Page 1

Aestiva/5

7900 Anesthesia Ventilator

Technical Reference Manual

Page 2

Aestiva 7900 Anesthesia Ventilator

Datex-Ohmeda products have unit serial numbers with coded logic which indicates a product

group code, the year of manufacture and a sequential unit number for identification.

AAA A 12345

This alpha character indicates the year of product manufacture

and when the serial number was assigned;

“D” = 2000, “E” = 2001, “F” = 2002, etc.

“I” and “O” are not used.

Aestiva

and

SmartVent

are registered trademarks of Datex-Ohmeda Inc.

Other brand names or product names used in this manual are trademarks or registered

trademarks of their respective holders.

05/04 1006-0453-000

Page 3

Technical Reference Manual

Aestiva 7900 Anesthesia Ventilator

Software Revisions 1.X, 3.X, and 4.X

This document is not to be reproduced in any manner, nor are the contents to be disclosed to

anyone, without the express authorization of the product service department, Datex-Ohmeda,

Ohmeda Drive, PO Box 7550, Madison, Wisconsin, 53707.

©

2004 Datex-Ohmeda Inc.

1006-0453-000 05/04

i

Page 4

Aestiva 7900 Anesthesia Ventilator

Important

The information contained in this service manual pertains only to those models of products

which are marketed by Datex-Ohmeda as of the effective date of this manual or the latest

revision thereof. This service manual was prepared for exclusive use by Datex-Ohmeda service

personnel in light of their training and experience as well as the availability to them of parts,

proper tools and test equipment. Consequently, Datex-Ohmeda provides this service manual to

its customers purely as a business convenience and for the customer's general information only

without warranty of the results with respect to any application of such information. Furthermore,

because of the wide variety of circumstances under which maintenance and repair activities

may be performed and the unique nature of each individual's own experience, capacity, and

qualifications, the fact that customer has received such information from Datex-Ohmeda does

not imply in anyway that Datex-Ohmeda deems said individual to be qualified to perform any

such maintenance or repair service. Moreover, it should not be assumed that every acceptable

test and safety procedure or method, precaution, tool, equipment or device is referred to within,

or that abnormal or unusual circumstances, may not warrant or suggest different or additional

procedures or requirements.

This manual is subject to periodic review, update and revision. Customers are cautioned to

obtain and consult the latest revision before undertaking any service of the equipment.

Comments and suggestions on this manual are invited from our customers. Send your

comments and suggestions to the Manager of Technical Communications, Datex-Ohmeda,

Ohmeda Drive, PO Box 7550, Madison, Wisconsin 53707.

wwww CAUTION

Servicing of this product in accordance with this service manual should never be

undertaken in the absence of proper tools, test equipment and the most recent revision

to this service manual which is clearly and thoroughly understood.

Technical Competence

The procedures described in this service manual should be performed by trained and authorized

personnel only. Maintenance should only be undertaken by competent individuals who have a

general knowledge of and experience with devices of this nature. No repairs should ever be

undertaken or attempted by anyone not having such qualifications.

Datex-Ohmeda strongly recommends using only genuine replacement parts, manufactured or

sold by Datex-Ohmeda for all repair parts replacements.

Read completely through each step in every procedure before starting the procedure; any

exceptions may result in a failure to properly and safely complete the attempted procedure.

ii

05/04 1006-0453-000

Page 5

Table of Contents

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Technical Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

1 Introduction

1.1 What this manual includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.1 Software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Standard service procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.1 Operation manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.2 Service manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.3 Ventilator tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1009-0357-000 11/03 iii

Page 6

Table of Contents

2 Theory of Operation

2.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Aestiva 7900 Ventilator features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1 Safety features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3 Aestiva 7900 Ventilator components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.1 Ventilator control electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3.2 Control panel and display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3.3 Sensor Interface Board (SIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3.4 Pneumatic Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.4.1 Electrical (original) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.4.2 Electrical (integrated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.4.3 Power supply (original) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.4 Power supply (integrated CPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.5 Sealed lead acid battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.6 CPU assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.7 Sensor Interface Board (SIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.5 Mechanical subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

3 Post-Service Checkout

2.5.1 Supply gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.5.2 Gas Inlet Valve (GIV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.5.3 Flow control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.5.4 Drive Gas Check Valve (DGCV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.5 Bellows Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.6 Exhalation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.7 Mechanical Overpressure Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.8 Bleed resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.9 Free breathing valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.5.10 Breathing circuit flow sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

3.1 Post-service checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.1 Test the Aestiva 7900 Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.2 Test the Aestiva Anesthesia Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

iv 11/03 1009-0357-000

Page 7

Table of Contents

4a Tests and Calibration — Software Revision 4.X

4a.1 Self tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4a-3

4a.2 Service Mode Confirmation menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4a-4

4a.3 Main Menu - Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4a-5

4a.3.1 Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4a-6

4a.3.2 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4a-7

4a.3.3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4a-8

4a.3.4 User Select Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-12

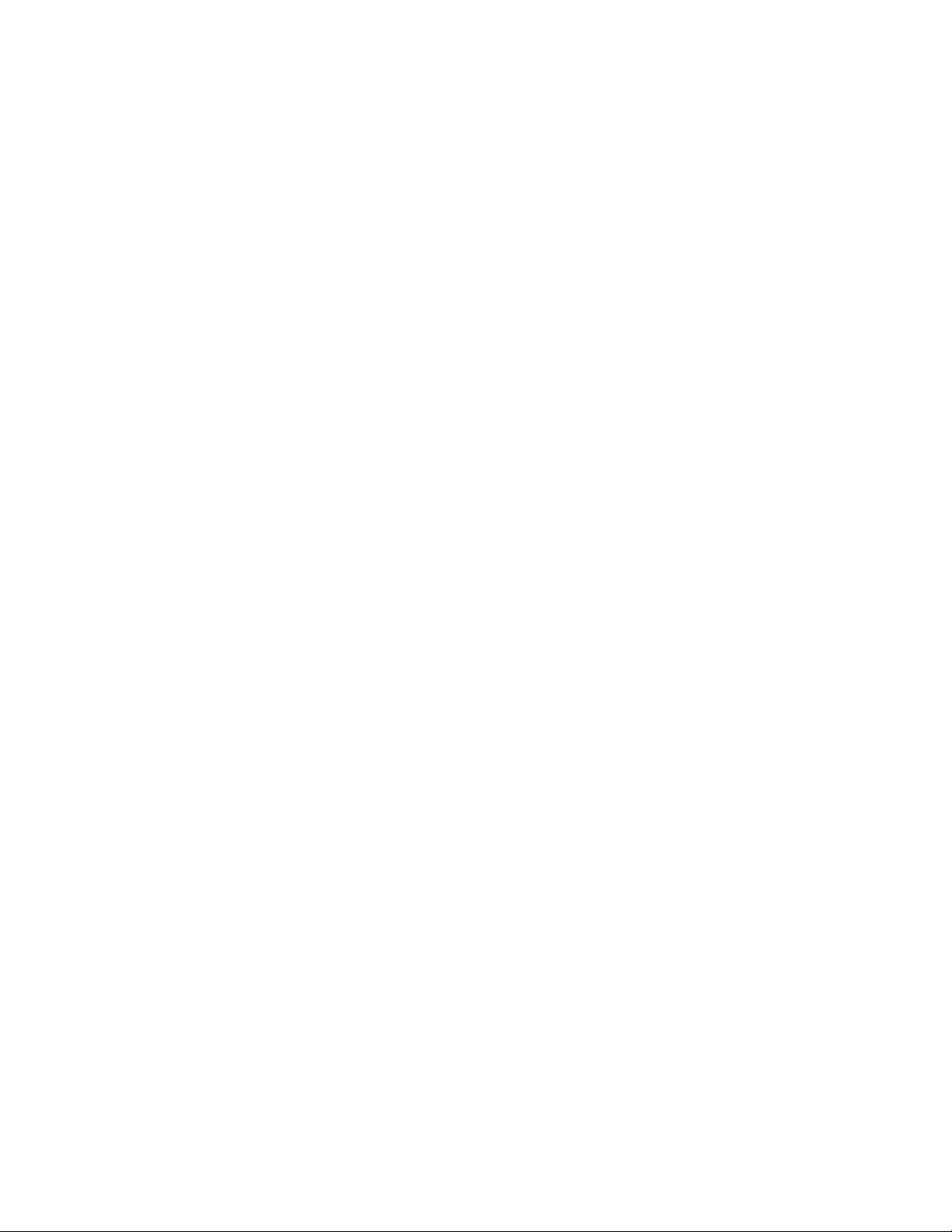

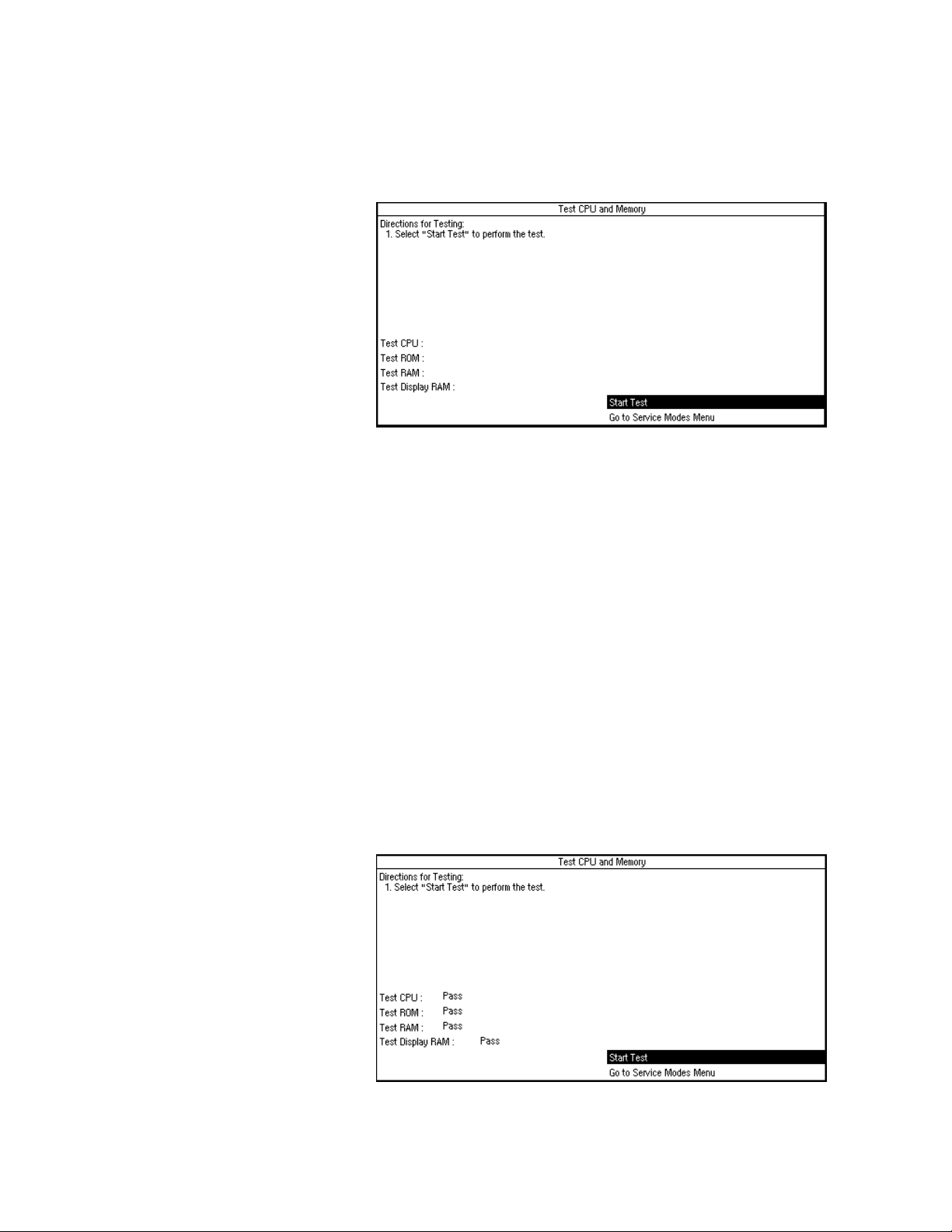

4a.3.5 Test CPU and Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-14

4a.3.6 Test EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-15

4a.3.7 Test GIV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-16

4a.3.8 Test Flow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-17

4a.3.9 Test Drive Pressure Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-18

4a.3.10 Test 5V Fail Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-19

4a.3.11 Test Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-20

4a.3.12 Breathing System Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-21

4a.3.13 Display A/D Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-22

4a.3.14 Display Discrete I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-24

4a.3.15 Display Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-25

4a.3.16 Test Panel Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-26

4a.3.17 Flow Valve Test Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-27

4a.3.18 Adjust Drive Gas Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-28

4a.3.19 O2 Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-29

4a.3.20 Calibrate Flow Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-30

4a.3.21 Pressure Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-31

4a.3.22 Calibrate Flow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-32

4a.3.23 Bleed Resistor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-33

4a.3.24 Service Calibrations Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4a-34

4b Tests and Calibration — Software Revisions 1.X and 3.X

4b.1 Self tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-3

4b.2 Service Mode Confirmation menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-4

4b.2.1 Set the altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-5

4b.2.2 Set the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-5

4b.2.3 Set the serial connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-5

4b.3 Main Menu - Service Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-6

1009-0357-000 11/03 v

Page 8

Table of Contents

4b.4 Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-7

4b.4.1 Test CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-7

4b.4.2 Test External RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-7

4b.4.3 Test Display RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-8

4b.4.4 Test Flash ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-8

4b.4.5 Test EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-9

4b.4.6 Test Panel Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-9

4b.4.7 Test Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-10

4b.4.8 Test Flow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-11

4b.4.9 Test GIV (Gas Inlet Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-12

4b.4.10 Test DPL (Drive Pressure Limit) switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-13

4b.4.11 Test 5V Fail Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-14

4b.5 Diagnostic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-15

4b.5.1 Display A/D channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-15

4b.5.2 Display I/O signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-17

4b.5.3 Battery Charge Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-18

4b.5.4 System Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-19

4b.5.5 Alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-19

4b.6 Flow Valve Test Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-20

4b.7 Test Breathing System For Leak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-21

4b.8 Adjust Drive Gas Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-22

4b.9 Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-23

4b.9.1 Calibrate O2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-23

4b.9.2 Calibrate Flow Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-24

4b.9.3 Pressure Sensitivity Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-25

4b.9.4 Calibrate Flow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-26

4b.9.5 Calibrate Bleed Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-27

4b.10 Schedule Service Calibration — Software 3.X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-28

4b.11 Sensor(s) cal due — Software 1.X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-29

4b.12 User Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-30

4b.12.1 Select Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-30

4b.12.2 Select Drive Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-30

4b.12.3 Adjust Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-31

4b.12.4 Select Heliox Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-31

4b.12.5 VE Alarm Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-32

4b.12.6 User Select Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4b-32

vi 11/03 1009-0357-000

Page 9

Table of Contents

5 Troubleshooting

5.1 Troubleshooting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.2 System Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2.1 Error messages for Software Revision 4.X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.2 Error codes for Software Revisions 1.X and 3.X . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4 Mechanical/electrical troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.5 Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.5.1 Ventilator assessment process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.5.2 No display troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.5.3 Inaccurate volume ventilation troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.5.4 No ventilation troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.5.5 High intrinsic PEEP troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.6 Power supply test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

6 Maintenance

7 Repair Procedures

5.6.1 Power supply board (original CPU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.6.2 Original CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.6.3 Power supply (Integrated CPU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

6.1 Supply gas inlet filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.2 Free breathing valve maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.3 MOPV differential relief valve test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.4 MOPV pressure relief valve test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

7.1 Control panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.2 Keyboard and EL display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3 Encoder switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.4 Alarm speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.5 Access to electrical enclosure components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.5.1 CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.5.2 Firmware replacement procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.5.3 Power supply board (for original CPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.5.4 Power supply (for Integrated CPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.5.5 Toroid (original CPU only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.5.6 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.6 Vent Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.7 Non-relieving regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

1009-0357-000 11/03 vii

Page 10

Table of Contents

8 Illustrated Parts

7.8 Flow control valve 7-17

7.9 Gas inlet valve 7-18

7.10 Mechanical Overpressure Valve (MOPV assembly) 7-20

7.10.1 To service the original MOPV assembly: 7-20

7.10.2 To service the MOPV assembly with the molded housing: 7-22

7.11 Drive gas check valve assembly 7-23

8.1 Special instructions 8-2

8.2 Service tools 8-2

8.3 Ventilator Harnesses 8-3

8.4 Electrical enclosure parts (original CPU) 8-4

8.5 Electrical enclosure parts (integrated CPU) 8-6

8.6 Display Module 8-8

8.6.1 Rear housing parts 8-8

8.6.2 Front housing parts 8-9

8.7 Aestiva 7900 Vent Engine 8-10

8.7.1 Gas Inlet Valve 8-11

8.7.2 Mechanical Over Pressure Valve (MOPV) 8-12

8.7.3 Inlet filter 8-13

8.7.4 Free Breathing Valve 8-14

8.7.5 Manifold 8-15

8.7.6 Tube Assembly 8-16

8.7.7 Twin Tube Lifter 8-17

8.8 Vent Engine mounting bracket 8-18

8.9 Sensor Interface Board (SIB) 8-19

viii 11/03 1009-0357-000

Page 11

1 Introduction

In this section

1006-0453-000 05/04 1-1

1.1 What this manual includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.1 Software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Standard service procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.1 Operation manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.2 Service manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.3 Ventilator tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Page 12

1 Introduction

1.1 What this manual includes

This manual covers the service information for the Aestiva 7900 SmartVent

Anesthesia Ventilator which is an integral component in the Aestiva Anesthesia

Machine.

The Aestiva Anesthesia Machine has its own service manual

(Stock Number 1006-0452-000).

Special notice

1.1.1 Software versions

Some information in this manual can possibly point the reader to electronic

troubleshooting and component/repair replacement level of service. This

information, when supplied, is only supplied to add clarity to service or

troubleshooting statements. Datex-Ohmeda Service Personnel are mandated

by Company Policy to service electronic equipment to a board replacement

level only.

• Read completely through each step in every procedure before starting

the procedure; any exceptions can result in a failure to properly and

safely complete the attempted procedure.

• Unless otherwise specified, values in this manual are nominal.

• Sections in this manual begin on odd numbered or right-hand pages.

If there is no text on the preceding, backup even numbered page, it is

labeled “Notes” for your use if you wish.

• Figures that require more than one page have the title and main text

on the left (even numbered) page. Additional figure information is on

the facing (odd numbered) page.

The revision level is displayed on the ventilator start-up menu. This manual

includes test and calibration procedures for Revision 1.X, 3.X, and 4.X

software.

1-2 05/04 1006-0453-000

Page 13

1.2 Standard service procedures

1 Introduction

1.2.1 Operation

manuals

1.2.2 Service

manuals

1.2.3 Ventilator

tests

wwwwWARNING

You must have, and be familiar with, the Operation manuals for this product.

Study the Aestiva Operation manuals if you need further information about the

operation of the system.

You must determine where a problem is located before you can determine

which service manual to use:

• Use this manual for 7900 Ventilator related problems.

• Use the Anesthesia Machine service manual (1006-0452-000)

for all other components of the Aestiva Anesthesia Machine.

Service calibration functions let Datex-Ohmeda trained users and DatexOhmeda service personnel perform ventilator setup functions, tests,

calibration and measurements from the front panel display.

Normal operational tests, calibration, and troubleshooting can be performed

on your Aestiva 7900 Ventilator without removing components from the

system. Repair may require removing the ventilator components from the

anesthesia machine.

Section 4,

whenever you access any internal component of the Ventilator to verify

that all critical parts of the Ventilator are still operational and within

specification.

“Service Mode Tests and Calibration”

must be performed

wwwwWARNING

wwwwWARNING

After the Ventilator has been serviced, you must perform

Checkout”

before the system can be returned to clinical use.

Do not perform testing or maintenance on this instrument while it is

being used to ventilate a patient, possible injury may result.

to verify the entire Anesthesia System is properly functioning

“Post -Service

1006-0453-000 05/04 1-3

Page 14

1 Introduction

1.3 Symbols used in the manual or on the equipment

w

Warnings and

w

can occur if you do not follow all instructions in this manual.

Warnings tell about a condition that can cause injury to the operator or the

patient.

Cautions tell about a condition that can cause damage to the equipment.

Read and follow all warnings and cautions.

Other symbols replace words on the equipment or in Datex-Ohmeda manuals.

No one device or manual uses all of the symbols. These symbols include:

Cautions tell you about dangerous conditions that

m

L

l

n

M

N

†

p

On (power)

Off (power)

Standby

Standby or preparatory state for part of

the equipment

“ON” only for part of the equipment

“OFF” only for part of the equipment

Direct current

Alternating current

A

j

J

D

w

wW

O

Alarm silence button

Alarm silence touch key

(Tec 6).

Type B equipment

Type BF equipment

Type CF equipment

Caution, ISO 7000-0434

Attention, refer to product

instructions, IEC 601-1

Dangerous Voltage

x

Protective earth ground

Earth ground

y

Frame or chassis ground

P

Equipotential

Y

Plus, positive polarity

+

Minus, negative polarity

-

1-4 05/04 1006-0453-000

h

G

k

E

REF

SN

Input

Output

Movement in one direction

Movement in two directions

Stock Number

Serial Number

Page 15

1 Introduction

t

T

g

o

z

Z

U

Variability Read top of float.

Variability in steps Vacuum inlet

This way up Suction bottle outlet

Lamp, lighting, illumination

Cylinder

Lock

Isolation transformer

Unlock

Close drain

Linkage system

Risk of Explosion.

u

134°C

Í

q

t

Open drain (remove liquid)

Autoclavable

Low pressure leak test

Mechanical ventilation

r

Not autoclavable

Bag position/ manual ventilation

R

Inspiratory flow

Q

O2+

O2 sensor connection.

Alarm silence touch key. Volume alarms On/Off touch key.

Expiratory flow

O2 Flush button

End case touch key Menu touch key.

1006-0453-000 05/04 1-5

Page 16

1 Introduction

< 345 kPa

< 414 kPa

Absorber on.

The primary regulator is set to

pressure less than 345 kPa

(50 psi).

Absorber off (CO

Bypass active). The primary regulator is set to

2

European Union Representative.

pressure less than 414 kPa

(60 psi).

Systems with this mark agree with

the European Council Directive

(93/42/EEC) for Medical Devices

when they are used as specified in

their Operation and Maintenance

Manuals. The xxxx is the

certification number of the

Notified Body used by DatexOhmeda’s Quality Systems.

1-6 05/04 1006-0453-000

Page 17

2 Theory of Operation

In this section This section provides functional descriptions and theory of operation for the major

components of the Aestiva 7900 Ventilator.

2.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Aestiva 7900 Ventilator features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1 Safety features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3 Aestiva 7900 Ventilator components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.1 Ventilator control electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3.2 Control panel and display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3.3 Sensor Interface Board (SIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3.4 Pneumatic Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.4.1 Electrical (original) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.4.2 Electrical (integrated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.4.3 Power supply (original) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.4 Power supply (integrated CPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.5 Sealed lead acid battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.6 CPU assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.7 Sensor Interface Board (SIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.5 Mechanical subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.5.1 Supply gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.5.2 Gas Inlet Valve (GIV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.5.3 Flow control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.5.4 Drive Gas Check Valve (DGCV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.5 Bellows Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.6 Exhalation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.7 Mechanical Overpressure Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.8 Bleed resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.9 Free breathing valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.5.10 Breathing circuit flow sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

1006-0453-000 05/04 2-1

Page 18

2 Theory of Operation

2.1 General description

The Aestiva 7900 Ventilator is a microprocessor based, electronicallycontrolled, pneumatically-driven ventilator with built in monitoring systems

for inspired oxygen, airway pressure and exhaled volume. The ventilator is

designed to be used as a medical device assisting in the delivery of

anesthesia and is part of the Aestiva Anesthesia Machine.

2.2 Aestiva 7900 Ventilator features

• Sensors in the breathing circuit are used to control and monitor patient

ventilation and measure inspired oxygen concentration. This lets the

ventilator compensate for compression losses, fresh gas contribution, valve

and regulator drift and small leakages in the breathing absorber, bellows

and system.

• Positive End Expiratory Pressure (PEEP) is regulated electronically. During

mechanical ventilation the software maintains the set airway pressure. PEEP

is not active when mechanical ventilation is off.

• User settings and microprocessor calculations control breathing patterns.

User interface settings are kept in non-volatile memory.

•Mechanical ventilation is started with the Bag/Vent switch on the breathing

system.

• The Aestiva 7900 Ventilator reads the status of the Bag/Vent switch and the

breathing circuit type (Circle, Bain-Mapleson D). The operator does not have

to set the breathing circuit type from a menu.

• The Aestiva 7900 Ventilator has an operator-selectable Heliox mode to

permit gas composition compensation when Heliox gas is used.

• All Aestiva 7900 Ventilators have minimum monitoring and alarms

managed on the ventilator panel (there is no other panel for safety

relevant alarm management, etc.).

• Ventilator hardware is regularly monitored by software tests.

• An RS-232 serial digital communications port connects to and

communicates with external devices.

• An exhalation valve modulates flow in the pressure mode.

• Pressure and volume modes are selectable by the operator.

• All pneumatic components are located on one manifold.

• Exhausted drive gas and bellows pressure relief valve gases are mixed and

go through the ventilator exhalation valve.

• Exhalation valve block is autoclavable.

• Excess fresh gas released from the bellows and ventilator drive gas is

transferred from the exhalation valve to the Anesthesia Gas Scavenging

System (AGSS).

• Optimized for service with a low number of components.

2-2 05/04 1006-0453-000

Page 19

2.2.1 Safety features • Dual redundant airway overpressure protection, linked to Pmax

setting.

• Volume over-delivery limits and protection.

• Proprietary hose connections and fixed manifolds.

• 10 VA electrical power limiting to potential oxygen enriched environment.

• 150 psi burst overpressure protection.

2.3 Aestiva 7900 Ventilator components

Components of the ventilator are found in different locations on the Aestiva

Anesthesia Machine. The ventilator package consists of:

1. Ventilator control electronics

2. Control panel and display (two mounting options shown)

3. Sensor interface board (SIB)

4. Pneumatic engine

2 Theory of Operation

Note For the Aestiva/5 MRI machine, the display is centrally mounted above the

flowhead.

1

2

3

4

1

2

3

4

Figure 2-1 • Aestiva Anesthesia Machine with hinged and outboard arm options

1006-0453-000 05/04 2-3

Page 20

2 Theory of Operation

2.3.1 Ventilator control

electronics

100-120 VAC

220-240 VAC

50/60 Hz

AC Inlet Module

-Fuses

-Voltage Selector

-Filter

The ventilator control electronics is found in the electrical enclosure of the

Aestiva machine behind the AC Inlet module.

In the original Aestiva machines, the power supply and the CPU are on

separate boards, as shown in Figure 2-2.

The ventilator control electronics includes the power supply and the CPU. The

power supply receives AC power from the machine’s AC Inlet module. All the

power necessary to operate the ventilator and light package comes from the

power supply. The CPU controls operation of the ventilator.

Tec6 Outlet

Toroid

AB.29.087

Battery

Connector Board

Front Panel

Assembly

Power Supply

Board

CPU Board

Connector Board

Pneumatic

Engine

Task Light

Proprietary RS232C

Primary RS232C On/StandBy

Vent On/StandBy Switch

O2 Supply Switch and O2 Flush Switch

BCID

Sensor

Interface Board

Patient Interface Harness

ACGO

Oxygen Sensor

Figure 2-2 • Aestiva 7900 Ventilator functional block diagram (Original CPU)

2-4 05/04 1006-0453-000

Page 21

100-120 VAC

220-240 VAC

50/60 Hz

2 Theory of Operation

In current Aestiva machines, the regulated power supplies and the CPU are

included on a single board (Integrated CPU Board), as shown in Figure 2-3.

A universal power supply is used to convert AC to DC that feeds into the power

supply circuits of the integrated CPU board. The universal power supply

eliminates the need for the toroidal transformer.

Tec6 Outlet

AC Inlet Module

-Fuses

-Voltage Selector

-Filter

Battery

Power Circuits

Integrated

CPU Board

Digital Circuits

Universal

Power Supply

Task Light

Proprietary RS232C

Primary RS232C On/StandBy

Vent On/StandBy Switch

O2 Supply Switch and O2 Flush Switch

Connector Board Connector Board

Front Panel

Assembly

AB.29.082

Pneumatic

Engine

Sensor

Interface Board

BCID

Patient Interface Harness

ACGO

Oxygen Sensor

Figure 2-3 • Aestiva 7900 Ventilator functional block diagram (Integrated CPU)

1006-0453-000 05/04 2-5

Page 22

2 Theory of Operation

2.3.2 Control panel and

display

The control panel on the Aestiva 7900 Ventilator is either outboard (on an

arm) or on a hinge to fold flat against the machine (depending on the option

ordered) and is made to permit you to grip the panel and push the buttons

with your thumbs. The ventilator control panel position is easily adjusted.

For the Aestiva/5 MRI machine, the display is centrally mounted above the

flowhead.

The front panel assembly has four submodules:

• The electroluminescent (EL) display

• The keyboard front panel

•A rotary encoder

•A speaker

Figure 2-4 • Ventilator control panel with software version 4.X

The keyboard and rotary encoder are used to control the operations of the

ventilator. The front panel uses a three step — selection, change, and approve

— setting scheme to prevent unwanted selections. The speaker supplies audio

input to the operator.

Logical layout of primary controls is left to right in the sequence: tidal volume

or inspiratory pressure level, respiratory frequency, I:E ratio, maximum

inspiratory pressure, and PEEP (positive end expiratory pressure).

Primary Ventilator interfaces include:

• Display

• Soft keys

• Rotary encoder (control wheel)

• Knob button (control wheel)

• LED

• Audio

2-6 05/04 1006-0453-000

Page 23

2 Theory of Operation

2.3.3 Sensor Interface

Board (SIB)

Figure 2-5 • Sensor Interface Board (SIB)

A Sensor Interface Board (SIB) serves as the interface between the ventilator

CPU board and the breathing circuit sensors.

The SIB processes signals from the:

• Inspiratory and expiratory flow transducers

sensor

•O

2

• Auxiliary Common Gas Outlet (ACGO) switch (optional)

•Module ID board

• Canister release switch

• Absorber CO

Bypass switch

2

• Bag/Vent switch

• Control panel switch

• Drive Pressure Limit (DPL) switch

•Manifold pressure transducer

• Patient airway pressure transducer

The SIB for the Aestiva 7900 Ventilator is located in the cable duct under the

rear subfloor of the breathing circuit chassis. The SIB uses a 50-conductor

cable that supplies the link between the Aestiva 7900 Ventilator CPU and the

breathing system signals.

2.3.4 Pneumatic Engine The pneumatic engine enclosure is located in the back chamber of the

breathing system and is shielded to contain EMI emissions. The enclosure

includes the Pneumatic Engine and a Pneumatic Engine Connector Board.

The Pneumatic Engine comprises the hardware that drives the ventilator

bellows. It includes:

•a 5-micron inlet filter

•a gas inlet valve (GIV)

•a pressure regulator

•a flow control valve

•a drive gas check valve

•a mechanical over-pressure relief valve

•a differential pressure relief valve

•a free-breathing check valve

Figure 2-6 • Pneumatic Engine

1006-0453-000 05/04 2-7

Page 24

2 Theory of Operation

2.4 Electrical

Power

Cord

2.4.1 Electrical

(original)

AC Inlet

Line Filter

Fuse

Voltage Selector

The original (non-integrated) Aestiva 7900 Ventilator electronic/electrical

subassemblies or modules include:

• Power entry toroid

• Power supply board

• CPU board

• Display and front panel assembly

• Sensor interface board

• Sealed lead acid battery

Inside Machine

Power Supply Board

EL voltage = +10--14.5V 10.5W max

2

Toroid

+12V light output @ 15W max

+15V @ 170mA max

-15V @ 100mA max

+5V @ 1.8A max

+5.5 @ 1.4A max

50

12 Volt Battery

2

& Harness

CMS

RS232

CPU Board

68340 Microcontroller

Memory and I/O Decoding

Flash, SRAM & EEPROM

SCR Circuitry

D/A Converter

Watchdog System

Inlet Valve Control & Drive

(10 VA limited)

Flow Valve Control & Drive

(10 VA limited)

A/D Converter

15 VDC Supply (10VA limited)

DC Supply Monitoring

2

2

O2 supply

O2 Flush

4

Machine/Ventilator

On/Standby switch

Shielded Cable

50

Shielded Cable

50

Shielded Cable

7

Pneumatic Engine

Connector board

Flow valve

Inlet valve

Breathing System

EL Display &

Membrane Switch

Key Components

EL Display

Membrane Switch

Connector Board

50 Pin Connector Series 3

50 Pin Ribbon Cable Header

Optical Encoder

50 Pin Ribbon Cable

20 Pin Ribbon Cable

Speaker

Inspiratory & Expiratory flow transducers

Drive Pressure Limit Switch

Manifold Pressure Transducer

Patient Airway Pressure Transducer

O2 Sensor

ACGO Switch

SIB

Flow Sensors

Bag/Vent Switch

Control Panel Switch

Canister Release Switch

Absorber Bypass Switch

Breathing Circuit ID

Figure 2-7 • Electronic functional block diagram (Original CPU)

2-8 05/04 1006-0453-000

Page 25

2 Theory of Operation

Pow er

Cord

CMS

RS232

2.4.2 Electrical

(integrated)

AC Inlet

Line Filter

Fuse

Voltage Selector

EL voltage = +10 –14.5V 10.5W max

+12V light output @ 15W max

+15V @ 170mA max

-15V @ 100mA max

+5V @ 1.8A max

+5.5 @ 1.4A max

Integrated

CPU Board

68340 Microcontroller

Memory and I/O Decoding

Flash, SRAM & EEPROM

SCR Circuitry

D/A Converter

Watchdog System

Inlet Valve Control & Drive

(10 VA limited)

Flow Valve Control & Drive

(10 VA limited)

A/D Converter

15 VDC Supply (10VA limited)

DC Supply Monitoring

The integrated Aestiva 7900 Ventilator electronic/electrical subassemblies or

modules include:

• Universal power supply (AC to DC converter)

• CPU board (with power supply and digital circuits)

• Display and front panel assembly

• Sensor interface board

• Sealed lead acid battery

Inside Machine

AC to DC Power Supply

2

5

2

12 Volt Battery

& Harness

7

VCHGR = 16.0 V Typical

VMAIN = 12.5 V Typical

50

Shielded Cable

Shielded Cable

50

Shielded Cable

Pneumatic Engine

Connector board

Flow valve

Inlet valve

EL Display &

Membrane Switch

Key Components

EL Display

Membrane Switch

Connector Board

50 Pin Connector Series 3

50 Pin Ribbon Cable Header

Optical Encoder

50 Pin Ribbon Cable

20 Pin Ribbon Cable

Speaker

Inspiratory & Expiratory flow transducers

Drive Pressure Limit Switch

Manifold Pressure Transducer

Patient Airway Pressure Transducer

SIB

O2 supply

2

O2 Flush

2

4

Machine/Ventilator

On/Standby switch

Breathing System

O2 Sensor

ACGO Switch

Flow Sensors

Bag/Vent Switch

Control Panel Switch

Canister Release Switch

Absorber Bypass Switch

Breathing Circuit ID

Figure 2-8 • Electronic functional block diagram (Integrated CPU)

1006-0453-000 05/04 2-9

AB.29.083

Page 26

2 Theory of Operation

2.4.3 Power supply

Power

30-60 VDC

VBOOT

Linear

Regulator

+16.6V

Primary

DC to DC

Converter

VBUS

(original)

Cord

0.25A

The power supply performs seven functions:

• AC to DC converter

• DC to DC step-down converter

• Battery charger

•Multiple output DC regulator

• Battery charge/discharge current monitor

• Battery voltage monitor

• Task light power supply 12V

Entry Module

- EMI Filter

- Fuse

- Voltage Selector

VSW

Linear

Regulator

VB

Toroid

Isolation

Transformer

Secondary

DC to DC

Converter #1

Secondary DC to DC

Converter #2

Linear

Regulator

24-45

VAC

Rectifier

& Filter

Bridge Rectifier

& Filter Caps

ON/Standby

Regulator

Switch

Linear

AC_LED

VSW

(+5V VDD Fail Buzzer

Rem_On

+12V (Task Lights)

+10-14.5V

VH_EL

-15V Analog

AB.29.097

Battery Charge

Controller

Thermal

Breaker

12 V Battery

Battery Voltage &

Current Sense

Transformer

Step-Down

Controller

+5.8V

Rectifier

& Filter

OVP &

Current Limit

Linear

Regulator

Linear

Regulator

+15V Analog

+5.5V Valves Supply

+5V VDD Digital

IBatt,VBatt

Charger

Disconnect

Figure 2-9 • Ventilator power supply (Original CPU)

2-10 05/04 1006-0453-000

Page 27

2 Theory of Operation

2.4.4 Power supply

(integrated CPU)

11

11

88

88

00

00

..

..

99

99

22

22

..

..

BB

BB

AA

AA

AB.29.081

CHARGER and TRICKLE

DISABLE

BATTERY CHARGER

BULK CHARGE = 400mA

12V BATTERY

THERMAL AUTO

RESETABLE FUSE

Aestiva machines with an integrated CPU board use a universal power supply

for AC to DC conversion. The remainder of the power supply functions are

derived in the power supply circuits on the integrated CPU:

• DC to DC step-down converter

• Battery charger

•Multiple output DC regulator

• Battery charge/discharge current monitor

• Battery voltage monitor

• Task light power supply 12V

VOLTAGE and CURRENT

MONITOR

VBatt, IBatt

TASK LIGHTS LDO

TYPICALLY 11.718V

VHEL DISPLAY LDO

TYPICALLY 11.718V

AC TO DC POWER SUPPLY

85 -- 264 VAC

VCHGR = 16.0 TYPICAL

VMAIN = 12.5V TYPICAL

AC INLET

POWER CORD

DIODE OR

VMAIN

VCHGR

VBAT

MOSFET

SWITCHES

SELECT VMAIN OR VBAT

AS OUTPUT TO VBUS

VBUZZER

OUTPUT TO VDD FAIL

BUZZER

VSWITCH

ON / STANDBY SWITCH CIRCUIT

VBUS

SIMPLE SWITCHER

DUAL OUTPUT

SWITCHER

POSITIVE OUTPUT

NEGATIVE OUTPUT

VALVES SUPPLY

5.8V OUTPUT and 10VA

VDD DIGITAL

OUTPUT LDO

5V +/- 2.5%

SIB_12V OUTPUT

and 10VA LDO

+15V ANALOG

SUPPLY LDO

-15V ANALOG

SUPPLY LDO

Rem_On

AC_LED

Figure 2-10 • Ventilator power supply (Integrated CPU)

1006-0453-000 05/04 2-11

Page 28

2 Theory of Operation

2.4.5 Sealed lead acid

battery

A sealed lead acid battery supplies battery backup for the Aestiva 7900

Ventilator. The Aestiva 7900 Ventilator is not a portable unit. Batteries for the

ventilator are used as back up power in case of a power failure. Thus the

battery is in a float charge state most of the time. Batteries meet the

following:

• Capacity to operate unit for 30 minutes.

• Long float charge life.

• Battery pack is internally fused - in line replaceable.

• Battery terminals and connecting wires are protected against short circuits.

tt

IIIInnnnppppuuuutt

Nominally 13.7 VDC at 25

tt

OOOOuuuuttttppppuuuutt

+10V to +14.8VDC during discharge

o

C during float charge.

2-12 05/04 1006-0453-000

Page 29

2 Theory of Operation

2.4.6 CPU assembly The CPU assembly contains all of the major circuit functions necessary to

control ventilator operation. In the original Aestiva 7900 machines, these

functions are on a separate CPU board. For current machines, they are part of

the digital circuits section of the integrated CPU board.

Production Connector

DRIVER

RS232C

Proprietary RS232C

Primary RS232C

Connector

Connector

FLASH MEM

( 512K X 16 )

STATIC RAM

( 128K X 16 )

EEPROM

( 2K X 8 )

VIDEO SRAM

( 32K X 8 )

VA0-VA11

VD8-VD15

SED1351F

VIDEO

CONTROLLER

FERRITE

BEADS

Front Panel Assembly

AUDIO AMP

+5VVH_EL

9

Connector

A0-A18,

D0-D15

3

A0-A18,

D0-D15

3

A0-A10,

D8-D15

3

A0-A11,

D8-D15

4

LM4860M

MICROCONTROLLER

SYSTEM DATA BUS & ADDRESS BUS

EPLD-EPM7064

WATCHDOG

LOGIC

ADDRESS

DECODING

YM2413

D0-D15

AUDIO

CHIP

1

2

O2 Supply

Connector

MC68340

A0-A20

D0-D15

A20, A0, A1

A14-A17,

D8-D10

FREQUENCY

DIVIDER

Connector

14

14

ADC

SEQUENCER

VENTILATION

CONTROL

1

O2 Flush

DS1232

WATCHDOG

& RESET

1

INTERFACE

D8-D15

2

2

SERIAL

EEPROM

12-BIT A/D

D0-D15

CONVERTER

6

D0-D15

1

12-BIT D/A

CONVERTER

4

D0-D15

1

12

7

SIB_+12V

10VA LIMIT

5

SIB Connector

DIGITAL

INPUT 0

DIGITAL

INPUT 1

11

+15V

+15V

1

-15V

P12V_LIGHT

INLET VALVE

DRIVE

FLOW VALVE

DRIVE

+5V LOSS

ALARM

VOLTAGE TEST

POINTS

+5V +5.8V +15V

Pneumatic Engine

Connector

2

4

Buzzer

-15V

24-CHANNEL

MUTIPLEXER

6

2

5

+5.8V

VSW

1.225V

VH_EL

SIB_12V

1

1

2

V

ANALOG

SIGNALS

1

10

DD

MONITOR

VH_EL

Power Supply Connector

Figure 2-11 • Ventilator CPU block diagram

Motorola 68340 processor core The CPU core consists of the following internal functions:

• Bus access control signals for all memory and peripheral devices

• Interrupt handling

• Clocks and timers for the system

• Background software development mode

• Two RS232C serial I/O ports

• Baud rate generator for serial ports

• Hard (power-up) and soft (watchdog error) reset generation

• Data bus buffers

•Memory and I/O decoding

• Program memory

• Safety Relevant Computing (SRC)

•Watchdog system

• Data acquisition

• Flow valve control

• Inlet valve drive

• Front panel interface

• Audio alarm

• Regulator output/manifold pressures

1006-0453-000 05/04 2-13

Page 30

2 Theory of Operation

System clock

An external 32.768 kHz crystal is used with the internal clock synthesizer to

generate a 24.12 MHz system clock.

Periodic interrupt timer

The periodic interrupt timer is the time base for the Real Time Operating

System.

Software watchdog timer

The software controlled internal watchdog timer guards against program

execution going astray.

External bus interface

The external bus interface handles the transfer of information between the

CPU32, external memory and peripherals.

Serial communications module Timing reference

An external 3.6864 MHz clock oscillator is used as the timing reference for the

Baud Rate Generator.

Configuration

Both of the serial communication channels are configured as full-duplex

asynchronous RS232C ports. The internal Baud Rate Generator establishes

the communication baud rate, with a higher limit of 19.2k Baud.

Special operating modes

The serial channels are capable of operating in various looping modes for self

testing as well as for remote testing of serial communications. These tests

include automatic echo, local loop-back, and remote loop-back.

Memory and I/O decoding Microprocessor Chip Selects

The four programmable chip selects from Motorola 68340 access external

memory and peripheral circuits, providing handshaking and timing signals as

well as a wait state generation, watchdog logic and ventilation control signals.

I/O lines

Spare I/O lines are used for digital control and/or sense lines.

Timer modules Counter/timer #1

The first counter/timer module is used to monitor the MC68340 system clock

frequency. The external 3.6864 MHz baud rate clock is the time base for this

measurement.

Counter/timer #2

The second counter/timer module can be used as desired by the application

software. The time base for this timer is the internal 24.12 MHz system clock.

2-14 05/04 1006-0453-000

Page 31

Program memory Flash memory

Two 512K x 8 Flash memory devices are used. This memory contains the real

time operating system (RTOS) and software code. The Flash memory devices

are socketed.

System RAM

This memory consists of two 128 K x 16 CMOS static RAMs with on-board

expansion capability to 512K x 16 SRAMs.

Non-volatile memory

This memory consists of a single 2K x 8 EEPROM and stores information which

needs to be retained when the system is powered down. This includes user

selectable operating parameters and a system error log.

2 Theory of Operation

Safety Relevant Computing

(SRC)

Watchdog systems MC68340 software watchdog timer

This section addresses the Safety Relevant Computing (SRC) requirements of

DIN V VDE 801. The electronic hardware design provides the necessary

capability for meeting these requirements. This includes:

• Digital monitoring of selected control signals.

• Analog monitoring of supply voltages, internal control voltages, feedback

signals from the flow and inlet valves, and battery voltage.

• Automatic switch-over to battery operation in the event of an interruption in

ac power.

• Use of the software watchdog timer in the 68340 processor for temporal

monitoring, with direct de-energizing of the flow and inlet valves in the event

of a non-recoverable error.

• Use of an operating mode watchdog for logic and timing monitoring, with

direct de-energizing of the flow and inlet valves in the event of a nonrecoverable error.

•Monitoring of the system clock to detect an operating frequency out of an

acceptable range.

• Use of a redundant high pressure limit safety switch in the bellows drive

circuit which directly de-energizes the flow valve.

Each mode of ventilator operation has a unique watchdog toggle channel that

is initialized at the legal program entry for that mode. The watchdog is then

toggled by writing that channel number to the watchdog check address during

any program paths that occur only in the selected mode of operation. An error

is detected if program flow is disrupted and an illegal sequence tries to toggle

the watchdog with its own different channel number. Each mode includes

multiple accesses to its watchdog channel number to improve detection of

incorrect program flow.

Watchdog operation

The channel number must be the same for both watchdog initialization and

toggle channel number. A difference is detected as errant program execution

and causes an immediate level 7 interrupt (IRQ7).

A legal watchdog toggle must occur at least once every 35 msec to prevent a

time-out and subsequent level 7 interrupts.

1006-0453-000 05/04 2-15

Page 32

2 Theory of Operation

DATA acquisition The data acquisition system for the Aestiva 7900 Ventilator consists of two

A system reset will occur between 62.5 msec and 250 msec if no legal toggle

addresses occur by that time. Multiple level 7 interrupts will occur prior to a

reset. The output of this watchdog is connected to IRQ7 on the 68340

processor.

Error response sequence

Errors detected by either watchdog are handled in the following sequence:

• At the first detection of any error, a watchdog responds by issuing an IRQ7

interrupt.

• If the exception handler software for IRQ7 cannot correct the error, then the

next detection of an error causes a soft system reset.

• If the error still cannot be corrected, then an audio alarm sounds

(independent of processor interaction) and a cyclic soft reset continues until

the error is corrected or the system is powered down.

major building blocks. The first is an analog to digital converter (ADC) system

and the second is a digital to analog converter (DAC) system.

This portion of the Aestiva 7900 Ventilator allows the microprocessor to

interface with valves and pressure transducers. The data acquisition system is

also used for internal monitoring of safety relevant signals.

The ADC system is designed to meet the following specifications:

Resolution 12 Bits

Input Voltage Range 0 - 4.095 Volts (1mV/LSB)

Number of Channels 24

Tot al Conversion Time 8 to 8.63 µsec max

Integral Nonlinearity ± 1 LSB max

Differential Nonlinearity ± 1 LSB max (guaranteed monotonic)

Full-Scale Error ± 6 LSB max

Unipolar Offset Error ± 3 LSB max

The DAC system is designed to meet the following specifications:

Resolution 12 Bits

Number of Channels 1

Settling time to 0.01% 30 µsec max

Output Voltage Range 0 - 4.095 Volts (1mV/LSB)

Integral Nonlinearity ± 1 LSB max

Differential Nonlinearity ± 1 LSB max (guaranteed monotonic)

Full-Scale Error ± 9 LSB max

Zero-Scale Error + 4 LSB max

2-16 05/04 1006-0453-000

Page 33

2 Theory of Operation

Analog to digital converter

System

A 24 channel multiplexer and buffer amplifier precedes the A/D converter.

The manifold pressure, patient pressure, inspiratory flow and expiratory flow

signal inputs to the multiplexer are filtered with an antialiasing filter. Other

inputs are filtered by low pass filters.

Signals that are monitored by the ADC system include:

• Patient Pressure

•Manifold Pressure

• Inspiratory Flow Sensor

• Expiratory Flow Sensor

• Flow Current sense

• Flow DAC output

• Inlet Valve Current sense

•O

Concentration

2

• Power Supplies

• Battery Backup system

The ADC system is based around a 12 bit A/D converter. It operates from ±

15V power supplies except for the A/D converter. The 12-bit converter is

powered by a filtered +5V supply and protected from over-voltage.

Multiplexer and buffer amplifier

The multiplexer settles quickly, within 8 µ sec to 0.01%, to be stable for the

ADC 12-Bit conversion and to maintain the overall 20 µ sec conversion time.

The system bandwidth requirement is from dc to 20Hz. The multiplexer is an 8

channel fault protected device and the amplifier used as a buffer to drive the

A/D converter (AD822AR).

A/D converter

The MAX191BCWG is a 12-Bit converter that operates from a single 5 Volt

power supply. The clock frequency to run the A/D converter is 1.507MHz. It is

derived from the microprocessor system clock.

With a 1.507MHz clock, the conversion time of the A/D converter is 13 clock

periods or 8.63 µ sec.

The MAX191BCWG has the following unadjusted dc accuracy specifications:

Integral Nonlinearity ± 1 LSB max

Differential Nonlinearity ± 1 LSB max (guaranteed monotonic)

Full-Scale Error ± 3 LSB max

Unipolar Offset Error ± 2 LSB max

Voltage reference

The MAX191BCWG has an internal 4.096 Volt ±1 mV voltage reference that

can be adjusted with a potentiometer. This reference voltage is buffered and

used for the digital to analog converter reference.

1006-0453-000 05/04 2-17

Page 34

2 Theory of Operation

Flow valve control The flow valve control circuit consists of a D/A converter and a voltage to

current conversion circuit.

D/A conversion

The D/A conversion for the flow valve drive circuit is based around the

MAX530 12-Bit DAC. The output of the DAC is fed to an input of the

A/D converter multiplexer allowing the microprocessor to monitor the DAC

output.

The MAX530 operates from the same 5V power supply as the A/D converter.

The output voltage range of the converter is 0 to 4.095V (1mV per LSB).

The MAX530BCWG has the following dc accuracy specifications:

Integral Nonlinearity ± 1 LSB max

Differential Nonlinearity ± 1 LSB max (guaranteed monotonic)

Full-Scale Error ± 1 LSB max

Zero-Scale Error + 4 LSB max

Flow valve drive circuit

The flow valve drive circuit does a voltage to current conversion of the DAC

output voltage signal FLW_DAC. With a 0 to 4.000 Volts input, the drive circuit

outputs 0 to 1.0 Amps typical into a 3 ohm load. This current is passed to the

flow valve and is used to proportionally control the flow valve during

mechanical ventilation. This circuit does not require adjustment and is

accurate within ± 2% of full scale.

This circuit also limits the flow valve output to less than 10VA under normal

operation and under a single fault condition. This is a requirement of the

international regulation IEC 601-2-13.

A signal proportional to the actual drive current is input to the A/D converter

to permit the processor to monitor the current and detect fault conditions.

Gas inlet valve drive circuit This circuit consists of a low-dropout regulator providing a regulated 5 Volts to

the inlet valve when enabled by the microprocessor. The SHUTDOWN pin of

the regulator provides on/off control.

This regulator has an output current of 250mA. It has an internal current limit

of 530mA max. This keeps the output under 10VA in a single fault condition.

A current sensing circuit is included to let the processor monitor the inlet valve

current via the A/D converter system and detect fault conditions.

2-18 05/04 1006-0453-000

Page 35

2 Theory of Operation

Front panel display interface All signals to and from the Front Panel are protected from ESD through the use

of transient suppression devices and appropriate filtering. All of these signals

are routed through a single connector from the microcontroller board to the

front panel assembly.

EL display controller

The S-MOS SED1351F flat panel display controller drives 480 horizontal

pixels by 240 vertical pixels of the EL display. Ferrite beads filter the signals

from the display controller to the display.

Video display memory

This memory consists of one high speed 32K x 8 CMOS static RAM directly

connected to the display controller. The video memory is mapped into

memory space, but access is controlled by the display controller to ensure

that the EL display is not disturbed during an access by the processor.

Membrane switch inputs

These signals are electronically debounced by an RC filter and sampled by the

68340 processor.

Audio alarm The circuit consists of a programmable sound generator and a LM4860M

External interface The external interface of the ventilator is an important design task from the

Communication interface

(RS232C)

LED driver outputs

The AC ON LED is turned on directly from the AC power applied.

Rotary encoder input

This quadrature signal is debounced and routed to a quadrature clock

converter which interrupts the 68340 processor at each detent position.

audio amplifier. The sound generator interfaces directly to the CPU and the

audio amplifier drives an 8 ohm speaker. It is normally powered from the low

dropout regulator using the 5.8 V supply. In the event of a loss of the 5.8 V

supply, the sound generator will be powered by the VDD supply to prevent

loading of the processor data bus.

standpoint of Electromagnetic compatibility (EMC). It is important to protect

the ventilator from conducted and radiated Electromagnetic Interference

(EMI) and from Electrostatic Discharge (ESD). In addition, EMI design

precautions are taken to control the emission of EMI via cabling and access

ports.

There are two RS232C interfaces. Each channel is configured for full-duplex

asynchronous operation at communication rates up to 19.2k baud. The

isolated interfaces help eliminate the possibility of ground loops. The RS-232

inputs and outputs completely conform to all EIA RS-232C and CCITT V28

specifications.

1006-0453-000 05/04 2-19

Page 36

2 Theory of Operation

2.4.7 Sensor Interface

Board (SIB)

ACGO

The breathing circuit Sensor Interface Board, (SIB), is the connection between

the flow transducers, patient airway pressure transducer, manifold pressure

transducer, oxygen sensor, and ventilator control module. It also passes

different switch functions through to the ventilator control module. These

switches are used to show the position of covers, breathing circuit modules

and pneumatic controls in the breathing circuit.

Respiratory gas flow, to and from the patient, is monitored by measuring the

differential pressure across a variable orifice in each flow sensor. The

pressure transducers for measuring the differential pressure are on the

Sensor Interface Board, (SIB). The patient airway pressure and the pressure in

the ventilator manifold are measured by pressure transducers on the SIB.

Conditioning circuitry is supplied for these transducers and for the Oxygen

sensor used in the breathing circuit.

The SIB for the Aestiva 7900 Ventilator is located in the cable duct in the

bottom of the breathing circuit chassis. Input gas hoses and signal cables are

routed from the sensors and switches in the breathing circuit to the SIB. A 50conductor cable is used to transfer power and signals to and from the Aestiva

7900 Ventilator CPU board.

O2 Sensor

Inspiratory Flow

Sensor

Tubing

Expiratory Flow

Sensor

4 Wires to Inspiratory and 4

Wires to Expiratory

4 Switches:

Control Panel

Bag/Vent

Canister Release

Absorber CO2 Bypass

8 Wires

Low

Inspiratory Flow

Transducer

High

± 3.5 cmH2O

Tubing

Low

Expiratory Flow

Transducer

High

± 3.5 cmH2O

26 pin HD Dsub

Breathing circuit

Module ID BD

Patient

Airway

Transducer

6 Wires

O2 Amplifier

-20 to 120

cmH2O

Manifold

Pressure

Transducer

Tubing

DPL

Switch

SIB BOARD in

Shielded Enclosure

50 Pin Series 3

-20 to 120

cmH2O

AB.29.089

Pneumatic Engine

Interface Cuff

CPU

Figure 2-12 • Breathing Circuit Sensor Interface Board (SIB)

2-20 05/04 1006-0453-000

Page 37

Functional description Power supply regulators

The SIB power supply is a 10VA limited +12V to +15V supply from the Aestiva

7900 Ventilator CPU board. The supply is filtered at the SIB.

There are two regulators on the SIB that are supplied by the 12V to 15V

supply. A digital +5V is supplied by a low dropout regulator. This supply is

used to power the flow sensor EEPROMs. The +5V to the EEPROMs can be

shut down by pulling the /SHUTDOWN control on the regulator low.

A +6.7V is supplied by another low dropout regulator. This voltage is used to

power all of the operational amplifiers and pressure transducers on the SIB.

The +6.7V is necessary for the AD707 bipolar OPAMP to allow for enough

overhead voltage. This supply is also used to power a switched mode

capacitor based inverter.

The voltage inverter supplies -6.7V for analog circuits. This supplies the

AD707 OPAMP and permits it to operate to ground. The ADM660 switches at

25 kHz.

Patient airway pressure measurement

Patient airway pressure is measured at the high side (patient side) of the

inspiratory pressure transducer. A pressure range of -20 to + 120 cm H2O

supplies a proportional DC output voltage in the range of 0.3 volts to 3.8V,

with zero pressure supplying 0.8V. The transducer is filtered by an RC filter

with a pole frequency of 1 kHz and buffered by an OPAMP. The output of the

OPAMP is driving a 0.001 mF capacitor. The capacitor is used to keep a low

output impedance at RF frequencies to improve EMI immunity.

2 Theory of Operation

Manifold pressure measurement

The manifold pressure is measured from a port on the ventilator pneumatic

engine. A pressure range of -20 to + 120 cm H2O produces a proportional DC

output voltage in the range of 0.3V to 3.8V, with zero pressure supplying 0.8V.

This pressure transducer is also filtered and buffered in the same manner as

the patient airway pressure transducer.

Oxygen concentration measurement

The oxygen sensor is connected to the SIB by a 6-pin, 4-conductor modular

jack. The oxygen sensor supplies a linear output voltage in proportion to the

O2 concentration being measured. The oxygen sensor supplies an output of 3

to 15 mV DC in air (21% O2). It supplies an output of 14 to 72 mV DC in 100%

oxygen concentration.

The oxygen sensor output is filtered for EMI, protected against ESD and

amplified by a factor of 35 by an OPAMP. The amplified signal is then sent to

the Aestiva 7900 Ventilator CPU board after being buffered by an OPAMP.

The O2 OPAMP is bias current compensated. The filter at its positive input is a

combination of a T-type EMI filter and RC filter. The RC filter has a pole

frequency of 2 kHz. The RC filter in the AD707 feedback has a pole frequency

of 47 Hz.

A “DISCONNECT” signal, in the form of a grounded wire, is sent through the

O2 cell and to the Aestiva 7900 Ventilator CPU board. This signal is used to

sense if a cell is connected to the cable. The CPU board has a resistor pull up

to the +5V (VDD) supply and monitors this signal on an I/O port.

1006-0453-000 05/04 2-21

Page 38

2 Theory of Operation

Drive pressure limit switch

The drive pressure limit switch, found on the SIB, is used to monitor the drive

gas pressure from the ventilator pneumatic engine. This normally closed

switch signal is sent to the Aestiva 7900 Ventilator CPU board. The switch will

open if the drive gas pressure is more than 104 +5/-4 cm H2O. The activation

of the switch will stop mechanical ventilation, stop the flow valve drive circuit,

and close the gas inlet valve.

Chassis ground connection

The shell of the 50-pin connector is a continuation of the machine chassis. It

supplies the connection to the SIB shielding box. A mounting hole on the SIB

is attached to the shell of the 50-pin connector and to the SIB shielding box. A

27.4K ohm resistor in parallel with a 0.01 mF capacitor supplies a DC and AC

path to chassis ground for the SIB signal ground.

Inspiratory and expiratory flow measurement

Differential pressure levels in the range of -3.5 cm H2O to +3.5 cm H2O are

applied to the differential pressure transducers by the flow of gasses past the

variable orifice in the flow sensor. This gives DC output voltages in the range of

0.3V to 3.8V, with zero pressure producing 2.05V. The output of the pressure