Page 1

Technical Manual

CL-S6621

Thermal Transfer Barcode & Label Printer

PZY90003-00

1.00E-1304

Page 2

Copyright © 2013 by CITIZEN SYSTEMS JAPAN CO., LTD.

CL-S6621 ii

Page 3

CHAPTER 1 SPECIFICATIONS

CHAPTER 2 OPERATING PRINCIPLE

CHAPTER 3 DISASSEMBLY AND MAINTENANCE

CHAPTER 4 TROUBLESHOOTING

CHAPTER 5 PARTS LISTS

CHAPTER 6 CIRCUIT DIAGRAMS

APPENDICES

iii

CL-S6621

Page 4

Safety Precautions

To prevent personal injury or property damage, the following shall be strictly observed.

The degree of possible injury and damage due to incorrect use/maintenance or improperly

following instructions is described below.

Indicates a situation which, if not observed and handled properly, could

Warning

Caution

: This is a mark to call attention to the reader.

• Before starting disassembly/reassembly or mechanical adjustment, be sure to

disconnect the power cord from the power source.

• Do not disassemble/reassemble or adjust the machine, if it functions properly.

Particularly, do not loosen screws on any component, unless necessary.

• After completing an inspection and before turning on the power, be sure to check that

there is no abnormality.

• Never try to print without media.

• Check that the media is properly set.

• Do not lay anything on the cover or lean against it during maintenance or while the

printer is in operation.

• During maintenance, be careful not to leave parts or screws unattached or loose

inside the printer.

• When handling a printed circuit board, do not use gloves, etc., which can easily

cause static electricity. Since ICs, such as CPU, RAM and ROM, might be destroyed

by static electricity, do not touch lead wires or windows unnecessarily.

• Do not put the printed circuit boards directly on the printer or on the floor.

• When disassembling or reassembling, check wires for any damage and do not pinch

or damage them. Also, run wires as they were.

Indicates a situation which, if not observed and handled properly, could

result in death or serious injury.

result in injury or property damage.

Warning

Caution

CL-S6621 iv

Page 5

CHAPTER 1

SPECIFICATIONS

1-1

CL-S6621

Page 6

CHAPTER 1 SPECIFICATIONS

TABLE OF CONTENTS

1-1. General Specifications.................................................................................................... 1-3

1-2. Printable Area .................................................................................................................1-8

1-3. Printing Position Accuracy.............................................................................................. 1-9

1-4. Adjustable Sensors......................................................................................................... 1-10

CL-S6621 1-2

Page 7

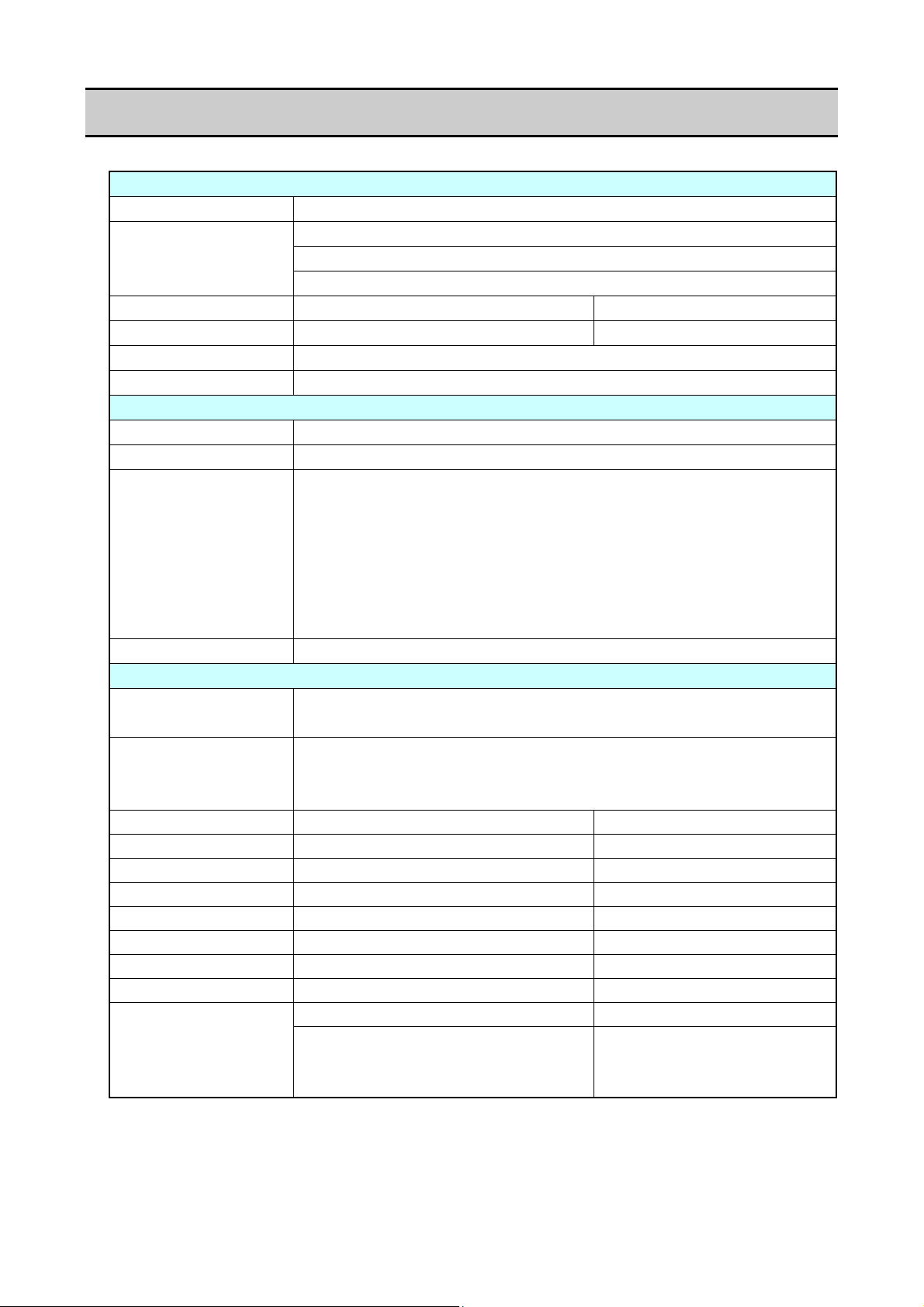

General Specifications

1-1. General Specifications

Printing

Printing method Thermal transfer/Direct thermal

Resolution

Max. print width 168 mm 6.6inch

Max. print length 2539.7 mm 99.99 inch

Print density Print density is adjustable with software

Printing speed setting 6, 5, 4, 3 or 2 inches per second

Print mode

Batch mode Normal printing (single or multiple sheets)

Tear off mode Feeds back media to the tear-off position after printing is completed.

Cut mode *1 Prints while cutting at designated sheet units.

Peel mode*1 Peels labels from the liners after printing them.

Media

Types of media Roll, fanfold

Recommended media Thermal transfer: label media (LR1111 Lintec)

Max. media width 178.0 mm 7.01"

Min. media width 50.0 mm 1.97"

Min. label width 50.0 mm 1.97"

Min. label pitch*2 19.0 mm 0.748"

Max. media thickness 0.254 mm 0.01"

Max. media length 2539.7 mm 99.99"

Min. media length 16.0 mm 0.63"

Min. media thickness 0.0635 mm 0.0025"

diameter

*1: Options can be separately purchased.

*2: When a media pitch of less than 1" is used, set the "Small Media Adjustment" setting in the

"Page Setup" menu to "On".

Main scanning line density: 203 dots/inch (8 dots/mm)

Sub-scanning line density: 203 dots/inch (8 dots/mm)

Head 1344 dots (effective dots: 1344 dots)

The following two kinds of cut mode operations are available.

• Back feed

• Cut through

(Cut through refers to stopping present printing to cut the previous

label when it reaches the cut position. After cutting, printing restarts

but a gap may be created at the seam of the printing at this time.)

(continuous media, die-cuts, continuous tags, paper or tickets)

Direct thermal media: label media (150LA-1 Ricoh),

tag media (130LHB Ricoh)

Max. external diameter: 127mm 5" On-board roll media

Media core: 25.4 to 76mm

Min. media core external diameter

(when using label media): 50.8 mm

1 to 3"

2"

1-3 CL-S6621

Page 8

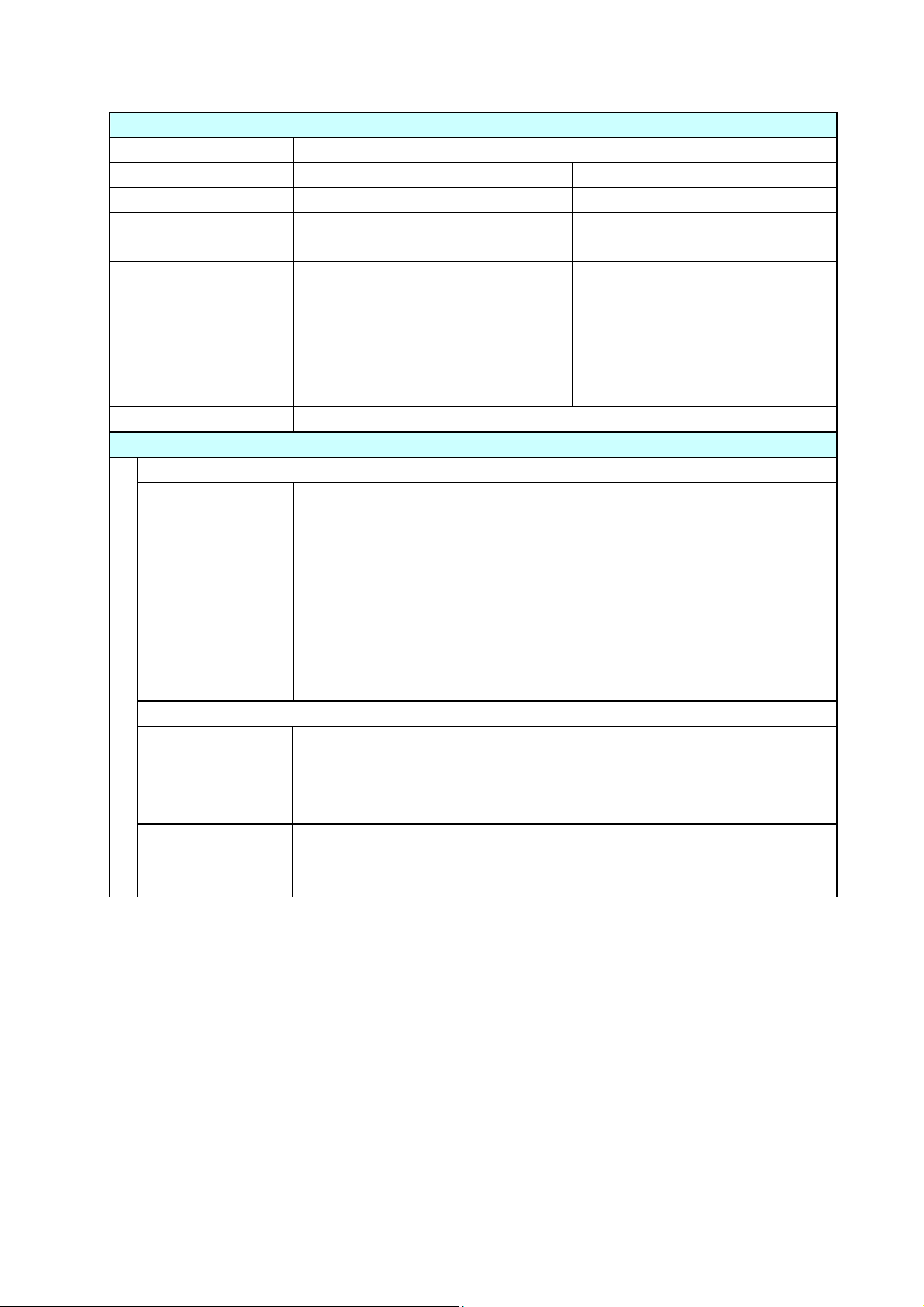

General Specifications

Ribbon

Recommended ribbon B110A Ricoh

Max. ribbon width 174.0 mm 6.85"

Min. ribbon width 50.0 mm 1.97"

Max. ribbon length 360.0 m 1181 ft

Max. roll diameter 74.0 mm 2.90"

Outer diameter of the

33.4±0.50mm 1.31 ± 0.02"

paper core

Inner diameter of the

25.4 ± 0.25 mm 1.00 ± 0.01"

paper core

Ribbon end tape

Max. 80.0 mm 3.15”

length

Ribbon end detection Ribbon out detection by a ribbon sensor

Bar code

For Datamax® emulation*3

One-dimension • Code 3 of 9 • UPC-A • UPC-E • EAN-13 (JAN-13)

• EAN-8 (JAN-8) • Interleaved 2 of 5 • Code 128

• HIBC (Modulus 43-used code 3 of 9) • Codabar (NW-7)

• Int 2 of 5 (Modulus 10-used Interleaved 2 of 5) • Plessey

• Case Code • UPC 2DIG ADD • UPC 5DIG ADD • Code 93

• Telepen • ZIP • UCC/EAN 128 • UCC/EAN128 (for K-MART)

• UCC/EAN128 Random Weight • FIM

Two-dimension • UPS Maxi Code • PDF-417 • Data Matrix • QR Code • Aztec

• GS1 DataBar

For Zebra® emulation*4

One-dimension • Code 11 • Interleaved 2 of 5 • Code 39 • EAN-8 • UPC-E

• Code 93 • Code 128 • EAN-13 • Industrial 2 of 5

• Standard 2 of 5 • ANSI CODABAR • LOGMARS • MSI • Plessey

• UPC/EAN Extensions • UPC-A • POSTNET • Planet

Two-dimension • Code 49 • PDF-417 • CODA BLOCK • UPS Maxi Code

• Micro PDF-417 • Data Matrix • QR Code • GS1 DataBar

• TLC39 • Aztec

*3: Datamax® is a registered trademark of Datamax Bar Code Products Corporation.

®

*4: Zebra

is a registered trade mark of ZIH Corp.

CL-S6621 1-4

Page 9

General Specifications

Font

For Datamax® emulation*3

1. Seven kinds of fixed pitch font

Overseas, English fonts and European fonts

2. OCR fonts

5

OCR-A*

, OCR-B*5

3. Proportional fonts

CG Triumvirate smooth font

CG Triumvirate Bold smooth font

(6, 8, 10, 12, 14, 18, 24, 30, 36, 48 points)

• Character set: Conforms with code page 850 standards

4. TrueType

TM

rasterizer *

6

For Zebra® emulation*4

1. Five kinds of fixed pitch font

Overseas, English fonts and European fonts

2. OCR fonts

OCR-A*

5

, OCR-B*5

3. Proportional font

CG Triumvirate Condensed Bold

6

4. True type™ rasterizer*

Symbol set

PC866U Ukraina*7, PC Cyrillic, ISO 60 Danish/Norwegian, DeskTop,

ISO 8859/1 Latin 1, ISO 8859/2 Latin 2, ISO 8859/9 Latin 5,

ISO 8859/10 Latin 6, ISO 8859/7 Latin/Greek, ISO 8859/15 Latin 9,

ISO 8859/5 Latin/Cyrillic, ISO 69: French, ISO 21: German,

ISO 15: Italian, Legal, Math-8, Macintosh, Math, PC-858 Multilingual,

Microsoft Publishing, PC-8, Code Page 437, PC-8 D/N,

Code Page 437N, PC-852 Latin 2, PC-851 Latin/Greek,

PC-862 Latin/Hebrew, Pi Font, PC-850 Multilingual,

PC-864 Latin/Arabic, PC-8 TK, Code Page 437T, PC-1004,

PC-775 Baltic, Non-UGL, Generic Pi Font, Roman-8, Roman-9,

ISO 17: Spanish, ISO 11: Swedish, Symbol, PS Text,

ISO 4: United Kingdom, ISO 6: ASCII, Ventura International,

Ventura Math, Ventura US, Windows 3.1 Latin 1, Wingdings,

Windows 3.1 Latin 2, Windows 3.1 Baltic (Latv, Lith),

Windows 3.0 Latin 1, Windows Latin/Cyrillic, Windows 3.1 Latin 5

Control language

Conforms to Datamax® programming language*3 and Zebra®

4

programming language*

*5: The OCR font may have a low recognition rate according to the reader.

*6: It is equipped with UFST

TM

and TrueTypeTM rasterizer that are licensed from Monotype Imaging,

Inc.

TM

TrueType

UFST

is a trademark of Apple Inc.

TM

is a trademark of Monotype Imaging, Inc.

*7: "PC866U Ukraina" is available for Datamax® emulation only.

1-5 CL-S6621

Page 10

General Specifications

Outline of electronic devices

CPU 32-bit RISC CPU

ROM Standard equipment: FLASH ROM 16MByte (User area: 4MByte)

RAM Standard equipment: SDRAM 32MByte (User area: 4MByte)

Media detection sensors

Transparent sensor Detects media gap between labels, notches on tags, and media out

Reflective sensor Detects reflective mark on back of media and media out

PNE (Paper Near

End) sensor

Detects the near end state of roll paper

(By default, issuing a paper near end alarm is disabled by the menu

settings.)

Label peeling sensor *1Detects labels that are peeled off.

Communication interfaces

Serial 2400, 4800, 9600, 19200, 38400, 57600, or 115200 bps

USB High-speed USB2.0 (480Mbps)

Communication interface (Options)

Parallel*8 IEEE1284 (Compatible, Nibble, ECP mode)

Network

Wired LAN:

Ethernet interface (10-Base-T/100-Base-TX)

Wireless LAN:

IEEE802.11n/IEEE802.11g/IEEE802.11b

Indications and switches

LED POWER, PRINT, CONDITION, ERROR

Buzzer Alarms, errors, etc.

Operating panel keys PAUSE, FEED, STOP, MODE/REPEAT

Head-up detection

Detects head open.

switch

Power switch Turns power on and off.

Power supply

120V (-10%+6%), 2.5A, 60Hz (U.S.A., Canada) 120V version

UL60950-1st/2nd Edition, CSA No. 950, FCC Part 15 Subpart B

(Class A)

220V-240V (-10%+6%), 1.5A, 50/60Hz (Europe) 220V version

EN60950-1, EN55022 (Class A), EN55024, EN61000-3-2,

EN61000-3-3, CCC GB4943-2001/GB9254-1998/GB17625.1-2003

Power consumption (max. value)

120V version 105W (operation at 6 IPS at 12.5% printing duty)

4.4W (printer standby in Normal mode)

2.3W (printer standby in Standby mode*

9

)

220V version 105W (operating at 6 IPS at 12.5% printing duty)

5.0W (printer standby in Normal mode)

9

2.8W (printer standby in Standby mode*

)

*8: This interface is Non-L. P. S. (Limited Power Source).

*9: Standby mode is default OFF.

CL-S6621 1-6

Page 11

General Specifications

Others

Environment Operating temperature conditions:

Operating temp. 0 to 40

°C, humidity 30 to 80%, condensation free

(Conditions: ventilation, and natural convection)

Storage temperature conditions

Temp. -20 to 60

°C, humidity 5 to 85%

(Store the printer with the Head Unit up, without paper installed and

without condensation.)

(Conditions: ventilation, and natural convection)

40

Humidity %

80

30

[Operating and printing assurance condition] [Storage assurance condition]

0

5

Temperature °C

Operating assurance temperature

Printing assurance temperature

35

40

85

Humidity %

5

-20

Temperature °C

Storage assurance

temperature

60

External dimensions Approx. 303 (W) X 290.1 (D) X 273.2 (H) mm

11.9 (W) X 11.4 (D) X 10.76 (H)"

Weight Approx. 7.9 kg (17.4 lb.)

Accessories Test label media, Test ribbon, CD-ROM (User's Manual), Quick start

guide, Head cleaner, Power cord, Media holder bar and Media holder

guide, Ribbon holder, Paper core

Option Auto-cutter unit, Peeler unit, IEEE1284 Parallel I/F board, Ethernet I/F

board, Wireless LAN I/F board

1-7 CL-S6621

Page 12

Printable Area

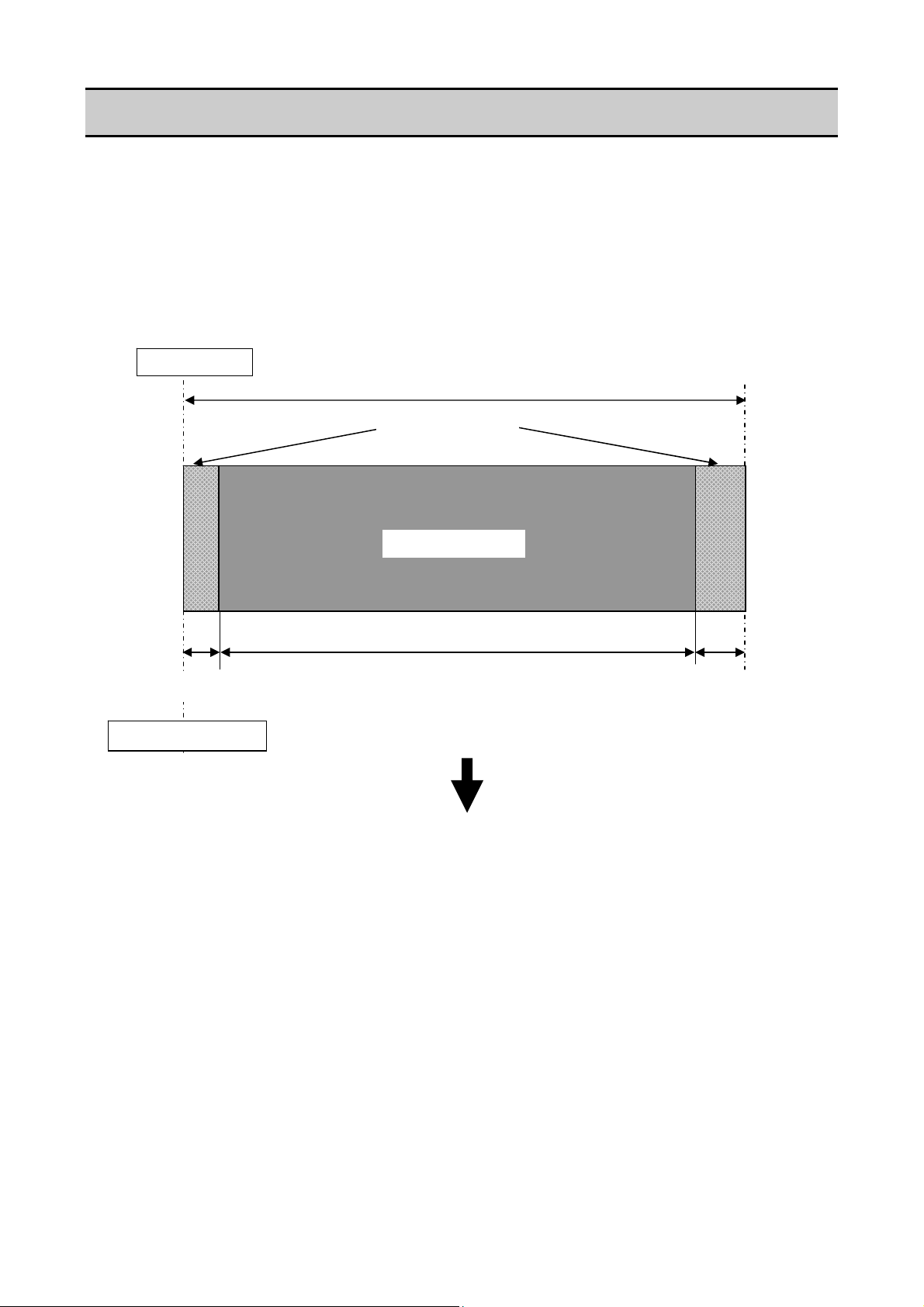

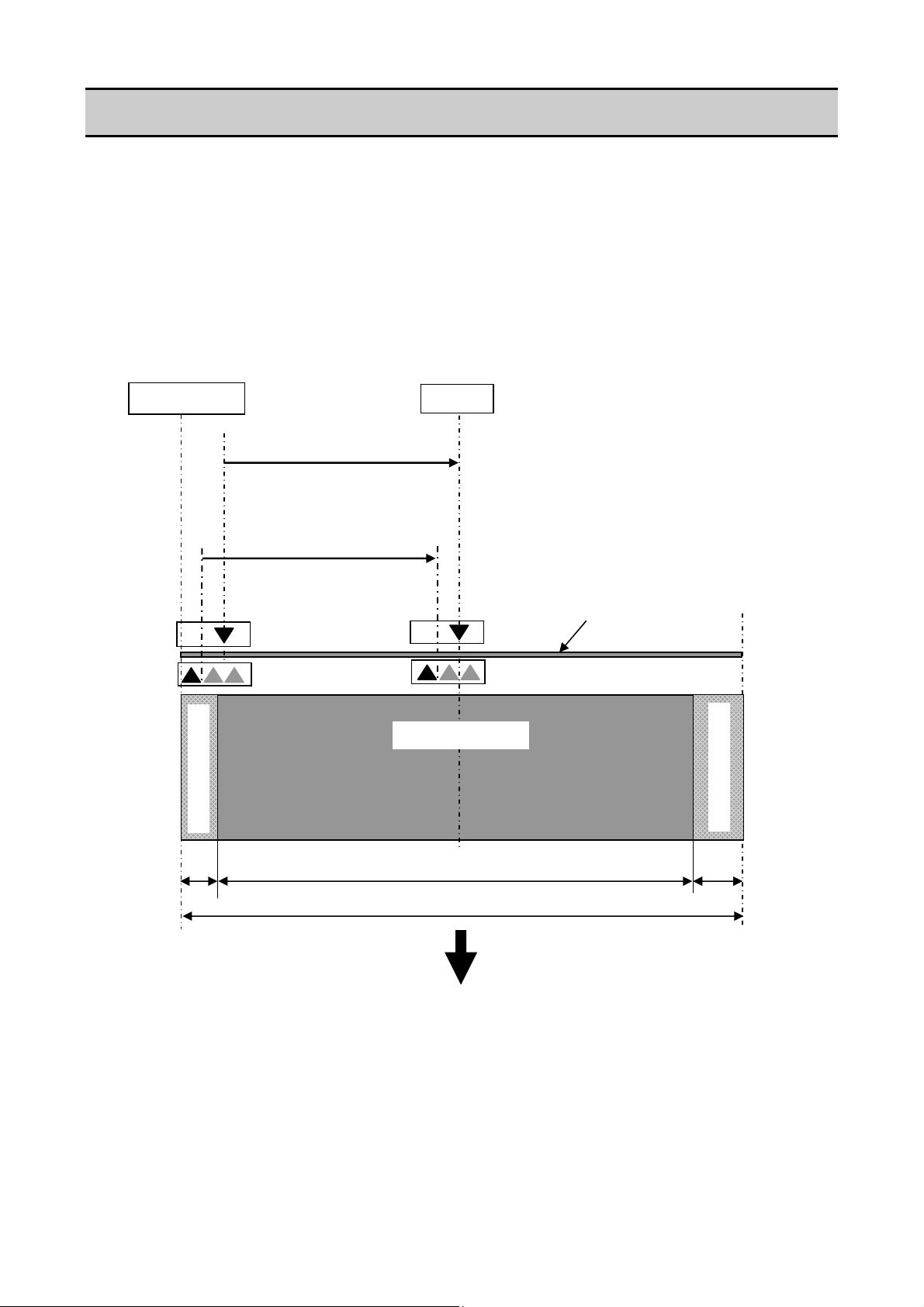

1-2. Printable Area

The printable area of the printer is as follows:

When media is set to the printer, it must be aligned with the media guide at the left of the printing

mechanism. Though the available maximum media width is 178 mm (7.01"), there are unprintable

areas on both sides: 2.5 mm (0.10") width is on the left side and 7.5 mm (0.30") width on the right

side as shown below.

The left side unprintable area applies for media of any size.

Media guide

2.5 mm (0.10")

Reference end

Maximum media width: 178 mm (7.01")

Unprintable area

Printable area

168 mm (6.61”)

7.5 mm (0.30")

Direction of media feed

CL-S6621 1-8

Page 13

Printing Position Accuracy

2

1

A

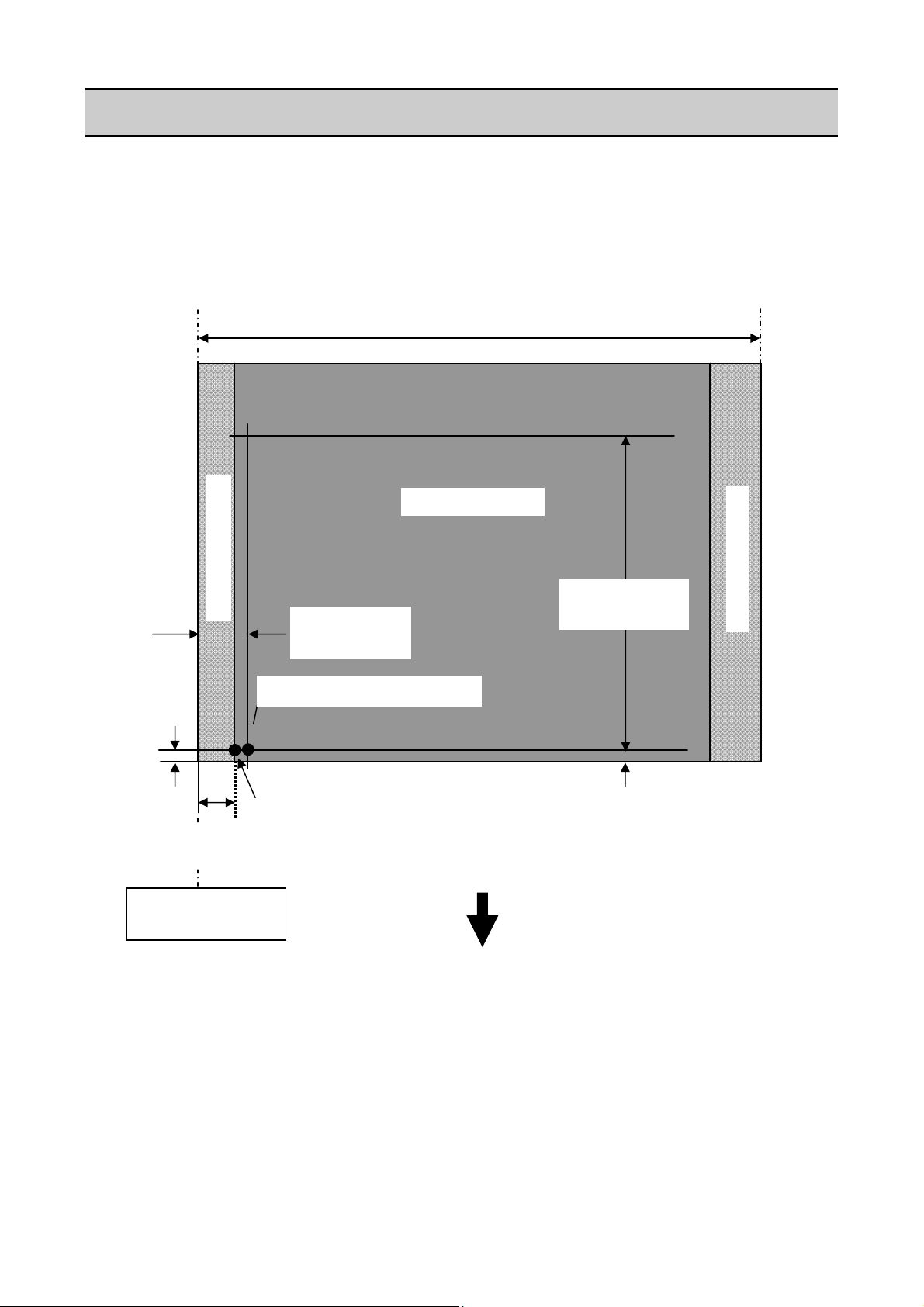

1-3. Printing Position Accuracy

By default, the printing start position is 2.5 mm (0.10") from the left end of the media and 1 mm

(0.04") backward the leading edge of the label, U-shaped notch, or black mark.

2.5 mm (0.10") is the necessary value to avoid printing in the unprintable area as mentioned in

Printable Area".

“

The printing start position can deviate from the ideal position as follows:

Unprintable area

2.5 ± 1 mm*3

(0.10 ± 0.04")

Actual printing start position*

BCDEFG

1 mm (0.04")

2.5 mm

(0.10")

Ideal printing start position

Reference edge

(Paper guide)

*1: Actual printing start position. May deviates from the ideal one in the indicated range.

*2: Deviation of vertical positioning when printing position is set to 0.

*3: Deviation of horizontal positioning when printing position is set to 0.

*4: Deviation of vertical printing position when 100 mm is specified from the printing start

position.

Maximum media width: 178 mm (7.01")

Printable area

100 ± 2 mm*4

(39.4 ± 0.08")

1 ± 2 mm*

(0.04 ± 0.08")

Direction of media feed

Unprintable area

1-9 CL-S6621

Page 14

Adjustable Sensors

1-4. Adjustable Sensors

There are two media sensors; the upper sensor (transparent sensor) and the bottom sensor

(reflective sensor). The upper sensor is used to detect the labels on the liner or the U-shaped

notches of tag. The bottom sensor is used to detect the black marks on tag. Also, both sensors are

used to detect media end.

The mechanical adjustable range of both sensors is equal and they are adjusted at the same time

by turning the blue knob (“Gear Bevel Lead Screw U”).

For details about the media sensors, refer to “2-1-3 Label/Tag Detection Mechanism".

2.5 mm

Media guide

(0.10")

4.8 to 88.9 mm

(0.19 to 3.5")

(Moveable range of the

transparent sensor)

2.7 to 86.8 mm

(0.11 to 3.42")

(Moveable range of the

reflective sensor)

Unprintable area

Maximum media width: 178 mm (7.01")

Center

Printable area

168 mm (6.61”)

Direction of media feed

Media

Unprintable area

7.5 mm

(0.30")

CL-S6621 1-10

Page 15

CHAPTER 2

OPERATING PRINCIPLES

2-1 CL-S6621

Page 16

CHAPTER 2 OPERATING PRINCIPLES

TABLE OF CONTENTS

2-1. Operation of Each Mechanism .......................................................................................2-4

2-1-1. Locations and Functions of Motors, Sensors and Thermal Head ......................2-4

(1) “Unit, Ribbon” section................................................................................ 2-4

(2) Printing section.......................................................................................... 2-5

2-1-2. Media Feed Mechanism ..................................................................................... 2-6

2-1-3. Label/Tag Detection Mechanism ........................................................................ 2-7

2-1-4. Printing and Ribbon Feed Mechanism ............................................................... 2-10

2-1-5. Print Head Up/Down Detection Mechanism .......................................................2-13

2-1-6. Paper Near End Detection Mechanism ..............................................................2-14

2-1-7. Head Balance Adjustment Mechanism ..............................................................2-15

2-1-8. Media Offset Adjustment Mechanism................................................................. 2-16

2-1-9. Transparent/Reflective Sensor Travelling Mechanism ....................................... 2-17

2-2. Operation of Control Parts .............................................................................................. 2-18

2-2-1. Configuration of Printer ......................................................................................2-18

(1) AC power supply .......................................................................................2-19

(2) SA, Main PCB............................................................................................ 2-19

(3) Operation panel (SA, Opepane PCB)........................................................ 2-20

(4) Thermal print head (SA, Head).................................................................. 2-20

(5) Sensors ..................................................................................................... 2-20

(6) Motors........................................................................................................ 2-20

(7) SA, Ribbon PCB........................................................................................ 2-20

(8) SA, Relay PCB ..........................................................................................2-21

(9) Optional I/F................................................................................................ 2-21

2-2-2. Memory map ......................................................................................................2-22

2-2-3. Sensors ..............................................................................................................2-23

(1) Head up switch.......................................................................................... 2-23

(2) Transparent sensor and reflective sensor ................................................. 2-24

(3) Ribbon Sensor F/R.................................................................................... 2-26

(4) Head temperature sensor.......................................................................... 2-27

(5) PF motor temperature sensor.................................................................... 2-28

(6) Ribbon motor temperature sensor............................................................. 2-29

(7) Paper Near End sensor............................................................................. 2-30

2-2-4. Drivers ................................................................................................................ 2-31

(1) PF motor driver.......................................................................................... 2-31

(2) Ribbon motor driver................................................................................... 2-32

(3) Head driver................................................................................................ 2-33

(4) Buzzer driver ............................................................................................. 2-35

(5) Fan driver .................................................................................................. 2-35

2-2-5. Other circuits ...................................................................................................... 2-36

(1) Power supply circuit................................................................................... 2-36

(2) Reset circuit............................................................................................... 2-37

(3) Clock circuit ...............................................................................................2-37

CL-S6621 2-2

Page 17

(4) Ope-pane circuit ........................................................................................2-38

(5) USB I/F control circuit................................................................................ 2-38

(6) RS232C I/F circuit ..................................................................................... 2-39

(7) Option I/F circuit ........................................................................................2-39

(8) Peeler circuit (for optional peeler).............................................................. 2-40

(9) Cutter control circuit (for optional cutter) ................................................... 2-41

2-3. Operation Panel.............................................................................................................. 2-43

2-3-1. External view ...................................................................................................... 2-43

(1) Keys........................................................................................................... 2-43

(2) LEDs.......................................................................................................... 2-43

2-3-2. Operation using the keys ................................................................................... 2-44

(1) Normal operation....................................................................................... 2-44

(1-1) Sensor adjustment mode ..................................................................2-44

(1-2) Menu setting mode ...........................................................................2-45

(2) Test mode.................................................................................................. 2-46

(2-1) Self print mode.................................................................................. 2-46

(2-2) Hex dump mode................................................................................ 2-47

(3) Factory/Service mode................................................................................ 2-47

(3-1) General ............................................................................................. 2-47

(3-2) How to enter the Factory/Service Mode............................................ 2-48

(3-3) Factory/Service Mode menu table .................................................... 2-54

2-4. Interface.......................................................................................................................... 2-59

2-4-1. Serial Interface ...................................................................................................2-59

(1) Specifications............................................................................................. 2-59

(2) Signal line and pin assignment.................................................................. 2-59

(3) Protocol ..................................................................................................... 2-60

2-4-2. USB Interface ..................................................................................................... 2-61

(1) Specifications............................................................................................. 2-61

(2) Signal line and pin arrangement................................................................ 2-61

2-4-3. Parallel Interface (Option) ..................................................................................2-61

(1) Specifications............................................................................................. 2-61

(2) Signal line and pin assignment.................................................................. 2-62

(3) Parallel port status signals when an error occurs ......................................2-62

(4) Compatible timing specification................................................................. 2-63

2-3

CL-S6621

Page 18

Operation of Each Mechanism

2-1. Operation of Each Mechanism

This printer is a thermal transfer barcode & label printer comprised of the following mechanisms:

media feed, ribbon feed, label/tag detection, print head up/down detection, paper near end

detection, head balance adjustment, media thickness adjustment and transparent/reflective sensor

travel.

This section describes the operation of each of these mechanisms.

2-1-1. Locations and Functions of Motors, Sensors and Thermal Head

This printer has the following motors, sensors and thermal head.

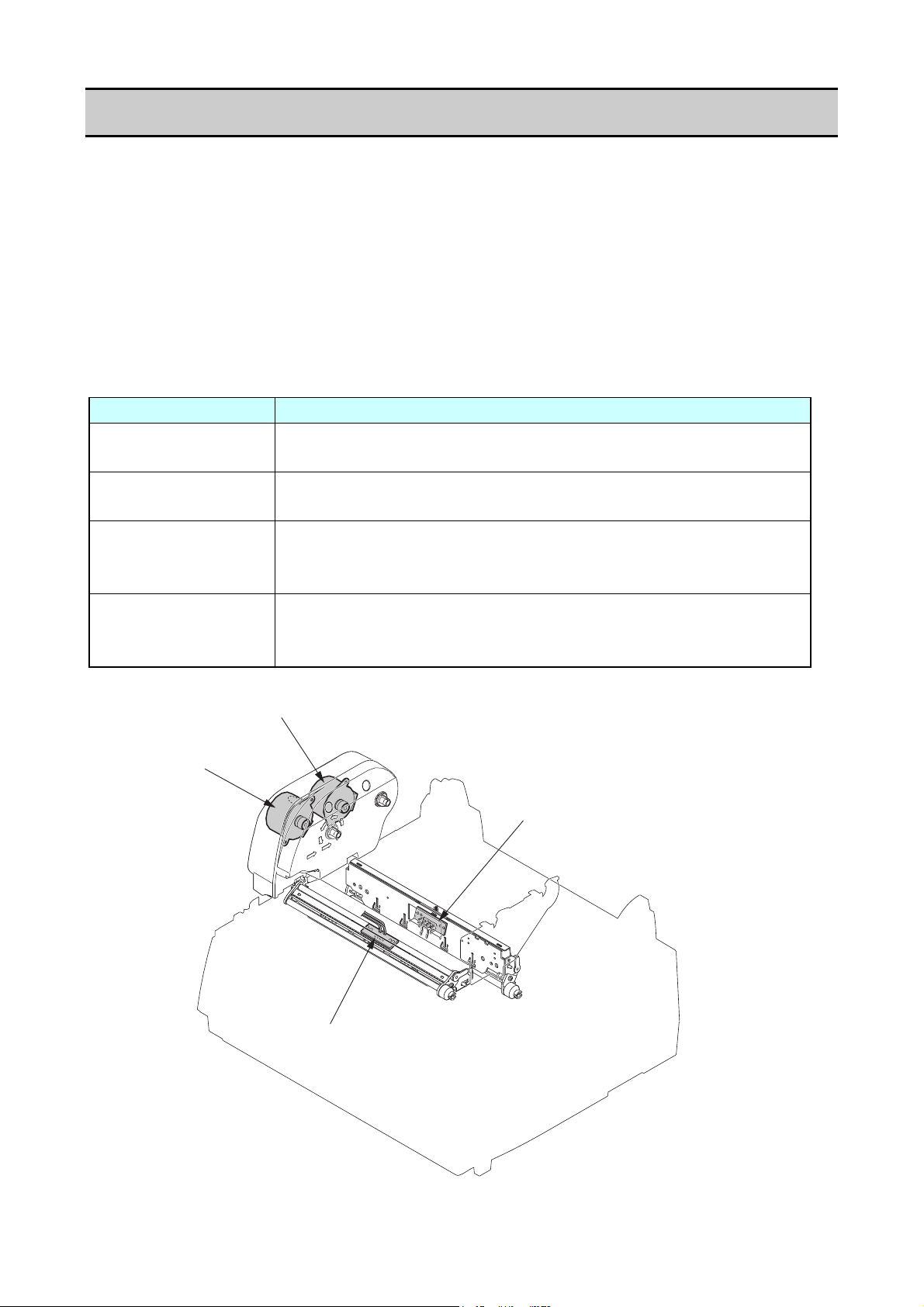

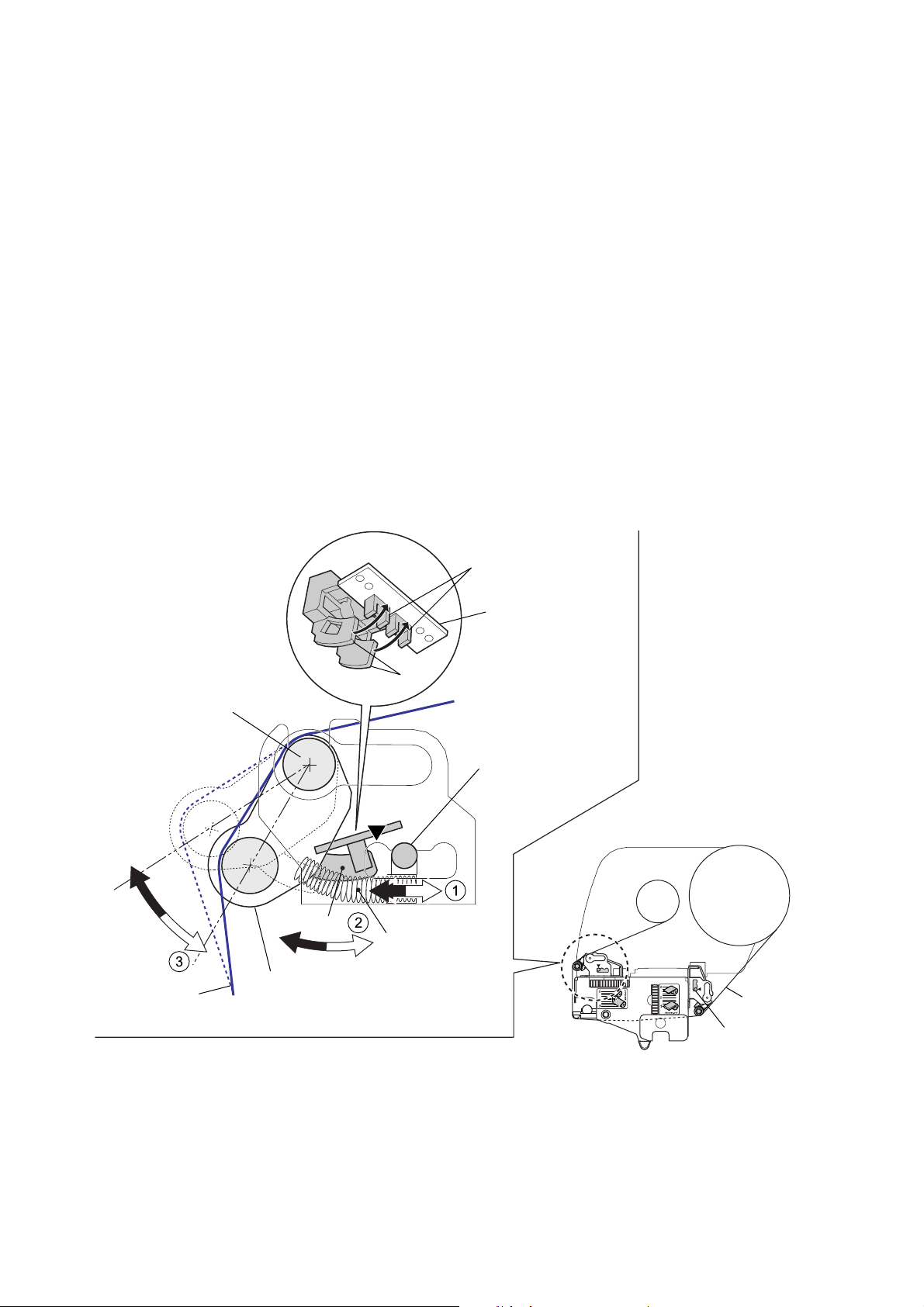

(1) “Unit, Ribbon” section

Part name Description

SA Ribbon Motor F

(Front side)

SA Ribbon Motor R

(Rear side)

Ribbon Sensor F

(“SA, Ribbon Sensor”

on the front side)

Ribbon Sensor R

(“SA, Ribbon Sensor”

on the rear side)

SA Ribbon Motor F

SA Ribbon Motor R

This motor takes up ribbon. A thermistor is attached to the side of

this motor to detect the motor temperature.

This motor gives back tension to ribbon.

This sensor consists of two photointerrupters to detect if appropriate

tension is given to the front side ribbon.

It also detects a ribbon-running error.

This sensor consists of two photointerrupters to detect if appropriate

tension is given to the rear side ribbon.

It also detects the ribbon end status.

Ribbon Sensor R

("SA, Ribbon Sensor" on the rear side)

Ribbon Sensor F

("SA, Ribbon Sensor" on the front side)

CL-S6621 2-4

Page 19

Operation of Each Mechanism

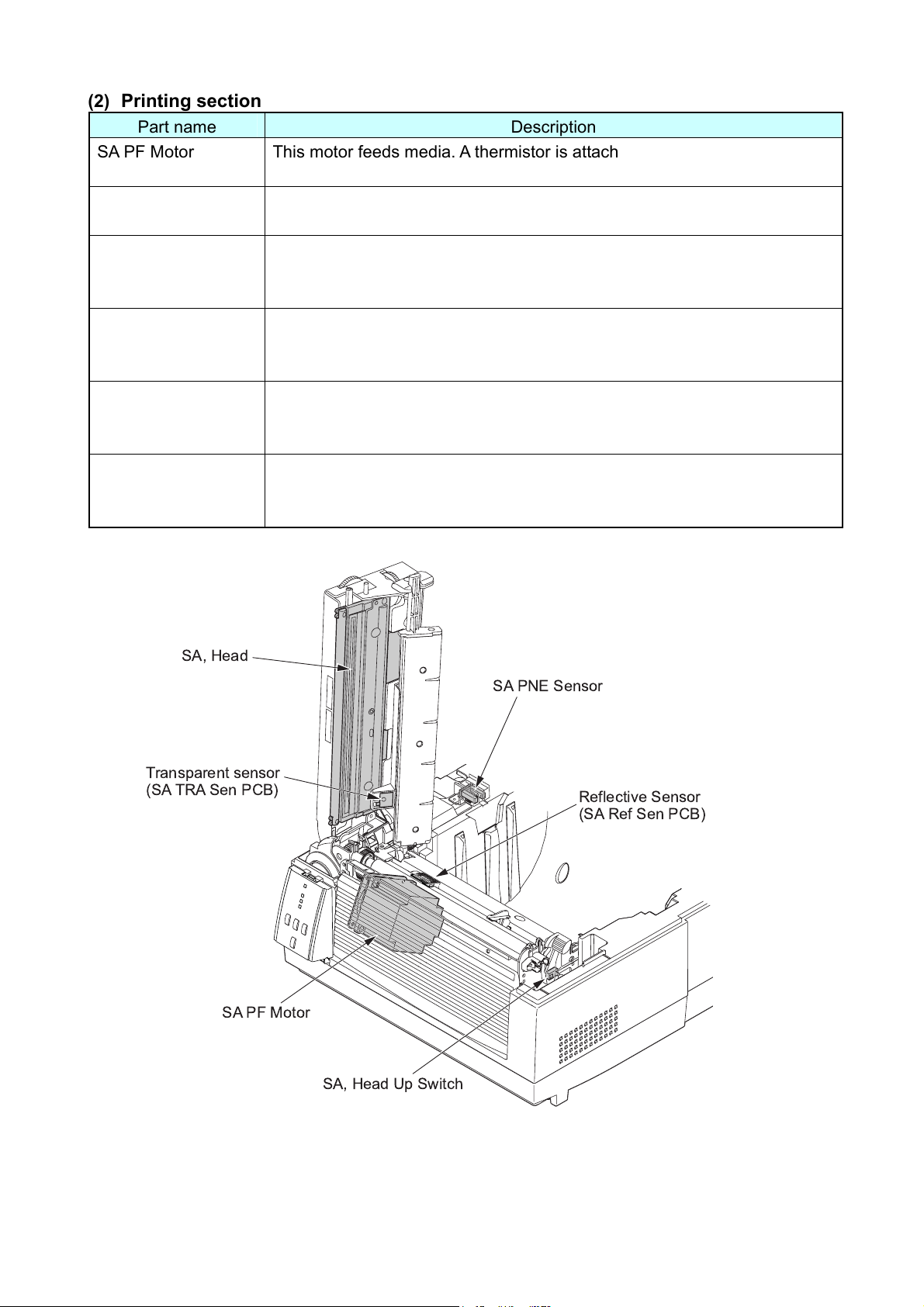

(2) Printing section

Part name Description

SA PF Motor This motor feeds media. A thermistor is attached to the side surface of this

motor to detect the motor temperature.

SA, Head Up Switch This switch is a mechanical lever switch to detect the print head position;

up or down.

Transparent Sensor

(Upper sensor)

This sensor is a photo sensor to detect the labels stuck on liner or

U-shaped notches on tag. It also detects the media end.

(SA TRA Sen PCB)

Reflective Sensor

(Bottom sensor)

This sensor is a photo sensor to detect the black marks on tag. It also

detects the media end.

(SA Ref Sen PCB)

SA, Head It consists of a head driver and thermal elements. Thermal elements are

heated to make printing on media. The thermal head incorporates a

thermistor to detect the thermal head temperature.

SA PNE Sensor

(Paper near end

This sensor is a photo sensor to detect a near end status of roll paper

installed.

sensor)

SA, Head

SA PNE Sensor

Transparent sensor

(SA TRA Sen PCB)

Reflective Sensor

(SA Ref Sen PCB)

SA PF Motor

SA, Head Up Switch

2-5 CL-S6621

Page 20

Operation of Each Mechanism

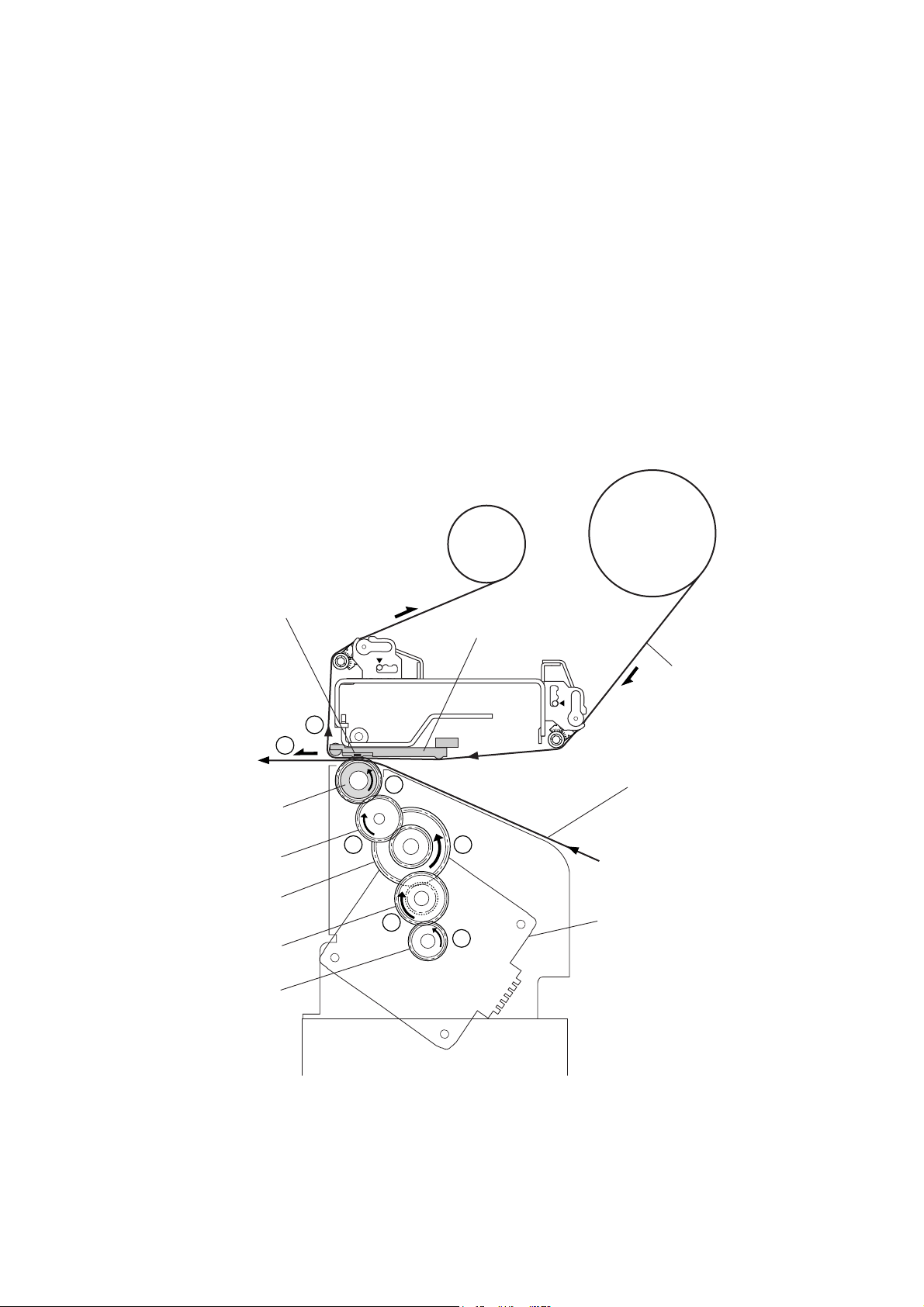

2-1-2. Media Feed Mechanism

The major components of the media feed mechanism are:

(a) SA PF Motor

(b) SA2_Platen

(c) Gear train

By setting the head block to the down position, media is pushed against the “SA2_Platen” by the

“SA, Head”.

As the “SA PF Motor” (stepping motor) turns counterclockwise viewing from the right side of the

printer, the “SA2_Platen” turns counterclockwise via the gear train (“Gear Reduction PF 1”, “Gear

Reduction PF 2” and “Gear Idle PF”) and media is fed forward by the friction force produced

between the “SA2_Platen” and the “SA, Head”.

When the “SA PF Motor” turns clockwise, media is fed backwards.

One step of the “SA PF Motor” feeds media by 1/16 mm (0.0025").

Gear Reduction PF 2

Gear Reduction PF 1

Thermal Elements

6

SA2_Platen

Gear Idle PF

Motor Gear

SA, Head

Ribbon

6

5

4

2

[Right side view]

3

1

Media

SA PF Motor

CL-S6621 2-6

Page 21

Operation of Each Mechanism

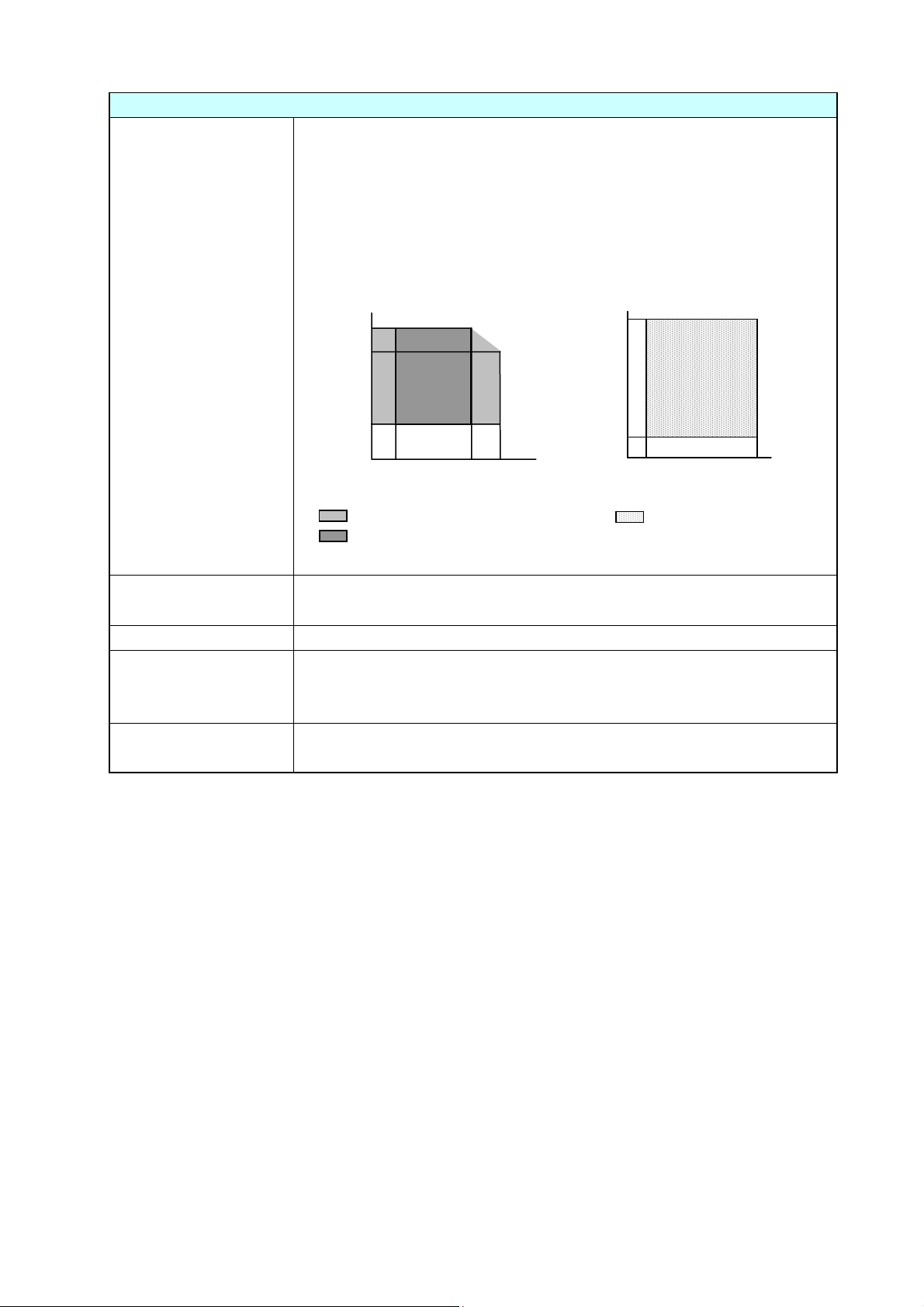

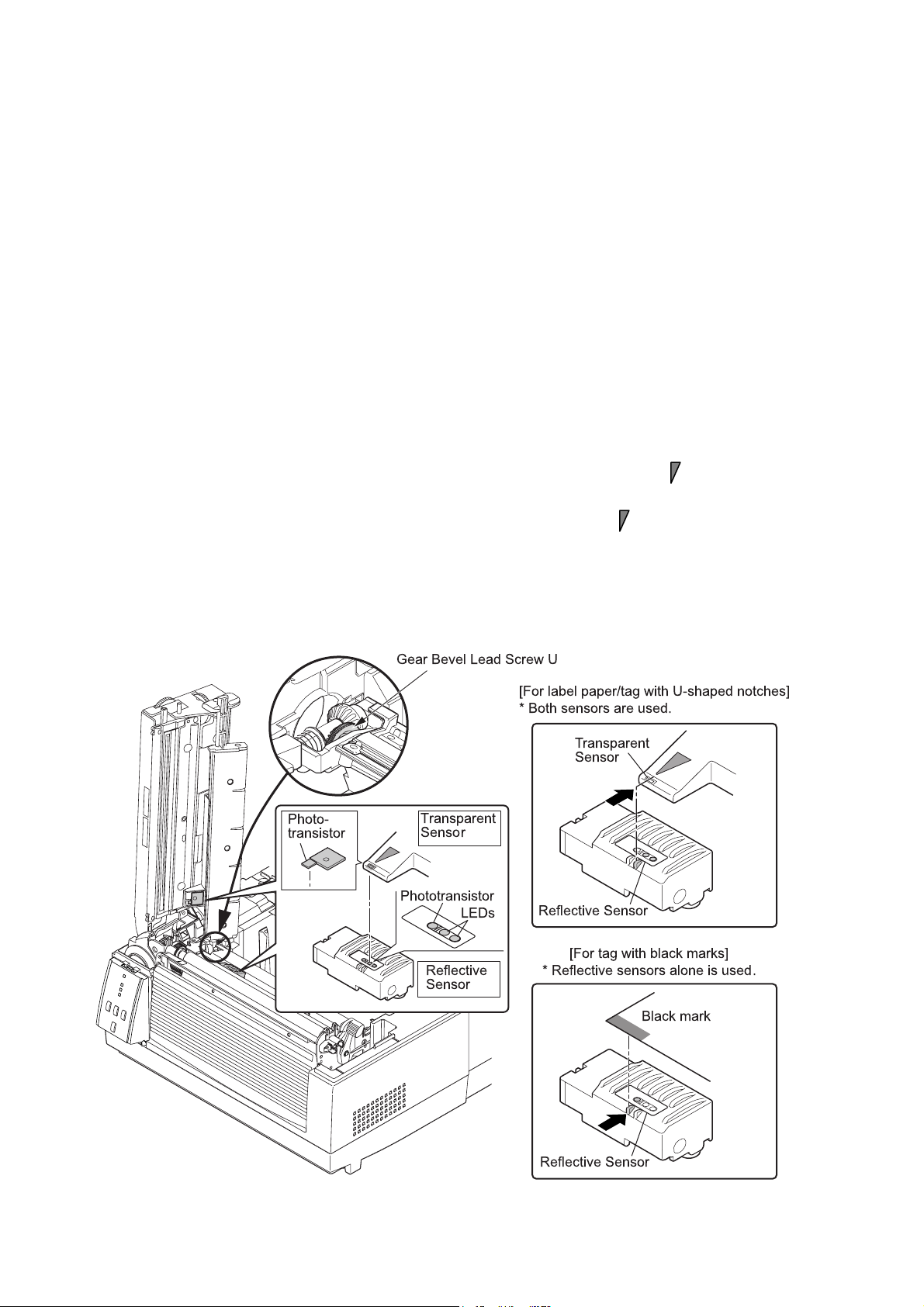

2-1-3. Label/Tag Detection Mechanism

The major components of the label/tag detection mechanism are:

(a) Reflective sensor (Bottom sensor) (SA Ref Sen PCB)

(b) Transparent sensor (Upper sensor) (SA TRA Sen PCB)

There are two movable sensors, the reflective sensor (bottom sensor) and the transparent sensor

(upper sensor). As you adjust the sensor position with the blue knob (“Gear Bevel Lead Screw U”),

both sensors move at the same time.

As shown in the figure below, the reflective sensor has two LEDs and one phototransistor. The

reflective sensor is used to detect black marks at the back of tag. On the other hand, the

transparent sensor is a phototransistor that will receive the transparent light from the LEDs through

the media. The transparent sensor is used to detect labels on liner or U-shaped notches of tag.

Both reflective and transparent sensors are used to detect the media end.

Aligning the sensors for label paper or tag with U-shaped notches:

For label paper, turn the blue knob (“Gear Bevel Lead Screw U”) to align the mark of the

transparent sensor at the center of label. (The transparent sensor and the reflective sensor move

at the same time.) For tags with U-shaped notches, turn it to align the mark with the U-shaped

notch.

Aligning the reflective sensor for tag with black marks:

For tag with black marks, turn the blue knob (“Gear Bevel Lead Screw U”) to align the left side

mark of the reflective sensor with the black mark of tag.

!

' " &

%

&

!

"#$

&

&

%

&

&

2-7 CL-S6621

Page 22

Operation of Each Mechanism

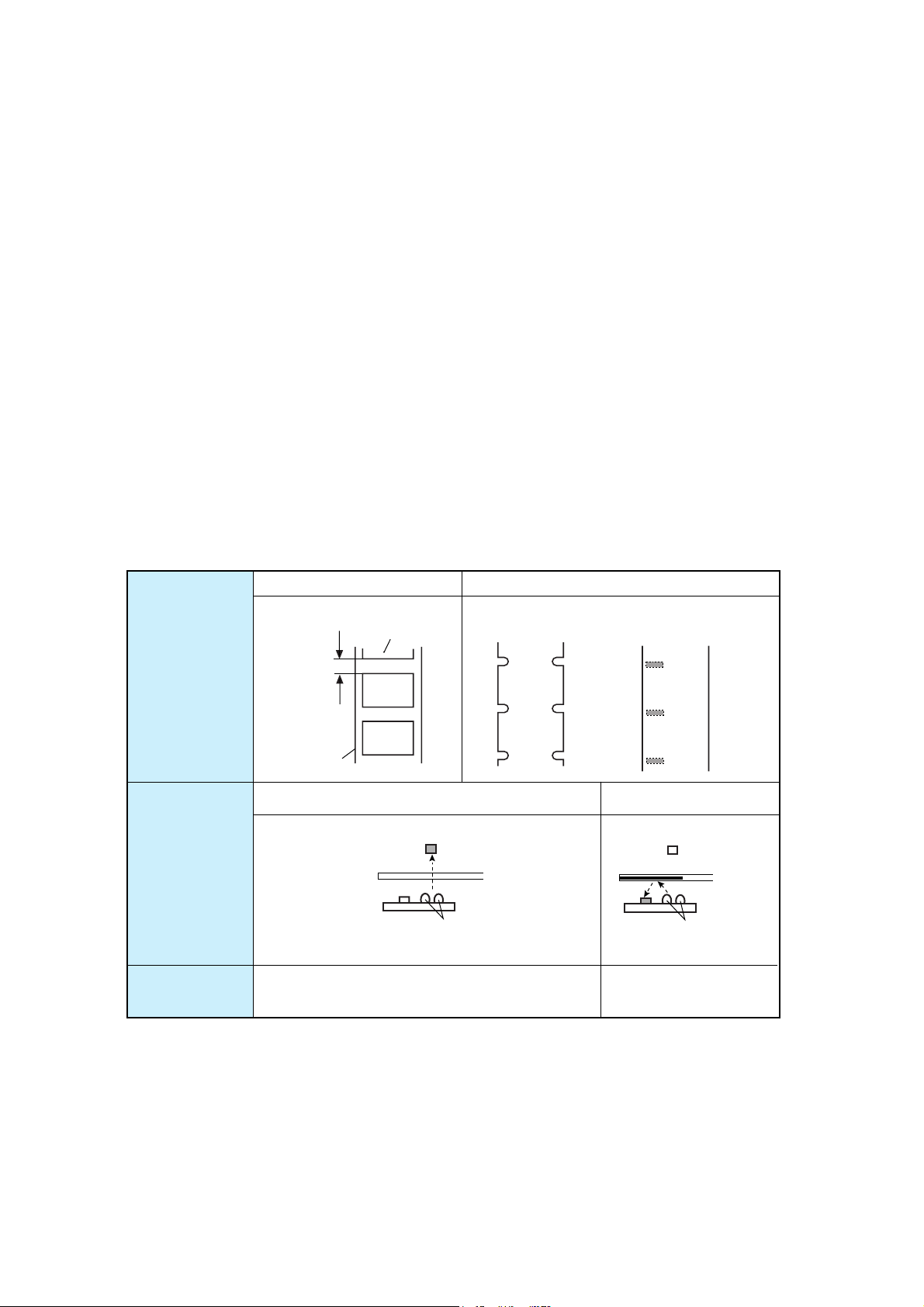

Detecting labels: (Media Sensor menu: “See Through”)

For detecting label, both reflective sensor and transparent sensor are used. Label paper passes

between both sensors. The light emitted from the LEDs of the reflective sensor passes through the

liner (base part of label paper) where no label is stuck on it, and the light reaches the transparent

sensor. Accordingly, the phototransistor of the transparent sensor turns ON. Meanwhile, in the

label part, the light is blocked by label and does not reach the phototransistor. So, the

phototransistor turns OFF. By sensing the output of the transparent sensor, the CPU on the Main

PCB can detect the label leading edge for printing.

Detecting U-shaped notches of tag: (Media Sensor menu: “See Through”)

For detecting U-shaped notches of tag, both reflective sensor and transparent sensor are used.

The U-shaped notches are detected in the same way as the label mentioned above, except that

the light is directly falls on the transparent sensor through the notch.

Detecting black marks on tag: (Media Sensor menu: “Reflect”)

For detecting black marks on tag, only the reflective sensor is used. Light emitted from the LEDs is

reflected by the tag (at other than the black mark) and reaches the phototransistor of the reflective

sensor. At the black mark, the light is not reflected. The CPU on the Main PCB detects the black

mark by sensing the output of the reflective sensor.

Label

Label

U-shaped

notch

Ta g

Black mark

Media

Sensor to be

used

Media Sensor

menu

Label gap

Liner

Transparent and Reflective sensors

Transparent sensor

Media

LEDs

Reflective sensor

See Trough

Reflective sensor

Media

LEDs

Reflective sensor

Reflect

CL-S6621 2-8

Page 23

Operation of Each Mechanism

Detecting continuous media: (Media Sensor menu: “None”)

For detecting continuous media, only the reflective sensor is used. In this case, only media end is

detected by the reflective sensor.

LED light amount control:

According to the media selected by the Media Sensor menu (“See Through”, “Reflect”, or “None”),

the amount of light is well controlled to detect the label/U-shaped notch, black mark, or continuous

media. The amount of light is as follows (the largest amount is for “See Through):

• Continuous media (None) < Black mark (Reflect) < Label/U-shaped notch (See Through)

2-9 CL-S6621

Page 24

Operation of Each Mechanism

2-1-4. Printing and Ribbon Feed Mechanism

The major components of the printing and ribbon feed mechanism are:

(a) SA, Head (d) SA, Ribbon Tension Shaft F/R

(b) SA Ribbon Motor F/R (e) SA, Ribbon Sensor (Front/Rear)

(c) Ribbon gear train

Ink ribbon is set to the printer using the ribbon holders. Ribbon is supplied from the supply reel and

is taken up by the take-up reel with adequate ribbon tension, via the “SA, Ribbon Tension Shaft R”

and “SA, Ribbon Tension Shaft F”. The “SA, Ribbon Tension Shaft F/R” is always pushed outward

by the internal springs, and, when ribbon slacks, it moves outward. When ribbon tightens, it moves

inward. (Refer to the figures on the later pages.)

The same ribbon sensor is installed on the front and rear sides. The ribbon sensor on the front side

is used to detect the position of the “SA, Ribbon Tension Shaft F” (i.e., the ribbon tension on the

front side). While, the ribbon sensor on the rear side is used to detect the position of the “SA,

Ribbon Tension Shaft R” (i.e., the ribbon tension on the rear side).

The ribbon sensor on the front side is also used to detect a ribbon running condition, and that on

the rear side is used to detect the ribbon end.

On the front side, the “SA Ribbon Motor F” turns to take up ribbon. On the rear side, the “SA

Ribbon Motor R” turns to supply ribbon, while applying adequate back tension to ribbon to

eliminate ribbon slack.

Gear Ribbon Shaft F

Take-up Side

SA Ribbon Motor R

SA Ribbon Motor F

Gear Reduction Ribbon 1

Gear Reduction Ribbon 2

Gear Reduction Ribbon 3

SA, Ribbon Tension

Shaft F

Gear Idle Ribbon

Ribbon

Thermal Head

SA2_Platen

[Front]

Printing:

When printing with ink ribbon, ink on the ribbon is melted by the heated thermal element of the “SA,

Head” and is transferred on the media surface.

Supply Side

Gear Reduction Ribbon 1

Gear Ribbon Shaft R

Gear Idle Ribbon

Gear Reduction Ribbon 3

Gear Reduction Ribbon 2

SA, Ribbon Tension

Shaft R

Media

CL-S6621 2-10

Page 25

Operation of Each Mechanism

Taking up Ribbon:

Ribbon will be taken up on the front side as follows:

(1) As media is fed, ribbon is also fed by the friction force produced between media and the “SA,

Head”.

(2) Ribbon slacks and the ribbon sensor on the front side turns OFF as the “SA, Ribbon Tension

Shaft F” is pushed outward.

(3) The “SA Ribbon Motor F” starts to turn and ribbon is taken up.

(4) Ribbon tightens and the ribbon sensor on the front side turns ON. Then, the “SA Ribbon Motor

F” stops.

Supplying Ribbon:

On the rear side, the “SA Ribbon Motor R” turns to supply ribbon, while applying adequate back

tension. In the same way as on the front side, the ribbon sensor on the rear side detects the ribbon

tension to keep the ribbon tension constant. However, when printing is made and ribbon is fed, the

ribbon sensor on the rear side turns ON since ribbon is tightened at this time.

Reel Drive Mechanism:

Though the ribbon holders are directly installed in the reels, ribbon is connected to the reels via the

spring mechanism of the ribbon holders. This means that ribbon is taken up via the spring

mechanism when the “SA Ribbon Motor F”/”SA Ribbon Motor R” turns.

On the front side, the “SA Ribbon Motor F” turns in the clockwise direction viewing from the right

side of the printer, and the “Gear Ribbon Shaft F” (take-up reel) turns in the counterclockwise

direction via the “Gear Reduction Ribbon 1”, “Gear Reduction Ribbon 2”, “Gear Reduction Ribbon

3” and “Gear Idle Ribbon”. Thus, ribbon is taken up.

On the rear side, the “SA Ribbon Motor R” turns in the counterclockwise direction, and the “Gear

Ribbon Shaft R” (supply reel) turns in the clockwise direction via the “Gear Reduction Ribbon 1”,

“Gear Reduction Ribbon 2”, “Gear Reduction Ribbon 3” and “Gear Idle Ribbon”, Ribbon”. Thus,

ribbon is supplied.

2-11 CL-S6621

Page 26

Operation of Each Mechanism

Detecting Ribbon Tension (Ribbon Sensors):

The same ribbon sensor is installed on the front and rear sides. Since the operation is the same on

both sides, the front side operation is explained here:

When ribbon is taken up, the ribbon tightens and the “SA, Ribbon Tension Shaft F” is pushed

inward (in the direction of “a”) by the ribbon. At this time, the claws “A” attached to the “SA, Ribbon

Tension Shaft F” are inserted into the photointerrupters of the “SA, Ribbon Sensor”, and the

photointerrupters turn OFF.

During printing, the ribbon is fed forward together with media and the ribbon will slack. This, the

“SA, Ribbon Tension Shaft F” is moved outward (in the direction of “b”) by the spring (“B”) force,

and the claws “A” come off the photointerrupters. So, the photointerrupters turn ON and the “SA

Ribbon Motor F” turns faster to take up the ribbon quickly. Then, the claws “A” are inserted into the

photointerrupters again, and the “SA Ribbon Motor F” resumes normal speed.

This cycle is repeated and constant tension is applied to the ribbon.

(The two claws “A” are arranged so that they are inserted into or released from the

photointerrupters with a slightly different timing. This function enables to finely control the ribbon

tension.)

On the rear side, during printing, ribbon will be tightened. If it is tightened, the ribbon sensor turns

ON and the “SA Ribbon Motor R” turns faster than normal speed to quickly supply ribbon.

Ribbon Sensor

SA, Ribbon Sensor

A

Supporting Point

Tension Adjustment

Knob (Front)

[Right side view]

b

Ribbon

Tension Adjustment

Knob (Rear)

Ribbon

A

a

SA, Ribbon

Tension Shaft F

B

Spring Ribbon

Tension (2 pcs.)

Tension Adjustment Mechanism:

To apply adequate ribbon tension, you can change the spring “B” force as follows:

The spring force is adjustable in 3 steps with the “Tension Adjustment Knob (Front/Rear)”. As you

move the knob toward the

T mark, the spring force becomes stronger since the spring “B” is

moved to the left in the above figure.

CL-S6621 2-12

Page 27

Operation of Each Mechanism

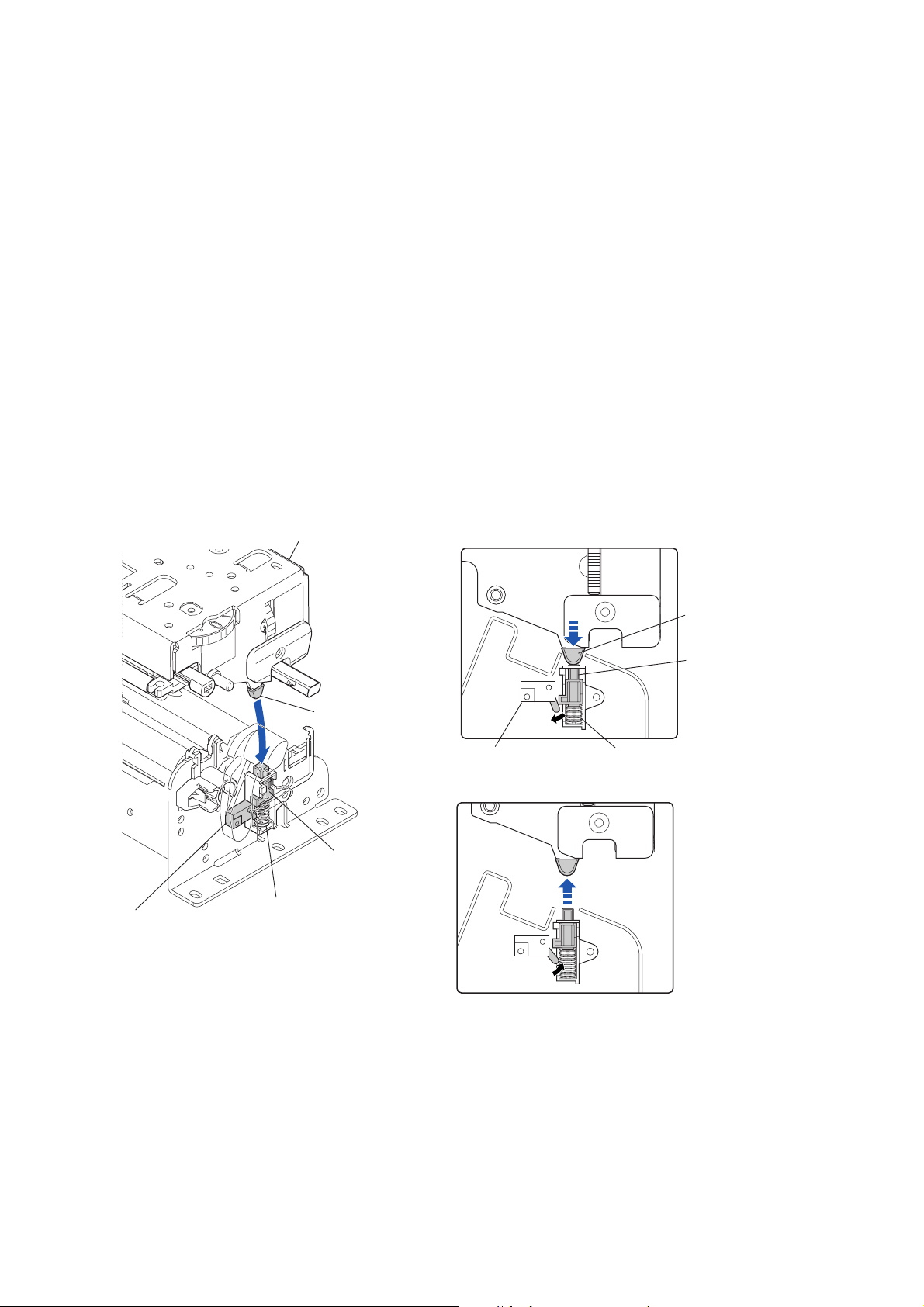

2-1-5. Print Head Up/Down Detection Mechanism

The component of the print head up/down detection mechanism is as follows:

(a) SA, Head Up Switch

(b) Pop Up Cover Frame

(c) Spring Pop Up

(d) Support Pop Up

The print head up/down detection mechanism detects the up (open)/down (close) status of the

“Unit, Head”.

When the “Unit, Head” is in the down position, the “Support Pop Up” (a part of the “Unit, Head”)

pushes down the top of the “Pop Up Cover Frame”, and the lever of the “SA, Head Up Switch” is

pushed. In this state, the “SA, Head Up Switch” turns ON and the signal line is in “Low” level.

While, the “Unit, Head” is in the up position, since the “Pop Up Cover Frame” is released from the

“Support Pop Up”, it pops up by the force of “Spring Pop Up” and the switch lever is set free. In this

state, the “SA, Head Up Switch” turns OFF and the signal line is in “High” level.

The CPU on the Main PCB detects up or down position of the “Unit, Head” by sensing the output of

the “SA, Head Up Switch.

Unit, Head

["Unit, Head" Down Position]

SA, Head Up Switch

Support Pop Up

Pop Up Cover Frame

Spring Pop Up

ON

SA, Head Up Switch

["Unit, Head" Up Position]

OFF

Support Pop Up

Pop Up Cover Frame

Spring Pop Up

2-13 CL-S6621

Page 28

Operation of Each Mechanism

2-1-6. Paper Near End Detection Mechanism

The component of the Paper near end detection mechanism is as follows:

(a) SA PNE Sensor (A part of the main body)

(b) Lever PNE (A part of the “Roll Paper Holder”)

(c) Slider PNE (A part of the “Roll Paper Holder”)

(d) Spring PNE (A part of the “Roll Paper Holder”)

The paper near end sensor is used to detect a paper near end status of roll paper installed in the

printer.

The knob of the “Lever PNE” is pushed by the side of roll paper and the “Slider PNE” engages with

the “SA PNE Sensor” (fixed part on the main body). In this state, the “SA PNE Sensor”

(photointerrupter) turns OFF.

When printing proceeds and the diameter of roll paper is reduced to the preset paper near end

point, the knob of the “Lever PNE” that was pushed by the roll paper pops up, and the “Slider PNE”

comes off the “SA PNE Sensor”. In this state, the “SA PNE Sensor” (photointerrupter) turns ON.

The CPU on the Main PCB detects the ON/OFF status of the “SA PNE Sensor” (photointerrupter)

and judges if the roll paper reaches the near end status.

The paper near end position can be changed mechanically by sliding the knob of the “Lever PNE”

up or down.

Spring PNE

SA PNE Sensor

[Normal Status]

Roll Paper Holder

Lever PNE

Roll Paper

[PNE (Paper Near End) Status]

Spring PNE

SA PNE Sensor

Lever PNE

Roll Paper

Slider PNE

CL-S6621 2-14

Slider PNE

Page 29

Operation of Each Mechanism

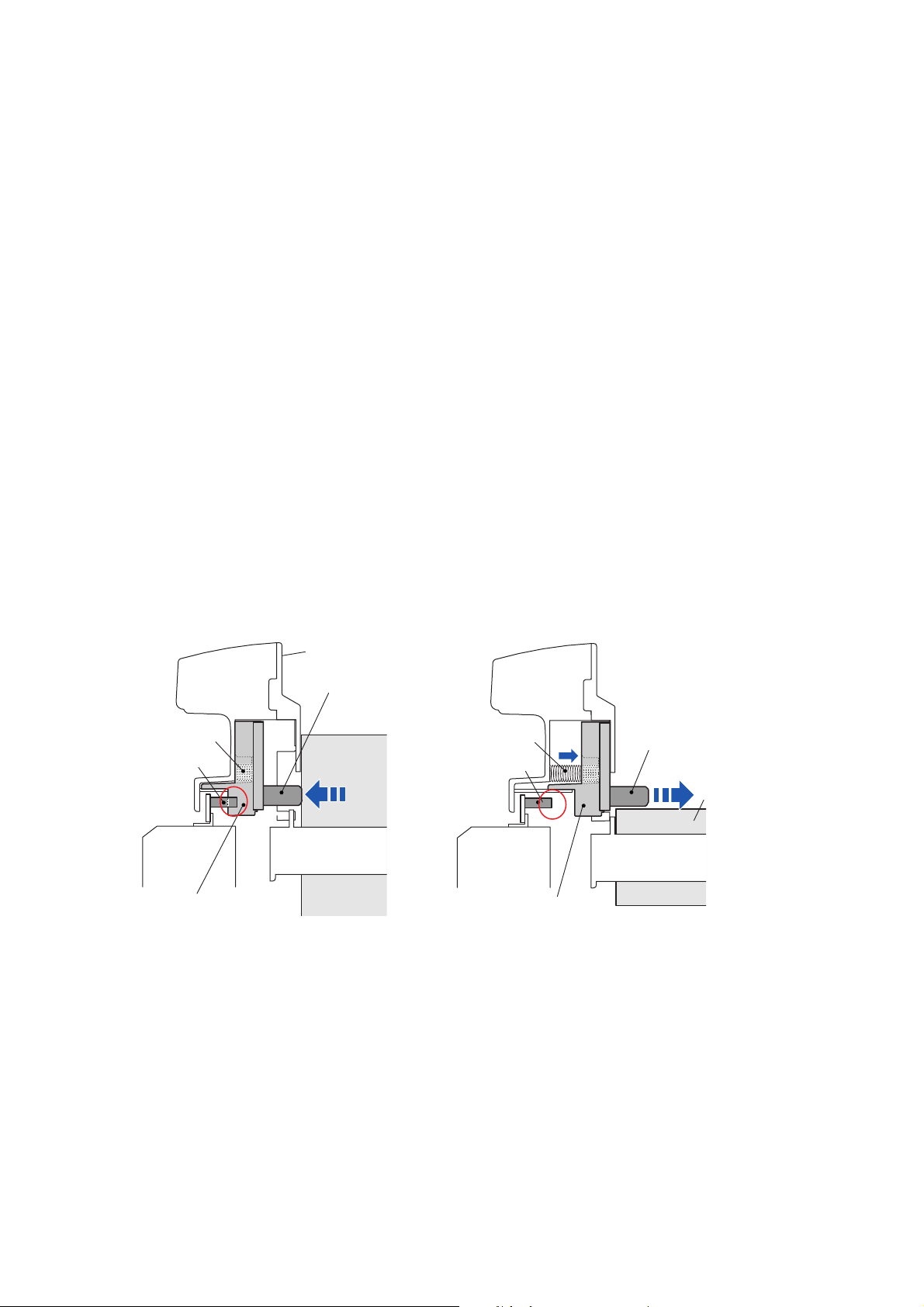

2-1-7. Head Balance Adjustment Mechanism

The major components of the head balance adjustment mechanism are:

(a) Cam Head Balance (c) Spring Head L/R

(b) Plate Head Balance

The head balance adjustment mechanism is used to eliminate uneven printing density on media.

The head balance adjustment is accomplished by changing the right side head pressure according

to media width to be used. To adjust, the blue Media width adjustment dial (“Cam Head Balance”)

is used. When narrow width media is used, the dial should be set toward “0” to give weaker

pressure. While, wide width media is used, it should be set toward “9” to give stronger pressure.

When narrow width media is used (need to give weak pressure):

The “Spring Head L” and “Spring Head R” (2 pcs.) act to press the “SA, Head” against the

“SA2_Platen”. For narrow width media, if the same pressure is given on both sides, since no media

exists on the right side of the “SA, Head”, the “SA, Head” will slant to the right, resulting in uneven

printing density. The part “A” of the “Plate Head Balance” is pushed against the cam part of the

“Cam Head Balance” by the force of “Spring Head R” and it moves up step by step () as the

Media width adjustment dial is turned toward “0” (). As it moves up, the “Spring Head R” is

pressed with weaker force by the “Plate Head Balance” (), and the right side pressure against

the “SA, Head” decreases, resulting in even printing density. You need to align the dial number

according to the media width to be used. (Smaller number for narrower media)

When wide width media is used (need to give strong pressure):

The same principle applies to wide media. However, in this case, the Media width adjustment dial

should be turned toward “9”. Then the part “A” of the “Plate Head Balance” moves down to apply

stronger pressure to the “SA, Head”. (Larger number for wider media)

For narrow media

Spring Head L

(Fixed)

Supporting point

Spring Head R

(Movable)

Weak

Toward "0"

Plate Head

Balance

SA, Head

Ribbon

For wide media

SA, Head

Ribbon

Media (Narrow width)

Media (Wide width)

SA2_Platen

Strong

T0ward "9"

Cam Head Balance

(Media Width Adjustment

A

Dial)

2-15 CL-S6621

Page 30

Operation of Each Mechanism

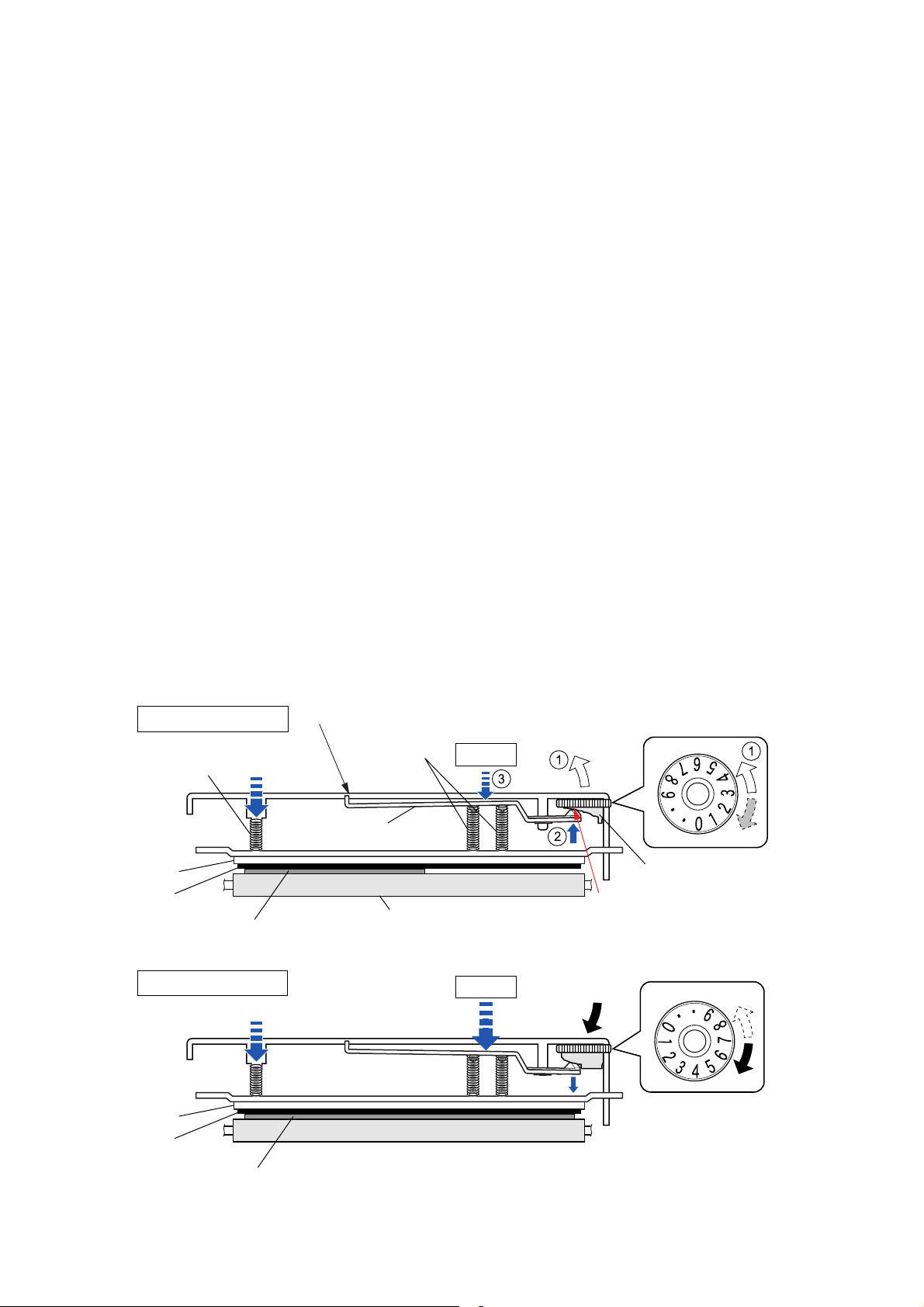

2-1-8. Media Offset Adjustment Mechanism

The major components of the media thickness adjustment mechanism are:

(a) Cam Head Adjust (c) Spring Head Holder

(b) SA Head Adjust Lever (d) Plate Holder Head

According to the softness of media, the thermal element position is displaced from the optimum

position. The head offset adjustment mechanism is used to correct this by moving the “SA Head”

back and forth a little. By performing the head adjustment properly, optimum printing quality is

obtained. (When shipping, the Media thickness adjustment dial is set to “1” for soft media.)

When soft media is used (thin thermal paper, label paper, etc.):

When soft media is used, the optimum position of the thermal elements will be nearly right above

the center of the “SA2_ Platen”. (In dial No. “1”, they are aligned with the platen center.)

When hard media is used (tag paper):

When hard media is used, the optimum position of the thermal elements will shift toward the front a

little from the center of the “SA2_Platen”, i.e. toward the left viewing from the right side of the

“SA2_ Platen” as shown below. As the optimum position varies according to the hardness of media,

it is necessary to adjust the Media thickness adjustment dial from “1” to up to “9” for optimum

printing. As the dial is turned (), the “SA Head Adjust Lever” swings up and down () as its

projection “A” moves along the groove of the dial.

The “Plate Holder Head” end is pinched by the “Spring Head Holder” at end “B” of the “SA, Head

Adjust Lever”. (Namely, both parts are connected via the “Spring Head Holder”.)

Therefore, as the “SA, Head Adjust Lever” swings up and down (), the “Plate Holder Head”

swings up and down accordingly (). With this movement of the “Plate Holder Head”, the thermal

element position slightly moves back and forth against the “SA2_Platen”.

Supporting

point

Ribbon

Media

SA2_Platen

For soft media

Plate Holder Head

For hard media

[Right side view]

SA Cover Frame (Fixed)

SA, Head

B

0

Spring Head Holder

0

9

B

9

[Section "B" upside-down view]

B

Groove

SA Head Adjust Lever

Supporting

point

Cam Head Adjust

(Media Thickness Adjustment Dial)

A

9

0

CL-S6621 2-16

Page 31

Operation of Each Mechanism

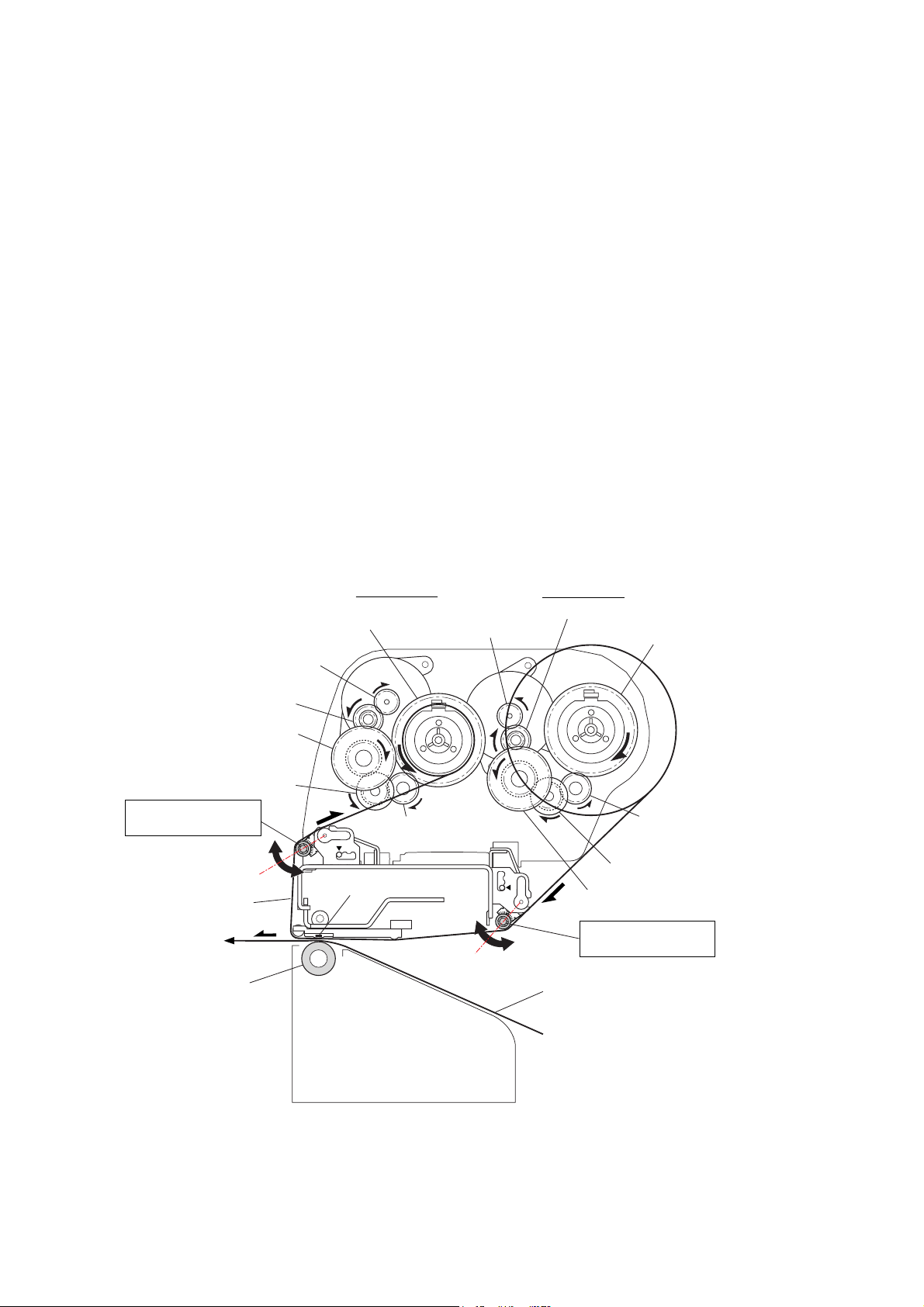

2-1-9. Transparent/Reflective Sensor Travelling Mechanism

The major components of the transparent/reflective sensor travelling mechanism are:

(a) Gear Bevel Lead Screw U (Blue) (d) Shaft Lead Screw (Upper/Lower)

(b) Gear Lead Screw L (e) Holder Sensor Adjust U (Transparent sensor)

(c) Gear train (f) Holder Sensor Adjust L (Reflective Sensor)

The transparent sensor is incorporated in the “Holder Sensor Adjust U” and the reflective sensor is

incorporated in the “Holder Sensor Adjust L”. Both sensor housings move to the right and left

simultaneously by turning the “Gear Bevel Lead Screw U” (blue).

Note that the sensor housings (“Holder Sensor Adjust U” and “Holder Sensor Adjust L”) are

engaged with the groove of respective “Shaft Lead Screw” (upper and lower). Therefore, they

move horizontally when the “Shaft Lead Screw” (upper and lower) turns.

When the “Gear Bevel Lead Screw U” (blue) turns in the direction as shown by the arrow (), the

“Screw Lead Screw” (upper) turns (“a”) and the “Holder Sensor Adjust U” moves to the right (“a’ ”).

At this time, via the gears (() and ()), the “Gear Lead Screw L” turns in the direction shown by

the arrow (), and the “Screw Lead Screw” (lower) turns (“b”) and the “Holder Sensor Adjust L”

moves to the right (“b’ “).

When the “Gear Bevel Lead Screw U” (blue) is turned reversely, the sensor housings move to the

left.

Gear Lead Screw L

Shaft Lead Screw

(Lower)

Holder Sensor Adjust L

(Reflective Sensor)

Gear Bevel Lead Screw U (Blue)

Shaft Lead Screw

a

(Upper)

b

a’

Holder Sensor Adjust U

(Transparent Sensor)

b’

2-17 CL-S6621

Page 32

Operation of Control Parts

r

r

r

2-2. Operation of Control Parts

2-2-1. Configuration of Printer

The following shows major configuration blocks.

(Option)

Auto Cutter

Cutter Moto

Cutter Motor

Temp. Sensor

(Option) Peeler

Peel Sensor

Head Up Switch

[SA, Head Up Switch]

Adjustable Paper Sensors

Transparent Sensor

[SA TRA Sen PCB]

Reflective Sensor

[SA Ref Sen PCB]

Thermal Head Temp. Sensor

PF Motor Temp. Sensor

[SA, Head]

[SA PF Motor]

Paper Near End Sensor

[SA PNE Sensor]

Operation Panel

(SWx4/LEDx4)

[SA, Opepane PCB]

(JM66720-*)

Ribbon Sensor F

[SA, Ribbon Sensor]

Ribbon Sensor R

[SA, Ribbon Sensor]

Ribbon Motor Temp. Sensor

[SA Ribbon Motor F]

SA Ribbon Motor F

SA Ribbon Motor R

Fan

CUTTER PCB

(PPS00065-*)

DC Motor

Driver

Cutter

Position

Sensor

SA, MAIN PCB (PPS00058-*)

UPD703111BGJ-13-UEV-A

Buzzer

EP2C5F256C8N

Fan

Driver

Stepping Moto

Driver x 2

SA, Ribbon PCB

(PPS00059-*)

CPU

128MHz

FPGA

SA, Relay PCB

(PPS00060-*)

AC Power Supply

PWT20005-* (100V)

PWT20006-* (200V)

Driver/Receiver

Control / C.G.

F-ROM (64Mbits)

F-ROM (64Mbits)

S-DRAM (256Mbits)

Stepping Moto

RS232C

RS232C

USB2.0

Controller

C.G.

Driver

(Option)

Interface Board

IEEE1284

Ethernet I/F

(Standard type)

Ethernet I/F

(Multi-function type)

Wi-Fi I/F

RS232C

USB 2.0

(High Speed)

Thermal Print Head

(203dpi)

[SA, Head]

SA PF Motor

CL-S6621 2-18

Page 33

Operation of Control Parts

Major functions of individual components are described below:

(1) AC power supply

Consists of a fuse, a filter circuit to eliminate external electric noise, and a switching type

regulator to transform an AC input to +24V DC output required to drive the printer.

(2) SA, Main PCB

Controls the entire operations of the printer. It consists of CPU, Flash ROM, S-DRAM, FPGA

(Field-Programmable Gate Array), driver circuits, etc.

(a) CPU

The CPU is a microprocessor with 32-bit architecture. The clock fed to the CPU is 16 MHz.

The CPU internally multiplies this 16 MHz by 8 times and uses 128 MHz clock. The CPU

includes cache memory, RAMs, DMA controller, serial I/F, USB function controller, A/D

converter, etc.

(b) Flash ROM

A flash ROM of 64M bits (8M bytes) that stores the firmware and CG (character generator)

(c) S-DRAM (Synchronous dynamic RAM)

An S-DRAM of 256M bits (32M bytes) that is used as working area, input buffer and

download buffer.

(d) FPGA

The FPGA (Field-Programmable Gate Array) incorporates a control circuit for the interface

I/O port, motors, print head, etc.

(e) Serial I/F (RS-232C Driver/Receiver)

This is a circuit to transmit and receive serial data between the printer and the host.

Serial I/F, USB I/F, Parallel I/F (Option), Wired LAN (Option) or Wireless LAN (Option) is

automatically selected when data is received.

(f) USB I/F (High-speed USB2.0 Controller)

This is a circuit to transmit and receive serial data between the printer and the host using

the high-speed USB2.0 I/F.

Serial I/F, USB I/F, Parallel I/F (Option), Wired LAN (Option) or Wireless LAN (Option) is

automatically selected when data is received.

(g) Stepping motor driver

This is a circuit to drive the “SA PF Motor”. The “SA PF Motor” is a stepping motor.

(h) Buzzer

The buzzer is driven when an alarm, etc. occurs.

2-19 CL-S6621

Page 34

Operation of Control Parts

(3) Operation panel (SA, Opepane PCB)

Used to indicate the operating status of the printer and to set specifications. It consists of 4

keys and 4 LEDs.

(4) Thermal print head (SA, Head)

Makes printing on paper. The number of thermal elements (dots) is as follows. The thermal

print head includes the print head driver circuit.

•1344 dots

(5) Sensors

The following 9 sensors are used in the printer:

Sensor name Description

Head Up Switch

A mechanical lever switch.

(SA, Head Up Switch)

Transparent Sensor A photo sensor using a phototransistor. (On the “SA

TRA Sen PCB”.)

Reflective Sensor A photo sensor consisting of 2 LEDs and 1

phototransistor. (On the “SA Ref Sen PCB”.)

Ribbon Sensor F Photo sensors (2 pcs.) using photointerrupters.

(Located on the “SA, Ribbon Sensor” on the front side.)

Ribbon Sensor R Photo sensors (2 pcs.) using photointerrupters.

(Located on the “SA, Ribbon Sensor” on the rear side.)

Thermal Head Temperature

A thermistor incorporated in the “SA, Head”.

Sensor

PF Motor Temperature Sensor A thermistor attached to the “SA PF Motor”.

Ribbon Motor Temperature Sensor A thermistor attached to the “SA Ribbon Motor F” (the

front side of ribbon motor).

Paper Near End Sensor A photo sensor using a photointerrupter. (On the “SA

PNE Sensor”.)

(6) Motors

Three motors are used.

- The “SA PF Motor” is a stepping motor to feed media.

- The “SA Ribbon Motor F” and “SA Ribbon Motor R” are stepping motors to take up and

supply ribbon, respectively.

(7) SA, Ribbon PCB

Controls the operations of the “Unit, Ribbon”.

(a) Stepping motor driver

This is a circuit to drive the “SA Ribbon Motor F” on the front side for taking up ribbon and

the “SA Ribbon Motor R” on the rear side for supplying ribbon. Both are stepping motors.

CL-S6621 2-20

Page 35

(b) Fan driver

This is a fan drive circuit. The fan is used to cool both “SA Ribbon Motor F” and “SA

Ribbon Motor R”. When the temperature of the “SA Ribbon Motor F” exceeds a certain

value, the fan starts to rotate.

(8) SA, Relay PCB

Relays the signals between the “SA, Main PCB” and an optional I/F board.

(9) Optional I/F

(a) Parallel I/F (IEEE1284) (Option)

This is the parallel I/F to transmit and receive parallel data between the printer and the host.

It supports Centronics Compatible mode, NIBBLE mode and ECP mode.

Parallel I/F, serial I/F, or USB I/F is automatically selected when data is received.

(b) Wired LAN I/F (Option)

This is a circuit which supports Ethernet protocol. LAN connection is possible.

(c) Wireless LAN I/F (Option)

This is a circuit which supports wireless LAN protocol (IEEE802.11n/IEEE802.11g/

EEE802.11b).

Operation of Control Parts

2-21 CL-S6621

Page 36

Operation of Control Parts

2-2-2. Memory map

0000000

001FFFF

0100000

0103FFF

0104000

0105FFF

0106000

0107FFF

0108000

011FFFF

0120000

030FFFF

0310000

04FFFFF

0710000

074FFFF

H

H

H

H

H

H

H

H

H

Command RAM

(Built-in CPU)

Boot Loader (1)

Setting Information

(User Settings)

Setting Information

(Factory-set Settings)

CPU

Boot Loader (2)

H

H

Firmware (Datamax)

H

H

Firmware (Zebra)

H

H

H

FPGA Data

8M bytes

Flash ROM

07E0000

07EFFFF

07F0000

07FFFFF

0800000

27FFFFF

8000000

80FFFFF

H

Service Information (Backup)

H

H

Service Information

H

H

Firmware (about 400K bytes)

Receiving Buffer (16K bytes x 4)*

SDRAM

32M bytes

Command Buffer (128K bytes)

Others

H

*: 16K bytes for each I/F

(USB, IEEE1284, Serial,

USB for optional I/F)

H

H

I/O

FPGA

C000000

C3FFFFF

C400000

C7FFFFF

F800000

F8FFFFF

FFFB000

FFFEFFF

FFFF000

FFFFFFF

H

H

H

H

H

H

H

Download Area (4MByte)

Kanji Font (4MByte)

I/O

FROM

8MByte

USB2.0 Controller

Data RAM (Built-in CPU)

H

H

H

I/O (Built-in CPU)

CPU

CL-S6621 2-22

Page 37

Operation of Control Parts

2-2-3. Sensors

(1) Head up switch

The “SA, Head Up Switch” is used to detect the head position (up or down).

When the “Unit, Head” is closed (in the down position), the ”Support Pop Up” of the “Unit,

Head” pushes the “Pop Up Cover Frame” and the “SA, Head Up Switch” pushes the lever of

the “SA, Head Up Switch” and the switch turns ON. Then, pin 117 (HDUSW) of U1A (CPU)

goes "Low" level.

When the “Unit, Head” is opened (in the up position), the ”Support Pop Up” is disengaged from

the “Pop Up Cover Frame”, the lever of the “SA, Head Up Switch” is set free, and the switch

turns OFF. Then, pin 117 (HDUSW) of U1A (CPU) goes "High" level.

R80

C99

+3.3V

R78

[SA, Main PCB]

["Unit, Head" Down Position]

SA, Head Up Switch

J11

(Blue)

ON

SA, Head Up Switch

Head Up Switch

1

2

Support Pop Up

Pop Up Cover Frame

Spring Pop Up

U1A

CPU

PDH3

117

HDUSW

Head Up: High

Head Down: Low

Unit, Head

Support Pop Up

["Unit, Head" Up Position]

Pop Up Cover Frame

SA, Head Up Switch

Spring Pop Up

OFF

2-23 CL-S6621

Page 38

Operation of Control Parts

(2) Transparent sensor and reflective sensor

The transparent sensor (“SA TRA Sen PCB”) is used to detect the label stuck on liner and the

U-shaped notch on tag. On the other hand, the reflective sensor (“SA Ref Sen PCB”) is used to

detect the black mark printed on the bottom surface of tag. Both sensors are also used to

detect the media end.

The upper side transparent sensor is the phototransistor, and the lower side reflective sensor

consists of 2 LEDs and 1 phototransistor. Media passes between these sensors.

Transparent sensor

output sensing terminal

Reflective sensor output

sensing terminal

U1A

CPU

ANI0

ANI1

U14

FPGA

B4_34

R14

B4_33

R13

From

U1A CPU

SD ATA

SCLK

DACCS

TRAMON

5

C96

REFMON

6

TSNSCTL1

TSNSCTL0

U7

D/A Converter

12

DI

11

CK

10

CSB

BH2227

C97

AO1

AO2

AO3

AO4

R65

U20B

7

BA2904

U20A

1

BA2904

Q9

DTC114EM

DTC114EM

PSNSLED

2

5

+

6

-

R72

3

+

2

-

Q10

Q7

DTC114EM

R66

R70

R73

R76

R74

R75

R68

R69

Q8

DTC114EM

R67

+3.3V

J9

(White)

(White)

+5V

Q6

2SC5658

R71

[SA, Main PCB]

Transparent Sensor

[SA TRA Sen PCB]

1

2

3

J8

1

2

3

4

5

4

[SA Ref Sen PCB]

Reflective Sensor

Transparent sensor (used for detecting the label or U-shaped notch):

When the liner without label stuck on it passes between both sensors, the light emitted from

the LEDs reaches the transparent sensor, passing through the liner. Thus, the transparent

sensor (phototransistor) conducts and the voltage corresponding to the amount of light is

applied to pin 5 (TRAMON) of U1A (CPU).

Meanwhile, when the liner with the label stuck on it passes between both sensors, the light is

blocked by the label and the transparent sensor (phototransistor) turns OFF. Thus, pin 5

(TRAMON) of U1A (CPU) goes "Low" level. From the difference in these levels at pin 5

(TRAMON) of U1A (CPU), U1A (CPU) can detect the leading edge (arrival) of the label on the

liner.

When media runs out, the light directly falls on the transparent sensor and media end is

detected. In this case, pin 5 of U1A (CPU) will go "High" level.

Media

CL-S6621 2-24

Page 39

Operation of Control Parts

When the transparent sensor is conducted, the voltage at pin 5 (TRAMON) varies depending

on the characteristics of the light receiving element (phototransistor) of the transparent sensor

and other factors. To solve this problem, U14 (FPGA) outputs TSNSCTL0 (pin R13) and

TSNSCTL1 (pin R14) signals to turn ON/OFF Q8 and Q7 to connect/disconnect R69 and R68

(voltage dividing resistors) to minimize the difference in level at pin5 (TRAMON).

The current flowing into the LEDs is determined by the data sent from the CPU to the

digital-to-analog converter (U7). The digital-to-analog converter converts the data received

from the CPU, and then outputs a resoultant level at pin 2. The base current of the transistor

Q6 is determined by this level. This means that the current flowing into the LEDs is also

determined by this level. In the actual control, the CPU changes data (for controlling the LED

current) to keep the level at pin 5 (TRAMON) of CPU constant.

Reflective sensor (used for detecting the black mark on tag):

When tag with black marks is used, light is reflected by the tag. In the place where no black

mark is there, the phototransistor of the reflective sensor conducts and the voltage

corresponding to the amount of light is applied to pin 6 (REFMON) of U1A (CPU).

When the light falls on the black mark, no light is reflected. In this case, the lower

phototransistor turns OFF and pin 6 (REFMON) of U1A (CPU) will go “Low” level.

When media runs out, the light is not reflected and no light falls on the reflective sensor. In this

case, pin 6 (REFMON) of CPU will go “Low” level and media end is detected.

When the reflective sensor is conducted, the voltage at pin 6 (REFMON) varies depending on

the characteristics of the light receiving element (phototransistor) of the reflective sensor and

other factors. To solve this problem, U14 (FPGA) outputs TSNSCTL0 (pin R13) and

TSNSCTL1 (pin R14) signals to turn ON/OFF Q10 and Q9 to connect/disconnect R75 and R74

(voltage dividing resistors) to minimize the difference in level at pin6 (REFMON).

As to the current control of the LEDs, the operation is the same as for the transparent sensor

mentioned above.

2-25 CL-S6621

Page 40

Operation of Control Parts

(3) Ribbon Sensor F/R

The ribbon sensor F (“SA, Ribbon Sensor” mounted on the front side) is used to detect the

ribbon tension on the front side as well as ribbon running. While, the ribbon sensor R (“SA,

Ribbon Sensor” mounted on the rear side) is used to detect the ribbon tension on the rear side

as well as the ribbon end. These sensors are photointerrupters.

Front (Take-up side)

PT501

PS501

Ribbon Sensor1

1

2

3

4

(SA, Ribbon Sensor)

Ribbon Sensor2

R501

Rear (Supply side)

PT501

1

2

(Same as above circuit)

3

4

(SA, Ribbon Sensor)

U1A

CPU

PCM0

PCM2

PCM3

PCM5

RIBSENS_A1

34

RIBSENS_A2

32

RIBSENS_B1

31

RIBSENS_B2

29

U2B

11

6

U2D

U2A

3

5

U2C

8

12

2

U21D

9

U21F

12

+3.3V

J102

J19

R137

R138

R136

C176

C177

RA20

C178

U21C

5

6

9

8

11

10

U21E

13

C175

R139

18-20 18-20

[SA, Main PCB]

1

1

13

13

SENS_A1

14

14

SENS_A2

15

15

SENS_B1

16

16

SENS_B2

[SA, Ribbon PCB]

+3.3V

+3.3V

J105

+3.3V

J104

1

2

3

4

1

2

3

4

Ribbon sensor F:

The ribbon sensor F is used to keep the ribbon tension on the front side constant. When

printing starts, ribbon is fed and then the front side ribbon slacks. Then, the claws of the “SA,

Ribbon Tension Shaft F” come off the photointerrupters on the “SA, Ribbon Sensor” and the

photointerrupters turn ON. Thus, pin 34/32 (RIBSENS_A1/A2) of U1A (CPU) goes "High" level.

In this case, U1A (CPU) increases the revolution speed of “SA Ribbon Motor F” to take up the

slack of ribbon. As a result, ribbon tightens and the claws are inserted into respective

photointerrupters. Thus, pin 34/32 (RIBSENS_A1/A2) of U1A (CPU) goes "Low" level. Then,

U1A (CPU) slows down the revolution speed of “SA Ribbon Motor F”. During printing, this cycle

is repeated and constant ribbon tension is maintained.

If ribbon is not correctly fed during printing, the ON/OFF state of the photointerrupters on the

“SA, Ribbon Sensor” becomes improper. Thus, the CPU can detect an abnormal ribbon feed.

Ribbon sensor R:

The ribbon sensor R is used to keep the ribbon tension on the rear side constant. When

printing starts, ribbon is fed and the rear side ribbon tightens. Then, the claws of the “SA,

Ribbon Tension Shaft R” are inserted into respective photointerrupters on the “SA, Ribbon

Sensor” and the photointerrupters turn OFF. Thus, pin 31/29 (RIBSENS_B1/B2) of U1A (CPU)

goes "Low" level. In this case, U1A (CPU) increases the revolution speed of “SA Ribbon Motor

R” to supply ribbon faster. As a result, ribbon slacks and the claw comes off the

photointerrupter. Thus, pin 31/29 (RIBSENS_B1/B2) of U1A (CPU) goes "High" level. Then,

U1A (CPU) slows down the revolution speed of the “SA Ribbon Motor R”. During printing, this

cycle is repeated and constant ribbon tension is maintained.

When ribbon runs out, the ON/OFF state of the photointerrupters on the “SA, Ribbon Sensor”

becomes unchangeable. Thus, the CPU can detect the ribbon end.

PS502

R502

CL-S6621 2-26

Page 41

Operation of Control Parts

(4) Head temperature sensor

The head temperature sensor is used to detect the temperature of the “SA, Head”. This sensor

is a thermistor incorporated in the “SA, Head”. Since the resistance of the thermistor changes

according to a temperature change, the voltage at pin 7 (HDTMP) of U1A (CPU) changes

accordingly. The CPU senses the voltage at pin 7 (HDTMP) to detect the head temperature.

According to the temperature of the “SA, Head”, the CPU controls the printing pulse width

applied to the thermal elements to keep the printing density constant.

U1A

CPU

ANI2

7

HDTMP

R54

C82

+3.3V

R53

HDTMP

J5

SA, Head

Head Temp.

8

5

Thermistor

U14

FPGA

B2_28

nTEMP_ENABLE

C11

B2_27

nTEMP_ERROR

C6

+3.3V

R40

R41

R42

Error: Low

TEMP ERROR Detection

+3.3V

HDTMP

C41

U16B

5

+

6

-

BA2903SFV

[SA, Main PCB]

7

R39

Printing operation when the head temperature rises:

If the head temperature reaches 70°C (158°F), printing stops after printing the current label. In

this case, the PRINT LED and CONDITION LED simultaneously blink on the operation panel.

When the temperature of the “SA, Head” falls below 60°C (140°F), the LEDs stop blinking and

printing will be resumed.

Printing

Printing

60°C

(140°F)

Printing

(Stop)

(Stops)

70°C

(158°F)

For further safety, an abnormally high temperature detection circuit is provided. In case this

circuit is activated, the System error is displayed, and the printer stops.

The comparator U16B detects if the level at pin 5 (HDTMP) (i.e., the temperature of the “SA,

Head”) exceeds a certain reference level determined by the output from pin C11

(nTEMP_ENABLE) of U14 (FPGA) (i.e., the predetermined allowable limit temperature). If it

does, nTEMP_ERROR at pin C6 goes “Low” level and this signal is fed to U14 (FPGA). Then,

the System error is displayed and the printer stops. At this time, nTEMP_ENABLE at pin C11 is

set to “Low” level so that nTEMP_ERROR is securely maintained at “Low” level. (To clear the

System error, you need to turn OFF the printer once and then turn it ON.)

2-27 CL-S6621

Page 42

Operation of Control Parts

(5) PF motor temperature sensor

The PF motor temperature sensor is used to detect the temperature of the “SA PF Motor”. This

sensor is a thermistor bonded to the “SA PF Motor”. Since the resistance of the thermistor

changes according to a temperature change, the voltage at pin 8 (PFTMP) of U1A (CPU)

changes accordingly. The CPU senses the voltage at pin 8 (PFTMP) to detect the PF motor

temperature.

U1A

CPU

ANI3

PFTMP

8

R64

C94

+3.3V

R63

J7

2

1

SA PF Motor

Thermistor

M

U14

FPGA

B2_28

nTEMP_ENABLE

C11

+3.3V

R40

R41

R42

TEMP ERROR Detection

U16A

PFTMP

C41

3

+

2

-

BA2903SFV

+3.3V

R39

1

B2_27

nTEMP_ERROR

C6

Error: Low

[SA, Main PCB]

Printing operation when motor temperature rises:

When the temperature of the “SA PF Motor” rises above 90°C (194°F), printing speed is

reduced to avoid overheating. If it reaches 95°C (203°F), the “SA PF Motor” stops after printing

the current label. In this case, the PRINT LED and CONDITION LED alternately blink on the

operation panel.

When the temperature of the “SA PF Motor” falls below 85°C (185°F), the LEDs stop blink and

printing will be resumed.

Normal speed

Normal speed

85°C

(185°F)

Normal speed

(Stop)

90°C

(194°F)

Low speed

(Stop)

(Stops)

95°C

(203°F)

For further safety, an abnormally high temperature detection circuit is provided. In case this

circuit is activated, the System error is displayed, and the printer stops.

The comparator U16A detects if the level at pin 8 (PFTMP) (i.e., the temperature of the “SA PF

Motor”) exceeds a certain reference level determined by the output from pin C11

(nTEMP_ENABLE) of U14 (FPGA) (i.e., the predetermined allowable limit temperature). If it

does, nTEMP_ERROR at pin C6 goes “Low” level and this signal is fed to U14 (FPGA). Then,

the System error is displayed and the printer stops. At this time, nTEMP_ENABLE at pin C11 is

set to “Low” level so that nTEMP_ERROR is securely maintained at “Low” level. (To clear the

System error, you need to turn OFF the printer once and then turn it ON.)

CL-S6621 2-28

Page 43

Operation of Control Parts

(6) Ribbon motor temperature sensor

The ribbon motor temperature sensor is used to detect the temperature of the “SA Ribbon

Motor F” on the front side. This sensor is a thermistor bonded to the “SA Ribbon Motor F”.

Since the resistance of the thermistor changes according to a temperature change, the voltage

at pin 11 (RBTMP) of U1A (CPU) changes accordingly. The CPU senses the voltage at pin 11

to detect the temperature of the “SA Ribbon Motor F”.

U1A

CPU

ANI6

11

RBTMP

R135

C172

+3.3V

R134

J19

17

18

17

18

J102

J107

RBMTH

SA Ribbon Motor F

(Take-up Side)

Thermistor

2

1

U14

FPGA

B2_28

B2_27

nTEMP_ENABLE

C11

nTEMP_ERROR

C6

+3.3V

R40

R41

R42

Error: Low

TEMP ERROR Detection

RBTMP

C41

U17A

3

+

2

-

BA2903SFV

[SA, Main PCB]

+3.3V

R39

1

[SA, Ribbon PCB]

Printing operation at ribbon motor temperature rise:

When the temperature of the “SA Ribbon Motor F” reaches 85

°C (185°F), the “SA Ribbon

Motor F” stops after printing the current label. In this case, the PRINT LED and CONDITION

LED alternately blink on the operation panel.

When the temperature of the “SA Ribbon Motor F” falls below 80

°C (176°F), the LEDs stop

blink and printing resumes.

Normal speed

Normal speed

80°C

(176

Normal speed

°F)

(Stop)

(Stops)

85°C

°F)

(185

For further safety, an abnormally high temperature detection circuit is provided. In case this

circuit is activated, the System error is displayed, and the printer stops.

The comparator U17A detects if the level at pin 3 (RBTMP) (i.e., the temperature of the “SA

Ribbon Motor F”) exceeds a certain reference level determined by the output from pin C11

(nTEMP_ENABLE) of U14 (FPGA) (i.e., the predetermined allowable limit temperature). If it

does, nTEMP_ERROR at pin C6 goes “Low” level and this signal is fed to U14 (FPGA). Then,

the System error is displayed and the printer stops. At this time, nTEMP_ENABLE at pin C11 is

set to “Low” level so that nTEMP_ERROR is securely maintained at “Low” level. (To clear the

System error, you need to turn OFF the printer once and then turn it ON.)

M

2-29 CL-S6621

Page 44

Operation of Control Parts

(7) Paper Near End sensor

The paper near end sensor (“SA PNE Sensor”) is used to detect a paper near end status of roll

paper installed in the printer.

By default, issuing a paper near end alarm is disabled. To enable it, you need to change the

Paper Near End Alarm submenu under the “PageSetup” main menu from Off to On.

Before a paper near end status occurs, the “Lever PNE” is pushed by the roll paper edge and

the “Slider PNE” of the paper shaft is engaged with the “SA PNE Sensor”. Then, pin 77

(PNESNS) of U1A (CPU) goes "High" level, and the non paper near end status is detected by

the CPU.

When the roll paper diameter reaches the paper near end point being mechanically set, the

“Lever PNE” that was pushed by the roll paper edge pops up and the “Slider PNE” of the paper

shaft comes off the “SA PNE Sensor”. Then, pin 77 (PNESNS) of U1A (CPU) goes "Low" level,

and the paper near end status is detected by the CPU. (Q12 turns ON in normal mode (i.e., in

other than power saving mode).)

U1A

CPU

D18

PCT7

L: Power Saving mode

H: Normal mode

PWRSAVE

114

PNESNS

77

U21A

2

Q13

DTC115EM

1

C103

R89

+3.3V

Q12

DTA114EM

R90

R91

J12

(White)

Paper Near End Sensor

(SA PNE Sensor)

PT301

1

1

2

2

3

3

PS301

[SA, Main PCB]

[Normal Status]

[PNE (Paper Near End) Status]

Roll Paper Holder

SA PNE Sensor

Spring PNE

Lever PNE

Roll Paper

Spring PNE

SA PNE Sensor

Lever PNE

Roll Paper

Slider PNE

Slider PNE

CL-S6621 2-30

Page 45

Operation of Control Parts

2-2-4. Drivers

(1) PF motor driver

This is a driving circuit to drive the “SA PF Motor” (stepping motor).

The following illustration shows a simplified circuit.

The “SA PF Motor” is driven by the unipolar constant current chopper method.

The exciting method for the motor is the 1-2 phase method.

The power to the “SA PF Motor” is controlled by U14 (FPGA). When pin P1 (VMTON) is “High”

level, Q27 and Q25 turn ON and +24V is supplied to the “SA PF Motor”.