Page 1

----------------------------------------------------------------------------------------------------------------------

VIBRATIONS TRANSMITTER mod. Ex TR-26

Function

The integrated transmitter mod. Ex TR-26 measures the Absolute Vibrations of any rotating

machine support and is able to interface itself directly (two-wires technique, current loop 4 to 20

mA) with an acquisition system (PLC or DCS).

The transmitter reduces at maximum installation and wiring incidence, that normally limits the

possibilities to apply the traditional systems for vibration monitoring.

The transmitter is certified for applications in areas classified as:

- Ex II 2 G Ex ia IIC T6 or T5 or T4

General description

The transmitter, assembled through direct fastening on the machinery, generates a current signal (4

to 20 mA) that is proportional respectively to vibration speed or acceleration.

The transmitter is composed of a stainless steel body having a threaded machine connection; the

connection with the users is performed bymeans of a MIL-C-5015 connector (2 poles), included.

NOTE: The transmitter is available in different configurations and becomes operative only after its

correct electrical connection, as per drawing no. 85465-P; it doesn’t need setup or maintenance.

Technical characteristics

Page 2

Composition

Integrated transmitter body, in AISI 316L stainless steel material.

Power supply

24 Vdc (10 to 35 Vdc) current loop 4 to 20 mA (two-wires)

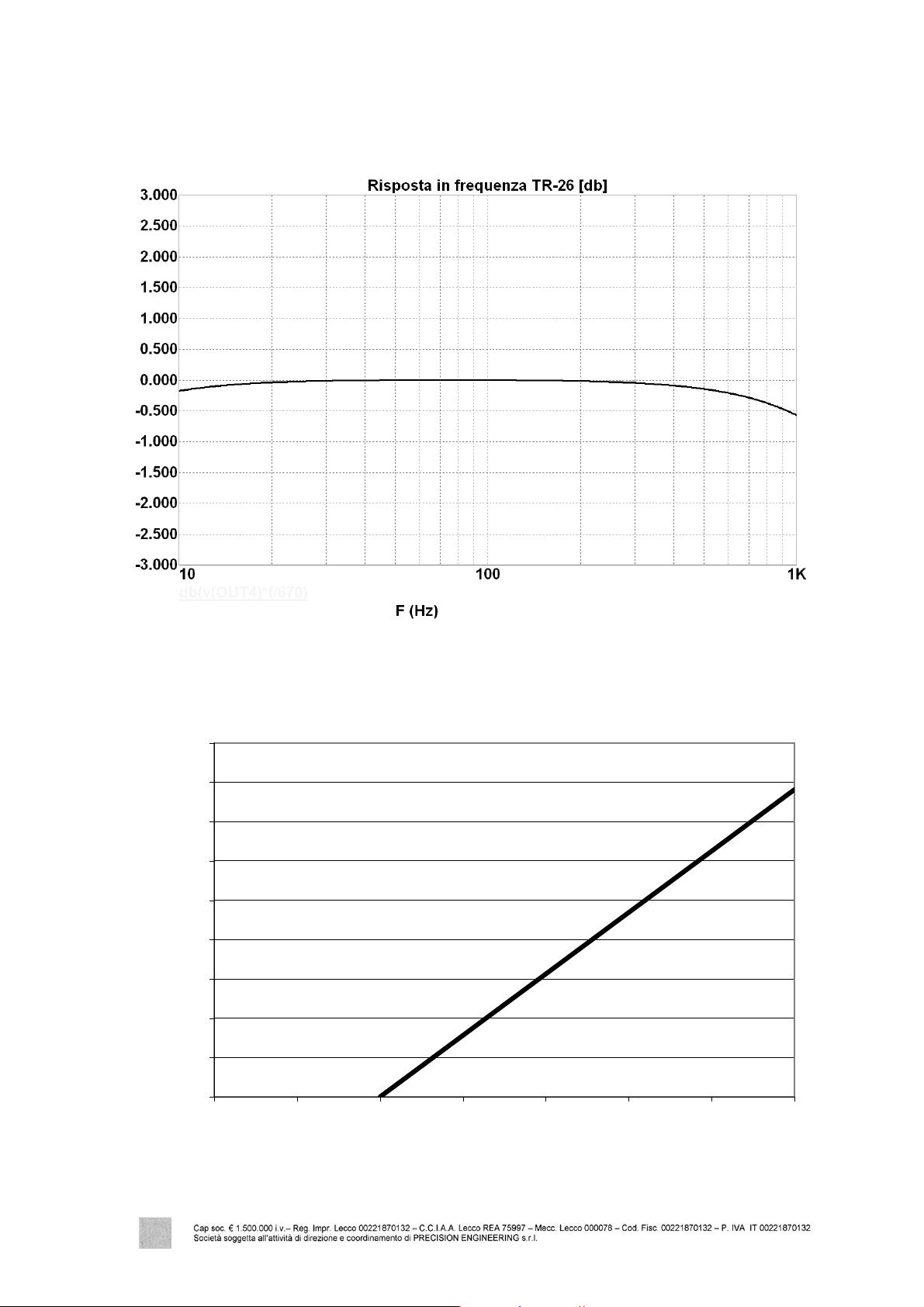

Maximum load as per figure 2

External connections

MIL-C-5015, 2 poles connector (conductors max section 2,5 mm²)

Environmental use field

- 50°C to + 120°C

IP 65 EN 60529/10.91 standards

Measurement type

Omnidirectional seismic (absolute vibrations)

Dynamic field

± 18 g

Transversal sensitivity

< 5 %

Linearity

± 2% - 75 Hz

Dynamic performances

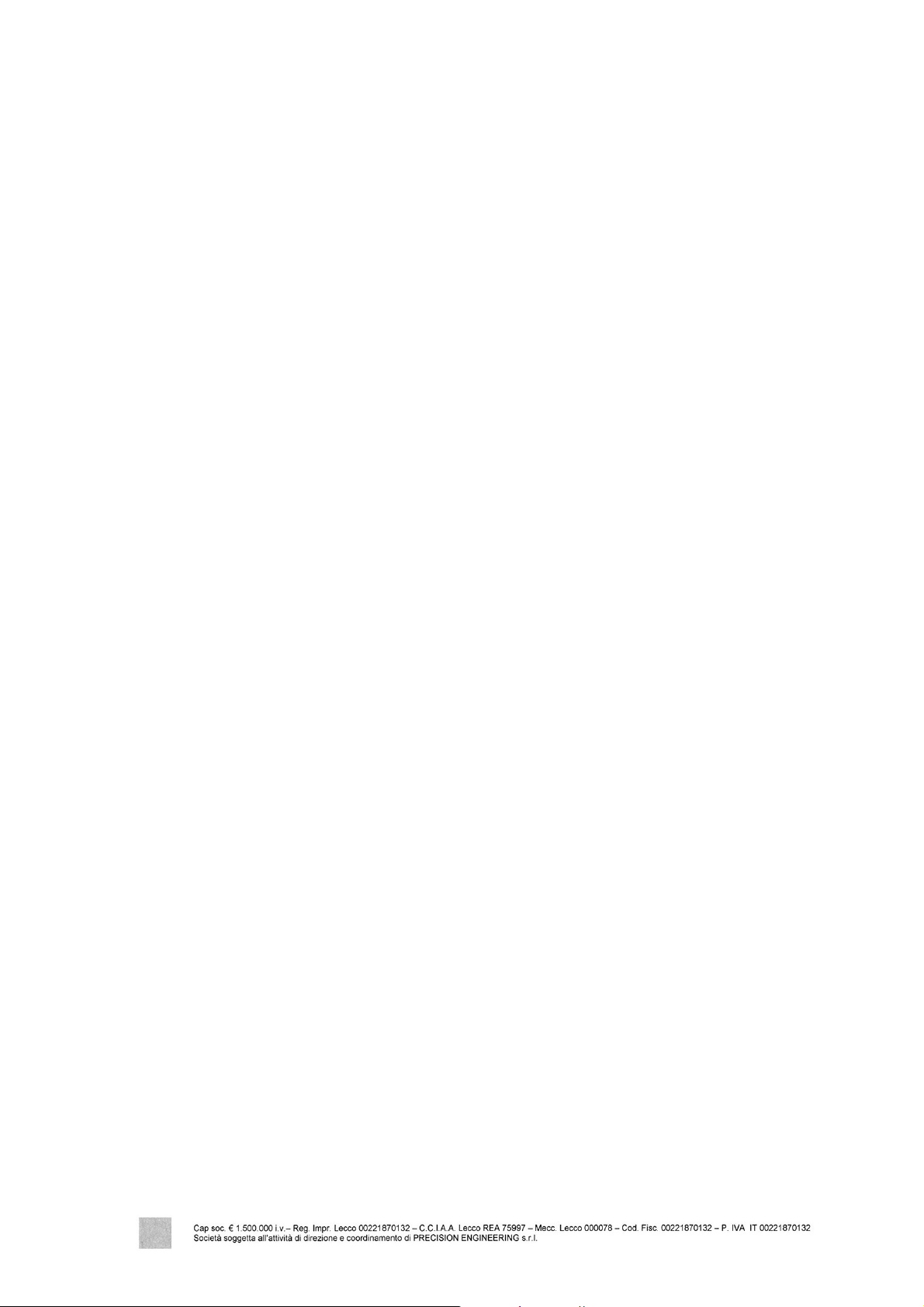

±3% / 10Hz-1kHz (See figure 1)

-3db / 1.5Hz – 2.5kHz

Insulation

108 between signal and container

Application axis

any

Process standard connections

M8x1,25

¼”-18NPT

¼’’-28UNF

Maintenance

none

Electrical connections

bipolar shielded cable, typical conductors section 2x1mm²

Possible prearrangements to the order

measuring field

fastening

ATEX certification type

Figure 1 – Frequency response [db]

2

Page 3

Figure 2 – Maximum allowable load on current loop

900

Power supply [V]

800

700

600

500

400

300

Maximum load [Ohm]

200

100

0

0 5 10 15 20 25 30 35

3

Page 4

ASSEMBLY

N.B.: the operations must be performed, if possible, when the machine is OFF andby using the

maximum delicateness in order to avoid any transmitter damages.

1) Predispose a special threaded hole on the support to be measured. The surface on which the

transmitter lies must be flat and smooth. It is better to interpose a silicon layer between the

transducer and the support surface.

N.B. : Avoid giving violent shocks to the transmitter body, the closure torque must be 5 to

10 N-m.

2) Connect electrically the transmitter to the measuring equipment through the movable connector

(included).

Notes for connection:

- The wiring MUST be made by using a cable, resistant to working environment agents (oils,

corrosive acids, temperatures, etc.).

- A shielded cable MUST BE used, bearing in mind that the screen must be connected to the

frame mass (GND=ground) at only one of the two cable ends (recommended instrumentation

side).

Notes for certification:

- The use of ATEX certified transmitters is not allowed for different hazardous conditions or

for those exceeding the data specified on the nameplate affixed to the transmitter.

- The transmitter does not require maintenance. Any work regarding performance checks or

repair should only be carried out in a laboratory duly authorized byCEMB S.p.A.

4

Page 5

Notes for identification:

The transmitter is constructed to be correctly used, according to the conditions set out by the

following table:

Certifications to ATEX 94/9/CE

0722 II 2 G Ex ia IIC T4

0722 II 2 G Ex ia IIC T5

0722 II 2 G Ex ia IIC T6

CESI 09 ATEX 045

Legend of nameplate safety data

Marking of conformity withthe applicable European directives

0722 Number of the Notified Body carrying out the surveillance (CESI)

Marking of conformity withDirective 94/9/CE

and relative technical standards

II Equipment suitable for surface applications (not for mining)

2

G Protection for gases, vapours, mists.

Ex ia Equipment belonging to category "ia" with instrinsic safety.

II C

T4

T5

T6

CESI 09 ATEX 045

Ta = 120°C (T4)

Ta = 90°C (T5)

Ta = 75°C (T6)

Equipment designed to environments in which explosive atmospheres

caused bygases, vapours, mists or mixtures of air and dust may occur, high

level of protection. Suitable for zone 1.

Suitable for substances (gases) of group IIC,

also suitable for groups IIA and IIB

Temperature class T4 (surface temperature 135°C)

Temperature class T5 (surface temperature 100°C)

Temperature class T6 (surface temperature 85°C)

Certificate identification:

Name of the laboratoryissuing the CE-type-examination certificate

09 = certificate issuing year

045 = certificate number

Ambient temperature –50 to +120 °C

Ambient temperature –50 to +90 °C

Ambient temperature –50 to +75 °C

5

Page 6

Ordering data

A B C

TR – 26 / / /

where,

A : measuring field

0 0 to 10 mm/s RMS

1 0 to 20 mm/s RMS

2 0 to 50 mm/s RMS

3 0 to 100 mm/s RMS

4 0 to 1 g RMS

5 0 to 5 g RMS

6 0 to 10 g RMS

S Special, to be defined

B : threaded connection

0 M8x1,25

1 ¼’’ – 18NPT

2 ¼’’ – 28UNF

C : ATEX certification

0 None

2 II 2 G Ex ia IIC T6 or T5 or T4 (Zone 1)

Ordering example

TR – 26 / 1 / 0 / 2

TR – 26 measuring field 0 to 20 mm/s RMS, connection M8x1,25, certification for Zone 1

6

Page 7

ASTM09120

Ex TR-26 05 gb

7

Loading...

Loading...