Page 1

VIBRATION MONITORING OF FANS INSTALLED IN ROAD TUNNELS

CEMB SPA

Via Risorgimento, 9

Mandello del Lario (Lc), Italy

stm@cemb.com

www.cemb.com

Page 2

CEMB SPA – Mandello del Lario

INSTRUMENT FOR MONITORING VIBRATIONS OF FANS INSTALLED IN ROAD

TUNNELS

PURPOSE OF THE INSTRUMENT

The instrument measures and monitors the vibrations of each fan installed. It allows

checking for correct machine operation over a period of time thus preventing catastrophic

failures.

Hence it is possible to stop the fan when the vibrations exceed a preset value and to

schedule maintenance work in order to replace damage parts as well as to clean the

blades (uneven deposits would generate unbalances and therefore vibrations) or to check

the fan fastenings, etc.

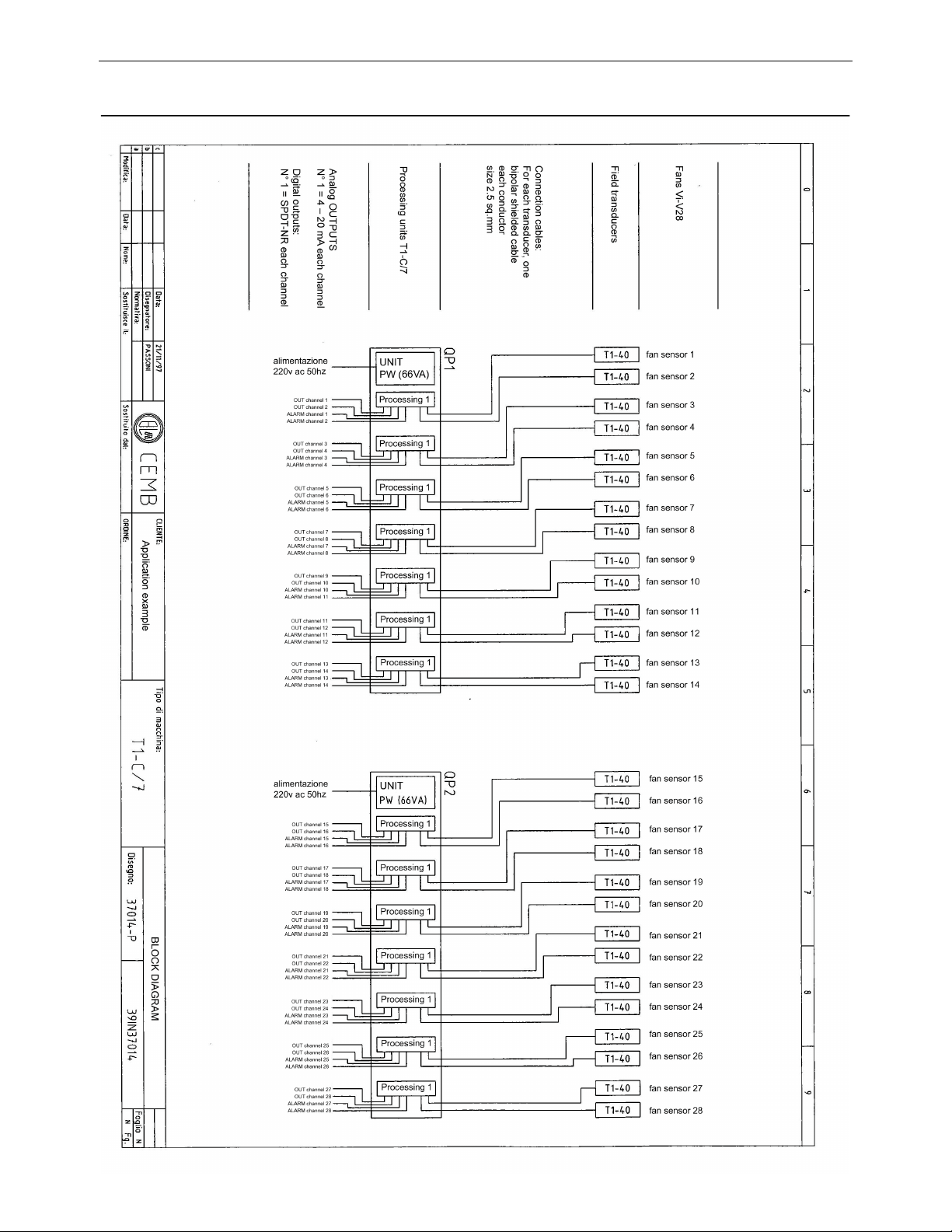

1. TECHNICAL DESCRIPTION OF THE SYSTEM

1.1. GENERAL

A seismic vibration transducer is installed on the housing for each fan according to

any radial direction at random.

The signal generated by the transducer is sent to an electronic processing unit.

Connection is via a suitably sized shielded cable (up to 200 metres 2x1mm2 - up to

400 metres 2x1.5mm2 - up to 800 metres 2x12.5m2 ).

The processing unit is normally installed in the centre of gravity position with

respect to the tunnel section where the monitored fans are installed.

1.2. VIBRATION TRADUCERS

1.2.1. Type of transducer.

The transducer is of the electrodynamic seismic type (velocity transducer), i.e.

designed for measuring the speed of vibration parameters; there are no amplifying

or signal linearizing circuits incorporated in the transducer).

1.2.2. Frequency range.

Frequency response of the transducer is linear in the range from 10 to 1000 Hz .

1.2.3. Temperature limits.

The transducers should be able to operate correctly in the temperature range from

– 10°C to + 100°C.

Page 3

CEMB SPA – Mandello del Lario

1.2.4. Resistance to environmental agents.

The transducer should be tightly sealed and insensitive to ambient humidity (max.

25%) and resistance to contamination by dusts and lubricating oils with a degree of

protection IP 65 (CEI standards)

1.2.5. Cables and connectors.

The transducers are complete with male-female connection to MIL standards, able

to withstand the mechanical and thermal stresses described in points 1.2.3 and

1.2.4.

1.2.6. Mounting.

It should be possible to install the transducer in any direction and fasten it with a

sufficiently rugged screw (e.g. M8 thread).

TEST INSTRUMENTS

1.3.1. Types of instruments.

All instruments are fully transistorized and the signal coming from a transducer is

sent to the respective conditioning and measuring circuit. The scanning system is

not permissible.

1.3.2. Measurement range.

The instrument should allow measurement and supervision of the RMS value of the

vibration speed within a range from 0 to 10 mm/s.

1.3.3. Frequency range.

The instrument response is linear in a frequency range from 10 to 1000 Hz.

1.3.4. Threshold discriminator circuit.

Each measuring channel is provided with a threshold discriminator circuit of static

type with amplitude comparator, suitable for driving an output relay (SPDT contact)

and indicator lamp (LED).

The tripping level of the alarm threshold is adjustable between 10% and 100% of

the measuring scale.

The alarm threshold is provided with a time delay device, independent from the

value and adjustable from 0 to 20 seconds.

The system output logic is as follows: under normal condition (vibration level below

the threshold) the relay is de-energized and the LED is unlit. The alarm threshold is

of the “unlatched” type, i.e. the output relay remains energized and the relative LED

is lit up only as long as the input signal is higher than the threshold value.

Page 4

CEMB SPA – Mandello del Lario

1.3.5. Analog output.

Each vibration channel sends an output signal 4 to 20 mA proportional to the RMS

value of the vibration speed measured.

1.3.6. Environmental conditions.

The instruments operate correctly within a temperature range from –10°C to +

50°C.

1.3.7. Power supply.

Instrument power supply is 220 Vac – 50 Hz

1.3.8. Composition of the instruments.

Each instrument is mounted in a 19” rack enclosure able to process at least 16

measuring channels. The following are installed in the unit:

- one power supply complete with main switch

- a number of signal processing boards which depend on the number of fans to be

monitored.

Page 5

CEMB SPA – Mandello del Lario

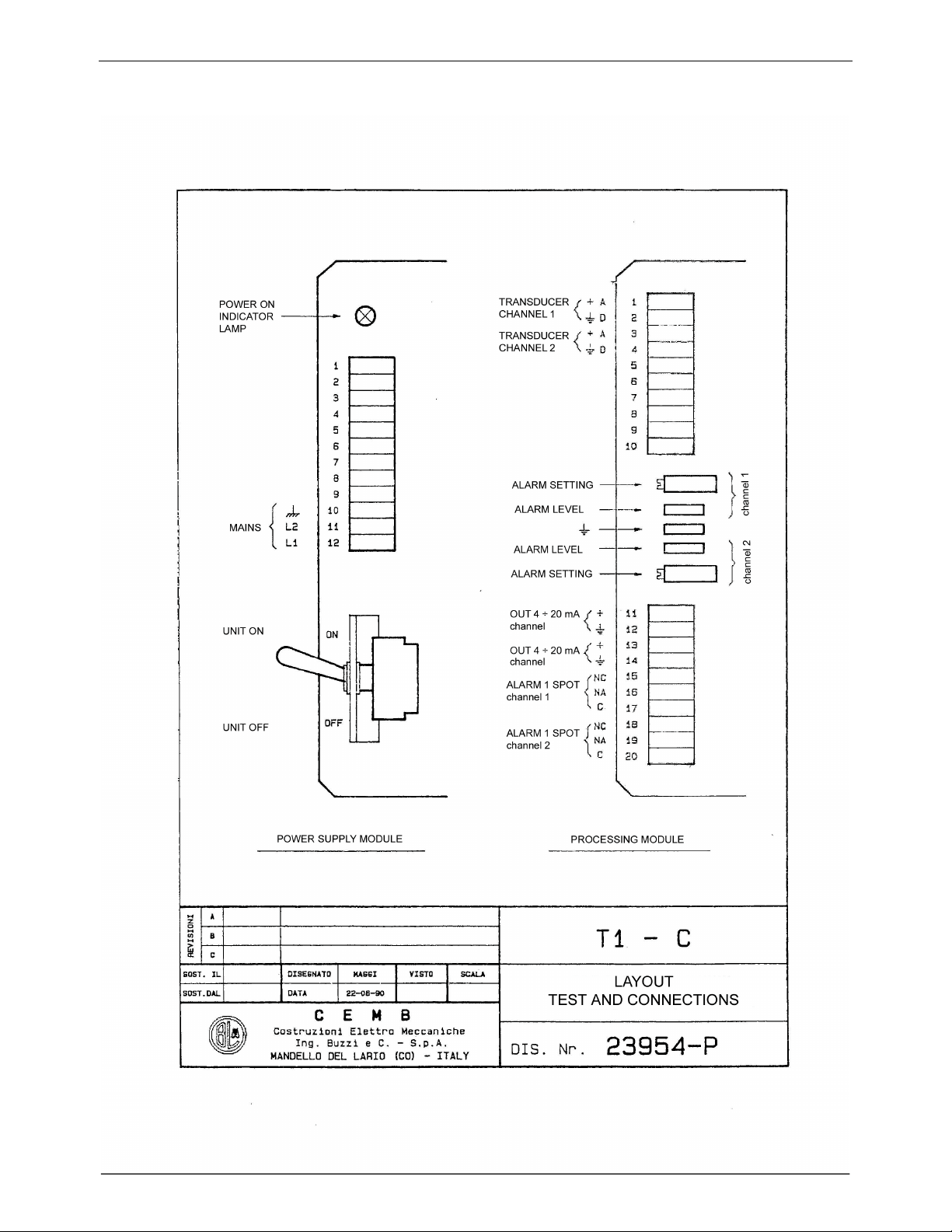

POWER SUPPLY MODULE PW T1-C

FUNCTION

Power supply module PW T1-C is able to supply stabilized voltage up to 8 processing

modules T1-C. The power supply is mounted in a wall-mounted unit.

The instrument can be mounted in suitable enclosure with degree of protection IP54 for

applications in protected environment.

TECHNICAL CHARACTERISTICS

External connections : terminal board WEIDMULLER TOP 1,5 GS

Supply voltage : 100 – 220 V 50 Hz ± 10%

Max. power consumption : 50 VA

Output voltages : + 15 V - 15 V

Max. output currents : + 15 V = 1 A

- 15 V = 0.5 A

Unit : dwg. 23950

Page 6

CEMB SPA – Mandello del Lario

OVERALL DIMENSIONS

4 HOLES dia. 6.5

POWER SUPPLY MODULE

PROCESSING MODULES

(up to 8 modules)

PROCESSING RACK

Page 7

CEMB SPA – Mandello del Lario

PROCESSING MODULE T1-C

FUNCTION

The T1-C processing module is able to process the signals coming from two vibration

transducers type T1-40 and to supply, for each signal, an analog output and an alarm

contact. The module can supply the analog outputs proportional to the axial position or

speed of vibration.

Such module is extremely compact in design while it allows simple and modular monitoring

of the vibrations.

Page 8

CEMB SPA – Mandello del Lario

TECHNICAL CHARACTERISTICS

External connections : terminal board WEIDMULLER TOP 1,5 GS

Supply voltage : + 15 V / - 15 V

Max. current drawn : + 15 V = 120 A

- 15 V = 16 A:

N° of channels processed : 2

Unit of measurement of vibration : 0 to 100 µm, 0 to 300 µm

0 to 10 mm/sec 0 to 30 mm/sec

Output signals (terminals

OUT1 and OUT2) : 4 TO 20 mA proportional to the input vibration

Alarm contacts (terminals

ALARM 1 – ALARM 2) : 1 SPDT for each channel

Max. current, alarm contacts : 3A

Max. voltage, alarm contacts : 250 V

Alarm adjustment : 0 to 100% of the measurement range

Alarm delay time : from 0 to 20 seconds (approx.)

Alarm condition indicator : Red LED located close to the alarm level

setting potentiometer

Page 9

CEMB SPA – Mandello del Lario

Page 10

CEMB SPA – Mandello del Lario

ASTA07120

Loading...

Loading...