Page 1

LINE THERMAL PRINTER

MODEL CT-S4000/CT-S4000DC

CT-S4000L/CT-S4000DCL

CT-S4000M/CT-S4000DCM

User’s Manual

Mode d’emploi

Benutzerhandbuch

Manuale dell’utente

Manual de Usuario

Page 2

Declaration of Conformity

This printer conforms to the following Standards:

The Low Voltage Directive 2006/95/EC, formerly 72/23/EEC,

the EMC Directive 2004/108/EC, formerly 89/336/EEC, the RoHS

Directive 2002/95/EC, and the WEEE Directive 2002/96/EC.

LVD:EN60950

EMC : EN55022 Class A

EN61000-3-2

EN61000-3-3

EN55024

This declaration is applied only for 230V model.

IMPORTANT: This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct

the interference.

CAUTION: Use shielded cable for this equipment.

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Gerät angebracht und

leicht zugänglich sein.

For Uses in Canada

This Class A digital apparatus complies with Canadian ICES-003.

This digital apparatus does not exceed the class A limits for radio noise emissions

from digital apparatus, as set out in the radio interference regulations of the Canadian

department of communications.

Pour L’utilisateurs Canadiens

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Cet appareil numérique ne dépasse pas les limites de carégorie a pour les émissions

de bruit radio émanant d’appareils numériques, tel que prévu dans les réglements

sur l’interférence radio du départment Canadien des communications.

Page 3

ENGLISH

Page 4

GENERAL PRECAUTIONS

● Before using this product, be sure to read through this manual. After having read

this manual, keep it in a safe, readily accessible place for future reference.

● The information contained herein is subject to change without prior notice.

● Reproduction or transfer of part or all of this document in any means is prohibited

without permission from Citizen Systems.

● Note that Citizen Systems is not responsible for any operation results regardless

of missing, error, or misprinting in this manual.

● Note that Citizen Systems is not responsible for any trouble caused as a result of

using options or consumables that are not specified in this manual.

● Except explained elsewhere in this manual, do not attempt to service, disassemble,

or repair this product.

● Note that Citizen Systems is not responsible for any damage attributable to

incorrect operation/handling or improper operating environments that are not

specified in this manual.

● Data is basically for temporary use and not stored for an extended period of time

or permanently. Please note that Citizen Systems is not responsible for damage

or lost profit resulting from the loss of data caused by accidents, repairs, tests or

other occurrence.

● If you find loss of information, error, or uncertain matter, please contact your

Citizen Systems dealer.

● If you find any disordered or missing page(s), contact your Citizen Systems dealer

for replacement.

THE TABLE OF CONTENTS

1. GENERAL OUTLINE ....................................................................7

2. EXPLANATION OF PRINTER PARTS........................................ 10

3. PREPARATION ...........................................................................12

4. MAINTENANCE AND TROUBLESHOOTING ........................... 17

5. OTHER .......................................................................................22

CITIZEN is a registered trade mark of Citizen Holdings Co., Japan

CITIZEN es una marca registrada de Citizen Holdings Co., Japón

Company names and product names in this manual are trademarks or

registered trademarks of relevant companies.

Copyright c 2009 by CITIZEN SYSTEMS JAPAN CO., LTD.

— 1 —

Page 5

SAFETY PRECAUTIONS ... WHICH SHOULD BE STRICTLY OBSERVED

Before using this product for the first time, carefully read these SAFETY PRECAUTIONS. Improper

handling may result in accidents (fire, electric shock or injury).

In order to prevent injury to operators, third parties, or damage to property, special warning symbols

are used in the User’s Manual to indicate important items to be strictly observed.

● After having read this Manual,

● Some of the descriptions contained in this manual may not be relevant to some printer models.

The following describes the degree of hazard and damage that could occur if the printer is improperly

operated by ignoring the instructions indicated by the warning symbols.

keep it in a safe, readily accessible place for future reference.

WARNING

Neglecting precautions indicated by this symbol may result in fatal or serious injury.

CAUTION

Neglecting precautions indicated by this symbol may result in injury or damage to properties.

This symbol is used to alert your attention to important items.

This symbol is used to alert you to the danger of electric shock or electrostatic damage.

This symbol denotes a request to unplug the printer from the wall outlet.

This symbol is used to indicate useful information, such as procedures, instructions or the

like.

This symbol is used to indicate prohibited actions.

— 2 —

Page 6

WARNING

■ Do not use or store this product in a place where it will be exposed to:

* Flames or moist air.

* Direct sunlight.

* Hot airflow or radiation from a heating device.

* Salty air or corrosive gases.

* Ill-ventilated atmosphere.

* Chemical reactions in a laboratory.

* Airborne oil, steel particles, or dust.

* Static electricity or strong magnetic field.

• Neglecting these warnings may result in printer failure, overheating, emission of

smoke, fire, or electric shock.

■ Do not drop any foreign object nor spill liquid into the printer. Do not place any

object on the printer either.

■ Do not drop any metallic object such as paper clip, pin or screw into the printer.

■ Do not place a flower vase, pot or cup containing water on the printer.

■ Do not spill coffee, soft drinks or any other liquid into the printer.

■ Do not spray insecticide or any other chemical liquid over the printer.

•A metallic foreign object, if accidentally dropped into the printer, may cause printer

failure, fire, or electric shock. Should it occur, immediately turn the printer off,

unplug it from the supply outlet, and call your local Citizen Systems dealer.

Do not handle the printer in the following ways:

■ Do not allow the printer to sustain strong impacts or hard jolts (e.g., trampling,

dropping, striking with a hard edge).

■ Never attempt to disassemble or modify the printer.

• Neglecting to handle properly may result in printer failure, overheating, emission

of smoke, fire, or electric shock.

■ Install, use, or store the printer out of the reach of children.

• Electric appliances could cause an unexpected injury or accident if they are handled

or used improperly.

•Keep the power cord and signal cables out of the reach of children. Also children

should not be allowed to gain access to any internal part of the printer.

• The plastic bag the printer came in must be disposed of properly or kept away

from children. Wearing it over the head may lead to suffocation.

— 3 —

Page 7

WARNING

Please observe the following precautions for power source and power cord:

■ Do not plug or unplug the power cord with a wet hand.

■ Use the printer only at the specified supply voltage and frequency.

■ Check to make sure that the supply outlet from which the printer is powered has a

sufficient capacity.

■ Do not supply the printer from a power strip or current tap shared with other

appliances.

■ Do not plug the power cord into a supply outlet with dust or debris left on its plug.

■ Do not use a deformed or damaged power cord.

■ Do not move the printer while the printer power is on.

• Neglecting to handle properly may result in printer failure, emission of smoke, fire,

or electric shock.

• An overload may cause the power cord to overheat or fire or the circuit breaker to

trip.

■ Do not allow anything to rest on the power cord. Do not place the printer where

the power cord will be trampled on.

■ Do not use or carry the printer with its power cord bent, twisted, or pulled.

■ Do not attempt to modify the power cord unnecessarily.

■ Do not lay the power cord in the neighbor of a heating device.

• Neglecting these cautions may cause wires or insulation to break, which could

result in leakage, electric shock, or printer failure. If the power cord sustains

damage, contact your Citizen Systems dealer.

■ Do not leave things around the supply outlet.

■ Supply power to the printer from a convenient wall outlet, readily accessible in an

emergency.

• The printer may not be immediately shut down in an emergency.

■ Insert the power plug fully into the outlet.

■ If the printer will not be used for a long time, leave it disconnected from its supply

outlet.

■ Hold the plug and connector when plugging or unplugging the power cord or signal

cable after turning off the printer and the appliance connected to it.

— 4 —

Page 8

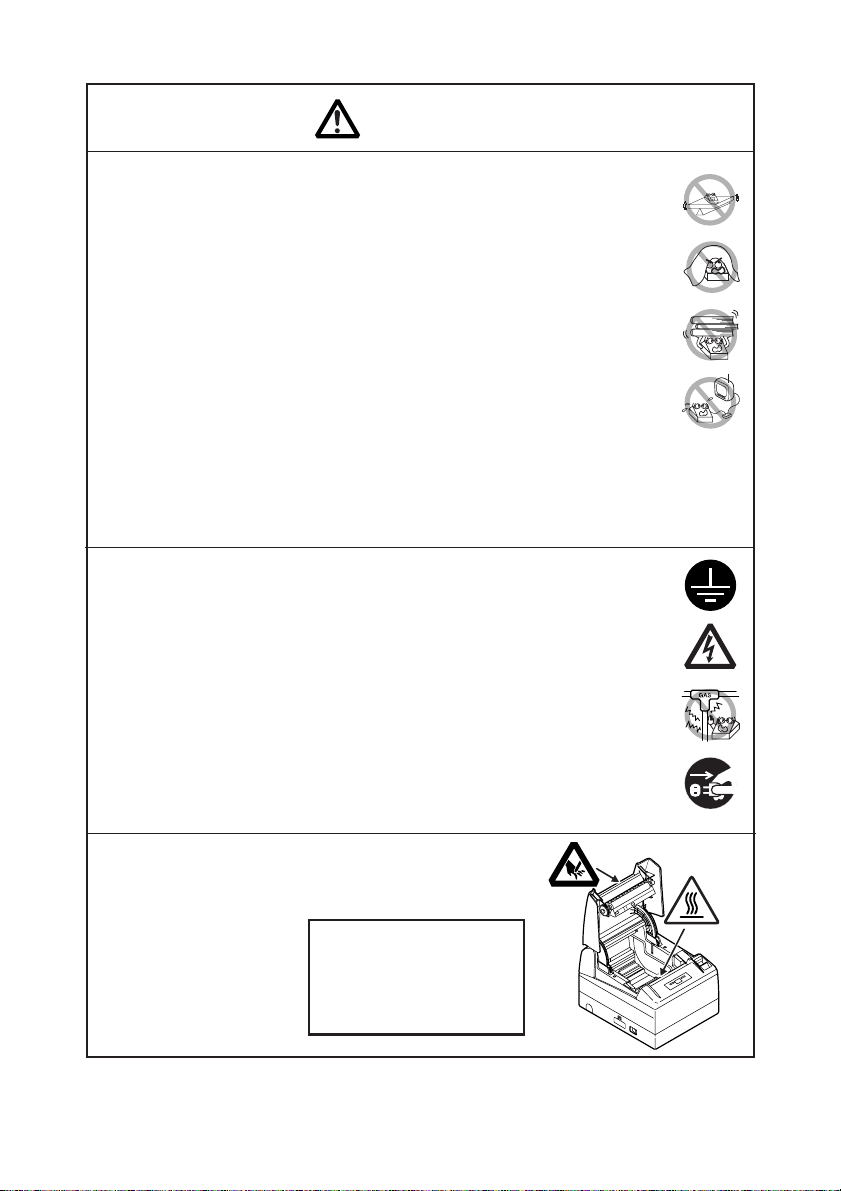

CAUTION

Do not use the printer under the following conditions.

■ A state subject to vibration or unstable state.

■ A state with this product slanted.

• Otherwise dropping may cause injury.

• Poor print quality may occur.

■ A state where the printer ventilation holes are obstructed by a nearby wall or other

equipment.

■ A state where any object is placed on the printer

■ A state where the printer is covered or wrapped by a cloth or bed clothing

• Be careful about internal heat buildup, which could cause fire and deform the case.

■ Avoid using the printer near a radio or TV set or from supplying it from the same

outlet as these appliances.

■ Avoid using the printer interconnected with a cable or cord that has no protection

against noise. (For interconnections, use shielded or a twisted pair of cables and

ferrite cores, or other anti-noise devices.)

■ Avoid using the printer with a device that is a strong source of noise.

• The printer may have an adverse effect on nearby radio or TV transmissions. There

may also be cases when nearby electrical appliances adversely influence the printer,

causing data errors or malfunction.

■ A state where this product is installed vertically or sidelong.

• Malfunction, failure, or electric shock may result.

■ Use the printer with its grounding post connected to a convenient grounding facility.

• If leakage occurs electric shock may result.

■ Do not connect the printer’s grounding post onto any of the following facilities:

* Utility gas piping

• A gas explosion could result.

* Telephone line ground

* Lightning rod

• If lightning strikes a large surge of current may cause fire or shock.

* Utility water pipes

• Plastic water pipes should not be used for grounding. (Those approved by

a Waterworks Department may be used.)

■ Before connecting or disconnecting the grounding lead to or from the printer, always

unplug it from supply outlet.

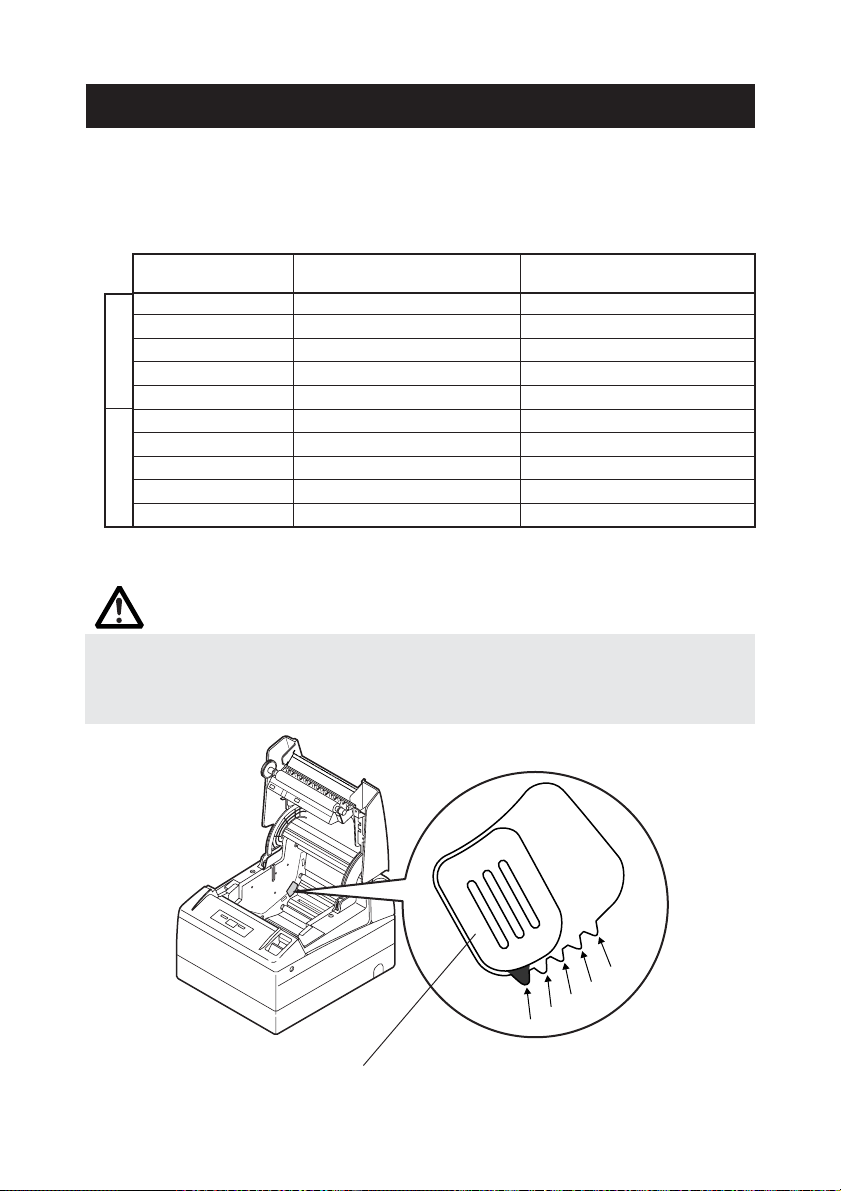

Caution label is attached on the position shown in

the following figure. Carefully read the precautions

in handling before using the printer.

THESE LABELS INDICATE THE

RISK OF ANY INJURY DUE TO

"HIGH TEMPERATURE" OF

THE PRINT HEAD AND "SAWTOOTHED EDGE" OF THE

MANUAL CUTTER.

— 5 —

Page 9

CAUTION

■ Do not transport this printer with the paper roll inside.

•Printer failure or breakage may occur.

To prevent possible malfunction or failure observe the following.

■ Avoid operating the printer without paper properly loaded.

■ Avoid the use of paper not complying with specifications.

•May result in poor print quality.

■ Avoid using torn pieces of paper or spliced with plastic adhesive tapes.

■ Avoid forcibly pulling already loaded paper by hand.

■ Avoid wedging the paper into the printer.

•May jam paper. To release, refer to “Removing Jammed Paper” in this manual.

■ Avoid using a sharp pointed device to operate panel keys.

■ Be sure to firmly insert the cable plug into its mating socket.

•A cross connection may damage the printer’s internal electronics or the host

system’s hardware.

■ Only use the printer with devices that have designated solenoid specifications for

the cash drawer interface connector.

• Neglecting this caution may result in malfunction or failure.

To prevent injury and printer failures from worsening, observe the following:

■ Do not touch the printing surface of the thermal head.

■ Do not touch any of the moving parts (e.g., paper cutter, gears, active electrical

parts) while the printer is working.

■ In case of trouble do not attempt to repair the printer. Ask Citizen Systems

service for repair.

■ Be careful that the printer cover does not entrap your hands or fingers.

■ Be careful with sharp edges on the printer. Do not allow them to injure you or

damage property.

•May result in electric shock, burn, or injury.

If the printer emits smoke, an odd smell, or unusual noise while printing, immediately

abort the current print session and unplug the printer from the supply outlet.

DAILY MAINTENANCE

Observe the following precautions for daily maintenance.

■ When cleaning the printer, always turn it off and unplug it from the supply outlet.

■ Use a soft, dry cloth for cleaning the surface of the printer case.

■ For severe stains, use a soft cloth slightly dampened with water.

■ Never use organic cleaning solvent such as alcohol, paint thinner, trichloroethylene,

benzene, or ketone. Never use a chemically processed cleaning cloth.

■ To remove paper dust, use a soft brush.

CAUTION

• The thermal head is at a dangerously high temperature immediately after printing.

Allow it to cool off before launching maintenance work.

— 6 —

Page 10

1. GENERAL OUTLINE

This product is thermal line printers designed for use with a broad array of terminal

equipment including data, POS, and kitchen terminals.

With extensive features, they can be used in a wide range of applications.

1.1 Features

● Versatile roll capacity with ability to use 80 mm, 82.5 mm and 112 mm wide paper

rolls.

● Can use paper roll with a maximum of 102 mm diameter.

● Drop-in paper loading mechanism facilitating easy paper handling and head cleaning.

● High speed (150 mm/s) printing.

● Equipped with USB interface as standard plus a choice of either a serial or parallel

interface.

● Replaceable interface board.

● High-speed parallel interface (Parallel interface model)

● Built-in cash drawer interface.

● Auto cutter mechanism provided as a standard.

● User customization such as memory switch setting are available.

● Page mode

● Registration of user-defined characters and logos into flash memory.

● Barcode & 2D Barcode printing is supported.

● 2-color printing is supported (When specified paper is used).

● Error indication is available with LED or buzzer.

[Only CT-S4000L, CT-S4000DCL]

● High speed (132 mm/s) printing.

●Label paper of 58 to 107 mm wide in addition to 112-mm wide label paper is usable

without step.

[Only CT-S4000L, CT-S4000DCL, CT-S4000M, CT-S4000DCM]

● Paper sensor sensitivity adjustment system by volume is adopted.

— 7 —

Page 11

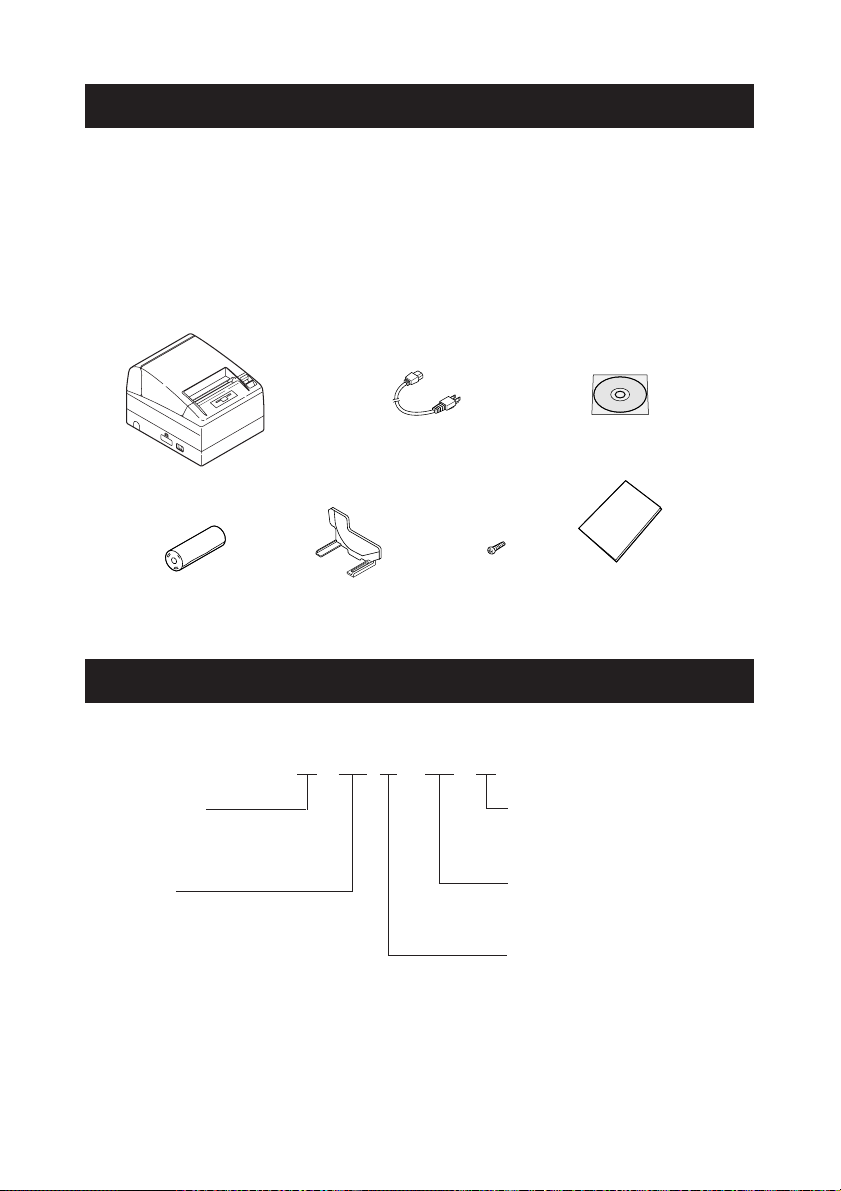

1.2 Unpacking

When unpacking the printer, confirm that the following are provided:

● Printer: 1

● AC power cord : 1 (for CT-S4000, CT-S4000L, CT-S4000M)

● CD-ROM: 1

● Sample paper roll: 1 roll

● Partition: 1

● Screw: 1

● Quick start guide: 1

CT-S4000

Sample paper roll

AC power cord

Partition Screw Quick start guide

CD-ROM

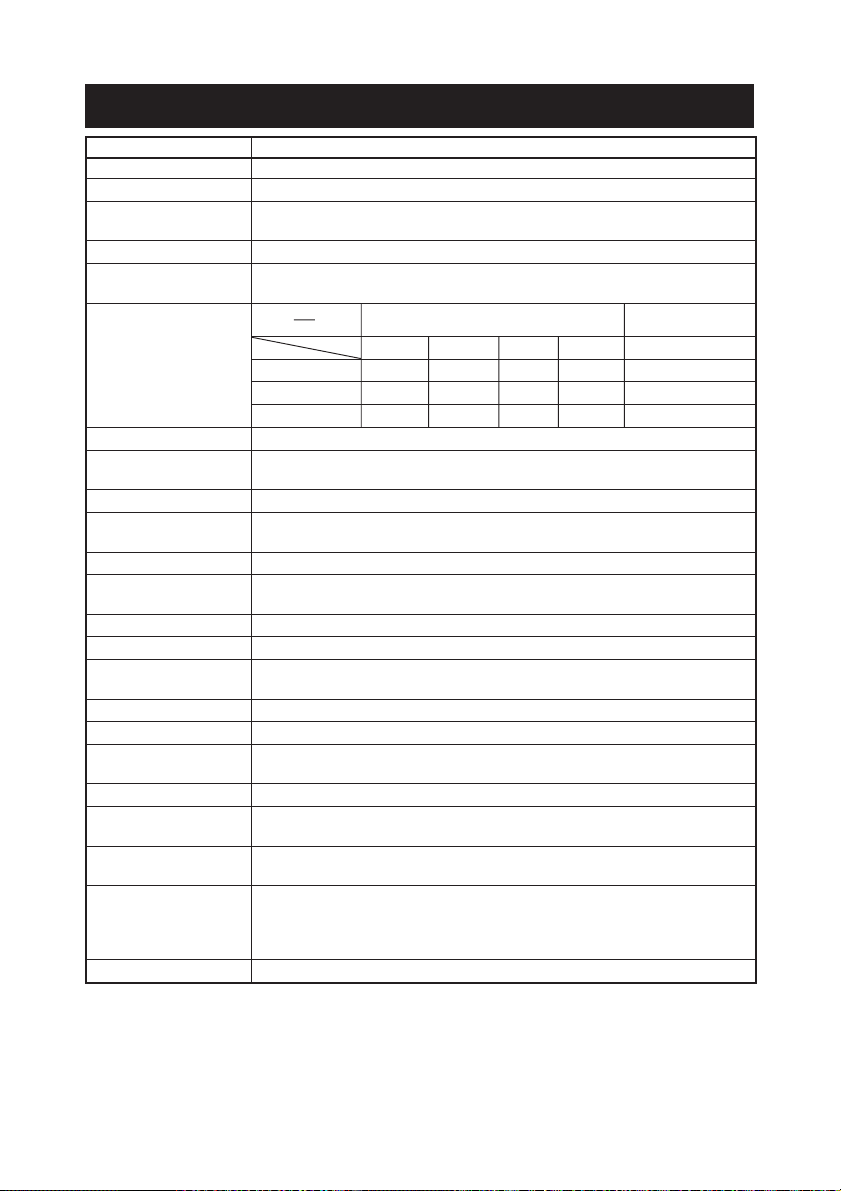

1.3 Model Classification

The printer models are classified by the following designation method:

CT - S4000 RS E - BK -

Power supply

No marking: AC power type

(built-in power supply)

DC: DC power supply type

Interface

PA: IEEE1284 & USB

RS: RS-232C & USB

UB: USB only (Option)

*Description marked “*L” in this manual is the description for CT-S4000L/CT-S4000DCL and that

marked “*M” for CT-S4000M/CTS4000DCM. Read this manual after confirming your model in

use.

Label/Black mark

No marking: Standard

L: Label

M: Black mark

Body case color

WH: Cool white

BK: Black

Character set, AC cable,

E: Europe

U: USA

— 8 —

Page 12

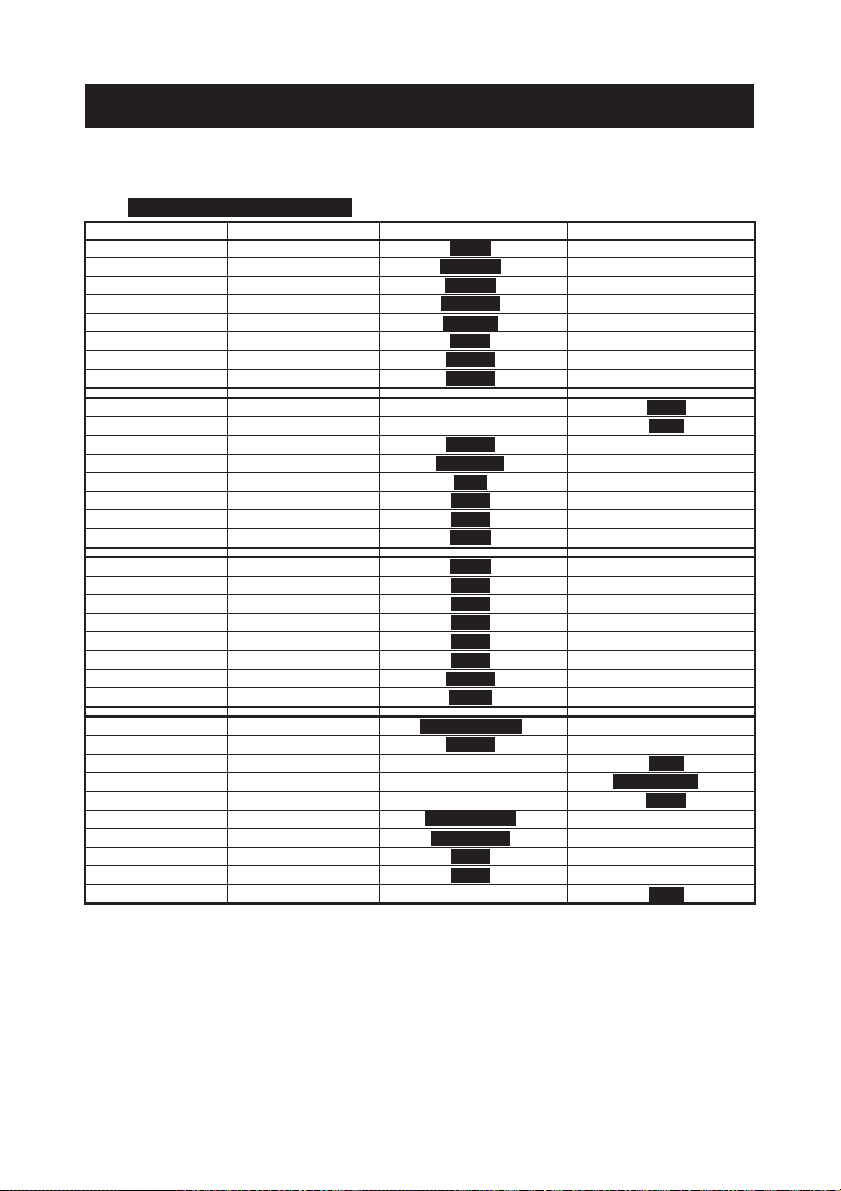

1.4 Basic Specifications

Item Specifications

Model CT-S4000 PA/RS/UB, CT-S4000DC PA/RS/UB

Print method Line thermal dot print method

Print width

Dot density 8 dots/mm (203 dpi) in holizontal & vertical

Print speed 150 mm/s (Fastest, print density 100 %), 1200 dot lines/s

Number of print

columns

Character size *3 Font A: 1.50 × 3.00 mm Font B: 1.13 × 3.00 mm Font C: 1.00 × 2.00 mm

Character type Alphanumeric, International, PC437 PC850/852/857/858/860/863/864/

User memory

Types of barcode and UPC-A/E, JAN (EAN) 13/8 columns, ITF, CODE 39, CODE 128,

2D barcode CODABAR, CODE 93, PDF417, QR Code

Line spacing *4 4.23 mm (1/6 inch)

Paper roll Thermal paper roll: 112 mm/82.5 mm/80 mm ×Maximum φ102 mm

Interfacing Serial (RS-232C compliant), Parallel (IEEE 1284 compliant), USB

Cash drawer interface 2 cash drawers are supported.

Input buffer 4K bytes/45 bytes (selectable) in Serial or Parallel interface, 16K bytes in

Supply voltage AC100 to 240V, 50/60 Hz, 130VA / DC24V, 2.0A

Power consumption Approx. 70W (in normal prining)

Weight Approx. 2.3 Kg for CT-S4000, CT-S4000L, CT-S4000M

Outside dimensions 177 (W) × 213 (D) × 147 (H) mm

Operating temperature 5 to 45°C, 10 to 90% RH (No condensation)

and humidity

Storage temperature −20 to 60°C, 10 to 90% RH (No condensation)

and humidity

Reliability Print head life: 100 km, 1 × 10

Safety standard UL, C-UL, FCC Class A, TÜV-GS, CE Marking

Notes:

*1: When paper width is 112, 82.5, 80 mm

*2: The number of printable columns are selectable with a Memory Switch.

The number of columns in this table refers to typical model. Printer varies partly in the number

of columns depending on printer specifications.

*3: As each character size includes the space inside the character font, actual character looks

smaller.

*4: The line spacing is selectable with a command or Memory Switch. When the printer is turned

on, it will be slelecte with the memory switch.

*1 104 mm/832 dots, 82.5 mm/660 dots, 72 mm/576 dots

104 mm/832 dots, 72 mm/576 dots, 50 mm/400 dots

Only in label mode, 132 mm/s (max), print density level is 88%, and 1056 dot lines/s.

Number of print columns

*2

Font

Paper width

112mm 82.5mm 80mm 58mm*L

(columns)

Font A 69 55 48 33 12 × 24

Font B 92 73 64 44 9 × 24

Font C 104 82 72 50 8 × 16

865/866/WPC1252/Katakana/Thai code 18

384 KB (Capable of registering user-defined characters and logos)

0

Paper thickness: 65-150 µm

−1

0

0

−1

−1

USB interface

Approx. 2.0 Kg for CT-S4000DC, CT-S4000DCL, CT-S4000DCM

8

pulses (At normal temperature/

humidity with recommended paper used)

Auto cutter life:1 million cuts (At normal temperature/

humidity with recommended paper used)

— 9 —

Dot configuration

(Dot)

Page 13

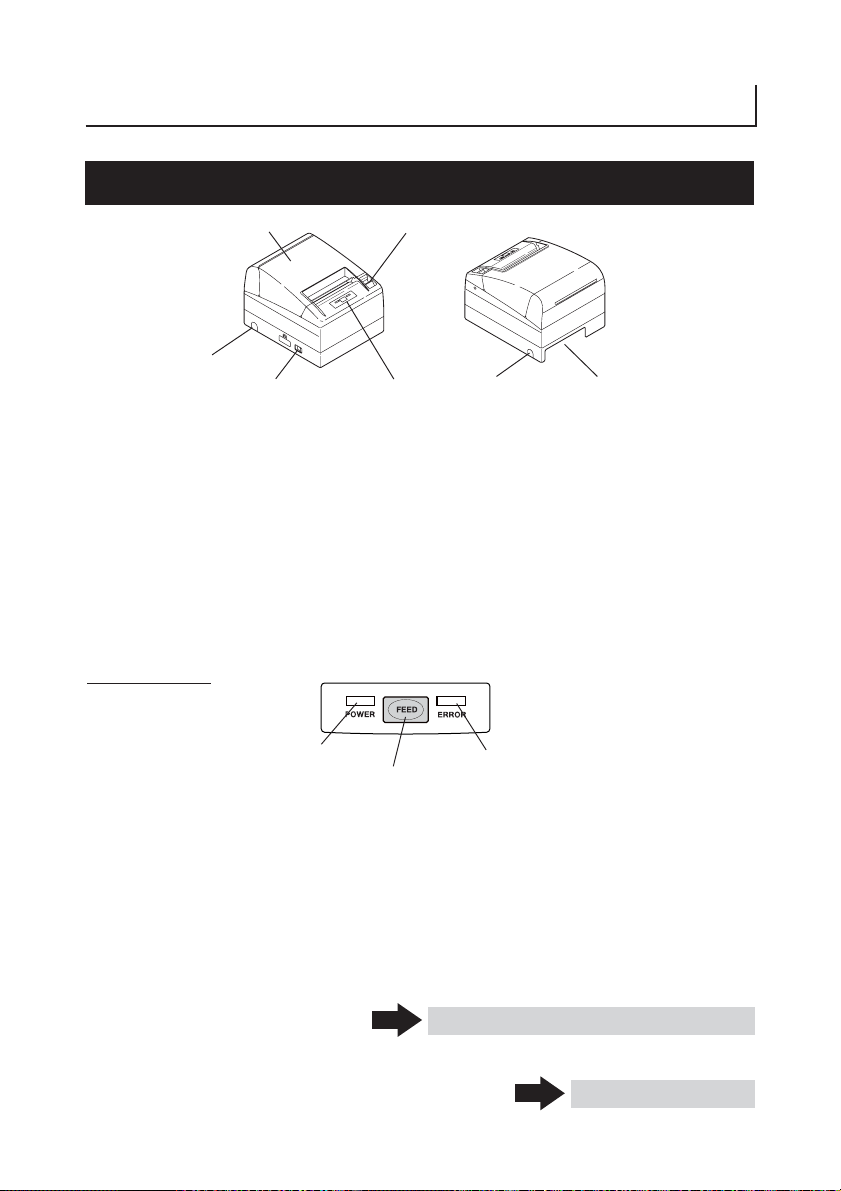

2.

EXPLANATION OF PRINTER PARTS

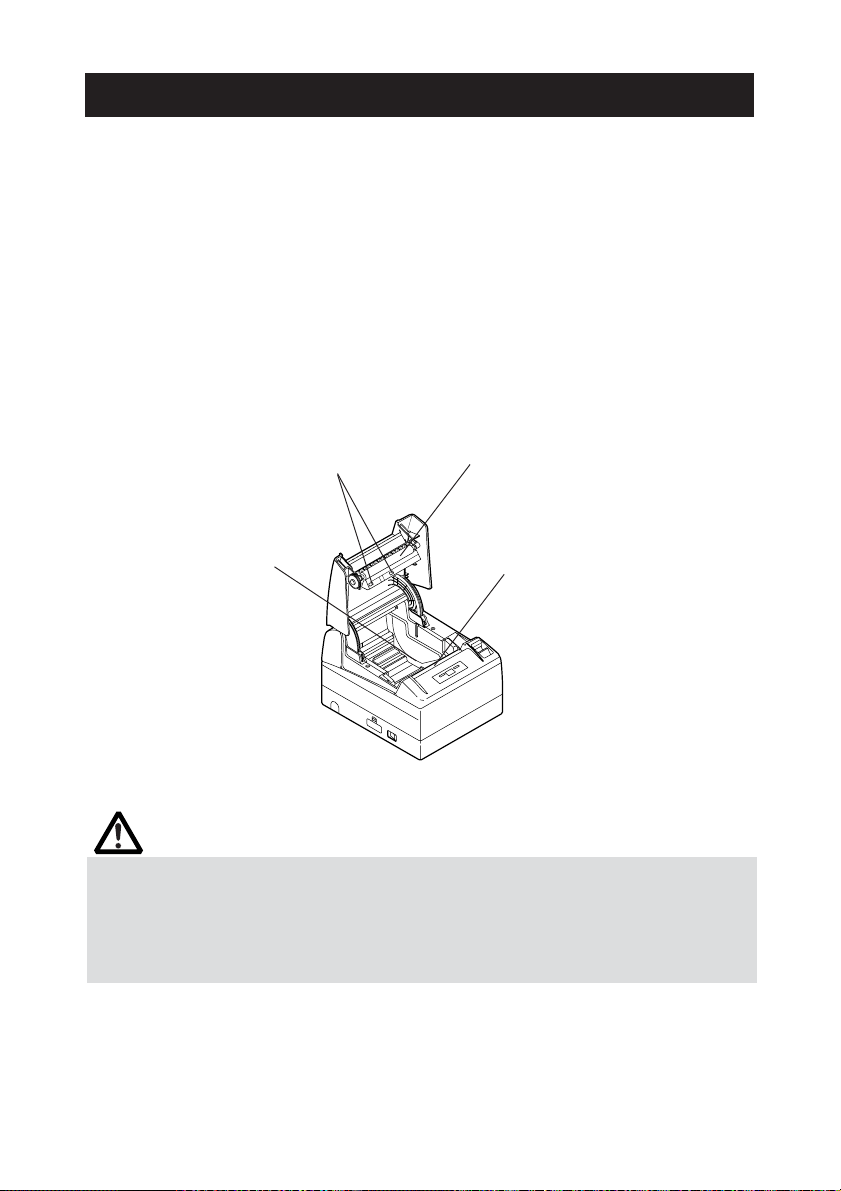

2.1 Printer Appearance

Printer cover

Side opening

Power switch

● Printer cover

Paper is loaded under this cover.

● Cover open button

To refill or replace paper, open the printer cover by pulling the cover open button

forward.

● Power switch

This switch turns the printer power ON/OFF.

● Side opening

The cables connected to the printer can be routed through this side opening. (Before

use, push the small plastic barrier on the cover until it brakes.)

Operation Panel

(Front view) (Rear view)

Cover open button

Operation panel

Side opening

Rear connector

POWER LED

● POWER LED

Illuminated when the printer power is on and off when the printer power is off. May

blink or light in a special mode or in case of failure.

● ERROR LED

Illuminated or blinks when paper is empty or in case of failure.

The interval length of blinking represents the type of error.

● FEED button

Pressing this button once causes the paper to feed one line. The longer the button is

pressed, the more paper is fed.

Pressing this button causes the paper to feed to the next Black Mark position in Black

Mark mode.

In case of auto cutter error, press the FEED button after removing the cause of the

error.

FEED button

— 10 —

ERROR LED

See 5.3 Manual Setting of Memory Switch

See 4.6 Error Indication

Page 14

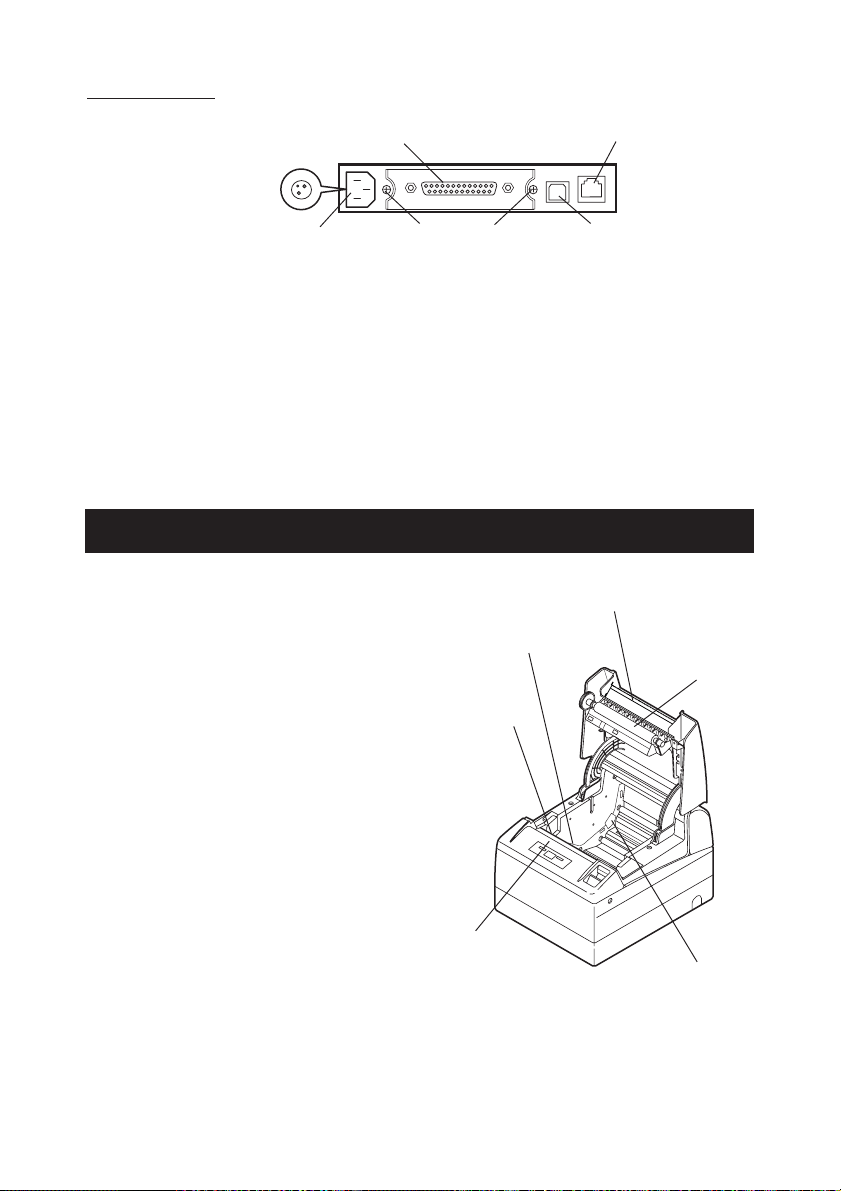

Rear Connectors

Power connector

(DC power supply type)

Interface connector

(Serial, parallel, etc.)

Cash drawer

kick-out connector

AC inlet

(AC power type)

Interface board

mounting screws

USB connector

● Interface connector (Serial, parallel, etc.)

Connects to the interface cable. A DIP switch is provided on the serial interface board.

● Cash drawer kick-out connector

Connects to the cable from the cash drawer.

● AC inlet (AC power type)

Connects to the AC power cord.

● Power connector (DC power supply type)

Connects to the cable from DC power source.

2.2 Printer Cover Inside

● Paper feed roller

Feeds paper as part of print

mechanism.

● Paper-near-end sensor

Detects near paper end, change

position in accordance with the outer

diameter of paper core.

● Auto cutter

Cuts the paper with a command at the

end of printing. Cutting method is

selectable between partial cut and full

cut with a command.

* Factory default of the memory SW4-8

is set to "Partial cut", so that a

command will be ignored.

However, full cutting is set for the

model supporting label.

Paper-end sensor

Print (thermal)

head

Manual cutter

Paper feed roller

● Manual cutter

Tears the paper by hand.

● Print (thermal) head

Prints characters and/or graphic data

on thermal paper.

● Paper-end sensor

Stops printing when this sensor

detects paper end.

Auto cutter

— 11 —

Paper-near-end

sensor

Page 15

3. PREPARATION

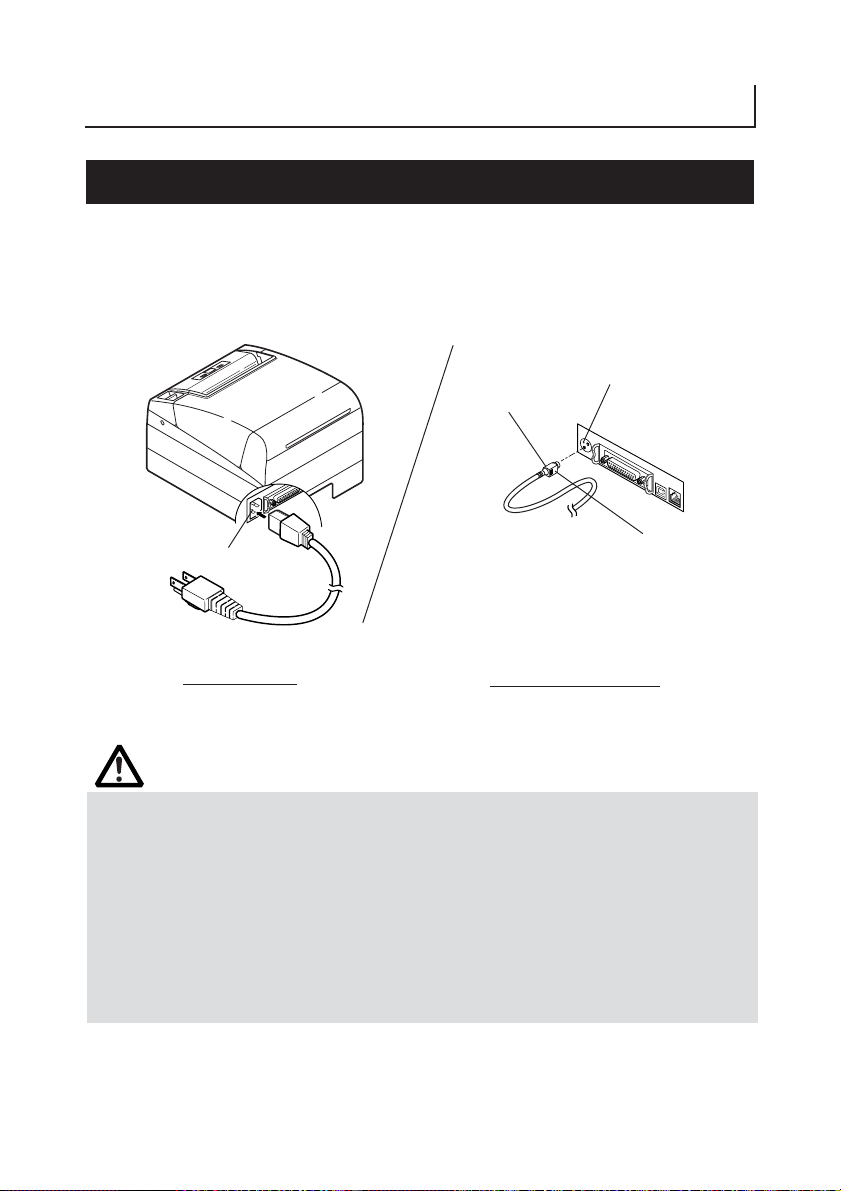

3.1 Connecting the AC Power Cord

1. Tu rn off the printer power switch.

2. For AC power type (with built-in power supply), connect the AC power cord

to the AC inlet at the back of the printer and plug the AC power cord into the

wall outlet.

Power connector

Cable connector

Flat side

AC inlet

AC power cord

AC power type

(built-in power supply)

DC power supply type

CAUTION!

■ When disconnecting a cable, DO NOT pull out by the cable. Always hold the plug.

■ Always keep the AC power supply away from other noise generating equipment.

■ DO NOT pull the AC power cord. Otherwise fire, electric shock, or power disconnection

may result.

■ If lightning is approaching, unplug the AC power cord from the wall outlet. Otherwise

fire or electric shock may result.

■ Keep the power cord away from heat generating appliances. Otherwise the shield of

power cord may be fused resulting in a fire or electric shock.

■ If the printer will not be used for a long time, leave it disconnected from its supply

outlet.

■ Avoid locating the AC power cord in places which may cause tripping or falling.

— 12 —

Page 16

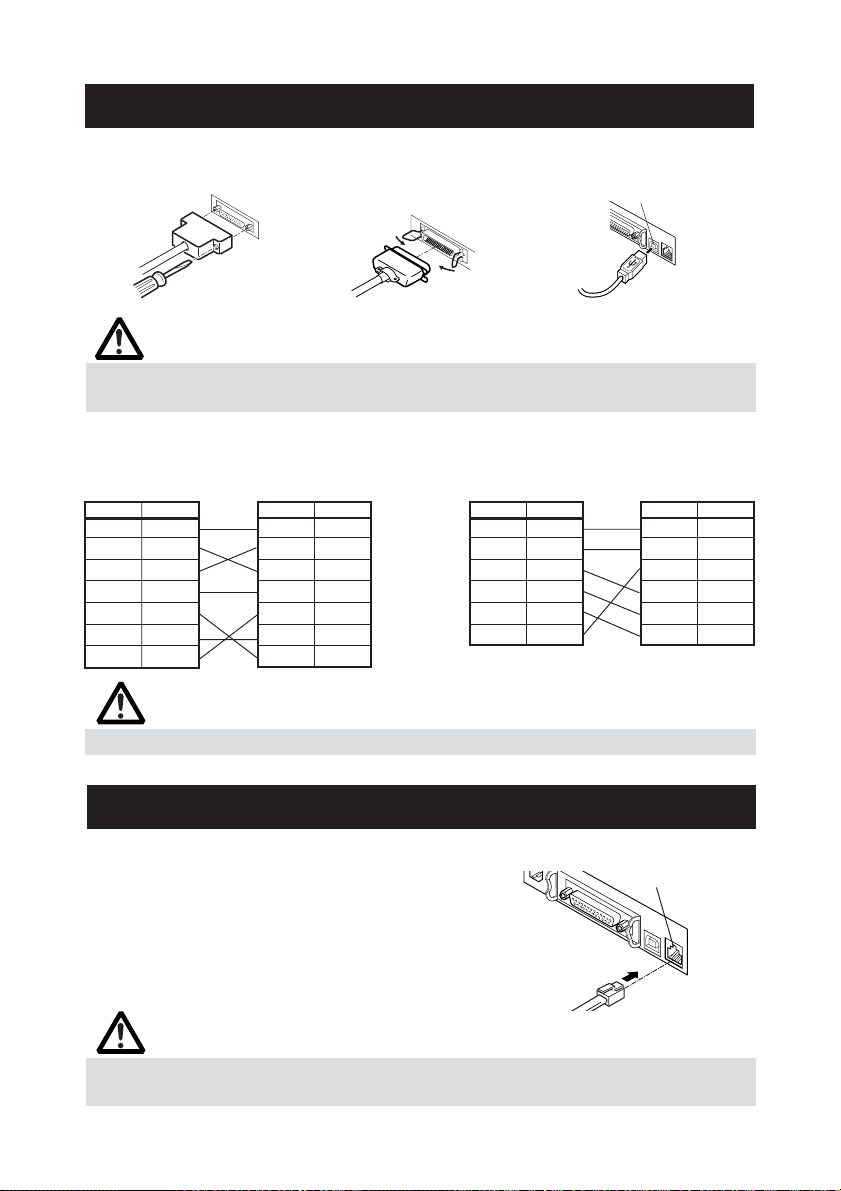

3.2 Connecting Interface Cables

Confirm that the power switch is OFF and connect the interface cable.

Orient the interface cable terminal correctly and insert it into the interface connector.

USB connector

Serial Interface Parallel Interface

USB Interface

CAUTION!

■ When disconnecting the cable, always hold the connector.

■ Be careful not to insert the USB interface cable into the cash drawer kick-out connector.

For serial interface cable, use the one with the following connection.

25-pin - 25-pin cable 9-pin - 25-pin cable

PC

Signal Pin

FG 1

TXD 2

RXD 3

CTS 5

DSR 6

SG 7

DTR 20

Printer

Pin Signal

1FG

2TXD

3RXD

4RTS

6 DSR

7SG

20 DTR

PC

Signal Pin

RXD 2

TXD 3

DTR 4

SG 5

DSR 6

CTS 8

Printer

Pin Signal

2 TXD

3 RXD

4RTS

6 DSR

7SG

20 DTR

CAUTION!

Avoid locating the interface cable in places which may cause tripping or falling.

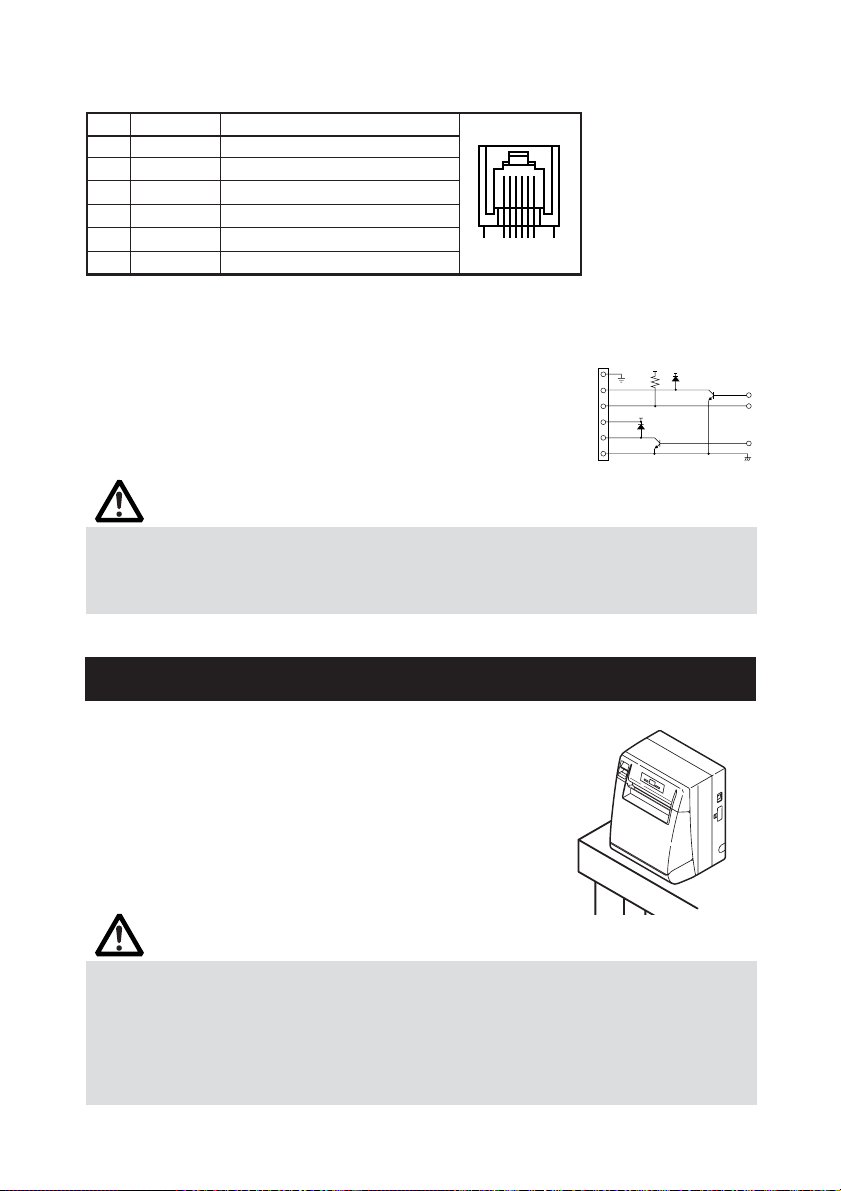

3.3 Connecting the Cash Drawer

1. Confirm that the power switch is OFF.

2. Confirm the top and bottom of the cash

drawer cable connector and insert it into

the cash drawer kick-out connector at the

back of the printer.

3. Screw the cash drawer's ground wire to

the body of the printer.

Cash drawer cable

connector

Cash drawer

kick-out connector

CAUTION!

DO NOT connect any other device than the specified cash drawer to the cash drawer

kick-out connector. (DO NOT connect a telephone line either.)

— 13 —

Page 17

(1) Connector Pin Configuration

VDR

1

2

3

4

5

6

VDR

5V

No. Signal Function

1FG Frame Ground

2 DRAWER 1 Drawer 1 drive signal

3 DRSW Drawer switch input

4 VDR Drawer drive power supply

5 DRAWER 2 Drawer 2 drive signal

6 GND Common ground on circuits

61

Connector used:

TM5RJ3-66 (Hirose)

or equivalent

Applicable connector:

TM3P-66P (Hirose) or

equivalent

(2) Electrical characteristics

1) Driving voltage: 24 VDC

2) Driving current: Approx. 1A max. (shall not exceed 510

ms.)

3) DRSW signal: Signal levels: “L” = 0 to 0.5 V, “H” = 3 to 5 V

(3) DRSW signal

DRSW signal status can be tested with the DLE+EOT,

GS+a, or GS+r command or

at pin 34 on the parallel interface port.

(4) Drive Circuit (printer side)

CAUTION!

■ No output is produced while printing.

■ The cash drawers 1 and 2 cannot be driven simultaneously.

■ A solenoid used for the cash drawer should be of 24 Ω or more. The output current

should be kept at 1A or less; otherwise, breakdown or burning could occur.

3.4 Installing the Printer

The printer can be installed horizontally, vertically, and on the wall.

At the time of shipment, the printer is set for horizontal

installation. To install the printer vertically or on the wall, the

following adjustments are required.

1. Adjustment of paper near-end sensor position (See

section 3.7)

2. Anti-slip rubber feet (for vertical setting)

3. Optional wall-mounting kit (for wall-mounting)

Ver tical position

CAUTION!

■ When used in vertical position, the printer ejects paper not to fall naturally even with

full cutting. Be careful in using the printer built in equipment, etc.

■ Ensure that the wall on which the printer is mounted has enough strength before

installation.

■ When using in horizontal setting, avoid cutting full. Otherwise, the cut paper may

drop into the cutter and may result in double cutting and narrow pieces of paper. This

may cause paper jam.

— 14 —

Page 18

80mm 82.5mm58mm

→

→

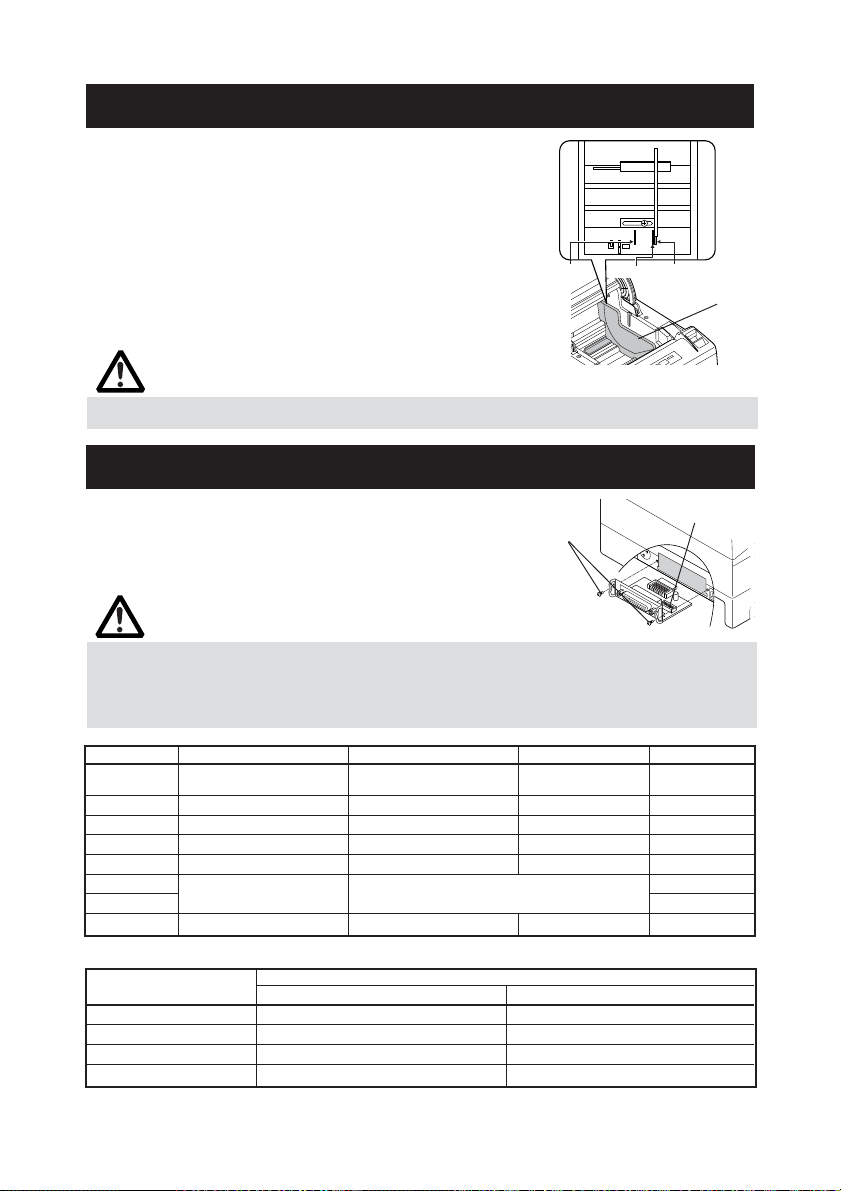

3.5 Partition for Paper Roll

At the time of shipment, this partition is not installed.

1. Confirm that the power switch is OFF.

2. Open the printer cover.

3. Insert the partition into the slot and align it

with the scale inside of the printer which

meets the width of the paper roll used. When

using the 80mm or 82.5mm wide paper roll,

set the partition by using the accessory screw.

*58 mm is only for label supporting model.

4. Change the setting of paper width by reffering

to the section 5.2, "Manual Setting of Memory

Switch".

Partition

Scales

Partition

CAUTION!

When using 112 paper roll, the partition is not used.

3.6 Setting DIP Switch

The DIP switch is present on the serial

interface board.

The function of each switch is as shown

below.

Interface board

mounting screws

DIP switch

CAUTION!

■ As for the setting of the serial interface, it gives priority to the setting of the memory

switch rather than the DIP switch as the factory default.

■ Consult with the dealer where the printer was purchased when the change of the DIP

switch setting is necessary.

Switch No. Function ON OFF

1

Communication condition

setting method

2 Hand shake XON/XOFF DTR/DSR OFF

3 Bit length 7 bits 8 bits OFF

4 Parity check With parity None OFF

5 Parity selection Even parity Odd parity OFF

6 OFF

Baud rate selection See Table below.

7 ON

8 INIT Reset Invalid OFF

Selecting baud rate

Baud Rate (bps)

2400 OFF OFF

4800 ON OFF

9600 OFF ON

19200 ON ON

DIP switch setting Memory switch OFF

67

setting

Switch No.

38400, 57600 and 115200 bps can also be selected by a command, etc.

— 15 —

InitialSettings

Page 19

3.7 Adjusting the Paper Near-end Sensor

1. Lightly push in the paper near-end sensor unit.

2. Move the paper near-end sensor unit to the right and left while keeping to

press it. The position to be set varies in accordance with the setting of the

printer, horizontal or vertical, or diameter of the paper roll as shown in the

following figure.

Sensor Position

**1 φ21.0 φ18.0

*2 φ24.5 φ21.5

3 φ28.0 φ25.5

Horizontal

Vertical

* Factory setting for USA version

** Factory setting for other country version

4 φ31.5 φ28.0

5 φ35.0 φ32.0

5 φ21.0 φ18.0

4 φ24.5 φ21.5

3 φ28.0 φ25.5

2 φ31.5 φ28.0

1 φ35.0 φ32.0

Roll paper diameter at the

detection of near-end

Outer core diameter of

roll paper used

CAUTION!

■ Paper remaining differs by the type of paper roll used.

■ The external diameter of the paper roll is only for reference.

■ When a paper end error is detected incorrectly during using a paper roll with a honey-

comb type core, move the sensor position to the larger number.

Paper-near-end

sensor unit

— 16 —

5

4

3

2

1

Page 20

4.

MAINTENANCE AND TROUBLESHOOTING

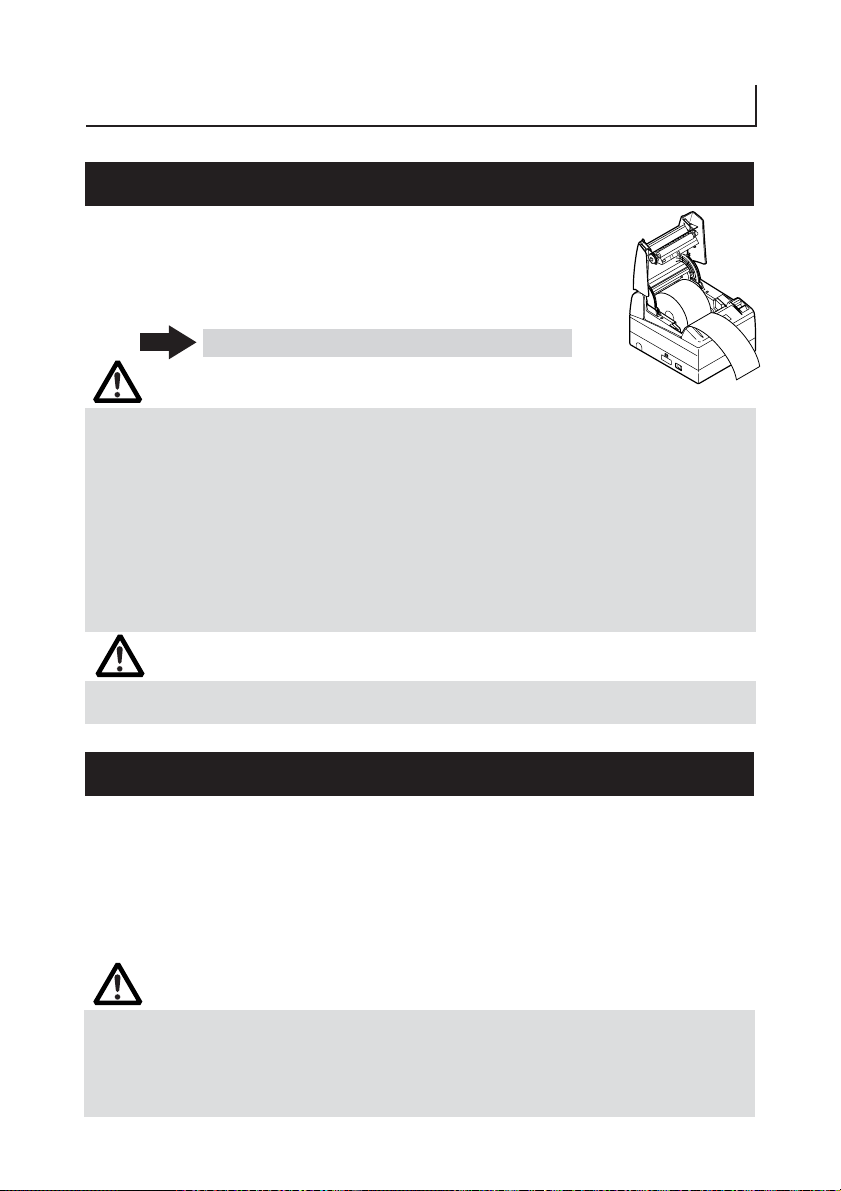

4.1 Setting/Replacing the paper roll

1. Pull the cover open button forward.

2. Open the printer cover.

3. Insert a paper roll with its print area facing down as shown

in the figure and pull out the paper end straightforward

several cm (or inches) out of the printer.

4. Firmly close the printer cover until a click can be heard.

See 5.3 Manual Setting of Memory Switch

CAUTION!

■ Always use the specified types of paper roll.

■ Confirm that the paper roll is set correctly.

■ When the paper is skewed and not extended straightforward from under the printer

cover, open the printer cover and adjust the paper correctly.

■

When the printer cover is opened after setting the paper, be sure to pull the paper

straightforward several cm (or inches) out of the printer, and then close the printer cover.

■ When closing the printer cover, press on the center part of the cover to close it firmly.

■ When setting paper, be careful not to have your finger injured by the manual cutter or

paper edge.

■ In the case of selecting "Valid" with memory SW4-3, the paper is fed and cut

automatically when the printer cover is closed.

WARNING

When opening the printer cover, DO NOT touch the print head or cutter blade. Otherwise,

burning or injury of hand may result.

4.2 Removing Jammed Paper

1. Tu rn the printer power off.

2. Open the printer cover.

If the cutter blade remains protruded with paper jammed, do not force the

printer cover to open. Referring to the section 4.7, restore the blade to the

normal position and then open the cover.

3. Remove the jammed paper including any remaining paper shreds.

4. Turn on the printer. The auto cutter mechanism is initialized and the alarm is

cleared.

CAUTION!

■ If the cutter blade remains protruded with paper jammed, DO NOT open the printer

cover foribly and try to turn OFF and ON the printer power. If the cutter blade cannot

be restored, refer to the section 4.7.

■ The print head is hot immediately after printing. DO NOT touch it with your hand. DO

NOT touch the heating element of the head with a bare hand or metal object either.

— 17 —

Page 21

4.3 Periodic cleaning

If the print head or platen is dirty, clear printing is not available or fault may occur. If

paper dust or the like is present on the sensor protection sheet, label paper or blackmark

paper may not be detected correctly. Periodic cleaning in accordance with the following

procedure is recommended.

1. Tu rn the printer power off.

2. Open the printer cover.

3. Wait several minutes. Wipe off any debris on the heating element of the

head using a cotton swab soaked in ethyl alcohol.Just after printing, high

temperature remains in the print (thermal) head. Be careful not to touch it by

hand.

4. Moisten the tip of the cotton swab with water and wipe the dirt on the surface

of the sensor protection sheet. Avoid using solvent such as alcohol. Use of

it may result in smoky sensor protection sheet.

Sensor

Sensor

Platen

Print (thermal) head

CAUTION!

■ Do not touch the surface of the heating element of the print head by bare hand or

metal.

■ Wipe the dust off the surface of the platen periodically with a cotton swab moistened

with ethyl alcohol. Especially, when full cutting is used for label paper, paper dust may

adhere on the platen depending on the property of liner sheet, roll paper diameter,

environmental condition of using the printer, etc.

— 18 —

Page 22

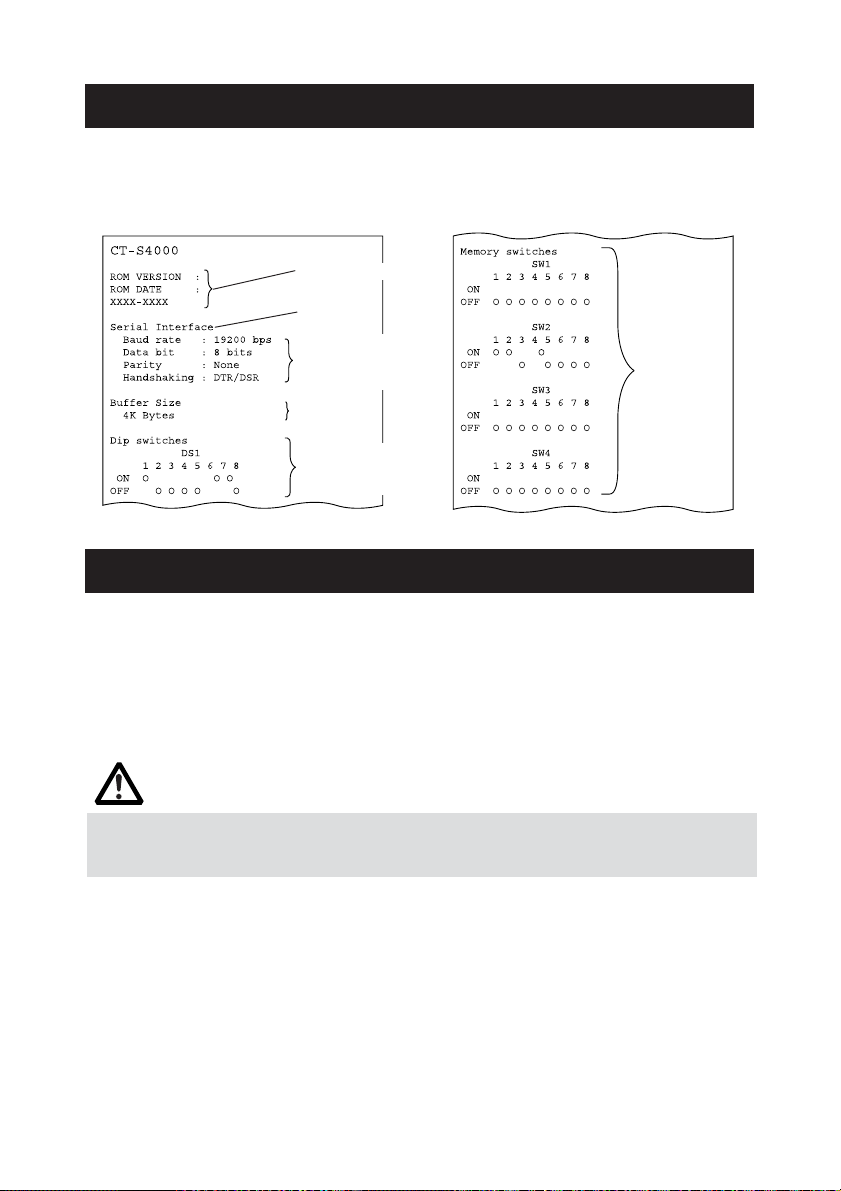

4.4 Self-printing

Insert paper into the printer. With the FEED button pressed and held, turn the printer

power on, keep the FEED button held for about 1 second, and then release the FEED

button. The printer starts self-printing. The printer prints model name, version, DIP

switch setting, memory switch setting, and built-in fonts.

Firmware version

Interface

Serial communication

condition (Only serial

interface model)

Buffer size

DIP switch setting

(Only serial interface

model)

Memory

switch

setting

4.5 Hexadecimal Dump Printing

This function is to print all received data in hexadecimal numbers. If problems such as

missing data, data duplication, etc. should occur, this function allows checking whether

or not the printer is receiving data correctly.

Load the paper into the printer and keep the printer cover open. With the FEED button

pressed and held, turn the printer power on and then close the printer cover. The printer

prints “HEX dump print mode” followed by the received data printed in hexadecimal

numbers and some characters.

CAUTION!

■ The printer prints “.” if there is no characters corresponding to data.

■ During hexadecimal dump, functions except some command will be disabled.

■ If print data DOES NOT cover a line, press the FEED button to print the line.

When you press the FEED button three times consecutively, or you turn the printer power

off, or the printer receives a reset signal from the interface, the hexadecimal dump printing

is terminated.

Print example

HEX DUMP PRINT MODE

1B 21 00 1B 20 04 41 42 43 44 .!.. .ABCD

45 46 47 48 49 4A 4B 4C 4D 4E EFGHIJKLMN

4F 50 0D 0A 31 32 33 0D 0A OP..123..

— 19 —

Page 23

4.6 Error Indication

● Paper end

Paper out is detected in two steps: paper near-end and paper end. ERROR LED will

light when the paper is empty. If paper end is detected, refill the paper. If the printer

cover is open, a paper-end is detected.

● Printer cover open

During printing, do not open the printer cover. If you open the printer cover accidentally,

the ERROR LED blinks. Check the paper, pull the paper straightforward several cm (or

inches) out of the printer, and then close the printer cover. Printing resumes

automatically. Sending a command to resume printing may be required depending on

the memory switch setting.

● Cutter lock

If the cutter blade stops operating due to paper jam or the like, the ERROR LED blinks.

Remove the cause of the trouble and press the FEED

move and the printer cover cannot be opened, refer to the section 4.7.

● Thermal head overheat

When you print dense characters or dark image, the head temperature rises. If the

head temperature exceeds a specified level, the printer stops printing operation and

waits till the head temperature is lowered. During waiting, the ERROR LED blinks.

When the head temperature is lowered, printing resumes automatically.

● Paper jam error

If paper feeding is not normal and paper jam occurs in the platen, etc., printing and line

feed operation stop and ERROR LED blinks.

● Power switch operation error

If you turn power on again just after powering off, an error may occur.

Before turning power on again, wait till POWER LED goes off completely after powering

off.

button

. If the blade still does not

● Black Mark detection error (in Black Mark mode)

When Black Mark cannot be detected even if a certain amount of paper feed is

carried out for Black mark detection, a Black Mark detection error occurs. If black

detection continues more than the specified period, a No Paper condition is

assumed and the same error as No Paper is indicated.

● Waiting for paper (label) cutting

If the “GS+FF” command is executed under the condition that auto cutter operation

is disabled (memory switch 2-2 is OFF), label paper is ejected and ERROR LED

blinks. When the FEED switch is pressed under this circumstance, paper returns

to the starting position of printing and ERROR LED goes off.

● Paper (label) detection error

If detection is not available even with paper feeding of given amount for detecting

space between labels or label paper, ERROR LED blinks. In this case, adjust the

sensor in the paper sensor adjustment mode. If no detection occurs even after

the sensor adjustment, replace the label paper. If replacing label paper is not

effective for detection, the sensor, etc. may be faulty (degraded). Contact the

service representative.

— 20 —

Page 24

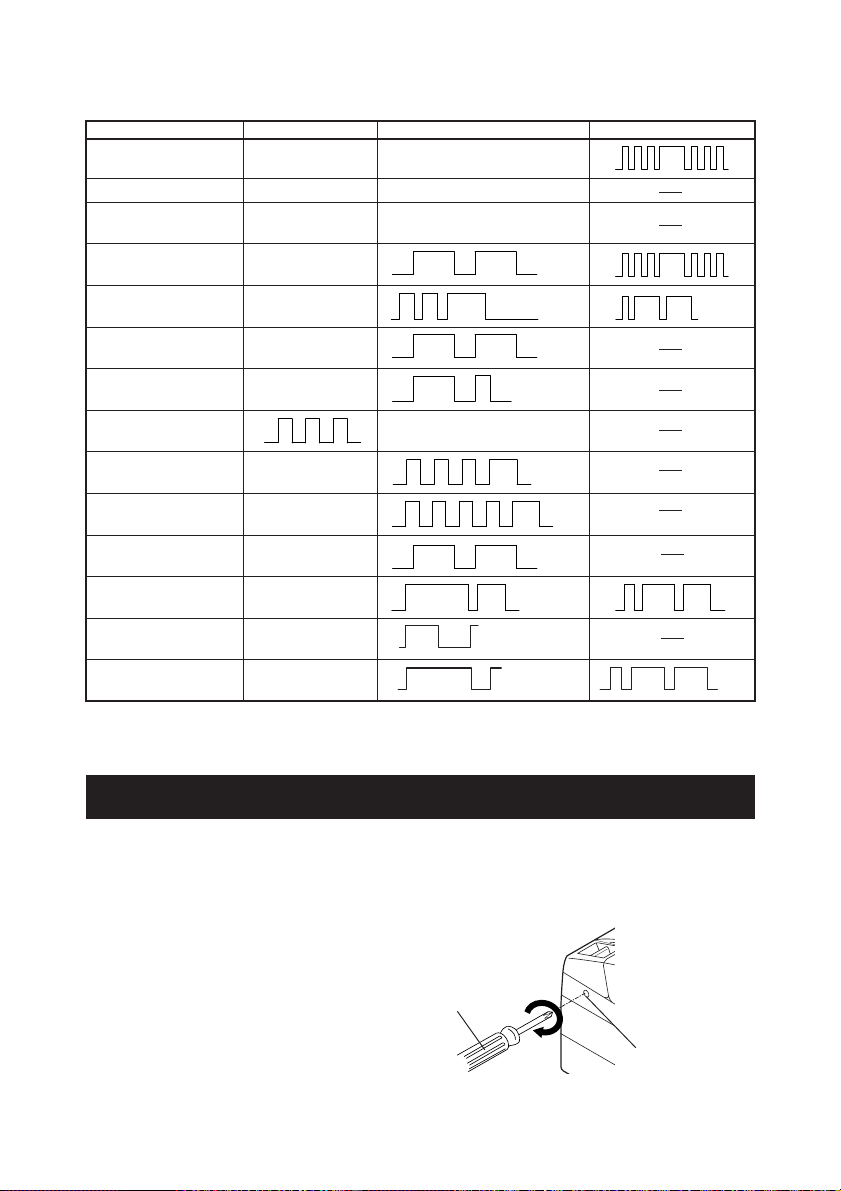

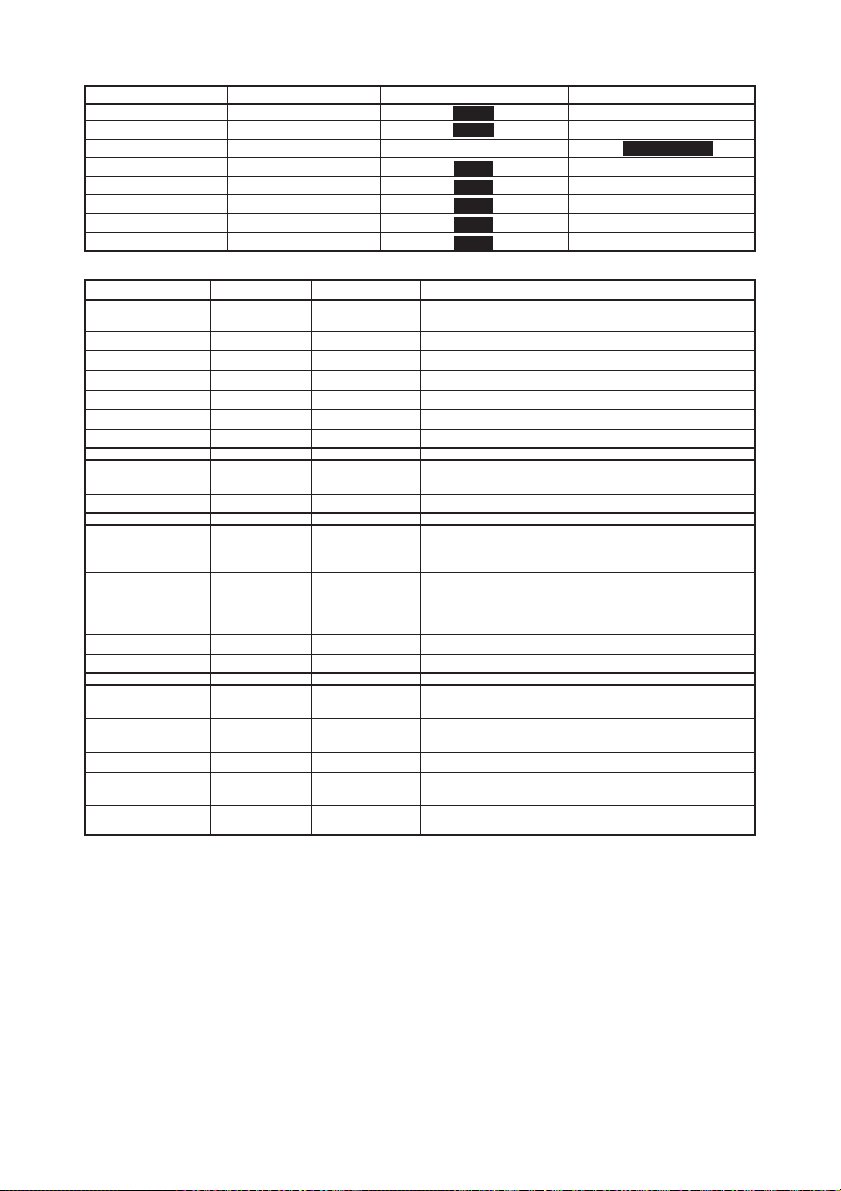

Lighting and blinking status of each error including the above is shown below.

Status POWER LED ERROR LED Buzzer

Paper-end Lights Lights

Paper near-end Lights Lights

Printer cover open Lights Lights

Printer cover open Lights

error *1

Cutter lock error Lights

Head overheat error Lights

Paper jam error Lights

Memory check error Lights

Low voltage error Lights

High voltage error or

Power switch operation error

Macro execution Lights

wait *2

Black Mark detection OFF

error

Waiting for paper OFF

(label) cutting*L, *M

Paper (label) OFF

detection error*L, *M

*1: When the printer is printing.

*2: The ERROR LED may blink even in the execution of macro function.

4.7

When the Paper Cover Cannot Be Opened

Lights

If the cutter blade remains protruded due to paper jam or for any abnormality, opening

the paper cover may be disabled. In this case, do not open the paper cover forcibly.

Insert a Phillips screwdriver (size #1) into the cutter lock releasing feed hole and turn it in

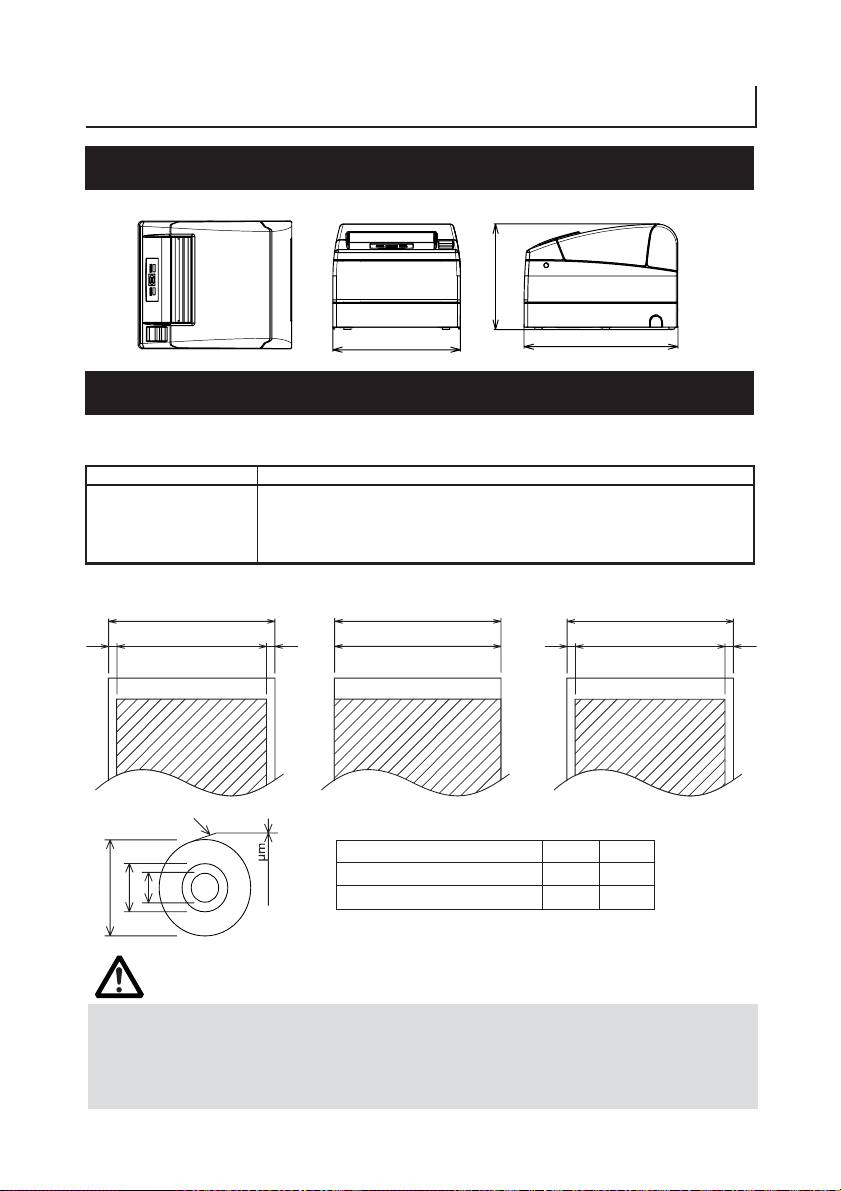

the direction of arrow (clockwise).

When you find that both ends of the

blade reached the lowest position,

stop turning the screwdriver. Open

the cover and follow the procedure

Phillips screwdriver

of removing jam or other cause of

trouble.

Cutter lock

releasing feed hole

— 21 —

Page 25

5. OTHER

5.1 External Views and Dimensions

147

(Unit: mm)

177

213

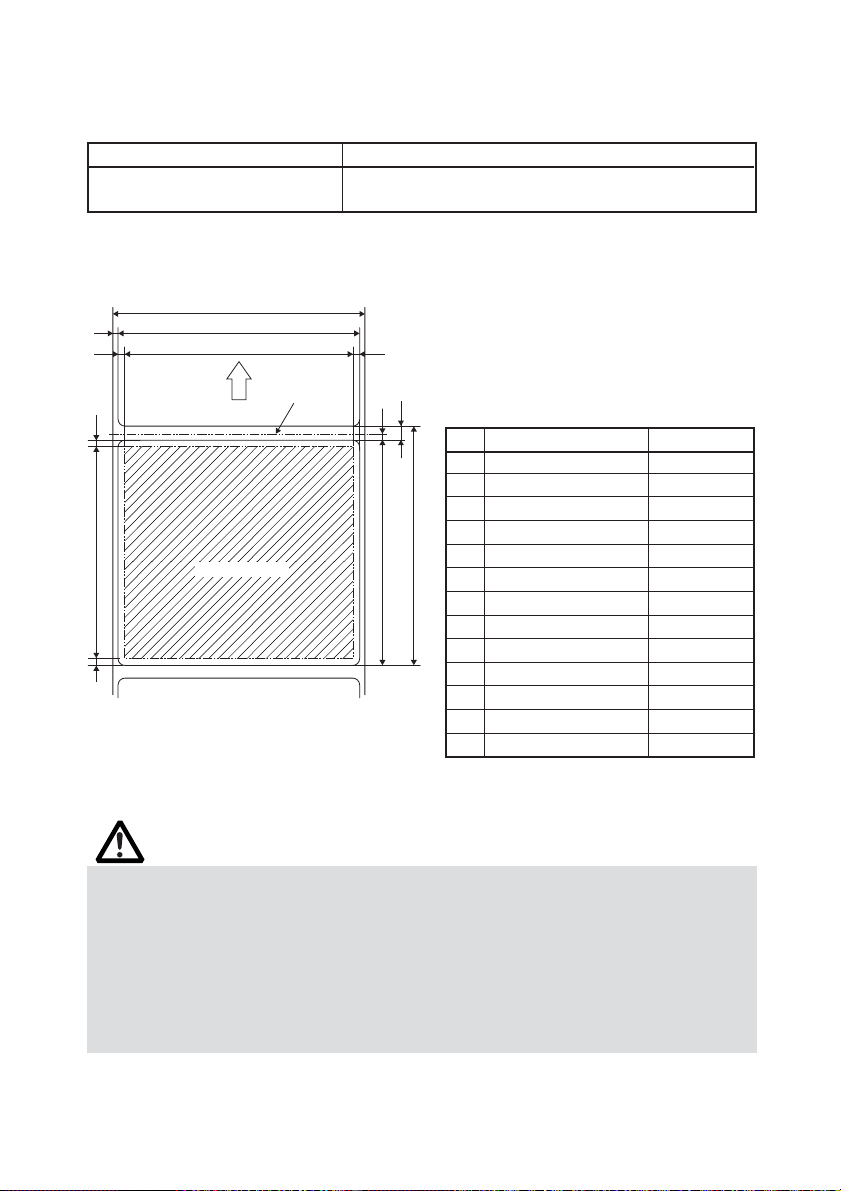

5.2 Printing Paper

Use the print paper shown in the following table or the paper with equivalent quality.

Paper Type Product Name

Recommended thermal F230AA, P220AG, HP220A, HP220AB-1, P220AB, P220AE-1,

paper roll PB670 (Red/Black), PB770 (Blue/Black) from Mitsubishi Paper

Paper width 112

Maximum print area 104

44

Printing surface

d

D

φ102 or less

TF50KS-E2D from Nippon Paper

PD150R, PD160R from Ohji Paper

0

−1

65~150

Paper width 82.5

Maximum print area 82.5

Paper thickness (µm)* 65-75 75-150

Core inner diameter d (mm) φ12 φ25.4

Core outer diameter D (mm) φ18 φ32

*Thickness of label paper is the total of the

thickness of “liner sheet” and “label”.

0

−1

Paper width 80

Maximum print area 72

44

0

−1

(Unit: mm)

CAUTION!

DO NOT use the following type of paper roll.

■ Paper with folds.

■ Paper with bent corners.

■ Paper pasted or glued to the core.

■ In-wound paper roll (print side in).

— 22 —

Page 26

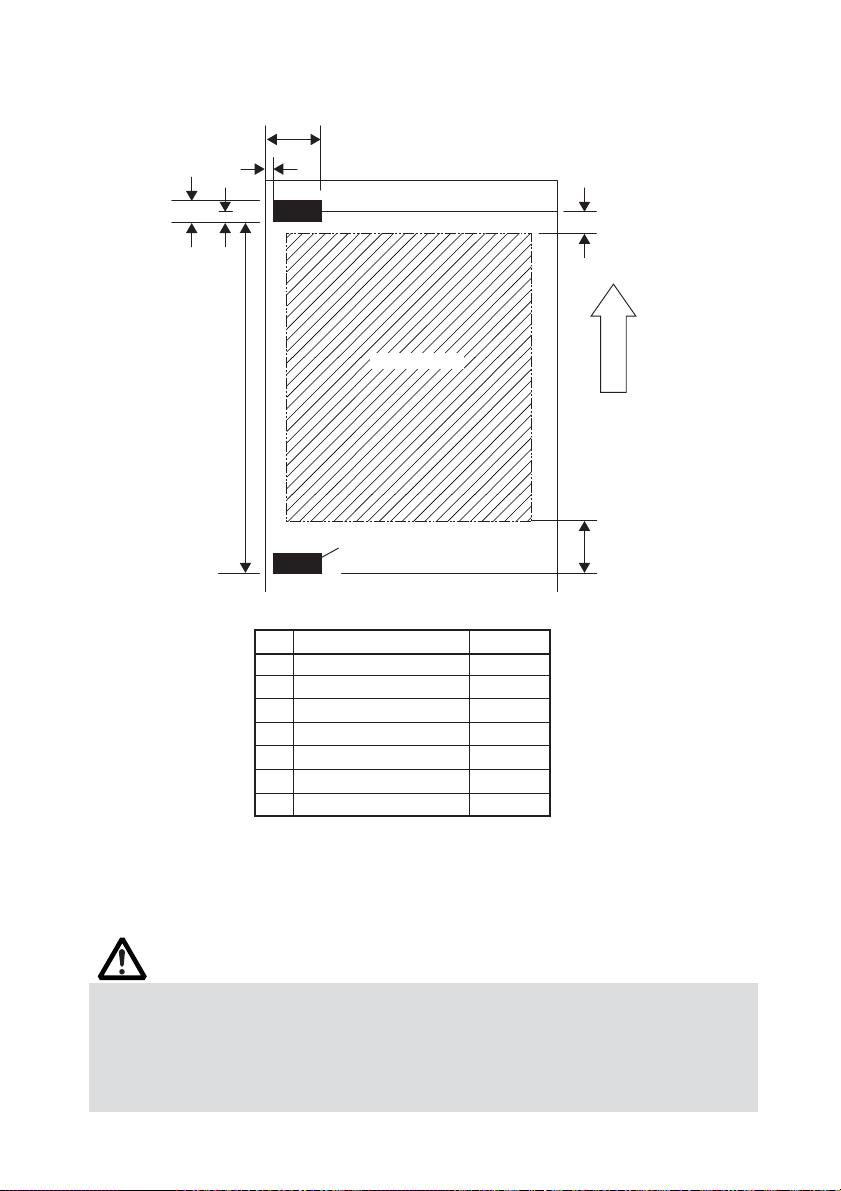

When using “label paper” with CT-S4000L and CT-S4000DCL, refer to the following. Use

the following paper or the equivalent paper.

Paper type Product name

Recommended thermal label paper 150LA-1 from Ricoh,

GG40/P22/G6B from Ojitac, HD75 from Nippon Paper

a) Label paper *L

A

BC

DLM

Full cut

Paper feeding

E

F

direction

Printable area

G

position

HI

JK

Unit: mm

Mark Item Dimensions

A Liner width 58 to 112

B Label width 54 to 108 + 0.5

C Left edge of label 2 + 0.5

D Print width 50 to 104

ETop margin 2 + 1

F Print length 21 to 296

G Bottom margin 2 + 1

H

Cut position between labels

I Gap between labels 4 to 30

JLabel length 25 to 300

K Label pitch I+J

L Left margin 2 + 1

M Right margin 2 + 1

1/2 x (Size I)

0

-1

_

_

_

_

_

CAUTION!

Pay attention to the following when using Auto Cutter. Otherwise, a cutter lock or a

cutter failure may occur.

■ Set the cut length of paper to 25 mm or more.

■ When using label paper, cut the gap between labels (liner sheet). Do not cut the label

paper (tack paper).

■ Adusting the paper sensor must be carried when the type of liner is changed.

Label paper cannot be used with the model supporting blackmark (CT-S4000M/CTS4000DCM).

— 23 —

Page 27

b) Black mark paper (BM paper)

A

B

D

C

F

Black Mark (printed on the reverse)

Mark Item Dimensions

A Right edge of black mark 15 or more

B Left edge of black mark 0 to 1.5

C Black mark height 5

D Cut position in black mark 2.5

ETop margin 6.5 / 12

F Black mark pitch 30 to 300

GBottom margin 9

Cut position

Printable area

Unit: mm

E

Paper feeding

direction

G

* In the case of the operation that the printer cuts the paper, the top margin will be

changed by the setting of the memory switch 4-8. It is 6.5mm at 0 (OFF) and 12mm at

1(ON).

* In the case of the operation that the printer does not cut the paper, the top margin is

6.5mm.

CAUTION!

■ PCS value of black mark must be 0.9 or more.

■ When using the black mark paper, consider the margin of +/- 2 mm for the print position

against the standard position and +/- 5 mm for print length.

■ Refer to the above drawing for the printable area and have enough margings specified

in the marks E and G. If the print data size is out of the printable area, the printer

should skip to next page.

— 24 —

Page 28

5.3 Manual Setting of Memory Switch

Memory switches can be set manually or by a command.

For manual setting, refer to the next page.

The function of each memory switch is shown in the following table.

(The white-on-black characters are factory setting.)

Switch No. Setting 0 (OFF) 1 (ON)

Memory SW1-1 Power ON Info Valid Not send

SW1-2 Buffer Size 4k bytes 45 bytes

SW1-3 Busy Condition Full/Err Full

SW1-4 Receive Error Print "?" No Print

SW1-5 CR mode Ignored LF

SW1-6 Reserved Fixed −

SW1-7 DSR Signal Invalid Valid

SW1-8 Init Signal Invalid Valid

Memory SW2-1 Reserved − Fixed

SW2-2 Auto Cutter Invalid Valid

SW2-3 Spool Print Invalid Valid

SW2-4 Full Col Print LineFeed WaitData

SW2-5 Resume aft PE Next To p

SW2-6 Reserved Fixed −

SW2-7 Reserved Fixed −

SW2-8 PNE Sensor Valid Invalid

Memory SW3-1 Resum Cttr Err Valid Invalid

SW3-2 Reserved Fixed −

SW3-3 Parallel 31 Pin Valid Invalid

SW3-4 Reserved Fixed −

SW3-5 Reserved Fixed −

SW3-6 Reserved Fixed −

SW3-7

SW3-8

Memory SW4-1 *M P. Length Set Auto Measure Command

SW4-2 *M Power on TOF Invalid Valid

SW4-3 Feed&Cut at TOF Invalid Valid

SW4-4 *L Paper Select *1 Thermal Roll BM.P / Lbl.P *4

SW4-5 *L Position detect *2 Black Mark Label

SW4-4 *M Paper Select *1 Thermal Roll BM.P

SW4-5 *M Position detect *2 Black Mark −

SW4-6 Reserved Fixed −

SW4-7 Reserved Fixed −

SW4-8 *3 Prtial Only Invalid Valid

Notes:

*1: The factory setting of "Paper Select" will be different, depending on the model classfication.

*2: In the case of selecting the thermal roll with the SW4-4, the SW4-5 will not be available. The

SW4-5 will be set to "Black Mark" status for the Black Mark version printer.

*3: In the label mode (with memory switches SW4-4 and SW4-5 set to ON), full cutting is used for

paper regardless of the setting of memory switch SW4-8.

*4: When printing on label paper, printing columns of 660 dots is not usable.

Memory switch SW2-8 is not usable with label paper.

CBM1000 Mode

Resum Open Err

Invalid Valid

Close Command

— 25 —

Page 29

Switch No. Setting 0 (OFF) 1 (ON)

Memory SW5-1 Buzzer Valid Invalid

SW5-2 Line Pitch 360 406

SW5-3 USB Mode Virtual COM Printer Class

SW5-4 Reserved Fixed −

SW5-5 Reserved Invalid −

SW5-6 Reserved Fixed −

SW5-7 Reserved Fixed −

SW5-8 Reserved Fixed −

Switch No. Setting Default Set Values

Memory SW7-1 Baud Rate 9600 bps 1200 bps, 2400 bps, 4800 bps, 9600 bps,

SW7-2 Data Length 8Bits 7Bits, 8Bits

SW7-3 Stop Bit 1Bit 1Bit, 2Bits

SW7-4 Parity NONE NONE, EVEN, ODD

SW7-5 Flow Control DTR/DSR DTR/DSR, XON/XOFF

SW7-6 DMA Control Valid Valid, Invalid

SW7-7

Memory SW8-1 Print Width 832dots

SW8-2 Paper Type 1 Color Normal 1 Color Normal, 2 Color Normal

Memory SW9-1 Code Page PC437 PC437/Katakana/PC850,858/PC860/PC863/

Memory SW9-2 Int'Char Set USA USA, France, Germany, England, Denmark,

Memory SW9-3* Kanji OFF ON, OFF

SW9-4* JIS/Shift JIS JIS JIS, Shift JIS

Memory SW10-1 Print Density 100% 70%, 75%, 80%, 85%, 90%, 95%, 100%, 105%,

SW10-2 Print Speed Level 9 Level 1, Level 2, Level 3, Level 4, Level 5,

SW10-3 ACK Timing Before Busy Before Busy, Same Period, After Busy

SW10-4 NV User 192K bytes 1K bytes, 64K bytes, 128K bytes, 192K bytes

SW10-5 NV Graphic 384K bytes 0 byte, 64K bytes, 128K bytes, 192K bytes,

* In this printer, Memory Switches 9-3 and 9-4 are not usable.

VCom Protocol

PC Setting PC Setting, DTR/DSR, XON/XOFF

19200 bps, 38400 bps, 57600 bps, 115200 bps

832dots(69 col.), 720dots(60col.), 660dots(55col),

576dots(48col.), 512dots(42col)

PC865/PC852/PC866/PC857/WPC1252/PC864/

Thai Code 18

Sweden, Italy, Spain, Japan, Norway,

Denmark 2, Spain 2, Latin America, Korea

Croatia, China

110%, 115%, 120%, 125%, 130%, 135%, 140%

Level 6, Level 7, Level 8, Level 9

256K bytes, 320K bytes, 384K bytes

Manual Setting of Memory Switch (Memory SW)

The memory switch can be selected, changed, or written by the combination of three

actions: pressing the FEED button, pressing and holding the FEED button, and opening

or closing the printer cover.

— 26 —

Page 30

1. Entering memory switch setting mode.

Set paper in the printer and keep the printer cover open. With the FEED button

pressed and held, turn the printer power on, and then press the FEED button twice.

Close the cover. If the current settings of the memory switch etc. are printed, the

printer is now in the memory switch setting mode.

Memory SW (1) 00000000

(No indication for 0/1 with memory switch SW7 through SW10)

0: OFF state

1: ON state

2. Selecting memory switch (MEMORY SWITCH SELECT MODE)

When the FEED button is pressed short (*1), printing occurs in the order of “Memory

SW1” → “Memory SW2” → “Memory SW3” → ......“Memory SW10” → “Save To

Memory” → “Memory SW1” → ...... repeatedly. When the memory switch you

want to change is reached, press and hold the FEED button (for more than 2 seconds).

3. Selecting each switch item

2-16 items are provided for setting in each switch. By pressing and holding the

FEED button long (*2), the printer goes to the next item and prints the current setting

of the item. Repeat pressing and holding untill the item you want to change is

reached.

Power ON Info (Valid )

(With memory switch SW7 through SW10, ERROR LED goes on only at the factory setting.)

OFF state: ERROR LED OFF

ON state: ERROR LED ON

4. Changing the setting

When the item you want to change is printed, press the FEED button short (*1).

The changed set value is printed. (When the change of the set value is repeated,

the original set value is recovered). When you press the FEED button long (*2), the

set value is accepted and then the printer goes to the next setting item.

5. Returning to the MEMORY SWITCH SELECT MODE (the above Item 2)

When the setting of the desired content is completed, open the printer cover and

then close the printer cover. This allows the printer to print the setting of the changed

memory switch.

6. Saving the setting and exiting the memory switch setting mode

Press the FEED button short (*1) to move to “Save To Memory”. Then press and

hold the FEED button. The printer prints the contents of new setting and exits the

memory switch setting mode to return to the normal standby state.

* Unless saving the setting is executed, the changed setting cannot be

enabled.

7. Initializing the memory switch

When you want to return the memory switch setting to the initial state, go to “Save

To Memory” in the above procedure. Here, open the printer cover and press and

hold the FEED button till buzzer sounds. This allows the printer to return to the

initial state.

* All the memory switches settings are returned to the factory set values.

*1: Press for less than 2 seconds *2: Press for more than 2 seconds

— 27 —

Page 31

5.4 Selecting Paper Type

Paper type selection is available by the combination of memory switches SW4-4 and

SW4-5 by the used of “Memory Switch Select Mode”. In addtion, the following procedure

is available.

1 Enter Selecting Paper Type mode.

*L, *M

1)Open the printer cover and remove paper. Pressing and holding the

FEED button, turn the printer power ON. The POWER LED starts blinking.

2)Release the FEED button and then close the printer cover. Buzzer sounds

and the paper type currently set is indicated by the LED on the operation

panel.

2 Select Paper Type.

Press the FEED button to match the paper type loaded to the LED indications in the

table below. (Refer to the table below.)

POWER LED ERROR LED

Label

Green lit (OFF)

Thermal paper roll

Black Mark paper

3Save the selected Paper Type to the Printer.

Open and close the printer cover. By this operation, selected paper type is stored in

the printer memory and the Selecting Paper Type mode is terminated.

Since then, "P.Length Set" of Memory switch 4-1 becomes disable.

When closing the printer cover during the setting a Black Mark paper or label paper in

the printer, paper length is measured, and the result will be printed out.

(OFF) Red lit

Green lit Red lit

* If Paper Detection error occurs at the measurement of paper length, the

printer automatically enters Adjusting Paper Sensor mode. Adjust the

sensor in accordance with “5-5 Adjusting Paper Sensor”.

5.5 Adjusting Paper Sensor

Before using Black Mark paper (BM paper) or label, adjust the Paper sensor. First, hold

the lever at the upper end of the sensor adjustment control cover located at the left of

the Power switch and press the lever down and toward the front to remove the cover

from the printer.

As shown below, the most left one is a label paper sensor adjuster, the next is Black

Mark paper sensor adjuster, and the right one is a level indicator LED. Adjust them in the

following procedure.

*L, *M

— 28 —

Page 32

Metal frame

Level indicator

LED

Black Mark sensor

Label light receiving

sensor *L

Label paper sensor

adjuster *L

1 Enter Adjusting Paper Sensor mode.

Open the printer cover, remove paper, and then set the printer power switch to ON.

Here, POWER LED and ERROR LED go on with the buzzer sound. Then close the printer

cover while pressing the FEED button. The ERROR LED starts blinking with the buzzer

sound.

2 Set Paper to be adjusted to the Printer.

This printer has three types of built-in paper sensors.

In case of label, set it so that label is positioned on the label light receiving sensor and

label light emitting sensor. In case of Black Mark paper, set it so that the printable

portion (other than black mark) is positioned on the Black Mark sensor. With this state

kept, closing the printer cover causes ERROR LED to blink with the buzzer sound.

3Adjust Paper Sensor.

Turn the corresponding adjuster counterclockwise by using a tapered flat screwdriver.

Set the adjuster at the position where LED begins to change from orange to green.

Tu rning the adjuster

counterclockwise

Black Mark paper

sensor adjuster

Label light emitting sensor *L

Green Orange Red

* While turning the adjuster by the screwdriver, do not let the part of the

screwdriver touch the metal frame. Otherwise proper LED light color

will not be displayed while touching.

4Perform Paper Measuring operation

When the FEED button is pressed, label is fed and paper measuring is carried.If the

FEED button is presed during the paper measuring, the result will be printed out as

follows, and the printer memory switch will be initialized.

* The measuring result is a reference value

showing a label length

showing a gap between labels

LabelLength

GapLength

< Example of label measuring result*L >

:

XXXmm

:

XXmm

showing a black mark pitch

showing a black mark height

BlackmarkInterval:XXXmm

:

BlackmarkLength

< Example of black mark paper measuring result *M>

— 29 —

XXmm

Page 33

5.6 Full cutting label paper

When full-cutting the label paper with the printer installed horizontally,Be sure that the

guide plate is mounted on the paper exit of the printer cover.

(This guide plate was set to the printer at the time of factory shipment.)

The Guide Plate prevents cut paper from dropping in the printer.

*L

CAUTION!

■ If about 10 sheets of cut paper accumulate on the paper exit, remove the paper.

• Stacking of 10 or papers, paper jam may occur.

■ Remove the guide plate in other than full-cutting label paper with the printer set

horizontally.

• The manual cutter cannot be used when the guide plate is mounted.

• Short label paper with the printer set vertically may be hard to exit.

●Mounting and Dismounting Guide Plate

• Mounting

With the printer cover kept open, insert the tabs of the guide plate to the two

mounting holes (either right or left hole) located at the inside of the cover front. Set

the guide plate with its lib facing toward you.

Then, with the guide plate warping toward you, insert the tabs to the two mounting

holes at the opposite side of the cover.

• Dismounting

With the printer cover kept open, pull the center portion of the guide plate toward

you to remove the guide plate.

Tabs for

mounting hole

Warp toward you

Lib

— 30 —

Set similarly at the

opposite side.

Page 34

FRANÇAIS

Page 35

PRÉCAUTIONS GÉNÉRALES

● Après l’avoir lu, le conserver dans un emplacement sûr, aisément accessible pour

une future référence.

● Les informations contenues dans ce manuel sont sujettes à des changements

sans préavis.

● La reproduction ou le transfert d’une partie ou de tout ce document par n’importe

quel moyen est interdite sans l’autorisation de Citizen Systems.

● Prière de prendre note que Citizen Systems n’est pas responsable de tout résultat

de fonctionnement indépendamment de manque, d’erreur ou de défaut

d’impression de ce manuel.

● Citizen Systems n’est pas responsable d’aucun problème causé par l’utilisation

des options ou produits consommables qui ne sont pas indiqués dans ce manuel.

● Sauf en cas de spécification contraire dans ce manuel, ne pas essayer d’entretenir,

démonter ou réparer cet appareil.

● Noter que Citizen Systems n’est pas responsable d’aucun dommage attribuable à

une opération/manipulation incorrecte ou à un environnement inexact d’opération

qui ne sont pas indiqués dans ce manuel.

● Les données sont prévues fondamentalement pour un usage provisoire, et ne

sont pas stockées pendant une longue période ou de manière permanente.

Veuillez noter que Citizen Systems n’est pas responsable des dommages ou de

toute manque de bénéfice résultant de la perte de données provoquées par des

accidents, réparations, essais ou toute autre occurrence.

● Si vous observez une perte d’informations, des erreurs ou des faits douteux,

veuillez contacter votre fournisseur Citizen Systems.

● Si vous trouvez n’importe quelle page désordonnée ou manquante, veuillez

contacter votre fournisseur Citizen Systems pour effectuer le remplacement.

TABLE DES MATIÈRES

1. PRÉSENTATION GÉNÉRALE ......................................................7

2. EXPLICATION DES COMPOSANTS DE L’IMPRIMANTE ........ 10

3. PRÉPARATION ...........................................................................12

4. ENTRETIEN ET DÉPANNAGE................................................... 17

5. DIVERS ......................................................................................22

CITIZEN is a registered trade mark of Citizen Holdings Co., Japan

CITIZEN es una marca registrada de Citizen Holdings Co., Japón

Company names and product names in this manual are trademarks or

registered trademarks of relevant companies.

Copyright c 2009 by CITIZEN SYSTEMS JAPAN CO., LTD.

— 1 —

Page 36

PRÉCAUTIONS DE SÉCURITÉ

Veuillez lire attentivement ces PRÉCAUTIONS DE SÉCURITÉ avant d’utiliser l’appareil

pour la première fois.

La manipulation incorrecte peut avoir comme conséquence des accidents (incendie,

décharge électrique ou blessures). Afin d'éviter des blessures aux opérateurs, tiers, ou

des dommages à la propriété, des symboles d'avertissement spéciaux sont utilisés

dans le Mode d’Emploi pour indiquer les items importants à observer rigoureusement.

● Après avoir lu ce mode d’emploi, conservez-le dans un endroit sûr et facilement

accessible pour référence ultérieure.

● Certaines des descriptions contenues dans ce mode d’emploi peuvent ne pas

s’appliquer à certains modèles d’imprimantes.

Ce qui suit indique le degré de danger et de dommage encouru si l’imprimante n’est pas

utilisée correctement, sans tenir compte des instructions indiquées par les symboles

d’avertissement.

...

QUI DEVRAIENT ÊTRE OBSERVÉES RIGOUREUSEMENT

AVERTISSEMENT

Le non-respect des précautions indiquées par ce symbole peut provoquer des

blessures mortelles ou graves.

ATTENTION

Le non-respect des précautions indiquées par ce symbole peut provoquer des

blessures ou des dommages matériels.

Ce symbole sert à attirer votre attention sur des points importants.

Ce symbole sert à vous avertir d’un risque d’électrocution ou de dommage

électrostatique.

Ce symbole indique la nécessité de débrancher l’imprimante de la prise murale.

Ce symbole est utilisé pour indiquer l'information utile, telle que procédures,

instructions ou autres données dans ce genre.

Ce symbole sert à indiquer des actions interdites.

— 2 —

Page 37

AVERTISSEMENT

■ N’utilisez pas et ne rangez pas cet appareil dans un endroit où il sera exposé à :

* des flammes ou de l’air humide

* la lumière directe du soleil

* de l’air chaud ou aux radiations d’un appareil de chauffage

* de l’air salin ou des gaz corrosifs

* une atmosphère mal ventilée

* des réactions chimiques en laboratoire

* de l’huile, des particules d’acier ou de la poussière contenue dans l’air

* de l’électricité statique ou des champs magnétiques puissants

• Le non-respect de ces avertissements risque de provoquer des pannes de

l’imprimante, une surchauffe, des émissions de fumée, un incendie ou une

électrocution.

■ Ne laissez pas pénétrer des objets étrangers et ne renversez pas de liquide dans

l’imprimante. Ne placez pas non plus d’objet sur l’imprimante.

■ Ne laissez pas des objets métalliques comme des trombones, des épingles ou des

vis pénétrer dans l’imprimante.

■ Ne placez pas un vase ou un pot de fleurs, ou un verre contenant de l’eau sur

l’imprimante.

■ Ne renversez pas de café, de boissons fraîches ou tout autre liquide dans

l’imprimante.

■ Ne vaporisez pas d’insecticide ou tout autre produit chimique liquide sur

l’imprimante.

• Un objet métallique tombé accidentellement dans l’imprimante risque de provoquer

une panne, un incendie ou une électrocution. Dans ce cas, mettez immédiatement

l’imprimante hors tension, débranchez-la de la prise d’alimentation et faites appel

à votre revendeur local Citizen Systems.

Ne manipulez pas l’imprimante de la manière suivante:

■ Ne soumettez pas l’imprimante à des vibrations ou des chocs violents (par ex.

piétinement, chute ou coups avec un objet dur).

■ Ne tentez pas de démonter ou de modifier l’imprimante.

• Le non-respect des procédures correctes risque de provoquer une panne de

l’imprimante, une surchauffe, une émission de fumée, un incendie ou une

électrocution.

■ Installez, utilisez et rangez l’imprimante hors de la portée des enfants.

• Les appareils électriques risquent de provoquer des blessures ou des accidents

inattendus s’ils sont manipulés ou utilisés de manière incorrecte.

• Laissez le cordon d’alimentation et les câbles de signaux hors de la portée des

enfants. Les enfants doivent également être interdits d’accès aux pièces internes

de l’imprimante.

• Le sac en plastique dans lequel l’imprimante est emballée doit être mis au rebut

correctement et conservé hors de la portée des enfants. Une suffocation peut se

produire si le sac est mis sur la tête.

— 3 —

Page 38

AVERTISSEMENT

Observez les précautions suivantes pour l’alimentation électrique et le cordon

d’alimentation:

■ Ne branchez pas et ne débranchez pas le cordon d’alimentation avec les mains

mouillées.

■ Utilisez l’imprimante uniquement avec la tension d’alimentation et la fréquence

spécifiées.

■ Vérifiez si la prise sur laquelle l’imprimante est alimentée a une capacité

suffisante.

■ N’alimentez pas l’imprimante à partir d’un circuit d’alimentation ou d’une prise

de courant servant déjà à d’autres appareils.

■ Ne branchez pas le cordon d’alimentation dans une prise comportant de la

poussière ou des débris.

■ N’utilisez pas un cordon déformé ou endommagé.

■ Ne déplacez pas l’imprimante tandis que le courant de l’imprimante circule.

• Le non-respect des procédures correctes risque de provoquer une panne de

l’imprimante, une émission de fumée, un incendie ou une électrocution.

• Une surcharge risque de provoquer une surchauffe du câble d’alimentation ou

de déclencher le disjoncteur.

■ Ne posez pas d’objet sur le cordon d’alimentation. Ne placez pas l’imprimante

dans un endroit où le cordon risque d’être piétiné.

■ N’utilisez pas et ne transportez pas l’imprimante avec le cordon d’alimentation

plié, tordu ou tiré.

■ Ne tentez pas de modifier inutilement le cordon d’alimentation.

■ Ne placez pas le cordon d’alimentation à proximité d’un appareil de chauffage.

• Le non-respect de ces précautions risque de provoquer la rupture des fils ou de

l’isolation et de causer des fuites, une électrocution ou une panne de

l’imprimante. Si le cordon d’alimentation a subit des dommages, veuillez

contacter votre revendeur Citizen Systems.

■ Ne laissez pas d’objets autour de l’imprimante afin qu’elle soit toujours facile

d’accès.

■ Fournir l’alimentation à l'imprimante à partir d'une prise murale commode,

aisément accessible en cas d'urgence.

•L’imprimante peut ne pas être mise à l’arrêt immédiatement en cas d’urgence.

■ Introduisez à fond la fiche d’alimentation dans la prise.

■ Si l'imprimante ne sera pas utilisée pendant longtemps, la laisser déconnectée

de sa prise d’alimentation.

■ Tenez la prise et le connecteur quand vous effectuez le branchement ou le

débranchement du cordon du secteur ou du câble de communication après avoir

désactivé l’imprimante et l’appareil qui est connecté à elle.

— 4 —

Page 39

ATTENTION

Ne pas utiliser l’imprimante dans les conditions suivantes.

■ En condition sujette à vibration ou en condition instable.

■ Avec cet appareil incliné.

• Autrement une chute de la machine peut causer des dommages.

• Une qualité d'impression médiocre peut se produire.

■ En condition où les trous de ventilation de l’imprimante sont obstrués par un

mur voisin ou tout autre équipement.

■ Une condition dans laquelle un objet quelconque est placé sur l’imprimante.

■ Une condition dans laquelle l’imprimante est couverte ou enveloppée par un

tissu ou un drap de lit.

•Faire attention à l’accumulation interne de la chaleur, qui pourrait causer un

incendie et déformer le coffret.

■ Éviter d’utiliser l’imprimante près d’une radio ou d’un téléviseur ou de

l’alimenter à partir de la même prise que ces appareils.

■ Éviter d’utiliser l’imprimante connectée ensemble avec un câble ou un cordon

qui ne présente aucune protection contre les parasites. (Pour les interconnexions,

utilisez des câbles blindés ou torsadés et des noyaux en ferrite, ou d’autres

dispositifs anti-parasites).

■

Eviter d’utiliser l’imprimante avec un appareil produisant une source de bruit puissante.

•

L’imprimante peut avoir un effet négatif sur les transmissions radio ou télévisées.

Dans certains cas également, les appareils électriques proches peuvent influencer

l’imprimante et causer des erreurs de données ou des pannes.

■ En condition où cet appareil est installé verticalement ou latéralement.

• Un défaut de fonctionnement, une panne, ou une décharge électrique peuvent

se produire.

■ Utiliser l’imprimante avec sa fiche de terre connectée à une installation de mise à

la terre commode.

• Des électrocutions risquent de se produire en cas de fuites:

■

Ne pas connecter la fiche de terre de l’imprimante sur l’une des installations suivantes:

* Canalisation de gaz

• Une explosion de gaz peut se produire.

* Terre d’une ligne téléphonique

* Paratonnerre

• En cas de foudre, une surtension de courant importante peut provoquer un

incendie ou des chocs électriques.

* Canalisation d’eau

• Les tuyaux d’eau en plastique ne doivent pas être utilisés pour la mise à la

terre. (Ceux approuvés par le Département des Eaux peuvent être utilisés.)

■ Avant de brancher ou de débrancher le fil de terre de l’imprimante, débrancher

tout d’abord de la prise d’alimentation.

L’étiquette d’avertissement est

attachée sur la position

représentée sur la figure suivante.

Lisez soigneusement les

précautions pour la manipulation

avant d’utiliser l’imprimante.

CES ÉTIQUETTES

INDIQUENT UN RISQUE DE

BLESSURE CAUSÉE PAR

«HAUTE TEMPÉRATURE»

DE LA TÊTE D'IMPRESSION

ET DU «BORD DENTELÉ»

DU COUPOIR MANUEL.

— 5 —

Page 40

ATTENTION

■ Ne pas transporter cette imprimante avec un rouleau de papier à l'intérieur.

• Une panne ou une rupture de l’imprimante peut se produire.

Pour éviter les problèmes de fonctionnement ou les pannes éventuelles, observez ce qui suit:

■

Evitez de faire fonctionner l’imprimante sans rouleau de papier correctement chargé.

■ Evitez l’usage de papier non conforme aux spécifications.

• Ceci risque de fournir une qualité d’impression médiocre.

■

Evitez d’utiliser du papier froissé ou comportant des morceaux de ruban adhésif plastique.

■ Evitez de tirer à la main en forçant du papier déjà chargé.

■ Éviter de coincer le papier dans l'imprimante.

• Risque de bourrage de papier. Pour retirer le bourrage, reportez-vous à «Retrait

du papier coincé» dans ce mode d’emploi.

■ Evitez d’utiliser un dispositif pointu pour manipuler les touches du panneau.

■ Assurez-vous d’insérer fermement la prise du câble dans sa douille de connexion.

• Un mauvais branchement risque d’endommager les pièces électroniques internes

de l’imprimante ou le matériel du système hôte.

■ Utilisez l’imprimante uniquement avec des dispositifs ayant des spécifications de

solénoïde prévus pour le connecteur de l’ouverture du tiroir-caisse.

• Le non-respect de cette précaution risque de provoquer un problème de

fonctionnement ou une panne.

Pour éviter d’empirer les pannes ou les problèmes de l’imprimante, observez ce qui suit:

■ Ne touchez pas à la surface d’impression de la tête thermique.

■ Ne touchez pas aux pièces mobiles (par ex. le massicot, les engrenages, les pièces

électriques actives) lorsque l’imprimante fonctionne.

■ En cas de problème, ne tentez pas de réparer l’imprimante. Confiez-la au service de

Citizen Systems pour la réparation.

■ Faites attention à ce que le capot de l’imprimante ne coince pas vos mains ou doigts.

■ Prenez garde aux bords acérés de l’imprimante. Ils risquent de vous blesser ou de

provoquer des dommages matériels.

• Risque de provoquer une électrocution, des brûlures ou des blessures.

Si l’imprimante émet de la fumée, une odeur ou un bruit anormal pendant l’impression,

abandonnez immédiatement le travail d’impression en cours et débrancher l’imprimante

de la prise murale.

ENTRETIEN JOURNALIER

Observez les précautions suivantes pour l’entretien quotidien.

■ Pour nettoyer l’imprimante, mettez-la toujours hors tension et débranchez-la de la

prise murale.

■ Utilisez un chiffon doux et sec pour nettoyer la surface du boîtier de l’imprimante.

■ Pour les taches tenaces, utilisez un chiffon doux légèrement imbibé d’eau.

■ N’utilisez jamais d’agent de nettoyage organique comme de l’alcool, un diluant

pour peinture, ou du benzène.

■ Pour enlever la poussière de papier, utiliser une brosse souple

ATTENTION

• La tête thermique conserve une température dangereusement élevée

immédiatement après usage. Ne la touchez pas avant qu’elle n’ait refroidi.

— 6 —

Page 41

1. PRÉSENTATION GÉNÉRALE

Ces produits sont des imprimantes en ligne thermique conçues pour un usage dans

diverses applications comme terminaux point de vente, systèmes de données,

imprimantes situées dans la cuisine, etc.

1.1 Caractéristiques

● La capacité de rouleau versatile avec possibilité d'utiliser des rouleaux de 80 mm, 82.5

mm et 112 mm de papier de largeur.

● Peut utiliser les rouleaux de papier avec un diamètre maximum de 102 mm.

● Mécanisme “Drop-in” facilitant la manipulation aisée du papier et le nettoyage de la

tête.

● Impression à grande vitesse (150 mm/s)

● Doté de l'interface USB en standard, plus un choix d'une interface sérielle ou parallèle.

● Interface de communication remplaçable

● Interface parallèle à grande vitesse (modèle d'interface parallèle)

● Interface de tiroir-caisse incorporée.

● Mécanisme de découpe automatique fourni en standard.

● La personnalisation par l'utilisateur par memory switch est disponible.

● Mode Page.

● Enregistrement des caractères utilisateur et des logos définis par l'utilisateur dans la

mémoire flash.

● L’impression de code à barres et de code à barres 2D est soutenue.

● Impression bicolore possible (Avec le papier spécifique).

● L'indication des erreurs est disponible avec la LED ou le buzzer.

[Seulement modèles CT-S4000L, CT-S4000DCL]

● Impression à grande vitesse (132 mm/s)

● Le papier pour étiquettes de 58 à 107 mm de large en plus du papier de 112 mm de

large peuvent être utilisés sans pas.

[Seulement modèles CT-S4000L, CT-S4000DCL, CT-S4000M, CT-S4000DCM]

● Le système de réglage de sensibilité du capteur de rouleau papier par volume est

adopté.

— 7 —

Page 42

1.2 Déballage

Vérifiez que les composants suivants sont dans le paquet lorsque vous déballez l’imprimante:

● Imprimante: 1

● Cordon secteur: 1 (Seulement pour CT-S4000, CT-S4000L, CT-S4000M)

● CD-ROM: 1

● Rouleau de papier échantillon: 1 rouleau

● Adaptateur: 1

● Vis: 1

● Guide de démarrage rapide: 1

CT-S4000

Rouleau de papier

échantillon

Adaptateur

Cordon secteur.

Vis

CD-ROM

Guide de

démarrage rapide

1.3 Classification des modèles