Page 1

CLP-6401

User’s Manual

C. ITOU

Page 2

FCC COMPLIANCE S TATEM E NT

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

"DESIGNED AND MANUFACTURED T O BE EQUIVALENT TO EUROPEAN

STANDARD FOR ITE, EN60950."

- i -

Page 3

EM I COMPLIANCE STATEM E NT

FOR CANADIAN USE RS

This equipment generates and uses radio frequency energy and if not installed and used

properly, that is, in strict accordance with the manufacturer's instructions, may cause

interference to radio and television reception. This digital apparatus does not exceed

the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications. This

equipment is designed to provide reasonable protection against such interference in a

residential installation. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

・ Reorient or relocate the receiving antenna.

・ Increase the separation between the equipment and receiver.

・ Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

・ Consult the dealer or an experienced radio/TV technician for help.

CAUTION: Use shielded cables to connect this device to computers.

Any changes or modifications not expressly approved by the

grantee of this device could void the user's authority to operate

the equipment.

ETAT DE CONFORMIT E E MI A L'USAG E

DES UTILIS ATEURS CANADIE NS

Cet équipment produit et utilise l'énergie à radiofréquences et s'il n'est pas installé et

utilisé correctment, c'esst à dire en accord strict avec les instructions du fabricant, il

risque de provoquer des intérferences avec la réception de la radio et de la télévision.

Le présent appareil numérique n'émet pas de bruite radioélectriques dépassant les

limites applicables aux appareils numériques de la classe A prescrites dans le Réglement

sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

Cet équipment est conçu pour fournir une protection satisfaisante contre de telles

interférences dans une installation résidentielle. Cependant, il n'y a pas de garantie

contre les interférences avec les réceptions radio ou télévison, provoquées par la mise

en et hors circuit de l'équipment; aussi, il est demandé a l'utilisateur d'essayer de corriger

l'interférence par l'une ou plus des mesures suivantes:

・ Réorienter l'antenne de réception.

・ Installer l'ordinateur autre part, par égard pour le récepteur.

・ Brancher l'ordinateur dans une prise de courant différente de façon à ce que

l'ordinateur et le récepteur soient branchés sur des circuits différents.

- ii -

Page 4

Important Safety Instructions

1. Read all of these instructions and save them for later reference.

2. Follow all warnings and instructions marked on the product.

3. Unplug this product from the wall outlet before cleaning. Do not use liquid or aerosol

cleaners. Use a damp cloth for cleaning.

4. Do not use this product near water.

5. Do not place this product on an unstable cart, stand or table. The product may fall, causing

serious damage to the product.

6. Slots and openings on the cabinet and the back or bottom are provided for ventilation.

To ensure reliable operation of the product and to protect it from overheating, do not block or

cover these openings. The openings should never be blocked by placing the product on a

bed, sofa, rug or other similar surface. This product should never be placed near or over a

radiator or heat register. This product should not be placed in a built-in installation unless

proper ventilation is provided.

7. This product should be operated from the type of power source indicated on the marking label.

If you are not sure of the type of power available, consult your dealer or local power company.

8. This product is equipped with a three-pronged plug, a plug having a third (grounding) pin.

This plug will only fit into a grounding-type power outlet. This is a safety feature. If you are

unable to insert the plug into the outlet, contact your electrician to replace your obsolete outlet.

Do not defeat the safety purpose of the grounding-type plug.

9. Do not allow anything to rest on the power cord. Do not locate this product where the cord

will be walked on.

10. If an extension cord is used with this product, make sure that the total of the ampere ratings

on the products plugged into the extension cord do not exceed the extension cord ampere

rating. Also, make sure that the total of all products plugged into the wall outlet does not

exceed 15 amperes for 120V outlet and 7.5 amperes for 220-240V outlet.

11. Never push objects of any kind into this product through cabinet slots as they may touch

dangerous voltage points or short out parts that could result in a risk of fire or electric shock.

Never spill liquid of any kind on the product.

12. Except as explained elsewhere in this manual, don't attempt to service this product yourself.

Opening and removing those covers that are marked "Do Not Remove" may expose you to

dangerous voltage points or other risks. Refer all servicing on those compartments to

service personnel.

13. The mains plug on this equipment must be used to disconnect mains power. Please ensure

that the socket outlet is installed near the equipment and shall be easily accessible.

14. Unplug this product from the wall outlet and refer servicing to qualified service personnel

under the following conditions:

A. When the power cord or plug is damaged or frayed.

B. If liquid has been spilled into the product.

C. If the product has been exposed to rain or water.

D. If the product does not operate normally when the operating instructions are followed.

Adjust only those controls that are covered by the operating instructions since

improper adjustment of other controls may result in damage and will often require

extensive work by a qualified technician to restore the product to normal operation.

E. If the product has been dropped or the cabinet has been damaged.

F. If the product exhibits a distinct change in performance, indicating a need for service.

- iii -

Page 5

Notice

1. Before use, be sure to read this manual. And keep it handy for

reference when needed.

2. The contents of this manu a l may change withou t p rior notice.

3. Reproduction, transfer, or transmission of the contents of this manual

without prior consent is strictly prohibited.

4. We are not liable for any damage resulting from the use of the

information contained herein, regardless of errors, omissions, or

misprints.

5. We are n ot liable for any problems resulting from the use of optional

products and consumable supplies other than the designated

products contained herein.

6. Do not handle, disassemble or repair the parts other than those

specified in this manual.

7. We are n ot liable for any damage caused by user's erroneous use of

the printer and inadequate environment.

8. Data residing in the printer is temporary. Therefore, all data will be

lost if power is lost. We are n ot liable for any damage or loss of

profits caused by data loss due to failures, repairs, inspections, etc.

9. Please contact us if there are any mistakes or ambiguities within this

manual.

10. If there are missing or incorrectly collated pages in this manu al,

contact us to obtain a new manual.

- iv -

Page 6

¾

¾

SAFETY SIGNS

n To prevent personal injury or property damage, the following shall be strictly

observed.

n The degree of possible injury and damage due to incorrect use or improperly

following instructions is described below.

¾

WARNING

must be strictly observed !

¾

Indicates a situation which, if not observed

and handled properly, could result in death

or serious injury.

CAUTION

This is a mark to call attention to the reader.

Indicates a situation which, if not observed

and handled properly, could result in injury.

- v -

Page 7

WARNING

n Never perform the following. If not avoided, these may cause damage or

trouble to the printer or cause the printer to overheat and release smoke

and cause burns or an electrical shock. If the printer is damaged or is

malfun ctioning, be sure to turn the power off and remove the power cord

from the outlet, then consult ou r service personnel.

· Do not jolt or impact to the printer by stepping on, dropping or hitting

the prin ter.

· Do not place the prin ter in a poorly ventilated area, or shut off the air

vent of the printer.

· Do not place the prin ter where chemical reactions occur, such as in

laboratories or where air is mixed with salt or gas.

· Do not use a power vol tage or frequency other than those specified.

· Do not plug/unplug the power cord or attach/detach the interface

cable by simply grabbing the power cord or in terface cable. Do not

pull or carry the printer when the tension of the power cord or

interface cable is increased.

· Do not drop or put foreign matter such as clips and p ins into the

printer . This may cause problems.

· Do not plug the power cord into an outle t with man y loads.

· Do not spill drinks such as tea, coffee and juice on the printer or spray

insecticide on the printer. If drin k or w a te r is spilled , first be su re to

tur n the power off an d remove the power cord from the outl e t, then

consult our service personnel.

· Do not disassemble or modify the printe r.

n Discard or safely store the plastic packing bag. This bag should be kept

away from children. If the bag is pulled over a child’s head, it may cause

suffocation.

- vi -

Page 8

General Precautions

1. Prior to operation, read the safety instruction s carefully and observe them.

2. Be careful when moving or carrying the printer. Dropping the printer may

cause injury or property damage.

3. Make sure if you open the top cover, it is opened all the way. If only partially

open, the cover could slam shut, possibly causin g injury.

4. Wh en the cover is open, be careful of the corners of cover. They could cause

injury.

5. Do not open the printer during printing.

6. Wh en cleaning the surface of the printer case, do not use the cloth that is

soaked in thinner, trich loroethylene, benzine, ketone or similar chemicals.

7. Do not use the printer where there is a lot of oil, iron particles, or dust.

8. Operate th e control pan el properly. A careless, rough handling may cause

problems or malfunction. Do not use such sharp-edged tool as a ballpoint

pen for operation .

9. Before attaching the auto-cutter drive board, be sure to unplug the power cord

from the outlet.

10. Attaching the auto-cutter drive board must not be done immediately after use

of printer .

11. Be careful not to damage the printer's drive pulley and belt.

12. Be careful of the edges of the plates so injury or property damage is possible.

13. If a problem occurs during printing, stop the printer immediately and unplug

the p ower cord from the outlet.

- vii -

Page 9

Precautions When Installing the Printer

1. Prior to operation, read the safety instruction s carefully and observe them.

2. Do not u se or store the p rinter near fire, excessive moisture, in direct

sunlight, near an air conditioner or heater or other source of unusually high

or low temperature or humidity or excessive dust.

3. Do not place the printer where chemical reactions occur, such as in a

laboratory.

4. Do not place the printer where air is mixed with salt or gas.

5. The printer must sit on a firm, level surface where there is ample ventilation.

Never allow the printer's air vent to be blocked by a wall or other object.

6. Do not place anyth ing on the top printer .

7. Do not place the printer near a radio or tel evision, and do not use the same

wall outl et for the printer and radio or tel evision. Radio or television

reception could be adversely affected.

8. Do not bundle the pow er cord when inserting the plug.

9. Gr ip the plu g housing, not the cord, to unp lug th e p ower cord.

10. Make certain the in terface cable is attached properly. If polarity direction is

not correct, this may cause internal damage.

11. Make certain the power is turn ed off before attaching/detaching the interface

cable.

12. Avoid lengthening the signal cable or attaching it to any noise-produ cing

device. If it is unavoidable, use the shielded cable or twisted pair for each

signal.

- viii -

Page 10

Chapters in This Manual

Chapter 1 Setup

Describes the packed items after opening the carton as

well as the names and functions of parts.

Chapter 2 Control Panel

Describes the necessa ry items for operations, such as

the control panel, printer settings and indications on the

LCD/LEDs.

Chapter 3 Preparation for Printing

Describes the procedures for loading the paper and

ribbon and includes notes on the use of paper and

ribbons.

Chapter 4 Troubleshootin g

Describes corrective a ct ions when pr oblems occur.

Chapter 5 Option s

Describes th e optional accessories for this printer.

Chapter 6 Specifications

Describes the basic specifications and commands for

this printer.

- ix -

Page 11

Table of Contents

FCC Compliance Statement for American Users . . . i

EMI Compliance Statement for Canadian Users . . . ii

Important Safety Instructions . . . . . . . . . iii

Notice . . . . . . . . . . . . . . . . . iv

Safety Signs . . . . . . . . . . . . . . . v

Warning . . . . . . . . . . . . . . . . vi

General Precautions . . . . . . . . . . . . vii

Precautions When Installing the Printer . . . . . viii

Brief Description of Chapters in This Manual . . . . ix

Chapter 1 Setup . . . . . . . . . . . . . . . 1-1

1.1 Confirmation of Carton Contents . . . . . . 1-2

1.2 Part Names and Functions . . . . . . . . 1-3

1.3 Connection to Power . . . . . . . . . . 1-7

1.4 Connection to a Computer . . . . . . . . 1-8

Chapter 2 Control Panel . . . . . . . . . . . . 2-1

2.1 Control Panel . . . . . . . . . . . . 2-2

2.2 LCD/LED Indications and Adjustment Controls . . 2-3

2.3 Normal Operating Mode . . . . . . . . . 2-3

2.4 Printer Setup Mode . . . . . . . . . . . . 2-4

2.5 Self-Test Mode . . . . . . . . . . . . . 2-4

2.6 System Maintenance Mode . . . . . . . . 2-6

Chapter 3 Preparation for Printing . . . . . . . . . 3-1

3.1 Kinds of Paper . . . . . . . . . . . . . 3-2

3.2 Specification of Label and Tag . . . . . . . 3-2

3.3 Paper Setting . . . . . . . . . . . . . 3-6

3.4 Ribbon . . . . . . . . . . . . . . . 3-8

3.5 Ribbon Setting . . . . . . . . . . . 3-9

3.6 Head Offset Adjustments . . . . . . . . . 3-10

3.7 Head Pressure Adjustments . . . . . . . . 3-11

3.8 Ribbon Tension Adjustments . . . . . . . 3-12

3.9 Adjustable Sensor . . . . . . . . . . . 3-13

3.9.1 Exterior view and part names . . . . . . . . 3-13

3.9.2 How to operate adjustable sensor . . . . . 3-14

3.9.3 Specification of paper (for adj ustable sensor) . . . 3-15

- x -

Page 12

3.10 Cleaning . . . . . . . . . . . . . . 3-16

Chapter 4 Troubleshooting . . . . . . . . . . 4-1

4.1 Error Messages . . . . . . . . . . . . 4-2

4.1.1 Error descriptions and indications . . . . . . 4-2

4.1.2 Error indications and corrective actions . . . 4-4

4.2 Power Troubleshooting . . . . . . . . . . 4-7

4.3 Paper Feed Troubleshooting . . . . . . . 4-8

4.4 Ribbon Feed Troubleshooting . . . . . . 4-9

4.5 Print Troubleshooting . . . . . . . . . . . 4-10

4.6 Interface Troubleshooting . . . . . . . . 4-11

Chapter 5 Options . . . . . . . . . . . . . . 5-1

Factory or Reseller (Deale r) Option s:

5.1 Auto-Cutter Unit . . . . . . . . . . . 5-2

5.2 Peeler Unit . . . . . . . . . . . . . . 5-2

User Options:

5.3 PCMCIA Memory Card . . . . . . . . 5-3

Chapter 6 Specifications . . . . . . . . . . . . 6-1

6.1 Main Specifications . . . . . . . . . . 6-2

6.2 Interface . . . . . . . . . . . . . . 6-6

6.2.1 System configuration . . . . . . . . . . 6-6

6.2.2 Specification of interface . . . . . . . . 6-7

6.2.3 RS-232C loopback test . . . . . . . . . 6-8

6.2.4 RS-232C protocol . . . . . . . . . . . 6-9

6.2.5 Interface pin assignment . . . . . . . . . 6-11

6.3 Outline of Command System . . . . . . . 6-13

6.4 Example of Connection to a Computer . . . . 6-14

6.5 Tear-Off Function . . . . . . . . . . . 6-15

6.5.1 Turning Tear ON/OFF . . . . . . . . . . 6-15

6.5.2 Tear-off when printing . . . . . . . . . . 6-15

6.5.3 Tear-off when feeding . . . . . . . . . . 6-16

6.5.4 Tear-off and type of data . . . . . . . . . 6-17

6.5.5 Cut position adjustments . . . . . . . . . 6-17

6.5.6 When "fnnn" command is executed

while Tear is OFF . . . . . . . . . . . . 6-18

6.5.7 Priority order . . . . . . . . . . . . . 6-18

- xi -

Page 13

- xii -

Page 14

Chapter 1

Setup

1.1 Confirmation of Carton Contents 1-2

1.2 Part Names and Functions 1-3

1.3 Connection to Power 1-7

1.4 Connection to a Computer 1-8

1-1

Page 15

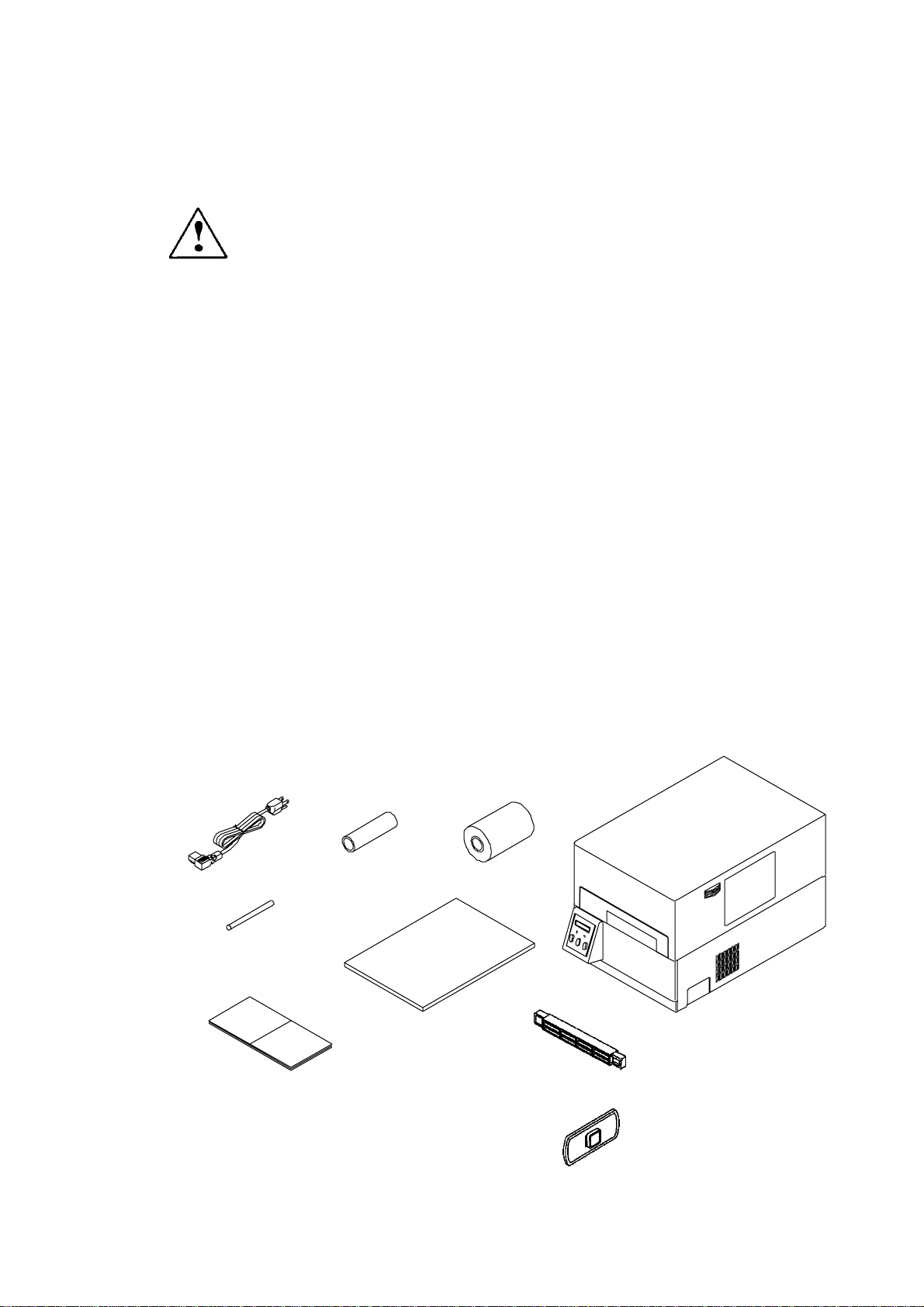

1. 1 Confirmation of Carton Contents

CAUTION Be careful when moving or carrying the prin ter and

when taking the printer out of the carton. The p rinter

may cause inj ury or property damage if dropped. Be

sure to grip the printer housing tightly when taking it

out of the carton. Do not grip th e p rinter b y the foam

packing material which may break, causing the printer

to drop.

Check that the fol lowing accessories are included with the printer in the carton.

· Power cord 1 pc

· Paper core 1 pc

· User's manual (this booklet) 1 copy

· Ink ribbon 1 pc

· Label paper 1 set

· Roll holder 1 pc

· Roll guide 1 pc

· Cleanin g pen 1 pc

Note: The empty carton and packing materials should be stored for future

shipping of the printer.

Power cord

Paper core

Ink ribbon

Cleaning pen

User’s manual

Printer

Label paper

Roll holder

Roll guide

1-2

Page 16

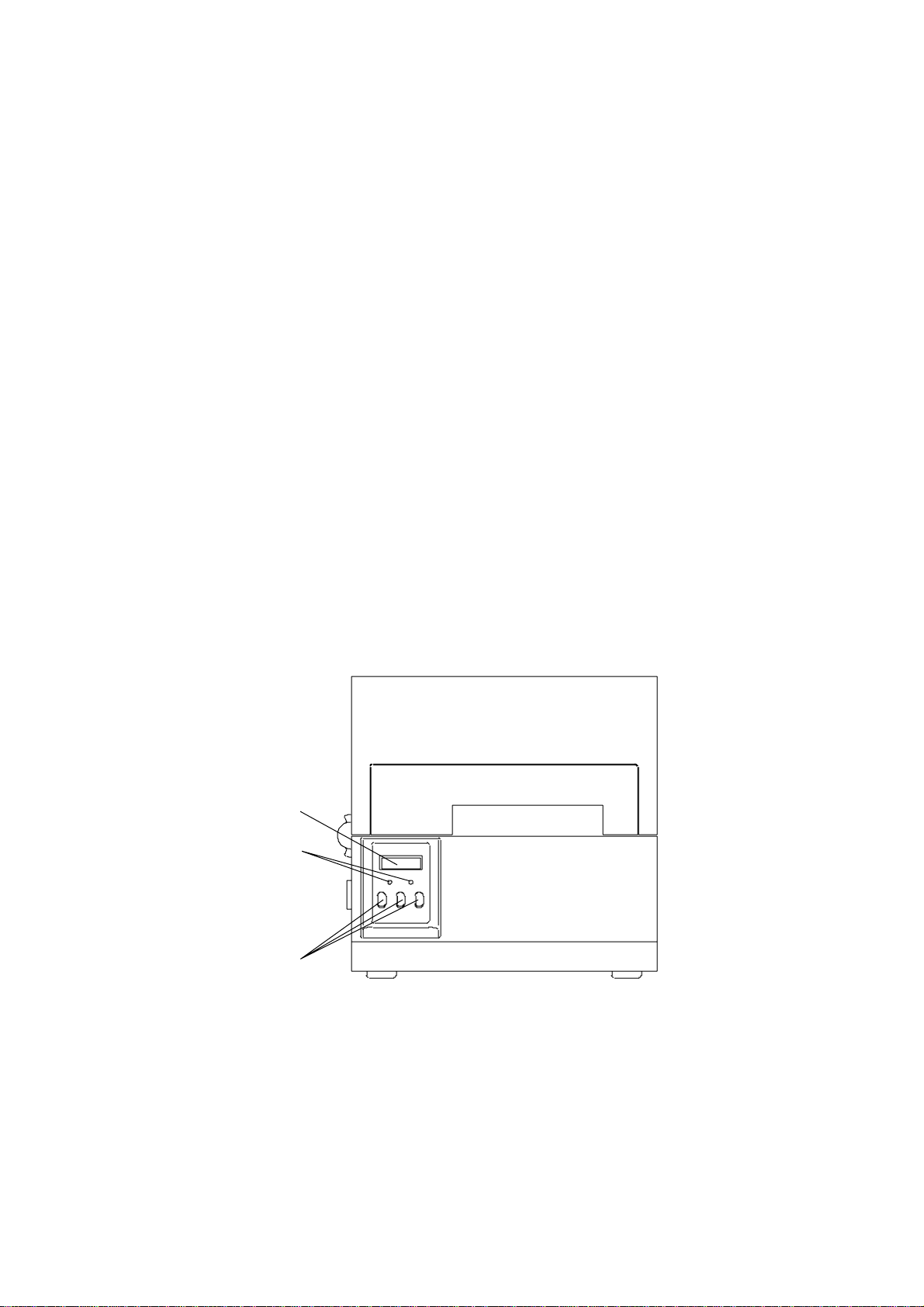

1. 2 Part Names and Functions

D

FRO N T VIEW

n Control panel

The printer has two LED indicator lights and an LCD screen that displays

printer messages.

① LEDs

One LED is the power indicator an d the other is the error indicator.

② LCD

Displays the current printer status, configuration settings, or an

error message.

③ Control keys

The Pause, Feed an d Stop keys are arranged from left to right and

are used to facilitate printer operating. (For details, see Chapter 2

Control Panel.)

① LC

② LEDs

③ Control keys

1-3

Page 17

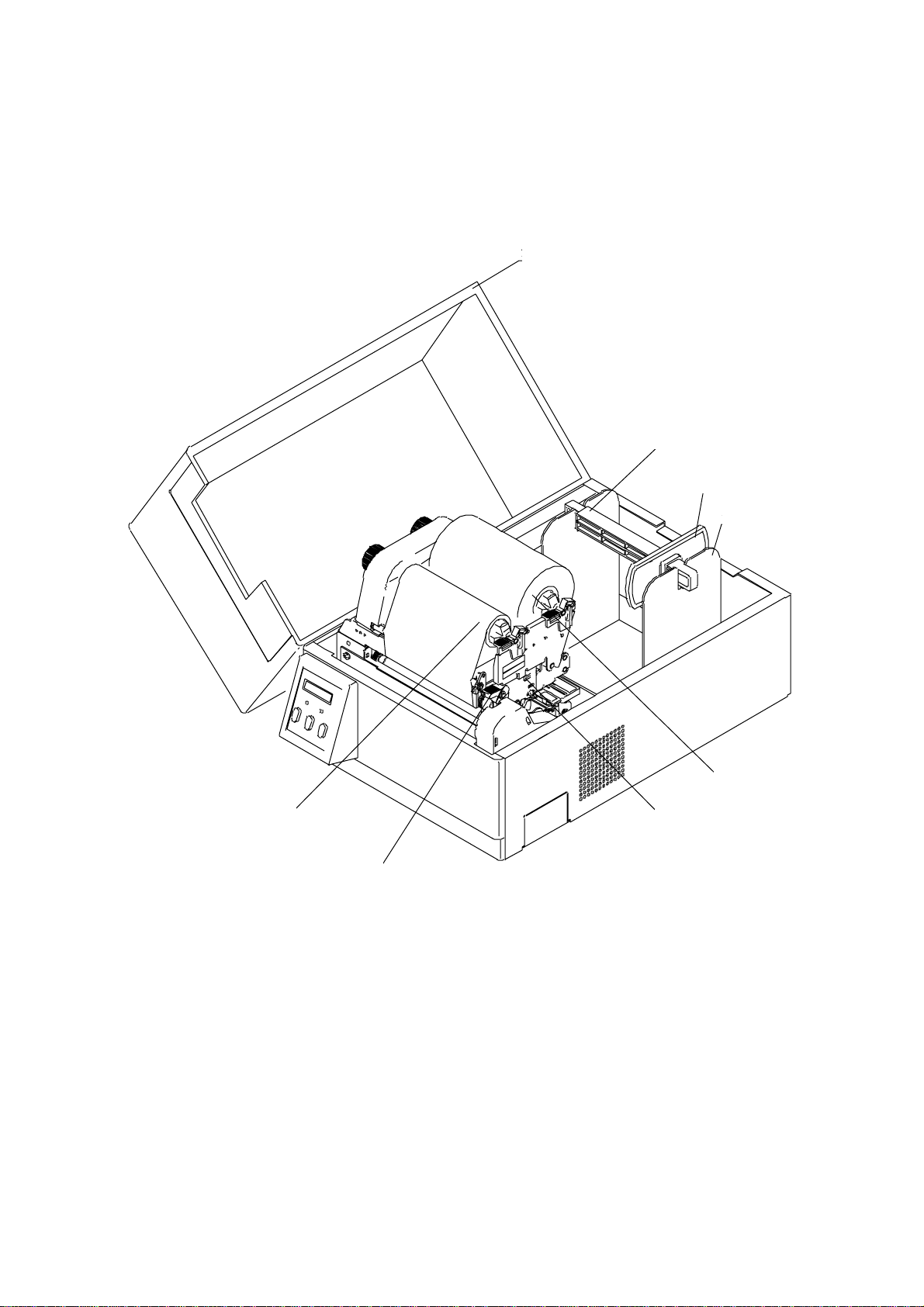

I NSIDE VIEW

① Cover

④ Roll holder

⑤ Roll guide

⑥ Paper holder

② Ribbon holder

③ Ribbon

⑧ Offset verification window

⑦ Open lever

1-4

Page 18

n Names and functions of each part

CAUTION · When opening the cover, open it all the way.

If on ly part way open, the cover could slam shu t,

possibly causing in jury.

· Be careful of th e edge of the cover when the cover

is open ed. It may cau se injury or property

damage.

· Be careful of the edges of the pl ates so injury or

property damage is possible.

① Cover

Opens to allow loading of th e paper and ribbon.

② Ribbon holder

To attach th e ribbon. (See Chapter 3.)

③ Ribbon winder

To win d the ribbon. (See Chapter 3.)

④ Roll holder

Hol ds the roll of paper.

⑤ Roll guide

Guides the roll of paper to be set on the roll holder. The roll guide can be

adjusted in accordance with the width of the paper. (See Chapter 3.)

⑥ Paper holder

Holds the roll holder w hich is inserted in the paper core.

⑦ Open lever

To swing the print head out of the way when loading the paper or cleaning

the print head.

⑧ Offset verification wi ndow

Allows you to check the position of the print head which may need adjustin g

based on the th ick ness of the paper used. (See Chapter 3.)

1-5

Page 19

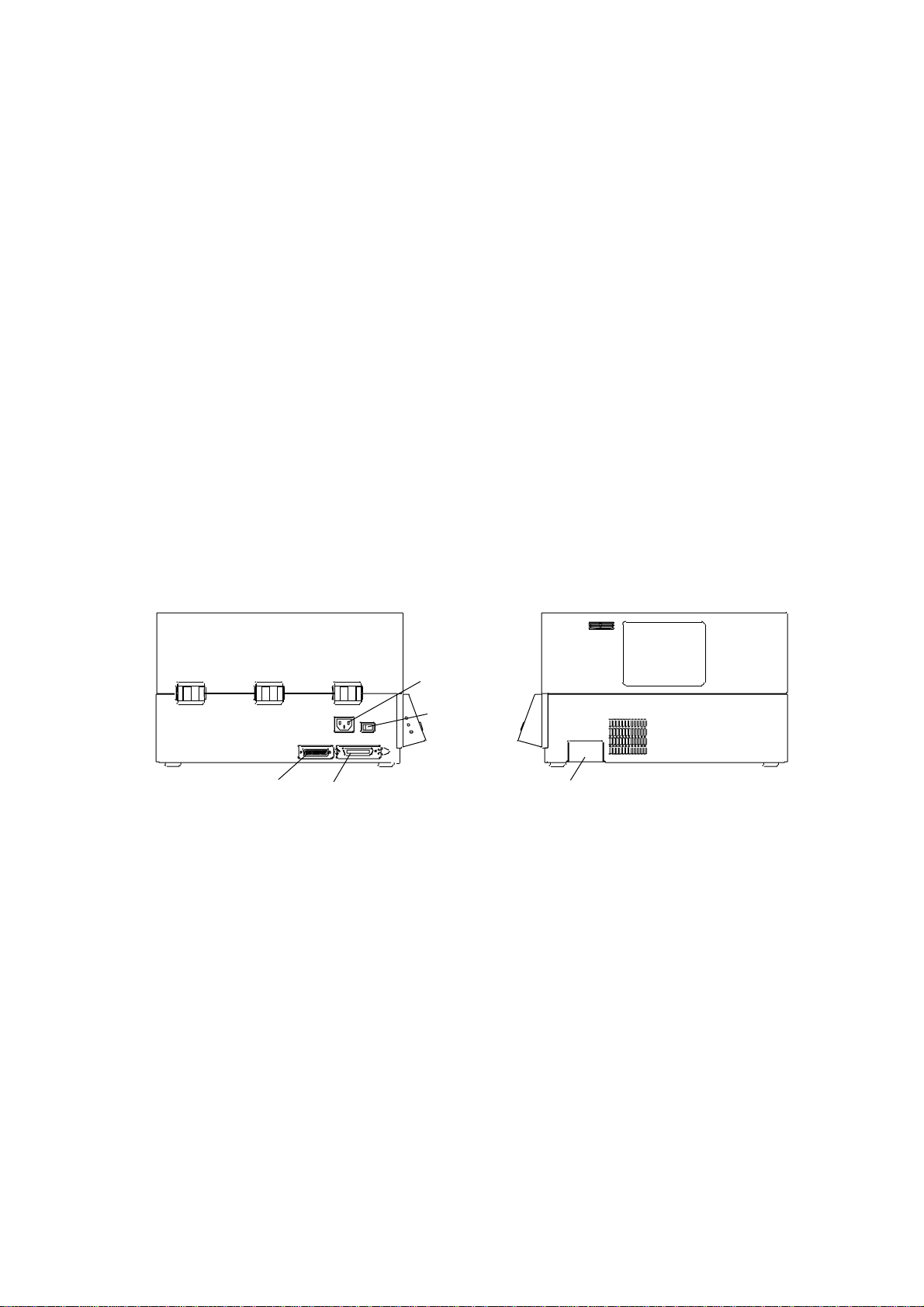

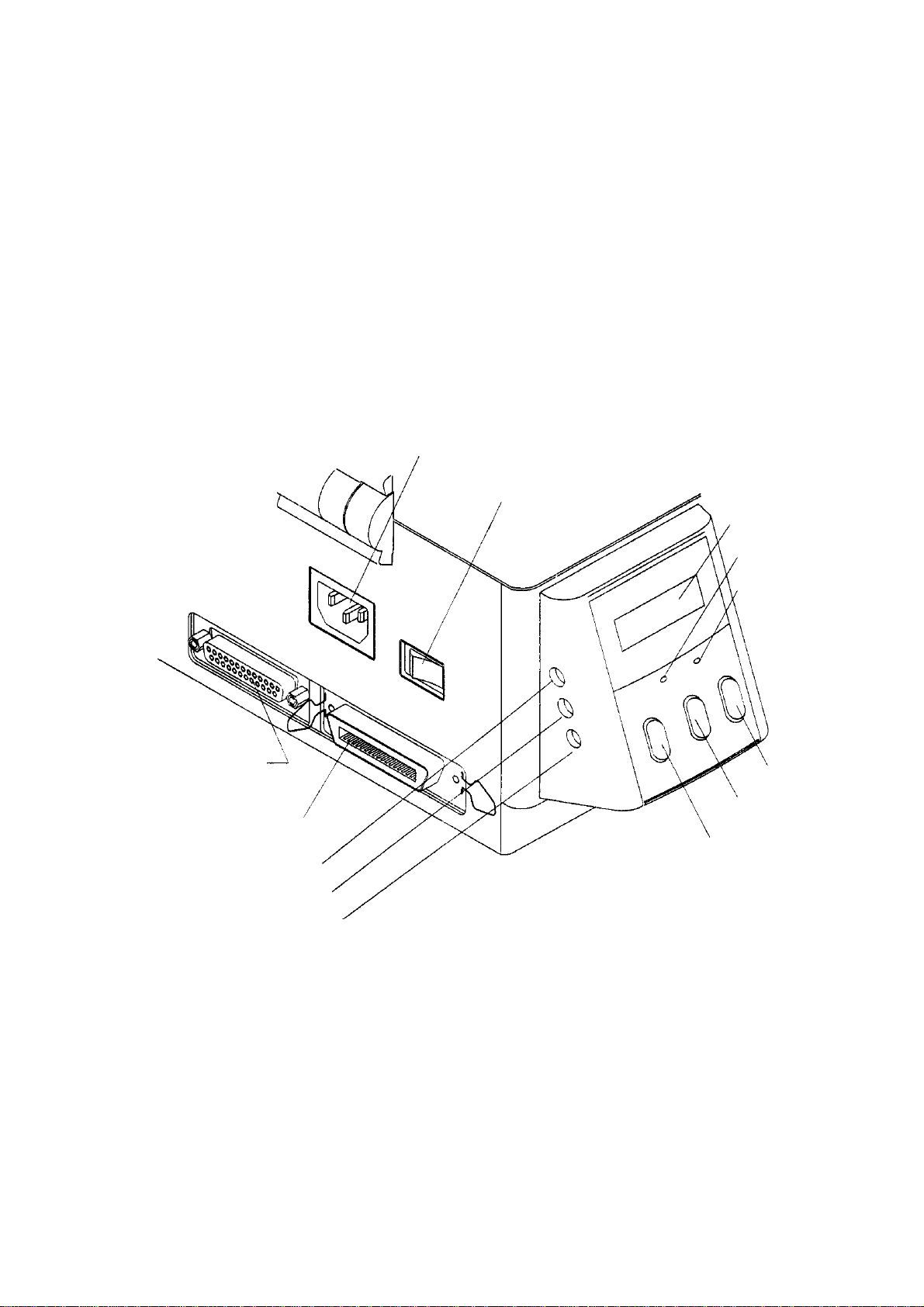

SI DE VIEW

n Interface connectors

To connect the interface cabl e.

n PCMCIA memory card cover

To protect the PCMCIA memory card from exposu re to dust and foreign

matter. To install a PCMCIA memory card, first unhook this cover , then

slide it out.

n Power switch

To turn on/off the power.

n Power inlet

To connect the power cord.

Power

switch

Serial

interface

connector

Parallel

interface

connector

PCMCIA memory card cover

1-6

Page 20

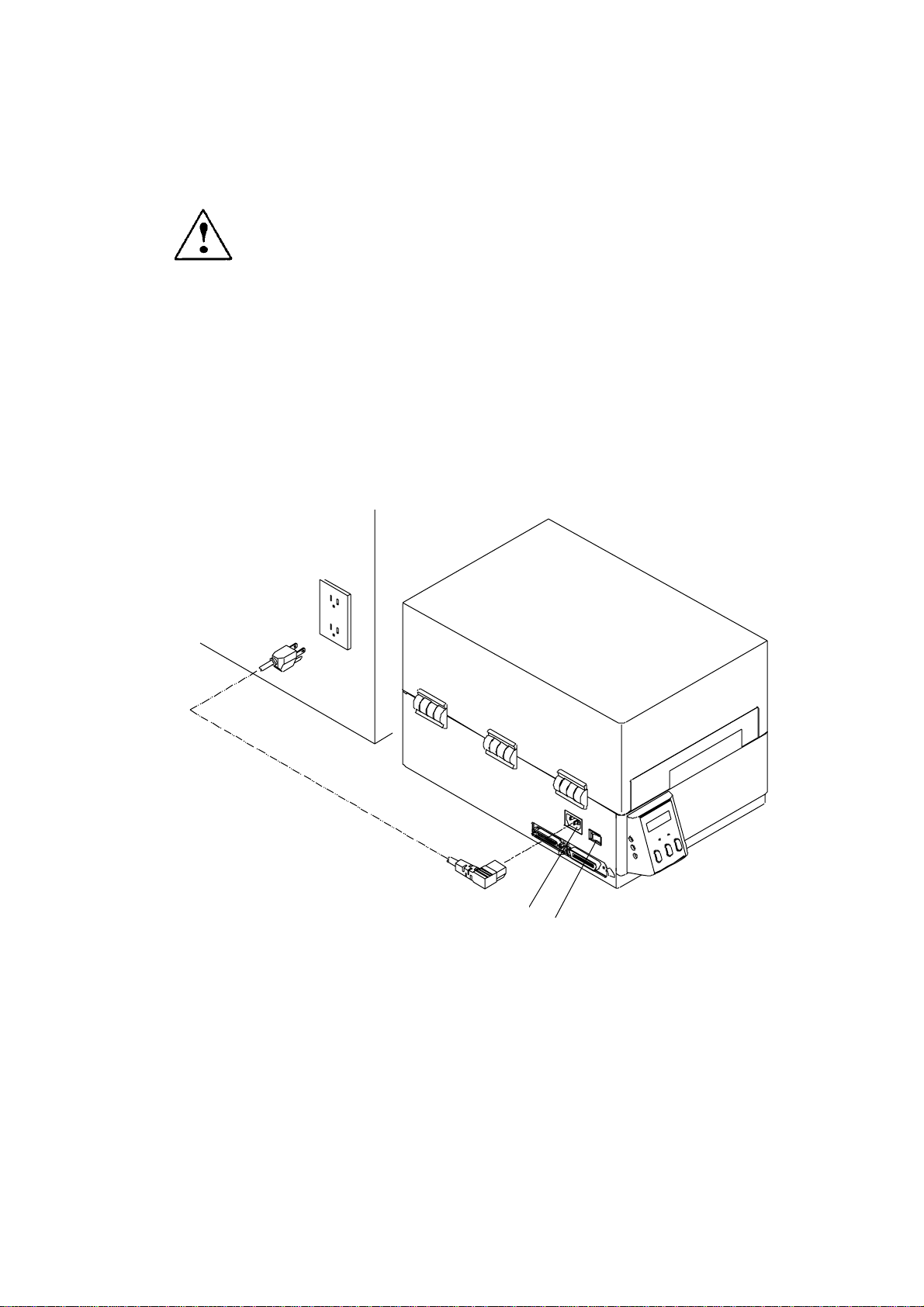

1.3 Connection to Power

A

t

CAUTION Use an AC outlet that accepts a three-pronged plug.

Otherw ise, static electricity may be generated and

there will be danger of electric shock.

Connect to an AC outlet as follows:

1 Check that the power sw itch on the p rinter is set to OFF.

2 Connect the connector of the power cord to the power inlet on th e p rinter.

3 Insert the plug of the power cord in the AC outlet.

C outle

Power

Power switch

1-7

Page 21

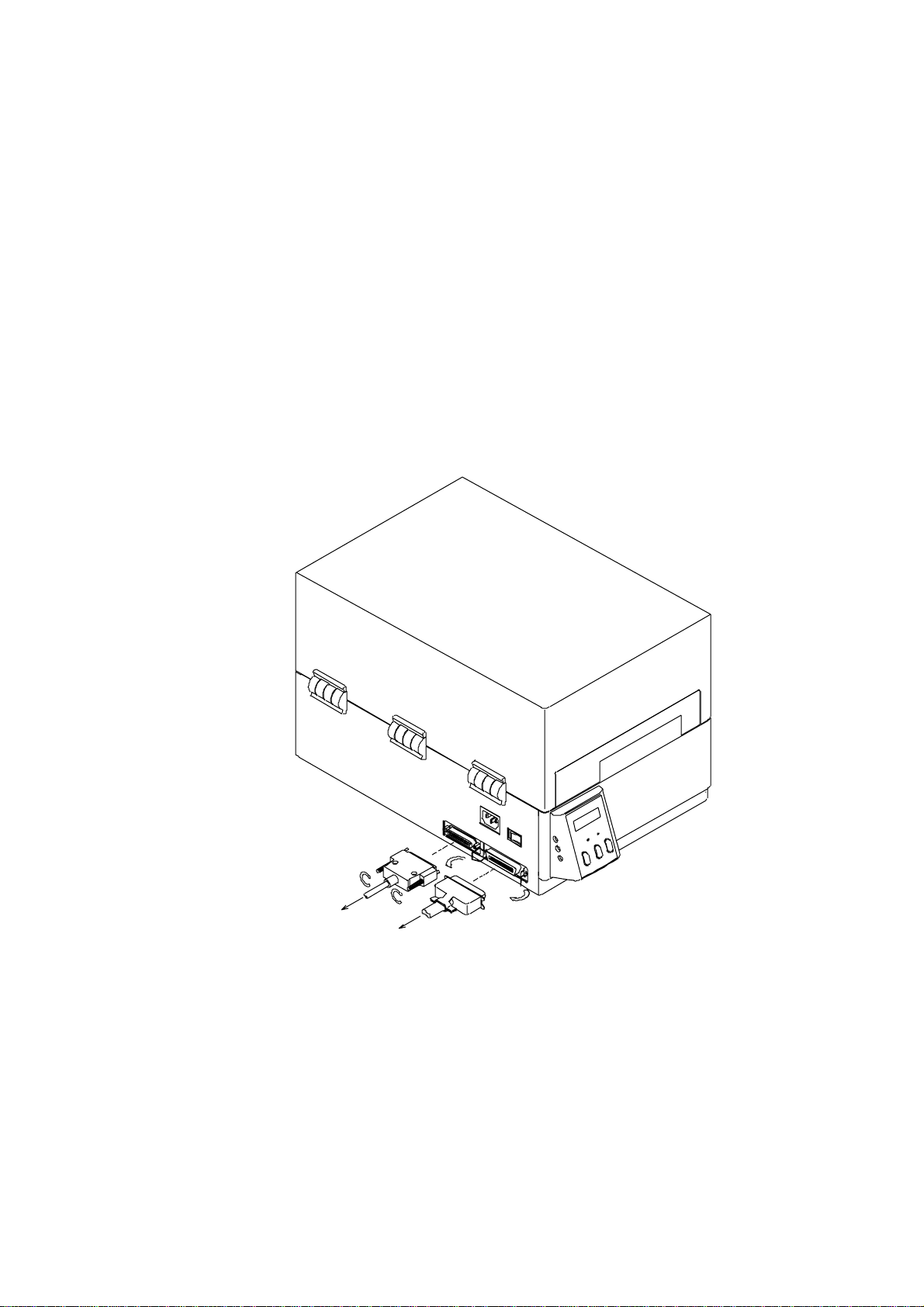

1.4 Connection to a Computer

An interface cable is necessary for connecting the printer to a computer.

To connect them, proceed as follows:

1 Turn off both power switches of the printer and the computer.

2 Connect the connector of one end of the interface cable to th e interface

connector at the lower side of the printer and secure it w ith screws.

3 Connect the connector of the other end of the interface cable to the interface

connector on the computer and secure it with screws.

1-8

Page 22

Chapter 2

Control Panel

2.1 Control Panel 2-2

2.2 LCD/LED Indications and Adjustmen t Controls 2-3

2.3 Normal Operating Mode 2-3

2.4 Printer Setup Mode 2-4

2.5 Self-Test Mode 2-4

2.6 System Maintenance Mode 2-6

2-1

Page 23

2.1 Control Panel

r

r

C

The control panel, on the front of the printer , con sists of three control keys

(Pause, Feed and Stop), two LED indicator lights (Power, Error), and a LCD

message screen. On the left side of the control panel there are three

adjustment controls (paper gap, black line and LCD contrast).

Exterior view of the control panel

Serial interface connecto

Parallel interface connecto

Paper gap adjustment control

Black line adjustment control

LCD contrast adjustment control

Power inlet

Power switch

D

L

LED power indicator

LED error indicator

Stop key

Feed key

Pause key

2-2

Page 24

2. 2 LCD/LED Indications and Adjustment C ontrols

1 LCD

The eight-ch aracter LCD screen displays the current printer status,

configuration settings, or an error message.

2 LEDs

Power: The green LED power indicator goes on when the power is tuned ON.

Error: The red LED error indicator goes on when an error occurs.

3 Adjustment controls

The three adjustment controls are used to adjust th e paper gap (transparent

type) sensor sensitivity, bl ack line (reflective type) sensor sensitivity, and LCD

contrast.

2.3 Normal Operating Mode

When the power is turned on, the printer enters normal operating mode.

The control keys function as follows:

n Pause key

Temporarily pauses prin ting. "Pause" is displayed on the LCD screen.

If pressed during printing, printin g will stop after the current label is printed.

Press the Pause key again to resume printing.

n Feed key

Advance to the top of the next label. When using continu ous paper,

make su re the Sensor selection is set to ContinuP or a Paper error will

resu lt.

n Stop key

With this key, the operator can stop and can cel the current print job. Pressing

the Stop key during printing stops the printing immediately. Pressing th e Stop

key again cancel s the print job.

2-3

Page 25

2. 4 Printer Setup Mode

To enter the Printer Setup Mode, press and hold down the Pause key then press

the Feed key and release both keys. In a few seconds you will hear a beep and

see Transfer or Dir ectTM displayed on the LCD screen. The functions of the

control keys are described below.

Changes to the prin ter configuration are stored in nonvolatile memory. This

guarantees that the prin ter configuration is maintained even after the power is

turned off.

[Functions]

Print mode selection, peeling sensor ON/OFF, auto-cutter ON/OFF, etc.

n Pause key: Selects the mode.

n Feed key: Selects the mode item.

n Stop key: Saves settings and returns the printer to normal operating mode.

Mode item Indication

¯

¯

¯¯

Direct-thermal/thermal Transfer ® Direct TM ®

transfer printing

¯¯¯¯

Peeling sensor Peel OFF ® Peel ON ®

¯¯¯¯

Auto-cutter Cut OFF® Cut ON ®

¯¯¯¯

Tearing Tear OFF ® T ear ON ®

¯¯¯¯

Sensor selection Edge ® Reflect ® ContinuP ®

2.5 Self-Test Mode

The printer can be placed into self-test mode by pressing and holding the Feed key

while turning the printer on.

Note: Proper use of this mode requires a minimum label size of 4” x 4”. Use of

a smaller label will prevent the user from seeing all printed information,

and verifying the print quality across the entire print head.

2-4

Page 26

During execution of the printer self-test, the prin ter will eject an alignment label,

then print a status report and finall y, print a series of head test patterns. Use the

head test patterns to identify any problems with missing dot rows, uneven head

pressure, heat setting and transfer smearing

.

The status page will look similar to the foll owing:

The Status Label gives the user information regarding the current system setting of

the printer. It references the Version #, shows th e date and time setting, validates

the on board ROM, indicates curren t serial communication values, Mode of printing

(Direct Thermal or Thermal Transfer), the type of media (Gap, Black Line) w ith

sensor voltage values, check s the head and even tells you the number of mm’s of

material that have passed under the head mechanism. All of this information can

be u sefu l when trying to troubleshoot your printer.

When the printer enters Monitor mode, any information communicated to the printer

will be printed on th e label material. After each carriage return a label will be

printed displaying in Hex and ASCII the contents of the data stream received at the

printe r. You can use this to test both the actual fact of communication with the

printer, and the exact contents of the data stream being sent.

T o return the print er to normal opera t ing cycle the power.

2-5

Page 27

2.6 System Maintenance Mode

To enter the printer’s maintenance mode, press and hold th e Pause, Feed and

Stop keys simultan eously while turning on the printer’s power. In a few

seconds you will hear a beep and see S Mainte displ ayed on the LCD screen.

Note: To reset al l values to defaul t settings, con tinue to hold these keys for

an additional four (4) seconds, until you hear a second beep an d see

S/I Init displayed on the screen. See the chart at the end of this

section for the prin ters default val ues.

After entering this mode the printer will display the first of several parameters

for you to set. Select each parameter (Mode) by pressing the Pause key, and

make changes to that selection by pressing the Feed key to cycle through the

available choices.

Pressin g th e Stop key will save your se ttings and return th e printer to normal

operating mode. After you press the Stop key, the printer will display RESET

in the LCD screen and, a few seconds later , On Line.

Note: Do not tur n off the printer until you see ‘On Line’ in the display, or

your changes may be lost.

Mode item Indication

¯

¯

¯¯

Baud rate 9600bps ® 19200bps ® ¼¼¼ ® 4800bps ®

¯¯¯¯

Data length 8 bits ® 7 bits ®

¯¯¯¯

Native NativeON® NativeOF ®

¯¯¯¯

Adjustable sensor AJSensOF ® AJSe n sO N ®

¯¯¯¯

Voltage setting PE#.##V ® BL#.##V®

2-6

Page 28

The final display in the maintenance mode is the Voltage setting mode. The

display will show ‘PE #.##V’ and as the second option ‘BL #.##V’ for Gap

mode and Black line mode. Th e ‘#.##’ represents the current voltage

reading for these sensors. For proper operation of the printer in these

modes the voltage needs to be set to a specific range of values for the

currently installed media.

Note: A small, flat blade, jewel ers screwdriver will be needed to make the

following adjustments.

To set the Paper- Gap vol tage;

1) Peel off a label from the media to expose the liner.

2) Place the material in to the printer so the exposed liner is under the sensor

guide (#3 on the illustration on page 3-7) and close the sensor guide.

3) Close the printer cover to prevent ambient l ight from skewing the readings.

4) Adjust the Paper Gap sensor (the top hol e on the front left-hand side of th e

printer (see illustration on page 2-2)) to read between 3.00V to 3.30V.

5) Open the printer cover and draw the media under the sensor guide, un til a

label is positioned under the sensor, close the cover .

6) The reading shoul d be less th an the reading voltage of Step 4. The difference

between the two should be more than 1.00V.

To set the Black Line voltage;

1) Place label material under the sensor guide with the media positioned so that

the b lack line is not at the sen sor.

2) Close the printer cover to prevent ambient l ight from skewing the readings.

3) Adjust the Black Line sensor (the middle hole on the front left-hand side of the

printer (see illustration on page 2-2)) to read between 3.00V to 3.30V.

4) Open the printer cover and draw the media under the sensor guide, un til a the

Black Line is positioned under the sensor, close the cover.

5) The reading shoul d be less th an the reading voltage of Step 3. The difference

between the two should be more than 1.00V.

2-7

Page 29

Printer Default Val u es

Baud Rate: 9600

RS-232C setting

Data Length : 8 bit

Print Mode Setting Thermal Transfer

Peeling: OFF

Optional F unctions

Paper Sensor Setting Edge

Adjustable sensor AJSensOF

Model Native ON

Auto-cutter: OFF

Tear-off: OFF

2-8

Page 30

Chapter 3

Preparati on f or

Printing

3.1 Kinds of Paper 3-2

3.2 Specification of Label and Tag 3-2

3.3 Paper Setting 3-6

3.4 Ribbon 3-8

3.5 Ribbon Setting 3-9

3.6 Head Offset Adjustments 3-10

3.7 Head Pressure Adjustments 3-1 1

3.8 Ribbon Tension Adjustments 3-12

3.9 Adjustable Sensor 3-13

3.9.1 Ex terior view and part names 3-13

3.9.2 How to operate adjustabl e sensor 3-14

3.9.3 Specification of paper

(for adjustable sensor) 3-15

3.10 Cleaning 3-16

3-1

Page 31

3. 1 Kinds of Paper

1 Kinds of Paper

The printer is capable of printing on direct-thermal or thermal-transfer

paper. The paper must be high-qu ality. Otherw ise, good print quality

and extended print head life can not be guaranteed.

2 Type of paper

· Label (con tinuous, die-cut, fanfold)

· Tag

· Ticket

Both in-wound and out-wound paper rolls may be used.

3 Size of paper

Paper width: 25.4 mm-118 mm (1 in-4.65 in)

Paper thickn ess: 0.063 mm-0.254 mm (0.0025 in-0.01 in)

Max. printing width: 104 mm (4.1 in)

Max. printing length: 406 mm (16 in)

Max. outer diameter of roll paper: 203 mm (8 in )

Paper core inner diameter: 38 mm-76 mm (1.5 in-3 in)

3. 2 Specification of Label and Tag

The position of a label or tags is detected by the printer's transparent-type

and reflective-type photosensors.

Transparent-type photosensor: Detects paper gap between label s

and tag notch.

Reflective-type photosen sor: Detects black line.

n Specification of paper

3-2

Page 32

Minimum value mm (in) Ma ximum value mm (in)

A Label width 7.62 (0.3) 118.00 (4.65)

B Liner width 25.40 (1.0) 118.00 (4.65)

C Label left-side edge position 0 2.54 (0.10)

D Label paper-gap length 2.54 (0.10) 2539.00 (99.96)

E Label length 2.54 (0.10) 2539.00 (99.96)

F Label pitch 5.08 (0.20) 2539.00 (99.96)

G Liner thickness 0.06 (0.0025) 0.125 (0.0049)

H Paper thickness 0.06 (0.0025) 0.25 (0.01)

I Notch right-side edge position 8.3 (0.32) 11 (0.43)

J Notch left-side edge position 0 4.7 (0.19)

K Notch length 2.54 (0.10) 17.80 (0.70)

L Black line right-side edge position 15.00 (0. 59) ¾

M Black line left-side edge position 0 1.5 (0.06)

N Black line width 3.18 (0.125) 17.80 (0.70)

Note: · I f paper has both label paper-gap and black-line, choose the paper-gap sensor.

· Fanfold uses the paper-gap sensor.

Size of paper

C

H

G

F D E

Label Continuous paper

B

Notch detection Black-line detection

A

I

L

M

I

J

K K

N

Black-lin e (back)

OD value: 1.5 or

more

Ink containing

carbon

Printing

area

Printing ar ea

Use of paper-gap sensor Use of paper-gap sensor Use of black-line sensor

Direction of paper feed

2.5mm 105.7mm (9.8mm)

Left-side

margin

Printing area Right-side

margin

3-3

Page 33

Units for position and l ength

The print positions may be specified in either inch or metric system.

Switching between the two systems is accomplished through software.

The print positions can be freely designated within the maximum label size,

regardless of which system you use.

n Inch system

Basic unit (point): 0.01 in (0.254 mm)

The position of each row address (in the direction of main scanning) and

column address (in the direction of subscanning) is designated in 0.01-inch

units. In the case of the 400 dpi head, if the print position changes by 1 point,

it will change by 2 dots.

1 point = 0.01 in = 4 dots

100 point = 1.00 in = 400

.

.

.

.

dots

n Metric system

Basic u nit (point): 0.1 mm

The position of each row address and column address is designated in

0.1-mm units. Since there is a slight difference between the main and

subscanning density and the point value, the nearest dot number to the

designated address is selected in one dot (0.125 mm) un its.

.

1 point = 0.1 mm = 2 dot

100 point = 10.0 mm = 157

.

.

.

dots

The basic unit is common to all label format and system-level commands.

The label format commands are used to specify the position, length,

whol e-screen offset, etc. The system-level commands are use d to

specify the maximum paper length, home-position offset, etc.

3-4

Page 34

Reference line and points

g

The reference line and points are described here. The position of 2.5

mm from the left edge of the paper is the reference line for paper.

Always the left bottom is the reference point for printing ch aracters and

bar codes. The concept of this referen ce line and points are common to

such commands as ru led line and graphics.

Left edge of paper

Paper reference line

Printing reference point

Printing reference point

2.5

Direction of paper feed

Printin

reference point

Printing reference point

3-5

Page 35

3.3 Paper Setting

CAUTION Be careful of the edges of the pl ates so injury or

The printer is designed for easy loading of paper and ribbon. After opening th e

cover, set the register paper as follows:

1 Push down the open lever ① to lift the prin t head up.

2 Push down the open guide lever ③ to lift the sensor arm ② up.

3 Attach the roll paper and roll gu ide ⑤ to the roll holder ④ and position it in the

paper holder ⑥. After installing the roll paper, adjust the roll guide ⑤ to the

width of the roll paper. The roll paper should be in its deepest position

(reference plane).

4 If necessary, move the paper guide ⑦ out to allow for paper insertion.

5 Set the roll paper as shown in the figure.

6 The left side of roll paper shoul d be flush against th e fixed paper guide ⑧.

Adjust the movable paper guide ⑦ to slightly contact the other end of the roll

so that the paper does not sk ew.

property damage is possible.

7 Push down the media guide ② until the lever ③ is hooked.

8 Align the paper with the positioning notch of the tear-off plate ⑨ and then

press down the blue tab ⑩ to close the printer me c hanis m. Press it until it

clicks to ensure proper closure.

9 Cl ose the prin ter cover.

10 Turn on the power to the printer. The LCD screen on the control panel will

display "On line." Press the Feed key. The paper will advance to the next

label and stop.

(For circled numbers, see figure on next page.)

3-6

Page 36

paper

①

⑩

②

Roll

⑤

⑩

①

Reference

plane

③

Roll paper

⑥

④

⑤

④

⑥

⑧

3-7

Notch for alignment

③

⑦

⑨

Page 37

3.4 Ribbon

1. Kinds of ribbon

This printer uses a melt in k ribbon.

1) Wax: multipurpose ribbon.

2) Wax resin: multipurpose higher-quality ribbon.

3) Resin: special ribbon with weather resistance. When using resin

ribbon, print speed must be slower an d the printing energy must be

greater.

2. Type of ribbon

Both in-wound and out-wound ribbons can be used.

3. Size of ribbon

Width of ribbon: 25.4 mm-114.3 mm (1 in -4.5 in)

The width of the ribbon is recommended to be the ±10% of the width of the

paper used.

Max. length: 360 m

Max. outer diameter: 70 mm

Paper core inner diameter: 25.4 mm (1 in) ±0.4 mm

With a single roll of the ribbon (360 m), about two rolls of the paper w ith outer

diameter of 203 mm (8 in) can be used for printing.

3-8

Page 38

3.5 Ribbon Setting

bbo

r

CAUTION Be careful of the edges of the pl ates so injury or

property damage does not occur.

After opening the cover, install the ribbon as follows:

1 Push down the open lever ① to lift the print head up.

2 Insert the ribbon in the ribbon shaft ⑪ until it is in its deepest position. Then

set the ribbon holder as shown in the figure.

3 Insert the ribbon shaft ⑫ in the paper core ⑬ until it is in its deepest position.

Then set the ribbon winder as shown in the figure.

4 Adhere the top end of the ribbon to the paper core with adhesive tape. Turn

the ribbon winder in the direction of ribbon winding to remove slackness and

wrinkles from the ribbon.

5 Press down the ribbon bearing flat ⑩ to close the printer mechanism.

Press it until it clicks.

6 Cl ose the prin ter cover.

7 Turn on the power to the printer. The LCD screen on the control panel will

display "On line." Press the Feed key. The paper will advance to the next

label and stop there.

⑫

Direction of ribbon winding

①

⑪

Ribbon

⑬

Print head opened

Roll pape

Ri

n

Completion of setting paper and ribbon

Thermal transfer frame

3-9

Page 39

3.6 Head Offset Adjustments

CAUTION Ensure the print head offset adjustments are made

properly according to the type of print media (thickness &

width). Incorrect adjustm e nts can cause failure of the

print head.

The printer has already been factory-set to the proper print quality when using

the recommended label paper. If the print quality is inferior because of the

paper, adjust it according to the following:

1 For standard label paper and thermal paper:

a) Look through the offset verification window . Set it to the center lin e

(middle of three lin es) by turning the offset adjustment screw with a

screwdriver.

b) Turn the offset adjustment screw countercl ockw ise two turns.

2 For tag stock:

a) Look through the offset verification window . Set it to the bottom line

position by turning the offset adjustment screw with a screwdriver.

Offset adjustment screw (M3)

Offset verification window

The relationship between the offset adj ustment screw and the print head

heating element is shown below:

a) Print head position for label

Heating element

Offset adjustment screw

Offset verification window

a

b) Print head position for tag

Offset adjustment

screw

Offset verification window

3-10

Page 40

Heating element

b

3-11

Page 41

3.7 Head Pressure Adjustments

The printer has already been factory-set with the label width of 118 mm. When

usin g paper with a different width, adjust the head pressure in the following way:

a) Look through the verification window on the upper frame, adjust the mark to

the value in mm that represents the width of the label by turning the head

pressure adjustment screw.

b) Make further adjustments after sampling the prin t image.

(1) When the print on the right side is too light:

Turn the head pressu re adjustment screw clockwise to move the mark

(white) to the right.

(2) When the p rint on the left side is too light:

Turn the head pressu re adjustment screw counterclockwise to move the

mark (white) to the left.

These adjustments are u seful for preventing ribbon wrinkle and paper sk ewing.

For more details, consul t our service person nel.

Verification Paper width

25.4 mm

(1 inch)

50.8 mm

(2 inch)

76.2 mm

(3 inch)

Upper f r am e

window

Head

pressure

adjustment

screw

Note: These v al ues are jus t f or cr it er ia.

101.6 mm

(4 inch)

Used for adjustment

wh en ribbon wr in kles or

skews w it h paper width

of 4 inches

Factory sett in g

3-12

Page 42

3.8 Ribbon Tension Adjustments

When the ribbon slips or wrinkles during printing, adjust the ribbon tension. The

printer h as already been factory set with the ribbon width of 114 mm. When using

ribbon with a different width, adjust it according to the following procedure:

a) Hold th e ribbon roll with one hand so that it does not turn.

b) Slightly push the knob toward the ribbon roll with the other hand an d rotate the

knob until the stopper comes to the desired position.

c) Gradually release the knob so that the stopper fits in the groove on the knob.

Set values to each ribbon width :

Ribbon width

Adjustment when r ibbon slips 5 5 Mild

25.4 mm (1 in) 4 4

50.8 mm (2 in) 3 3

76.2 mm (3 in) 2 2

101.6 mm (4 in): f actory sett ing 1 1 Strong

Ribbon winding

section

Ribbon feed

section

Tension

d) After printing, che ck for ribbon wrinkle or slipping. If it occurs, adjust it further

according to the following procedure:

(1) When the ribbon wrinkles, the ten sion on th e ribbon winding section

shoul d be increased.

(2) When the ribbon slips, the tension on the ribbon feed section should be

decreased. If the problem is not resolved even when the tension on

the ribbon feed section is set to 3, the tension on the ribbon w inding

section should be in creased.

If ribbon problems are not resolved, consult our service person nel.

Variable knob

Ribbon feed section

Ribbon winding section

Mild

Strong

Strong

Mild

3-13

Page 43

3.9 Adjustable Sensor

3.9. 1 Exteri or view and part names

Adjust-knob

192.4

Mark (Yellow) Guide rail upper

37.7 70.6

Exterior view and part names

3-14

Page 44

3.9. 2 How t o operat e adjustable sensor

(1) Move the adj ustable sensor unit to your required position by turning the

adjust-knob. First measure the position to detect, then align the mark of the

measure on the guide rail upper with the sensor position mark (yellow) on the

upper sensor to set to the position to detect.

The sensor movable range is sh own below.

(2) Load the liner and close the guide rail upper and set voltage to 3V.

For voltage setting, see the chapter on Control Panel.

Left- side edge of paper

0 mm

118 m m ( m ax. width of paper )

59 mm (s ensor movabl e r ange)

Sensor movable range

3-15

Page 45

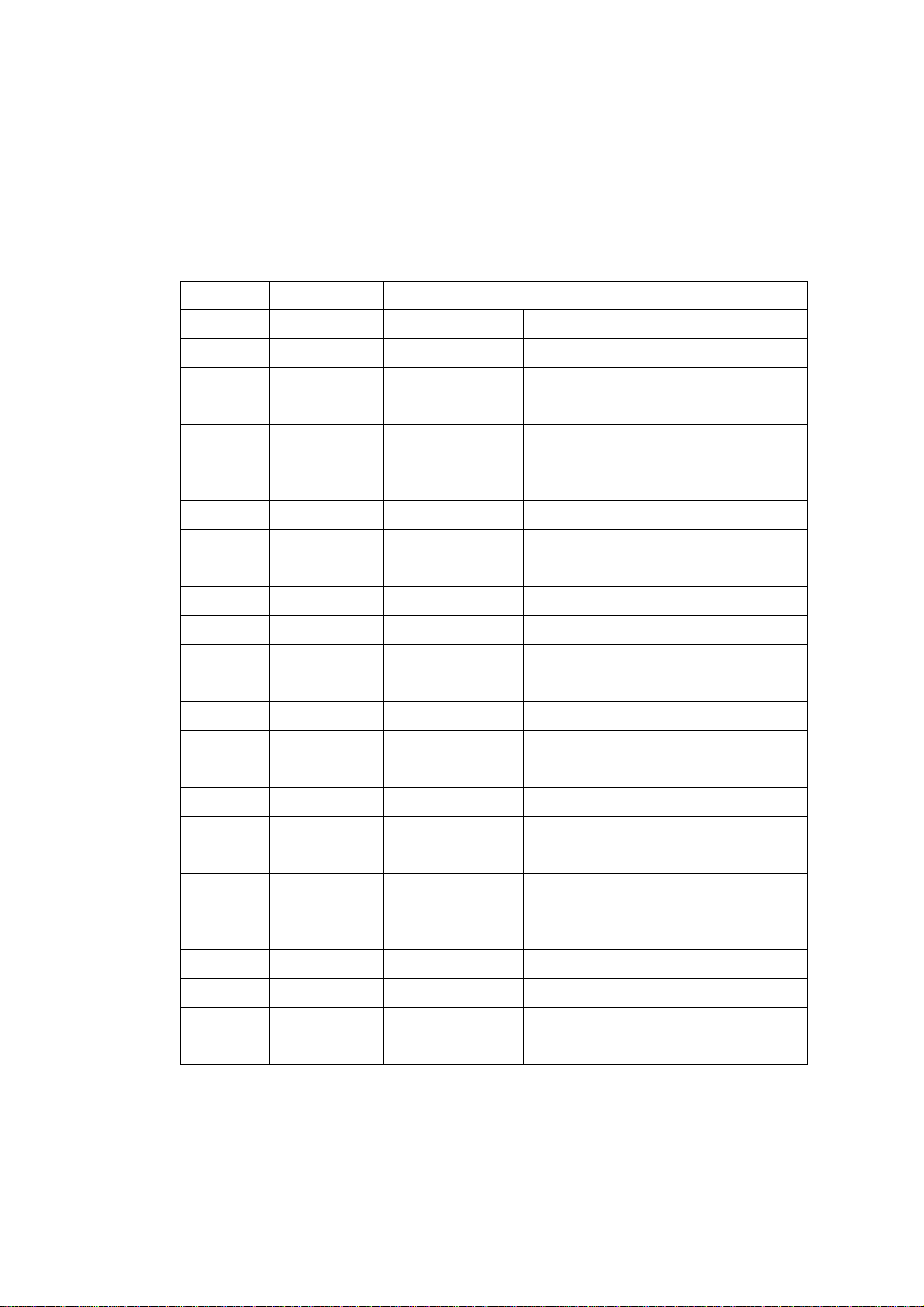

3.9. 3 Specification o f paper (for adjustable sensor)

Minimum value mm (in) Ma ximum value mm (in)

A Label width 25.40 (1.0) 118.00 (4.65)

B Liner width 25.40 (1.0) 118.00 (4.65)

C Label left-side edge position 0 2.54 (0.10)

D Label paper-gap length 2.54 (0.10) 2539.00 (99.96)

E Label length 12.70 (0.50) 2539.00 (99.96)

F Label pitch 12.70 (0.50) 2539.00 (99.96)

G Liner thickness 0.06 (0.0025) 0.125 (0.0049)

H Paper thickness 0.06 (0.0025) 0.25 (0.01)

I Notch right-side edge position 3.6 (0.14) 60.8 (2.39)

J Notch left-side edge position 0 57.2 (2.25)

K Notch length 2.54 (0.10) 17.80 (0.70)

L Black line right-side edge position 15.00 (0. 59) 66.5 (2.62)

M Black line left-side edge position 0 51.5 (2.02)

N Black line width 3.18 (0.125) 17.80 (0.70)

Note: · I f paper has both label paper-gap and black-line, choose the paper-gap sensor.

· Fanfold uses the paper-gap sensor.

Size of paper

C

H

G

F D E

Label Continuous paper

B

Notch detection Black-line detection

A

I

L

M

I

J

K K

N

Black-lin e (back)

OD value: 1.5 or

more

Ink containing

carbon

Printing

area

Printing ar ea

Use of paper-gap sensor Use of paper-gap sensor Use of black-line sensor

Direction of paper feed

2.5mm 104.0mm (11.5mm)

Left-side

margin

Printing area Right-side

margin

3-16

Page 46

3.10 Cleaning

Wipe off any foreign matter such as dust, ribbon residue, and adhesive substance

stuck to the thermal head, ribbon guide roller, and platen with a soft cloth soaked

in ethyl alcohol. Periodic cleaning of the thermal print head is essential to

guarantee quality printing and extended print head life.

Do not use solvent such as benzene and thinner that will dissol ve the plastic.

Ribbon guide roller

Ribbon guide roller

Thermal head

Platen roller

3-17

Page 47

Chapter 4

Troubleshooting

4.1 Error Messages 4-2

4.1.1 Error descriptions and indications 4-2

4.1.2 Error indications and corrective actions 4-4

4.2 Power Troubleshooting 4-7

4.3 Paper Feed Troubleshooting 4-8

4.4 Ribbon Feed Troubleshooting 4-9

4.5 Print Troubleshooting 4-10

4.6 Interface Troubleshooting 4-11

4-1

Page 48

4.1 Error Messages

When there is a problem with the printer:

- A buzzer sounds

- Th e error indicator lights up

- An error message is displayed on the LCD screen

Error descriptions and corrective actions are shown below.

4.1. 1 Error descript ions an d indicati ons

Description Indication LED Buzzer

Batter y dead ( f or c lock and backup RAM) Battery Lights Sound s long

Low head temperature ColdHead Lights Sounds long

Low PCB temperature Cold PCB Lights So unds l ong

Abnormal head resistance value

Error contents and head information

repeatedly displayed

Rank: Rank of head resistance value

Average: Average of resistance values

(A/D reading value decimal

system)

Maximum: Max. value of r esistance

Minimum: Min. value of resistance

Communicat ion error (receive buffer overrun) OverFlow Lights Sound s long

Communicat ion error ( par ity, f r aming) S/I Err Lights Sound s long

Communicat ion error (transmit buffer overflow) HostBusy

Pause key pressed Pause - - - -

Pause comma nd r eception ( re m ot e cont ro l ) Pause - - - -

Head overheat OverHeat

Stop key pressed Stop - - Sounds short

St op comm and re cept ion (r emo te control ) Cancel - - - -

Mechanism head open HeadOpen Lights Sounds short

Paper end (no paper left) PaperEnd Lights Sounds short

Head Err

Rank ***

Ave.***

Max.***

Min. ***

T .D.Full

Cooling

Lights Sound s long

Blinks Sounds short

3 times

Blinks Sounds short

3 times

3 times

3 times

3 times

4-2

Page 49

Description Indication LED Buzzer

Paper out (paper position can't be detected)

Error contents and sensor inf or mation

repeatedly displayed

M command: Sets length for detection

miss checking with system

comma nd M

M a ximum: Max. val ue of senso r

reading volt age

M i nimum: Min. va l ue of s ensor

reading volt age

Ribbon end RibonOut Lights Sounds short

PCB overheat

(PCB or sensor abnormality)

Fan stop Fan stop Blinks Sounds short

Option board abnormality OP Err Light s Sounds shor t

Auto-cutter abnormality (such as poor

engagement)

ROM checksum error ROM Err Lights S ounds lo ng

RAM check error RAM Err Ligh ts Sounds lo ng

PaperErr

M CMND

Max*.**V

Min*. **V

OverHeat Ligh ts Sounds short

Cut Err Lights Sounds short

Lights Sounds short

3 times

3 times

3 times

3 times

3 times

3 times

4-3

Page 50

4.1. 2 Error indications and corrective actions

Indication Description Corrective actions

Battery Batter y dead Automatically returned after displaying the error

for a certain time.

Change the lithium battery (CR2032).

Note: Contact our service personnel to replace

the battery.

If the battery runs down, the r ea ltime clock will

sto p a nd t he co nte nts o f the memor y s witch w ill

be lost.

ColdHead Low head temperature Automatically returned after displaying the error

for a certain time.

Raise the temperature around t he printer.

Print density becomes low and print quality

becomes inferior w hen the head temperature

is low.

Cold PCB Low PCB temperature Automatically returned after displaying the error

for a certain time.

Raise the temperature around t he printer.

Print density becomes low and print quality

becomes inferior w hen the head temperature

is low.

Head Err Abnor mal head

resistance value

OverFlow Communication error

(receive buffer

overrun)

S/I Err Communicat ion error

(parity, f r aming)

HostBusy

T .D.Full

Pause Pause key pr ess ed Press t he Pause key once again to resume

Communicat ion error

(transmit buffer

overflow)

Check the contents and clear with the St op k ey.

Replace the print head.

Print quality is affect ed at the section where the

head resistance value is abnormal.

Check the contents and clear with the St op k ey.

Correct the communication control system or

communication cable failure.

Check the contents and clear with the St op k ey.

Correct the communication parameter or

communication cable failure.

Automatically returned if the computer receives

data and the buf fer becomes empty.

printing.

If t he Stop key is pressed, t he stored pr inting

content s will be los t and "on line" will t urn on.

Pause Pa use com m and

reception

(communication

control)

Same as above.

4-4

Page 51

Indication Description Corrective actions

OverHeat

Cooling

Stop Stop key pressed Enters a pause after displaying the stop by the

Cancel Stop command

HeadOpen Mechanism head

PaperEnd Paper end (no paper

PaperErr Paper out (paper

Head overheat Wait unt il the head temperature goes down.

When the temperature becomes low, the

remaining print ing r e s umes.

Stop key.

If the Pause key is p r e s s e d, the pr int ing w ill

resume.

If t he Stop key is pressed again, the stored

printing c ont e nts will be los t and "on line" will

turn on.

Displays the stop by the stop command,

reception

(communication

control)

open

left)

position can' t be

detected)

discards the stored pr inting contents, and

enters a pause.

If the Pause key is p r e s s e d, "on line" will turn

on.

Close the mechanism head.

Install the paper.

Check the contents and clear with the St op

key.

Correct the faulty setting of the paper detection

(paper gap, black line, continuous paper).

Correct the faulty parameter f or paper ( max.

le ngt h, continuous paper) .

Adjust the sensor or change for t he paper that

accepts t he paper position detection.

Specify the length for det ect ion miss checking

with the M command.

When the paper position c an't be det ect ed

during paper f eeding by the specified length, it

is judged error. G enerally specify the length

about three times the label length.

In case of the continuous paper, specify the

label lengt h with the C command.

Difference betw een the maximum and

minimum values of the sensor reading voltage

must be 0.8 V or more.

Sensor adjust ments and paper characteristic

verification (voltage verification) can be

performed with the Maintenance mode.

4-5

Page 52

Indication Description Correc tive act ions

RibonOut Ribbon end Check the contents and clear with the St op

key.

Install the ribbon.

Check that the ribbon winds fully.

Correct the faulty setting of the print mode

(direct-thermal or thermal-transfer).

OverHeat PCB overheat Turn off the power and reset the printer. If

this recurs, contact our service personnel.

Fan stop Fan stop Check for the fan stop caused by the problems

such as foreign matter entered in the air vent.

Automatically returned if the fan turns again.

If disassembling is needed t o r emove foreign

matter or t he problem can't be identified,

contact our service personnel.

OP Err Option board

abnormal ity

Cut Err Auto-cutter

abnormality (such as

poor engagement )

ROM Err ROM checksum error Turn off the power and reset the print er. If

RAM Err RAM checksum error Turn off the power and reset the print er. If

- - System error (such as

timer or CPU

malfunction)

Turn off the power and reset the printer. If

this recurs, contact our service personnel.

Check the contents and clear with the St op

key.

If t his can't be cleared, t urn off the power and

remove foreign matter from the auto-cutter.

If this recurs, contact our service personnel.

this recurs, contact our service personnel.

this recurs, contact our service personnel.

First protect t he system, then reset t he printer.

4-6

Page 53

4.2 Power Troubleshooting

Problem Cause and remedy

No power even

with power switch

turned ON.

• Power cord is not

properly connected to the

outlet.

• Power cord is not

properly connected to the

power inlet.

• I nput voltage is not

correct ; input voltage is

greater or less t han the

rated voltage.

• Corr ec t RS-232C cable is

not us ed.

® Turn off t he power switch and

properly reconnect the power

cord to the outlet.

® Turn off t he power switch and

properly reconnect the power

cord to the power inlet.

® Set input voltage within the rated

voltage (punct ure voltage may

occur. Contact our service

personnel).

® Turn off t he power switch and

unplug the int er f ace c able.

Check that power is pr ovided by

turning on the power swit ch and

then use the correct RS-232C

cable.

4-7

Page 54

4. 3 Paper Feed Troubleshooting

Problem Cause and remedy

Paper doesn't

feed.

Paper skew. ・ Paper end is not in

Paper doesn't

align w ith the print

position.

・ Wr ong paper path.

・ M echanism head is open.

contact with the paper

guide.

・ Roll g uide is not in

contact with the roll

paper.

・ Head pressure is not

correct.

・ Set t ing mode is not

correct.

・ Paper gap ( black line)

sensor adjustment failure.

・ Transfer data is abnormal.

® Use correct pat h.

® Close the mechanism head.

® Slightly push the paper guide

against the paper end.

® Slig htly p ush the r o ll guide

against the roll paper.

® Adjust it with the offset adjustment

screw accor ding to the paper

width.

® Check whether the setting mode

is for paper gap or black line

sensor and if it is not, change it as

necessary.

® Adjust the voltage of t he paper

gap and black line sensor f r om

the voltage sett ing in the system

maint enance mode.

® If the contents of the transfer data

are incorrect, set them pr oper ly

again.

4-8

Page 55

4. 4 Ribbon Feed Troubleshooting

Problem Cause and remedy

Ribbon doesn't

wind.

Ribbon wrinkles. ・ Tension of ribbon holder

・ Print mode is set to

direct-thermal printing.

・ Wr ong ribbon path.

・ Ribbon wind direction is

reversed.

・ Ribbon wind tens ion is

not correct.

and ribbon winder is not

correct.

・ Print density (heating

factor) is not correct.

・ Angle of ribbon guide bar

is not correct.

・ Ribbon and paper are not

proper.

® Change to the thermal-transfer

printing.

® Use correct pat h.

® Set it pr oper ly.

® Set it pr oper ly.

® Set it pr oper ly.

® Correct the parameter of the Hnn

command with the printing

contents definition mode.

® Contact our service personnel to

adjust the ribbon guide bar.

® Contact our service personnel.

Note: I f narrow paper is used, the ribbon may wrinkle. Decrease

the right-side head pressure by turning t he offs et adjustment screw t o

prevent the ribbon from wrinkling.

4-9

Page 56

4.5 Print Troubleshooting

Problem Cause and remedy

Printing doesn't

start.

Missing lines. ・ Pr int head connector

Dropouts. ・ Print head is dirty.

・ Power to the printer is off.

・ Printer is not properly

connected to computer.

・ Printer setting is not

correct.

connect ion failure.

・ Platen is dirty.

® Turn the power switch to ON.

If p o wer s till doesn't turn on,

follo w ste p s in Section 4.2

Power Troubleshoot ing.

® Turn the power switch to OFF and

connect it properly.

® Correct the printer setting.

® If the print head connector is not

properly connected, insert it

correctly.

® Check the print head

heat-generation body for dirt. I f

it's dirt y, wipe t he surface of t he

print head heat- generation body

with a soft cloth soaked in

ethylalcohol et c.

® Remove dirt or label or tape

scraps st uck to t he platen.

Note: If t hose can't be removed,

contact our service personnel for

maintenance.

Print is too light o r

dark.

Other printing

abnormal ities

・ I nk ribbon and paper are

not the recommended

type.

・ Paper quality doesn't

match the print head

offset.

・ Paper width doesn' t

match the print head

pressure.

・ Printer set up mode is not

correct.

・ Set t ing of printing energy

level is not c o r rect .

・ Check the error message on the control panel and correct it

according to the descriptions on Sect ion 2) Error s and corr ect ive

actions, 4.1 Err or M essages.

® Change to the recommended

type after checking the ink

ribbon and paper maker and

identification number.

® Adjust the offset. See Section

3.6 Print Head Offset

Adjustments.

® Adjust the print head pressure.

See Section 3.7 Print Head

Pressure A dj ustme nts.

® Check whether the setting mode

is for direct-thermal or

thermal-transfer printing and if it is

not, change it as necessary.

® Check the setting value of printing

energy level and adjust it as

necessary.

4-10

Page 57

4-11

Page 58

4.6 Interface Troubleshooting

Problem Cause and remedy

Printer doesn't

print.

Print disordered.

Error message is

displayed and

printer doesn't

print.

The following are the probable causes:

・ I nterf ac e cable is not

properly connected.

・ I nterf ac e cable is not the

standard type.

・ Communication

parameter set t ing is not

correct.

® Check that the interface cable

® Replace it.

® Set t he system maintenance

is connect ed pr oper ly.

mode from the control panel and

check/correct the communication

parameter value.

4-12

Page 59

4-13

Page 60

Chapter 5

Options

Factory or Reseller (Deale r) Option s:

5.1 Auto-Cutter Unit 5-2

5.2 Peeler Unit 5-2

User Options:

5.3 PCMCIA Memory Card 5-3

5-1

Page 61

5.1 Auto-Cutter Unit

The cutter mechanism is a rotary cu tter designed to handle paper, labels, ticket and

tag stock. It has an extremel y durable mechan ism designed for in excess of

1,000,000 cuts. See the Cutter User’s Manual for details.

n Specifications

・ Cutting method: Rotary cutter

・ Max. thickness of cut paper: 0.01 in (0.254 mm)

・ Min. length of cut paper: 1 in (25.4 mm)

5.2 Peeler Unit

The peeler unit is designed to automatically strip the label from the liner. See th e

Peeler User’s Manual for details.

n Specifications

・ Width of paper: 1-4.65 in (25.4-118 mm)

・ Max. diameter for roll paper: 8 in (203 mm)

・ Inner diameter for roll paper: 3 in (76 mm) or more

・ Min. length of label: 1 in (25.4 mm)

・ Thickness of paper: 0.0067 in (0.17 mm), max .

・ Thickness of liner: 0.0027 in (0.07 mm), max.

・ Unusable paper: Special paper (Whitepet, etc.) or too

flexible paper causing jams

5-2

Page 62

5.3 PCMCIA Memory Card

The PCMCIA memory card is used to:

1 Store print format files. Data in the field register area can be stored and

loaded.

2 Store graphic data. For example, graphic data such as a corporate logo can

be stored and recalled from the PCMCIA memory card an d printed.

3 Store downloaded HP Soft fon ts.

n Installation

1 Turn off the power to the printer.

2 Remove the PCMCIA memory card cover at the bottom of the printer (see

figu re).

3 Insert the memory card (make sure the card is not inverted).

4 Repl ace the PCMCIA memory card cover.

Notes: ・ Before use, carefully read and understand the instructions

・ Never try to in se r t or remove the PCMCIA m e mory card before the

・ Always close the PCMCIA memory card cover to keep out dirt.

・ If the PCMCIA me mory card write failu re occurs, check it w ith the

Note description facing up

regarding the PCMCIA memory card.

power to the printer is turn e d off.

test command (STX.w).

5-3

Page 63

5-4

Page 64

Chapter 6

Specifications

6.1 Main Specifications 6-2

6.2 Interface 6-6

6.2.1 System configuration 6-6

6.2.2 Specification of interface 6-7

6.2.3 RS-232C loopback test 6-8

6.2.4 RS-232C protocol 6-9

6.2.5 Interface pin assignment 6-11

6.3 Outline of Command System 6-13

6.4 Example of Connection to a Computer 6-14

6.5 Tear-Off Function 6-15

6.5.1 Turning Tear ON/OFF 6-15

6.5.2 Tear-off when printing 6-15

6.5.3 Tear-off when feeding 6-16

6.5.4 Tear-off and type of data 6-17

6.5.5 Cut position adju stments 6-17

6.5.6 When "fnnn" command is

executed while Tear is OFF 6-18

6.5.7 Priority 6-18

6-1

Page 65

6.1 Main Specifications

Item Description

Printing ・ Direct - t hermal or thermal-transfer pr inting

・ 400 dpi (16 dot s / mm) print head

(Main scanning line density: 15.75 dots/ mm)

( Subscanning l ine density: 16 l ines/ m m )

・ M ax. print widt h: 4.2 in (105.7 mm)

・ M ax. paper width: 4.65 in (118 mm)

・ Max. print length: 10 in (254 mm)

Print speed ・ 2, 3, and 4 inches/ sec onds

Print mode ・ Batch mode: Perfor ms normal printing (single or multi sheets)

・ Peel mode: Print s and peels label from liner

・ Cut mode: Prints and cuts by the specified number of sheets

(label back-feed enabled)

・ Tear-off mode: Presents paper to t ear - bar and feeds back t o t he

print starting position

Bar code generator One-dimensional bar code:

・ Code 3 of 9 ・ POSTNET

・ Interleaved 2 of 5 ・ UCC/EAN128

・ UCC/EAN ・ Telepen

・ Code 128 ・ EAN-13 (JAN-13)

・ Codabar (NW-7) ・ HIBC (Modulus 43- used code 3 of 5)

・ EAN-8 (JAN-8) ・ Int 2 of 5 ( M odulus 10-used Inter

・ UPC-A ・ UPC-E

・ Plessey ・ CASE CODE

・ Code 93 ・ UPC2DIG ADD

・ UPC5DIG ADD

Two-dimensional bar code:

・ UPS Maxi Code ・ PDF-417

leaved 2 of 5)

6-2

Page 66

Item Description

Standard fonts ・ Font No. 0-6 ( f ixed pitch, alphanumeric)

・ Font No. 7-8: OCR-A, OCR-B

・ Font No. 9: CG Triumvirate smooth font; 3 pt, 4 pt, 5 pt, 6 pt, 8 pt,

10 pt, 12 pt , 14 pt, 18 pt , 24 pt , 30 pt, 36 pt , and 48 pt

Character set is in accordance with code page 850

Media sensors ・ Transparent type sensor:

Detects paper gap bet ween labels, tag notch and paper end

・ Reflective type sensor:

Detects black line on back of paper and paper end

・ Position of top edge of paper ( paper home-position) adjus t able w ith

software

・ Ribbon end sensor:

Detects r ibbon absence or end (holder revolution)

・ Label peeling sensor ( optional)

Paper ・ Type of paper: Roll, fanfold

(continuous, die-cut, fanfold, tag or ticket)

・ Kinds of paper: Direct-t hermal paper, thermal-transfer paper

・ M ax. paper width: 4.65 in (118 mm)

・ M in. paper w idth: 1 in (25.4 mm)

・ M in. label width: 0.3 in (7.62 mm)

・ Min. print length: 0.1 in (2.54 mm)

・ M ax. paper t hickness: 0.01 in (0.254 mm)

・ M in. paper thickness: 0.0025 in (0.063 mm)

・ Roll paper diam.: max. outer diam.: 8 in (203 mm)

paper core: 1.5-3 in (38-76 mm)

・ Print density adjustable with softwar e

Ribbon ・ Width: 1-4.5 in (25.4-114 mm) adjust able

・ Length: 1181 feet (360 m), max.

・ M ax. outer diam.: 2.75 in ( 70 mm)

・ Paper c or e inner diam.: 1 in (25.4 mm) ± 0.01 in (0.254 mm)

6-3

Page 67

Item Description

Communication

interface

Indications, keys and

switches

Options By factor y or dealer ( r eseller) :

Appearance and

weight

・ RS-232C (standard)

・ Centronics (standard)

・ LEDs: Power and error

・ LCD: Displays printer status, error contents,

mode switch cont ents, etc

・ Control panel keys: Pause, Feed and Stop

・ M ode switch: For par ameter setting for switc hing

bet w een direct- t hermal and thermal transfer, communication, etc.

・ Head up detection switch

・ Power switch

・ Auto-cutter unit ・ Peeler unit ・ Adjustable sensor unit

By user:

・ PCMCIA memory card

・ Height: 10.2 in (260 mm)

・ Widt h: 10.2 in ( 260 mm)

・ Depth: 16. 9 in (430 mm)

・ Weight: 24.2 lbs (11.0 kg)

Power ・ I nput voltage 120V: -10%+6%, 2. 5A, 60 Hz (U. S. A. , Canada)

・ I nput voltage 220V-240V: -10%+ 6% , 1.2A, 50/60 Hz (Europe)

Standards 120V: UL1950 CSA: No. 950 FCC: Class A

220V-240V: EN60950, EN55022 Class A, EN61000-3-2, EN61000-3-3,

EN55024

6-4

Page 68

Item Description

Env ironm en t ・ Operating conditions:

Temperature: 5-35°C (4 1-95°F)

Humidity: 30-80% (noncondensing)

・ Storage:

Temperature: -20-60°C (-4-140°F)

Humidity: 5-85%

・ Ventilation:

Convect ive circulation. Air vent must be away from wall etc

(to pr event fire)

・ Dust:

Free from conductive or corrosive matter

6-5

Page 69

6.2 Interface

6.2.1 System configuration

The printer is connected to a computer and prints labels according to the

command from the computer.

Two methods of interface with a computer are as follows:

(1) Serial interface: RS-232C (standard)

(2) Parallel interface: Centronics (standard)

Computer

RS-232C interface

RS-232C interface

Printer

Computer

Ce ntroni cs i nte rface

Ce ntroni cs i nte rface

Printer

6-6

Page 70

6.2. 2 Specification of int erface

(1) Serial interface

Method Asynchronous serial interface

RS-232C

Connector DSUB 25-pin

Protocol control XON/XO FF and CTS/ DTR

Receive buf fer

size

Baud rate 300, 600, 1200, 2400, 4800, 9600, 19200, 38400 bps

Bit length 7- or 8- bit

Stop bit Fixed

Parity No

32K bytes

Receiving data stops when the r emaining buffer r eac hes 2K

bytes and resumes when the remaining buf f er r eac hes 4K bytes

When pr inter r eceives data, stop bit is fixed at 1, and when

printer transmits data, s t op bit is fixed at 2. But computer can

transmit and receive data, regardless of s t op bit at 1 or 2

(2) Parallel interface

Method 8- bit par allel

Connector 36 -pin unphenol ty pe

Synchronous

system

Handshaking ACKNLG and BUSY signals

Signal level TTL

Strobe pulse

6-7

Page 71

6.2.3 RS-232C loopback test

After connector wiring as shown in the figure, th e te st m ode is tu rne d on.

The printer will receive data that h as been transmitted by printer itself and the

test of receiving and transmitting data will be performed.

RS-232C test

Fig. Loopback test

6-8

Page 72

6.2.4 RS-232C protocol

(1) X-ON/X-OFF system (see the figure)

This is a control system in which the da t a transmission request

signal (X-ON (11H) code) and the data transmission stop request

signal (X-OFF (13H) code) are output.

Requirements of output of X-ON code:

・ When the power is switched to ON.

・ When the remaining buffer is 2K bytes or less, the X-OFF is

output, an d the remaining buffer is 4K bytes or more.

Requiremen ts of output of X-OFF code:

・ When printer error occurs.

・ When the remaining buffer is 2K bytes or less.

Receive buffer size = 32K bytes

4K bytes

Receiving data

2K bytes

X-ON code output

X-OFF code output

Note: Even if each code is ready for output, the same code cannot be

transmitted twice successively (except wh en the power is turned on

or the printer is reset from the contr ol pa nel).

Fig. Buffer in use

6-9

Page 73

(2) Ready/Busy system (se e the figure )

This is a control system in which the DTR signal is output at Ready

(High)/Busy(Low) level.

Requirements of DTR "High":

・ When the printer is "on line."

・ When the Receive buffer has at least 2K bytes available.

DTR signal is "Low":

・ When the Receive buffer has less than 2K bytes available.

When this condition is detected, the printer keeps the DTR

signal “Low” until the Receive buffer has at least 4K bytes

available.

・ When a printer alarms occurs (i.e. when the printer is switched

to "off line").

6-10

Page 74

6.2. 5 In t erf ace pin assignment

Serial and parallel interface pin assign ment tables are shown bel ow.

n Serial interface pin assignment table

Pin No. Signal Input/Output Description

1 F.GND - Frame ground

2 TXD Output RS-232C output data

3 RXD Input RS - 2 3 2 C input da ta

4 RTS - RS-2 3 2C (pull up to +5 V with 2 KW]

5 CTS Input RS-232C data t r ansmission on

6 NC - No connection

7 S.GND - Signal ground

8 NC - No connection

9 NC - No connection

computer per mitted

10 NC - No connection

11 NC - No connection

12 NC - No connection

13 S.GND - Signal ground

14 +5VDC - +5 V (max. load 100 mA)

15 NC - No connection

16 NC - No connection

17 NC - No connection

18 NC - No connection

19 NC - No connection

20 DTR Output RS-232C data transmission ( busy) on

printer permitted

21 NC - No connection

22 NC - No connection

23 NC - No connection

24 NC - No connection

25 NC - No connection

6-11

Page 75

n Parallel interface pin assignmen t table

Pin No. Signal Input/Output Description

1 STROBE Input St r obe s ignal for reading 8-bit data

2-9 DATA1-8 Input 8- bit par allel signal

10 ACKNLG O utput 8-bit dat a r equest signal

11 BUSY Output Signal specifying printer busy

12 PERROR Output Signal specif ying paper absence

13 SELECT O utput Signal specifying printer "on line"

(printing) or "off line" (pause)

14 AUTOFD Input Invalidness (ignorance)

15 NC - No use

16 S.GND - Signal ground

17 FGND - Frame ground

18 P.L. H Output Signal specifying peripher al logic high

(pull up to +5V with 2 KW]

19-30 GND - Ground for twisted pair return

31 INIT Input Printer reset

32 FAULT Output Signal specifying print er er r o r

33-35 NC - No use

36 SELECTIN Input Invalidness (ignorance)

6-12

Page 76

6.3 Outline of Command System