Carnes VDBA Installation Manual

CARNES COMPANY, 448 S.Main St., P.O.Box 930040, Verona, WI. 53593-0040 Phone:608/845-6411 Fax: 608/845-6470 carnes@carnes.com www.carnes.com

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

MODEL VDBA

SERIES BLOWER

CAUTION!

DO NOT INSTALL, USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL HAD BEEN READ AND UNDERSTOOD.

READ AND SAVE THESE SHEETS FOR FUTURE USE.

FORM 1500

RECEIVING INSPECTION:

Check for damage or missing parts immediately upon receipt. Ensure that wheel rotates freely.

REPORT ANY DAM-

AGE PROMPTL

Y TO CARRIER.

INSTALLATION:

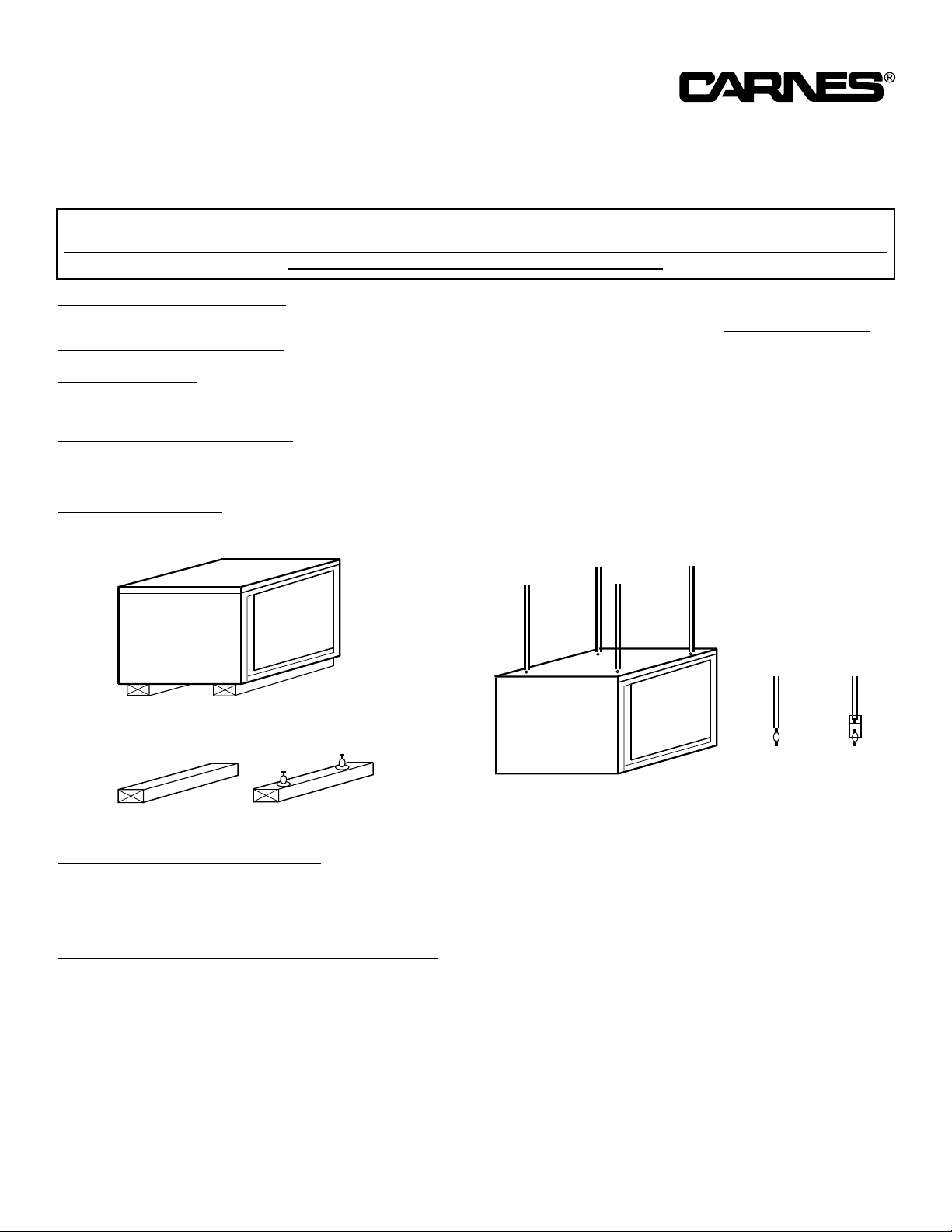

Model VDBA series blowers are suitable for both suspension or base mounting.

SUSPENSION MOUNTING:

Suspend the unit using 4 — 1/2” diameter threaded rods through 4 — 9/16” clearance holes located in the top of the

unit. Ensure the unit is level.

BASE MOUNTING:

For base mounting, secure the unit through the bottom 4 — 9/16” holes to a solid base.

S

S

S

S

S

S

SUSPENDED MOUNT

OR

OR

RIGID

MOUNT

SPRING

ISOLATOR

VDBA

SERIES

BLOWER

VDBA

SERIES

BLOWER

BASE MOUNT

RIGID MOUNT

RUBBER ISOLATOR

Flexible inlet and outlet collars are recommended to minimize vibration transmission.

MOTOR AND V-BELT DRIVES:

Mount motor with hardware provided and install pulleys and belt(s) with proper tension. Follow illustrated recommendations on belt installation on page 2.

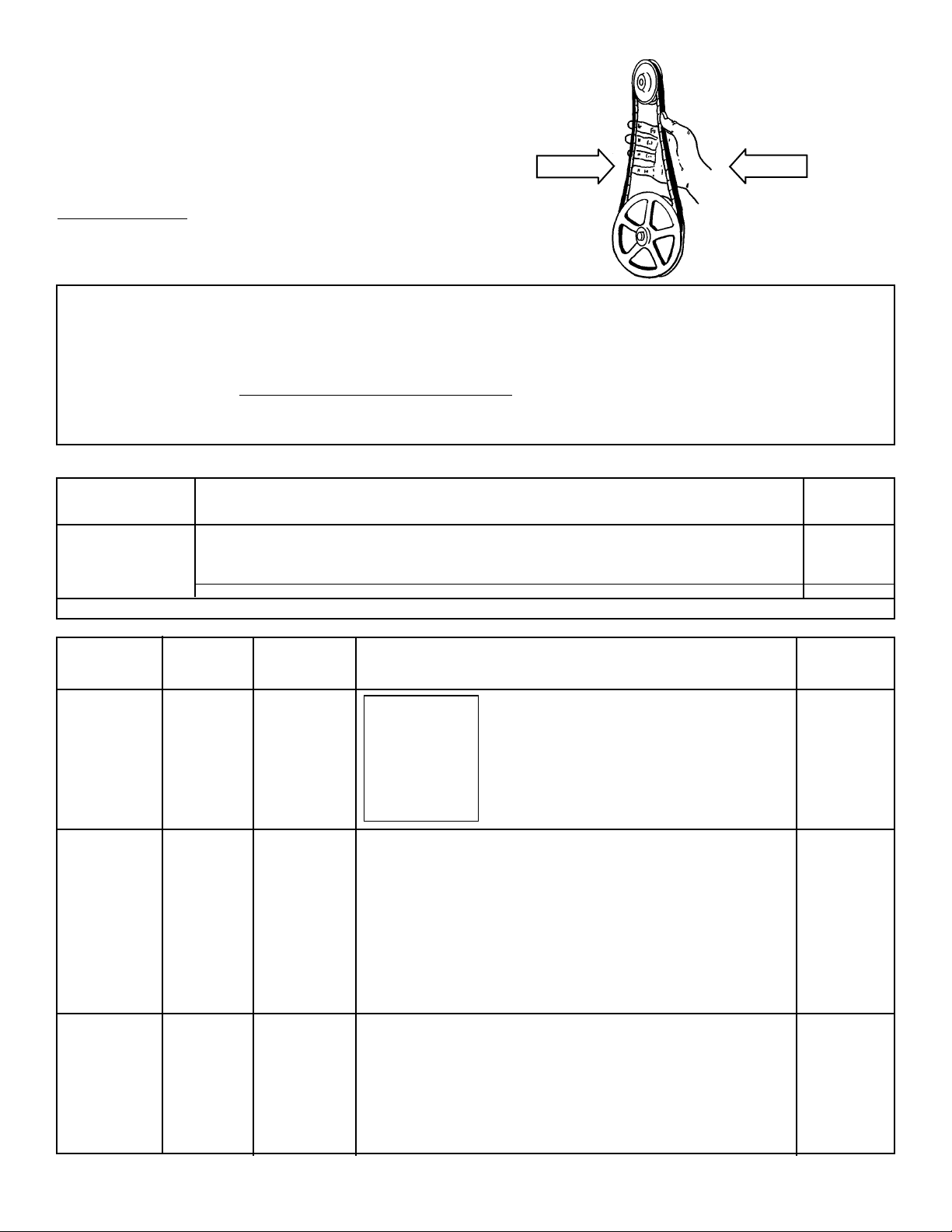

BELT TENSION AND PULLEY ALIGNMENT:

1. Excessive belt tension is the number 1 cause of blower bearing failure.

2. Proper belt tension and pulley alignment are essential for trouble free operation.

3. A simple “Rule of Thumb” for checking belt tension is illustrated on page 2.

4. When belt is grasped as shown on page 2, a total deflection of approximately 1” should be easily attained.

5. Insufficient deflection indicates that the belt is too tight, resulting in noise from excessive vibration, premature

bearing failure, and short belt life. Tight belts may overload a motor that would otherwise be adequate.

6. Excessive deflection is a indication that the belt is not tight enough. If not corrected, slippage could cause

loss of blower speed and belt failure through wear.

(Continued on next page)

FORM 1500

7. A belt should be just tight enough to avoid slippage.

8. Align pulleys with a straight edge to conserve belt life

and eliminate unnecessary noise.

9. Check tension before start-up, after every pulley

adjustment and regularly thereafter.

SET SCREWS:

Ensure all set screws on both pulleys and blower wheel are tight.

BELT SHOULD SQUEEZE

BY NO MORE THAN 1”

ELECTRICAL:

Connect motor in accordance with applicable codes. Provide properly sized motor overload protection to protect motor against electrical faults and system changes. Confirm proper motor rotation on star t-up.

MAINTENANCE:

Inspect periodically for mounting rigidity. Verify belt for wear and tension and adjust as required. Inspect wheel for any dust accumulation and clean as needed. Caution — Do not dislodge balancing clips. Check set screw for tightness.

LUBRICATION:

Ball bearings with sealed in lubricant is used on all models. No additional lubrication is required.

3-1/4” Dia. Zinc Die Cast Blower Pulley — Dia. & RPM RangeBlade Length

Blower Model 5” 6” 7” 8” 9” 10” 12” Based On

824-1125 RPM 680-929 RPM 580-792 RPM 505-690 RPM 447-611 RPM 401-548 RPM 533-455 RPM Motor Frame

07 4L33 4L34• 4L36• 4L38• 4L40• - - - - - -

09 4L36 4L38 4L40• 4L42 4L44 4L45 - - - 48 Frame

10 4L38 4L40 4L41 4L43• 4L45 4L47 - - -

12 4L42 4L43 4L45 4L47 4L48• 4L50 4L54

15 - - - - - - - - - - - - 4L54 4.55•• 4L59 56 Frame

• Standard Drive with 3-1/4” x 1/2” v. s. Motor Pulley •• Standard Drive with 3-1/4”x 5.8” v. s. Motor Pulley

Model VDBA Series Blower Belt Length Selection Table

Motor Blower Blower Model Belt Length

Pulley Pulley Based On

Cast Iron Cast Iron RPM Range 07 09 10 12 15 Motor Frame

HB77T 756-568 - - - - - - - - - B49 143

HB87T 667-500 Note: - - - - - - - - - B51

HB97T 596-447 Blower Pulley - - - - - - - - - B52 &

#8325 HB107T 538-404 Model Number - - - - - - - - - B54

HB117T 491-368 Specifies O.D. - - - - - - - - - B56 145T

HB127T 452-339 - - - - - - - - - B58

O.D. 3.25” HB137T 418-314 Eg. - - - - - - - - - - - - Frame

HB157T 364-273 HB47T = 4.7” O.D. - - - - - - - - - - - HB187T 304-228 - - - - - - - - - - - -

HB47T 1630-1232 B32 B36 B38 B42 - - - Models

HB57T 1329-1005 B34 B38 B40 B43 - - - 07 - 12

HB67T 1121-848 B36 B39 B41 B45 - - -

#IVL44 HB77T 969-733 B37 B41 B43 B47 B51

HB87T 854-645 B39 B43 B45 B48 B42 48 Frame

HB97T 763-577 B41 B45 B47 B50 B54 (Add 1” For

O.D. 4.15” HB101T 690-521 B43 B45 B49 B51 B56 56 Frame)

HB117T 629-476 B45 B48 B50 B54 B58

HB127T 678-437 B47 B50 B52 B56 B60 Model 15

HB137T 535-404 B49 B52 B54 B57 - - HB157T 466-352 - - - B56 B58 B61 - - - 143, 145T

HB187T 390-295 - - - B63 B64 B67 - - - Frame

HB77T 1253-1017 - - - - - - - - - - - - B52

HB87T 1104-896 - - - - - - - - - - - - B54 182, 184T

HB97T 1005-815 - - - - - - - - - - - - B56 Frame

#8400 HB107T 907-750 - - - - - - - - - - - - B58

HB117T 828-686 - - - - - - - - - - - - B59 (Deduct 2”

HB127T 756-618 - - - - - - - - - - - - B61 For 56,

O.D. 4.15” HB137T 697-575 - - - - - - - - - - - - B63 143, 145T)

HB157T 616-509 - - - - - - - - - - - - B56

HB187T 522-435 - - - - - - - - - - - - - - -

FOR FRACTIONAL HP APPLICATIONS “4L”BELTS MAY BE SUBSTITUTED BY ADDING 2” TO THE SPECIFIED “B” BELT. EG. 850 BELT = 4L52.

2

Loading...

Loading...