Carpigiani Pastomaster 30 RTX, Pastomaster 120 RTX, Pastomaster 60 RTX Instruction Handbook Manual

Page 1

APPLICARE

T ARGA

CARATTERISTICHE

INSTRUCTIONS HANDBOOK

Page 2

- 2 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

CARPIGIANI

Via Emilia, 45 - 40011 Anzola Emilia (Bologna) - Italy

Tel. 051-6505111 - Fax 051-732178

This handbook may not be reprinted, transferred, registered, recorded in a retrieval system,

nor translated in other languages unless otherwise previously agreed with CARPIGIANI.

The purchaser has the wright to reprint it for his own office use.

CARPIGIANI policy pursues a steady reasearch and development, thus it reserves the right

to make changes and revisions whenever deemed necessary and without being bound to

previous statements to the purchaser.

We wish to thank you for the preference granted to us by purchasing one of

CARPIGIANI machines.

To the best guarantee, since 1993 CARPIGIANI has submitted its own Quality

System to the certification according to the international Standard ISO 900194, nowadays its production has got UNI-EN-ISO 9001-2000 Certified Quality

System.

Moreover, Carpigiani machines comply with following European Directives:

- “Machinery” Directive 98/37/EC,

- “Low Voltage” Directive 73/23/EEC,

- “EMC” Directive 89/336/EEC,

- “PED” Directive 97/23/EC,

- Regulation 2004/1935/EC relating to “Materials and articles in contact

with foodstuffs”

Page 3

PASTOMASTER RTX

- 3 - pastomaster rtx_G - 07/02 - ed. 3

INDEX

SECT. FOREWORD .......................................................................................................... 5

INSTRUCTION HANDBOOK ................................................................................ 5

PURPOSE.................................................................................................................. 5

HANDBOOK STRUCTURE ................................................................................... 5

ADDITIONAL DOCUMENTATION ...................................................................... 5

CONVENTIONAL SYMBOLS ............................................................................... 6

SAFETY .................................................................................................................... 7

QUALIFICATION OF THE STAFF ....................................................................... 7

WARNING ................................................................................................................ 7

SECT. 1 GENERAL INFORMATION

1.1 GENERAL INFORMATION ................................................................................ 9

1.1.1 MANUFACTURER'S IDENTIFICATION DATA ...................................... 9

1.1.2 INFORMATION ABOUT SERVICE .......................................................... 9

1.1.3 INFORMATION TO THE USER ................................................................ 9

1.2 INFORMATION ABOUT THE MACHINE ...................................................... 9

1.2.1 GENERAL DATA ......................................................................................... 9

1.2.2 TECHNICAL FEATURES.......................................................................... 10

1.2.3 MACHINE GROUPS LOCATION ............................................................ 11

1.3 INTENDED USE ................................................................................................... 11

1.4 NOISE..................................................................................................................... 11

1.5 STORING A MACHINE ..................................................................................... 11

1.6 DISPOSAL OF PACKING STUFFS .................................................................. 11

1.7 WEEE ..................................................................................................................... 12

SEC. 2 INSTALLATION

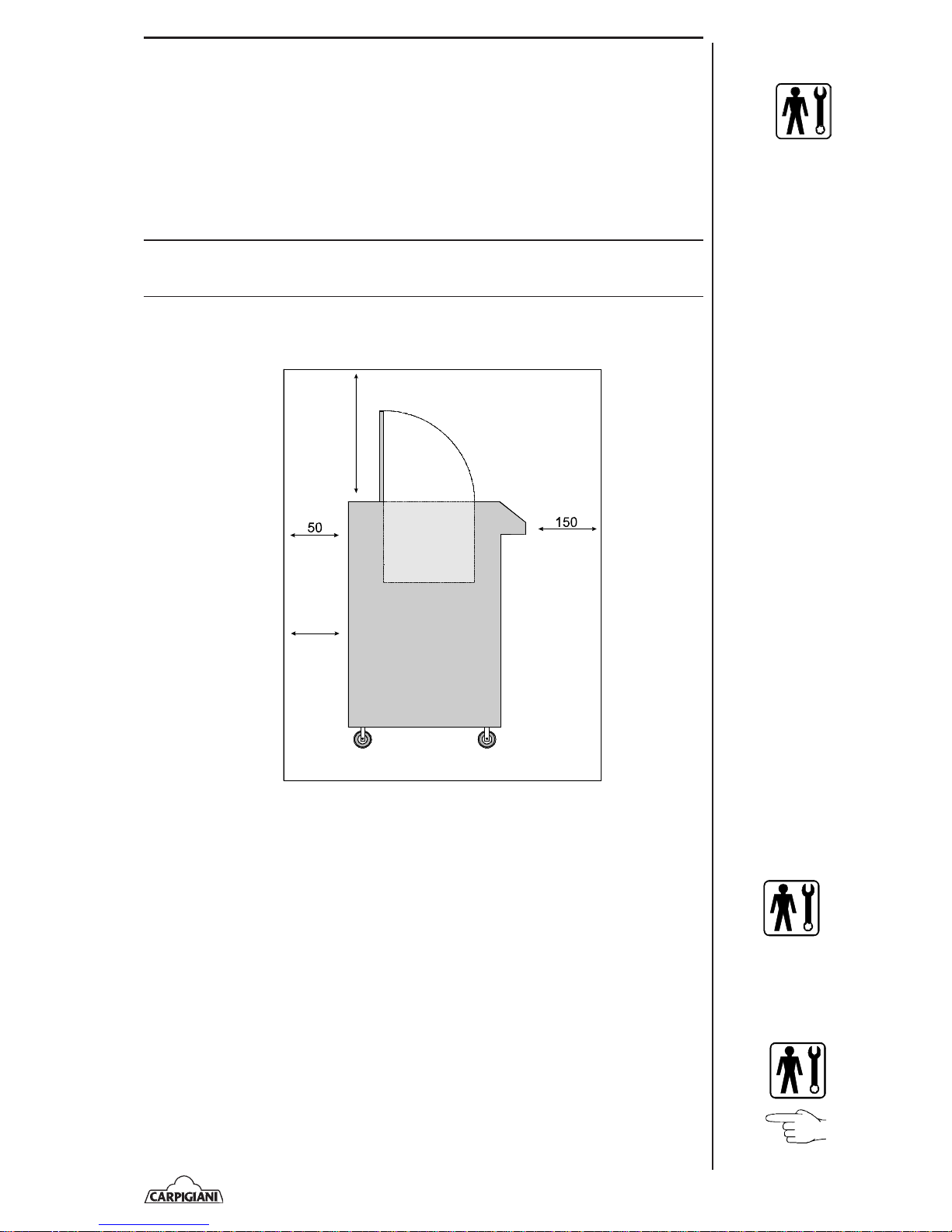

2.1 ROOM NECESSARY TO THE MACHINE USE ........................................... 13

2.2 WATER SUPPLY CONNECTION .................................................................... 13

2.3 MACHINES WITH AIRCOOLED CONDENSER .......................................... 13

2.4 MACHINES WITH WATERCOOLED CONDENSER .................................. 14

2.4.1 WATER VALVE ADJUSTMENT............................................................. 14

2.5 ELECTRICAL CONNECTION .......................................................................... 14

2.5.1 REPLACING A POWER CABLE ............................................................. 14

2.5.2 EQUIPOTENTIAL CONNECTION ........................................................... 14

2.6 LOCATION ........................................................................................................... 15

2.7 REFILLING ........................................................................................................... 15

2.8 MACHINE TESTING .......................................................................................... 15

SEC. 3 INSTRUCTIONS FOR USE

3.1 MACHINE SAFETY WARNINGS .................................................................... 17

3.2 MACHINE CONFIGURATION ......................................................................... 17

3.3 CONTROLS........................................................................................................... 18

3.3.1 PUSH-BUTTON PANEL ............................................................................ 18

3.3.2 COMMON FUNCTIONS ........................................................................... 18

3.3.3 MANUAL FUNCTIONS ............................................................................ 18

3.3.4 AUTOMATIC FUNCTIONS ...................................................................... 2 0

3.3.5 SERIAL CONNECTOR .............................................................................. 20

3.4 AUTOMATIC WORKINGS ............................................................................... 21

3.4.1 AUTOMATIC WORKING START PROCEDURE .................................. 21

3.5 ICE CREAM MIX WORKINGS ....................................................................... 21

3.5.1 WORKING NR 01 HIGH PASTEURIZATION ..................................... 21

3.5.2 WORKING NR 02 LOW PASTEURIZATION ...................................... 22

3.5.3 WORKING NR 03 MID PASTEURIZATION ........................................ 22

3.5.4 WORKING NR 04 CHOCOLATE PASTEURIZATION ....................... 22

3.5.5 WORKING NR 05 COOLING AGEING ................................................ 22

3.5.6 WORKING NR 06 SUGAR SYRUP ....................................................... 23

Page 4

- 4 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.6 SPECIAL WORKINGS (PASTOMASTER 60, ONLY) ................................. 23

3.6.1 WORKING NR 01 INVERT SUGAR ..................................................... 23

3.6.2 WORKING NR 02 CREAM-SAUCE ...................................................... 24

3.6.3 WORKING NR 03 ZABAIONE-SAUCE ................................................ 24

3.6.4 WORKING NR 04 CHOCOLATE-SAUCE ............................................ 24

3.6.5 WORKING NR 05 FRUIT-SAUCE ......................................................... 25

3.6.6 WORKING NR 06 PUDDING ................................................................. 25

3.6.7 WORKING NR 07 PANNA COTTA ........................................................ 2 6

3.6.8 WORKING NR 08 BAVARIAN CREAM ................................................ 26

3.6.9 WORKING NR 09 LIQUID YOGURT ..................................................... 27

3.6.10 WORKING NR 10 THICK YOGURT ...................................................... 27

3.7 FREE WORKINGS .............................................................................................. 28

3.7.1 EXAMPLE OF PERSONALIZED WORKING ........................................ 29

3.7.2 NOTES TO READ THE FLOW OF A PERSONALIZED WORKING ........ 30

3.7.3 DELETING PERSONALIZED WORKING .............................................. 30

3.8 PROGRAMMING USER ..................................................................................... 30

3.9 MACHINE STARTING ....................................................................................... 31

3.9.1 AUTOMATIC OPERATION...................................................................... 31

3.9.2 MANUAL OPERATION ............................................................................ 31

3.9. 3 USE OF THE DISPENSING SPIGOT (PASTOMASTER 60 AND 120) . 31

3.9.4 USE OF THE DISPENSING SPIGOT (PASTOMASTER 30 RTX) ...... 32

3.9.5 CONVENYING THE MIX FROM PASTOMASTER 60 RTX AND

PASTOMASTER 120 RTX TO OTHER PRODUCTION UNITS .......... 32

SEC. 4 SAFETY DEVICES

4.1 MACHINE SAFETY DEVICES ......................................................................... 33

4.2 BLACKOUT .......................................................................................................... 34

SEC. 5 CLEAN OUT, DISASSEMBLING AND REASSEMBLING OF PARTS IN

CONTACT WITH THE PRODUCT

5.1 EXTERIOR CLEAN OUT .................................................................................. 35

5.2 PRELIMINARY CLEAN OUT .......................................................................... 35

5.3 DISASSEMBLING THE SPIGOT PISTON ..................................................... 35

5.4 DISASSEMBLING THE TANK COVER ......................................................... 36

5.5 DISASSEMBLING THE BEATER .................................................................... 37

5.6 HYGIENE .............................................................................................................. 38

5.7 SANITIZATION .................................................................................................... 38

SEC. 6 MAINTENANCE

6.1 SERVICE TYPOLOGY ....................................................................................... 39

6.2 WATERCOOLING ............................................................................................... 39

6.3 AIRCOOLING....................................................................................................... 39

6.4 ORDERING SPARE PARTS .............................................................................. 39

6.5 TABLE OF EQUIPMENT .................................................................................. 40

SEC. 7 TROUBLESHOOT GUIDE

7.1 TROUBLESHOOT GUIDE ................................................................................. 41

Page 5

PASTOMASTER RTX

- 5 - pastomaster rtx_G - 07/02 - ed. 3

FOREWORD

INSTRUCTION HANDBOOK

Editing this handbook, it was taken into due account European Community directions on

safety standards as well as on free circulation of industrial products within E.C.

PURPOSE

This handbook was conceived taking machine users' needs into due account.

Topics relevant to a correct use of the machine have been analyzed in order to keep unchanged

in the long run quality features charachterizing CARPIGIANI machines all over the world.

A significant part of this handbook refers to the conditions necessary to the machine use and

to the necessary procedure during cleanout as well as routine and special maintenance.

Nevertheless, this handbook cannot meet all demands in details. In case of doubts or missing

information, please apply to:

CARPIGIANI Via Emilia, 45 - 40011 Anzola Emilia (Bologna) - Italy

Tel. 051- 6505111 - Fax 051-732178

HANDBOOK STRUCTURE

This handbook is divided in sections, chapters and subchapters in order to be consulted more

easily.

SECTION

A section is the part of the handbook identifying a specific topic related to a machine part.

CHAPTER

A chapter is that part of a section describing an assembly or concept relevant to a machine

part.

SUBCHAPTER

It is that part of a chapter detailing the specific component of a machine part.

It is necessary that each person involved in the machine operation reads and clearly understands

those parts of the handbook of his/her own concern, and particularly:

- The Operator must read the chapters concerning the machine star-up and the operation of

machine components.

- A skilled technician involved in the installation, maintenance, repair, etc., of the machine

must read all parts of this handbook.

ADDITIONAL DOCUMENTATION

Along with an instruction manual, each machine is supplied also with additional documentation:

- Part list: A list of spare parts which is delivered together with the machine for its maintenance.

- Wiring diagram: A diagram of wiring connections is placed in the machine.

ATTENTION

Before using the machine read carefully the instruction handbook.

Pay attention to the safety instructions.

Page 6

- 6 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

CONVENTIONAL SYMBOLS

CAUTION: ELECTRIC SHOCK DANGER

The staff involved is warned that the non-obsevance of safety rules in carrying out the operation

described may cause an electric shock.

CAUTION: GENERAL HAZARD

The staff involved is warned that the operation described may cause injury if not performed

following safety rules.

NOTE

It points out significant information for the staff involved.

WARNINGS

The staff involved is warned that the non-observance of warning may cause loss of data and

damage to the machine.

PROTECTIONS

This symbol on the side means that the operator must use personal protection against an

implicit risk of accident.

EQUIPOTENTIAL CONNECTION

For connecting all appliances with this type of connection.

Warning: Not intended to be used for protection earth

QUALIFICATION OF THE STAFF

MACHINE OPERATOR

He/she is an unskilled person, who has no specific expertise and can only carry out easy

chores, such as the machine operation by means of controls available on the push-button

panel, and filling and drawing of products used during operations.

MAINTENANCE ENGINEER

He/she is a skilled engineer for the operation of the machine under normal conditions; he/she

is able to carry out interventions on mechanical parts and all adjustments, as well as

maintenance and repairs. He/she is qualified for interventions on electrical and refrigeration

components.

CARPIGIANI ENGINEER

He/she is a skilled engineer the manufacturer assigned to field interventions for complex jobs

under particular conditions or in accordance with agreements made with the machine's owner.

Page 7

PASTOMASTER RTX

- 7 - pastomaster rtx_G - 07/02 - ed. 3

SAFETY

When using industrial equipment and plants, one must be aware of the fact that drive

mechanisms (rotary motion), high voltage components, as well as parts subject to high

temperatures may cause serious damage to persons and things.

Who is in charge of plant safety must be on the look-out that

- An incorrect use or handling shall be avoided

- Safety devices must neither be removed nor tampered with

- The machine shall be regularly serviced

- Only original spare parts are to be used especially as far as those components with safety

functions are concerned (ex.: protection microswitches, thermostats).

To achieve the above, the following is necessary:

- At the working place an instruction manual relevant to the machine should be available.

- Such documentation must be carefully read and requirements must conse quently be met.

- Only adequately skilled personnel should be assigned to electrical equipment.

- Be on the look out that no technician will ever carry out interventions outside his own

knowledge and responsibility sphere.

QUALIFICATION OF THE STAFF

Staff attached to the machine can be distinguished according to training and responsibility as

follows:

OPERATOR

- A person who has not necessarily a high technical knowledge, just trained for ordinary operation

of the machine, such as: startup, stop, filling, basic maintenance (cleanout, simple blocking,

instrumentation checkings, etc.).

SKILLED ENGINEER

- A person enganged on more complicated operations of installation, maintenance, repairs, etc.

IMPORTANT!

One must be on the look-out that the staff does not carry out any operation outside its own sphere

of konwledge and responsibility.

NOTE:

According to the standard at present in force, a SKILLED ENGINEER is who, thanks to

- training, experience and education,

- knowledge of rules, prescriptions and interventions on accident prevention,

- knowledge of machine operating conditions,

is able to realize and avoid any danger and has also been allowed by the person in charge of plant

safety to carry out all kinds of interventions.

WARNING

When installing the machine, insert a differential magnetothermal protection switch on all

poles of the line, adequately sized to the absorption power shown on machine data plate and

with contact opening of 3 mm at least.

• Never put your hand into the machine, alike during production and cleaning operations.

Before carrying out any maintenance operation, make sure that the machine is in “STOP”

position and main switch has been cut out.

• It is forbidden to wash the machine by means of a bolt of water under pressure.

• It is forbidden to remove panels in order to reach the machine inside before having

disconnected the machine.

• CARPIGIANI is not responsible for any accident that might happen during operation,

cleaning and/or servicing of its units, if this warning has not been fully complied with.

Page 8

- 8 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

Page 9

PASTOMASTER RTX

- 9 - pastomaster rtx_G - 07/02 - ed. 3

1 GENERAL INFORMATION

1.1 GENERAL INFORMATION

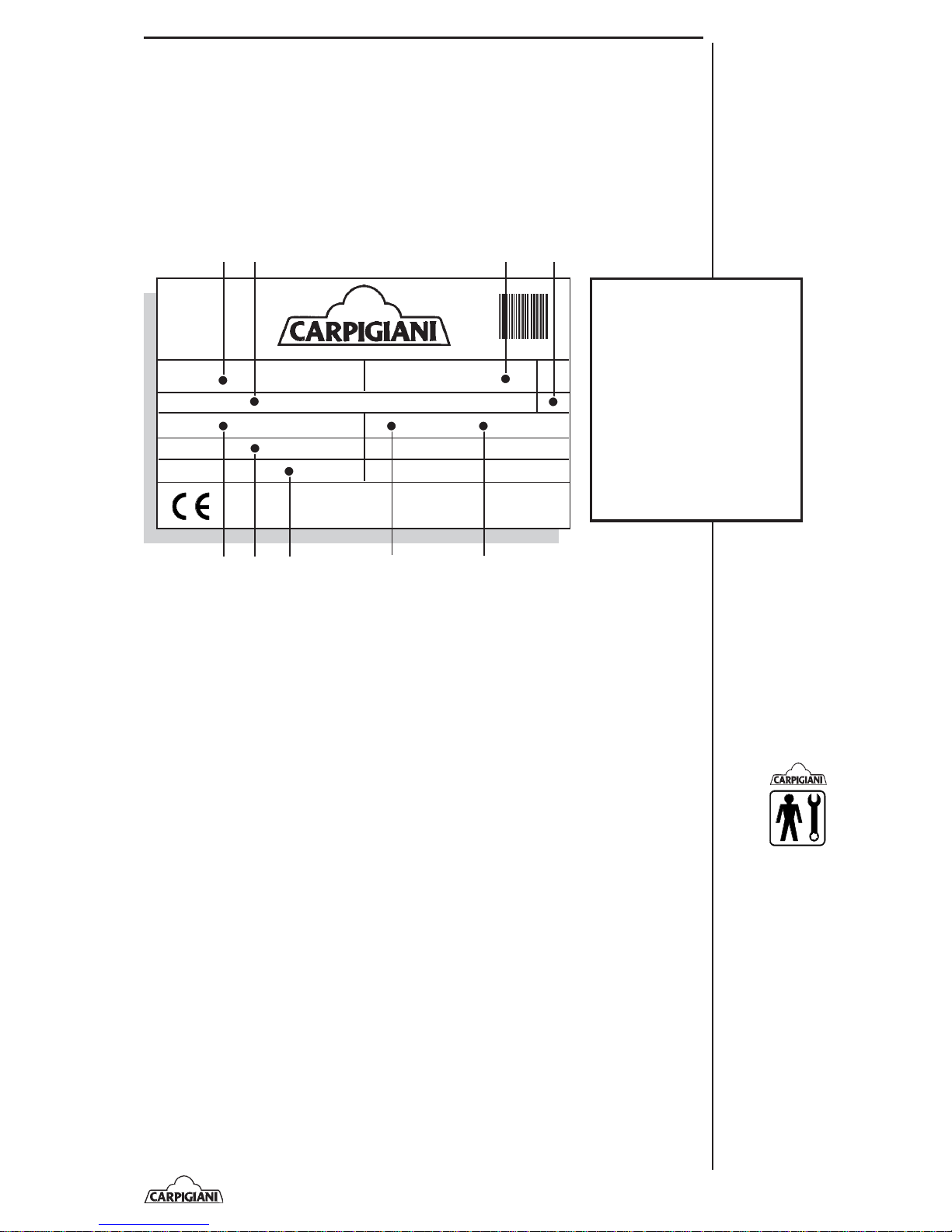

1.1.1 Manufacturer's identification data

The machine has a data plate carrying manufacturer data, machine type and serial number,

assigned when it is manufactured.

Copy of machine data plate to be found on first page of this handbook.

1.1.2 Information about service

All operations of routine maintenance are here described in section "Maintenance"; any

additional operation requiring technical intervention on the machine must be cleared with the

manufacturer, who will also examine the possibility of a factory technician field intervention.

1.1.3 Information to the user

z The manufacturer of the machine is at user's disposal for any explanation and information

about the machine operation.

z In case of need, please call the local distributor, or the manufacturer if no distributor is

available.

z Manufacturer's service department is available for any information about operation, and

requests of spare parts and service.

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 General data

PASTOMATER RTX are pasteurizers which prepare, pasteurize, homogenize, age and

transfer ice cream mixes to other units.

An electronic microprocessor steadily checks each working cycle selected.

Two alphanumerical monitors display all steps of a working cycle and send audio-visible

messages.

The following are the main components:

z five-speed heat pump;

z ergonomic display console with low voltage 24V controls;

z electrical, freezing and soundproofing units complying with international standards;

z graduated tank, with inside water dispenser for wash;

z high resistant steel frame, treated with rust inhibitors; glazed stainless steel panels.

VHzkW

A

Gas kg

Cod.

ANZOLA EMILIA - BOLOGNA - ITALY

Matr.

AB

CDE H

FG

I

100089654588-4

Legend:

A=Serial number

B= Machine type

C=Voltage

D= Main-switch amperometric

value

E= Gas type and weight

F= Machine code

G=Condensation

H=Frequency

I= Power input

Page 10

- 10 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

CARPIGIANI recommends to always use high quality ingredients for the preparation of

confectionery products, in order to satisfy your customers, even the most hard-to-please ones.

Any saving made to the prejudice of quality will surely turn into a loss much bigger than the

saving itself.

Bearing in mind the above statements, please take heed of the following suggestions:

z Choose high quality natural ingredients.

z Follow closely instructions given by your supplier.

z Do not alter your supplier's recipies, by adding, for instance, water or sugar.

z Taste your products before serving and start selling only if entirely satisfactory.

z Make sure your staff always keeps the machine clean.

z Have your machine serviced always by companies authorized by CARPIGIANI.

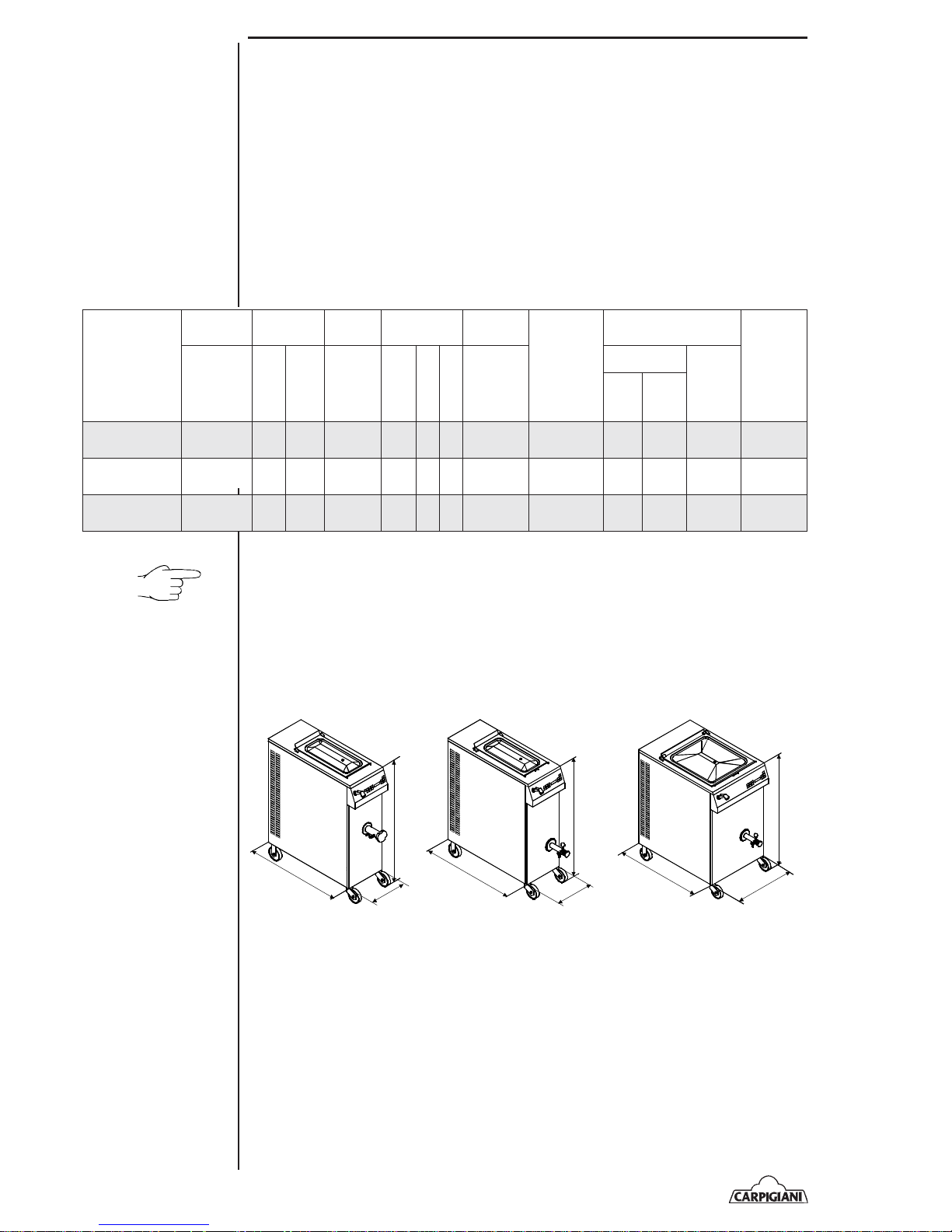

1.2.2 Technical features

NOTE:

Dimensions herebelow reported may change depending on type of condensation.

Performances featured by a 25°C room temperature and 20°C cooling water temperature.

Pastomaster 30 RTX Pastomaster 60 RTX

P

L

H

P

L

H

P

H

L

Pastomaster 120 RTX

LEDOM

noitcudorP

sruoh2ni

knaT

yticapac

etarxim

cirtcelE

rewop

dellatsnI

rewop

resnednoC

mcsnoisnemiD

teN

thgieW

gk

gk

.NIM

sertil

.XAM

sertil

°nstlovzHhPWk

esabehtta

thgieH

mm

)H(

htdiW

mm

)W(

htpeD

mm

)P(

RETSAMOTSAP

XTR03

03 51 03 1 004 05 3 4,3 retaW 53 68 301 041

RETSAMOTSAP

XTR06

0651065004053 5,6retaW5368301261

RETSAMOTSAP

XTR021

021 03 021 5 004 05 3 6,9 retaW 56 68 301 962

Page 11

PASTOMASTER RTX

- 11 - pastomaster rtx_G - 07/02 - ed. 3

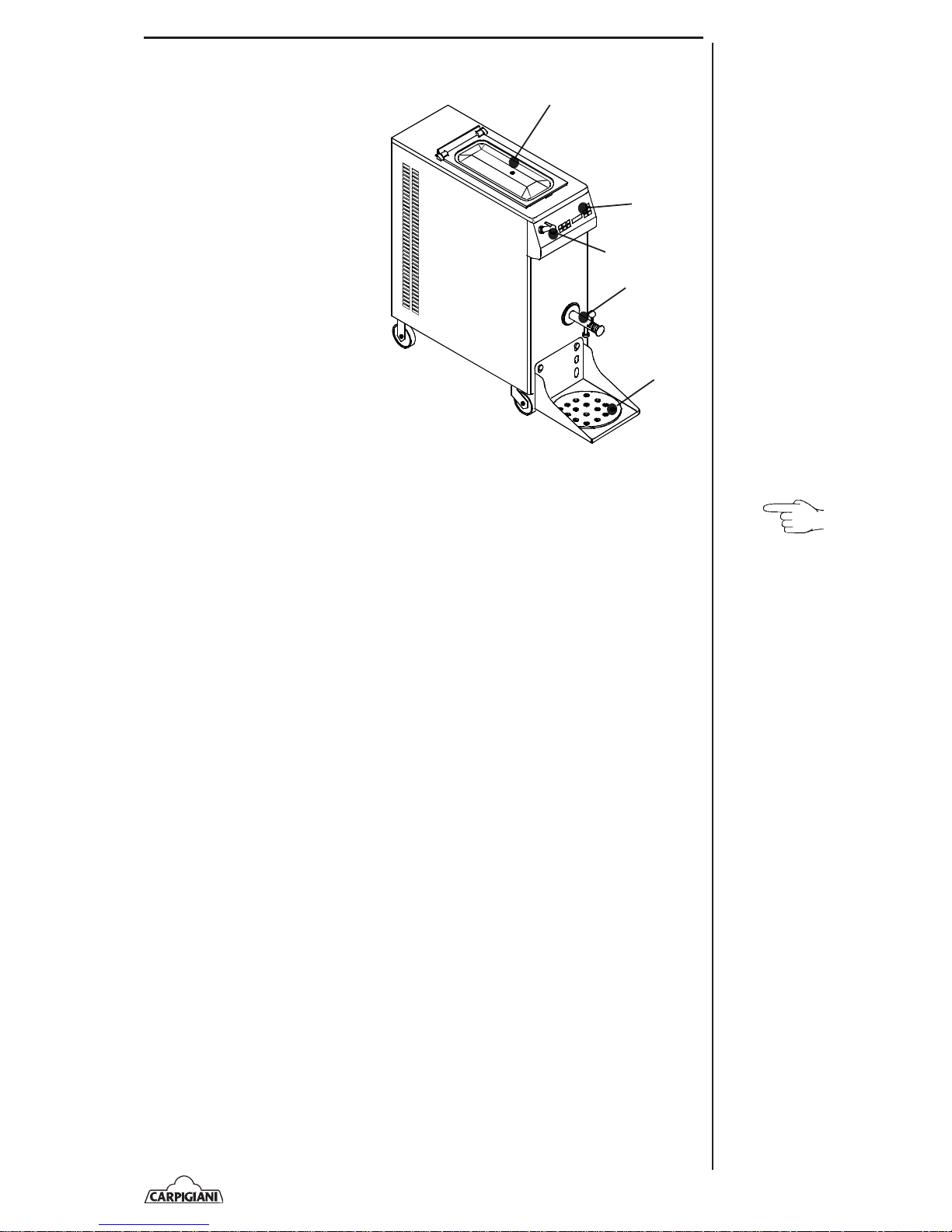

1.2.3 Machine groups location

Caption

1 Tank with cover

2 Control panel

3 Dispensing spigot

4 Spout

5 Bucket holder

Note : this drawing refers to Pastomaster 60 RTX

1.3 INTENDED USE

PASTOMASTER RTX, models 30, 60, 120 must only be used conforming with contents of

paragraph 1.2.1 "General Information", within the functional limits hereunder reported:

Voltage: ±10%

Air min. temperature 10°C

Air max. temperature 43°C

Water min. temperature 10°C

Water max. temperature 30°C

Water min. pressure 0.1 MPa (1 bar)

Water max. pressure 0.8 MPa (8 bar)

Max air relative humidity: 85%

- This machine has been designed for its use in rooms not subject to explosion-proof laws;

its use is thus bound to complying rooms and normal atmosphere.

1.4 NOISE

The steady acoustic pressure level weighed A in a working place alike by watercooled and

by aircooled machines is less than 70 dB(A).

1.5 STORING A MACHINE

The machine must be stored in a dry and dump-free place.

Before storing the machine, wrap it in a cloth in order to protect it against dust and else.

1.6 DISPOSAL OF PACKING STUFFS

When opening the packing crate, divide packing stuffs per type and get rid of them according

to laws in force in machine installation country.

1

2

3

4

5

Page 12

- 12 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

1.7 WEEE (Waste Electrical and Electronic Equipment)

In accordance with European Directive 2002/96/EC on WEEE (Waste Electrical and

Electronic Equipment), the presence of the above symbol on the product or on its packaging

indicates that this item must not be disposed of in the normal unsorted municipal waste

stream. Instead, it is the user’s responsibility to dispose of this product by returning it

to a collection point designated for the recycling of electrical and electronic equipment

waste. Separate collection of this waste helps to optimize the recovery and recycling of

any reclaimable materials and also reduces the impact on human health and the environment.

For more information concerning the correct disposal of this product, please contact

your local authority or the retailer where this product was purchased.

Page 13

PASTOMASTER RTX

- 13 - pastomaster rtx_G - 07/02 - ed. 3

2. INSTALLATION

2.1 ROOM NECESSARY TO THE MACHINE USE

The machine must be installed in such a way that air can freely circulate all around.

Rooms for the approach to the machine must be left free in order to enable the operator to

act without constraint and also to immediately leave working area, if need be.

The minimum approach room to working area should be at least 150 cm in consideration of

space taken by opened doors.

ATTENTION

Machines with aircooled condenser must be installed no closer than 50 cm to any wall

in order to allow free air circulation around the condenser.

NOTE

An insufficient air circulation affects operation and output capacity of the machine.

10

60

water

air

2.2 WATER SUPPLY CONNECTION

The machine must be connected to the water supply respecting the applicable national

requirements; moreover the water mains pressure must not exceed 0.8 MPa (8 bar).

By aircooled machines, water connection for drinking water (for machine wash) is placed

under the machine.

By watercooled machines water connections (for machine wash and gas cooling) are placed

on upper panel.

2.3 MACHINE WITH AIRCOOLED CONDENSER

Machines with aircooled condenser must be installed no closer than 50 cm to any wall in

order to allow free air circulation around the condenser.

NOTE

An insufficient air circulation affects operation and output capacity of the machine.

dimensions in cm

Page 14

- 14 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

2.4 MACHINES WITH WATERCOOLED CONDENSER

The machine must be connected to the water supply respecting the applicable national

requirements.

To make the machine run, a watercooled machine must be connected to running water supply,

or to a cooling tower. Water must have a pressure of 0.1 MPa and 0.8 MPa (1-8 bar) at

least, and a delivery at least equal to the estimated hourly consumption. Connect inlet pipe

marked by plate "Water Inlet" to water supply installing a shut-off valve, and outlet pipe

marked by plate "Water Outlet" to a drain pipe, installing a shut-off valve.

2.4.1 Water valve adjustment

IMPORTANT

If water valve needs be reset, this operation will have to be carried out by skilled personnel,

only.

Valve adjustment must be carried out in such a way that no water flows when machine is

off and lukewarm water flows when machine is on.

NOTE

Water consumption increases if temperature of entering water is above 20°C.

ATTENTION:

Do not leave the machine in a room with temperature below 0°C

without first draining water from the condenser.

2.5 ELECTRIC CONNECTION

Before connecting the machine to the mains, check that machine voltage indicated in data

plate corresponds with the mains.

Insert a differential magnetothermal protection switch adequately sized to absorption capacity

required and with contact opening of 3 mm at least.

The machines are delivered with a 5 wire cable: blue wire must be connected to the neutral

lead.

IMPORTANT

Yellow/green ground wire must be connected to an adeguate ground plate.

2.5.1 Replacing the power cable

Should the machine main cable be damaged, it must be replaced immediately with one having

similar features. Replacement shall be carried out by skilled technicians, only.

IMPORTANT

Direction of rotation

Direction of rotation of the BEATER in Pastomaster 30 RTX is anticlockwise.

By Pastomaster 60/120 RTX beater rotation direction is, instead, clockwise and it is

indicated on the CAP covering the beater in its upper part.

2.5.2 Equipotential connection

A equipotential connection point is present on the back of the machine and this is marked

with the symbol:

WARNING:

Not intended to be used for protection earth

Page 15

PASTOMASTER RTX

- 15 - pastomaster rtx_G - 07/02 - ed. 3

Reversal of rotation direction

If the beater rotation is not correct, reverse it by interchanging two of the three leads coming

from the circuit breaker.

2.6 LOCATION

The machine is provided with castors for an easy positioning; a mechanical block system,

once engaged, prevents machine from moving and keeps it standstill.

2.7 REFILLING

Motor installed in the machine is of the type with lubrication for life; no action of checking/

replacing or topping up is necessary.

Gas filling necessary to the freezing system is carried out at CARPIGIANI works during

machine postproduction testing .

If a gas addition happens to be made, this must be carried out by skilled technicians, only,

who can also find out trouble origin.

2.8 MACHINE TESTING

A postproduction test of the machine is carried out at CARPIGIANI premises; operation

and output functionality of the machine are thoroughly tested.

Machine test at end user's must be carried out by skilled technicians or by one of

CARPIGIANI engineers.

After the machine positioning and correct connections, also carry out all operations necessary

to functional check and test of the machine.

CAP

Pastomaster 60/120 RTX

Pastomaster 30 RTX

Beater

Beater

Page 16

- 16 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

Page 17

PASTOMASTER RTX

- 17 - pastomaster rtx_G - 07/02 - ed. 3

Mix

End product

3. INSTRUCTIONS FOR USE

3.1 MACHINE SAFETY WARNINGS

When using industrial equipment and plants, one must be aware of the fact that drive

mechanisms (rotary motion), high voltage components, as well as parts subject to high

temperatures may cause serious damages to persons and things.

Who is in charge of plant safety must be on the look-out that

- an uncorrect use or handling is avoided

- Safety devices are neither removed nor tampered

- Only are original spare parts to be used especially as far as those components with safety

functions are concerned (ex.: protection microswitches, thermal relays).

To achieve the above, the following is necessary:

- At working place an instruction manual relevant to the machine should be available.

- Such documentation must be carefully read and regulations must consequently be followed.

- Only must adequately skilled personnel be assigned to electrical equipment.

3.2 MACHINE CONFIGURATION

The machine consists of a transmission of movement for beater assembly, a heating and

cooling system with aircooled or watercooled condenser.

The product is prepared by pouring a mix into the tank and starting the production cycle,

while referring to minimum and maximum quantities reported in Section 1.

As the machine is provided with specific programs for the preparation of various products,

one must set the program relevant to the selected product before starting the cycle.

When the cycle ends, the product can be taken out from the special spigot.

Page 18

- 18 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.3.3 Manual functions

In order to enter manual functions, it is necessary to set the machine to the STOP position.

Press thence the push-button relevant to the manual function yu want to insert.

Heating

The function insert is indicated by relevant led which switches on. Automatic

mixing start is indicated by the "beating" check lamp and the monitor displays the

following message:

Down on the right side one can read the ACTUAL TEMPERATURE of the

product inside the tank, whereas down on the left side the TEMPERATURE

TO BE REACHED (set) set by the user and last, on top, time and day of the

week.

BEATING is always active when heating mode is activated.

By pressing BEATING button and relevant led is off, the beater will stop as

as soon as the programmed temperature 8SET) is reached.

11:15:08 LUN

set +85°c +25°c

3.3 CONTROLS

3.3.1 Push-button panel

The machine is provided with a push-button panel on its front side; each push-button has

symbols explaining relevant functions.

DISPLAY

Pastomaster RTX is provided with an alphameric display usually displaying

a series of messages as soon as the machine is switched on and during its

operation.

When in STOP, the display shows time and day of the week.

STOP push-button

When inserting STOP function, relevant warning light is on.

From STOP you can enter AUTO or manual functions, directly. In order to

change or to stop any AUTOMATIC and MANUAL working program, you

will have just to press STOP.

STOP push-button is also used to reset motors thermal relays if they have

tripped.

3.3.2 Common functions

Function insert leds

When one of the leds on top left side of each push button switches on, it means the the

function corresponding with the symbol next to the same led, has been inserted.

Beating

The function insert is indicated by relevant led which switches on. By pressing

the BEATING push-button, the beater motor starts and keeps on running until

STOP is pressed, or press BEATING button again.

Note: Opening the cover does not stop beating, when this has been inserted

manually.

Page 19

PASTOMASTER RTX

- 19 - pastomaster rtx_G - 07/02 - ed. 3

Cooling

The function insert is indicated by relevant led which switches on. Mixing

starts automatically ("beating" light is however off) and the display shows

following message:

Down on the right side you see the ACTUAL TEMPERATURE of the product

inside the tank, whereas down on the left side, one reads THE

TEMPERATURE TO BE REACHED (set) which was set by the user; on top

you will last read time and day of the week.

The product is mixed and cooled till the temperature set value is reached (set)

and then HELD. The beater stops at the same time with the compressor and,

during the storage, if the temperature goes up and the compressor starts again,

the beater, too, will restart. The beater anyway starts every 30' and runs 10".

When mix has reached the temperature set value (set), you might wish the

mix to be kept mixing during storage and independently of compressor starting,

then, besides "Beating", also press "Cooling".

With "decrement" and "increment" ARROWS you can decrease and increase

the temperature set value (set). A 10' fixed sound signal and the blinking of

the display indicate that the temperature set has been reached.

11:15:08 LUN

set +04°c +76°c

Note:

In HEATING and COOLING steps at 50°, 60° and 70°C, the beater stops 2 seconds so

that the tank will be completely filled with mix; this will avoid that, especially by very thick

mixes, air locks are formed.

Timer

When pressing the TIMING push-button, relevant led will switch on and

following message will be displayed:

On top, you will always read time and day of the week. Down on the left

side, you will read the set total time and, down on the right side, you see

time decreasing value. Time always starts from 30' and can be changed 1' to

99 minutes with increcement and decrement ARROWS.

When count is over, a sound signal will be emitted for 10" the timer will set

to zero as at the starting point.

14:15:08 MAR

set 30' 30:00

If the the set has already been reached, the Heating function (as well as

Cooling) starts 5" after pressing relevant button, so that the operator can

change the set.

Once Heating button has been pressed, the set temperature always sets to

85°C (this value can be changed 10°C to 105°C)

An acoustic signal lasting 10" and blinking of the display warn that the

programmed temperature has been reached.

If the mix inside the tank is in heating mode and the temperature is lower

than 50°C and one opens the tank cover, the machine continues its normal

operation and it will only display the message "cover open", in order to

make it possible ingredients to be poured into the mix being stirred, thus being

easily amalgamated. If the temperature is at 50°C or more and one opens the

tank cover, the beater will stop in order to avoid mix splashes.

Wash water

The function insert is indicated by its led, which will switch on.

Water inlet starts by pressing relevant push-button. By pressing the push-button

you start water inlet through the nozzle on the machine front side.

Water inlet ends by pressing "wash water" or by pressing "stop". The machine

is provided with an automatic block system after 3 minutes water inlet.

Page 20

- 20 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

Record

This function is used to store working operations (such as: beating, rheating,

etc.) in free workings programming mode (see par. 3.7).

Start

This function is used to automatically start both automatic and personalized

workings.

Auto

This function is used to recall stored workings, both automatic and personalized

ones.

Decrement

Backward function

Increment

Forward function

3.3.5 Serial connector

The Pastomaster RTX are provided with a serial connector on the machine rear (see the

picture).

If you connect your PCT to your machine, you can consult, roll the machine events out.

If you instead connect your machine to a modem, you can receive and operation data and

transfer them to after-sale service, in order to get a technical diagnosis and remote maintenace.

ATTENTION

For connection to PC, one has to place an order for Easydloader kit code 193.013.520 to

Messrs Carpigiani. The kit is complete with connecting cable and CD with the program

allowing PC-machine dialog.

To connect the machine to modem, use the cable usually supplied together with modem.

Spigot wash water (by Pastomaster 30 RTX, only)

The function insert is indicated by its led, which will switch on.

By pressing this push-button, mix spigot wash is allowable and it is carried

out through a solenoid valve which activates water inlet for 2 seconds.

3.3.4 Automatic functions

Emulsifier (Pastomaster 60 and 120 RTX, only)

Emulsifier function can be "booked" by pressing relevant button. The led is

ON to indicate that the Emulsifier will be activated by the programmed

temperature (see Programming User).

A second pressure of the same button cancel yuor booking and the led is off.

Once booked, the Emulsifier will be activated by the programmed temperature

at the step “Set Temper.Emuls.” in Heating mode and it will be deactivated

by the same temperature in Cooling.

Page 21

PASTOMASTER RTX

- 21 - pastomaster rtx_G - 07/02 - ed. 3

3.4 AUTOMATIC WORKINGS

Pastomaster 30 RTX and Pastomaster 120 RTX have 2 types of automatic workings:

z Ice cream mix workings: 7 automatic workings

z Free workings: 9 workings that can be personalized by the user for realizing his own

specialties.

Pastomaster 60 RTX has 3 types of automatic workings:

z Ice cream mix workings: 7 automatic workings

z Special workings: 10 "special" automatic workings

z Lavorazioni libere: 9 workings that can be personalized by the user for realizing his

own specialties.

3.4.1 Automatic working start procedure

z Press "auto".

z Select type of working between "ice cream mix workings", "special workings" (by

Pastomaster 60, only), "free working", through the arrow push-buttons.

z Press "auto".

z The last program used will be display; through the arrow buttons select the desired

working.

z Pres "start" in order to start the working.

Working will start and, during the production, the display will show you the cooking

temperature, cooling temperature, pause times, recommended ingredients to be poured into

the machine, always after a sound warning .

When the program is complete, working name will alternate with date and time of process

end on display .

IMPORTANT

When, in any working step, it is possible to change the value, arrow leds will switch

on.

If, during the working, you change the value, this will be stored and by next

executiuons of the same working will be left unchanged.

Note:

To skip a step, press "auto" a few seconds.

3.5 ICE CREAM MIX WORKINGS

The electronic memory has been added with 6 essential and fully automatic workings which

are described hereafter.

3.5.1 Working Nr 1 High Pasteurization 85°C

1. Mix sugar with stabilizing agents and skimmed powder milk, separately.

2. Press AUTO and select “ICE CREAM MIX WORKINGS” through the arrow pushbuttons.

3. Press AUTO and select “HIGH PASTEURIZATION” through the arrow buttons.

4. Press START and following instructions on display, pour “Milk”into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar

+ Stabiliz. ” into, and other ingredients, if any, such as powder milk.

6. Next acoustic signal means filling with “Cream”.

7. Once the temperature of 85°C has been reached, the cooling step will start.

8. Next acoustic signal at 65°C calls operator's attention to the addition of “cream”, if

any, during cooling step.

9. When a new acoustic signal warns that the temperature of 4°C has been reached, the

display shows the message “OK High Pasteuriz.” alternated with “Ageing 00:00” and

the ageing time count, essential to a high quality ice cream, will start. While mix is

aged, it is also mixed at electronically pre-set intervals. For continuous beating during

ageing function, press the push-button BEATING.

Page 22

- 22 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.5.2 Working Nr 2 Low Pasteurization 65°C

1. Mix sugar with stabilizing agents and skimmed powder milk, separately.

2. Press AUTO and select “ICE CREAM MIX WORKINGS” through the arrow push-

buttons.

3. Press AUTO and select “LOW PASTEURIZATION” through the arrow buttons.

4. Press START and following instructions on display, pour “Milk” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar

+ Stabiliz.” into, and other ingredients, if any, such as powder milk.

6. Next acoustic signal means filling with “Cream”.

7. Once the temperature of 65°C has been reached, the cooling step will start.

8. Next acoustic signal at 65°C calls operator's attention to the addition of “cream”, if any,

during cooling step.

9. When a new acoustic signal warns that the temperature of 4°C has been reached, the

display shows the message “OK Low Pasteuriz.” alternated with the message “Ageing

00:00” and the ageing time count, essential to a high quality ice cream, will start. While

mix is aged, it is also mixed at electronically pre-set intervals. For continuous beating

during ageing function, press the push-button BEATING.

3.5.3 Working Nr 3 Mid Pasteurization

1. Mix sugar with stabilizing agents and skimmed powder milk, separately.

2. Press AUTO and select “ICE CREAM MIX WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “MID PASTEURIZATION” through the arrow buttons.

4. Press START and following instructions on display, pour “Milk” into.

5. This pasteurization program makes it possible to choose the final heating temperature

between 65 and 95°C through the arrow buttons.

6 On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar

+ Stabiliz.” into, and other ingredients, if any, such as powder milk.

7 Next acoustic signal means filling with “ Cream”.

8. Once the temperature of 65°C has been reached, the cooling step will start.

9. Next acoustic signal at 65°C calls operator's attention to the addition of “cream”, if any,

during cooling step.

10. When a new acoustic signal warns that the temperature of 4°C has been reached, the

display shows the message “OK Mid Pasteuriz.” alternated with the message “Ageing

00:00” and the ageing time count, essential to a high quality ice cream, will start. While

mix is aged, it is also mixed at electronically pre-set intervals. For continuous beating

during ageing function, press the push-button BEATING.

3.5.4 Working Nr 4 Chocolate Pasteurization 90°C

1. Mix sugar with cocoa, stabilizing agents and skimmed powder milk, separately.

2. Press AUTO and select “ICE CREAM MIX WORKINGS” through the arrow pushbuttons.

3. Press AUTO and select “CHOCOLATE PASTEURIZATION AT 90°” through the

arrow buttons.

4. Press START and following instructions on display, pour “Milk” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar

+ Cocoa + Stabiliz.” into, and other ingredients, if any, such as powder milk.

6. Next acoustic signal means filling with “Cream”.

7. Once the temperature of 90°C has been reached, the cooling step will start.

8. Next acoustic signal at 65°C calls operator's attention to the addition of “cream”, if any,

during cooling step.

9. When a new acoustic signal warns that the temperature of 4°C has been reached, the

display shows the message “OK Choc. Pasteuriz.” alternated with the message “Ageing

00:00” and the ageing time count, essential to a high quality ice cream, will start. While

mix is aged, it is also mixed at electronically pre-set intervals. For continuous beating

during ageing function, press the push-button BEATING.

3.5.5 Working Nr 5 Cooling/Ageing

This program can be used to either cool the mix or to continue ageing if this was accidentally

broken in one of workings described above.

Page 23

PASTOMASTER RTX

- 23 - pastomaster rtx_G - 07/02 - ed. 3

1. Press AUTO and select “ICE CREAM MIX WORKING” through the arrow push-

buttons

2. Press AUTO and select “COOLING/AGEING” through the arrow push-buttons

3. Press START.

4. When reaching the temperature of 4°C, which is warned by an acoustic signal, the message

"OK Cool. Ageing" alternates with "Ageing 00:00" on display and ageing time count

starts: this is absolutely necessary to good quality icecream. While ageing, the mix is

stirred at intervals pre-set from the machine CPU. For continuous beating during ageing

function, press the push-button BEATING.

3.5.6 Working Nr 6 Sugar Syrup

1. Press AUTO and select “ICE CREAM MIX WORKING” through the arrow pushbuttons

2. Press AUTO and select “SUGAR SYRUP” through the arrow push-buttons

3. Press START and following instructions on display, pour “Water” into

4. On a sound warning, indicating the temperature of 40°C has been reached, pour “Glucose

Syrup” into, and other ingredients, if any.

5. Next acoustic signal at 50°C calls operator's attention to the addition of “Sugar”.

6. Once the temperature of 85°C has been reached, the cooling step will start.

7. When a new acoustic signal warns that the temperature of 35°C has been reached, the

display shows the message “OK Sugar Syr.” alternated with the message “Extraction”.

The acoustic signal will go on ringing a few minutes and will stop by pressing the pushbutton BEATING.

3.6 SPECIAL WORKINGS (by PASTOMASTER 60 RTX, only)

The electronic memory of PASTOMASTER 60 RTX, only, has been added 10 automatic

workings more which are hereafter described.

3.6.1 Working Nr 1 Invert Sugar

IMPORTANT

This programme can also be found in Pastomaster 30 RTX and 120 RTX as

SEVENTH Ice cream Mix Working

WARNING

We recommend you not to fill Pastomaster RTX beyond half tank in order to avoid

overflows during the operation

Sugar 17 kg

water 6 L

citric acid 64 g

baking soda 20 g

Procedure:

1. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

2. Press AUTO and select “INVERT SUGAR” through the arrow push-buttons.

3. Press START and following instructions on display, pour “Water” into.

4. On a sound warning, indicating the temperature of 40°C has been reached, pour "Sugar".

5. Once the temperature of 90°C has been reached, the display advises you to pour “Citric

acid” into and a 5 minutes pause will start so as to make it possible citric acid melts.

6. Next step includes a 6 hours pause at 90°C. This puase time can be cahnged from a

minimum of 4 hours to a maximum of 8 hours.

7. Next acoustic signal means that the first working step is complete.

8. The displays advises you to add “baking soda” previously dissolved in water. Reaction to

the addition of baking soda is effervescence and also overflow in case of tank overfilling.

9. Next cooling bring the temeprature down to 35°C.

10. When a new acoustic signal warns that the temperature of 35°C has been reached, the display

shows the message “OK Invert sugar” alternated with the message “Extraction”. The acoustic

signal will go on ringing a few minutes and will stop by pressing the push-button BEATING.

Use:

Invert sugar ahas a high sweetening value and it is used in ice cream mixes as complementary

sugar, in order to decrease solids but no sweetening contents.

Page 24

- 24 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.6.2 Working Nr 2 Cream Sauce

Water 5,4 L

Sugar 3,8 kg

Egg-yolks 5 kg

Procedure:

1. Prepare ingredients.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “CREAM SAUCE” through the arrow push-buttons.

4. Press START and following instructions on display, pour “Water+ Egg-yolks” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar” into.

6. Next acoustic signal means the temperature of 65°C has been reached and held for 30

minutes before cooling starts.

7. When a new acoustic signal warns that the temperature of 4°C has been reached, the

display shows the message “OK Cream sauce” alternated with the message “Date/time

end”. The temperature is kept at 4°C to allow the product be preserved.

Use to produce classic custard ice cream:

Cream Sauce 250 g

Mix White Base 1 kg

3.6.3 Working Nr 3 Zabaione Sauce

"Marsala" wine 8,5 L

Sugar 3,4 kg

Egg-yolks 2,4 kg

Maize meal 250 g

Jelly 60 g

Procedure

1. Prepare ingredients and soften the jelly in cold water.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “ZABAIONE SAUCE” through the arrow push-buttons.

4. Press START and following instructions on display, pour “Marsala+ Egg-yolks” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar+

maize meal (starch)” into.

6. Next acoustic signal means the temperature of 80°C has been reached, pour “Jelly”

into after well wringing it out.

7. When a new acoustic signal warns that the temperature of 25°C has been reached, the

display shows the message “OK Zabaione sauce” alternated with the message

“Extraction”. The acoustic signal will go on ringing a few minutes and will stop by

pressing the push-button BEATING.

Use to produce the savoury Zabaione ice cream :

Zabaione Sauce 200 g

Mix White Base 1 kg

Note:

It is also possible to obtain best quality ZABAIONE TOPPING by selecting the same

working program and using following recipe:

"Marsala" wine 8 L

Sugar 3,2 kg

Egg-yolks 2,2 kg

Maiz meal 240 g

3.6.4 Working Nr 4 Chocolate Sauce

Water 8 L

Sugar 3,4 kg

Cocoa 4 kg

Page 25

PASTOMASTER RTX

- 25 - pastomaster rtx_G - 07/02 - ed. 3

Procedure:

1. Prepare ingredients.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “CHOCOLATE SAUCE” through the arrow push-buttons.

4. Press START and following instructions on display, pour “Water+ 50% cocoa” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “50%

cocoa +Sugar” into.

6. Next acoustic signal means the temperature of 70°C has been reached cooling step starts.

7. When a new acoustic signal warns that the temperature of 25°C has been reached, the

display shows the message “OK Choc. sauce” alternated with the message “Extraction”.

The acoustic signal will go on ringing a few minutes and will stop by pressing the pushbutton BEATING. The product must be taken out to avoid itsolidifies inside the tank.

Use to produce the traditional Chocolate ice cream:

Chocolate Sauce 300 g

Mix White base 1 kg

Note:

It is also possible to obtain a first quality CHOCOLATE TOPPING, by selecting the same

working program and using following recipe:

cream 5 L

sugar 2,4 kg

water 2 L

Glucose 500 g

dark choc. surrogate10 kg

dark choc. coating 1 kg

Surrogate and coating shall be added at 70°C. This sauce will be taken out at 40°C.

3.6.5 Working Nr 5 Fruit Sauce

water 1,6 L

sugar 5,7 kg

fruit pulp 8 kg

Procedure:

1. Prepare ingredients.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “FRUIT SAUCE” with arrow push-buttons.

4. Press START and following instructions on display, pour “Fruit purée+ Water” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar” into.

6. Next acoustic signal means the temperature of 65°C has been reached and held for 30

minutes before cooling starts.

7. When a new acoustic signal warns that the temperature of 4°C has been reached, the

display shows the message “OK Fruit sauce” alternated with the message “Date/time

end”. The temperature is kept at 4°C to allow the product be preserved.

Use to produce perfect Sherbets at 30% fruit and 30% sugar contents:

Fruit sauce 2 kg

sugar syrup 290 g

water 1,2 L

Note:

It is also possible to obtain a first quality FRUIT TOPPING, by selecting the same working

program and using following recipe:

Pectine 30 g (to melt in sugar cotnents)

citric acid 10 g (to be adde on cooling process start, after the 30' minutes pause at 65°C)

3.6.6 Working Nr 6 Pudding

Milk 6 L

Cream 1 L

Preparation for puddings 1,3 kg

Procedure:

1. Prepare ingredients and soften the jelly in cold water.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

Page 26

- 26 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3. Press AUTO and select “PUDDING” through the arrow push-buttons.

4. Press START and following instructions on display, pour “Milk+cream+thickening agent” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar",

into, if any, as per recipe directions.

6. Next acoustic signal means the temperature of 85°C has been reached, pour “Jelly” into,

if any, after wringing it out thoroughly.

7. A few minutes after reaching 85°C, pudding can be taken out, flavoured and put into the

special pudding-moulds.

8. The acoustic signal will go on ringing a few minutes and the beater will keep on running;

it will stop by pressing the push-button BEATING. The product must be taken out to

avoid it solidifies inside the tank.

Use:

To get puddings with different flavours, this mix shall be worked with all ice cream pastries

(hazel-nut, pistachio, strawberry, caramel, etc.) in same proportions as with ice cream (80÷100

gr per litre). Puddings shall be then put in positive refrigerator to solidify.

3.6.7 Working Nr 7 Panna Cotta

Milk 5 L

Cream 5 L

Sugar 3 kg

Jelly 300 g

Procedure:

1. Prepare ingredients and soften the jelly in cold water.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “PANNA COTTA” through the arrow push-buttons.

4. Press START and following instructions on display, pour “Milk+cream” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar", into.

6. Next acoustic signal means the temperature of 90°C has been reached, pour “Jelly”

into, after wringing it out thoroughly.

7. The cooling step will start a few minutes later.

8. When a new acoustic signal warns that the temperature of 25°C has been reached, the

display shows the message “OK Panna cotta” alternated with the message “Extraction”.

The acoustic signal will go on ringing a few minutes and the beater will keep on running;

it will stop by pressing the push-button BEATING. The product must be taken out to

avoid it solidifies inside the tank.

Use:

Pour mix into moulds, directly: Solidification is also obtained at room temeprature.

3.6.8 Working Nr 8 Bavarian Cream

Milk 10 L

sugar 4 kg

egg yolks 1,8 kg

Jelly 450 g

Procedure:

1. Prepare ingredients and soften the jelly in cold water.

2. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

3. Press AUTO and select “BAVARIAN CREAM” through the arrow push-buttons.

4. Press START and following instructions on display, pour “Milk+egg yolks” into.

5. On a sound warning, indicating the temperature of 40°C has been reached, pour “Sugar",

into.

6. Next acoustic signal means the temperature of 70°C has been reached, pour “Jelly”

into, after wringing it out thoroughly.

7. The temperature is held at 70°C for the time necessary to full pasteurize the product

before cooling starts.

8. When a new acoustic signal warns that the temperature of 25°C has been reached, the

display shows the message “OK Bavarian cream” alternated with the message

“Extraction”. The acoustic signal will go on ringing a few minutes and the beater will

keep on running; it will stop by pressing the push-button BEATING. The product must

be taken out to avoid it solidifies inside the tank.

Page 27

PASTOMASTER RTX

- 27 - pastomaster rtx_G - 07/02 - ed. 3

Use:

Product to be mixed with possibly sweetened whipped cream, according to the proportion of

l bavarian cream, 1÷1,5 liter whipped cream. It can be flavoured with sauces mentioned before

or with ice cream pastries. Spread soaked sponge-cake in the special moulds, coat with a 4

cm bavarian cream layer and keep it into a freezer or a negative cabinet 2 hours.

3.6.9 Working Nr 9 Liquid Yogurt

High quality milk 15 L

natural whole yogurt 2 kg

or lactic ferments according to instructions' maker

Procedure

1. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

2. Press AUTO and select “LIQUID YOGURT” through the arrow push-buttons.

3. Press START and following instructions on display, pour high quality "milk" into.

4. This working process includes milk pasteurization at 90°C and following cooling at the

inoculation temperature, which reaching means that “lactic fermetns” are to be added.

5. After the inolucation of lactic ferments, a fermentation step will start during which

Pastomaster RTX keep the temperature steadily at 42°C for a time of 6 to 7 hours.

6. The operator sets fermentation time through arrow-buttons directly; the longer the

fermentation time lasts, the higher the sourness of end-product is.

7. When fermentation process is complete, the product is cooled down to 4°C: at this

temperature the working is complete. The display will show the message “OK liquid

Yogurt” alternating with “date/time end”. Temperature is held at 4°C, to store the product.

Use :

Excellent yogurt to drink as it is or flavoured with fruit sauces. It is also ideal for producing

yogurt ice cream:

Hard ice cream: Yogurt 1 L

Sugar 250 g

Cold-stabilizer 5 g

Soft ice cream: Yogurt 1 L

Sugar 220 g

Cold-stabilizer 3 g

3.6.10 Working Nr 10 Thick Yogurt

High quality milk 15 L

natural whole yogurt 2 kg

or lactic ferments according to instructions' maker

Procedure:

1. Press AUTO and select “SPECIAL WORKINGS” through the arrow push-buttons.

2. Press AUTO and select “THICK YOGURT” through the arrow push-buttons.

3. Press START and following instructions on display, pour high quality "milk" into.

4. This working process includes milk pasteurization at 90°C and following cooling at the

inoculation temperature, which reaching means that “lactic ferments” are to be added.

5. After the inolucation of lactic ferments, a fermentation step will start during which

Pastomaster RTX keep the temeprature steady at 42°C for a time of 6 to 7 hours.

6. The operator directly sets the fermentation time through the arrow push-buttons; the longer

the fermentation time lasts, the higher the sourness of end-product is.

7. When fermentation process is complete, the working is complete.

Use:

Final product is an excellent dessert yogurt to be served natural in a cup or with fresh fruitsalad.

Page 28

- 28 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.7 FREE WORKINGS

N. 9 workings are available to add personalize mix treatment programs, which once stored

can be recalled and automatically executed.

To program a personalized working not included among the ones described in paragraphs

3.5 and 3.6, follow the procedure below:

1. From Stop, press "record": the machine will automaticaly set to the first free working.

Display will be (if first available working is Nr 1) the following:

2. Select the first working operation by pressing the push-button relevant to the operation

itself (Beating, Heating, Cooling, Timer) The function choice will activate led relevant

to the function and it indicates the first step P.01 of the program you are going to create.

3. Press "REC" in order to store this operation; on display you will read “P.02”, which the

second step of the working you are going to insert.

4. Select the second operation you desire, thence repeat STORING procedure in order to

store it.

5. Go ahead as described above up to reach the last step desired (if, among the function

selected, you have also included a timing function, the display will show time set value.

6. To complete storing and to leave personalized programming, press "REC" idling (it means,

without first selecting any function). Machine will go to STOP, now.

7. To reacall this free working, press "AUTO" and, through arrow-buttons, "FREE

WORKINGS".

8. Press "AUTO" and select number 1 through the arrow-buttons.

9. To start this free working automatically, press "start".

Note

Maximum step number for each working is 25. If you go beyond it, the display will show

"NO STEPS" and will go back to STOP so deleting the working.

Note

For a thermostatic control on an indefinite time:

- set the

last but one step, such as heating or cooling, at the desired temperature;

- set the last step with timer at "0 minutes", i.e., at NON determined time .

LAVORAZIONE No.1

set P.01

Page 29

PASTOMASTER RTX

- 29 - pastomaster rtx_G - 07/02 - ed. 3

3.7.1 E xample of Personalized Programming

Mixing and heating to 90°C, temperature holding for 5 minutes, cooling to 2°C, holding at 2°C

(by thermostatic control) for an indefinite time.

snoitarepolaitneuqeSnottub-hsuPyalpsiD

)1gnikrowtratsot"DROCER"sserP

gnimmargorp

1rNGNIKROW

tes10.P

)2lliwgnitaeb("GNITAEH"sserP

)detresniebyllacitamotua

1rNGNIKROW

°58+tes10.P

)3C°09otpu"TNEMERCNI"sserP 1rNGNIKROW

°09+t

es10.P

)4"DROCER"sserP 1rNGNIKROW

tes20.P

)5"REMIT"sserP 1rNGNIKROW

03:0tes20.P

)6'5otpu"TNEMERCED"sserP 1rNGNIKROW

50:0tes20.P

)7"DROCER"sserP 1rNGNIKROW

tes30.P

)8lliwgnitaeb("GNILLOC"sserP

)detresniebyllacitamotua

1rNGNIKROW

°40+tes30.P

)9C°2otpu"TNEMERCED"sserP 1rNGNIKROW

°20+tes30.P

)01"DROCER"sserP 1rNGNIKROW

tes40.P

)11"REMIT"sserP 1r

NGNIKROW

03:0tes40.P

)21'0otpu"TNEMERCED"sserP 1rNGNIKROW

00:0tes40.P

)31"DROCER"sserP 1rNGNIKROW

tes50.P

)41noitcn

ufynatuohtiw"DROCER"sserP 80:51:41

60/01

RAM

°20+

Page 30

- 30 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.7.2 Notes t o read the flow of a pesonalized program

z Press push-button "auto".

z Select working type (ice cream mixes, special, free workings) with "increment" e

"decrement" push-buttons.

z Press push-button "auto".

z Select working with "increment" e "decrement" push-buttons.

z Press push-button "record".

This procedure will enable you to page through any program and each program step with no

need of executing it. While reading the steps, temperature and time values can be changed

by means of the ARROW push-buttons (relevant leds will switch on).

The new value will be stored.

To page up the following step, press "record" again.

When you finish reading, press "stop".

The maximum number of workings personalized by the user is 9. If you exceed this number,

the message "NO WORKINGS " will be shown on the display. To get memory space for a

new program you will have to erase one.

3.7.3 Deleting Personalized Programs

To delete a personaized program:

zz

zz

z Press push button "auto"

z Select free workings with "increment" e "decrement" push-buttons.

zz

zz

z Press push button "auto"

z Select working with "increment" e "decrement" push-buttons.

z Press push-button "record" in order to highlight it.

z Press push-button "record" again and hold it down 5 seconds.

On display: "SURE? [Y/N]".

If you press push-button "start" you confirm program deletion (Yes).

If you press push-button "auto" you quit the operation (No).

3.8 PROGRAMMING USER

From STOP press the button about 3 seconds.

On display:

Set Temper.Emuls

+40°c [ °c]

meaning that Emulsifier starting temperature in Heating mode (both in Automatic and Manual

cycles) is 40°C (the same temeprature will make Emulsifier deactivate in Cooling mode).

Select the temperature between 20°C and 70°C by using the button and .

Going on pressing START, following sequence will appear on the display:

Language (ITA,ENG, FRA, DEU, ESP, JPN)

Hours

Minutes

Seconds

Day of the Week

Day of the Month

Month

and all of them can be changed with the arrow buttons.

To exit from Programming User, press STOP or simply do not press any button about 15".

Modified values will automatically be stored.

Page 31

PASTOMASTER RTX

- 31 - pastomaster rtx_G - 07/02 - ed. 3

3.9.2 Manual operation

Manual operation starts after inserting STOP (led is on) .

z Press the push-button relevant to the manual function you want to insert (Beating, Heating,

Cooling, Timer).

z The function you have inserted will end after pressing push-button "stop" or the push-

button for any other manual function.

3.9.3 Use of the dispensing spigot (Pastomaster 60 and 120)

The dispensing spigot is closed when its lever is fully on the right side (position F).

To take the mix out, turn the spigot lever to the left, see the picture below (position A).

NOTICE

The spigot can adequately stir the mix in relation to its quantity and thickness.

Beating gets faster and faster by moving the lever clockwise from left to rightside, so

obtaining 5 beating speed modes.

3.9.1 Automatic operation

In a pasteurizer, a program with AUTOMATIC and FREE WORKINGS starts from the

STOP position insert (led is on) .

z Press push-button "auto": the name of the working you last used will be displayed.

z Select the type of working desired through "decrement" and "increment" arrow buttons.

z Press push-button "auto" per confermare.

z Select the type of working desired through "decrement" and "increment" arrow buttons.

z When the working you wish to use is displayed on the screen, press push-button "start".

z The working ends when you read "END" on display, soon followed by end-of-cycle time.

A

B

C

D

E

F

3.9 MACHINE STARTING

After washing, sanitizing and thoroughly rinsing the machine right before its use, as per

previous descriptions, pour the mix into the tank according to the quantity desired and

respecting the minimum and maximum values shown in the table (Sec. 1.2.2); the tank is

provided with an inside graduation for an approximate indication of mix quantity therein

contained (see picture below).

Before pouring the mix, make sure that the dispensing spigot is perfectly closed.

10

20

30

10

20

30

40

50

60

20

40

60

80

100

120

Note: The spigot is always involved in the mix inside recirculating, thus it is fully pasteurizered and

kept chilled: it is, as a consequence, unlike to be attacked by bacteria.

Page 32

- 32 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

3.9.5 Conveying the mix from Pastomaster 60 RTX and 120 RTX to other

production units

The spigothead is standardized to be connected to the clamp pos. 276 of the transfer pipe.

The mix can be so be transferred quickly and hygienically to other units.

Parts pos. 276, 352 and 287 are not included in the machine kit. You can place order to your

Carpigiani local agent, by always specifying the machine type and its serial number indicated

in the data plate to be found on the machine rear.

424B

287

352

276

3.9.4 Use of the dispensing spigot in Pastomaster 30 RTX

To take the mix out, turn the knob anticlockwise.

KNOB

Note: After extruding the product, it is possible to automatically wash the spigot, each time, by

pressing the special push-button on the control panel (page 20).

Page 33

PASTOMASTER RTX

- 33 - pastomaster rtx_G - 07/02 - ed. 3

4. SAFETY DEVICES

4.1 MACHINE SAFETY DEVICES

The Pastomaster RTX has been provided with a series o safety devices to protect both machine

and the operators. The tripping of each safety device comes up to an alarm on control unit

display.

When the machine is in STOP, the alarm will be displayed in both lines of the monitor.

For example:

Alarm Pressure switch

Alarm Pressure switch

The message in the lower line indicates the alarm is still active and it disappears after alarm

reset.

The message in the first line reminds us that an alarm has occurred.

To cancel the message, press START.

An alarm that does not send the machine to STOP:

Alarm Pressure switch

set +04°c +28°C

alarm message is displayed in the upper line, whilst the lower one keeps on indicating values

of temperatures or times. On alarm reset, the message in the upper line continues being

displayed, as alarm reminder, till the button START is pressed.

List of alarms

ATRmralA gniyalpsidPOTSotstesenihcamehT.gnippirtyalerlamrehtretaeB

"ATRmralA"

CTRmralA gniyalpsidPOTSotst

esenihcamehTT.gnippirtyalerlamrehtrosserpmoC

"CTRmralA"

RPmralA hcihw,potsrosserpmocehtsesuacmralasihT.g

nippirthctiwserusserP

nisetunimgninnur2rognippirtsemitevitucesnoc3.yllacitamotuasteser

"RP"mralA"gniyal

psid,POTSottesenihcamehtekamsutatsnepo

VETmralA swohsyalpsidehT.detiucrictrohsronekorbrosneserutarepmet

"VET"

POTSotstesenihcamehtdna"VETmralA"

CETmralA "CETmralA"swohsyalpsidehT.detiucrictrohsrosneserutarepm

et"CET"

,detiucrictrohssiCETfi,edomgnitaeHnI.noitisoppotSnisienihcamehtfi

CETsagnolsanoitcnufgnitaeHsti

bihnidnaPOTSotstesenihcameht

,detiucrictrohssiCETfi,edomgnilooCnI.niagaaeragnidaerehtsehcaer

emasehttat

eseblliweulavCETdnadeyalpsidtonsiCETmralAeht

.VETsaeulav

SETmralA spotsenihcamehtdna"SETmralA"swohsyalps

idehT.tatsomrehtytefaS

.POTSottestonseodtubgnitaeh

dnaneporevoC

SMImralA

:swollofsasetareporevoceht,sledo

mtnereffidehtnI

mehterotserdnastuptuospots"nepOrevoC"1SMIgninepOXTR03MSP

lliwynafi,tnuocremit,revocehtg

nineponehW.niagadesolcsidilnehw

.potston

POTSotstesenihcamehtl,"SMImralA"1SMIgninepOXTR06MSP

niC°05<VETf

ià,2SMIgninepO.)revocydobtogipsnosi1SMI(

stuptuospotstiesiwrehto,yllamrondeunitnocsinoitarepo,ylno,gni

taeH

siegassemmralAl.niagadesolcpsirevocehtnehwmehtserotserdna

ehT.desolcsirevocehtsanoossasraeppasidhc

ihw"nepOrevoC"

.UMEsetavitcaedistfelpotnonottub

tiesiwrehto,yllamrondeunitnocsinoitarepo,ylno,gnitaeHni

C°05<VET

mralAl.niagadesolcpsirevocehtnehwmehtserotserdnastuptuospots

sirevocehtsanoossasraeppasidhcihw

"nepOrevoC"siegassem

UMEsetavitcaedistfelpotnonottubehT.desolc

Page 34

- 34 -

PASTOMASTER RTX

pastomaster rtx_G - 07/02 - ed. 3

4.2 BLACKOUT

Whether in manual or automatic cycle, the CPU stores the temperature and counts blackout

time.

On power return, the CPU restarts the running function, only provided that temperature and

time parameters guarantee that the mix has not gone bad during the blackout.

If, instead, the CPU senses through temperature and time values that the mix has gone bad,

a new Pasteurization program will start and the oeprator will be informed of by a warning

message.

On the display:

RESTART Automat.

Min=012 TEV +28°c

meaning that the blackout lasted 12 minutes and that, on power return, TEV is at 28°C. A

few seconds later, following message will be displayed :

BLACK OUT alternating with Working1 P.01

set=+50°c +28°c set=+50°c +28°c

meaning that the pasteurization cycle will restart from step 1 (heating to 50°C).

Therefore, on power return, the temperature of the mix in tanks is checked.

No deterioration of mix means that if blackout time during COOLING is LESS than the

one indicated in the table below, within relevant temperature range, the machine will start

the running funciton again.

Page 35

PASTOMASTER RTX

- 35 - pastomaster rtx_G - 07/02 - ed. 3

5. CLEAN OUT, DISASSEMBLING AND

REASSEMBLING OF PARTS IN CONTACT

WITH PRODUCT

IMPORTANT

Cleaning and sanitizing must be carried out at the end of every working day with utmost

care in order to guarantee quality of production in the respect of all hygienic rules.

5.1 EXTERIOR CLEAN OUT

Eliminate dust from your machine and also the protective film which, before delivery, it was

covered with.

Use water, only, with addition of a mild soap-detergent and a soft coth, if need be.

WARNING

Do not use solvents, alchools or detergents that can damage the machine parts or

pollute those parts involved in the production.

5.2 PRELIMINARY CLEAN OUT

With machine off and STOP led on, make sure that the mix dispensing tap is closed; pour

thence water into the tank, according to the quantity necessary for the machine wash, by

pressing "water inlet" push-button and ajusting the wash nozzle.

Press the "beating" push-button and leave in that position a few minutes.

Press "stop" push-button.