Page 1

LINE THERMAL PRINTER

MODEL CT-S4000L/CT-S4000DCL

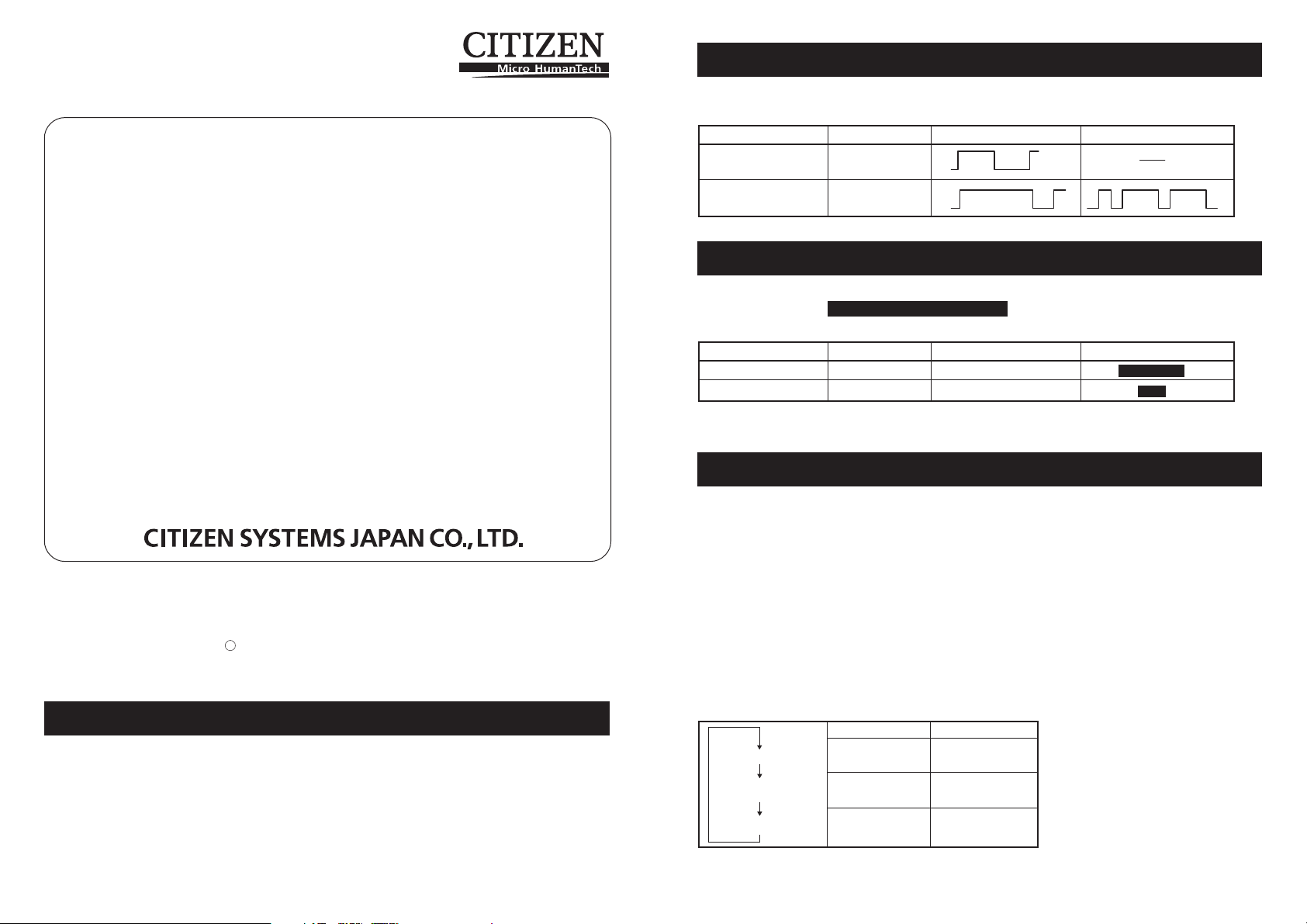

4.6 Error Indication

The following LED indications are added to CT-S4000L/CT-S4000DCL.

Status POWER LED ERROR LED Buzzer

Wait for cutting label OFF

Paper detection error OFF

User’s Manual

Refer to CT-S4000/CT-S4000DC User’s Manual of standard model when reading this manual.

Contents

1.1 Features

4.6 Error Indications

5.3 Manual Setting of Memory Switch

5.4 Selecting Paper Type

5.5 Adjusting Paper Sensor

5.6 Printing Paper

CITIZEN is a registered trade mark of Citizen Holdings Co., Japan

CITIZEN es una marca registrada de Citizen Holdings Co., Japón

Company names and product names in this manual are trademarks or

registered trademarks of relevant companies.

Copyright c 2007 by CITIZEN SYSTEMS JAPAN CO., LTD.

5.3 Manual Setting of Memory Switch

Functions of memory switches SW4-4 and SW4-5 of CT-S4000L/CT-S4000DCL are as

shown below. (The white-on-black characters are factory setting.)

Memory Switch Function 0 (OFF) 1 (ON)

SW4-4 Paper Select Thermal Roll BM.P/Lbl.P *

SW4-5 Position detect Black Mark Label

* The Print Width 660 dots is not available for printing a label paper.

* The memory switches SW2-8 will be ignored for Label.

5.4 Selecting Paper Type

Paper type selection is available by the combination of memory switches SW4-4 and

SW4-5 by the used of “Memory Switch Select Mode”. In addtion, the following

procedure is available.

1 Enter Selecting Paper Type mode.

1)Open the printer cover and remove paper. Pressing and holding the FEED button,

turn the printer power ON. The POWER LED starts blinking.

2)Release the FEED button and then close the printer cover. Buzzer sounds and

the paper type currently set is indicated by the LED on the operation panel.

2 Select Paper Type.

Press the FEED button to match the paper type loaded to the LED indications in the

table below. (Refer to the table below.)

1.1 Features

●High-speed printing at a maximum of 120 mm/sec

●2-dimensional barcode

●Label of nonstep 58 to 105 mm wide as well as 112 mm is usable

●Paper sensor sensitivity adjustment by variable resistor is adopted.

Label

Thermal paper roll

Black Mark paper

POWER LED ERROR LED

Green lit (OFF)

(OFF) Red lit

Green lit Red lit

Page 2

3Save the selected Paper Type to the Printer.

Open and close the printer cover. By this operation, selected paper type is stored in

the printer memory and the Selecting Paper Type mode is terminated.

Since then, "P.Length Set" of Memory switch 4-1 becomes disable.

When closing the printer cover during the setting a Black Mark paper or label paper

in the printer, paper length is measured, and the result will be printed out.

* If Paper Detection error occurs at the measurement of paper length, the printer

automatically enters Adjusting Paper Sensor mode. Adjust the sensor in

accordance with “5-5 Adjusting Paper Sensor”.

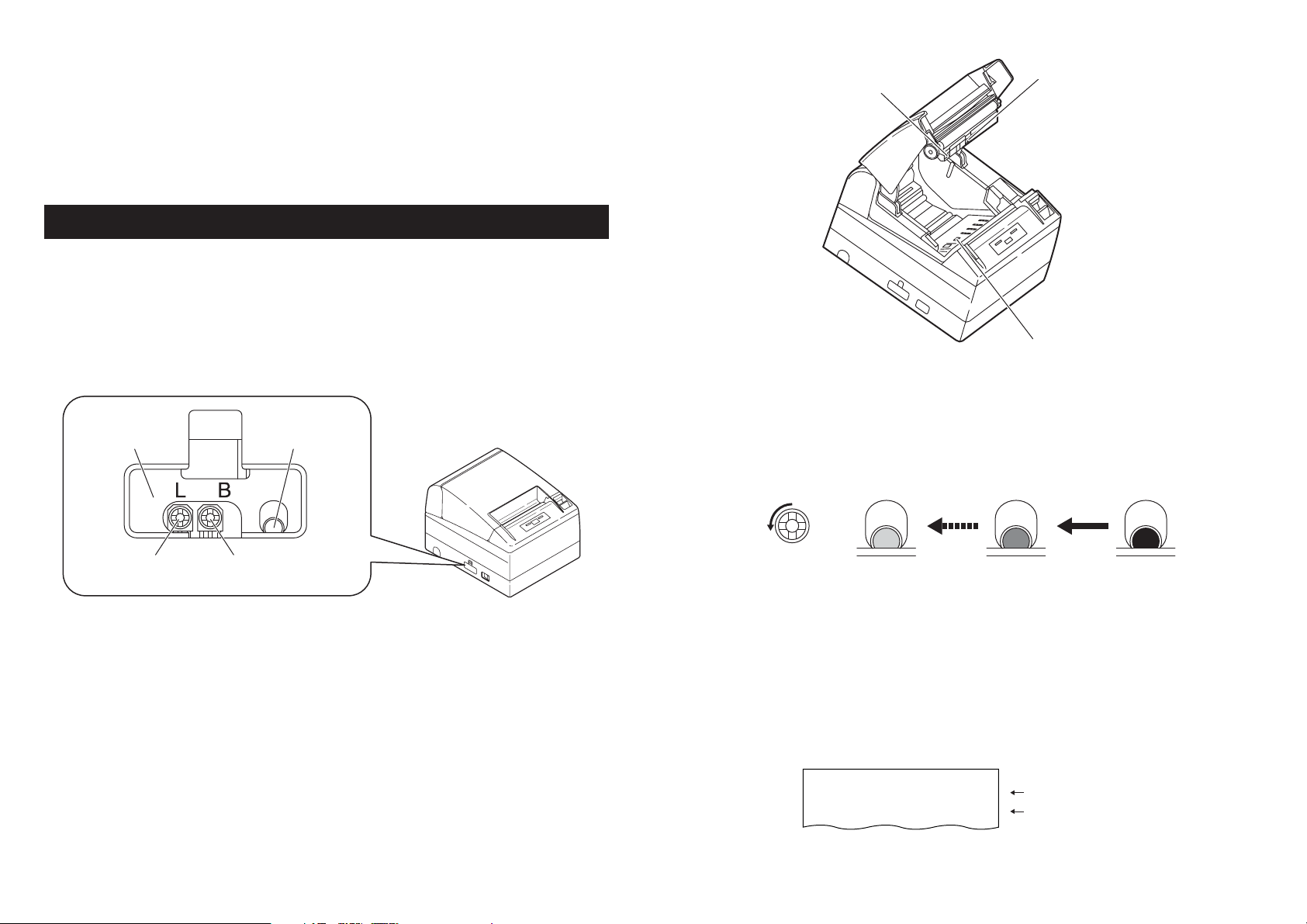

5.5 Adjusting Paper Sensor

Before using Black Mark paper (BM paper) or label, adjust the Paper sensor. First,

hold the lever at the upper end of the sensor adjustment control cover located at the

left of the Power switch and press the lever down and toward the front to remove the

cover from the printer.

As shown below, the most left one is a label paper sensor adjuster, the next is Black

Mark paper sensor adjuster, and the right one is a level indicator LED. Adjust them in

the following procedure.

Metal frame

Level indicator LED

Black Mark sensor

Label light receiving sensor

Label light emitting sensor

3Adjust Paper Sensor.

Turn the corresponding adjuster counterclockwise by using a tapered flat screwdriver.

Set the adjuster at the position where LED begins to change from orange to green.

Turning the adjuster

counterclockwise

Label paper sensor

adjuster

Black Mark paper

sensor adjuster

1 Enter Adjusting Paper Sensor mode.

Open the printer cover, remove paper, and then set the printer power switch to ON.

Here, POWER LED and ERROR LED go on with the buzzer sound. Then close the

printer cover while pressing the FEED button. The ERROR LED starts blinking with

the buzzer sound.

2 Set Paper to be adjusted to the Printer.

This printer has three types of built-in paper sensors.

In case of label, set it so that label is positioned on the label light receiving sensor

and label light emitting sensor. In case of Black Mark paper, set it so that the printable

portion (other than black mark) is positioned on the Black Mark sensor. With this

state kept, closing the printer cover causes ERROR LED to blink with the buzzer

sound.

Green Orange Red

* While turning the adjuster by the screwdriver, do not let the part of the

screwdriver touch the metal frame. Otherwise proper LED light color will not

be displayed while touching.

4Perform Paper Measuring operation

When the FEED button is pressed, label is fed and paper measuring is carried.If the

FEED button is presed during the paper measuring, the result will be printed out as

follows, and the printer memory switch will be initialized.

* The measuring result is a reference value

Label Length

Gap Length

< Example of label measuring result >

:

XXXmm

:

XXmm

showing a label length

showing a gap between labels

Page 3

5.6 Printing Paper

Also refer to the core dimension and notes of “5.2 Printing Paper” in User’s Manual of

standard model. Use print paper shown in the following table or the equivalent.

Paper type Product name

Recommended thermal label paper GG40/P22/G6B from Ojitac, HD75 from Nippon Paper,

150LA-1 from Ricoh

a) Label paper

A

BC

D

Full cut

Paper feeding

E

direction

position

HI

A

BC

D

Paper feeding

direction

Partial cut

position

HI

E

Unit: mm

Mark Item Dimensions

F

Printable area

JK

G

A Liner width 58 to 112

B Label width 54 to 108 + 0.5

C Left edge of label 2 + 0.5

D Print width 50 to 104

ETop margin 2 + 1

F Print length 21 to 296

GBottom margin 2 + 1

H

Cut position between labels

I Gap between labels 4 to 30

J Label length 25 to 300

K Label pitch I+J

1/2 x (Size I)

In the case of memory switch 4-8 set to 0 (OFF)

0

-1

_

_

_

F

Printable area

JK

G

In the case of memory switch 4-8 set to 1 (ON)

Mark Item Dimensions

A Liner width 58 to 112

B Label width 54 to 108 + 0.5

C Left edge of label 2 + 0.5

D Print width 50 to 104

ETop margin

F Print length 16 to 296

G Bottom margin 2 + 1

H

Cut position between labels

I Gap between labels 4 to 30

JLabel length 28 to 300

K Label pitch I+J

Unit: mm

0

-1

_

12 - (I-2) +1, min2

_

_

2 + 1

_

CAUTION!

Pay attention to the following when using Auto Cutter. Otherwise, a cutter lock or a cutter

failure may occur.

■ Set the cut length of paper to 25 mm or more.

■ When using label paper, cut the gap between labels (liner sheet). Do not cut the label paper

(tack paper).

■ Adusting the paper sensor must be carried when the type of liner is changed.

Page 4

b) Black mark paper (BM paper)

A

B

D

C

F

Black Mark (printed on the reverse)

Mark Item Dimensions

A Right edge of black mark 15 or more

BLeft edge of black mark 0 to 1.5

C Black mark height 5

D Cut position in black mark 2.5

ETop margin 6.5 / 12

F Black mark pitch 30 to 300

GBottom margin 9

Cut position

Printable area

Unit: mm

E

Paper feeding

direction

G

Top margin will be changed by the setting of the memory SW4-8.

In the case of 0 (OFF), the top margin is 6.5mm.

In the case of 1 (ON), the top margin is 12mm.

CAUTION!

■ PCS value of black mark must be 0.9 or more.

■ When using the black mark paper, consider the margin of +/- 2 mm for the print position

against the standard position and +/- 5 mm for print length.

■ Refer to the above drawing for the printable area and have enough margings specified in the

marks E and G. If the print data size is out of the printable area, the printer should skip to next

page.

TB74905-02F

1.02E-0705

Printed in Japan

Loading...

Loading...