Page 1

2010-09-24

5012602300

C0

-2L

..

..

DVP-1071070-01

Page 2

………………………………………………………………… ENGLISH …………………………………………………………………

Thank you for choosing Delta’s DVP series PLC. Delta releases DVP02LC-SL load cell

module of weight measurement function. DVP02LC-SL provides 24-bit resolution

applicable for 4-wire or 6-wire load cells with various eigenvalues. Therefore, the

response time can be adjusted in coordination with each other according to users’ needs.

On this basis, the market requirements on weight measurement can easily be met.

a This instruction sheet provides introductory information on electrical specifications,

general specifications, installation and wiring.

a This is an OPEN TYPE I/O module and therefore should be installed in an enclosure

free of airborne dust, humidity, electric shock and vibration. The enclosure should

prevent non-maintenance staff from operating the device (e.g. key or specific tools

are required to open the enclosure) in case danger and damage on the device may

occur.

a DO NOT connect the input AC power supply to any of the I/O terminals; otherwise

serious damage may occur. Check all the wiring again before switching on the power.

Make sure the ground terminal is correctly grounded in order to prevent

electromagnetic interference.

a The tightening torque for I/O terminal block is 1.95 kg-cm (1.7 in-lbs). Use 60/75°C

copper conductors only.

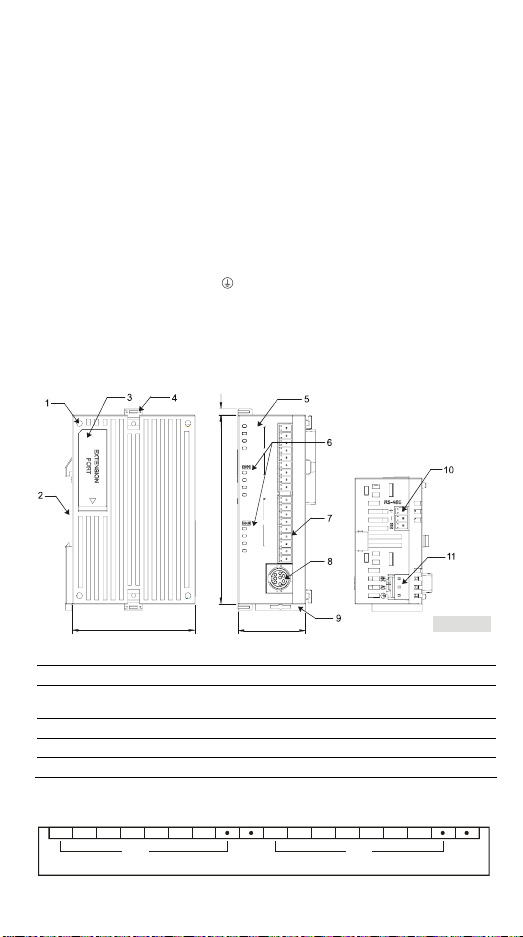

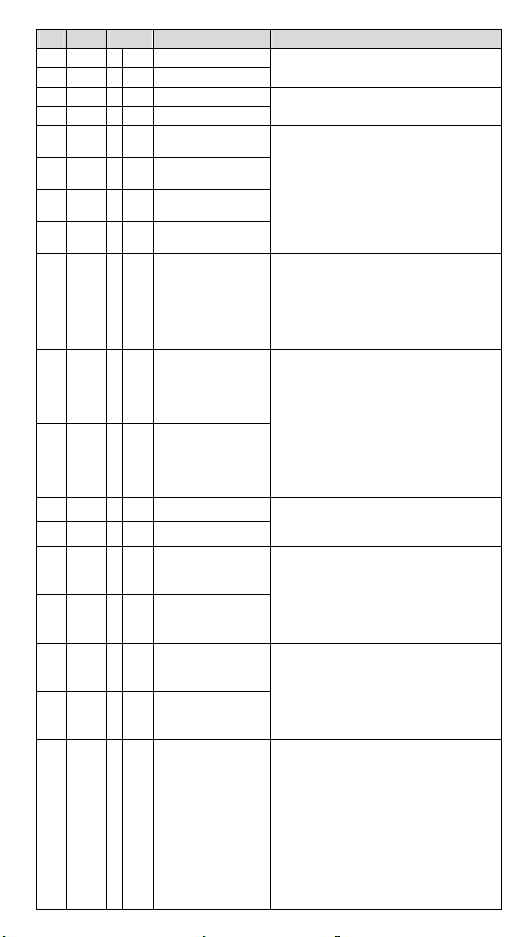

Product Profile & Dimensions

3 mm

DVP02LC

POWER

EXC+

RUN

EXC-

ERROR

SIG+

L.V

CH1

SIG-

SEN+

SEN-

NET

SHD

ZERO

MAX

MOTION

EXC+

90 mm

EXC-

SIG+

CH2

SIG-

NET

SEN+

ZERO

SEN-

MAX

SHD

MOTION

60 mm

33 mm

1. Mounting hole of the I/O module 2. DIN rail mounting slot (35mm)

3. I/O module connection port 4. I/O module clip

Status indicator

5.

(POWER, RUN, ERROR and L.V)

Function status indicator

6.

(NET, ZERO, MAX, MOTION)

7. I/O terminals 8. RS-232 port

9. Mounting slot clip 10. RS-485 port

11. DC power input

I/O Terminal Layout

SEN-SEN+SIG-SIG+EXC-EXC+ SIG+EXC-EXC+SHD SHDSEN-SEN +SIG-

DVP02LC-SL

CH1 CH2

- 1 -

[ Fi gure 1 ]

Page 3

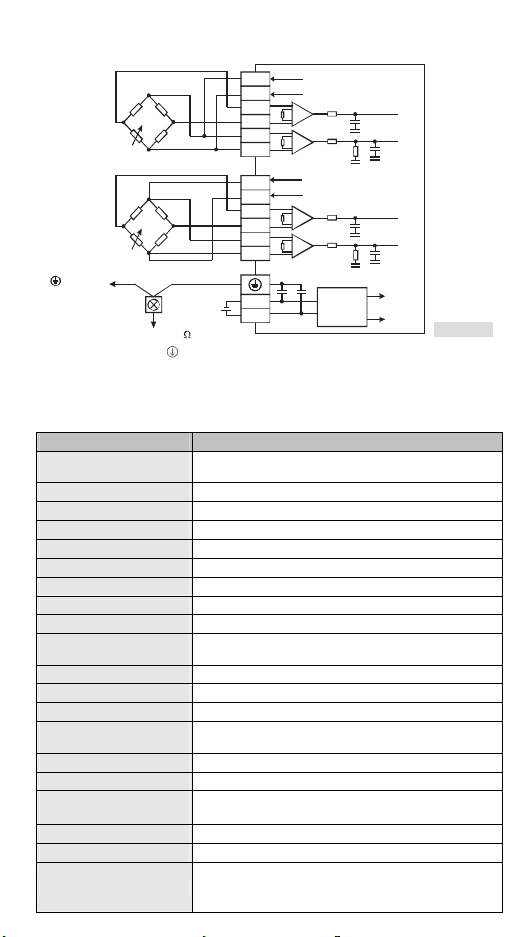

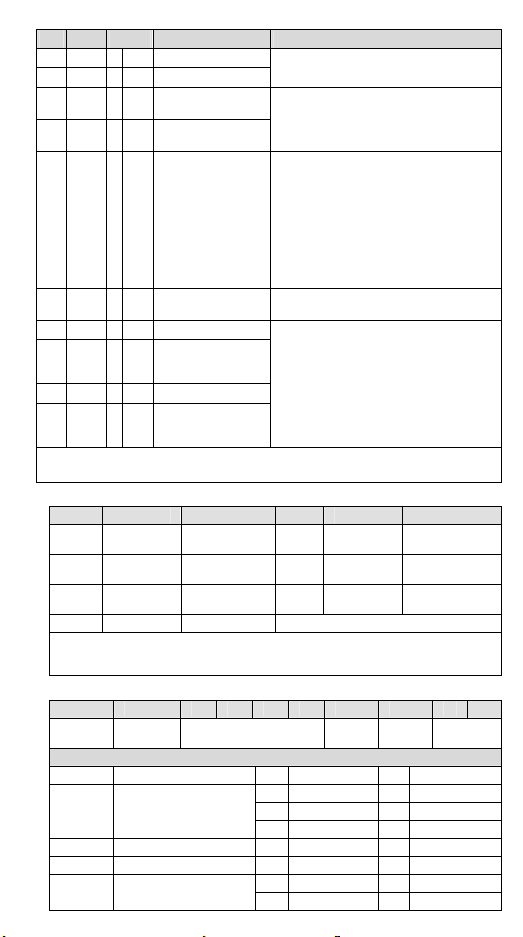

External Wiring

4 strain guage

6 strain guage

Terminal

of power

module

Note 1: Please connect the terminal on both the power module and Load Cell module to the system

earth point and ground the system contact or connect it to the cover of power distribution

cabinet.

Grounding

*1

System

grounding

(100 or less)

EXC+

EXCSIG+

SIG-

SEN+

SEN-

EXC+

EXCSIG+

SIG-

SEN+

SEN-

0V

24V

A+5V

AGND

A+5V

AGND

DC/DC

Converter

CH1

CH2

A+5V

AGND

[ Fig ure 2 ]

Electrical Specifications

Load cell module Voltage output

Rated power supply voltage/

power consumption

Voltage Boundary 18 to 31.2 VDC

Max. current consumption 125 mA

Input signal range ± 40 mVDC

Sensibility +5 VDC +/-10%

Internal resolution 24 bits

Communication port RS-232, RS-485

Applicable sensor type 4-wire or 6-wire strain gauge

Temperature coefficient span ≤ ± 50 ppm/K v. E

Temperature coefficient zero

point

Linearity error ≤ 0.02%

Response time 2, 10, 20, 40, 80 ms × channels

4 measuring ranges 0 to 1 mV/V, 0 to 2 mV/V, 0 to 4 mV/V, 0 to 6mV/V

Max. distance for connecting

to load cell

Max. current output 5 VDC * 300 mA

Permitted load cell resistance 40 to 4,010 Ω

Common mode rejection

(CMRR @50/60 Hz)

Dynamic value filter Setting range: K1 to K5

Average value filter Setting range: K1 to K100

Isolation method

24 VDC (-15 to +20%) / 3W

≤ ± 0.4 μV/K

100 M

≥100dB

500 VAC between digital circuits and Ground

500 VAC between analog circuits and Ground

500 VAC between analog circuits and digital circuits

- 2 -

Page 4

Load cell module Voltage output

Series connection to

DVP-PLC MPU

Operation / storage

temperature

Vibration / shock immunity

Complying with DIN1319-1, the tolerance of measured value should be ≤ 0.05% under 20°C

+ 10K temperature range

When the corrected ambient temperature and the actual temperature have a difference of

more than 10°C, it is suggested that you re-correct it.

Connectable to the left side of MPU, numbered from 100 to

107 according to the position of module from the closest to

farthest to MPU.

Operation: 0 to 55°C (temp.), 50 to 95% (humidity), pollution

degree 2

Storage: -25 to 70°C (temp.), 5 to 95% (humidity)

International standards: IEC61131-2, IEC 68-2-6 (TEST Fc)/

IEC61131-2 & IEC 68-2-27 (TEST Ea)

.

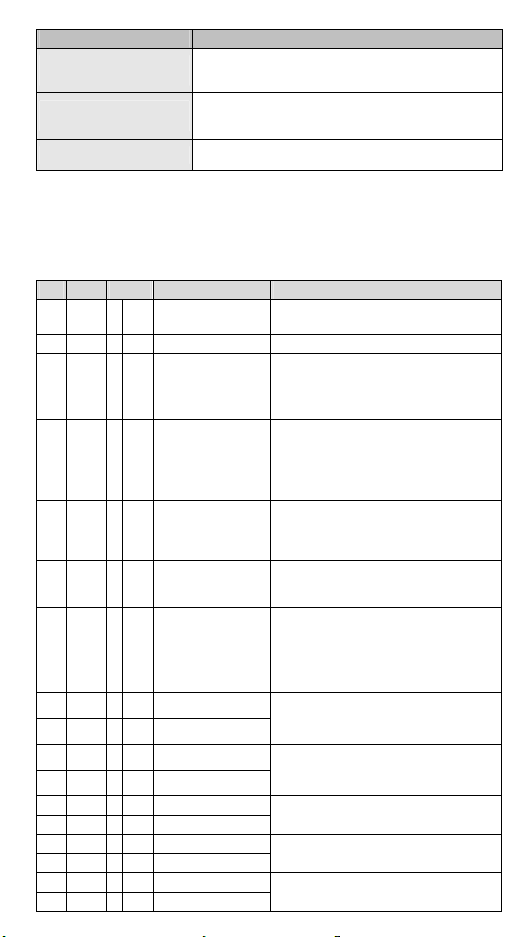

Control Register

CR# Add. Attrib. Register name Explanation

#0 H1000 O R Model name

#1 H1001 O R Firmware version Display the current firmware version in hex.

#2 H1002 O R/W Characteristic value

#3 H1003 O R/W

#4 H1004 O R

#6 H1006 X R/W

#7 H1007 O R/W

#8 H1008 O R/W CH1 tare weight

#9 H1009 O R/W CH2 tare weight

#10 H100A O R/W CH1 average times

#11 H100B O R/W CH2 average times

#12 H100C X R CH1 average weight

#13 H100D X R CH2 average weight

#14 H100E X R CH1 present weight

#15 H100F X R CH2 present weight

#16 H1010 O R/W CH1 standstill times

#17 H1011 O R/W CH2 standstill times

Reaction time for

measurement

Average value of all

channels

CH1 to CH2 read tare

weight

CH1 to CH2 gross/net

weight

Set up by the system:

DVP02LC-SL model code = H’4206

Mode 0 (H’0000): 1 mV/V

Mode 1 (H’0001): 2 mV/V, default

Mode 2 (H’0002): 4 mV/V

Mode 3 (H’0003): 6 mV/V

Mode 0 (H’0000): 2 ms

Mode 1 (H’0001): 10 ms

Mode 2 (H’0002): 20 ms

Mode 3 (H’0003): 40 ms

Mode 4 (H’0004): 80 ms, default

Sum up CH1 average value and CH2

average value and equalize them.

Equation: (CH1 average value + CH2

average value)/2

Read present average value as tare weight

value

bit0: CH1; bit1: CH2; bit2 to bit15: reserved

Display present weight as Gross (K0) or Net

(K1). bit0 to bit3: CH1; bit4 to bit7: CH2; bit8

to bit15: reserved.

Take CH1 for example: bit3 to bit0 = 0000,

gross; bit3 to bit0 = 0001, net; bit3 to bit0 =

1111, channel disabled.

The user can write in the weight or read it by

commands.

Default: K0; Range: -K32,768 to K32,767.

Default: K10; Range: K1 to K100.

When the set value exceeds the range, it will

automatically be changed to K1 or K100.

Display average weight.

Display present weight.

Default: K5

Range: K1 to K500

- 3 -

Page 5

CR# Add. Attrib. Register name Explanation

#18 H1012 O R/W CH1 standstill range

#19 H1013 O R/W CH2 standstill range

#20 H1014 O R/W CH1 decimal place

#21 H1015 O R/W CH2 decimal place

#22 H1016 O R/W

#23 H1017 O R/W

#24 H1018 O R/W

#25 H1019 O R/W

#26 H101A X R/W

#33 H1021 O R/W

#34 H1022 O R/W

CH1 unit of

measurement

CH1 unit of

measurement

CH2 unit of

measurement

CH2 unit of

measurement

Weight correction

command

CH1 weight base

point

CH2 weight base

point

#35 H1023 O R CH1 max. weight

#36 H1024 O R CH2 max. weight

#37 H1025 O R/W

#38 H1026 O R/W

#39 H1027 O R/W

#40 H1028 O R/W

#41 H1029 X R/W

Upper limit for CH1

zero point check

Upper limit for CH2

zero point check

Lower limit for CH1

zero point check

Lower limit for CH2

zero point check

Saving set value

(H’5678)

Default: K10

Range: K1 to K10,000

Default: K2

Range: K1 to K4

Enter max. 4 ASCII words.

CR#22, CR#24: High word

CR#23, CR#25: Low word

For the user to correct the weight.

Default: H’0000

H’0001: CH1 Reset to zero command

H’0002: CH1 Weight base point command

H’0003: CH2 Reset to zero command

H’0004: CH2 Weight base point command

For CR#33 to CR#34 default = K1,000;

Range: K-32,768 to K32,767

Steps for correction: Take CH1 for example

1: Place no weights on the load cell

2: Set up CR#26 command = “H’0001”

3: Place standard weights on load cell

4: Write the weight of the weights on the plate

into CR#33.

5: Set up CR#26 command = “H’0002”

Set up the max. weight. When the measured

value exceeds the set value, error codes will

be recorded.

Reference for reset to zero. When the weight

is within this range, the status code will be set

to “zero bit”, indicating the current zero

weight status.

Default: K10

Range: K-32,768 to K32,767

Reference for reset to zero. When the weight

is within this range, the status code will be set

to “zero bit”, indicating the current zero

weight status.

Default: K-10

Range: K-32,768 to K32,767

Save the present set value and write all the

set values into the internal Flash for use next

time DVP02LC-SL is switched on.

H0: No action, Default

H’FFFF: Saving is successful

H’5678: Write to internal Flash

When H’5678 is written in, all set values will

be saved in Flash. When the saving is

completed, CR#41 will become H’FFFF. If the

value written in is not H’5678, it will

automatically return to H0, e.g. write K1 into

CR# to return to K0.

- 4 -

Page 6

CR# Add. Attrib. Register name Explanation

#43 H102B X R/W CH1 filter percentage

#44 H102C X R/W CH2 filter percentage

#45 H102D X R/W

#46 H102E X R/W

#50 H1032 X R Status code

#51 H1033 X R Error code

#52 H1034 O R/W RS-232 node address

#53 H1035 O R/W

#54 H1036 O R/W RS-485 node address

#55 H1037 O R/W

Symbols: O means latched. X means not latched.

R means can read data. W means can write data.

c Error Code Table for CR#51:

bit Content Error bit Content Error

b0 K1 (H’0001)

b2 K4 (H’0004)

b4 K16 (H’0010)

b6 ~ b15 K64 (H’0040) Reserved

Note: Every error status is decided by its corresponding bit, so there might be more than

2 error statuses occurring at the same time. 0 refers to no error; 1 refers to error

occurring.

c Communication Format Table for CR#53, CR#55:

bit15 bit14~bit8 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

ACSII/RTU Reserved Baudrate

bit15 ACSII/RTU

bit7~bit4 Baudrate

bit3 Data length (RTU = 8 bits)

bit2 Stop bit

bit1~bit0 Parity

CH1 filter average

value

CH2 filter average

value

RS-232

communication

setting

RS-485

communication

setting

Power supply

abnormality

CH1 conversion

error

CH2 conversion

error

Default: K2

Range: K1 to K5 (Unit: 10%)

Display average weight after filtering.

Condition to enable filter: average time ≥ 30

b0 (H’0001): CH1 zero weight (empty)

b1 (H’0002): CH2 zero weight (empty)

b2 (H’0004): CH1 exceeds max. weight

(overload)

b3 (H’0008): CH2 exceeds max. weight

(overload)

b4 (H’0010): CH1 stable measured value

b5 (H’0020): CH2 stable measured value

b6 ~ b15: Reserved

Store all the error statuses. See “Error Code

Table” below. Default: H’0000

For CR#52, CR#54 default = 1

Range: K1 to K255

For CR#53, CR#55 default = H’0000; Range:

ASCII, 9600, 7, E, 1. See “Communication

Format Table” below.

b1 K2 (H’0002)

b3 K8 (H’0008)

b5 K32 (H’0020)

Data

Description

0 ASCII 1 RTU

0 9,600 bps 1 19,200 bps

2 38,400 bps 3 57,600 bps

4 115,200 bps 5 Else none

0 7 1 8

0 1 bit 1 2 bits

0 Even 1 Odd

2 None 3 None

- 5 -

length

Hardware

abnormality

CH1 SEN voltage

error

CH2 SEN voltage

error

Stop bit Parity

Page 7

……………………………………………………………… 繁體中文 …………………………………………………………………………

感謝您採用台達 DVP 系列產品。台達再度推出 Load Cell 秤重量測模組 DVP02LC-SL。

DVP02LC-SL 提供 24 bit 高解析度,可適用 4 或 6 線式的多種特徵值 Load Cell,可配合

客戶需求進行反應速度的搭配調整,輕易地滿足目前荷重應用市場上的全面需求。

a 請在使用之前,詳細閱讀本使用說明書。

a 實施配線前,務必關閉電源。於輸入電源切斷後,一分鐘之內,請勿觸摸內部電路。

a 本機為開放型(OPEN TYPE)機殼,因此使用者使用本機時,必須將之安裝於具防塵、

防潮及免於電擊∕衝擊意外之外殼配線箱內。另必須具備保護措施(如:特殊之工具

或鑰匙才可打開)防止非維護人員操作或意外衝擊本體,造成危險及損壞。

a 交流輸入電源不可連接於輸入∕出信號端,否則可能造成嚴重損壞,請在上電之前再

次確認電源配線,並請勿在上電時觸摸任何端子。

a 本體上之接地端子 務必正確的接地,可提高產品抗雜訊能力。

a 端子螺絲扭力為 1.95 kg-cm (1.7 in-lbs),並請使用 60/75°C 銅導線。

產品外觀尺寸與部位介紹

詳細圖示請參閱英文版頁碼 1 之[Figure 1],單位:mm。

1. I/O 模組定位孔 2. DIN 導軌槽 (35mm)

3. I/O 模組連接埠 4. I/O 模組固定扣

電源、運行、錯誤及低電壓指示燈

5.

(POWER, RUN, ERROR, L.V)

7. I/O 端子 8. RS-232 通訊埠

9. DIN 軌固定扣 10. RS-485 通訊埠

11. 電源輸入口

通道淨重、零點、最大值、穩定功能狀態

6.

燈 (NET, ZERO, MAX, MOTION)

輸入∕輸出端子台配置

請參閱英文版頁碼 1 之端子配置圖,在此語言版本省略說明。

外部配線

詳細圖示請參閱英文版頁碼 2 之[Figure 2]。

註 1:請將電源模組之 端及 Load Cell 秤重量測模組之 端連接到系統接地點,再將系統接

點作第三種接地或接到配電箱之機殼上。

規格

Load cell 模組 電壓輸出

電源額定電壓∕消耗功率 24 VDC (-15 ~ +20%) / 3W

電壓範圍 18 ~ 31.2 VDC

最大消耗電流 125 mA

輸入訊號範圍 ±40 mVDC

感測度 +5 VDC +/-10%

內部解析度 24 bits

通訊介面 RS-232, RS-485

適合感應器形式 4線制或 6 線制荷重單元(Load Cell)

溫度係數擴展 ≤ ± 50 ppm/K v. E

溫度係數偏移 ≤ ± 0.4 μV/K

線性誤差 ≤ 0.02%

- 6 -

Page 8

Load cell 模組 電壓輸出

反應時間 2, 10, 20, 40, 80 ms × 通道數

適用 Load Cell 特徵值 0 ~ 1, 0 ~ 2, 0 ~ 4, 0 ~ 6 mV/V

連接 Load Cell 最大距離 100 公尺

最大輸出電流 5 VDC * 300 mA

允許負載能力 40 ~ 4,010 Ω

共模拒斥比

(CMRR @50/60 Hz)

動態值濾波 可設定範圍 K1 ~ K5

平均功能 可設定範圍 K1 ~ K100

隔離方式

與 DVP-PLC 主機

連接說明

操作∕儲存環境

耐振動∕衝擊

符合 DIN1319-1 在量測範圍最終值為 20°C + 10K 的錯誤極限需 ≤ 0.05%。

Load Cell 校正環境溫度與實際操作溫度相差 10°C 以上時,建議重新校正以獲得最佳精確值。

100dB 以上

數位電路與接地之間:500 VAC

類比電路與接地之間:500 VAC

類比電路與數位電路之間:500 VAC

連接於主機左側,模組編號依靠近主機之順序自動編號由100 到

107。

操作:0 ~ 55°C(溫度),50 ~ 95%(濕度),污染等級 2

儲存:-25 ~ 70°C(溫度),5 ~ 95%(濕度)

國際標準規範 IEC 61131-2, IEC 68-2-6 (TEST Fc)/IEC 61131-2

& IEC 68-2-27 (TEST Ea)

控制暫存器 CR

位址 屬性 暫存器名稱 說明

CR#

#0 H1000 O R

#1 H1001 O R

#2 H1002 O R/W

#3 H1003 O R/W

#4 H1004 O R

#6 H1006 X R/W

#7 H1007 O R/W

#8 H1008 O R/W

#9 H1009 O R/W

#10 H100A O R/W

#11 H100B O R/W

機種型號 系統內定,DVP02LC-SL 機種代碼 = H’4206

韌體版本 16 進制,顯示目前韌體版本

特徵值

量測反應時間

總通道平均值

CH1 ~ CH2 皮重讀取

毛重/淨重顯示設定

CH1 皮重重量值

CH2 皮重重量值

CH1 平均次數

CH2 平均次數

模式 0 (H’0000):1 m V/V

模式 1 (H’0001):2 m V/V,預設值。

模式 2 (H’0002):4 m V/V

模式 3 (H’0003):6 m V/V

模式 0 (H’0000):2 m s

模式 1 (H’0001):10 ms

模式 2 (H’0002):20 ms

模式 3 (H’0003):40 ms

模式 4 (H’0004):80 ms,預設值。

以 CH1 平均值及 CH2 平均值做加總平均

計算式:( CH1 平均值 + CH2 平均值 ) ÷ 2

讀取目前的平均值做為皮重的重量值

bit0:CH1。bit1:CH2。bit2 ~ bit15:保留。

選擇目前重量顯示為毛重(K0) 或淨重(K1)

bit0~bit3:CH1。bit4~bit7:CH2。bit8~bit15:

保留。以 CH1 說明:bit3~bit0=0000,毛重。

bit3~bit0=0001,淨重。bi t3~ bi t0= 1111,關閉

通道。

使用者可自行寫入或由指令讀取皮重。

預設值 K0,設定值範圍 K-32768 ~ K32767。

設定範圍在 K1 ~ K100,預設值 K10。

設定值超過範圍時,則自動變更為臨界值 K1

或 K100。

- 7 -

Page 9

位址 屬性 暫存器名稱 說明

CR#

#12 H100C X R

#13 H100D X R

#14 H100E X R

#15 H100F X R

#16 H1010 O R/W

#17 H1011 O R/W

#18 H1012 O R/W

#19 H1013 O R/W

#20 H1014 O R/W

#21 H1015 O R/W

#22 H1016 O R/W

#23 H1017 O R/W

#24 H1018 O R/W

#25 H1019 O R/W

#26 H101A X R/W

#33 H1021 O R/W

#34 H1022 O R/W

#35 H1023 O R

#36 H1024 O R

#37 H1025 O R/W

#38 H1026 O R/W

#39 H1027 O R/W

#40 H1028 O R/W

#41 H1029 X R/W

#43 H102B X R/W

#44 H102C X R/W

#45 H102D X R/W

#46 H102E X R/W

CH1 平均重量

CH2 平均重量

CH1 現在重量

CH2 現在重量

CH1 穩定檢查次數

CH2 穩定檢查次數

CH1 穩定檢查範圍

CH2 穩定檢查範圍

CH1 小數點位數設定

CH2 小數點位數設定

CH1 重量量測單位

CH1 重量量測單位

CH2 重量量測單位

CH2 重量量測單位

調校重量指令

CH1 砝碼基點重量

CH2 砝碼基點重量

CH1 重量上限

CH2 重量上限

CH1 零點判斷檢查範

圍上限

CH2 零點判斷檢查範

圍上限

CH1 零點判斷檢查範

圍下限

CH2 零點判斷檢查範

圍下限

儲存設定值 (H’5678)

CH1 濾波比例設定

CH2 濾波比例設定

CH1 濾波平均值

CH2 濾波平均值

平均重量值顯示

現在重量值顯示

預設值 K5,設定值範圍 K1 ~ K500。

預設值 K10,設定值範圍 K1 ~ K10000。

設定範圍在 K1 ~ K4,預設值 K2。

ASCII 輸入,最多四個字元。

CR#22, CR#24 為 high word

CR#23, CR#25 為 low word

使用者調校重量使用,預設值 H’0000。

H’0001:CH1 歸零指令

H’0002:CH1 砝碼基點指令

H’0003:CH2 歸零指令

H’0004:CH2 砝碼基點指令

CR#33 ~ CR#34 預設值 K1000,設定值範圍

K-32768 ~ K32767。

使用者調整步驟:以 CH1 說明

Step1:荷重單元(Load Cell)上不放任何砝碼

Step2:CR#26 設定調整指令為”H’0001”

Step3:荷重單元(Load Cell)上加上標準砝碼

Step4:將目前底盤上的砝碼重量寫入CR#33

Step5:CR#26 設定調整指令為”H’0002”

使用者可設定最大重量值,當量測值超出設定

值時會記錄錯誤碼。

歸零狀態判斷參考,當重量值在此範圍內,狀

態碼會設定為歸零位元(zero bit),表示目前是

空載狀態。

預設值 K10,設定值範圍 K-32768 ~ K32767。

歸零狀態判斷參考,當重量值在此範圍內,狀

態碼會設定為歸零位元(zero bit),表示目前是

空載狀態。

預設值 K-10,設定值範圍 K-32768 ~ K32767。

儲存目前設定值,將目前所有設定值寫入內存

Flash,以待下次開機使用。

H0:不動作,預設值

H’FFFF:儲存成功

H’5678:寫入內存

寫入 H’5678 時會將所有設定值儲存於 Flash

中,當儲存完成後,CR#41 為 H’FFFF。若寫

入值不為 H’5678,則自動回復為 H0。例 如 CR#

寫入 K1,會回復為 K0。

預設值 K2,設定值範圍 K1 ~ K5(單位:10%)。

濾波後平均重量顯示

濾波功能啟動條件:當平均次數≥30。

- 8 -

Page 10

位址 屬性 暫存器名稱 說明

CR#

#50 H1032 X R

#51 H1033 X R

#52 H1034 O R/W

#53 H1035 O R/W

#54 H1036 O R/W

#55 H1037 O R/W

符號定義:O 表示為保持型。X 表示為非保持型。

R 表示為可讀取資料。W 表示為可寫入資料。

※ CR#51 錯誤狀態表:

bit 內容值 錯誤狀態 bit 內容值 錯誤狀態

b0 K1 (H’0001)

b2 K4 (H’0004)

b4 K16 (H’0010)

b6 ~

K64 (H’0040)

b15

註:每個錯誤狀態由相對應之位元決定,有可能會同時產生兩個以上之錯誤狀態,0 代表

正常無錯誤,1 代表有錯誤狀態產生。

※ CR#53、CR#55 通設格式:

bit15 bit14~bit8 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

ACSII/RTU 保留 串列傳輸速率 資料長度 停止位元 同位元

bit15 ACSII/RTU 0 ASCII 1 RTU

bit7~bit4 串列傳輸速率

bit3 資料長度 (RTU = 8 bits) 0 7 1 8

bit2 停止位元 0 1 bit 1 2 bits

bit1~bit0 同位元

狀態代碼

錯誤代碼

RS-232 站號

RS-232 通訊格式

RS-485 站號

RS-485 通訊格式

電源異常

CH1 轉換錯誤

CH2 轉換錯誤

保留

b0 (H’0001):CH1 零點重量(空載)

b1 (H’0002):CH2 零點重量(空載)

b2 (H’0004):CH1 超出重量上限(超載)

b3 (H’0008):CH2 超出重量上限(超載)

b4 (H’0010):CH1 量測值穩定

b5 (H’0020):CH2 量測值穩定

b6 ~ b15:保留

儲存所有錯誤狀態的資料暫存器,請參照錯誤

資訊表,預設值為 H’0000。

CR#52、CR#54 預設值 K1,設定值範圍

K1~K255。

CR#53、CR#55 通設格式,預設值 H’0000,

設定值範圍 ASCII, 9600, 7, E, 1,請參照通訊

格式資訊表。

b1 K2 (H’0002)

b3 K8 (H’0008)

b5 K32 (H’0020)

Description

0 9,600 bps 1 19,200 bps

2 38,400 bps 3 57,600 bps

4 115,200 bps 5 Else none

0 Even 1 Odd

2 None 3 None

硬體故障

CH1 SEN 電壓錯誤

CH2 SEN 電壓錯誤

- 9 -

Page 11

………………………………………………………………… 简体中文 ……………………………………………………………………

感谢您采用台达 DVP 系列产品。台达再度推出 Load Cell 秤重测量模块 DVP02LC-SL。

DVP02LC-SL 提供 24 bit 高分辨率,可适用 4 或 6 线式的多种特征值 Load Cell,可配合

客户需求进行反应速度的搭配调整,轻易地满足目前荷重应用市场上的全面需求。

a 请在使用之前,详细阅读本使用说明书。

a 实施配线前,务必关闭电源。于输入电源切断后,一分钟之内,请勿触摸内部电路。

a 本机为开放型(OPEN TYPE)机壳,因此使用者使用本机时,必须将其安装于具防尘、

防潮及免于电击∕冲击意外的外壳配线箱内。另必须具备保护措施(如:特殊的工具

或钥匙才可打开)防止非维护人员操作或意外冲击本体,造成危险及损坏。

a 交流输入电源不可连接于输入∕出信号端,否则可能造成严重损坏,请在上电之前再

次确认电源配线。请勿在上电时触摸任何端子。本体上的接地端子 务必正确的接

地,可提高产品抗干扰能力。

a 端子螺丝扭力为 1.95 kg-cm (1.7 in-lbs),并请使用 60/75°C 铜导线。

產品外觀尺寸與部位介紹

详细图示请参阅英文版页码 1 之[Figure 1],单位:mm。

1. I/O 模块定位孔 2. DIN 导轨槽 (35mm)

3. I/O 模块连接端口 4. I/O 模块固定扣

电源、运行、错误及低电压指示灯

5.

(POWER, RUN, ERROR, L.V)

7. I/O 端子 8. RS-232 通讯端口

9. DIN 轨固定扣 10. RS-485 通讯端口

11. 电源输入口

通道净重、零点、最大值、稳定功能状态

6.

灯 (NET, ZERO, MAX, MOTION)

輸入∕輸出端子台配置

请参阅英文版页码 1 之端子配置图,在此语言版本省略说明。

外部配線

详细图示请参阅英文版页码 2 之[Figure 2]。

注 1:请将电源模块的 端及 Load Cell 秤重测量模块的 端连接到系统接地点,再将系统

接点作第三种接地或接到配电箱的机壳上。

規格

Load cell 模块 电压输出

电源额定电压/消耗功率

电压范围

最大消耗电流 125 mA

输入讯号范围 ±40 mVDC

感测度 +5 VDC +/-10%

内部分辨率 24 bits

通讯接口 RS-232, RS-485

适合感应器形式 4线制或 6 线制荷重单元(Load Cell)

温度系数扩展 ≤ ± 50 ppm/K v. E

温度系数偏移 ≤ ± 0.4 μV/K

线性误差 ≤ 0.02%

24VDC (-15% ~ +20%) / 3W

18 ~ 31.2 VDC

- 10 -

Page 12

Load cell 模块 电压输出

响应时间 2, 10, 20, 40, 80 ms × 通道数

适用 Load Cell 特征值 0 ~ 1, 0 ~ 2, 0 ~ 4, 0 ~ 6 mV/V

连接 Load Cell 最大距离 100 公尺

最大输出电流 5 VDC * 300 mA

允许负载能力 40 ~ 4,010 Ω

共模拒斥比

(CMRR @50/60 Hz)

动态值滤波 可设定范围 K1 ~ K5

平均功能 可设定范围 K1 ~ K100

隔离方式

与 DVP-PLC 主机

连接说明

操作∕储存环境

耐振动∕冲击

符合 DIN1319-1 在测量范围最终值为 20°C + 10K 的错误极限需 ≤ 0.05%。

Load Cell 校正环境温度与实际操作温度相差 10°C 以上时,建议重新校正以获得最佳精确值。

100dB 以上

数字量电路与接地之间:500 VAC

模拟量电路与接地之间:500 VAC

模拟量电路与数字量电路之间:500 VAC

连接于主机左侧,模块编号依靠近主机之顺序自动编号由 100 到

107。

操作:0 ~ 55°C(温度),50 ~ 95%(湿度),污染等级 2

储存:-25 ~ 70°C(温度),5 ~ 95%(湿度)

国际标准规范 IEC 61131-2, IEC 68-2-6 (TEST Fc)/IEC 61131-2 &

IEC 68-2-27 (TEST Ea)

控制寄存器 CR

位址 属性 寄存器名称 说明

CR#

#0 H1000 O R

#1 H1001 O R

#2 H1002 O R/W

#3 H1003 O R/W

#4 H1004 O R

#6 H1006 X R/W

#7 H1007 O R/W

#8 H1008 O R/W

#9 H1009 O R/W

#10 H100A O R/W

#11 H100B O R/W

机种型号 系统内定,DVP02LC-SL 机种代码 = H’4206

韧体版本 16 进制,显示目前韧体版本

特征值

测量反应时间

总通道平均值

CH1~CH2 皮重读取

毛重/净重显示设定

CH1 皮重重量值

CH2 皮重重量值

CH1 平均次数

CH2 平均次数

模式 0 (H’0000):1 m V/V

模式 1 (H’0001):2 m V/V,默认值。

模式 2 (H’0002):4 m V/V

模式 3 (H’0003):6 m V/V

模式 0 (H’0000):2 m s

模式 1 (H’0001):10 ms

模式 2 (H’0002):20 ms

模式 3 (H’0003):40 ms

模式 4 (H’0004):80 ms,默认值。

以 CH1 平均值及 CH2 平均值做加总平均

计算式:( CH1 平均值 + H2 平均值 ) ÷ 2

读取目前的平均值做为皮重的重量值

bit0:CH1。bit1:CH2。bit2 ~ bit15:保留。

选择目前重量显示为毛重(K0) 或净重(K1)

bit0~bit3:CH1。bit4~bit7:CH2。bit8~bit15:

保留。以 CH1 说明:bit3~bit0=0000,毛重。

bit3~bit0=0001,净重。b it3 ~bi t0 =1111,关 闭

通道。

使用者可自行写入或由指令读取皮重。

默认值 K0,设定值范围 K-32768~ K32767。

设定范围在 K1 ~ K100,默认值 K10。

设定值超过范围时,则自动变更为临界值 K1

或 K100。

- 11 -

Page 13

位址 属性 寄存器名称 说明

CR#

#12 H100C X R

#13 H100D X R

#14 H100E X R

#15 H100F X R

#16 H1010 O R/W

#17 H1011 O R/W

#18 H1012 O R/W

#19 H1013 O R/W

#20 H1014 O R/W

#21 H1015 O R/W

#22 H1016 O R/W

#23 H1017 O R/W

#24 H1018 O R/W

#25 H1019 O R/W

#26 H101A X R/W

#33 H1021 O R/W

#34 H1022 O R/W

#35 H1023 O R

#36 H1024 O R

#37 H1025 O R/W

#38 H1026 O R/W

#39 H1027 O R/W

#40 H1028 O R/W

#41 H1029 X R/W

#43 H102B X R/W

#44 H102C X R/W

#45 H102D X R/W

#46 H102E X R/W

CH1 平均重量

CH2 平均重量

CH1 现在重量

CH2 现在重量

CH1 稳定检查次数

CH2 稳定检查次数

CH1 稳定检查范围

CH2 稳定检查范围

CH1 小数点位数设定

CH2 小数点位数设定

CH1 重量测量单位

CH1 重量测量单位

CH2 重量测量单位

CH2 重量测量单位

调校重量指令

CH1 砝码基点重量

CH2 砝码基点重量

CH1 重量上限

CH2 重量上限

CH1 零点判断检查范

围上限

CH2 零点判断检查范

围上限

CH1 零点判断检查范

围下限

CH2 零点判断检查范

围下限

储存设定值 (H’5678)

CH1 滤波比例设定

CH2 滤波比例设定

CH1 滤波平均值

CH2 滤波平均值

平均重量值显示

现在重量值显示

默认值 K5,设定值范围 K1 ~ K500。

默认值 K10,设定 值范围 K1 ~ K10000。

设定范围在 K1 ~ K4,默认 值 K2。

ASCII 输入,最多四个字符。

CR#22, CR#24 为 high word

CR#23, CR#25 为 low word

使用者调校重量使用,默认值 H’0000。

H’0001:CH1 归零指令

H’0002:CH1 砝码基点指令

H’0003:CH2 归零指令

H’0004:CH2 砝码基点指令

CR#33 ~ CR#34 默认值 K1000,设定值范围

K-32768 ~ K32767。

使用者调整步骤:以 CH1 说明

Step1:荷重单元(Load Cell)上不放任何砝码

Step2:CR#26 设定调整指令为“H’0001”

Step3:荷重单元(Load Cell)上加上标准砝码

Step4:将目前底盘上的砝码重量写入 CR#33

Step5:CR#26 设定调整指令为“H’0002”

使用者可设定最大重量值,当量测值超出设定

值时会记录错误码。

归零状态判断参考,当重量值在此范围内,状

态码会设定为归零位(zero bit),表示目前是空

载状态。

默认值 K10,设定值范围 K-32768 ~ K32767。

归零状态判断参考,当重量值在此范围内,状

态码会设定为归零位(zero bit),表示目前是空

载状态。

默认值 K-10,设定值范围 K-32768 ~ K32767。

储存目前设定值,将目前所有设定值写入内存

Flash,以待下次开机使用。

H0:不动作,默认值

H’FFFF:储存成功

H’5678:写入内存

写入 H’5678 时会将所有设定值储存于 Flash

中,当储存完成后,CR#41 为 H’FFFF。若写

入值不为 H’5678,则自动回复为 H0。例如

CR# 写入 K1,会回复为 K0。

默认值 K2,设定值范围 K1 ~ K5(单位:10%)

滤波后平均重量显示

滤波功能启动条件:平均次数≥30。

- 12 -

Page 14

位址 属性 寄存器名称 说明

CR#

#50 H1032 X R

#51 H1033 X R

#52 H1034 O R/W

#53 H1035 O R/W

#54 H1036 O R/W

#55 H1037 O R/W

符号定义:O 表示为保持型。X 表示为非保持型。

R 表示为可读取数据。W 表示为可写入数据。

※ CR#51 错误状态表:

Bit 内容值 错误状态 Bit 内容值 错误状态

b0 K1 (H’0001) 电源异常 b1 K2 (H’0002) 硬件故障

b2 K4 (H’0004) CH1 转换错误 b3 K8 (H’0008) CH1 SEN 电压错误

b4 K16 (H’0010) CH2 转换错误 b5 K32 (H’0020) CH2 SEN 电压错误

b6 ~

K64 (H’0040) 保留

b15

注:每个错误状态由相对应之位决定,有可能会同时产生两个以上之错误状态,0 代表正

常无错误,1 代表有错误状态产生。

※ CR#53、CR#55 通设格式:

bit15 bit14~bit8 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

ACSII/RTU 保留 波特率 数据长度 停止位 同位

bit15 ACSII/RTU 0 ASCII 1 RTU

bit7~bit4 波特率

bit3 数据长度 (RTU = 8 bits) 0 7 1 8

bit2 停止位 0 1 bit 1 2 bits

bit1~bit0 同位

状态代码

错误代码

RS-232 站号

RS-232 通讯格式

RS-485 站号

RS-485 通讯格式

b0 (H’0001):CH1 零点重量(空载)

b1 (H’0002):CH2 零点重量(空载)

b2 (H’0004):CH1 超出重量上限(超载)

b3 (H’0008):CH2 超出重量上限(超载)

b4 (H’0010):CH1 测量值稳定

b5 (H’0020):CH2 测量值稳定

b6 ~ b15:保留

储存所有错误状态的数据缓存器,请参照错误

信息表,默认值为 H’0000。

CR#52、CR#54 默认值 K1,设定值范围 K1 ~

K255。

CR#53、CR#55 通设格式,默认值 H’0000,

设定值范围 ASCII, 9600, 7, E, 1,请参照通讯

格式信息表。

Description

0 9,600 bps 1 19,200 bps

2 38,400 bps 3 57,600 bps

4 115,200 bps 5 Else none

0 Even 1 Odd

2 None 3 None

- 13 -

Page 15

………………………………………………………………… TÜRKÇE …………………………………………………………………

Delta’nın DVP serisi PLC’lerini seçtiğiniz için teşekkürler. Delta, load cell ile ağırlık

ölçümü için DVP02LC-SL modülünü sunar. DVP02LC-SL, 4-telli ve 6-telli özgün değerli

yük hücreleri (load cell) için uygulanabilir 24-bit çözünürlük sağlar. Buna bağlı olarak,

cevap zamanı (response time) kullanıcı ihtiyaçlarına göre herbiri ile koordinasyon

halinde çalışma için ayarlanabilir. Bu temelde, ağırlık ölçümünde pazar ihtiyaçları

rahatça karşılanabilir.

a Bu bilgi dökümanı ürünün elektriksel özellikleri, genel özellikleri, kurulumu ve

bağlantısı ile ilgili bilgiler sağlar.

a Bu ürün AÇIK TİP I/O modülü olduğu için toz, nem, elektrik şoku ve titreşimden uzak

yerlere kurulumu yapılmalıdır. Ürünün zarar görmemesi ve tehlike durumları

oluşmaması için yetkili olmayan kişilerin ürüne müdahale etmesini önleyecek

koruyucu önlemler alınmalıdır. (Örneğin ürünün bulunduğu panoya kilit konulması

gibi).

a Ürünün I/O terminallerine AC besleme bağlamayınız; aksi halde ciddi zararlar

meydana gelebilir. Ürüne enerji vermeden önce tüm bağlantıların doğru olduğunu

tekrar kontrol ediniz. Elektromanyetik gürültüyü önlemek için toprak terminalinin

düzgün topraklandığından emin olunuz.

a I/O terminal bloğu sıkma torku 1.95 kg-cm (1.7 in-lbs) olmalı ve sadece 60/75°C bakır

iletkenler kullanılmalıdır.

Ürün Profili & Ölçüler

İngilizce bölümde Şekil 1 [Figure 1]’e bakınız. Birim = mm

1. I/O modülü montaj yuvası 2. DIN ray montaj slotu (35mm)

3. I/O modül bağlantı portu 4. I/O modül klip

Durum indikatör

5.

(POWER, RUN, ERROR ve L.V)

7. I/O terminaller 8. RS-232 port

9. Montaj slot klipsi 10. RS-485 port

11. DC besleme girişi

Fonksiyon durum göstergesi

6.

(NET, ZERO, MAX, MOTION)

I/O Terminal Yerleşimi

İngilizce bölümde “terminal layout” şekline bakınız.

Harici Bağlantı

İngilizce bölümde Şekil 2 [Figure 2]’ye bakınız.

Not 1: Power modülü ve load cell modülü terminallerini sistemin toprak ucunda

birleştirdikten sonra topraklamayı güç dağıtım panelinin kasasına bağlayarak yapınız.

Elektriksel Özellikler

Load cell modülü Volt aj çıkışı

Besleme voltajı /Güç

tüketimi aralığı

Volt aj sınırları 18 to 31.2 VDC

Max. akım tüketimi 125 mA

Giriş sinyal aralığı ±40 mVDC

Hassasiyet +5 VDC +/-10%

Dahili çözünürlük 24 bits

24 VDC (-15 to +20%) / 3W

- 14 -

Page 16

Load cell modülü Volt aj çıkışı

Haberleşme portu RS-232, RS-485

Uygulanabilir sensör

tipi

Sıcaklık span Katsayısı ≤ ± 50 ppm/K v. E

Sıcaklık zero point

Katsayısı

Linearite hatası

Cevap Zamanı 2, 10, 20, 40, 80 ms × kanal

4 ölçme aralığı 0 to 1 mV/V, 0 to 2 mV/V, 0 to 4 mV/V, 0 to 6mV/V

Load cell bağlantısı için

maksimum mesafe

Max. Akım çıkışı 5 VDC * 300 mA

Müsade edilen load cell

direnci

Ortak mod reddetme

(CMRR @50/60 Hz)

Dinamik değer filtresi

Ortalama değer filtresi

İzolasyon metodu

DVP-PLC MPU’ya seri

bağlantı

Çalışma/Saklama

Sıcaklığı

Titreşim / Şok

Bağışıklığı

DIN1319-1 ile uyumlu, ölçüm değeri toleransı 20°C + 10K sıcaklık aralığında ≤ 0.05 %

olmalıdır.

Düzeltilmiş sıcaklık ortamı ve gerçek sıcaklık arasında 10°C’den fazla fark varsa, tekrar

düzeltilmesi önerilir.

4-telli veya 6-telli gerinim ölçer

≤ ± 0.4 μV/K

≤ 0.02%

100m

40 to 4,010 Ω

≥ 100dB

Ayar aralığı: K1 to K5

Ayar aralığı: K1 to K100

Dijital devreler ve Ground arası 500 VAC

Analog devreler ve ground arası 500 VAC

Analog devreler ve dijital devreler arası 500 VAC

MPU’nun sol kenarına bağlanabilir, MPU’ya uzaklığına göre

yakından uzağa doğru 100 – 107 arası adreslenir.

Çalışma: 0 to 55°C (sıcaklık), 50 to 95% (rutubet), kirlenme derece 2

Saklama: -25 to ~70°C (sıcaklık), 5 to 95% (rutubet)

Uluslararası standartlar: IEC61131-2, IEC 68-2-6 (TEST Fc)/

IEC61131-2 & IEC 68-2-27 (TEST Ea)

Kontrol Register

CR# Add. Özellik Register adı Açıklama

#0 H1000 O R Model adı

#1 H1001 O R Yazılım versiyonu

#2 H1002 O R/W Karakteristik Değer

#3 H1003 O R/W

#4 H1004 O R

Ölçüm için tepki

zamanı

Tüm kanalların

ortalama değeri

Sistem tarafından ayarlanır:

DVP02LC-SL model kodu = H’4206

Mevcut yazılım versiyonunu Hex. olarak

gösterir.

Mod 0 (H’0000) : 1 mV/V

Mod 1 (H’0001) : 2 mV/V (Varsayılan)

Mod 2 (H’0002) : 4 mV/V

Mod 3 (H’0003) : 6 mV/V

Mod 0 (H’0000): 2 ms

Mod 1 (H’0001): 10 ms

Mod 2 (H’0002): 20 ms

Mod 3 (H’0003): 40 ms

Mod 4 (H’0004): 80 ms (Varsayılan)

CH1 ortalama değeri ve CH2 ortalama değeri

toplamını alır ve eşitler.

Eşitleme: (CH1 ortalama değeri + CH2

ortalama değeri) / 2

- 15 -

Page 17

CR# Add. Özellik Register adı Açıklama

#6 H1006 X R/W

CH1~2 brüt (daralı)

ağırlık okuma

#7 H1007 O R/W CH1~2 brüt/net ağırlık

#8 H1008 O R/W CH1 dara ağırlığı

#9 H1009 O R/W CH2 dara ağırlığı

#10 H100A O R/W CH1 ortalama adeti

#11 H100B O R/W CH2 ortalama adeti

#12 H100C X R CH1 ortalama ağırlık

#13 H100D X R CH2 ortalama ağırlık

#14 H100E X R CH1 mevcut ağırlık

#15 H100F X R CH2 mevcut ağırlık

#16 H1010 O R/W CH1 durgunluk adeti

#17 H1011 O R/W CH2 durgunluk adeti

#18 H1012 O R/W CH1 durgunluk aralığı

#19 H1013 O R/W CH2 durgunluk aralığı

#20 H1014 O R/W CH1 ondalık yeri

#21 H1015 O R/W CH2 ondalık yeri

#22 H1016 O R/W CH1 ölçüm birimi

#23 H1017 O R/W CH1 ölçüm birimi

#24 H1018 O R/W CH2 ölçüm birimi

#25 H1019 O R/W CH2 ölçüm birimi

#26 H101A X R/W

#33 H1021 O R/W

#34 H1022 O R/W

Ağırlık düzeltme

komutu

CH1 ağırlık temel

noktası

CH2 ağırlık temel

noktası

#35 H1023 O R CH1 max. ağırlık

#36 H1024 O R CH2 max. ağırlık

#37 H1025 O R/W

#38 H1026 O R/W

CH1 sıfır noktası

kontrol üst limiti

CH2 sıfır noktası

kontrol üst limiti

Mevcut ortalama değeri brüt ağırlık olarak

okur. bit0: CH1; bit1: CH2; bit2 ~ bit15:

rezerve

Mevcut ağırlığı Net (k0) veya Brüt (K1)

gösterir. bit0 ~ bit3: CH1; bit4~bit7: CH2; bit8

~ bit15: rezerve.

CH1 örneği: bit3 ~ bit0=0000, Brüt; bit3 ~

bit0=0001, Net; bit3 ~ bit0=1111, kanal pasif.

Kullanıcılar ağırlığı yazabilir veya komutlar ile

okuyabilir.

Var sa yılan: K0; Aralık: -K32,768 ~ K32,767.

Var sa yılan: K10; Aralık: K1 ~ K100.

Set değeri aralığı aştığı zaman, otomatik

olarak K1 ve K100 olarak değişir.

Ortalama ağırlığı gösterir.

Mevcut ağırlığı gösterir.

Var sa yılan: K5

Aralık: K1 ~ K500

Var sa yılan: K10

Aralık: K1 ~ K1,000

Var sa yılan: K2

Aralık: K1 ~ K4

Maksimum 4 ASCII word girilir.

CR#22, CR#24: Yüksek word

CR#23, CR#25: Düşük word

Kullanıcıların ağırlığı düzeltmesi için.

Var sa yılan: H’0000

H’0001: CH1 Sıfır komutuna resetle

H’0002: CH1 Ağırlık taban noktası komutu

H’0003: CH2 Sıfır komutuna resetle

H’0004: CH2 Ağırlık taban noktası komutu

CR#33~CR#34 için Varsayılan = K1,000;

Aralık: K-32,768 ~ K32,767

Düzeltme adımları: CH1 örneği

1: Load cell üzerine hiçbir ağırlık koymayınız.

2: CR#26 komutunu “H’0001” ayarlayınız.

3: Load cell üzerine standart ağırlığı

yerleştiriniz

4: Tabaka üzerindeki ağırlığı ikinci ağırlık

değeri olarak CR#33 içine yazınız.

5: CR#26 komutunu “H’0002” ayarlayınız

Maksimum ağırlık ayarı. Ölçüm değeri set

değerini aştığı zaman, hata kodları

kaydedilecek.

Sıfıra resetlemek için referans. Ağırlık bu

aralığın için de olduğu zaman, durum (Status)

kodu mevcut ağırlık durumunu gösteren

“zero bitini” set edecek.

Var sa yılan: K10

Aralık: K-32,768 ~ K32,767

- 16 -

Page 18

CR# Add. Özellik Register adı Açıklama

#39 H1027 O R/W

#40 H1028 O R/W

#41 H1029 X R/W

#43 H102B X R/W CH1 filtre yüzdesi

#44 H102C X R/W CH2 filtre yüzdesi

#45 H102D X R/W

#46 H102E X R/W

#50 H1032 X R Status (durum) kodu

#51 H1033 X R Hata kodu

#52 H1034 O R/W RS-232 slave adresi

#53 H1035 O R/W

#54 H1036 O R/W RS-485 slave adresi

#55 H1037 O R/W

Sembol:

O: Kalıcı; X: Kalıcı-değil; R: Okunabilir data; W: Yazılabilir data.

c CR#51 için Hata Kodu Tablosu:

bit İçeriği Hata bit İçeriği Hata

b0 K1 (H’0001)

b2 K4 (H’0004) CH1 dönüşüm hatası b3 K8 (H’0008) CH1 SEN voltaj hatası

b4 K16 (H’0010) CH2 dönüşüm hatası b5 K32 (H’0020) CH2 SEN voltaj hatası

b6 ~

K64 (H’0040) Rezerve

b15

Not: Her hata durumu ona karşılık gelen bir bit ile tanımlanır. Aynı anda 2 veya daha fazla

hata meydana gelebilir. 0 hata olmadığını; 1 hata olduğunu gösterir.

CH1 sıfır noktası

kontrol alt limiti

CH2 sıfır noktası

kontrol alt limiti

Set değeri kaydetme

(H’5678)

CH1 filtre ortalama

değeri

CH2 filtre ortalama

değeri

RS-232 haberleşme

formatı

RS-485 haberleşme

formatı

Power supply

anormal

Sıfıra resetlemek için referans. Ağırlık bu

aralığın için de olduğu zaman, durum (status)

kodu mevcut ağırlık durumunu gösteren

“zero bitini” set edecek.

Var sa yılan: K-10

Aralık: K-32,768 ~ K32,767

Mevcut set değerini kaydeder ve

DVP02LC-SL daha sonra enerjilendiğinde

kullanabilmesi için tüm set değerlerini dahili

flash içine yazar.

H0: Çalışma yok, Varsayılan

H’FFFF: Kayıt başarılı

H’5678: Dahili Flash’a yazar.

H’5678 yazıldığı zaman, tüm set değerleri

Flash içine kaydedilecek. Kayıt tamamlandığı

zaman, CR#41 H’FFFF olacak. Eğer yazılan

değer H’5678 değilse, otomatik olarak H0’a

dönecek. Örneğin CR# içine K1 yazılırsa

K0’a dönecek.

Default: K2; Aralık: K1 ~ K5 (Birim: 10%)

Filtrelemeden sonra ortalama ağırlığı gösterir

Filtre aktif etme şart: ortalama zam an ≥ 30

b0 (H’0001): CH1 sıfır ağırlık (boş)

b1 (H’0002): CH2 sıfır ağırlık (boş)

b2 (H’0004): CH1 maksimum ağırlığı aşar

(aşırı yük)

b3 (H’0008): CH2 maksimum ağırlığı aşar

(aşırı yük)

b4 (H’0010): CH1 sabit ölçüm değeri

b5 (H’0020): CH2 sabit ölçüm değeri

b6 ~ b15: Rezerve

Tüm hata durumlarını kaydeder. Lütfen

aşağıdaki “Hata kodu tablosu” na bakınız.

Var sa yılan: H’0000

CR#52, CR#54 için Varsayılan = 1; Aralık: K1

~ K255

CR#53, CR#55 için Varsayılan = H’0000;

Aralık: ASCII, 9600, 7, E ,1. “Haberleşme

Formatı Tablosu” na bakınız.

b1 K2 (H’0002) Hardware anormal

- 17 -

Page 19

c CR#53, CR#55 için Haberleşme Formatı Tablosu:

bit15 bit14 ~ bit8 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

ACSII/RTU Rezerve Baudrate

bit15 ASCII / RTU 0 ASCII 1 RTU

bit7 ~ bit4 Baudrate

bit3 Data uzunluğu (RTU = 8 bits) 0 7 1 8

bit2 Stop bit 0 1 bit 1 2 bits

bit1 ~ bit0 Parity

Açıklama

0 9,600 bps 1 19,200 bps

2 38,400 bps 3 57,600 bps

4 115,200 bps 5 Else none

0 Even 1 Odd

2 None 3 None

Data

Uzunluğu

Stop bit Parity

- 18 -

Loading...

Loading...