Page 1

3800 Pulse Oximeter

TruTrak

®

+

User’s Manual

SpO

–

+

♥

2

–

+

85

+

♥

–

+

–

PI

1.25

r

130

40

3800

TruTrak®

6050-0006-380

Printed in USA

Page 2

Important

This device performs as described in this manual, and in accompanying labels

and inserts, when assembled, operated, maintained, and repaired in accordance

with the instructions provided.

Attention! Consult the accompanying instructions before using this

device.

The safety, reliability, and performance of this device can be assured only under

the following conditions:

• If it is used according to the accompanying operating instructions.

• If fittings, extensions, readjustments, changes, or repairs are carried out by

agents authorized by Datex-Ohmeda.

• If it is used in buildings having ground equalization wiring that complies with

relevant local standards and regulations.

CAUTION: US Federal law restricts this device to sale by or on the order of a licensed medical

practitioner. Outside the USA, check local laws for any restriction that may apply.

This device must be cleaned and checked periodically. Do not use a defective

device. Parts that are broken, missing, plainly worn, distorted, or contaminated

should be replaced immediately. If repair or replacement becomes necessary,

request service advice from Datex-Ohmeda (information is listed on the back

cover). Do not repair this device or any of its parts other than in accordance with

written instructions provided by Datex-Ohmeda.

The user of this device shall have the sole responsibility for any malfunction that

results from improper use, faulty maintenance, improper repair, unauthorized

service, damage, or alteration by anyone other than Datex-Ohmeda.

Trademarks

Datex®, Ohmeda®, OxyTip®, PerfTrak®, TruTrak®, and PIr™ are the property of

Instrumentarium Corp. or its subsidiaries.

Cidex is a registered trademark of Johnson & Johnson.

Microsoft Windows Terminal is a trademark of Microsoft Corporation.

ProComm is a trademark of DataStorm Technologies.

All other product and company names are the property of their respective owners.

Text revised: October 2002

© 2002 Datex-Ohmeda, Inc. All rights reserved.

Page 3

Table of Contents

1/Overview

Product description.....................................................................................................................................1-1

Intended use........................................................................................................................................1-1

TruTrak

PIr pulsatile value............................................................................................................................1-2

Other features.....................................................................................................................................1-2

Functional components................................................................................................................1-3

Principles of operation..................................................................................................................1-4

Front panel.......................................................................................................................................................1- 6

Alarm silence button......................................................................................................................1-7

Numeric display...............................................................................................................................1-7

Graphic display .................................................................................................................................1-8

SpO2 alarm limits, high and low............................................................................................1-8

Pulse rate alarm limits, high and low..................................................................................1-9

Display contrast adjuster..............................................................................................................1-9

Power/Standby button/AC power light..............................................................................1-9

Carrying handle ................................................................................................................................1-9

Sensor connector...........................................................................................................................1-10

Pulse beep volume button .......................................................................................................1-10

Alarm volume button..................................................................................................................1-10

Rear panel......................................................................................................................................................1-11

Power entry module .................................................................................................................... 1-11

Equipotential ground connector........................................................................................... 1-11

Product information label ........................................................................................................ 1-11

Mode Switch ....................................................................................................................................1-11

RS-232 serial connector..............................................................................................................1-12

Precautions....................................................................................................................................................1-12

Warnings............................................................................................................................................1-12

Cautions..............................................................................................................................................1-14

+ technology......................................................................................................................1-1

Calibration..............................................................................................................................1-5

Alarm silence ........................................................................................................................1-7

All mute....................................................................................................................................1-7

Battery operation.................................................................................................................1-9

Failure of operation........................................................................................................1-12

Explosion hazard..............................................................................................................1-12

Electrical shock and flammability hazard........................................................1-12

Electrical shock hazard ................................................................................................ 1-12

Data validity........................................................................................................................1-13

Patient safety.......................................................................................................................1-13

Patient safety (sensors)..................................................................................................1-13

RS-232 system interconnection................................................................................1-13

Handle the monitor with care.................................................................................. 1-14

Cleaning................................................................................................................................1-14

Battery.....................................................................................................................................1-14

Sensors...................................................................................................................................1-14

Disposal.................................................................................................................................. 1-14

Miscellaneous.....................................................................................................................1-14

i

Page 4

Table of Contents

2/Setup and Operations

Powering the oximeter...............................................................................................................................2-1

Setup....................................................................................................................................................................2- 2

Factory settings and default settings .....................................................................................2-2

Mode switch settings......................................................................................................................2-3

Checkout procedure...................................................................................................................................2- 5

Signal and data validity............................................................................................................................2- 8

Plethysmographic waveform.....................................................................................................2-8

Numeric display...............................................................................................................................2-9

Trend data......................................................................................................................................................2-10

Before powering on the oximeter ..............................................................................2-2

After powering on the oximeter .................................................................................2-2

Language..................................................................................................................................2-3

Averaging mode...................................................................................................................2-4

Patient mode..........................................................................................................................2-4

PIr pulsatile value display.............................................................................................2-4

EMI line frequency ............................................................................................................2-4

Low perfusion.......................................................................................................................2-8

Signal noise............................................................................................................................2-9

SpO2...........................................................................................................................................2-9

Pulse rate ..............................................................................................................................2-10

PIr pulsatile value............................................................................................................2-10

3/Messages and Troubleshooting

Messages.............................................................................................................................................................3-1

Alarm categories............................................................................................................................................3-4

High priority........................................................................................................................................3-4

Medium priority................................................................................................................................3-4

Low priority.........................................................................................................................................3-5

System failure.....................................................................................................................................3-5

Troubleshooting.............................................................................................................................................3-6

4/Maintenance and Service

Cleaning.............................................................................................................................................................4-1

Oximeter................................................................................................................................................4-1

Recharging the battery..............................................................................................................................4-2

Replacing the battery.................................................................................................................................4-2

Replacing the fuses.....................................................................................................................................4-3

Repair policy and procedure.................................................................................................................4-4

Packaging and return procedure............................................................................................4-4

Parts list ..............................................................................................................................................................4-5

ii

Page 5

Table of Contents

A/Compliance and Specifications

Compliance with standards...................................................................................................................A-1

General safety requirements.....................................................................................................A-1

Electromagnetic compatibility (EMC) .................................................................................A-2

Electromagnetic effects...................................................................................................A-2

Safety checks for software..........................................................................................................A-2

Specifications.................................................................................................................................................A-3

Circuitry................................................................................................................................................A-3

Audio indicators...............................................................................................................................A-3

Audible alarms.................................................................................................................................A-3

Alarm limits ..........................................................................................................................A-3

Displays.................................................................................................................................................A-4

Numeric display (Light-Emitting Diodes–LEDs) ..............................................A-4

Graphic display (Liquid Crystal Display–LCD)................................................A-4

Mode switch.......................................................................................................................................A-4

SpO2.......................................................................................................................................................A-4

Interfering substances.....................................................................................................A-4

Pulse rate..............................................................................................................................................A-5

PIr pulsatile value...........................................................................................................................A-5

Sensor emitter wavelength ranges........................................................................................A-5

Environmental...................................................................................................................................A-5

Electrical...............................................................................................................................................A-5

Battery.......................................................................................................................................A-5

Power........................................................................................................................................A-6

Current leakage...................................................................................................................A-6

Fuses..........................................................................................................................................A-6

Serial output, RS-232.....................................................................................................................A-6

Dimensions and weight ...............................................................................................................A-6

B/Communications

Serial device communications..............................................................................................................B-1

Requirements....................................................................................................................................B-1

RS-232 interface cable—serial pinout...................................................................................B-2

Connection..........................................................................................................................................B-2

Serial communication output................................................................................................................B-3

Auto-output mode............................................................................................................................B-3

Trend-output mode......................................................................................................................... B-4

Warranty

iii

Page 6

List of Figures

Name Page

Figure 1-1. Signal processing block diagram ...........................................................................1-3

Figure 1-2. Comparative light absorption...................................................................................1-4

Figure 1-3. Extinction versus wavelength graph....................................................................1-4

Figure 1-4. 3800 Pulse Oximeter front panel............................................................................1-6

Figure 1-5. 3800 Pulse Oximeter rear panel..........................................................................1-11

Figure 2-1. Typical adult plethysmographic waveform .....................................................2-8

Figure 2-2. Typical neonate plethysmographic waveform...............................................2-8

Figure 2-3. Low perfusion waveform............................................................................................2-8

Figure 2-4. Noisy plethysmographic waveform ......................................................................2-9

iv

Page 7

1/Overview

This chapter

• Introduces the product, including the principles of its operation.

• Describes the oximeter’s controls and features.

• Lists the precautions you must take when using the oximeter.

Product description

The Datex-Ohmeda Model 3800 pulse oximeter with TruTrak

features two easy-to-read displays that present patient data and status information.

• The numeric display shows the SpO2 and pulse rate values.

• The graphic display shows the plethysmographic waveform, messages, the

Relative Perfusion Index (PIr™) pulsatile value, and the high and low alarm

limit settings for SpO2 and pulse rate.

Intended use

The 3800 pulse oximeter with TruTrak+ technology is indicated for spot-checking

and continuous monitoring of functional oxygen saturation and pulse rate,

including monitoring during conditions of clinical patient motion.1 This device is

intended for use with adult, pediatric, and neonatal patients in both hospital and

non-hospital environments.

Important: Only Datex-Ohmeda OxyTip

TruTrak+ technology

TruTrak+ technology improves pulse oximetry performance during conditions of

clinical patient motion. In the clinical environment, oximetry readings are affected

by several types of patient motion. The types of motion include clenching,

pressing, and rubbing as well as extending, flexing, and kicking. Unlike motion

technologies that use only a single method to correct for motion, TruTrak+ selects

one of many proprietary motion-correction algorithms, depending on the type and

intensity of the motion.

®

+ technology

®

+ sensors can be used with this monitor.

TruTrak+ technology employs a patented five-step process that consists of

1) high-speed data sampling; 2) motion identification, quantification, and

1

Anesthesia & Analgesia. 2002;94,1S, S54-S60

1-1

Page 8

3800 User’s Manual

PIr pulsatile value

correction; 3) calculation of the SpO2 value; 4) weighting and averaging of the

SpO2 value; and 5) the display of an improved SpO2 value. The result of this

process is a more accurate and stable displayed SpO2 value, with fewer false

alarms or dashed displays.

Important: For TruTrak+ performance, the averaging mode must be set to Long.

See Setup in chapter 2.

The PIr pulsatile value indicates the strength of the pulse signal at the sensor site:

the higher the PIr value, the stronger the pulse signal. A strong pulse signal

increases the validity of SpO2 and pulse rate data.

PIr is a relative value that varies from patient to patient. Clinicians can use the PI

value to compare the strength of the pulse signal at different sites on a patient in

order to locate the best site for the sensor (the site with the strongest pulse signal).

You can choose to display or not display the PIr value (see Setup in chapter 2).

Other features

• PerfTrak® waveform display, an automatic scale of the plethysmographic

• Large SpO2 digital display for clear differentiation from the pulse rate value.

• Backlit display and contrast control for excellent visibility in subdued lighting

• Direct access to user-selectable high and low alarm limits for SpO2 and pulse

• An audible pulse indicator with an adjustable volume; the automatic pitch

• Visual and audible (adjustable volume) alarms.

• An alarm-silence feature that silences audible alarms for 120 seconds.

• An all-mute feature that silences audible alarms until deactivated.

• Automatic tiered alarm messages.

• Short, medium, or long SpO2 response averaging modes.

• Adult or neonatal patient modes for default pulse rate alarm settings.

• Automatic storage of up to 12 hours of SpO2, pulse rate, and alarm limit

• An automatic self-test and calibration check at start-up. After start up, the

• Rechargeable, sealed, lead-acid battery operation, including battery status

r

waveform to provide a relative indication of the sensor site perfusion level.

conditions; adjustable viewing angle, using the pull-down feet under the

monitor.

rate.

modulation reflects changing SpO2 level.

violations data in trend memory, which can be output through the RS-232

serial connector.

oximeter continuously performs background self-tests.

reporting.

1-2

Page 9

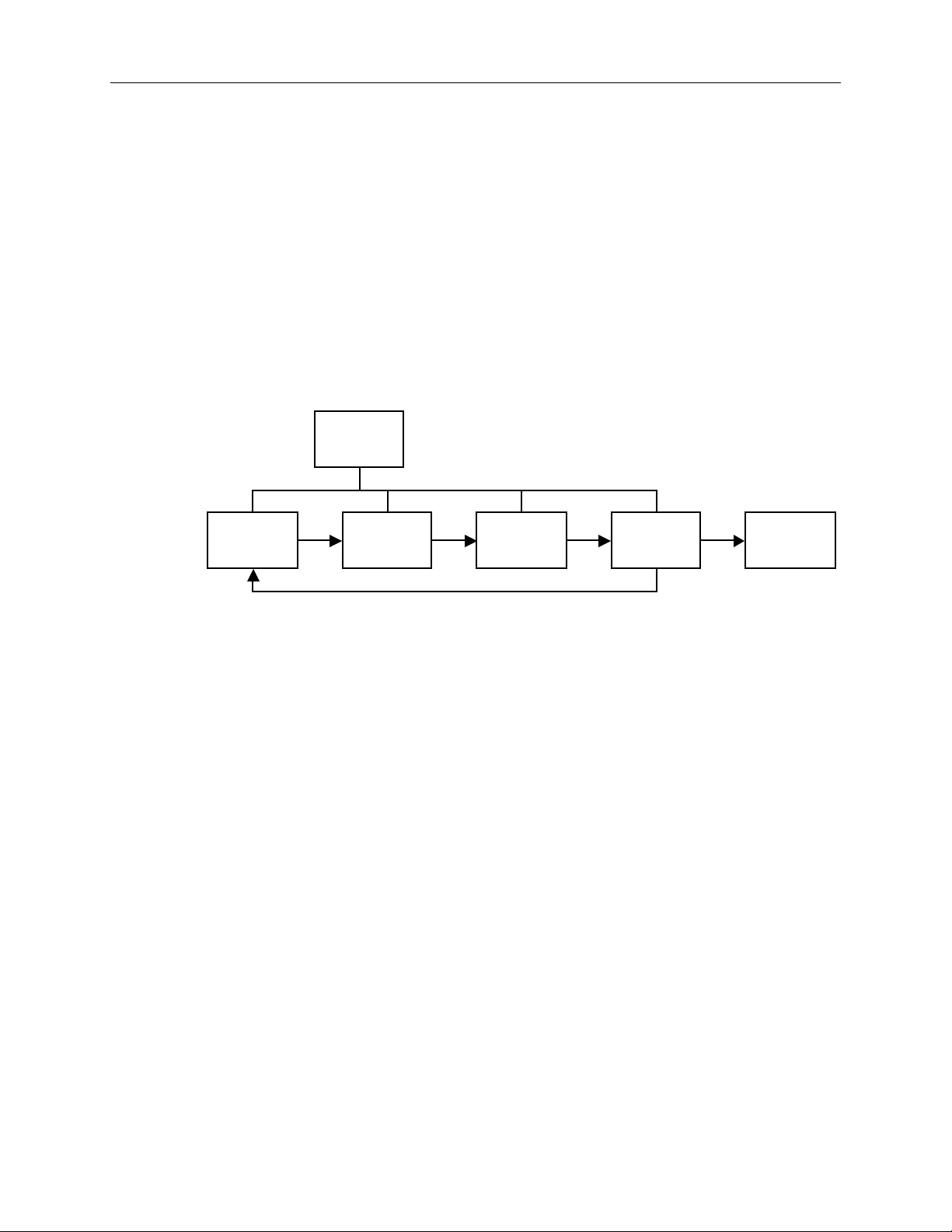

Functional components

The 3800 oximeter uses the following key electrical component elements to

determine SpO2, pulse rate, and PIr pulsatile values:

• The sensor

• Sensor-signal processing

• Microprocessor calculations

The sensor consists of

• The light source—red and infrared light-emitting diodes (LEDs)

• The photodetector—an electronic device that produces an electrical current

proportional to incident light intensity

Timing

Control

1/Overview

Sensor

Figure 1-1. Signal processing block diagram

The two light wavelengths generated by the LEDs pass through the tissue at the

sensor site. The photodetector collects this light (partially absorbed and modulated) and converts it into an electronic signal that is sent to the oximeter for

further processing.

The electronic circuitry receives the photodetector’s electronic signal, processes it,

and passes it on to the microprocessor for calculation of the SpO2, pulse rate, and

PIr pulsatile value.

Analog

Processing

A/D

Converter

Digital

Processing

Input/

Output

1-3

Page 10

3800 User’s Manual

T

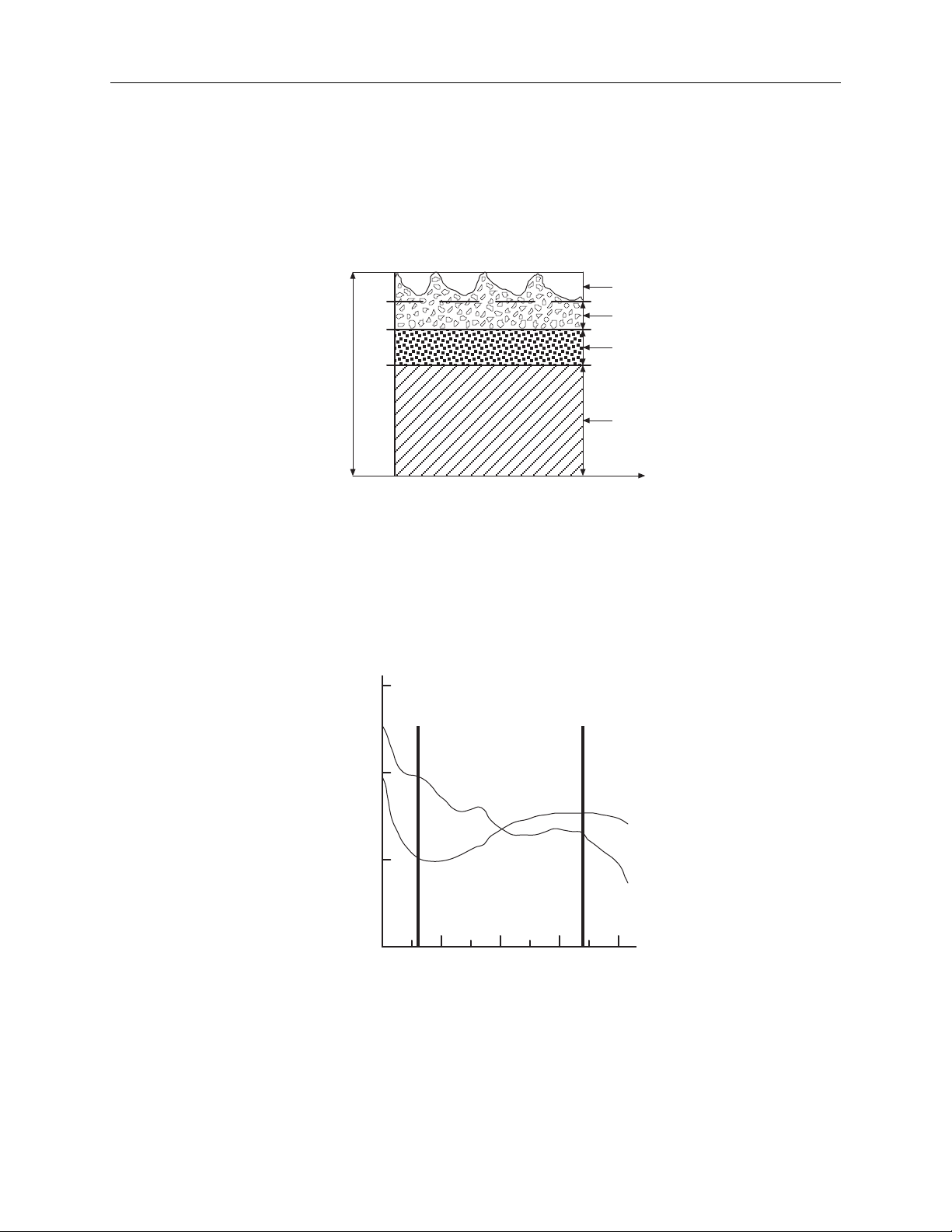

Principles of operation

The 3800 pulse oximeter uses a two-wavelength pulsatile system—red and infrared

light—to distinguish between oxygenated (O2Hb) and reduced (HHb) hemoglobin,

each of which absorbs different amounts of light emitted from the oximeter

sensor. The system then calculates the relative percentage of these two

constituents and displays SpO

.

2

Variable absorption

(due to arterial pulse)

Arterial blood absorption

Venous blood absorption

Absorption

Other tissue absorption

ime

Figure 1-2. Comparative light absorption

Arterial blood pulsation at the test site modulates transmission of the oximeter

sensor’s light. Since other fluids and tissues present generally don’t pulsate, they

don’t modulate the light passing through that location. The attenuation of light

energy due to arterial blood flow is detected and isolated by using the pulsatile

portion of the incoming signal. PIr pulsatile value is a measure of the relative size

of this portion of the signal.

1

(Red)

660 nm

0

(Infrared)

940 nm

Extinction (10x)

O2Hb

-1

HHb

-2

600 700 800 900 1000

Wavelength (nm)

Figure 1-3. Extinction versus wavelength graph

The sensor’s photodetector converts the light, which is partially absorbed and

modulated as it passes through the tissue sample, into an electronic signal. Since

O2Hb and HHb allow different amounts of light to reach the photodetector at the

selected wavelengths, the electronic signal varies according to the light source that

1-4

Page 11

1/Overview

is “on” and the oxygenation of the arterial hemoglobin. Analog and digital signal

processing then converts the light-intensity information into SpO2, pulse rate, and

PIr pulsatile values for display on the monitor.

Calibration

A CO-oximeter typically uses four or more wavelengths of light and calculates

reduced hemoglobin (HHb), oxyhemoglobin (O2Hb), carboxyhemoglobin (COHb),

and methemoglobin (MetHb). Datex-Ohmeda pulse oximeters use two

wavelengths ranges, 650 nm - 665 nm and 930 nm - 950 nm, both with an average

power of less than 1 mW. These wavelengths are used to calculate the presence of

O2Hb and reduced HHb. Because of this, pulse oximetry readings will be

different than CO-oximetry readings in situations where a patient’s COHb or

MetHb are increased.

Two different methods of calibration are currently used by manufacturers of pulse

oximeters: fractional and functional.

Important: This pulse oximeter uses the functional calibration method. The user

cannot change the calibration method to fractional.

• Fractional saturation is represented mathematically as the percentage of the

total amount of hemoglobin carrying oxygen. It is determined by dividing the

oxyhemoglobin by the total hemoglobin.

Fractional SpO2 = x 100 = x 100

• Functional saturation is represented mathematically as the percentage of

hemoglobin capable of carrying oxygen that is carrying oxygen.

Functional SpO2 = x 100 = x 100

The calculation of SpO2 assumes 1.6% carboxyhemoglobin (COHb), 0.4%

methemoglobin (MetHb), and no other pigments. Appreciable variation from these

values will influence SpO2 accuracy. These values are based on the DatexOhmeda Pulse Oximeter Empirical Calibration Study.

O2Hb

Hb

Hb

TOTAL

O2Hb

- COHb - MetHb O2Hb + HHb

TOTAL

O2Hb + HHb + COHb + MetHb

O2Hb

O2Hb

1-5

Page 12

3800 User’s Manual

Front panel

11

10

12

+

♥

–

+

–

9

PI

1.25

r

8

3

Figure 1-4. 3800 Pulse Oximeter front panel

1 Alarm silence button

2 Numeric display (LED)

3 Graphic display (LCD)

4 SpO2 alarm limits, high/low setting buttons

5 Pulse rate alarm limits, high/low setting buttons

6 Display contrast adjust slide

7 Power/Standby button

8 Carrying handle

9 Sensor connector

10 Pulse beep volume button

11 Alarm volume button

3800

TruTrak®

85

130

40

SpO

–

+

♥

2

–

+

4

5

6

7

1-6

Page 13

1/Overview

1 Alarm silence button

This button has two functions:

• 120-second alarm silence—activated by a single press.

• Continuous all mute—activated by three quick presses (if the all-mute

feature is enabled). Press once to deactivate.

Alarm silence

When an active alarm condition exists, press this button to silence the audible

portion of the alarm for 120 seconds. The flashing red or yellow alarm light

becomes a steady light. If an alarm condition still exists after 120 seconds, the

audible tone and flashing light resume.

Exceptions: Both NO SENSOR and SENSOR OFF audible alarms will not be

activated until after the unit obtains a valid signal. The same conditions apply

to an active audible alarm for NO SENSOR, SENSOR OFF, or SENSOR

FAILURE that has been silenced; i.e., once the sensor alarm condition is

acknowledged by silencing the audible alarm, a new audible alarm will not

sound until the condition has been cleared and the unit obtains a valid signal.

NOTE: Pressing the alarm silence button produces 120 seconds of silence,

regardless of other alarm conditions that may occur during this 120-second

interval, except for the SYSTEM FAILURE, CONNECT UNIT TO LINE

POWER, and BUTTON STUCK alarms.

All mute

To continuously silence any alarm that can be silenced, press the alarm

silence button three times within three seconds. After you have activated all

mute, the all mute icon flashes between the SpO2 and pulse rate alarm limit

settings on the right side of the screen display. When an alarm condition

occurs, the alarm button light flashes and the alarm message appears on the

waveform display but no audible alarm sounds.

When all mute is active, press the alarm silence button once to deactivate this

feature and enable all audible alarms.

2 Numeric display

SpO2 numeric area—calculated SpO

Pulse rate numeric area—calculated pulse rate

2

1-7

Page 14

3800 User’s Manual

3 Graphic display

21

85

3

PI

r

4

1 Plethysmographic waveform

2 Message area

3 SpO2 and pulse rate alarm limits

1.25

The PerfTrak waveform display appears after the monitor has detected

data from the sensor. It represents the blood volume change of the

hemodynamic system, assuming no other factors (e.g., motion artifact) are

present. This waveform scales automatically to the perfusion level or

strength of the signal being received at the patient monitoring site.

Status and alarm messages appear above the waveform area on the

waveform display (the height of the waveform is reduced while messages

are displayed). Status messages give you information about the oximeter's

operating condition. Alarm messages alert you to conditions that need

your attention. See chapter 3 for complete alarm and status message

information.

The high and low alarm limit settings appear here. If a limit is set to OFF,

three dashes appear in the location for that limit.

When an SpO2 or pulse rate limit is violated, the LED on the numeric

display and the LCD’s limit value flashes for that alarm.

130

40

1-8

SpO

4 PIr pulsatile value

Dashes (- - -) appear if the following conditions exist: no sensor is

connected to the unit, the sensor is not attached to the patient, the sensor

has failed, there is insufficient light penetrating the tissue site, or there is

too much ambient light.

4 SpO2 alarm limits, high and low

2

+

–

The top button sets the high alarm limit and the bottom button sets the low

alarm limit. For either limit, press the + side of the button to raise the value or

the – side to lower it. As you press one of these buttons, the values do not

cycle through the available settings; e.g., when you reach 100, the value does

not cycle (or wrap) to 50 or OFF.

Page 15

♥

y

1/Overview

5 Pulse rate alarm limits, high and low

+

–

The top button sets the high alarm limit, the bottom button sets the low alarm

limit. For either limit, press the + side to raise the value or the – side to lower

it. As you press one of these buttons, the values do not cycle through the

available settings; e.g., when you reach 235, the value does not cycle (or wrap)

to 30 or OFF.

6 Display contrast adjuster

Use this sliding lever to adjust the vertical viewing angle of the graphic

display Slide the lever to the left to reduce the contrast and to the right to

increase it.

7 Power/Standby button/AC power light

This button toggles between On (operational mode) and Off (standby mode).

The battery recharges as long as the unit is plugged into the AC power supply.

No displays are visible in the Off/Standby mode.

The green light to the right of the button is lit when the unit is connected to

an AC power supply.

85

130

40

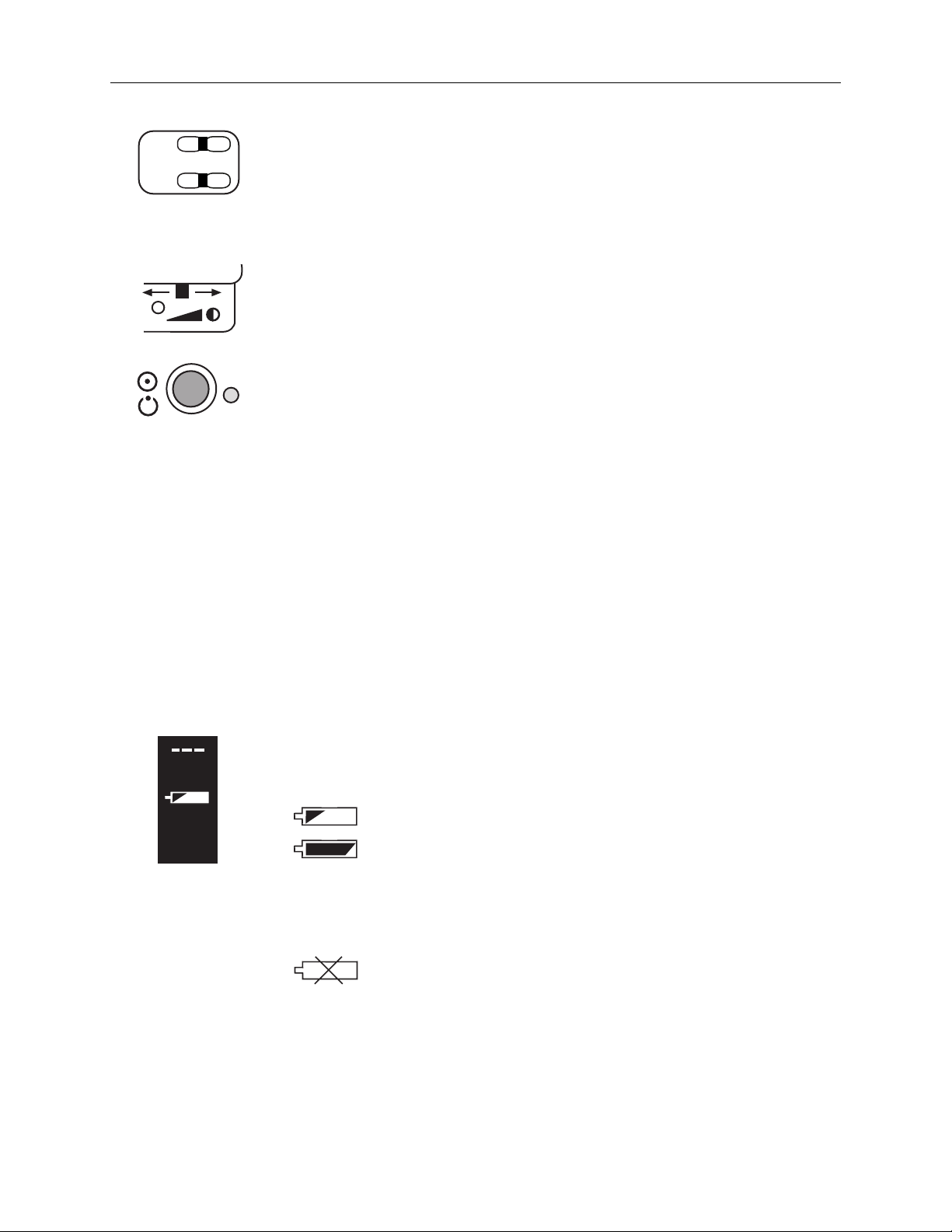

Battery operation

The oximeter runs for at least five and one-half hours on a new, fully charged

battery at normal operating temperatures. LOW BATTERY appears when

between 5 and 15 minutes of battery operation time remain. Plug the

monitor into AC power to continue monitoring and recharge the battery. The

unit will operate with a dead or defective battery when it is connected to the

AC power supply.

When the CONNECT UNIT TO LINE POWER message appears, you must

immediately plug the oximeter into the AC power supply or the unit turns

itself off after 10 seconds.

When operating on battery power, an icon appears between the two pairs of

alarm limit values on the right side of the LCD. This icon indicates the batter

condition as follows:

Charged/not low

Low

If the all mute condition exists, the display of this icon alternates with the

display of the all mute icon.

This icon appears on the status screen:

Depleted, not installed, or defective

8 Carrying handle

The lower front portion of the oximeter’s case is designed to be a carrying

handle for ease of moving the unit from one place to another.

1-9

Page 16

3800 User’s Manual

9 Sensor connector

The sensors for this oximeter plug into this nine-contact connector. Use only

Datex-Ohmeda sensors compatible with this oximeter (see Parts list in

chapter 4).

♥

+

–

+

–

10 Pulse beep volume button

This button adjusts the volume level for the pulse indicator in incremental

steps from OFF to level 5 (default is 2). Press the + side of the button to

increase the volume or the – side to decrease it; you will hear the volume

level as you press the button. As you press one of these buttons, the values do

not cycle through the available settings; e.g., when you reach 5, the value does

not cycle (or wrap) to OFF.

As you adjust the volume, the volume setting is shown in the message area

above the waveform.

NOTE: The pitch of the pulse tone changes as the SpO2 value increases or

decreases—the higher the SpO2 value, the higher the pitch of the pulse tone.

11 Alarm volume button

This button adjusts the audible alarm volume level in incremental steps from

1 to 5 (default is 3). You cannot set the alarm volume to OFF. Press the + side

of the button to increase the alarm volume or the – side to decrease it; you

will hear the volume level as you press the button. As you press one of these

buttons, the values do not cycle through the available settings; e.g., when you

reach 5, the value does not cycle (or wrap) to 1.

As you adjust the volume, the volume setting is shown in the message area

above the waveform.

1-10

Page 17

Rear panel

1/Overview

100 – 240V~ 50–60 Hz 0.45 A T2.0AH/250V

Mode Switch

1315 West Century Drive

Louisville, CO 80027-9560 USA Made in USA

12 3 45

Figure 1-5. 3800 Pulse Oximeter rear panel

WARNING: Electrical shock hazard. Because the unit is not grounded when it is operating on

battery power, do not connect any equipment to the RS-232 connector on the rear panel

unless the unit is connected to the AC power supply.

RS 232

1 Power entry module

This module contains

• Fuses

• Power connector for the power cord that connects the oximeter to the

AC power supply for continuous operation and/or battery recharging.

2 Equipotential ground connector

In locations where this type of ground is required, connect your grounding

system here.

Mode Switch

3 Product information label

The following symbols may appear on the monitor, on labels affixed to the

monitor, and/or on shipping materials. Refer to Compliance with standards in

Appendix A for definitions of symbols that indicate compliance with

standards set by regulatory agencies.

CAUTION: US Federal law restricts this device to sale by or on

the order of a licensed medical practitioner. Outside the USA,

check local laws for any restriction that may apply.

The serial number for this product appears as SN AAAYxxxxx.

The first three letters are specific to the product type, the fourth

letter indicates the year of manufacture (F=2002, G=2003, etc. “I”

and “O” are not used.). The last five digits are the sequential

number for the unit as produced in the indicated year.

G

The warranty expiration date for this product is printed near

this symbol.

4 Mode Switch

This symbol identifies the two-position switches that set the display language,

the averaging mode, the patient mode, the display of the PIr pulsatile value,

and the EMI line frequency. See chapter 2 for instructions.

1-11

Page 18

3800 User’s Manual

RS 232

Precautions

Warnings

5 RS-232 serial connector

This 9-pin connector provides serial digital information on SpO2, pulse rate,

alarm limit violations, and alarm messages. It is compatible with most RS-232

devices capable of accepting a 9600 baud input. See Appendix B for

instructions.

Two types of precautions appear in this manual: warnings and cautions.

• A WARNING indicates the possibility of injury to the patient or operator.

• A CAUTION indicates a condition that may lead to equipment damage or

malfunction.

Failure of operation

If the oximeter fails any part of the checkout procedures or current leakage test,

remove it from operation until qualified service personnel have corrected the

situation.

It is possible for any device to malfunction; therefore, always verify unusual data

by performing a formal patient assessment.

Explosion hazard

Do not use the monitor in the presence of any flammable anesthetic mixture.

Electrical shock and flammability hazard

Before cleaning or servicing the oximeter, always turn it off and disconnect the

power cord from the AC power supply.

Electrical shock hazard

Do not remove the monitor cover. An operator may perform only maintenance

procedures specifically described in this manual. Refer servicing to qualified

service personnel trained in the repair of this equipment.

Measure the oximeter’s leakage current whenever an external device is connected

to the RS-232 port. Forward and reverse polarity = 100 microamperes maximum.

This equipment must be properly grounded.

• Electrical safety specifications (e.g., current leakage and ground resistance) can

be assured only when the monitor is connected to a three-wire, grounded

receptacle without the use of extension cords or adapters.

• If there is any doubt about the integrity of the AC power supply protective

earth conductor, operate the monitor on internal battery power.

• Because the unit is not grounded when it is operating on battery power, do not

connect any equipment to the RS-232 connector on the rear panel unless the

unit is connected to the AC power supply.

1-12

Page 19

1/Overview

Data validity

Conditions that may cause inaccurate readings and impact alarms include

interfering substances, excessive ambient light, electrical interference, excessive

motion, low perfusion, low signal strength, incorrect sensor placement, poor sensor

fit, and movement of the sensor on the patient.

To prevent erroneous readings, do not use an inflated blood pressure cuff or arterial

blood pressure measurement device on the same limb as the oximeter sensor.

Patient safety

The correct use of the oximeter is to measure only arterial oxygen saturation

(SpO2), pulse rate, and Relative Perfusion Index pulsatile value.

• A pulse oximeter does not measure respiration and should never be used as a

substitute for an apnea monitor or as the primary monitor for infants being

monitored for apnea.

• A pulse oximeter may be used during sleep studies of adults only to gather

information regarding SpO2, pulse rate, and PIr pulsatile value.

This device is not intended for use in a magnetic resonance imaging (MRI)

environment.

Patient safety (sensors)

Patient conditions (such as reddening, blistering, skin discoloration, ischemic skin

necrosis, and skin erosion) may warrant changing the sensor site frequently or

using a different style of sensor.

To prevent patient injury or equipment damage, use only Datex-Ohmeda oximeter

sensors approved for use with this oximeter. For complete information about the

safe and appropriate use of a sensor, consult the instructions for that sensor.

Discard a damaged sensor immediately. Do not repair a damaged sensor or use a

sensor repaired by others.

RS-232 system interconnection

Accessory equipment connected to the RS-232 serial connector must be certified

according to the current version of the respective IEC/EN standards (e.g., IEC

60950 for data processing equipment and IEC/EN 60601-1 for medical equipment).

All configurations shall also comply with IEC/EN 60601-1-1. Anyone who connects

additional equipment to the RS-232 serial connector configures a medical system,

and is therefore responsible that the system complies with the requirements of

IEC/EN 60601-1-1. If in doubt, call your local authorized service office, as listed on

the back cover of this manual. The 3800 is referred to as an IEC/EN 60601/F

device in the summary of situations table contained in IEC/EN 60601-1-1.

1-13

Page 20

3800 User’s Manual

Cautions

Handle the monitor with care

Cleaning

Battery

Improper handling can cause damage or inaccurate results.

Do not autoclave, pressure sterilize, or gas sterilize the oximeter.

Use cleaning solution sparingly. Do not soak or immerse the monitor in liquid.

Excessive solution can flow into the monitor and damage internal components.

When cleaning the display area, do not use abrasive cleaning compounds or other

materials that could damage the screen.

Do not use petroleum-based solutions, acetone solutions, or other harsh solvents to

clean the oximeter. These substances may damage the oximeter and cause a

malfunction.

The 3800 internal battery, containing lead and acid, is a hazardous waste. Dispose

of the battery through an approved hazardous materials disposal facility or return

it to Datex-Ohmeda for disposal.

To prevent damage to the lead-acid battery, do not turn the monitor on after the

LOW BATTERY message appears without first plugging it in to the AC power

supply.

Sensors

Do not apply tension to the sensor cable; sensor damage may result.

Disposal

Dispose of this medical device and its packing materials according to local

requirements.

Miscellaneous

US Federal law restricts this device to sale by or on the order of a licensed

medical practitioner.

1-14

Page 21

2/Setup and Operations

This chapter provides the following information and instructions:

• Powering the oximeter.

• Selecting the language, averaging mode, patient mode, PIr pulsatile value

display, and EMI (electromagnetic interference) line frequency.

• Checkout procedure—to determine that all functions of the oximeter are

working properly.

• Signal and data validity guidelines.

• Trend data.

To operate the oximeter effectively, you must

• Know how the oximeter derives its readings (see Principles of operation in

chapter 1).

• Be familiar with its controls and components (see chapter 1).

• Understand its messages (see chapter 3).

Powering the oximeter

The 3800 pulse oximeter is designed to operate on battery power and on all

commonly available voltage supplies. Your oximeter was shipped with the correct

power cord for your local AC power supply. Any hospital-grade power cord,

however, with the female connector end that fits into the power module (IEC-320

type) on the 3800 can be used; the male connector that plugs into the grounded

“wall” outlet may be whatever is needed locally. The oximeter accepts a range of

AC mains power; see Appendix A for details.

To protect data validity in cases of possible electromagnetic interference, make

sure the EMI line frequency mode switch is set to the same frequency as your

local AC power supply before using the unit for patient monitoring; see EMI line

frequency under Mode switch settings later in this chapter.

A battery does not need to be installed for the oximeter to operate on the AC

power supply.

2-1

Page 22

3800 User’s Manual

Setup

Factory settings and default settings

Before powering on the oximeter

When you turn on the oximeter, the following settings are in effect and remain in

operation until you change them.

Use the mode switches in the oximeter’s rear panel to set the language, averaging

mode, patient mode, PIr pulsatile value display, and EMI line frequency.

Parameter Factory Setting Range

Language English English, French, German,

Italian, Japanese, Portuguese,

Spanish, or Swedish

Averaging mode

Patient mode Adult Adult or Neonate

PIr pulsatile value display Yes Yes (display PIr value) or No

EMI line frequency 60 Hz 50 Hz or 60 Hz

Long / TruTrak+

(12 seconds)

Long / TruTrak+ (12 seconds),

Medium (6 seconds) or

Short (3 seconds)

After powering on the oximeter

Changes you make to the parameters shown below take effect immediately.

Parameter Default Setting Range

High SpO2 limit OFF

(appears as: – – –)

Low SpO2 limit 85% 50% to 100% or OFF

High pulse rate 130 bpm*

(adult mode)

200 bpm

(neonatal mode)

Low pulse rate 40 bpm

(adult mode)

50% to 100% or OFF

30 to 235 bpm or OFF

30 to 235 bpm or OFF

2-2

100 bpm

(neonatal mode)

Alarm volume 3 1 to 5

Pulse volume 2 1 to 5 or OFF

* bpm= beats-per-minute

Page 23

Mode switch settings

A bank of eight numbered, two-position switches is accessed through the rear

panel. The up position is ON and the down position is OFF.

2/Setup and Operations

=

Important: If you change the switch settings while the oximeter is on, the new

settings do not take effect until you power off, then on again.

=

Language

Switches 1, 2, and 3 set the language used for the display and data transmitted

through the RS-232 port. (For Japanese, data transmissions are in English only.)

Switches Language

123

English

123

French

123

German

123

Italian

123

Japanese

123

123

123

Portuguese

Spanish

Swedish

2-3

Page 24

3800 User’s Manual

Averaging mode

Switches 4 and 5 set the averaging mode. The averaging mode selects the time

period of data used to calculate a weighted average SpO2 value to be displayed by

the oximeter.

Switches SpO2 and Pulse Rate Averaging

45

45

45

45

Long (12 seconds) Yes (enabled)

Medium (6 seconds) No

Short (3 seconds) No

Patient mode

Switch 6 sets the patient mode.

Switch Patient mode Low pulse rate alarm limit High pulse rate alarm limit

6

Adult 40 bpm 130 bpm

6

Neonate 100 bpm 200 bpm

PIr pulsatile value display

Switch 7 sets the display of the PIr pulsatile value.

TruTrak+

2-4

Switch Display PIr value

7

Yes

7

No

EMI line frequency

Switch 8 sets the EMI line frequency. To optimize EMI (electromagnetic

interference) immunity, make sure switch 8 is in the correct position for the AC

power line frequency in use.

Switch EMI Line Frequency

8

60 Hz

8

50 Hz

Page 25

Checkout procedure

WARNING: Failure of operation. If the oximeter fails any part of the checkout procedures or

current leakage tests, remove it from operation until qualified service personnel have

corrected the situation.

WARNING: Explosion hazard. Do not use the monitor in the presence of any flammable

anesthetic mixture.

WARNING: Electrical shock hazard. This equipment must be properly grounded.

• Electrical safety specifications (e.g., current leakage and ground resistance) can be

assured only when the monitor is connected to a three-wire, grounded receptacle without

the use of extension cords or adapters.

• If there is any doubt about the integrity of the AC power supply protective earth conductor,

operate the monitor on internal battery power.

• Because the unit is not grounded when it is operating on battery power, do not connect

any equipment to the RS-232 connector on the rear panel unless the unit is connected to

the AC power supply.

2/Setup and Operations

If you plan to send serial data to another device, make sure the connection

between the device and the rear panel connector is made before you power on

the monitor and make sure the monitor is connected to the AC power supply.

Important: For TruTrak+ performance, the averaging mode must be set to Long.

1. Inspect the oximeter case for damage. Make sure the display windows are

clean.

WARNING: Sensors

• Discard a damaged sensor immediately. Do not repair a damaged sensor or use a

sensor repaired by others.

• To prevent patient injury or equipment damage, use only Datex-Ohmeda oximeter

sensors approved for use with this oximeter. For complete information about the safe

and appropriate use of a sensor, consult the instructions for that sensor.

CAUTION: Do not apply tension to the sensor cable; sensor damage may result.

2. Check that the sensor is a compatible model before connecting it to the

oximeter. Only Datex-Ohmeda OxyTip+ sensors can be used with this monitor.

If you’re using a reusable sensor, make sure it opens and closes smoothly.

Remove substances that may interfere with the transmission of light between

the sensor's light source and detector.

3. Connect the sensor cable to the sensor connector on the monitor. Make sure it

is a firm connection and that the cable is not twisted, sliced, or frayed.

4. Attach the sensor to a finger or an ear, depending on the sensor you are using.

2-5

Page 26

3800 User’s Manual

5. To turn on the oximeter, press the power button.

The first screen shows the Datex-Ohmeda logo and the model name

(Model 3800).

The next screen shows the averaging mode in effect, the patient mode, the

progress of the self-test, and the status of the battery charge.

Averaging Mode: Long

Patient Mode: Adult

Self-test in progress …

(indicates battery-charge status)

Below the bar graph, the version number of the unit’s system and oximetry

software appears as Version X.XXX/YY.YYY, where X’s represent the system

software version and Y’s the oximetry software version.

Diagnostic self-test

During this time, the system performs a diagnostic self-test (electronics,

battery status, analog signal path integrity, calibration check) and sets the

default parameters. This self-test takes approximately 10 seconds.

• A start-up tone sequence tests the audio circuit; all display LEDs and

the LCD backlight are illuminated, then blanked.

• The alarm LED toggles between red and yellow while a numeric

countdown from 9 to 0 occurs on each seven-segment LED display

ending with a decimal point.

• A battery icon is displayed to indicate the battery condition as either

charged, depleted, or defective/missing (see chapter 3).

Upon successful completion of all diagnostic self-tests, the unit is

considered to be in calibration and begins normal operation. This message

is displayed:

Test passed. In calibration.

If the unit does not pass the self-test, an error message is displayed and the

unit is inoperable.

6. On the displays, verify

• The high and low alarm limits for SpO2 and pulse rate.

• Dashes (– – –) appear for any limit set to OFF.

• The readings for SpO2, pulse rate, and PIr pulsatile value.

Dashes may appear on the display until the SpO2, pulse rate, and PI

pulsatile value readings have stabilized (approximately 12 seconds).

r

2-6

Page 27

2/Setup and Operations

NOTE: The audible alarm feature for all alarm conditions is silenced for the first

two minutes after powering on.

7. If two minutes have elapsed since you powered on, verify that the patient

alarms are functional by setting the high and low SpO2 and pulse rate alarm

limits beyond the current readings. Make sure

• An alarm tone sounds.

• The violated alarm limit and reading flash on the display.

• Depending on the priority of the alarm, a red or yellow alarm light flashes.

8. Verify the sensor alarms are functional by removing the sensor from the

sensor site. Make sure

• SENSOR OFF or CHECK SENSOR SITE appears in the message area of

the graphic display.

• The alarm tone sounds; the alarm light flashes.

9. Unplug the sensor from the oximeter. Make sure

• NO SENSOR appears.

• The alarm tone sounds; the alarm light flashes.

10. Press the alarm silence button. Make sure

• The alarm tone ceases.

• The alarm light is steady.

11. To begin patient monitoring, connect the desired Datex-Ohmeda sensor to the

oximeter. Attach that sensor to the patient.

To verify the sensor is on correctly and that the data are verifiable, see Signal and

data validity in this chapter.

WARNING: Patient safety. Patient conditions (such as reddening, blistering, skin discoloration,

ischemic skin necrosis, and skin erosion) may warrant changing the sensor site frequently or

using a different style of sensor.

2-7

Page 28

3800 User’s Manual

Signal and data validity

Plethysmographic waveform

The oximeter’s PerfTrak waveform display provides a visual indicator of the

validity of the values that appear on the display. The waveform is scaled to

correspond to the perfusion level or strength of the signal being received at the

patient monitoring site.

NOTE: When a message appears in the upper portion of the LCD, the waveform

rectangle becomes smaller but the correspondence between signal strength and

waveform height is maintained.

You should be able to easily identify three complete passes of the

plethysmographic waveform. Although the waveform shape may vary from patient

to patient, under normal conditions it corresponds to the arterial pressure

waveform. Use Figures 2-1 (adult) and 2-2 (neonate) as guidelines to determine a

sensor placement that generates the fewest noise spikes.

Figure 2-1. Typical adult plethysmographic waveform

Figure 2-2. Typical neonate plethysmographic waveform

The “typical” neonate waveform differs from that of an adult, including the

absence of a dicrotic notch (a notch on the descending limb of the normal arterial

pulse tracing that corresponds to aortic valve closure).

Low perfusion

As the perfusion at the patient monitoring site decreases, so will the height of the

waveform. (The PIr pulsatile value is a numeric representation of the relative

height of the waveform.) The height will decrease to the point where the signal

quality becomes too small or too poor for accurate, reliable readings. At that point,

the message CHECK SENSOR SITE appears in the message area and an alarm is

generated. The waveform will be similar to Figure 2-3.

CHECK SENSOR SITE

2-8

Figure 2-3. Low perfusion waveform

Page 29

2/Setup and Operations

Signal noise

The following conditions can cause noisy waveforms:

• Poor sensor placement.

• Motion at the sensor site.

• Electrical interference.

Figure 2-4. Noisy plethysmographic waveform

If three easily identifiable passes of a “typical” waveform do not occur,

• Make sure the sensor’s detector is flush with the sensor site (for sensor

application, see the instructions for the sensor you are using).

• Make sure the light source and detector are directly opposite each other.

• Select a site where the distance between the light source and the detector is

less.

• Make sure the patient site is stable; minimize movement of the sensor site.

• Massage the sensor site with a 70% isopropyl alcohol pad or rubefacient cream

(10-30% methyl salicylate and 2-10% menthol) for 20-30 seconds. Strong

vasodilator creams, such as nitroglycerin paste, are not recommended.

• If possible, remove electrical noise sources such as electrosurgery or

electrical/electronic devices (e.g., fans). If these solutions are not possible,

operate the oximeter on battery power, or try plugging the oximeter into a

different electrical outlet.

• If artificial nails or excessive fingernail polish are present, select another site

or remove the polish/artificial nails.

Numeric display

SpO

2

Stability of the SpO2 readings is a good indicator of signal validity. Although

“stability” is a relative term, with practice you’ll get a good feeling for changes that

are artifactual or physiological and the speed of each. The stability of the readings

over time is affected by which averaging mode you're using. In Long / TruTrak+

mode (12-second averaging), the readings tend to be more stable because the

signal is averaged over a longer period of time than the Short (3 seconds) or

Medium (6 seconds) modes.

Too great a distance between the sensor emitter and detector can reduce signal

strength and result in a poor signal. When the value is too low, the message

CHECK SENSOR SITE may appear to alert you that the SpO2 value may not be

accurate. Perfuse the sensor site or relocate the sensor to a site with higher blood

flow.

2-9

Page 30

3800 User’s Manual

Pulse rate

PIr pulsatile value

Trend data

Compare the displayed pulse rate to the patient’s palpated pulse rate. If the unit’s

rate varies significantly from the palpated rate, the data may be less accurate due

to motion artifact or other noise.

A cough or other hemodynamic pressure disturbance can disrupt the pulse rate,

which is determined from the plethysmographic waveform. The time span

between the waveform’s peaks determines the pulse rate. The unit uses the same

averaging mode (long, medium, or short) as that selected for SpO2.

The PIr pulsatile value is a measurement of the strength of the photoplethysmographic signal read by the oximeter. The greater the number, the greater the

pulsatility and the validity of the SpO2 and pulse rate data. This value is useful

when determining that the sensor is correctly attached and that the data are

verifiable. It is also an indicator of relative perfusion at the sensor site.

The oximeter stores a maximum of 12 hours of trend data. The process maintains

the lowest SpO2 value that occurs during each 6-second interval along with the

corresponding pulse rate, and highest-priority error message and all alarm limit

violations. You can access the trend data stored in the 3800 through the serial port

on the rear of the oximeter. See Appendix B for details.

The trend data are maintained as long as the unit’s battery is connected and

charged to minimum operating level.

To clear trend data:

1. Hold down the alarm silence button while you power on the oximeter.

2. At the Clear Trend Data? prompt,

• To select YES to clear all data from the trend buffer, press the high SpO

button (+ or –).

• To select NO to retain the data, press the low pulse rate limit button (+ or –).

If you don’t press either button within 10 seconds, the trend data are retained and

the unit proceeds with the power-on sequence.

2

2-10

Page 31

3/Messages and Troubleshooting

This chapter contains

• Descriptions of the messages and indicators that appear on the screen.

• Alarm categories and their characteristics.

• A chart for troubleshooting situations that may occur while using the oximeter.

Become thoroughly familiar with this information before using the oximeter to

monitor a patient.

Messages

The pulse oximeter acknowledges your actions and the monitor’s conditions by

displaying messages in the waveform screen message display area. Alarm

messages appear when any alarm condition occurs.

The following chart alphabetically lists the messages that may appear on the

oximeter, why the message appears, and the action(s) to take if the message

indicates a problem.

Message Possible cause(s) Recommended action(s)

The all mute feature is activated. No action required. (Press the

Appears between the alarm

limit settings.

Indicates a fully charged battery.

alarm silence button once to

deactivate.)

No action required.

Appear on status screen

during power-on sequence

and on right side of LCD

during battery operation.

Appears on status screen

during power-on sequence.

Appears in message area on

waveform screen.

Indicates a low-charged battery.

Indicates battery failure, or a

depleted or missing battery.

The alarm or pulse tone volume

is being adjusted.

To recharge, plug the unit into AC

mains power.

To recharge, plug the unit into AC

mains power. If the condition

persists, the unit requires service.

No action required. To adjust

audio volume, see Front panel in

chapter 1.

3-1

Page 32

3800 User’s Manual

y

Message Possible cause(s) Recommended action(s)

AMBIENT LIGHT Excessive ambient light. Relocate the sensor to a site more

BUTTON STUCK Appears if something is pressing

against the buttons on the

monitor.

shielded from light or reduce the

amount of light shining on the

sensor.

Make sure nothing is pressing

against the front of the unit.

Appears when the last button

you pressed has not released

properly or has been pressed for

more than 30 seconds.

CHECK SENSOR SITE Appears when SpO2 readings ma

be invalid due to motion, an

unacceptable sensor site, poor

placement, low perfusion, or

because the sensor is off the

patient.

Clear Trend Data?

YES/NO

CONNECT UNIT TO LINE POWER The battery needs immediate

INSUFFICIENT LIGHT Dirt on the sensor emitter or

Appears when the alarm silence

button is held down while you’re

turning on the oximeter.

recharging.

detector. Sensor detector failure.

Press that button again or turn the

power off and then on. If the

condition persists, the unit

requires service.

For all causes, reposition or

relocate the sensor, and/or

increase perfusion (see the sensor

user instructions).

Press the high SpO2 alarm limit

button (+ or –) to clear trend data

from memory (YES).

Press the low pulse rate alarm

limit button (+ or –) to retain trend

data in memory (NO).

If you take no action within 10

seconds, the trend data are

retained in memory.

Plug the oximeter into the AC

power supply; otherwise the unit

will turn itself off in 10 seconds.

Clean the sensor (if reusable) or

replace it.

3-2

Test site dirty. Misaligned or

poorly positioned sensor.

Insufficient light penetrating the

tissue site. Dark pigmentation.

Fingernail polish present.

Clean the test site. Reposition the

sensor or select another test site.

Reposition the sensor or select

another test site.

Remove polish or select another

test site.

Page 33

Message Possible cause(s) Recommended action(s)

INTERFERENCE DETECTED Appears when the signal Is too

erratic to be processed due to

proximity of other electrical

equipment generating highfrequency electromagnetic noise.

LOW BATTERY Appears when 5 to 15 minutes of

battery operation remain.

LOW QUALITY SIGNAL

(appears only in serial

communication output)

NO SENSOR

(also see

CHECK SENSOR SITE)

Sensor off patient.

Perfusion not sufficient for valid

readings. Motion at sensor site,

electrical noise, or incorrect

sensor placement.

Sensor not connected or not fully

inserted into the sensor

connector.

3/Messages and Troubleshooting

No action required. May be

caused by strong radio frequency

(RF) interference possibly

generated by electrosurgery.

SpO2 and PR readings do not

change during detected interference (or become dashes if

interference persists). When

interference ceases, signal

processing resumes.

Plug the oximeter into the AC

power supply to recharge the

battery and continue monitoring.

Important: To prevent permanent

damage to the battery, recharge a

discharged battery within eight

hours after the LOW BATTERY

message is displayed.

Reattach the sensor.

Check patient and oximeter setup.

Insert sensor cable into the

connector.

May be an incorrect sensor.

SENSOR FAILURE The connected sensor is not an

OxyTip+ sensor.

Oximeter can’t identify the

connected sensor.

Broken sensor cable wire,

inoperative LEDs, or faulty

detector; the sensor has failed.

SENSOR OFF Sensor off patient. Reattach the sensor.

SYSTEM FAILURE #XXX:

SERVICE UNIT

TruTrak+ OFF TruTrak+ technology is not

An internal component of the

unit has failed. XXX represents

the error code.

active; the averaging mode is not

set to Long.

Refer to the instructions for the

sensor you are using.

Connect a Datex-Ohmeda

OxyTip+ sensor.

Replace sensor. Refer to the

instructions for the sensor you are

using.

Replace sensor.

Unit requires service.

For TruTrak+ performance, set the

averaging mode to Long (see

Setup in chapter 2).

3-3

Page 34

3800 User’s Manual

Alarm categories

3800 oximeter tiered alarms fall into three priority categories: high, medium and

low. Depending on what is occurring at the time, an alarm may fall into more

than one category.

NOTE: The audible alarm feature for all alarm conditions is silenced for the first

two minutes after powering on.

High priority

Requires immediate operator response.

Red alarm button light flashes.

Two five-tone sequences (beep-beep-beep, beep-beep) sound every 10 seconds

until the condition is removed or the alarm is silenced

• A violation of the low or high SpO2 limit (violated limit flashes).

• BUTTON STUCK

• CONNECT UNIT TO LINE POWER

If the following alarms occur during active monitoring, they also fall into the high

priority category.

• AMBIENT LIGHT

• CHECK SENSOR SITE

• INSUFFICIENT LIGHT

• NO SENSOR

• SENSOR FAILURE

• SENSOR OFF

3-4

NO SENSOR and SENSOR OFF alarm conditions are not active until after the

oximeter displays an initial valid reading.

Medium priority

Requires prompt operator response.

Yellow alarm button light flashes.

One three-tone sequence (beep-beep-beep) every 20 seconds until the condition is

removed or the alarm is silenced.

• A violation of the low or high pulse rate limit (violated limit flashes).

• INTERFERENCE DETECTED

• LOW BATTERY

Page 35

Low priority

3/Messages and Troubleshooting

If the following alarms occur before active monitoring, these alarms are

considered to be of medium priority:

• AMBIENT LIGHT

• CHECK SENSOR SITE

• INSUFFICIENT LIGHT

• NO SENSOR

• SENSOR FAILURE

• SENSOR OFF

Requires operator awareness.

Yellow alarm button light illuminates continuously.

One tone (beep) sounds; no repetition.

• INTERFERENCE DETECTED

Requires operator awareness.

Yellow alarm button light illuminates continuously.

• LOW QUALITY SIGNAL

System failure

A special category of alarms exists for system failure and the imminent failure of

pulse oximeter operation.

Requires immediate operator response.

Red alarm button light continuously flashes.

A continuous tone sounds; overrides all mute condition.

• SYSTEM FAILURE #XXX, SERVICE UNIT

For more information, refer to the 3800/3900/3900P Technical Reference Manual.

3-5

Page 36

3800 User’s Manual

Troubleshooting

The following chart list some conditions that may occur with the oximeter along

with the cause(s) and recommended action(s) for correcting them.

Condition Possible cause(s) Recommended action(s)

Unit does not power on. The battery is fully discharged or

disconnected and/or the unit is

not plugged into the AC power

supply.

To charge the battery and begin

monitoring, plug the unit into the

AC power supply.

If the condition persists, the unit

requires service.

One or both of the fuses have

blown.

Unit powers on but the

graphic display is blank.

Continuous speaker tone. Internal failure. Unit requires service.

Buttons don’t work when

pressed.

Unit doesn’t beep when

powered on.

Dashed display, waveform

may appear erratic; various

alarm messages

The viewing contrast is not

correct.

Internal failure. Unit requires service.

Disconnected or failed speaker. Unit requires service.

Sensor failure. Replace sensor.

Replace the fuse(s). See Replacing

the fuses in chapter 4.

If the new fuse blows shortly after

installation, the unit requires

service.

Use the display contrast adjust

slide to adjust the viewing angle.

If the condition persists, the unit

requires service.

See CHECK SENSOR SITE under

Messages in this chapter.

3-6

Page 37

4/Maintenance and Service

This chapter covers

• Maintenance procedures:

Cleaning the oximeter, as necessary.

Recharging the battery, as necessary.

Replacing the fuses in the power module, as necessary.

• The Datex-Ohmeda repair policy.

• A list of items you may order for the oximeter.

Cleaning

To clean a reusable sensor, refer to the instructions for the sensor.

Oximeter

WARNING: Electrical shock and flammability hazard. Before cleaning the oximeter, always turn

it off and disconnect the power cord from the AC power supply.

CAUTION:

• Do not autoclave, pressure sterilize, or gas sterilize this oximeter.

• Use cleaning solution sparingly. Do not soak or immerse the monitor in liquid. Excessive

solution can flow into the monitor and damage internal components.

• When cleaning the display area, do not use abrasive cleaning compounds or other materials

that could damage the screen.

• Do not use petroleum-based solutions, acetone solutions, or other harsh solvents to clean

the oximeter. These substances may damage the oximeter and cause a malfunction.

Be sure that the oximeter is turned off and unplugged from the AC power supply

before cleaning and that the unit is completely dry before use.

To clean the display panel, use a cotton swab moistened with 70% isopropyl

alcohol and gently wipe the panel.

4-1

Page 38

3800 User’s Manual

To clean the outer surface of the oximeter, use a soft cloth dampened with a mild

soap and water solution or one of the following solutions:

70 vol% isopropyl or ethyl alcohol

quaternary ammonia

3 vol% hydrogen peroxide in water

100:1 bleach solution

Cidex® plus activator (ready solution contains 2 vol% glutaraldehyde)

Recharging the battery

The oximeter's internal battery (a sealed pack of 8V lead-acid batteries) provides

the following operation times when it is new, used at normal temperatures, and

charged to full capacity: at least 5 -1/2 hours of continuous operation.

A LOW BATTERY message appears when 5 to 15 minutes of battery operation

remain. When the alarm message CONNECT UNIT TO LINE POWER appears

during operation on battery power, an audible alarm sounds and the oximeter

automatically shuts off in approximately 10 seconds.

Important: To prevent permanent damage to the battery, recharge a discharged

battery within eight hours after the LOW BATTERY message is displayed.

To recharge the battery, plug the oximeter into the AC power supply. The

oximeter is operational while recharging the battery.

The battery charging times are approximately