Page 1

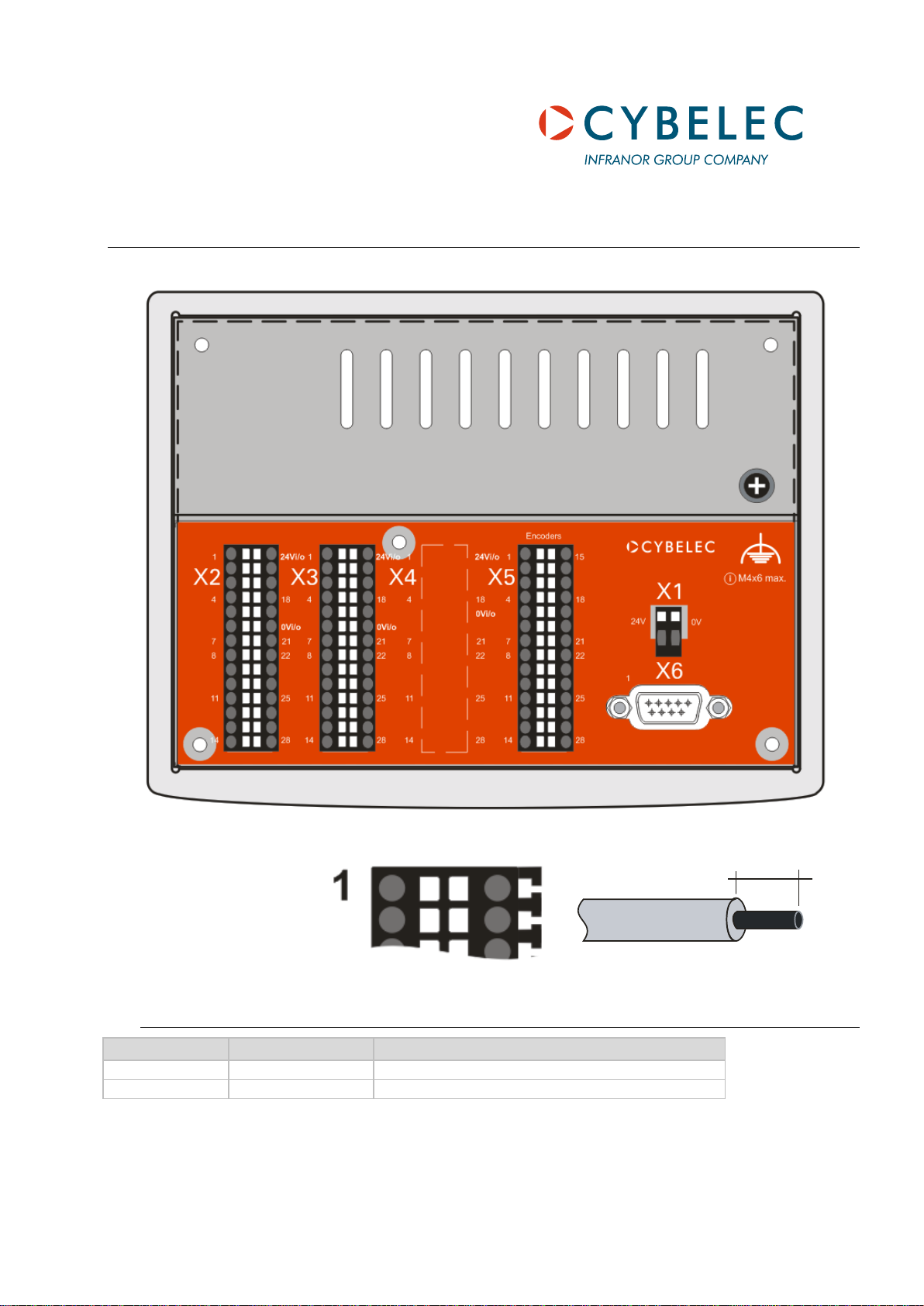

CybTouch 6 P

for Press Brake with Torsion Bar

Technical Manual

Page 2

Numerical Control CybTouch 6 P for Conventional Press Brakes

Option: Earthing kit to easily mount and earth the

cable shields.

Option: Wireless RFlink USB key for PC.

The CybTouch 6 P for conventional* press brakes is specifically intended for sheet metal bending.

*Press brakes with torsion bar.

Options

Ordering information

Product: Reference number:

CybTouch 6 P

Without earthing kit S-CT6-1B1612PNN

With earthing kit S-CT6-1B1612PNA

Earthing kit (option), see above S-CT6-OPT_A

RFlink USB key for PC (option), with CybTouchTools software S-OPT-RFLINK

CDS_CybTouch6_P_v1.1.doc 1/5

Page 3

Advantages

FOR OEM

FOR END USER

3A outputs for direct operation of non safety

valves without passing through relays.

Can easily be integrated into existing

electrical box diagrams. Ideal for upgrading

machines without NC with minimal

changes.

Reduced electrical wiring, electrical cabinet

size and equipment for lower start-up costs

on each press brake.

Flexible software for configuration of axes,

inputs-outputs and auxiliary functions

according to specific needs.

Screen content can be simplified to its

minimum by removing all unnecessary

functions, buttons or information.

Quick set-up thanks to wizards for adjusting

axes, gains, speeds, beam and indexes.

New indexing functions reduce the quantity

of switches and wiring, while providing

more reliable indexing.

CybTouch 6 accepts encoders with or

without complementary signals.

RFlink, a wireless radio frequency

transmission integrated in the CybTouch,

allows easy parameters backups or

firmware upgrades. This provides modern,

fast and simple communication, with no

need to open the housing, no need of

connecting cable *.

Very intuitive, no explanations required.

Operator immediately feels confident and

comfortable using this control.

User intuitively enters the angle, the desired

position of the bend and the thickness of the

material. No need to erase, memorize or

change modes. The depth and back gauges,

pressure and crowning are automatically

adjusted.

EasyBend page provides immediate easy use

of the machine: a second operator can briefly

interrupt production without changing the

program when an urgent bend is required.

Energy saving thanks to integrated Eco mode

function that automatically stops the main

pump after x minutes of inactivity.

Full touch screen human machine interface

offers the best of modern technology.

Colors are vivid but not aggressive, providing

excellent readability thanks to the large

characters and big buttons.

Recurrent programs for producing complex

parts can be created and memorized for easy

reuse.

Pop-up messages for security or external

malfunctions.

RFlink wireless radio frequency data

communication allows backup and restoring

operations without any cable connection to the

numerical control *.

Many languages available directly in the

CybTouch 6.

Internal backup in a special safe memory

allows the user to restore at any time the

original parameters; machine is running again

in an extremely short time in the event of a

memory loss or involuntary parameter

modification.

CDS_CybTouch6_P_v1.1.doc 2/5

*Need RFlink USB key (option)

Page 4

Axis and bending functions

Back gauge axis & depth gauges

Auto-tuning of the axes.

Configurable retraction of the back gauge during the bending process.

Indexing in several modes.

Encoders with or without complementary signals.

Inch / mm.

Bending features

Program page at start up for quick accessibility.

User friendly tool management.

Automatic calculation of:

Bend depth.

Bend pressure.

Back gauge positioning.

Crowning.

Angle correction.

Bend allowance.

According to the programmed material, thickness, bend angle and selected tools.

Pressure management.

Crowning (pressure or mechanical type).

Up to 10 pre-programmable types of materials.

Backgauge clearance during the bending process (yes / no).

Automatic back gauge correction according to the bend and flange length.

Sequence repetition.

Part counter with auto-stop.

Time and stroke counters for oil service.

Eco mode.

Pump start button.

The below elements are available and can be configured on CybTouch P by the OEM. However, some functions

depend on the machine construction.

Available features depend on the number of available axes and inputs/outputs.

CDS_CybTouch6_P_v1.1.doc 3/5

Page 5

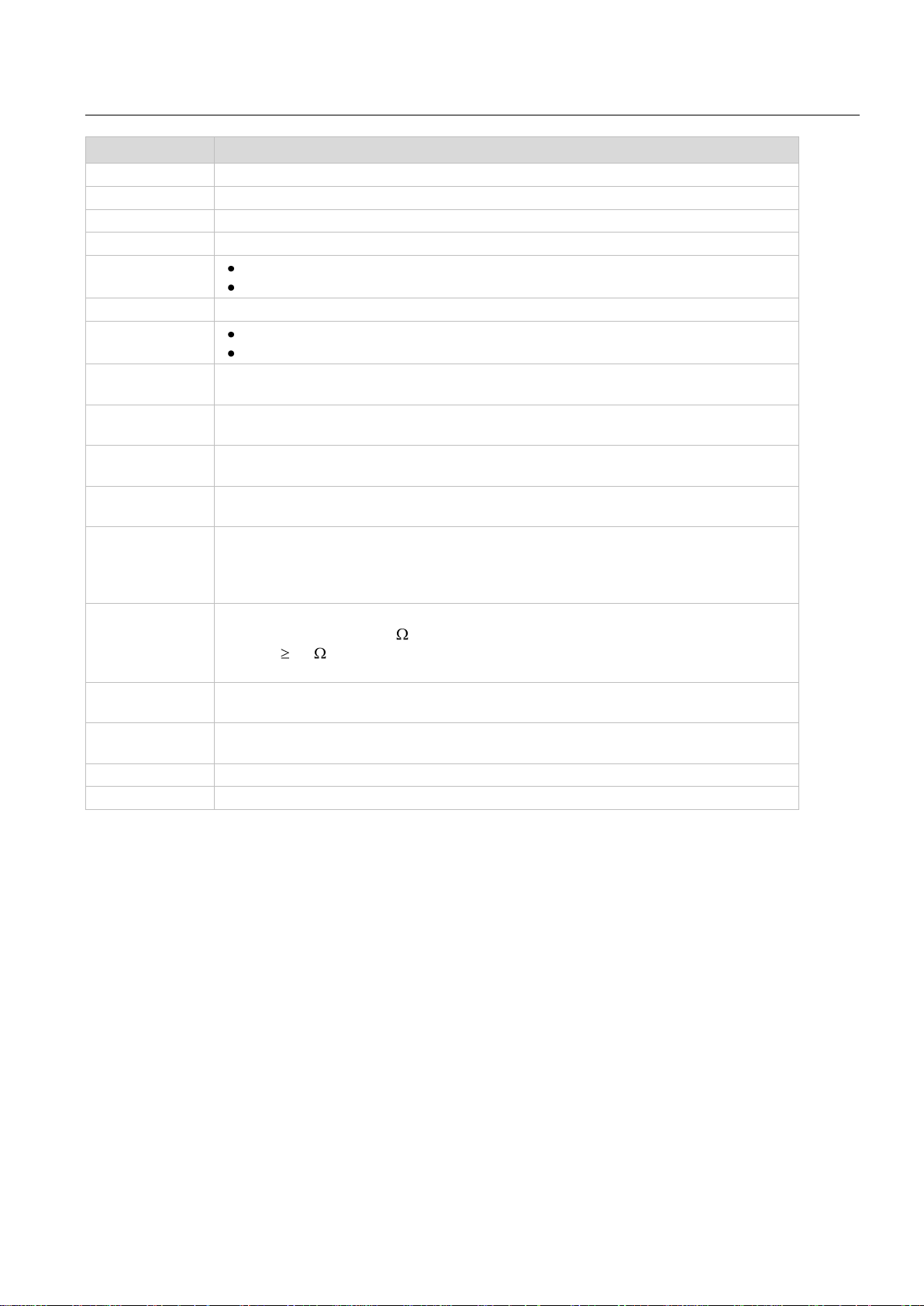

Technical Characteristics

Characteristic

CybTouch 6 P

Screen

5.7" color graphic CRT screen 640 x 480 pixels with LED backlight control.

Work memory

SRAM

System memory

FLASH memory with firmware update via RFlink.

Communication

Cybelec RFlink (radio frequency link).

Axis

+/- 10VDC management of AC/DC drives and motors, or

0-10 VDC frequency converter for AC asynchronous motors.

Units

Conversion Inch/mm.

Power supplies

NC: stabilized + 24VDC -15% / + 20% 15W

digital inputs/outputs: stabilized + 24VDC -15% / + 20% 24V_I/O

Encoder inputs

5 VDC or 12 VDC* or 24 VDC* (* = external power supply).

Complementary signals are not necessary, but recommended.

Power supplies

for encoders

5 VDC (supplied by CybTouch) max. 250 mA for each encoder.

Optocoupled

Digital inputs

16 inputs.

Analog inputs

2 analog inputs 0-10 VDC.

Short circuit proof.

Digital outputs

12 outputs

Optocoupled short circuit proof.

24 VDC source mode, max. 3A.

Possibility to define 2 outputs for doubling the current.

Analog outputs

4 analog outputs -/+10 VDC,

impedance out < 100 ,

load 2 k (max 15 mA).

Short circuit proof.

Reference

voltage

One of the above analog outputs is used for the 10VDC reference.

Operating

conditions

Min. 5° Celsius, max. 40° Celsius.

Relative humidity 10 to 85% noncondensing. DMA

Dimensions

See diagram next page.

EC Directives

IEC61131-2 type 1-3 compliant.

CDS_CybTouch6_P_v1.1.doc 4/5

Page 6

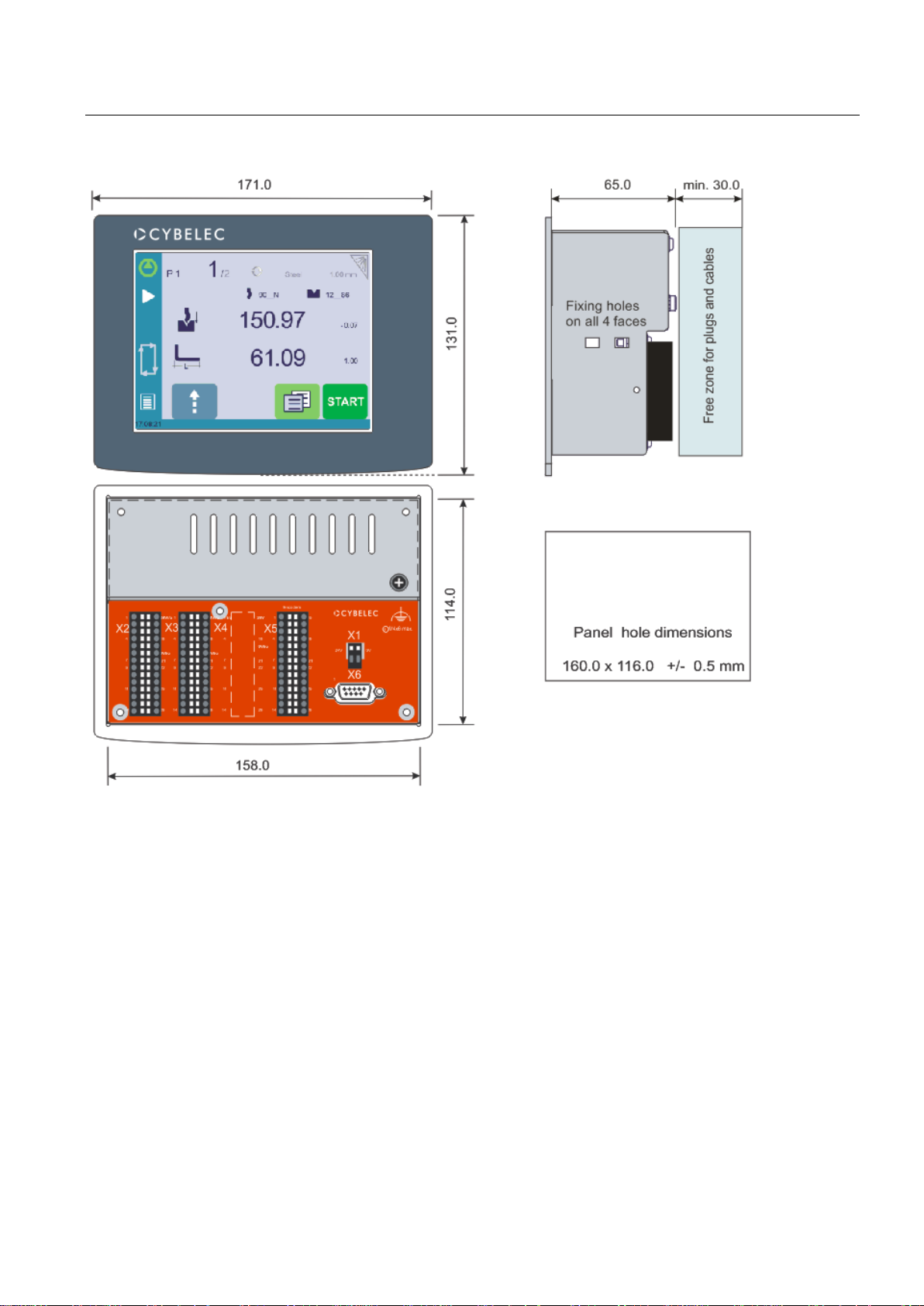

Dimensions

CybTouch 6 P for conventional press-brakes, 2 axes, 16 inputs, 12 outputs:

CDS_CybTouch6_P_v1.1.doc 5/5

Page 7

Rue des Uttins 27 CH-1401 Yverdon Switzerland TEL:+ 41 24 447 02 00 FAX:+ 41 24 447 02 01 E-Mail: info@cybelec.ch

Connectors X2 to X5 =

Weidmüller B2L 3.5/28/180

SN BK

Max 4 A / connector pin.

max 8 mm0.75 mm

2

X1

Signal

Default I/0

1

24 V

24 VDC DNC

2

0V

0V DNC

Input/output list for CybTouch 6 P (16/12 i/o)

X1 Power Connector

CybTouch6_P_1612io_v1.1b.doc Page 1 of 6

Page 8

A 4 wires shielded cable must

be used for the potentiometer.

X3/27and X3/28 terminals

must be connected together

at one side of the potentiometer.

Generalities

All 0V_I/O pins are connected together.

All digital outputs are capable to drive load (for example valves) up to 3 A maximum.

Digital outputs are short-circuit and overload protected.

Inductive loads must be equipped with surge suppressors.

The 24V_I/O pins from connectors X2 and X5 are connected together.

The symbols mentioned in this list (,,) are only a sample of use.

See basic diagram also.

Crowning Wiring

CybTouch6_P_1612io_v1.1b.doc Page 2 of 6

Page 9

X2

Signal

Default I/0

X2

Signal

Default I/0

1

24V_I/O

24 VDC electrical box in

Max 4 A / connector pin.

15

24V_I/O

24 VDC electrical box in

Max 4 A / connector pin.

2

OUT 1

Pump on / Eco mode off

16

IN 1

Pressure reached

3

OUT 2

Machine ready

17

IN 2

X retraction

4

0V_I/O

0 V electrical box out

18

IN 3

TDC

5

OUT 3

Enable X axis

19

IN 4

Start

6

OUT 4

X moving

20

0V_I/O

0 V electrical box in

7

0V_I/O

0 V electrical box out

21

IN 5

Stop

8

OUT 5

Enable Y axis

22

IN 6

X index zone

9

OUT 6

23

IN 7

Y index zone

10

0V_I/O

0 V electrical box out

24

IN 8

11

AOUT 1

X analog out

25

0Vanalog

0V analog

12

0Vanalog

X 0V analog out

26

AIN1 +

13

AOUT 2

Y analog out

27

AIN1 -

14

0Vanalog

Y 0V analog out

28

0Vanalog

0V analog

X3

Signal

Default I/0

X2

Signal

Default I/0

1

24V_I/O

24 VDC electrical box in

Max 4 A / connector pin.

15

24V_I/O

24 VDC electrical box in

Max 4 A / connector pin.

2

OUT 7

Return to TDC

16

IN 9

3

OUT 8

17

IN 10

4

0V_I/O

0 V electrical box out

18

IN 11

5

OUT 9

19

IN 12

6

OUT 10

20

0V_I/O

0 V electrical box in

7

0V_I/O

0 V electrical box out

21

IN 13

8

OUT 11

22

IN 14

9

OUT 12

23

IN 15

10

0V_I/O

0 V electrical box out

24

IN 16

11

AOUT 3

Proportional pressure valve (0-10VDC)

25

0Vanalog

0V analog

12

0Vanalog

26

AIN2 +

Crowning potentiometer / cursor *

13

AOUT 4

10 VDC reference

27

AIN2 -

Crowning potentiometer / 0V ,

14

0Vanalog

28

0Vanalog

Crowning potentiometer / 0V -

Refer to electrical box wiring diagram

All pin attributions below are programmable. The list below is a default proposal.

X2 I/O Connector

X3 I/O Connector

* Crowning depends on the machine and can be set or not in machine parameters.

CybTouch6_P_1612io_v1.1b.doc Page 3 of 6

Page 10

X5

Signal

Assignation

X5

Signal

Assignation

1

5V encoder

5V out for encoder X

15

Z1+

Index encoder X

2

0V encoder

0V out for encoder X

16

Z1 -

Index - encoder X

3

A1+

A signal of encoder X

17

B1+

B signal of encoder X

4

A1 -

A - signal of encoder X

18

B1 -

B - signal of encoder X

5

0V encoder

19

0V encodeur

6

5V encoder

5V out for encoder Y

20

Z2+

Index encoder Y

7

0V encoder

0V out for encoder Y

21

Z2 -

Index - encoder Y

8

A2+

A signal of encoder Y

22

B2+

B signal of encoder Y

9

A2 -

A - signal of encoder Y

23

B2 -

B - signal of encoder Y

10

0V encoder

24

0V encodeur

11

5V encoder

25

Z3+

12

0V encoder

26

Z3 -

13

A3+

27

B3+

14

A3 -

28

B3 -

Z+ Z-

X5 Encoder Connector

Use twisted pair cables for encoder signals.

Do not invert index signals (normal and inverted, Z+ and Z-).

It will result in a bad indexation procedure (lost of precision) difficult to trace or no indexation at all. If this

happens try to invert index signals.

Use twisted pair cables for encoder signals.

Encoder inputs support 12VDC and 24VDC signals. In this case encoder must be powered externally with its own power supply.

Encoder inputs support encoders without inverted signals.

CybTouch6_P_1612io_v1.1b.doc Page 4 of 6

0V encoder must be common. See page 7 of this document for more details.

Page 11

Emitter follower encoder outputs must be

connected to the negative (A+ B+) inputs

on the CybTouch.

Any unused inputs must be left

disconnected.

5V single ended encoders may take their

5V power supply from the CybTouch.

Open collector encoder outputs must be

connected to the positive (A- B-) inputs

on the CybTouch

Any unused inputs must be left

disconnected.

5V single ended encoders may take their

5V power supply from the CybTouch.

Push-pull encoder outputs must be

connected to the positive (A+ B+) inputs

on the CybTouch.

Any unused inputs must be left

disconnected.

5V single ended encoders may take their

5V power supply from the CybTouch.

Differential encoders (TTL / 422 / 485)

are usually 5V powered. All channels

must be connected.

Usually, the 5V of emulated encoders

(servo-drives) output must NOT be

connected to the 5V encoder of the

CybTouch.

This may be dangerous for the drive or

the CybTouch.

But some drives are fully opto-coupled

and 5V encoder must be provided like for

a normal encoder.

Please refer to the drive datasheet.

12 / 24 V Single Ended (Unipolar) Encoders

Encoder inputs support 12VDC and 24VDC signals. In this case encoder must be powered externally with its

own power supply. 0V encoder must be common.

Encoder inputs support encoders without inverted signals.

5 V Differential Encoders / Emulated Encoders

CybTouch6_P_1612io_v1.1b.doc Page 5 of 6

Page 12

4 mm²

0V and gro und connection

X2

24Vio

0Vio

4

7

0Vio

11

14

X3 X4

4

7

0Vio

11

14

Encoders

1

4

7

8

11

14

X1

24V

12

X5

1

M4x6 max.

i

0V

4 mm²

0 V

Power

230 V

supply

24V NC

24V I/O

24 V

Page 13

Default Configuration for Press Brakes

With pressure. With pressure.

Without crowning. With mechanical crowning (potentiometer feedback).

CybTouch6_P_1612io_v1.1b.doc Page 6 of 6

Page 14

0 1 2 3 4 5 6 7 8 9

S10

12345

Q12

6

142

K27

553

12345

12345

K26

6

6

K25

12345

K28

6

F15

1

65432

1

EMO RELAY

65432

L11/5.0

L21/5.0

L31/5.0

G17

1

F17

L1 L2 L3 PE

0V 24V

65432

L1XL2

L3

PE

M12

U

X

UZVXWYPE

M

3~

V

W

PE

YZX

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

MAIN POWER SUPPLY

WITH EXTERNAL FUSES POWER SUPPLY

3x400V - 50/60Hz

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

PUMP MOTOR

NomDate Nom

JFG

MAIN POWER SUPPLY - PUMP MOTOR

POWER SUPPLY SERVO DRIVES

POWER SUPPLY 24VDC FOR COMMAND

SERVO DRIVES

24VDC

0VDC

24VDC POWER SUPPLY MUST BE FILTERED AND REGULATED

RELAYS AND VALVES MUST BE EQUIPPED WITH SUPPRESSORS

POWER SUPPLY

24VDC FOR COMMAND

24V/2.0

0V/2.0

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

12-0130-01PRESS

<

>

2

N° Pg.

17

1

Pg.

Page 15

0 1 2 3 4 5 6 7 8 9

24V/1.7

0V/1.7

U20

24VDC

0VDC 0VDC

13

F20

1

1A

2

K28

14

EMERGENCY

RELAY

13

24VDC BEFORE EMO

24VDC ELECTRICAL BOX

K27

L N

SCHAFFNER FILTER

FN332-1/05

OR SIMILAR

L' N'

K25

14

14

13

55

INFO_2/10.1

24V/5.1

24VDC/3.0

0V/3.1

6mm2

COVER

PE

CYBTOUCH

DIRECTLY CONNECTED TO THE FILTER

1 2 1 15 1 15 20

A20

/3.2

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

TO USE A FILTER IN THE DNC POWER LINE

X1 X1

IT'S HIGHLY RECOMMENDED

X2

24V

24V

X3

24V

24V

0V

X2

OUTPUT CURRENT

11

2

X2

PUMP ON

!! WARNING !!

MAX. 3A

K25

K27

K26

56

22

21

A1

A2

21

/1.3

43

/1.3

65

/1.3

1413

.5

2221

.5

INFO_1/10.1

K26

K25

22

21

A1

A2

A1

K27

A2

21

/1.3

43

/1.3

65

/1.3

1413

2221

.5

21

43

65

1413

5655

H27

/1.2

/1.2

/1.2

.5

.5

X1

X2

S25

1

2

24V

K28

12

A1

A2

21

/1.5

43

/1.5

65

/1.5

1413

.2

POWER SUPPLY

24VDC DNC

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

POWER SUPPLY

24VDC I/O

POWER SUPPLY - DNC - I/O

PUMP START WITH CYBTOUCH START

BUTTON AND INTEGRATED ECO MODE

PUMP START WITH CYBTOUCH START BUTTON AND INTEGRATED ECO MODE

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

EMERGENCY

PUSH-BUTTON

12-0130-01PRESS

EMERGENCY

RELAY

1

<

3

>

N° Pg.

17

2

Pg.

Page 16

0 1 2 3 4 5 6 7 8 9

INFO_3/10.1

24VDC/2.9

47ohm

63V

PROPORTIONAL PRESSURE VALVE

G30

V-A CONVERTER

MVP100

1 2 36 4

R31

5

A20

/2.0

/4.1

40

12 11

X3

0V 10V

41

S32

COVER

RETRACTION

S33

X AXIS

3

P34

4

1516 24V

X2

ENABLE Y

OPTIONAL

24V

1

2

1314

24 1617 18

X2

PRESSURE

REACHED

3

P

4

X2

S36

1718 24V

CYBTOUCH

X2

X3

X3

33 2

TOP DEAD

CENTER

3

4

X2

42

19

K33

1

TOP DEAD FOOTSWITCH

CENTER

2

20 24V

S37

3

DOWN

4

21 24V

13

K32

14

13

21

K33

14

22

21

K34

22

24VDC ELECTRICAL BOX

24VDC/5.7

13

K34

14

470uF

0.5W

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

C31

24V

+

-

51

= IN4007

OR ANY PLUG WITH

INTEGRATED SURPRESSOR

K32

A1

A2

24

2221

25

K33

A1

A2

1413

.7

1413

2221

Y30

PRESSURE

VALVE

MACHINE

READY

RETURN

TO TDC

K34

.6

.7

INFO_4/10.1

OPTIONAL

DECOMPPRESSION

A1

A2

31

2221

3

SPEED

4

23 22

54

+

-

CHANGE

0V

0V/4.00V/2.9

55

+

-

Y39

OPTIONAL

DECOMPRESSION

ACC. TO HYDR. SYST.

S38

0VDC

1413

.9

.7

0V

52

+

-

Y36

BEAM

UP

0V

53

+

-

Y37

BEAM

DOWN LOW SPEED

0V

Y38

OPTIONAL

BEAM DOWN

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

DNC INPUTS - HYDRAULIC COMMAND

PROPORTIONAL PRESSURE VALVE

INTERFACE BY THE ELECTRICAL BOX

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

PRESS

12-0130-01

<

>

2

4

N° Pg.

17

3

Pg.

Page 17

0 1 2 3 4 5 6 7 8 9

MEASURE

CROWNING

ANALOG.CROWNING / SP-SN AND MEASURE WITH POTENTIOMETER

L1

L2

L3

3x400 VAC

A20

/3.2

/5.4

13 27

X3

X3

R41

2-5 kohm

2826

COVER

26

FOR CROWNING WITH PROPORTIONAL VALVE, SEE ON PAGE 4A

!! WARNING !!

A 4 WIRES SHIELDED CABLE MUST

BE USED FOR THE POTENTIOMETER.

X3/27 AND X3/28 TERMINALS

MUST BE CONNECTED TOGETHER

AT ONE SIDE OF THE POTENTIOMETER

INFO_5/10.1

CYBTOUCH

X3

98

27

LINK/4A.4

Q47

K41

1

65432

1

1

K42

65432

65432

21

K42

22

K41

A1

A2

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

21

43

65

2221

SP SN

ANALOG. CROWNING

K42

.7

.7

.7

.2

K41

21

22

A1

A2

0VDC

21

.7

43

.7

65

.7

2221

.1

0V/5.10V/3.9

U2V2W2

M47

ANALOG. CROWNING

M

3~

80

PEWVU

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

DNC INPUTS - HYDRAULIC COMMAND

ANALOG CROWNING

INTERFACE BY THE ELECTRICAL BOX

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

PRESS

12-0130-01

<

>

3

5

N° Pg.

17

4

Pg.

Page 18

0 1 2 3 4 5 6 7 8 9

L11/1.6

L21/1.6

L31/1.6

U50

3x400 VAC

24V/2.9

0V/4.3

T51

1

F51

L1 L2 L3 PE

AC MAINS

65432

AC SERVO-DRIVE CYBMOTION

MOTOR 1

U1 1 5V1 W1 4

24VDC BEFORE EMO

ONLY FOR 230V

SERVO-DRIVE

0VDC

12

11

IO

24V GND

ENC 1 IN

0V/4A.1

3

IO IO

OP2

4 8 6 75PE 2 6 3 13 9 10 14

4

AXIS 1 OK

ENC 1 OUT CMD / CAN

3 1 2 8 9 5 615 7 11 12 6 1

SERVO-AMPLIFIER SETTINGS

PROPORTIONAL GAIN = NO

ACCELERATION / DECELERATION RAMPS = NO

DNC SETTINGS

P09.01 ENABLE +/- 10V

P09.02 CLOSED LOOP = YES / TIME BEFORE ? 0.5s

P11.02 INDEX ZONE REVERSE LOGIC = YES

ANALOG VOLTAGEENABLE

ENABLE

IO

0V 10V

24VDC/3.9

24VDC ELECTRICAL BOX

PL1 NL1

IO IO

24VDC/6.7

XM

1

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

M50

3~

AC BRUSHLESS

MOTOR

234 6XR5 12 11 8 7 2 15 9 14 1

A B Z

M

A/ B/ Z/

INCREMENTAL

ENCODER

13 4 3 10

U V W

U/ V/ W/5V0V

HALL

RESOLVER

/4.1

/6.4

A20

28

9 23 20 14 1321 8 22 8 23

X5 X2 X2 X2

A/ B

Z/

B/ A

7

COVERCOVER

Z

0V

29

30

CYBTOUCH

POSITION

Y AXIS Y AXIS

INDEX ZONE

X2

S57

323324V

1

1

S58

2

Y AXIS

SP + SN -

2

24V

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

Y AXIS

AC SERVO-DRIVE CYBMOTION DUAL

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

12-0130-01PRESS

<

>

4

6

N° Pg.

17

5

Pg.

Page 19

0 1 2 3 4 5 6 7 8 9

U60

SERVO-AMPLIFIER SETTINGS

PROPORTIONAL GAIN = NO

ACCELERATION / DECELERATION RAMPS = NO

DNC SETTINGS

P09.01 ENABLE +/- 10V

P09.02 CLOSED LOOP = YES / TIME BEFORE ? 0.5s

P11.02 INDEX ZONE REVERSE LOGIC = YES

1

IO IO

AC SERVO-DRIVE CYBMOTION

MOTOR 2 ENC 2 IN ENC 2 OUT

U1 1 5V1 W1 4

4 8 6 85PE 2 6 3 13 9 10 14 3 1 2 8 9 9 1015 7 11 12 7 2

OP4 AXIS 2 OK

2

ENABLE

IO

ANALOG VOLTAGEENABLE

0V 10V

CMD / CAN

24VDC/5.9

24VDC ELECTRICAL BOX

PL2 NL2

IO IO

24VDC/4A.0

XM

1

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

M60

3~

AC BRUSHLESS

MOTOR

234 6XR5 12 11 8 7 2 15 9 14 1

A B Z

M

A/ B/ Z/

INCREMENTAL

ENCODER

13 4 3 10

U V W

U/ V/ W/5V0V

HALL

RESOLVER

/5.4

A20

34

4 18 15 12 1116 3 17 5 22

X5 X2 X2 X2

A/ B

Z/

B/ A

2

COVERCOVER

Z

0V

35

36

CYBTOUCH

POSITION

X AXIS X AXIS

INDEX ZONE

X2

37

S67

38

24V

1

1

S68

2

X AXIS

SP + SN -

2

39

24V

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

X AXIS

AC SERVO-DRIVE CYBMOTION DUAL

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

12-0130-01PRESS

<

>

5

8

N° Pg.

17

6

Pg.

Page 20

0 1 2 3 4 5 6 7 8 9

WIRING OPTIONS

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

PRESS

12-0130-01

<

>

6

N° Pg.

17

8

Pg.

Page 21

0 1 2 3 4 5 6 7 8 9

24V/1.7

0V/1.7

U20

24VDC

0VDC 0VDC

13

24VDC BEFORE EMO

24VDC ELECTRICAL BOX

K28

1

1A

F20

2

L N

SCHAFFNER FILTER

FN332-1/05

OR SIMILAR

L' N'

EMERGENCY

RELAY

14

ECO MODE RELAY

A1

ECO

A2

21.522

ECO

START

21

22

3

4

56

K27

K25

14

13

13

14

INFO_6/10.1

24V/5.1

24VDC/3.0

0V/3.0

PE

DIRECTLY CONNECTED TO THE FILTER

1 2 1 15 1 15 20 2

A20

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

TO USE A FILTER IN THE DNC POWER LINE

X1 X1

IT'S HIGHLY RECOMMENDED

X

6mm2

COVER

CYBTOUCH

X2

24V

24V

X3

24V

24V

0V

X2

11

X2

ECO MODE OFF

S25

1

2

24V

12

K25

K27

K26

55

21

22

A1

A2

21

K25

22

A1

K26

A2

21

/1.3

43

/1.3

65

/1.3

1413

.6

2221

.6

21

/1.3

43

/1.3

65

/1.3

1413

2221

.5

K27

A1

A2

X1

H27

21

/1.2

43

/1.2

65

/1.2

1413

.6

5655

.5

K28

X2

A1

A2

21

43

65

1413

.2

POWER SUPPLY

24VDC DNC

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

POWER SUPPLY

24VDC I/O

POWER SUPPLY - DNC - I/O

PUMP START WITH CONVENTIONAL

START BUTTON AND ECO MODE

EMERGENCY

PUSH-BUTTON PUMP START WITH CONVENTIONAL START BUTTON AND ECO MODE

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

12-0130-01PRESS

EMERGENCY

RELAY

1

<

3

>

N° Pg.

17

2A

Pg.

Page 22

0 1 2 3 4 5 6 7 8 9

24V/1.7

0V/1.7

U20

24VDC

0VDC 0VDC

13

F20

1

1A

2

K28

EMERGENCY

RELAY

14

13

PUMP_ON

14

14

24VDC BEFORE EMO

24VDC ELECTRICAL BOX

K27

L N

SCHAFFNER FILTER

FN332-1/05

OR SIMILAR

L' N'

PUMP ON RELAY

PUMP_ON

A1

A2

13 14

K25

56

.5

13

13

14

INFO_7/10.1

24V/5.1

24VDC/3.0

0V/3.0

PE

DIRECTLY CONNECTED TO THE FILTER

1 2 1 15 1 15 20 2

A20

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

TO USE A FILTER IN THE DNC POWER LINE

X1 X1

IT'S HIGHLY RECOMMENDED

X

6mm2

COVER

CYBTOUCH

X2

24V

24V

X3

24V

24V

0V

X2

11

X2

PUMP ON

S25

1

2

24V

12

K25

K27

K26

55

21

22

A1

A2

21

K25

22

A1

K26

A2

21

/1.3

43

/1.3

65

/1.3

1413

.6

2221

.6

21

/1.3

43

/1.3

65

/1.3

1413

2221

.5

K27

A1

A2

X1

H27

21

/1.2

43

/1.2

65

/1.2

1413

.6

5655

.5

K28

X2

A1

A2

21

43

65

1413

.2

POWER SUPPLY

24VDC DNC

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

POWER SUPPLY EMERGENCY

24VDC I/O

PUSH-BUTTON

PUMP START WITH CYBTOUCH START

BUTTON AND INTEGRATED ECO MODE

BIG CONTACTOR (>3A) OR AC VOLTAGE

PUMP START WITH CYBTOUCH START BUTTON AND INTEGRATED ECO MODE

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

12-0130-01PRESS

EMERGENCY

RELAY

1

<

3

>

N° Pg.

17

2B

Pg.

Page 23

0 1 2 3 4 5 6 7 8 9

PROPORTIONAL CROWNING VALVE

24VDC/6.9

G40

24VDC ELECTRICAL BOX

5

V-A CONVERTER

MVP100

1 2 36 4

42

14 13

X3

A20

0V 10V

43

COVER

24VDC

CROWNING WITH PROPORTIONAL VALVE

CYBTOUCH

LINK/4.5

BACK TO PAGE 4

47ohm

63V

470uF

0.5W

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

C41

24V

+

R41

55

0VDC

0V0V/5.3

-

Y40

CROWNING

VALVE

Revision Date

a

b

c

d

Dess.

Appr.

05.03.12

NomDate Nom

JFG

DNC INPUTS - HYDRAULIC COMMAND

PROPORTIONAL CROWNING VALVE

INTERFACE BY THE ELECTRICAL BOX

Projet

CYBTOUCH 6 P

N° d'affaire N° du dessin

PRESS

12-0130-01

<

>

N° Pg.

17

4A

Pg.

Page 24

0 1 2 3 4 5 6 7 8 9

INFO_1/2.5 This diagram can be used as long as the two contactors (star/delta) do not need more than 3A total.

If the star/delta set requires more than 3A (24VDC) or other voltage (AC for example) please use the diagram on page 2B

INFO_2/2.6 For other ways of starting the pump, please refer to the chapter "Wiring Options" at the end of this document

INFO_3/3.2 Optional safety input "Enable Y" :

This function prevents the depht gauge Y axis from moving if the beam is pressing against it.

Usually a switch informs the numerical control if the Y axis is free to move.

If the Enable Y input is configured, it must be active to allow a Y movement.

If the input is not activate while starting the Y axis, a message "Y - beam collision" is displayed.

INFO_4/3.4 Optional output "Decompression" :

This optional output becomes active at the end of the Dwell time, before the "Return to TDC" output.

Use this signal to make a pressure decompression on the machine.

If a proportional pressure valve is available, the pressure will drop to a

"decompression pressure" value set in machine parameters.

INFO_5/4.2 Important : A 4-wire shielded cable must be used for each of the potentiometers.

27 and 28 terminals must be connected together at one side of the potentiometer.

Refer to the wiring explanation in the inputs/outputs list. (bottom of X2 connector list)

INFO_6/2A.7 Conventional Start-Stop panel buttons.

This diagram shows the conventional pump start-stop buttons (usualy placed on the panel)

The Eco-mode relay is used to stop the main motor after x minutes of inactivity.

The EcoModeOff output is configured instead of the PumpOn output.

Whenever possible, we recommend that the Pump start button on the CybTouch and related PumpOn output be used.

This saves using the conventional start/stop buttons, is much more user friendly for the operator and integrates

the Eco-mode function.

INFO_7/2B.7 This diagram is used if more than 3A is needed to activate the 2 simultaneous star/delta contactors.

It is also used when star/delta contactors are 24 VAC or 48 VAC.

La copie ou remise à un tiers sans notre autorisation écrite est strictement interdite.

DateRevision NomDate Nom

a

b

c

d

Dess.

Applied Materials Confidential

05.03.12

JFG

NOTES ON DIAGRAMS

Projet

CYBTOUCH 6 P

N° d'affaire

PRESS

N° du dessin

12-0130-01

<

>

N° Pg.

17

10

Pg.

Loading...

Loading...