Carpigiani MAGICA Installation Manual

APPLICARE

TARGA

CARATTERISTICHE

INSTRUCTIONS HANDBOOK

191 P/SP Magica USA

191 P/SP Magica Colore PP USA

191 P/SP MAGICA PP

We wish to thank you for the preference granted to us by purchasing one of

Carpigiani machines.

T o the best guarantee, since 1993 Carpigiani has submitted its own Quality System

to the certifi cation according to the international Standard ISO 9001, nowadays

its production has got UNI-EN-ISO 9001:2008 Certifi ed Quality System.

Moreover, Carpigiani machines comply with following European Directives:

- “Machinery” Directive 2006/42/EC,

- “Low Voltage” Directive 2006/95/EC,

- “EMC” Directive 2004/108/EC,

- “PED” Directive 97/23/EC,

- Regulation 2004/1935/EC relating to “Materials and articles in contact with

foodstuffs”

CARPIGIANI

Via Emilia, 45 - 40011 Anzola dell'Emilia (Bologna) - Italy

Tel. +39 051 6505111 - Fax +39 051 732178

This manual contains a TRANSLATION OF THE ORIGINAL INSTRUCTIONS and may not

be reproduced, transmitted, transcribed, fi led in a data retrieval system or translated into other

languages, without the prior written permission of CARPIGIANI.

The purchaser has the wright to reprint it for his own offi ce use.

CARPIGIANI policy pursues a steady reasearch and development, thus it reserves the right to

make changes and revisions whenever deemed necessary and without being bound to previous

statements to the purchaser.

Issue no.: 02 Date: 2011/09 Changes: Conventional symbol, sez. 2.4.2 -

Written by: AM Checked by: JC Approved by: RV

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

3.2.3 - 3.2.7 - 5 - 5.10 - 5.17 - 6.1 - 7

- 2 -

INDEX

FOREWORD ..................................................................................................................... 5

INSTRUCTION HANDBOOK ................................................................................ 5

PURPOSE .................................................................................................................. 5

HANDBOOK STRUCTURE .................................................................................... 5

ADDITIONAL DOCUMENTATION ....................................................................... 5

CONVENTIONAL SYMBOLS ................................................................................ 6

SYMBOLOGY QUALIFICATION OF THE STAFF ............................................. 6

SAFETY ..................................................................................................................... 7

WARNING ................................................................................................................. 7

SECT. 1 GENERAL INFORMATION

1.1 GENERAL INFORMATION ................................................................................. 9

1.1.1 MANUFACTURER'S IDENTIFICATION DATA ........................................ 9

1.1.2 INFORMATION ABOUT SERVICE ............................................................ 9

1.1.3 INFORMATION TO THE USER ................................................................. 9

1.2 INFORMATION ABOUT THE MACHINE ....................................................... 9

1.2.1 GENERAL DATA .......................................................................................... 9

1.2.2 MACHINE LAYOUT .................................................................................. 10

1.2.3 TECHNICAL FEATURES .......................................................................... 10

1.3 INTENDED USE ....................................................................................................11

1.4 NOISE ......................................................................................................................11

1.5 STORING A MACHINE .......................................................................................11

1.6 DISPOSAL OF PACKING STUFFS ...................................................................11

1.7 WEEE (Waste Electrical and Electronic Equipment) ......................................11

191 P/SP MAGICA PP

SECT. 2 INSTALLATION

2.1 ROOM NECESSARY TO THE MACHINE USE ............................................ 13

2.2 MACHINE WITH AIRCOOLED CONDENSER ............................................ 13

2.3 MACHINES WITH WATERCOOLED CONDENSER ................................... 13

2.3.1 WATER VALVE ADJUSTMENT ............................................................... 14

2.4 ELECTRIC CONNECTION ................................................................................ 14

2.4.1 REPLACEMENT OF POWER SUPPLY CORD ....................................... 14

2.4.2 CREDIT CARD/USD BILL READER CONNECTION (OPTIONAL) ... 14

2.5 REFILLING ........................................................................................................... 14

2.6 MACHINE TESTING ........................................................................................... 14

SECT. 3 DIRECTION FOR USE

3.1 MACHINE CONFIGURATION .......................................................................... 15

3.2 CONTROLS ........................................................................................................... 15

3.2.1 KEYBOARD 191 P/SP MAGICA .............................................................. 15

3.2.2 KEYBOARD 191 P/SP MAGICA COLORE ............................................ 15

3.2.3 FUNCTIONS ................................................................................................ 16

3.2.4 SYRUP CHECK .......................................................................................... 19

3.2.5 DIGITAL FRAME (OPTIONAL) ............................................................... 20

3.2.6 TOKEN BOX (OPTIONAL) ....................................................................... 21

3.2.7 USD Bill reader (optional) .......................................................................... 21

3.3 PRELIMINARY OPERATIONS, WASHING AND SANITIZING ................ 21

3.4 STARTING THE MACHINE .............................................................................. 21

3.4.1 LOADING THE SYRUP LINES

(ONLY IN THE COLORE VERSION) ...................................................... 22

3.4.2 ADJUSTMENT OF THE SYRUPS

(ONLY IN THE COLORE VERSION) ...................................................... 22

3.5 PRODUCTION ...................................................................................................... 22

3.5.1 ICE CREAM DISPENSING ....................................................................... 23

3.6 PASTEURIZATION (ONLY P/SP VERSION) .................................................. 23

- 3 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

191 P/SP MAGICA PP

3.7 DAILY CLEANING - OPEN & CLOSING PROCEDURE ........................... 24

3.7.1 CLOSING PROCEDURE ............................................................................ 24

3.7.2 OPENING PROCEDURE ........................................................................... 27

3.8 USER PROGRAMMING ..................................................................................... 29

SECT. 4 CHECK AND SAFETY DEVICES

4.1 MACHINE SAFETY DEVICES ......................................................................... 31

4.2 BLACKOUT ........................................................................................................... 33

SECT. 5

DISASSEMBLING AND CLEANING THE PARTS

IN CONTACT WITH MIX

5.1 HOW TO USE XSAN DETERGENT/SANITIZER ......................................... 35

5.2 DAILY CLEANING .............................................................................................. 36

5.3 SCHEDULED CLEANING .................................................................................. 36

5.4 EMPTYING THE ICE CREAM CIRCUIT ...................................................... 36

5.4.1

(ONLY IN THE COLORE VERSION) – EVERY 14 DAYS ......................37

5.5 DISASSEMBLING OF THE TANK MIXER ................................................... 38

5.6 DISASSEMBLING PUMP AND COMPRESSION PIPE................................ 38

5.7 REMOVING THE FRONT LID ......................................................................... 39

5.8 DISASSEMBLING THE BEATER ..................................................................... 39

5.9 REMOVING THE ICE CREAM DISCHARGE TRAY (OPTIONAL) ........ 40

5.10 WASHING AND SANITIZING COMPONENTS ............................................. 40

5.11 REASSEMBLING OF THE HOPPER MIXER ............................................... 40

5.12 REASSEMBLING PUMP AND COMPRESSION PIPE ................................. 41

5.13 REASSEMBLING OF THE BEATER ............................................................... 41

5.14 REFITTING THE FRONT LID ......................................................................... 42

5.15 REFITTING THE ICE CREAM DISCHARGE TRAY (OPTIONAL)......... 42

5.16 SANITIZING THE MACHINE .......................................................................... 43

5.17 MIX FILLING ....................................................................................................... 43

SANITIZATION OF THE SYRUP LINES

SECT. 6 MAINTENANCE

6.1 TYPE OF INTERVENTION ............................................................................... 45

6.2 INSTRUCTIONS FOR THE SUBSTITUTION OF THE TUBE

OF THE PERISTALTIC PUMP ......................................................................... 46

6.2.1 REMOVAL OF THE PUMP TUBE ........................................................... 46

6.2.2 INSTALLATION OF THE PUMP TUBE .................................................. 47

6.3 WATERCOOLING ................................................................................................ 47

6.4 AIRCOOLING ....................................................................................................... 47

6.5 TABLE OF SPARE PARTS EQUIPMENT ....................................................... 48

SECT. 7 TROUBLESHOOTING GUIDE ..........................................49

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

- 4 -

FOREWORD

INSTRUCTION HANDBOOK

Editing this handbook, it was taken into due account European Community directions on safety

standards as well as on free circulation of industrial products within E.C.

PURPOSE

This handbook was conceived taking machine users' needs into due account.

T opics relevant to a correct use of the machine have been analyzed in order to keep unchanged in

the long run quality features charachterizing CARPIGIANI machines all over the world.

A signifi cant part of this handbook refers to the conditions necessary to the machine use and to

the necessary procedure during cleanout as well as routine and special maintenance.

Nevertheless, this handbook cannot meet all demands in details. In case of doubts or missing

information, please apply to:

CARPIGIANI Via Emilia, 45 - 4001 1 Anzola dell'Emilia (Bologna) - Italy

Tel. +39 051 6505111 - Fax +39 051 732178

HANDBOOK STRUCTURE

This handbook is divided in sections, chapters and subchapters in order to be consulted more

easily.

191 P/SP MAGICA PP

Section

A section is the part of the handbook identifying a specifi c topic related to a machine part.

Chapter

A chapter is that part of a section describing an assembly or concept relevant to a machine part.

Subchapter

It is that part of a chapter detailing the specifi c component of a machine part.

It is necessary that each person involved in the machine operation reads and clearly understands

those parts of the handbook of his/her own concern, and particularly:

The Operator must read the chapters concerning the machine star-up and the operation of

machine components.

A skilled technician involved in the installation, maintenance, repair, etc., of the machine must

read all parts of this handbook.

ADDITIONAL DOCUMENTATION

Along with an instruction manual, each machine is supplied also with additional documentation:

Part list: A list of spare parts which is delivered together with the machine for its mainte-

nance.

Wiring diagram: A diagram of wiring connections is placed in the machine.

Before using the machine read carefully the instruction handbook.

Pay attention to the safety instructions.

- 5 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

191 P/SP MAGICA PP

CONVENTIONAL SYMBOLS

CAUTION: ELECTRIC SHOCK DANGER

The staff involved is warned that the non-obsevance of safety rules in carrying out the operation

described may cause an electric shock.

CAUTION DANGER FROM HIGH TEMPERATURES

This warns the staff involved that failure to abide by safety rules in carrying out the operation

described involves the risk of burns and scalds.

WARNING DANGER FROM MOVING PARTS

This informs the staff concerned of the presence of moving parts and the risk of injury from failure

to comply with safety regulations.

CAUTION CRUSHING HAZARD

This warns the staff involved that failure to abide by safety rules in carrying out the operation

described involves the risk of suffering crushed fi ngers or hands.

CAUTION: GENERAL HAZARD

The staff involved is warned that the operation described may cause injury if not performed following safety rules.

NOTE

It points out signifi cant information for the staff involved.

WARNINGS

The staff involved is warned that the non-observance of warning may cause loss of data and

damage to the machine.

PROTECTIONS

This symbol on the side means that the operator must use personal protection against an implicit

risk of accident.

SYMBOLOGY QUALIFICATION OF THE STAFF

The staff allowed to operate the machine can be differentiated by the level of preparation and responsibility in:

MACHINE OPERATOR

Identify unqualifi ed personnel, those without any specifi c technical abilities who are capable of

carrying out simple jobs, such as: operating the machine using the commands available on the

keypad, the loading and unloading of products used during production, the loading of any consumable materials, basic maintenance operations, (cleaning, simple blockages, controls of the

instrumentation, etc.).

MAINTENANCE ENGINEER

He/she is a skilled engineer for the operation of the machine under normal conditions; he/she is

able to carry out interventions on mechanical parts and all adjustments, as well as maintenance

and repairs. He/she is qualifi ed for interventions on electrical and refrigeration components.

CARPIGIANI ENGINEER

He/she is a skilled engineer the manufacturer assigned to fi eld interventions for complex jobs

under particular conditions or in accordance with agreements made with the machine's owner.

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

- 6 -

SAFETY

When using industrial equipment and plants, one must be aware of the fact that drive mechanisms

(rotary motion), high voltage components, as well as parts subject to high temperatures may cause

serious damage to persons and things.

Who is in charge of plant safety must be on the look-out that:

an incorrect use or handling shall be avoided;

safety devices must neither be removed nor tampered with;

the machine shall be regularly serviced;

only original spare parts are to be used especially as far as those components with safety

functions are concerned (ex.: protection microswitches, thermostats);

suitable personal protective equipment is worn;

high care must be payed during hot product cycling.

To achieve the above, the following is necessary:

at the working place an instruction manual relevant to the machine should be available;

such documentation must be carefully read and requirements must conse quently be met;

only adequately skilled personnel should be assigned to electrical equipment;

IMPORTANT!

One must be on the look-out that the staff does not carry out any operation outside its own sphere

of knowledge and responsibility (refer to “Symbology qualifi cation of the staff”).

191 P/SP MAGICA PP

NOTE:

According to the standard at present in force, a SKILLED ENGINEER is who, thanks to:

- training, experience and education,

- knowledge of rules, prescriptions and interventions on accident prevention,

- knowledge of machine operating conditions,

is able to realize and avoid any danger and has also been allowed by the person in charge of

plant safety to carry out all kinds of interventions.

WARNING

When installing the machine, insert a differential magnetothermal protection switch on all poles

of the line, adequately sized to the absorption power shown on machine data plate and with

contact opening of 3 mm at least.

Never put your hand into the machine, alike during production and cleaning operations. Before

carrying out any maintenance operation, make sure that the machine is in “STOP” position

and main switch has been cut out.

It is forbidden to wash the machine by means of a bolt of water under pressure.

It is forbidden to remove panels in order to reach the machine inside before having discon-

nected the machine.

CARPIGIANI is not responsible for any accident that might happen during operation, clean-

ing and/or servicing of its units, if this warning has not been fully complied with.

- 7 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

191 P/SP MAGICA PP

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

- 8 -

1. GENERAL INFORMATION

1.1 GENERAL INFORMATION

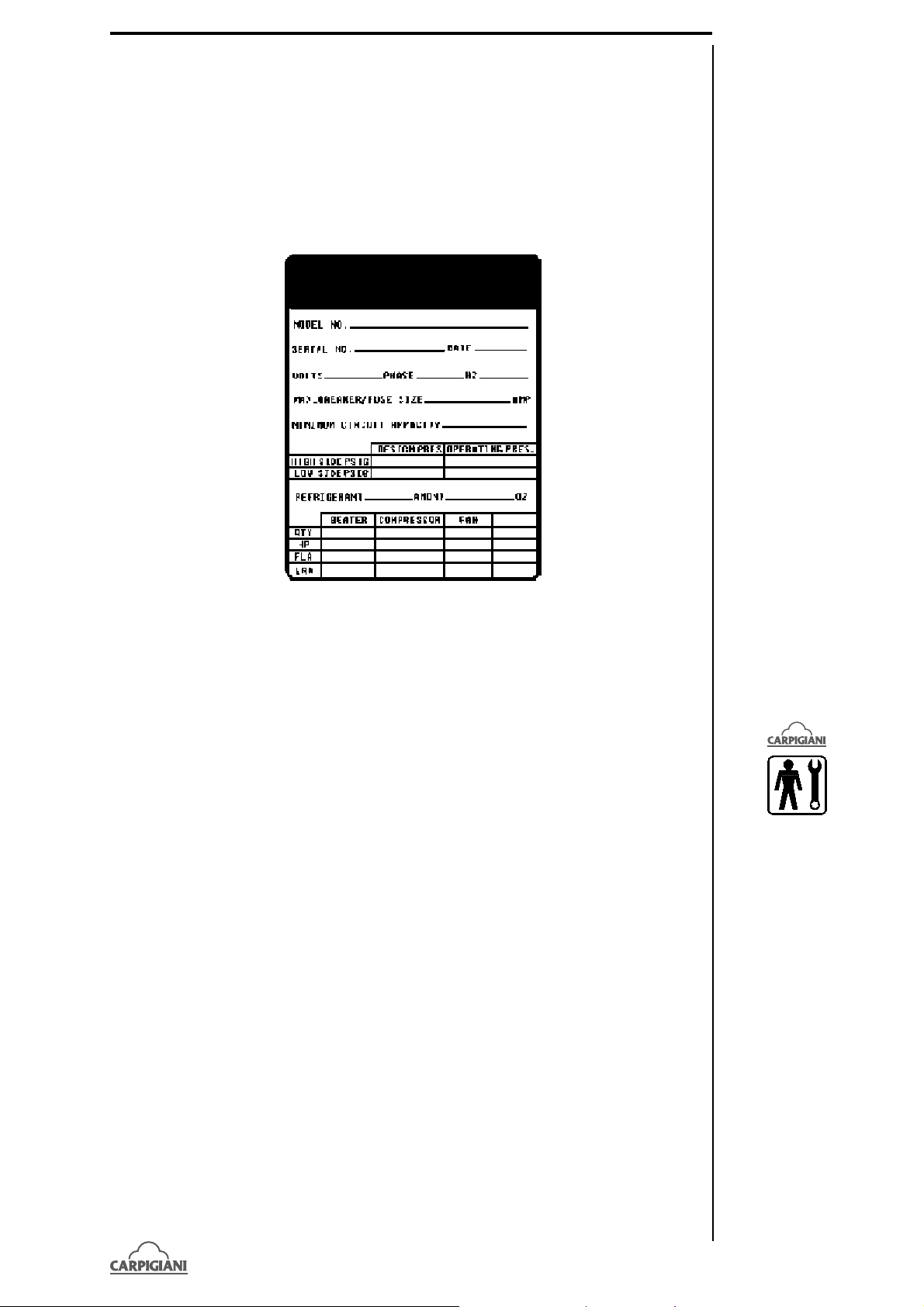

1.1.1 Manufacturer's identifi cation data

The machine has a data plate carrying manufacturer data, machine type and serial number, assigned when it is manufactured.

Copy of machine data plate to be found on fi rst page of this handbook.

191 P/SP MAGICA PP

1.1.2 Information about service

All operations of routine maintenance are here described in section "Maintenance"; any additional

operation requiring technical intervention on the machine must be cleared with the manufacturer,

who will also examine the possibility of a factory technician fi eld intervention.

1.1.3 Information to the user

The manufacturer of the machine is at user's disposal for any explanation and information

about the machine operation.

In case of need, please call the local distributor, or the manufacturer if no distributor is avail-

able.

Manufacturer's service department is available for any information about operation, and re-

quests of spare parts and service.

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 General data

Electronic machine for the production and instantaneous distribution of rippled soft ice cream,

with following main features:

- refrigerated upper tank;

- cylinder feeding pump for a higher ice cream overrun;

- for Colore version: Automatic system for rippling ice cream with the special syrups (you can

choose among three colours/fl avours);

- automatic plant for pasteurizing the product in the upper tank, as well as in the production

cylinder during idle times (for example on night pause).

- 9 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

191 P/SP MAGICA PP

CARPIGIANI recommends to always use high quality mix for ice cream production in order to

satisfy your customers, even the most hard-to-please ones. Any saving made to the prejudice of

quality will surely turn into a loss much bigger than the saving itself.

Bearing in mind the above statements, please take heed of the following suggestions:

Make your mixes yourselves from high quality natural ingredients or buy them from reliable

companies.

Follow closely instructions given by your mix supplier for the preparation of the mixes.

Do not alter your mix supplier's recipies, by adding, for instance, water or sugar.

Taste ice cream before serving it and start selling it only if entirely satisfactory.

Make sure your staff always keeps the machine clean.

Have your machine serviced always by companies authorized by CARPIGIANI.

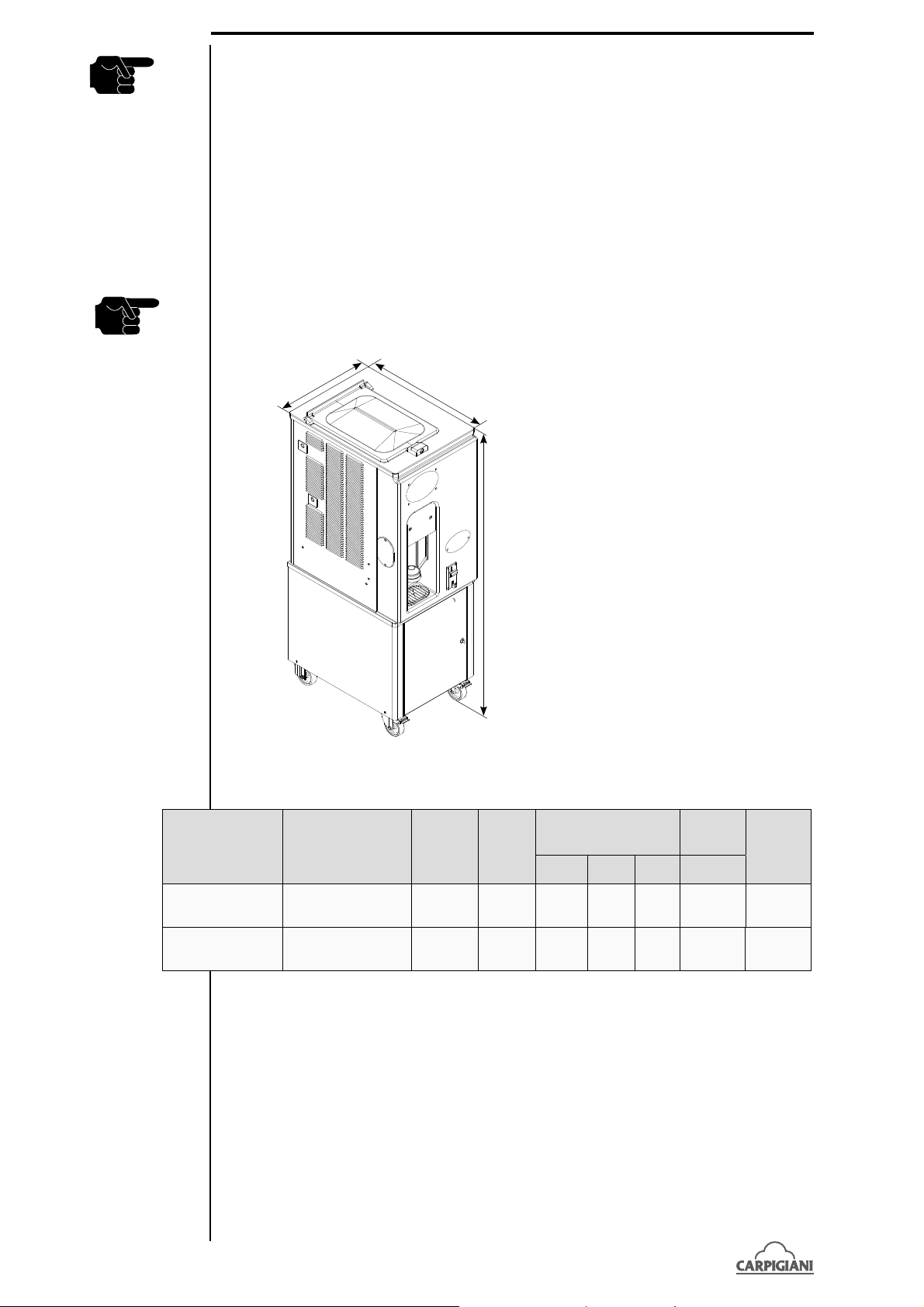

1.2.2 Machine layout

NOTE:

dimensions in the lay-out can vary in relation to the type of condenser.

505 mm

1.2.3 Technical features

MODELL

Hourly output*

100 gr portions

675 mm

Tank

capacity

litres

1475 mm

Fig. 1

Flavours

Electic Power

Installed

Power

Volt Phases Cycles kW

Net W eigt

kg

191 P/SP Magica 190 12 1 208 230 1 60 2,1 120

191 P/SP Magica

Colore PP USA

* Hourly output and mix quantity may vary depending on the temperature and the mix used, as well as on overrun you may require.

** Upon request also available with aircooled condenser.

Performances featured by a room temperature of 25°C and a temperature of cooling water at 20°C.

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

190 12 1 + 2 208 230 1 60 2.6 213

- 10 -

1.3 INTENDED USE

The machines must be used solely for the purpose described in chapter 1.2.1, "General information" within the functional limits decribed below.

Voltage: ±10%

Min air temperature °C: 10°C

Max air temperature °C: 43°C

Min water temperature: 10°C

Max water temperature: 30°C

Min. water pressure: 0,1 MPa (1 bar)

Max water pressure: 0,8 MPa (8 bar)

Max relative humidity: 85%

The machine has been designed for its use in places which are not subject to explosion-proof

standards; its use is thus bound to conforming places and normal atmospher.

1.4 NOISE

The steady acoustic pressure level weighed A in a working place alike by watercooled and by

aircooled machines is less than 70 dB(A).

1.5 STORING A MACHINE

191 P/SP MAGICA PP

The machine must be stored in a dry and dump-free place.

Before storing the machine, wrap it in a cloth in order to protect it against dust and else.

1.6 DISPOSAL OF PACKING STUFFS

When opening the packing crate, divide packing stuffs per type and get rid of them according to

laws in force in machine installation country.

1.7 WEEE (Waste Electrical and Electronic Equipment)

In conformity with the European Directives 2006/66/EC, on batteries and accumulators and waste

batteries and accumulators, and 2002/96/EC, also known as WEEE, the presence of the symbol on

the side of the product or packaging means that the product must not be disposed of with normal

urban waste. Instead, it is the user’s responsibility to dispose of this product by returning it to a

collection point designated for the recycling/treatment of electrical and electronic equipment waste.

Differentiated collection of this waste material helps to optimize the recovery and recycling of any

reclaimable materials and also reduces the impact on human health and the environment.

For more information concerning the correct disposal of this product, please contact your local

authority or the retailer where this product was purchased.

- 11 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

191 P/SP MAGICA PP

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

- 12 -

2. INSTALLATION

2.1 ROOM NECESSARY TO THE MACHINE USE

The machine must be installed in such a way that air can freely circulate all around.

Rooms for the approach to the machine must be left free in order to enable the operator to act

without constraint and also to immediately leave working area, if need be.

The minimum approach room to working area should be at least 150 cm in consideration of space

taken by opened doors.

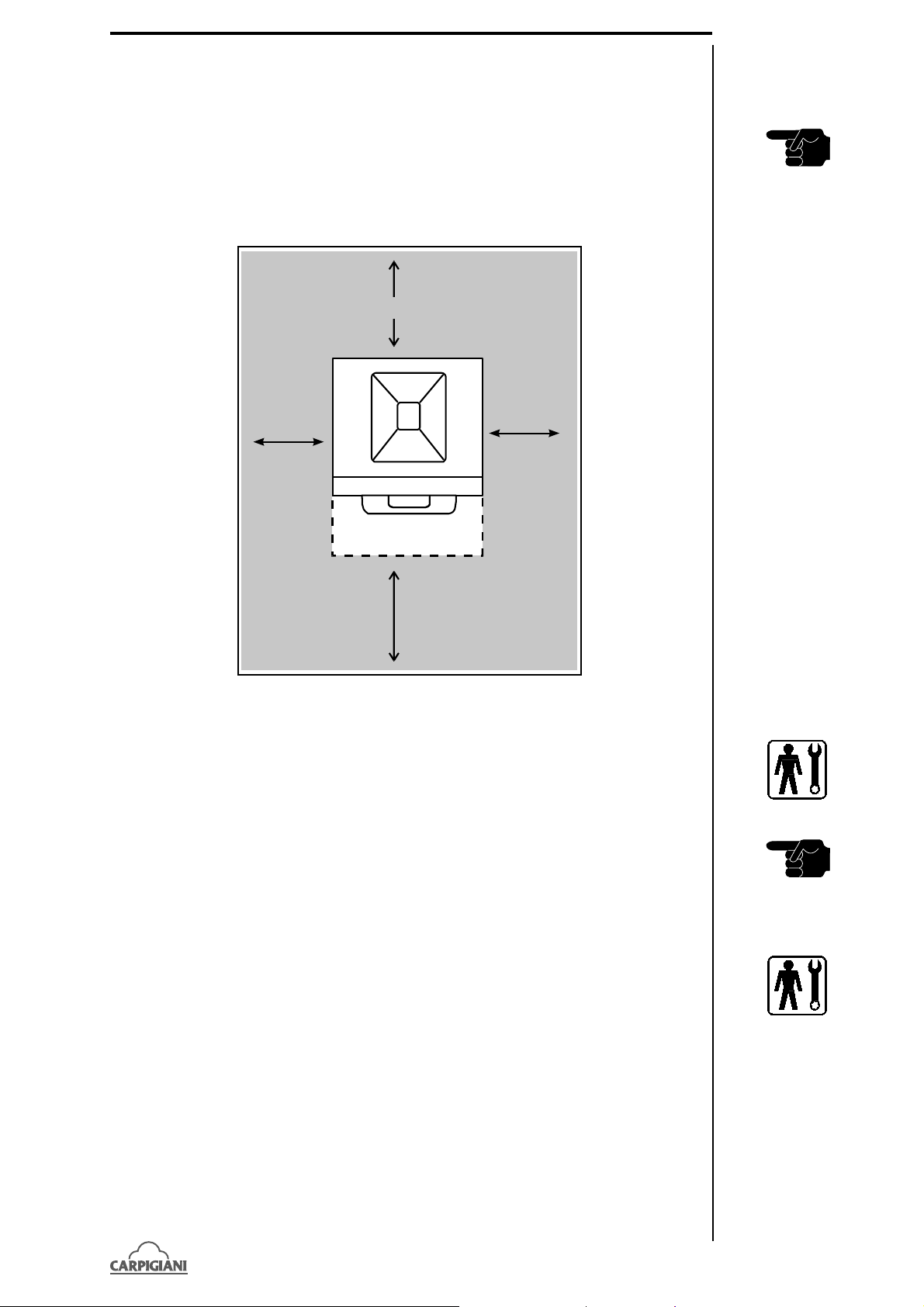

80 mm only air

191 P/SP MAGICA PP

80 mm

150 cm

80 mm

Fig. 3

2.2 MACHINE WITH AIRCOOLED CONDENSER

Machines with aircooled condenser must be installed no closer than 80 mm to any wall in order

to allow free air circulation around the condenser.

NOTE

An insuffi cient air circulation affects operation and output capacity of the machine.

2.3 MACHINES WITH WATERCOOLED CONDENSER

To make the machine run, a watercooled machine must be connected to running water supply,

or to a cooling tower.

Water must have a pressure of 0.1 MPa and 0.8 MPa (1-8 bar) at least, and a delivery at least

equal to the estimated hourly consumption.

Connect inlet pipe marked by plate "Water Inlet" to water supply installing a shut-off valve, and

outlet pipe marked by plate "Water Outlet" to a drain pipe, installing a shut-off valve.

- 13 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

191 P/SP MAGICA PP

2.3.1 Water valve adjustment

WARNING

If water valve must be retarded, this operation will have to be carried out by skilled personnel, only.

Valve adjustment must be carried out in such a way that no water fl ows when machine is off and

lukewarm water fl ows when machine is on.

NOTE:

Water consumption increases if temperature of entering water is above 20°C.

ATTENTION

Do not leave the machine in a room with temperature below 0°C

without fi rst draining water from the condenser.

2.4 ELECTRIC CONNECTION

Before connecting the machine to the mains, check that machine voltage indicated in data plate

corresponds with the mains (see sec. 1.1.1 point C).

Insert a differential magnetothermal protection switch adequately sized to absorption capacity

required (see sec. 1.1.1 point D) and with contact opening of 3 mm at least.

WARNING

Yellow/green ground wire must be connected to a good ground outlet.

IMPORTANT

If the machine is not permanently connected to the mains power, but has a power cord

with EEC plug, please make sure that a suitable EEC power socket is available and that

this has been correctly installed.

The socket must be earthed.

The use of adaptors and extension leads is not permitted.

Rotation direction by three-phased machines

The beater rotates anticlockwise.

2.4.1 Replacement of power supply cord

If the machine main cable is damaged, it must be replaced through a cable with similar features.

Replacement will have to be carried out by skilled technicians only.

2.4.2 Credit card/USD bill reader connection (optional)

When the machine is provided with credit card/USD bill reader,

there is on right panel the plug for external connection. Before

to connect, check that electrical data of accessory are proper

with data on marking label.

2.5 REFILLING

Motor installed in the machine is of the type with lubrication for life; no action of checking/

replacing or topping up is necessary. Gas fi lling necessary to the freezing system is carried out

at CARPIGIANI works during machine postproduction testing. If a gas addition happens to be

made, this must be carried out by skilled technicans, only, who can also fi nd out trouble origin.

2.6 MACHINE TESTING

A postproduction test of the machine is carried out at Carpigiani premises; Operation and output

functionality of the machine are thoroughly tested. Machine test at end user's must be carried

out by skilled technicians or by one of CARPIGIANI engineers. After the machine positioning

and correct connections, also carry out all operations necessary to functional check and test of

the machine.

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

- 14 -

3. DIRECTION FOR USE

3.1 MACHINE CONFIGURATION

The machine has a motor to drive the beater, and a cooling system with water or air condenser.

Soft ice cream is prepared by fi lling the tank with cold mix (+4°C) and starting the automatic

production cycle, until the ideal ice cream consistency set by CARPIGIANI is reached.

3.2 CONTROLS

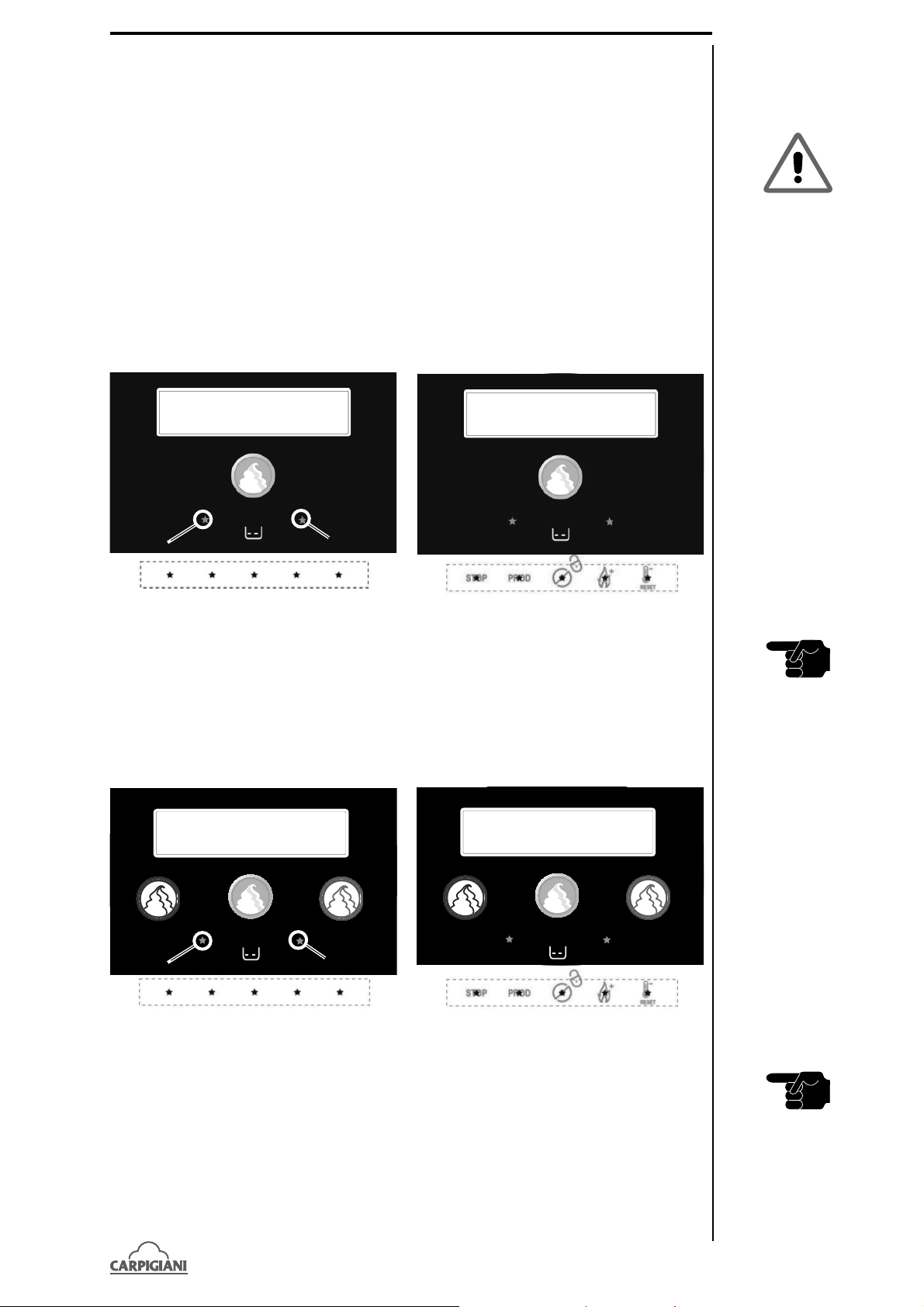

3.2.1 Keyboard 191 P/SP Magica

The machine keyboard consists of 8 keys. Only 1 of them is visible (picture 4), whilst the other

ones are hidden (picture 5). The stars indicate the position of hidden keys. The drawing in picture

4 shows the functions of each key with clear symbols.

191 P/SP MAGICA PP

1

NOTE:

When a key is pressed and relevant function is accepted, the key panel emits an acoustic signal.

2

Fig. 4

Fig. 5

3.2.2 Keyboard 191 P/SP Magica Colore

The machine keyboard consists of 10 keys. Only 3 of them are visible (picture 6), whilst the other

ones are hidden (picture 7). The stars indicate the position of hidden keys. The drawing in picture

7 shows the functions of each key with clear symbols.

1

2

Fig. 6

NOTE:

When a key is pressed and relevant function is accepted, the key panel emits an acoustic signal.

- 15 -

191 P/SP MAGICA PP_EN - 2011/09 - Ed. 02

Fig. 7

Loading...

Loading...