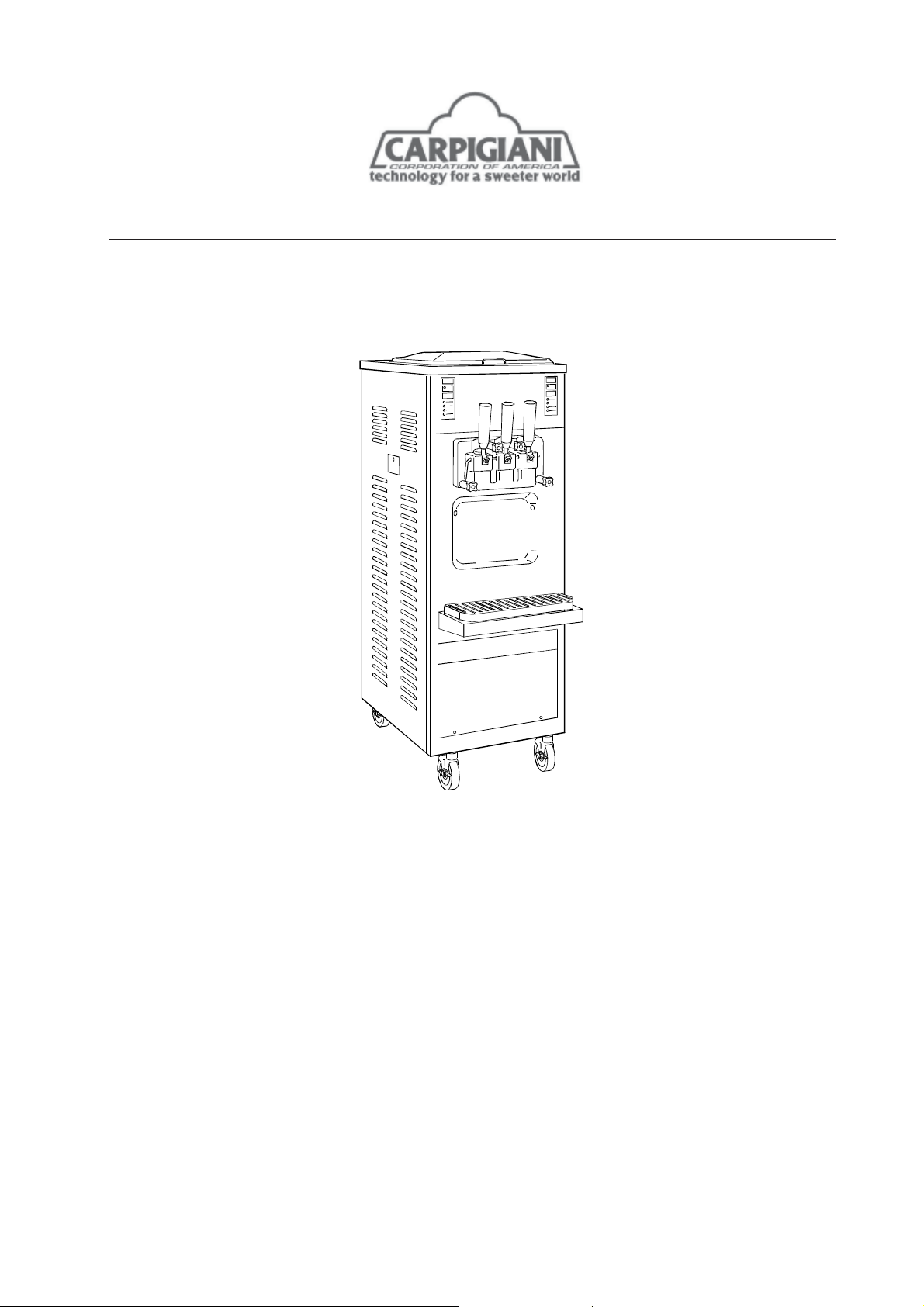

Carpigiani UF 263 Installation Manual

P.O. Box 4069 • Winston-Salem, NC 27115 • 336-661-9893 • 336-661-9895 (Fax)

UF 263

Soft Serve Freezer

Double Flavor Floor Model

OPERATION MANUAL

Foreword

Thank you for selecting Carpigiani to meet your operation and growing

demands. Your Carpigiani freezer has been manufactured utilizing the most

advanced technology and modern equipment available in the industry . We at

Carpigiani, take great pride and care in the manufacturing of each and every freezer,

using only the finest components available, to provide you with many years of

trouble free operation.

Many years of experience in the manufacturing of soft serve dispensing

equipment have guided us in the preparation of this Operation Manual. PLEASE

READ IT CAREFULLY and keep it in an available place for future reference and

most of all, follow the instructions carefully .

On the following pages, you will find important information and procedures,

which describe the proper installation, sanitizing, operation, and maintenance of

your Carpigiani freezer . We feel certain that your compliance with these instructions

will assure excellent performance, trouble-free operation and profitable business for

years to come.

ed. 1 - 03/04

2

Index

Foreword Page #

Part I Installation

A) Uncrating 4

B) Positioning the Machine 4-5

C) Electrical Requirements 5

D) Completing the Installation 5

Part II Explanation of Controls

A) Electronic Control Panel 6

B) Dispensing Handles 7

C) Phosensor Switches 7

D) Dispensing Head Safety Switch 7

E) Electric Control Panel 7-8

F) Other Controls 8

Part III Initial Cleaning Procedure

A) Gravity Fed Cleaning Procedure 9

B) Pump Fed Cleaning Procedure 10

C) Disassembling the Dispensing Head 10

D) Removing the beater/augers 11

E) Cleaning Operations 11

Part IV Assembling the Freezer

A) Installing the Beaters / Augers 12

B) Assembling the Dispensing Head 12-14

C) Assembling the Gravity Feed Tubes 14-15

Part V Sanitizing the Freezer 16-17

Part VI Starting the Freezer

A) Gravity Fed Machines 18

Part VII Operating the Freezer

A) Stand By Mode 19-20

B) Gravity Fed Machines – How to Operate and Make Adjustments 21-22

Part VIII Periodic Cleaning Procedures

A) Gravity Fed Machines 21-22

Part IX Technical Information

A) Refrigeration 22

B) Beater Drive Motor 22

C) Thermal Overload 22

D) Proximity Switches 23

Part X Maintenance

A) Troubleshooting Guide 24-26

3

!! IMPORTANT !!

Failure to closely follow operational and

maintenance procedures may result in damage to

the unit and / or void your warranty . Carpigiani

Corporation will not be responsible for any machine

not properly operated or maintained.

Part I – Installation

Before starting this procedure, ensure that the

shipping carton does not show any evidence of

damage due to dropping or mishandling. This may

indicate that the freezer was damaged during transit

or delivery .

!! IMPORTANT !!

Should the outside of the shipping carton give any

indication of possible damage, state this on the bill

of lading prior to signing. Contact the freight

carrier and request an inspection of damage. If this

procedure is not adhered to, you will forfeit your

rights to file a damage claim and be responsible for

subsequent repair costs.

Prior to choosing a location keep in mind that the

freezer should be accessible for periodic

maintenance and have adequate space for necessary

airflow.

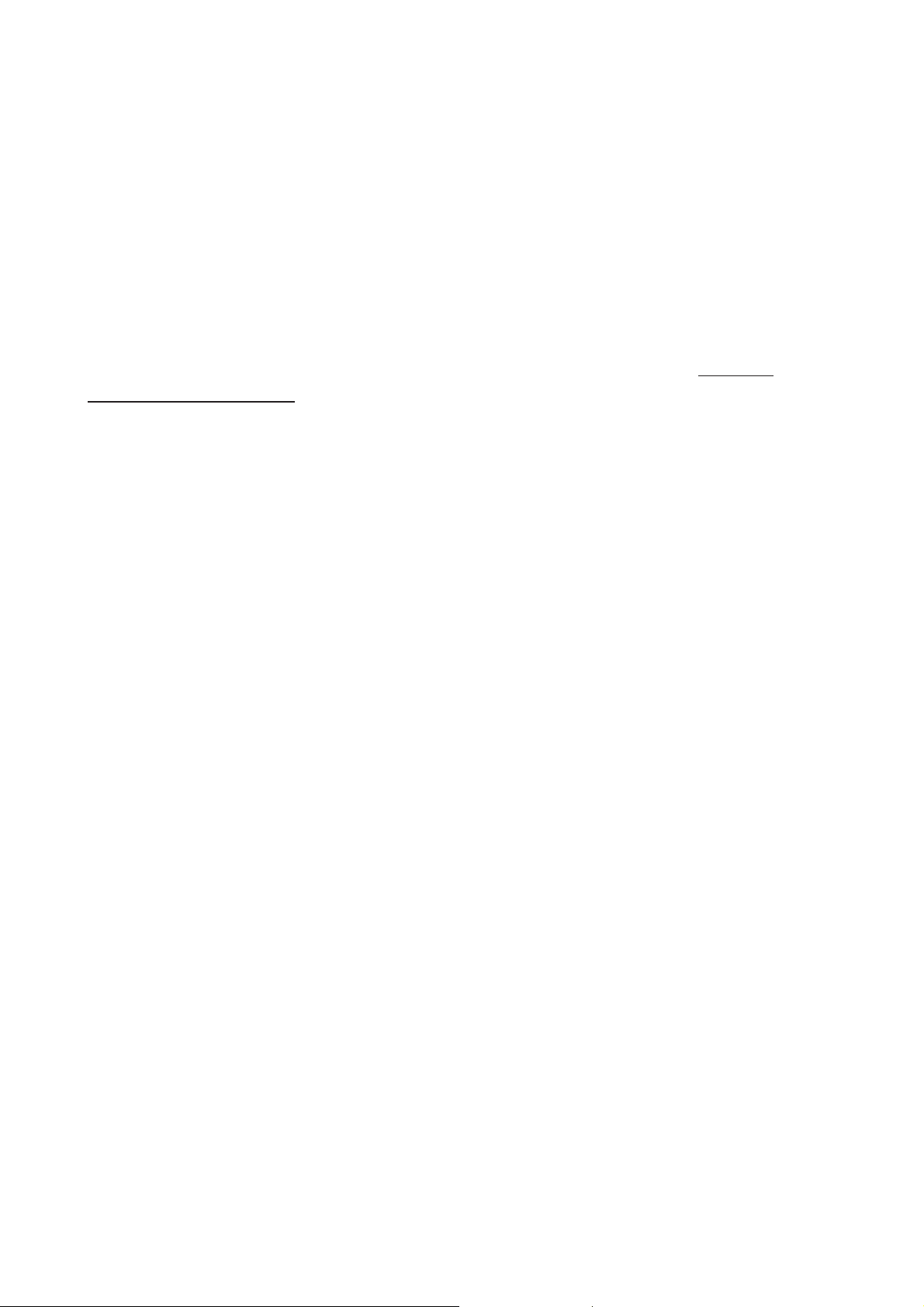

Figure 1

1) The freezer is equipped with pivoting casters to

allow for ease of movement. When placed in its

final location, lock the caster brakes to prevent

unwanted movement of the freezer. (Refer to Figure 1)

2) The freezer must also be level to ensure proper

drainage from the mix tanks and cylinders. T o

level, place a level on all corners and shim the

casters as needed.

A)Uncrating the Freezer

1) The outer shipping carton is secured to the

shipping pallet with strapping. When cutting this

strapping, do so with caution as it may spring out

quickly . After cutting the strapping, lift the shipping

carton straight up and off of the freezer .

2) Remove the protective foam boards and plastic

wrapping from the outside of the freezer.

3) The freezer is also secured to the shipping pallet

with strapping. Again, exercise caution when

cutting this strapping since it may spring out

quickly.

4) You must now remove the side panels from the

freezer prior to lifting the freezer off of the pallet

with a lift truck. To remove the side panels, first

remove the side drip chutes and lower chute cover

on both side panels. Next remove the screws in each

side panel and gently pull down and away from the

machine frame. Remove the protective plastic

coating from the outer panel surfaces.

12 in

4 in

Figure 2

3) If your freezer is air cooled, you

adequate spacing on both sides and rear of the

machine. You should have a minimum of 4 inches

of clearance on both sides and 12 inches of

clearance on the rear of the machine. This will

ensure an adequate airflow is maintained.

(Ref. to Figure 2)

MUST have

B) Positioning the Machine

After removing the machine from the shipping

pallet, it is now ready to be located in its final

location.

Note: If these clearances are not maintained, the

production capacity will be reduced, cycling will be

increased and the potential will exist that the machine

will stop completely

4

4) It is necessary to clean the air condenser each

month to remove dust, paper, etc., which may

obstruct airflow . Prior to cleaning the condenser

from the inside, disconnect the machines power

supply.

5) The machine should be connected to a fused

disconnect no more than six feet away . Electrical

installation MUST comply with state and / local

electrical codes.

6) Never position the machine in direct sunlight or

near a heat source. This will reduce its performance

and possible damage the freezer.

7) W ater connections (Water Cooled Only)are made

at the rear of the machine. A minimum of ½ inch

(ID) water supply and drain lines are recommended.

Both the water inlet and outlet lines must remain

unobstructed or the machine performance will be

affected.

C) Electrical Requirements

All wiring installed to operate the freezer must be in

accordance with the National Electric Code and / or

local electrical codes and regulations.

!! IMPORTANT !!

This machine must be properly grounded.

Failure to properly gr ound the freezer may r esult

in dangerous and / or fatal electric shock.

The main machine power supply must meet

requirements at all times of operation. Voltage

fluctuations must not exceed plus or minus 5% of

the rated nameplate voltage.

All Carpigiani machines are equipped with step

down transformers for the control circuit supply .

These transformers have a “multi-tap” input which

must be wired to match the inlet voltage

(ie. 208 or 230 vac). Failure to wire to the correct

supply voltage can result in machine malfunction.

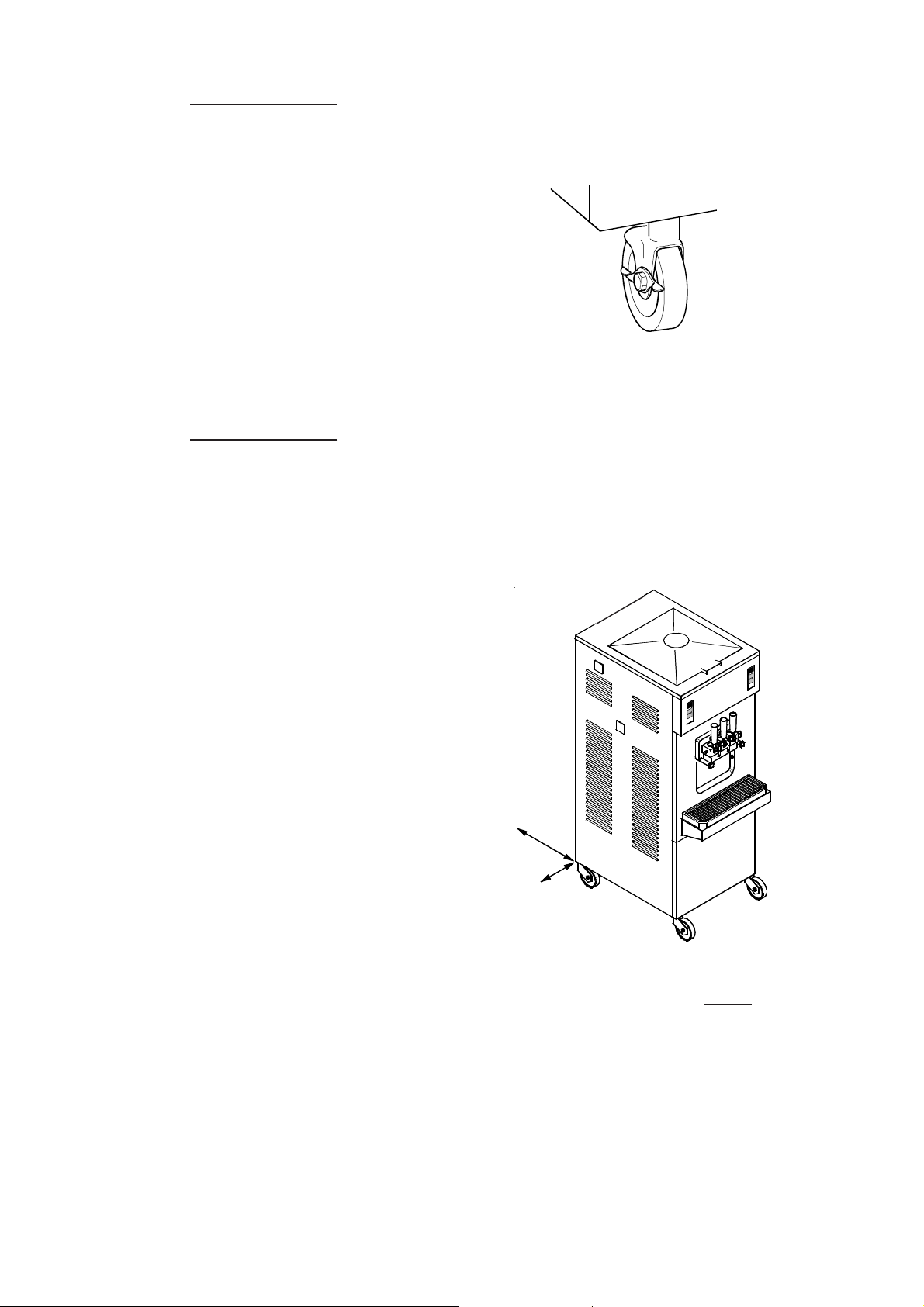

Electrical Connection – ( Refer to Fig. 3 )

Having removed the side panels from the frame, the

main power connection box is located on the bottom

of the frame. The connection box is labeled

“Connect Power Line Here”. Connect the power

supply wires to the machines using the appropriate

electrical hardware and strain relief devices.

Figure 3

After the electrical connections are completed,

turn the power supply on. At this time you must

check the beater / auger motor rotation. The

correct beater rotation ( Facing the front of the

machine ) should be clockwise.

D) Completing the Installation

1) All of the setup and calibration of this freezer

should be performed by an approved Carpigiani

Service T echnician. Failure to calibrate this freezer

properly can result in freezer damage and a voided

warranty.

2) After installation and calibration of both

electrical and refrigeration circuits, the side panels

should be reinstalled.

!! IMPORTANT !!

Failure to closely follow factory setup and

maintenance procedures will result in a voided

warranty . Carpigiani Corporation will not be

responsible for any freezer which is not setup or

maintained in accordance with factory procedures.

NOTE: Always turn the machine OFF and

disconnect the power supply switch to the freezer

prior to exposing any electrical connections or

moving parts.

On the following pages you will find important

information and procedures which describe the

proper sanitizing, operation, and maintenance of

your Carpigiani Freezer . We are certain that your

full compliance with instructions and procedures

will result in many years of trouble free operation.

In the event this unit should malfunction or need

maintenance, please contact your local Carpigiani

Distributor or Authorized Service Agent.

5

Part II – Explanation of Controls

A) Electronic Touch Pad – (Refer to figure 4)

570

L1

571.1

571.2

L2

L3

following machine modes:

- Automatic

- Stand-by

- Beater

The indicator light will illuminate corresponding to

the mode selected with the touch pad.

Automatic Mode

When placed in this mode the indicator light L2 will

illuminate and the machine will start the freezing

process in the cylinder . During this freezing process, a

number indicating the cylinder consistency will be

displayed (monitor #570, the lower the number, softer

the product). The machine will continue to freeze the

product in the cylinder (numbers will increase) until

the preset HOT number value is achieved. After

achieving the preset cylinder consistency number

(HOT) the machine will then start cooling the mix

tank and display mix tank temperature.

L4

L5

Figure 4

This machine is equipped with two independent

electronic touch control pads. Each electronic touch

pad operates one side of the freezer.

Indicator Lights – L1 through L4

These indicators illuminate to show the selected

machine function. When illuminated, the machine is

in that respective mode.

Indicator Light – L5

This light will illuminate when the mix tank is low

or out of mix. It is also possible to activate a low

mix level beeper in the programming mode.

Monitor – Position 570

This numerical monitor will display the cylinder

product consistency while the machine is freezing

product in the automatic mode. When not freezing

the product in the cylinder, it will display mix tank

temperature in ALL modes.

Stop / Reset – Position 571.1

When in this mode, the indicator light L1 will be lit

and the machine functions off. From this mode you

can access the programming mode or switch to

operating modes.

Push to Select – Position 571.2

By pressing this button you can select any of the

Stand-By Mode

When placed in this mode the indicator light L3 will

illuminate. This mode is used during prolonged idle

periods. The mix temperature in both cylinder and

mix storage tank is maintained below 40 degrees F by

the electronic temperature probes. Product should not

be served while in this mode as it will be too soft. The

Monitor (#570) will only display the temperature in

the mix tank while in this mode.

NOTE: If the mix level in the tank is below ½ full,

a warmer than actual temperature will be displayed

on the Monitor #570. The actual mix temperature

will remain at a safe temperatur e below 40 degr ees F.

Beater Mode

When placed in this mode the indicator light L4 will

illuminate. This mode is used during the start-up

(pump fed), cleaning and sanitizing of the machine.

While in this mode the ONLY the beater / auger drive

motor will operate. This mode has a built in safety

device which will automatically switch the machine to

the stop mode after 15 minutes of operation. This

safety prevents an operator from inadvertently leaving

the freezer in this mode for extended periods of time,

which could damage the freezer .

Mix T ank Low Level Indicator

When low on mix in the mix storage tank, the

indicator light L5 will illuminate. This will indicate

that more mix is needed to operate the freezer . Each

mix tank has a maximum capacity of 18 quarts each.

DO NOT attempt to operate the freezer while low on

mix or your freezer may be damaged. It is also

possible to activate a beeper to sound when mix is

low in the Automatic and Stand-By modes. This is

done through the programming mode.

6

B) Dispensing Handles – (Refer to Figure 5)

The dispensing handles control the flow and

extraction rate of finished product. The left handle

serves product from the left cylinder, the right

handle serves product from the right cylinder and

the center dispenses equally from both cylinders.

Y ou should ONLY dispense

machine is in the automatic mode.

product when the

D) Dispensing Head Safety Switch

This machine is equipped with a dispensing head

safety switch. W ith the dispensing head removed,

the machine will not operate and Alarm 9 (AL9)

will appear on the front touch pad monitor . Please

refer to machine alarms on page 27 for more

details.

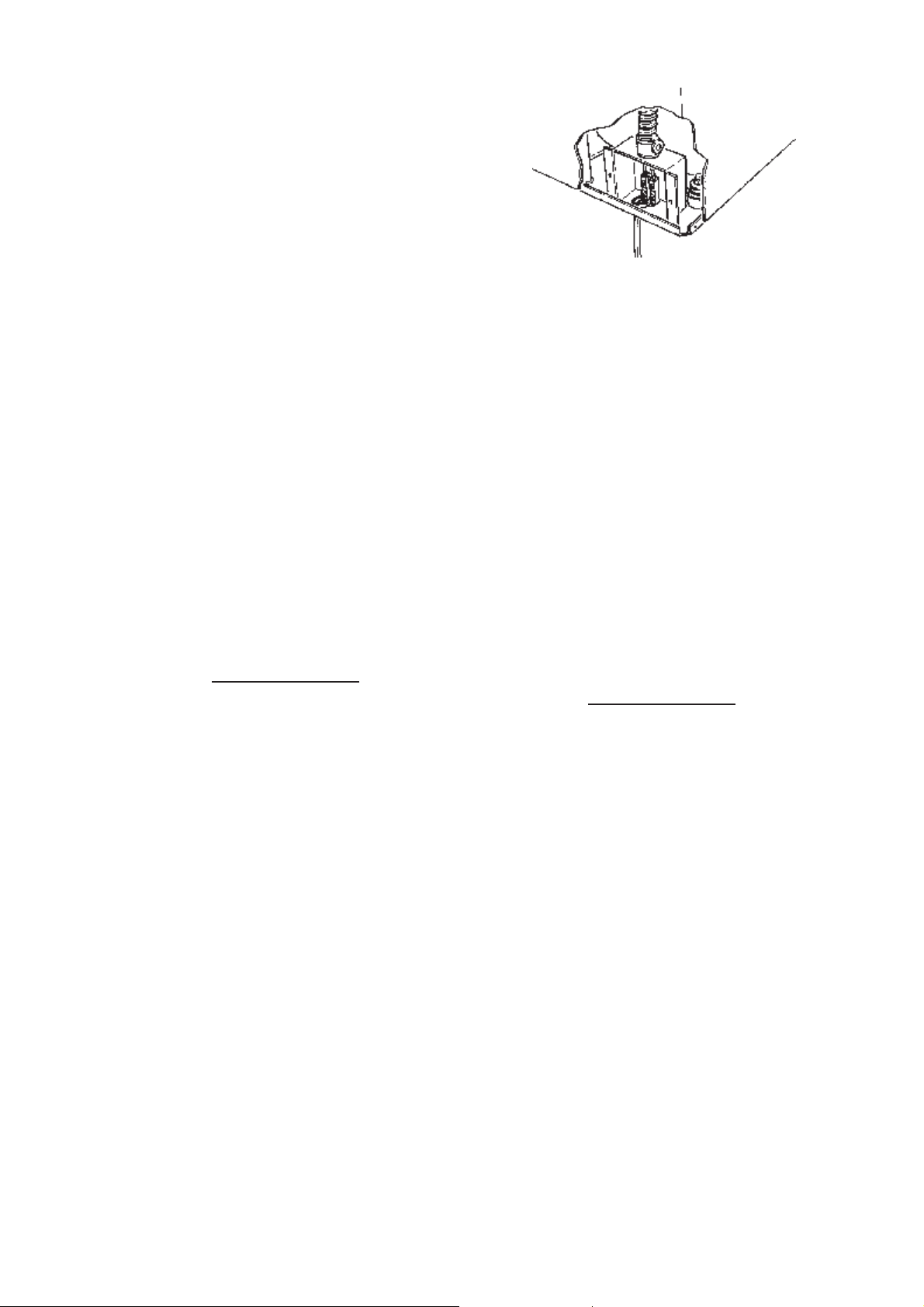

E) Electrical Control Panel – (Refer to figure

7)

The electrical control panel is located on the

bottom of the front panel. This control panel

contains all of the machines electrical control

components. ONLY a Carpigiani Authorized

T echnician should access this control panel.

!! IMPORTANT WARNING !!

Disconnect the freezer power supply before

opening the Electrical Control Panel and /

or servicing.

Figure 5

C) Photo Sensor Switches -(Refer to Figure 6)

In the Automatic mode the Photo Sensor Switches

(Position #920) activate the beater / auger motors

to dispense product. T o activate the photo sensor

switches, simply place your hand with a cone or

cup under the dispensing head, pull the dispensing

handle and dispense product.

NOTE: You must activate the photo sensor switch,

starting the beater drive motor prior to dispensing

product.

4

2

6

8

1

3

7

5

Figure 7

The following is an explanation of some of the

components inside the electrical control panel.

1) Beater Motor Contactors -

(Left /Right) –

Activates the beater drive motor. In the “BEATER”

mode, the contactor is energized by the front

switch pad. In the “AUTO” mode, the contactor is

energized by the photo sensor or

10 minute cycling timer .

5

Figure 6

920

2) Compressor Contactor – Activates the

refrigeration compressor . When the unit is in the

“AUTO” mode, the compressor contactor can be

energized by the electronic HOT setting or the T ev

T emperature probe. In the “Stand-By” mode, the

contactor is energized by the Tev and Tec

temperature probes.

7

3) Beater Motor Overload Protector - (Left/Right) –

Monitors the current draw of the beater drive

motor. If the motor draws excessive amperage, the

overload will trip and Alarm 1 (RtA) will be

displayed on the touch pad monitor .

4) Main Transformer – This transformer reduces

the incoming line voltage to 24 volts for the primary

control circuit.

5) Electronic Control Boards – (Left / Right) – These

boards control and monitor ALL functions of the

machine.

6) Safety Fuse – This fuse protects the high voltage

side of the main transformer in the event of a short

circuit. If tripped, all of the machines controls and

touch pads will be inoperative.

7) Current Monitoring T ransformer –

These transformers monitor the current draw of the

beater drive motors.

8) Secondary Transformer – This transformer

reduces the voltage from 24 volts to 11 volts for the

electronic control circuit.

(Left / Right) –

F) Other Controls

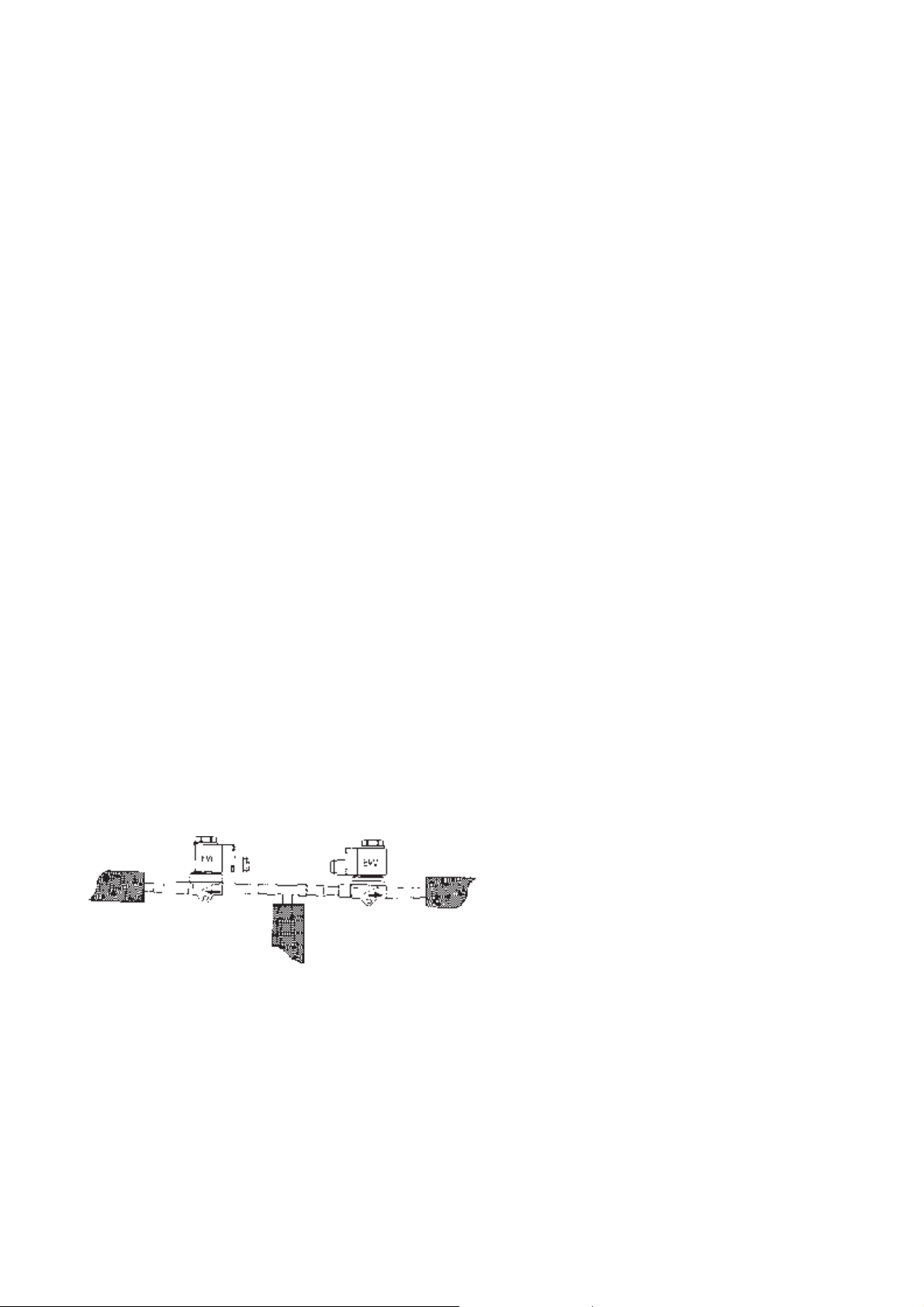

1) Refrigeration Solenoid Valves – These valves are

located behind the front panel. These valves are

used to control the flow of refrigerant to the

cylinders or mix storage tanks. These valves are

designated with EVC for each cylinder and EVV

for the mix storage tank. (Refer to Figure 8)

Figure 8

2) High Pressure Safety Switch – In the event of

restricted airflow (Air Cooled) or restricted water

flow (W ater Cooled), this switch will turn off the

compressor contactor .

While tripped, the beater motors will continue to

run until the refrigerant pressure is reduced enough

to reset the safety switch. After resetting, both the

compressor and motor(s) will resume running.

8

Loading...

Loading...