Daikin EWAQ009ACV3, EWAQ010ACV3, EWAQ011ACV3, EWYQ009ACV3, EWYQ010ACV3 Installation manuals

...

INSTALLATION MANUAL

Packaged air-cooled water chillers and

packaged reversible air to water heatpumps

EWAQ009ACV3

EWAQ010ACV3

EWAQ011ACV3

EWYQ009ACV3

EWYQ010ACV3

EWYQ011ACV3

EWAQ009ACW1

EWAQ011ACW1

EWAQ013ACW1

EWYQ009ACW1

EWYQ011ACW1

EWYQ013ACW1

D2D2

L1

L2

B1

B2

D2D2

L1

L2

1

B2

B2

D2

D2D2

EE

L1

L1

CC

HH

B1B1B1

L2

L2

AA

D1D1D1

1

B2B2B2

D2D2

D2

EE

L1

CC

L2

L2

AA

D1D1D1

L1

HH

B1

B1

1

2

1

2

W1V3

DCAC DCAC

2

.

01

02

03

04

05

06

07

08

09

10

11

12

13

14

ATITIKTIES-DEKLARACIJA

ATBILSTĪBAS-DEKLARĀCIJA

VYHLÁSENIE-ZHODY

CE -

CE -

CE -

CE - UYUMLULUK-BİLDİRİSİ

ZJAVA O SKLADNOSTI

VASTAVUSDEKLARATSIOON

ДЕКЛАРАЦИЯ-ЗА-СЪОТВЕТСТВИЕ

CE - I

CE -

CE -

deklaruje na własną i wyłączną odpowiedzialność, że modele klimatyzatorów, których dotyczy niniejsza deklaracja:

m

IZJAVA-O-USKLAĐENOSTI

DEKLARACJA-ZGODNOŚCI

DECLARAŢIE-DE-CONFORMITATE

CE - MEGFELELŐSÉGI-NYILATKOZAT

CE -

CE -

CE -

15

16

17

18

19

20

21

22

23

24

25

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

.

.

.

.

*

.

. 07

*

.

.

.

.

Direktive z vsemi spremembami.

Direktiivid koos muudatustega.

Директиви, с техните изменения.

Direktyvose su papildymais.

Direktiver, med senere ændringer.

Direktiv, med företagna ändringar.

Direktiver, med foretatte endringer.

Direktiivejä, sellaisina kuin ne ovat muutettuina.

declară pe proprie răspundere că aparatele de aer condiţionat la care se referă această declaraţie:

z vso odgovornostjo izjavlja, da so modeli klimatskih naprav, na katere se izjava nanaša:

kinnitab oma täielikul vastutusel, et käesoleva deklaratsiooni alla kuuluvad kliimaseadmete mudelid:

декларира на своя отговорност, че моделите климатична инсталация, за които се отнася тази декларация:

visiška savo atsakomybe skelbia, kad oro kondicionavimo prietaisų modeliai, kuriems yra taikoma ši deklaracija:

ar pilnu atbildību apliecina, ka tālāk uzskaitīto modeĮu gaisa kondicionētāji, uz kuriem attiecas šī deklarācija:

vyhlasuje na vlastnú zodpovednosť, že tieto klimatizačné modely, na ktoré sa vzťahuje toto vyhlásenie:

tamamen kendi sorumluluğunda olmak üzere bu bildirinin ilgili olduğu klima modellerinin aşağıdaki gibi olduğunu beyan eder:

r

o

x

b

t

v

k

w

25

megfelelnek az alábbi szabvány(ok)nak vagy egyéb irányadó dokumentum(ok)nak, ha azokat előírás szerint használják:

spełniają wymogi następujących norm i innych dokumentów normalizacyjnych, pod warunkiem że używane są zgodnie z naszymi

instrukcjami:

sunt în conformitate cu următorul (următoarele) standard(e) sau alt(e) document(e) normativ(e), cu condiţia ca acestea să fie utilizate în

conformitate cu instrucţiunile noastre

skladni z naslednjimi standardi in drugimi normativi, pod pogojem, da se uporabljajo v skladu z našimi navodili:

on vastavuses järgmis(t)e standardi(te)ga või teiste normatiivsete dokumentidega, kui neid kasutatakse vastavalt meie juhenditele:

съответстват на следните стандарти или други нормативни документи, при условие, че се използват съгласно нашите

инструкции:

atitinka žemiau nurodytus standartus ir (arba) kitus norminius dokumentus su sąlyga, kad yra naudojami pagal mūsų nurodymus:

tad, ja lietoti atbilstoši ražotāja norādījumiem, atbilst sekojošiem standartiem un citiem normatīviem dokumentiem:

sú v zhode s nasledovnou(ými) normou(ami) alebo iným(i) normatívnym(i) dokumentom(ami), za predpokladu, že sa používajú v súlade

s našim návodom:

ürünün, talimatlarımıza göre kullanılması koşuluyla aşağıdaki standartlar ve norm belirten belgelerle uyumludur:

Directives, as amended.

Direktiven, gemäß Änderung.

Directives, telles que modifiées.

Richtlijnen, zoals geamendeerd.

.

.

.

i

.

.

.

*

.

.

Direktīvās un to papildinājumos.

Smernice, v platnom znení.

Değiştirilmiş halleriyle Yönetmelikler.

<B>

v platném znění.

Smjernice, kako je izmijenjeno.

irányelv(ek) és módosításaik rendelkezéseit.

z późniejszymi poprawkami.

и оценено

Directivelor, cu amendamentele respective.

съгласно

<A>

ir kaip teigiamai nuspręsta

<B>

<A>

Sertifikatą <C>

положително от

pagal

както е изложено в

Cертификата <C>

kaip nustatyta

21 Забележка *

22 Pastaba *

Directivas, según lo enmendado.

Direttive, come da modifica.

√‰ËÁÈÒv, fiˆ˜ ¤¯Ô˘Ó ÙÚÔÔÔÈËı›.

Directivas, conforme alteração em.

Директив со всеми поправками.

, pozytywną opinią

şi apreciat pozitiv

igazolta a megfelelést,

<A>

<A>

<B>

szerint.

alapján, a(z)

Świadectwem <C>

<A>

<C> tanúsítvány

a(z)

a(z)

zgodnie z dokumentacją

<B>

aşa cum este stabilit în

.

.

.

*

01

02

03

04

<A> DAIKIN.TCF.025C14/11-2008

<B> KEMA (NB0344)

<C> 2082543.0551-QUA/EMC

v

<B>

pozitīvajam

<C> Sertifikasına

<B>

a pozitívne zistené

sertifikātu <C>

<A>

un atbilstoši

<A>

kā norādīts

tarafından olumlu olarak

<B>

osvedčením <C>

‘da belirtildiği gibi ve

vērtējumam saskaņā ar

değerlendirildiği gibi.

súlade s

ako bolo uvedené v

<A>

göre

Not

23 Piezīmes *

24 Poznámka *

25

v

<B>

ja heaks

<A>

sertifikaadile <C>

Certificatul <C>

in odobreno s strani

<A>

järgi vastavalt

certifikatom <C>

<B>

în conformitate cu

<B>

de

kiidetud

kot je določeno v

nagu on näidatud dokumendis

skladu s

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PROHLÁŠENÍ-O-SHODĚ

CE - ERKLÆRING OM-SAMSVAR

CE - ILMOITUS-YHDENMUKAISUUDESTA

CE -

заявляет, исключительно под свою ответственность, что модели кондиционеров воздуха, к которым относится настоящее заявление:

erklærer under eneansvar, at klimaanlægmodellerne, som denne deklaration vedrører:

u

q

CE - DECLARAÇÃO-DE-CONFORMIDADE СЕ - ЗАЯВЛЕНИЕ-О-СООТВЕТСТВИИ

CE - OPFYLDELSESERKLÆRING

CE - FÖRSÄKRAN-OM-ÖVERENSTÄMMELSE

CE - ¢H§ø™H ™YMMOPºø™H™

CE - DECLARACION-DE-CONFORMIDAD

CE - DICHIARAZIONE-DI-CONFORMITA

prohlašuje ve své plné odpovědnosti, že modely klimatizace, k nimž se toto prohlášení vztahuje:

izjavljuje pod isključivo vlastitom odgovornošću da su modeli klima uređaja na koje se ova izjava odnosi:

deklarerar i egenskap av huvudansvarig, att luftkonditioneringsmodellerna som berörs av denna deklaration innebär att:

erklærer et fullstendig ansvar for at de luftkondisjoneringsmodeller som berøres av denne deklarasjon innebærer at:

s

n

teljes felelőssége tudatában kijelenti, hogy a klímaberendezés modellek, melyekre e nyilatkozat vonatkozik:

ilmoittaa yksinomaan omalla vastuullaan, että tämän ilmoituksen tarkoittamat ilmastointilaitteiden mallit:

j

c

y

h

declaración:

referencia la

estão em conformidade com a(s) seguinte(s) norma(s) ou outro(s) documento(s) normativo(s), desde que estes sejam utilizados de

acordo com as nossas instruções:

соответствуют следующим стандартам или другим нормативным документам, при условии их использования согласно нашим

инструкциям:

overholder følgende standard(er) eller andet/andre retningsgivende dokument(er), forudsat at disse anvendes i henhold til vore

instrukser:

respektive utrustning är utförd i överensstämmelse med och följer följande standard(er) eller andra normgivande dokument, under

förutsättning att användning sker i överensstämmelse med våra instruktioner:

respektive utstyr er i overensstemmelse med følgende standard(er) eller andre normgivende dokument(er), under forutssetning av at

disse brukes i henhold til våre instrukser:

vastaavat seuraavien standardien ja muiden ohjeellisten dokumenttien vaatimuksia edellyttäen, että niitä käytetään ohjeidemme

mukaisesti:

za předpokladu, že jsou využívány v souladu s našimi pokyny, odpovídají následujícím normám nebo normativním dokumentům:

u skladu sa slijedećim standardom(ima) ili drugim normativnim dokumentom(ima), uz uvjet da se oni koriste u skladu s našim uputama:

Machinery 98/37/EC

Low Voltage 2006/95/EC

Electromagnetic Compatibility 2004/108/EC *

ob upoštevanju določb:

vastavalt nõuetele:

следвайки клаузите на:

laikantis nuostatų, pateikiamų:

ievērojot prasības, kas noteiktas:

održiavajúc ustanovenia:

bunun koşullarına uygun olarak:

under iagttagelse af bestemmelserne i:

enligt villkoren i:

gitt i henhold til bestemmelsene i:

noudattaen määräyksiä:

za dodržení ustanovení předpisu:

prema odredbama:

követi a(z):

zgodnie z postanowieniami Dyrektyw:

în urma prevederilor:

Notă *

16 Megjegyzés *

17 Uwaga *

18

on

<B>

ja jotka

enligt

<B>

och godkänts av

<A>

enligt

11 Information *

e giudicato positivamente

<A>

delineato nel

mukaisesti.

<A>

Sertifikat <C>

og gjennom positiv

<A>

ifølge

<B>

Sertifikaatin <C>

hyväksynyt

Certifikatet <C>

som det fremkommer i

bedømmelse av

jotka on esitetty asiakirjassa

12 Merk *

13 Huom *

Certificado <C>

¶ИЫЩФФИЛЩИОfi <C>

e com o parecer

Î·È ÎÚ›ÓÂÙ·È ıÂÙÈο

<A>

<A>

Certificato <C>

de acordo com o

Û‡Ìʈӷ Ì ÙÔ

<B>

<B>

secondo il

<B>

positivo de

·fi ÙÔ

tal como estabelecido em

da

* fiˆ˜ ηıÔÚ›˙ÂÙ·È ÛÙÔ

™ËÌ›ˆÛË

06 Nota *

08 Nota

<B>

positiv

<B>

<C>

<C>

et évalué positivement par

Certificat <C>

<A>

Certificate

and judged positively by

Zertifikat

aufgeführt und von

<A>

<A>

conformément au

beurteilt gemäß

according to the

as set out in

wie in der

tel que défini dans

<B>

19 Opomba *

20 Märkus

v

<B>

a pozitivně zjištěno

i pozitivno ocijenjeno od

<A>

Certifikatu <C>

<A>

prema

osvědčením <C>

<B>

strane

jak bylo uvedeno v

kako je izloženo u

souladu s

14 Poznámka *

15 Napomena *

i

<B>

согласно

<B>

и в соответствии с

og positivt vurderet af

<A>

<A>

Certifikat <C>

положительным решением

henhold til

как указано в

Свидетельству <C>

som anført i

09 Примечание *

10 Bemærk *

y es valorado

de acuerdo con el

<A>

Certificaat <C>

en positief beoordeeld door

<B>

<A>

overeenkomstig

zoals vermeld in

<B>

como se establece en

Certificado <C>

positivamente por

Jiro Tomita

Director Quality Assurance

Ostend, 1st of April 2009

declares under its sole responsibility that the air conditioning models to which this declaration relates:

erklärt auf seine alleinige Verantwortung daß die Modelle der Klimageräte für die diese Erklärung bestimmt ist:

déclare sous sa seule responsabilité que les appareils d'air conditionné visés par la présente déclaration:

verklaart hierbij op eigen exclusieve verantwoordelijkheid dat de airconditioning units waarop deze verklaring betrekking heeft:

declara baja su única responsabilidad que los modelos de aire acondicionado a los cuales hace

dichiara sotto sua responsabilità che i condizionatori modello a cui è riferita questa dichiarazione:

a

d

f

l

e

CE - DECLARATION-OF-CONFORMITY

CE - KONFORMITÄTSERKLÄRUNG

CE - DECLARATION-DE-CONFORMITE

CE - CONFORMITEITSVERKLARING

Daikin Europe N.V.

i

‰ЛПТУВИ МВ ·ФОПВИЫЩИО‹ ЩЛ˜ В˘ı‡УЛ fiЩИ Щ· МФУЩ¤П· ЩˆУ ОПИМ·ЩИЫЩИОТУ Ы˘ЫОВ˘ТУ ЫЩ· ФФ›· ·У·К¤ЪВЩ·И Л ·ЪФ‡Ы· ‰‹ПˆЫЛ:

declara sob sua exclusiva responsabilidade que os modelos de ar condicionado a que esta declaração se refere:

g

p

EWAQ009ACV3****, EWAQ010ACV3****, EWAQ011ACV3****, EWYQ009ACV3****, EWYQ010ACV3****, EWYQ011ACV3****,

EWAQ009ACW1****, EWAQ011ACW1****, EWAQ013ACW1****, EWYQ009ACW1****, EWYQ011ACW1****, EWYQ013ACW1****,

* = , , -, 1, 2, 3, ..., 9, A, B, C, ..., Z

are in conformity with the following standard(s) or other normative document(s), provided that these are used in accordance with our

instructions:

der/den folgenden Norm(en) oder einem anderen Normdokument oder -dokumenten entspricht/entsprechen, unter der Voraussetzung,

daß sie gemäß unseren Anweisungen eingesetzt werden:

sont conformes à la/aux norme(s) ou autre(s) document(s) nor matif(s), pour autant qu'ils soient utilisés conformément à nos instructions:

conform de volgende norm(en) of één of meer andere bindende documenten zijn, op voorwaarde dat ze worden gebruikt overeenkomstig

onze instructies:

están en conformidad con la(s) siguiente(s) norma(s) u otro(s) documento(s) nor mativo(s), siempre que sean utilizados de acuerdo con

nuestras instrucciones:

sono conformi al(i) seguente(i) standard(s) o altro(i) documento(i) a carattere normativo, a patto che vengano usati in conformità alle

nostre istruzioni:

В›У·И Ы‡МКˆУ· МВ ЩФ(·) ·ОfiПФ˘ıФ(·) ЪfiЩ˘Ф(·) ‹ ¿ППФ ¤ББЪ·КФ(·) О·УФУИЫМТУ, ˘fi ЩЛУ ЪФ¸fiıВЫЛ fiЩИ ¯ЪЛЫИМФФИФ‡УЩ·И

Û‡Ìʈӷ Ì ÙȘ Ô‰ËÁ›Â˜ Ì·˜:

following the provisions of:

gemäß den Vorschriften der:

conformément aux stipulations des:

overeenkomstig de bepalingen van:

EN60335-2-40,

siguiendo las disposiciones de:

secondo le prescrizioni per:

Ì ًÚËÛË Ùˆv ‰È·Ù¿Íˆv Ùˆv:

de acordo com o previsto em:

в соответствии с положениями:

01 Note *

02 Hinweis *

03 Remarque *

04 Bemerk *

05 Nota

3PW33163-3D

EWAQ009~011ACV3

EWAQ009~013ACW1

EWYQ009~011ACV3

EWYQ009~013ACW1

Packaged air-cooled water chillers and

packaged reversible air to water heatpumps

Installation manual

CONTENTS Page

Introduction ....................................................................................... 1

General information ................................................................................... 1

Scope of this manual ................................................................................. 1

Model identification.................................................................................... 2

Accessories....................................................................................... 2

Accessories supplied with the unit............................................................. 2

Safety considerations........................................................................ 2

Before installation.............................................................................. 3

Important information regarding the refrigerant used........................ 3

Selecting installation site................................................................... 4

Selecting a location in cold climates.......................................................... 4

Precautions on installation ................................................................4

Installation method for prevention of falling over........................................ 5

Installation servicing space........................................................................ 5

Typical application examples............................................................. 6

Application 1 .............................................................................................. 6

Application 2 .............................................................................................. 6

Overview of the unit .......................................................................... 7

Opening the unit ........................................................................................ 7

Main components ...................................................................................... 7

Water pipework.......................................................................................... 8

Charging water ........................................................................................ 10

Piping insulation....................................................................................... 10

Field wiring .............................................................................................. 11

Specifications of standard wiring components ........................................ 13

Installation of the digital controller ........................................................... 15

Start-up and configuration............................................................... 16

Pump operation configuration.................................................................. 16

Initial start-up at low outdoor ambient temperatures ............................... 16

Pre-operation checks............................................................................... 16

Powering up the unit ................................................................................ 17

Failure diagnosis at the moment of first installation................................. 17

Setting the pump speed........................................................................... 17

Field settings............................................................................................ 18

Field settings table................................................................................... 21

Test run and final check .................................................................. 22

Test run operation (manual)..................................................................... 22

Final check............................................................................................... 22

Maintenance.................................................................................... 22

Chiller unit................................................................................................ 22

Digital controller....................................................................................... 23

Troubleshooting............................................................................... 23

General guidelines................................................................................... 23

General symptoms................................................................................... 23

Error codes .............................................................................................. 24

Technical specifications................................................................... 25

General.................................................................................................... 25

Electrical specifications ........................................................................... 25

READ THESE INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION. KEEP THIS MANUAL IN A HANDY

PLACE FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY DAIKIN WHICH ARE

SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DAIKIN DEALER FOR

ADVICE AND INFORMATION.

The English text is the original instruction. Other languages are

translations of the original instructions.

INTRODUCTION

General information

Thank you for purchasing this Daikin inverter chiller.

This unit is designed for outdoor installation and used for both

heating and cooling applications. The unit is designed to be

combined with fan coil units or air handling units for air conditioning

purposes.

Heat pump and cooling only versions

This chiller range consists of 2 main versions: a heat pump (EWYQ)

version and a cooling only (EWAQ) version, available in 6 standard

sizes:

■ V3: 9, 10, and 11 kW (single phase)

■ W1: 9, 11, and 13 kW (3 phase)

Options

■ Remote alarm kit EKRP1HB

■ Heater tape option OP10

Both versions are also available with a heater tape option

(OP10) for protecting internal water pipework at cold outdoor

temperatures.

Connection to a benefit kWh rate power supply

This equipment allows for connection to benefit kWh rate power

supply delivery systems. Full control of the unit will remain possible

only in case the benefit kWh rate power supply is of the type that

power supply is not interrupted. Refer to "Connection to a benefit

kWh rate power supply" on page 14 for more details.

Installation manual

1

Scope of this manual

This manual describes the procedures for unpacking, installing and

connecting all EWA/YQ models, as well as instructions for

maintenance and troubleshooting of the unit.

EWAQ+EWYQ009~011ACV3 + EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

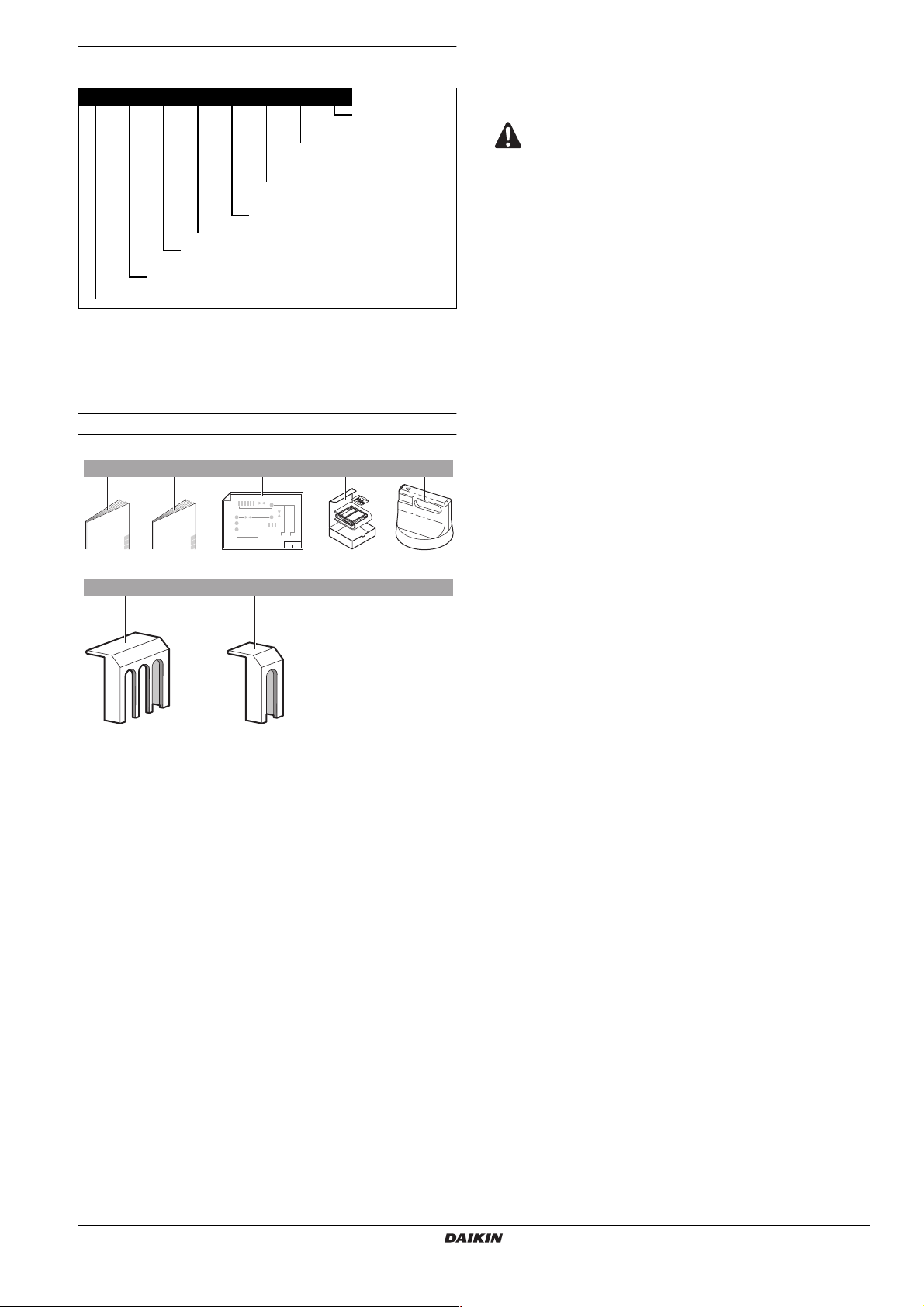

Model identification

SAFETY CONSIDERATIONS

EW A Q 009 AC V3 P -H-

P = Pump included

H = OPHP

Nominal voltage

V3: 1~ 230 V 50 Hz

W1: 3N~ 400 V 50 Hz

Major/minor change

Indication of heating/cooling capacity (kW)

R410A refrigerant

A = cooling only,

Y = heating and cooling

European water chiller

(a) OPHP = High ESP pump.

(b) Please see "Technical specifications" on page 25 for exact values.

ACCESSORIES

Accessories supplied with the unit

12

1x 1x 2x 1x

67

1x 1x

1 Installation manual

2 Operation manual

3 Wiring diagram sticker (inside unit cover doors 1 and 2)

4 User interface kit

(digital remote controller, 4 fixing screws and 2 plugs)

5 Main switch handle

6 Protection cap

7 Protection cap (only for W1 models)

341x5

Option heater tape

(a)

included

(b)

The precautions listed here are divided into the following two types.

Both cover very important topics, so be sure to follow them carefully.

WARNING

If the warning is not observed, it may cause serious casualties.

CAUTION

If the caution is not observed, it may cause injury or damage to the

equipment.

Warning

■ For use of units in applications with temperature alarm settings it

is advised to foresee a delay of 10 minutes for signalling the

alarm in case the alarm temperature is exceeded. The unit may

stop for several minutes during normal operation for "defrosting

of the unit" or when in "thermostat-stop" operation.

■

Ask your dealer or qualified personnel to carry out installation work

Do not install the machine by yourself.

Improper installation may result in water leakage, electric shocks

or fire.

■ Perform installation work in accordance with this installation

manual.

Improper installation may lead to water leakage, electric shocks

or fire.

■ Be sure to use only the specified accessories and parts for

installation work.

Failure to use the specified parts may result in water leakage,

electric shocks, fire, or the unit falling.

■ Install the unit on a foundation that can withstand its weight.

■ Insufficient strength may result in the fall of equipment and

causing injury.

■ Carry out the specified installation work in consideration of

strong winds, typhoons, or earthquakes.

Improper installation work may result in accidents due to fall of

equipment.

■ Make certain that all electrical work is carried out by qualified

personnel according to the local laws and regulations and this

installation manual, using a separate circuit.

Insufficient capacity of the power supply circuit or improper

electrical construction may lead to electric shocks or fire.

■ Make sure that all wiring is secure, using the specified wires and

ensuring that external forces do not act on the terminal

connections or wires.

Incomplete connection or fixing may cause a fire.

■ When wiring the power supply, form the wires so that the

frontside panel can be securely fastened.

If the frontside panel is not in place, overheat of the terminals,

electric shocks or a fire may be caused.

■ After completing the installation work, check to make sure that

there is no leakage of refrigerant gas.

■ Before touching electric terminal parts, turn off power switch.

■ Live parts can be easily touched by accident.

Never leave the unit unattended during installation or servicing

when the service panel is removed.

■ Never directly touch any accidental leaking refrigerant. This

could result in severe wounds caused by frostbite.

.

EWAQ+EWYQ009~011ACV3 + EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

Installation manual

2

Caution

■ Earth the unit.

Earthing resistance should be according to national regulations

Do not connect the earth wire to gas or water pipes,

lightning conductor or telephone earth wire.

Incomplete earthing may cause electric shocks.

■ Gas pipe.

Ignition or explosion may occur if the gas leaks.

■ Water pipe.

Hard vinyl tubes are not effective earths.

■ Lightning conductor or telephone earth wire.

Electric potential may rise abnormally if struck by a lightning

bolt.

■ Be sure to install an earth leakage circuit breaker.

Failure to install an earth leakage circuit breaker may cause

electric shocks and fire.

■ Install the power wire at least 1 meter away from televisions or

radios to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not

be sufficient to eliminate the noise.)

■ Do not rinse the unit. This may cause electric shocks or fire.

■ Do not install the unit in places such as the following:

■ Where there is mist of mineral oil, oil spray or vapour.

Plastic parts may deteriorate, and cause them to fall out or

water to leak.

■ Where corrosive gas, such as sulphurous acid gas, is

produced.

Corrosion of copper pipes or soldered parts may cause the

refrigerant to leak.

■ Where there is machinery which emits electromagnetic

waves.

Electromagnetic waves may disturb the control system, and

cause malfunction of the equipment.

■ Where flammable gases may leak, where carbon fiber or

ignitable dust is suspended in the air or where volatile

flammables, such as thinner or gasoline, are handled.

Such gases may cause a fire.

■ Where the air contains high levels of salt such as that near

the ocean.

■ Where voltage fluctuates a lot, such as that in factories.

■ In vehicles or vessels.

■ Where acidic or alkaline vapour is present.

BEFORE INSTALLATION

Installation

■ Be sure to confirm the model name and the serial no. of the

outer (front) plates when attaching/detaching the plates to avoid

mistakes.

■ When closing the service panels, take care that the tightening

torque does not exceed 4.1 N•m.

■ In case ambient temperatures below 0°C are expected,

countermeasures need to be taken to prevent the water in the

unit from freezing. In such cases, we recommend to install the

heater tape option OP10 or we advise to put glycol in the

system. See "Protecting the water circuit against freezing" on

page 10. It is also allowed to drain the water from the system

when longer periods of standstill are expected.

Model

EWAQ and EWYQ units include optional special equipment

(insulation, heater tape,...) to ensure good operation in areas where

low ambient temperature can occur together with high humidity

conditions. In such conditions the units may experience problems

with severe ice build up on the aircooled coil. In case such conditions

are expected, the heater tape option OP10 must be installed instead.

■ Possible options

Model OP10

EWA/YQ_AC*P — —

EWA/YQ_AC*P-H- Factory mounted —

EWA/YQ_AC*H — Factory mounted

EWA/YQ_AC*H-H- Factory mounted Factory mounted

(a) Heater tape option OP10

(b) High ESP pump

(a)

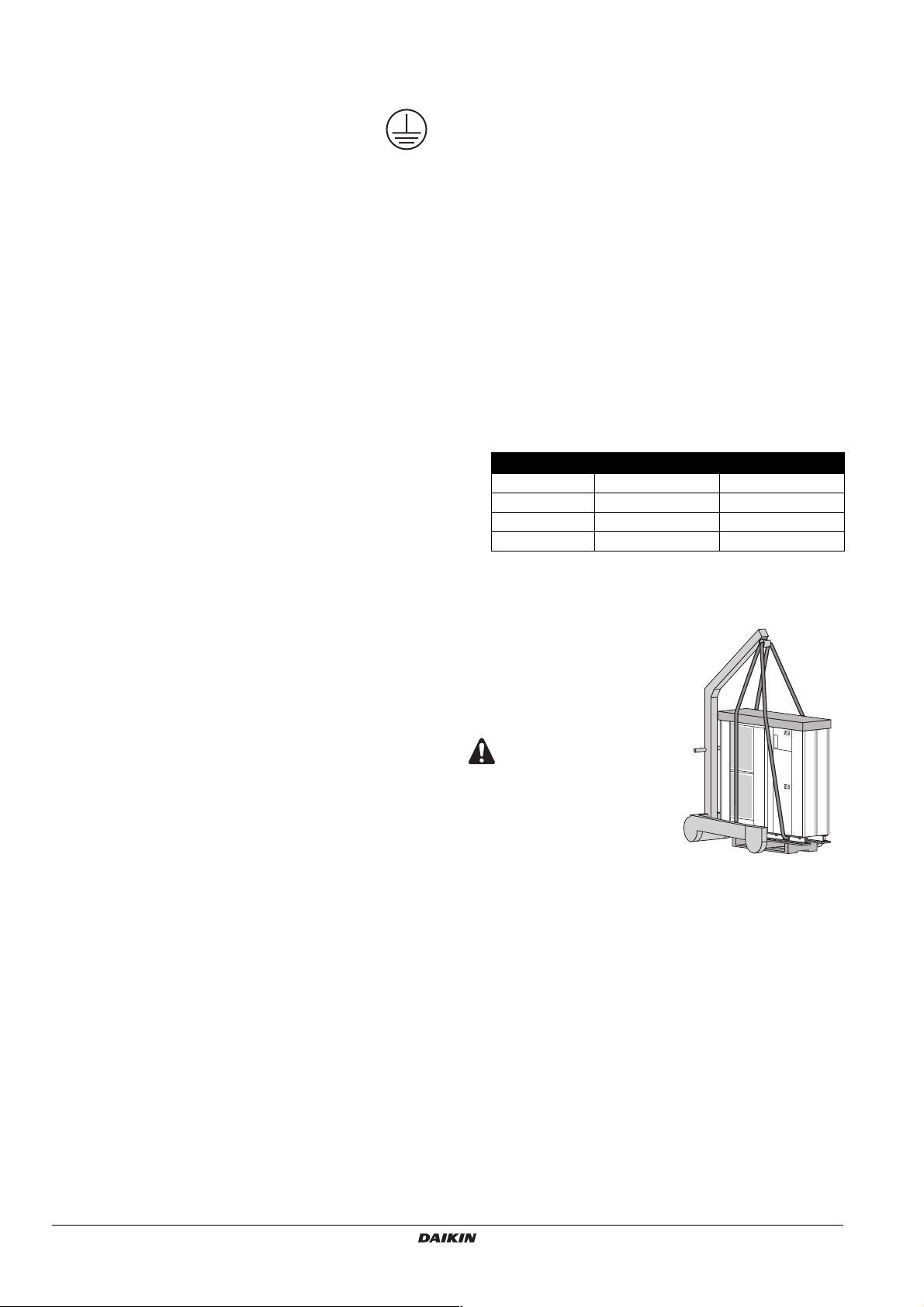

Handling

Due to relatively large dimensions

and high weight, the handling of the

unit is only to be done by means of

lifting tools with slings. These slings

can be fitted into specially for this

purpose foreseen sleeves at the

base frame.

■ To avoid injury, do not

touch the air inlet or

aluminium fins of the

unit.

■ Do not use the grips

in the fan grills to

avoid damage.

OPHP

(b)

Installation manual

3

IMPORTANT INFORMATION REGARDING THE

REFRIGERANT USED

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type: R410A

(1)

GWP

value: 1975

(1)

GWP = global warming potential

The refrigerant quantity is indicated on the unit name plate

EWAQ+EWYQ009~011ACV3 + EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

SELECTING INSTALLATION SITE

■ Make sure to provide for adequate measures in order

to prevent that the unit be used as a shelter by small

animals.

■ Small animals making contact with electrical parts can

cause malfunctions, smoke or fire. Please instruct the

customer to keep the area around the unit clean.

1 Select an installation site where the following conditions are

satisfied and that meets with your customer's approval.

- Places which are well-ventilated.

- Places where the unit does not bother next-door neighbours.

- Safe places which can withstand the unit's weight and

vibration and where the unit can be installed level.

- Places where there is no possibility of flammable gas or

product leak.

- The equipment is not intended for use in a potentially

explosive atmosphere.

- Places where servicing space can be well ensured.

- Places where the units' piping and wiring lengths come within

the allowable ranges.

- Places where water leaking from the unit cannot cause

damage to the location (e.g. in case of a blocked drain pipe).

- Places where the rain can be avoided as much as possible.

2 When installing the unit in a place exposed to strong wind, pay

special attention to the following.

Strong winds of 5 m/sec or more blowing against the unit's air

outlet causes short circuit (suction of discharge air), and this

may have the following consequences:

- Deterioration of the operational capacity.

-Frequent frost acceleration in heating operation.

- Disruption of operation due to rise of high pressure.

- When a strong wind blows continuously on the face of the

unit, the fan can start rotating very fast until it breaks.

Refer to the figures for installation of this unit in a place where

the wind direction can be foreseen.

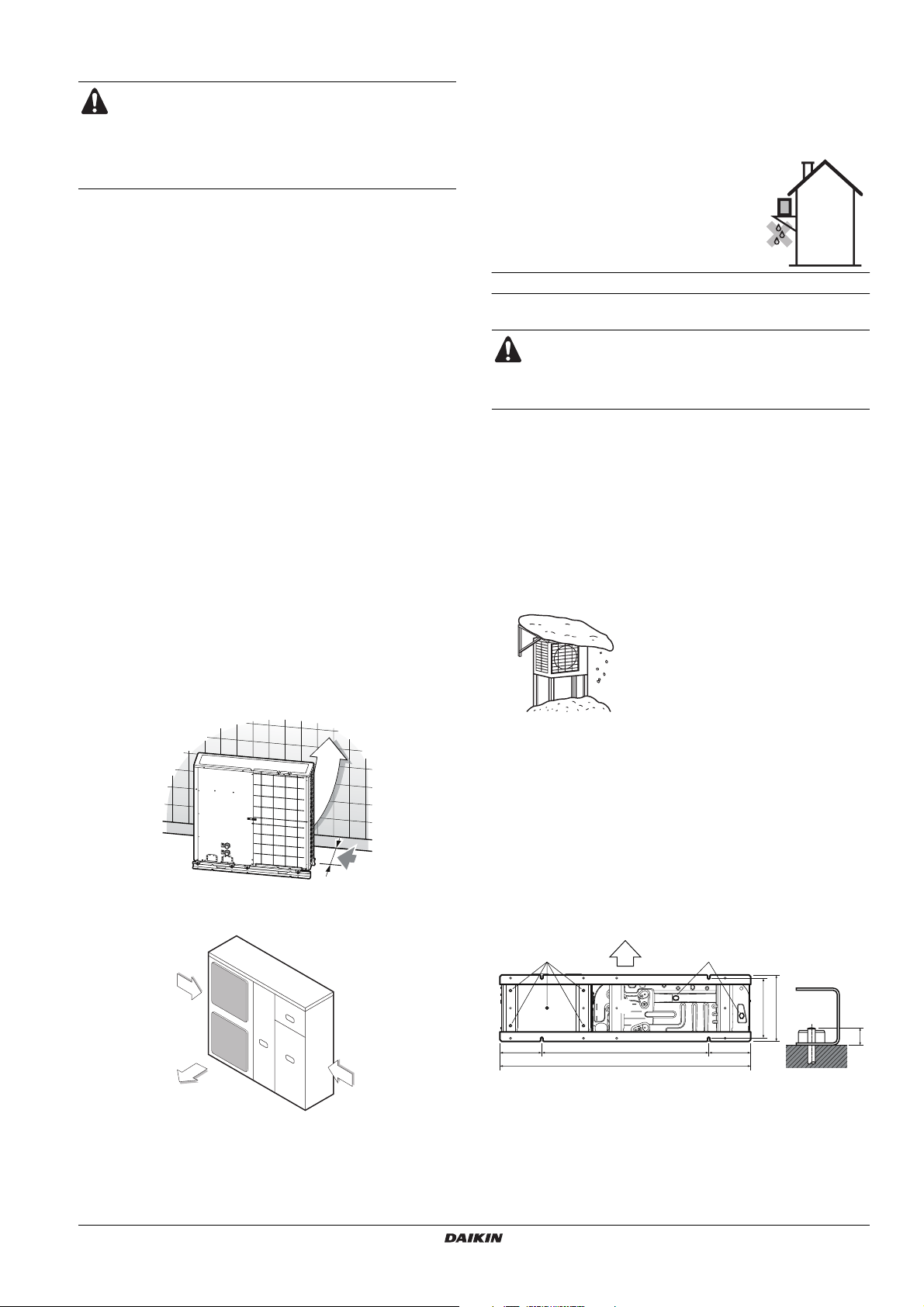

■ Tu rn the air outlet side toward the building's wall, fence or

screen.

5 If you install the unit on a frame, please install a waterproof plate

within 150 mm of the underside of the unit in order to prevent the

invasion of water from the lower direction.

6 When installing the unit in a place frequently exposed to snow,

pay special attention to elevate the foundation as high as

possible.

7 If you install the unit on a building frame,

please install a waterproof plate (field

supply)(within 150 mm of the underside of

the unit). (See figure).

Selecting a location in cold climates

Refer to "Model" on page 3.

CAUTION

When operating the unit in a low outdoor ambient

temperature, be sure to follow the instructions described

below.

■ To prevent exposure to wind, install the unit with its suction side

facing the wall.

■ Never install the unit at a site where the suction side may be

exposed directly to wind.

■ To prevent exposure to wind, install a baffle plate on the air

discharge side of the unit.

■ In heavy snowfall areas it is very important to select an

installation site where the snow will not affect the unit. If lateral

snowfall is possible, make sure that the heat exchanger coil is

not affected by the snow (if necessary construct a lateral

canopy).

1 Construct a large canopy.

2 Construct a pedestal.

Install the unit high enough off the

ground to prevent burying in snow.

Make sure there is enough room to do the installation

■ Set the outlet side at a right angle to the direction of the wind.

Strong wind

Blown air Strong wind

3 Prepare a water drainage channel around the foundation, to

drain waste water from around the unit.

4 If the water drainage of the unit is not easy, please build up the

unit on a foundation of concrete blocks, etc. (the height of the

foundation should be maximum 150 mm).

PRECAUTIONS ON INSTALLATION

■ Check the strength and level of the installation ground so that

the unit will not cause any operating vibration or noise after

installation.

■ In accordance with the foundation drawing in the figure, fix the

unit securely by means of the foundation bolts. (Prepare four

sets of M12 foundation bolts, nuts and washers each which are

available on the market.)

■ It is best to screw in the foundation bolts until their length are

20 mm from the foundation surface.

AC C

B

240 955 240

1435

A Discharge side

B Bottom view (mm)

C Drain hole

345

380

20

EWAQ+EWYQ009~011ACV3 + EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

Installation manual

4

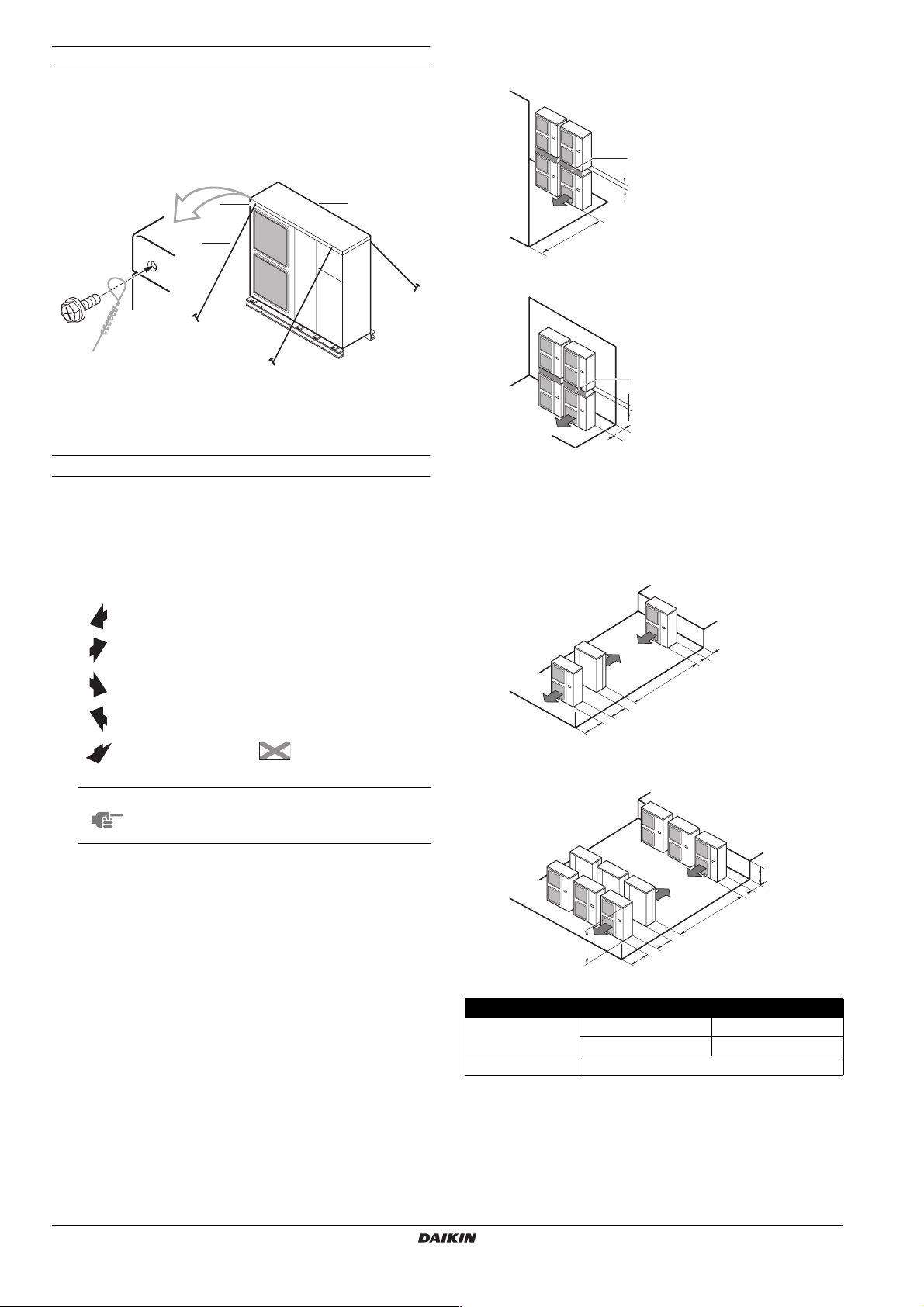

Installation method for prevention of falling over

If it is necessary to prevent the unit from falling over, install as shown

in the figure.

■ prepare all 4 wires as indicated in the drawing

■ unscrew the top plate at the 4 locations indicated A and B

■ put the screws through the nooses and screw them back tight

(B) In case of stacked installation

1. In case obstacles exist in front of the outlet side.

A

AA

B

C

A Location of the 2 fixation holes on the front side of the unit

B Location of the 2 fixation holes on the rear side of the unit

C Wires: field supply

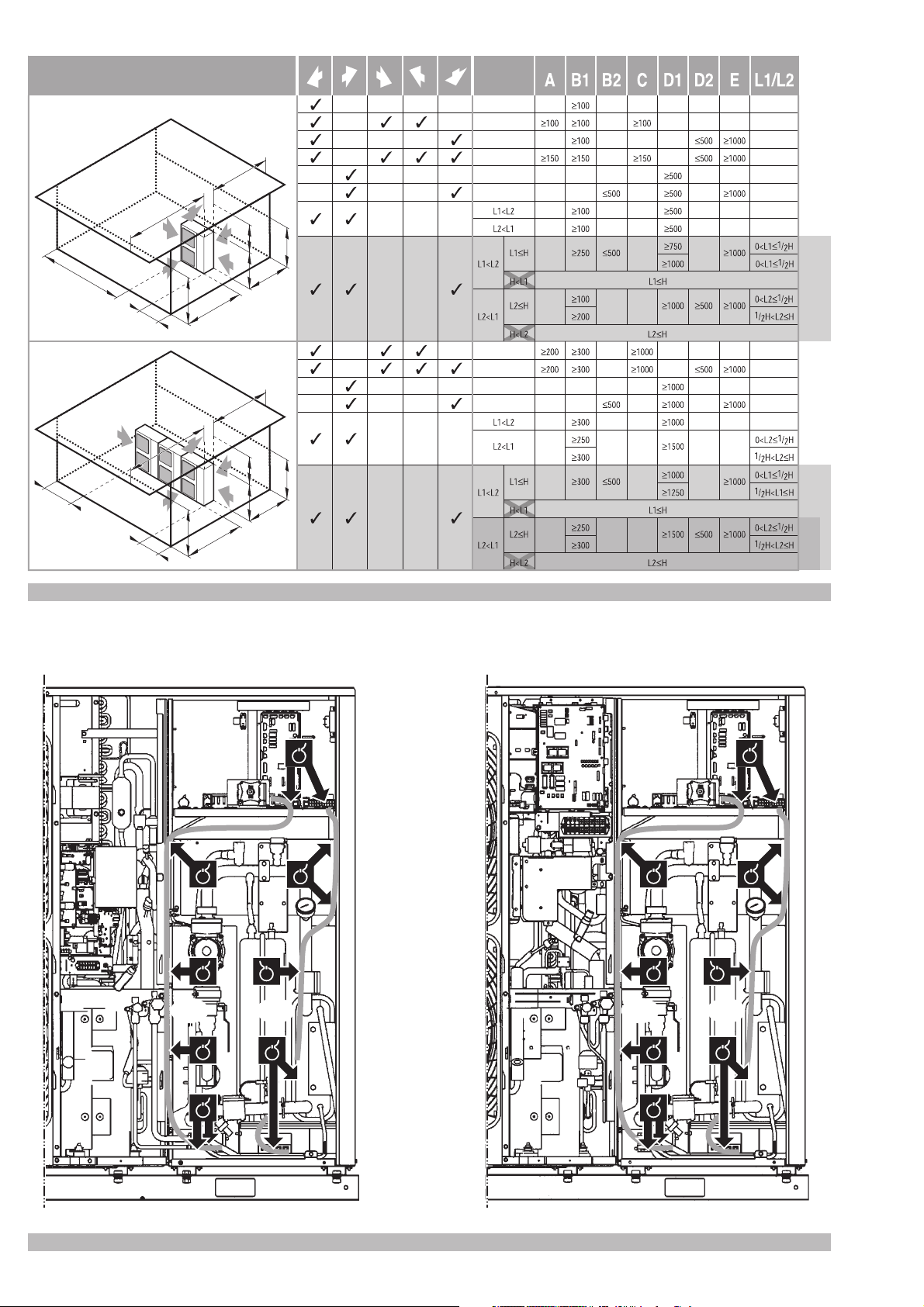

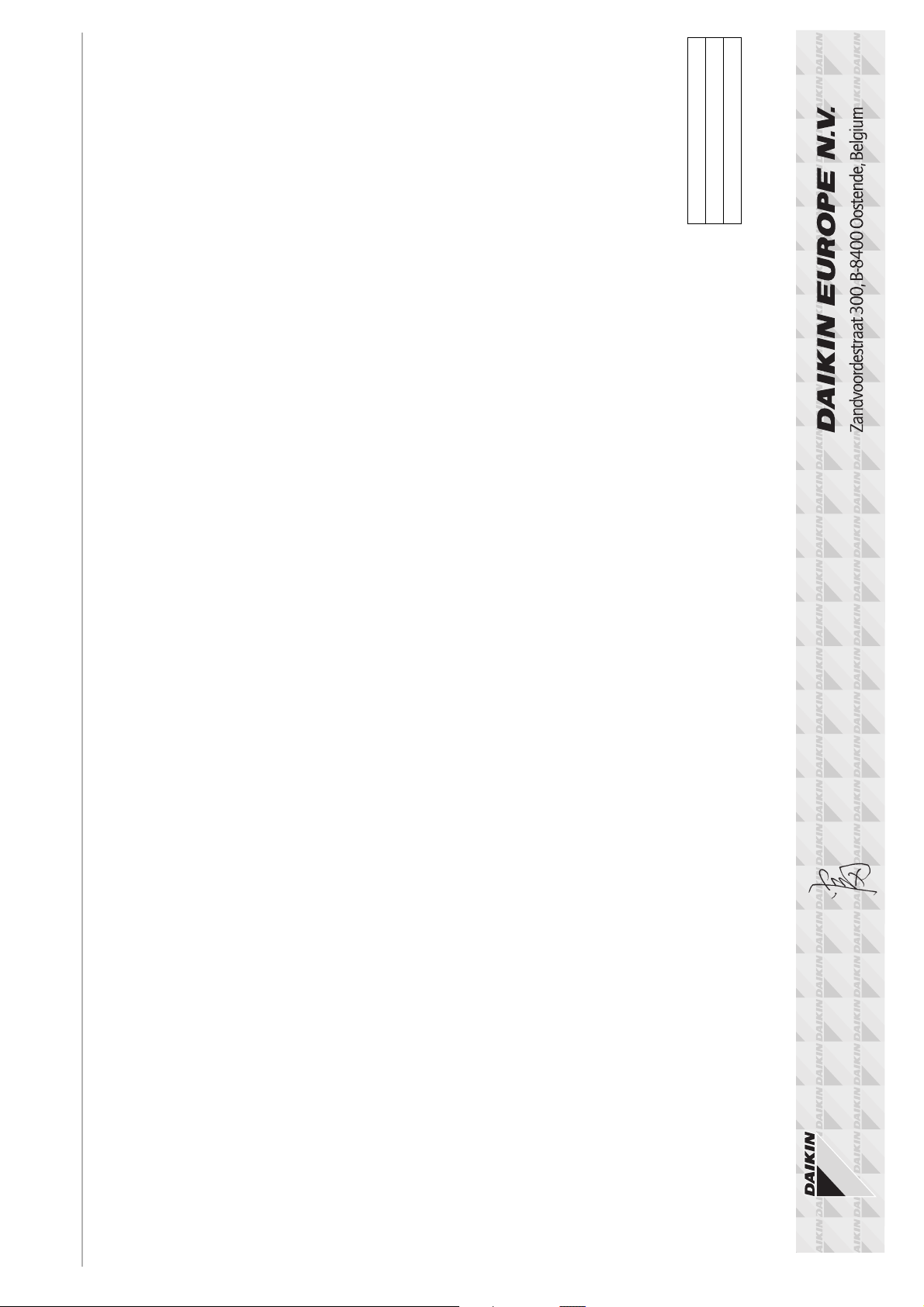

Installation servicing space

The numerical figures used in the figures represent the dimensions in

mm.

(Refer to "Precautions on installation" on page 4)

Precaution

(A) In case of non-stacked installation (See figure 1)

Suction side obstacle

Discharge side obstacle

Left side obstacle

Right side obstacle

Top side obstacle

Obstacle is present

✓

In these cases, close the

1

bottom of the installation

frame to prevent the

discharged air from

being bypassed

In these cases, only

2

2 units can be installed.

This situation is not

allowed

≥100

≥1000

2. In case obstacles exist in front of the air inlet.

A

≥100

≥300

Do not stack more than one unit.

About 100 mm is required as the dimension for laying the upper unit's

drain pipe. Get the portion A sealed so that air from the outlet does

not bypass.

(C) In case of multiple-row installation (for roof top use, etc.)

1. In case of installing one unit per row.

≥100

≥2000

≥200

≥1000

2. In case of installing multiple units (2 units or more) in lateral

connection per row.

NOTE

Installation manual

5

Minimum distance B1 in figure 1 mentions the

space required for correct operation of the unit.

Required space for servicing though is 300 mm.

L

A

≥3000

H

≥600

≥1500

Relation of dimensions of H, A and L are shown in the table below.

L A

L≤H

H<L Installation not allowed

0<L≤1/2H 250

1/2H<L 300

EWAQ+EWYQ009~011ACV3 + EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

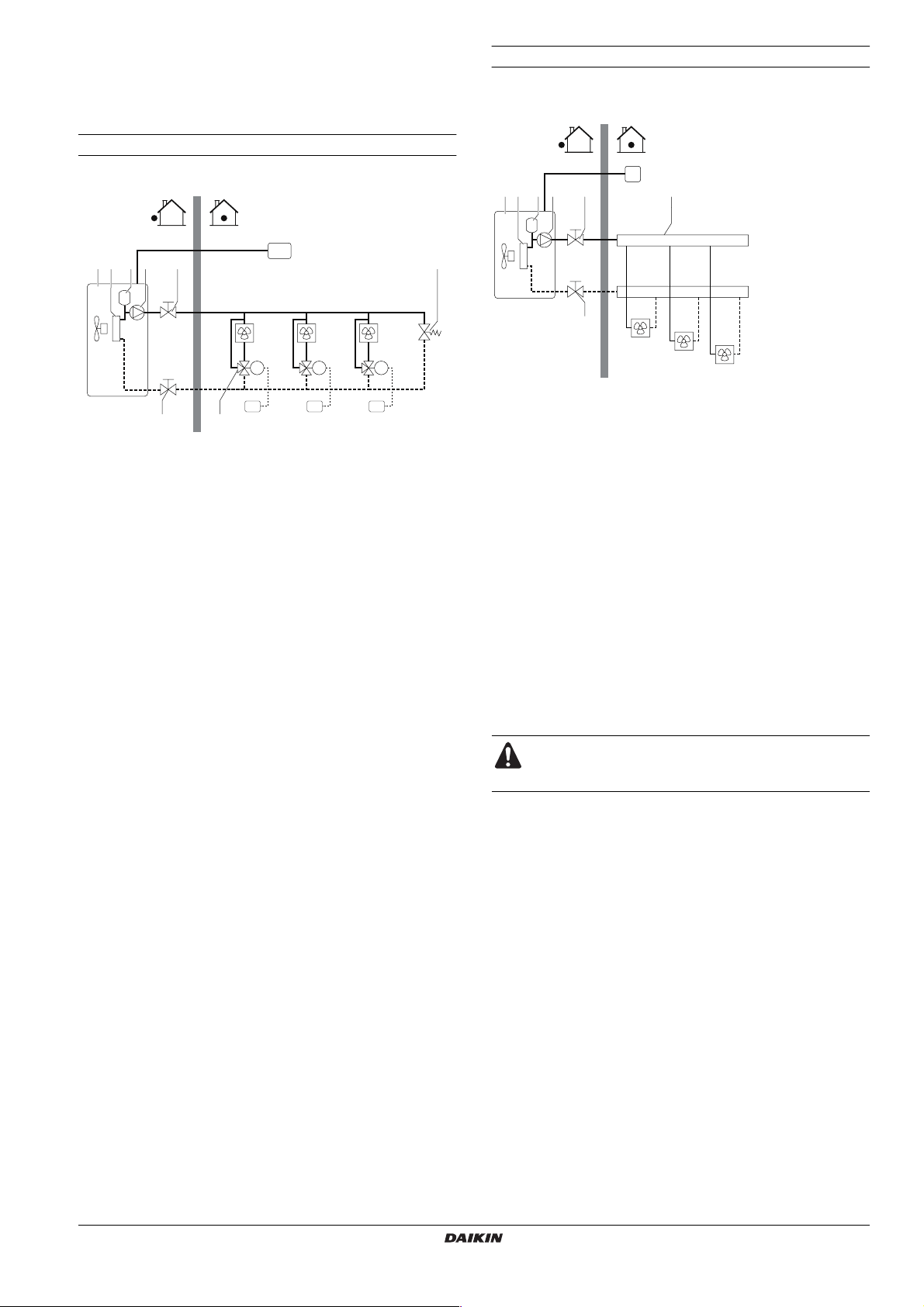

TYPICAL APPLICATION EXAMPLES

Application 2

The application examples given below are for illustration purposes

only.

Application 1

Cooling and heating application (without room thermostat)

FCU1

M

RT1

DC

FCU2

M

RT2

7

FCU3

M

RT3

(field supply)

(field supply)

2 3 4 51

56

1 Reversible heat pump 7 Bypass valve

2 Plate heat exchanger FCU1..3 Fan coil unit

3 Expansion vessel

4 Pump DC Digital controller

5 Shut-off valve RT1..3 Room thermostat

6 Motorised valve (field supply)

The digital controller (DC) is installed indoors and allows the user to

turn the unit (1) ON or OFF, to select between cooling and heating

mode (only in case of a heat pump model) and to set the water

temperature. When the unit is turned on, it will provide water at the

set temperature to the fan coil units (FCU1..3).

Cooling and heating application with a room thermostat suitable for

cooling/heating changeover connected to the unit.

T

62 3 4 51

7

FCU1

FCU2

FCU3

1 Reversible heat pump 7 Shut-off valve

2 Plate heat exchanger FCU1..3 Fan coil unit

3 Expansion vessel

4 Pump T Room thermostat or

5 Shut-off valve

6 Collector (field supply)

(field supply)

room thermostat with

cooling/heating switch

(field supply)

■ Pump operation and heating and cooling (cooling and heating

application with a room thermostat suitable for cooling/heating

changeover connected to the unit)

According to the season, the customer will select cooling or

heating on the room thermostat (T). This selection is not

possible by operating the user interface.

When cooling/heating is requested by the room thermostat (T),

the pump will start operating and the unit will switch to “cooling

mode”/”heating mode”. The unit will start operating to achieve

the target leaving cold/hot water temperature.

The ON/OFF setting of the heating/cooling operation is done by

the room thermostat and cannot be done by the user interface

on the unit.

Make sure to connect the thermostat wires to the correct

terminals (see "Connection of the thermostat cable" on

page 13).

EWAQ+EWYQ009~011ACV3 + EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

Installation manual

6

Loading...

Loading...