Page 1

LINE THERMAL PRINTER

FEED

MODEL CT-S281

User’s Manual

D

E

E

F

Page 2

Declaration of Conformity

This printer conforms to the following Standards:

The Low Voltage Directive 2006/95/EC, the EMC Directive 2004/108/EC, the RoHS

Directive 2002/95/EC, and the WEEE Directive 2002/96/EC.

LVD:EN60950-1

EMC : EN55022 Class B

EN61000-3-2

EN61000-3-3

EN55024

This declaration applies only to the 230-V model.

CITIZEN is a registered trade mark of Citizen Holdings Co., Japan

CITIZEN es una marca registrada de Citizen Holdings Co., Japón

Company names and product names in this manual are trademarks or

registered trademarks of relevant companies.

Copyright c 2010 by CITIZEN SYSTEMS JAPAN CO., LTD.

Page 3

IMPORTANT: This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found to comply with

the limits for a Class B computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct

the interference.

CAUTION: Use shielded cable for this equipment.

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Gerät angebracht und

leicht zugänglich sein.

For Uses in Canada

This digital apparatus does not exceed the class B limits for radio noise emissions

from digital apparatus, as set out in the radio interference regulations of the Canadian

department of communications.

Pour L’utilisateurs Canadiens

Cet appareil numérique ne dépasse pas les limites de carégorie a pour les émissions

de bruit radio émanant d’appareils numériques, tel que prévu dans les réglements

sur l’interférence radio du départment Canadien des communications.

Page 4

GENERAL PRECAUTIONS

● Before using this product, be sure to read through this manual. After having read

this manual, keep it in a safe, readily accessible place for future reference.

● The information contained herein is subject to change without prior notice.

● Reproduction or transfer of part or all of this document in any means is prohibited

without permission from CITIZEN SYSTEMS.

● Note that CITIZEN SYSTEMS is not responsible for any operation results regardless

of missing, error, or misprinting in this manual.

● Note that CITIZEN SYSTEMS is not responsible for any trouble caused as a result

of using options or consumables that are not specified in this manual.

● Except explained elsewhere in this manual, do not attempt to service, disassemble,

or repair this product.

● Note that CITIZEN SYSTEMS is not responsible for any damage attributable to

incorrect operation/handling or improper operating environments that are not

specified in this manual.

● Data are basically for temporary use, not stored for a long period or permanently.

Please note that CITIZEN SYSTEMS is not responsible for damage or lost profit

resulting from the loss of data caused by accidents, repairs, tests or other

occurrence.

● If you find loss of information, error, or uncertain matter, please contact your

CITIZEN SYSTEMS dealer.

● If you find any disordered or missing page(s), contact your CITIZEN SYSTEMS

dealer for replacement.

— 1 —

Page 5

SAFETY PRECAUTIONS ... WHICH SHOULD BE STRICTLY OBSERVED

Before using this product for the first time, carefully read these SAFETY PRECAUTIONS.

Improper handling may result in accidents (fire, electric shock or injury).

In order to prevent injury to operators, third parties, or damage to property, special

warning symbols are used in the User’s Manual to indicate important items to be strictly

observed.

● After having read this Manual, keep it in a safe, readily accessible place for future

reference.

● Some of the descriptions contained in this manual may not be relevant to some printer

models.

The following describes the degree of hazard and damage that could occur if the printer

is improperly operated by ignoring the instructions indicated by the warning symbols.

WARNING

Neglecting precautions indicated by this symbol may result in fatal or serious injury.

CAUTION

Neglecting precautions indicated by this symbol may result in injury or damage to

properties.

This symbol is used to alert your attention to important items.

This symbol is used to alert you to the danger of electric shock or electrostatic

damage.

This symbol denotes a request to unplug the printer from the wall outlet.

This symbol is used to indicate useful information, such as procedures, instructions

or the like.

This symbol is used to indicate prohibited actions.

— 2 —

Page 6

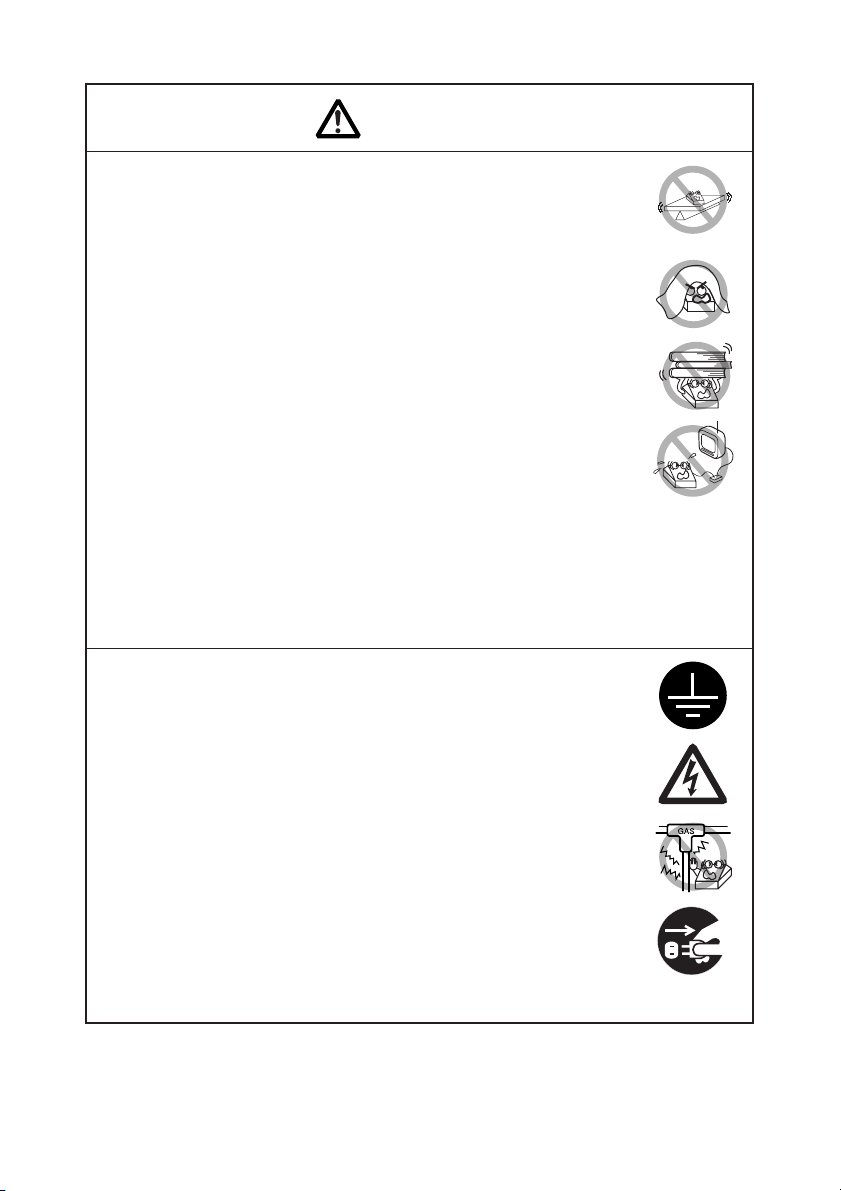

PRECAUTIONS ON PRINTER INSTALLATION

WARNING

■ Do not use or store this product in a place where it will be exposed

to:

* Flames or moist air.

* Direct sunlight.

* Hot airflow or radiation from a heating device.

* Salty air or corrosive gases.

* Ill-ventilated atmosphere.

* Chemical reactions in a laboratory.

* Airborne oil, steel particles, or dust.

* Static electricity or strong magnetic field.

• Neglecting these warnings may result in printer failure, overheating,

emission of smoke, fire, or electric shock.

■ Do not drop any foreign object nor spill liquid into the printer. Do not

place any object on the printer either.

■ Do not drop any metallic object such as paper clip, pin or screw into

the printer.

■ Do not place a flower vase, pot or cup containing water on the printer.

■ Do not spill coffee, soft drinks or any other liquid into the printer.

■ Do not spray insecticide or any other chemical liquid over the printer.

•A metallic foreign object, if accidentally dropped into the printer, may

cause printer failure, fire, or electric shock. Should it occur,

immediately turn the printer off, unplug it from the supply outlet,

and call your local Citizen Systems dealer.

Do not handle the printer in the following ways:

■ Do not allow the printer to sustain strong impacts or hard jolts (e.g.,

trampling, dropping, striking with a hard edge).

■ Never attempt to disassemble or modify the printer.

• Neglecting to handle properly may result in printer failure,

overheating, emission of smoke, fire, or electric shock.

■ Install, use, or store the printer out of the reach of children.

• Electric appliances could cause an unexpected injury or accident if

they are handled or used improperly.

•Keep the power cord and signal cables out of the reach of children.

Also children should not be allowed to gain access to any internal

part of the printer.

• The plastic bag the printer came in must be disposed of properly or

kept away from children. Wearing it over the head may lead to

suffocation.

— 3 —

Page 7

CAUTION

Do not use the printer under the following conditions.

■ A state subject to vibration or unstable state.

■ A state with this product slanted.

• Otherwise dropping may cause injury.

• Poor print quality may occur.

■ A state where the printer ventilation holes are obstructed by a nearby

wall or other equipment.

■ A state where any object is placed on the printer

■ A state where the printer is covered or wrapped by a cloth or bed

clothing

• Be careful about internal heat buildup, which could cause fire and

deform the case.

■ Avoid using the printer near a radio or TV set or from supplying it

from the same outlet as these appliances.

■ Avoid using the printer interconnected with a cable or cord that has

no protection against noise. (For interconnections, use shielded or a

twisted pair of cables and ferrite cores, or other anti-noise devices.)

■ Avoid using the printer with a device that is a strong source of noise.

• The printer may have an adverse effect on nearby radio or TV

transmissions. There may also be cases when nearby electrical

appliances adversely influence the printer, causing data errors or

malfunction.

■ A state where this product is installed vertically or sidelong.

• Malfunction, failure, or electric shock may result.

■ Use the printer with its grounding post connected to a convenient

grounding facility.

• If leakage occurs electric shock may result.

■ Do not connect the printer’s grounding post onto any of the following

facilities:

* Utility gas piping

• A gas explosion could result.

* Telephone line ground

* Lightning rod

• If lightning strikes a large surge of current may cause fire or

shock.

* Utility water pipes

• Plastic water pipes should not be used for grounding. (Those

approved by a Waterworks Department may be used.)

■ Before connecting or disconnecting the grounding lead to or from

the printer, always unplug it from supply outlet.

— 4 —

Page 8

PRECAUTIONS IN HANDLING THE PRINTER

WARNING

Please observe the following precautions for power source and power

cord:

■ Do not plug or unplug the power cord with a wet hand.

■ Use the printer only at the specified supply voltage and frequency.

■ Use only the specified AC adapter with the printer.

■ Check to make sure that the supply outlet from which the printer is

powered has a sufficient capacity.

■ Do not supply the printer from a power strip or current tap shared

with other appliances.

■ Do not plug the power cord into a supply outlet with dust or debris

left on its plug.

■ Do not use a deformed or damaged power cord.

■ Do not move the printer while the printer power is on.

• Neglecting to handle properly may result in printer failure, emission

of smoke, fire, or electric shock.

• An overload may cause the power cord to overheat or fire or the circuit

breaker to trip.

■ Do not allow anything to rest on the power cord. Do not place the

printer where the power cord will be trampled on.

■ Do not use or carry the printer with its power cord bent, twisted, or

pulled.

■ Do not attempt to modify the power cord unnecessarily.

■ Do not lay the power cord in the neighbor of a heating device.

• Neglecting these cautions may cause wires or insulation to break,

which could result in leakage, electric shock, or printer failure. If the

power cord sustains damage, contact your Citizen Systems dealer.

■ Do not leave things around the supply outlet.

■ Supply power to the printer from a convenient wall outlet, readily

accessible in an emergency.

• The printer may not be immediately shut down in an emergency.

■ Insert the power plug fully into the outlet.

■ If the printer will not be used for a long time, leave it disconnected

from its supply outlet.

■ Hold the plug and connector when plugging or unplugging the power

cord or signal cable after turning off the printer and the appliance

connected to it.

— 5 —

Page 9

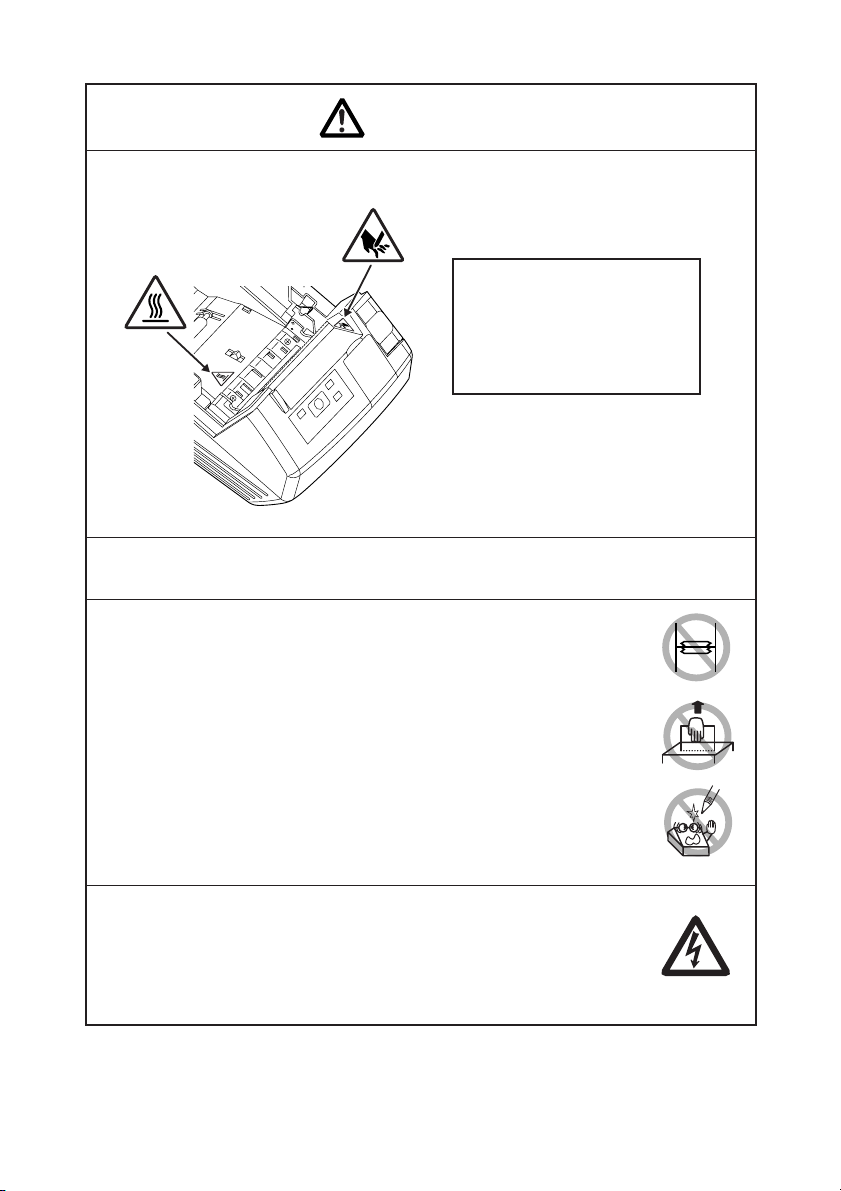

CAUTION

Caution label is attached on the position shown in the following figure. Carefully

read the precautions in handling before using the printer.

THESE LABELS INDICATE THE

RISK OF ANY INJURY DUE TO

"HIGH TEMPERATURE" OF THE

PRINT HEAD AND "SAWTOOTHED EDGE" OF THE

MANUAL CUTTER.

■ Do not transport this printer with the paper roll inside.

•Printer failure or breakage may occur.

To prevent possible malfunction or failure observe the following.

■ Avoid operating the printer without paper properly loaded.

■ Avoid the use of paper not complying with specifications.

•May result in poor print quality.

■ Avoid using torn pieces of paper or spliced with plastic adhesive

tapes.

■ Avoid forcibly pulling already loaded paper by hand.

■ Avoid wedging the paper into the printer.

•May jam paper. To release, refer to “Removing Jammed Paper” in

this manual.

■ Avoid using a sharp pointed device to operate panel keys.

■ Be sure to firmly insert the cable plug into its mating socket.

•A cross connection may damage the printer’s internal electronics or

the host system’s hardware.

■ Only use the printer with devices that have designated solenoid

specifications for the cash drawer interface connector.

• Neglecting this caution may result in malfunction or failure.

— 6 —

Page 10

CAUTION

To prevent injury and printer failures from worsening, observe the

following:

■ Do not touch the printing surface of the thermal head.

■ Do not touch any of the moving parts (e.g., paper cutter, gears, active

electrical parts) while the printer is working.

■ In case of trouble do not attempt to repair the printer. Ask Citizen

Systems service for repair.

■ Be careful that the printer cover does not entrap your hands or fingers.

■ Be careful with sharp edges on the printer. Do not allow them to

injure you or damage property.

•May result in electric shock, burn, or injury.

If the printer emits smoke, an odd smell, or unusual noise while printing,

immediately abort the current print session and unplug the printer from

the supply outlet.

DAILY MAINTENANCE

Observe the following precautions for daily maintenance.

■ When cleaning the printer, always turn it off and unplug it from the

supply outlet.

■ Use a soft, dry cloth for cleaning the surface of the printer case.

■ For severe stains, use a soft cloth slightly dampened with water.

■ Never use organic cleaning solvent such as alcohol, paint thinner,

trichloroethylene, benzene, or ketone. Never use a chemically

processed cleaning cloth.

■ To remove paper dust, use a soft brush.

■ When transporting the printer, remove the paper roll from the printer.

CAUTION

• The thermal head is at a dangerously high temperature immediately

after printing. Allow it to cool off before launching maintenance work.

— 7 —

Page 11

THE TABLE OF CONTENTS

1. GENERAL OUTLINE .................................................................... 9

1.1 Features .......................................................................................... 9

1.2 Unpacking ..................................................................................... 10

1.3 Model Classification .....................................................................10

1.4 Basic Specifications ..................................................................... 11

2. EXPLANATION OF PRINTER PARTS........................................12

2.1 Printer Appearance ...................................................................... 12

2.2 Paper Cover Inside .......................................................................14

2.3 Other Built-in Functions ...............................................................14

3. PREPARATION ........................................................................... 15

3.1 Connecting the AC Adapter and AC Power Cord ...................... 15

3.2 Connecting Interface Cables ....................................................... 16

3.3 Installing the Printer ..................................................................... 17

3.4 Setting DIP Switch (Only serial interface type) .......................... 18

3.5 Adjusting the Paper Near-end Sensor ........................................ 19

3.6 Selecting Paper Type ................................................................... 20

3.7 Adjusting Paper Sensor ............................................................... 20

3.8 Full cutting label paper ...............................................................22

4. MAINTENANCE AND TROUBLESHOOTING ........................... 23

4.1 Setting/Replacing Paper Rolls ..................................................... 23

4.2 Removing Jammed Paper ........................................................... 24

4.3 Cleaning the Print Head ............................................................... 24

4.4 When the Paper Cover Cannot Be Opened ................................ 25

4.5 Self-printing .................................................................................. 26

4.6 Hexadecimal Dump Printing ....................................................... 26

4.7 Error Indication .............................................................................27

5. OTHER ....................................................................................... 28

5.1 External Views and Dimensions ................................................. 28

5.2 Manual Setting of Memory Switch ............................................. 29

5.3 Printing Paper ............................................................................... 32

— 8 —

Page 12

1. GENERAL OUTLINE

The CT-S281 is a thermal line printer designed for use with a broad array of

terminal equipment including, data, POS, and kitchen terminals.

With extensive features, it can be used in a wide range of applications.

1.1 Features

● Compact design.

● The printer allows horizontal or wall mounting installation.

● Auto Cutter provided as a standard unit (performs full cut or partial cut).

● Paper drop-in mechanism facilitating easy paper handling and head cleaning.

● Highly reliable printer mechanism.

● High speed printing with 80 mm/s (60 mm/s at label print mode).

● Fast graphic printing.

● Printer class or Virtual COM can be selected for USB port.

● A variety of functions selectable by memory switches.

● Registration of user-defined characters and logos into flash memory.

● Barcode & 2D Barcode printing is supported.

●2-color printing is supported.

●Can use paper roll with a maximum thickness of 100µm.

●Label and Blackmark paper are usable as option (Label printing).

— 9 —

Page 13

FEED

1.2 Unpacking

When unpacking the printer, confirm that the following are provided:

● Printer: 1

● AC adapter: 1

● AC power cord: 1

● Sample paper roll: 1 roll

● USB cable clamp(USB Interface model): 1

● Operation panel(for wall mounting): 1

● Quick start guide: 1

● CD-ROM: 1

D

E

FE

Printer

AC adapter

CD-ROM

USB cable clamp

(USB Interface model)

PAPER

ERROR

FEED

POWER

Sample paper roll **

* The AC power cord plug will vary depending of the region.

** In case of label model, Label paper is used for sample paper roll.

AC power cord *

Quick start guide

Operation panel

(for wall mounting)

1.3 Model Classification

The printer models are classified by the following designation method:

CT-S 281 RS U - WH - PX - M1

Model name

Interface

RS:

Serial RS-232C compliant

UB: USB

Destination

(Letters + Power cord)

J: Japan

E: Europe

U: USA

Case color

WH: Cool white

BK: Black

— 10 —

Optional feature

M1: With blackmark sensor (Applicable only

for the printer with label sensor)

Optional feature

No sign: Standard printing

PX: With paper near-end sensor

XL: With label sensor

PL: With paper near-end sensor and label sensor

Page 14

1.4 Basic Specifications

Item Specifications

Model CT-S281RSU CT-S281RSE

Print method Line thermal dot print method

Print width 48 mm/384 dots

Dot density 8 (horizontal) × 8 (vertical) dots/mm (203 dpi)

Print speed 80 mm/s (Fastest, print density: Standard level),

Number of print columns Font A: 32 columns; 12 × 24 dots horizontal and vertical

Character size Font A: 1.50 × 3.00 mm

Character type Alphanumeric, International, PC437/850/852/857/858/860/863/

User memory 256KB (User-defined characters and logos can be registered)

Types of bar code UPC-A/E, JAN (EAN) 13/8 columns, ITF, CODE 39, CODE 128,

Line spacing 4.23 mm (1/6 inch) settable with command

Paper roll

Interfacing Serial (RS-232C compliant), USB

Input buffer 4k bytes/45 bytes

Supply voltage DC 8.5 V ±5%

Power consumption

AC adapter Rated input: AC 100 to 240 V, 50/60 Hz

Weight Approx. 630 g

Outside dimensions 106 (W) × 180 (D) × 105 (H) mm

Operating temperature and humidity

Storage temperature and humidity

Reliability Print head life: 50 km, 1 × 108 pulses (At normal temperature/

Safety standard *

60mm/sec in label printing

Font B: 42 columns; 9 × 24 dots

Font C: 48 columns; 8 × 16 dots

Font B: 1.13 × 3.00 mm

Font C: 1.00 × 2.00 mm

864/865/866/WPC1252/Katakana/Thai code 18

CODABAR, CODE 93, PDF417, QRCODE

Thermal paper roll: 58 mm × φ83 mm, Label paper: 58 mm x φ80 mm

Paper thickness: 0.06 to 0.1 mm

Standby: Approx. 2 W, Printing: Approx. 18 W (Approx. 26 W max.)

Rated output: DC 8.5 V, 2.5 A

5 to 40°C, 10 to 85% RH (No condensation)

−20 to 60°C, 10 to 90% RH (No condensation)

humidity with recommended paper used)

Auto cutter life: 1million cuts(At normal temperature/

humidity with recommended paper used)

UL, C-UL, FCC Class B TUV, GS, CE marking

CT-S281UBU CT-S281UBE

*Represents the safety standards acquired when CITIZEN SYSTEMS-made adapters (28AD series)

are used.

— 11 —

Page 15

FEED

2.

EXPLANATION OF PRINTER PARTS

2.1 Printer Appearance

Printer cover

D

E

E

F

Cover open button

Cutter gear cover

Power switch

Operation panel

● Printer cover

Paper is located inside this cover.

● Cover open button

To refill or replace paper, open the paper cover by pushing this button.

● Power switch

This switch turns the printer power ON/OFF.

● Cutter gear cover

To release the cutter lock, open this cover and rotate cutter gear.

— 12 —

Page 16

Operation Panel

POWER LED ERROR LEDFEED button

PAPER LED

FEED

ERROR

PAPER

POWER

● POWER LED

Lights when the printer power is on and goes off when the printer power is

off. May blink or light in a special mode or in case of a failure.

● FEED button

Pressing this button once causes a paper feed of one line. Pressing the button

continuously causes the paper to feed continuously.

● ERROR LED

Lights or blinks when paper is empty or in case of a failure.

The interval length of blinking shows the type of error.

● PAPER LED

Lights when there is no paper or the paper is low with the optional PNE sensor.

Rear Connectors

USB interface TypeSerial interface Type

Power connector

Sensor adjuster

cover

Serial interface

connector

Sensor adjuster

cover

● Power connector

Connects to the cable from AC adapter.

● USB Interface connector

Connects to the USB interface cable.

● Serial interface connector

Connects to the serial interface cable.

● Sensor adjuster cover

When adjusting the Paper sensor, remove this cover.

— 13 —

Power connector

USB Interface

connector

Page 17

2.2 Paper Cover Inside

FEED

Paper feed roller

Paper near-end sensor

Auto cutter

Manual cutter

Paper-end sensor

FEED

Print (thermal) head

● Auto Cutter

Cuts the paper when software command is sent to the printer. Cutting method

could be partial cut or full cut, “Partial Only”is set to valid by the default

memory switch 4-8, so that the full cut command will execute as partial cut

operation.

● Manual cutter

Tears the paper by hand.

To cut the printed paper, gently pull the paper from the edge of the paper at the angle

so that paper firmly contacts the manual cutter. Improper direction of pull may result

in poor cutting or excessive unwinding of paper. In some case, characters may be

destroyed at the first printing after the paper is cut.

● Paper near-end sensor (Factory option)

If installed, detects when paper roll goes low. The external diameter of paper

roll remainder will vary depending on the position of the paper near-end

sensor lever.

● Paper-end sensor

Stops printing when this sensor detects paper end.

● Print(thermal)head

Prints characters and/or graphics data on thermal paper.

● Paper feed roller

Feeds paper as part of print mechanism.

2.3 Other Built-in Functions

● User memory

Allows registration of user-defined characters and logo data in nonvolatile

memory. Data remain registered even if the printer is OFF.

● Memory switches

Allow printer configuration, could be set by software command or manually

on the printer, changes remain registered in nonvolatile memory even if the

printer is OFF.

— 14 —

Page 18

3. PREPARATION

3.1

Connecting the AC Adapter and AC Power Cord

1. Tu rn off the printer power.

2. Plug in the cable connector of the AC adapter to the power connector at the

rear of the printer.

3. Connect the AC power cord to the inlet of AC adapter, and insert the AC powercord plug into a suitable wall outlet.

AC adapter

Inlet

AC power cord

Cable connector

CAUTION!

● Use only the specified AC adapter with the printer.

● When disconnecting a cable, do not pull out by the cable. Always hold the plug.

● Always keep the AC power supply away from other noise generating equipment.

● Do not pull the power cord. Otherwise fire, electric shock, or power disconnection

may result.

● If lightning is approaching, unplug the AC power cord from the wall outlet. Otherwise

fire or electric shock may result.

● Keep the power cord away from heat generating appliances. Otherwise the shield of

power cord may be fused resulting in a fire or electric shock.

● If the printer will not be used for a long time, leave it disconnected from its supply

outlet.

● Lay the cable not to be caught by the leg or the like.

— 15 —

Page 19

3.2 Connecting Interface Cables

Turn off the printer and unplug the power connector. Then follow the procedure

for interface cable connection.

Orient the interface cable terminal correctly and insert it into the interface

connector.

USB cable clamp

Serial Interface

USB Interface

CAUTION!

● When disconnecting the cable, always hold the connector.

● Lay the cable not to be caught by the leg or the like.

For serial interface use cable with the following configuration:

9-pin - 25-pin cable

PC

Signal Pin

RXD 2

TXD 3

DTR 4

SG 5

DSR 6

CTS 8

Printer

Pin Signal

2TXD

3RXD

4RTS

6 DSR

7SG

20 DTR

— 16 —

Page 20

FEED

3.3 Installing the Printer

The printer can be installed horizontally or mounted vertically on the wall.

At the time of shipment, the printer is set for horizontal installation. To install

the printer on the wall, put the accessory operation panel on to the original

one. This will allow easy operation panel reading when printer is wall mounted.

CAUTION!

● No screw for wall mounting is provided. Check the structure and strength of the wall

(plaster board or stronger one) and prepare two appropriate screws (round-head wood

screws of φ3.1, 16 mm or more). And fix the printer by tightening the screws in

accordance with the specified dimensions.

D

E

E

F

D

E

E

F

Horizontal position

Wall mounting

56mm

3

.5

m

m

φ3.1mm

φ5.7mm

D

E

E

F

Hooks for wall mounting

— 17 —

Page 21

3.4 Setting DIP Switch

FEED

(Only serial interface type)

DIP switch is provided only for serial interface specification.

The DIP switch is located at the bottom of the paper holder. To set the DIP

switch open the printer cover and remove the paper.

ON

OFF

18

F

E

E

D

Switch No. Function ON OFF

Communication condition

1

setting method

DIP switch setting Internal memory ON

setting

Initial

Settings

2 Flow Control XON/XOFF DTR/DSR OFF

3 Bit length 7 bits 8 bits OFF

4 Parity check With parity None OFF

5 Parity selection Even parity Odd parity OFF

6 OFF

Baud rate selection See Table below.

7 ON

8 Reserved − Fixed OFF

Selecting baud rate

Switch No.

Baud Rate (bps)

67

2400 OFF OFF

4800 ON OFF

9600 OFF ON

19200 ON ON

1200 bps and 38400 bps can also be selected by a command or the memory

switch. 9600bps is factory setting.

— 18 —

Page 22

3.5 Adjusting the Paper Near-end Sensor

FEED

Move the paper near-end sensor lever to forward or backward. The position to

be set varies in accordance with the paper roll as shown in the following table.

unit: mm

Lever Position External Diameter of Paper Poll Remainder

1 φ24

2 φ34

CAUTION!

● Paper remainder (outside diameter of roll) differs by the type of paper roll used.

● The external diameter of the paper roll is only for reference.

● In the wall-mount status, you cannot use the paper near-end sensor.

● Not usable for a label paper roll.

Lever

1

2

FEED

— 19 —

Page 23

3.6 Selecting Paper Type

Paper type selection is available by the combination of memory switches SW44 and SW4-5 by the used of “Memory Switch Select Mode”. In addtion, the

following procedure is available.

1 Enter Selecting Paper Type mode.

1)Open the printer cover and remove paper. Pressing and holding the

FEED button, turn the printer power ON. The POWER LED starts blinking.

2)Release the FEED button and then close the printer cover. Buzzer sounds

and the paper type currently set is indicated by the LED on the operation

panel.

2 Select Paper Type.

Press the FEED button to match the paper type loaded to the LED indications

in the table below. (Refer to the table below.)

*PAPER LED is kept lit.

Label

Thermal paper roll

Black Mark paper

POWER LED ERROR LED

Green lit (OFF)

(OFF) Red lit

Green lit Red lit

3Save the selected Paper Type to the Printer.

Open and close the printer cover. By this operation, selected paper type is

stored in the printer memory and the Selecting Paper Type mode is terminated.

(Then, POWER LED, ERROR LED, and PAPER LED go on.) Since then, "P.Length

Set" of Memory switch 4-1 becomes disable.

When closing the printer cover during the setting a Black Mark paper or label

paper in the printer, paper length is measured, and the result will be printed

out.

* If Paper Detection error occurs at the measurement of paper length, the

printer automatically enters Adjusting Paper Sensor mode. Adjust the

sensor in accordance with “3.7 Adjusting Paper Sensor”.

3.7 Adjusting Paper Sensor

Before using Black Mark paper (BM paper) or label, adjust the Paper sensor.

First remove the Sensor adjuster cover located at the opposite side of the Power

switch from the printer.

As shown in Figure 1, Level indicator LED, Black Mark sensor adjuster, and

Label paper sensor adjuster are located here in this order from the left. Adjust

them in the following procedure.

— 20 —

Page 24

Black Mark sensor

Label light receiving sensor

Label light emitting sensor

Sensor adjuster cover

Black Mark paper

sensor adjuster

Level indicator

LED

Label paper sensor

adjuster

Figure 1

1 Enter Adjusting Paper Sensor mode.

Open the printer cover, remove paper, and then set the printer power switch

to ON. Then close the printer cover while pressing the FEED button. Then,

ERROR LED starts blinking.

2 Set Paper to be adjusted to the Printer.

This printer has three types of built-in paper sensors.

In case of label, set it so that label is positioned on the label light receiving

sensor and label light emitting sensor. In case of Black Mark paper, set it so

that the printable portion (other than black mark) is positioned on the Black

Mark sensor. In this case, closing the Printer cover causes ERROR LED to

blink.

3Adjust Paper Sensor.

Using a narrow flat or Phillips screwdriver, turn the adjuster clockwise to let

the LED go off. Then slowly turn the adjuster counterclockwise to set the

LED to be lit. Excessively turning the adjuster results in blinking of the LED.

In this case, return the adjuster to let the LED go on.

Turning the adjuster

counterclockwise

blink Orange Turning off

* While turning the adjuster by the screwdriver, do not let the part of the

screwdriver touch the metal frame. Otherwise proper LED light color

will not be displayed while touching.

4Perform Paper Measuring operation

When the FEED button is pressed, label is fed and paper measuring is carried.If

the FEED button is presed during the paper measuring, the result will be

printed out as follows, and the printer memory switch will be initialized.

* The measuring result is a reference value

showing a label length

showing a gap between labels

LabelLength

GapLength

< Example of label measuring result >

:

XXXmm

:

XXmm

< Example of black mark paper measuring result >

— 21 —

showing a black mark pitch

showing a black mark height

BlackmarkInterval:XXXmm

:

BlackmarkLength

XXmm

Page 25

3.8 Full cutting label paper

When full-cutting the label paper with the printer installed horizontally,Be sure

that the guide plate is mounted on the paper exit of the printer cover.

(This guide plate was set to the printer at the time of factory shipment.)

The Guide Plate prevents cut paper from dropping in the printer.

CAUTION!

■ If about 10 sheets of cut paper accumulate on the paper exit, remove the paper.

• Stacking of 10 or papers, paper jam may occur.

●Mounting and Dismounting Guide Plate

• Mounting

With the printer cover kept open, insert the tabs of the guide plate to one of the

mounting holes (either right or left hole) located at the inside of the cover front. Set

the guide plate with its lib facing toward you.

Then, with the guide plate warping toward you, insert the tabs to the mounting

holes at the opposite side of the cover.

• Dismounting

With the printer cover kept open, pull the center portion of the guide plate toward

you to remove the guide plate.

Tabs for

mounting hole

Lib

— 22 —

Set similarly at the

opposite side.

Page 26

4.

FEED

MAINTENANCE AND TROUBLESHOOTING

4.1 Setting/Replacing Paper Rolls

1. Press the cover open button down.

2. Open the printer cover.

3. Insert a paper roll with the print surface facing down as shown on the figure

below and pull the paper end out of the printer.

4. Close the printer cover until a click can be heard.

F

E

E

D

Cover open button

WARNING

● When opening the printer cover, take care not to touch the print head or cutter blade.

Otherwise, burning or injury of hand may result.

CAUTION!

● Always use the specified types of paper roll.

● Confirm that the paper roll is set correctly.

● When the paper is skewed and not extended straightforward from under the cover,

open the cover and adjust the paper correctly.

● When closing the cover, press on the both front sides marked or the center of the cover

to close it firmly.

● When setting paper, pay attention not to let your fingers get injured by the edge of

paper.

● When setting a label paper roll to the printer, be sure that there is no uneven portion

on the roll paper side. If the roll paper side is uneven, set it evenly.

— 23 —

Page 27

4.2 Removing Jammed Paper

1. Tu rn the printer power off.

2. Open the printer cover. If the cutter blade remains protruded with paper

jammed, do not open the printer cover forcibly. Referring to section 4.4, restore

the blade to the normal position and then open the cover.

3. Remove paper roll and clean the printer from any jammed paper or remaining

small pieces of paper, then install the paper roll and close printer cover firmly.

4. Turn on the printer. The auto cutter mechanism is initialized and the alarm is

cleared.

CAUTION!

● The print head is hot immediately after printing. Do not touch it with your hand. Do

not touch the heating element of the head with a bare hand or metal object either.

4.3 Cleaning the Print Head

1. Tu rn the printer power off.

2. Open the printer cover.

3. Wait for several minutes and then wipe the dust or the like off the surface of

head heating element using a cotton swab containing ethanol.

4. Head cleaning shall be done about once a month for standard paper. In case

of label paper, clean the head about once every 10,000 sheets because the

head is likely to catch the adhesive.

CAUTION!

● The print head is hot immediately after printing. Do not touch it with your hand. Do

not touch the heating element of the head with a bare hand or metal object either.

— 24 —

Page 28

O

PA

APER

4.4

When the Printer Cover Cannot Be Opened

Cutter lock error may occur with the Auto Cutter due to dropping of foreign

object, paper jam, etc. If the cutter blade remains protruded with cutter lock

error, the printer cover does not open.

The Auto Cutter can also be restored to the initial position by turning the printer

on again or by pressing the FEED button, when the memory SW3-1 is set to

OFF.

If the cutter lock error cannot be recovered by the above method, release cutter

lock in the following procedure.

1. Tu rn the printer power off.

2. If a cutter lock error occurs, the printer cover is held unopened. To open the

cover, open the cutter gear cover on the front of the printer, turn the cutter

gear under the protection sheet in the arrow direction, and return the movable

blade to the initial position. (Return the movable blade to the position where

the printer cover can open.)

3. Open the printer cover and remove the cause of the cutter lock.

4. Set paper correctly, close the printer cover, and turn the printer power on.

(Check to make sure ERROR LED goes off.)

CAUTION!

● Do not touch the printer head by hand just after printing because high temperature

remains on it.

● Do not touch the surface of the heating element of the print head by bare hand or by

metal.

● Do not touch the blade of the cutter.

R

R

E

P

Cutter gear

Protection sheet

— 25 —

Power connector

Page 29

4.5 Self-printing

Insert paper into the printer. With the FEED button pressed and held, turn the

printer power on, keep the FEED button held for about 1 second, and then

release the FEED button. The printer starts self-printing. The printer prints

model name, version, DIP switch setting, memory switch setting, and built-in

fonts.

Firmware version

Interface

Serial communication

condition (Only serial

interface model)

Buffer size

DIP switch setting

(Only serial interface

model)

Memory

switch

setting

4.6 Hexadecimal Dump Printing

This function is to print all received data in hexadecimal numbers. If problems

such as missing data, data duplication, etc. should occur, this function allows

checking whether or not the printer is receiving data correctly. Set paper to the

printer and keep the paper cover open.

With the FEED button pressed and held, turn the printer power on and then

close the paper cover.

The printer prints “HEX dump print mode” followed by the received data printed

in hexadecimal numbers and some characters.

CAUTION!

● The printer prints “.” if there is no characters corresponding to data.

● During hexadecimal dump, functions except some command will be disabled.

● If print data does not cover a line, press the FEED button to print the line.

When you press the FEED button three times consecutively, or you turn the

printer power off, or the printer receives a reset signal from the interface, the

hexadecimal dump printing is terminated.

Print example

HEX DUMP PRINT MODE

1B 21 00 1B 20 04 41 42 43 44 .!.. .ABCD

45 46 47 48 49 4A 4B 4C 4D 4E EFGHIJKLMN

4F 50 0D 0A 31 32 33 0D 0A OP..123..

— 26 —

Page 30

4.7 Error Indication

● Paper-end

Paper empty is detected in two steps: paper-end and paper near-end(factory

option). It causes the PAPER LED to light. If paper-end is detected, replace

the paper roll.

● Cover open error

When the printer cover is opened, Printer cover open is detected and the

ERROR LED goes on.

During printing, do not open the printer cover. If you open the printer cover

accidentally, the ERROR LED blinks. Confirm the paper and close the cover.

Printing resumes automatically.

● Head overheat error

When you print dense characters or dark image, the head temperature rises.

If the head temperature exceeds a specified level, the printer stops printing

operation and waits till the head temperature is lowered. During waiting, the

ERROR LED blinks. When the head temperature is lowered, printing resumes

automatically.

● Cutter lock error

If the cutter blade stops operating due to paper jam or the like, the ERROR

LED blinks.

Remove the cause of the trouble and press the FEED button. If the blade does

not move and the cover does not open yet even in the above procedure,

follow the procedure in section 4.4 to open the paper cover.

● Waiting for cutting label

If cutter disabled is selected, label paper is ejected by the GS FF (print and

eject blackmark paper/label paper) command and the printer is waiting for

cutting label paper. (The printer is waiting for cutting by manual cutter or

peeling label.)

If FEED SW is pressed, the printer returns to the print start position and is

restored to normal state. When MSW3-7=OFF is set, if FEED SW is not pressed

for more than 3 seconds (default), the printer performs the same operation

as FEED SW is pressed.

● Blackmark/label paper detection error

If blackmark/label paper cannot be detected or non-standard paper is used,

blackmark/label paper detection error occurs.

In this case, perform sensor adjustment in the sensor adjust mode. If

adjustment is not successful regardless of the use of standard paper, faulty

(degraded) sensor or the like is suspected. Contact our service agent.

— 27 —

Page 31

The LED status of each error including the above is shown below.

Status POWER LED ERROR LED PAPER LED

Paper-end Lights Lights Lights

Paper near-end Lights Turning off Lights

Cover open error Lights Lights Turning off

Cover open error *1 Lights Turning off

Cutter lock error Lights Turning off

Head overheat error Lights Turning off

Memory check error Turning off Turning off

Low voltage error Lights Turning off

High voltage error Lights Turning off

Macro execution Lights Turning off

wait *2

Waiting for cutting Turning off Lights

label

Blackmark/label paper Lights Turning off

detection error

*1: When the printer is printing.

*2: The ERROR LED may blink even in the execution of macro function.

5. OTHER

5.1 External Views and Dimensions

FEED

106

FEED

105

180

— 28 —

(Unit: millimeter)

Page 32

5.2 Manual Setting of Memory Switch

Memory switches can be set manually or by a command.

For manual setting, refer to the next page.

The function of each memory switch is shown in the following table. (The

white-on-black characters are factory setting.)

Switch No. Setting 0 (OFF) 1 (ON)

Memory SW1-1 Power ON Info Valid Not Send

SW1-2 Buffer Size 4k bytes 45 bytes

SW1-3 Busy Condition Full/Err Full

SW1-4 Receive Error Print “?” No Print

SW1-5 CR Mode Ignored LF

SW1-6 Reserved Fixed −

SW1-7 DSR Signal Invalid Valid

SW1-8 Reserved Fixed −

Memory SW2-1 Reserved − Fixed

SW2-2 Auto Cutter Invalid Valid

SW2-3 Spool Print Invalid Valid

SW2-4 Full Col Print LineFeed WaitData

SW2-5 Resume aft PE Next To p

SW2-6 Reserved − Fixed

SW2-7 Reserved Fixed −

SW2-8 PNE Sensor * Valid Invalid

Memory SW3-1 Resume Cttr Err Valid Invalid

SW3-2 Reserved Fixed −

SW3-3 Reserved − Fixed

SW3-4 Reserved Fixed −

SW3-5 Reserved Fixed −

SW3-6 Reserved Fixed −

SW3-7

SW3-8

CBM-270 Mode

Resume Open Err

Invalid Valid

Close Command

Memory SW4-1 *1 P. Length Set Auto Measure Command

SW4-2 *2 Power on TOF Invalid Valid

SW4-3 *3 Feed&Cut at TOF Invalid Valid

SW4-4 *4 Paper Select Thermal Roll BM.P / Lbl.P

SW4-5 *5 Position detect Black Mark Label

SW4-6 C.Close Action Find TOF Auto Measure

SW4-7 *6 Auto paper Select Invalid Valid

SW4-8 *7 Partial Only Invalid Valid

*Factory option

— 29 —

Page 33

Switch No. Setting 0 (OFF) 1 (ON)

Memory SW5-1 Reserved − Fixed

SW5-2 Reserved Fixed −

SW5-3 USB Mode Virtual COM Printer Class

SW5-4 Reserved Fixed −

SW5-5 Reserved Fixed −

SW5-6 Reserved Fixed −

SW5-7 Clear PNE LED Auto Set Paper

SW5-8 Reserved Fixed −

Switch No. Setting Default Set Values

Memory SW7-1 Baud Rate 9600 bps 1200 bps, 2400 bps, 4800 bps, 9600 bps,

SW7-2 Data Length 8bits 7bits, 8bits

SW7-3 Stop Bit 1bit 1bit, 2bits

SW7-4 Parity NONE NONE, EVEN, ODD

SW7-5 Flow Control DTR/DSR DTR/DSR, XON/XOFF

SW7-6 Reserved −

SW7-7

Memory SW8-1 Reserved −

SW8-2 Paper Type 1 Color Normal 1 Color Normal, 2 Color Normal

Memory SW9-1 Code Page PC437 PC437/Katakana/PC850,858/PC860/PC863/

Memory SW9-2 Int’ char Set U.S.A U.S.A, France, Germany, England, Denmark,

Memory SW9-3 Kanji OFF ON, OFF

SW9-4 JIS/Shift JIS JIS JIS, Shift JIS

Memory SW10-1 Print Density 100% 70%, 75%, 80%, 85%, 90%, 95%, 100%, 105%,

SW10-2 Print Speed Level 9 Level 1, Level 2, Level 3, Level 4, Level 5,

SW10-3 Reserved −

SW10-4 Reserved −

*1: When paper length setting is assigned as a command, use the command (GS1) when

specifying paper layout. If there is no specification, paper length is set to default value. This

is valid only when Blackmark paper/Label paper is selected with memory switch 4-4.

*2: Only valid when Blackmark paper/Label paper is selected with memory switch 4-4.

*3: No cutting operation occurs when cutter is disabled with memory switch 2-2.

When thermal paper roll is selected, cutting operation occurs after paper is fed by about

24mm.

When Blackmark paper/Label paper is selected, cutting operation occurs after paper feed to

the top of the next print position.

*4: Paper select setting at the time of shipment depends on the model.

Standard: OFF (Thermal paper roll) Label: ON (Blackmark paper/Label paper)

*5: Valid only when Blackmark paper/Label paper is selected with memory switch 4-4.

Factory setting of paper position detection is subject to the model.

Standard: OFF (Blackmark detection) Label: ON (Label detection)

*6: MSW4-6/4-7 functions only when blackmark paper/label paper is selected by MSW4-4.

*7: Invalid when Blackmark paper/Label paper is selected with memory switch 4-4. (Only for full

cut)

VCom Protocol

PC Setting PC Setting, DTR/DSR, XON/XOFF

19200 bps, 38400 bps

PC865/PC852/PC866/PC857/WPC1252/

Space page/PC864/Thai Code 18

Sweden, Italy, Spain, Japan, Norway,

Denmark 2, Spain 2, Latin America, Korea,

Croatia, China

110%, 115%, 120%, 125%, 130%, 135%, 140%

Level 6, Level 7, Level 8, Level 9

— 30 —

Page 34

Manual Setting of Memory Switch (Memory SW)

The memory switch can be selected, changed, or written by the combination of

three actions: pressing the FEED button, pressing and holding the FEED button,

and opening or closing the printer cover.

1. Entering memory switch setting mode.

Set paper to the printer and keep the printer cover open. With the FEED

button pressed and held, turn the printer power on, and then press the

FEED button twice. Close the cover. If the current settings of the memory

switch etc. are printed, the printer is now in the memory switch setting

mode.

Memory SW (1) 00000000

0: OFF state

1: ON state

2. Selecting memory switch

When the FEED button is pressed button shotly (within 2 seconds), printing

occurs in the order of “Memory SW1” → “Memory SW2” → “Memory

SW3” → “Write/Factory Setting” → “Memory SW1” → ...... repeatedly.

When the memory switch you want to change is reached, press and hold

the FEED button (for more than 2 seconds). The reserved memory switch

setting will be skipped and not printed.

3. Selecting each switch item

There are eight setting items for each switch. Press and hold the FEED

button continuously, the printer goes to the next item and prints the current

setting of the item. Repeat pressing and holding till the item you want to

change setting is reached.

Power ON Info (Valid)

Items with ERROR LED lit are

those values elected currently

4. Changing the setting

When the item you want to change is reached, press the FEED button

shortly. The changed set value is printed. (To return to the previous setting

press the FEED button shortly). When you press the FEED button

continuously, the set value is accepted and then the printer goes to the

next setting item.

5. Returning to the memory switch select mode

When the setting of the desired content is completed, open the printer

cover and then close the printer cover. This allows the printer to print the

setting of the changed memory switch.

— 31 —

Page 35

6. Saving the setting and exiting the memory switch setting mode

Press the FEED button shortly to move to “Write/Factory Setting”. Then

press and hold the FEED button. The printer prints the content of new

setting and exits the memory switch setting mode to return to the normal

standby state.

* Unless saving the setting is executed, the changed setting cannot be

enabled.

7. Initializing the memory switch

When you want to return the memory switch setting to the initial state, go

to “Write/Factory Setting” in the above procedure. Here, open the paper

cover and press and hold the FEED button till buzzer sounds. This allows

the printer to return to the initial state.

* All the memory switches settings are returned to the factory set values.

5.3 Printing Paper

a) Thermal paper

Use the print paper shown in the following table or the paper with equivalent

quality.

Paper Type Product Name

Recommended thermal TF50KS-E2D, TF77KS-EY from Nippon Paper

paper roll PD160R from Ohji Paper

F230AA, PB670 (2-color) from Mitsubishi Paper

Paper width 58

Maximum print area 48

+0

−1

Printing surface

d

D

φ83 or less

Paper thickness t (µm) d D

60µm≦t≦75µm φ12 φ18

75µm<t≦100µm φ25.4 φ32

CAUTION!

Use the paper with the start of winding to roll core is as shown below.

● No fold line is present and paper is along the inner diameter.

● No turnup is present.

● No pasting to core is present.

● Outer winding (print side out) is used.

— 32 —

(Unit: millimeter)

Page 36

When using “label paper” with CT-S281XL/OL, refer to the following. Use the

following paper or the equivalent paper.

Paper type Product name

Recommended thermal label paper HD75 from Nippon Paper

150HBW from Ricoh

b) Label paper

A

BC

DLM

Full cut

Paper feeding

E

F

G

direction

Printable area

position

HI

JK

Unit: mm

Mark Item Dimensions

A Liner width 58

B Label width 54 + 0.5

C Left edge of label 2 + 0.5

D Print width 48

ETop margin 2 + 1

F Print length 21 to 156 + 1

G Bottom margin 2 + 1

H

Cut position between labels

I Gap between labels 5 + 1

JLabel length 25 to 160

K Label pitch I+J

L Left margin 3 + 1

M Right margin 3 + 1

0

-1

_

_

_

_

2 or more

_

_

_

_

CAUTION!

■ Do not use full sheet label paper.

■ Use label paper with peel force of 200 mN/50mm between label and liner. Using label

paper with weak peel force may result in paper jam.

■ In some case, adhesive may be present between label papers or at the edge of label.

Fixing adhesive on the paper path such as print head, etc. may result in paper jam. At

the occurrence of paper jam, check for fixed adhesive. Remove the fixed adhesive

using close moistened with ethanol.

■ When label length is less than 30 mm and the cutter is set to be disabled, feeding the

unlabelled area to the manual cut position and then to the first print position by using

the GS FF command may cause label paper to feed one or two sheets without printing.

■ Observe the life and storage condition of label paper when using label paper.

— 33 —

Page 37

c) Black mark paper (BM paper)

A

B

D

C

F

Black Mark (printed on the reverse)

Mark Item Dimensions

A Right edge of black mark 15 or more

B Left edge of black mark 0 to 1.5

C Black mark height 5

D Cut position in black mark 2.5

ETop margin 7 + 1

F Black mark pitch 30 to 165

GBottom margin 7 + 1

Cut position

Printable area

Unit: mm

_

_

E

Paper feeding

direction

G

CAUTION!

1) PCS value of black mark must be 0.9 or more.

2) When using the black mark paper, consider the margin of +/- 2 mm for the print position

against the standard position and +/- 5 mm for print length.

3) Refer to the above drawing for the printable area and have enough margings specified

in the marks E and G. If the print data size is out of the printable area, the printer

should skip to next page.

4) When using preprinted paper, consider the layout of the paper.

— 34 —

Page 38

TE74905-02F

1.02E-1001

Loading...

Loading...