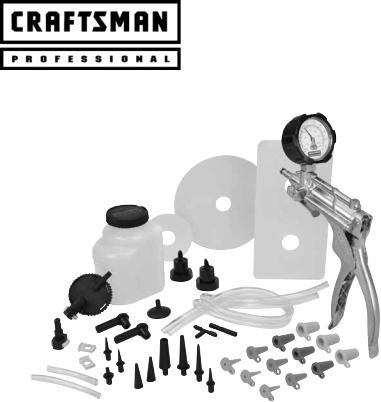

Craftsman 14005 Owner's Manual

Operator’s Manual

AUTOMOTIVE TEST & Brake bleed Kit

Model 14005

CAUTION: Before using this product, read this manual and follow all its Safety Rules

and Operating Instructions.

•Safety

•Operation

•Specifications

•Vacuum Systems

•Diagnostics

•Parts and Accessories

•Español, p. 25

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A. www.craftsman.com

contents

Service Parts & Accessories. |

. . . . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

.3 |

|||

The Pump. . |

. . . . . . . . . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

.4 |

|||

The Automotive Vacuum System. |

. . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

.5 |

|||

Diagnosing Mechanical Engine Conditions. . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

. 7 |

||||

Positive Crankcase Ventilation System. . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . |

. .9 |

||||

Fuel Pressure Regulator. . |

. . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . 10 |

||||||

Turbocharger Wastegate. . . |

. . . |

. . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . |

.12 |

||

Exhaust Gas Recirculation (EGR). |

. . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

13 |

|||

Spark Delay Valves (SDV). |

. . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . 17 |

||||||

Electrical/Vacuum Solenoid. |

. |

. . . . . . . . . . . . . . . . . . . . . . . . . . . .18 |

||||||

Thermal-Controlled Vacuum Switching Valves. |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

18 |

||||

Automatic Fluid Refill Kit. . |

. . . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

.20 |

|||

Brake Bleeding. . |

. . . . . . . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

21 |

|||

Spanish Section. . |

. . . . . . . . . . |

. . . . . . . . . . . . . . . . |

. . . . . |

. |

25 |

|||

craftsman one year full warranty

If this Craftsman product fails due to a defect in material or workmanship within one year from the date of purchase, RETURN IT TO ANY SEARS STORE OR OTHER CRAFTSMAN OUTLET IN THE UNITED STATES FOR FREE REPLACEMENT.

This warranty applies for only 90 days from the date of purchase if this product is ever used for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

2

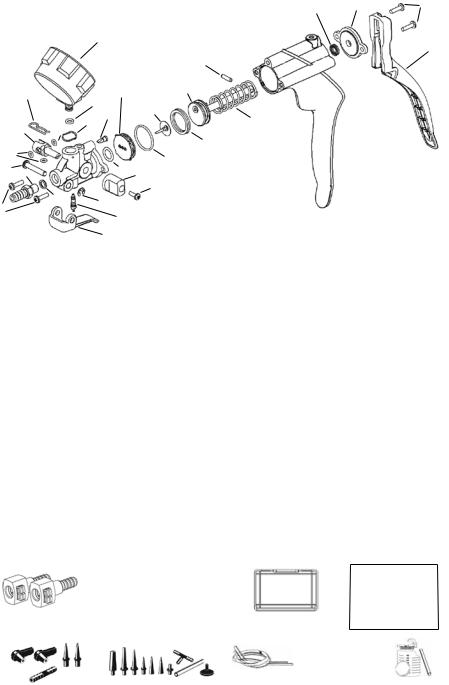

service parts & accessories

|

|

|

|

|

|

|

|

|

|

4 |

3 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

|

|

11 |

|

7 |

|

|

|

|

|

|

|

|

|

|

26 |

9 |

|

|

|

|

|

|

|

|

|

|

23 |

22 |

27 |

12 |

|

6 |

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

22 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

10 |

|

|

|

|

|

|

|

||

21 |

|

|

|

13 |

|

|

|

|

|

|

|

||

20 |

|

|

15 |

|

|

|

|

|

|

|

|||

|

|

|

19 |

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

17 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

PUMP SERVICE KITS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Description |

801330 |

MVM8900 |

MVA6183 |

801333 |

801334 |

801335 |

801336 |

824492 |

824493 |

||

1 |

Handle |

|

|

X |

|

|

|

|

|

|

|

|

|

|

2 |

Screw |

|

|

|

X |

|

|

|

|

|

|

|

|

3 |

Back Cap |

|

|

|

|

|

|

X |

|

|

|

|

|

4 |

Piston Rod Seal |

|

|

X |

|

|

|

|

|

|

|

|

|

5 |

Dowel Pin |

|

|

|

X |

|

|

|

|

|

|

|

|

6 |

Spring |

|

|

|

X |

|

|

|

|

|

|

|

|

7 |

Piston Assy |

|

|

|

X |

|

|

|

|

|

|

|

|

8 |

Piston Seal |

|

|

|

X |

|

|

|

|

|

|

|

|

9 |

Umbrella Valve |

|

|

X |

|

|

|

|

|

X |

|

|

|

10 |

O-Ring |

|

|

|

X |

|

|

|

|

|

|

|

|

11 |

Seal Plate |

|

|

|

|

|

|

|

X |

|

|

|

|

12 |

Duckbill Valve |

|

|

X |

|

|

|

|

|

|

|

|

|

13 |

O-Ring |

|

|

|

X |

|

|

|

|

|

|

|

|

14 |

Screw |

|

|

|

X |

|

|

|

|

|

|

|

|

15 |

Vac/Press Knob |

|

|

X |

|

|

|

|

|

|

|

|

|

16 |

Lever |

|

|

|

|

|

X |

|

|

|

|

|

|

17 |

Schrader Valve |

|

|

X |

|

|

|

|

|

|

X |

|

|

18 |

E-Clip |

|

|

|

|

|

X |

|

|

|

|

|

|

19 |

O-Ring |

|

|

|

|

|

|

|

|

X |

|

|

|

20 |

Outlet Port |

|

|

|

|

|

|

|

|

X |

|

|

|

21 |

Lever Pin |

|

|

|

|

|

X |

|

|

|

|

|

|

22 |

O-Ring |

|

|

|

X |

|

|

|

|

|

|

|

|

23 |

Vac/Press Valve |

|

|

X |

|

|

|

|

|

|

|

|

|

24 |

Retaining Clip |

|

|

|

X |

|

|

|

|

|

|

|

|

25 |

Gauge |

|

|

|

|

X |

|

|

|

|

|

|

|

26 |

O-Ring |

|

|

|

|

X |

|

|

|

|

|

|

|

27 |

Spring Washer |

|

|

|

X |

|

|

|

|

|

|

|

824461 – Tube Connectors |

|

MVA6004 – Vacuum Caps |

|

MVA6915 – Replacement Case |

823396 – Bottle Adapters |

|

|

|

|

822391 – |

|

823398 – |

|

824645 – |

MVA6913 – Bleed Adapter Kit |

|

MVA6912 – Diagnostic Adapter Kit |

|

Tubing (2 pieces) |

|

Refill Plates |

|

Reservoir Kit |

3

the pump

The vacuum/pressure pump is an extremely versatile service tool that can be used to test a variety of automotive systems and perform a number of useful tasks. Though the pump has obvious uses for testing various vacuum motors, control valves and vacuum sources, its applications don’t end there. Almost any part or system that requires proper sealing, pressure or vacuum to operate can be tested with the vacuum pump. The pump and its accessories also transfer fluids, help to bleed brakes and aid in other tasks. The pump also meets diagnostic tool requirements when such tools are specified for some state vehicle inspection programs.

This section will describe the pump, give specifications, tell how to use the pump and provide some service tips to help you keep your pump in tip top-shape.

DESCRIPTION

The hand-held vacuum/pressure pump is simple, accurate, easy to use, and has many applications. It consists of a pump body, moveable handle, compound vacuum/pressure gauge, vacuum/pressure converter switch, and connection fitting. The pump is easily held in your hand, and when the handle is squeezed, either vacuum or pressure is produced at the front fitting. If the front fitting of the pump is connected to a closed container or system, the gauge will show the vacuum or pressure level.

Selecting whether to have the pump produce either vacuum or pressure at the connection fitting is as simple as turning the knob located on the front left side of the pump. The vacuum/pressure valve housing is marked with “Pressure” and “Vacuum”.

Rotate the knob such that the arrow aligns with the desired output. Depending on the position of the knob, either vacuum or pressure is produced by squeezing the pump handle. The return of the handle has no effect on the output.

VACUUM RELEASE

The vacuum or pressure can be released by lifting up on the Release Lever. This action allows air to enter the system, thus relieving the vacuum/pressure. Vacuum/pressure will also be released when the hose is detached from the front fitting.

SPECIFICATIONS |

|

Maximum Vacuum |

Approx. 25” Hg |

@ Sea Level: |

(85 kPa) |

Stroke Volume: |

1 cu. in. (16cc) |

Maximum Pressure: |

30 psi (205 kPa) |

Gauge Accuracy:

3% between 0% and 25% of span

2% between 25% and 75% of span

3% between 75% and 100% of span

USING THE PUMP

The pump is simple to use. In most cases, it’s attached directly to a component, used in place of a vacuum line or connected into a vacuum circuit with a tee connector. The pump can be operated as a test instrument in two ways:

1)When vacuum or pressure is desired for a test, the converter switch is turned to the desired output, and the movable handle of the pump is simply squeezed with your hand, as in clenching your fist.

Continue strokes until desired vacuum or pressure is indicated on the gauge.

2)The pump can be connected into a vacuum

or pressure circuit and used to measure existing amounts of vacuum or pressure, just as any gauge would be used. When used this way, do not pump the handle, or incorrect readings may result.

PROPER CARE

Your pump is a sturdily built, precision test instrument. Do handle it carefully! Don’t drop or handle roughly as the gauge accuracy may be affected. Never exceed the rated pressure of the gauge, as this can cause loss of accuracy and permanent damage. Care for your pump and it will give you years of trouble-free service.

LUBRICATION

The factory-installed lubricant is silicone oil and should provide very long service. If you find it necessary to lubricate your pump, use silicone oil.

If unavailable, you may use DOT 5 (not DOT 3) silicone-based brake fluid or a salad vegetable oil.

Do not use petroleum based fluids or spray lubricants (WD-40, motor oil, etc.), as these will

damage the pump.

4

THE AUTOMOTIVE VACUUM SYSTEM

This manual deals with vacuum and pressure, how it is used in various automotive systems and how the vacuum pump can be used to test and diagnose these systems. This section discusses what vacuum is, how it is measured, where it comes from on an automobile, the system for distributing and using vacuum, and some troubleshooting basics.

WHAT IS VACUUM?

Put simply, vacuum is empty space, and may exist as either a total or partial vacuum. Vacuum does not, of itself, create power. Rather, power for vacuum devices depends on the presence of atmospheric pressure. The atmosphere exerts a pressure of 14.7 pounds per square inch (psi) on everything at sea level. If a portion of the air is removed from one side of a diaphragm (partial vacuum), the atmospheric pressure will exert a force on the diaphragm. The force is equal to the pressure difference times the diaphragm area

(FIGURE 1). Generally, the less air (greater vacuum) in a given space, the more the atmosphere tries to get in and the more force is created.

HOW IS VACUUM MEASURED?

In the United States, vacuum is commonly measured in inches of Mercury (“ Hg). It may also be measured in centimeters of Mercury (cm Hg) and kiloPascals (kPa). Atmospheric pressure will support a column of Mercury in a manometer gauge about 30 inches high or about 76 cm high. This is the barometric pressure in “ Hg which varies as the weather changes. Vacuum readings in “ Hg are really negative pressure readings. For example, 30” Hg vacuum would be a complete vacuum. Half of a complete vacuum would be 15” Hg. A gasoline engine at idle usually pulls about 16-22” Hg vacuum. On deceleration, because the throttle is closed, the vacuum will increase. The pump will pull about 25” Hg as indicated on its vacuum gauge which is calibrated in both “ Hg and kPa.

WHY ENGINES CREATE VACUUM

Vacuum is created when air is withdrawn from a given volume, or a sealed volume is increased. That is why vacuum is available in an engine.

On the intake stroke, the piston moves down, this creates a partial vacuum because the volume of the

cylinder is increased. Air cannot rush through the intake system fast enough to totally fill the space created when the piston moves down (FIGURE 2).

This is the most common automotive vacuum supply source.

GASOLINE VS. DIESEL VACUUM

Because a diesel engine does not produce as much vacuum as a gasoline engine, a mechanical vacuum pump must be employed to operate vacuum devices. The pump is useful in testing devices

on both types of engines.

Piston area 10 sq. in.

14.7 PSI

10.7 PSI

40 Pounds

14.7 - 10.7 = 4 PSI

Figure 1:

Vacuum vs. Atmospheric Pressure

Vacuum Port

Intake Stroke

Air

Vacuum

Figure 2: the engine as a vacuum source

5

THE AUTOMOTIVE VACUUM SYSTEM

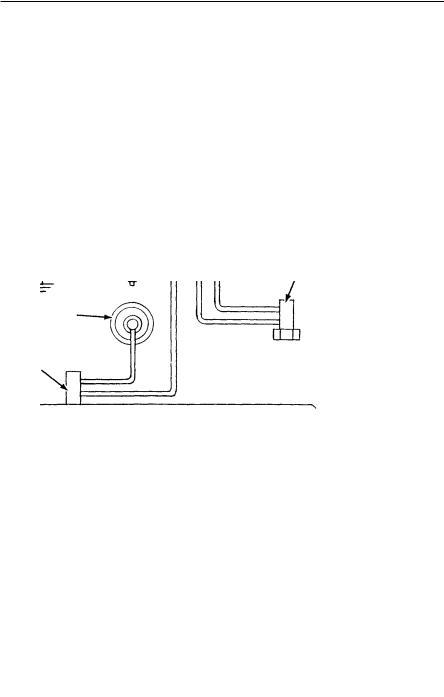

VACUUM DISTRIBUTION

All modern automobiles have a vacuum distribution system (FIGURE 3), consisting of lines, hoses, fittings and vacuum devices. This system must be leak proof. If it is not, the engine air/fuel mixture will be leaned out by the extra air entering the system through the leaks, thus causing problems such as burned exhaust valves, uneven idle, stalling, pre-ignition, burned spark plugs, etc. Additionally, any vacuum operated device affected by the vacuum leak will not function properly.

A normal gasoline engine should develop 16-22”

Hg of intake manifold vacuum at idle. This is an indication that the engine is breathing properly. If the vacuum is lower, the engine is running less

efficiently. The lower the manifold vacuum, the less efficiently the engine is running and the lower the gas mileage will be.

The vacuum distribution system supplies vacuum to vacuum motors (servos) in the air conditioning, power brake booster, speed control servo, emission controls, manifold absolute pressure (MAP) sensor,

and automatic transmission control systems. In older vehicles, vacuum is also supplied to the distributor vacuum advance or retard mechanism. These devices can be connected directly to manifold vacuum, or can be controlled through electric solenoids, thermostatic switches, or other

vacuum controls.

TROUBLESHOOTING THE VACUUM SYSTEM

Most vacuum problems can be traced to leaks, which occur in hoses, connectors, motor diaphragms or valves. Pinched lines or clogged valves will also not allow vacuum flow. Problems can also be traced to improper mechanical operation of devices driven by vacuum motors.

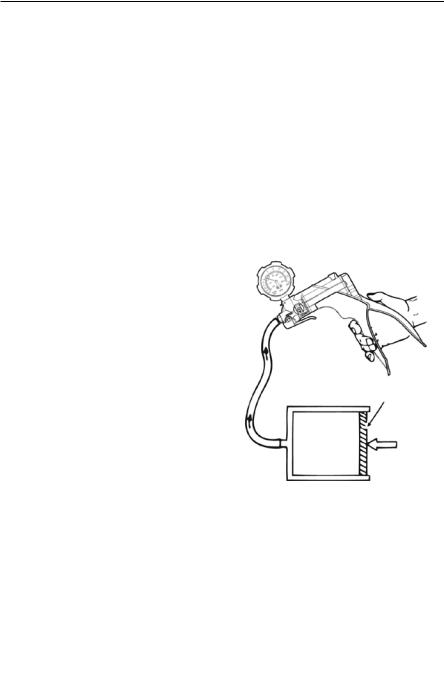

The vacuum pump can be used to measure the amount of vacuum in a hose. The vacuum gauge feature is very useful for detecting a fluctuating vacuum supply or a leaky hose. The vacuum pump feature enables you to check all types of vacuum operated devices.

On a vacuum motor, for example, the pump is used to evacuate the diaphragm chamber, which allows you to check the mechanical operation of the device as well as the amount of vacuum required to actuate it. Test for a leaking diaphragm by applying

10” Hg vacuum to the device (FIGURE 4). Observe the gauge to see if the needle drops after the actuator stops moving. If the needle continues

to drop, a leaking diaphragm is indicated. If the diaphragm is okay, the vacuum should hold for one minute with the needle steady.

vacuum distribution block

To Intake Manifold |

|

|

|

|

|

|

To A/C |

|

|

|

Heater |

|

|

|

Auto |

|

|

|

Trans |

|

|

|

PRNDL Switch |

|

|

To Speed |

|

Power Brake |

|

Control |

Brake |

Booster |

|

|

|

|

|

Release Motor |

|

|

Distributor |

|

|

|

|

|

|

Intake Air Motor |

Advance |

|

|

|

|

|

Figure 3: typical vacuum distribution system

6

THE AUTOMOTIVE VACUUM SYSTEM

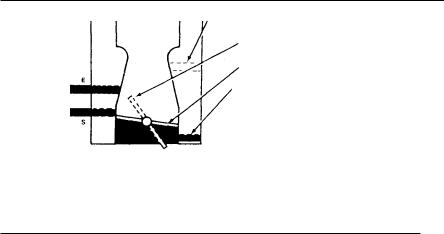

Carburetor or Throttle Body

EGR Vacuum

•Zero at closed throttle

•Still zero when “S” vacuum is on

•Equal to manifold at greater throttle opening

Spark Port Vacuum

•No vacuum at closed throttle

•Equal to manifold vacuum off idle

•Originally used to control “spark” vacuum to distributor advance diaphragm

Figure 4: Typical carburetor vacuum supply points

Venturi Vacuum

•Weak or zero at cruise or idle

•Strong at wide open throttle

Position when “S” and “E” vacuum are “on”

Throttle plate (closed position) Manifold Vacuum

•Available with engine running

•Strongest at closed throttle

•Gradually weakens as throttle opens

•But stays strong if the choke is closed

DIAGNOSING MECHANICAL ENGINE CONDITIONS

VACUUM GAUGE CHECKS & DIAGNOSIS

The pump’s vacuum gauge readings give indications of possible mechanical problems, but they are not foolproof. Observe the gauge carefully and follow the vacuum readings with further tests, where possible, to confirm your diagnosis.

Do not look for the engine to produce specific (numerical) amounts of vacuum. Much more important than specific numbers, are the range of the vacuum readings and the movement of the

needle (FIGURE 5). Important things to notice about the needle movement are HOW the needle moves

(in a smooth or jerky manner, erratic, etc.), what direction it moves, whether movement is regular or varying, and how far the needle moves.

The following gives some examples of what to look for and the meanings of a variety of vacuum gauge readings.

NORMAL ENGINE

Run engine at idle and connect the pump to an intake manifold vacuum port. Watch the needle’s movement on the gauge. At idle, the vacuum gauge reading should be 16-22” Hg and steady.

BURNED OR LEAKING VALVE

At idle, burned or leaking valves will cause the pointer on the gauge to drop to a low reading and

return to normal at a regular interval. The needle will drop from 1 to 7” Hg at regular intervals whenever the defective valve attempts to close.

STICKING VALVE

A sticking valve will exhibit a rapid, intermittent drop from the normal pointer indication. This is unlike the regular drop that characterizes a burned or leaking valve.

A sticking valve condition may be pin-pointed by directly applying lightweight oil to each valve guide. When the sticking valve is reached, the situation will be temporarily remedied.

WEAK OR BROKEN VALVE SPRING

Weak valve springs are indicated when the pointer of the vacuum pump gauge fluctuates rapidly between 10” and 21” Hg at idle. The fluctuations will increase with engine speed. A broken valve spring will cause the needle to fluctuate rapidly

at a regular interval. Again, this will occur every time the valve attempts to close.

WORN VALVE GUIDES

Worn valve guides admit air which upsets the air/ fuel mixture. The vacuum gauge reading will

be lower than normal and will fluctuate rapidly in a range of about 3” Hg. As the speed of the engine is increased, the needle will steady.

7

DIAGNOSING MECHANICAL ENGINE CONDITIONS

LEAKING PISTON RING

Vacuum at idle will be low but steady at about 12 to 16” Hg. Open the throttle and allow the engine to pick up speed to about 2000 RPM, and then close the throttle quickly. The pointer should jump 2 to 5”

Hg above its low steady reading. A lesser gain may indicate faulty rings, and a complete cylinder leakage or compression test should be done.

BLOWN CYLINDER HEAD GASKET

At idle, the vacuum pump gauge pointer will fluctuate between normal and a low reading.

The needle will drop sharply about 10” Hg from

a normal reading and return each time the defective cylinder or cylinders reach firing position.

EXHAUST RESTRICTION TEST

An exhaust restriction will cause normal or near normal performance at engine idle, but cause very poor engine performance under load or at higher speeds.

1)Connect the pump hose to an intake manifold vacuum fitting. Operate the engine at idle and note the vacuum reading and needle movement. Compare readings and movements against descriptions listed for burned valves and late ignition or valve timing.

2)Watch the vacuum gauge as engine speed is increased to approximately 2500 RPM.

3)An increase in vacuum over that obtained at idle indicates an exhaust system that is free of restrictions.

4)If the needle drops toward zero as engine RPM is increased, either an exhaust restriction or an over-active Exhaust Gas Recirculation (EGR) valve is causing the problem.

5)Test the EGR valve separately. If it is found to be in good condition, the problem is a restricted exhaust. Check and replace if necessary.

INCORRECT IDLE AIR/FUEL MIXTURE

If the gauge needle drifts slowly back and forth at idle, over a range of 4 to 5” Hg, the fuel mixture is too rich. A lean mixture will cause an irregular drop of the needle over about the same range.

INTAKE MANIFOLD OR AIR INDUCTION LEAKS

If there are any air leaks in the air induction system, the gauge needle will be about 3 to 9” Hg below normal, but will remain steady.

LATE IGNITION OR VALVE TIMING

An extremely low but steady reading at idle indicates late ignition or valve timing, or a uniformly close setting of the valve lash.

Perform separate tests to determine which of these problems, if any, have affected the engine.

With motor at idle speed, vacuum pointer should hold steady between 16 and 22.

With motor at idle speed, dropping back of vacuum pointer indicates sticky valves.

With motor at idle speed, floating motion right and left of vacuum pointer indicates carburetor too rich or too lean.

With motor at idle speed, low reading of vacuum pointer indicates late ignition timing or intake manifold air leak.

Figure 5: Vacuum gauge readings

8

POSITIVE CRANKCASE VENTILATION SYSTEM

SYSTEM OPERATION

The Positive Crankcase Ventilation (PCV) system is used on all modern engines to reduce air pollution by providing a more complete scavenging of crankcase vapors. Air is drawn through a filter

located in the air cleaner, through a hose in the valve cover, into the crankcase, across and up into the rear of the intake manifold or opposite valve cover, through the PCV valve, through a hose, into the intake manifold. Intake manifold vacuum draws in all vapors from the crankcase to be burned in the engine

When air flow through the carburetor or throttle body is high, added air from the PCV system has no effect on engine operation. However, at idle, air flow through the carburetor or throttle body is so low that any large amount added by the ventilation system would upset the air/fuel mixture, causing a rough idle. For this reason, the PCV valve restricts the ventilation system flow when intake manifold vacuum is high.

SERVICE PROCEDURES

After a period of operation, the PCV valve may become clogged and reduce the amount of crankcase ventilation. The PCV valve should be replaced periodically toprevent the formation of

acids in the crankcase, and the build up of excessive crankcase pressure, which could force engine oil out past the seals. Use the following procedure to check the PCV system using your pump:

1)Inspect the system for kinked, plugged or deteriorated hoses. Check to be sure all hoses are connected properly. Repair as necessary.

2)Connect your pump to an intake manifold port and check the vacuum reading of the warmed and idling engine.

3)Clamp off the vacuum hose to the PCV valve. The engine speed should decrease 100 RPM to indicate the loss of the calibrated air leak into

the intake manifold. The vacuum gauge reading should increase slightly, indicating that the vacuum leak has been plugged. If this does not happen, replace the PCV valve and/or replace any damaged, plugged or loose hoses.

4)If the engine is idling too slow or is rough, this may be caused by a clogged PCV valve or hose. Do not adjust the idle speed without first checking the PCV system.

5)After installing a new PCV valve, always adjust the idle speed, and if possible, the idle air mixture.

The installation of the wrong valve may cause too much vapor to flow through the system if the calibrated bleed is too large. This will lean out the air/fuel mixture excessively. If the opening is too small, the plugging effect will be nullified, emissions will increase, acids will form and oil leaks may develop. Be sure you get the correct PCV valve

for your car.

9

fuel pressure regulator

SYSTEM OPERATION

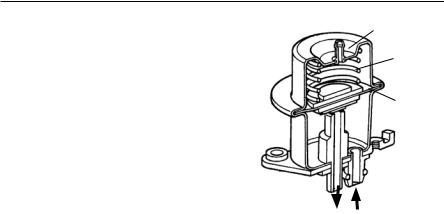

Fuel pressure regulators are used to maintain fuel pressure at a steady level, consistent with the requirements of the engine. Automotive manufacturers employ different methods for controlling

fuel pressure. Most utilize a mechanical spring and diaphragm style pressure regulator such as the one shown in figure 6. Mechanical regulators most often utilize engine vacuum and/or pressure to vary fuel pressure in response to immediate engine requirements. A vacuum or vacuum/pressure pump with appropriate gauge is required to properly diagnose these types of regulators.

Vacuum/pressure controlled fuel pressure regulators are commonly mounted on or immediately after the fuel rail, and inline with the flow of fuel. When the fuel pump is not operating, the spring causes the diaphragm to close so that no fuel can pass. Once the fuel pump is activated, the pressure it produces begins to overcome the spring force and the diaphragm opens to allow fuel to flow. The spring and diaphragm maintain a constant pressure

on the flow of fuel. This creates back-pressure in the fuel system, which is commonly referred to as “fuel pressure”. The job of the fuel pressure regulator is to maintain the “fuel pressure” at a level specified by the vehicle manufacturer.

A vacuum/pressure-modulated fuel pressure regulator is connected to the intake manifold by a small hose. Vacuum from the manifold assists the spring in opening the diaphragm. When a load is placed on the powertrain, engine vacuum drops. This drop in vacuum causes the diaphragm to increase the resistance to fuel flow. The additional resistance increases the fuel pressure to the injectors to compensate for the higher fuel demand of the engine.

On forced-air induction systems (turbochargers/ superchargers), the boost pressure created in the manifold functions the opposite of the vacuum produced in normally aspirated systems. Under boost conditions, the pressure in the manifold causes the regulator to increase fuel pressure, resulting in a richer fuel mixture.

Figure 6: |

Vacuum/Pressure |

|

Pressure |

||

Connection |

||

Regulator |

Spring |

|

|

||

|

Diaphragm |

Fuel Out |

Fuel In |

|

SERVICE PROCEDURES

Visual Inspection

1)Consult the vehicle’s service manual to determine if the pressure regulator is vacuum/pressure modulated, and to identify its location.

2)Inspect the exterior of the pressure regulator for fuel leaks, and the vacuum hose for visible damage or cracks. Replace if necessary.

3)Disconnect the vacuum hose from the fuel pressure regulator.

4)Check inside the hose for liquid fuel. If present, replace the regulator. If not present, reconnect the vacuum hose.

Diagnostics

5)Install a fuel pressure tester.

6)Start the engine and allow it to idle.

7)Disconnect the vacuum line from the fuel pressure regulator.

8)Fuel pressure should increase 8 to 12 psi when the line is disconnected. No change would indicate a faulty regulator, or leaky or plugged vacuum line.

9)Connect the vacuum pump to the vacuum hose extending from the manifold.

10

fuel pressure regulator

10)The pump gauge should indicate 16-22” Hg.

Consult the vehicle’s service manual for a more accurate specification. No reading or a low reading would indicate a leaky or plugged vacuum line, or more serious engine problem.

11)Disconnect the vacuum pump from the vacuum line, and plug the line temporarily. Connect the pump to the vacuum port on the regulator.

12)Use the pump to apply vacuum to the regulator while watching the gauge on the fuel pressure tester.

13)Fuel pressure should increase one pound for every two inches of Hg vacuum applied to the regulator. If not, replace the fuel pressure regulator.

Turbochargers and Superchargers

14)For forced-air induction systems (turbochargers and superchargers) switch the pump from “Vacuum” to “Pressure” without disconnecting it from the regulator.

15)Use the pump to apply pressure to the regulator while watching the gauge on the fuel pressure tester.

16)Fuel pressure should increase one pound for every one pound of pressure applied to the regulator. If not, replace the fuel pressure regulator.

11

turbocharger wastegate

SYSTEM OPERATION

The turbocharger wastegate (exhaust bypass valve) limits the amount of boost (intake manifold pressure) created by the turbo. When intake manifold pressure becomes too high, the wastegate opens

to allow some exhaust to bypass the turbo. This reduces the turbo boost.

Most turbo wastegate actuators operate using a mechanical spring and diaphragm design. Under normal operating conditions, the spring holds the wastegate valve closed, and all exhaust is directed to the turbocharger. A small tube connects the wastegate actuator to the intake manifold or turbo air outlet. When boost pressure becomes too high, it pushes against the diaphragm until it overcomes the spring force, causing the wastegate to open.

Testing the function of the wastegate and wastegate actuator involves attaching the hand pump to wastegate and applying pressure.

SERVICE PROCEDURES

Follow the procedures below to diagnose a turboor super-charger wastegate and actuator:

Cold Test for Visual Movement

1)Locate the wastegate actuator, and inspect it for damage. Check the pressure hose for visible leaks or cracks. Replace if necessary.

2)Disconnect the pressure hose from the wastegate actuator and connect the hand pump in its place.

3)Use the pump to apply pressure according to the manufacturer’s specification.

4)Watch for the control rod to move and then hold its position.

5)If the rod doesn’t move or hold its position, or if the pressure leaks down as indicated by the gauge on the hand pump, replace or repair the wastegate actuator.

6)If no leak is found, disconnect the actuator rod and move the wastegate flapper lever to determine if it is stuck or seized.

7)If it does not move freely, the wastegate should be replaced or repaired.

Idle Test

8)Start with the exhaust system cold.

9)Disconnect the pressure hose from the wastegate actuator and connect the hand pump in its place.

10)Start the engine and allow it to idle.

11)After a short time, the exhaust inlet to the wastegate should warm up, but the bypass line out of the wastegate should remain cool.

12)If the bypass line heats up at this point, exhaust is leaking past the wastegate, and the wastegate should be replaced or repaired.

13)Use the pump to apply pressure to open the wastegate according to the manufacturer’s specification.

14)Feel the bypass line. It should begin to warm up as the wastegate opens.

15)If not, the wastegate is stuck closed and should be replaced or repaired.

16)Once testing is complete, bleed the pressure from the pump and watch for the wastegate to close.

Bench Testing

A hand pump should be used to bench testing the turbocharger wastegate, and adjusting the control arm after replacement or repair. Follow the manufacturer’s procedures for performing these precision tests and adjustments.

Pressure |

|

Connection |

Wastegate Actuator |

|

Figure 7: Turbocharger

12

EXHAUST GAS RECIRCULATION (EGR)

An Exhaust Gas Recirculation (EGR) system is used on most modern engines to reduce Oxides of Nitrogen (NOx) emissions. During the combustion process, nitrogen, which makes up 80 percent of the air, will mix with oxygen at temperatures above 2,500°F. During the combustion process, temperatures in the cylinders go well above

3,500°F providing the ideal conditions for the formation of NOx.

SYSTEM OPERATION

To reduce the formation of NOx, it is necessary to lower the combustion temperature. This is most often done by introducing exhaust gases back into the combustion chamber through the use of an

EGR valve. The EGR valve (FIGURE 8) may be operated by ported vacuum from above the throttle plates, or by a sophisticated control system that modulates the amount of EGR depending on the temperature of the coolant, ambient air temperature, engine speed or load.

An EGR valve that does not have a sophisticated control system must be fully closed with a vacuum of less than 2” Hg and begin to open with 2 to 8.5”

Hg of vacuum. At idle and wide-open throttle, the ported vacuum supply is low and the valve should be closed.

Some cars have a Back-Pressure Transducer Valve (BPV) to modulate the operation of the EGR system. Some cars have a Venturi Vacuum Amplifier (VVA) to do the same job. The effect is to modulate the amount of EGR according to the load on the engine.

To improve cold drivability, most cars are equipped with some type of vacuum control device to shut off

EGR while the engine is cold.

EGR systems fail in two ways. Either the valve may fail due to a fault of its own, such as a ruptured diaphragm, or due to a loss of control vacuum. Always check whether there is vacuum at the hose connected to the EGR valve, before replacing the valve. Connect the pump to the vacuum supply hose at the EGR valve and check whether at 2000 RPM there is at least 4 to 5” Hg vacuum available. Remember also that clogged exhaust passages that lead to or from the valve can restrict the flow even if the valve is opening.

An EGR valve that remains open will cause the engine to idle roughly, die at idle, and lose power and full-throttle smoothness. Dirt or damage in the valve seat area usually cause the valve to fail. An

EGR valve can operate normally with the engine warm but remain open when the engine is cold. That condition could be caused by a faulty thermal switching device that does not cut off the vacuum supply when the engine is cold.

To Vacuum Source |

To Vacuum Source |

No Vacuum Signal |

Vacuum Signal Applied |

Valve closed, exhaust blocked |

Valve open, exhaust admitted to intake manifold |

Figure 8: EGR Valve operation

EXHAUST GAS RECIRCULATION (EGR)

EGR SERVICE PROCEDURES/GENERAL TEST EXCEPT GM OR BACKPRESSURE CONTROLLED TYPE

If the symptoms of an engine lead you to believe that an EGR valve is staying open, follow this procedure:

1)Connect a tachometer to the engine and run the engine at idle speed until it reaches normal operating temperature. Use the pump to check for at least 10” Hg vacuum at the valve. Replace the hose and note the engine RPM.

2)Remove the vacuum hose from the valve and notice whether engine RPM increases.

3)If engine speed does increase, there may be some type of problem in the vacuum control circuit. Check the routing of all vacuum hoses.

4)If engine speed or the quality of idle changes, remove the valve and check the pintle and valve seat to make sure both are clean. If they are not, replace the valve, gasket and adapter if it is burned, warped or damaged.

If the engine symptoms lead you to believe that the EGR valve is staying closed, follow the procedure below:

1)Operate the engine at idle until it reaches full operating temperature. Use the pump to check for the presence of 10” Hg vacuum at the valve. Set the engine speed at approximately 2000 RPM. Plug the vacuum supply hose. Connect the vacuum pump to the EGR valve and apply 10 to 15” Hg vacuum.

2)The diaphragm should move to the open position and a decrease in engine RPM should be noted. If

not, the valve is defective or the manifold passages are plugged. Release the vacuum on the EGR valve.

3)The diaphragm should move to the closed position and an increase in engine RPM should be noted. Return the engine to idle and turn it off.

4)Connect the pump to the EGR valve and test by applying at least 9” Hg of vacuum to the diaphragm and watch the gauge carefully for any vacuum loss.

5)If the valve diaphragm does not move, or cannot hold vacuum, replace the EGR valve.

GM EGR VALVES

General Motors produces three types of EGR valves. Each valve can be identified by the design of its diaphragm plate (FIGURE 9). The first valve is a ported vacuum EGR that has only a circular rib on the back of its diaphragm plate. The second is a positive backpressure valve with X-shaped ribs that are raised only slightly above the plate. Finally, there is a negative back-pressure valve with X-shaped ribs raised well above the diaphragm plate. Both the ported vacuum and negative back-pressure valves are tested the same way.

A separate test is listed to check the positive back -pressure valve.

GM PORTED VACUUM AND NEGATIVE BACK-PRESSURE EGR TEST

1)Make sure all vacuum hoses are routed according to the emission control label.

2)Check the vacuum connection to the EGR valve for obstructions.

Ported Vacuum |

Positive Backpressure |

Negative Backpressure |

Figure 9: GM EGR Diaphragms

14

EXHAUST GAS RECIRCULATION (EGR)

3)Connect the pump between the EGR valve and the carburetor or vacuum source. Start the engine and run it at idle until it reaches operating temperature (195°F approx.). Check for vacuum at 3000 RPM; it should be 5” Hg minimum.

4)If no vacuum is available in step 3, check for it between the EGR thermal vacuum switch (TVS) and the carburetor. If the vacuum is available there, replace the TVS.

5)If the vacuum supply between the EGR and the carburetor is adequate, connect the pump to the

EGR valve inlet. Depress the valve diaphragm and apply approximately 10” Hg vacuum to the EGR.

Release the diaphragm and record the time it takes for the diaphragm to return to its seated position.

6) If it takes less than 20 seconds for the valve to seat, replace the valve.

GM POSITIVE BACKPRESSURE EGR TEST

1)Follow steps 1 through 4 of the ported vacuum and negative back-pressure EGR test.

2)Remove the EGR valve from the engine. Connect the pump to the EGR vacuum inlet and apply 10” Hg of vacuum. The valve should not open. If it does, replace the valve.

3)Continue the test by keeping the vacuum applied and shooting a low-pressure stream of air into the valve’s exhaust inlet. The valve should now open.

If it does not, replace the valve.

Manifold Vacuum

To Starter Relay

To Ignition

Vacuum Amplifier

EGR Delay

Solenoid

EGR Delay

Timer

Coolant Control Engine Vacuum Switch

EGR Valve

CCEGR Temperature Valve

Figure 10: Chrysler venturi vacuum-control egr system

15

Loading...

Loading...