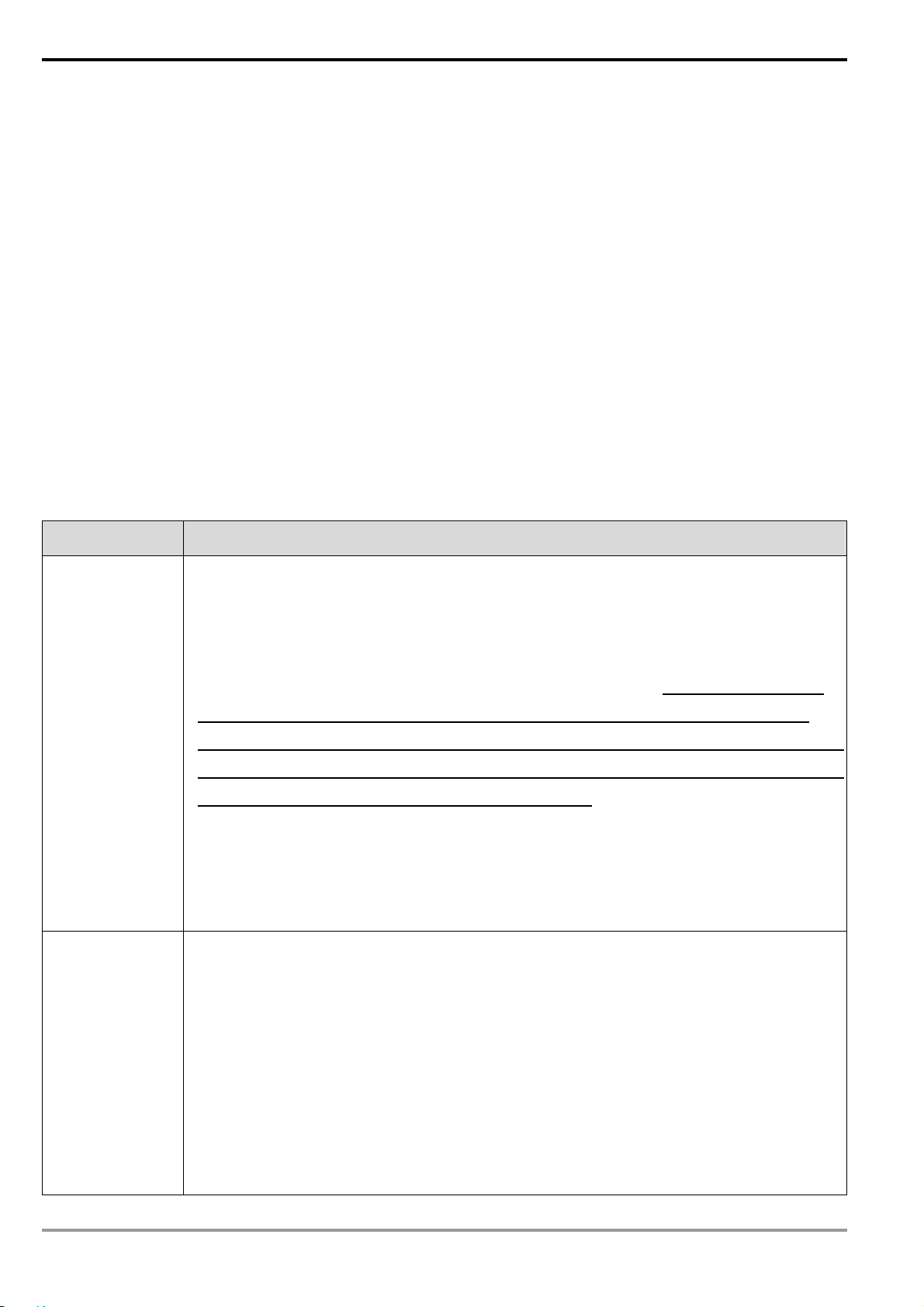

Device Functions

The input relay is an internal memory (storage) unit in the PLC corresponding to a external

input point and is used for connecting to the external input switches and receiving external

input signals. The input relay will be driven by the external input signals which make it “0” or

“1". Program designing cannot modify the status of the relay, i.e. it cannot re-write the basic

unit of a relay, nor can it force On/Off of the relay by HPP/WPLSoft. SA/SX/SC/EH/EH2/SV

series MPU can simulate input relay X and force On/Off of the relay. But the status of the

Input relay

external input points will be updated and disabled, i.e. the external input signals will not be read

into their corresponding memories inside PLC, but only the input points on the MPU. The input

points on the extension modules will still operate normally. There are no limitations on the times

of using contact A and contact B of the input relay. The input relays without corresponding input

signals can only be left unused and cannot be used for other purposes.

& Device indication: X0, X1,…X7, X10, X11,… are indicated as X and numbered in octal

form. The No. of input points are marked on MPU and extension modules.

The output relay is an internal memory (storage) unit in the PLC corresponding to a external

Output relay

1-4

output point and is used for connecting to the external load. The output relay will be driven by

the contact of an input relay, contacts of other internal devices and the contacts on itself. A

normally open contact of the output relay is connected to the external load. Same as the input

contacts, there are no limitations on the times of using other contacts of the output relay. The

output relay without corresponding output signals can only be left unused and can be used as

input relay if necessary.

& Device indication: Y0, Y1,…Y7, Y10, Y11,…are indicated as Y and numbered in octal

form. The No. of output points are marked on MPU and extension modules.

DVP-PLC Application Manual

Page 9

Internal relay

Step

1 Basic Principles of PLC Ladder Diagram

The internal relay does not have connection with the external. It is an auxiliary relay inside the

PLC with the functions same as those of the auxiliary (middle) relay in the electric control

circuit. Every internal relay corresponds to a basic internal storage unit and can be driven by

the contacts of the input relay, contacts of the output relay and the contacts of other internal

devices. There are no limitations on the times of using the contacts of the internal relay and

there will be no output from the internal relay, but from the output point.

& Device indication: M0, M1,…, M4095 are indicated as M and numbered in decimal form.

DVP series PLC offers a step-type control program input method. STL instruction controls the

transfer of step S, which makes it easy for the writing of the control program. If you do not use

any step program in the control program, step S can be used as a internal relay M as well as an

alarm point.

& Device indication: S0, S1,…S1023 are indicated as S and numbered in decimal form.

The timer is used for timing and has coil, contact and register in it. When the coil is On and the

Timer

Counter

Data register

estimated time is reached, its contact will be enabled (contact A closed, contact B open). Every

timer has its fixed timing period (unit: 1ms/10ms/100ms). Once the coil is Off, the contact iwlwl

be disabled (contact A open, contact B closed) and the present value on the timer will become

“0”.

& Device indication: T0, T1,…,T255 are indicated as T and numbered in decimal form.

Different No. refers to different timing period.

The counter is used for counting. Before using the counter, you have to give the counter a set

value (i.e. the number of pulses for counting). There are coil, contact and registers in the

counter. When the coil goes from Off to On, the counter will regard it as an input of 1 pulse and

the present value on the counter will plus “1”. We offer 16-bit and 32-bit high-speed counters

for our users.

& Device indication: C0, C1,…,C255 are indicated as C and numbered in decimal form.

Data processing and value operations always occur when the PLC conducts all kinds of

sequential control, timing and counting. The data register is used for storing the values or all

kinds of parameters. Every register is able to store a word (16-bit binary value). Double words

will occupy 2 adjacent data registers.

& Device indication: D0, D1,…,D9,999 are indicated as D and numbered in decimal form.

DVP-PLC Application Manual

1-5

Page 10

1 Basic Principles of PLC Ladder Diagram

The file register is used for storing the data or all kinds of parameters when the data registers

required for processing the data and value operations are insufficient. Every file register is able

to store a 16-bit word. Double words will occupy 2 adjacent file registers. In SA/SX/SC series

File register

Index register

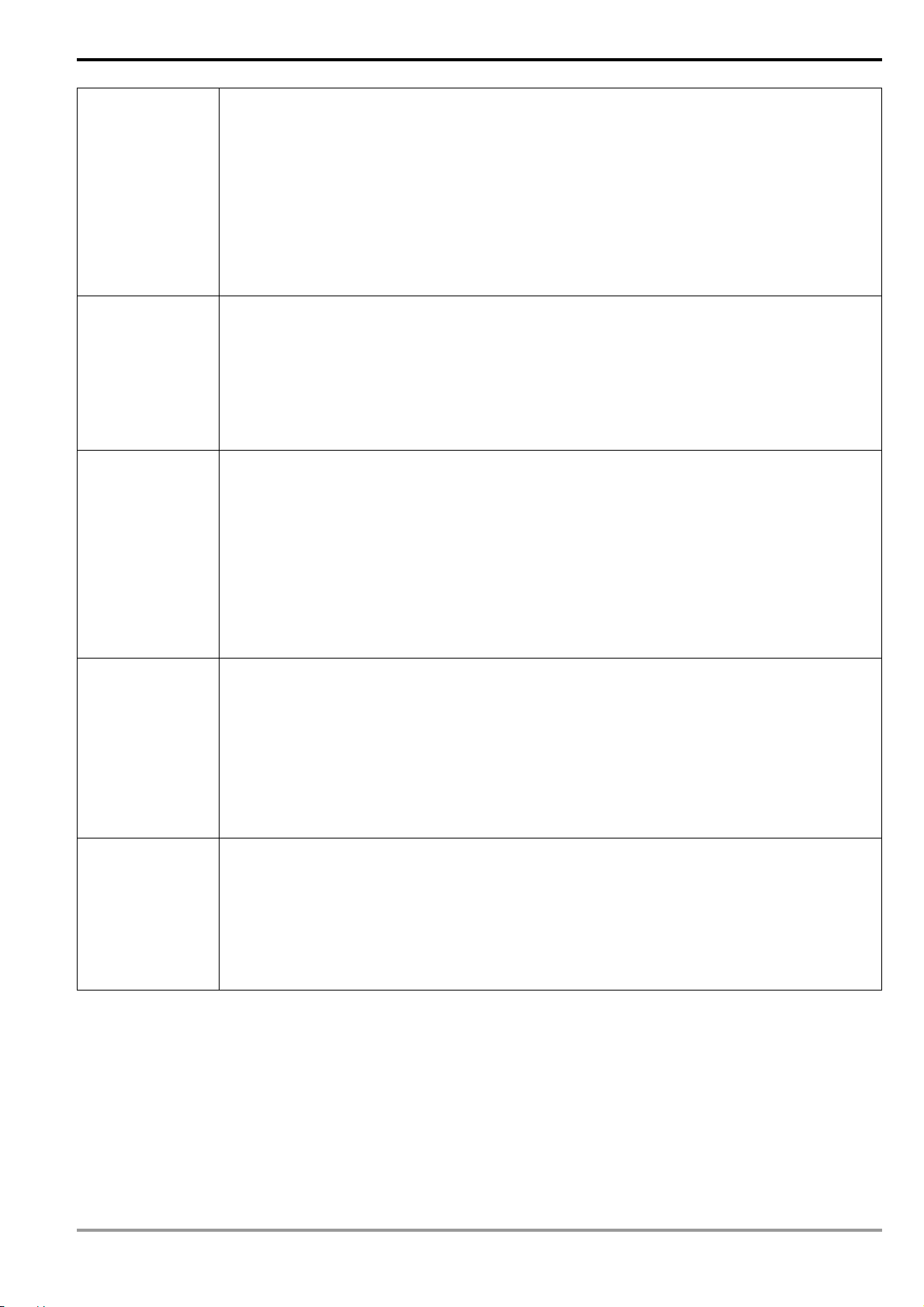

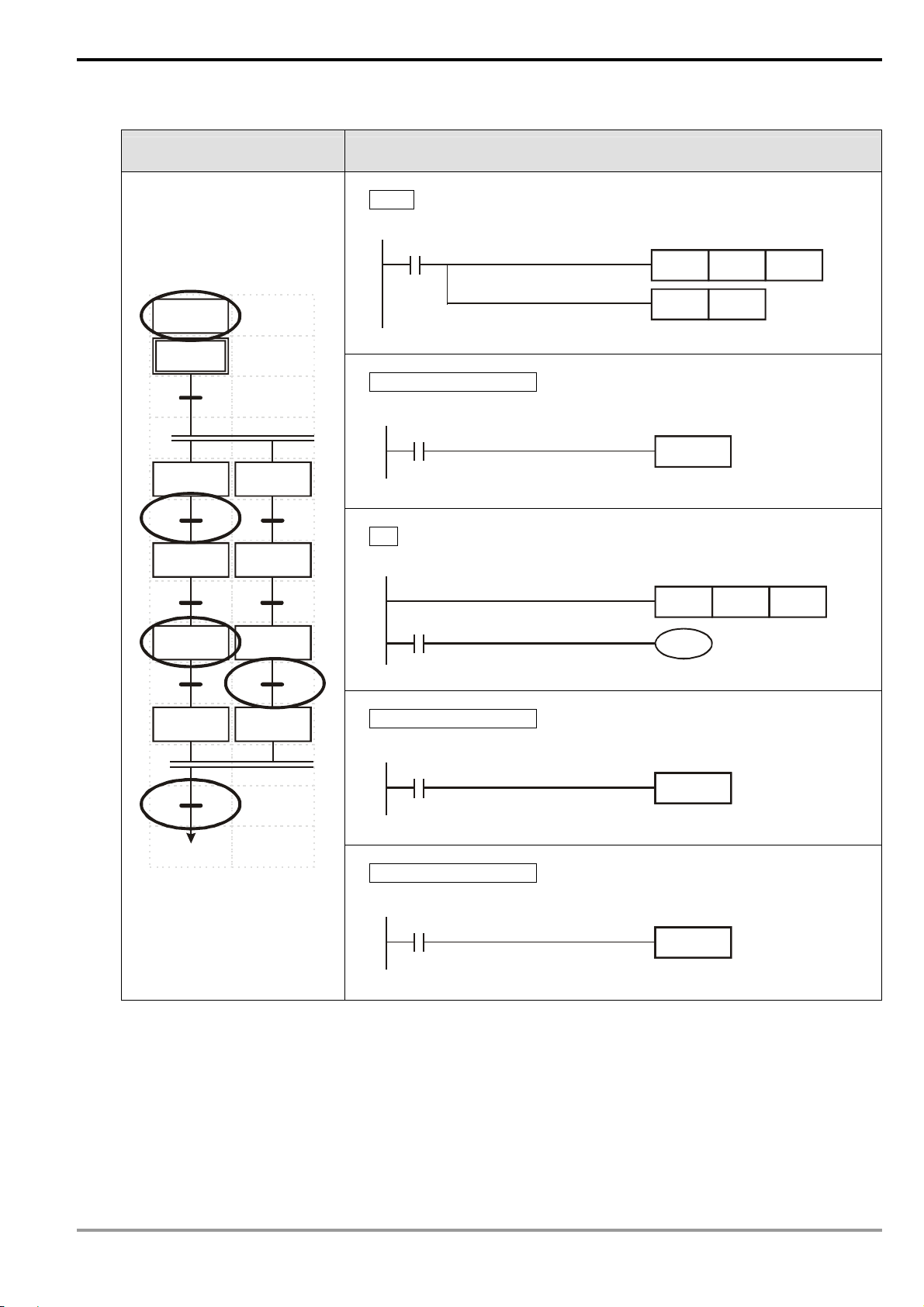

The structure of a ladder diagram:

Structure Explanation Instruction Devices Used

MPU, there are 1,600 file registers. In EH/EH2/SV series MPU, there are 10,000 file registers.

There is not an actual device No. for a file register. The reading and writing of file registers

should be executed by instructions API 148 MEMR, API 149 MEMW, or through the peripheral

device HPP02 and WPLSoft.

& Device indication: K0 ~ K9,999, numbered in decimal form.

E and F index registers are 16-bit data registers as other data registers. They can be read and

written and can be used in word devices, bit devices or as a constant for index indication.

& Device indication: E0 ~ E7, F0 ~ F7 are indicated as E and F and numbered in decimal

form.

Normally open, contact A LD X, Y, M, S, T, C

Normally closed, contact B LDI X, Y, M, S, T, C

Normally open in series

connection

Normally closed in series

connection

AND X, Y, M, S, T, C

ANI X, Y, M, S, T, C

Normally open in parallel

connection

Normally closed in parallel

connection

Rising-edge trigger switch LDP X, Y, M, S, T, C

Falling-edge trigger switch LDF X, Y, M, S, T, C

Rising-edge trigger in series

connection

Falling-edge trigger in series

connection

Rising-edge trigger in parallel

connection

Falling-edge trigger in parallel

connection

Block in series connection ANB -

Block in parallel connection ORB -

OR X, Y, M, S, T, C

ORI X, Y, M, S, T, C

ANDP X, Y, M, S, T, C

ANDF X, Y, M, S, T, C

ORP X, Y, M, S, T, C

ORF X, Y, M, S, T, C

1-6

DVP-PLC Application Manual

Page 11

1 Basic Principles of PLC Ladder Diagram

Structure Explanation Instruction Devices Used

MPS

Multiple output

Coil driven output instruction OUT Y, M, S

MRD

MPP

-

SS

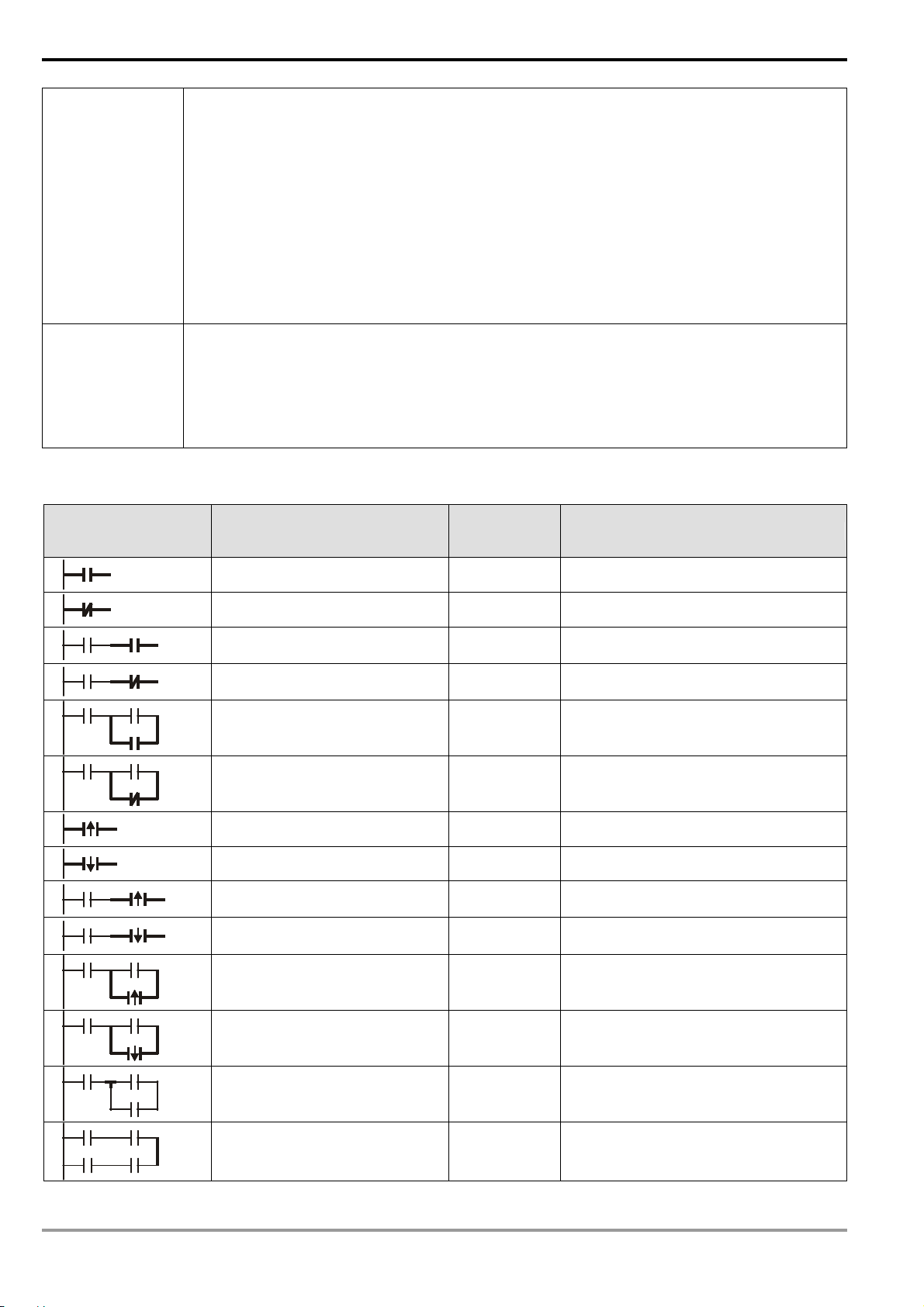

Block:

A block is a series or parallel operation composed of more than 2 devices. There are series block and parallel block.

Series block

Step ladder STL S

Basic instruction

Application instruction

Inverse logic INV -

Application

instructions

See Ch.3 for basic instructions

(RST/SET and CNT/TMR) and Ch.5 ~

10 for application instructions

Parallel block

Separation line and combination line:

The vertical line is used for separating the devices. For the devices on the left, the vertical line is a combination line,

indicating that there are at least 2 rows of circuits on the left connected with the vertical line. For the devices on the

right, the vertical line is a separation line, indicating that there are at least 2 rows of circuits interconnected on the right

side of the vertical line).

1

Combination line for block 1

Separation line for block 2

Network:

A complete block network is composed of devices and all kinds of blocks. The blocks or devices connectable by a

vertical line or continuous line belong to the same network.

2

Combination line for block 2

DVP-PLC Application Manual

1-7

Page 12

1 Basic Principles of PLC Ladder Diagram

Network 1

An independent network

Network 2

An incomplete network

1.4 How to Edit a PLC Ladder Diagram

The editing of the program should start from the left power line and ends at the right power line, a row after

another. The drawing of the right power line will be omitted if edited from WPLSoft. A row can have maximum 11

contacts on it. If 11 is not enough, you can continuously connect more devices and the continuous number will be

generated automatically. The same input points can be used repeatedly. See the figure below:

X0 X1 X2 X3 X4 X5

X11 X12 X13

00000

Continuous number

X6 X7 X10 C0 C1

00000

Y0

The operation of the ladder diagram program is scanning from top left to bottom right. The coil and the operation

frame of the application instruction belong to the output side in the program and are placed in the right if the ladder

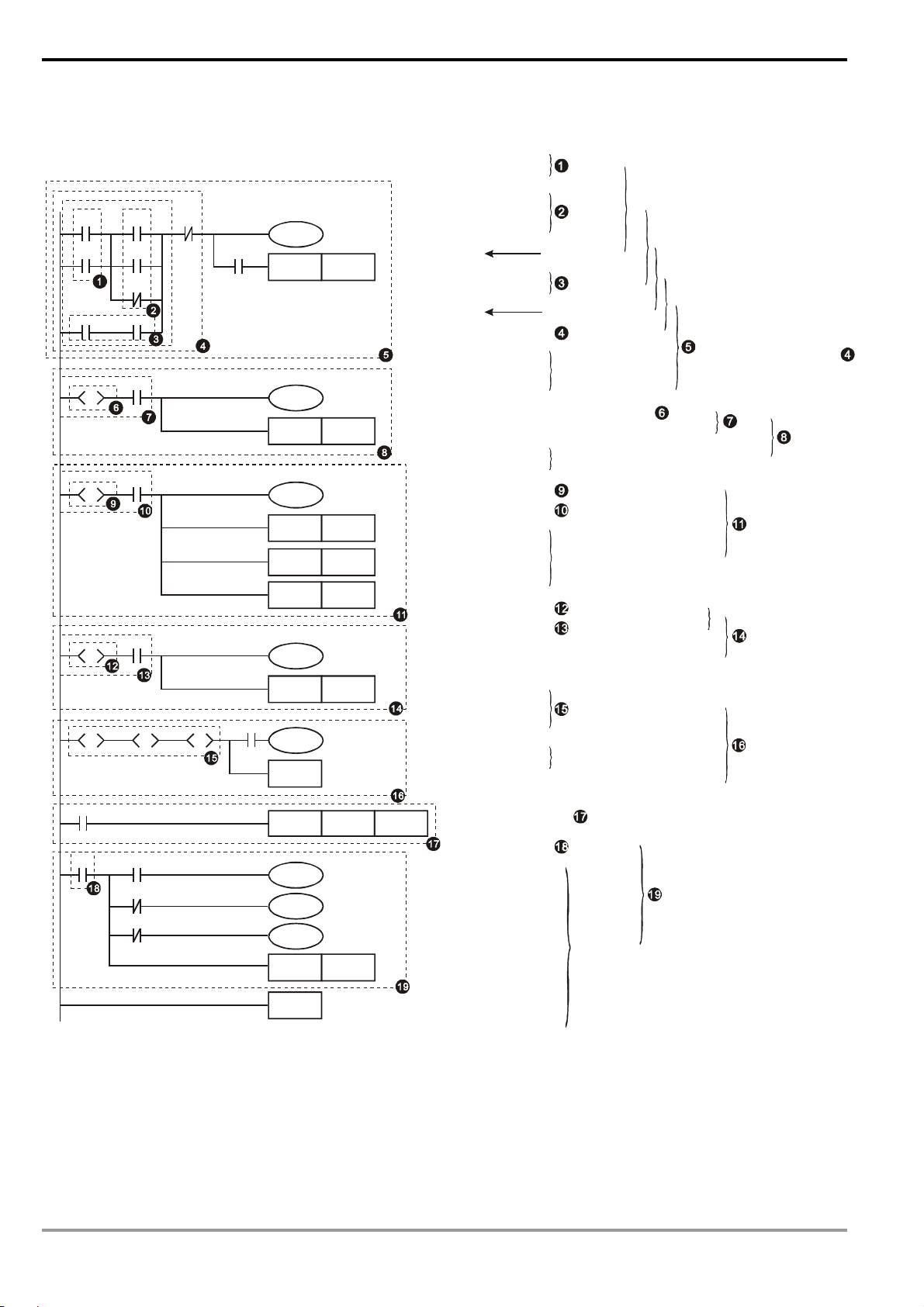

diagram. Take the figure below for example, we will step by step explain the process of a ladder diagram. The

numbers in the black circles indicate the order.

X0 X1 Y1 X4

M0

X3

M1

Y1

T0

M3

TMR T0 K10

The order of the instructions:

1 LD X0

2 OR M0

3 AND X1

4 LD X3

AND M1

1-8

DVP-PLC Application Manual

Page 13

1 Basic Principles of PLC Ladder Diagram

n

ORB

5 LD Y1

AND X4

6 LD T0

AND M3

ORB

7 ANB

8 OUT Y1

TMR T0 K10

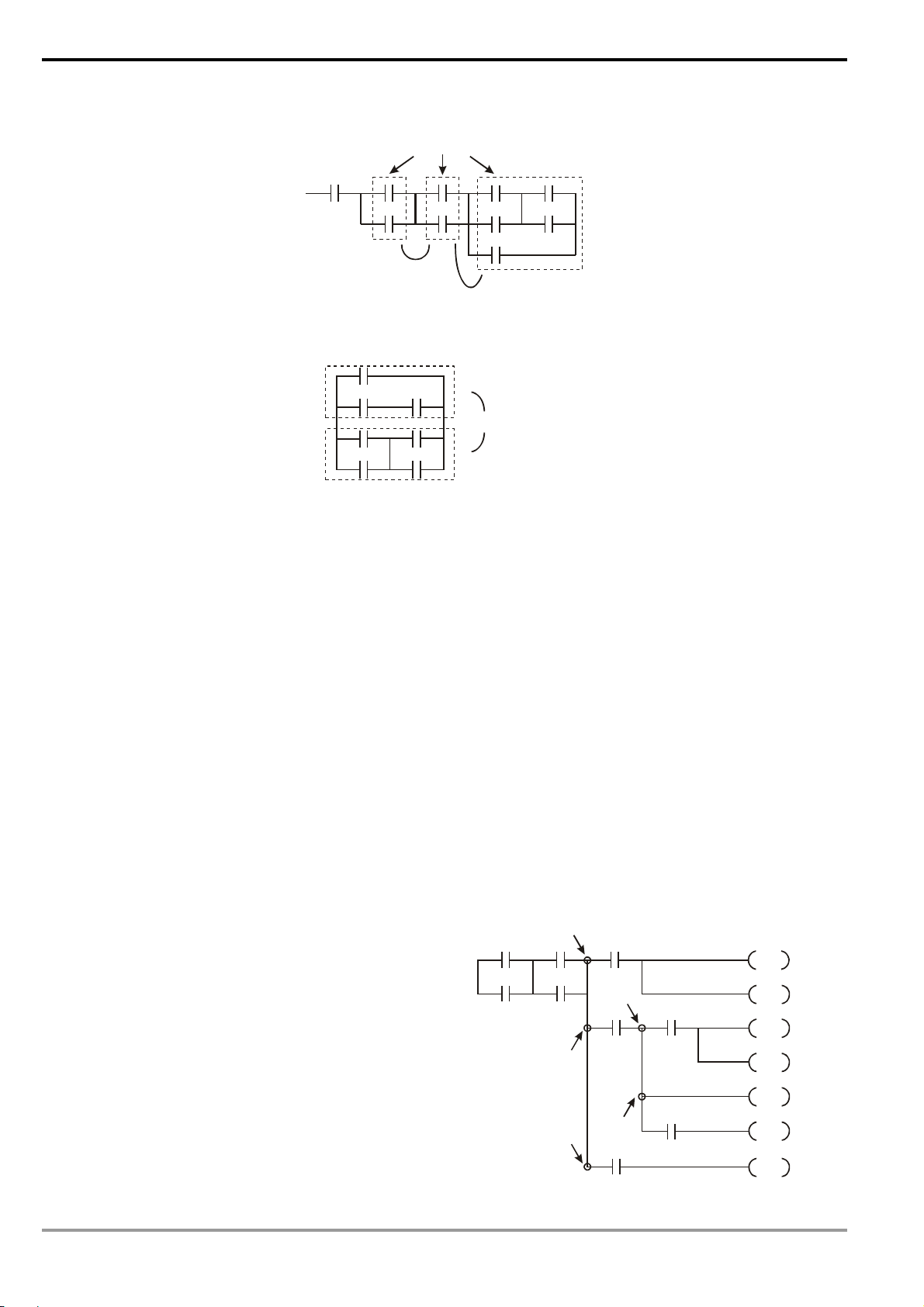

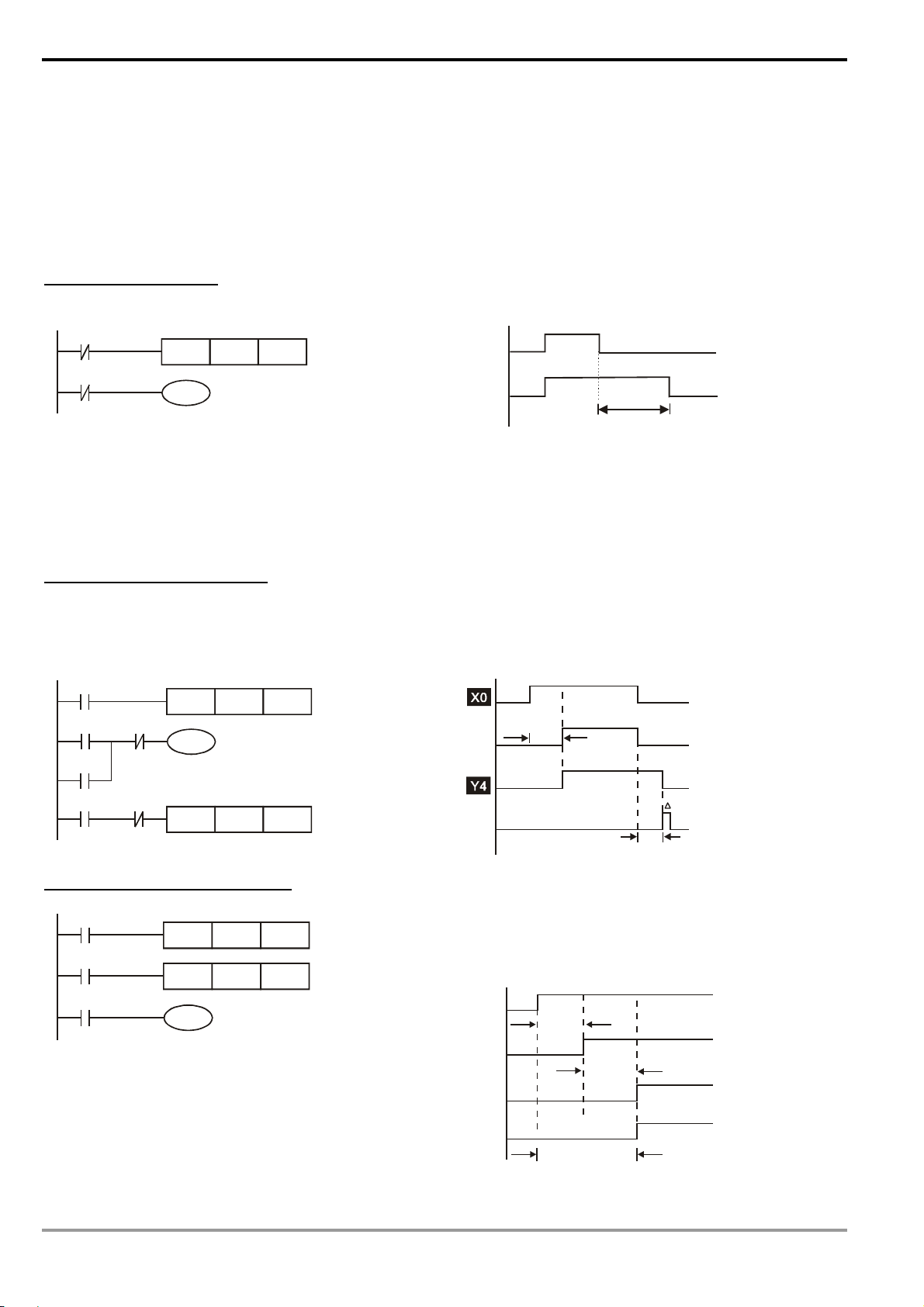

Explanations on the basic structures in the ladder diagram:

1. LD (LDI) instruction: Given in the start of a block.

LD instruction LD instruction

AND block OR block

The structure of LDP and LDF instructions are the same as that of LD instruction, and the two only differ in their

actions. LDP and LDF instructions only act at the rising edge or falling edge when the contact is On, as shown in the

figure below.

X0

Rising edge

OFF

ON

OFF

Time

X0

OFF

Falling edge

ON

OFF

Time

2. AND (ANI) instruction: A single device connects to another single device or a block in series

AND instructio

AND instruction

The structure of ANDP and ANDF instructions are the same. ANDP and ANDF instructions only act at the rising

edge or falling edge.

3. OR (ORI) instruction: A single device connects to another single device or a block

OR instruction OR instruction OR instruction

The structure of ORP and ORF instructions are the same. ORP and ORF instructions only act at the rising edge

or falling edge.

DVP-PLC Application Manual

1-9

Page 14

1 Basic Principles of PLC Ladder Diagram

4. ANB instruction: A block connects to a device or another block in series

ANB instruction

5. ORB instruction: A block connects to a device or another block in parallel

ORB instruction

If the ANB and ORB operations are with several blocks, the operation should be performed from up to down or

left to right, combining into a block or network.

6. MPS, MRD, MPP instructions: Bifurcation point of multiple outputs, for generating many and diverse outputs.

MPS instruction is the start of the bifurcation point. The bifurcation point is the intersection of the horizontal line

and vertical line. We will have to determine whether to give a contact memory instruction by the contact status of the

same vertical line. Basically, every contact can be given a memory instruction, but considering the convenience of

operating the PLC and the limitation on its capacity, some parts in the ladder diagram will be omitted during the

conversion. We can determine the type of contact memory instruction by the structure of the ladder diagram. MPS is

recognized as “┬” and the instruction can be given continuously for 8 times.

MRD instruction is used for reading the memory of the bifurcation point. Due to that the same vertical line is of

the same logic status, in order to continue analyzing other ladder diagrams, we have to read the status of the original

contact again. MRD is recognized as “├”.

MPP instruction is used for reading the start status of the top bifurcation point and popping it out from the stack.

Since MPP is the last item on the vertical line, the vertical line ends at this point.

MPP is recognized as “└”. Using the method

MPS

given above for the analysis cannot be wrong.

However, sometimes the compiling program will ignore

MPS

the same output status, as shown in the figure.

1-10

MRD

MPP

MPP

DVP-PLC Application Manual

Page 15

1 Basic Principles of PLC Ladder Diagram

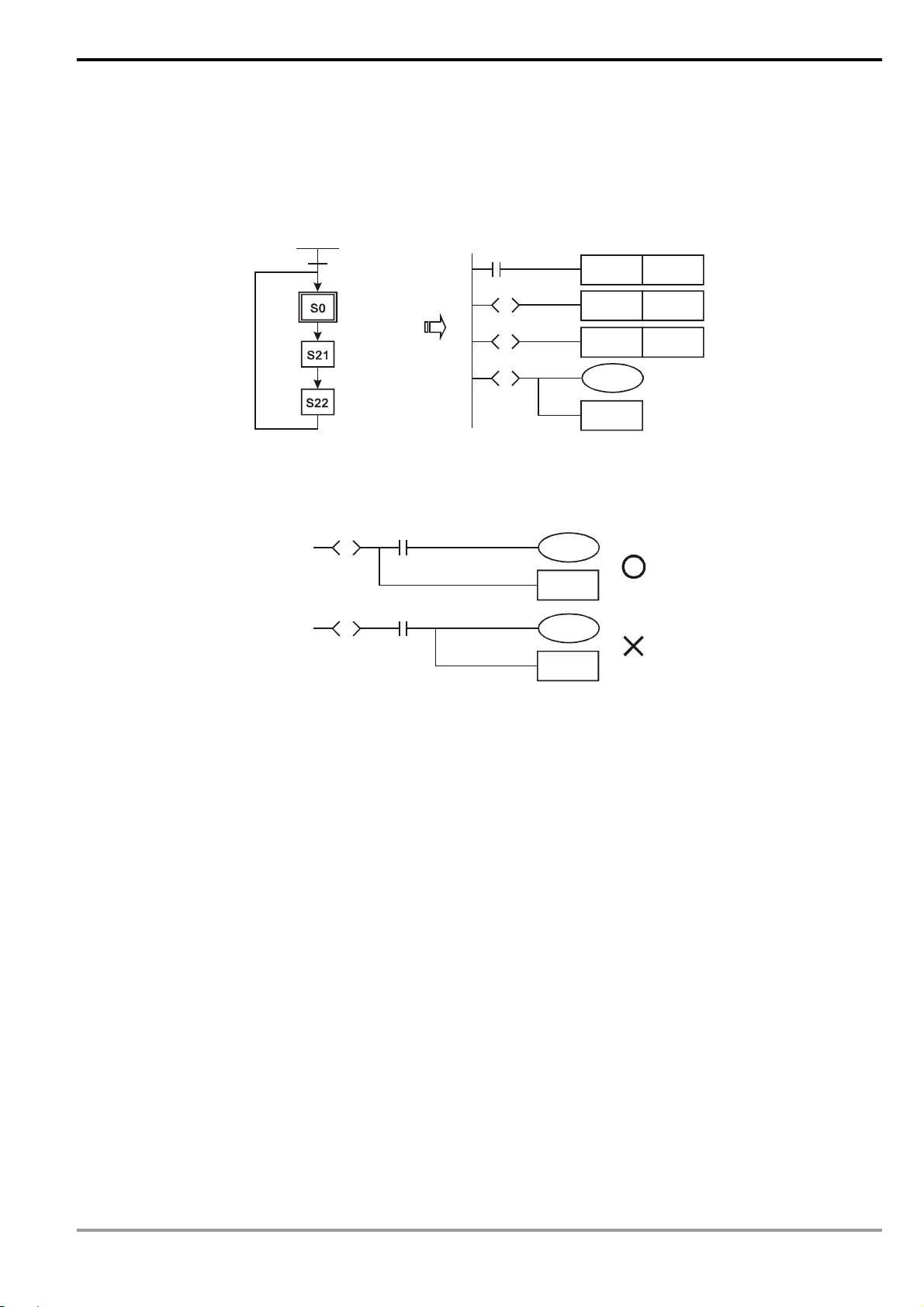

7. STL instruction: Used for designing the syntax of the sequential function chart (SFC).

STL instruction allows the program designer a clearer and readable picture of the sequence of the program as

when they draw a sequence chart. From the figure below, we can see clearly the sequence to be planned. When the

step S moves to the next step, the original S will be “Off". Such a sequence can then be converted into a PLC ladder

diagram and called “step ladder diagram”.

M1002

M1002

S0

S

S21

S

S22

S

8. RET instruction: Placed after the completed step ladder diagram.

RET also has be placed after STL instruction. See the example below.

S20

S

S20

S

X1

X1

RET

RET

SET

SET

SET

S0

RET

S0

S21

S22

See step ladder instructions [STL], [RET] in Ch. 4 for the structure of the ladder diagram.

DVP-PLC Application Manual

1-11

Page 16

1 Basic Principles of PLC Ladder Diagram

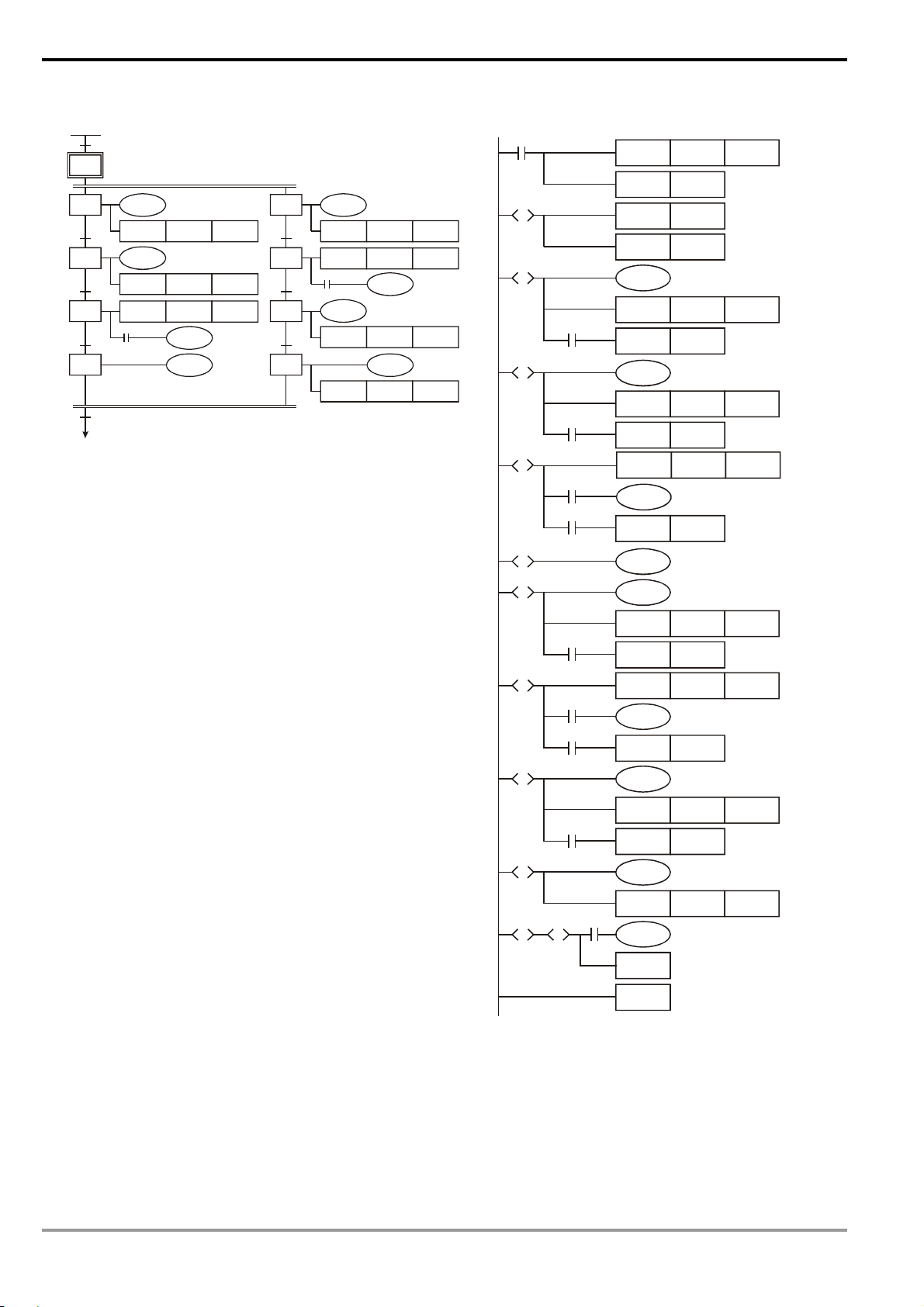

1.5 The Conversion of PLC Command and Each Diagram Structure

Ladder Diagram

X0 X2 X1

S0

S

S

S

S

M0

M1

Y0

X10

X11

X12

S12SS13

X1

X1

M2

X1

M2

S10

S11

S20

X0

C0

LD X0

OR X1

LD X2

OR M0

Y0

C0

SET S0

OR I M1

ANB

LD M2

AND Y0

ORB

AN I X1

OU T Y0

AND C0

Y10

SET S0

STL S0

SET S10

LD X10

OU T Y10

SET S10

Y11

STL S10

LD X11

SET S11

SET S12

SET S13

OU T Y11

SET S11

SET S12

SET S13

STL S11

LD X12

Y12

OU T Y12

SET S20

SET S20

STL S20

STL S12

X13

S

S0

RET

STL S13

LD X13

OU T S0

RET

LD X0

CNT

C0

K10

CNT C0 K 10

LD C0

M0

MPS

AND X1

M1

M2

RST C0

OU T M0

MRD

AN I X1

OU T M1

MPP

END

AN I M2

OU T M2

RST C0

END

OR

block

OR

block

Series

connection blcok

AND

block

Parallel

connection block

ANI

Multiple

outputs

Step ladder Start

Status S0 and X10 operation

Status working item and

step point transfer

Withdraw S10 status

Withdraw X11 status

Status working item and

step point transfer

Withdraw S11 status

Withdraw X12 status

Status working item and

step point transfer

Bifurcation

convergence

Status working item

and step point transfer

Return

Read C0

Multiple

outputs

End of program

The output will continue

following the status of

End of step ladder

Fuzzy Syntax

The correct ladder diagram analysis and combination should be conducted from up to down and left to right.

However, without adopting this principle, some instructions can make the same ladder diagram.

1-12

DVP-PLC Application Manual

Page 17

1 Basic Principles of PLC Ladder Diagram

Example Program 1

See the ladder diagram below. There are 2 ways to indicate the ladder by instruction programs with the same result.

X0 X2 X4

Ideal way Less ideal way

LD X0 LD X0

X5X3X1

OR X1 OR X1

LD X2 LD X2

OR X3 OR X3

ANB LD X4

LD X4 OR X5

OR X5 ANB

ANB ANB

The two instruction programs will be converted into the same ladder diagram. The difference between the ideal

one and less ideal one is the operation done by the MPU. For the ideal way, the combination is done block by block

whereas the less idea way combines all the blocks combine with one another in the last step. Though the length of

the program codes of the two ways are equal, the combination done in the last step (by ANB instruction, but ANB

cannot be used continuously for more than 8 times) will have to store up the previous calculation results in advance.

In our case, there are only two blocks combined and the MPU allows such kind of combination. However, once the

number of blocks exceed the range that the MPU allows, problems will occur. Therefore, the best way is to execute

the block combination instruction after a block is made, which will also make the logic sequence planned by the

programmer more in order.

Example Program 2

See the ladder diagram below. There are 2 ways to indicate the ladder by instruction programs with the same result.

Ideal way Less ideal way

X0

X1

X2

LD X0 LD X0

OR X1 LD X1

OR X2 LD X2

OR X3 LD X3

X3

ORB

ORB

ORB

In this example, the program codes and the operation memory in the MPU increase in the less ideal way.

Therefore, it is better that you edit the program following the defined sequence.

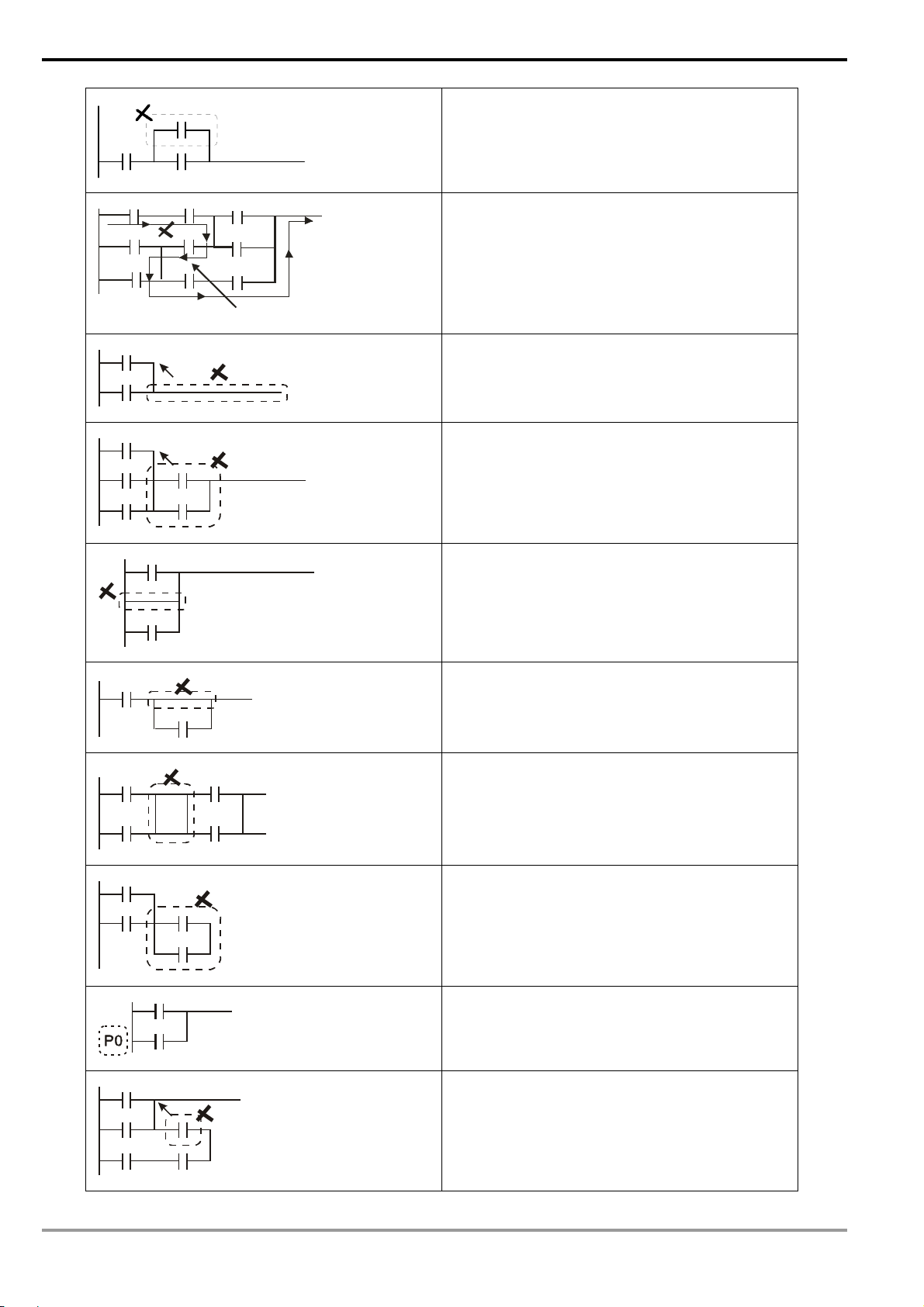

Incorrect Ladder Diagram

PLC processes the diagram program from up to down and left to right. Though we can use all kinds of ladder

symbols to combine into various ladder diagrams, when we draw a ladder diagram, we will have to start the diagram

from the left power line and end it at the right power line (In WPLSoft ladder diagram editing area, the right power line

is omitted), from left to right horizontally, one row after another from up to down. See bellows for the frequently seen

incorrect diagrams:

DVP-PLC Application Manual

1-13

Page 18

1 Basic Principles of PLC Ladder Diagram

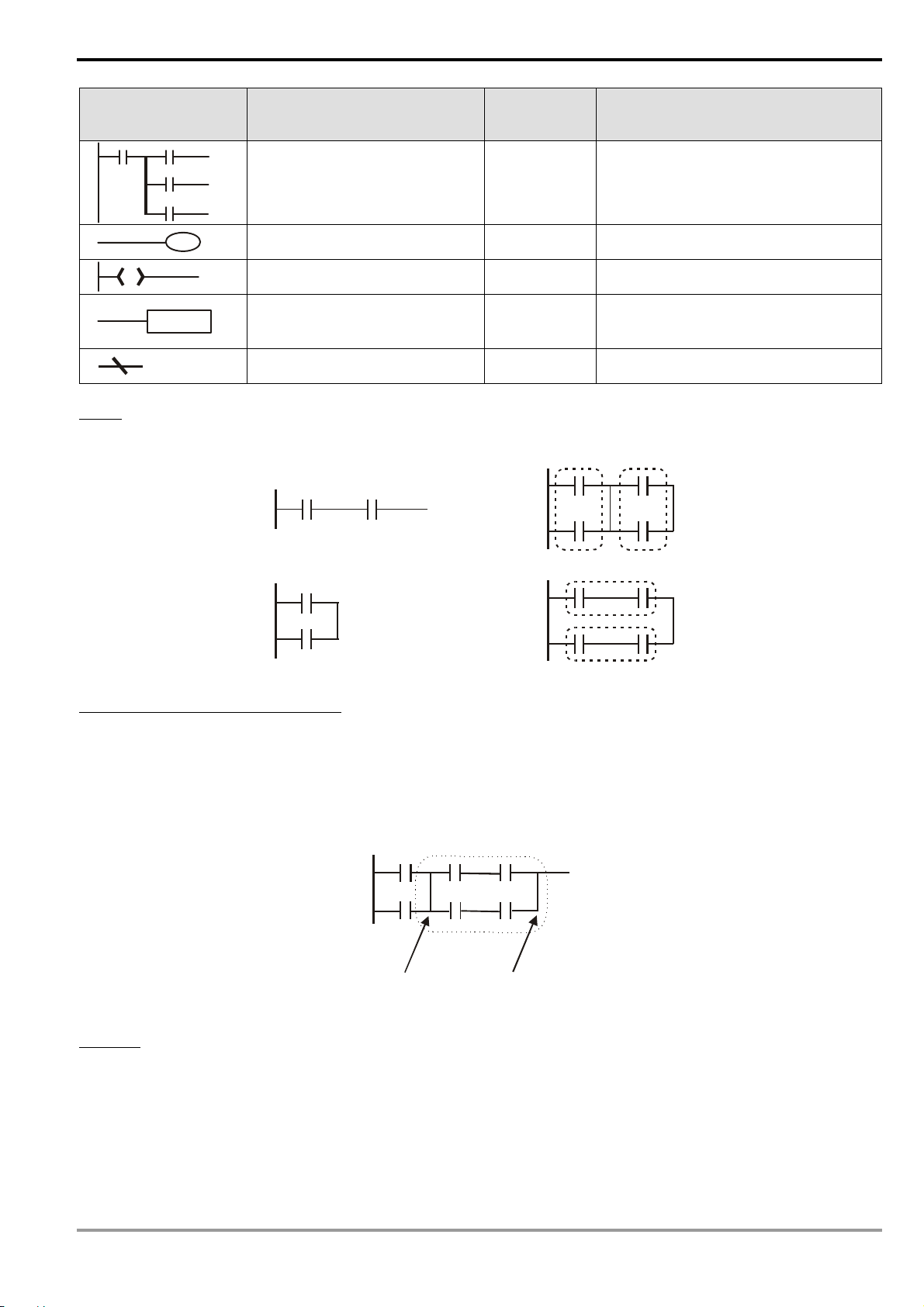

OR operation upward is not allowed.

“Reverse flow” exists in the signal circuit from the

beginning of input to output.

Re verse flow

The up-right corner should output first.

Combining or editing should be done from the

up-left to the bottom-right. The dotted-lined area

should be moved up.

Parallel operation with empty device is not allowed.

Empty device cannot do operations with other

devices.

1-14

No device in the middle block.

Devices and blocks in series should be horizontally

aligned.

Label P0 should be in the first row of a complete

network.

Blocks connected in series should be aligned with

the upmost horizontal line.

DVP-PLC Application Manual

Page 19

1 Basic Principles of PLC Ladder Diagram

1.6 Simplified Ladder Diagram

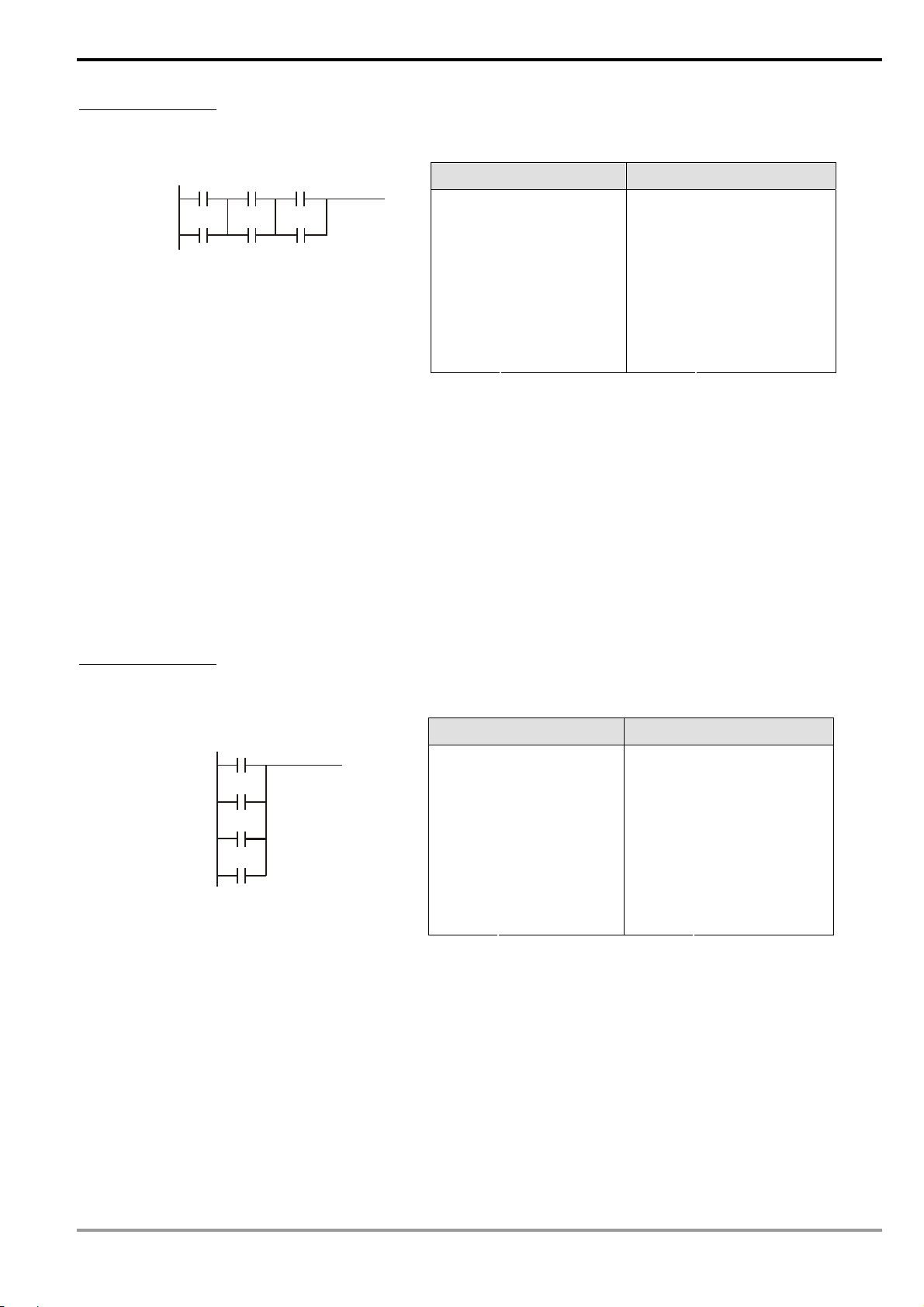

When a series block is connected to a parallel block in series, place the block in the front to omit ANB instruction.

X0 X1

Ladder diagram complied into instruction

LD X0

X2

Ø

X0X1

LD X1

OR X2

ANB

Ladder diagram complied into instruction

LD X1

X2

OR X2

AND X0

When a single device is connected to a block in parallel, place the block on top to omit ORB instruction.

T0

Ladder diagram complied into instruction

LD T0

X1

X1

X2

X2

Ø

LD X1

AND X2

ORB

Ladder diagram complied into instruction

LD X1

T0

AND X2

OR T0

In diagram (a), the block on top is shorter than the block in the bottom, we can switch the position of the two

blocks to achieve the same logic. Due to that diagram (a) is illegal, there is a “reverse flow” in it.

Ladder diagram complied into instruction

X0

LD X0

X1

X3

X2

X4

OR X1

AND X2

LD X3

(a)

Ø

AND X4

ORB

Ladder diagram complied into instruction

X3

X1

X4

X2

LD X3

AND X4

LD X1

X0

(b)

OR X0

AND X2

DVP-PLC Application Manual

ORB

1-15

Page 20

1 Basic Principles of PLC Ladder Diagram

w

MPS and MPP instruction can be omitted when the multiple outputs in the same horizontal line do not need to

operate with other input devices.

X0

Y1

Ladder diagram complied into instruction

MPS

AND X0

Ø

Y0

OUT Y1

MPP

OUT Y0

Ladder diagram complied into instruction

X0

Y0

Y1

OUT Y0

AND X0

OUT Y1

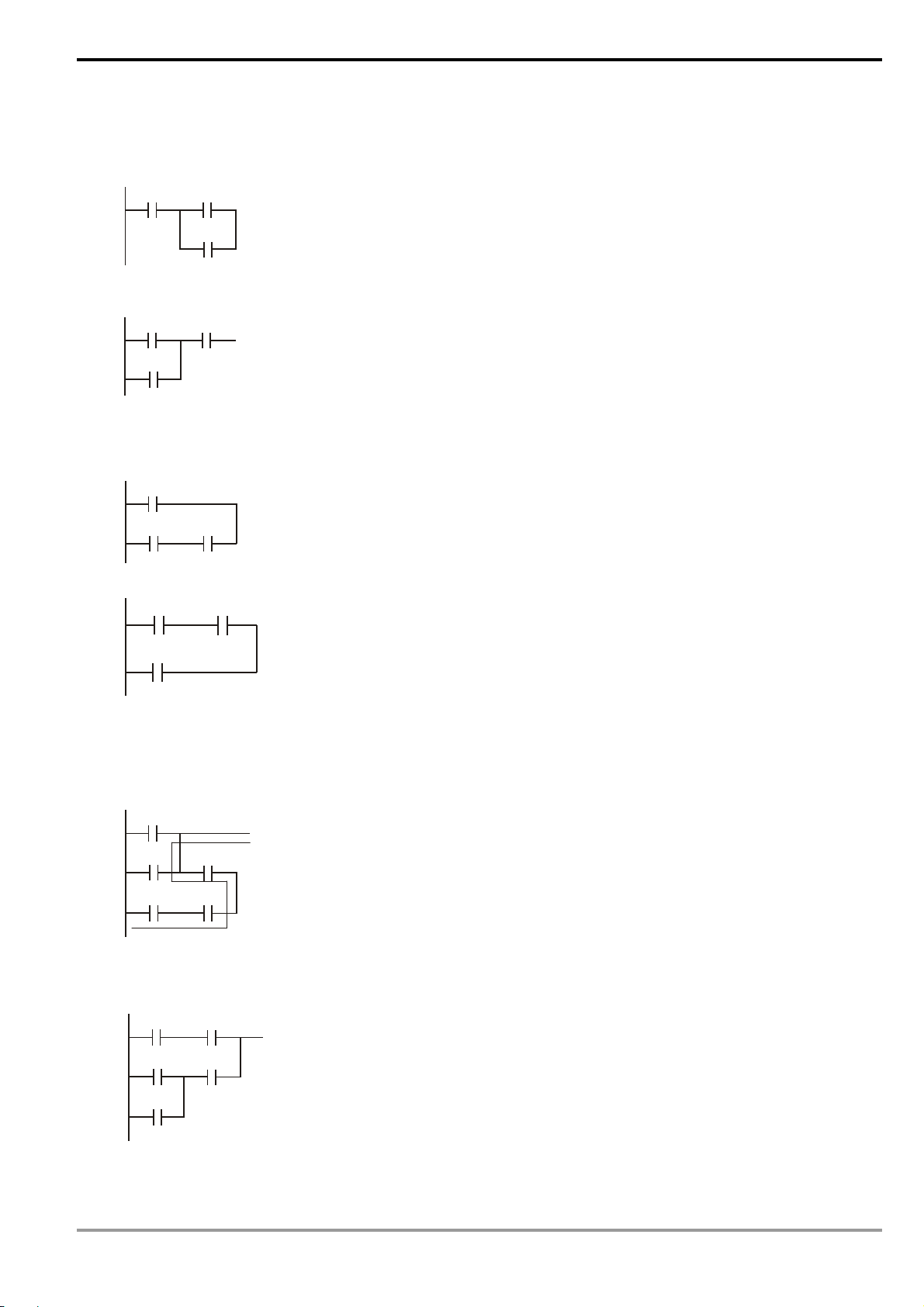

Correct the circuit of reverse flow

In the following two examples, the diagram in the left hand side is the ladder diagram we desire. However, the illegal

“reverse flow” in it is incorrect according to our definition on the ladder diagram. We modify the diagram into the

diagram in the right hand side.

Example 1

Example 2

X0

X3

X6

rever se fl o

X0

X3

X6

Re verse f l ow

X0

X3

X1

X4

X7

X1

X4

X7

re ver se fl ow

X1

X4

X2

X10

X2

X5

X2

X5

X10

X5

LOOP 1

LO OP 1

X0 X1 X2

X3 X4 X5

X10

Ö

X6 X7 X5

X10

LOOP1

X0 X1 X2

X3 X4 X5

X6

X3 X7 X10

Ö

X6

LOOP1

X0 X1 X7 X10

X4

1-16

X6

X7

X10

LOOP2

LOOP

2

DVP-PLC Application Manual

Page 21

1 Basic Principles of PLC Ladder Diagram

1.7 Basic Program Designing Examples

Start, Stop and Latched

In some application occasions, we need to use the transient close/open buttons for the start and stop of an equipment.

To maintain its continuous action, you have to design latched circuits.

Example 1: Stop first latched circuit

When the normally open contact X1 = On and the

normally closed contact X2 = Off, Y1 will be On. If you make

X2 = On at this time, Y1 will be Off. It is the reason why this is

called “stop first”.

Example 2: Start first latched circuit

When the normally open contact X1 = On and the

normally closed contact X2 = Off, Y1 will be On and latched. If

you make X2 = On at this time, Y1 will continue to be On

because of the latched contact. It is the reason why this is

called “start first”.

Example 3: Latched circuit for SET and RST instructions

See the diagram in the right hand side for the latched

circuit consist of RST and SET instructions.

In the stop first diagram, RST is placed after SET. PLC

executes the program from up to down, so the On/Off of Y1 will

be determined upon its status in the end of the program.

Therefore, when X1 and X2 are enabled at the same time, Y1

will be Off. It is the reason why this is called “stop first”.

In the start first diagram, SET is placed after RST. When

X1 and X2 are enabled at the same time, Y1 will be On. It is

the reason why this is called “start first”.

Y1

X1

X1

Y1

Stop first

X1

X2

Start first

X2

X1

X2

X2

SET

RST

RST

SET

Y1

Y1

Y1

Y1

Y1

Y1

Example 4: Power shutdown latched

The auxiliary relay M512 is latched (see instruction

sheets for DVP series PLC MPU). The circuit can not only be

latched when the power is on, but also keep the continuity of

the original control when the power is shut down and switched

on again.

DVP-PLC Application Manual

X1

X2

M512

SET

M512

RST M512

Y1

1-17

Page 22

Frequently Used Control Circuit

1 Basic Principles of PLC Ladder Diagram

Example 5: Conditional control

X1

Y1

X2

Y2

X3

X4

Y1

X1

Y1

Y2

X3

X2

X4

Y1

Y2

X1 and X3 enables and disables Y1; X2 and X4 enables and disables Y2, and all are latched. Due to that the

normally open contact of Y1 is connected to the circuit of Y2 in series, Y1 becomes an AND condition for Y2.

Therefore, only when Y1 is enabled can Y2 be enabled.

Example 6: Interlock control

X1

Y1

X3

Y2

Y1

X1

X3

X2

X2

Y2

X4

Y1

Y2

X4

Y1

Y2

Which of the X1 and X2 is first enabled decides either the corresponding output Y1 or Y2 will be enabled first.

Either Y1 or Y2 will be enabled at a time, i.e. Y1 and Y2 will not be enabled at the same time (the interlock). Even X1

and X2 are enabled at the same time, Y1 and Y2 will not be enabled at the same time due to that the ladder diagram

program is scanned from up to down. In this ladder diagram, Y1 will be enabled first.

Example 7: Sequential control

X1

Y1

X2

Y2

X3

X4

Y2

Y1

If we serially connect the normally closed contact

Y1

of Y2 in example 5 to the circuit of Y1 as an AND

condition for Y1 (as the diagram in the left hand side),

the circuit can not only make Y1 as the condition for Y2,

Y2

but also allow the stop of Y1 after Y2 is enabled.

Therefore, we can make Y1 and Y2 execute exactly the

sequential control.

1-18

DVP-PLC Application Manual

Page 23

1 Basic Principles of PLC Ladder Diagram

Y1

Y1

T T

Example 8: Oscillating circuit

An oscillating circuit with cycle ΔT+ΔT

Y1

The ladder diagram above is a very simple one. When the program starts to scan the normally closed contact

Y1, Y1 will be closed because coil Y1 is Off. When the program then scan to coil Y1 and make it On, the output will be

1. When the program scans to the normally closed contact Y1 again in the next scan cycle, because coil Y1 is On, Y1

will be open and make coil Y1 Off and output 0. The repeated scans will result in coil Y1 outputs oscillating pulses by

the cycle ΔT(On)+ΔT(Off).

An oscillating circuit with cycle nT+ΔT

X0

T0

Y1

TMR

Y1

T0

Kn

X0

Y1

TTn

The ladder diagram program controls the On time of coil Y1 by timer T0 and disable timer T0 in the next scan

cycle, resulting in the oscillating pulses in the output of Y1. n refers to the decimal set value in the timer and T is the

cycle of the clock.

Example 9: Flashing circuit

X0

T1

X0 T1

T2

TMR

Y1

T1

T2TMR Kn2

Kn1

X0

Tn2

*

Y1

T

n1

*

The ladder diagram is an oscillating circuit which makes the indicator flash or enables the buzzer alarms. It

uses two timer to control the On/Off time of coil Y1. n1 and n2 refer to the set values in T1 and T2 and T is the cycle

of the clock.

Example 10: Trigger circuit

X0

M0

M0

M0

Y1

Y1

Y1

DVP-PLC Application Manual

X0

T

M0

Y1

1-19

Page 24

1 Basic Principles of PLC Ladder Diagram

The rising-edge differential instruction of X0 makes coil M0 generate a single pulse of ΔT (one scan cycle).

Coil Y1 will be On during this scan period. In the next scan period, coil M0 will be Off and the normally closed contact

M0 and Y1 will all be closed, making coil Y1 continue to be On until another rising-edge arrives in input X0, making

coil M0 On for another scan period and Y1 Off. Such kind of circuit relies on an input to make two actions execute

interchangeably. Also from the timing diagram on the last page, we can see that input X0 are square pulse signals of

the cycle T and coil Y1 output are square pulse signals of the cycle 2T.

Example 11: Delay circuit

X0

T10

TMR

Y1

T10

K1000

X0

Y1

Time base: T = 0.1 sec

100 seconds

When input X0 is On, due to that its corresponding normally closed contact is Off, time T10 will be Off and the

output coil Y1 will be On. T10 will be On and start to count until input X0 is Off. Output coil Y1 will be delayed for

100 seconds (K1,000 × 0.1 sec = 100 secs) and be Off. See the timing diagram above.

Example 12: Output delay circuit

The output delay circuit is the circuit composed of two timers. When input X0 is On and Off, output Y4 will be

delayed.

X0

T5

K50

5 secs

T5

T5

Y4

TMR

T6

Y4

Y4

X0

TMR

T6

K30

Example13: Timing extension circuit

X0

Y1

T11

T12TMR Kn2

Kn1

TMR

T11

T12

Timer = T11, T12

Clock cycle: T

1-20

T

T6

3 secs

The total delay time from input X0 is closed to output

Y1 is On = (n1+n2)* T. T refers to the clock cycle.

X0

T11

T12

Y1

n1*

T

(n1+n2)*

n2*

T

T

DVP-PLC Application Manual

Page 25

1 Basic Principles of PLC Ladder Diagram

Kn1

The counting range of a 16-bit counter is 0 ~ 32,767. As

the circuit in the left hand side, using two counters can

increase the counting range to n1*n2. When the counting

of counter C5 reaches n1, C6 will start to count for one

time and reset for counting the pulses from X13. When

the counting of counter C6 reaches n2, the pulses from

input X13 will be n1*n2.

Example 14: How to enlarge the counting range

X13

CNT

C5

C5

C6CNT Kn2

C5RST

X14

RST

C6

C6

Y1

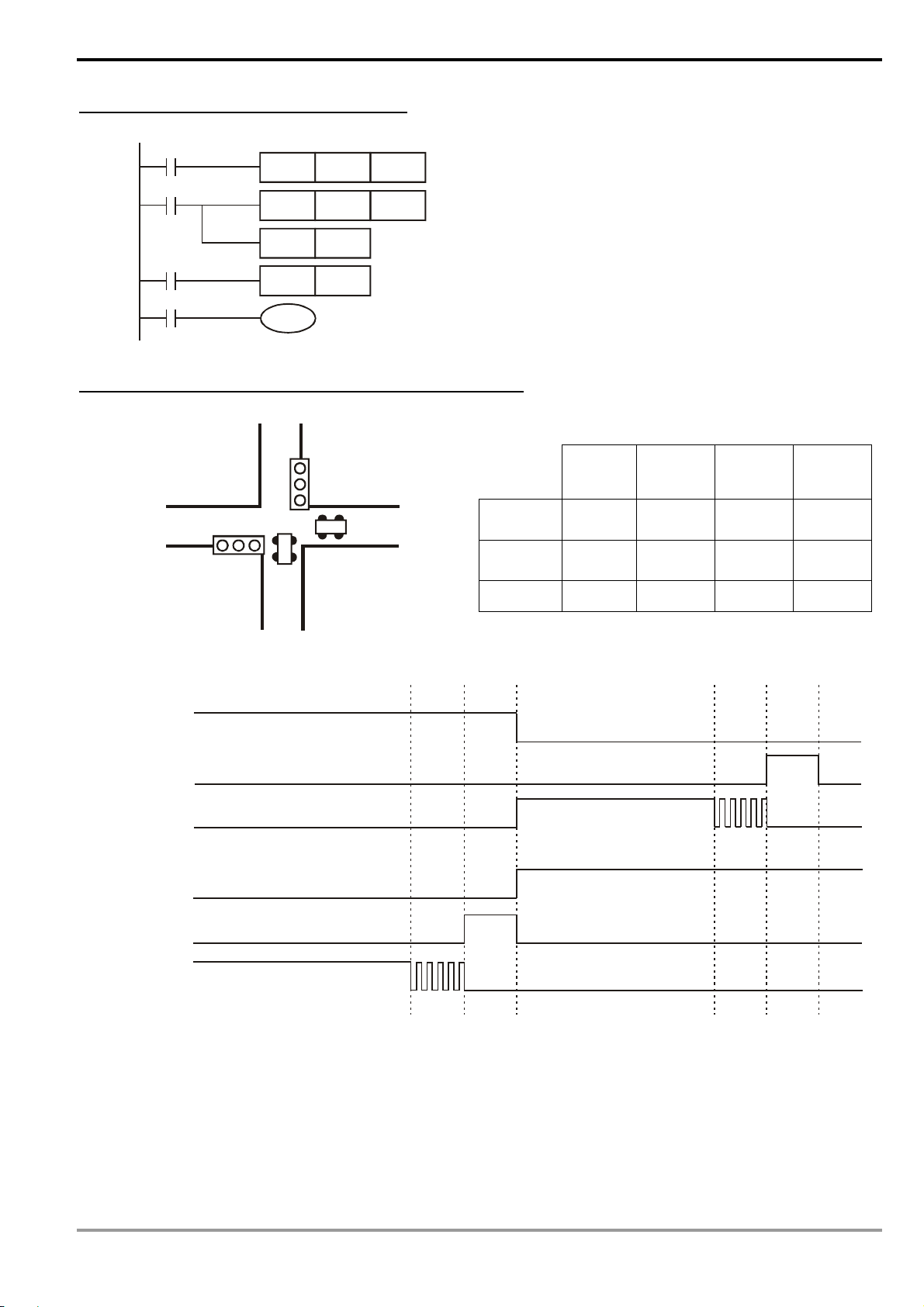

Example 15: Traffic light control (by using step ladder instruction)

Traffic light control

Vertical

Light

Vertical

light

Horizontal

Horizontal

Light

light

On time 35 secs 5 secs 25 secs 5 secs

Red light

Y0 Y1 Y2 Y2

Y10 Y11 Y12 Y12

Yellow

light

Green

light

Green

light

flashes

Timing Diagram:

Vertical

Light

Red

Y0

Yel l ow

Y1

Green

Y2

Horizontal

Light

Red

Y10

Ye ll o w

Y11

Green

Y12

25 secs

5 secs 5 secs

25 secs

5 secs

5 secs

DVP-PLC Application Manual

1-21

Page 26

1 Basic Principles of PLC Ladder Diagram

SFC Figure:

M1002

S0

S20

T0

S21

T1

S22

T2

S23

T13

S0

TMR T0 K350

TMR T1 K250

TMR T2 K50

M1013

Y0

Y2

Y2

Y1

T10

T11

T12

S30

S31

S32

S33

Y12

TMR T10 K250

TMR T11 K50

M1013

Y11

TMR T12 K50

TMR T13 K350

Y12

Y10

Ladder Diagram:

M1002

S0

S

S20

S

S21

S

S22

S

S23

S

S30

S

T0

T1

M1013

T2

ZRST S0 S127

SET S0

SET S20

SET S30

Y0

TMR T0

K350

SET S21

Y2

TMR T1

K250

SET S22

TMR T2

K50

Y2

SET S23

Y1

Y12

TMR T10

T10

K250

SET S31

S31

S

M1013

TMR T11

K50

Y12

T11

SET S32

S32

S

T12

Y11

TMR T12

K50

SET S33

S33

S

Y10

TMR T13 K350

S23SS33

T13

S

S0

RET

END

1-22

DVP-PLC Application Manual

Page 27

Drawing by SFC Editor (WPLSoft )

Drawn by SFC Internal Ladder Diagram

1 Basic Principles of PLC Ladder Diagram

LAD-0

M1002

S0ZRST S127

LAD-0

S0

0

S20

1

S21

2

S22

3

S23

S30

S31

S32

S33

S0SET

Transferring Condition 1

T0

TRANS*

5

6

7

S22

T2TMR K50

M1013

Y2

Transferring Condition 4

S0

T13

T13

T13

T13

T13

T13

T13

TRANS*

TRANS*

TRANS*

TRANS*

TRANS*

TRANS*

TRANS*

4

Transferring Condition 7

T12

T12

T12

T12

T12

T12

T12

TRANS*

TRANS*

TRANS*

TRANS*

TRANS*

TRANS*

TRANS*

DVP-PLC Application Manual

1-23

Page 28

1 Basic Principles of PLC Ladder Diagram

MEMO

1-24

DVP-PLC Application Manual

Page 29

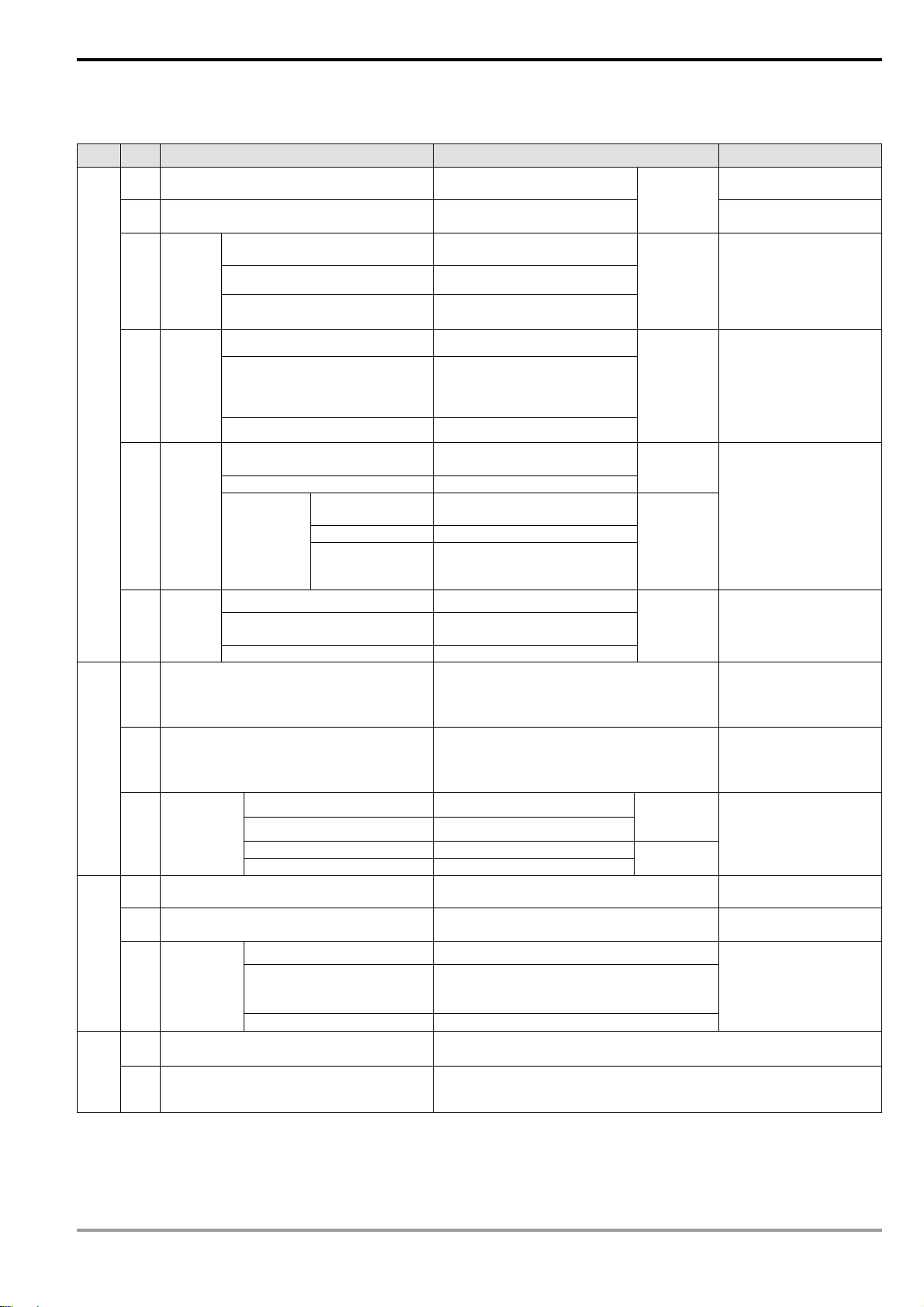

2.1 All Devices in DVP-PLC

ES/EX/SS series MPU:

Device

Type

X External input relay X0 ~ X177, 128 points, octal

Y External output relay Y0 ~ Y177, 128 points, octal

General purpose

Auxiliary

M

relay

T Timer

Relay (bit)

C Counter

S Step

T Present value of timer T0 ~ T127, 128 points

C Present value of counter

Register (word data)

Pointer

Constant

* The latched area is fixed and cannot be changed.

Data

D

register

N For master control nested loop N0 ~ N7, 8 points

P For CJ, CALL instructions P0 ~ P63, 64 points

I Interruption

K Decimal form

H Hexadecimal form

Latched* M512 ~ M767, 256 points

Special purpose

100ms timer T0 ~ T63, 64 points

10ms timer (M1028 = On)

1ms timer T127, 1 points

16-bit counting up

(general purpose)

16-bit counting up (latched*) C112 ~ C127, 16 points

32-bit

counting

up/down

high-speed

counter

(latched*)

Initial step (latched*) S0 ~ S9, 10 points

Zero return (latched*)

Latched* S20 ~ S127, 108 points

Item Range Function

1-phase 1 input

1-phase 2 inputs C246, C247, C249, 3 points

2-phase 2 inputs C251, C252, C254, 3 points

General purpose D0 ~ D407, 408 points

Latched* D408 ~ D599, 192 points

Special purpose D1000 ~ D1311, 312 points

Index indication E, F, 2 points

External interruption I001, I101, I201, I301, 4 points

Timed interruption

Communication interruption I150, 1 point

2 Functions of Devices in DVP-PLC

Corresponds to external

To ta l

256 points

M0 ~ M511, M768 ~ M999, 744

points

M1000 ~ M1279, 280 points

(some are latched)

T64 ~ T126, 63 points (M1028

= Off: 100ms)

C0 ~ C111, 112 points

C235 ~ C238, C241, C242,

C244, 7 points

S10 ~ S19, 10 points (used with

IST instruction)

C0 ~ C127, 16-bit counter, 128 points

C235 ~ C254, 32-bit counter, 13 points

I6□□, 1 point (□□=10 ~ 99, time base =

1ms ) (for V5.7 and above)

K-32,768 ~ K32,767 (16-bit operation)

K-2,147,483,648 ~ K2,147,483,647 (32-bit operation)

H0000 ~ HFFFF (16-bit operation)

H00000000 ~ HFFFFFFFF (32-bit operation)

To ta l

1,280 points

Tota l

128 points

Tota l

128 points

Tota l

13 points

Tota l

128 points

To ta l

600 points

To ta l

312 points

input points

Corresponds to external

output points

The contact can be

On/Off in the program.

Timer indicated by TMR

instruction. If timing

reaches its target, the T

contact of the same No.

will be On.

Counter indicated by

CNT (DCNT) instruction.

If counting reaches its

target, the C contact of

the same No. will be On.

Used for SFC.

When the timing

reaches the target, the

contact of the timer will

be On.

When the counting

reaches the target, the

contact of the counter

will be On.

Memory area for data

storage; E, F can be

used for index

indication.

Control point for main

control loop

Position index for CJ

and CALL

Position index for

interruption subroutine.

DVP-PLC Application Manual

2-1

Page 30

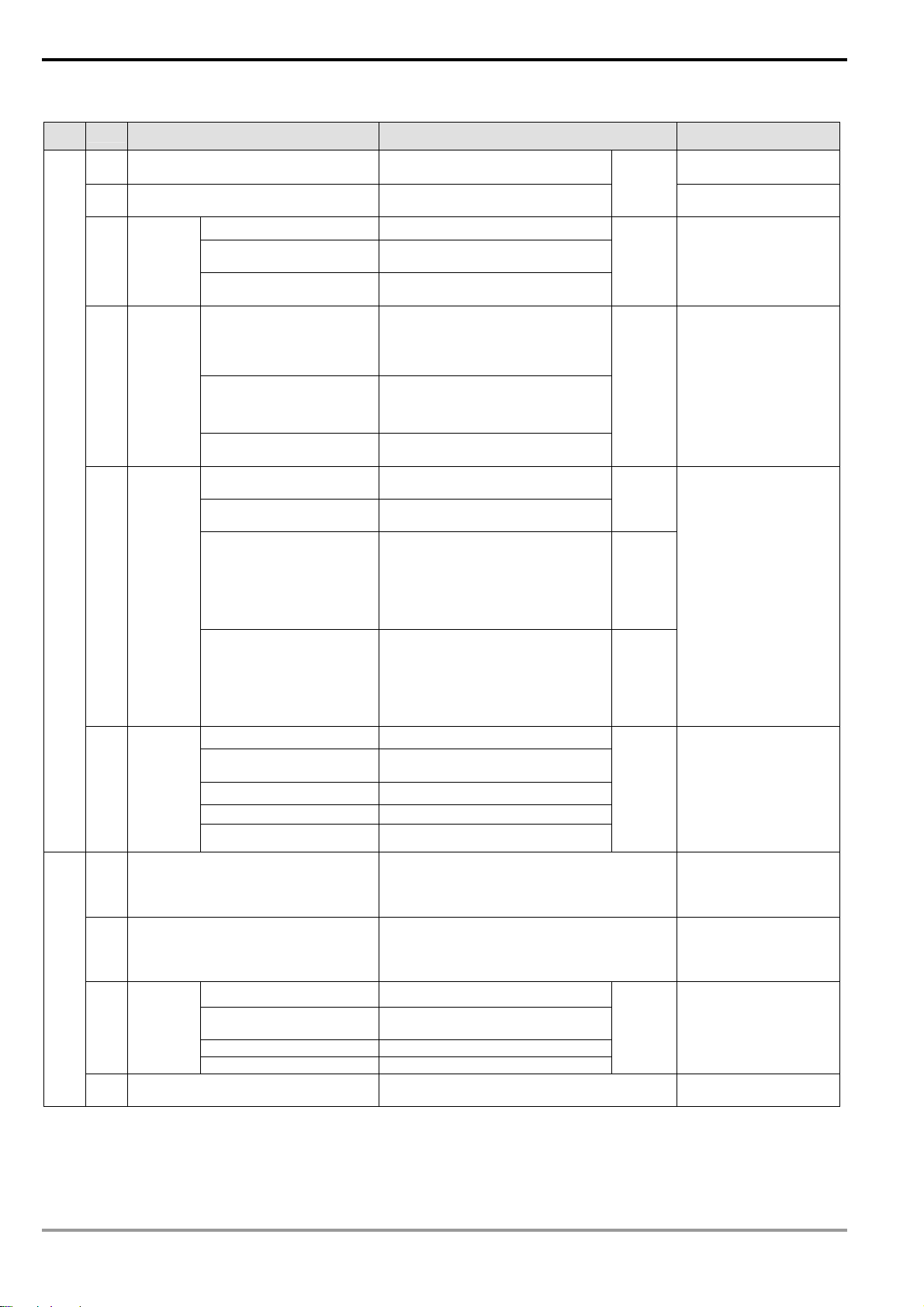

SA/SX/SC series MPU:

Device

Type

X External input relay X0 ~ X177, 128 points, octal

Y External output relay Y0 ~ Y177, 128 points, octal

Auxiliary

M

Relay

T Timer

Relay (bit)

C Counter

S Step point

T Present value of timer T0 ~ T255, 256 points

C Present value of counter

Data

D

Register (word data)

register

N/A File register K0 ~ K1,599 (1,600 points) (*4)

2 Functions of Devices in DVP-PLC

Item Range Function

Corresponds to external

input points

Corresponds to external

output points

The contact can be

On/Off in the program.

Timer indicated by TMR

instruction. If timing

reaches its target, the T

contact of the same No.

will be On.

Counter indicated by

CNT (DCNT) instruction.

If counting reaches its

target, the C contact of

the same No. will be On.

Used for SFC.

When the timing

reaches the target, the

contact of the timer will

be On.

When the counting

reaches the target, the

contact of the counter

will be On.

Memory area for data

storage; E, F can be

used for index

indication.

Expanded register for

data storage.

General purpose M0 ~ M511, 512 points (*1)

Latched*

Special purpose

100ms

10ms

1ms

16-bit counting up

32-bit counting up/down

For SA/SX, 32-bit

high-speed counter

For SC, 32-bit high-speed

counter

Initial step S0 ~ S9, 10 points (*1)

Zero return

General purpose S20 ~ S511, 492 points (*1)

Latched* S512 ~ S895, 384 points (*3)

Alarm S896 ~ S1023, 128 points (*3)

General purpose D0 ~ D199, 200 points (*1)

Latched*

Special purpose D1000 ~ D1999, 1,000 points

Index indication E0 ~ E3, F0 ~ F3, 8 points (*1)

M512 ~ M999, 488 points (*3)

M2000 ~ M4095, 2,096 points (*3)

M1000 ~ M1999, 1,000 points

(some are latched)

T0 ~ T199, 200 points (*1)

T192 ~ T199 for subroutine

T250 ~ T255, 6 accumulative points

(*4)

T200 ~ T239, 40 points (*1)

T240 ~ T245, 6 accumulative points

(*4)

T246 ~ T249, 4 accumulative points

(*4)

C0 ~ C95, 96 points (*1)

C96 ~ C199, 104 points (*3)

C200 ~ C215, 16 points (*1)

C216 ~ C234, 19 points (*3)

C235 ~ C244, 1-phase 1 input, 9

points (*3)

C246 ~ C249, 1-phase 2 inputs, 3

points (*3)

C251 ~ C254, 2-phase 2 inputs, 4

points (*3)

C235 ~ C245, 1-phase 1 input, 11

points (*3)

C246 ~ C250, 1-phase 2 inputs, 4

points (*3)

C251 ~ C255, 2-phase 2 inputs, 4

points (*3)

S10 ~ S19, 10 points (used with IST

instruction) (*1)

C0 ~ C199, 16-bit counter, 200 points

C200 ~ C254, 32-bit counter, 50 points (SC: 53

points)

D200 ~ D999, 800 points (*3)

D2000 ~ D4999, 3,000 points (*3)

To ta l

256

points

To ta l

4,096

points

To ta l

256

points

To ta l

235

points

Tota l

16

points

To ta l

19

points

To ta l

1,024

points

To ta l

5,000

points

2-2

DVP-PLC Application Manual

Page 31

2 Functions of Devices in DVP-PLC

N For Master control loop N0 ~ N7, 8 points

P For CJ, CALL instructions P0 ~ P255, 256 points

External interruption I001, I101, I201, I301, I401, I501, total 6 points

Timed interruption

Pointer

Constant

*1. Non-latched area cannot be modified.

*2. The preset non-latched area can be modified into latched area by setting up parameters.

*3. The preset latched area can be modified into non-latched area by setting up parameters.

*4. The fixed latched area cannot be modified

Interruption

I

K Decimal form

H Hexadecimal form

Interruption inserted when

high-speed counter

reaches target

Communication interruption I150, 1 point

I6□□, I7□□, 2 points (□□ = 1 ~ 99, time

base = 1ms)

I010, I020, I030, I040, I050, I060, total 6 points

K-32,768 ~ K32,767 (16-bit operation)

K-2,147,483,648 ~ K2,147,483,647 (32-bit operation)

H0000 ~ HFFFF (16-bit operation)

H00000000 ~ HFFFFFFFF (32-bit operation)

Latched settings for all devices in SA/SX/SC series MPU:

General purpose Latched Special auxiliary relay Latched

M0 ~ M511 M512 ~ M999 M1000 ~ M1999 M2000 ~ M4095

M

(Auxiliary relay)

It is fixed to be non-latched

Default: latched Default: latched

Start: D1200 (K512)

End: D1201 (K999)

Some are latched and

cannot be modified

Control point for main

control loop

Position index for CJ

and CALL

Position index for

interruption subroutine.

Start: D1202 (K2,000)

End: D1203 (K4,095)

T

(Timer)

C

(Counter)

S

(Step relay)

D

(Register)

100 ms 10 ms 10 ms 1 ms 100 ms

T0 ~ T199 T200 ~ T239 T240 ~ T245 T246 ~ T249 T250 ~ T255

It is fixed to be non-latched It is fixed to be non-latched

16-bit counting up 32-bit counting up/down

C0 ~ C95 C96 ~ C199 C200 ~ C215 C216 ~ C234 C235 ~ C255

It is fixed to be

non-latched

Initial Zero return General purpose Latched Alarm step

S0 ~ S9 S10 ~ S19 S20 ~ S511 S512 ~ S895 S896 ~ S1023

It is fixed to be non-latched

General purpose Latched Special register Latched

D0 ~ D199 D200 ~ D999 D1000 ~ D1999 D2000 ~ D4999

It is fixed to be non-latched

Default: latched Default: latched Default: latched

Start: D1208 (K96)

End: D1209 (K199)

Start: D1216 (K200)

End: D1217 (K999)

It is fixed to be

non-latched

Default: latched Default: latched

Start: D1210 (K216)

End: D1211 (K234)

Default: latched

Start: D1214 (K512)

End: D1215 (K895)

Some are latched and

cannot be modified.

Accumulative type

It is fixed to be latched

32-bit high-speed counting

up/down

Start: D1212 (K235)

End: D1213 (K255)

It is fixed to be latched

Start: D1218 (K2,000)

End: D1219 (K4,999)

File Register

DVP-PLC Application Manual

K0 ~ K1599

It is fixed to be latched.

2-3

Page 32

EH/EH2/SV series MPU:

Device

Type

2 Functions of Devices in DVP-PLC

Item Range Function

X External input relay X0 ~ X377, 256 points, octal

Y External output relay Y0 ~ Y377, 256 points, octal

General purpose M0 ~ M499, 500 points (*2)

Auxiliary

M

relay

T Timer

Relay (bit)

C Counter

S Step

T Present value of timer T0 ~ T255, 256 points

C Present value of counter

Data

D

Register (word data)

Pointer

register

N/A File register K0 ~ K9,999 (10,000 points) (*4)

N For master control loop N0 ~ N7, 8 points

P For CJ, CALL instructions P0~P255, 256 points

I

Interruption

Latched

Special purpose M1000 ~ M1999, 1,000 points (some are latched)

100ms

10ms

1ms T246 ~ T249, 4 accumulative points (*4)

16-bit counting

up

32-bit counting

up/down

32-bit high-speed

counter

Initial step point S0 ~ S9, 10 points (*2)

Zero return

General purpose S20 ~ S499, 480 points (*2)

Latched S500 ~ S899, 400 points (*3)

Alarm S900 ~ S1023, 124 points (*3)

General purpose D0 ~ D199, 200 points, (*2)

Latched

Special purpose D1000 ~ D1999, 1,000 points

Index indication E0 ~ E7, F0 ~ F7, 16 points (*1)

External interruption

Timed interruption

Interruption inserted

when high-speed

counter reaches target

Pulse interruption I110, I120, I130, I140, 4 points

Communication

interrruption

M500 ~ M999, 500 points (*3)

M2000 ~ M4095, 2,096 points (*3)

T0 ~ T199, 200 points (*2)

T192 ~ T199 is for subroutine

T250~T255, 6 accumulative points (*4)

T200 ~ T239, 40 points (*2)

T240 ~ T245, 6 accumulative points (*4)

C0 ~ C99, 100 points (*2)

C100 ~ C199, 100 points (*3)

C200 ~ C219, 20 points (*2)

C220 ~ C234, 15 points (*3)

C235 ~ C244, 1-phase 1 input, 10 points (*3)

C246 ~ C249, 1-phase 2 inputs, 4 points(*3)

C251 ~ C254, 2-phases 2 inputs, 4 points (*3)

S10 ~ S19, 10 points (used with IST instruction)

(*2)

C0 ~ C199, 16-bit counter, 200 points

C200 ~ C254, 32-bit counter, 53 points

D200 ~ D999, 800 points (*3)

D2000 ~ D9999, 8,000 points (*3)

I00□(X0), I10□(X1), I20□(X2), I30□(X3), I40□(X4),

I50□(X5), 6 points (□ = 1, rising-edge trigger

0, falling-edge trigger

I6□□, I7□□, 2 points(□□ = 1~99ms) time base = 1ms

I8□□, 1 point (□□ = 1~99, time base = 0.1ms)

I010, I020, I030, I040, I050, I060, 6 points

I150, I160, I170, 3 points

Corresponds to external

To ta l

input points

512

points

4,096

points

points

points

1,024

points

10,000

points

, □ =

)

Corresponds to external

output points

To ta l

The contact can be

On/Off in the program.

Timer indicated by TMR

To ta l

instruction. If timing

reaches its target, the T

256

contact of the same No.

will be On.

Counter indicated by

CNT (DCNT)

To ta l

instruction. If counting

253

reaches its target, the C

contact of the same No.

will be On.

To ta l

Used for SFC.

When the timing

reaches the target, the

contact of the timer will

be On.

When the counting

reaches the target, the

contact of the counter

will be On.

Memory area for data

To ta l

storage; E, F can be

used for index

indication.

Expanded register for

data storage.

Control point for main

control loop

Position index for CJ

and CALL

Position index for

interruption subroutine.

2-4

DVP-PLC Application Manual

Page 33

2 Functions of Devices in DVP-PLC

Device

Type

K Decimal form

H Hexadecimal form

Constant

*1. Non-latched area cannot be modified.

*2. The preset non-latched area can be modified into latched area by setting up parameters.

*3. The preset latched area can be modified into non-latched area by setting up parameters.

*4. The fixed latched area cannot be modified

Latched settings for all devices in EH/EH2/SV series MPU:

M

(Auxiliary relay)

T

(Timer)

C

(Counter)

S

(Step relay)

D

(Register)

File register

*1: K-1 refers to the default setting is non-latched.

Item Range Function

Frequency

measurement card

interruption

General purpose Latched Special auxiliary relay Latched

M0 ~ M499 M500 ~ M999 M1000 ~ M1999 M2000 ~ M4095

Start: D1200 (K500)

End: D1201 (K999)

100 ms 10 ms 10 ms 1 ms 100 ms

T0 ~ T199 T200 ~ T239 T240 ~ T245 T246 ~ T249 T250 ~ T255

Default: non-latched Default: non-latched

Start: D1204 (K-1)*1

End: D1205 (K-1)*1

16-bit counting up 32-bit counting up/down 32-bit high-speed counting up/down

C0 ~ C99 C100 ~ C199 C200 ~ C219 C220 ~ C234 C235 ~ C245 C246 ~ C255

Default:

non-latched

Start: D1208 (K100)

End: D1209 (K199)

Initial Zero return

S0 ~ S9 S10 ~ S19 S20 ~ S499 S500 ~ S899 S900 ~ S1023

Non-latched (default) Latched (default)

General purpose Latched Special register Latched

D0 ~ D199 D200 ~ D999 D1000 ~ D1999 D2000 ~ D9999

Default: non-latched Default: latched Default: latched

Start: D1216 (K200)

End: D1217 (K999)

I180, 1 point

K-32,768 ~ K32,767 (16-bit operation)

K-2,147,483,648 ~ K2,147,483,647 (32-bit operation)

H0000 ~ HFFFF (16-bit operation)

H00000000 ~ HFFFFFFFF (32-bit operation)

Some are latched and

cannot be modified.

Start: D1206 (K-1)*1

End: D1207 (K-1)*1

Default: latched

Start: D1214 (K500)

End: D1215 (K899)

Default:

non-latched

Start: D1210 (K220)

End: D1211 (K234)

General

purpose

K0 ~ K9,999

It is fixed to be latched.

Default: latched Default: latched

Latched Step alarm

Some is latched and

cannot be modified.

It is fixed to be latched.

Start: D1202 (K2,000)

End: D1203 (K4,095)

Accumulative type

Start: D1212 (K235)

End: D1213 (K255)

It is fixed to be latched.

Start: D1218 (K2,000)

End: D1219 (K9,999)

Power On/Off or the MPU switches between RUN/STOP:

Memory of ES/EX/SS V5.5 (and above)

Memory type

Non-latched Clear

Latched Unchanged Unchanged Clear Unchanged

Special M,

Special D,

index register

Power

Off→On

Initial Unchanged Unchanged Initial setting

STOP→RUN RUN→STOP

Clear when M1033 = Off

Remain unchanged when M1033 = On

Clear all non-latched

areas (M1031)

Clear Unchanged 0

Clear all latched

areas (M1032)

Default

setting

Memory of SA/SX/SC/EH/EH2/SV series MPU:

DVP-PLC Application Manual

2-5

Page 34

2 Functions of Devices in DVP-PLC

Memory type

Non-latched Clear Unchanged

Latched Unchanged Unchanged Clear 0

Special M,

Special D,

index register

File Register Unchanged 0

Power

Off→On

Initial Unchanged Unchanged

STOP→RUN RUN→STOP

Clear when M1033 = Off

Remain unchanged when

M1033 = On

Clear all non-latched

area (M1031)

Clear Unchanged 0

Clear all latched

area (M1032)

Default

setting

Initial

setting

2.2 Values, Constants [K] / [H]

K Decimal form

Constant

H Hexadecimal form

For different control purposes, there are five types of values inside DVP-PLC for executing the operations. See

the explanations bellows for the functions and works of every type of value.

1. Binary value (BIN)

K-32,768 ~ K32,767 (16-bit operation)

K-2,147,483,648 ~ K2,147,483,647 (32-bit operation)

H0 ~ HFFFF (16-bit operation)

H0 ~ HFFFFFFFF (32-bit operation)

All the operations and storage of values in PLC are conducted in BIN. Belows are the terms for BIN values.

Bit:

Nibble:

The basic unit for a BIN value, either 1 or 0.

Composed of 4 continuous bits (e.g. b3 ~ b0). Presented as the decimal value 0 ~ 9 of a digit

or 0 ~ F in hex.

Byte:

Word:

Composed of 2 continuous nibble (i.e. 8 bits, b7 ~ b0). Presented as 00 ~ FF in hex.

Composed of 2 continuous bytes (i.e. 16 bits, b15 ~ b0). Presented as 4-digit 0000 ~ FFFF in

hex.

Double word:

Composed of 2 continuous words (i.e. 32 bits, b31 ~ b0). Presented as 8 digit 00000000 ~

FFFFFFFF.

Bit, nibble, byte, word, and double word in a binary system:

DW

W1

BY3 BY2 BY1 BY0

W0

Double Word

Word

Byte

2. Octal value (OCT)

The No. of external input and output terminals in DVP-PLC is numbered in octal system.

For example:

External input: X0 ~ X7, X10 ~ X17…(device No.)

2-6

NB0NB1NB2NB3NB4NB5NB6NB7

Nibble

Bit

DVP-PLC Application Manual

Page 35

2 Functions of Devices in DVP-PLC

External output: Y0 ~ Y7, Y10 ~ Y17…(device No.)

3. Decimal value (DEC)

Occassions of using decimal values in DVP-PLC:

Set value in timer T and counter C, e.g. TMR C0 K50 (constant K)

No. of device S, M, T, C, D, E, F, P, I, e.g. M10, T30. (device No.)

Operands in application instructions, e.g. MOV K123 D0 (constant K)

4. Binary code decimal (BCD)

A decimal datum is presented by a nibble or 4 bits. Therefore, a continuous 16 bits can be presented as a 4-digit

decimal value. BCD is mainly used on reading the input value from the DIP switch or the data output to a 7-section

display.

5. Hexadecimal value (HEX)

Occassion of using hexadecimal values:

Operands in application instructions, e.g. MOV H1A2B D0 (constant H)

Constant K:

“K” is normally placed before a decimal value in the PLC. For example, K100 refers to a decimal value, 100.

Exception:

K and bit devices X, Y, M and S can combine into data in bit, byte, word or double word, e.g. K2Y10, K4M100.

Here K1 refers to a 4-bit data and K2 ~ K4 refer to 8-bit, 12-bit and 16-bit data.

Constant H:

“H” is normally placed before a hexadecimal value in the PLC. For example, H100 refers to a hexadecimal value,

100.

Reference table:

Binary

(BIN)

For PLC internal operation

0000 0000 0 0 0 0 0 0 0 0 0 0 0

0000 0001 1 1 0 0 0 0 0 0 0 1 1

0000 0010 2 2 0 0 0 0 0 0 1 0 2

0000 0011 3 3 0 0 0 0 0 0 11 3

0000 0100 4 4 0 0 0 0 0 1 0 0 4

0000 0101 5 5 0 0 0 0 0 1 0 1 5

0000 0110 6 6 0 0 0 0 0 11 0 6

0000 0111 7 7 0 0 0 0 0 1 1 1 7

0000 1000 10 8 00 0 0 1 0 0 0 8

0000 1001 11 9 0 0 0 0 1 0 0 1 9

0000 1010 12 10 0 0 0 1 0 0 0 0 A

0000 1011 13 11 0 0 0 1 0 0 0 1 B

0000 1100 14 12 0 0 0 1 0 0 1 0 C

0000 1101 15 13 0 0 0 1 0 0 1 1 D

0000 1110 16 14 0 0 0 1 0 1 0 0 E

0000 1111 17 15 0 0 0 1 0 1 0 1 F

0001 0000 20 16 0 0 0 1 0 1 1 0 10

Octal

(OCT)

No. of device

X, Y

Decimal

(DEC)

Constant K,

No. of device M, S, T, C,

D, E, F, P, I

Binary Code Decimal

(BCD)

For DIP switch and 7-section

display

Hexadecimal

Constant H

(HEX)

DVP-PLC Application Manual

2-7

Page 36

2 Functions of Devices in DVP-PLC

Binary

(BIN)

For PLC internal operation

0001 0001 21 17 0 0 0 1 0 1 1 1 11

:

:

:

0 1 1 0 0 0 1 1 143 99 1 0 0 1 1 0 0 1 63

Octal

(OCT)

No. of device

X, Y

:

:

:

Decimal

(DEC)

Constant K,

No. of device M, S, T, C,

D, E, F, P, I

:

:

:

Binary Code Decimal

(BCD)

For DIP switch and 7-section

display

:

:

:

Hexadecimal

(HEX)

Constant H

:

:

:

2.3 Numbering and Functions of External Input/Output Contacts [X] / [Y]

No. of input/output contacts (in octal):

The No. of input and output contacts on the PLC MPU starts from X0 and Y0. The range of the No. varies upon

the number of points on the MPU. For I/O extension units, the No. of input and output contacts is calculated according

to its connection sequence with the MPU.

ES/EX/SS series MPU:

Model DVP-14ES DVP-14SS DVP-20EX DVP-24ES DVP-32ES DVP-40ES DVP-60ES I/O Extension Unit

Input X

Output Y

Note: The input points on I/O extension units start from X20 and output points from Y20, except input points on

DVP-40ES start from X30 and output from Y20; input points on DVP-60ES start from X50 and output from Y30. The No. of

input/output points on the I/O extension units increases by 8’s multiple. If the number of points is less than 8, it will be

counted as 8.

X0 ~ X7

(8 points)

Y0 ~ Y5

(6 points)

X0 ~ X7

(8 points)

Y0 ~ Y5

(6 points)

X0 ~ X7

(8 points)

Y0 ~ Y5

(6 points)

X0 ~ X17

(16 points)

Y0 ~ Y7

(8 points)

X0 ~ X17

(16 points)

Y0 ~ Y17

(16 points)

X0 ~ X27

(24 points)

Y0 ~ Y17

(16 points)

X0 ~ X43

(36 points)

Y0 ~ Y27

(24 points)

X20/30/50 ~ X177

(Note)

Y20/30 ~ Y177

(Note)

SA/SX/SC serues MPU:

Model DVP-10SX (Note1) DVP-12SA DVP-12SC I/O Extension Unit (Note 2)

Input X X0 ~ X3 (4 points) X0 ~ X7 (8 points) X0 ~ X5, X10 ~ X11 (8 points) X20 ~ X177

Output Y Y0 ~ Y1 (2 points) Y0 ~ Y3 (4 points) Y0 ~ Y1, Y10 ~ Y11 (4 points) Y20 ~ Y177

Note 1: Besides 4DI and 2DO, SX series MPU has also 2AI (12-bit) and 2AO (12-bit) of analog input/output.

Note 2: SX/SA/SC series MPU share the extension units with SS series MPU. The input points on I/O extension units start

from X20 and output points start from Y20. The calculation on the No. of I/O points is the same as that in SS series.

EH series MPU:

Model DVP-16EH

Input X

X0 ~ X7

(8 points)

DVP-20EH

(Note 1)

X0 ~ X13

(12 points)

DVP-32EH

(Note1, 2)

X0 ~ X17

(16 points)

DVP-40EH DVP-48EH DVP-64EH DVP-80EH

X0 ~ X27

(24 points)

X0 ~ X27

(24 points)

X0 ~ X37

(32 points)

X0 ~ X47

(40 points)

Extension

Unit (Note 3)

X※~X377

I/O

Output Y

Note 1: The output type of 20EH00T and 32EH00T is transistor, among which Y0 and Y2 are high-speed transistor output

(200KHz) and other outputs are normal transistor output (10KHz). The output type of other MPUs with 16/48/64/80 points is

transistor and all outputs are normal transistor output (10KHz).

Note 2: The terminal layouts of 32EH00T, 32EH00R and 32EH00M are different. See the instruction sheets of EH series

MPU. In 32EH00M, CH0 (Y0, Y1) and CH1 (Y2, Y3) are high-speed differential output.

Note 3: The start No. of the input and output points on the I/O extension unit resumes from the last No. in the MPU. The start

No. of input points on the I/O extension unit of DVP-16EH and DVP-20EH start from X20 and output points start from Y20.

The No. on the I/O extension unit are in sequence, with max. input point No. X377 and max. output point No. Y377.

Y0 ~ Y7

(8 points)

2-8