Page 1

Systems

TM1

Vibration monitoring equipment, single/dual channel

BALANCING MACHINES

Page 2

Vibration monitoring equipment,

TM1

single/dual channel

Function

The TM1 equipment continuously measures the

vibrations of rotating machines by supplying analog

outputs (for interfaces to PLC or DCS) or digital

outputs (alarm and trip contacts) with the display on

a digital readout of the found value. The equipment

can be connected to other instruments (max. 32)

via serial line RS485 or to a PC (through appropriate

interface) for setting and reading the stored data by

the various measuring parameters.

Main characteristics

The TM1 instrument has been designed and

implemented with the latest digital technologies

which have allowed to improve the ß exibility

and performance of the system, by reducing its

overall dimensions and simplifying the procedures

for installation, setting and modiÞ cation of all the

operating parameters.

The instrument can be interfaced to 1 or 2 sensors

(velocity transducers or acceleration transducers)

besides with two phase reference transducers.

Digital readout of the vibration value allows the

operator to have an immediate check of the vibratory

state of the machine during set-up operations.

The control panel is provided with various buttons

Typical applications

Testing of the vibration of one or two channels

of any type of rotating machine (motors, fans,

compressors, turbines, pumps, etc.). It is normally

installed near the machine and performs all the

functions required for protection and monitoring:

measurement, protection, alarm signalling,

interfaceability with supervisory system, selfdiagnostics.

for presetting the operating parameters of

the instrument (selection of: measuring unit,

alarm thresholds, alarm time delay, threshold

multiplier, by-pass) as well as LED’s for displaying

the status regarding alarm, self-diagnostics

and BNC sockets for connection to a vibration

analyzer. The instrument is also provided with

a serial link RS485 for transferring stored data

and settings of all operating parameters of the

instrument by a PC.

The TM1 equipment can be installed in an

electrical cabinet (Þ xing on Din rail) or inside

a junction box positioned next to the machine

being monitored

.

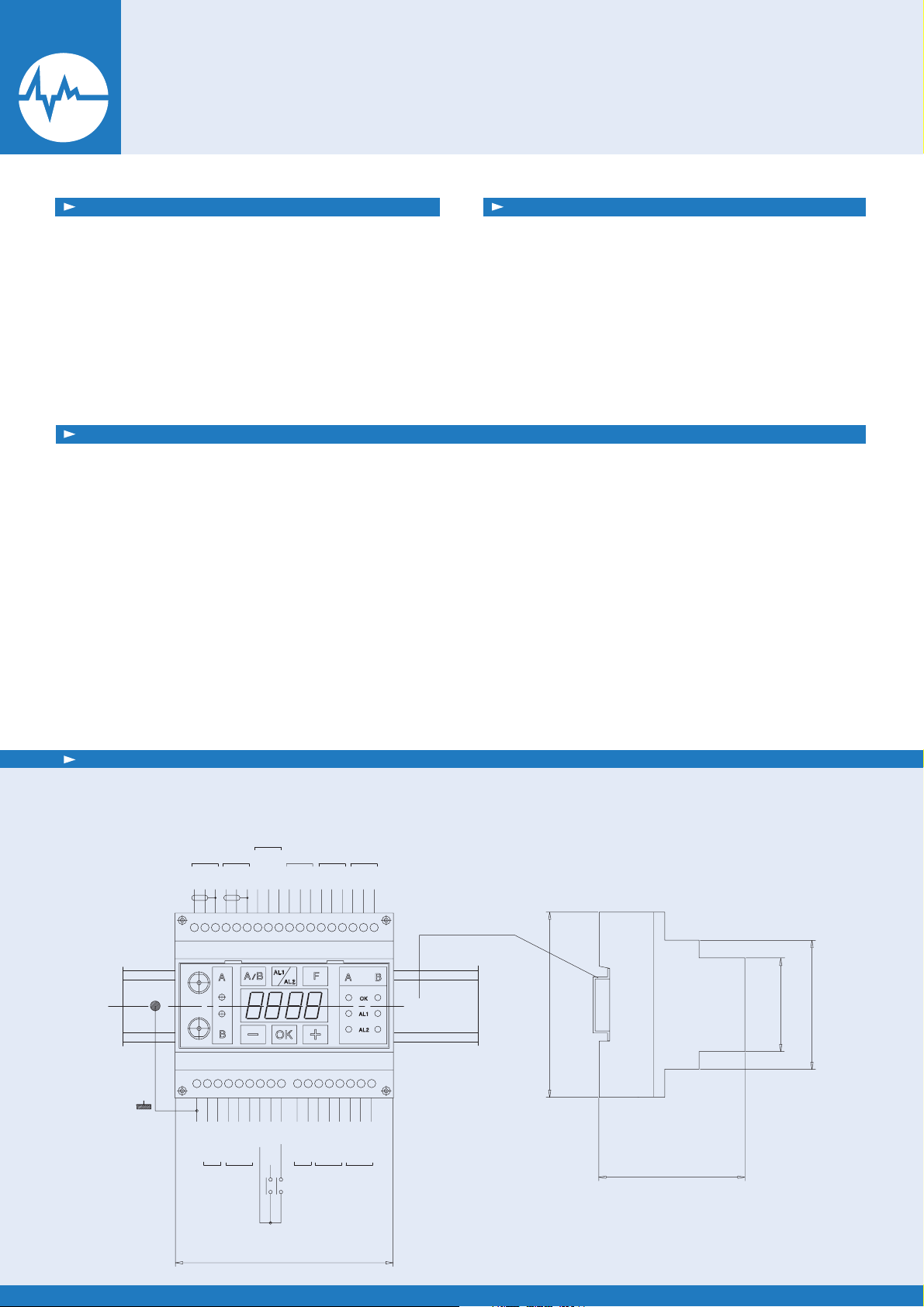

Connection wiring diagram and overall dimensions

OUTPUTS

TRANSD. Ch.A

SIG+

SIG+

SIG-

GND

GND

COM+

VDCin

GROUND

+24Vdc +/-10%

200 mA max.

POWER SUPPLY

ANALOG

TRANSD. Ch.B

SIG-

GND

OUT Ch.A

OUT Ch.B

sig+

sig+

sig-

GND

COM-

schield

BYP/RST

RS485

SPEED TRANSD.

GND

IDX A

IDX B

10 11 12 13 14 15 16 17987654321

CC

TRM

NO (NC)

RL5 (OK)

SELF DIA.

+24

CCNONC

AL1 Ch.B

RL3 1SPDT

CC

NC

NO

AL1 Ch.A

RL1 1SPDT

AL2 Ch.B

RL4 1SPDT

353433323130292827262524232221201918

CCNCNO

AL2 Ch.A

RL2 1SPDT

CCNCNO

NS35 EN50022

90

75

62

45

105

Page 3

Composition:

5

Inputs:

1 instrument in plastic box

1 or 2 measuring traducers (velocity or

acceleration transducer)

2 velocity transducers (optional)

Transducers which can be used:

Velocity transducers T1-40; T1-40V;

T1-40BF; T1-38: T1-38V; T1-38BF

Acceleration transducers (ICP) TA 18; M16; M602

Power supply:

24 Vdc nominal (22÷26 Vdc)

110/220 Vac 50 to 60 Hz (optional)

External connection:

Terminal board for connecting transducers

(max. cable section 2.5 mm2)

Terminal board for connecting alarm contacts

(max. cable section 2.5 mm2)

Terminal board for serial port RS485

BNC connectors for connection to the

analyzer

Ambient temperature range:

2 inputs, vibration transducers

2 inputs, velocity transducers

2 inputs for TRIP MULTIPLIER and

BYPASS/RESET

Serial link RS485

Analog outputs:

2 analog outputs 4:20 mA / 0: 10 V

Output relays:

SPDT contacts, I level, channel A/B

SPDT contacts, II level, channel A/B

SPDT contact, self-diagnostics

Max. measuring range:

velocity: 200 mm/s

acceleration: 50g

displacement: 1000 µm

Type of measurement:

RMS, peak, peak-to-peak

Protection degree:

-20° / +70°C

IP30 EN 529/10.91

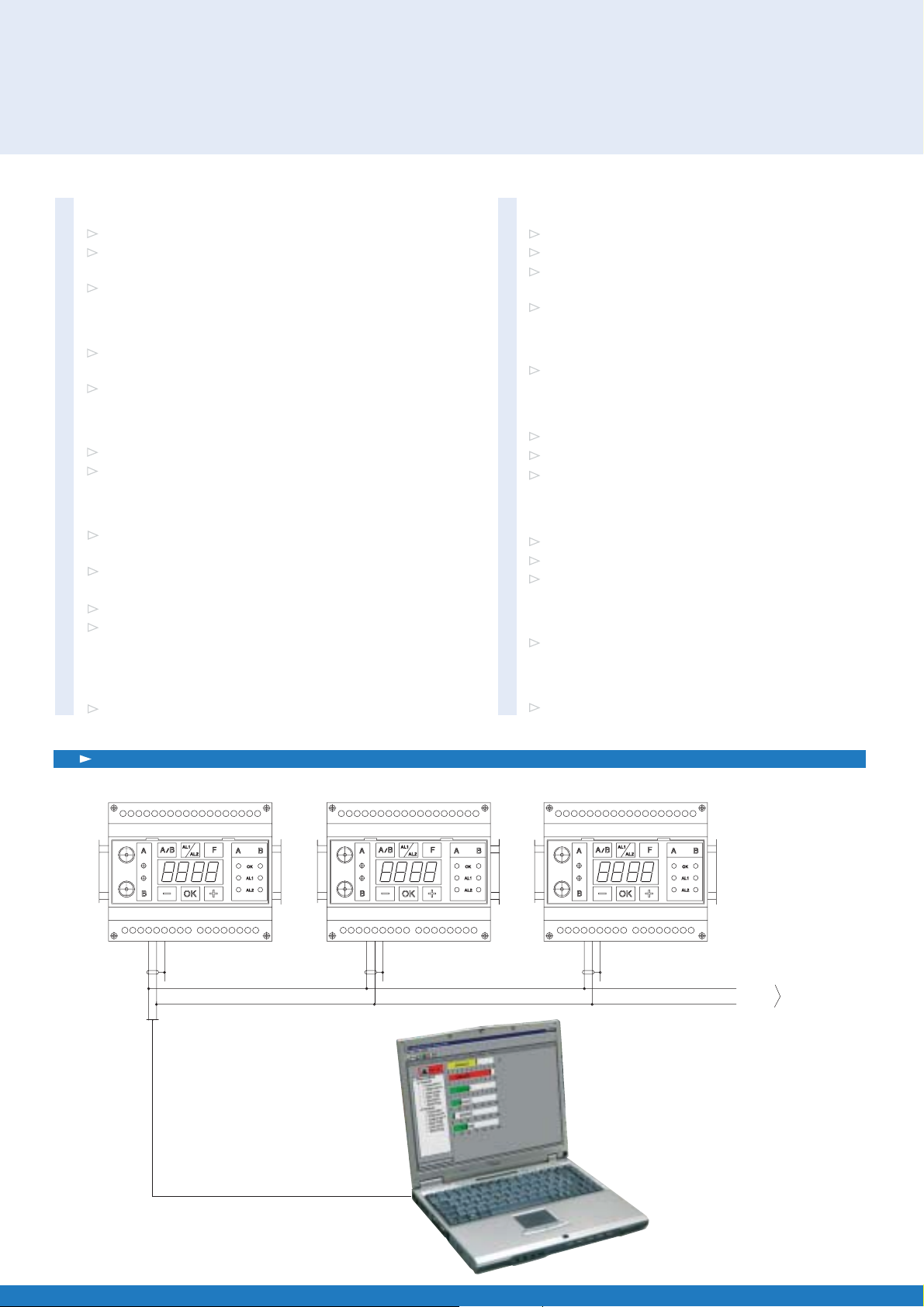

TM1: example of multiple application

TM1/1 TM1/2 TM1/3 .......... max. 32

10 11 12 13 14 15 16 17987654321

COM+

COM-

353433323130292827262524232221201918

123456789 10 1211 13 1514 16 17

COM+

COM-

272118 19 20 2422 23 25 26 333028 29 31 32 34 35

18 2019 21 2322 24 2625 27 2928 30 3231 33 3534

1 32 4 65 7 98 10 11 1312 14 1615 17

COM-

COM+

COM+

COM-

RS 48

Page 4

ORDER INFORMATION

The TM1 equipment is supplied according to the conÞ guration selected by the

Customer. However the setting of the operating parameters can be varied

during installation of the system by using the buttons on the control panel or

via serial link RS485 using a PC provided with the appropriate program.

/ A / B / C / D / E / F / G / H

TM1

//// ///

/

A: Type of transducer

V velocity transducer

A acceleration transducer

B: Dimension measured

0 displacement

1 velocity

2 acceleration

C:Mode of measurement

0 RMS

1 peak

2 peak-to-peak

D: Range of measurement

0 0: 100 µm

1 0: 200

2 0:

250

µm

µm

3 0: 10 mm/sec

4 0: 20 mm/sec

5 0: 50 mm/sec

6 0: 1 g

7 0: 5 g

8 0: 10 g

9 0: 20 g

S special to be deÞ ned

E: High bandpass Þ lter

0 without Þ lter

1 5 Hz

2 10 Hz

3 20 Hz

4 50 Hz

5 100 Hz

S special to be deÞ ned

F: Low bandpass

N.B:

The low pass Þ lter

Þ lter

frequency

should be at least double that of the

high bandpass Þ lter

0 without Þ lter

1 100 Hz

2 1000 Hz

3 2500 Hz

4 5000 Hz

5 10000 Hz

S special to be deÞ ned

G: Output signal

0 4: 20 mA

1 0: 20 mA

2 0: 10 V

S special to be deÞ ned

H: Power supply

0 24 Vdc

1 110/220 VAC 50÷60 Hz

CEMB S.p.A.

Via Risorgimento, 9

23826 MANDELLO DEL LARIO (LC) Italy

www.cemb.com

e-mail: cemb@cemb.com

Vibration analysis division:

phone +39 0341 706111

fax +39 0341 735678

e-mail: stm@cemb.com

BALANCING MACHINES

Order example:

/ A / B / C / D / E / F / G / H

TM1

/ V / 1 / 0 / 3 / 2 / 2 /

0 / 0

H: power supply 24Vdc

G: output 4 : 20 mA

F: low bandpass Þ lter 1000 Hz

E: high bandpass Þ lter 20 Hz

measuring range 10 mm/sec

D:

C: mode of measurement RMS

B: dimension,

velocity

A: transducer, velocity

All the dat a and features me ntioned in this c atalogue are pur ely for informa tion and

do not con stitute a ny commitm ent on the par t of our company, which re serves t he

right to ma ke any and all alte ration s it may consi der suita ble withou t notice.

STA21220

A

Loading...

Loading...