Page 1

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

18 Xinglong Road, Taoyuan District,

Taoyuan City 33068, Taiwan (R.O.C.)

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province, P.R.C. 215200

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C. 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

DVP02TK-S / DVP02TU-S

Temperature Control

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173, 5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55 11 3568-3855 / FAX: 55 11 3568-3865

Europe

Delta Electronics (Netherlands) B.V.

Eindhoven Ofce

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL: +31 (0)40-8003800 / FAX: +31 (0)40-8003898

DVP-0002220-02

*We reserve the right to change the information in this catalogue without prior notice.

Module Manual

2017-12-06

www.deltaww.com

Page 2

DVP02TK-S / DVP02TU-S

Temperature Control Module Manual

Chapter 1 Introduction

1.1 Specification ...................................................................................... 1-3

1.2 Dimensions (mm) .............................................................................. 1-7

1.2.1 DVP02TU-S .................................................................................. 1-7

1.2.2 DVP02TK-S .................................................................................. 1-8

1.3 Installation ........................................................................................ 1-9

1.4 Terminal arrangement ....................................................................... 1-9

1.5 Wiring Diagram ............................................................................... 1-10

1.6 LED Indicator Description ................................................................ 1-13

1.7 RS-485 Communication for DVP02TK-S Series ................................ 1-13

Chapter 2 Control Register

2.1 Control Registers ............................................................................... 2-2

2.1.1 List of the Control Registers ........................................................... 2-2

2.1.2 Basic Setup Page .......................................................................... 2-3

2.1.3 PID Setup Page ............................................................................ 2-6

2.1.4 Program Control Setup Page ........................................................... 2-8

2.1.5 Pattern0, 1 Setup Page .................................................................. 2-8

2.1.6 Pattern2, 3 Setup Page .................................................................. 2-9

2.1.7 Pattern4, 5 Setup Page ................................................................ 2-10

2.1.8 Pattern6, 7 Setup Page ................................................................ 2-11

2.2 Analog Input Description ................................................................. 2-12

2.3 Outputs ........................................................................................... 2-13

2.3.1 The output value varies with the PV value. ..................................... 2-13

2.3.2 Alarm Outputs ............................................................................ 2-13

2.4 ON/OFF Control Mode ...................................................................... 2-15

2.5 PID Control Mode ............................................................................ 2-16

2.6 Programmable SV Control Mode ...................................................... 2-20

2.7 ERROR LED Indicator ....................................................................... 2-20

i

Page 3

1

Chapter 1 Introduction

Table of Contents

1.1 Specification ...................................................................................... 1-3

1.2 Dimensions (mm) .............................................................................. 1-7

1.2.1 DVP02TU-S .................................................................................. 1-7

1.2.2 DVP02TK-S .................................................................................. 1-8

1.3 Installation ........................................................................................ 1-9

1.4 Terminal arrangement ....................................................................... 1-9

1.5 Wiring Diagram ............................................................................... 1-10

1.6 LED Indicator Description ................................................................ 1-13

1.7 RS-485 Communication for DVP02TK-S Series ................................ 1-13

1-1

Page 4

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_1

Thank you for using Delta DVP02TK-S/DVP02TU-S Temperature Control Module. To ensure a successful installation and

for safety reasons, please read this manual carefully before operating.

This manual contains important safety instructions.

Cette notice contient des instructions importantes concernant la sécurité.

Disconnect all sources of supply before servicing.

Couper toutes les sources d’alimentation avant de faire l’entretien et les réparations.

For use in a controlled environment. Refer to manual for environmental conditions.

Pour utilisation en atmosphère contrôlée. Consulter la notice technique.

Warning: proper ventilation is required to reduce the risk of hazardous or explosive gas buildup during indoor charging.

Avertissement : une ventilation adéquate est nécessaire afin de réduire les risques d’accumulation de gaz dangereux

ou explosifs durant la recharge à l’intérieur.

The analog input circuits shall not be connected to MAINS CIRCUIT for measuring or sensing and limited to SELV

circuit only.

The supply voltage and transistor (analog) outputs are SELV circuit and limited energy.

This is an OPEN TYPE module and therefore should be installed in an enclosure free of airborne dust, humidity, electric

shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key or

specific tools are required for operating the enclosure) in case danger and damage on the device may occur. Do not

touch any terminal when the power is on.

This manual provides you with the introductions on the specifications, installation, basic operations, setups and

temperature measurements.

Read this manual carefully and follow the instructions to avoid danger and damage to people and property.

DVP02TK-S series includes DVP02TKR-S, DVP02TKN-S and DVP02TKL-S. DVP02TU-S series inc ludes

DVP02TUR-S, DVP02TUN-S and DVP02TUL-S.

1-2

Page 5

_

1.1 Specification

Supply voltage 24VDC

Chapter 1 Introduction

DVP02TK-S/DVP02TU-S

Max. rated power

consumption

Connector Type European standard removable terminal block (Pin pitch: 3.5mm)

Operation/storage

temperature

Vibration/Shock

resistance

Connection to

DVP-PLC

I/O points

Input

Hardware Resolution 16 bits

CH1,

CH2

2.4W, supplied by external power source in compliance with UL61010-2-201 \ IEC61131-2

Operation: 0°C ~ 55°C (temperature), 5 ~ 95% (humidity), Pollution degree: 2

Storage: -25°C ~ 70°C (temperature), 5 ~ 95% (humidity), Attitude: up to 2000m;

For use in dry location only

International standards: IEC 61131-2, IEC 68-2-6 (TEST Fc) / IEC 61131-2 & IEC 68-2-27 (TEST

Ea)

The modules are numbered from 0 to 7 automatically by their distance from DVP-PLC. Max. 8

modules are allowed to connect to DVP-PLC and will not occupy any digital I/O points.

2 points of universals analog inputs (CH1, CH2), 2 analog outputs (OUT1, OUT2) or 4 digital

outputs (OUT1~OUT4)

General Analog Input

Thermal resistance: Pt100, JPt100, Pt1000, Ni100, Ni1000, Cu50, Cu100, GNi1000

Thermocouple : J, K, R, S, T, E, N, B, U, L, TXK (L), C, PL II

Voltage input: 0~+50mV, 0~+5V, 0~+10V

Current input: 0mA~+20mA, 4~+20 mA

1

Distance 100 meters

Input disconnection

detection

Analog

Digital

A/D Function Specification

Analog / Digital Voltage Input

Maximum rated input 0V~10V 0V~5V

Overall accuracy

(normal temperature)

Overall accuracy

(full temperature range)

OUT1~

OUT2

OUT1~

OUT4

Supported by exceeded temperature input range

Analog / Digital Output

Analog output, 12-bit: 0~+10V, 0/4~+20mA

4 channels digital output, 250VAC, 60Hz/24VDC, 2A, Relay

4 channels digital output, Voltage pulse output, 24VDC, 300mA

0.5%

1%

Hardware resolution 16 bits

1-3

Page 6

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_1

Input impedance 650KΩ

Analog / Digital Current Input

Maximum rated input 0mA~20mA 4mA~20mA

Overall accuracy

(normal temperature)

Overall accuracy

(full temperature range)

Hardware resolution 16 bits

Input impedance 249Ω

Analog / Digital Temperature Input

Maximum rated input Thermocouple Thermistor

Overall accuracy

(normal temperature)

Overall accuracy

(full temperature range)

Hardware resolution 24 bits

Input impedance 2MΩ

Analog sampling time (by channel)

0.5%

1%

0.4%

0.8%

Analog input type AI Thermocouple Thermistor Quick AI (0~10V)*2

Setting time (ms)

Conversion time (ms)

Response time (ms)

Response time = setting time + conversion time

*1. Compared to the response time of the thermocouple temperature, it needs two times of time for the thermistor

temperature to respond, since the thermistor channels require a temperature compensation.

*2. Since there is only one channel used, the time to stabilize the circuit is not required.

80 80 160 3

50 50 100 2

130 130 260 5

1-4

Page 7

_

DVP02TKL-S/DVP02TUL-S D/A Function Specification

Analog / Digital Voltage Output

Maximum rated input 0V~10V

Chapter 1 Introduction

Overall accuracy

0.5%

(normal temperature)

Overall accuracy

1%

(full temperature range)

Hardware resolution 12 bits

Allowable load impedance 1kΩ ~ 2MΩ at 0V~10V

Analog / Digital Current Output

Maximum rated output 0mA~20mA 4mA~20mA

Overall accuracy

0.5%

(normal temperature)

Overall accuracy

(full temperature range)

1%

(average number of 100

times)

Hardware resolution 12 bits

1

Allowable load impedance

Analog setup time (by channel)

Analog output type

Setting time (µs)

Conversion time (µs)

Response time (µs)

Response time = setting time + conversion time

≦550Ω

Voltage Current

100 250

500 500

600 750

1-5

Page 8

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_1

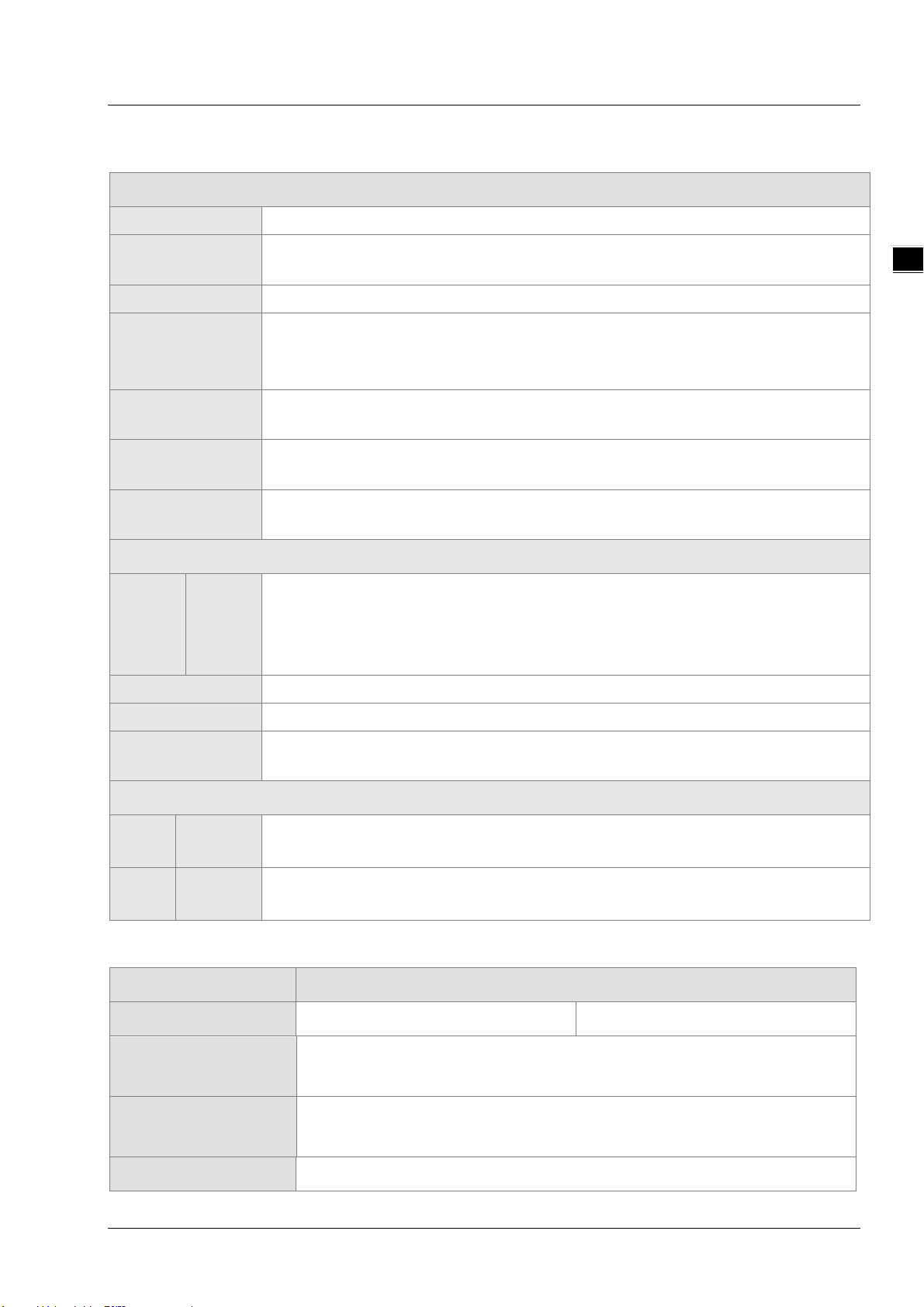

DVP02TKR-S/DVP02TUR-S/DVP02TKN-S/DVP02TUN-S DO Function Specification

Item

Model

DVP02TKR-S

DVP02TUR-S

DVP02TKN-S

DVP02TUN-S

Output points 4 4

Connector Type Removable terminal block

Output point type

Voltage specification

Maximum load

Below 250VAC, 30VDC 12~30VDC

Resistive

Inductive Life curves

Relay-R Transistor-T (NPN)

2A/1point

(3A/COM)

*1

*2, 4

7.2W (24VDC)

0.3A/1 point

(0.6A/COM)

Resistive 1Hz 100Hz

Maximum output

Inductive 0.5Hz 0.5Hz

frequency

Lamp 1Hz 10Hz

Maximum

OFF→ON

10ms 0.5ms

response time

*1

. Complied with UL61010-2-201 & IEC61131-2(AC or DC resistance)

*2

. Complied with UL61010-2-201 & IEC61131-2 (AC/DC general-use or AC pilot duty)

ON→OFF

*1

*3

Rated making capacity: 7.5A; rated breaking capacity: 0.75A; 2.5A thermal continuous at 240VAC

DC pilot duty; rated making capacity: 0.22A; rated breaking capacity: 0.22A; 1A thermal continuous at 30VDC

*3

. Complied with IEC/UL61010-2-201 (DC general-use)

*4

. Life curves

Disconnect power before servicing to avoid the risk of electric shock.

Utilisez relay est sous tension. Risque de choc électrique, couper le courant avant l’entretien.

120VAC Resi stive

30VDC Inductive(t=7ms)

240VAC I nd uct i ve(cos 0.4)

120VAC Ind uct i ve( cos =0.4 )

30VDC

Inductive

(t=40ms)

ψ

=

ψ

3

)

0

1

X

(

n

o

i

t

a

r

e

p

O

3000

2000

1000

500

300

200

100

50

30

20

0.1

0.2

0.5

0.3 0.7 1 2

Contact Current(A)

1-6

Page 9

_

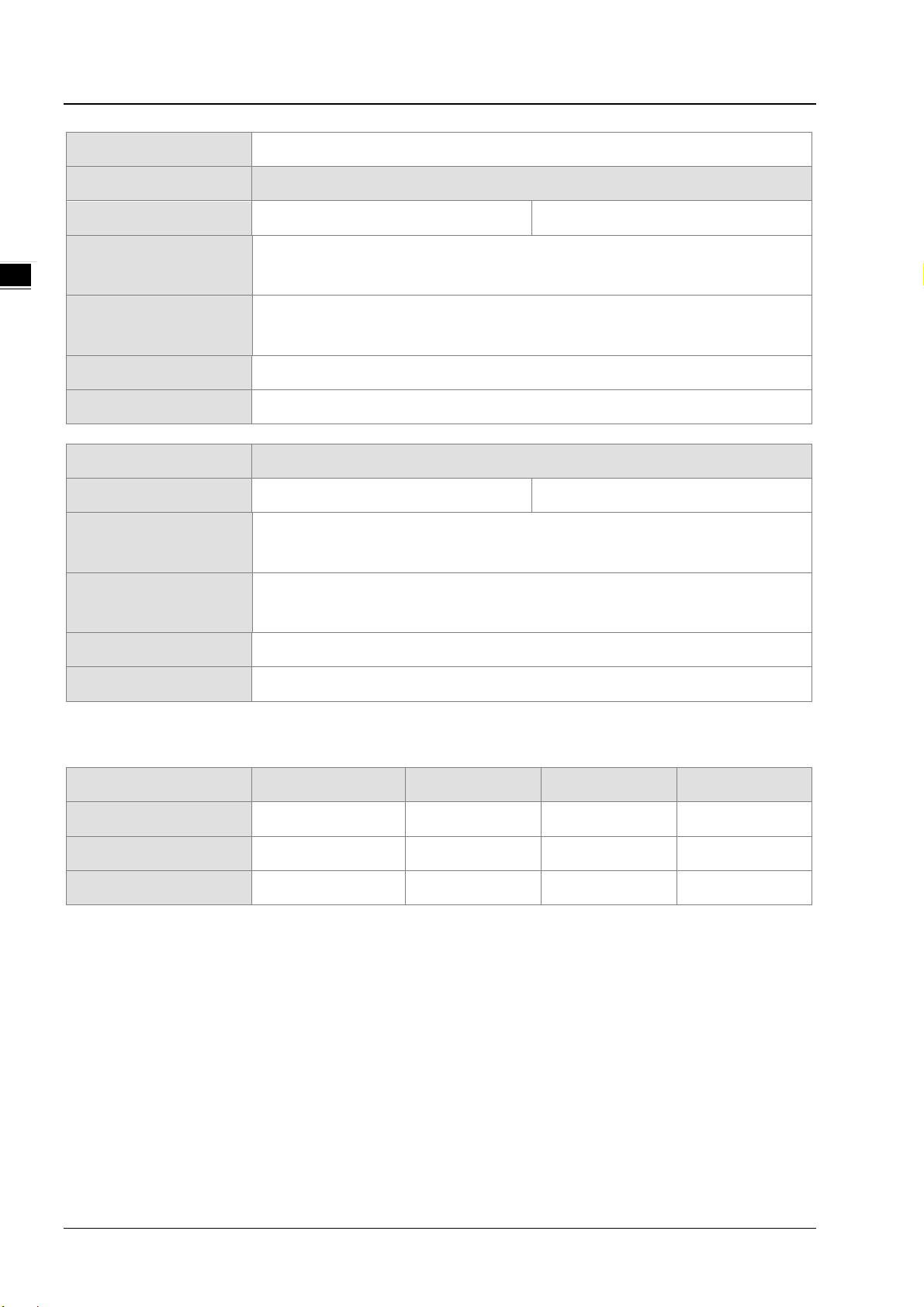

1.2 Dimensions (mm)

1.2.1 DVP02TU-S

Chapter 1 Introduction

25.20

3.00

1

3

90.00

2

DVP-02TU

4

3.00

1 Run/Error indicator

2 Model name

60.00

3.00

3.40

1

6

7

8

5

Description

60.00

3 Removable terminal block

4 I/O terminal layout

5 I/O module clip

6 I/O module connection port

7 Label

8 DIN rail clip

1-7

Page 10

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_1

1.2.2 DVP02TK-S

25.20

3.00

1

3

90.00

2

4

5

3.00

1 Run/Error indicator

2 Model name

3 Removable terminal block

4 I/O terminal layout

60.00

3.00

6

7

8

9

Description

3.40

60.00

10

11

5 Run/Stop switch

6 I/O module clip

7 I/O module connection port

8 Label

9 DIN rail clip

10 Power connection port

11 RS-485 communication port

1-8

Page 11

Chapter 1 Introduction

_

2TU-S

.

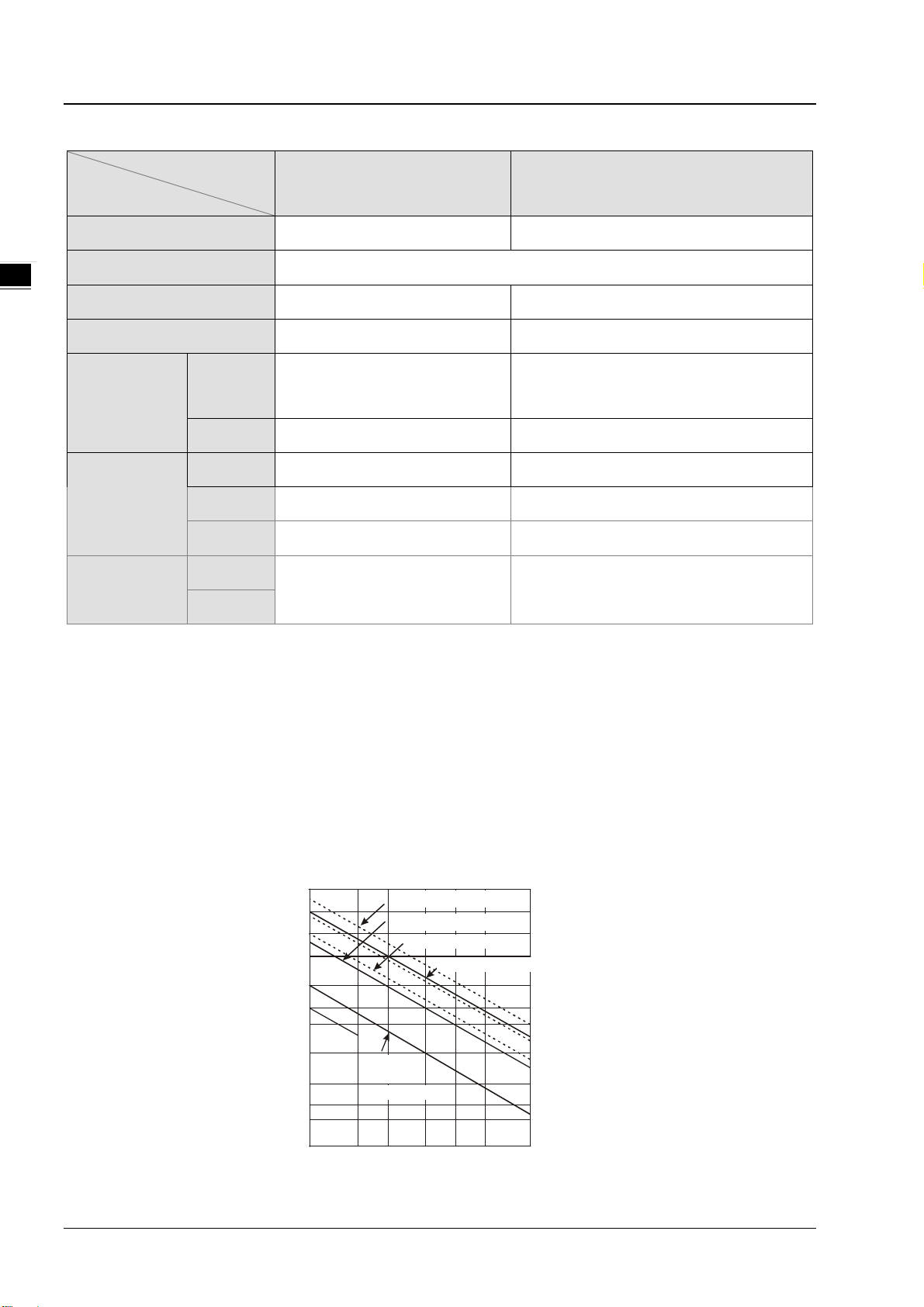

1.3 Installation

Users can connect DVP02TU-S series modules to the right side of the DVP02TK-S series modules as the image sho wn

below. Up to DVP02TU-S can be connected.

DVP02 TK- S

1

1.4 Terminal arrangement

DVP02TKR-S/DVP02TKN-S

DVP02TUR-S/DVP02TUN-S

L+

I+

CH1

L-

I-

L+

I+

CH2

L-

I-

SLD

.

OUT1

OUT2

C0

.

OUT3

OUT4

C1

.

DVP0

DVP02TKL-S/DVP02TUL-S

L+

I+

CH1

L-

I-

L+

I+

CH2

L-

I-

SLD

.

VO

IO

OUT1

AG

.

VO

IO

OUT2

AG

Warning: DO NOT connect wires to the terminals with No Connection (marked by a dot symbol ).

1-9

Page 12

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_1

Mounting Arrangements and Wiring Notes

How to install DIN rail

DVP-PLC can be secured to a cabinet by using the DIN rail of 35mm in height and

7.5mm in depth. When mounting PLC to DIN rail, be sure to use the end bracket to

stop any side-to-side movement of PLC and reduce the chance of wires being

loosen. A small retaining clip is at the bottom of PLC. To secure PLC to DIN rail,

place the clip onto the rail and gently push it up. To remove it, pull the retaining clip

down and gently remove PLC from DIN rail, as shown in the figure.

Please install PLC in an enclosure with sufficient space around it to allow heat dissipation as shown in the figure.

D

DD

DVP

MP

D

D > 50 mm

Warning: shock hazard. Only for mounting in a rack or enclosure fully enclosing all live parts.

Avertissement : risque d’électrocution. Ne doit être installé que dans un bâti ou un boîtier recouvrant entièrement toutes

les pièces sous tension.

1.5 Wiring Diagram

22-16AWG

<1.5mm

1. Use 22-16AWG (1.5mm) single or multiple core wire on I/O wiring terminals. The specification of the terminal is

shown in the figure above. The PLC terminal screws shall be tightened to 1.95 kg-cm (1.7 in-lbs).

2. DO NOT place the I/O signal wires and power supply wire in the same wiring duct.

3. Warning: use conductors with insulation rated for at least 75 °c

Avertissement : employer des conducteurs pour au moins 75 °c.

4. For use with copper conductors only (excluding thermocouplers).

destiné à être utilisé avec des conducteurs en cuivre seulement (sauf thermocouples).

1-10

Page 13

_

Sensor input wiring

Ni100/Ni1000/

LG-Ni1000/Cu50/Cu100

Pt10 0 /JPt100 /P t1000

2-Wire

Shielded

cable*1

CH1

L+

I+

L-

I-

SLD

AG

Chapter 1 Introduction

CurrentOutput

ADC

INA

1

Pt100/JPt100

/Pt1000

3-Wire

Shielded

cable*1

Voltage/Current input wiring

0mV~50mV,

0V~+5V,

0V~+10V

+

-

0mA~+20mA,

4mA~+20mA

+

-

Sh ielded

cabl e*1

CH2

CH 1

CH2

L+

I+

L-

I-

SLD

L+

I+

L-

I-

SL D

L+

I+

L-

I-

SL D

AG

Current Output

ADC

INA

AG

AG

1-11

Page 14

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_1

Thermocouple input wiring

Thermocouple

+

-

DVP02TKN-S/DVP02TUN-S Output point wiring

D

24VDC

+

D: 1N4001

Diode or equivalent com ponent

D

24VDC

+

D: 1N4001

Diode or equivalent com ponent

OUT1

OUT 2

C0

OUT3

OUT4

C1

L+

I+

L-

I-

SLD

Current Output

ADC

INA

AG

DVP02TKR-S/DVP02TUR-S Output point wiring

240V AC

OUT3

OUT4

C1

24V DC

OUT3

OUT4

C1

1-12

Page 15

_

DVP02TKL-S/DVP02TUL-S Output point wiring

e

c

e

*

c

e

*

Chapter 1 Introduction

0V~+10V

0mA ~+2 0m A,

4mA ~+20mA

RS-485 Wiring

Term inal

impedaan ce

(120 ohm)

OUT1

VO

IO

AG

OUT2

VO

IO

AG

Mast

D+ D- SG D+ D- SG SG D+ D-

r Sl ave S lave

AG

AG

CH1

1

CH2

Shielded

abl

1

Shielded

abl

1

1.6 LED Indicator Description

LED Indicator LED Color Description

POWER Green Power status

A/D Green Operating status

ERROR Red Error display

OUT1~OUT4 Red Output status

1.7 RS-485 Communication for DVP02TK-S Series

Data Transmission

Speed

Communication

Format

Communication

Protocool

Stop bit: 1, 2 Parity bit: None, Odd, Even Data bit: 7, 8

9,600; 19,200; 38,400; 57,600; 115,200bps

MODBUS ASCII/RTU

1-13

Page 16

2

Chapter 2 Control Register

Table of Contents

2.1 Control Registers ...................................................................... 2-2

2.1.1 MODBUS Address List for DVP02TK-S Series ................................ 2-2

2.1.2 MODBUS Hex Address List for DVP02TK-S Series .......................... 2-2

2.1.3 List of the Control Registers ....................................................... 2-3

2.1.4 Basic Setup Page ...................................................................... 2-5

2.1.5 PID Setup Page ........................................................................ 2-9

2.1.6 Program Control Setup Page .................................................... 2-11

2.1.7 Pattern0, 1 Setup Page ........................................................... 2-12

2.1.8 Pattern2, 3 Setup Page ........................................................... 2-13

2.1.9 Pattern4, 5 Setup Page ........................................................... 2-15

2.1.10 Pattern6, 7 Setup Page ......................................................... 2-16

2.2 Analog Input Description ........................................................ 2-17

2.3 Outputs .................................................................................. 2-19

2.3.1 The output value varies with the PV value. ................................. 2-19

2.3.2 Alarm Outputs ....................................................................... 2-19

2.4 ON/OFF Control Mode ............................................................. 2-21

2.5 PID Control Mode ................................................................... 2-22

2.6 Programmable SV Control Mode ............................................. 2-24

2.7 ERROR LED Indicator .............................................................. 2-25

2.8 RS-485 Communication Setup for DVP02TK-S ........................ 2-25

2.8.1 MODBUS Communication Protocol ............................................. 2-25

2.8.2 Restore to Factory Settings ...................................................... 2-25

2.8.3 RS-485 Communication Setup .................................................. 2-25

2.9 TK Wizard – Connection Setup ................................................ 2-28

2.9.1 Restore to Factory Settings for DVP02TK-S ................................ 2-28

2.9.2 COMMGR Set Up .................................................................... 2-28

2.9.3 Settings in TKSoft .................................................................. 2-28

2.9.4 TKSoft – Scan the Connected Devices ....................................... 2-29

2-1

Page 17

DVP02TK-S/DVP02TU-S Temper ature Control Module Manual

_2

Number of connected

Detecting number of the extension modules

Code of the 1st module on the right side of

Code of the 2nd module on the right side of

Code of the 4th module on the right side of

Code of the 5th module on the right side of

Code of the 6th module on the right side of

TK series

Code of the 7th module on the right side of

Code of the 8th module on the right side of

TK series

Refer to sections for setting up the RS -485

2.1 Control Registers

2.1.1 MODBUS Address List for DVP02TK-S Series

MODBUS Address Description

H0000 TK series, CR#0: starting address

H1000 The 1st module on the right side of TK series, CR#0: starting address

H2000 The 2nd module on the right side of TK series, CR#0: starting address

H3000 The 3rd module on the right side of TK series, CR#0: starting addr es s

H4000

H5000

H6000

H7000

H8000

th

module on the right side of TK series, CR#0: starting addr es s

The 4

th

module on the right side of TK series, CR#0: starting addr es s

The 5

th

module on the right side of TK series, CR#0: starting addr es s

The 6

th

module on the right side of TK series, CR#0: starting addr es s

The 7

th

module on the right side of TK series, CR#0: starting addr es s

The 8

2.1.2 MODBUS Hex Address List for DVP02TK-S Series

Address

(Hex)

0F00 R X

0F01 R X Code of the 1

0F02 R X Code of the 2nd module

0F03 R X Code of the 3rd module

0F04 R X Code of the 4th module

Attribute Name Description Default

extension modules

st

module

connected to the right side of the TK s eries

TK series

TK series

Code of the 3rd module on the right side of

TK series

TK series

--

--

--

--

--

0F05 R X

0F06 R X

0F07 R X

0F08 R X

0F09 R/W O RS-485 c om munication setup

0F0A R/W X Reserved

0F0B R/W O RS-485 communic ation format

0F0C R/W O TK station number TK station number setup K1

0F0D R/W X TK operation

2-2

Code of the 5th module

Code of the 6th module

Code of the 7th module

Code of the 8th module

TK series

TK series

communication mode

0:ASCII / 1:RTU

0:Stop / 1:Run

--

--

--

--

K0

K0

--

Page 18

2_

2.1.3 List of the Control Registers

setups to

CH2 setups to

Setups to switch

Chapter 2 Control Register

TU

CR#

#0

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

TK

Add.

(Hex)

009

00A

Attribute Name Description Default

000

001

002

003

004

005

006

007

008

R O Model

R O Firmware version

R O CH1 PV

R O CH2 PV

R/W O CH1 SV setups

R/W O CH2 SV setups

R/W X

R/W X

R/W X CH1 Auto tuning

R/W X CH2 Auto tuning

R/W X

CH1

run/stop an operation

run/stop an operation

pages

By default, users can see the model name in the

program and determine whether there is any

extension module.

DVP02TUL-S: H014F

DVP02TUN-S: H024F

DVP02TUR-S: H034F

DVP02TKL-S: H044F

DVP02TKN-S: H054F

DVP02TKR-S: H064F

Hexadecimal, displaying the curr ent firmware

version, for example the current firmware is 1.02 and

it will display H’0102.

Channel current value --

Channel target value K0

K0: stop

K1: run

K2: pause (programmable)

K0: Auto control mode

K1: Auto adjust mode, after adjusting it will switch to

the auto control mode and input the most suitable

parameters, e.g., Kc_Kp, Ti_Ki, Td_Kd and Tf.

CR#11~CR#42: Definitions may vary according to

different setups on the specifi c page.

K0: Basic setup page for CH1

K1: PID setup page for CH1

K2: Program control setup page for CH1

K3: Pattern 0, 1 setup page for CH1

K4: Pattern 2, 3 setup page for CH1

K5: Pattern 4, 5 setup page for CH1

K6: Pattern 6, 7 setup page for CH1

K10: Basic setup page for CH2

K11: PID setup page for CH2

K12: Program control setup page for CH2

K13: Pattern 0, 1 setup page for CH2

K14: Pattern 2, 3 setup page for CH2

K15: Pattern 4, 5 setup page for CH2

--

--

K0

K0

K0

2-3

Page 19

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

According to each

TU

CR#

#11~

#42

--

--

--

--

--

--

--

--

--

--

--

--

--

--

#43

#45

TK

Add.

(Hex)

--

00B

02B

04B

06B

08B

0AB

0CB

0EB

10B

12B

14B

16B

18B

1AB

24B

24D

Attribute Name Description Default

K16: Pattern 6, 7 setup page for CH2

R/W X

R/W -- Page0 Basic setup page for CH1 --

R/W -- Page1 PID setup page for CH1 --

R/W -- Page2 Program control setup page for CH1 --

R/W O Page3 Pattern 0, 1 setup page for CH1 --

R/W O Page4 Pattern 2, 3 setup page for CH1 --

R/W O Page5 Pattern 4, 5 setup page for CH1 --

R/W O Page6 Pattern 6, 7 setup page for CH1 --

R/W O Page10 Basic setup page for CH2 --

R/W O Page11 PID setup page for CH2 --

R/W O Page12 Program control setup page for CH2 --

R/W O Page13 Pattern 0, 1 setup page for CH2 --

R/W O Page14 Pattern 2, 3 setup page for CH2 --

R/W O Page15 Pattern 4, 5 setup page for CH2 --

R/W O Page16 Pattern 6, 7 setup page for CH2 --

X Error code Please refer to error code descriptions. K0

R/W X User-defined

setup page

Please refer to each setup page. K0

0x0501: Restore to defaults

0x0502: Settings written on flash

0x0504: RS-485 mode and latched

(parameter/mode/station number)

0x51CC: Manually export

0x51DD:Auto export

(the PID will be invalid after switc hing to manually

export mode.)

CR control can be set up by the analog output of

DVP02TUL-S/DVP02TKL-S and the digital output of

/DVP02TUN-S/DVP02TKR-S/DVP02TKN-S.

DVP02TUL-S/DVP02TKL-S:

K0

#46

#47

Symbols: O: Latched. X: Non-latched.

2-4

24E

24F

CR#4: CH1 analog output value range K0~K4000

CR#5: CH2 analog output value range K0~K4000

DVP02TUR-S/DVP02TUN-S/DVP02TKR-S/DVP02

TKN-S:

CR#4 (bit0/bit1): CH1 digital output Y0/Y1

CR#5 (bit0/bit1): CH2 digital output Y2/Y3

R O CH1 display value

R O CH2 display value

The display value is the measured value after being

rounded off or the value set to be displayed for the

channels.

Page 20

Chapter 2 Control Register

2_

TU

CR#

R: Able to read data by FROM instruct ion. W: Able to write data by TO instruc tion.

TK

Add.

(Hex)

Bit0 Power Supply abnormal Abnormal Normal

Bit1 Hardware abnormal Abnormal Normal

Bit2 CH1 conversion error Abnormal Normal

Bit3 CH2 conversion error Abnormal Normal

Bit4 CH1 circuit control abnormal Abnormal Normal

Bit5 CH2 circuit control abnormal Abnormal Normal

Bit6 Manually / Auto Output Manually Output Auto Output

Bit7-15 Reserved

Attribute Name Description Default

Error Code 1 0

2.1.4 Basic Setup Page

TU

CR#

#11

TK CH1

Page0

Add. (Hex)

00B 0EB

TK CH2

Page10

Add. (Hex)

Attribute Name Description Default

K-1: Channel closed

K0: 0 ~ 5V

K1: 0~10V

K2: 0 ~ 20mA

K3: 4 ~ 20mA

K4: 0 ~ 50mV

K5: Pt100

K6: JPt100

K7: Pt1000

K8: J

R/W O Sensor type

K9: K

K10: R

K11: S

K12: T

K13: E

K14: N

K15: B

K16: L

K17: U

K18: TXK

K19: C

K20: PL II

K0

2-5

Page 21

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

Temperature filter ranging

10 of the last inputted

value, the system will run the

Output 2

TU

CR#

#12

#13

#14

#15

#16

#17

#18

TK CH1

Page0

Add. (Hex)

00C 0EC

00D 0ED

00E 0EE

00F 0EF

010 0F0

011 0F1

012 0F2

TK CH2

Page10

Add. (Hex)

Attribute Name Description Default

K21: Cu50

K22: Cu100

K23: Ni100

K24: Ni1000

K25: LGNi1000

K26: 0~10V (Quick AI)

O

K0:

R/W O

R/W O

R/W O

R/W O Filtering factor

R/W O Control type

R/W O Output 1 control

R/W O

Unit of

temperature

Offset

temperature

error

Temperature

filter range

C

O

K1:

F

K-999 ~ K999 K0

10~10000

When the value inputted is in the

range of ±

filtering measurement. Hence, when

the noise interference is bigger, the

filter range should set to bigger too.

Ranging 0~50.

Operational formula: value = (last

value*n + this measurement ) / (n+1)

When the set value is less, the PV

will be closer to this measurement.

When the set value is bigger, the

filtering factor will be bigger and the

PV will be similar.

K0: PID Auto

K1: PID Manual

K2: PID program control

K3: ON/OFF

(for DVP02TUR-S/DVP02TUN-S/

DVP02TKR-S/DVP02TKN-S)

K0: Heating

K1: Cooling

K2: Alarm

(for DVP02TUR-S /DVP02TUN-S/

DVP02TKR-S /DVP02TKN-S)

K3: Proportion (for DVP02TUL-S/

DVP02TKL-S)

K0: Heating K0

K10

K0

K1

K0

K0

2-6

Page 22

Chapter 2 Control Register

2_

and when the reading is 1000, the

TU

CR#

#21

#23

#24

#25 R/W O Alarm 1 output

#26 R/W O Alarm 2 output K0

#27

#28

#29

#30

#32

#33

TK CH1

Page0

Add. (Hex)

015 0F5

TK CH2

Page10

Add. (Hex)

Attribute Name Description Default

control K1: Cooling

K2: Alarm

Note: not for DVP02TUL-S/

DVP02TKL-S

K0: cyclic output

K1: immediately output

DVP02TUN-S/ DVP02TKN-S:

R/W O Output setup

Output 1:

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

heating/cooling

control cycle

setup

Output 2:

heating/cooling

control cycle

setup

Alarm output 1

upper-limit

setup

Alarm output 1

lower-limit

setup

Alarm output 2

upper-limit

setup

Alarm output 2

lower-limit

setup

PV upper-limit

setup for a

corresponding

output

PV lower-limit

setup for a

corresponding

K0 (default)

DVP02TUR-S/ DVP02TKR-S:

K1 (default)

Note: not available for

DVP02TUL-S/DVP02TKL-S

DVP02TUN-S/ DVP02TKN-S:

1~990 at 0.1 per second, default:

K10.

DVP02TUR-S/ DVP02TKR-S:

30~990 at 0.1 per second (default)

Note: not available for

DVP02TUL-S/DVP02TKL-S.

K0~K12, please refer to the error

code description.

Note: not available for

DVP02TUL-S/DVP02TKL-S.

For DVP02TUL-S series

When the input value varies, the

corresponding output will vary

accordingly. Take 4~20mA as an

example, and set the upper-limit to

1000, lower-limit to 0; when the

reading is 0, the output will be 4mA

K0/K1

K10

K30

K1000

K0

K0

K0

K0

K0

K0

2-7

Page 23

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

TU

CR#

#34

#35

#36

#37

#38

#39

#40

TK CH1

Page0

Add. (Hex)

TK CH2

Page10

Add. (Hex)

Attribute Name Description Default

output output will be 20mA. When set it to

a negative slope, and set the range

to 0~1000; when the reading is 0,

the output will be 20mA and when

the reading is 1000, the output will

be 4mA.

R/W X

R/W O

R/W O

R/W O

R/W O

R/W O

R X Outputting

For system

usage

Heating

hysteresis

setup

Cooling

hysteresis

setup

Analog output

mode

Out of the LED

setting range

Dead band

setup for dual

outputs

X

ON-OFF

(For DVP02TUN-S / DVP02TUR-S

/ DVP02TKN-S / DVP02TKR-S)

For DVP02TUL-S / DVP02TKL-S

K0: 0~10V

K1: 0~20mA

K2: 4~20mA

K0=LED blinking

K1=LED not blinking

Setting range: -32768~32767

Note: not for DVP02TUL-S /

DVP02TKL-S

DVP02TUL-S / DVP02TKL-S:

analog output value 0~4000

DVP02TUN-S/DVP02TUR-S/DVP0

2TKN-S/DVP02TKR-S:

K10

K10

K0

K0

K0

--

Bit0: Digital output point, OUT1

Bit1: Digital output point OUT2

#41

Symbols: O: Latched. X: Non-latched.

R: Able to read data by FROM instruct ion. W: Able to write data by TO instruc tion.

R O

Set up the

display value

for the channel.

If the preset value (PV) is bigger

than the display value, set the PV

to be the same as the display

value, ranging from 0~100.

2-8

K2

Page 24

2_

2.1.5 PID Setup Page

0~100, and the unit is 0.01.

#14-

otherwise the present error will be

Chapter 2 Control Register

TU

CR#

#11

#12

#13

#17

#18 032 112

#19 033 113

#20 034 114

TK CH1

Page1

Add. (Hex)

02B 10B

02C 10C

02D 10D

Reserved

TK CH2

Page11

Add. (Hex)

Attribute Name Description Default

K0:Normal, the value of MOUT

won’t be changed with the value of

R/W O MOUT_AUTO

R/W O MOUT

R/W O α value

R/W O PID_EQ

R/W O PID_DE

R/W O ERR_DBW

MV.

K1:Auto, the value of MOUT will be

changed with the value of MV.

When set to PID Manual, the MV

value will be outputted as the

manually set MOUNT value,

between MV_MAX and MV_MIN.

Adjust the interface setup range

PID formula types

0: Independent Formula

1: Dependent Formula

The calculation of the PID

derivative error

1: Using the variations in the PV t o

calculate the control value of the

derivative (Derivative of the PV) .

0: Using the variations in the error

(E) to calculate the control value of

the derivative (Derivative of the

error).

Error dead bandwidth: Range

within which an error (E) is 0. An

error (E) is equal to SV−PV or

PV-SV. If the setting value is 0, the

function will not be enabled;

otherwise the CPU module will

check whether the present error is

less than the absolute value of

ERR_DBW, and check whether the

present error meets the cross

status condition. If the present error

is less than the absolute value of

ERR_DBW, and meets the cross

status condition, the present error

will be count as 0, and the PID

algorithm will be implemented,

K65

K0

K0

K0

K0

K0

2-9

Page 25

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

PID working:

#26

03A

11A

R/W O β value

K0 ~ K100 and the unit is 0.1%.

K65

TU

CR#

#21 035 115

#22 036 116

#23 037 117

#24 038 118

#25 039 119 R/W O

TK CH1

Page1

Add. (Hex)

TK CH2

Page11

Add. (Hex)

Attribute Name Description Default

R/W O BIAS

R/W X MV

R/W X

R/W X

I_MV(Low

word)

I_MV(High

word)

AUTO Tuning

(PID

hysteresis)

brought into the PID algorithm

according to the normal

processing.

Feedforward output value, used for

the PID feedforward.

The MV output value is 0~K1000

and the unit is 0.1%.

Accumulated integral value

temporarily stored is usually f or

reference. Users can still clear or

modify it according to their needs.

When the MV is greater than the

MV_MAX, or when the MV is less

than MV_MIN, the accumulated

integral value in I_MV is

unchanged.

Accumulated integral value

temporarily stored is usually f or

reference. Users can still clear or

modify it according to their needs.

When the MV is greater than the

MV_MAX, or when the MV is less

than MV_MIN, the accumulated

integral value in I_MV is

unchanged.

SV - PID Range < PV < SV +

PID Range

K0

--

--

--

K8

#27 03B 11B R/W O

#28 03C 11C R/W O

#29 03D 11D R/W O

#30 03E 11E R/W O

#31 03F 11F R/W O

#32 040 120 R/W O

2-10

Kc_Kp floating

point format

(Lo word)

Kc_Kp floating

point format

(Hi word)

Ti_Ki floating

point format

(Lo word)

Ti_Ki floating

point format

(Hi word)

Td_Kd floating

point format

(Lo word)

Td_Kd floating

point format

(Hi word)

Calculated proportional coefficient

(Kc or Kp)

If the P coefficient is less than 0,

the Kc_Kp will be 0. Independentl y,

if Kc_Kp is 0, it will not be

controlled by P.

Integral coefficient (Ti or Ki)

If the calculated coefficient I is l es s

than 0, Ti_Ki will be 0. If Ti_Ki is 0,

it will not be controlled by I.

Derivative coefficient (Td or Kd)

If the calculated coefficient D is less

than 0, Td_Kd will be 0. If Ti_Ki is

0, it will not be controlled by D.

K100

K10

-1

Page 26

Chapter 2 Control Register

2_

Tf floating point

TK CH1

TK CH2

Pattern6_ set up for the

TU

CR#

#33 041 121 R/W O

#34 042 122 R/W O

#35 043 123 R/W O

Symbols: O: Latched. X: Non-latched.

R: Able to read data by FROM instruct ion. W: Able to write data by TO instruction.

TK CH1

Page1

Add. (Hex)

TK CH2

Page11

Add. (Hex)

Attribute Name Description Default

format

(Lo word)

Tf floating point

format

(Hi word)

Default integral

coefficient

Derivate-action time constant (TF)

If the derivate-action time constant

is less than 0, Tf will be 0 and it will

not be controlled by the

derivate-action time constant.

(Derivative Smoothing)

0~10000 K1000

2.1.6 Program Control Setup Page

TU

CR#

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

#21

#22

#23

Page2

Address

(Hex)

04B 12B

04C 12C

04D 12D

04E 12E

04F 12F

050 130

051 131

052 132

053 133

054 134

055 135

056 136

057 137

Page12

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R X

R X

R X

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Name Description Default

Pattern number to start

running

Step number to start

running

The Cycle index of the

Pattern number 0~7 to

repeat running

Read the current running

pattern number

Read the current running

step number

Read the step running

time left

Pattern0_set up for the

max. step number to run

Pattern1_ set up for the

max. step number to run

Pattern2_ set up for the

max. step number to run

Pattern3_ set up for the

max. step number to run

Pattern4_ set up for the

max. step number to run

Pattern5_ set up for the

max. step number to run

0~7 K0

0~7 K0

K0~K99 indicates the running

times of the Pattern has

reached 100

0~8 (8 indicates ending) K0

0~7 K0

Unit (seconds) K0

0~7 K0

0~7 K0

0~7 K0

0~7 K0

0~7 K0

0~7 K0

0~7 K0

1

K0

2-11

Page 27

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

TK CH1

TK CH2

TU

CR#

#24

#25

#26

Page2

Address

(Hex)

058 138

059 139

05A 13A

Page12

Address

(Hex)

Attribute

R/W O

R X

R/W O

max. step number to run

Pattern7_ set up for the

max. step number to run

The current cycle index

number of the Pattern

number 0~7 to repeat

running

Temperature hysteresis

setup

2.1.7 Pattern0, 1 Setup Page

TU

CR#

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

#21

#22

#23

#24

#25

#26

#27

TK CH1

Page3

Address

(Hex)

06B 14B

06C 14C

06D 14D

06E 14E

06F 14F

070 150

071 151

072 152

073 153

074 154

075 155

076 156

077 157

078 158

079 159

07A 15A

07B 15B

TK CH2

Page13

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Pattern0-0 Target temperature Range: -32768~32767

Pattern0-1 Target temperature Range: -32768~32767

Pattern0-2 Target temperature Range: -32768~32767

Pattern0-3 Target temperature Range: -32768~32767

Pattern0-4 Target temperature Range: -32768~32767

Pattern0-5 Target temperature Range: -32768~32767

Pattern0-6 Target temperature Range: -32768~32767

Pattern0-7 Target temperature Range: -32768~32767

Pattern0-0 Running time

Pattern0-1 Running time

Pattern0-2 Running time

Pattern0-3 Running time

Pattern0-4 Running time

Pattern0-5 Running time

Pattern0-6 Running time

Pattern0-7 Running time

Pattern1-0 Target temperature Range: -32768~32767

Name Description Default

0~7 K0

0~7 K0

0~999 (unit: 0.1) K0

Name Description Default

K0

K0

K0

K0

K0

K0

K0

K0

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

K0

K0

K0

K0

K0

K0

K0

K0

K0

2-12

Page 28

Chapter 2 Control Register

2_

TK CH1

TK CH2

TU

CR#

#28

#29

#30

#31

#32

#33

#34

#35

#36

#37

#38

#39

#40

#41

#42

TK CH1

Page3

Address

(Hex)

07C 15C

07D 15D

07E 15E

07F 15F

080 160

081 161

082 162

083 163

084 164

085 165

086 166

087 167

088 168

089 169

08A 16A

TK CH2

Page13

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Name Description Default

Pattern1-1 Target temperature Range: -32768~32767

Pattern1-2 Target temperature Range: -32768~32767

Pattern1-3 Target temperature Range: -32768~32767

Pattern1-4 Target temperature Range: -32768~32767

Pattern1-5 Target temperature Range: -32768~32767

Pattern1-6 Target temperature Range: -32768~32767

Pattern1-7 Target temperature Range: -32768~32767

Pattern1-0 Running time

Pattern1-1 Running time

Pattern1-2 Running time

Pattern1-3 Running time

Pattern1-4 Running time

Pattern1-5 Running time

Pattern1-6 Running time

Pattern1-7 Running time

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

2.1.8 Pattern2, 3 Setup Page

TU

CR#

#11

#12

#13

#14

#15

#16

#17

#18

#19

Page4

Address

(Hex)

08B 16B

08C 16C

08D 16D

08E 16E

08F 16F

090 170

091 171

092 172

093 173

Page14

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Pattern2-0 Target temperature Range: -32768~32767

Pattern2-1 Target temperature Range: -32768~32767

Pattern2-2 Target temperature Range: -32768~32767

Pattern2-3 Target temperature Range: -32768~32767

Pattern2-4 Target temperature Range: -32768~32767

Pattern2-5 Target temperature Range: -32768~32767

Pattern2-6 Target temperature Range: -32768~32767

Pattern2-7 Target temperature Range: -32768~32767

Pattern2-0 Running time

Name Description Default

K0

K0

K0

K0

K0

K0

K0

K0

Range: 0~90 Unit

(minutes)

K0

2-13

Page 29

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

TK CH1

TK CH2

TU

CR#

#20

#21

#22

#23

#24

#25

#26

#27

#28

#29

#30

#31

#32

#33

#34

#35

#36

#37

#38

#39

#40

#41

#42

Page4

Address

(Hex)

094 174

095 175

096 176

097 177

098 178

099 179

09A 17A

09B 17B

09C 17C

09D 17D

09E 17E

09F 17F

0A0 180

0A1 181

0A2 182

0A3 183

0A4 184

0A5 185

0A6 186

0A7 187

0A8 188

0A9 189

0AA 18A

Page14

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Name Description Default

Pattern2-1 Running time

Pattern2-2 Running time

Pattern2-3 Running time

Pattern2-4 Running time

Pattern2-5 Running time

Pattern2-6 Running time

Pattern2-7 Running time

Pattern3-0 Target temperature Range: -32768~32767

Pattern3-1 Target temperature Range: -32768~32767

Pattern3-2 Target temperature Range: -32768~32767

Pattern3-3 Target temperature Range: -32768~32767

Pattern3-4 Target temperature Range: -32768~32767

Pattern3-5 Target temperature Range: -32768~32767

Pattern3-6 Target temperature Range: -32768~32767

Pattern3-7 Target temperature Range: -32768~32767

Pattern3-0 Running time

Pattern3-1 Running time

Pattern3-2 Running time

Pattern3-3 Running time

Pattern3-4 Running time

Pattern3-5 Running time

Pattern3-6 Running time

Pattern3-7 Running time

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

2-14

Page 30

2_

2.1.9 Pattern4, 5 Setup Page

TK CH1

TK CH2

Chapter 2 Control Register

TU

CR#

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

#21

#22

#23

#24

#25

#26

#27

#28

#29

#30

#31

#32

#33

#34

#35

#36

#37

Page5

Address

(Hex)

0AB 18B

0AC 18C

0AD 18D

0AE 18E

0AF 18F

0B0 190

0B1 191

0B2 192

0B3 193

0B4 194

0B5 195

0B6 196

0B7 197

0B8 198

0B9 199

0BA 19A

0BB 19B

0BC 19C

0BD 19D

0BE 19E

0BF 19F

0C0 1A0

0C1 1A1

0C2 1A2

0C3 1A3

0C4 1A4

0C5 1A5

Page15

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Name Description Default

Pattern4-0 Target temperature Range: -32768~32767

Pattern4-1 Target temperature Range: -32768~32767

Pattern4-2 Target temperature Range: -32768~32767

Pattern4-3 Target temperature Range: -32768~32767

Pattern4-4 Target temperature Range: -32768~32767

Pattern4-5 Target temperature Range: -32768~32767

Pattern4-6 Target temperature Range: -32768~32767

Pattern4-7 Target temperature Range: -32768~32767

Pattern4-0 Running time

Pattern4-1 Running time

Pattern4-2 Running time

Pattern4-3 Running time

Pattern4-4 Running time

Pattern4-5 Running time

Pattern4-6 Running time

Pattern4-7 Running time

Pattern5-0 Target temperature Range: -32768~32767

Pattern5-1 Target temperature Range: -32768~32767

Pattern5-2 Target temperature Range: -32768~32767

Pattern5-3 Target temperature Range: -32768~32767

Pattern5-4 Target temperature Range: -32768~32767

Pattern5-5 Target temperature Range: -32768~32767

Pattern5-6 Target temperature Range: -32768~32767

Pattern5-7 Target temperature Range: -32768~32767

Pattern5-0 Running time

Pattern5-1 Running time

Pattern5-2 Running time

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~90 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~90 Unit

(minutes)

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

2-15

Page 31

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

TK CH1

TK CH2

TU

CR#

#38

#39

#40

#41

#42

Page5

Address

(Hex)

0C6 1A6

0C7 1A7

0C8 1A8

0C9 1A9

0CA 1AA

Page15

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

Pattern5-3 Running time

Pattern5-4 Running time

Pattern5-5 Running time

Pattern5-6 Running time

Pattern5-7 Running time

2.1.10 Pattern6, 7 Setup Page

TU

CR#

#11

#12

#13

#14

#15

#16

#17

#18

#19

#20

#21

#22

#23

#24

#25

#26

TK CH1

Page6

Address

(Hex)

0CB 1AB

0CC 1AC

0CD 1AD

0CE 1AE

0CF 1AF

0D0 1B0

0D1 1B1

0D2 1B2

0D3 1B3

0D4 1B4

0D5 1B5

0D6 1B6

0D7 1B7

0D8 1B8

0D9 1B9

0DA 1BA

TK CH2

Page16

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Pattern6-0 Target

temperature

Pattern6-1 Target

temperature

Pattern6-2 Target

temperature

Pattern6-3 Target

temperature

Pattern6-4 Target

temperature

Pattern6-5 Target

temperature

Pattern6-6 Target

temperature

Pattern6-7 Target

temperature

Pattern6-0 Running time Range: 0~90 Unit (minutes)

Pattern6-1 Running time Range: 0~90 Unit (minutes)

Pattern6-2 Running time Range: 0~90 Unit (minutes)

Pattern6-3 Running time Range: 0~90 Unit (minutes)

Pattern6-4 Running time Range: 0~90 Unit (minutes)

Pattern6-5 Running time Range: 0~90 Unit (minutes)

Pattern6-6 Running time Range: 0~90 Unit (minutes)

Pattern6-7 Running time Range: 0~90 Unit (minutes)

Name Description Default

Range: 0~90 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Range: 0~900 Unit

(minutes)

Name Description Default

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

2-16

Page 32

Chapter 2 Control Register

2_

TK CH1

TU

CR#

#27

#28

#29

#30

#31

#32

#33

#34

#35

#36

#37

#38

#39

#40

#41

#42

Symbols: O: Latched. X: Non-latched.

R: Able to read data by FROM instruct ion. W: Able to write data by TO instruction.

Page6

Address

(Hex)

0DB 1BB

0DC 1BC

0DD 1BD

0DE 1BE

0DF 1BF

0E0 1C0

0E1 1C1

0E2 1C2

0E3 1C3

0E4 1C4

0E5 1C5

0E6 1C6

0E7 1C7

0E8 1C8

0E9 1C9

0EA 1CA

TK CH2

Page16

Address

(Hex)

Attribute

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

R/W O

Name Description Default

Pattern7-0 Target

temperature

Pattern7-1 Target

temperature

Pattern7-2 Target

temperature

Pattern7-3 Target

temperature

Pattern7-4 Target

temperature

Pattern7-5 Target

temperature

Pattern7-6 Target

temperature

Pattern7-7 Target

temperature

Pattern7-0 Running time Range: 0~900 Unit (minutes)

Pattern7-1 Running time Range: 0~900 Unit (minutes)

Pattern7-2 Running time Range: 0~900 Unit (minutes)

Pattern7-3 Running time Range: 0~900 Unit (minutes)

Pattern7-4 Running time Range: 0~900 Unit (minutes)

Pattern7-5 Running time Range: 0~900 Unit (minutes)

Pattern7-6 Running time Range: 0~900 Unit (minutes)

Pattern7-7 Running time Range: 0~900 Unit (minutes)

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

Range: -32768~32767

2.2 Analog Input Description

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

K0

The analog input value of the CH1 is shown at CR#2, and CH2 at CR#3. Please refer to the f ollowing table to set the

input sensor type register. The temperat ure of the platinum and ther mocouple can be set in Celsius or Fahrenheit, unit

0.1 degree. Users can use offset to edit the settings.

Mode Analog Range Digital Range

Channel Closed X X

K0 ~ K32000

2-17

Current / Voltage

-1

0 0~5V 0 ~ 5V

1 0 ~ 10V 0 ~ 10V

2 0 ~ 20mA 0 ~ 20mA

3 4 ~ 20mA 4 ~ 20mA

Page 33

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

0~10V

Mode Analog Range Digital Range

4 0 ~ 50mV 0 ~ 50mV

Platinum

Thermocouple

26

5 Pt100 -200 ~ 600°C K-2000 ~K6000

6 JPt100 -20 ~ 400°C K-200 ~ K4000

7 Pt1000 -200 ~ 600°C K-2000 ~K6000

8 J -100 ~ 1200°C K-1000~K12000

9 K -200 ~ 1300°C K-2000~K13000

10 R 0 ~ 1700°C K0 ~K17000

11 S 0 ~ 1700°C K0 ~K17000

12 T -200 ~ 400°C K-2000~K4000

13 E 0 ~ 600°C K0 ~K6000

14 N -200 ~ 1300°C K-2000~K13000

15 B 100 ~ 1800°C K1000~K18000

16 L -200 ~ 850°C K-2000~K8500

17 U -200 ~ 500°C K-2000~K5000

18 TXK -200 ~ 800°C K-2000~K8000

19 C 0~1800°C K0~K18000

(Quick AI)

0 ~ 10V

Copper thermal

resistance

Nickel thermal

resistance

20 PL II -100~1370°C K-1000~K13700

21 Cu50 -50~150°C K-500~K1500

22 Cu100 -50~150°C K-500~K1500

23 Ni100 -100~180°C K-1000~K1800

24 Ni1000 -100~180°C K-1000~K1800

25 LGNi1000 -60~200°C K-600~K2000

2-18

Page 34

Chapter 2 Control Register

2_

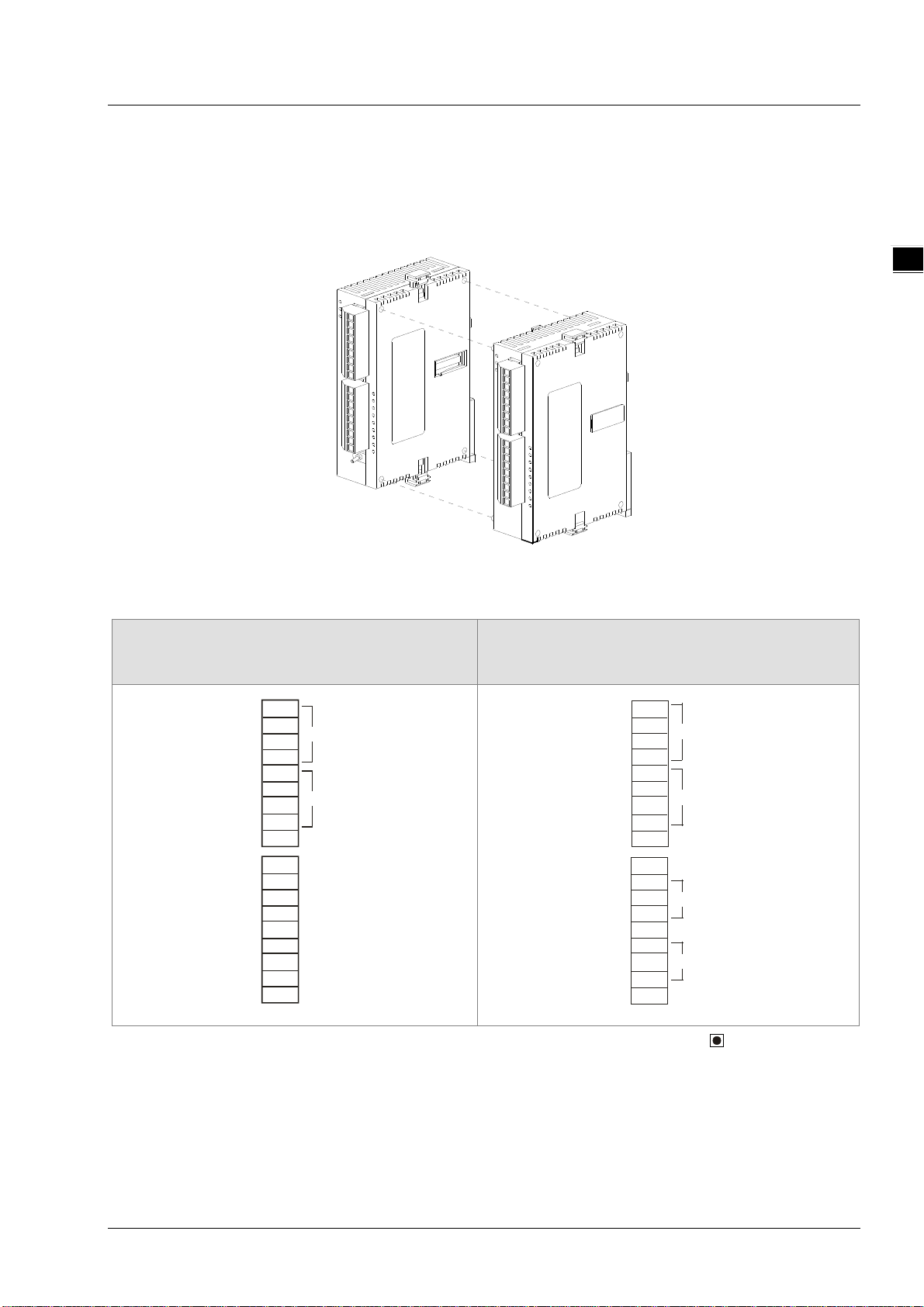

Analog Output

Max.

OutputValue

Min.

OutputValue

Temperature

Lower-limit o f P V

Upper-limit o f PV

ON

OFF

SVAL-L AL-H

ON

OFF

SV AL-H

ON

OFF

SVAL-L

2.3 Outputs

2.3.1 The output value varies with the PV value.

This functionality is only availabl e for DVP02TUL-S/DVP02TKL-S series. When the PV v aries, the corr esponding o utput

will vary accordingly. Take 4~20mA as an examp le, and set the upper-limit to 1000, lo wer-limit to 0; when PV is 0, the

output will be 4mA and when PV is 10 00, th e output will be 20mA. When set it to a negative slope, and set the range t o

0~1000; when the PV is 0, the output will be 20mA an d when the PV is 1000, the output will be 4mA. As the linear graph

shown below, the analog output will vary according to the PV value.

2.3.2 Alarm Outputs

The alarm output is only available for DVP02TUN-S, DVP02TUR-S, DVP02TKN-S and DVP02TKR-S series, not for

DVP02TUL-S and DVP02TKL-S series. Alarm function is to set the input value to trigger the outputs to do corresponding

actions. There are 12 modes availabl e for setups. The alarm output operations are shown below.

Setting

Value

Alarm Type Alarm Output Operation

0 Alarm function disabled. None

Deviation upper- and lower-limit: This alarm output operates

1

2

when the PV is higher than the set ting value SV+AL-H or lower

than the setting value SV-AL-L.

Deviation upper-limit: This alarm output operates when the PV

is higher than the setting value SV+ AL-H.

3

Deviation lower-limit: This alarm output operates when the PV is

lower than the setting value SV-AL-L.

2-19

Page 35

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

ON

OFF

SVAL-L AL-H

ON

OFF

AL-L AL-H

ON

OFF

AL-H

ON

OFF

AL-L

ON

OFF

SVAL-L AL-H

ON

OFF

SV AL-H

ON

OFF

SVAL-L

ON

OFF

AL-L

AL-H

ON

OFF

AL-L

AL-H

Setting

Value

4

5

6

7

8

Alarm Type Alarm Output Operation

Upper and lower alarm reverse action: This alarm output

operates when the PV is between SV+AL-H and SV- AL_L.

Absolute value upper- and lower-limit: This alarm output

operates when the PV is higher than the set ting value AL-H or

lower than the setting value AL-L.

Absolute value upper-limit: This alarm output operates when the

PV is higher than the setting value AL-H.

Absolute value lower-limit: This alarm output oper ates when the

PV is lower than the setting value AL-L.

Standby alarm value upper - and lower-limit: This alarm output

operates when the PV is at the set value and the temperature is

higher than the setting value SV+AL-H or lower than the setting

value SV- AL_L.

Standby alarm value upper-limit: This alarm output operates

9

10

11

12

when the PV is at the set value and the temperature is higher

than the setting value SV+AL-H.

Standby alarm value lower-limit: This alarm output operates

when the PV is at the set value an d the temperature is lower

than the setting value SV- AL_L.

Hysteresis upper-limit alarm output: This alar m output opera tes

if PV value is higher than the setting value SV+AL-H. This alarm

output is OFF when the PV is lower than the setting value

SV+AL-L.

Hysteresis lower-limit alarm out put: This alarm output oper ates

if PV value is lower than the setting value SV-AL-H. T his alarm

output is OFF when the PV is higher than the setting value

SV-AL-L.

2-20

Page 36

Chapter 2 Control Register

2_

PV

SV

ON

OFF

Heating

Heating sensitivity

adjustment

Cooling

Cooling sensitivity

adjustment

PV

SV

ON

OFF

2.4 ON/OFF Control Mode

DVP02TUR/DVP02TUN-S/DVP02TKR/DVP02TKN-S series, every channel has 2 digital outputs. Outputs control the

ON/OFF mode.

Actions for the heating output:

The output is OFF, when the input is great er than t he setting valu e. Output is ON, when the input is smaller than the total

value of the setting value + a djustme nt sens itivi ty set ting va lue. For example, set the setting value to 10 0 degre e and the

heating sensitivity adjustment to 10 degree; when the temperature reached 100 degree, the digital output switches to OFF.

When the temperature is 90 degree, i t will heat up to 100 degree, and then the digital output will switch to OFF.

Actions for the cooling output:

The output is ON, when the input is gre ater than the total value of t he setti ng value + adj ustm ent sensit ivit y setting va lue.

Output is OFF, when the input is smaller than the setting valu e. For example, set the setting value t o 10 degree and the

cooling sensitivity adjustment to 5 degree; when the temperature reached 10 degree, the digital output switches to OFF.

When the temperature is 15, it will cool down to 10 degree, and then the digital output will switch to OFF.

• Actions for dual outputs:

When setting one output for heating and the other for cooling, a non-action zone (dead band) can be set as below. For

example, set the setting value to 100 degre e, heating sensi tivity adjustment to 10 degr ee, cooling sen sitivity adjustment

to 5 degree and dead band to 20 degre e; when the tempera ture is 90~100 degr ee, the outputs will be OF F. Heating up

the temperature to 90 degree, the output will switch to OFF. When the temperature is below 80 degree, the heating up will

be started. Cooling down the temperature to 110 degree, the output will switch to OFF. When the temperature is over 115

degree, the cooling will be started.

2-21

Page 37

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

SV

ON

OFF

PV

Dead band

Cooling

Cooling sensitivity

adjustment

Heating

Heating sensitivity

adjustment

2.5 PID Control Mode

When the PV is in the range of ERR_DBW, the PLC will run the PID operation according t o the E value. When the PV is

over the SV, the cross status will be establis hed and the E value will be seen as 0 while runn ing the PID operation until

the PV goes over the range of E RR_DBW. If PID_DE is True, the PLC will run the derivative of PV. When the cross

status is established, the Delta PV will be seen as 0 while running the derivative of PID operation. As the example shown

below, the PLC will run the PID operation i n the section A and will see the values of E and De lta PV as 0 while runnin g

the PID operation.

PID Formula:

Independent Formula & Derivative of E(PID_EQ=False & PID_DE=False)

Independent Formula & Derivative of PV(PID_EQ=False & PID_DE=Ture)

2-22

Page 38

Chapter 2 Control Register

2_

PID Block Diagram (Independent)

SV

PV

+

-

+

REVERSE

X(-1)

PID_DIR

E

DEAD BAND

ERR_DBW

0

1

PID-P

Kc_Kp

Kc_Kp

>0

<=0

0

PID-I

Ti_Ki

Ti_Ki

>0

<=0

0

0

>0

<=0

PID-D

Td_Kd , Tf

Td_Kd

BIAS

PID_MAN

0

1

0

1

MOUT

MOUT_AUTO

MOUT

PID_MAN

0

1

MOUT

MV

MV_LIMIT

MV_MAX, MV_MI N

+

+

+

+

+

+

+

Dependent Formula & Derivative of E(PID_EQ=True & PID_DE=False)

Dependent Formula & Derivative of PV(PID_EQ=True & PID_DE=True)

※ All the CVs stated above are the MVs in the formula.

Auto tuning mode: When auto tuning is done, the value will become 0 and switch to the auto tuning mode automatically.

PID Control Block Diagram:

2-23

Page 39

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

PID Bl ock Diagram (Dependent)

SV

PV

+

-

+

PID-P

Kc_Kp

REVERSE

X(-1)

PID_DIR

0

1

E

DEAD BAND

ERR_DBW

PID-I

Ti_Ki

Kc_Kp

>0

<=0

0

Ti_Ki

>0

<=0

0

PID-D

Td_Kd, Tf

0

>0

<=0

Td_Kd

BIAS

PID_MAN

+

+

+

MV

MV_LIMIT

MV_MAX, MV_MIN

MOUT_AUTO

MOUT

MOUT

PID_MAN

MOUT

0

1

0

1

0

1

Note:

1. When tuning these 3 parameters, Kc_Kp, Ti_Ki and Td_Kd, set the Kc_Kp value first (according to their experiences),

and set the Ti_Ki and Td_Kd value to 0. When it can be controlled, users can increase the values of Ti_Ki and Td_Kd.

When the value of Kc_Kp is 1, it means that the proportional gain is 100%. That is, the error is increased by a factor of

one. When the proportional gain is less th an 100%, t he error is decrease d. When th pro portional gain is gr eater than

100%, the error is increased.

2. The parameters which have been tuned automat ically are not necessarily suitab le for every controlled environm ent.

Therefore, users can further modify the automatically-tuned parameters. However, it is suggested to modify the

values of Ti_Ki or Td_Kd only.

2.6 Programmable SV Control Mode

The temperature setting value is not fi xe d but a set ting curve defined by users acc ord ing t o their requirements. By way of

PID control, the temperature input rises along with the defined temperature curve. T he device provides 8 patterns and

each pattern with 8 steps, a linking parameter, a loop parameter, and a number of execution steps respectively. Each step

has 2 parameters (temperature setting value and time). After setting these parameters up, each temperature controller will

have its own set of initial pattern and step for creating its own temperature setting curve. Some of the terms are explained

as follows:

1. Initial pattern: set the program to start running at a sequential number of patterns.

2. Initial Step: set the progr am to start running at a sequential n umber of steps.

3. Running time: set the temperature duration time, if not neces s ary, it can be set to 0.

2-24

Page 40

Chapter 2 Control Register

2_

4. Step: includes 2 parameter settings: a setting point X and a Running time T, indicating the setting value (SV) to rise to

X degree after the time T. I f the setting point X is identical to the previous setting, this process is called a Soak,

otherwise a Ramp; therefore this control procedure is also called a Ramp Soak control. The first running procedure is

preset as a Soak control, to set the temperature control to setting point X degree in advanced and keep the

temperature at X degree, at a durati on time of T.

5. Number of loops: Extra loops to be carried out for the pattern. I f set to 1, the pattern will be carried out 2 t i m es.

6. Executing step: Number of steps executed for each pattern .

7. Execution: Before exec ution, users need to set up all the parameters . If the setting control is in the running mode, the

program will start running from the init ial pattern and initial step, carrying out comman ds one by one by their set

orders. When the setting control is in the ending mode, the SV will stop at the final setting. When the setting control is

in the stop mode and the temperature will be at the value before the stop, by re-selecting to run, the program will start

running from the initial pattern and initial step. When the setting control is in the pause mode and the temperature is at

the value before the pause, by re-selecting to run, the program will start running from the step where the program was

paused, carrying out the remaining parts. During execution, the SV cannot be set up.

2.7 ERROR LED Indicator

When the analog input channel out of range is detected, the error code will show up and the error LED will also blinking to

notify. Users can disable this func tionality to inactivate the err or LED blinking, but the error code will still show up.

Page CR Description Setting Value

Basic Setup Page 38 Output out of range

K0=LED blinking (default)

K1=LED not blinking

2.8 RS-485 Communication Setup for DVP02TK-S

2.8.1 MODBUS Communication Protocol

For DVP02TK-S series, MODBUS supports formats such as RTU and ASCII. When RTU is selected, the data length is 8

and the following function codes are s upported.

Function code 03: read multiple words, up to 32 words can be read.

Function code 06: write a single word.

Function code 10: write multiple words, up to 32 words can be written.

2.8.2 Restore to Factory Settings

Users can restore the RS-485 communication settings back to defaults (9600/7/1/E, station number 1) by switching RUN

to STOP and then STOP to RUN after turning on the device within 5 seconds.

2.8.3 RS-485 Communication Setup

There are 2 methods to setup RS-485 communication, via TK Wizard and setting the MODBUS address.

• TK Wizard (TKSoft): click the Module Inform ation and set up baud rate, transfer mode a nd then click “Send” to

save the settings.

2-25

Page 41

DVP02TK-S/DVP02TU-S Temperature Control Module Manual

_2

• MODBUS address setup:

Write the value 0x00XY (refer to the f ol lowing list for X and Y setups) in MODBUS address (0x0F09).

Example: the value 0x0000 (X=0/Y=0) indicates the baud rate is 9600, data length is 7, stop bits is 1 an d the parity is

Even.

RS-485 Communication Setting Addr ess = 0x0F09, written value is 0x00XY

Value Description

0 9600 (default)

1 19200

X Bit7~Bit4

Y Bit3 Data Length

Baud Rate

(bps)

2 38400

3 57600

4 115200

5~16 reserved

0 7 (default)

1 8

2-26

Page 42

2_

RS-485 Communication Setting Addr ess = 0x0F09, written value is 0x00XY

1: 8

1: 2-bit

0 1-bit (default)

Bit2 Stop Bits

1 2-bit

0 Even (default)

1 Odd

Bit1~Bit0 Parity

2 None

3 Reserved

Data Length Stop Bits Parity

Chapter 2 Control Register

Y

value

0 0 0 0 0 7 1 even

1 0 0 0 1 7 1 odd