Dayton 2E511D, 3E219C, 3E218D User Manual

Operating Instructions & Parts Manual |

2E510D, 2E511D, 3E218D, and 3E219C |

|

|

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Dayton® Portable

Oil-Fired Heaters

Description

The Dayton models 2E510D, 2E511D, 3E218D, and 3E219C heaters are 30,000 to 150,000 Btu/Hr heaters. These heaters use Kerosene #1 fuel oil for combustion and electricity to run the motor. They are primarily intended for indoor and outdoor temporary heating of buildings under construction, alteration, or repair. They may be used in agricultural, industrial, and commercial environments.

Unpacking

1.Remove all packing items supplied with heater for shipment.

2.Remove all items from carton.

3.Check heater for any shipping damage. If heater is damaged, promptly inform dealer where you bought heater.

Figure 1 – Models 2E510D and 2E511D |

® |

Figure 2 – Models 3E218D and 3E219C |

GENERAL SPECIFICATIONS

|

Output |

|

Fuel Tank Capacity |

Fuel Consumption |

|

Model |

Rating Btu |

Fuel |

(U.S. Gallons) |

(U.S. Gallons/Hr.) |

Motor RPM |

2E510D |

35,000 |

Kerosene or No. 1 fuel oil |

3.0 |

0.3 |

1725 |

2E511D |

55,000 |

Kerosene or No. 1 fuel oil |

5.0 |

0.4 |

1725 |

3E218D |

110,000 |

Kerosene or No. 1 fuel oil |

9.0 |

0.8 |

3450 |

3E219C |

150,000 |

Kerosene or No. 1 fuel oil |

13.5 |

1.1 |

3450 |

|

Hot Air |

Air Pump |

Shipping Weight |

Heater Weight |

Spark Plug Gap |

Model |

Output (CFM) |

Pressure (PSI) |

(Pounds) |

(Pounds - without fuel) |

(Inches) |

2E510D |

165 |

3.0 |

38 |

35 |

.055 |

2E511D |

175 |

3.4 |

39 |

36 |

.075 |

3E218D |

490 |

4.5 |

65 |

55 |

.075 |

3E219C |

500 |

5.0 |

65 |

55 |

.075 |

Form 5S1792

© 1995 W.W. Grainger, Inc. Printed in U.S.A.

03430

0895/206/VCPVP

®

Version B - For Reduction |

G016.J |

Dayton Operating Instructions and Parts Manual

Dayton® Portable

Oil-Fired Heaters

ELECTRICAL SPECIFICATIONS

|

|

Amperage |

Model |

Electrical Input |

(during normal run) |

2E510D |

120 Volt/60 Hertz |

2.0 |

2E511D |

120 Volt/60 Hertz |

2.0 |

3E218D |

120 Volt/60 Hertz |

4.5 |

3E219C |

120 Volt/60 Hertz |

4.5 |

Product Identification

Hot Air |

|

|

Outlet |

|

|

|

Handle |

|

|

Upper Shell |

|

|

Fan Guard |

|

Lower |

|

|

Shell |

Air Filter |

|

|

End Cover |

|

Fuel |

Fuel |

|

Cap |

||

Tank |

||

|

Side Cover |

|

|

|

Flame-Out Control |

Power Cord |

Figure 3 – Models 2E510D and 2E511D |

Reset Button |

|

Hot Air Outlet |

Fuel Cap |

Upper Shell |

|

|

|

|

Fan |

|

|

Guard |

|

|

Fuel |

|

|

Tank |

|

Lower Shell |

|

|

Side Cover |

Power Cord |

|

|

|

Figure 4 – Models 3E218D and 3E219C |

|

Flame-Out Control |

|

Reset Button |

|

|

|

101421

2

Dayton Operating Instructions and Parts Manual

Models 2E510D, 2E511D, 3E218D, and 3E219C

General Safety Information

Make certain you read and understand all warnings. Keep these instructions for reference. They are your guide to safe and proper operation of this heater.

Safety information appears throughout these instructions. Pay close attention to them. Below are definitions for the safety information listed throughout this manual.

Under this heading, installation, operat-

ing and maintenance procedures or practices will be found that, if not carefully followed, WILL result in IMMEDIATE serious personal injury or death.

Under this heading, installation, operating, and maintenance proce-

dures or practices will be found that, if not carefully followed, COULD result in severe personal injury or death.

Under this heading, installation, operat-

ing, and maintenance procedures or practices will be found that, if not carefully followed, COULD result in minor personal injury, product or property damage.

IMPORTANT: Every possible circumstance that might involve a hazard cannot be anticipated. The warnings in this manual and on tags or decals affixed to the unit are therefore not all-inclusive. If a procedure, work method, or operating technique not specifically recommended by Dayton is used, you must make sure it is safe for you and others. You should also ensure that equipment will not be damaged or made unsafe by the operating or maintenance method you choose.

Carbon monoxide poisoning may lead

to death! Carbon monoxide poisoning: Some people are more affected by carbon monoxide than others. Early signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness, and/or nausea. If you have these signs, the heater may not be working properly. Get fresh air at once! Have heater serviced.

Improper use of this heater can

cause serious injury or death from burns, fire, explosion, electrical shock, and carbon monoxide poisoning.

Make certain you read and understand all warnings. Keep these instructions for reference. They are your guide to safe and proper operation of this heater.

• Use only kerosene or No. 1 fuel

oil to avoid risk of fire or explosion. Never use gasoline, naphtha, paint thinners, alcohol, or other highly flammable fuels.

•Fueling

a)Personnel involved with fueling shall be qualified and thoroughly familiar with the manufacturer's instructions and applicable federal, state, and local regulations regarding the safe fueling of heating units.

b)Only the type of fuel specified on the heater's data plate shall be used.

c)All flame, including the pilot light, if any, shall be extinguished and the heater allowed to cool, prior to fueling.

d)During fueling, all fuel lines and fuel-line connections shall be inspected for leaks. Any leaks shall be repaired prior to returning the heater to service.

e)At no time shall more than one day's supply of heater fuel be stored inside a building in the vicinity of the heater. Bulk fuel storage shall be outside the structure.

f)All fuel storage shall be located a minimum of 25 feet from heaters, torches, welding equipment, and similar sources of ignition (exception: the fuel reservoir integral with the heater unit).

g)Whenever possible, fuel storage shall be confined to areas where floor penetrations do not permit fuel to drip onto or be ignited by a fire at lower elevation.

h)Fuel storage shall be in accordance with the federal, state, or local authority having jurisdiction.

•Never use heater where gasoline, paint thinner, or other highly flammable vapors are present.

•Follow all local ordinances and codes when using heater.

•Use only in well-vented areas. Provide at least three square feet of fresh, outside air for each 100,000 BTU/Hr of rating. This heater produces carbon monoxide, which is listed by the State of California as a reproductive toxin under Proposition 65.

•Use only in places free of flammable vapors or high dust content.

•Use only with the electrical voltage and frequency specified on model plate.

•Use only a three-prong, grounded extension cord.

®

101421

3

Dayton Operating Instructions and Parts Manual

Dayton® Portable

Oil-Fired Heaters

General Safety Information

(Continued)

•Heaters used in the vicinity of tarpaulins, canvas, or similar enclosure materials shall be located a safe distance from such materials. The recommended minimum safe distance is 10 feet. It is further recommended that these enclosure materials be of a fire retardant nature. These enclosure materials shall be securely fastened to prevent them from igniting or from upsetting the heater due to wind action.

•Minimum heater clearances from combustibles:

Outlet: 8 Ft. |

Sides: 4 Ft. |

Top: 4 Ft. |

Rear: 4 Ft. |

•Locate heater on a stable and level surface while hot or running or a fire may occur.

•When moving or storing heater, keep heater in a level position or fuel spillage may occur.

•Keep children and animals away from heater.

•Unplug heater when not in use.

•When used with thermostat, heater may start anytime.

•Never use heater in living or sleeping areas.

•Never block air inlet (rear) or air outlet (front) of heater.

•Never move, handle, refuel, or service a hot, operating, or pluggedin heater.

•Never attach duct work to front or rear of heater.

THEORY OF OPERATION

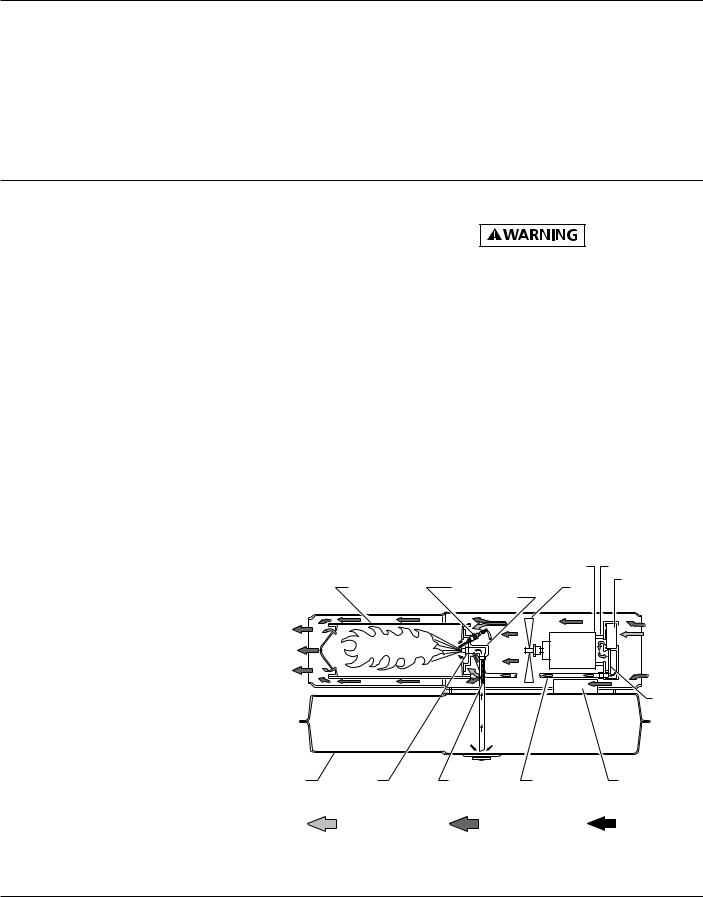

THE FUEL SYSTEM: The air pump forces air through the air line. The air is then pushed through the burner head nozzle. This air causes fuel to lift from the tank. A fine mist of fuel is sprayed into the combustion chamber.

THE AIR SYSTEM: The motor turns the fan. The fan pushes air into and around the combustion chamber. This air is heated and provides a stream of clean, hot air.

THE IGNITION SYSTEM: The electronic ignitor sends voltage to the spark plug. The spark plug ignites the fuel and air mixture.

THE FLAME-OUT CONTROL SYSTEM: This system causes the heater to shut down if the flame goes out.

FUELS

Use only kerosene or No. 1 fuel oil to

avoid risk of fire or explosion. Never use gasoline, naphtha, paint thinners, alcohol, or other highly flammable fuels.

Do not use heavy fuels such as No. 2 fuel oil or No. 2 Diesel. Using heavy fuels will result in:

•clogged fuel filter and nozzle

•carbon build-up on spark plug

•the need of non-toxic anti-icer in fuel during very cold weather

IMPORTANT: Use a KEROSENE ONLY container. Be sure storage container is clean. Foreign matter such as rust, dirt, or water will cause the flame-out control to shut down heater. Foreign matter may also require you to clean fuel system often.

|

|

|

|

Motor |

Air Pump |

|

Combustion |

Spark |

|

Fan |

Air Intake |

|

Chamber |

Plug |

Burner |

Filter |

|

|

|

|

Head |

|

|

Clean |

|

|

|

|

|

Heated |

|

|

|

|

Cool |

Air Out |

|

|

|

|

Air In |

|

|

|

|

|

Air |

|

|

|

|

|

Output |

|

|

|

|

|

Filter |

Fuel |

Nozzle |

Fuel |

|

Air Line |

Electronic |

Tank |

Filter |

|

To Burner |

Ignitor |

|

|

|

||||

|

Air For Fuel |

|

Air For Combus- |

Fuel |

|

|

System |

|

tion and Heating |

||

|

|

|

|||

Figure 5 - Cross Section Operational View

101421

4

Dayton Operating Instructions and Parts Manual

Models 2E510D, 2E511D, 3E218D, and 3E219C

General Safety Information

(Continued)

ASSEMBLY

(For Models 3E218D and 3E219C Only)

These models are furnished with wheels and handles. Wheels, handles, and the mounting hardware are found in the shipping carton.

TOOLS NEEDED

•Medium Phillips Screwdriver

•3/8" Open or Adjustable Wrench

•Hammer

1.Slide axle through wheel support frame. Install wheels on axle.

Front Handle

Rear Handle

IMPORTANT: When installing wheels, point extended hub of wheels toward wheel support frame (see Figure 6).

2.Place cap nuts on axle ends. Gently tap with hammer to secure.

3.Place heater on wheel support frame. Make sure air inlet end (rear) of heater is over wheels. Line up holes on fuel tank flange with holes on wheel support frame.

4.Place front handle and rear handle on top of fuel tank flange. Insert screws through handles, fuel tank flange, and wheel support frame. Attach nut finger tight after inserting each screw.

5.After inserting all screws, tighten nuts firmly.

VENTILATION

Operation

Review and understand the

warnings in the Safety Information Section. They are needed to safely operate this heater. Follow all local codes when using this heater.

TO START HEATER

1.Follow all ventilation and safety information.

2.Fill fuel tank with kerosene or No. 1 fuel oil.

3.Attach fuel cap.

4.Plug power cord of heater into three-prong, grounded extension cord. Extension cord must be at least six feet long.

EXTENSION CORD WIRE SIZE

REQUIREMENTS

•6 to 10 feet long, use 18 AWG rated cord.

|

Screw |

|

Hot Air |

|

|

Outlet |

|

|

Fuel |

Air |

|

Tank |

||

Inlet |

||

Flange |

||

|

Wheel Support

Frame

Nut

Extended

Hub

Axle

Cap Nut

Wheel

Figure 6 - Wheel and Handle Assembly,

Models 3E218D and 3E219C Only

Follow the minimum fresh, outside

air ventilation requirements. If proper fresh, outside air ventilation is not provided, carbon monoxide poisoning can occur. Provide proper fresh, outside air ventilation before running heater.

Provide a fresh air opening of at least three square feet for each 100,000 Btu/Hr rating. Provide extra fresh air if more heaters are being used.

Example: A 150,000 Btu/Hr heater requires one of the following:

•a two-car garage door raised six inches

•a single-car garage door raised nine inches

•two, thirty-inch windows raised twelve inches

•11 to 100 feet long, use 16 AWG rated cord.

•101 to 200 feet long, use 14 AWG rated cord.

Flame-out Control

Reset Button

Figure 7 - Flame-out Control Reset

Button, Models 2E510D and 2E511D

®

101421

5

Dayton Operating Instructions and Parts Manual

Dayton® Portable

Oil-Fired Heaters

Operation (Continued)

Flame-out

Control Reset

Button

Figure 8 - Flame-out Control Reset

Button, Models 3E218D and 3E219C

5.Plug extension cord into standard 120 volt/60 hertz, three-hole, grounded outlet. Heater will start when extension cord is plugged into outlet. If not, push in flame-out control reset button (see Figures 7 and 8).

TO STOP HEATER

1. Unplug extension cord from outlet.

TO RESTART HEATER

1.Wait 2 minutes after stopping heater.

2.Repeat steps under To Start Heater.

NOTE: For automatic operation, use Model 2E535 or Model 2E817 thermostat (see Accessories, page 20).

Maintenance

Never service heater while it is

plugged in, operating, or hot. Severe burns and electrical shock can occur.

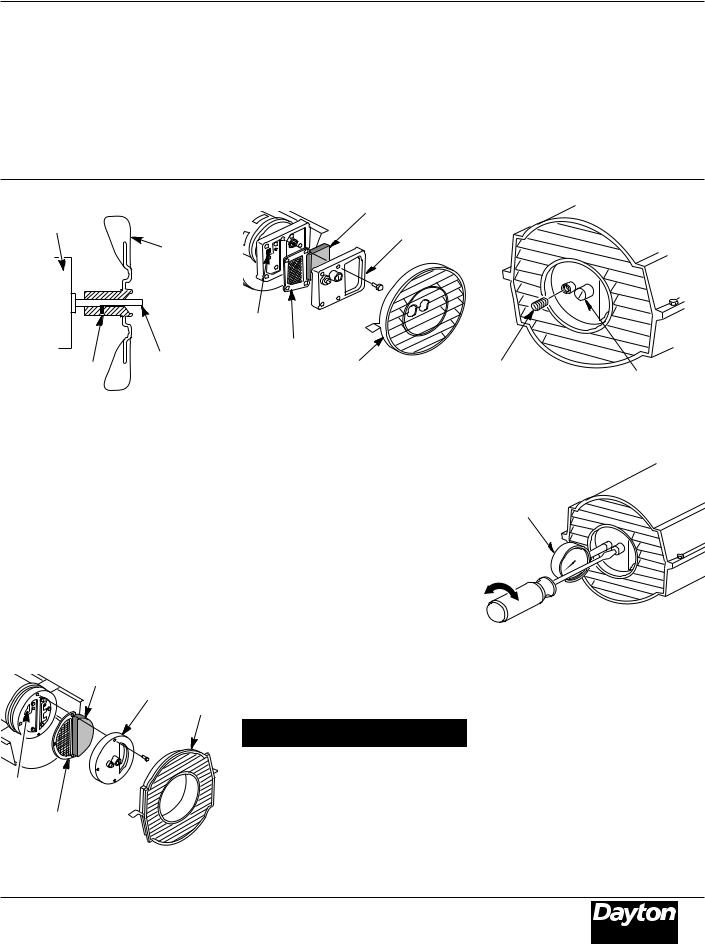

UPPER SHELL REMOVAL

1.Remove screws along each side of heater using 5/16" nut-driver. These screws attach upper and lower shells together (see Figures 9 and 10).

2.Lift upper shell off.

3.Remove fan guard.

Upper Shell

Fan Guard

Figure 9 - Upper Shell Removal, Models 2E510D and 2E511D

1.Remove upper shell.

2.Use 1/8" Allen wrench to loosen setscrew which holds fan to motor shaft.

3.Slip fan off motor shaft.

4.Clean fan using a soft cloth moistened with kerosene or solvent.

5.Dry fan thoroughly.

6.(Models 2E510D, 2E511D, and 3E218D) Replace fan on motor shaft. Place fan hub flush with end of motor shaft (see Figure 11).

(Model 3E219C) Replace fan on motor shaft. Make sure set screw is touching back of flat surface on motor shaft (see Figure 12, page 7).

7.Place setscrew on flat of shaft. Tighten setscrew firmly (40-50 inch-pounds).

8.Replace fan guard and upper shell.

Upper |

Fan |

|

|

Shell |

Motor |

|

|

|

Setscrew |

Flush

Fan

Guard

Figure 10 - Upper Shell Removal,

Models 3E218D and 3E219C Motor

Shaft

FAN

IMPORTANT: Remove fan from motor shaft before removing motor from heater. The weight of the motor resting

on the fan could damage the fan pitch. Figure 11 - Fan Cross Section, Models

2E510D, 2E511D, and 3E218D

101421

6

Dayton Operating Instructions and Parts Manual

Models 2E510D, 2E511D, 3E218D, and 3E219C

Maintenance (Continued)

Motor

Fan

Motor

Setscrew Shaft

Figure 12 - Fan Cross Section, Model 3E219C

AIR OUTPUT, AIR INTAKE, AND LINT FILTERS

Air Intake Filter

Filter End Cover

Lint |

|

|

|

Filter |

|

|

|

Air Output |

|

|

|

Filter |

Pressure |

|

|

Fan Guard |

|

||

|

Gauge Plug |

Relief |

|

Figure 14 - Air Output, Air Intake, and |

|

Valve |

|

Figure 15 - Pressure Gauge Plug |

|||

Lint Filters, Models 3E218D and 3E219C |

|||

|

Removal |

|

|

1.Remove upper shell (see Figure 10).

2.Remove filter end cover screws using 5/16" nut-driver.

3.Remove filter end cover.

4.Replace air output and lint filters.

5.Wash and dry with soap and water or replace air intake filter.

6.Replace filter end cover.

7.Replace fan guard and upper shell.

IMPORTANT: Do not oil filters.

PUMP PRESSURE ADJUSTMENT

1.Remove pressure gauge plug from filter end cover (see Figure 15).

2.Install accessory pressure gauge (part number HA1180) (see Figure 16).

3.Start heater (see Operation, page 5). Allow motor to reach full speed.

4.Adjust pressure. Turn relief valve to right to increase pressure. Turn relief valve to left to decrease pressure. See specification chart below for correct pressure for each model.

Pressure

Gauge

PRESSURE ADJUST |

P |

Figure 16 - Adjusting Pump Pressure

Air Intake Filter |

|

Filter End Cover |

|

Fan Guard |

|

|

Pump |

Model |

Pressure |

|

2E510D |

3.0 PSI |

Lint Filter |

2E511D |

3.4 PSI |

|

3E218D |

4.5 PSI |

Air Output Filter |

3E219C |

5.0 PSI |

Figure 13 - Air Output, Air Intake, and |

5. Remove pressure gauge. Replace |

|

pressure gauge plug in filter end cover. |

||

Lint Filters, Models 2E510D and 2E511D |

FUEL FILTER

1.Remove side cover screws using 5/16" nut-driver.

2.Remove side cover.

3.Pull upper fuel line off fuel filter neck (see Figure 17, page 8).

4.Carefully pry bushing, fuel filter, and lower fuel line (Models 3E218D and 3E219C only) out of fuel tank (see Figure 18, page 8).

®

101421

7

Dayton Operating Instructions and Parts Manual

Dayton® Portable

Oil-Fired Heaters

Maintenance (Continued)

5.Wash fuel filter with clean fuel and replace in tank.

6.Attach upper fuel line to fuel filter neck.

7.Replace side cover.

Fuel Filter

Side |

Upper Fuel Line |

|

Cover |

||

|

Figure 17 - Fuel Filter Removal, Models 2E510D and 2E511D

Fuel Filter, Bushing, and

Lower Fuel Line

Upper

Fuel

Line

Side

Cover

Figure 18 - Fuel Filter Removal, Models 3E218D and 3E219C

SPARK PLUG

(Models 2E510D and 2E511D)

1.Remove upper shell (see page 6).

2.Remove fan (see page 6).

3.Remove fuel and air line hoses from nozzle assembly.

4.Remove spark plug wire from spark plug.

Burner Strap

45° |

5.Remove two screws using 5/16" nutdriver and remove burner strap.

6.Place hex-body of spark plug into vise and tighten.

7.Remove spark plug mounting nut using 11/16" open-end wrench.

8.Remove burner strap from spark plug.

Combustion |

Spark Plug |

|

Chamber |

||

Mounting Nut |

||

|

||

|

Burner Strap |

|

|

Spark Plug |

|

|

Wire |

Nozzle |

Spark Plug |

|

Assembly |

|

|

Air Line |

Fuel Line |

|

Hose |

||

Hose |

||

|

Figure 19 - Spark Plug Removal, Models 2E510D and 2E511D

Bend Here to

Adjust Gap

Gap

Figure 20 - Spark Plug Gap, Models 2E510D and 2E511D

Figure 21 - Spark Plug Rotation, Models 2E510D and 2E511D

9.Clean and regap spark plug electrodes to .055" 2E510D and .075" 2E511D gap.

10.Replace burner strap onto spark plug. Rotate burner strap to position spark plug electrodes (see Figure 21).

11.Tighten spark plug with spark plug mounting nut.

12.Release hex-body of spark plug from vise.

13.Replace burner strap onto combustion chamber.

14.Attach spark plug wire to spark plug.

15.Attach fuel and air line hoses to nozzle assembly.

16.Replace fan (see page 6).

17.Replace fan guard and upper shell.

SPARK PLUG

(Models 3E218D and 3E219C)

1.Remove upper shell (see page 6).

2.Remove fan (see page 6).

3.Remove spark plug wire from spark plug.

4.Remove spark plug from burner head using 13/16" open-end wrench.

101421

8

Loading...

Loading...