Dayton 1P579F User Manual

Form 5S5193

Rev. 01/2005

E

N

G

L

I

S

H

E

S

P

A

Ñ

O

L

F

R

A

N

Ç

A

I

S

Operating Instructions and Parts Manual 1P579F

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by obeying all Safety Information. Failure to comply with Instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Dayton

™

Marine Utility Pump

Description

Dayton marine utility pump is designed for general commercial and

industrial applications. Unit is designed for water, but is not submersible.

For use transferring liquids, emptying or filling tanks, sinks or bowls. The

pump can be used to pump bilge water, but the pump must not be

located in the bilge area. Self-priming to 7 ft. if the impeller is initially

wet (primed). Intermittent duty. Carrying handle included.

NOTE: Unit is NOT RECOMMENDED for use with soap detergents, gasoline,

waste oil, fuel oil, flammable, explosive or combustible liquids or other

fluids not compatible with pump component materials. Do not use unit

in enclosed areas. Intermittent duty only (15 minutes per hour).

Unpacking

When unpacking the unit, inspect carefully for any damage that may

have occurred during transit. Check for loose, missing, or damaged parts.

Two extra impellers and gaskets are included with pump.

Specifications

Power supply required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115V, 60Hz

Fuse requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Amps

Maximum liquid temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140°F

Minimum liquid temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40°F

Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatic Resetting

Motor amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.60 Amps

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent

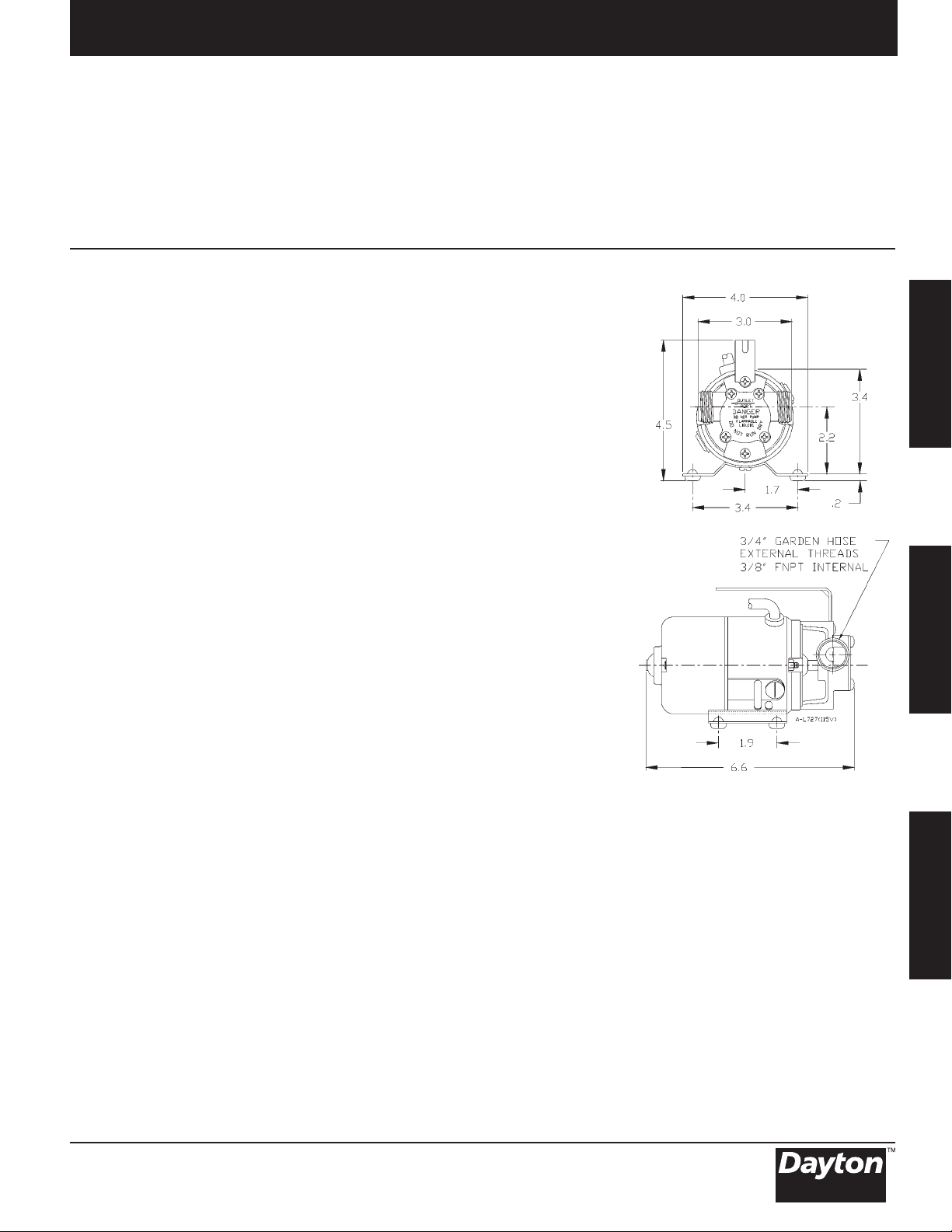

Dimensions

Figure 1 - Dimensions

Printed in U.S.A.

05655

1204/399/VCPVP

998327

Dayton Operating Instructions and Parts Manual 1P579F

E

N

G

L

I

S

H

2

Safety Guidelines

Do not use to pump flammable

or explosive fluids such as

gasoline, fuel oil, kerosene,

etc. Do not use in flammable

and/or explosive atmospheres.

Pump should only be used with

liquids compatible with pump

component materials. Failure

to follow this warning can

result in personal injury and/or

property damage.

1. Know the pump application,

limitations, and potential hazards.

2. WARNING: Do not handle a

pump or pump motor with wet

hands or when standing on a

wet or damp surface, or in water.

3. The pump is not submersible and

is intended for open-air use only.

4. Disconnect power before

servicing a motor or its load.

If the power disconnect is outof-sight, lock it in the open

position and tag it to prevent

unexpected application of power.

5. Release all pressure within the

system before servicing any

component.

6. Drain all liquids from the system

before servicing.

7. The pump motor is equipped

with an automatic resetting

thermal protector and may

restart unexpectedly. Protector

tripping is an indication of

motor overloading as a result

of operating the pump at low

heads (low discharge restriction), excessively high or low

voltage, inadequate wiring,

pumping too hot a liquid,

incorrect motor connections,

or a defective motor or pump.

Read troubleshooting chart.

WARNING

8. Do not touch an operating

motor. Modern motors are

designed to operate at high

temperatures.

9. Provide adequate protection and

guarding around moving parts.

10. Secure the discharge line

before starting the pump. An

unsecured discharge line will

whip, possibly causing personal

injury and/or property damage.

11. Check hoses for weak or worn

condition before each use, making

certain that all connections are

secure.

12. Periodically inspect pump and

system components. Perform

routine maintenance as required

(see Maintenance section).

13. Provide a means of pressure

relief for pumps whose discharge line can be shut-off or

obstructed.

14. Personal Safety: Wear safety

glasses at all times when

working with pumps.

Electrical Connections

1. Make certain that power

source conforms to the requirements of your equipment.

2. When wiring an electrically

driven pump, follow all electrical

and safety codes, as well as the

most recent National Electrical

Code (NEC) and the Occupational

Safety and Health Act (OSHA)

in the United States.

3. This equipment is only for use

on 115 volt (single-phase) and

is equipped with an approved

3-conductor cord and 3-prong,

grounding-type plug.

4. To reduce the risk of electric

shock, the unit should be

plugged directly into a properly

installed and grounded 3-prong

grounding-type receptacle. The

green (or green and yellow)

conductor in the cord is the

grounding wire. The motor

must be securely and adequately

grounded for your protection

against shock hazards! Never

connect the green (or green and

yellow) wire to a live terminal!

5. Where a 2-prong wall receptacle

is encountered, it must be

replaced with a properly

grounded 3-prong receptacle

installed in accordance with

the National Electrical Code

and local codes and ordinances.

6. To ensure a proper ground, the

grounding means must be tested

by a qualified electrician. Use

only 3-wire extension cords

that have 3-prong, groundingtype plugs and receptacles that

accept the equipment plug.

7. All wiring should be performed

by a qualified electrician.

8. Protect electrical cord from

sharp objects, hot surfaces, oil

and chemicals. Avoid kinking

the cord. Replace or repair

damaged or worn cords

immediately.

9. When using an extension cord,

make sure wire is of adequate

size to minimize voltage drop

at the motor.

Dayton

™

Marine Utility Pump

E

N

G

L

I

S

H

Installation

In any installations where

property damage and/or personal

injury might result from an

inoperative or leaking pump due

to power outages, discharge

line blockage, or any other

reason, a backup system(s)

should be used. In order to

safely use this product, familiarize yourself with this pump and

also with the liquid (chemical,

etc.) that is going to be pumped

through the unit. This pump is

not suitable for many liquids.

1. Pump should be placed as close

to source of liquid and power as

possible, not more than 7 feet

above liquid source and not more

than 25 feet from power source.

2. Use reinforced plastic or fabric

tubing or metal pipe for the

suction side of the pump. This

will prevent collapse of the

suction piping. Discharge piping

should never be larger than

suction piping!

3. Attach suction line piping to the

suction inlet and discharge line

piping to the discharge outlet.

4. Avoid using looped sections of

pipe which might permit air to

become entrapped.

5. Piping should be checked for any

leaks at the connections. Small

leaks in suction line greatly

reduce efficiency of pump and

may prevent priming. Pump

should be permanently mounted;

never operate a pump unless it

is secured to a solid foundation.

6. Do not operate pump dry.

Impeller and mechanical seal

damage will result.

WARNING

7. Protect pump from extreme

heat, cold. and humidity. This

unit is not waterproof and is

not intended to be used in

showers, saunas, or other

potentially wet locations.

8. The motor is designed to be

used in a clean, dry location

with access to an adequate

supply of cooling air. Ambient

temperature around the motor

should not exceed 104°F (40°C).

For outdoor installations motor

must be protected by a cover

that does not block airflow to

and around the motor. This unit

is not weatherproof, nor is it

able to be submersed in water

or any other liquid. Do not use

in or near swimming pool or spa.

9. Install a foot valve and prime

pump when suction lift is over

six feet or when suction line is

longer than six feet.

10. It is strongly recommended that

this unit is plugged into a GFCI

(Ground Fault Circuit Interrupter).

Consult your local electrician

for installation and availability.

Operation

1. Pumps are self-priming and

should prime themselves within

30 seconds after pump is started.

Wetting impeller with pumped

fluid and keeping the impeller

coated with petroleum jelly will

lengthen its life and improve

priming action. Running the

impeller dry for as short as 30

seconds can ruin the impeller. Keep

suction line as short as possible.

NOTE: An easy way to prime the

pump (wet impeller), if using a

garden hose, is to fill the discharge

hose; elevate the discharge hose

slightly to retain water and start

WARNING

the pump. Another method would

be to disconnect the discharge hose

from the pump, making a U-bend

of the discharge hose. Fill the hose

then reconnect (without losing the

water) to the pump. In both cases

the water behind the impeller will

seal the pump and it should prime

almost immediately.

2. Unit can be turned on and off

by plugging & unplugging cord

into 115V outlet.

3. Do not run at heads greater

than 35 feet (15psig).

Because unit is thermally protected, it is designed to shut off

temporarily in an over-heat

condition; therefore, pumping

extremely hot liquids is not

recommended. Also, to protect

the impeller from breakage, do

not pump liquids with a temperature less than 40°F.

Do not submerge pump or

motor in water.

Maintenance

Make certain the unit is disconnected from the power source

before attempting to service or

remove any component!

1. Always drain pump when not

in use.

2. If pump is not going to be used

for a month or longer, flush with

fresh water and remove body

cover, take impeller out, clean

inside body and apply generous

coating of Vaseline

®

, to both

inside body and impeller before

replacing impeller in body.

CAUTION

WARNING

CAUTION

3

Dayton Operating Instructions and Parts Manual

Model 1P579F

E

N

G

L

I

S

H

Dayton Operating Instructions and Parts Manual 1P579F

3. Pump should be checked daily,

weekly, monthly, etc., for proper

operation. If anything has changed

since unit was new, unit should

be removed and repaired or

replaced. Only qualified electricians

or servicemen should attempt

to repair this unit. Improper

repair and/or assembly can

cause an electrical shock hazard.

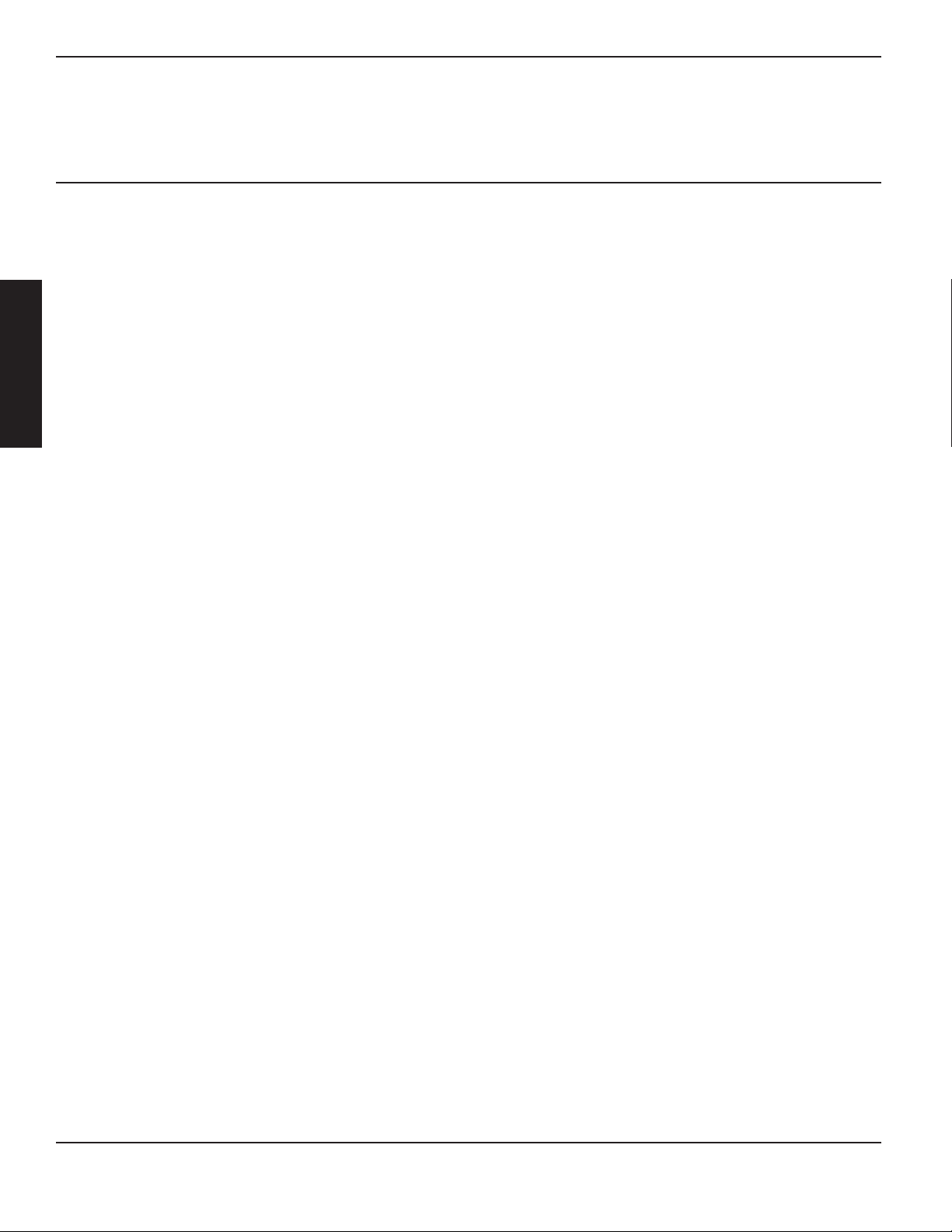

TO REPLACE IMPELLER:

NOTE: Impeller replacement is not

a warranty item.

1. Replace impeller when worn,

damaged by foreign objects, run

dry or when pumping a liquid

not compatible with impeller.

2. Obtain service Repair Kit

No.1R387A.

3. Remove cover plate and gasket.

4. Remove impeller.

5. Grease the new impeller with

Vaseline petroleum jelly or similar

lubricant and align the flat on the

inside of the impeller with the

flat on the motor shaft. Push

impeller into place and at the same

time twist in clockwise direction.

This will bend the blades in the

direction required for running.

6. Replace cover using new gasket

provided with each 1R387A Repair

Kit. Tighten all screws evenly and

snugly. DO NOT over-tighten.

4

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not run

1. No electricity

2. Brushes worn out

3. Impeller jammed

4. Motor has open circuit

5. Motor overheated

1. Determine that outlet is for 115VAC

2. Replace

3. Clear obstruction

4. Replace

5. Motor has Automatic Thermal Protector. Wait for

fifteen minutes for motor to cool, then restart.

Liquid may be too hot.

Pump runs but no fluid is

pumped.

1. Faulty suction piping

2. Defective impeller

3. Suction lift too high

4. Discharge height too great

5. Clogged inlet

6. Pump too far from liquid

1. Repair or replace

2. Replace

3. Lower pump

4. Lower the height

5. Clean or replace

6. Relocate

Pump will not prime or retain

prime after operating.

1. Air leak in suction line

2. Defective impeller

3. Seal worn

4. Gasket leaking

5. Groove worn in shaft at seal area

6. Suction lift too high

7. Hose kinked

8. Hose fitting not tight on head

9. Inadequate impeller lubrication

1. Repair or replace.

2. Replace

3. Replace

4. Replace

5. Replace motor

6. Lower pump

7. Straighten hose

8. Tighten hose

9. Lubricate through inlet or outlet of pump head.

See note in Operation.

Flow rate is low

1. Piping or hose is fouled or damaged

2. Clogged impeller

3. Worn cam or impeller

4. Voltage incorrect

1. Clean or replace

2. Clear obstruction

3. Replace

4. Supply to be 115VAC, 60Hz

Shaft seal leaks

1. Seal worn out

2. Shaft grooved

3. Pump head loose on motor

1. Replace

2. Replace motor

3. Repair

Motor runs too hot

1. Voltage incorrect

2. Excessive discharge pressure

3. Impeller swollen

4. Liquid too viscous

5. Plugged or kinked discharge

6. Insufficient air flow on motor

1. Supply to be 115VAC, 60Hz

2. Reduce pressure

3. Replace

4. Reduce viscosity of liquid

5. Examine and repair

6. Be sure ample fresh air is available at the motor.

Dayton

™

Marine Utility Pump

E

N

G

L

I

S

H

5

Dayton Operating Instructions and Parts Manual

For Repair Parts, call 1-800-323-0620

Please provide the following information:

— Model number

— Serial number (if any)

— Part description and number as shown in parts list

Address parts correspondence to:

Grainger Parts

P.O. Box 3074

1657 Shermer Road

Northbrook, IL 60065-3074

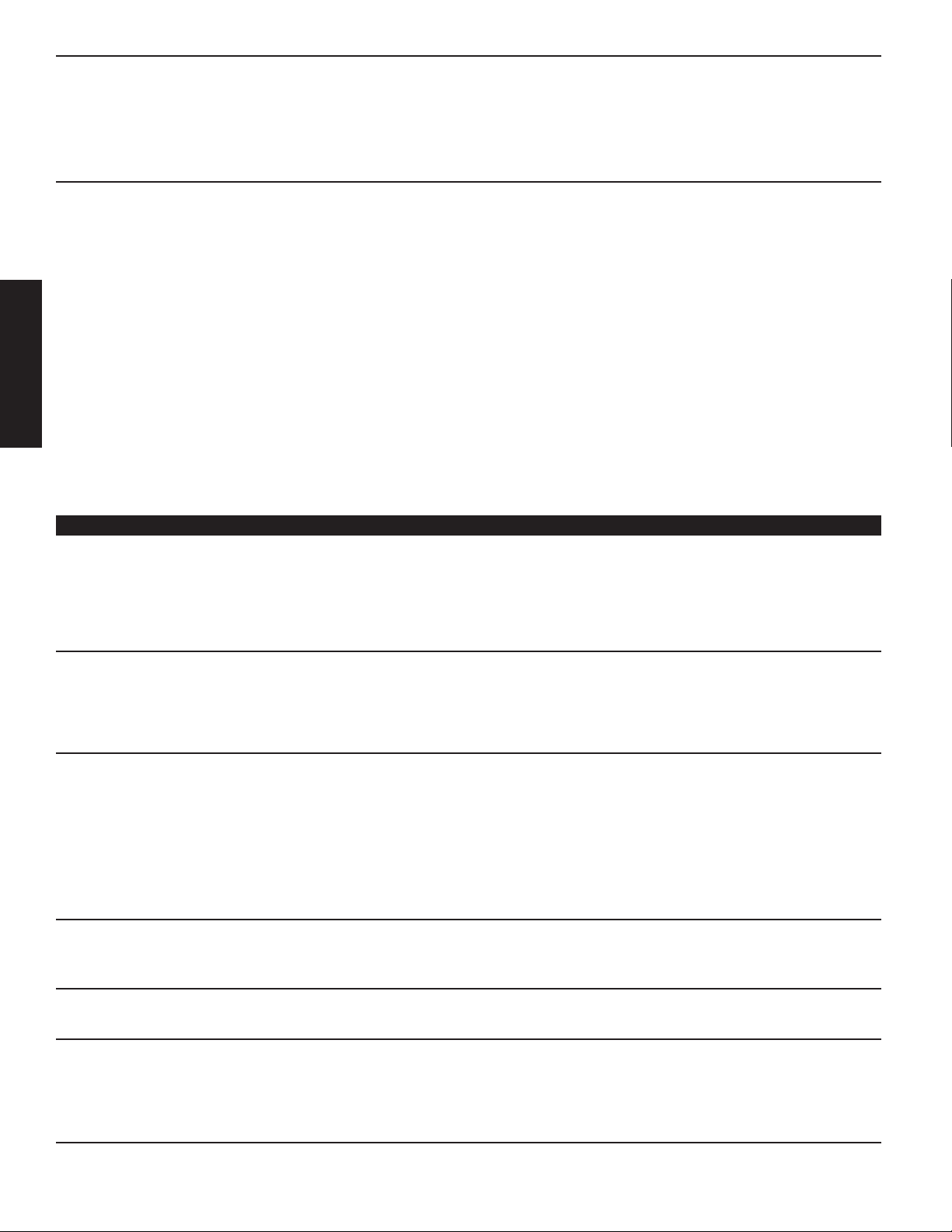

1P579F Repair Kit

Repair Parts List

Part No. Description Qty.

155331 Gasket 2

155310 Impeller 2

Impeller

Cover Mounting Screws

Cover Plate

Gasket

Figure 2 - Repair Parts Illustration

Model 1P579F

E

N

G

L

I

S

H

Limited Warranty

DAYTON 90-DAY LIMITED WARRANTY. Dayton marine utility pump, Models covered in this manual, are war-

ranted by Dayton Electric Mfg. Co. (Dayton) to the original user against defects in workmanship or materials under

normal use for 90 days after date of purchase. Any part which is determined to be defective in material or workmanship and returned to an authorized service location, as Dayton designates, shipping costs prepaid, will be, as

the exclusive remedy, repaired or replaced at Dayton’s option. For limited warranty claim procedures, see

PROMPT DISPOSITION below. This limited warranty gives purchasers specific legal rights which vary from jurisdiction to jurisdiction.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, Dayton’s liability for consequential

and incidental damages is expressly disclaimed. Dayton’s liability in all events is limited to and shall not exceed

the purchase price paid.

WARRANTY DISCLAIMER. Dayton has made a diligent effort to provide product information and illustrate the

products in this literature accurately; however, such information and illustrations are for the sole purpose of

identification, and do not express or imply a warranty that the products are merchantable, or fit for a particular

purpose, or that the products will necessarily conform to the illustrations or descriptions.

Except as provided below, no warranty or affirmation of fact, expressed or implied, other than as stated in the

”LIMITED WARRANTY” above is made or authorized by Dayton.

PRODUCT SUITABILITY. Many jurisdictions have codes and regulations governing sales, construction, installation, and/or use of products for certain purposes, which may vary from those in neighboring areas. While Dayton

attempts to assure that its products comply with such codes, it cannot guarantee compliance, and cannot be

responsible for how the product is installed or used. Before purchase and use of a product, review the product

applications, and all applicable national and local codes and regulations, and be sure that the product, installation,

and use will comply with them.

Certain aspects of disclaimers are not applicable to consumer products; e.g., (a) some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply

to you; (b) also, some jurisdictions do not allow a limitation on how long an implied warranty lasts, consequently

the above limitation may not apply to you; and (c) by law, during the period of this limited warranty, any implied

warranties of implied merchantability or fitness for a particular purpose applicable to consumer products purchased

by consumers, may not be excluded or otherwise disclaimed.

PROMPT DISPOSITION. Dayton will make a good faith effort for prompt correction or other adjustment with

respect to any product which proves to be defective within limited warranty. For any product believed to be

defective within limited warranty, first write or call dealer from whom the product was purchased. Dealer will

give additional directions. If unable to resolve satisfactorily, write to Dayton at address below, giving dealer’s

name, address, date, and number of dealer’s invoice, and describing the nature of the defect. Title and risk of

loss pass to buyer on delivery to common carrier. If product was damaged in transit to you, file claim with carrier.

Manufactured for Dayton Electric Mfg. Co., 5959 W. Howard St., Niles, Illinois 60714 U.S.A.

Dayton Operating Instructions and Parts Manual 1P579F

Dayton

™

Marine Utility Pump

Manufactured for Dayton Electric Mfg. Co.

Niles, Illinois 60714 U.S.A.

Loading...

Loading...