Page 1

User’s Manual

CONTROL BOARD FOR LT-286

MODEL

Rev.1.01 Added notes Mar.19th,1999

BD2-2860

Page 2

BD2-2860 User’s Manual

<CAUTIONS>

1. Before using this equipment, be sure to read this User's m anual thoroughly.

Please keep this with care so as to referred to anytime at need.

2. Portions of the contents of this User's manual may be changedwithout prior notice.

3. The reproduction of parts or all of the contents of this User's manual without permission is

strictly forbidden.

4. Absolutelydo not carry out m aintenance, disassembly, or repair of parts that are not

specified in this User's manual.

5. Note that losses which may be attributed to the user's wrong operation method or operating

environment will be outside the responsibility of this company.

6. Do not carry out the operations other than those explained in this User's manual, since doing

do so may become a cause of accidents or breakdowns.

7. Because data is basically transient, long-period and permanent storage of data will not be

possible. Please note in advance that this company will not be responsible in any way for

losses or lost profits caused through the clearing of the data due to breakdowns, repairs,

investigations, etc.

8. If any questionable points, mistakes, omitted explanations, etc. are found in the contents of

thismanual, please contact this company.

9. Please note that notwithstanding the conditions in above 8; this company will not be

responsible for the consequences o f results obtained through operation of this equipment.

2

CITIZEN

Page 3

<CAUTIONS>

BD2-2860 User’s Manual

CONTENT

...................................................................................................................................................... 2

1. OUTLINE

1.1 F

EATURES...............................................................................................................................................................5

RECAUTION...........................................................................................................................................................5

1.2 P

AINTENANCE AND SERVICE................................................................................................................................... 6

1.3 M

2.BASIC SPECIFICATIONS

2.1 M

ODEL CLASSIFICATION..........................................................................................................................................7

ASIC SPECIFICATIONS............................................................................................................................................8

2.2 B

.......................................................................................................................................................... 5

..................................................................................................................... 7

3.CONNECTING CONNECTORS

3.1 CN1 C

3.2 CN2 C

3.3 CN3 C

3.4 CN4 C

4.DIP SWITCH SETTING

5.POWER SUPPLY

5.1 S

5.2 P

6.PARALLEL INTERFACE

ONNECTOR FOR PRINTER MECHANISM (FOR PRINT HEAD)..............................................................................9

ONNECTOR FOR PRINT MECHANISM (FOR MOTOR &SENSOR)......................................................................10

ONNECTOR FOR INTERFACE......................................................................................................................... 11

ONNECTOR FOR PAPER CUTTER ...................................................................................................................12

.........................................................................................................................13

........................................................................................................................................15

PECIFICATIONS ....................................................................................................................................................15

RECAUTIONS.......................................................................................................................................................15

.....................................................................................................................16

......................................................................................................... 9

6.1 S

PECIFICATIONS ....................................................................................................................................................16

XPLANATION OF INPUT /OUTPUT SIGNALS ............................................................................................................ 16

6.2 E

LECTRICAL CHARACTERISTICS .............................................................................................................................17

6.3 E

IMING CHART......................................................................................................................................................18

6.4 T

ATA RECEIVING CONTROL....................................................................................................................................18

6.5 D

UFFERING...........................................................................................................................................................18

6.6 B

7. SERIAL INTERFACE

7.1 S

PECIFICATIONS ....................................................................................................................................................19

XPLANATION OF INPUT /OUTPUT SIGNALS ...........................................................................................................20

7.2 E

ATE CONFIGURATION...........................................................................................................................................21

7.3 D

RROR DETECTION ...............................................................................................................................................22

7.4 E

ATA RECEIVING CONTROL....................................................................................................................................22

7.5 D

UFFERING...........................................................................................................................................................22

7.6 B

LECTRICAL CHARACTERISTICS .............................................................................................................................23

7.7 E

............................................................................................................................19

3

CITIZEN

Page 4

BD2-2860 User’s Manual

8. ERROR HANDLING

8.1 P

ERIPHERAL CIRCUITERRORS ...............................................................................................................................24

PERA TION ERRORS .............................................................................................................................................. 25

8.2 O

RROR INDICATION ...............................................................................................................................................26

8.3 E

9. PRINTER MECHANISM CONTROL SYSTEM

9.1 T

HERMAL HEADCONTROL SYSTEM (DIVISION DRIVING SYSTEM)...........................................................................27

...............................................................................................................................24

..................................................................27

9.1.1 Fixed Division Number System......................................................................................................................27

9.1.2 Variable Division Number System ..................................................................................................................27

OTOR DRIVE ......................................................................................................................................................28

9.2 M

9.2.1 Motor Drive Features....................................................................................................................................28

9.2.2 Maximum Motor Drive Speeds at Major Voltage ............................................................................................28

10. PRINT CONTROL FUNCTIONS

10.1 C

OMMAND LIST..................................................................................................................................................29

OMMAND DETAILS............................................................................................................................................30

10.2 C

.................................................................................................29

10.2.1 Description of Items.....................................................................................................................................30

10.2.2 Details.........................................................................................................................................................31

11. CHARACTER CODE TABLE

11.1 I

NTERNATIONAL..................................................................................................................................................77

APANESE............................................................................................................................................................78

11.2 J

NTERNATIONAL CHARACTER SET........................................................................................................................79

11.3 I

........................................................................................................77

APPENDIX 1. BLOCK DIAGRAM........................................................................................................................80

APPENDIX 2. OUTER DIMENSION.....................................................................................................................81

4

CITIZEN

Page 5

BD2-2860 User’s Manual

1. OUTLINE

This control boards is designed to be used to control our thermal printer, "LT-286" series through the

computer etc.

As being provided with many abundant functions, it can be used widely in various applications.

Before you start using it, read this manual thoroughly and understand the content.

1.1 Features

(1) Ultra compact

(2) Both interface of Serial and Parallel can be selected by dip switch.

(3) Input buffer incorporated.

(4) Bar code printingis available.

(5) Autopaper cutter control incorporated.

(6) User-definedcharacter registration function (94 characters)

1.2 Precaution

(1) Make sure to turn OFF the power supply in case of connecting / disconnecting the connectors.

(2) Absolutely do not make a short circuit between the terminals of connectors.

(3) Use power supply, LED, interface etc. following their specifications.

(4) Use the recommended paper shown below.

• Thermal Paper TF50KS-E2(Nippon-Seishi)

5

CITIZEN

Page 6

BD2-2860 User’s Manual

1.3 Maintenance and Service

For the information on maintenance and service, please contact our dealer or at the following address.

Northern America Other Areas

CBM America Corporation Japan CBM Corporation

Service Center Information Systems Division

365 Van Ness Way Suite 510 5-68-10, Nakano Nakano-ku,

Torrance, CA 90501, U.S.A Tokyo 164-0001 Japan

TEL 310-781-1460 TEL 03-5345-7540

FAX 310-781-9157 FAX 03-5345-7541

6

CITIZEN

Page 7

2. BASIC SPECIFICATIONS

2.1 Model classification

BD2-2860 U

Character Set

U : International model

Model Name of applied printer mechanism

2860: ForLT-286

Model Name

BD2-2860 User’s Manual

7

CITIZEN

Page 8

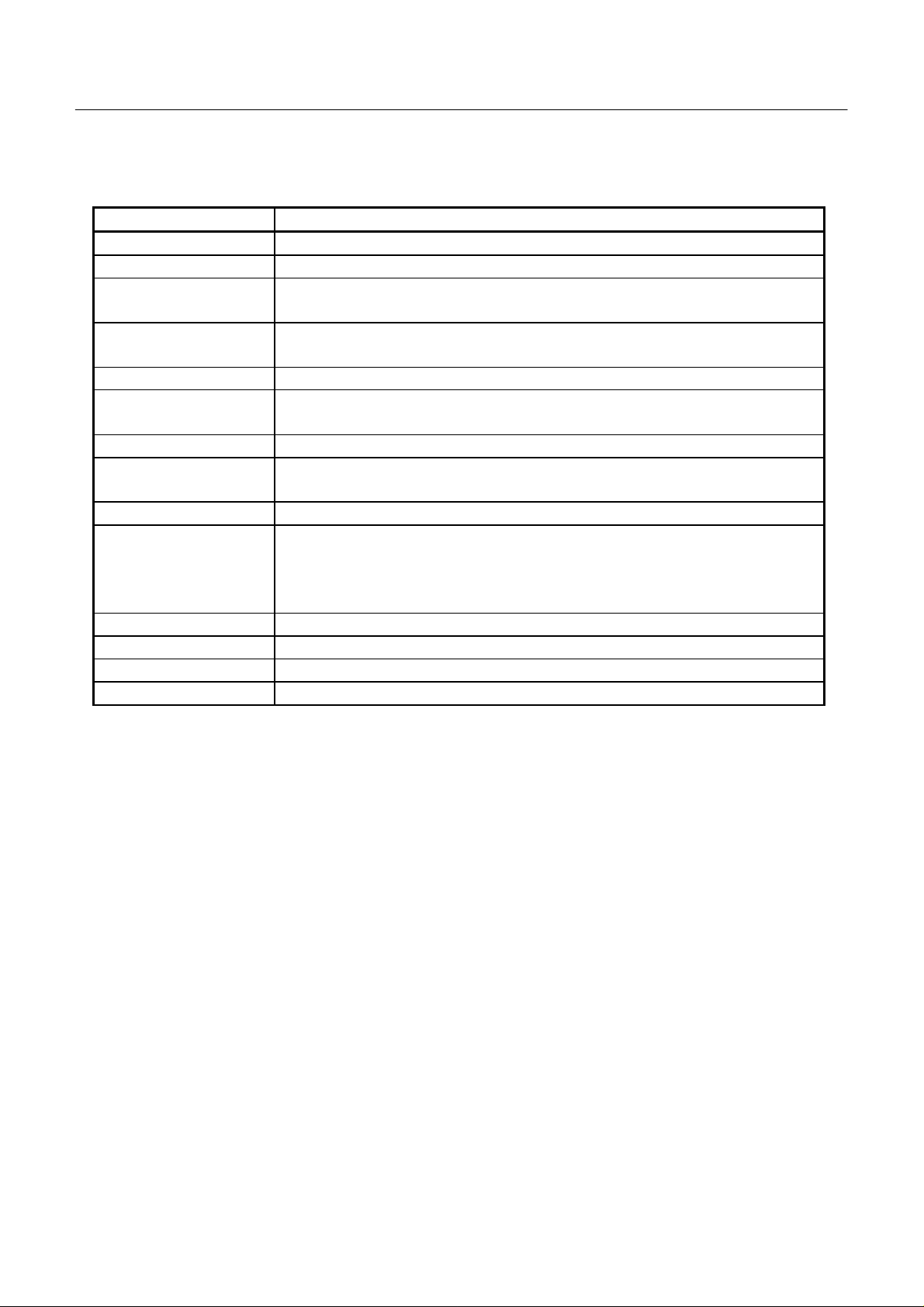

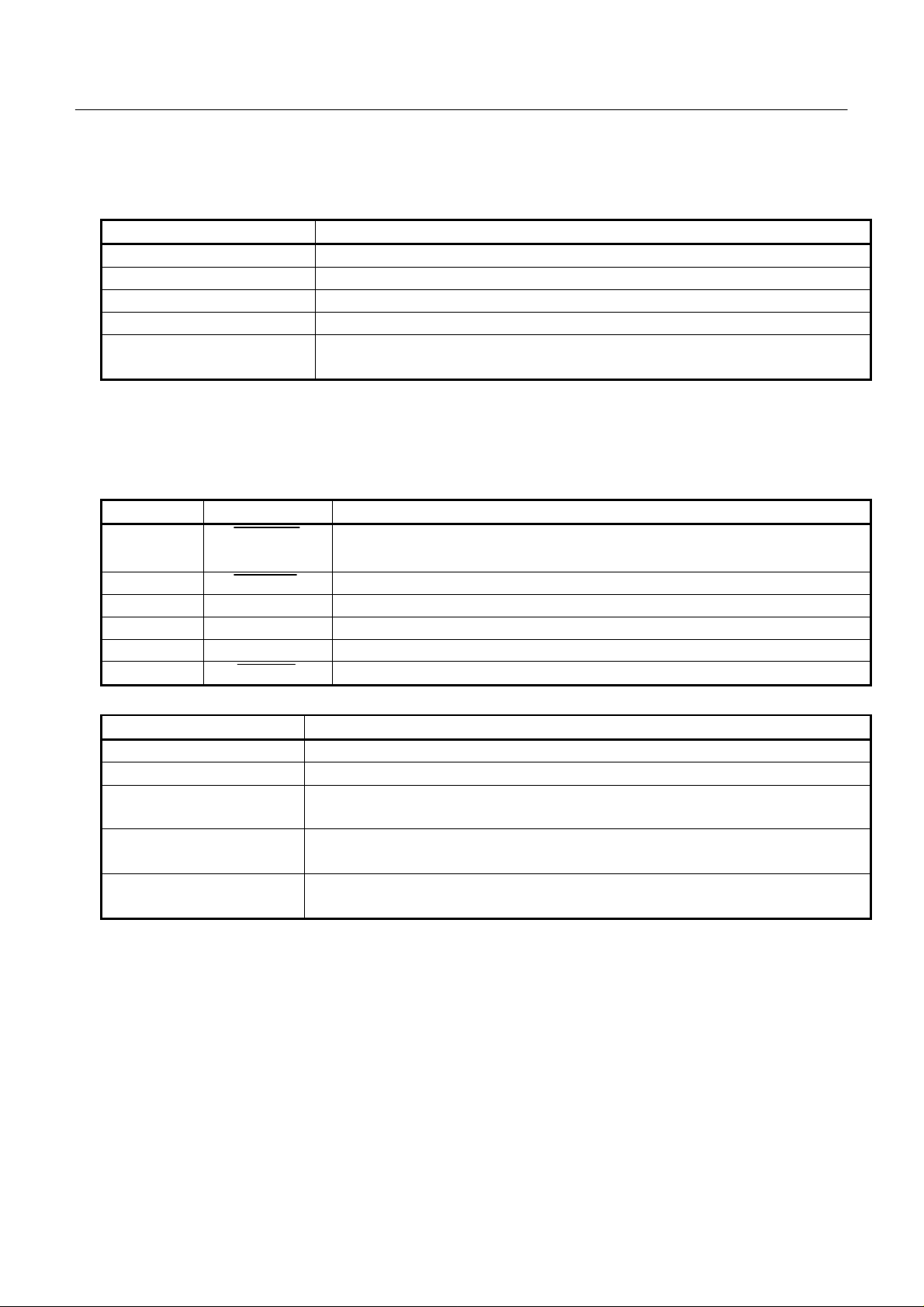

2.2 Basic Specifications

Items Contents

Print width 48 mm

Print Speed 400 dot line / sec (When 7.2V)

Number of columns Font A : 32 columns

Font B : 42 columns

Character dimensions Font A : 1.25 mmx 3.00 mm (10 + 2 dots space x 24 dots)

Font B : 0.88 mm x 2.13 mm( 7 + 2 dots space x 24 dots)

Character types Alphanumeric, international characters

Bar code type UPC-A/E, JAN (EAN) 13 / 8 columns, ITF

CODE 39, CODE 128, CODABAR

Linepitch 4.23 mm(Canbe changed by command)

Interface Parallel (Conforms to Centronics) or Serial (Conforms to RS-232C)

(Selectable by dip switch)

Input buffer 2 K bytes

Supply voltage 5V ± 5 % Approx. 180mA

4.2V ~ 8.5V Approx. 1.3A(Ave) Approx. 4.0A(Peak) When 7.2V

Ordinal voltageis to be 7.2V(Max)

8.5V is a voltage, which is right after charging.

Operating Environment 0 ~ 40°C (Print guaranteed at 5 ~ 40°C)

Storage Environment -20 ~ 60°C

Outer Dimension 75mm(W) x 80mm (D) (For height of component parts, see outer drawing.)

Weight Approx. 50 g

BD2-2860 User’s Manual

8

CITIZEN

Page 9

3. CONNECTING CONNECTORS

3.1 CN1 Connector forPrinter Mechanism (For Print Head)

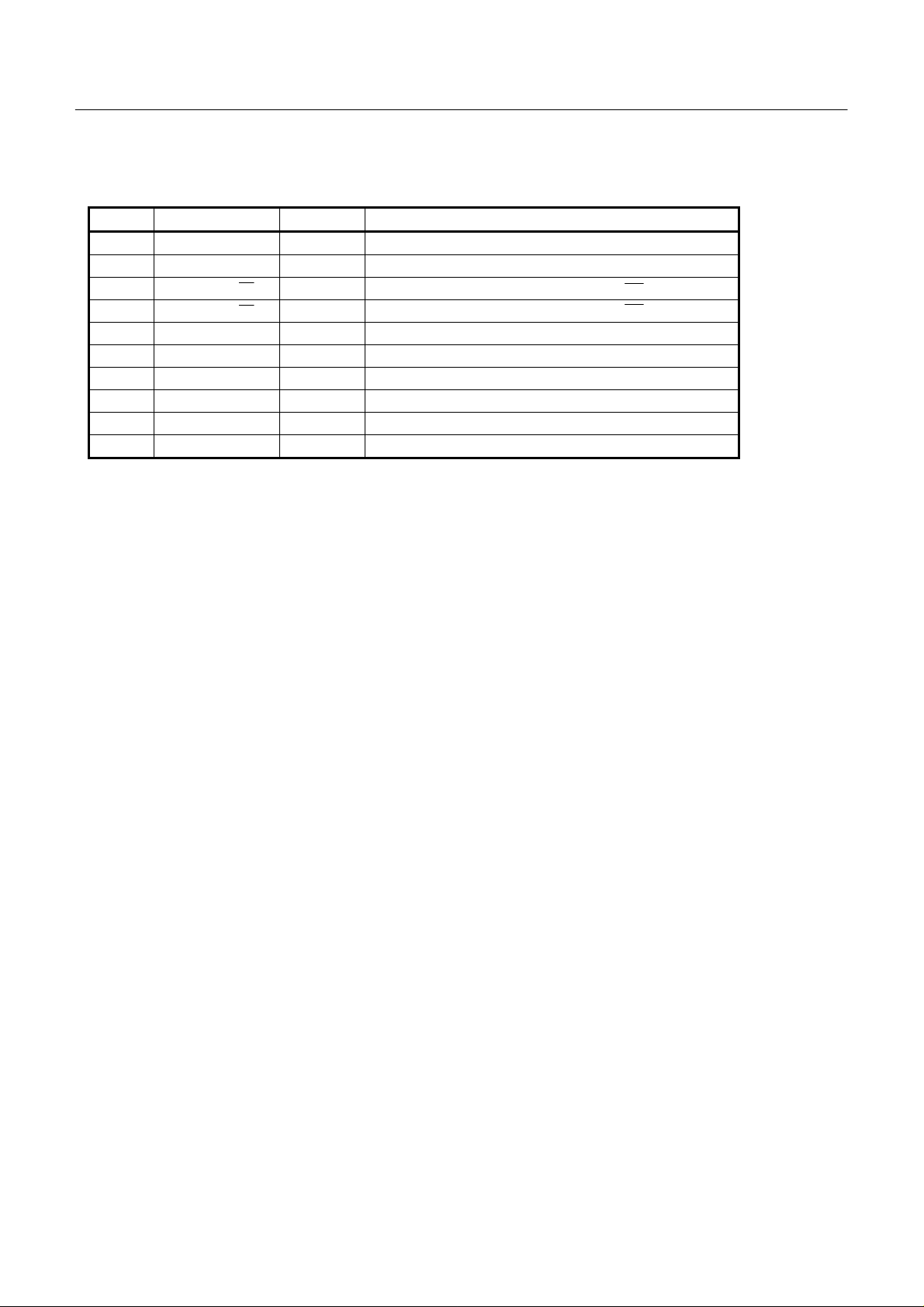

Pin No. Signal Name I/O Function

1VH– Power for print head

2VH– Power for print head

3VH– Power for print head

4 DO Output Headdata output signal

5 LATCH Output Latch signal

6 CP Output Clock pulse

7Vdd– Power for circuit

8 STRB1 Output Strobe 1

9 STRB2 Output Strobe 2

10 STRB3 Output Strobe 3

11 TH Input Thermistor

12 GND – Power GND

13 GND – Power GND

14 GND – Power GND

15 GND – Power GND

16 GND – Power GND

17 GND – Power GND

18 GND – Logic GND

19 NC – No connection

20 NC – No connection

21 STRB4 Output Strobe 4

22 STRB5 Output Strobe 5

23 STRB6 Output Strobe 6

24 NC – No connection

25 DI Input Print data serial input

26 VH – Power for print head

27 VH – Power for print head

28 VH – Power for print head

BD2-2860 User’s Manual

Applicable Connector : 6216-28 000 808 (Kyocera Elco)

9

CITIZEN

Page 10

3.2 CN2 Connector forPrint Mechanism (For Motor & Sensor)

Pin No. Signal Name I/O Function

1 MOTOR A Output Operation signal for motor A

2 MOTOR B Output Operation signal for motor B

3 MOTOR A Output Operation signal for motor A

4 MOTOR B Output Operation signal for motor B

5PEC – Photo-transistor collector (Paper sensor)

6 GND – Photo-transistor emitter (Paper sensor)

7PEA – Photo-LED anode (Paper sensor)

8 GND – Photo-LED cathode (Paper sensor)

9 GND – Head-up sensor GND

10 H-UP Input Head-up signal

UsingConnector : 53047-1010 (Molex)

BD2-2860 User’s Manual

10

CITIZEN

Page 11

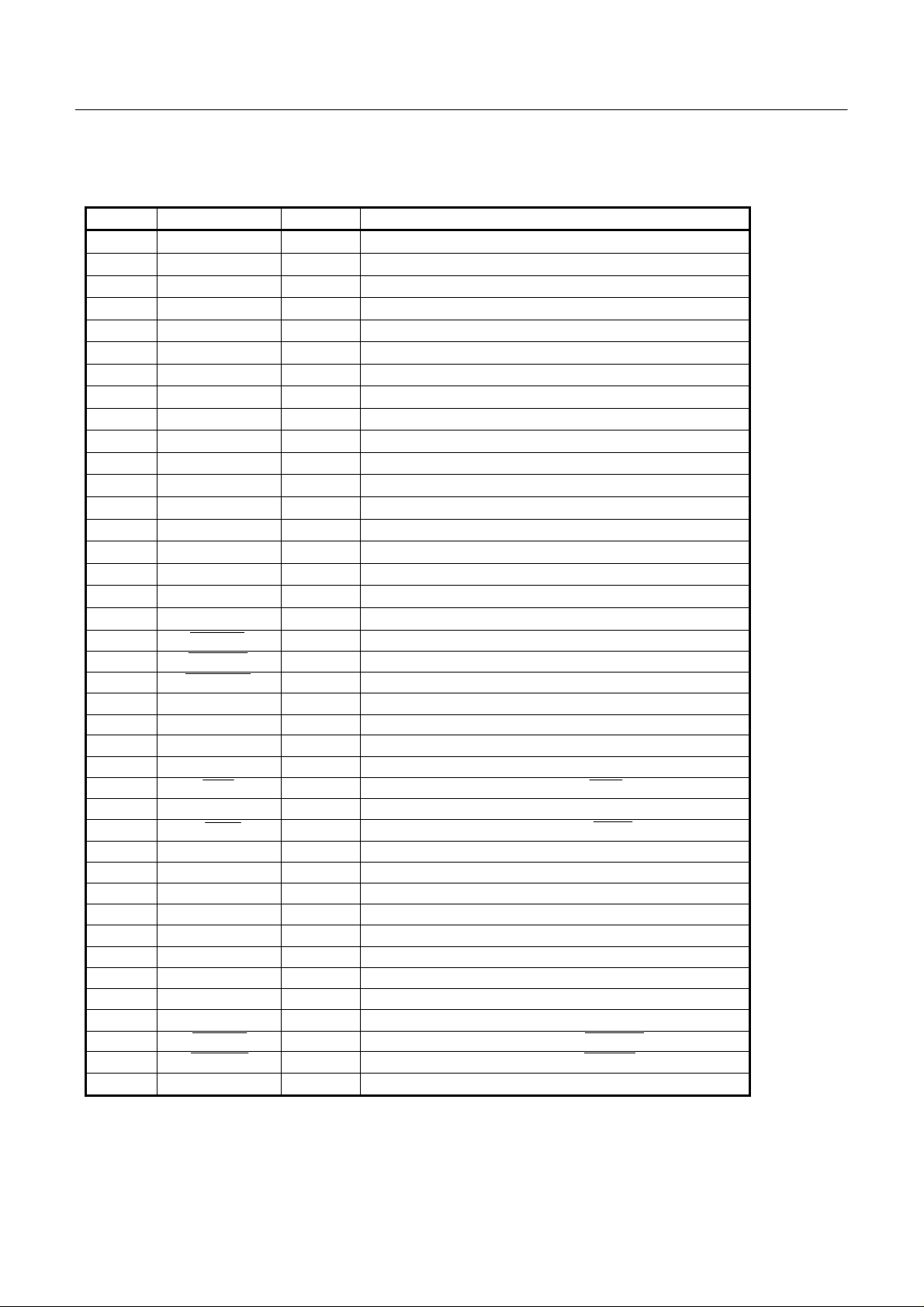

3.3 CN3 Connector for Interface

Pin No. Signal Name I/O Function

1Vdd

2Vdd

3Vdd

4 GND

5 GND

6 GND

7VH

8VH

9VH

10 VH

11 VH

12 VH

13 P-GND

14 P-GND

15 P-GND

16 P-GND

17 P-GND

18 P-GND

19 LF-SW Input LF Switch input

20 ERROR Output Error LED output (Can be connected directly)

21 PE OUT Output PE LED output (Can be connected directly)

22 DTR Output Serial Interface DTR

23 TXD Output Serial Interface TXD

24 RXD Input Serial Interface RXD

25 DSR Input Serial Interface DSR

26 STB Input Parallel Interface STB

27 BUSY Output Parallel Interface BUSY

28 ACK Output Parallel Interface ACK

29 DATA 0 Input Parallel Interface DATA 0

30 DATA 1 Input Parallel Interface DATA 1

31 DATA 2 Input Parallel Interface DATA 2

32 DATA 3 Input Parallel Interface DATA 3

33 DATA 4 Input Parallel Interface DATA 4

34 DATA 5 Input Parallel Interface DATA 5

35 DATA 6 Input Parallel Interface DATA 6

36 DATA 7 Input Parallel Interface DATA 7

37 PE Output Parallel Interface PE

38 FAULT Output Parallel Interface FAULT

39 RESET Input Parallel Interface RESET

40 NC

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Using Connector : LY20-40P-DT1-P5 (JAE)

Applicable Connector : LY10-DC40 (JAE)

Power supply for circuit (5V)

Power supply for circuit (5V)

Power supply for circuit (5V)

GND

GND

GND

Power supply for operation (4.2~8.5V)

Power supply for operation (4.2~8.5V)

Power supply for operation (4.2~8.5V)

Power supply for operation (4.2~8.5V)

Power supply for operation (4.2~8.5V)

Power supply for operation (4.2~8.5V)

GND for operation

GND for operation

GND for operation

GND for operation

GND for operation

GND for operation

No Connection

BD2-2860 User’s Manual

11

CITIZEN

Page 12

BD2-2860 User’s Manual

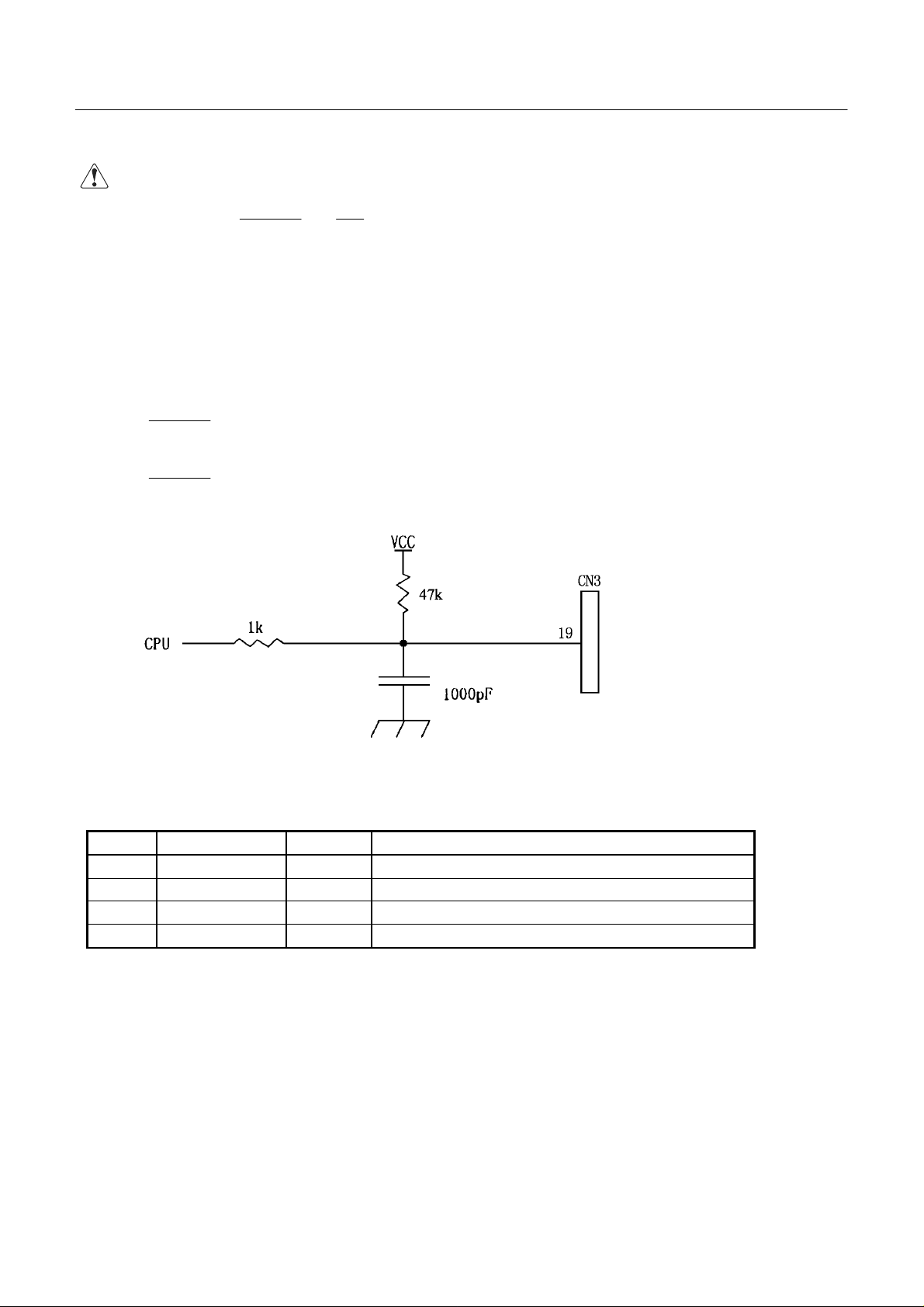

CAUTION:

1. For LED of ERROR and PE, there is a resister of 330Ω on the circuit side tomake current

value 10mA.

Please use LED which its voltage is approx. 2V. LED over 10mA may break a control board.

2. Control circuit requires power supply only for one pin of each VCC and GND.

However, Operation voltage is to be supplied to all of pin for safety use.

3. Serial interface equips a driver and receiver of RS-232C, make sure to use it at RS-232C

level.

4. RESET terminal is pulled up by 3.3KW. Make sure tomake this terminal NC, when this

terminal is not used.

5. LF-SW input circuit is as below.

3.4 CN4 Connector for Paper Cutter

Pin No. Signal Name I/O Function

1 M + Output Cutter motor operational signal M +

2M– Output Cutter motor operational signal M –

3 GND – GND

4 SW Input Cutter switch input signal

UsingConnector : 5207-0410A (Molex)

Note ) Use the specifiedPaper Cutter(Model Name : ACS-220-5V)

12

CITIZEN

Page 13

BD2-2860 User’s Manual

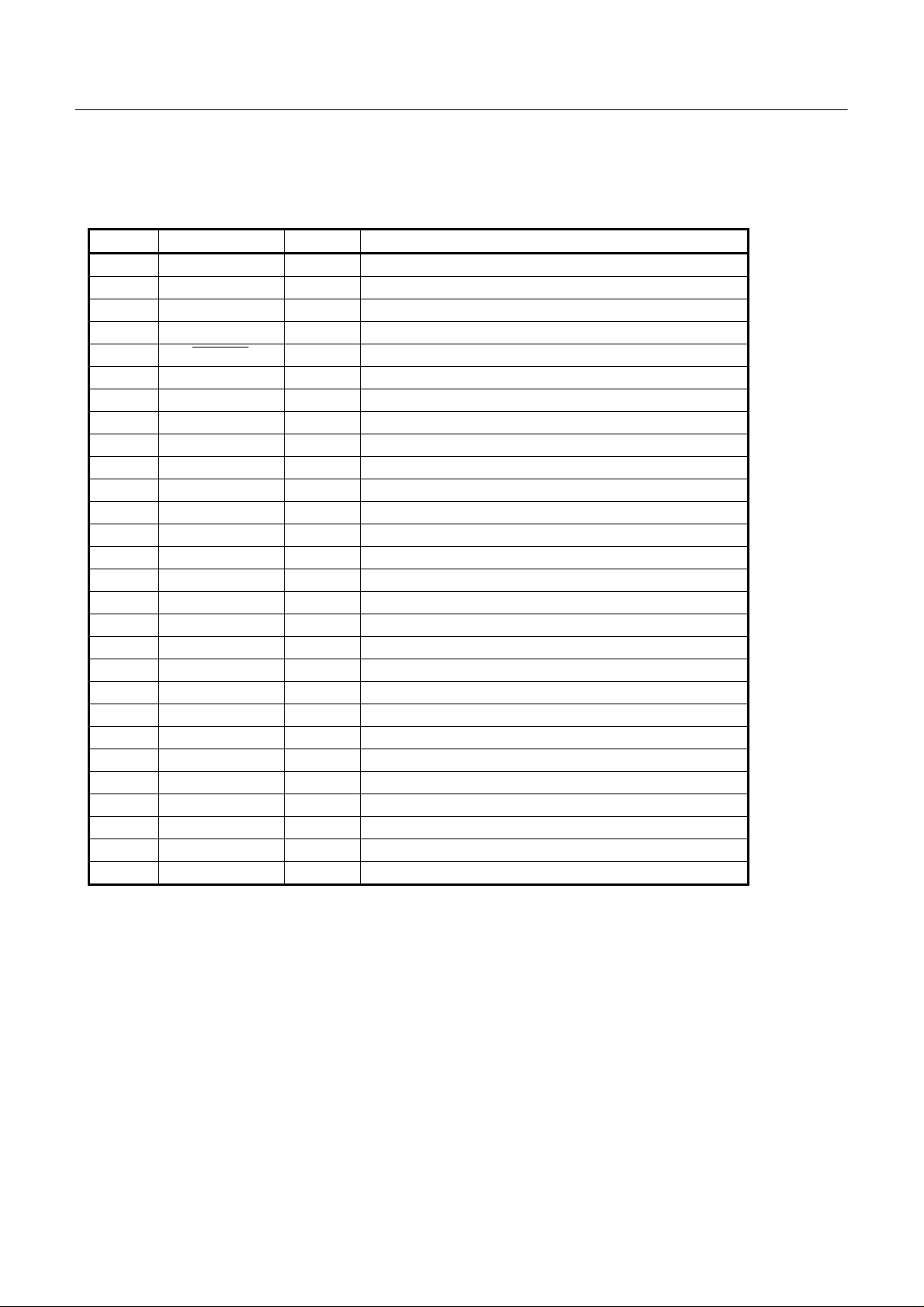

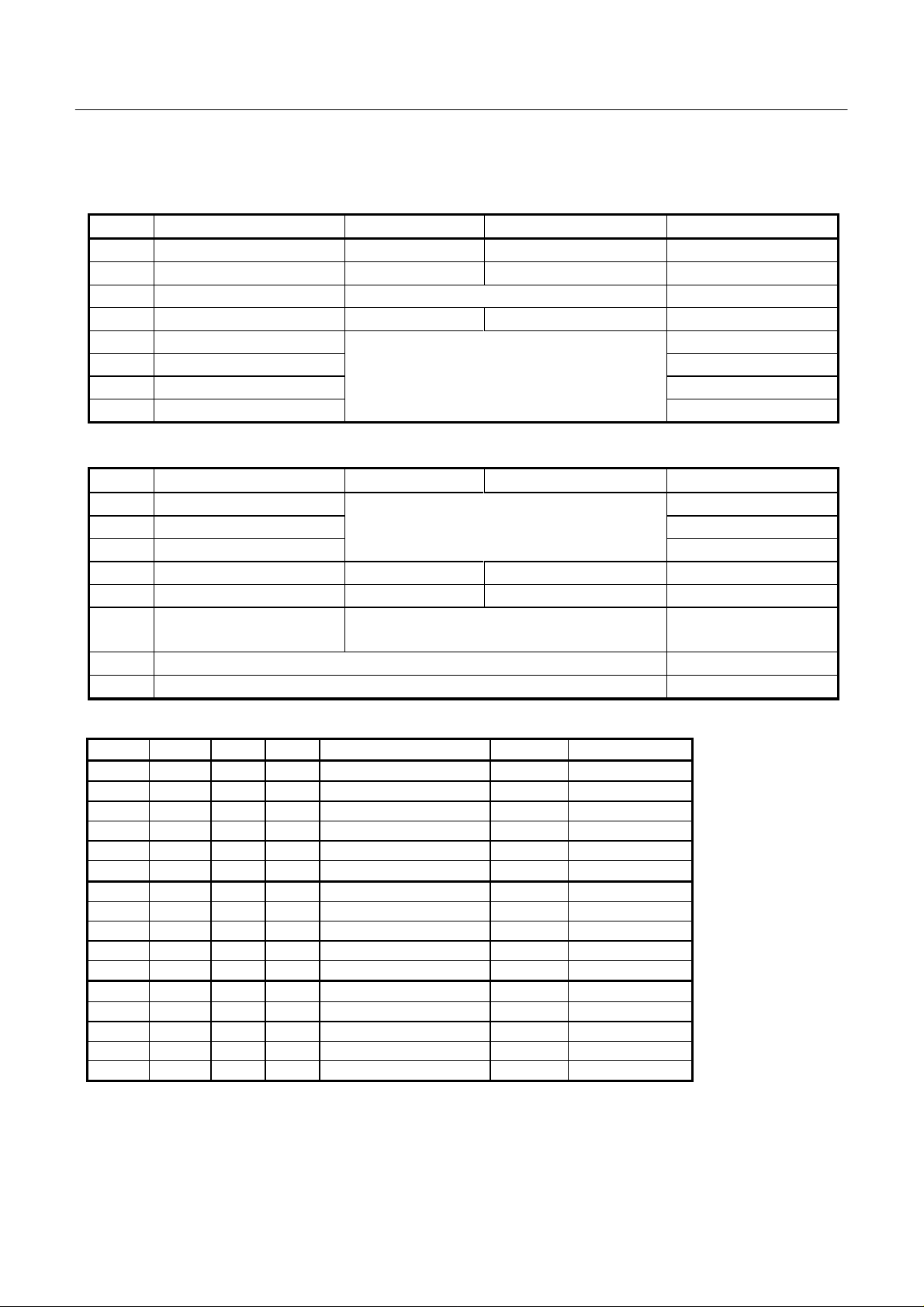

4. DIP SWITCH SETTING

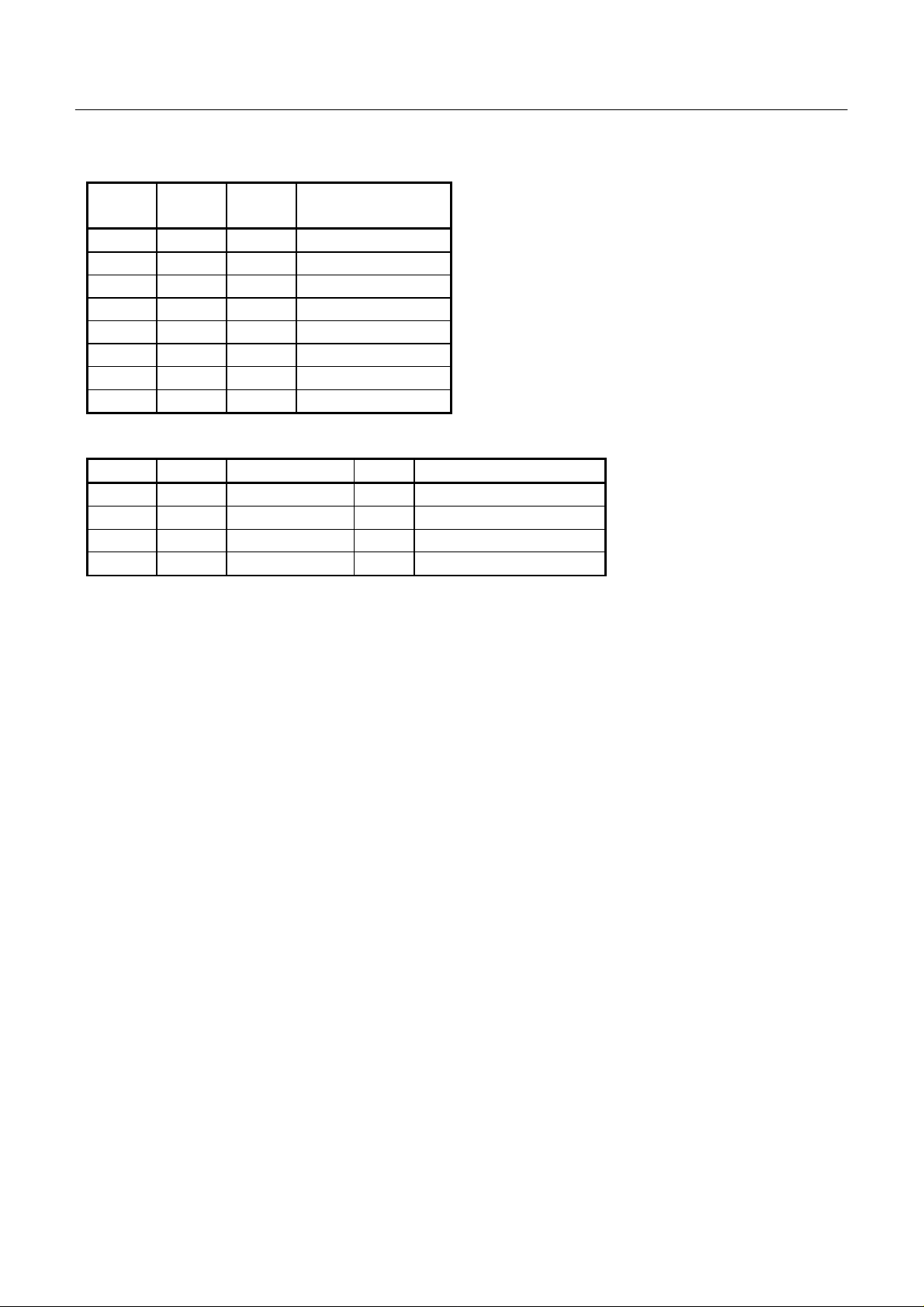

(1) DIP SWITCH

Pin No. Function ON OFF Factory Setting

DS1-1 Auto Cutter Enable Disable OFF

2 CR Selection LF Enable LF Disable ON

3 Print Density Combination with (2)-J6 (See below) OFF

4 DTR/XON-XOFF XON-XOFF DTR/DSR OFF

5 Baud Rate OFF

6 " See below (3) OFF

7" OFF

8" OFF

(2) JUMPER

No. Function Short Open FactorySetting

J1 International Char acter set Open (Short circuit)

J2 " See below (4) Open (Short circuit)

J3 " Open (Short circuit)

J4 Paper Auto Loading Enable Disable Short circuit

J5 Prin t Drive System Variable division Fixed division Short circuit

J6 Print Density Combination with DS1-3 Short circuit

(Supplementary) See below(5)

J7 Not Used Short circuit

J8 Not Used Short circuit

(3) INTERFACE & BAUD RATE

DS1-8 7 6 5 Input Method Parity Baud Rate

OFF OFF OFF OFF Parallel Input -- -OFF OFF OFF ON Serial Input None 1200 bps

OFF OFF ON OFF " " 2400 bps

OFF OFF ON ON " " 4800 bps

OFF ON OFF OFF " " 9600 bps

OFF ON OFF ON " " 19200 bps

OFF ON ON OFF " Odd 1200 bps

OFF ON ON ON " " 2400 bps

ON OFF OFF OFF " " 4800 bps

ON OFF OFF ON " " 9600 bps

ON OFF ON OFF " " 19200 bps

ON OFF ON ON " Even 1200 bps

ON ON OFF OFF " " 2400 bps

ON ON OFF ON " " 4800 bps

ON ON ON OFF " " 9600 bps

ON ON ON ON " " 19200 bps

13

CITIZEN

Page 14

(4) INTERNATIONAL CHARACTERSET

J-3 2 1 International

Character

Open Open Open Japan (JIS)

Open Open Short Japan (Shift-JIS)

Open Short Open Sweden

Open Short Short Denmark 1

Short Open Open U.K.

Short Open Short Germany

Short Short Open France

Short Short Short U.S.A

(5) PRINTDENSITY

DS1-3 J-6 Print Density Level Print DensityRate

OFF Open Light 0 80%

OFF Short Standard 1 100%

ON Open Slightly Dark 2 120%

ON Short Dark 3 150%

Note)

1. Input Buffer is 2k byte.(Fixed)

2. Serial data length is 8 bits.(Fixed)

BD2-2860 User’s Manual

14

CITIZEN

Page 15

BD2-2860 User’s Manual

5. POWER SUPPLY

5.1 Specifications

VCC : 5V± 5% 180 mA

VP : 4.2V ~ 8.5V 1.3A (Peak : Approx.4.0A)

Ordinal Voltage is to be 7.2V(Max). 8.5V is a voltage that is right after charging.

8.5V cannot be used for ordinal voltage.

5.2 Precautions

(1) Design the product to supply power to Vdd before VH When power is suppliedto this control board.

(2) Design the product to turn off the power for Vdd after VH when power is turned off.

(3) Make sure to turn off the power in case of connecting / disconnecting connectors.

(4) Make sure to use Vdd and VH following their specifications.

(5) Make sure to use this control board connecting all of terminals between VH and P-GND.

15

CITIZEN

Page 16

6. PARALLEL INTERFACE

6.1 Specifications

Data input me thod : 8 bit parallel signal (DATA0~7)

Control signals : ACK, BUSY, STB, FAULT, PE, RESET

6.2 Explanation of Input /Output Signals

DATA0~7 : 8 bit parallel signal (Positive logic)

STB : Strobe signal to read8 bitdata (Negative logic)

RESET : Signal to reset control board (Negative logic)

BD2-2860 User’s Manual

ACK : 8 bitdata request signal. Pulse signal output at the endofthe BUSY signal

(Negative logic)

BUSY : Signal to indicate BUSY state of the printer, Input new data for "LOW"

(Positive logic)

FAULT : Signal which is made "LOW" when printer is in alarm state.(Negative logic)

PE : Signal which is output when paper runs out.(Positive logic)

16

CITIZEN

Page 17

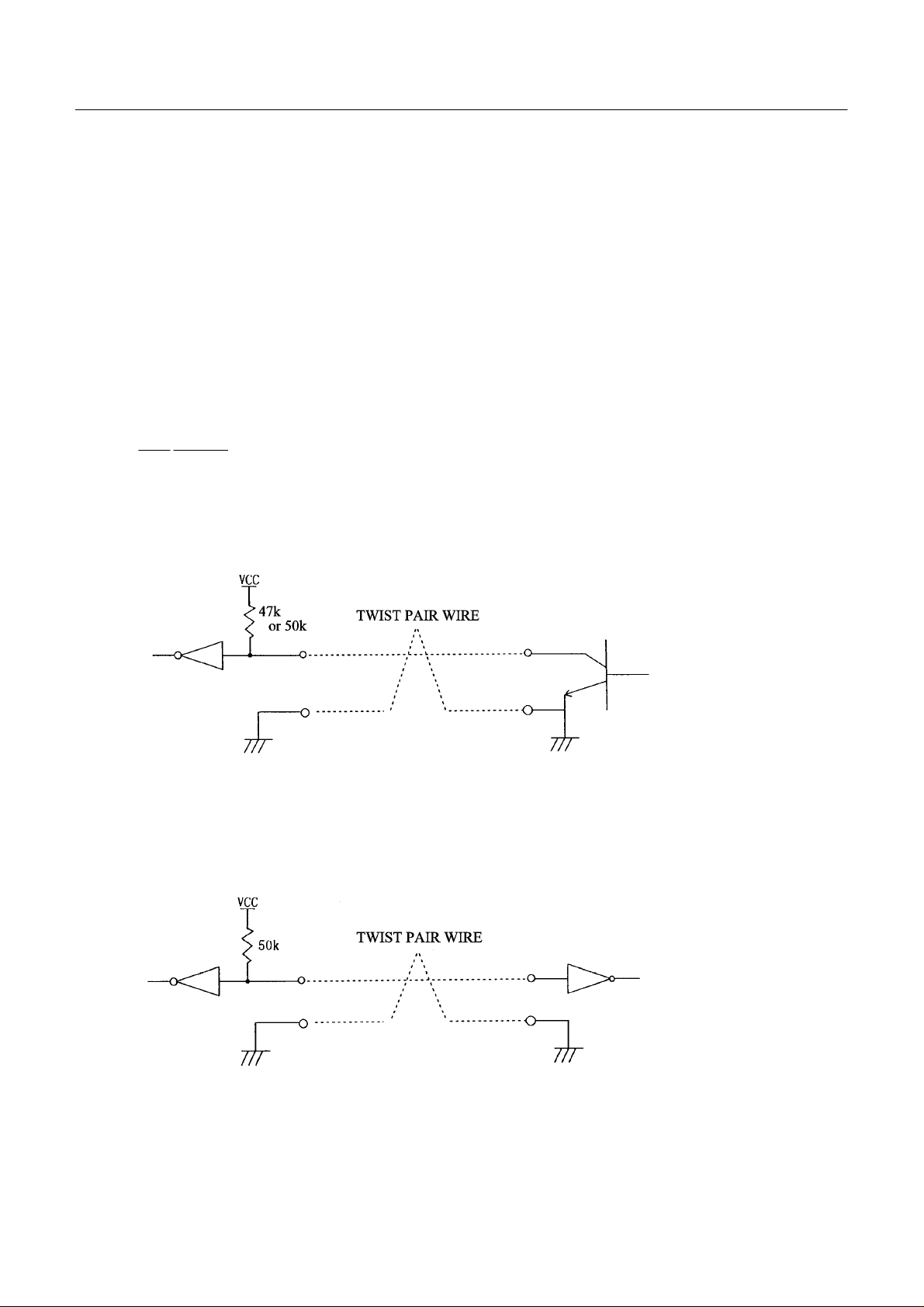

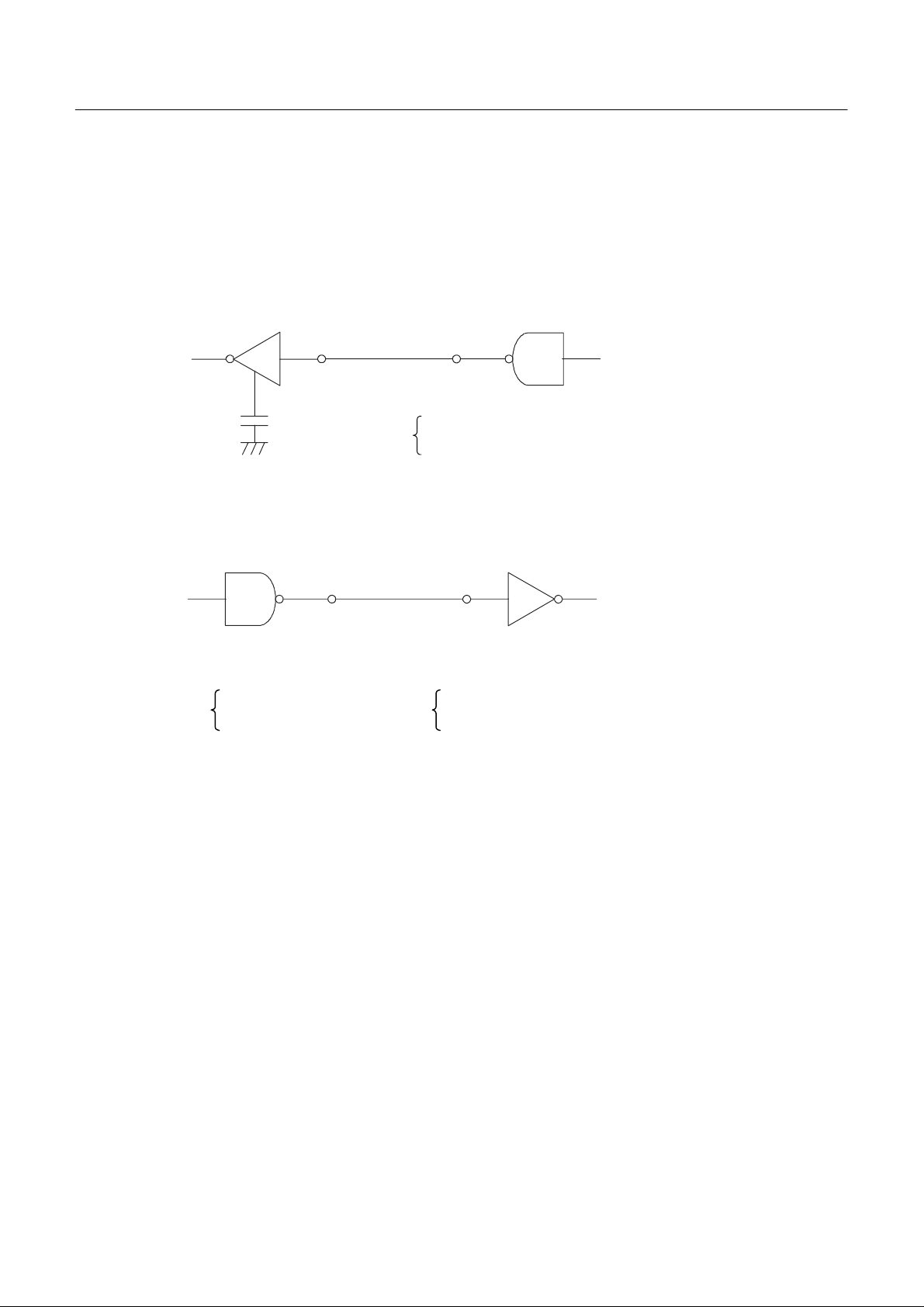

6.3 Electrical characteristics

(1) Input Signal Level

"HIGH" level : 0.7Vdd MIN

"LOW" level : 0.3Vdd MAX

(2) Output Signal Level

BD2-2860 User’s Manual

"HIGH" level : Vdd

"LOW" level : 0.1V MAX

(3) I/O Conditions

STB, RESET input signals are pulled up by 47K

Other input signals are pulled up by 50K

<Printer side> <Host side>

All the output signals are pulled up by 50K

–

0.1V MIN

Ω

Ω

.

Ω

.

.

<Printer side> <Host side>

17

CITIZEN

Page 18

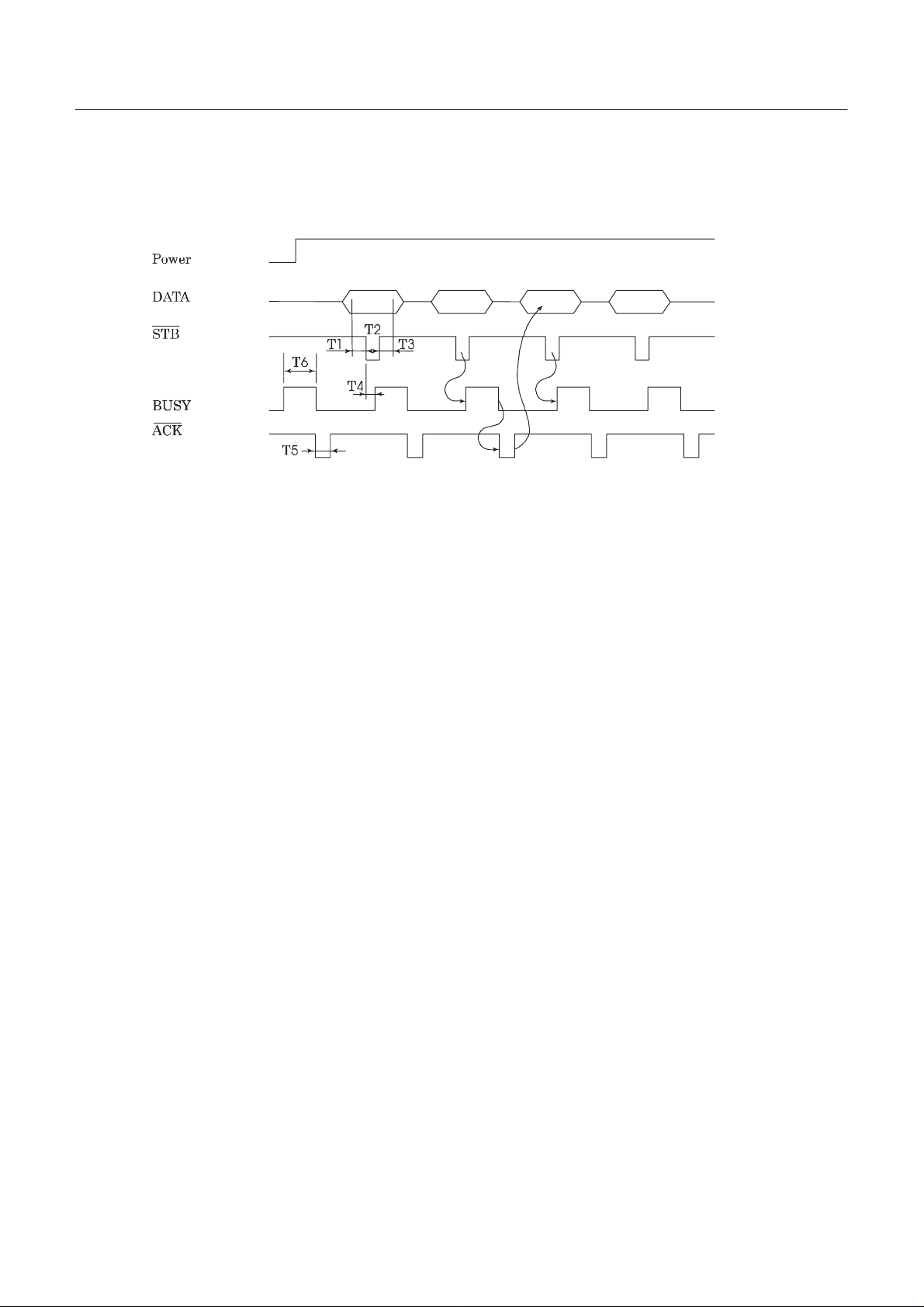

6.4 Timing chart

(1) Data Input and Printing Timing

Supply

BD2-2860 User’s Manual

T1, T2, T3 : 0.5

T4 : 270 ns (MAX)

T5 : 2.3

T6 : 500 ms (MIN) *On supplying power

µ

s(MIN)

µ

s(TYP)

6.5 Data receiving control

When BUSY signal is "LOW", data from the host can be received. When it being "HIGH", data

cannot be received.

6.6 Buffering

This control board incorporates 2K byte buffer.

Therefore, big data can be buffered in inputbuffer, and the hostside can bereleased immediately.

18

CITIZEN

Page 19

7. SERIAL INTERFACE

7.1 Specifications

(1) Data transfer system : Asynchronous

(2) Baud rates

1200, 2400, 4800, 9600, 19200 bps (Selectableby user)

(3) Configuration of one word

Start bit : 1 bit

Data bit : 8 bits Fixed

Parity bit : Odd/Even or No parity (Selectable by user)

Stop bit : 1 bit or more

(4) Signal polarity

RS-232C

BD2-2860 User’s Manual

• Mark = logic " 1" (

• Space = logic " 0" (+3V ~ +12V)

–3V ~ –12V)

(5) Receiving data (RD signal)

RS-232C

• Mark = 1

• Space = 0

(6) Receiving control (DTR signal)

RS-232C

• Mark : Data transfer is not available

• Space : Data transfer is available

(7) Transmission control (TD signal)

DC1 code (11H) X-ON : Data reception is available

DC3 code (13H) X-OFF : Data reception is not available

19

CITIZEN

Page 20

7.2 Explanation of Input / Output signals

(1) RXD

Serial receiving data signal. Onoccurrence of f raming error, overrun error, or parity error, the data is

printedas "?".

(2) DTR

When this signal is READY, write data or a command.When they are written in BUSY, overrun error is

occurred and data is ignored. Even during printing, data can be loaded in the input buffer. Further, BUSY

can take place on supply of power, during test printing, during on-line, or on resetting.

(3) TXD

When, whilein data reception, the rest of input buff eron the printer side goes less than 256 bytes , DC3

(13H) data reception impossible signals are output, when the rest of input buffer goes more than 256 bytes,

BD2-2860 User’s Manual

DC1 (11H) data reception possible signals are output to the host.

When DTR/DSR control having been selected in status information transmission, it is first confirmed that

DSR is "space" and data is sent.

When DTR/DSR control has not been selected, DSR is ignored and data is transmitted.

(4) GND

Common GND on the circuit.

20

CITIZEN

Page 21

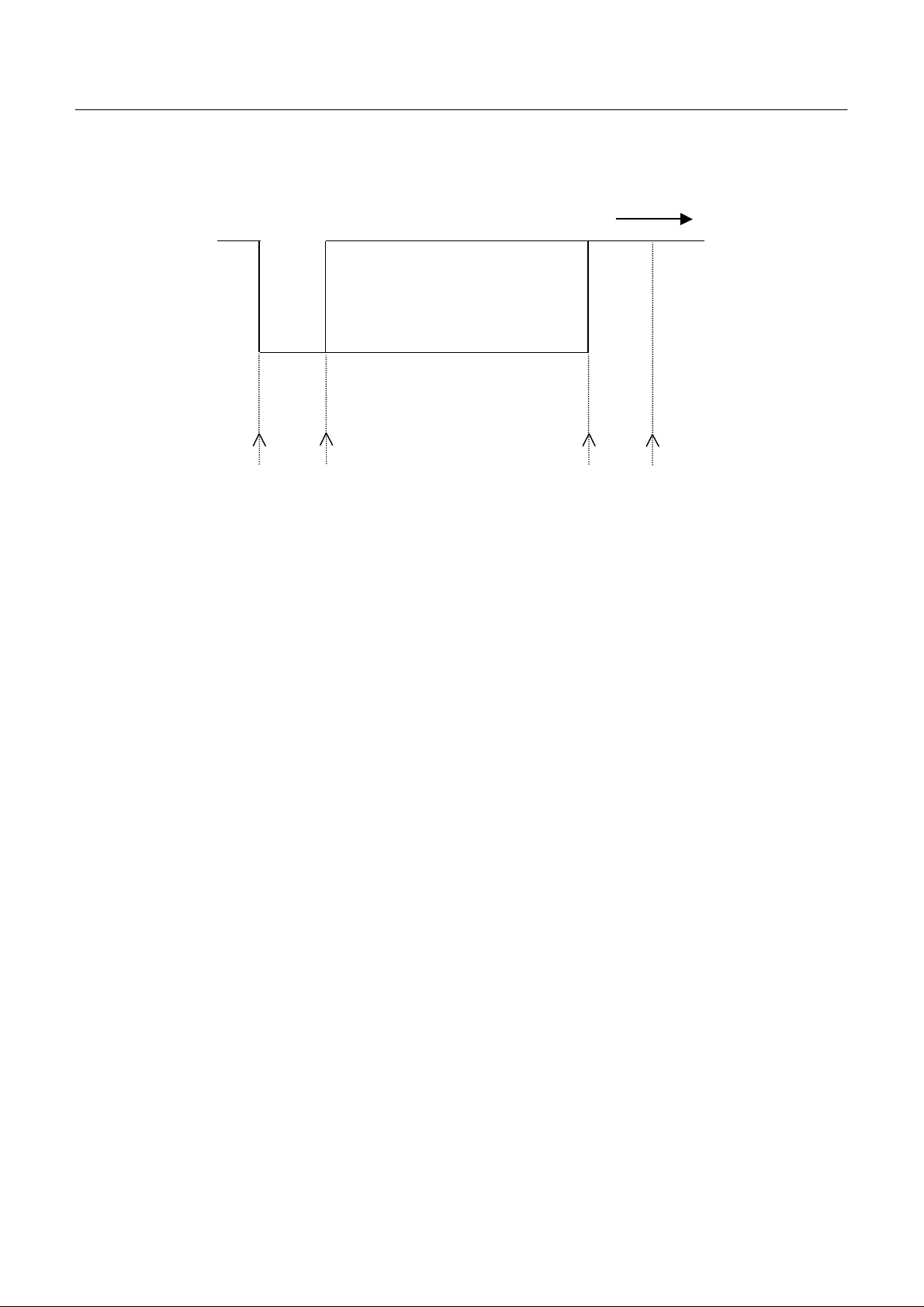

7.3 Date configuration

Mark

(1) Start bit

(2) Data bit (+ Parity bit)

(3) Stop bit ( 1 or more )

BD2-2860 User’s Manual

b1,b2,b3 ····

(1) (2) (3)Space

(1) Start Bit

In 1/2 bit from the m ark-to-space starting edge, state is read once again. When "space" state is confirmed, it

is recognized as the start bit. If it is "mark" state, it is not taken as the start bit.

Without taking it as an error, detection of a start bit is carriedout onceagain.

(2) Data Bit + Parity Bit

Data bit and parity bit are sampledat 1/2 start bit for time length equal to 1 bit. The state thus sampled is

taken as the data for the bit concerned. Bits are named as Bit 0, Bit 1.…. Parity bit counted from the one

close to the start bit.

(3) Stop Bit

The stop bit is a mark level of 1 bit or more. With "space" having been detected on detection of a stop bit,

framingerror takes place.

21

CITIZEN

Page 22

BD2-2860 User’s Manual

7.4 Error Detection

Parity, framing, and overrun are detected. On detection of any error, the data are stored in the buffer as "?".

(1) Framing Error

With "space" state having been detected on detection of a stop bit, error takes place.

The data are stored in the buffer as "?".

(2) Parity Error

With an error having been detected under specifying paritycheck, the data is stored in the buffer as "?".

(3) Overrun Error

On detection of an overrun error, the data are stored in the buffer as "?".

7.5 Data receiving control

When DTR/DSR control having been selected, with BUSY signal at "LOW", data from the host side are

received. With the signal at "HIGH", they can not be received.

When DTR/DSR control not having been selected, after X-ON transmission, data is received from the host

side. No transmission of data can take place after X-OFF is transmitted.

7.6 Buffering

Data transfer to the input buffer include DTR signals and TD signals as the control signals concerned.

(1) DTR signals (See the page 20

(2) TXD signals (See the page 20

–

7.2(2))

–

7.2(3))

22

CITIZEN

Page 23

7.7 Electrical characteristics

(

p

(1) RS-232C Circuit

Input (RXD, DSR)

<Printer side> <Host side>

Mark=

RXD

Equivalent MAX232

Output (DTR, TXD)

-8V):Stopbit

ace=(+8V): Start bit

S

BD2-2860 User’s Manual

DTR

Equivalent MAX232

Mark=(-8V): At Busy Mark=(-8V): 1

Space=(+8V):At Ready Space=(+8V): 0

TD

23

CITIZEN

Page 24

BD2-2860 User’s Manual

8. ERROR HANDLING

8.1 Peripheral Circuit Errors

These errors are detected at power-on or initialization just after a reset.

(1) Error Types

Error Description

Memory error The CPU made a self-diagnosis of the circuit and detected an error with the external

RAM.

Cutter error With the auto cutter enabled at the function selection terminal (DS1-1), the auto

cutter (ACS-220-5V) is not connected to the cutter connector (CN4).

(2) External signal outputs

Interface Connector (CN3)

Pin No. Signal Name Remarks

20 ERROR LED output. For a blinking pattern, see 8.3 Error Indication.

22 DTR Serial interface

27 BUSY Parallel interface

38 FAULT Parallel interface

(3) Resetting me thods

Error ResettingMethod

Memory error Unrecoverable

Cutter error After turningoff the power, connect the auto cutter (ACS-220-5V) or turnoff the

function selection terminal (DS1-1) and turn on the power again.

24

CITIZEN

Page 25

BD2-2860 User’s Manual

8.2 Operation Errors

(1)Error types

Error Description

No paper The printing paper set is not set

Head –up The head-up lever is at its up position

VH voltage error A VHvoltage is beyond its allowable range (4.2 to 8.5V)

Headtemperature error A headtemperature is less than 0°Cor 65°C or higher.

Cutter lock

(ACS-220-5V)

Note 1) The 8.5V upper-limit voltage for VH voltage error is only an assumptive voltage just after charging the

battery when usingthe battery power. It cannot be normallyused.A normalmaximum voltage is 7.2V.

(2) External signal outputs

Interface Connector (CN3)

Pin No. Signal Name Remarks

20 ERROR LED output. For a blinking (Lighting) pattern, see 8.3 Error Indication.

When driving the cutter, the cutter is locked due to an external factor (Paper jam,

etc.).

21 PE OUT LED output. This is always output at the time of no paper.

22 DTR Serial interface

27 BUSY Parallel interface

37 PE Parallel interface

38 FAULT Parallel interface

(3) Resetting methods

Error ResettingMethod

No paper Set the paper. See Note 1.

Head –up Bring down the head-up lever.

VH voltage error Set toavoltage within the allowable range (4.2 to 8.5V) and turn on the power

again. Alternatively, activate the Pin19 (LFSW) of the CN3(interface connector).

Headtemperature error At the lower limit (less than 0°C ), printing becomes operational at 0°C higher.

At the upper limit (65°C or higher), it become operational at 60°Cor lower.

Cutter lock

(ACS-220-5V)

Note 1) When auto loading has not been selected with the function selection jumper(J4), set the paper manually.

When it has been selected, the auto loading function is enabled to facilitate replacement of the paper.

Note 2) The 8.5V upper-limit voltage for VH voltage error is only an assumptive voltage just after charging the

battery when using the battery power. It cannot be normally used. A normalmaximum voltage is 7.2V.

Eliminate paper jam and activate the Pin19(LFSW) of the CN3(Interface

Connector) or turn on the power again.

25

CITIZEN

Page 26

BD2-2860 User’s Manual

8.3 Error Indication

The errors other than no paper are indicated by a LED output (Illumination or blinking) of the

Pin20 (ERROR) of the CN3 (Interface connector).

Error Display Pattern Description

Memory error Blinki ng cycle of 200ms

Cutter lock (Cutter error) Blinking cycle of 150ms(6 times)

and 500ms(1 time).

Head –up Illuminated until reverted

VH voltageerror Illuminateduntil reverted

Headtemperature error Blinking cycleof1 sec.

Macro executionwait Blinking cycle of 500ms.

26

CITIZEN

Page 27

BD2-2860 User’s Manual

9. PRINTER MECHANISM CONTROL SYSTEM

9.1 Thermal Head Control System (Division Driving system)

The LT-286(Linethermal printer) is driven by this control board has a384 dots/line head dividedinto 6

block of 64 dots each. When actually driving the head, you can select either Fixed Division Number

system, which drives the head, always dividing it into 6 blocks or Variable Division Number system which

collectively drives several blocks at the time according to the number of activated head dots.

For selection by function selection, see 4. DIP SWITCH SETTING.

For selection by a command, see 10.2 Command Details.

9.1.1 Fixed Division NumberSystem

This system always drives each block in the same sequence.

1st Bloc k

64 Dots

2ndBlock

64 Dots

1st Step of Motor

3rd Block

64 Dots

4th Block

64 Dots

5th Block

64 Dots

2ndStepofMotor

6th Block

64 Dots

Note) for a stepping motor driving method, see 9.2 Motor Drive.

9.1.2 Variable Division Number System

This system counts the number of printingdots for each block of the printing dot line and drives the blocks

collective in such a manner not to exceed themaximu mnumber of driving dots (64 dots).

1st Bloc k

64 Dots

Unlike the Fixed Division Number system, this system drives all the head in the head in the head in the 1st

step of the motor and simply feeds the paper in the 2nd step of the motor.

2ndBlock

64 Dots

3rd Block

64 Dots

4th Block

64 Dots

5th Block

64 Dots

6th Block

64 Dots

2ndStepof Motor

6.Dot Line

6.Dot Line

27

CITIZEN

Page 28

BD2-2860 User’s Manual

9.2 Motor Drive

The LT-286 uses a 4-phase bipolar stepping motor. It feeds the 1 dot line worth of paper intwo steps by 2to-2 phase excitation.

9.2.1 Motor Drive Features

1) Drive at an optimum drive speed by the VH voltage.

2) Prevents heat generation of the motor by PWM control to restrain current consumption.

3) Provides acceleration control at the time of start.

9.2.2 MaximumMotor Drive Speeds at Major Voltage

VH Voltage Motor Drive Speed

5V 300pps

6V 490pps

7.2V 800pps

Note ) The maximum drive speed depends on the VH voltage.

A printing speed may slightly differ depending on a processing time o r voltage detection accuracy.

During the course of printing, amotor drive speed may be slower than themaximum drive speed,

dependingon what is printed or the head divided drive system.

28

CITIZEN

Page 29

BD2-2860 User’s Manual

g

10. PRINT CONTROL FUNCTIONS

10.1 Command List

Control Code Function Code

1 HT Horizontal tab command 09H 31

2 LF Printing and paper feed 0DH 32

3 CR Print command 0DH 33

4 ESC SP Setting the right space amount of the character 1BH 20H n 34

5 ESC ! Collective specifying printing mode 1BH 21Hn 35

6 ESC % Specifying/canceling download character set 1BH 25Hn 37

7 ESC & Defining download characters 1BH 26H 5 n m[a p1 p2 ... psxa]m-n+1 38

8 ESC * Specifying the bit image mode 1BH 2AH mn1n2[d]k 40

9

10 ESC 2 Specifying 1/6-inch line feed rate 1BH32H 43

11 ESC 3 Setting line feed rate of minimum pitch 1BH 33H n 44

12 ESC = Data input control 1BH 3DH n 45

13 ESC

14 ESC D Setting h orizontal tab posi tion 1BH 44H [n]k00H 47

15 ESC E Specifying/canceling highlighting 1BH 45H n 48

16 ESC G Specifying/canceling double printing 1BH 47Hn 49

17 ESC J Printing and feeding paper n/203 inch 1BH 4AHn 50

18 ESC R Selecting the international character set 1BH 52H n 51

19 ESC V Specifying/Canceling 90°-right- turned Characters 1BH 56H n 52

20 ESCa Aligning the characters 1BH 61H n 53

21 ESC c3 NOP

22 ESC c4 NOP

23 ESC c5 Enabling/disabling the panel switches 1BH 63H 35H n 54

24 ESC d Printing and feeding the paper by n lines 1BH 64H n 55

25 ESC i Activating auto cutter (Full cut) 1BH 69H 56

26 ESC m Activating auto cutter (Partial cut) 1BH 6DH 57

27 ESC p NOP

28 ESC t Selecting th e character codetable 1BH 74H n 58

29 ESC u NOP

30 ESC v Transmitting the printer status (Serial type) 1BH76H n 59

31 ESC { Specifying/canceling the inverted characters 1BH 7BH n 60

32 ESC $ Specifying the absolute positions 1BH 24H n1 n2 61

33 ESC \ Specifying th e relative positions 1BH 5C n1 n2 62

34 GS k Printing the bar code 1DH6BH n [“d”]k00H 63

35 GS w Selecting the horizontal size (scale factor) of bar code 1DH 77H n 67

36 GS h Selecting the height of the bar code 1DH 68H n 68

37 GS H Selecting of print position of HRI code 1DH48H n 69

38 GS f Selecting the font of HRI code 1DH 66H n 70

39 GS * Defining the download, bit image 1DH2An1n2[d]n1xn2x8 71

40 GS / Printing the download, bit image 1DH 2FH m 73

41 GS : Starting/ending macro definition 1DH3AH 74

42 GS ^ Executing the macro 1DH 5E n1n2 n3 75

43 DC2 A Selecting the Print drive system

ESC

–

@

Specifying/canceling underline 1BH 2DH n 42

Initializing the Printer 1BH 40H 46

12H 41H n

Pa

e

76

29

CITIZEN

Page 30

BD2-2860 User’s Manual

10.2 Command Details

10.2.1 Description of Items

XXXX ALL

[Function] Command Function

[Code] A sequence of code constituting a command is represented in hexadecimalnumber for <

>H, binarynumber for < >B, anddecimal number for < >, respectively; [ ]k represents a

repeat count of k-times.

[Range] Describes an argument value(setting range) for the command.

[Outline] Describes a command outline.

[Caution] Describes a caution as required.

[Default] Describes an initial value for the commandwhen accompanied by an argument.

[See Also] Describes the associated commands for use.

[Sample Program] Describes a coding example in the Q-BASIC sample program.

* This example is only for your reference and differs depending on the language

used, version, and so on. For details, see themanual for the language used.

30

CITIZEN

Page 31

10.2.2 Details

HT

[Function] Horizontal Tab Command

[Code] <09>H

[Outline] Shifts the printing position to the next horizontal tab position.

• Ignored when the next horizontal tab position has not been set.

[Caution] • The horizontal tab position is set by ESC D.

• Initial setting of thehorizontal tab position is each8 characters in 9th, 17th,

25th,columns.

[SeeAlso] ESC D

BD2-2860 User’s Manual

[Sample Program]

[PrintResults]

LPRINT "0123456789012345678901”;

LPRINT CHR$ (&HA);

LPRINT CHR$ (&H9) + "AAA”;

LPRINT CHR$ (&H9) + "BBB”;

LPRINT CHR$ (&HA);

LPRINT CHR$ (&H1B) + "D”;

LPRINT CHR$ (3) + CHR$ (7) + CHR$ (14) + CHR$ (0);

LPRINT CHR$ (&H9) + "AAA”;

LPRINT CHR$ (&H9) + "BBB”;

LPRINT CHR$ (&H9) + "CCC" + CHR$ (&HA);

31

CITIZEN

Page 32

BD2-2860 User’s Manual

LF

[Function] Printing and Paper Feed Command

[Code] <0A>H

[Outline] Prints data inside the input buffer and feeds lines based on the lin e feed amount having been set.

• The head of the line becomes the next print starting position.

[SeeAlso] ESC 2, ESC 3

[Sample Program] [Print Results]

LPRINT "AAA" + CHR$ (&HA);

LPRINT "BBB" + CHR$ (&HA);

LPRINT CHR$ (&HA);

LPRINT "CCC" + CHR$ (&HA);

32

CITIZEN

Page 33

CR

[Function] Print Command

[Code] <0D>H

[Outline] 1) When DS 1-2 is OFF:

This command is ignored.

2) WhenDS 1- 2 is ON:

Withdata heldinside the internalprint buffer, printing and line feed are performed.

Without data inside the internal print buffer, however, no printing is performed.

[SeeAlso] LF

[Sample Program] [Print Results]

LPRINT "AAA" + CHR$ (&HD);

LPRINT "BBB" + CHR$ (&HD);

LPRINT CHR$ (&HD);

LPRINT "CCC" + CHR$ (&HD);

BD2-2860 User’s Manual

33

CITIZEN

Page 34

BD2-2860 User’s Manual

ESC SP n

[Function] Settingthe right space amount of the character

[Code] <1B>H<20>H<n>

[Range] {0 =< n=< 20} Data is described in Hex code.

[Outline] Therightward space amount is set in dot unit (1/20 3inch unit). In the initial value, it is n=0.

[Caution] The rightward space amount in doublewi d emode is made doubleof the set volume.

[Default] n = 0

[Sample Program]

LPRINT CHR$ (&H1B) + " " + CHR$ (0);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + " " + CHR$ (1);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + " " + CHR$ (12);

LPRINT "AAAAA" + CHR$ (&HA);

[PrintResults]

34

CITIZEN

Page 35

ESC ! n

[Function ] Collective SpecifyingPrintingMode

[Code] <1B>H<21>H<n>

[Range] {0 =< n=< FF} Data is described in Hex code.

[Outline] Printingmode is assigned. Each n bit indic ates the following:

Value

Bit Function 0 1

0 Character Font Font A Font B

1 Undefined

2 Undefined

3 High-lighting Canceled Specified

4 Double height Canceled Specified

5 Double width Canceled Specified

6 Undefined

7 Un d erline Canceled Specified

BD2-2860 User’s Manual

[Caution] • With double height and double width being specified simultaneously, double wide and

double high characters are consisted.

• An underline is attached to the full character width, which, however, is not attached to

the part having been skipped by the horizontal tab.

Neither is it attached to 90°-right-turned characters.

• The underline width is as having been specified by <ESC ->.

(The default setting is 1 dot width. )

• Specification with this comm and is invalid to Kanji, except specification and cancellation

of highlighting

• In case that double wide character and n ormal character exist insame one line, the layout

of underline is consistent one.

[Default] n = 0

[See Also] ESC E, ESC

–

35

CITIZEN

Page 36

[Sample Program]

[PrintResults]

BD2-2860 User’s Manual

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H00) + "H" ;

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H01) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H08) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H10) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H20) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&H80) + "H";

LPRINT CHR$ (&H1B) + " ! " + CHR$ (&HB9) + "H";

LPRINT CHR$ (&HA);

36

CITIZEN

Page 37

BD2-2860 User’s Manual

ESC % n

[Function] Specifying/Canceling Download Character Set

[Code] <1B>H<25>H<n>

[Range] {0 =< n =< FF} data is described in Hex code.

[Outline] Specifying/canceling download characters.

Further, only the lowest bit (n0) is valid for n.

The lowest bit (n0) indicates the following.

n0 Function

0 Canceling download character set

1 Specifying download character set

[Caution] Download characters and download bitimages cannot be defined simultaneously.

[Default] n = 0

[SeeAlso] ESC &

[Sample Program]

GOSUB SETCHR DATA 6

LPRINT CHR$ (&H1B) + "%" + CHR$ (0); DATA &HFF, &H80, &H00

LPRINT "@A" + CHR$ (&HA); DATA &H80, &H80, &H00

LPRINT CHR$ (&H1B) + "%" + CHR$ (1); DATA &H80, &H80, &H00

LPRINT "@A" + CHR$ (&HA); DATA &H80, &H80, &H00

END DATA &HFF, &HFF, &HFF

SETCHR: DATA &HFF, &HFF, &HFF

LPRINT CHR$ (&H1B) + "&”; DATA 12

LPRINT CHR$ (3) + "@" + "A”; DATA &HFF, &HFF, &HFF

FOR J=1 TO 2 DATA &H80, &H07, &HF9

READ REP DATA &H80, &HFF, &HF9

LPRINT CHR$ (REP); DATA &H87, &HFE, &H01

FOR I=1 TO REP*3 DATA &H9F, &H06, &H01

READD DATA &HF8, &H06, &H01

LPRINTCHR$ (D); DATA &HF8, &H06, &H01

NEXT I DATA &H9F, &H06, &H01

NEXT J DA TA &H87, &HFE, &H01

RETURN DATA &H80, &HFF, &HF9

DATA &H80, &H07, &HF9

DATA &HFF, &HFF, &HFF

[PrintResults]

37

CITIZEN

Page 38

ESC & s n m [a [p] s × a] m – n +1

[Function] Defining Download Character

[Code] <1B>H<26>H<s><n><m> [<a><p1><p2><ps×a>]m-n+1

[Range] {s = 03}

{20 ( Hex) =< n =< m =< 7E (Hex)}

{0 =< a =< 0C(Hex)} (Font A)

{0 =< a =< 0A(Hex)} (Font B)

[Outline] Defines the font of download characters of alphanumeric characters.

• "s" indicates the number of bytes in vertical direction.

• "n" indicates the start character code and m the end character code. To defineonly one character,

set n=m.

• Character codes definable includes 95 ASCII codes in total between <20>H ~<7E>H.

BD2-2860 User’s Manual

• "a" indicates the number of dots in horizontal direction for definition.

• "p" is the data to be defined, which indicate a pattern equal to "a" dot in horizontal direction from

the left end. The rest of the pattern on the right side is filled withspace.

The rest of data to be defined is s x a.

• Download characters thus defined remain valid until redefinition, ESC @ execution,

GS * execution, or power OFF is practiced.

[Caution] Download characters and download bitimages c an not be defined simultaneously.

Running this command clears the definition of the download bit image.

[Default] Same as the internal character set

38

CITIZEN

Page 39

[Example]

BD2-2860 User’s Manual

Create eac h data bit by setting "1"for a printed dot and "0" for an unprinted dot.

[Sample Program] [Print Results]

SeeSampleProgramandPrint Resultsfor ESC % on Page 37.

39

CITIZEN

Page 40

BD2-2860 User’s Manual

ESC * m n1 n2 [d ] k

[Function] Specifying the Bit Image Mode

[Code] <1B>H<2A>H<m><n1><n2> [ <d> ] k

[Range] {m= 0, 1, 32, 33 bit imagemode (See the table below.)}

{0 =< n1 =< FF(Hex)}

{0 =< n2 =< 03(Hex)}

{0 =< d =< FF(Hex)}

{k = n1 + FF(Hex) × n2 (m = 0, 1)

{k = (n1+ FF(Hex) × n2) × 3} (m = 32, 33)

[Outline] According to the number of dots specified in n1, n2, specify the bit imageof mode n.

• The No. of dots printed is divided by 256, whose quotient is takenas n2 and residual as n1.

• The total no. of dots printed in the bit image is equalto n1 + (256 x n2).

• Whenbitimagedatahave been input in excess of dot position of one line (448 d ots) ,

theexcessdata arediscarded.

• d is bit imagedata, the bits subject to printing are taken as "1" and those not as "0".

• The bit image modes specified by m are shown as follows:

m(Hex) Mode

0 8-dot single density 8 67 DPI 101 DPI 192

1 8-dot double density 8 67 DPI 203 DPI 384

32 24-dot single density 24 203 DPI 101 DPI 192

33 24-dot double density 24 203 DPI 203 DPI 384

[Caution] • When the values set in m (bit image mode) are out of the above range, the data

followingafter n1 is processed as normalprintingdata.

• After completionof bitimage printing, printerreturns tonormal data processing mode.

[Example]

Vertical Direction Horizontal Direction

No. of Dots Dot Density Dot Density Max. No. of Dots

40

CITIZEN

Page 41

[Sample Program]

[PrintResults]

BD2-2860 User’s Manual

LPRINT CHR$ (&H1B) + "*”;

LPRINT CHR$ (0) + CHR$ (20) + CHR$ (0); IMG1 :

GOSUB IMG1 LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HA); FOR I=1 TO 18

LPRINT CHR$ (&H1B) + "*”; LPRINT CHR$ (&H85) ;

LPRINT CHR$ (1) + CHR$ (20) + CHR$ (0); NEXT I

GOSUB IMG1 LPRI NT CHR$ (&HFF) ;

LPRINT CHR$ (&HA); RETURN

LPRINT CHR$ (&H1B) + "*”; IMG2 ;

LPRINT CHR$ (32) + CHR$ (20) + CHR$ (0); LPRINT CHR$ (&HFF) ;

GOSUB IMG2 LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HA); LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&H1B) + "*”; FOR I=1 TO 18

LPRINT CHR$ (33) + CHR$ (20) + CHR$ (0); LPRINTCHR$ (&H80) ;

GOSUB IMG2 LPRINTCHR$ (&H00) ;

LPRINT CHR& (&HA); LPRINTCHR$ (&H05) ;

END NEXT I

LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HFF) ;

LPRINT CHR$ (&HFF) ;

RETURN

41

CITIZEN

Page 42

BD2-2860 User’s Manual

ESC – n

[Function] Specifying/ Canceling Underline

[Code] <1B>H<2D>H<n>

[Range] {0 =< n =< 02} data is described in Hex code.

[Outline] Specifying/cancelingan underline.

• Types of underlines by n value are shown below:

n (Hex) Type

0 Canceling an underline.

1 Specifying an underline for 1-dot width.

2 Specifying an underline for 2-dots width.

[Caution] • An underline is attached to the full character width. It is, however, not attached to

the part havingbeenskipped by ho rizontal tab command.

• An underline is not attached to a 90 °- right-turned characters.

• Specification/cancellation with this command is invalid to Kanji.

[See Also] ESC !, FS

[Sample Program]

LPRINT CHR$ (&H1B) + "–" + CHR$ (0);

LPRINT "AAAAA" ;

LPRINT CHR$ (&H1B) + "

LPRINT "AAAAA" + CHR$ (&HA);

[PrintResults]

–

–" + CHR$ (1);

42

CITIZEN

Page 43

ESC 2

[Function] Specify ing 1/6-inch line feedrate

[Code] <1B>H<32>H

[Outline] The line feed rate per line is specified by 1/6 inch.

[Sample Program] [Print Results]

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "3" + CHR$ (0);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "3" + CHR$ (50);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "2”;

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "J" + CHR$ (100);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT "AAAAA" + CHR$ (&HA);

BD2-2860 User’s Manual

43

CITIZEN

Page 44

ESC 3 n

[Function] Settingline feed rate of minimum pitch

[Code] <1B>H<33>H<n>

[Range] {0 =< n =< FF} Data is described in Hex code.

[Outline] The line feed rate per line is specifiedby n/360 inch.

Since an actual mechanical pitch is 1/203 inch, it is internally converted approximate

to the value specified with this com mand.

[Default] • The initial value is n = 60 (1/6 inch) (18H), being 4.23 mm line feed rate.

[Sample Program] [Print Results]

SeeSampleProgramandPrint Resultsfor ESC 2 on Page 43.

BD2-2860 User’s Manual

44

CITIZEN

Page 45

ESC = n

[Function] Data Input Control

[Code] <1B>H<3D>H<n>

[Range] {0 =< n =< FF} Data is described in Hex code.

[Outline] Selecting equipment in which data input from the host is effective.

• Each bit of n indicates as follows:

Bit Equipment

01

0 Printer Invalid Valid

1 Not defined

2 Not defined

3 Not defined

4 Not defined

5 Not defined

6 Not defined

7 Not defined

Value

BD2-2860 User’s Manual

• When the printer has not been selected, this printer abandons all the received data

until it is selectedby thiscommand.

[Caution] • Even when the printer has not been selected, it can become BUSY state through

printer operation.

• Whenthe printer is deselected, this printer discards all thedatauntil it is selected

with this command.

[Default] • The initial value of n is "1".

[SampleProgram]

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "=" + CHR$ (0);

LPRINT "aaaaa" + CHR$ ( &HA);

LPRINT CHR$ (&H1B) + "=" + CHR$ (1);

LPRINT "AAAAA" + CHR$ (&HA);

[Print Results]

45

CITIZEN

Page 46

BD2-2860 User’s Manual

ESC @

[Function] Initializing the Printer

[Code] <1B>H<40>H

[Range] Clears data stored in the print buffer and brings various settings to the initial state (Default state).

[Caution]

• Data inside the internal input buffer are not clear ed.

• Dip switches setting are red once again.

[SampleProgram] [Print Results]

LPRINT CHR$ ( &H1B) + " ! " + CHR$ (&H30) ;

LPRINT CHR$ ( &H1B) + "V" + CHR$ (1) ;

LPRINT "AAA" + CHR$ (&HA);

LPRINT CHR$ ( &H1 B) + "@”;

LPRINT "AAA" + CHR$ (&HA);

46

CITIZEN

Page 47

ESC D [ n ] k NUL

[Function] Setting Horizontal Tab Position

[Code] <1B>H<44>H [ <n> ] k<00>H

[Range] {0 =< n =< FFH} Data isdescribedin Hex code.

{0 =< k =< 20H} Data is describedin Hex code.

[Outline] Specifying a horizontal tab position.

• "n" indicates the no. of columns from the beginning to the horizontal tab position.

BD2-2860 User’s Manual

At this time, n= set position

column, n=8 is to be specified.

• k denotes the number of horizontal tab positions you want to set.

• The tab position is set at position where it is "character width x n" from the line beginning.

The cha racter width, at thistime,includes the rightward space amount.

In double wide characters, it is made double of the ordinary case.

• Tab positions can be specified are maximum 32. Specifying exceeding this is ignored.

• <n> k, which denotes a setting position, is input in the increasing order and ends at <00> H.

• ESC D NUL clears all the set tab positions. Following clearing, horizontal tab command is

ignored.

[Caution] Whenthedata, <n> k, is equal to or smaller than its preceding data, <n> k-1, it is assumed

that tab setting is finished. If this is the case, the next dataonward will be processed as normal

data.

When the data, <n> k, exceeds a 1-line print area, set the horizontal tabposition, assuming

"Set digit position = Maximum print digits + 1." The horizontal tab position does not

change even if the character width is altered after setting the horizontal tab position.

–

1 is to be specified. For example, to set the position at 9th

[Default]

[See Also] HT

[SampleProgram] [Print Results]

•

Initial value is specified for each eight characters(9th.17th.25thcolumn)ofANKcharacters.

See Sample Program and Print Results for HT on Page 31.

47

CITIZEN

Page 48

ESC E n

[Function] Specifying/canceling highlighting

[Code] <1B>H<45>H<n>

[Range] {0 =< n =<FF} Data is described in Hexcode.

[Outline] Specifying/canceling the highlighting characters.

•

"n" is valid only for the lowest bit (n0).

•

Control by the lowest bit (n0) is shown as follows:

n0 Type

0 Canceling highlighting.

1 Specifying highlighting.

• This is effective to all characters.

• Dot configuration of a highlighted character includes one extra dot added at its side.

BD2-2860 User’s Manual

[Caution] • The print result of Double printing and highlight character printing is completely same.

[See Also] ESC !

[Example]

[SampleProgram]

LPRINT CHR$ (&H1B) + "E" + CHR$ (0);

LPRINT "AAA BBB" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "E" + CHR$ (1);

LPRINT "AAA BBB" + CHR$ (&HA);

[Print Results]

48

CITIZEN

Page 49

ESC G n

[Function] Specifying/canceling Double Printing (ESC G n)

[Code] <1B>H<47>H<n>

[Range] {0 =< n =< FF} Data is described in Hexcode.

[Outline] Specifying/canceling the double printing.

•

"n" is valid only for the lowest bit (n0).

•

Control by n is shown as follows.

n0 Type

0 Canceling double printing.

1 Specifying double printing.

• This is effective to all characters.

BD2-2860 User’s Manual

[Caution] • The print result of Double printing and highlight character printing is completely same.

[See Also] ESC E

[SampleProgram]

LPRINT CHR$ (&H1B) + "G" + CHR$ (0);

LPRINT "AAABBB" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "G" + CHR$ (1);

LPRINT "AAABBB" + CHR$ (&HA);

[Print Results]

49

CITIZEN

Page 50

BD2-2860 User’s Manual

ESC J n

[Function] Printing and feeding paper n/203 inch

[Code] <1B>H<4A>H<n>

[Range] {0 =< n =< FF} Data is described in Hexcode.

[Outline] Prints data inside the print buffer and feeds paper by n/360 inch. Since an actual mechanical

pitch is 1/203 inch, it is internally converted approximate to the value specified with this

command.

• Specified volume does not remain.

• The beginning of the line is to be considered as the next printing start position.

• Initial value is not defined.

[SampleProgram] [Print Results]

See Sample Program and Print Results for ESC 2 on Page 43.

50

CITIZEN

Page 51

ESC R n

[Function] Selecting the International Character set

[Code] <1B>H<52>H<n>

[Range] {0 =< n =< 0A) Data is described in Hex code.

[Outline] Depending on the value of n, following character sets are specified.

n(Hex) Character Set

0 U.S.A.

1France

2Germany

3 U.K.

4DenmarkI

5Sweden

6 Italy

7Spain

8 Japan

9Norway

ADenmarkII

BD2-2860 User’s Manual

[Default] • The initial value of n indicates the character set specified by Jumper (J1~J3).

[See Also] Character Code Table (International Character Set)

[SampleProgram] [Print Results]

FOR I=0 TO 10

LPRINT CHR$ (&H1B) + "R" + CHR$ (I);

LPRINT " #$@[¥]^”;

LPRINT CHR$ (&H60) + "{¥} ˜";

LPRINT "n=" + STR$ (I);

LPRINT CHR$ (&HA);

NEXT I

51

CITIZEN

Page 52

ESC V n

[Function] Specifying/Canceling 90°-right- turned Characters

[Code] <1B>H<56>H<n>

[Range] {0 =< n =< 1} Data is described in Hex code.

[Outline] Specifying/canceling characters 90°-right- turned character.

• "n" means the followings.

n (Hex) Conditio n

0

1

[Caution] • No underlines are attached to 90°-right- turned characters.

[Default] • The initial value of n is "0".

Canceling

Specifying

90°-right- turned Characters

90°-right- turned Characters

BD2-2860 User’s Manual

[SampleProgram] [Print Results]

LPRINT CHR$ (&H1B) + "V" + CHR$ (0);

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "V" + CHR$ (1);

LPRINT "AAAAA" + CHR$ (&HA);

52

CITIZEN

Page 53

ESC a n

[Function] Aligning the characters

[Code] <1B>H<61>H<n>

[Range] {0 =< n =< 2} Data is described in Hex code.

[Outline] All the printed data within one line are aligned in the specified position.

• Depending on n value, positional alignment is carried out as in the table below:

n (Hex) Position

0 Left end alignment

1Centering

2 Right end alignment

[Caution] • This is valid only when n is inputted at thebeginning of line.

• The initial value of n is "0".

BD2-2860 User’s Manual

[SampleProgram]

LPRINT CHR$ (&H1B) + "a" + CHR$ (0);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "a" + CHR$ (1);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "a" + CHR$ (2);

LPRINT "AAAAA" + CHR$ (&HA);

[Print Results]

53

CITIZEN

Page 54

BD2-2860 User’s Manual

ESC c5 n

[Function] Enabling/Disabling Panel Switches

[Code] <1B>H<63>H<35>H<n>

[Range] {0 =< n =< FF} Data is described in Hexcode.

[Outline] Selecting the LF switch valid/invalid.

• "n" is valid only in the lowest bit (n0).

• "n" bit means the followings.

n0 Condition

0 LFSW valid.

1 LFSW invalid.

[Caution] When the panel switch is disabled with this command, the LF switchis disabled. Therefore,

the paper cannot be fed by operating the LF switch.

[Default] • The initial value of n is "0".

[SampleProgram]

LPRINT CHR$ (&H1B) + "c5" + CHR$ (0); ………When enabling the LF switch

LPRINT CHR$ (&H1B) + "c5" + CHR$ (1); ………When disabling theLF switch

54

CITIZEN

Page 55

ESC d n

[Function] Printing and Feeding the paper by n lines

[Code] <1B>H<64>H<n>

[Range] * {0 =< n =< FF} Data is described in Hex code.

[Outline] Prints data inside the buffer and feeds paper by n lines.

• Specified line does not remain.

• The beginning of the line is to be considered as the next printing start position.

[Default] • The initial value is not defined.

[SampleProgram]

LPRINT "AAAAA"

LPRINT CHR$ (&H1B) + "d" + CHR$ (2);

LPRINT "AAAAA" + CHR$ (&HA);

BD2-2860 User’s Manual

[Print Results]

55

CITIZEN

Page 56

ESC i (When Using Auto Paper Cutter)

[Function] Full Cut

[Code] <1B>H<69>H

[Outline] Activating auto cutter unit (Full cut)

BD2-2860 User’s Manual

[Caution]

•

• Prior to cutting the paper, feed the paper from the printing position to beyond the

[SampleProgram]

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "J”;

LPRINT CHR$ (150);

LPRINT CHR$ (&H1B) + "i”;

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "J”;

LPRINT CHR$ (150);

LPRINT CHR$ (&H1B) + "i”;

[Print Results]

This is valid only when n is inputted at the beginning of line.

paper cutting position of the cutter. Otherwise,the character just after print will

remain on this side of the cutter.

56

CITIZEN

Page 57

ESC m (When Using Auto Paper Cutter)

[Function] Partial Cut

[Code] <1B>H<6D>H

[Outline] Activating auto cutter unit (Partial cut)

BD2-2860 User’s Manual

[Caution]

•

• Prior to cutting the paper, feed the paper from the printing position to beyond the paper

[SampleProgram]

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "J”;

LPRINT CHR$ (150);

LPRINT CHR$ (&H1B) + "m”;

LPRINT "AAAAA”;

LPRINT CHR$ (&H1B) + "J”;

LPRINT CHR$ (150);

LPRINT CHR$ (&H1B) + "m”;

[Print Results]

This is valid only when n is inputted at the beginning of line.

cutting position of the cutter. Otherwise, the character just after print will remain on th is side

of the cutter.

57

CITIZEN

Page 58

BD2-2860 User’s Manual

ESC t n

[Function] Selecting Character Code Table

[Code] <1B>H<74>H<n>

[Range] {0 =< n =< 1} Data isdescribedin Hex code.

[Outline] Selecting Page n on the character code table:

The character code table is selected depending on the value of n.

"n" means the followings.

n (Hex) Conditio n

0 Page0(IBM Character #2)

1 Page1(Domestic Character)

[Default] The initial value of n is subject to the character set for the country specified

by the Jumper(J1~J3).

• When Japan is selected: Domestic characters

• When non-Japan is selected: IBM characters #2

[See Also] Character Code Table

[SampleProgram]

LPRINT CHR$ (&H1B) + "t" + CHR$ (0);

LPRINT " n=0 “;

FOR C=&HB1 TO &HB5

LPRINT CHR$ (C);

NEXT C

LPRINT CHR$ (&HA);

LPRINT CHR$ (&H1B) + "t" + CHR$ (1);

LPRINT " n=1 “;

FOR C=&HB1 TO &HB5

LPRINT CHR$ (C);

NEXT C

LPRINT CHR$ (&HA);

[Print Results]

58

CITIZEN

Page 59

ESC v (Serial Interface Only)

[Function] Transmitting the printer status (Serial Type)

[Code] <1B>H<76>H

[Outline] Current printer status is transmitted.

BD2-2860 User’s Manual

[Caution]

• Status sent out consistsof 1 byte whose content is as in the table below.

• In DTR/DSR control, after revertible state of the host (DSR signal beingin SPACE

state) isconfirmed,only 1 byte is transmitted. In XON/XOFF c ontrol, DSR signal state

not being confirmed, only 1 byte is transmitted.

• In DTR/DSR control, when the host is in unrespectable state (DSR signal being in

MARK state), it waits until receptacle state is created.

• In paper end (paper near end) status, this command may be unrespectable state due to

BUSY state.

Remarks. This command is valid only for serial interface model.

ValueBit Function

01

0 Not defined

1 Not defined

2 Paper end With paper Without paper

3 Not defined

4 Not used Fixed to 0

5 Not defined

6 Not defined

7 Not defined

–

[SampleProgram]

OPEN "COM1: N81NN" AS #1;

PRINT #1, CHR$ (&H1B) + "v”;

A$ = INPUT$ (1, #1);

CLOSE #1

59

CITIZEN

Page 60

ESC { n

[Function] Specifying/Canceling the Inverted Characters

[Code] <1B>H<7B>H<n>

[Range] {0 =< n =< FF} Data is described in Hex code.

[Outline] Specifying/canceling inverted characters.

• "n" is valid only for the lowest bit (n0).

• Bit n (n0) means the followings.

n0 Condition

0 Canceling inverted characters.

1 Specifying inverted characters.

[Caution] • Inverted-printing means printing the line at 180°turned.

• This is valid only when this is specified at the beginning of a line.

BD2-2860 User’s Manual

[Default] • The initial value of n is "0".

[SampleProgram]

LPRINT CHR$ (&H1B) + "{" + CHR$ (0);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT "BBBBB" + CHR$ (&HA);

LPRINT CHR$ (&H1B) + "{" + CHR$ (1);

LPRINT "AAAAA" + CHR$ (&HA);

LPRINT "BBBBB" + CHR$ (&HA);

[Print Results]

60

CITIZEN

Page 61

BD2-2860 User’s Manual

ESC $ n1 n2

[Function] Specifying the Absolute Positions

[Code] <1B>H<24>H<n1><n2>

[Range] {0=<n1=<FF}

{0 =< n2 =< 1} Data is describedin Hex code.

[Outline] The printing start position is specified in the number ofdots (1/203inch unit) from

the beginning of line.

• The number of dots is dividedby 256, whose quotient is taken as n2 and the residual as n1.

• Therefore, the printing start position is equal to n1+n2 x 256 from the beginning of line.

[Caution]

•

Specifying beyond the line end is ignored.

[Default] • The initial value is not specified.

[See Also] ESC \

[SampleProgram]

LPRINT CHR$ (&H1B) + "$”;

LPRINT CHR$ (0) + CHR$ (0) + "A”;

LPRINT CHR$ (&H1B) + "$”;

LPRINT CHR$ (50) + CHR$ (0) + "B”;

LPRINT CHR$ (&H1B) + "$”;

LPRINT CHR$ (0) + CHR$ (1) + "C”;

LPRINT CHR$ (&HA);

LPRINT CHR$ (&H1B) + "$”;

LPRINT CHR$ (100) + CHR$ (0) + "A”;

LPRINT CHR$ (&H1B) + "¥”;

LPRINT CHR$ (&HC2) + CHR$ (&HFF) + "B”;

LPRINT CHR$ (&HA);

[Print Results]

61

CITIZEN

Page 62

BD2-2860 User’s Manual

ESC ¥ n1 n2

[Function] Specifying the Relative Positions

[Code] <1B>H<5C>H<n1>< n2>

[Range] {0=<n1=<FF}

{0 =< n2 =< FF} Data is described in Hexcode.

[Outline] The printing start position is specified in the number ofdots(1/203inch unit) from

the current position.

• Rightwarddirection is taken as plus and leftward direction as minus.

•

To specify N dot in minus (left) direction, use a complement of N for assignment.

–

N dots = 65536–N

• The number of dots is dividedby 256, whose quotient is taken as n2 and the residual as n1.

[Caution] • Specifying exceeding the top of line or the end of line is ignored.

[Default] • The initial value is not specified.

[See Also] ESC $

[SampleProgram] [Print Results]

See Sample Program and Print Results for ESC $ on Page 61.

62

CITIZEN

Page 63

GS k n [ d ] k NUL

[Function] Printing the Bar Code

[Code] <1D>H<6B>H<n> [ < d> ] k <00>H

[Range] {0 =< n =< 7} Data are described in Hexcode.

[Outline] Specifying a type of bar code and printing bar codes.

• The beginning of line is considered as the next printing start position.

• Depending on the value of n, the following bar code can be selected.

d indicates a character code to be printed and k indicatesthe number of character to be

printed.

n (Hex) Bar Code System Maximum Columns

0 UPC-A --1 UPC-E --2 JAN13 (EAN) --3 JAN 8 (EAN) --4 CODE 39 13

5ITF 22

6 CODABAR (NW-7) 17

7 CODE 128 15

BD2-2860 User’s Manual

[Caution] • When data being held in the print buffer, this command is ignored.

• Regardless of the specified feed pitch, this command feeds the paper to be required to

print a bar code.

• If the character code d cannot be printed in the respective bar code system, the bar

code so far will be printed, processing the subsequent data as normal data.

• When a bar code whose number of characters to be printed is fixed has been selected,

the number of characters k have to be always made equal to the number of characters

to be printed. (The bar code is not printed when not matching.)

• When the horizontal direction exceeds one line length, the excess part is not printed.

[Default] • The initial value is not specified.

63

CITIZEN

Page 64

BD2-2860 User’s Manual

[Description of Bar Codes] <For print examples, see Page 66. >

UPC-A This bar code, consisting of numerals only, has a fixed length of 12 column; a 11-columns

number entered from the host or application software plus a check column(12th column)

automatically calculated inside the printer. If the 12th-column numeral is sent from the host,

the entire bar code will be printed as it is.

UPC-E This bar code, consisting of numerals only, has a fixed length of 8 column; the first

number system character is "0" stationary. A 12-column numeral entered from the host or

applicationsoftwareiscompressedto8columnswithacheckcolumnandprinted. The12thcolumn check column is automatically calculated inside the printer and sent from the host, the

entire bar code will be printed, compressed to 8 columns.

JAN- 13( EAN) This bar code, consisting of numerals only, has a fixed length of 13 column; a 12-column

number entered from the host or application software plus a check column(13th column)

automatically calculated inside the printer. If the 13th-column numeral is sent from the host,

the entire bar code will be printed as it is.

JAN-8( EAN) This bar code, consisting of numerals only, has a fixed length of 8 column; a 7-column number

entered from the host or application software plus a check column(8th column) automatically

calculated inside the printer. If the 8th-column numeral is sent from the host, the entire bar

code will be printed as it is.

CODE39 This bar code, consisting of uppercase alphabets and numerals, has a variable length of column.

A start/stop code "*" is automatically added by the printer. Available characters include a

spaceand"$,%,+,-,·,/,0,1,2,3,4,5,6,7,8,9,"anduppercasealphabets.

ITF This bar code, consisting of numerals only, has a variable length of even column. If an odd-

column code is transferred, nothing will be printed.

CODABAR (NW-7)

This bar code, consisting of alpha numerals, has a variable length of column. Available

characters include "0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, D, D, $, +, -,., /, :." A start/stop codeis

required; any one of A, B, C, and D is used.

CODE128 • This bar code consists of all of 128 ASCII code characters and has a variable length of

column. This printer supportsthecode subsets A, B, and C. By prefixing a transfer

code with any one character of A, B, and C, you can select the code subset to start from.

If not prefixed with A, B, or C, the code subset B will be selected.

• The codesubset A is the bar code consisting of standard uppercase alphabets, numerals,

symbols, and special codes.

• The codesubset B is the bar code consistingof standard uppercase/lowercase alphabets,

numerals, symbols, control codes, and special codes.

• The code subset C is the bar code consisting of special characters and 100 kinds of

numbers ranging from 00 to 99.

• The check column automatically calculated inside the printer is added to the end of the

entered column to be printed.

64

CITIZEN

Page 65

BD2-2860 User’s Manual

• Processing of the special characters

The characters above the ASCII code number 96 are considered special characters. The

following lists the converted characters for entering these characters.

ASCII Code Converted Character Subset Code Subset Code B Subset Code C

96 80h FNC 3 FNC 3 -N/A97 81h FNC 2 FNC 2 -N/A98 82h SHIFT SHIFT -N/A-

99 83h CODE C CODE C -N/A100 84h CODE B FNC 4 CODE B

101 85h FNC 4 CODE A CODE A

102 86h FNC 1 FNC 1 FNC 1

The following exemplifies a selection of the code subset as a me thod to utilize the special

characters.

<Selection of Code Subset>

• Initial selection: Enter any one character of A, B, and C.

• Conversion on the way: Enter any one character of 82h through 85h

Example) When initially testing with the code subset B, and then, printing the bar code,

"123," with the code subset A

• Input code : B TEST <85> 123

• Bar code data : <CODE B>TEST<CODE A>123

[SampleProgram]

LPRINT CHR$ (&H1D) + "H" + CHR$ (2);

LPRINT CHR$ (&H1D) + "k”;

LPRINT CHR$ (4);

LPRINT "123" + CHR$ (0);

[Print Results]

65

CITIZEN

Page 66

BD2-2860 User’s Manual

[Description of Bar Codes]

UPC-A, UPC-E, JAN-13 (EAN), JAN-8 (EAN), CODE39, ITF, CODABAR, CODE128

Type Print Sample Outline of Symbol Max. column

12-column fixed-length bar code consisting

UPC-A

UPC-E

JAN-13

JAN-8

of numerals only –

8-column fixed-length bar code consisting

of numerals only. Abbreviated version of

UPC-A

13-column fixed-length bar code consisting

of numerals only –

8-column fixed-length bar code consisting

of numerals only –

–

CODE39

ITF

CODABAR

(NW-7)

CODE128

Printing is done depending on bar code specification type, number of print column, bar code

height, width (Magnification), visible code presence, and bar code data specification.

Variable-length bar codeconsisting of

alphabets and numerals. The start/stopcode

"*"is automatically added.

Even-column variable-length bar code

consisting of numerals only

Variable-length bar codeconsisting of

alpha numerals. Any one of A, B, C, and D

is required as the start/stop code.

Variable-length bar codeconsisting of all

128 ASCII code characters.

13

22

17

15

66

CITIZEN

Page 67

GS w n

[Function] Selecting the horizontal size (Scale factor) of the Bar Code

[Code] <1D>H <77>H<n>

[Range] {2 =< n =< 4} Data isdescribedin Hex code.

[Outline] Selecting bar code width.

n denotes the number of dots in fine element width.

BD2-2860 User’s Manual

[Default]

•

[SampleProgram]

LPRINT CHR$ (&H1D) + "h" + CHR$ (30);

LPRINT CHR$ (&H1D) + "w" + CHR$ (2);

GOSUB BC

LPRINT CHR$ (&H1D) + "h" + CHR$ (50);

LPRINT CHR$ (&H1D) + "w" + CHR$ (3);

GOSUB BC

LPRINT CHR$ (&H1D) + "h" + CHR$ (80);

LPRINT CHR$ (&H1D) + "w" + CHR$ (4);

GOSUB BC

END

BC:

LPRINT CHR$ (&H1D) + "k”;

LPRINT CHR$ (4);

LPRINT "12" + CHR$ (0);

RETURN

[Print Results]

The initial value of this width is "3".

67

CITIZEN

Page 68

GS h n

[Function] Selecting the height of the Bar Code

[Code] <1D>H<68>H<n>

[Range] {1 =< n =< FF} Data is describedin Hex code.

[Outline] Selecting bar code height.

n denotes the number of dots in the vertical direction.

BD2-2860 User’s Manual

[Default]

[SampleProgram] [Print Results]

•

The initial valueof n is "162".

SeeSample Programand Print Results for GS w on page 67.

68

CITIZEN

Page 69

GS H n

[Function] Selecting of Printing Position of HRI Code

[Code] <1D>H<48>H<n>

[Range] {0 =< n =< 3} Data is described inHex code.

[Outline] Selecting printing position of HRI code in printing bar codes.

• "n" means the followings.

n (Hex) PrintingPosition

0 No printing

1 Above the bar code

2 Below the bar code

3 Both above and below the bar code

The HRI code refers to the bar code-turned characters so that you can read them.

BD2-2860 User’s Manual

[Caution] The HRI code is printed in the font selected with GS f. Specify before the GS k command.

[Default] • The initial value of n is "0".

[See Also] GS f

[SampleProgram] [Print Results]

LPRINT CHR$ (&H1B) + "3" + CHR$ (5);

LPRINT CHR$ (&H1D) + "h" + CHR$ (50);

LPRINT CHR$ (&H1D) + "H" + CHR$ (0);

GOSUB BC

LPRINT CHR$ (&H1D) + "H" + CHR$ (1);

GOSUB BC

LPRINT CHR$ (&H1D) + "H" + CHR$ (2);

GOSUB BC