Daikin ERGA04DAV3, ERGA06DAV3, ERGA08DAV3, EHVH04S23DAV, EHVH08S23DAV User reference guide

...Page 1

Installer reference guide

Daikin Altherma – Low temperature split

ERGA04DAV3(A)

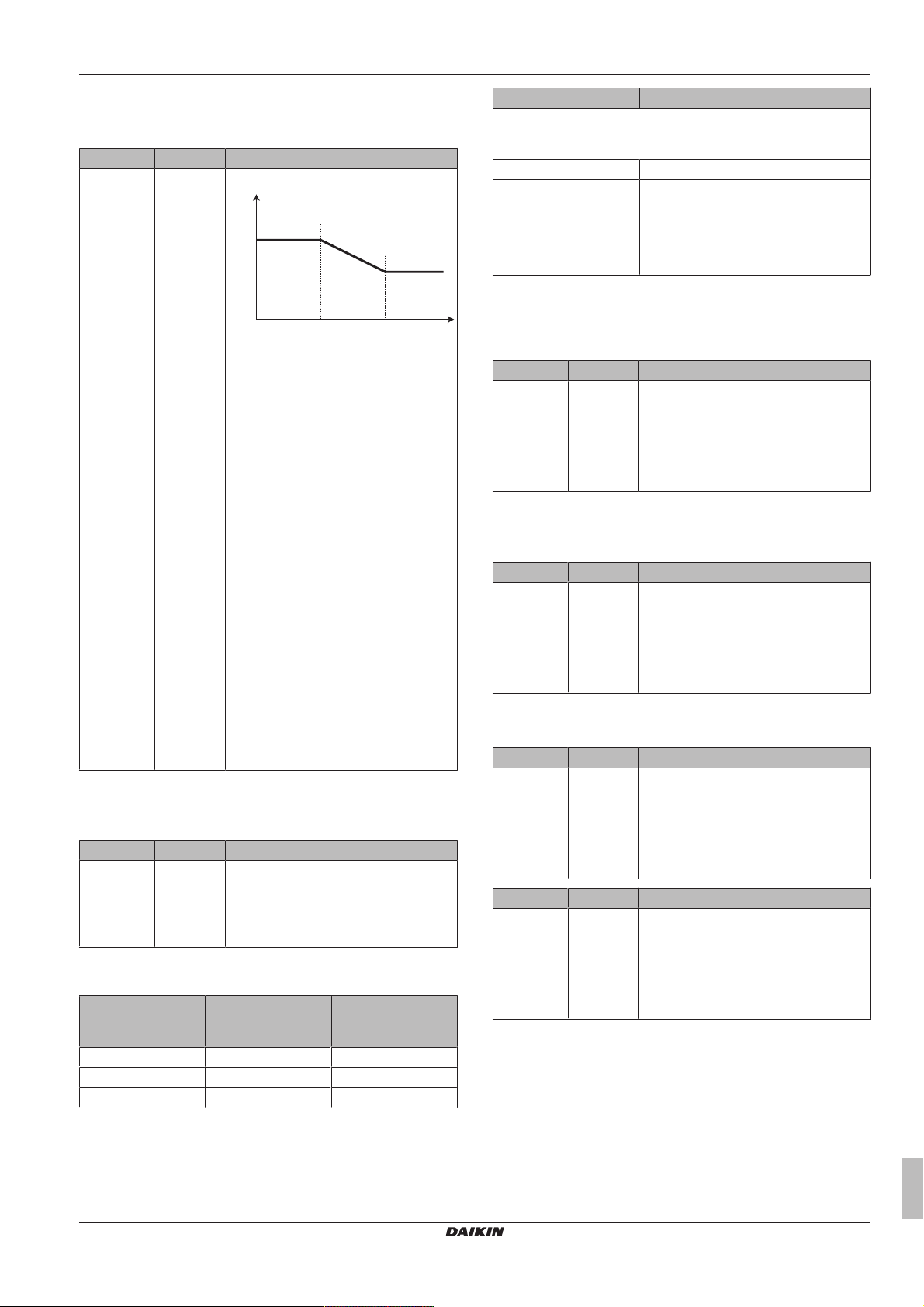

ERGA06DAV3(A)

ERGA08DAV3(A)

EHVH04S23DAV(G)

EHVH08S23DAV(G)

Installer reference guide

Daikin Altherma – Low temperature split

English

Page 2

Table of contents

Table of contents

1 General safety precautions 3

1.1 About the documentation .......................................................... 3

1.1.1 Meaning of warnings and symbols.............................. 3

1.2 For the installer.......................................................................... 4

1.2.1 General ....................................................................... 4

1.2.2 Installation site ............................................................ 4

1.2.3 Refrigerant .................................................................. 4

1.2.4 Brine............................................................................ 5

1.2.5 Water .......................................................................... 5

1.2.6 Electrical ..................................................................... 6

2 About the documentation 6

2.1 About this document.................................................................. 6

2.2 Installer reference guide at a glance ......................................... 7

3 About the box 7

3.1 Overview: About the box ........................................................... 7

3.2 Outdoor unit............................................................................... 7

3.2.1 To unpack the outdoor unit ......................................... 7

3.2.2 To handle the outdoor unit.......................................... 7

3.2.3 To remove the accessories from the outdoor unit....... 8

3.3 Indoor unit ................................................................................. 8

3.3.1 To unpack the indoor unit ........................................... 8

3.3.2 To remove the accessories from the indoor unit......... 8

3.3.3 To handle the indoor unit ............................................ 8

4 About the units and options 9

4.1 Overview: About the units and options...................................... 9

4.2 Identification .............................................................................. 9

4.2.1 Identification label: Outdoor unit ................................. 9

4.2.2 Identification label: Indoor unit .................................... 9

4.3 Combining units and options ..................................................... 9

4.3.1 Possible options for the outdoor unit........................... 9

4.3.2 Possible options for the indoor unit............................. 9

4.3.3 Possible combinations of indoor unit and outdoor

unit .............................................................................. 10

5 Application guidelines 10

5.1 Overview: Application guidelines............................................... 10

5.2 Setting up the space heating system ........................................ 11

5.2.1 Single room................................................................. 11

5.2.2 Multiple rooms – OneLWT zone ................................ 12

5.2.3 Multiple rooms – TwoLWT zones............................... 14

5.3 Setting up an auxiliary heat source for space heating............... 15

5.4 Setting up the domestic hot water tank ..................................... 16

5.4.1 System layout – Integrated DHW tank........................ 16

5.4.2 Selecting the volume and desired temperature for

the DHW tank.............................................................. 16

5.4.3 Setup and configuration – DHW tank.......................... 17

5.4.4 DHW pump for instant hot water................................. 17

5.4.5 DHW pump for disinfection ......................................... 17

5.5 Setting up the energy metering ................................................. 18

5.5.1 Produced heat............................................................. 18

5.5.2 Consumed energy....................................................... 18

5.5.3 Normal kWh rate power supply................................... 18

5.5.4 Preferential kWh rate power supply............................ 19

5.6 Setting up the power consumption control ................................ 19

5.6.1 Permanent power limitation ........................................ 19

5.6.2 Power limitation activated by digital inputs ................. 20

5.6.3 Power limitation process ............................................. 20

5.7 Setting up an external temperature sensor ............................... 21

6 Preparation 21

6.1 Overview: Preparation............................................................... 21

6.2 Preparing the installation site .................................................... 21

6.2.1 Installation site requirements of the outdoor unit ........ 21

6.2.2 Additional installation site requirements of the

outdoor unit in cold climates ........................................ 22

6.2.3 Installation site requirements of the indoor unit ........... 23

6.3 Preparing refrigerant piping........................................................ 25

6.3.1 Refrigerant piping requirements................................... 25

6.3.2 Refrigerant piping insulation ........................................ 25

6.4 Preparing water piping ............................................................... 25

6.4.1 Water circuit requirements ........................................... 25

6.4.2 Formula to calculate the expansion vessel pre-

pressure ....................................................................... 26

6.4.3 To check the water volume and flow rate .................... 26

6.4.4 Changing the pre-pressure of the expansion vessel.... 27

6.4.5 To check the water volume: Examples ........................ 28

6.5 Preparing electrical wiring .......................................................... 28

6.5.1 About preparing electrical wiring.................................. 28

6.5.2 About preferential kWh rate power supply ................... 28

6.5.3 Overview of electrical connections except external

actuators ...................................................................... 29

6.5.4 Overview of electrical connections for external and

internal actuators ......................................................... 29

7 Installation 29

7.1 Overview: Installation ................................................................. 29

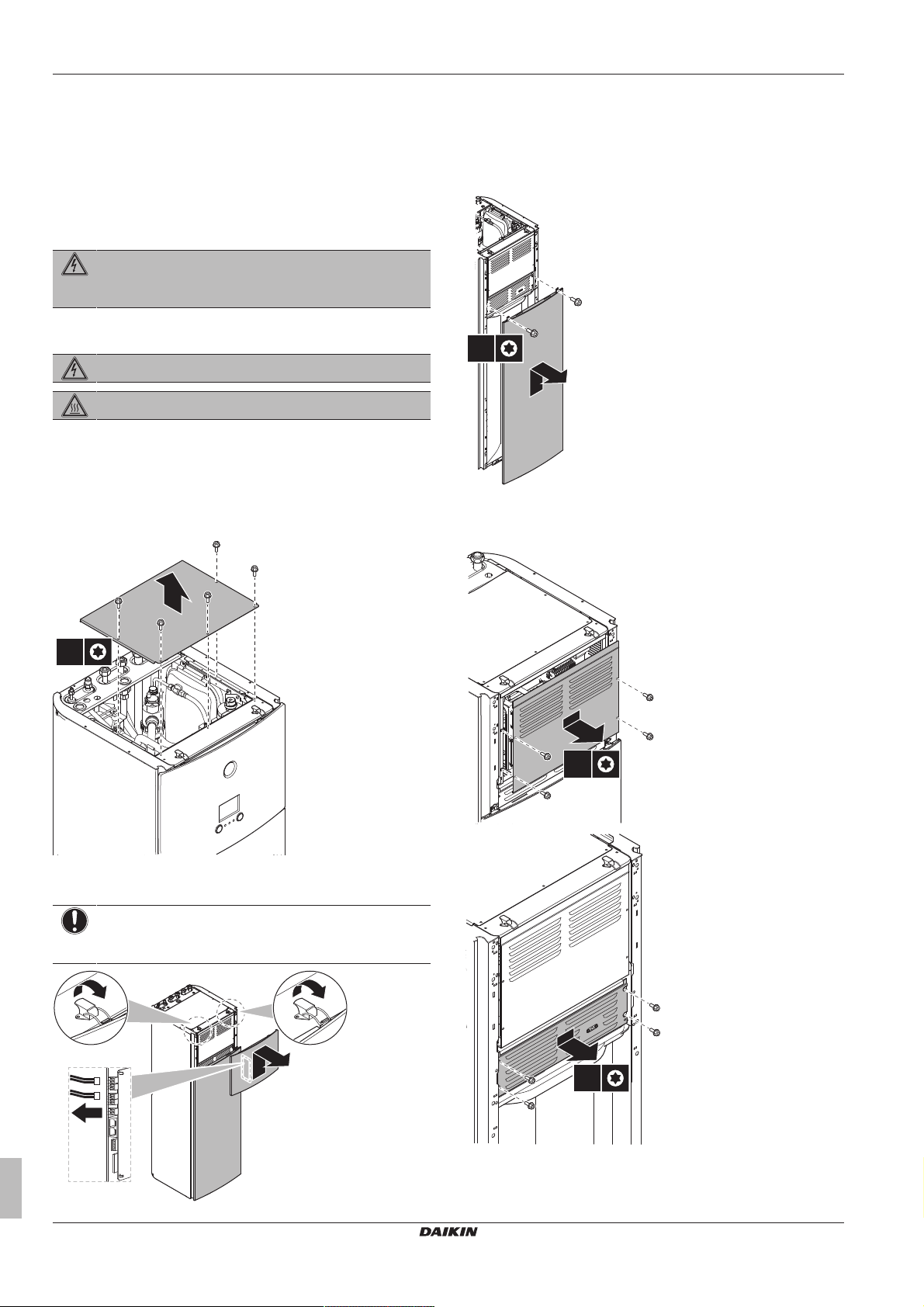

7.2 Opening the units ....................................................................... 30

7.2.1 About opening the units ............................................... 30

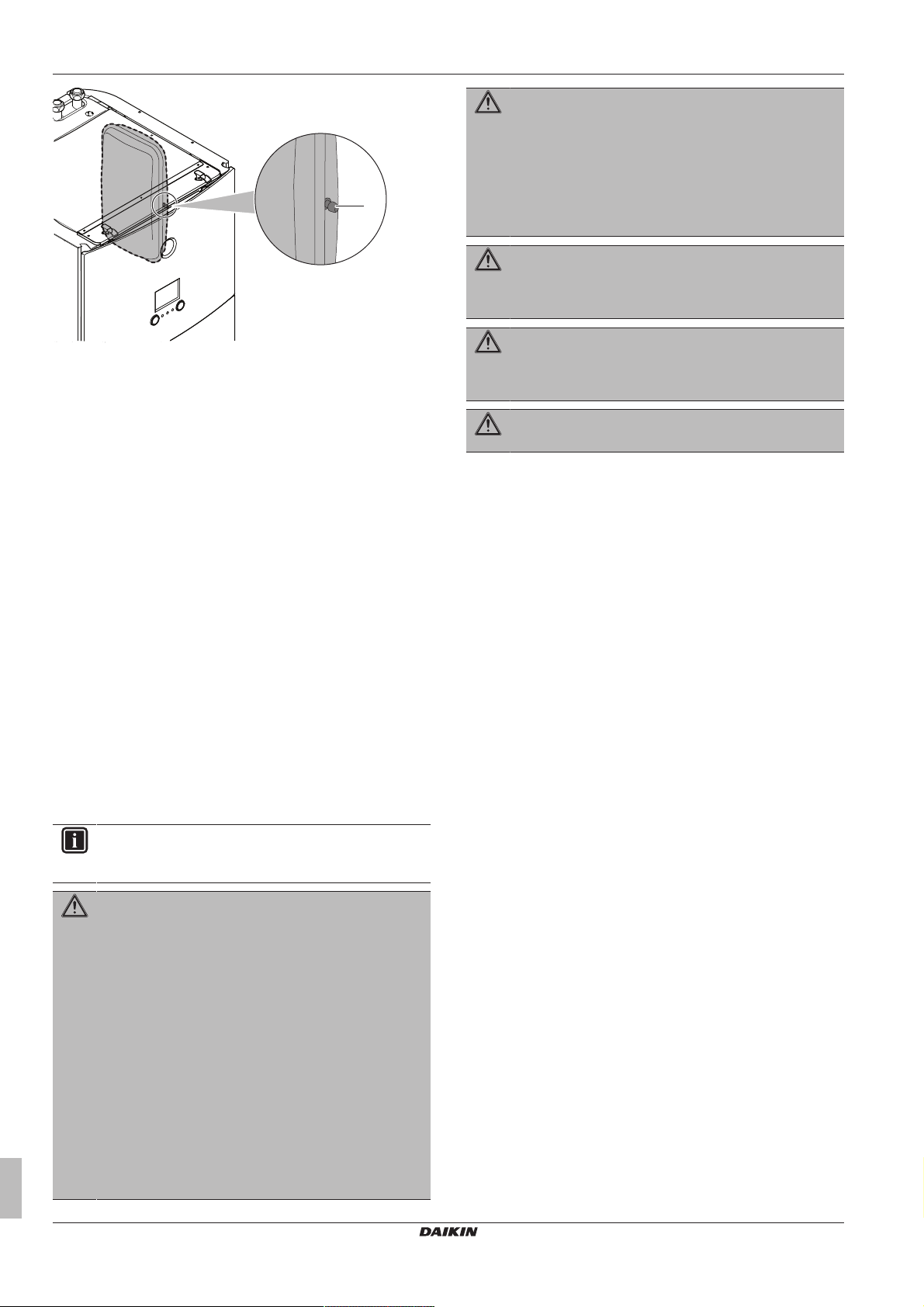

7.2.2 To open the outdoor unit.............................................. 30

7.2.3 To open the indoor unit ................................................ 30

7.2.4 To open the switch box cover of the indoor unit .......... 30

7.2.5 To lower the switch box on the indoor unit................... 31

7.3 Mounting the outdoor unit........................................................... 31

7.3.1 About mounting the outdoor unit.................................. 31

7.3.2 Precautions when mounting the outdoor unit............... 31

7.3.3 To provide the installation structure ............................. 31

7.3.4 To install the outdoor unit............................................. 32

7.3.5 To provide drainage ..................................................... 33

7.3.6 To prevent the outdoor unit from falling over ............... 34

7.4 Mounting the indoor unit............................................................. 34

7.4.1 About mounting the indoor unit.................................... 34

7.4.2 Precautions when mounting the indoor unit................. 34

7.4.3 To install the indoor unit............................................... 34

7.4.4 To connect the drain hose to the drain ........................ 34

7.5 Connecting the refrigerant piping ............................................... 35

7.5.1 About connecting the refrigerant piping ....................... 35

7.5.2 Precautions when connecting the refrigerant piping.... 35

7.5.3 Guidelines when connecting the refrigerant piping...... 36

7.5.4 Pipe bending guidelines............................................... 36

7.5.5 To flare the pipe end .................................................... 36

7.5.6 To braze the pipe end .................................................. 36

7.5.7 Using the stop valve and service port .......................... 36

7.5.8 To connect the refrigerant piping to the outdoor unit ... 37

7.5.9 To connect the refrigerant piping to the indoor unit ..... 37

7.6 Checking the refrigerant piping .................................................. 38

7.6.1 About checking the refrigerant piping .......................... 38

7.6.2 Precautions when checking the refrigerant piping ....... 38

7.6.3 To check for leaks........................................................ 38

7.6.4 To perform vacuum drying ........................................... 38

7.7 Charging refrigerant ................................................................... 39

7.7.1 About charging refrigerant ........................................... 39

7.7.2 Precautions when charging refrigerant ........................ 39

7.7.3 To determine the additional refrigerant amount........... 39

7.7.4 To determine the complete recharge amount.............. 39

7.7.5 To charge additional refrigerant ................................... 39

7.7.6 To fix the fluorinated greenhouse gases label ............. 39

7.8 Connecting the water piping....................................................... 40

7.8.1 About connecting the water piping............................... 40

7.8.2 Precautions when connecting the water piping............ 40

7.8.3 To connect the water piping......................................... 40

7.8.4 To connect the recirculation piping .............................. 41

7.8.5 To fill the water circuit .................................................. 41

7.8.6 To fill the domestic hot water tank ............................... 41

Installer reference guide

2

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 3

1 General safety precautions

7.8.7 To insulate the water piping........................................ 41

7.9 Connecting the electrical wiring................................................. 41

7.9.1 About connecting the electrical wiring......................... 41

7.9.2 About electrical compliance ........................................ 41

7.9.3 Precautions when connecting the electrical wiring ..... 41

7.9.4 Guidelines when connecting the electrical wiring ....... 42

7.9.5 Specifications of standard wiring components............ 42

7.9.6 To connect the electrical wiring on the outdoor unit.... 42

7.9.7 To connect the electrical wiring on the indoor unit...... 43

7.9.8 To connect the main power supply ............................. 44

7.9.9 To connect the shut-off valve...................................... 44

7.9.10 To connect the electrical meters ................................. 44

7.9.11 To connect the domestic hot water pump ................... 44

7.9.12 To connect the alarm output ....................................... 44

7.9.13 To connect the space heating ON/OFF output ........... 45

7.9.14 To connect the changeover to external heat source ... 45

7.9.15 To connect the power consumption digital inputs ....... 45

7.9.16 To connect the safety thermostat (normal closed

contact) ....................................................................... 45

7.9.17 To connect the anti-legionella heater power supply.... 46

7.10 Finishing the outdoor unit installation ........................................ 46

7.10.1 To finish the outdoor unit installation .......................... 46

7.11 Finishing the indoor unit installation .......................................... 46

7.11.1 To close the indoor unit............................................... 46

8 Configuration 47

8.1 Overview: Configuration ............................................................ 47

8.1.1 To access the most used commands ......................... 47

8.2 Configuration wizard.................................................................. 48

8.3 Possible screens ....................................................................... 48

8.3.1 Possible screens: Overview........................................ 48

8.3.2 Home screen............................................................... 48

8.3.3 Main menu screen ...................................................... 49

8.3.4 Menu screen ............................................................... 49

8.3.5 Setpoint screen........................................................... 49

8.3.6 Detailed screen with values ........................................ 50

8.3.7 Detailed screen with weather-dependent curve.......... 50

8.3.8 Schedule screen: Example ......................................... 50

8.4 Settings menu ........................................................................... 52

8.4.1 Malfunction.................................................................. 52

8.4.2 Room .......................................................................... 52

8.4.3 Main zone ................................................................... 53

8.4.4 Additional zone ........................................................... 56

8.4.5 Space heating............................................................. 57

8.4.6 Tank ............................................................................ 60

8.4.7 User settings ............................................................... 63

8.4.8 Information .................................................................. 64

8.4.9 Installer settings .......................................................... 65

8.5 Menu structure: Overview user settings .................................... 73

8.6 Menu structure: Overview installer settings............................... 74

11.5.1 To remove the water filter ............................................ 80

11.5.2 To clean the water filter in case of trouble ................... 81

11.5.3 To install the water filter ............................................... 81

12 Troubleshooting 81

12.1 Overview: Troubleshooting......................................................... 81

12.2 Precautions when troubleshooting ............................................. 82

12.3 Solving problems based on symptoms....................................... 82

12.3.1 Symptom: The unit is NOT heating as expected ......... 82

12.3.2 Symptom: The compressor does NOT start (space

heating or domestic water heating).............................. 82

12.3.3 Symptom: The system is making gurgling noises

after commissioning ..................................................... 83

12.3.4 Symptom: The pump is making noise (cavitation) ....... 83

12.3.5 Symptom: The pressure relief valve opens.................. 83

12.3.6 Symptom: The water pressure relief valve leaks ......... 84

12.3.7 Symptom: The space is NOT sufficiently heated at

low outdoor temperatures ............................................ 84

12.3.8 Symptom: The pressure at the tapping point is

temporarily unusually high ........................................... 84

12.3.9 Symptom: Decoration panels are pushed away due

to a swollen tank .......................................................... 84

12.3.10 Symptom: Tank disinfection function is NOT

completed correctly (AH-error)..................................... 84

12.4 Solving problems based on error codes ..................................... 85

12.4.1 To display the help text in case of a malfunction ......... 85

12.4.2 Error codes: Overview ................................................. 85

13 Disposal 86

13.1 Overview: Disposal..................................................................... 86

13.2 To pump down............................................................................ 86

13.3 To start and stop forced cooling ................................................. 87

14 Technical data 88

14.1 Piping diagram: Outdoor unit...................................................... 88

14.2 Piping diagram: Indoor unit ........................................................ 89

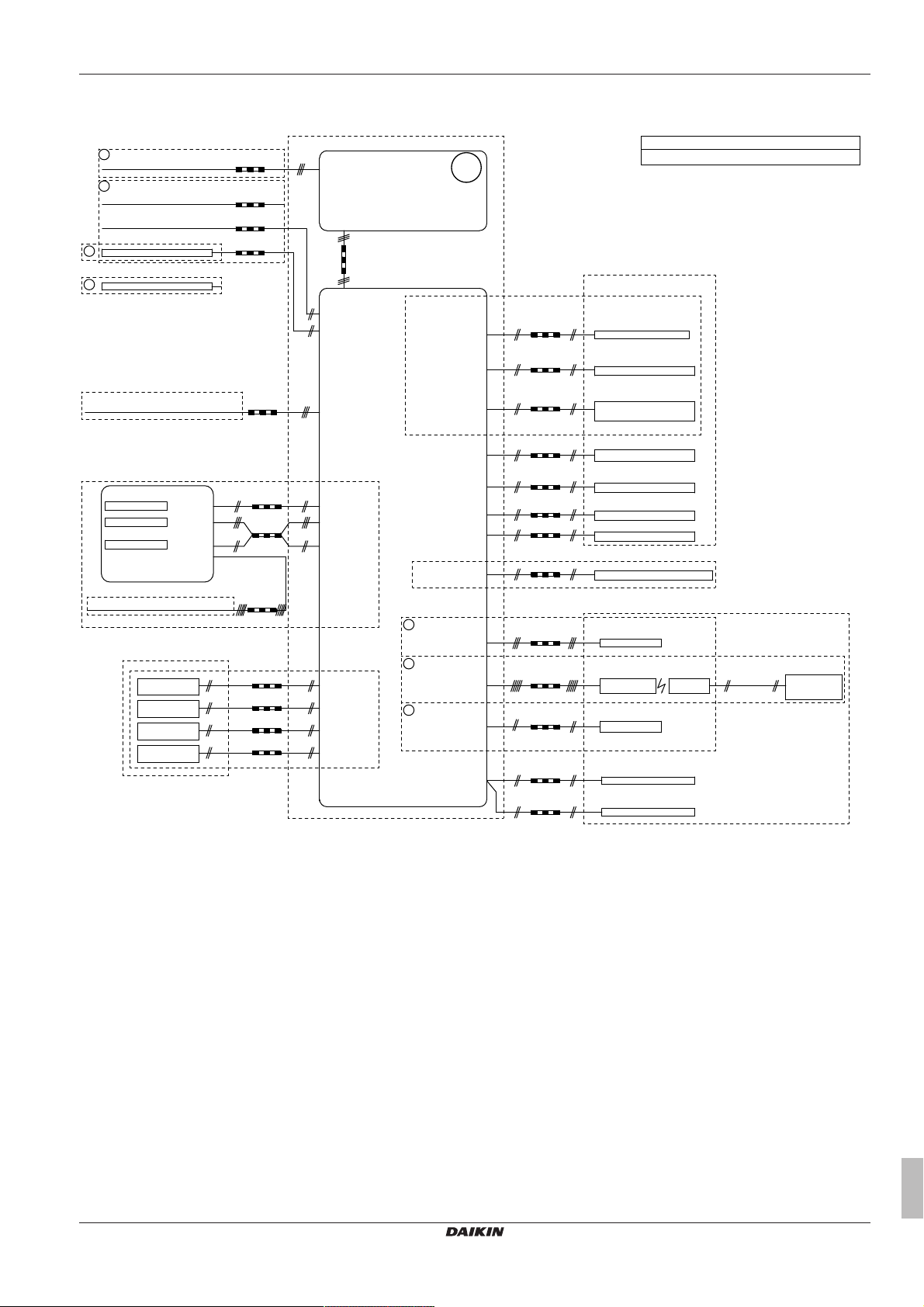

14.3 Wiring diagram: Outdoor unit ..................................................... 90

14.4 Wiring diagram: Indoor unit ........................................................ 91

14.5 Table 1 – Maximum refrigerant charge allowed in a room:

indoor unit................................................................................... 94

14.6 Table 2 – Minimum floor area: indoor unit .................................. 94

14.7 Table 3 – Minimum venting opening area for natural

ventilation: indoor unit ................................................................ 94

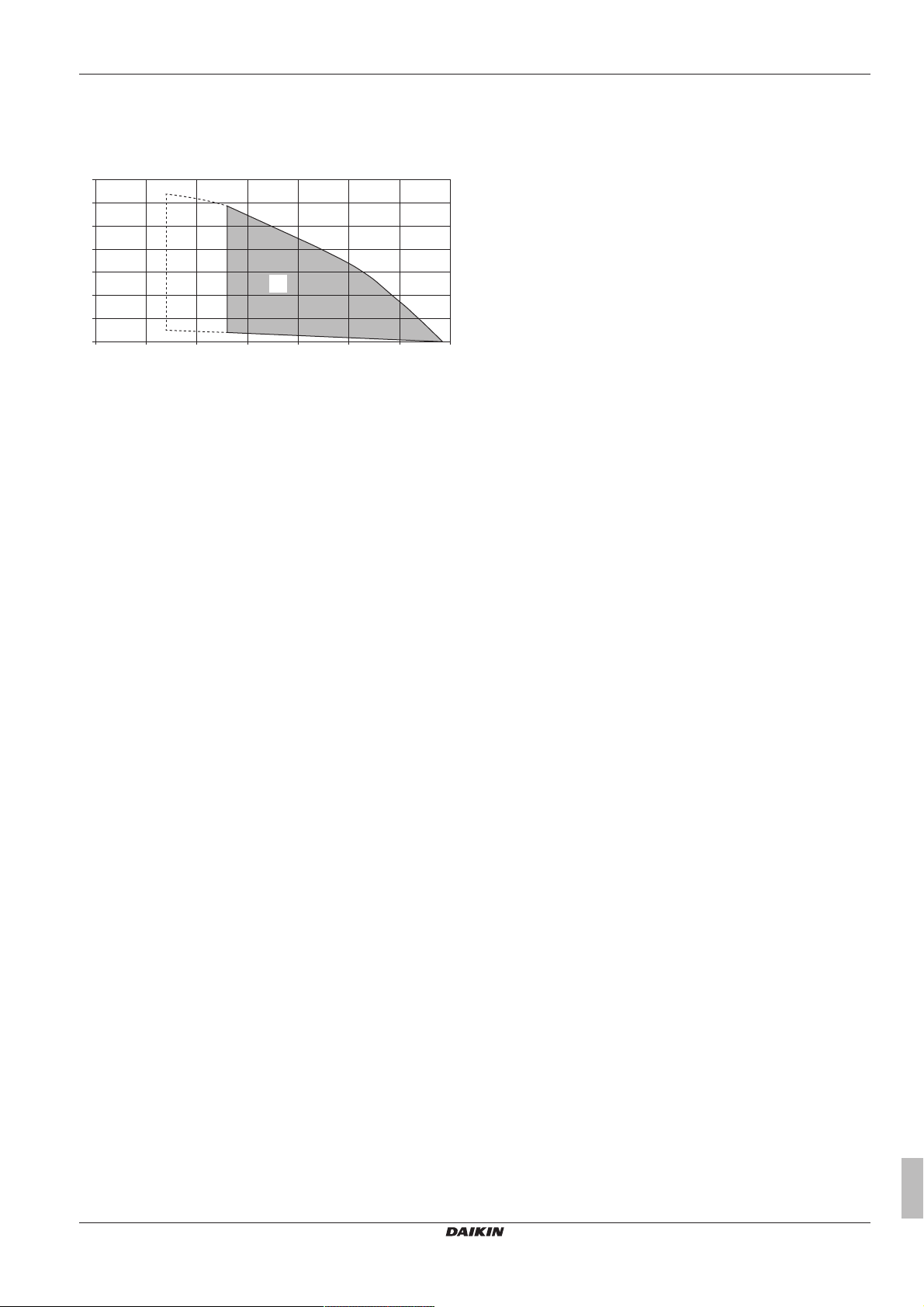

14.8 ESP curve: Indoor unit ............................................................... 95

15 Glossary 95

16 Field settings table 96

1 General safety precautions

9 Commissioning 75

9.1 Overview: Commissioning......................................................... 75

9.2 Precautions when commissioning ............................................. 75

9.3 Checklist before commissioning................................................ 75

9.4 Checklist during commissioning ................................................ 75

9.4.1 To check the minimum flow rate ................................. 76

9.4.2 Air purge function........................................................ 76

9.4.3 To perform an operation test run ................................ 76

9.4.4 To perform an actuator test run .................................. 77

9.4.5 Underfloor heating screed dryout................................ 77

10 Hand-over to the user 78

11 Maintenance and service 78

11.1 Overview: Maintenance and service ......................................... 78

11.2 Maintenance safety precautions................................................ 78

11.3 Checklist for yearly maintenance of the outdoor unit ................ 79

11.4 Checklist for yearly maintenance of the indoor unit................... 79

11.4.1 To drain the domestic hot water tank .......................... 80

11.5 About cleaning the water filter in case of trouble....................... 80

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

1.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and the installer reference guide MUST be

performed by an authorised installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

Installer reference guide

3

Page 4

1 General safety precautions

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious

injury.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

Symbol Explanation

Before installation, read the installation and

operation manual, and the wiring instruction sheet.

Before performing maintenance and service tasks,

read the service manual.

For more information, see the installer and user

reference guide.

1.2 For the installer

1.2.1 General

If you are NOT sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by Daikin.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information MUST be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

1.2.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the unit's weight and

vibration.

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

Installer reference guide

4

1.2.3 Refrigerant

If applicable. See the installation manual or installer reference guide

of your application for more information.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 5

1 General safety precautions

NOTICE

Make sure refrigerant piping installation complies with

applicable legislation. In Europe, EN378 is the applicable

standard.

NOTICE

Make sure the field piping and connections are NOT

subjected to stress.

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas may be produced if refrigerant gas comes

into contact with fire.

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage. If you want to pump

down the system, and there is a leak in the refrigerant

circuit:

▪ Do NOT use the unit's automatic pump down function,

with which you can collect all refrigerant from the

system into the outdoor unit. Possible consequence:

Self-combustion and explosion of the compressor

because of air going into the operating compressor.

▪ Use a separate recovery system so that the unit's

compressor does NOT have to operate.

WARNING

ALWAYS recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

▪ When the refrigerant system is to be opened,

refrigerant MUST be treated according to the applicable

legislation.

WARNING

Make sure there is no oxygen in the system. Refrigerant

may only be charged after performing the leak test and the

vacuum drying.

▪ In case re-charge is required, refer to the nameplate of the unit. It

states the type of refrigerant and necessary amount.

▪ The unit is factory charged with refrigerant and depending on pipe

sizes and pipe lengths some systems require additional charging

of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the

system, this to ensure pressure resistance and prevent foreign

materials from entering into the system.

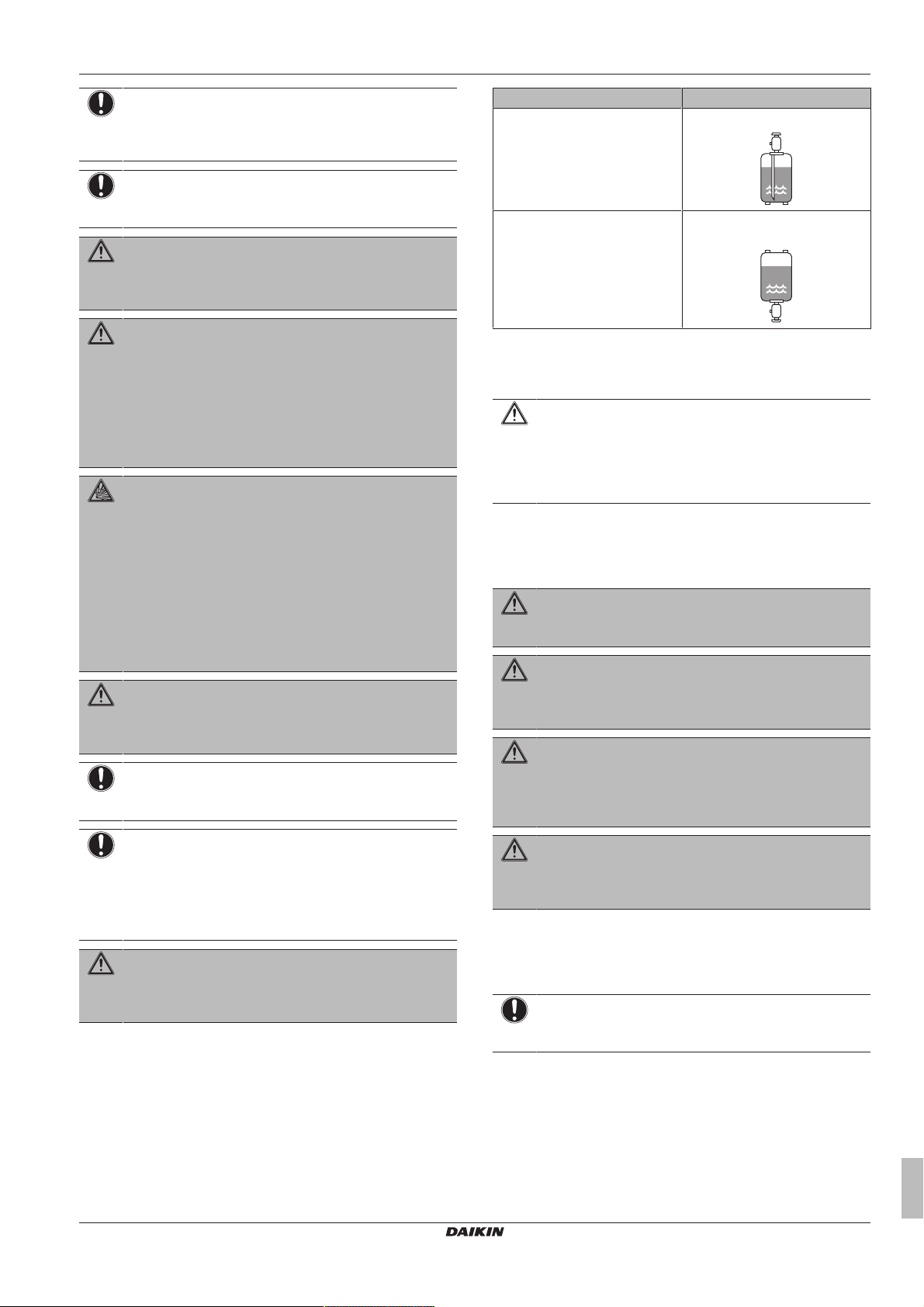

▪ Charge the liquid refrigerant as follows:

If Then

A siphon tube is present

(i.e., the cylinder is marked with

"Liquid filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may

prevent normal operation.

CAUTION

When the refrigerant charging procedure is done or when

pausing, close the valve of the refrigerant tank

immediately. If the valve is NOT closed immediately,

remaining pressure might charge additional refrigerant.

Possible consequence: Incorrect refrigerant amount.

Charge with the cylinder upright.

down.

1.2.4 Brine

If applicable. See the installation manual or installer reference guide

of your application for more information.

WARNING

The selection of the brine MUST be in accordance with the

applicable legislation.

WARNING

Take sufficient precautions in case of brine leakage. If

brine leaks, ventilate the area immediately and contact

your local dealer.

WARNING

The ambient temperature inside the unit can get much

higher than that of the room, e.g. 70°C. In case of a brine

leak, hot parts inside the unit can create a hazardous

situation.

WARNING

The use and installation of the application MUST comply

with the safety and environmental precautions specified in

the applicable legislation.

1.2.5 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure water quality complies with EU directive

98/83EC.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Installer reference guide

5

Page 6

2 About the documentation

1.2.6 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1 minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage category III

condition, MUST be installed in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring MUST be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do NOT come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

CAUTION

When connecting the power supply, the earth connection

must be made before the current-carrying connections are

established. When disconnecting the power supply, the

current-carrying connections must be separated before the

earth connection is. The length of the conductors between

the power supply stress relief and the terminal block itself

must be as such that the current-carrying wires are

tautened before the earth wire is in case the power supply

is pulled loose from the stress relief.

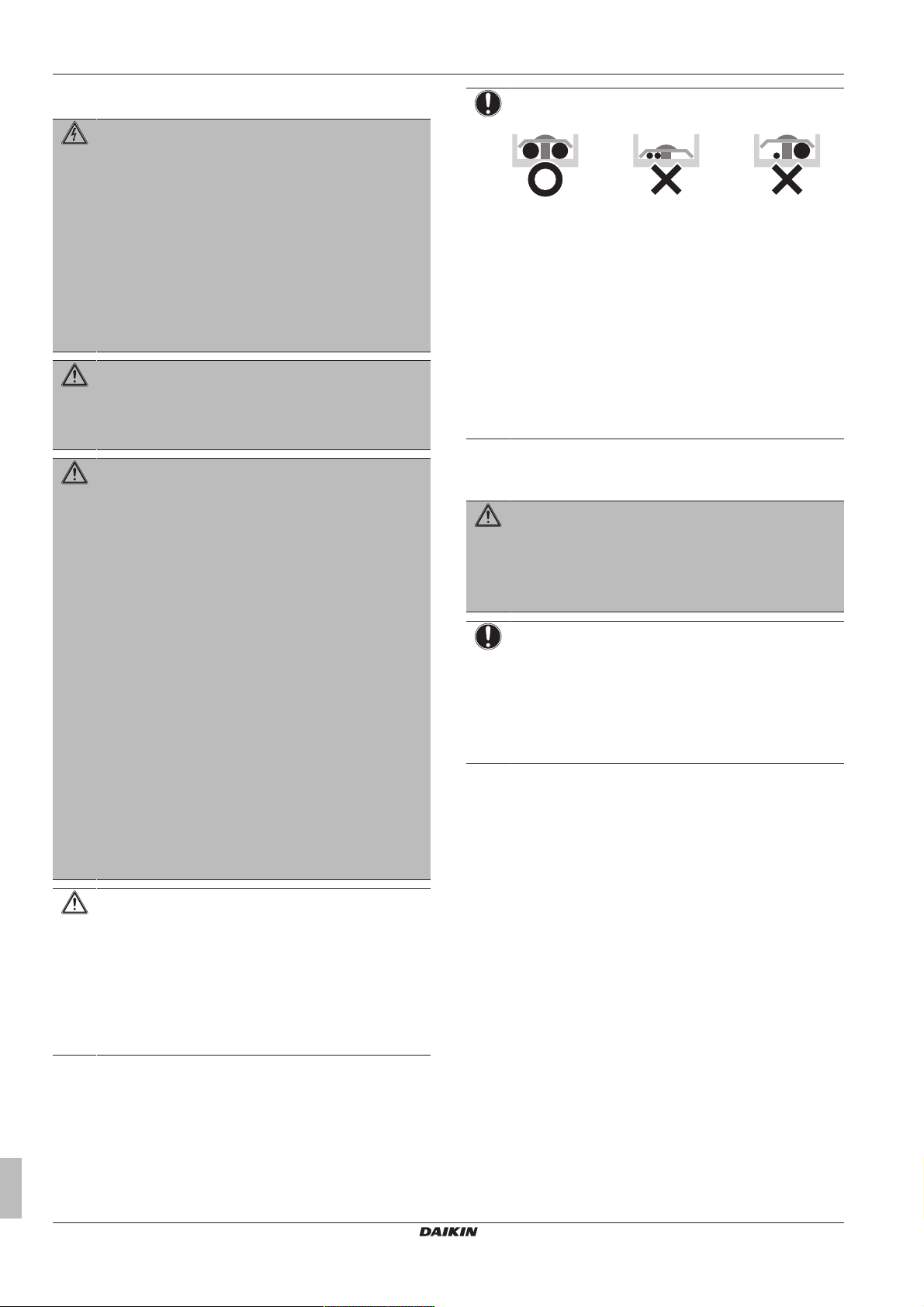

NOTICE

Precautions when laying power wiring:

▪ Do NOT connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure above.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

Install power cables at least 1 metre away from televisions or radios

to prevent interference. Depending on the radio waves, a distance of

1metre may not be sufficient.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

2 About the documentation

2.1 About this document

Target audience

Authorised installers

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the indoor unit)

▪ Indoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the indoor unit)

▪ Outdoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the outdoor unit)

Installer reference guide

6

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 7

3 About the box

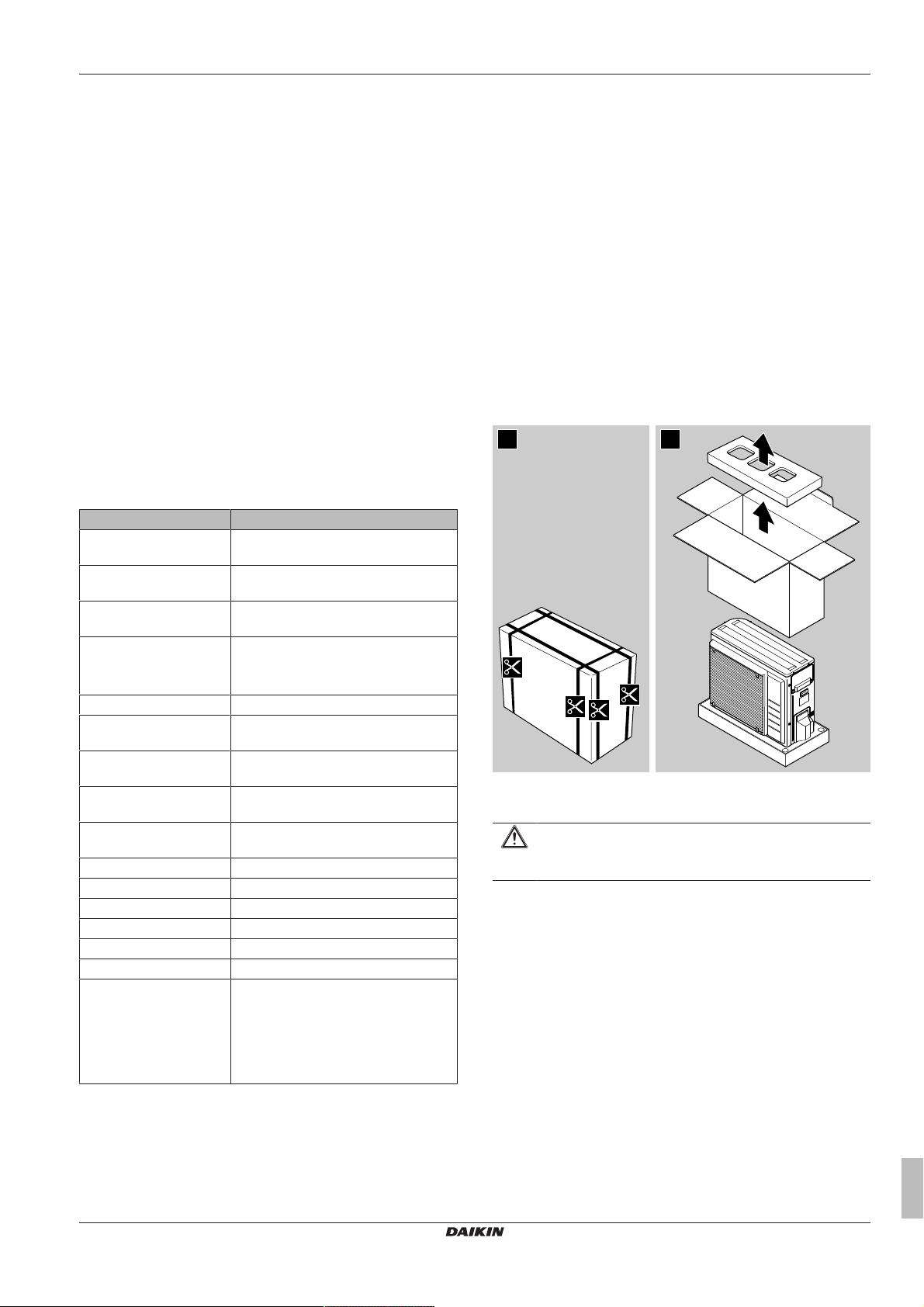

1 2

▪ Installer reference guide:

▪ Preparation of the installation, good practices, reference data,…

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

▪ Addendum book for optional equipment:

▪ Additional info about how to install optional equipment

▪ Format: Paper (in the box of the indoor unit) + Digital files on

http://www.daikineurope.com/support-and-manuals/productinformation/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

extranet (authentication required).

2.2 Installer reference guide at a glance

Chapter Description

General safety

precautions

About the documentation What documentation exists for the

About the box How to unpack the units and remove

About the units and

options

Application guidelines Various installation setups of the system

Preparation What to do and know before going

Installation What to do and know to install the

Configuration What to do and know to configure the

Commissioning What to do and know to commission the

Hand‑over to the user What to give and explain to the user

Maintenance and service How to maintain and service the units

Troubleshooting What to do in case of problems

Disposal How to dispose of the system

Technical data Specifications of the system

Glossary Definition of terms

Field settings table Table to be filled in by the installer, and

Safety instructions that you must read

before installing

installer

their accessories

▪ How to identify the units

▪ Possible combinations of units and

options

on‑site

system

system after it is installed

system after it is configured

kept for future reference

Note: There is also an installer settings

table in the user reference guide. This

table has to be filled in by the installer

and handed over to the user.

3 About the box

3.1 Overview: About the box

This chapter describes what you have to do after the boxes with the

outdoor and indoor unit are delivered on-site.

Keep the following in mind:

▪ At delivery, the unit MUST be checked for damage. Any damage

MUST be reported immediately to the carrier's claims agent.

▪ Bring the packed unit as close as possible to its final installation

position to prevent damage during transport.

▪ Prepare the path along which you want to bring the unit inside in

advance.

3.2 Outdoor unit

3.2.1 To unpack the outdoor unit

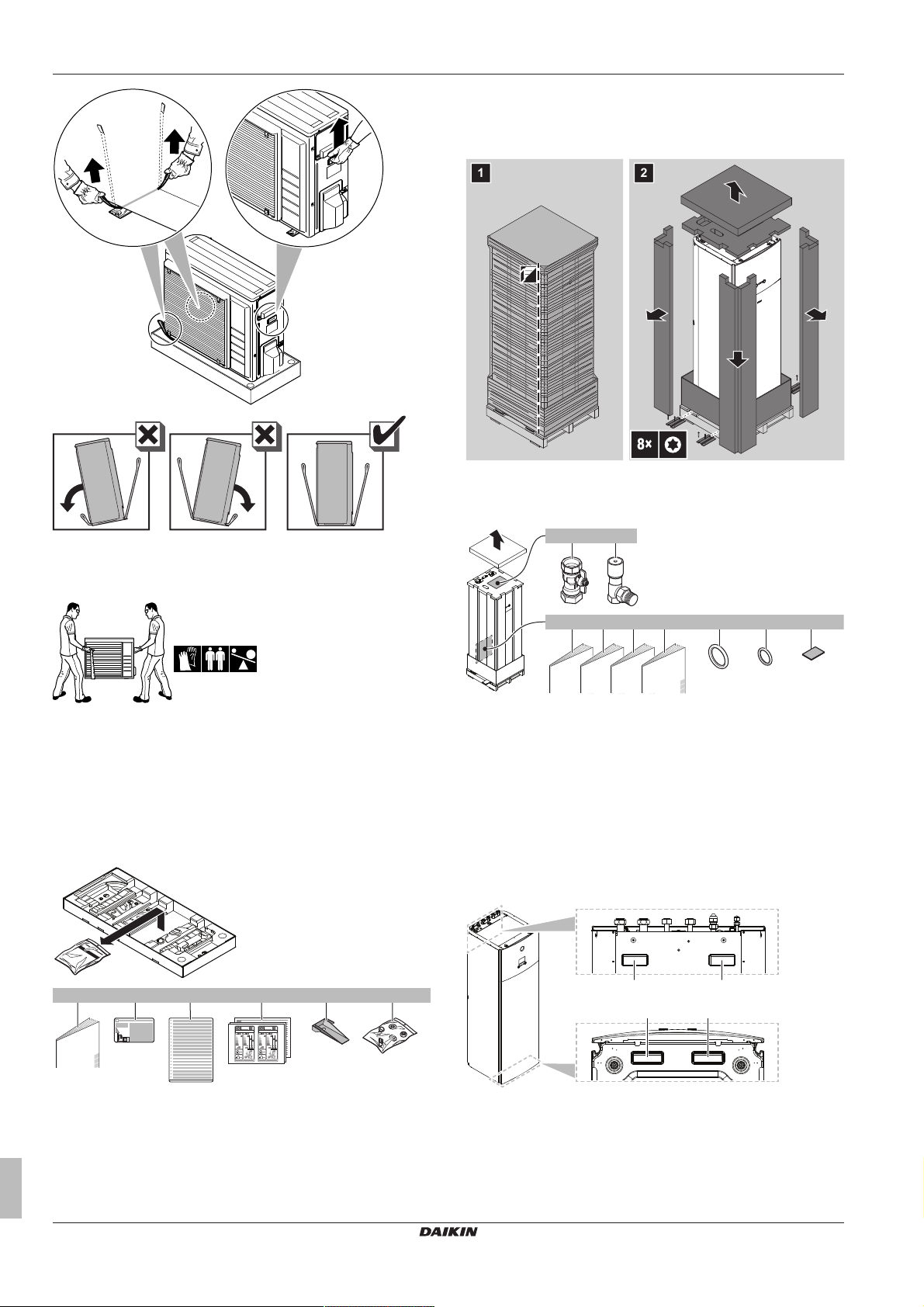

3.2.2 To handle the outdoor unit

CAUTION

To avoid injury, do NOT touch the air inlet or aluminium

fins of the unit.

1 Handle the unit using the sling to the left and the handle to the

right. Pull up both sides of the sling at the same time to prevent

disconnection of the sling from the unit.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Installer reference guide

7

Page 8

3 About the box

2

1

1

ENERG

IJAY

IAIE

ENERG

IJAY

IAIE

1×1× 1× 1× 2× 1×

da b c e f

1 2

8×

2×

4×

1×

4× 1×

1× 1× 1× 1×

a b

g h ic d e f

b

a a

b

3.3 Indoor unit

3.3.1 To unpack the indoor unit

3.3.2 To remove the accessories from the indoor unit

2 While handling the unit:

▪ Keep both sides of the sling level.

▪ Keep your back straight.

3 After mounting the unit, remove the sling from the unit by pulling

1 side of the sling.

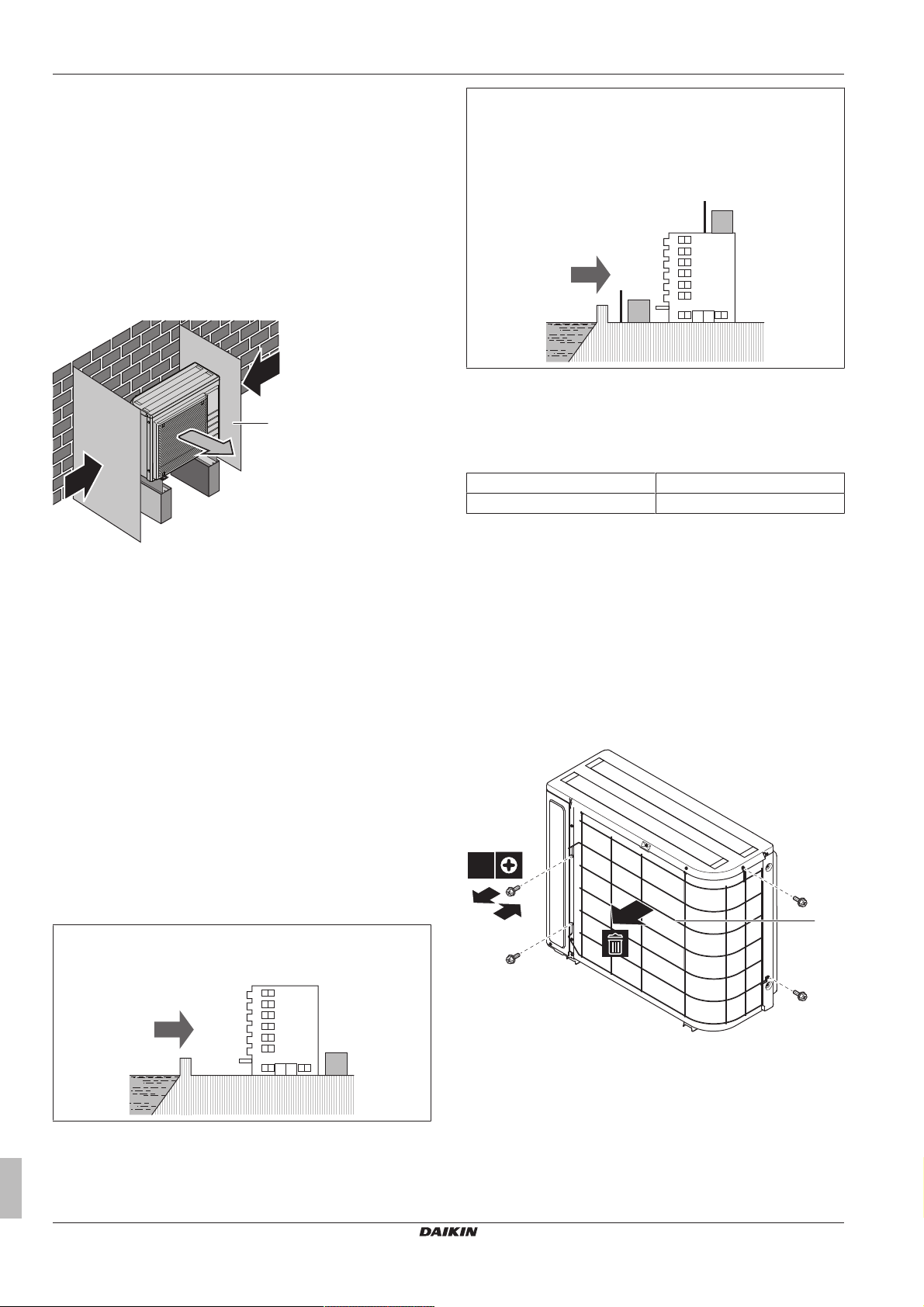

3.2.3 To remove the accessories from the outdoor unit

1 Lift the outdoor unit. See "3.2.2 To handle the outdoor unit"on

page7.

2 Remove the accessories at the bottom of the package.

a Shut-off valves for water circuit

b Overpressure bypass valve

c General safety precautions

d Addendum book for optional equipment

e Indoor unit installation manual

f Operation manual

g Sealing rings for shut-off valves (space heating water

circuit)

h Sealing rings for field-supplied shut-off valves (domestic

hot water circuit)

i Sealing tape for low voltage wiring intake

3.3.3 To handle the indoor unit

Use the handles at the back and at the bottom to carry the unit.

a Outdoor unit installation manual

b Fluorinated greenhouse gases label

c Multilingual fluorinated greenhouse gases label

d Energy label

e Unit mounting plate

f Bolts, nuts, washers, spring washers and wire clamp

Installer reference guide

8

a Handles at the back of the unit

b Handles at the bottom of the unit. Carefully tilt the unit to

the back so that the handles become visible.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 9

4 About the units and options

4 About the units and options

4.1 Overview: About the units and options

This chapter contains information about:

▪ Identifying the outdoor unit

▪ Identifying the indoor unit

▪ Combining the outdoor unit with options

▪ Combining the indoor unit with options

4.2 Identification

NOTICE

When installing or servicing several units at the same time,

make sure NOT to switch the service panels between

different models.

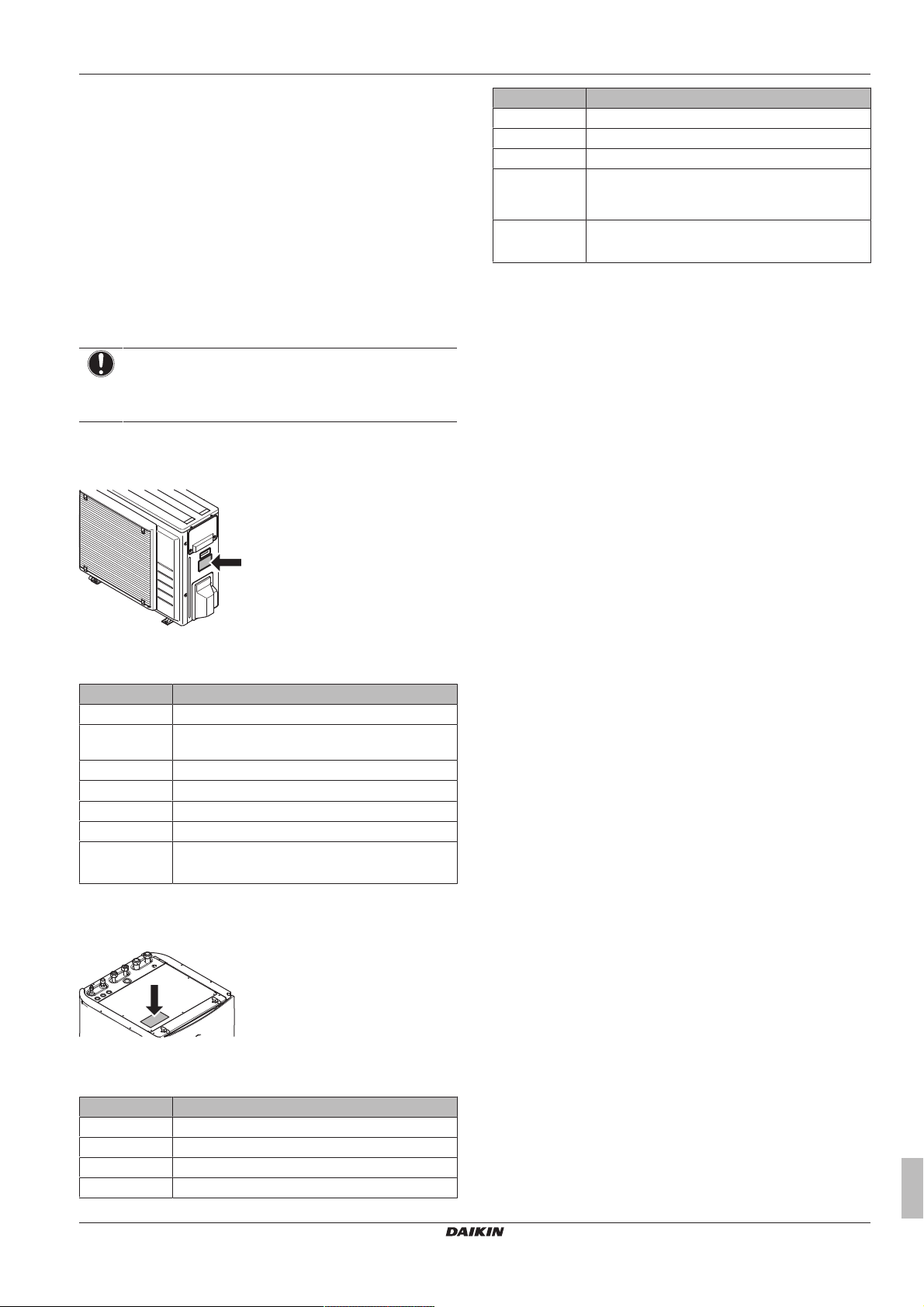

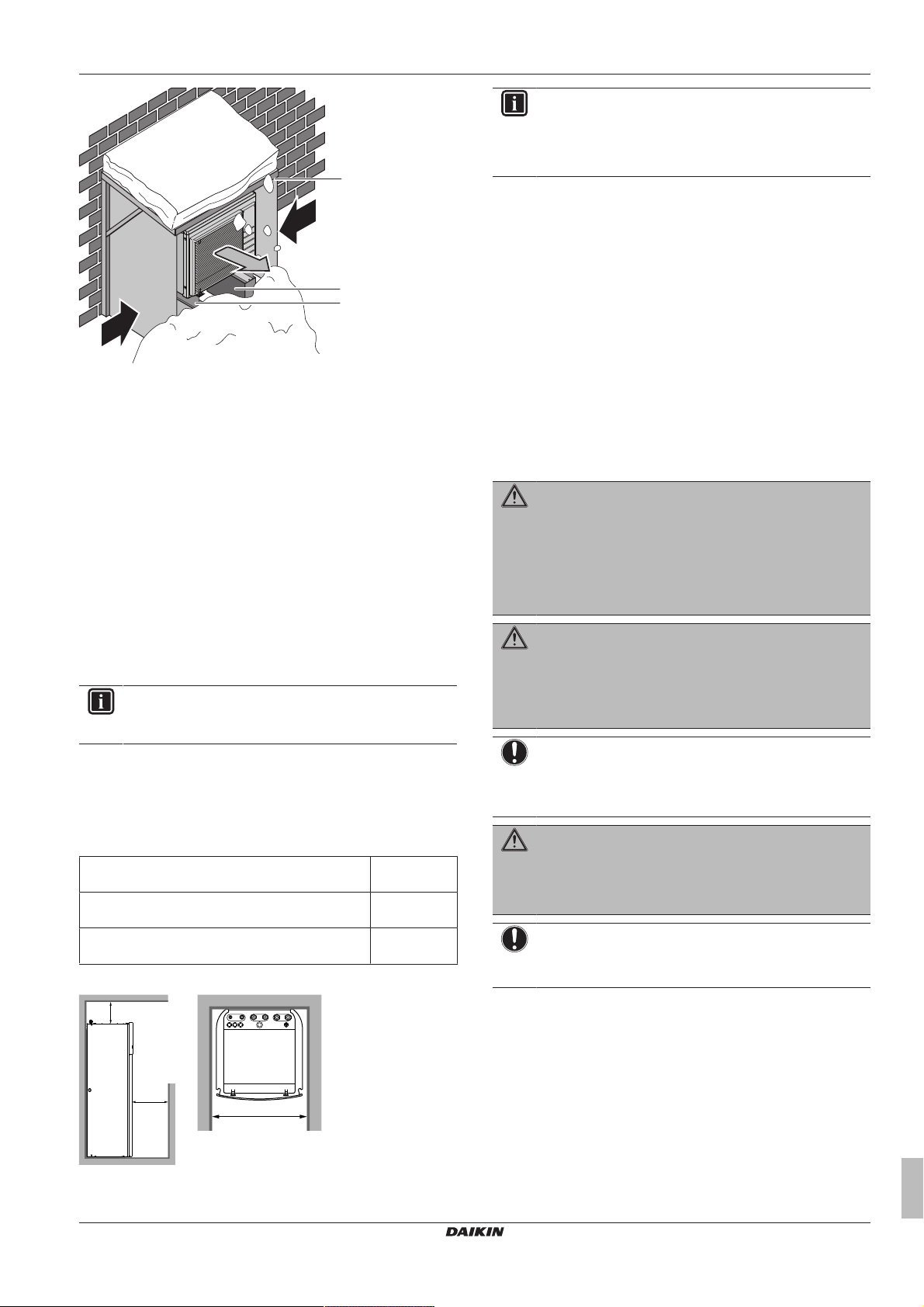

4.2.1 Identification label: Outdoor unit

Location

Model identification

Example: ERGA06DAV3 A

Code Explanation

ER European split outdoor pair heat pump

G Medium water temperature – ambient zone: −10~

−20°C

A Refrigerant R32

06 Capacity class

DA Model series

V3 Power supply

A A=Austrian model

[—]=Non-Austrian model

4.2.2 Identification label: Indoor unit

Location

Code Description

S Integrated tank material: Stainless steel

23 Integrated tank volume

DA Model series

V Model with single phase anti-legionella heater in

the domestic hot water tank. (Without backup

heater in the space heating circuit.)

G G=Grey model

[—]=White model

4.3 Combining units and options

4.3.1 Possible options for the outdoor unit

Drain pan kit (EKDP008D)

The drain pan kit is required to gather the drain from the outdoor

unit. The drain pan kit consists of:

▪ Drain pan

▪ Installation brackets

For installation instructions, see the installation manual of the drain

pan.

Drain pan heater (EKDPH008CA)

The drain pan heater is required to avoid freezing-up of the drain

pan.

It is recommended to install this option in colder regions with

possible low ambient temperatures or heavy snowfall.

For installation instructions, see the installation manual of the drain

pan heater.

U-beams (EKFT008D)

The U-beams are installation brackets on which the outdoor unit can

be installed.

It is recommended to install this option in colder regions with

possible low ambient temperatures or heavy snowfall.

For installation instructions, see the installation manual of the

outdoor unit.

Low sound cover (EKLN08A1)

In sound sensitive areas (e.g. near a bedroom), you can install the

low sound cover to decrease the operation noise of the outdoor unit.

You can install the low sound cover:

▪ On mounting feet to the ground. This must withstand 200kg.

▪ On brackets to the wall. This must withstand 200kg.

If you install the low sound cover, you also need to install one of the

following options:

▪ Recommended: Drain pan kit (with or without drain pan heater)

▪ U-beams

For installation instructions, see the installation manual of the low

sound cover.

Model identification

Example: EHVH04S23DAVG

Code Description

E European model

HV Floor-standing indoor unit with integrated tank

H H=Heating only

04 Capacity class

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

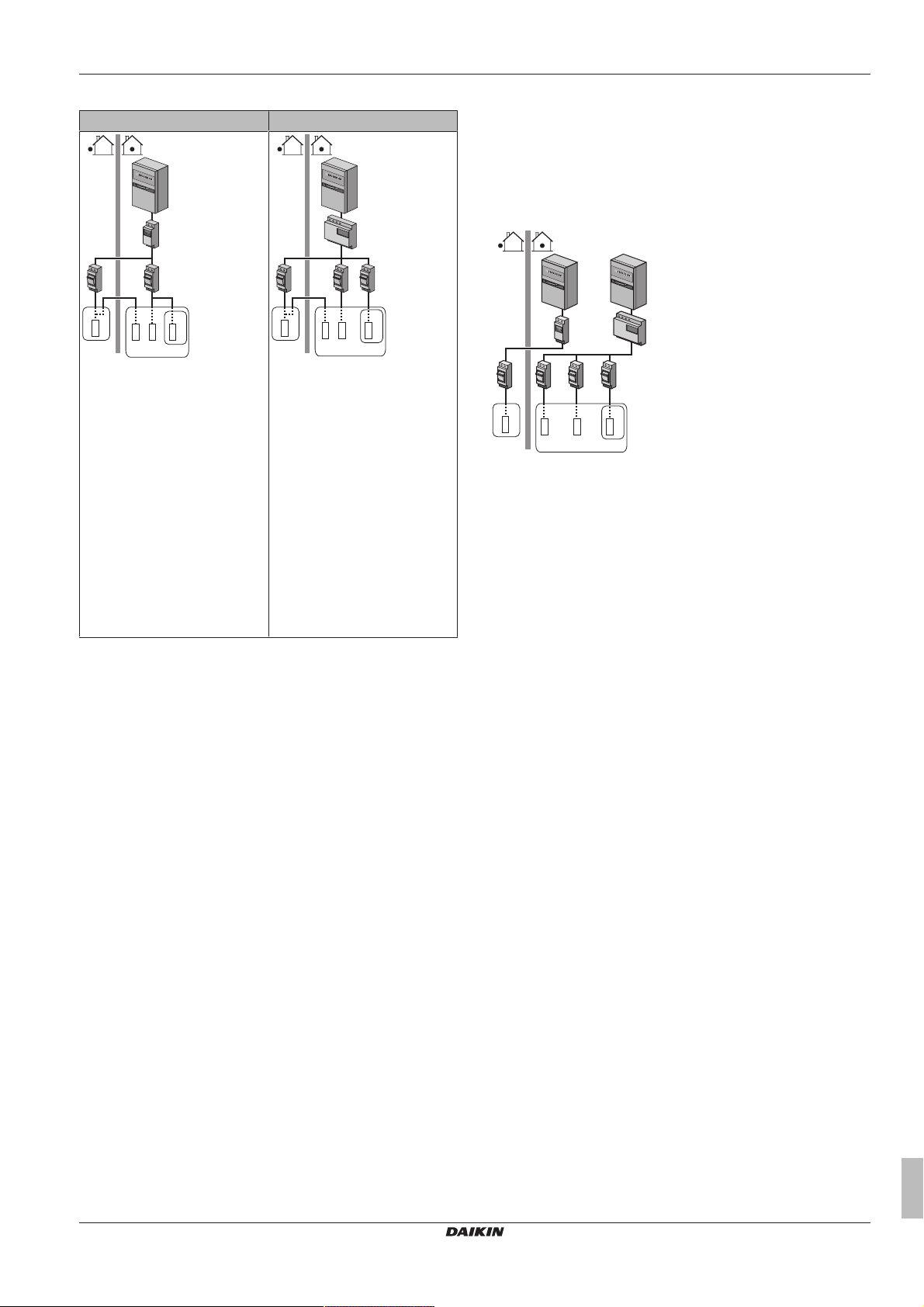

4.3.2 Possible options for the indoor unit

User interface used as room thermostat (EKRUDAS)

▪ The user interface used as room thermostat can only be used in

combination with the user interface connected to the indoor unit.

▪ The user interface used as room thermostat needs to be installed

in the room that you want to control.

For installation instructions, see the installation and operation

manual of the user interface used as room thermostat.

Installer reference guide

9

Page 10

5 Application guidelines

Room thermostat (EKRTWA, EKRTR1)

You can connect an optional room thermostat to the indoor unit. This

thermostat can either be wired (EKRTWA) or wireless (EKRTR1).

For installation instructions, see the installation manual of the room

thermostat and addendum book for optional equipment.

Remote sensor for wireless thermostat (EKRTETS)

You can use a wireless indoor temperature sensor (EKRTETS) only

in combination with the wireless thermostat (EKRTR1).

For installation intructions, see the installation manual of the room

thermostat and addendum book for optional equipment.

Digital I/O PCB (EKRP1HB)

The digital I/O PCB is required to provide following signals:

▪ Alarm output

▪ Space heating/cooling On/OFF output

▪ Changeover to external heat source

For installation instructions, see the installation manual of the digital

I/O PCB and addendum book for optional equipment.

Demand PCB (EKRP1AHTA)

To enable the power saving consumption control by digital inputs

you must install the demand PCB.

For installation instructions, see the installation manual of the

demand PCB and addendum book for optional equipment.

Remote indoor sensor (KRCS01-1)

By default the internal user interface sensor will be used as room

temperature sensor.

As an option the remote indoor sensor can be installed to measure

the room temperature on another location.

For installation instructions, see the installation manual of the remote

indoor sensor and addendum book for optional equipment.

INFORMATION

▪ The remote indoor sensor can only be used in case the

user interface is configured with room thermostat

functionality.

▪ You can only connect either the remote indoor sensor

or the remote outdoor sensor.

Remote outdoor sensor (EKRSCA1)

By default the sensor inside the outdoor unit will be used to measure

the outdoor temperature.

As an option the remote outdoor sensor can be installed to measure

the outdoor temperature on another location (e.g. to avoid direct

sunlight) to have an improved system behaviour.

For installation instructions, see the installation manual of the remote

outdoor sensor.

INFORMATION

You can only connect either the remote indoor sensor or

the remote outdoor sensor.

PC cable (EKPCCAB)

The PC cable makes a connection between the switch box of the

indoor unit and a PC. It gives the possibility to update the software of

the indoor unit.

For installation instructions, see the installation manual of the PC

cable and "8Configuration"on page47.

Pipe bend kit (EKHVTC)

When the indoor unit is installed in a place with limited space, a pipe

bend kit can be installed to facilitate the connection to the refrigerant

liquid and gas connections of the indoor unit.

For installation instructions, see the instruction sheet of the pipe

bend kit.

Heat pump convector (FWXV)

For installation instructions, refer to the installation manual of the

heat pump convectors, and the addendum book for optional

equipment.

Backup heater (EKLBUHCB6W1)

You can install an optional backup heater.

For installation instructions, see the installation manual of the

backup heater and addendum book for optional equipment.

LAN adapter for smartphone control + Smart Grid applications

(BRP069A61)

You can install this LAN adapter to:

▪ Control the system via a smartphone app.

▪ Use the system in various Smart Grid applications.

For installation instructions, see the installation manual of the LAN

adapter.

LAN adapter for smartphone control (BRP069A62)

You can install this LAN adapter to control the system via a

smartphone app.

For installation instructions, see the installation manual of the LAN

adapter.

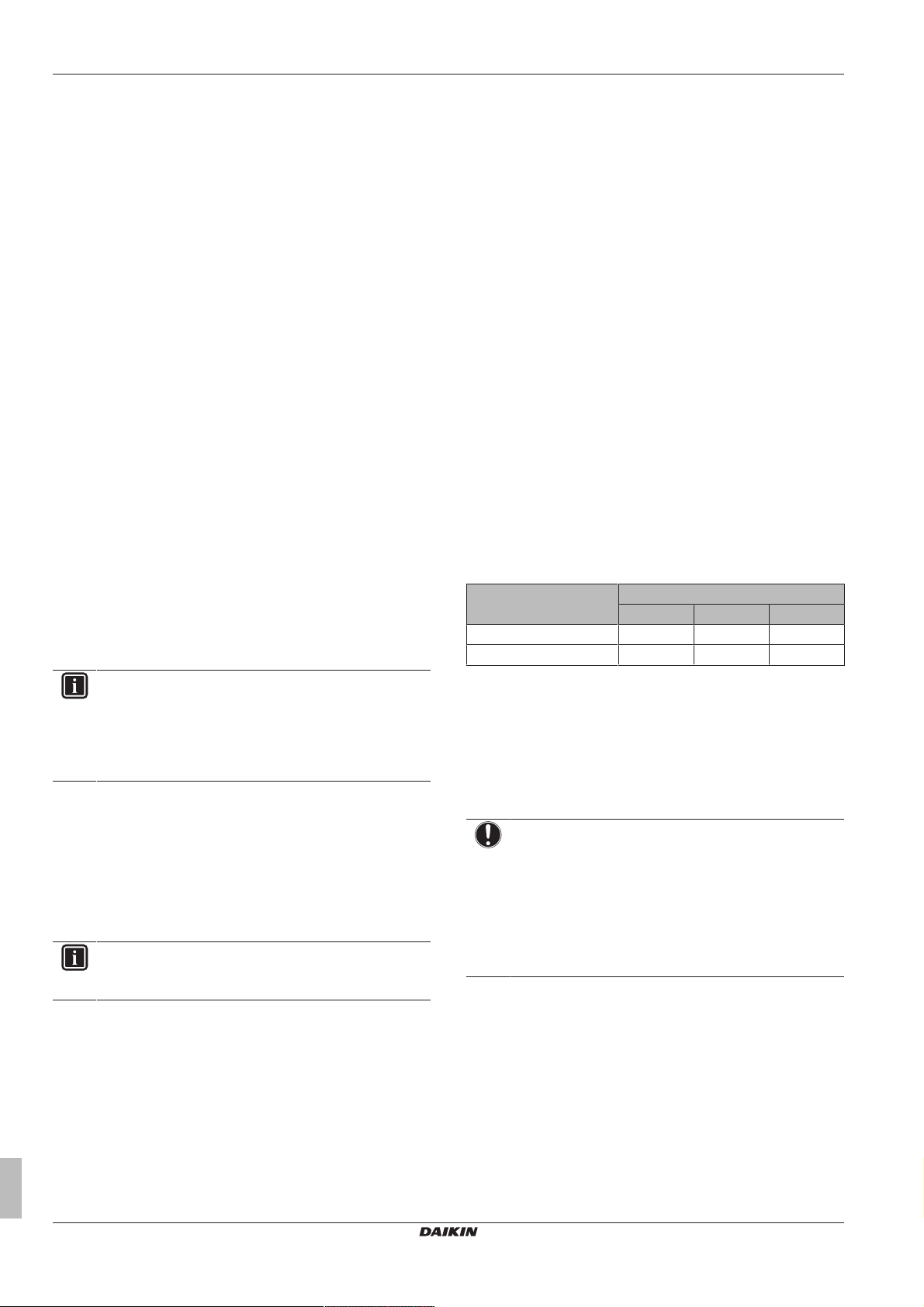

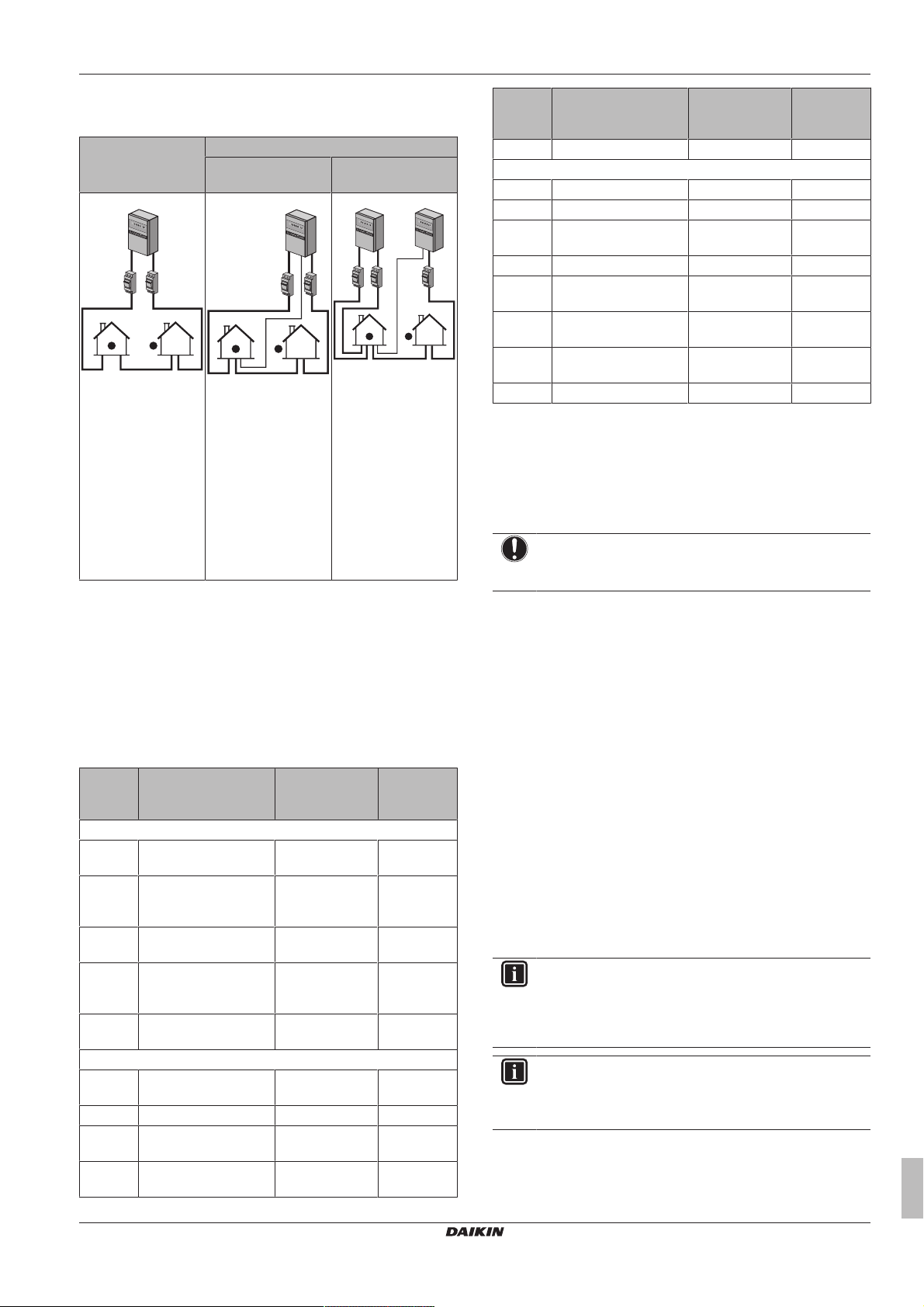

4.3.3 Possible combinations of indoor unit and outdoor unit

Indoor unit Outdoor unit

ERGA04 ERGA06 ERGA08

EHVH04 O — —

EHVH08 — O O

5 Application guidelines

5.1 Overview: Application guidelines

The purpose of the application guidelines is to give a glance of the

possibilities of the Daikin heatpump system.

NOTICE

▪ The illustrations in the application guidelines are meant

for reference only, and are NOT to be used as detailed

hydraulic diagrams. The detailed hydraulic

dimensioning and balancing are NOT shown, and are

the responsibility of the installer.

▪ For more information about the configuration settings to

optimize heatpump operation, see "8Configuration"on

page47.

This chapter contains application guidelines for:

▪ Setting up the space heating system

▪ Setting up an auxiliary heat source for space heating

▪ Setting up the domestic hot water tank

▪ Setting up the energy metering

▪ Setting up the power consumption control

▪ Setting up an external temperature sensor

Installer reference guide

10

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 11

5 Application guidelines

B

A

a

B

A

b

a

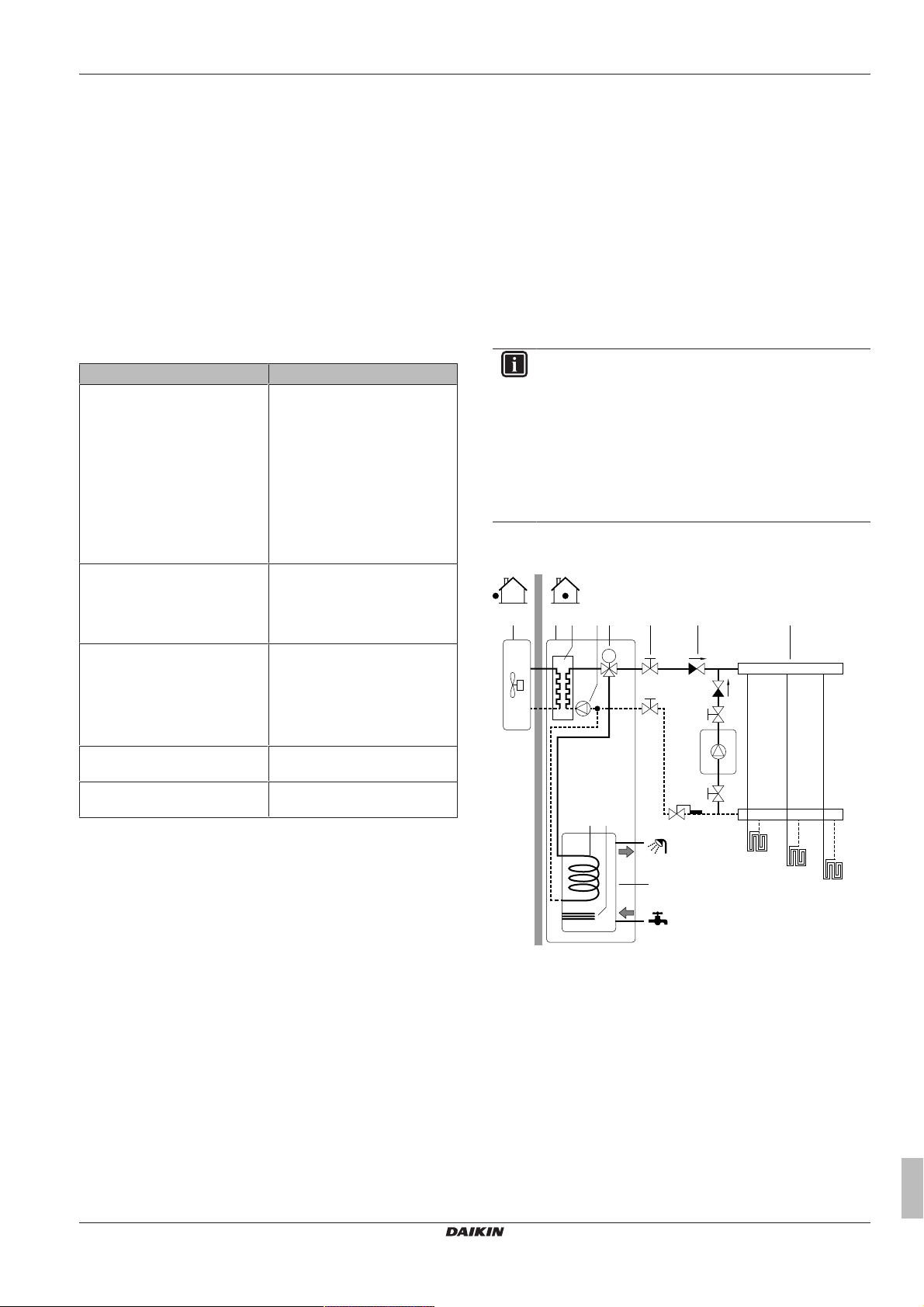

5.2 Setting up the space heating system

The Daikin heat pump system supplies leaving water to heat

emitters in one or more rooms.

Because the system offers a wide flexibility to control the

temperature in each room, you need to answer the following

questions first:

▪ How many rooms are heated by the Daikin heatpump system?

▪ Which heat emitter types are used in each room and what is their

design leaving water temperature?

Once the space heating requirements are clear, Daikin recommends

to follow the setup guidelines below.

NOTICE

If an external room thermostat is used, the external room

thermostat will control the room frost protection. However,

the room frost protection is only possible if the leaving

water temperature control on the unit's user interface is

turned ON.

INFORMATION

In case an external room thermostat is used and room frost

protection needs to be guaranteed in all conditions, then

you have to set Emergency [9.5] to Automatic.

Benefits

▪ Highest comfort and efficiency. The smart room thermostat

functionality can decrease or increase the desired leaving water

temperature based on the actual room temperature (modulation).

This results in:

▪ Stable room temperature matching the desired temperature

(higher comfort)

▪ Less ON/OFF cycles (more quiet, higher comfort and higher

efficiency)

▪ Lowest possible leaving water temperature (higher efficiency)

▪ Easy. You can easily set the desired room temperature via the

user interface:

▪ For your daily needs, you can use preset values and schedules.

▪ To deviate from your daily needs, you can temporarily overrule

the preset values and schedules, use the holiday mode…c

Underfloor heating or radiators – Wireless room

thermostat

Setup

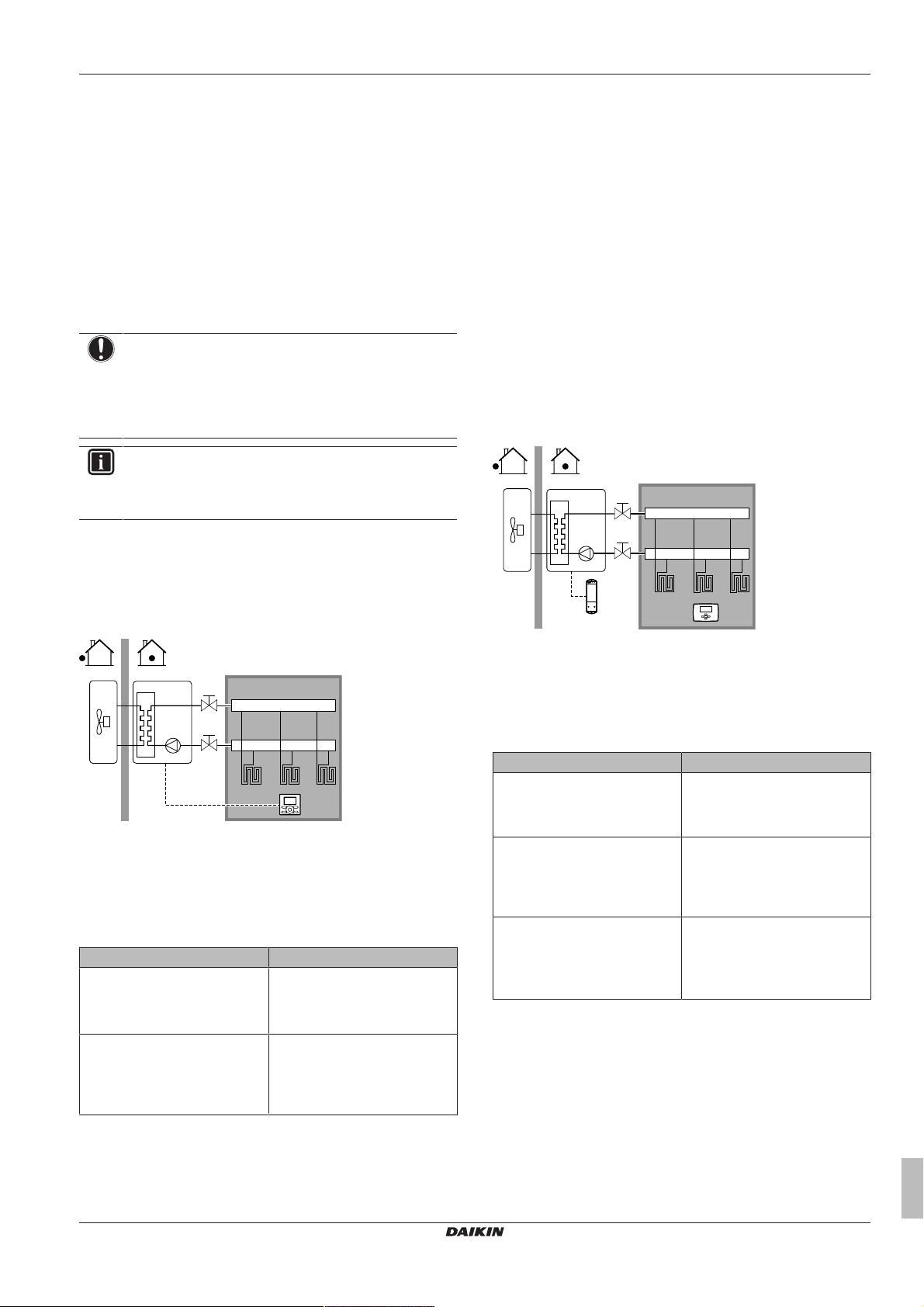

5.2.1 Single room

Underfloor heating or radiators – Wired room

thermostat

Setup

A Main leaving water temperature zone

B One single room

a User interface used as room thermostat

▪ The room temperature of the main room is controlled by the user

interface used as a room thermostat (optional equipment

EKRUDAS).

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

▪ Code: [C-07]

Number of water temperature

zones:

▪ #: [4.4]

▪ Code: [7-02]

2 (Room thermostat): Unit

operation is decided based on

the ambient temperature of the

user interface.

0 (Single zone): Main

A Main leaving water temperature zone

B One single room

a Receiver for wireless external room thermostat

b Wireless external room thermostat

▪ The room temperature is controlled by the wireless external room

thermostat (optional equipment EKRTR1).

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

▪ Code: [C-07]

Number of water temperature

zones:

▪ #: [4.4]

▪ Code: [7-02]

External room thermostat for the

main zone:

▪ #: [2.A]

▪ Code: [C-05]

Benefits

▪ Wireless. The Daikin external room thermostat is available in a

wireless version.

▪ Efficiency. Although the external room thermostat only sends ON/

OFF signals, it is specifically designed for the heatpump system.

1 (External room thermostat):

Unit operation is decided by the

external thermostat.

0 (Single zone): Main

1 (1 contact): When the used

external room thermostat or

heatpump convector can only

send a thermo ON/OFF

condition.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Installer reference guide

11

Page 12

5 Application guidelines

B

A

a

B

A

a

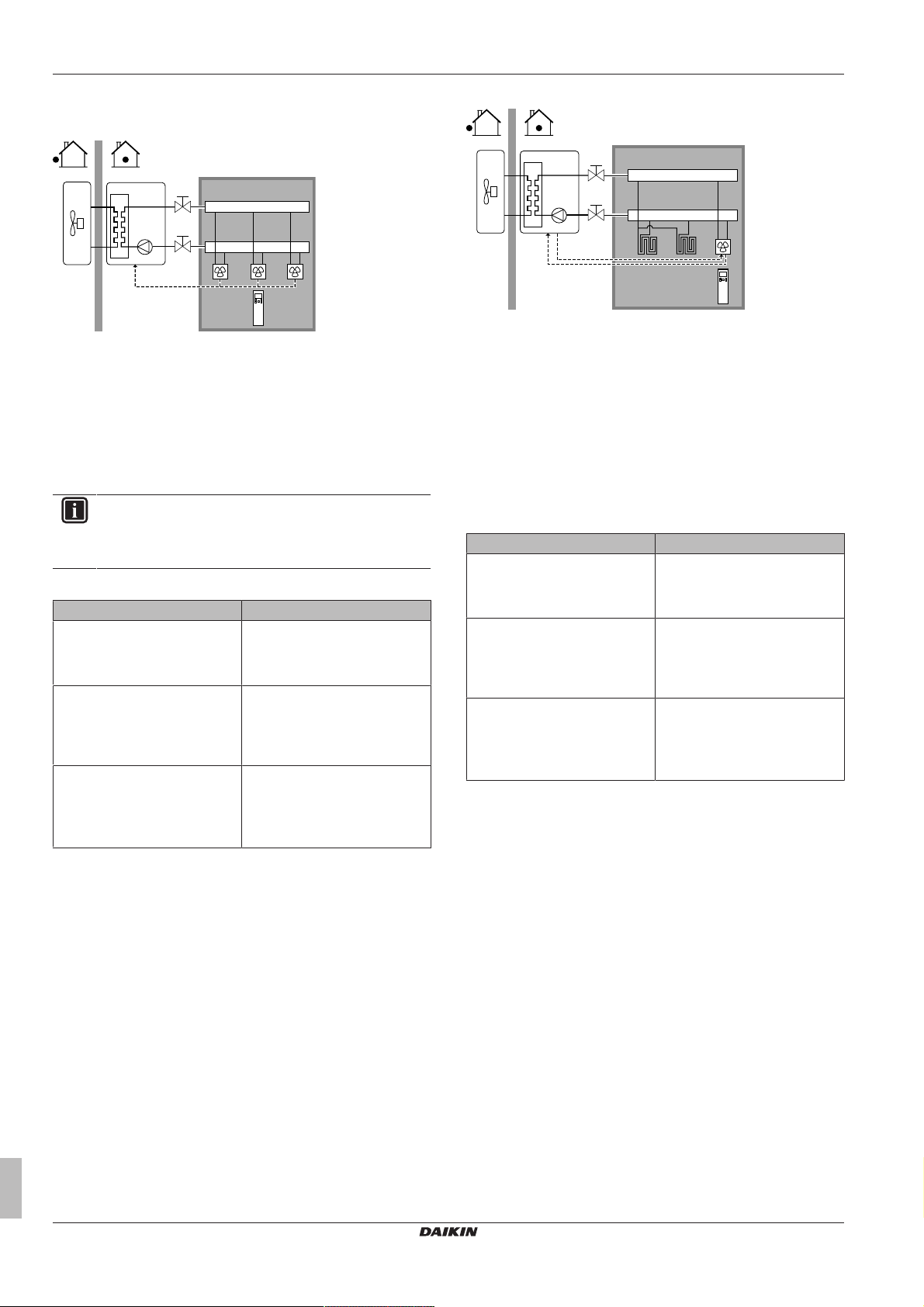

Heatpump convectors

Setup

▪ The heat pump convectors are directly connected to the indoor

unit.

▪ The desired room temperature is set via the remote controller of

the heatpump convectors.

▪ The space heating demand signal is sent to one digital input on

the indoor unit (X2M/35 and X2M/30).

▪ The space operation mode is sent to the heatpump convectors by

one digital output on the indoor unit (X2M/4 and X2M/3).

INFORMATION

When using multiple heat pump convectors, make sure

each one receives the infrared signal from the remote

controller of the heatpump convectors.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

▪ Code: [C-07]

Number of water temperature

zones:

▪ #: [4.4]

▪ Code: [7-02]

External room thermostat for the

main zone:

▪ #: [2.A]

▪ Code: [C-05]

Benefits

▪ Efficiency. Optimal energy efficiency because of the interlink

function.

▪ Stylish.

1 (External room thermostat):

Unit operation is decided by the

external thermostat.

0 (Single zone): Main

1 (1 contact): When the used

external room thermostat or

heatpump convector can only

send a thermo ON/OFF

condition.

Combination: Underfloor heating + Heatpump

convectors

▪ Space heating is provided by:

▪ The underfloor heating

▪ The heatpump convectors

Setup

A Main leaving water temperature zone

B One single room

a Remote controller of the heatpump convectors

▪ The heat pump convectors are directly connected to the indoor

unit.

▪ The desired room temperature is set via the remote controller of

the heatpump convectors.

▪ The space heating demand signal is sent to one digital input on

the indoor unit (X2M/35 and X2M/30).

▪ The space operation mode is sent to the heat pump convectors by

one digital output (X2M/4 and X2M/3) on the indoor unit.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

▪ Code: [C-07]

Number of water temperature

zones:

▪ #: [4.4]

▪ Code: [7-02]

External room thermostat for the

main zone:

▪ #: [2.A]

▪ Code: [C-05]

Benefits

▪ Efficiency. Under floor heating has the best performance with

Altherma LT.

▪ Comfort. The combination of the two heat emitter types provides

excellent heating comfort of the underfloor heating.

1 (External room thermostat):

Unit operation is decided by the

external thermostat.

0 (Single zone): Main

1 (1 contact): When the used

external room thermostat or

heatpump convector can only

send a thermo ON/OFF

condition.

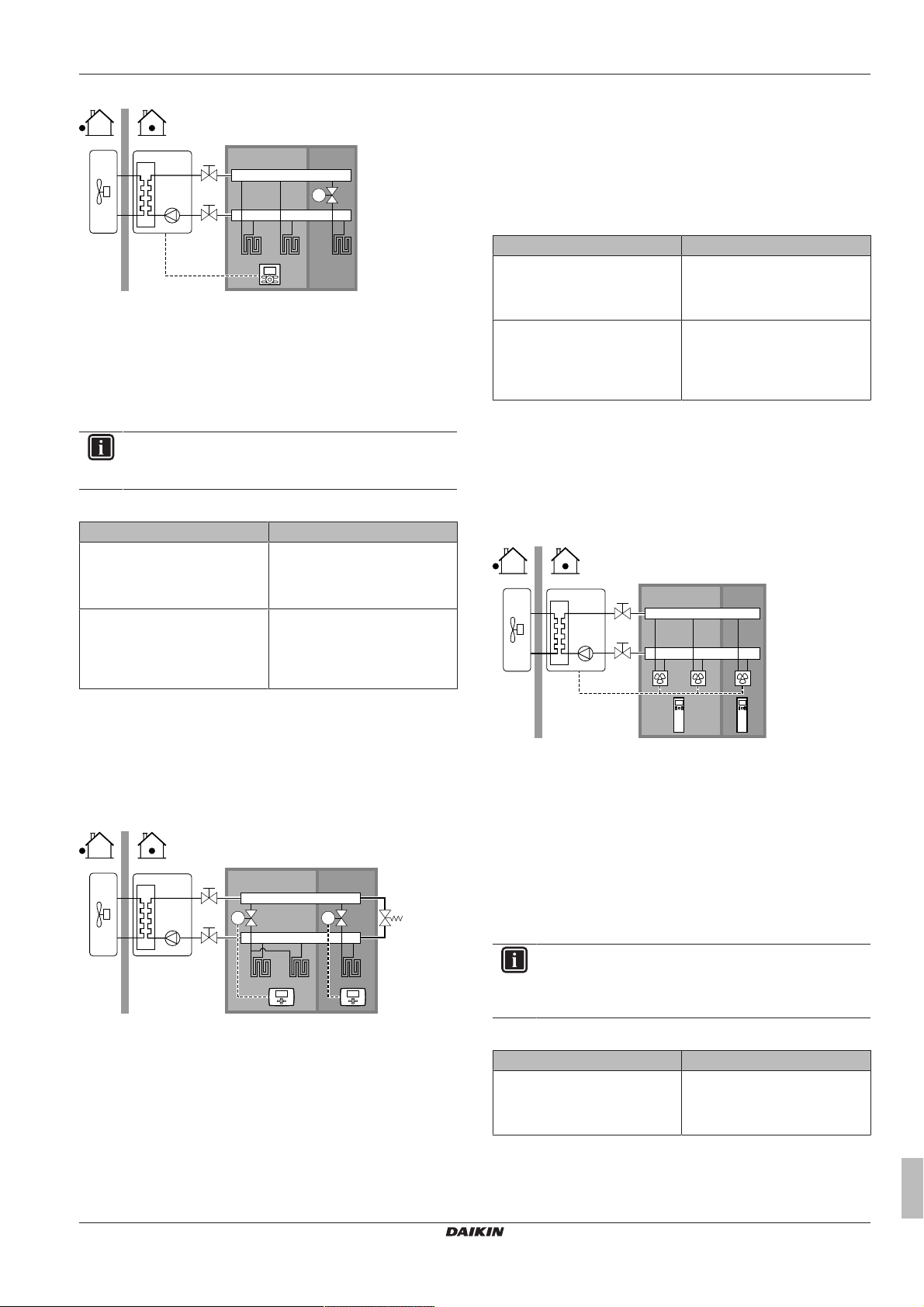

5.2.2 Multiple rooms – OneLWT zone

If only one leaving water temperature zone is needed because the

design leaving water temperature of all heat emitters is the same,

you do NOT need a mixing valve station (cost effective).

Example: If the heat pump system is used to heat up one floor

where all the rooms have the same heat emitters.

Underfloor heating or radiators – Thermostatic

valves

If you are heating up rooms with under floor heating or radiators, a

very common way is to control the temperature of the main room by

using a thermostat (this can either be the user interface or an

external room thermostat), while the other rooms are controlled by

so-called thermostatic valves, which open or close depending on the

room temperature.

Installer reference guide

12

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 13

5 Application guidelines

T

B C

A

a

M2

B C

A

a

b

a

M1

B

A

a a

C

Setup

▪ The under floor heating of the main room is directly connected to

the indoor unit.

▪ The room temperature of the main room is controlled by the user

interface used as a room thermostat (optional equipment

EKRUDAS).

▪ A thermostatic valve is installed before the under floor heating in

each of the other rooms.

INFORMATION

Mind situations where the main room can be heated by

another heating source. Example: Fireplaces.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

▪ Code: [C-07]

Number of water temperature

2 (Room thermostat): Unit

operation is decided based on

the ambient temperature of the

user interface.

0 (Single zone): Main

zones:

▪ #: [4.4]

▪ Code: [7-02]

▪ The user interface connected on the indoor unit decides the space

operation mode. Mind that the operation mode on each room

thermostat must be set to match the indoor unit.

▪ The room thermostats are connected to the shut-off valves, but do

NOT have to be connected to the indoor unit. The indoor unit will

supply leaving water all the time, with the possibility to program a

leaving water schedule.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

0 (Leaving water): Unit operation

is decided based on the leaving

water temperature.

▪ Code: [C-07]

Number of water temperature

0 (Single zone): Main

zones:

▪ #: [4.4]

▪ Code: [7-02]

Benefits

Compared with underfloor heating or radiators for one room:

▪ Comfort. You can set the desired room temperature, including

schedules, for each room via the room thermostats.

Heatpump convectors – Multiple rooms

Setup

Benefits

▪ Easy. Same installation as for one room, but with thermostatic

valves.

Underfloor heating or radiators – Multiple external

room thermostats

Setup

A Main leaving water temperature zone

B Room 1

C Room 2

a External room thermostat

b Bypass valve

▪ For each room, a shut-off valve (field supplied) is installed to avoid

leaving water supply when there is no heating demand.

▪ A bypass valve must be installed to make water recirculation

possible when all shut-off valves are closed. To guarantee reliable

operation, provide a minimum water flow as described in table "To

check the water volume and flow rate" in "6.4 Preparing water

piping"on page25.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

A Main leaving water temperature zone

B Room 1

C Room 2

a Remote controller of the heatpump convectors

▪ The desired room temperature is set via the remote controller of

the heatpump convectors.

▪ The user interface connected on the indoor unit decides the space

operation mode.

▪ The heating demand signals of each heat pump convector are

connected in parallel to the digital input on the indoor unit (X2M/1

and X2M/4). The indoor unit will only supply leaving water

temperature when there is an actual demand.

INFORMATION

To increase comfort and performance, Daikin recommends

to install the valve kit option EKVKHPC on each heatpump

convector.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

1 (External room thermostat):

Unit operation is decided by the

external thermostat.

▪ Code: [C-07]

Installer reference guide

13

Page 14

5 Application guidelines

b

B C

A

a

M1

B

A

a a

C

E

D

b

c

d

Setting Value

Number of water temperature

0 (Single zone): Main

zones:

▪ #: [4.4]

▪ Code: [7-02]

Benefits

Compared with heatpump convectors for one room:

▪ Comfort. You can set the desired room temperature, including

schedules, for each room via the remote controller of the

heatpump convectors.

Combination: Underfloor heating + Heatpump

convectors – Multiple rooms

Setup

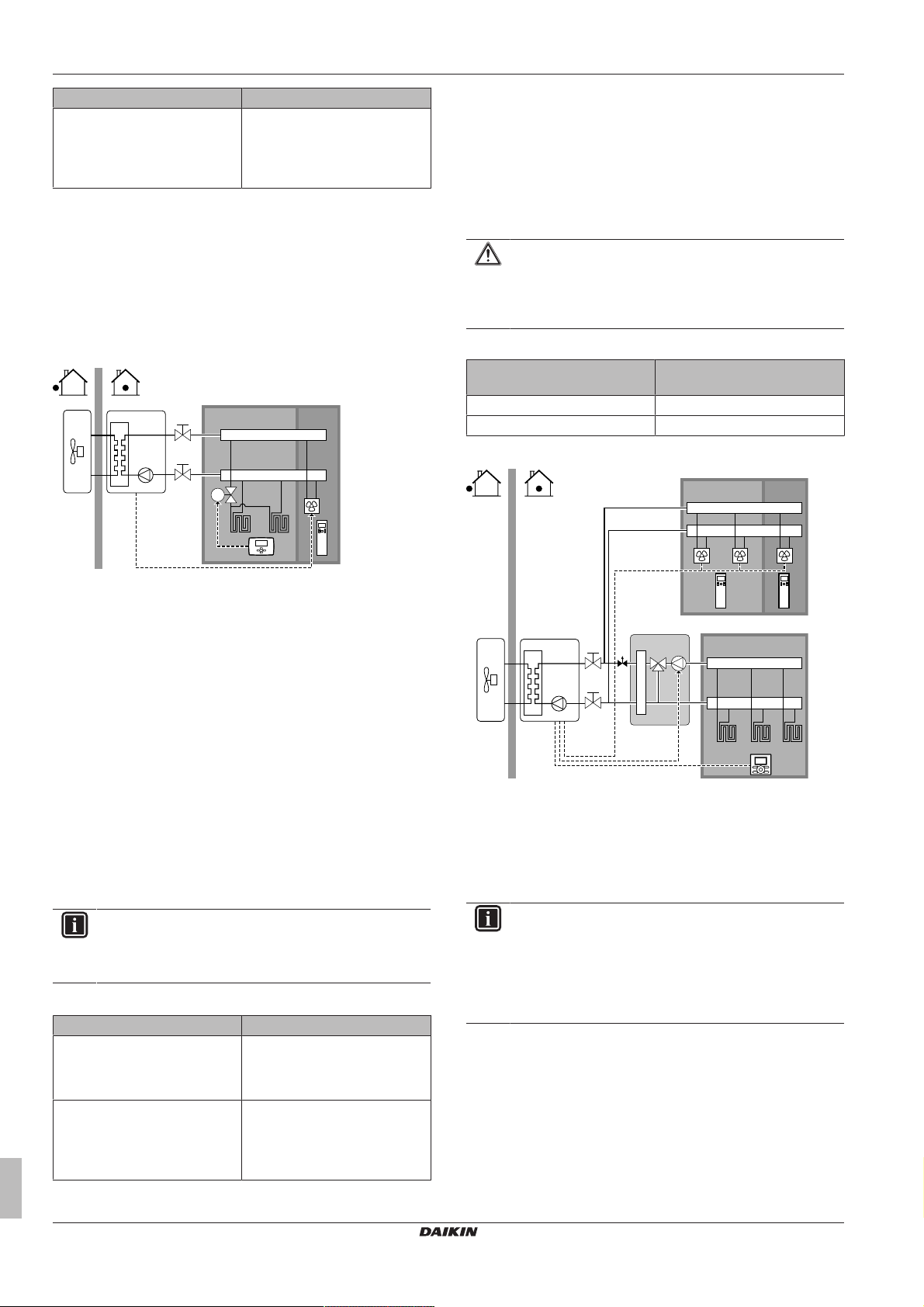

5.2.3 Multiple rooms – TwoLWT zones

If the heat emitters selected for each room are designed for different

leaving water temperatures, you can use different leaving water

temperature zones (maximum 2).

In this document:

▪ Main zone = Zone with the lowest design temperature

▪ Additional zone = Zone with the highest design temperature

CAUTION

When there is more than one leaving water zone, you must

ALWAYS install a mixing valve station in the main zone to

decrease (in heating) the leaving water temperature when

the additional zone has demand.

Typical example:

Room (zone) Heat emitters: Design

temperature

Living room (main zone) Underfloor heating: 35°C

Bed rooms (additional zone) Heatpump convectors: 45°C

Setup

A Main leaving water temperature zone

B Room 1

C Room 2

a External room thermostat

b Remote controller of the heatpump convectors

▪ For each room with heat pump convectors: The heat pump

convectors are directly connected to the indoor unit.

▪ For each room with under floor heating: A shut-off valve (field

supply) is installed before the underfloor heating. It prevents hot

water supply when the room has no heating demand.

▪ For each room with heat pump convectors: The desired room

temperature is set via the remote controller of the heat pump

convectors.

▪ For each room with under floor heating: The desired room

temperature is set via the external room thermostat (wired or

wireless).

▪ The user interface connected to the indoor unit decides the space

operation mode. Mind that the operation mode on each external

room thermostat and remote controller of the heat pump

convectors must be set to match the indoor unit.

INFORMATION

To increase comfort and performance, Daikin recommends

to install the valve kit option EKVKHPC on each heatpump

convector.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

0 (Leaving water): Unit operation

is decided based on the leaving

water temperature.

▪ Code: [C-07]

Number of water temperature

zones:

▪ #: [4.4]

▪ Code: [7-02]

0 (Single zone): Main

A Additional leaving water temperature zone

B Room 1

C Room 2

D Main leaving water temperature zone

E Room 3

a Remote controller of the heatpump convectors

b User interface used as room thermostat

c Mixing valve station

d Pressure regulating valve

INFORMATION

A pressure regulating valve should be implemented before

the mixing valve station. This is to guarantee the correct

water flow balance between the main leaving water

temperature zone and the additional leaving water

temperature zone in relation to the required capacity of

both water temperature zones.

▪ For the main zone:

▪ A mixing valve station is installed before the underfloor heating.

▪ The pump of the mixing valve station is controlled by the ON/

OFF signal on the indoor unit (X2M/29 and X2M/21; normal

closed shut-off valve output).

▪ The room temperature is controlled by the user interface, which

is used as room thermostat (optional equipment EKRUDAS).

Installer reference guide

14

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 15

5 Application guidelines

a b c e f

f

g h j

FHL1

FHL2

FHL3

M

h

i

il

k

m

n

d

▪ For the additional zone:

▪ The heat pump convectors are directly connected to the indoor

unit.

▪ The desired room temperature is set via the remote controller of

the heatpump convectors for each room.

▪ The heating demand signals of each heatpump convector are

connected in parallel to the digital input on the indoor unit

(X2M/35 and X2M/30). The indoor unit will only supply the

desired additional leaving water temperature when there is an

actual demand.

▪ The user interface connected to the indoor unit decides the space

operation mode. Mind that the operation mode on each remote

controller of the heatpump convectors must be set to match the

indoor unit.

Configuration

Setting Value

Unit temperature control:

▪ #: [2.9]

▪ Code: [C-07]

2 (Room thermostat): Unit

operation is decided based on

the ambient temperature of the

user interface.

Note:

▪ Main room = user interface

used as room thermostat

functionality

▪ Other rooms = external room

thermostat functionality

Number of water temperature

1 (Dual zone): Main + additional

zones:

▪ #: [4.4]

▪ Code: [7-02]

In case of heatpump convectors:

External room thermostat for the

additional zone:

▪ #: [3.A]

1 (1 contact): When the used

external room thermostat or

heatpump convector can only

send a thermo ON/OFF

condition.

▪ Code: [C-06]

Shut-off valve output Set to follow the thermo demand

of the main zone.

At the mixing valve station Set the desired main leaving

water temperature.

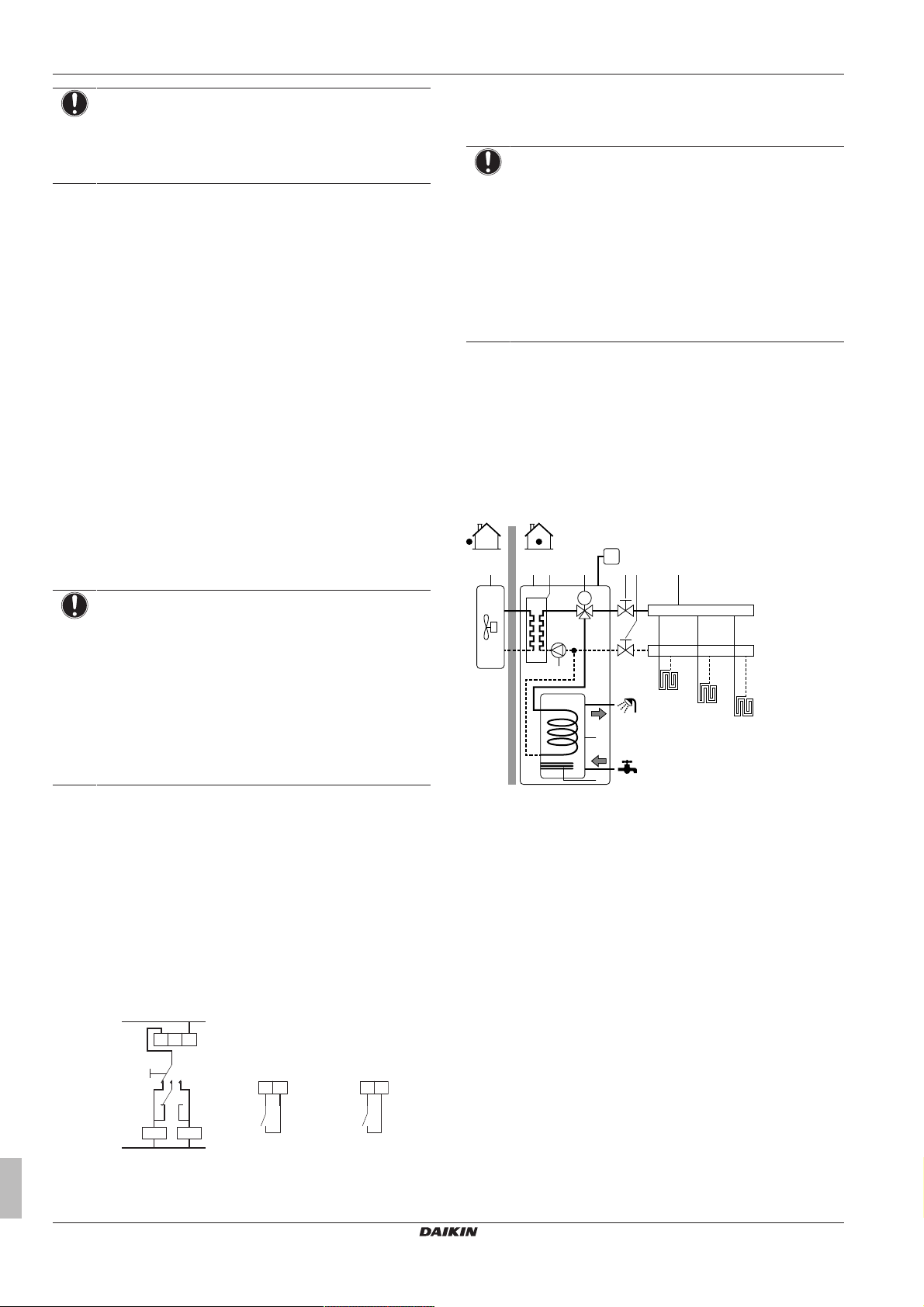

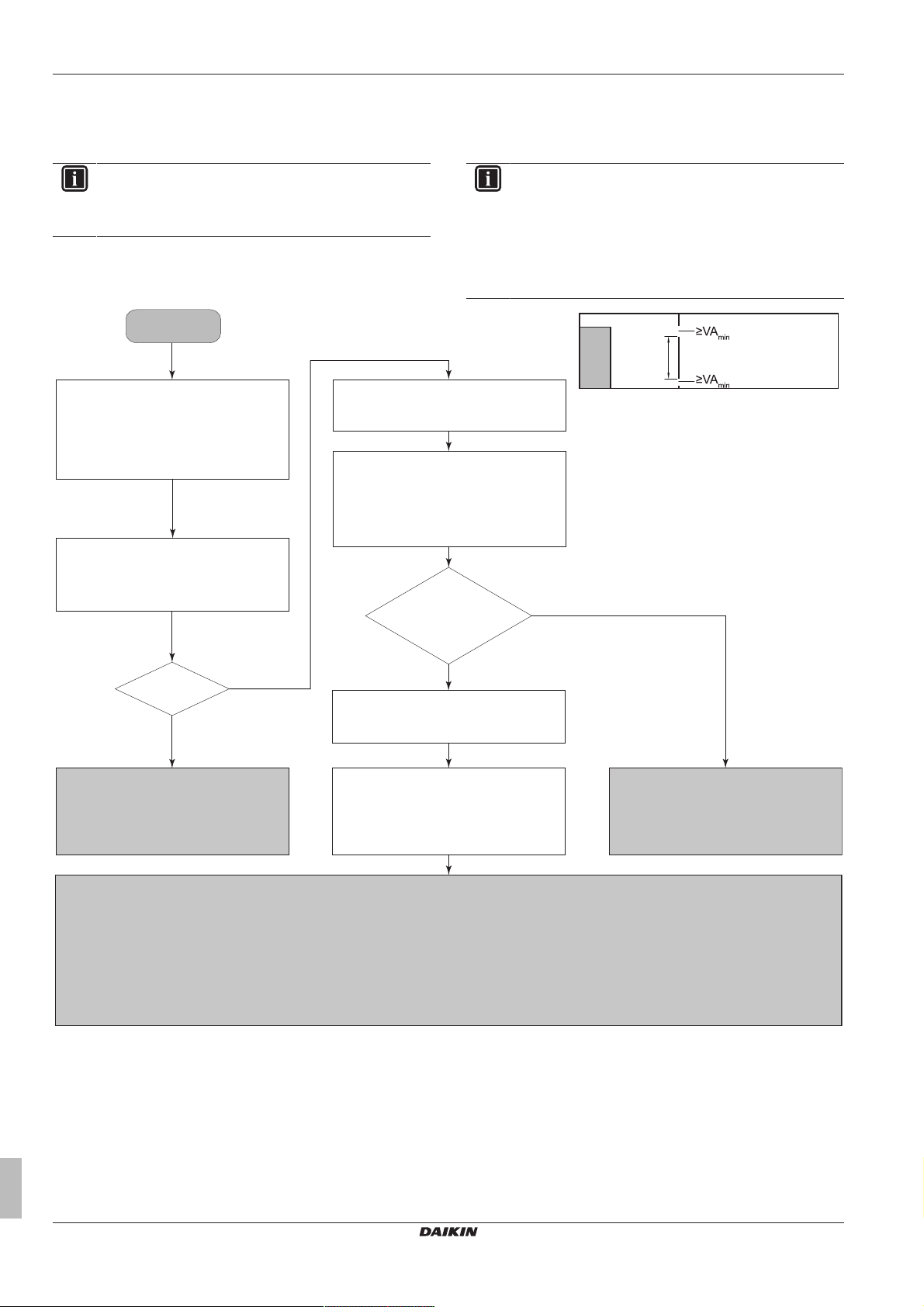

5.3 Setting up an auxiliary heat source for space heating

▪ Space heating can be done by:

▪ The indoor unit

▪ An auxiliary boiler (field supply) connected to the system

▪ When the room thermostat requests heating, the indoor unit or the

auxiliary boiler starts operating depending on the outdoor

temperature (status of the changeover to external heat source).

When the permission is given to the auxiliary boiler, the space

heating by the indoor unit is turned OFF.

▪ Bivalent operation is only possible for space heating, NOT for

domestic hot water production. Domestic hot water is always

produced by the DHW tank connected to the indoor unit.

INFORMATION

▪ During heating operation of the heat pump, the

heat pump operates to achieve the desired

temperature set via the user interface. When weatherdependent operation is active, the water temperature is

determined automatically depending on the outdoor

temperature.

▪ During heating operation of the auxiliary boiler, the

auxiliary boiler operates to achieve the desired water

temperature set via the auxiliary boiler controller.

Setup

▪ Integrate the auxiliary boiler as follows:

Benefits

▪ Comfort.

▪ The smart room thermostat functionality can decrease or

increase the desired leaving water temperature based on the

actual room temperature (modulation).

▪ The combination of the two heat emitter systems provides the

excellent heating comfort of the under floor heating, and the

rapid air heat up of the heat pump convectors (e.g., living

room=under floor heating and the bedroom=convector (no

continuous heating)).

▪ Efficiency.

▪ Depending on the demand, the indoor unit supplies different

leaving water temperature matching the design temperature of

the different heat emitters.

▪ Underfloor heating has the best performance with Altherma LT.

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

a Outdoor unit

b Indoor unit

c Heat exchanger

d Anti-legionella heater

e Pump

f Shut-off valve

g Motorised 3‑way valve

h Non-return valve (field supply)

i Shut-off valve (field supply)

j Collector (field supply)

k Auxiliary boiler (field supply)

l Aquastat valve (field supply)

m DHW tank

n Heat exchanger coil

FHL1...3 Underfloor heating

Installer reference guide

15

Page 16

5 Application guidelines

L

N

H

Com

A

K2AK1A

X2M

B

TI

K2AK1A

Indoor/Auto/Boiler

3530 X Y

Indoor

FHL1

FHL2

FHL3

M

UI

a b c hh if

e

g

d

NOTICE

▪ Make sure the auxiliary boiler and its integration in the

system complies with applicable legislation.

▪ Daikin is NOT responsible for incorrect or unsafe

situations in the auxiliary boiler system.

▪ Make sure the return water to the heatpump does NOT exceed

55°C. To do so:

▪ Set the desired water temperature via the auxiliary boiler

controller to maximum 55°C.

▪ Install an aquastat valve in the return water flow of the

heatpump.

▪ Set the aquastat valve to close above 55°C and to open below

55°C.

▪ Install non-return valves.

▪ Make sure to only have one expansion vessel in the water circuit.

An expansion vessel is already pre-mounted in the indoor unit.

▪ Install the digital I/O PCB (option EKRP1HB).

▪ Connect X1 and X2 (changeover to external heat source) on the

digital I/O PCB to the auxiliary boiler thermostat.

▪ To setup the heat emitters, see "5.2Setting up the space heating

system"on page11.

Configuration

Via the user interface (quick wizard):

▪ Set the use of a bivalent system as external heat source.

▪ Set the bivalent temperature and hysteresis.

K2A Auxiliary relay for activation of boiler (field supply)

Indoor Indoor unit

Auto Automatic

Boiler Boiler

NOTICE

▪ Make sure the auxiliary contact has enough differential

or time delay to prevent frequent changeover between

indoor unit and auxiliary boiler.

▪ If the auxiliary contact is an outdoor temperature

thermostat, install the thermostat in the shadow so that

it is NOT influenced or turned ON/OFF by direct

sunlight.

▪ Frequent changeover may cause corrosion of the

auxiliary boiler. Contact the manufacturer of the

auxiliary boiler for more information.

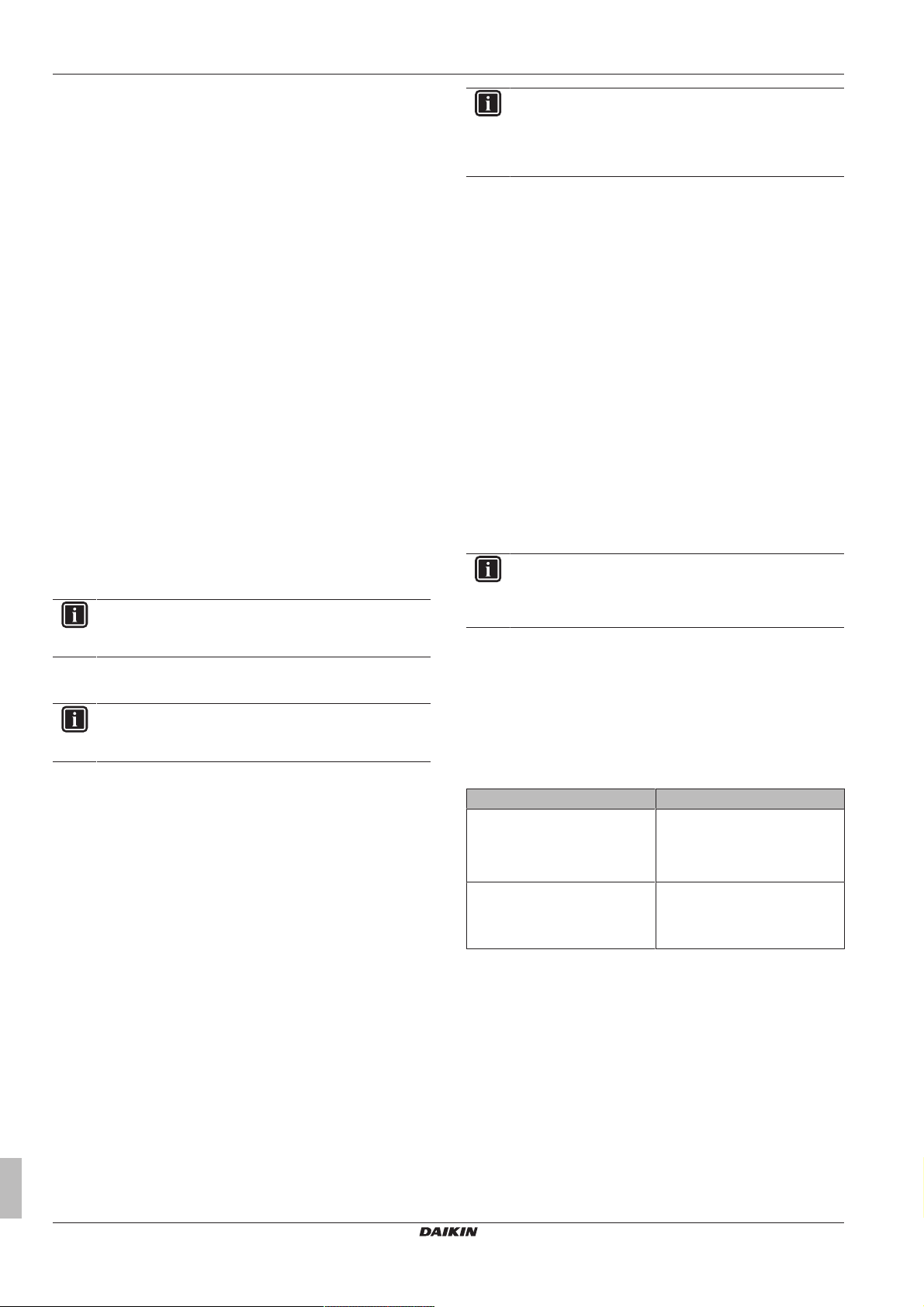

5.4 Setting up the domestic hot water tank

The DHW tank is integrated in the indoor unit, and contains a 2.4kW

anti-legionella heater. The anti-legionella heater contains 2 safeties:

a thermal cut-out and a thermal fuse. If a certain temperature is

exceeded, the safeties deactivate the anti-legionella heater.

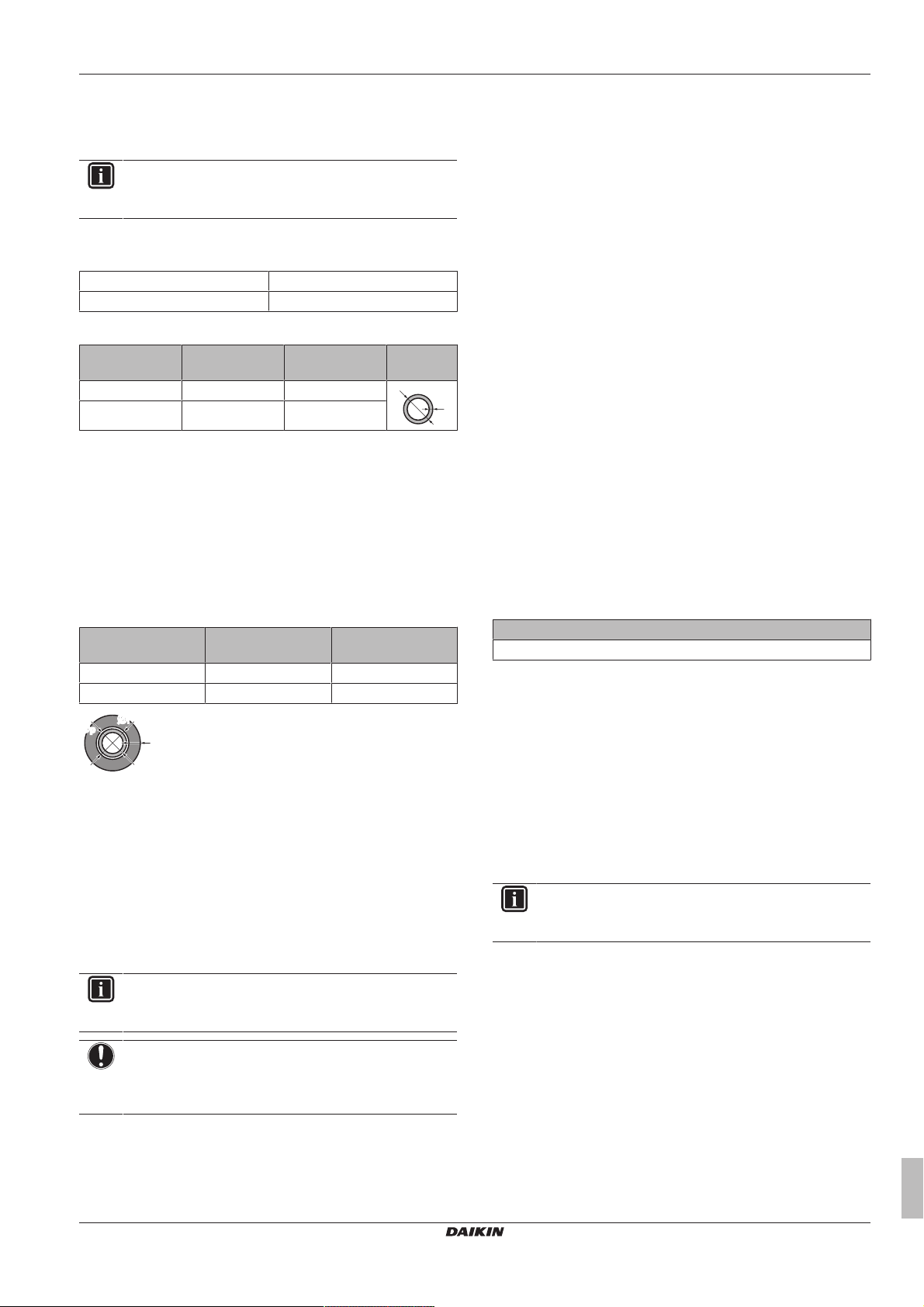

5.4.1 System layout – Integrated DHW tank

Changeover to external heat source decided by an auxiliary

contact

▪ Only possible in external room thermostat control AND one

leaving water temperature zone (see "5.2 Setting up the space

heating system"on page11).

▪ The auxiliary contact can be:

▪ An outdoor temperature thermostat

▪ An electricity tariff contact

▪ A manually operated contact

▪ …

▪ Setup: Connect the following field wiring:

Installer reference guide

16

NOTICE

▪ Make sure the bivalent hysteresis has enough

differential to prevent frequent changeover between

indoor unit and auxiliary boiler.

▪ Because the outdoor temperature is measured by the

outdoor unit air thermistor, install the outdoor unit in the

shadow so that it is NOT influenced or turned ON/OFF

by direct sunlight.

▪ Frequent changeover may cause corrosion of the

auxiliary boiler. Contact the manufacturer of the

auxiliary boiler for more information.

BTIBoiler thermostat input

A Auxiliary contact (normal closed)

H Heating demand room thermostat (optional)

K1A Auxiliary relay for activation of indoor unit (field supply)

a Outdoor unit

b Indoor unit

c Heat exchanger

d Anti-legionella heater

e Pump

f Motorised 3‑way valve

g DHW tank

h Shut-off valve

i Collector (field supply)

FHL1...3 Underfloor heating

UI User interface

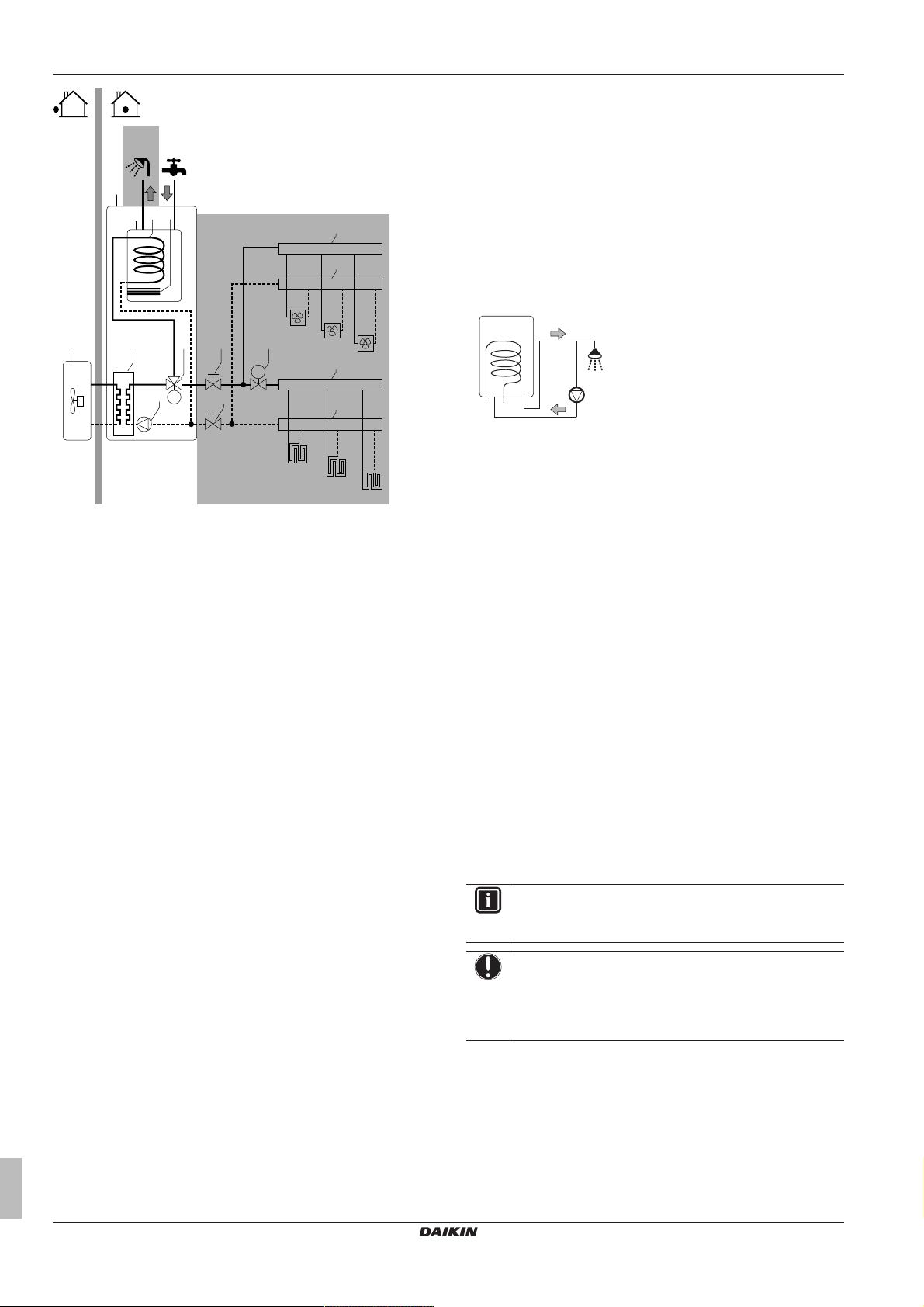

5.4.2 Selecting the volume and desired temperature for the DHW tank

People experience water as hot when its temperature is 40°C.

Therefore, the DHW consumption is always expressed as equivalent

hot water volume at 40°C. However, you can set the DHW tank

temperature at a higher temperature (example: 53°C), which is then

mixed with cold water (example: 15°C).

Selecting the desired temperature for the DHW tank consists of:

1 Determining the DHW consumption (equivalent hot water

volume at 40°C).

2 Determining the desired temperature for the DHW tank.

Determining the DHW consumption

Answer the following questions and calculate the DHW consumption

(equivalent hot water volume at 40°C) using typical water volumes:

ERGA04~08DAV3(A) + EHVH04+08S23DAV

Daikin Altherma – Low temperature split

4P499573-1A – 2018.11

Page 17

5 Application guidelines

c

f

a

j

b

g

h

i

c

a

d f

e g

h

i

j

b

Question Typical water volume

How many showers are needed

per day?

How many baths are needed per

day?

How much water is needed at the

kitchen sink per day?

Are there any other domestic hot

water needs?

1shower = 10min×10l/min =

100l

1bath = 150l

1sink = 2min×5l/min = 10l

—

▪ The higher the outdoor temperature, the better the performance of

the heatpump.

▪ If energy prices are the same during the day and the night,

Daikin recommends to heat up the DHW tank during the day.

▪ If energy prices are lower during the night, Daikin recommends

to heat up the DHW tank during the night.

▪ When the heatpump produces domestic hot water, it cannot heat

up a space. In case you need domestic hot water and space

heating at the same, Daikin recommends to produce the domestic

hot water during the night when there is lower space heating

Example: If the DHW consumption of a family (4 persons) per day

demand.

is as follows:

▪ 3 showers

▪ 1 bath

▪ 3 sink volumes

Then the DHW consumption = (3×100l)+(1×150l)+(3×10l)=480l

Determining the volume and desired temperature for the DHW

tank

Formula Example

V1=V2+V2×(T2−40)/(40−T1) If:

▪ V2=180l

▪ T2=54°C

▪ T1=15°C

5.4.3 Setup and configuration – DHW tank

▪ For large DHW consumptions, you can heat up the DHW tank

several times during the day.

▪ To heat up the DHW tank to the desired DHW tank temperature,

you can use the following energy sources:

▪ Thermodynamic cycle of the heatpump

▪ Anti-legionella heater

▪ For more information about optimizing the energy consumption for

producing domestic hot water, see "8Configuration"on page47.

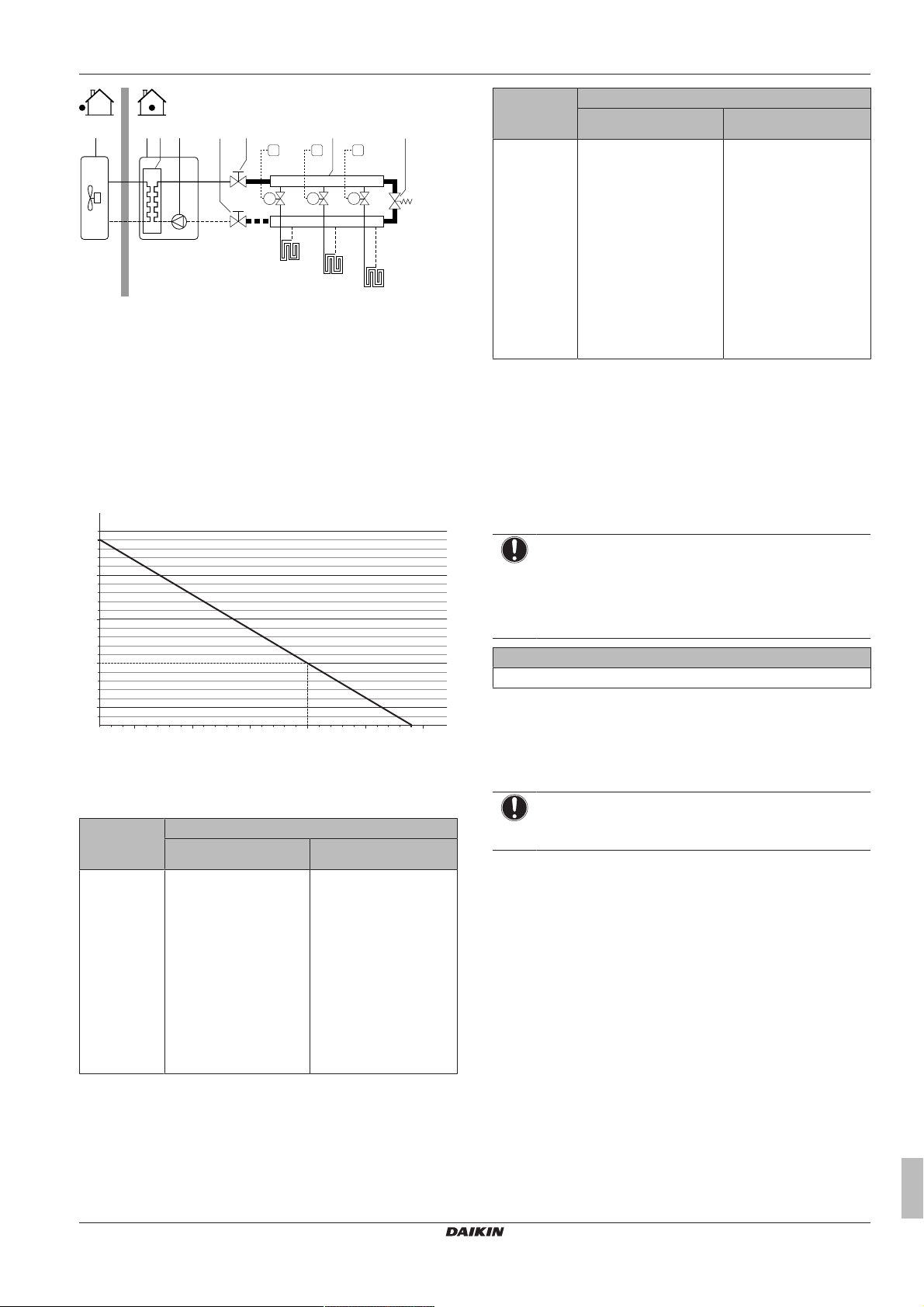

5.4.4 DHW pump for instant hot water

Setup

Then V1=280l

V2=V1×(40−T1)/(T2−T1) If:

▪ V1=480l

▪ T2=54°C

▪ T1=15°C

Then V2=307l

V1DHW consumption (equivalent hot water volume at 40°C)

V2Required DHW tank volume if only heated once

T2DHW tank temperature

T1Cold water temperature

Possible DHW tank volumes

Type Possible volumes

Integrated DHW tank ▪ 230l

Energy saving tips

▪ If the DHW consumption differs from day to day, you can program

a weekly schedule with different desired DHW tank temperatures

for each day.

▪ The lower the desired DHW tank temperature, the more cost

effective. By selecting a larger DHW tank, you can lower the

desired DHW tank temperature.

▪ The heatpump itself can produce domestic hot water of maximum

55°C (50°C if outdoor temperature is low). The electrical

▪ By connecting a DHW pump, instant hot water can be available at

the tap.

▪ The DHW pump and the installation are field supply and the

responsibility of the installer.

▪ For more information about connecting the recirculation

connection: see "7Installation"on page29.

Configuration

▪ For more information, see "8Configuration"on page47.

▪ You can program a schedule to control the DHW pump via the

user interface. For more information, see the user reference

guide.

a Indoor unit

b DHW tank

c DHW pump (field supply)

f Shower (field supply)

g Cold water

h Domestic hot water OUT

i Recirculation connection

j Anti-legionella heater