Canon Pixma iP4600, Pixma iP4680 Simplified Service Manual

iP4600 / iP4680

SIMPLIFIED SERVICE MANUAL

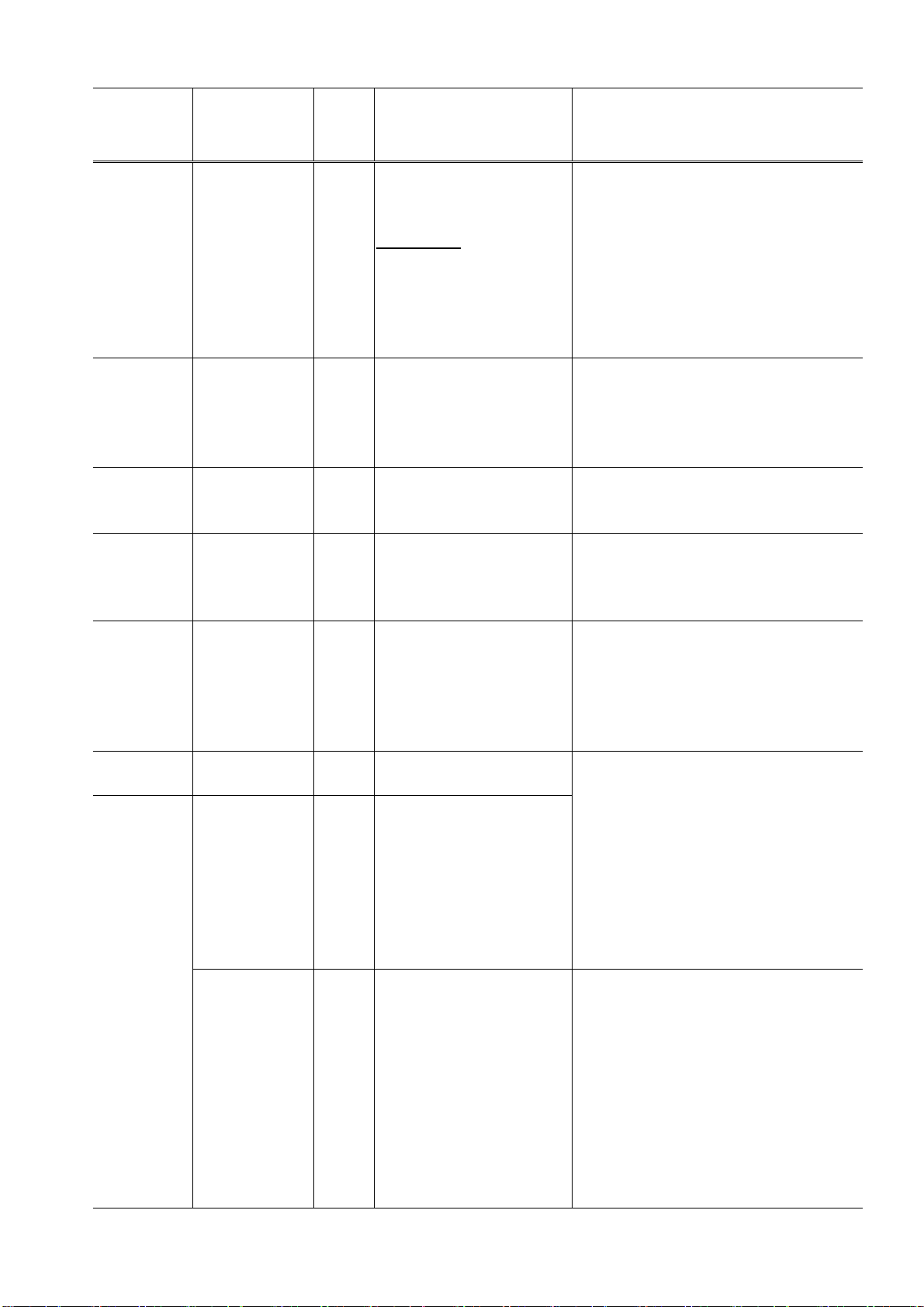

1. LIST OF ERROR DISPLAY

2. ADJUSTMENT / SETTINGS

QY8-13BY-000

Rev.00

July 25, 2008

Canon Inc.

(1/21)

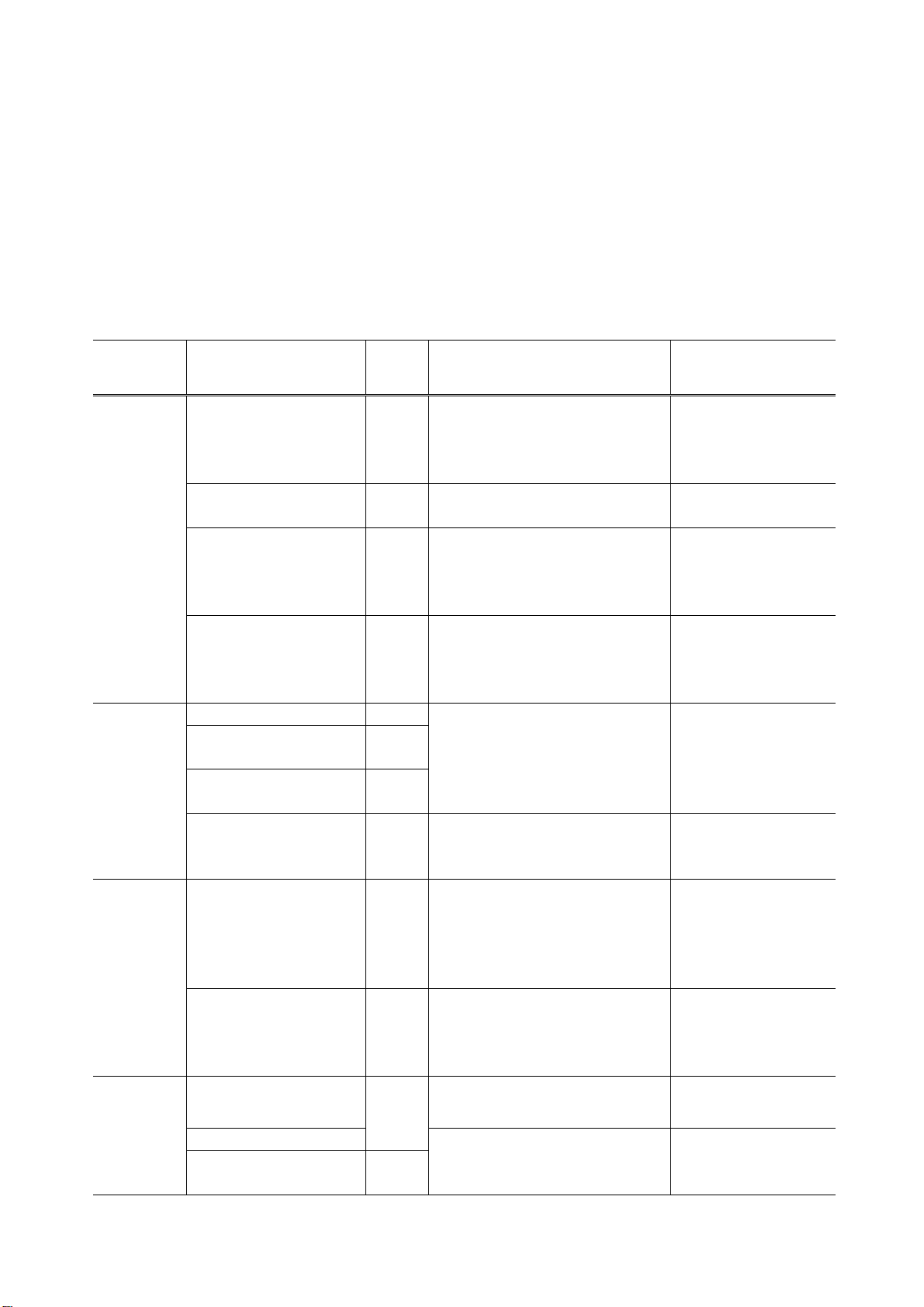

1. LIST OF ERROR DISPLAY

1-1. Operator Call Errors (Alarm LED Lit In Orange)

Errors and warnings are displayed by the following ways:

- Operator call errors are indicated by the Alarm LED lit in orange, and messages are displayed

on the printer driver Status Monitor.

- Error codes (the latest 10 error codes at the maximum) are printed in the "operator call/service

call error record" area in EEPROM information print.

Buttons valid when an operator call error occurs:

- Power button: To turn the printer off and on again.

- Resume/Cancel button: To cancel the job at error occurrence, and to clear the error.

LED

(Blinking in

orange)

2 times

3 times

4 times

5 times

Error

No paper in the rear tray. [1000] Confirm that the rear tray is

No CD / DVD tray [1001] Set the CD / DVD tray, and press

No CD or DVD [1002] Set a CD or DVD in the CD / DVD

No paper in the cassette. [1003] Confirm that the cassette is

Paper jam. [1300]

Paper jam in the rear

guide.

Paper jam in the under

guide.

The front door is closed. [1250] Open the front door. The error is detected

Ink may have run out. [1600] Replace the applicable ink tank

Ink tank not installed. [1660] Install the applicable ink tank(s)

Print head not installed,

or not properly installed.

Error

code

[1303]

[1304]

[1401]

Solution Remarks

selected as the paper source. Set

the paper in the rear tray, and

press the Resume/Cancel button.

the Resume/Cancel button.

tray, and inset the CD / DVD tray

in the proper position. Then, press

the Resume/Cancel.

selected as the paper source. Set

the paper in the cassette, and

press the Resume/Cancel button.

Remove the jammed paper, and

press the Resume/Cancel button.

and close the cover.

properly, and confirm that the

LED's of all the ink tanks light in

red.

Install the print head properly.

at the start of printing

or during printing.

When the error is

cleared by pressing

the Resume/Cancel

button, ink may run out

during printing.

Faulty print head ID.

Print head temperature

sensor error.

[1403]

Re-set the print head. If the error

is not cleared, the print head may

be defective. Replace the print

(2/21)

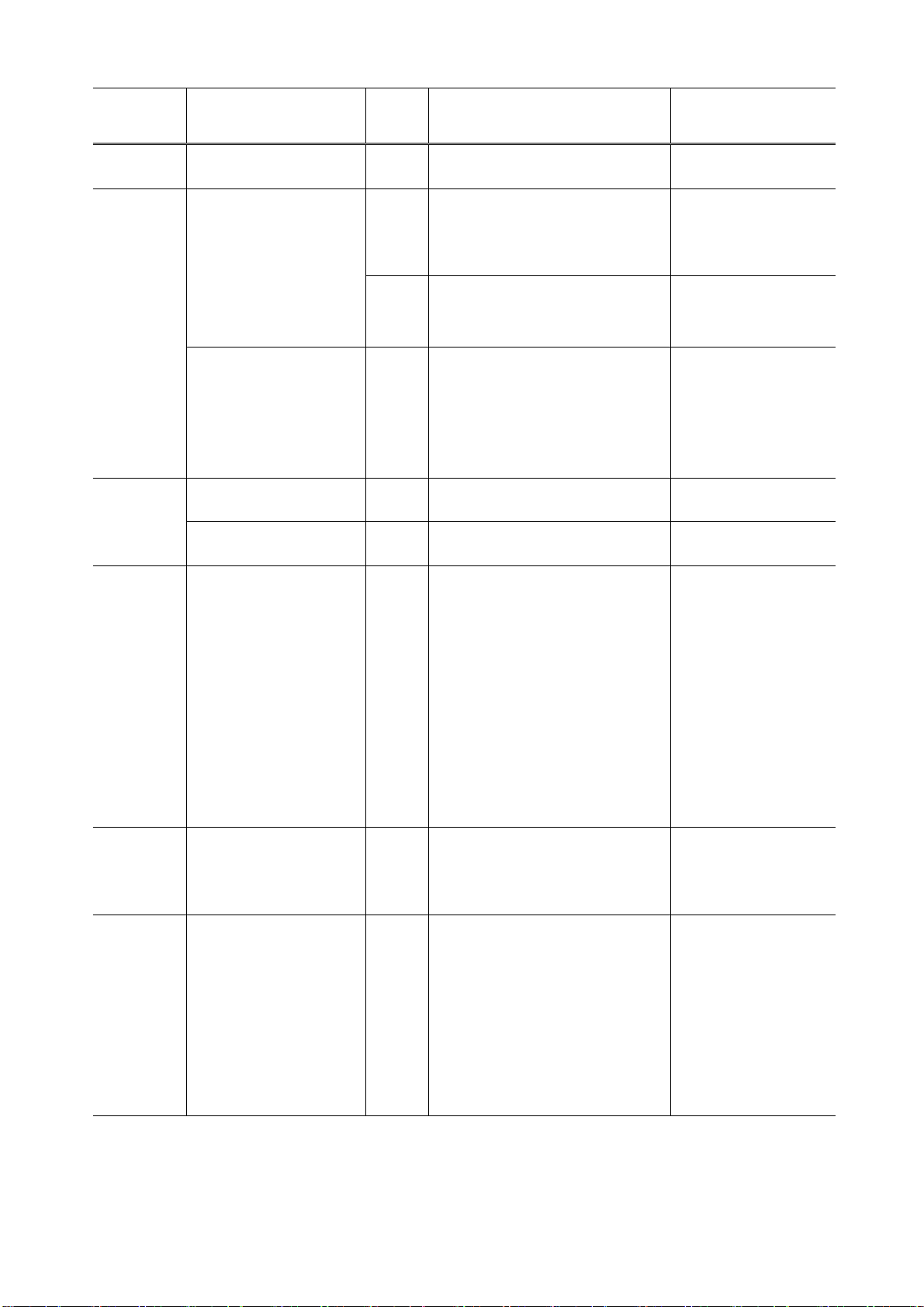

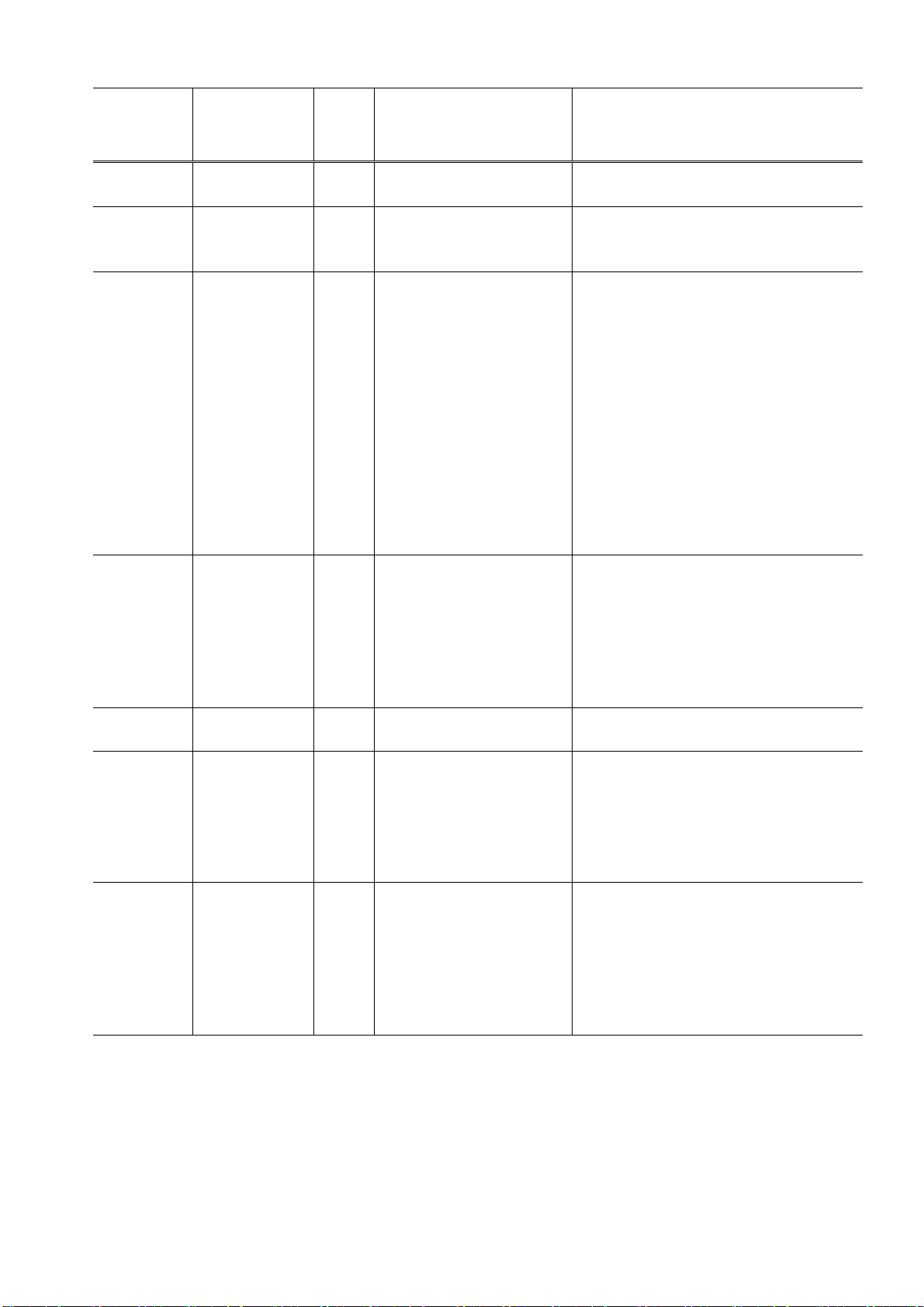

LED

(Blinking in

Error

orange)

Faulty EEPROM data of

the print head.

6 times

Inner cover error.

Time-out in CD / DVD

print operation.

Multiple ink tanks of the

same color installed.

Ink tank in a wrong

position.

8 times Warning: The ink

absorber becomes

almost full.

9 times The connected digital

camera or digital video

camera does not support

Camera Direct Printing.

10 times Automatic duplex

printing cannot be

performed.

Error

code

[1405]

[1841*2,

*2

1846

,

*1

1851

,

*1

1856

]

*1

[1850

*1

1855

]

head.

Close the inner cover, and press

the Resume/Cancel button.

,

Open the inner cover, place the

CD-R tray and press

Solution Remarks

Resume/Cancel.

*1

[1830

] A prescribed period of time (12

minutes) has elapsed without any

printing since printing was

attempted. Press the

Resume/Cancel button to clear

the error.

[1681] Replace the wrong ink tank(s)

with the correct one(s).

[1680] Install the ink tank(s) in the correct

position.

[1700/

1701]

Replace the ink absorber, and

reset its counter. [See 2-2.

Adjustment / Settings, (4) Service

mode]

Pressing the Resume/Cancel

button will exit the error, and

enable printing without replacing

the ink absorber. However, when

the ink absorber becomes full, no

further printing can be performed

unless the applicable ink absorber

is replaced.

[2001] Remove the cable between the

camera and the printer.

[1310] The paper length is not supported

for duplex printing.

Press the Resume/Cancel button

to eject the paper being used at

error occurrence.

Data which was to be printed on

the back side of paper at error

occurrence is skipped (not

printed).

7 times

The error “The ink

absorber becomes

almost full (service

call)” may occur soon.

Data which was to be

printed on the back

side of paper at error

occurrence is not

printed.

(3/21)

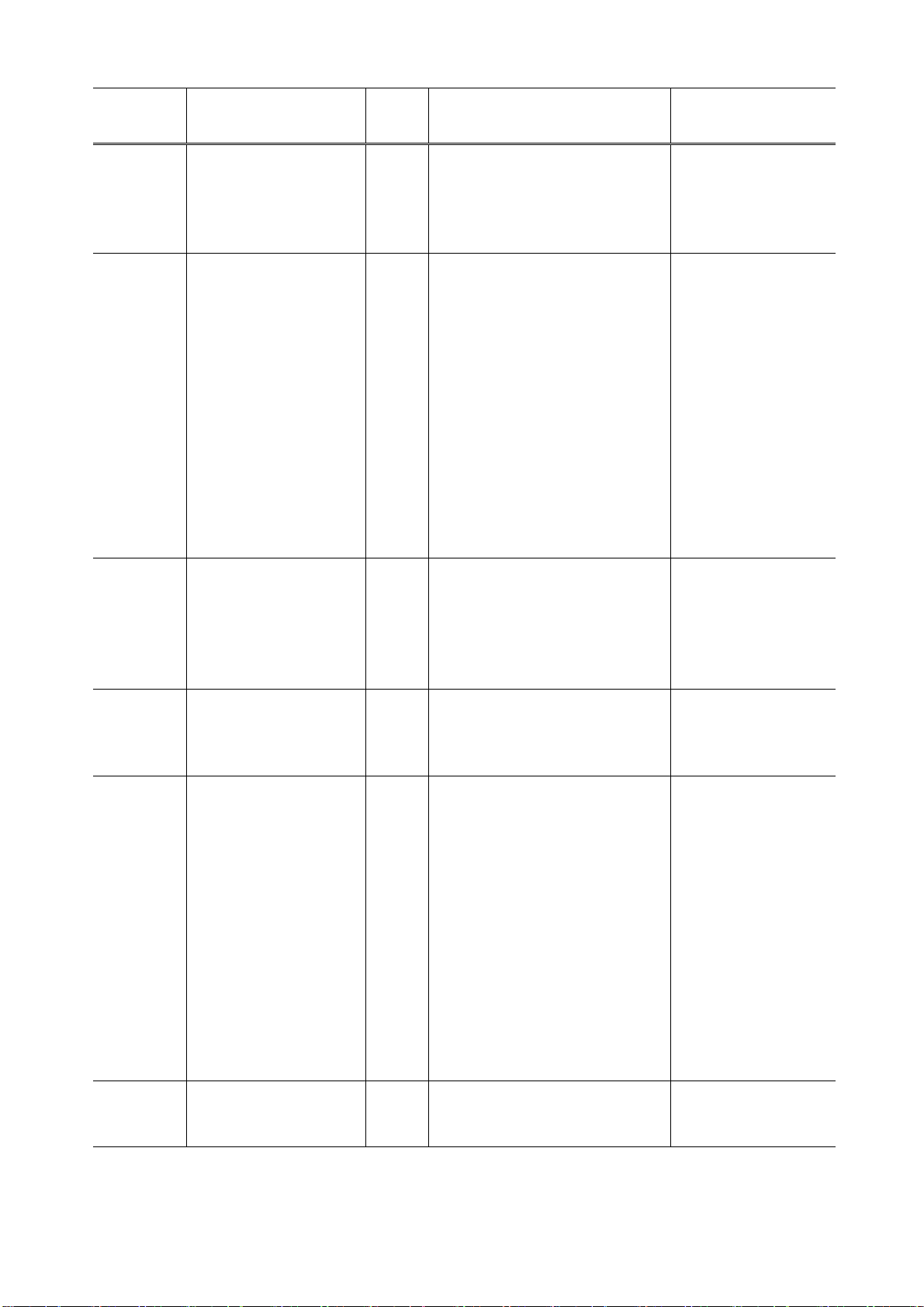

LED

(Blinking in

Error

orange)

11 times Failed in automatic print

head alignment.

Error

code

Solution Remarks

[2500] Press the Resume/Cancel button

to clear the error, then perform the

automatic print head again.

(In the iP4600 / iP4680, use Matte

Photo Paper MP-101.)

13 times The remaining ink

amount unknown.

[1683] Replace the applicable ink tank

with a new one. Printing with a

once-empty ink tank can damage

the printer.

To continue printing without

replacing the ink tank(s), press

the Resume/Cancel button for 5

sec. or longer to disable the

function to detect the remaining

ink amount. After the operation, it

is recorded in the printer

EEPROM that the function to

detect the remaining ink amount

was disabled.

14 times Ink tank not recognized. [1684] A non-supported ink tank (an ink

tank that is sold in a different

region from where the printer was

purchased) is installed (the ink

tank LED is turned off). Install the

supported ink tanks.

15 times Ink tank not recognized. [1410 to

1419]

A hardware error occurred in an

ink tank (the ink tank LED is

turned off). Replace the ink

tank(s).

16 times No ink (no raw ink). [1688] Replace the empty ink tank(s),

and close the scanning unit

(cover).

Printing with an empty ink tank

can damage the printer.

To continue printing without

replacing the ink tank(s), press

the Resume/Cancel button for 5

sec. or longer to disable the

function to detect the remaining

ink amount. After the operation, it

is recorded in the printer that the

function to detect the remaining

ink amount was disabled.

19 times Non-supported hub [2002] Remove the applicable USB hub

from the PictBridge (USB)

connector.

*1: Only for models supporting CD / DVD printing

*2: Only for models not supporting CD / DVD printing

The ink tank installed

is judged to have once

been empty.

(4/21)

1-2. Service Call Errors (by Cyclic Blinking of Alarm and Power LEDs)

Cycles of

blinking of

Alarm and

Power LEDs

2 times Carriage error [5100] An error occurred in the

3 times Line feed error [6000] An error occurred in the LF

4 times Purge cam

5 times ASF (cam)

6 times Internal

Error

sensor error

sensor error

temperature

error

Error

code

carriage encoder signal.

encoder signal.

[5C00] An error occurred in the

purge unit.

[5700] An error occurred in the

ASF cam sensor.

[5400] The internal temperature is

not normal.

Conditions

Solution

(Check points and replacement items)

1) Smearing or scratches on the carriage

slit film;

clean the timing slit film.

2) Foreign material or paper debris that

obstructs the carriage movement;

remove foreign material.

3) Ink tank conditions;

re-set the ink tanks.

4) Cable connection

5) Part replacement:

- Timing slit disk film

- Carriage unit

- Logic board

- Carriage motor

1) Smearing or scratches on the LF / EJ

slit film;

clean the LF / EJ slit film.

2) Foreign material or paper debris in the

LF drive;

remove foreign material.

3) Cable connection

4) Part replacement:

- LF / EJ slit film

- LF / EJ timing sensor unit

- Paper feed roller unit

- Logic board

- Paper feed motor

1) Foreign material or paper debris

around the purge drive system unit;

remove foreign material.

2) Cable connection

3) Part replacement:

- Purge drive system unit

- Logic board

1) Cable connection

2) Part replacement:

- ASF unit

- PE sensor board unit

- Logic board

1) Cable connection

2) Part replacement:

- Carriage unit

- Logic board

- Print head

(5/21)

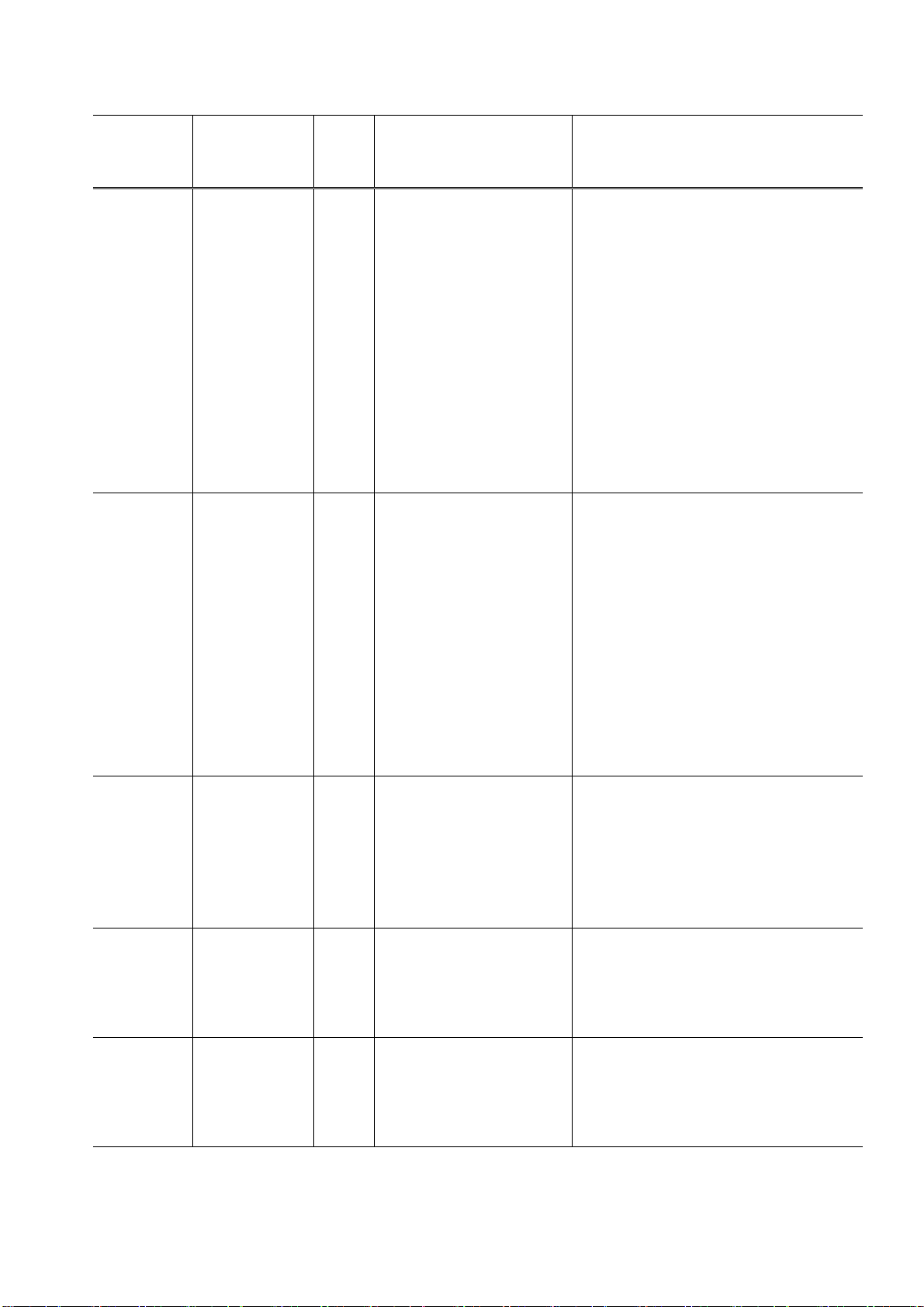

Cycles of

blinking of

Alarm and

Power LEDs

7 times Ink absorber full [5B00,

8 times Print head

9 times EEPROM error [6800,

10 times VH monitor error [B200] The print head voltage is

11 times Carriage lift

12 times APP position

14 times

Error

temperature rise

error

mechanism

error

error

APP sensor

error

Paper feed cam

sensor error

Error

code

The ink absorber is

5B01]

[5200] The print head temperature

[6801]

[5110] The carriage did not move

[6A80] An error occurred in the

[6A90] An error occurred during

[6B10] An error occurred in the

supposed to be full.

Error codes:

5B00: Main ink absorber is

full (overseas).

5B01: Main ink absorber is

full (Japan).

exceeded the specified

value.

A problem occurred in

reading from or writing to

the EEPROM.

abnormal.

up or down properly.

APP motor.

paper feeding or paper

ejection.

paper feed cam sensor

during paper feeding from

the cassette, or the paper

absorbing a large amount

of ink jammed in the PF

rear guide.

Conditions

Solution

(Check points and replacement items)

1) Ink absorber condition

2) Part replacement:

- Ink absorber kit

3) Ink absorber counter value in the

EEPROM;

reset the ink absorber counter.

1) Print head condition

2) Cable connection

3) Part replacement:

- Print head

- Logic board

1) Part replacement:

- Logic board

1) Part replacement:

- Print head and logic board

(Replace them at the same time.)

- Power supply unit

1) Foreign material or paper debris that

obstructs the carriage movement;

remove foreign material.

2) Part replacement:

- Switch system unit

- Carriage unit

1) Foreign material or paper debris

around the purge drive system unit;

remove foreign material.

2) Foreign material or paper debris

around the ASF unit;

remove foreign material.

3) Cable connection

4) Part replacement:

- Purge drive system unit

- Logic board

1) Jammed paper in the PF rear guide

(when a large amount of ink was

absorbed in the paper);

remove the jammed paper and

foreign material.

2) Foreign material or paper debris in the

cassette or in the PF rear guide;

remove foreign material.

3) Part replacement:

- PF pick-up unit

- Logic board

(6/21)

Cycles of

blinking of

Alarm and

Power LEDs

15 times USB Host VBUS

16 times Pump roller

17 times Paper eject

19 times Ink tank position

20 times Other errors [6500] An unidentified error

21 times Drive switch

23 times Valve cam

Error

overcurrent

sensor error

encoder error

sensor error

error

sensor error

Error

code

[9000] The USB Host VBUS is

overloaded.

[5C20] The pump roller position

cannot be detected.

[6010] Paper eject encoder error 1) Smearing or scratches on the LF / EJ

[6502] None of the ink tank

position is detected.

occurred.

[C000] Drive was not switched

properly.

[6C10] The valve cam sensor was

faulty at power-on or when

purging was attempted.

Conditions

(Check points and replacement items)

1) Part replacement:

- Logic board

1) Cable connection

2) Part replacement:

- Purge drive system unit

slit film;

clean the LF / EJ slit film.

2) Foreign material or paper debris in the

paper path;

remove foreign material.

3) Cable connection

4) Part replacement:

- LF / EJ slit film

- LF / EJ timing sensor unit

- Platen unit

- Logic board

- Paper feed motor

1) Ink tank position;

confirm the ink tank position.

2) Re-set or replacement of ink tanks

3) Cable connection

4) Part replacement:

- Spur unit

- Logic board

1) Part replacement:

- Logic board

1) Foreign material or paper debris in the

drive switch area;

remove foreign material.

2) Part replacement:

- Purge drive system unit

- ASF unit

1) Foreign material or paper debris

around the purge drive system unit;

remove foreign material.

2) Cable connection

3) Part replacement:

- Purge drive system unit

- Logic board

Solution

Note: Before replacement of the logic board ass'y, check the ink absorber counter value (by service

test print or EEPROM information print). If the counter value is 7% or more, also replace the ink

absorber kit when replacing the logic board ass'y. If the counter value is less than 7%, register

the current ink absorber counter value to the replaced new logic board instead.

(7/21)

Loading...

Loading...