Page 1

2010-09-28

5012605500

0

-P1M

DVP-1170030-01

Page 2

……………………………………………………….…….…… ENGLISH …………………………………………………………………..

This instruction sheet only provides information on electrical specifications, functions,

wiring. For detailed information on programming and instructions, please refer to

“DVP-PM Application Manual: Programming”. For more information about the

optional peripherals, please see individual product instruction sheet or “DVP-PLC

Application Manual: Special Modules”.

DVP-10PM is an OPEN TYPE device and therefore should be installed in an

enclosure free of airborne dust, humidity, electric shock and vibration. The enclosure

should prevent non-maintenance staff from operating the device (e.g. key or specific

tools are required for operating the enclosure) in case danger and damage on the

device may occur.

DO NOT connect the input AC power supply to any of the I/O terminals; otherwise

serious damages may occur. Check all the wirings before switching on the power.

Make sure the ground terminal is correctly grounded in order to prevent

electromagnetic interferences.

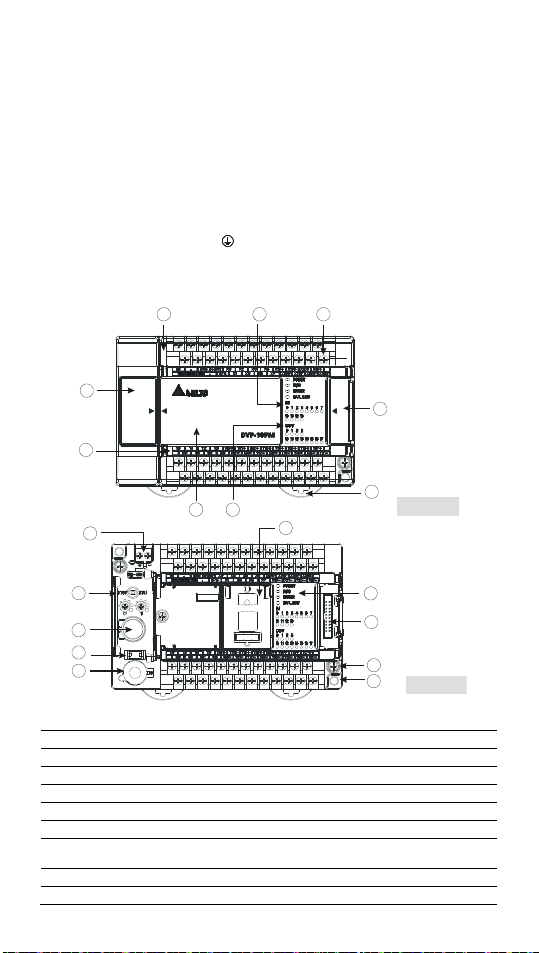

Product Profile & Dimensions

2

3

4

1

6

7

8

10

11

12

13

14

15

9

16

17

18

19

5

[ Figure 1 ]

[ Figure 2 ]

1 Communication port cover 2 I/O terminal cover

3 Input indicators 4 I/O terminals

5 I/O module connection port cover 6 Numbers of I/O terminals

7 Function card/memory card cover 8 Output indicators

9 DIN rail clip 10 COM2 (RS-485)

11 STOP/RUN switch 12 COM1 (RS-232)

13 Battery socket 14 Battery

15 Function card port 16

POWER/RUN/ERROR/BAT.LOW

indicators

17 I/O module connection port 18 Mounting screw

19 Mounting hole

- 1 -

Page 3

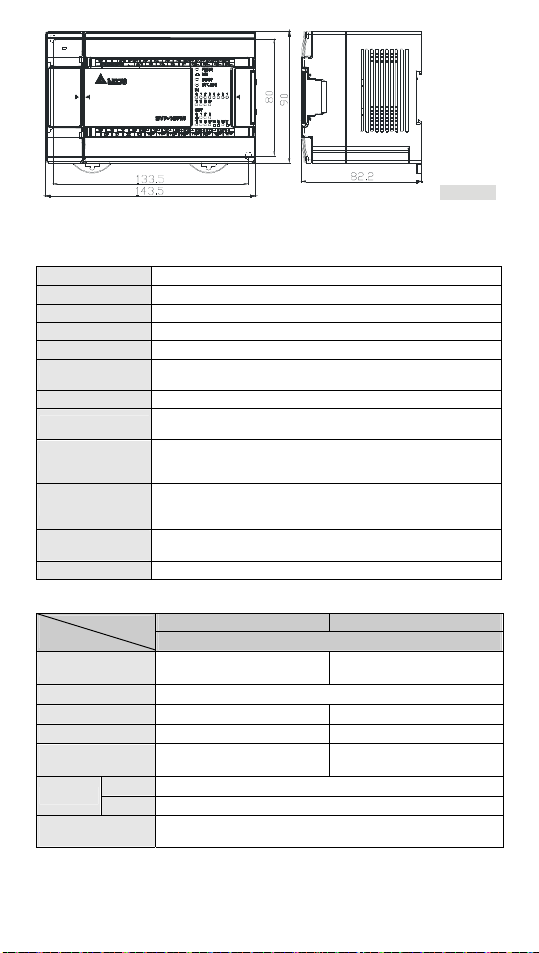

Unit: mm

Electrical Specifications

Power supply voltage

Fuse capacity 2 A/250 VAC

Power consumption 60 VA

DC24V current output 500 mA

Power protection 24 VDC, output short-circuited

Withstand voltage

Insulation impedance > 5 MΩ (all I/O point-to-ground 500 VDC)

Noise immunity

Earth

Operation/storage

Vibration/shock

immunity

Weight (g) 612

Input Points

Spec.

Items

Input wiring type Independent wiring

Input indicator LED display; light on = ON, light off = OFF

Input voltage (±10%) 5 to 24 VDC 24 VDC

Max. input current 15 mA 15 mA

Input point

configuration

Active level

Response time/noise

immunity

100 ~ 240 VAC (-15 to 10%), 50/60 Hz 5%

1,500 VAC (Primary-secondary); 1,500 VAC (Primary-PE); 500 VAC

(Secondary-PE)

ESD: 8 kV Air Discharge, EFT: Power Line: 2 kV, Digital I/O: 1 kV,

Analog & Communication I/O: 250 V

The diameter of grounding wire shall not be less than that of the L, N

terminal of the power. (When many PLCs are used at the same time,

make sure every PLC is properly grounded.)

Operation: 0 to 55°C (temperature), 50 to 95% (humidity), pollution

degree 2

Storage: -25 to 70°C (temperature), 5 to 95% (humidity)

International standards: IEC61131-2, IEC 68-2-6 (TEST Fc) /

IEC61131-2 & IEC 68-2-27 (TEST Ea)

OffOn

OnOff

Two differential inputs 24 VDC single common port input

X10+, X10-, X11+, X11-

X12-, X13+, X13-

200 kHz

Change wiring from S/S to SINK

#2

, X12+,

#3

20 μs

30 μs

0.5 μs

or SOURCE

X0 to X7

[ Figu re 3 ]

#1

- 2 -

Page 4

#1:X0, X2, X4 and X6 can separately be the DOG signal for X, Y, Z and A axes. X1, X3, X5

and X7 can be the PG0 signal for the four axes

#2:X10、X11 are MPG pulse inputs.

#3:X12、X12 and X13 can only receive differential pulse signals for counting.

Output Points

Spec.

Items

Max. frequency

Output indicator LED display; light on = ON, light off = OFF

Output point configuration

Working voltage 5 VDC 5 to 30 VDC

Max. output current 40 mA 40 mA

Insulation

Maximum load

Max. output

response time

Over-current protection N/A

#1:Y10+,Y10-,Y12+,Y12-,Y14+,Y14-,Y16+,Y16-:Forward-running pulse output;

Y11+,Y11-,Y13+,Y13-,Y15+,Y15-,Y17+,Y17-: Reverse-running pulse output; Pulse

#2:Y0 to Y3 are 4 groups of PWM outputs; and can be the independent outputs.

Resistive

Inductive

Lamp

OffOn

OnOff

Pulse/direction: Pulse output; A/B phase output: A phase

direction: Direction output; A/B phase: output: B phase

Two differential outputs

1 MHz 200 kHz

#1

Y10 to Y17

Y0 to Y3#2

Line driver Photocoupler isolation

< 25 mA

--

--

0.2 μs 0.2 μs

Single common port transistor

High speed

0.5A/1 point (4 A/COM)

12 W (24 VDC)

2 W (24 VDC)

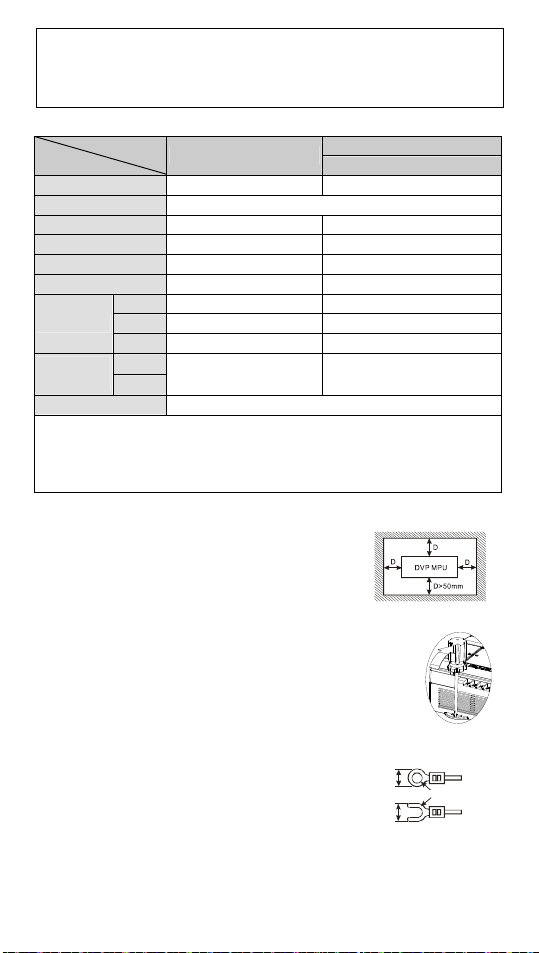

Installation

Please install the PLC in an enclosure with sufficient space

around it to allow heat dissipation.

Direct Mounting: Please use M4 screw according to the

dimensions of the product.

DIN Rail Mounting: When mounting the PLC to a 35mm DIN rail, be sure to use the

retaining clip to stop any side-to-side movement of the PLC and

reduce the chance of wires being loosened. The retaining clip is at

the bottom of the PLC. To secure the PLC to the DIN rail, pull down

the clip, place it onto the rail and gently push it up. To remove the

PLC, pull the retaining clip down with a flat screwdriver and gently

remove the PLC from the rail

Wiring

1. Use the O-type or Y-type terminal. See the figure in the

right hand side for the specifications. The PLC terminal

screws should be tightened to 9.50 kg-cm (8.25 in-Ibs)

and use only 60/75ºC copper conductors.

2. DO NOT wire empty terminals, or place the input signal cable and output power

cable in the same wiring circuit.

3. DO NOT drop tiny metallic conductors into the PLC while screwing and wiring. Tear

off the sticker on the heat dissipation hole to prevent alien substances from

dropping in to ensure normal heat dissipation of the PLC.

- 3 -

Below

6.2 mm

Below

6.2 mm

To s uit M3 .5

screw terminals

Page 5

Power Supply

DVP-10PM accepts AC power input. When operating the PLC, please note the following

points:

1. The input voltage should be current, and the range is 100 to 240 VAC. Connect the

power supply to the L and N terminals. Wiring AC110V or AC220V to the +24V

terminal or input terminal will result in serious damages on the PLC.

2. The AC power input for DVP-10PM and I/O modules should be ON or OFF at the

same time.

3. Use wires of 1.6mm (or longer) for the grounding.

4. The power shutdown of less than 10 ms will not affect the operation of the PLC.

However, the power shutdown time that is too long or the drop of power voltage will

stop the operation of the PLC and all outputs will go OFF. When the power returns to

normal status, the PLC will automatically resume its operation. (Care should be

taken on the latched auxiliary relays and registers inside the PLC during the

programming).

5. The maximum supply from the +24 V output terminal is 0.5 A. DO NOT connect other

external power supplies to this terminal. Every input terminal requires 6 to 7 mA to be

driven, e.g. the 16-point input will require approximately 100 mA. Therefore, the

+24V terminal cannot output to the external load that is bigger than 400 mA.

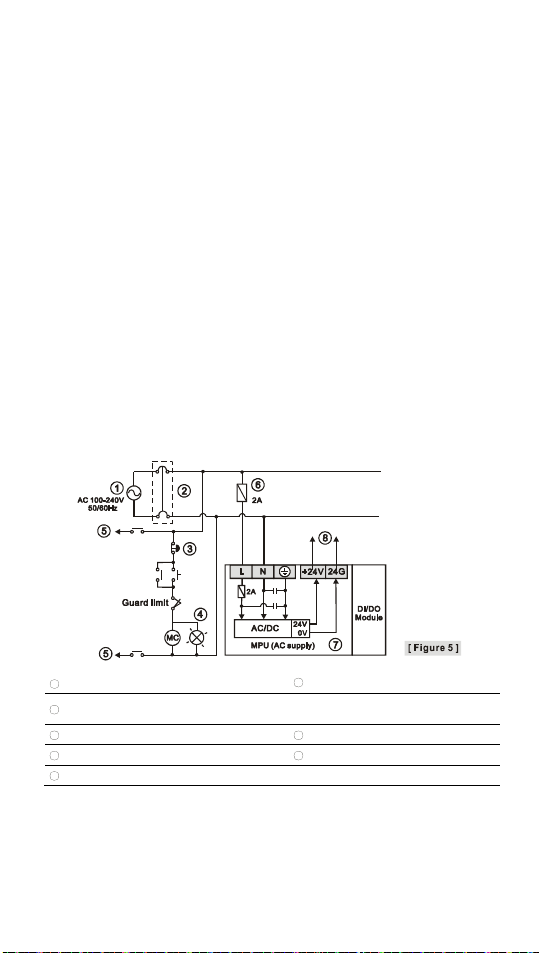

Safety Wiring

In a PLC control system, many devices are controlled at the same time and actions of

any device could affect each other, e.g. breakdown of one device may cause the

breakdown of the entire auto-control system. Therefore, wiring a protection circuit at the

power supply input terminal is highly suggested. See the figure below.

1

AC power supply: 100 to 240 VAC, 50/60 Hz2Breaker

Emergency stop: This button cuts off the system power supply when an accidental

3

emergency takes place.

4

Power indicator

6

Power supply circuit protection fuse (2 A)

8

DC power supply output: 24 VDC, 500 mA

5

AC power supply load

7

DVP-PLC (main processing unit)

Input Points Wiring

There are 2 types of DC inputs, SINK and SOURCE. See the examples below. For

detailed configuration methods, please refer to the specification of each model.

DC Signal IN – SINK mode

Input point loop equivalent circuit

- 4 -

Page 6

+24V

t

P

24G

S/S

X0

24VDC

X1

[ Fig ure 6 ]

DC Signal IN – SOURCE mode

Input point loop equivalent circuit

+24V

24G

S/S

X0

X1

24VDC

[ Figure 7 ]

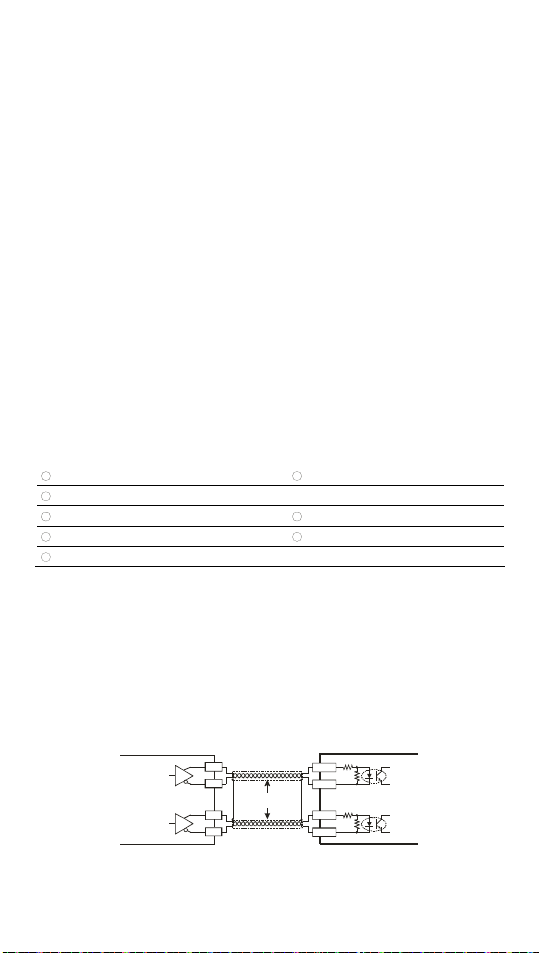

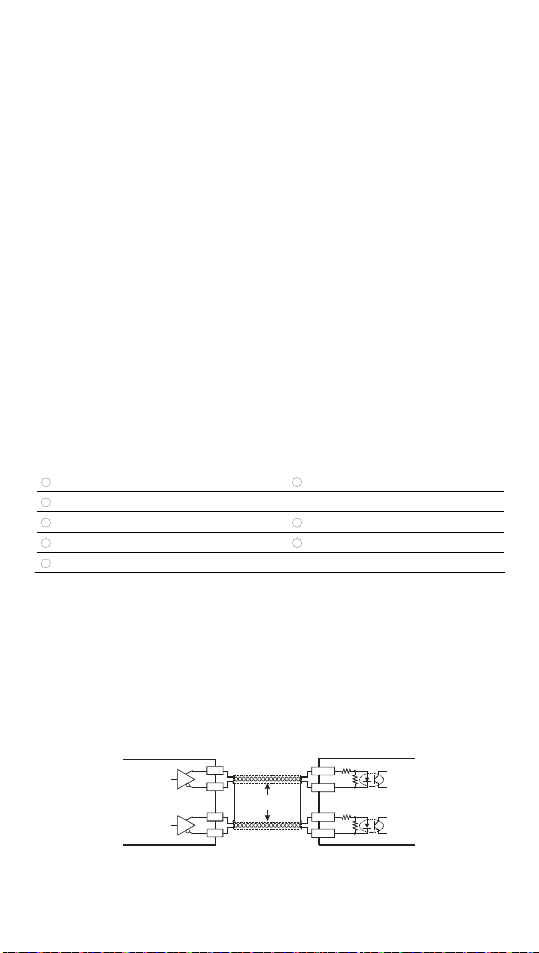

Wiring of Differential Inputs

X10 to X13 on DVP-10PM are 5 to 24 VDC high-speed input circuits; other inputs are 24

VDC). The frequency of high-speed input circuits can be up to 200 kHz and is for

connecting to differential (double-wire) LINE DRIVER output circuits.

Wiring in high-speed, high-noise environment

Enc oder ou tput

A

Differential output

B

A +

A -

Twisted pair

cable

B +

B -

DVP-10PM high-speed inpu

X10+

X10-

X11+

X11-

[ Figure 8 ]

Wirings of sensors for differential points (24 VDC):

X10+

X10-

PN

SENSOR

SOURCE

+

24VDC

[ Figure 10 ]

X10+

X10-

SINK

NPN

SENSOR

+

24VDC

[ Figure 9 ]

Output Points Wiring

Transistor (T) contact circuit wiring

- 5 -

Page 7

1

DC power supply

4

The output of the transistor model is “open collector”. If Y0/Y1 is set to pulse output, the

output current has to be bigger than 0.1 A to ensure normal operation of the model.

2

Emergency stop

3

Circuit protection fuse

1. Diode suppression: Used when in smaller power (Figure 13)

2. Diode + Zener suppression: Used when in larger power and frequent On/Off (Figure 14)

5

Manually exclusive output: For example, Y4 and Y5 control the forward running and reverse

running of the motor, forming an interlock for the external circuit, together with the PLC

internal program, to ensure safe protection in case of any unexpected errors.

Wiring of Differential Outputs

Differential output with ASDA-A & A+, ASDA-A2 series servo drives

DVP-10PM differential output

Y10+

FP

Y10-

Twis ted pai r

cable

Y11+

RP

Y11-

/PLS

PLS

FG0

/SIGN

SIGN

Differential output with ASDA-B series servo drive

DVP-10PM differential output

Y10+

FP

Y10-

Twis ted pai r

cable

Y11+

RP

Y11-

/PLS

PLS

FG0

/SIGN

SIGN

Differential output with ASDA-AB series servo drive

DVP-10PM differential output

Y10+

FP

Y10-

Twisted pair

cable

Y11+

RP

Y11-

PLS

/PLS

FG0

SIGN

/SIGN

- 6 -

Driver

43

41

36

37

Circuit for

Photocouple

Circuit for

Photocouple

[ Fi gure 15 ]

Driver

21

22

19

20

Circuit for

Photocouple

Circuit for

Photocouple

[ Fi gure 16 ]

Drive r

43

41

36

37

Circuit for

Photocouple

Circuit for

Photocouple

[ Fi gure 17 ]

Page 8

BAT.LOW Indicator

BAT.LOW indicator will be on when the battery is in low voltage. When this happens,

change the battery as soon as possible in case your program and data saved in the

latched area will be lost.

After the power is switched off, the data in the latched area will be stored in the SRAM

memory, and its power will be supplied by the battery. Therefore, when the battery is in

low voltage and the power-off status has been lasting for more than 1 minute, the data in

the latched area will be lost. If you need to permanently save the data in the latched

area in the program and device D, see the “permanently saved mechanism” and

“recover mechanism” sections below.

Permanently saved mechanism

Use PMSoft (Options -> PLC<=>Flash) to permanently save the data in the latched area

in Flash ROM memory. The newly indicated data will replace all data previously saved in

the memory.

Recover mechanism

If the battery is in low voltage before the power is switched off when the BAT.LOW

indicator is on, and the power is off for more than 1 minute, the PLC will automatically

restore the data in the latched area in the program and device D of Flash ROM into

SRAM memory next time when it is re-powered.

Battery Life

Temperature (ºC) -30 0 25 50 70

Life (year) 10 9 8 6 5

- 7 -

Page 9

………………………………………………………………… 繁體中文 ………………………………………………………………………

本使用說明書僅提供電氣規格、功能規格、安裝配線部份說明,其它詳細之程式設計

及指令說明請見《DVP-PM 應用技術手冊:程式篇》,選購之週邊裝置詳細說明請見該

產品隨機手冊或《DVP-PLC 應用技術手冊:特殊模組篇》。

本機為開放型(OPEN TYPE)機殼,因此使用者使用本機時,必須將之安裝於具防塵、

防潮及免於電擊∕衝擊意外之外殼配線箱內。另必須具備保護措施(如:特殊之工具

或鑰匙才可打開)防止非維護人員操作或意外衝擊本體,造成危險及損壞。

交流輸入電源不可連接於輸入∕出信號端,否則可能造成嚴重損壞,請在上電之前再

次確認電源配線。請勿在上電時觸摸任何端子。本體上之接地端子 務必正確的接

地,可提高產品抗雜訊能力。

யݡγ៍ᄃొҜ

詳細圖示請參閱英文版頁碼1 之[Figure 1] 及[Figure 2]。

1 通訊口上蓋 2輸入∕輸出端子蓋

3 輸入點指示燈 4輸入∕輸出端子

5 I/O 模組連接口上蓋 6輸入∕輸出端子編號

7 功能卡∕記憶卡上蓋 8輸出點指示

9 DIN 軌固定扣 10 COM2 通訊埠 (RS-485)

11 停止∕執行開關 12 COM1 通訊埠 (RS-232)

13 電池插槽 14 電池

15 功能卡插槽 16 電源、運行、錯誤及電池狀態指示燈

17 I/O 模組連接口 18 機身固定螺絲

19 直接固定孔

詳細尺寸圖示請參閱英文版頁碼1 之[Figure 3],單位:mm。

ঈఢ

電源電壓

電源保險絲容量

消耗功率

DC24V 電流輸出

電源保護 24 VDC 輸出具短路保護

突波電壓耐受量

絕緣阻抗 5 MΩ 以上(所有輸出∕入點對地之間 500 VDC)

雜訊免疫力

接地

操作∕儲存環境

耐振動∕衝擊

重量(約 g)

100 ~ 240 VAC (-15 ~ 10%),50/60 Hz 5%

2A/250 VAC

60 VA

500 mA

1,500 VAC (Primary-secondary)

1,500 VAC (Primary-PE)

500 VAC (Secondary-PE)

ESD: 8 kV Air Discharge, EFT: Power Line: 2 kV, Digital I/O: 1 kV, Analog &

Communication I/O: 250 V

接地配線之線徑不得小於電源端 L, N 之線徑(多台 PLC 同時使用時,請務

必單點接地)

操作:0 ~ 55°C(溫度),50 ~ 95%(濕度),污染等級 2

儲存:-25 ~ 70°C(溫度),5 ~ 95%(濕度)

國際標準規範 IEC61131-2,IEC 68-2-6 (TEST Fc)/IEC61131- 2 & IEC

68-2-27 (TEST Ea)

612

- 8 -

Page 10

Ꮾˢᕇఢ

規格

項目

輸入接線型式 獨立接線

輸入動作指示 LED 顯示,燈亮表示為 ON,不亮表示為’OFF’

輸入信號電壓

最大電流輸入值

輸入點配置

動作位準

反應時間∕雜訊抑制

#1:X0、X2、X4 及X6 分別可為 XYZA 四軸 DOG 訊號,而 X1、X3、X5 及X7 分別為 XYZA

#2:X10、X11為手搖輪脈波輸入。

#3:X12、X13 僅接收差動脈波訊號做為計數使用。

OffOn

OnOff

四軸 PG0 訊號。

雙端差動輸入 24 VDC 單端共點輸入

200 kHz

由端子 S/S 變換接線為 SINK 或

5 ~ 24 VDC 24 VDC

15 mA 15 mA

#2

X10+、X10-、X11+、X11-

X12-、X13+、X13-

、X12+、

#3

20 μs

30 μs

0.5 μs

SOURCE

X0 ~ X7

#1

Ꮾᕇఢ

規格

項目

最高交換(工作)頻率

輸出動作指示 LED 顯示,燈亮表示為 ON,不亮表示為 OFF。

輸出點配置 Y10 ~ Y17#1 Y0 ~ Y3#2

工作電壓 5 VDC 5 ~ 30 VDC

最大輸出電流值 40 mA 40 mA

隔離方式 驅動級電源隔離 光耦合隔離

電流規格

最大輸出延

遲時間

輸出過電流保護 N/A

#1:Y10+、Y10-、Y12+、Y12-、Y14+、Y14-、Y16+、Y16-之正反轉模式為正轉方向脈波輸

Y11+、Y11-、Y13+、Y13-、Y15+、Y15-、Y17+、Y17-之正反轉模式為反轉方向脈波輸出;

#2:Y0 ~ Y3 為四組PWM 輸出;可作高速獨立輸出點使用。

電阻性 < 25 mA

電感性 --

燈泡 --

OffOn

OnOff

出;脈波∕方向:脈波輸出端;AB 相模式:A 相輸出。

脈波∕方向:方向輸出端;AB 相模式:B 相輸出。

雙端差動輸出

1 MHz 200 kHz

0.2 μs 0.2 μs

單端共點電晶體輸出

高速

0.5 A/1 點(4 A/COM)

12 W (24 VDC)

2 W (24 VDC)

щ྅ё

PLC 在安裝時,請裝配於封閉式之控制箱內,其周圍應保持一定之空間,以確保 PLC 散

熱功能正常,請參閱英文版頁碼 3 之配置示意圖。

直接鎖螺絲方式:請依產品外型尺寸並使用M4 螺絲。

DIN 鋁軌之安裝方法:適用於 35mm 之 DIN 鋁軌。在將主機掛上鋁軌時,請先將主機

(或 I/O 模組)下方之固定塑膠片,以一字形起子插入凹槽並向外撐開拉出(請參閱英

文版頁碼 3 之圖示),再將主機(或 I/O 模組)掛上鋁軌,之後將固定塑膠片壓扣回去

即可。欲取下主機時,同樣以一字形起子先將固定塑膠片撐開,再將主機以往外向上的

- 9 -

Page 11

方式取出即可。該固定機構塑膠片為保持型,因此撐開後便不會彈回去。

ቢბ

1. 輸出/入配線端請使用 O 型或 Y 型端子,端子規格請參閱英文版頁碼 3 之圖示。PLC 端

子螺絲扭力為 9.50 kg-cm (8.25 in-Ibs)。只能使用60/75°C 的銅導線。

2. 空端子請勿配線。輸入點信號線與輸出點等動力線請勿置於同一線槽內。

3. 鎖螺絲及配線時請避免微小的金屬導體掉入 PLC 內部,並在配線完成後,將位於 PLC

上方散熱孔位置的防異物掉入之貼紙撕去,以保持散熱良好。

ბ

DVP-10PM 系列 PLC 電源輸入為交流輸入,在使用上應注意下列事項:

1. 交流電源輸入電壓,範圍寬廣(100 ~ 240 VAC),電源請接於 L、N 兩端,如果將 AC110V

或 AC220V 接至+24 V 端或輸入點端,將造成PLC 嚴重損壞,請使用者特別注意。

2. 主機及 I/O 模組之交流電源輸入請同時作 On 或 Off 的動作。

3. 主機之接地端使用 1.6mm 以上之電線接地。

4. 當停電時間低於 10 ms 時,PLC 不受影響繼續運轉,當停電時間過長或電源電壓下降

將使 PLC 停止運轉,輸出全部 Off,當電源恢復正常時,PLC 亦自動回復運轉。(PLC

內部具有停電保持的輔助繼電器及暫存器,使用者在程式設計規劃時應注意使用。)

5. +24 V 電源供應輸出端,最大為 0.5 A,請勿將其他的外部電源連接至此端子。每個輸

入點驅動電流必須 6 ~ 7 mA,若以 16 點輸入計算,大約需100 mA,因此+24 V 輸出

給外部負載不可大於 400 mA。

щБቢаྮ

由於 PLC 控制許多裝置,任一裝置的動作可能都會影響其它裝置的動作。因此任一裝置

的故障都可能會造成整個自動控制系統失控,甚至造成危險。所以在電源端輸入回路,建

議的保護回路配置圖請參閱英文版頁碼 4 之[Figure 5]所示:

1

交流電源供應:100 ~ 240 VAC, 50/60Hz

8

緊急停止:為預防突發狀況發生,設置緊急停止按鈕,可在狀況發生時,切斷系統電源。

4

電源指示燈

6

電源回路保護用保險絲(2A)

8

直流電源供應輸出:24 VDC,500 mA

Ꮾˢᕇቢ

輸入點之入力信號為直流電源 DC 輸入,DC 型式共有兩種接法:SINK 及SOURCE,其

定義與輸入點回路等效電路配線圖,請參閱英文版頁碼 5 之[Figure 6]及[Figure7]。

જᏮˢቢ

DVP-10PM 系列之 X10 ~ X13 均為 5 ~ 24 VDC 高速輸入電路(其餘則為 24 VDC 輸入)。

此高速輸入電路工作頻率可達 200 kHz,主要是用以連接差動(雙線式)LINE DRIVER

輸出電路用。

差動輸入之接線圖(高速、高雜訊時使用)

編碼器輸出 DVP-10PM 高速輸入

A +

A

差動輸出

A -

B +

B

B -

差動獨立點使用感測器之接線圖,請參考英文版頁碼5 之[Figure 9]及[Figure 10]。

雙絞線

2

斷路器

5

交流電源負載

7

DVP PLC 主機本體

X10+

X10-

X11+

X11-

- 10 -

Page 12

Ꮾᕇቢ

電晶體(T)接點回路配線

詳細配線圖請參閱英文版頁碼 5 ~ 6 之[Figure 11 ~ 14]。

1

直流電源供應

4

因電晶體模組輸出均為開集極輸出(Open Collector),若 Y0/Y1 設定為脈波串輸出,為確

保電晶體模組能夠動作正常,其輸出提升電阻,必須維持輸出電流大於0.1 A。

1. 二極體抑制:功率較小時使用(請參閱英文版頁碼 7 之[Figure 13])

2. 二極體+Zener 抑制:大功率且 On/Off 頻繁時使用(請參閱英文版頁碼 7 之[Figure 14])

5

互斥輸出:例如,將 Y2 與 Y3 用以控制對應馬達的正轉及反轉,使外部電路形成互鎖,配

合 PLC 內部程式,確保任何異常突發狀況發生時,均有安全的保護措施。

DVP-**-**-**-T

LED

2

緊急停止

負載

觸

發

回

路

Y0

C0

電晶體輸出

< 0. 5A

3

電路回路保護用保險絲

જᏮቢ

DVP-10PM 差動輸出與伺服系列驅動器之詳細配線圖,請參閱英文版頁碼6 之[Figure 15

~ 17]。

Ѱ BAT.LOW ϯ፶

當電池電壓過低使 BAT.LOW 指示燈亮起時,請儘速更換電池以避免使用者程式及停電保

持資料消失。在電源下電後,停電保持區域的資料皆存放於 SRAM 記憶體中,此時由電

池提供維持 SRAM 內資料的電源,故當電池電力不足且下電後達 1 分鐘以上時,其程式

區與停電保持區之資料將會消失。因此,若程式設計者需將程式區與 D 裝置停電保持區做

永久保存時,請參照下述 Flash ROM 永久保持與回復機制。

ϖ˳ܲ፟טĈ

程式設計者可使用 PMSoft 軟體提供之設定選項(”設定”--> “PLC<=>Flash”)來指定程式

區及 D 裝置停電保持區的資料是否永久保持至 Flash ROM 記憶體中。每次指定後之資料

將會覆蓋掉前次存於 Flash ROM 內的所有資料。

аೇ፟טĈ

當電池電力不足(即電源下電前電池低電壓燈亮),且電源下電達 1 分鐘以上時,則 PLC

內部會在下次電源上電時,自動將 Flash ROM 內之程式區與D 裝置停電保持區的資料,

全部回存至 SRAM 記憶體中。

Ѱု

溫度 (°C) -30 0 25 50 70

壽命 (年) 10 9 8 6 5

- 11 -

Page 13

…………………………………………………………………… 简体中文 …………………………………………………………………

本使用说明书仅提供电气规格、功能规格及安装配线部份说明,其它详细的程序设计

及指令说明请见《DVP-PM 技术手册:程序篇》,选购外围装置详细说明请见该产品随

机手册或《DVP-PLC 应用技术手册:特殊模块篇》。

本机为开放型(OPEN TYPE)机种,因此使用者使用本机时,必须将其安装于具防尘、

防潮及免于电击/冲击意外的外壳配线箱内。另必须具备保护措施(如:特殊的工具

或钥匙才可打开)防止非维护人员操作或意外冲击本体,造成危险及损坏。

交流输入电源不可连接于输入/出信号端,否则可能造成严重损坏,请在上电之前再

次确认电源配线。请勿在上电时触摸任何端子。本体上的接地端子

务必正确的接

地,可提高产品抗干扰能力。

யݡγ៍ᄃొҜ

详细图示请参阅英文版页码1 之[Figure 1] 及[Figure 2]。

通讯口上盖

1

输入点指示灯

3

I/O 模块连接口上盖

5

功能卡/记忆卡上盖

7

DIN 轨固定扣

9

停止/执行开关

11

电池插槽

13

功能卡插槽

15

I/O 模块连接口

17

直接固定孔

19

输入/输出端子盖

2

输入/输出端子

4

输入/输出端子编号

6

输出点指示

8

COM2 通讯端口(RS-485)

10

COM1 通讯端口(RS-232)

12

电池

14

电源、运行、错误及电池状态指示灯

16

机身固定螺丝

18

详细尺寸图请参阅英文版页码1 的[Figure 3],单位:mm。

ঈఢ

电源电压

电源保险丝容量

消耗功率

DC24V 电流输出

电源保护 24 VDC 输出具短路保护

突波电压承受量

绝缘阻抗

干扰免疫力

接地

操作/储存环境

耐振动/冲击

重量(约 g)

100 ~ 240 VAC (-15 ~ 10%),50/60 Hz 5%

2A/250 VAC

60 VA

500 mA

1,500 VAC (Primary-secondary)

1,500 VAC (Primary-PE)

500 VAC (Secondary-PE)

5 MΩ 以上(所有输出/入点对地之间:500 VDC)

ESD: 8 kV Air Discharge, EFT: Power Line: 2 kV, Digital I/O: 1 kV, Analog &

Communication I/O: 250 V

接地配线的线径不得小于电源端 L, N 的线径(多台 PLC 同时使用时,请务

必单点接地)

操作:0 ~ 55°C(温度),50 ~ 95%(湿度),污染等级 2

储存:-25 ~ 70°C(温度),5 ~ 95%(湿度)

国际标准规范 IEC61131-2,IEC 68-2-6 (TEST Fc)/IEC61131- 2 & IEC

68-2-27 (TEST Ea)

612

- 12 -

Page 14

Ꮾˢᕇఢ

规格

项目

输入接线型式 独立接线

输入动作指示 LED 显示,灯亮表示为 ON,不亮表示为’OFF’

输入信号电压

最大输入电流值

输入点配置

动作位准

反应时间∕噪声抑制

#1:X0、X2、X4 及 X6 分别可为 XYZA 四轴 DOG 讯号,而 X1、X3、X5 及 X7 分别为 XYZA

#2:X10、X11为 手摇轮脉冲输入。

#3:X12、X13 仅接收差动脉冲讯号做为计数使用。

OffOn

OnOff

四轴 PG0 讯号。

双端差动输入 24 VDC 单端共点输入

200 kHz

由端子 S/S 变换接线为 SINK 或

5 ~ 24 VDC 24 VDC

15 mA 15 mA

X10+、X10-、X11+、X11-

X12+、X12-、X13+、X13-

#2

、

#3

20 μs

30 μs

0.5 μs

SOURCE

X0 ~ X7#1

Ꮾᕇఢ

规格

项目

最高交换(工作)频率

输出动作指示 LED 显示, 灯亮表示为’ON’, 不亮表示为’OFF’

输出点配置 Y10 ~ Y17#1 Y0 ~ Y3#2

工作电压 5 VDC 5 ~ 30 VDC

最大输出电流值

隔离方式 驱动级电源隔离 光耦合隔离

电流规格

最大输出延

迟时间

输出过电流保护 N/A

#1:Y10+、Y10-、Y12+、Y12-、Y14+、Y14-、Y16+、Y16-之正反转模式为正转方向脉冲输出;

Y11+、Y11-、Y13+、Y13-、Y15+、Y15-、Y17+、Y17-之正反转模式为反转方向脉冲输出;

#2:Y0 ~ Y3 为四组 PWM 输出;可作高速独立输出点使用。

电阻性 < 25 mA

电感性 --

灯泡 --

OffOn

OnOff

脉波⁄方向:脉波输出端;AB 相模式:A 相输出。

脉波⁄方向:方向输出端;AB 相模式:B 相输出。

双端差动输出

1 MHz 200 kHz

40 mA 40 mA

0.2 μs 0.2 μs

单端共点晶体管输出

高速

0.5 A/1 点(4A/COM)

12 W (24 VDC)

2 W (24 VDC)

щ྅ё

PLC 在安装时,请装配于封闭式的控制箱内,其周围应保持一定的空间,以确保 PLC 散

热功能正常,请参阅英文版页码 3 的配置示意图。

直接锁螺丝方式:请依产品外型尺寸并使用M4 螺丝。

DIN 铝轨的安装方法:适用于 35mm 的 DIN 铝轨。在将主机挂上铝轨时,请先将主机

(或 I/O 模块)下方的固定塑料片,以一字形起子插入凹槽并向外撑开拉出(请参阅英

文版页码 3 的图示),再将主机(或 I/O 模块)挂上铝轨,之后将固定塑料片压扣回去

即可。欲取下主机时,同样以一字形起子先将固定塑料片撑开,再将主机以往外向上的

- 13 -

Page 15

方式取出即可。该固定机构塑料片为保持型,因此撑开后便不会弹回去。

ቢბ

1. 输出/入配线端请使用 O 型或 Y 型端子,端子规格请参阅英文版页码 3 的图示。PLC 端

子螺丝扭力为 9.50 kg-cm (8.25 in-Ibs)。只能使用60/75°C 的铜导线。

2. 空端子请勿配线。输入点信号线与输出点等动力线请勿置于同一线槽内。

3. 锁螺丝及配线时请避免微小的金属导体掉入 PLC 内部,并在配线完成后,将位于 PLC

上方散热孔位置的防异物掉入的贴纸撕去,以保持散热良好。

ბ

DVP-10PM 系列 PLC 电源输入为交流输入,在使用上应注意下列事项:

1. 交流电源输入电压,范围大小(100 ~ 240 VAC),电源请接于 L、N 两端,如果将 AC110V

或 AC220V 接至+24 V 端或输入点端,将造成PLC 严重损坏,请使用者特别注意。

2. 主机及 I/O 模块的交流电源输入请同时作 On 或 Off 的动作。

3. 主机的接地端使用 1.6mm 以上的电线接地。

4. 当停电时间低于 10 ms 时,PLC 不受影响继续运转,当停电时间过长或电源电压下降

将使 PLC 停止运转,输出全部 Off,当电源恢复正常时,PLC 亦自动回复运转。(PLC

内部具有停电保持的辅助继电器及寄存器,使用者在作程序设计规划时应注意使用。)

5. +24 V 电源供应输出端,最大为 0.5 A,请勿将其它的外部电源连接至此端子。每个输

入点驱动电流必须 5 ~ 7 mA,若以 16 点输入计算,大约需 100 mA,因此+24 V 输出

给外部负载不可大于 400 mA。

щБቢаྮ

由于 PLC 控制许多装置,任一装置的动作可能都会影响其它装置的动作。因此任一装置

的故障都可能会造成整个自动控制系统失控,甚至造成危险。所以在电源端输入回路,建

议的保护回路配置图请参阅英文版页码 4 的[Figure 5]所示:

1

交流供应电源:100 ~ 240 VAC, 50/60Hz

3

紧急停止:为预防突发状况发生,设置紧急停止按钮,可在状况发生时,切断系统电源。

4

电源指示灯

6

电源回路保护用保险丝(2A)

8

直流供应电源输出:24 VDC,500 mA

Ꮾˢᕇ۞ቢ

输入点的接入信号为直流电源 DC 输入,DC 型式共有两种接法:漏型及源型,其定义与

输入点回路等效电路配线图,请参阅英文版页码 5 的[Figure 6]及[Figure7]。

જᏮˢ۞ቢ

DVP-10PM 系列之 X10 ~ X13 均为 5 ~ 24 VDC 高速输入电路(其余则为 DC24V 输入)。

此高速输入电路工作频率可达 200 kHz,主要是用以连接差动(双线式)LINE DRIVER

输出电路用。

差动输入的接线图(高速、高干扰时使用)

编码器输出 DVP-10PM 高速输入

A +

A

差动输出

A -

B +

B

B -

差动独立点使用传感器之接线图,请参考英文版页码 5 之[Figure 9]及[Figure 10]。

双绞线

2

断路器

5

交流电源负载

7

DVP PLC 主机本体

X10+

X10-

X11+

X11-

- 14 -

Page 16

Ꮾᕇ۞ቢ

T

晶体管(T)接点回路配线

详细配线图请参阅英文版页码 5 ~ 6 的[Figure 11 ~ 14]。

1

直流供应电源

因晶体管模块输出均为开集极输出(Open Collector),若 Y0/Y1 设定为脉冲式输出,为确

4

保晶体管模块能够动作正常,其输出负载电阻,必须维持输出电流大于0.1 A。

1. 二极管抑制:功率较小时使用(请参阅英文版页码 7 的[Figure 13])

2. 二极管+Zener 抑制:大功率及 On/Off 频繁时使用(请参阅英文版页码 7 的[Figure 14])

互斥输出:例如,将 Y4 与 Y5 用于控制对应马达的正转及反转,使外部电路形成互锁,配

5

合 PLC 内部程序,确保任何异常突发状况发生时,均有安全的保护措施。

DVP-**-**-**-

LED

负载

触

发

回

路

Y0

C0

晶体管输出

< 0.5 A

2

紧急停止

3

电路回路保护用保险丝

જᏮ۞ቢ

DVP-10PM 差动输出与伺服系列驱动器的详细配线图,请参阅英文版页码6 的[Figure 15

~ 17]。

Ѱ BAT.LOW ϯ፶

当电池电压过低使 BAT.LOW 指示灯将亮起时,请尽速更换电池以免使用者程序及停电保

持数据消失。在电源下电后,停电保持区域的数据皆存放于 SRAM 内存中,此时由电池

提供维持 SRAM 内资料的电源,故当电池电力不足且下电后达 1 分钟以上时,其程序区

与停电保持区的数据将会消失。因此,若程序设计者需将程序区与 D 装置停电保持区做永

久保存时,请参照下述 Flash ROM 永久保持与回复机制。

ϖ˳ܲᨚטĈ

程序设计者可使用 PMSoft 软件提供的设定选项(”设定”--> “PLC<=>Flash”)来指定程序

区及 D 装置停电保持区的数据是否永久保持至 Flash ROM 内存中。每次指定后的数据将

会覆盖掉前次存于 Flash ROM 内的所有数据。

аᲺᨚטĈ

当电池电力不足(即电源下电前电池低电压灯亮),且电源下电达 1 分钟以上时,则 PLC

内部会在下次电源上电时,自动将 Flash ROM 内的程序区与D 装置停电保持区的数据,

全部回存至 SRAM 内存中。

Ѱု

温度 (°C) -30 0 25 50 70

寿命 (年) 10 9 8 6 5

- 15 -

Loading...

Loading...