Canon Pixma iP4500 Service Manual

Canon Pixma iP4500

SIMPLIFIED SERVICE MANUAL

1. PRODUCT LIST

2. PRODUCT SPECIFICATIONS

3. ERROR DISPLAY

4. REPAIR

5. SERVICE MODE

6. SERVICE POLICY

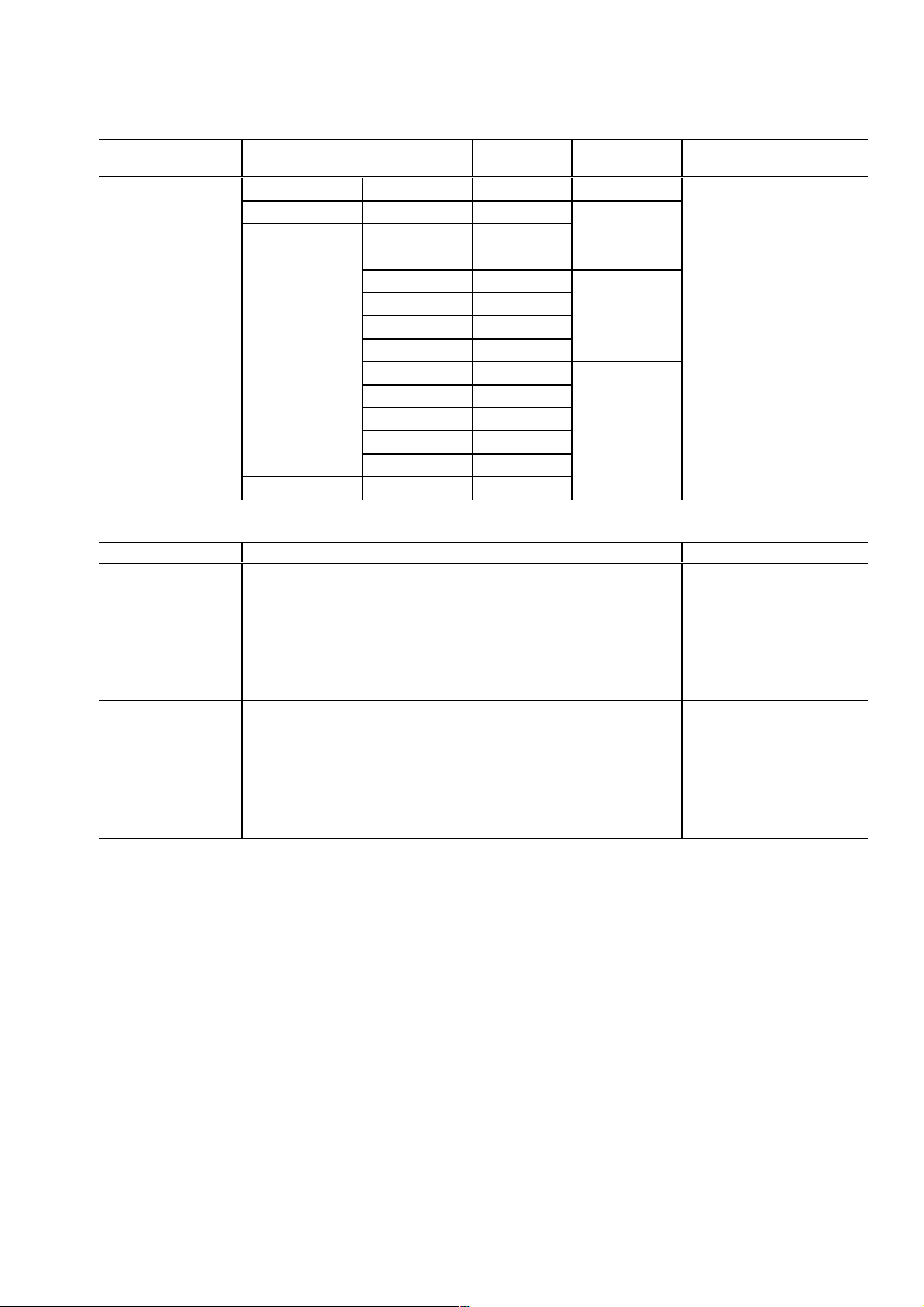

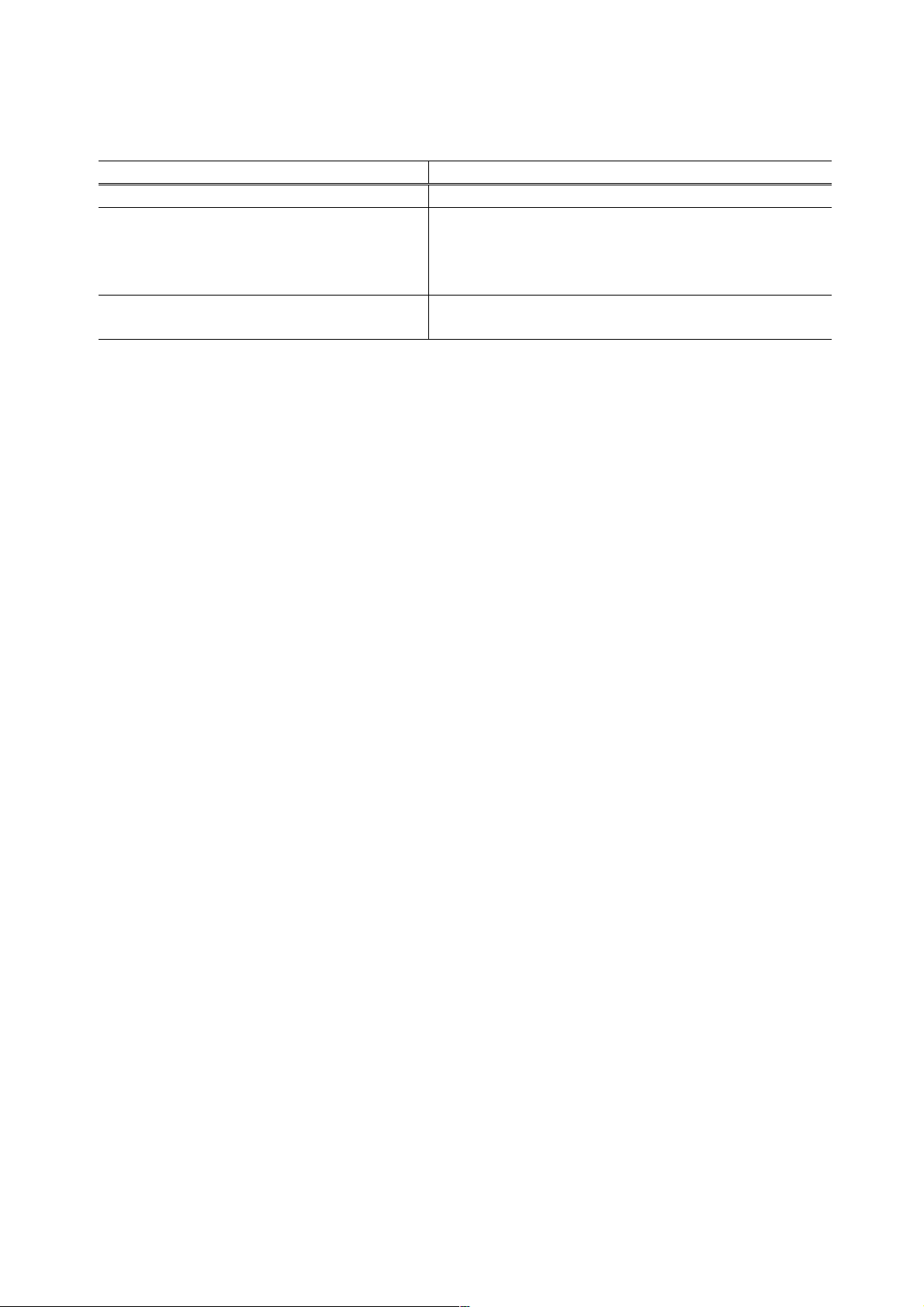

1. PRODUCT LIST

1-1. Main Units

Product name Product code Destination

Canon Inkjet Printer

iP4500

Q30-4400-000 2171B001AA JPN 180,000

Q30-4401-000 2171B002AA US

Q30-4400-000

2171B003AA CA

2171B004AA LAM

--- EUM

--- EMB

2171B008AA GB

2171B009AA EUM / EMB

2171B011AA AU

2171B012AA ASA

2171B013AA HK

Production q'ty

(for 3 months)

39,000

58,000

18,000

Print head

Ink tanks

(Japan /

Non-Japan)

BCI-9BK / PGI-5BK

BCI- 7eBK / CLI-8BK

BCI- 7eC / CLI-8C

BCI- 7eM / CLI-8M

BCI- 7eY / CLI-8Y

CD / DVD tray

8cm CD / DVD adapter

Power cord

*1: US and KR

2171B014AA CN

2171B015AA TW

Q30-4401-000 2171B016AA KR

1-2. Consumables

Product name Product code Destination Remarks

Canon Ink Tank

BCI-9BK 0372B001AA

JP

BCI-7eBK 0364B001AA

BCI-7eC 0365B001AA

BCI-7eM 0366B001AA

BCI-7eY 0367B001AA

Canon Ink Tank

PGI-5BK 0628B001AA to 0628B005AA

CLI-8BK 0620B001AA to 0620B005AA

CLI-8C 0621B001AA to 0621B005AA

CLI-8M 0622B001AA to 0622B005AA

CLI-8Y 0623B001AA to 0623B005AA

001: EUR / OCN

002: AMR

003: ASA

004: W/O BOX

005: AMR S

1-3. Options

None

Accessories

*1

*1

1

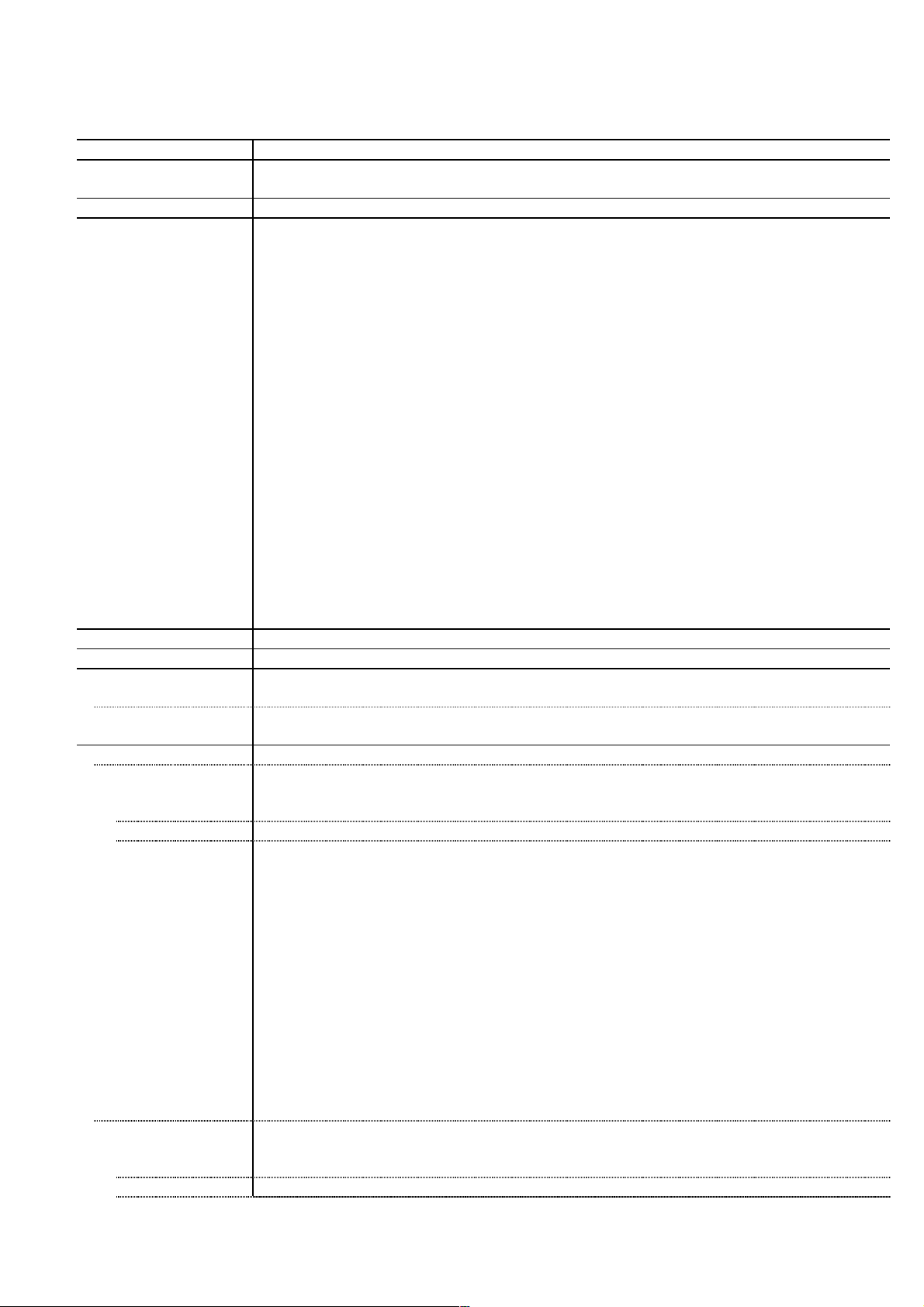

2. PRODUCT SPECIFICATIONS

2-1. Printer Main Unit Specifications

Type Desktop serial color inkjet printer

Paper feeding method Auto sheet feed (rear tray, cassette, automatic duplex printing, CD / DVD printing*)

* Not supported in the US and KR models

Resolution 9,600 dpi x 2,400 dpi (Max.)

Throughput

(Target value)

- Photo (4" x 6")*1 PP-201 / Standard / Borderless: Approx. 21 sec.

- Photo (L size)

- Camera Direct

- Camera Direct

*1

GL-101 / Standard / Borderless: Approx. 18 sec.

*2

PP-101 / 4" x 6" / Borderless: Approx. 58 sec.

*2

GL-101 / L size / Borderless: Approx. 50 sec.

For reference:

- Black text (plain paper / FINE pattern)

Max speed (Custom setting 5): 31 ppm

Standard: 14.9 ppm

- Color (plain paper / FINE pattern)

Max speed (Custom setting 5): 24 ppm

Standard: 11.7 ppm

*1: Based on Canon standard pattern. Print speed may vary depending on system configuration,

interface, software, document complexity, print mode, page coverage, type of paper used and

does not take into account data processing time on host computer.

*2: When printing equivalent to the 7.1megapixel image taken by certain Canon digital camera from

PictBridge with “Default” settings on Print Effect without border using Photo Paper Plus Glossy.

Actual print speed may vary depending on image data, print mode, type of paper and camera

that is connected to, etc.

Note: Notations for the Americas should be confirmed with the related marketing section of each

sales company in the Americas.

Printing direction Bidirectional, uni-directional

Print width Max. 203.2 mm (216 mm in borderless printing)

Interface

Computer USB 2.0 Hi-Speed

Camera Direct PictBridge with a PictBridge-supported digital camera, digital video camera, or

camera-equipped mobile phone

Paper feed

Rear tray

Stacking

capacity

Max. 13 mm (Approx. 150 sheets of 64 g/m

2

plain paper)

Paper weight 64 to 105 g/m2, Canon specialty paper 273 g/m2 at the maximum

Paper

specifications

Plain paper: A4, A5, B5, Letter, Legal, custom

Super White Paper SW-201: A4, Letter

High Resolution Paper HR-101N: A4, Letter

Photo Paper Pro PR-101: A4, Letter, 4x6, 4x8, 8x10, Wide

Photo Paper Plus Glossy PP-101: A4, Letter, 4x6, 5x7

Photo Paper Plus Glossy II PP-201: A4, Letter, 8x10, 4x6, 5x7

Photo Paper Plus Semi-gloss SG-201: A4, Letter, 4x6, 8x10

Glossy Photo Paper GP-401: A4, Letter, 4x6, Credit Card

GP-501: A4, 4x6

GP-502: Letter, 4x6

Matte Photo Paper MP-101: A4, Letter, 4x6

Photo Paper Plus Double Sided PP-101D: A4, Letter, 5x7

Photo Stickers PS-101

T-shirt Transfer TR-301: A4

Envelope: DL-size, COM #10

Cassette

Stacking

capacity

Max. 13 mm (Approx. 150 sheets of 64 g/m

2

plain paper)

Paper weight 64 to 105 g/m2, Canon specialty paper 273 g/m2 at the maximum

2

Paper

specifications

Same as the Rear tray, except that the Legal and Credit Card sizes and Photo Stickers

cannot be used in the cassette.

DVD / CD print*

Supported media CD / DVD printable media

Media size 120 mm / 80 mm

Print operation Front loading

Acoustic noise

(Target value)

Environmental

requirements

Power supply

(Power

consumption)

External dimensions With the trays retracted: Approx. 445 (W) x 303 (D) x 160 (H) mm

Weight Approx. 6.9 kg, including the print head and the ink tanks

Related standards Electromagnetic radiance:

Serial number

location

Remaining ink

amount detection

Paper type detection Not available

Print head alignment Available (automatic or manual alignment via the printer driver Maintenance tab, automatic

Approx. 34.5 dB

(Highest print quality settings: Photo Paper Pro, Custom 1, paper feeding from the rear

tray)

During operation Temperature 5C to 35C (41F to 95F)

Humidity 10%RH to 90%RH (no condensation)

Non operation Temperature 0C to 40C (32F to 104F)

Humidity 5%RH to 95%RH (no condensation)

Power supply voltage Frequency Printing Standby OFF

AC 100 to 240 V 50/60 Hz Approx. 13 W Approx. 1.2 W Approx. 1.0 W

With the trays extended: Approx. 445 (W) x 582 (D) x 338 (H) mm

VCCI, FCC, IC, CE Mark, Taiwan EMC, C-Tick, CCC (EMC), Korea MIC, Gost-R

Electrical safety:

Electrical Appliance and Material Safety Law (DENAN), UL, C-UL, CB Report, CE Mark,

GS, Gost-R, FT, SASO, CCC, SPRING, Korea EK, IRAM (Argentine)

Environmental regulations:

RoHS (EU), WEEE (EU), Korea Package Recycle Law, Green Point (Germany), Energy

Star, Eco Mark, Law on Promoting Green Purchasing

On the carriage flexible cable holder (visible when the access cover is opened)

Available (detection by optical method and dot count, enabled at default)

alignment at default)

* Not supported in the US and KR models

2-2. Print Head Specifications

Print head

Type Single head with 5 removable ink tanks (each color)

Print head Pigment-based BK: 512 nozzles (30 pl), 600 dpi

Dye-based BK / Y: 512 nozzles for each color (5 pl), 1,200 dpi

Dye-based C / M: 512 x 2 nozzles for each color (5 pl), 2,400 dpi

512 x 2 nozzles for each color (2 pl), 2,400 dpi

512 x 2 nozzles for each color (1 pl), 2,400 dpi

Ink color Pigment-based black

Dye-based black, cyan, magenta, yellow

Ink tank Japan: BCI-9BK (pigment-based), BCI-7eBK / C / M / Y (dye-based)

Others: PGI-5BK (pigment-based), CLI-8BK / C / M / Y (dye-based)

Weight (Net) Print head: Approx. 58.4 g

Supply method As a service part (not including ink tanks)

Part number QY6-0067-000

3

2-3. Supported Ink Tanks

Pigment-based

ink

BCI-

Model Destination

Japan O X O O O O X X X X iP4500

Others X O X X X X O O O O

O: Usable

X: Not usable

9BK

PGI-

5BK

BIC-

7eBK

BCI7eC

BIC7eM

Dye-based ink

BCI-

7eY

CLI8BK

CLI-

8C

Note: The ink tanks for the Japanese model are not compatible with those for the other models. Be

sure to use the appropriate ink tanks in servicing.

CLI-

8M

CLI-

8Y

4

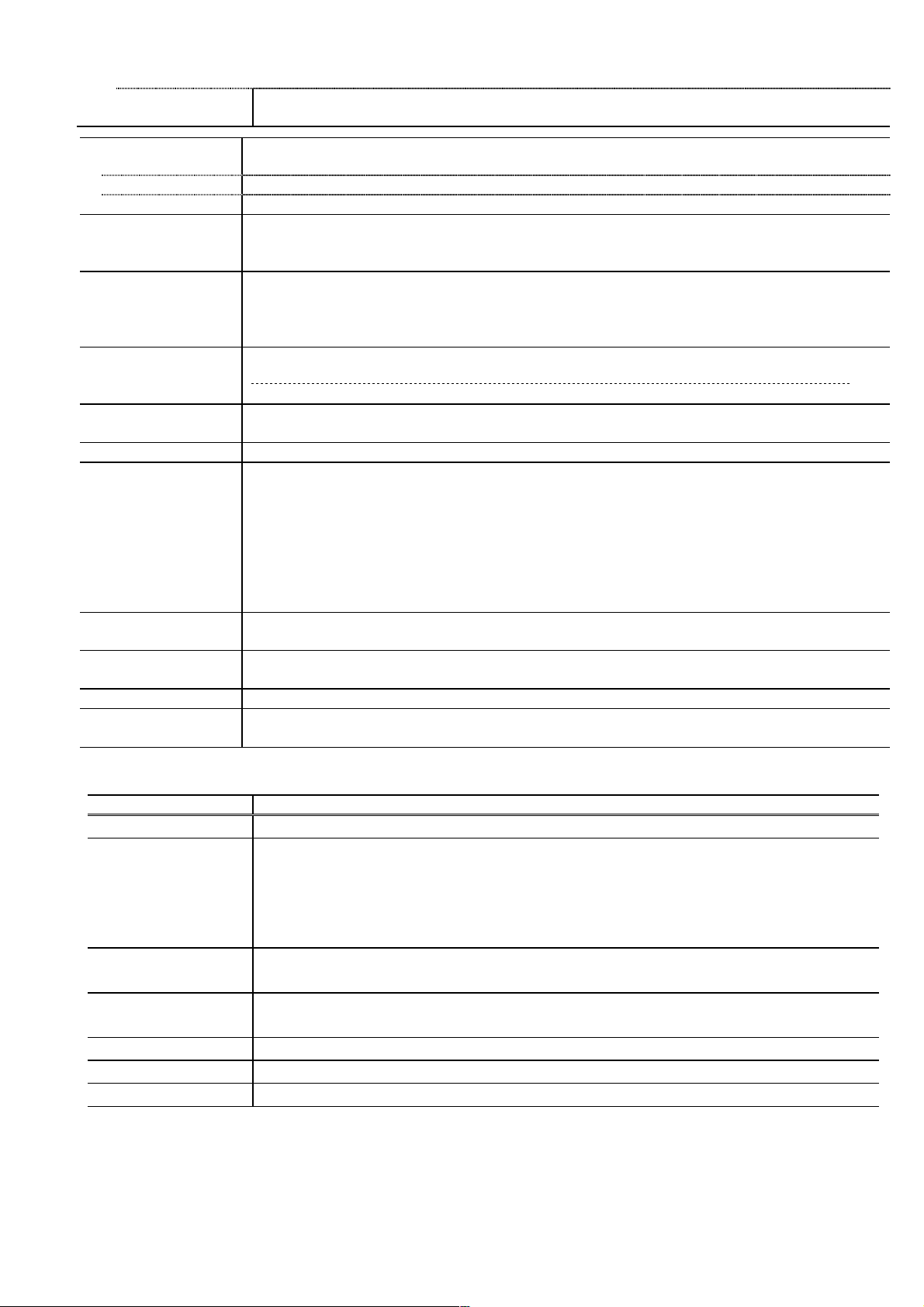

3. ERROR DISPLAY

Errors are displayed by the LEDs, and ink low warnings are displayed by the Status Monitor.

3-1. Operator Call Error (Alarm LED Blinking in Orange)

Alarm LED

blinking

2 times

3 times

4 times

5 times - Print head not installed, or

No paper in the rear tray.

[1000]

No CD / DVD tray. [1001] Set the CD / DVD tray, and press the

No paper in the cassette.

[1003]

No CD or DVD. [1002] Set a CD or DVD in the CD / DVD tray

Paper jam. [1300] Error during paper feeding

Paper jam in the rear guide.

[1303]

Paper jam in the under

guide. [1304]

Front door close error.

[1250]

No ink. [1600] Replace the applicable ink tank, or press

Ink tank not installed. [1660] Install the applicable ink tank(s) properly,

not properly installed.

[1401]

- Print head temperature

sensor error. [1403]

- Faulty EEPROM data of

the print head. [1405]

Error Corrective action Remarks

Set the paper in the rear tray, and press

the Resume/Cancel button.

Resume/Cancel button.

Set the paper in the cassette, and press

the Resume/Cancel button.

(which is ejected at error occurrence), and

inset the CD / DVD tray in the proper

position. Then, press the Resume/Cancel

button.

Remove the jammed paper, and press the

Resume/Cancel button.

Open the paper output tray. The error is indicated if the

the Resume/Cancel button to clear the

error without ink tank replacement.

and confirm that the LED's of all the ink

tanks light red.

Install the print head properly.

from the rear tray

Error in the duplexing

transport unit

Error during paper feeding

from the cassette

paper output tray is closed at

start of a print job, or while a

print job is being performed.

When the error is cleared by

pressing the Resume/Cancel

button, ink may run out

during printing.

5

6 times

7 times

8 times Warning: The ink absorber

9 times The connected digital

10 times Automatic duplex printing

Inner cover open before start

of printing on paper. [1841]

(At CD-R is not supported.)

Inner cover open during

printing on paper. [1846]

(At CD-R is not supported.)

Inner cover open before start

of printing on paper (print

continuable). [1856]

Inner cover closed before

start of CD / DVD printing

(print continuable). [1850]

Inner cover open before start

of CD / DVD printing (print

continuable). [1851]

Inner cover closed during

CD / DVD printing (print

NOT continuable). [1855]

Multiple ink tanks of the

same color installed. [1681]

Ink tank in a wrong position.

[1680]

becomes almost full. [1700]

camera or digital video

camera does not support

Camera Direct

Printing. [2001]

cannot be performed. [1310]

Close the inner cover, and press the

Resume/Cancel button. (At CD-R is not

supported.)

Close the inner cover, and press the

Resume/Cancel button. (At CD-R is not

supported.)

Close the inner cover, and press the

Resume/Cancel button to clear the error.

The paper being printed at error

occurrence will be ejected without printing

the remaining data for the ejected paper,

then printing will resume from the next

page.

Open the inner cover which functions as

the CD / DVD tray feeder, set the CD /

DVD tray in the feeder, and press the

Resume/Cancel button.

Close the inner cover, and press the

Resume/Cancel button.

Open the inner cover, and press the

Resume/Cancel button to clear the error.

The CD or DVD being printed at error

occurrence will be ejected without printing

the remaining data for the ejected CD or

DVD, then the next print job will be

performed.

Replace the wrong ink tank(s) with the

correct one(s).

Install the ink tank(s) in the correct position.

Press the Resume/Cancel button. The service call error,

Remove the cable between the camera

and the printer.

Press the Resume/Cancel button to eject

the paper being used at error occurrence.

Printing will resume from on the front side

of the next page.

Install the ink cartridge(s),

and close the access cover.

indicating the ink absorber is

full, is likely to occur soon.

Data which was to be printed

on the back side of paper at

error occurrence is skipped

(not printed).

6

11 times Failed in automatic print

head alignment. [2500]

13 times The remaining ink amount

unknown. [1683]

14 times Ink tank not recognized.

[1684]

15 times Ink tank not recognized.

[1410 to 1414]

16 times No ink. [1688] Replace the empty ink tank(s), and close

19 times Non-supported hub An unsupported USB hub is connected.

Press the Resume/Cancel button.

- If paper is being fed at error occurrence,

the error is indicated after the paper is

ejected.

- If the error occurs, the print head

alignment values are not changed.

- After exit from the error by the

Resume/Cancel button, the automatic

print head alignment will not be re-done.

Replace the applicable ink tank with a new

one, and close the scanning unit (printer

cover).

Printing with a once-empty ink tank can

damage the printer.

To continue printing without replacing the

ink tank(s), press the Resume/Cancel

button for 5 sec. or longer to disable the

function to detect the remaining ink

amount. After the operation, it is recorded

in the printer EEPROM that the function to

detect the remaining ink amount was

disabled.

A non-supported ink tank is installed (the

ink tank LED is turned off). Install the

supported ink tanks.

An error occurred in an ink tank (the ink

tank LED is turned off). Replace the ink

tank(s).

Each error code corresponds to each ink

tank, from left (the opposite side of the

home position) to right, respectively. Error

code 1410 is for the leftmost ink tank

(PGI-5BK).

the top cover.

Printing with an empty ink tank can

damage the printer.

To continue printing without replacing the

ink tank(s), press the Resume/Cancel

button for 5 sec. or longer to disable the

function to detect the remaining ink

amount. After the operation, it is recorded

in the printer that the function to detect the

remaining ink amount was disabled.

Remove the hub.

The error will occur (a) when

the print head alignment

pattern is not printed due to

no ink or non-ejection of ink,

(b) when the sensor's AD

value is incorrect, or (c)

when the paper is shorter

than the specified length.

The error is indicated when

raw ink is detected but the

dot count number exceeds

the threshold of complete

exhaustion of ink

Ink tank positioning (from left

to right): BK, PigBK, Y, M, C

The error is indicated when

"no raw ink" is detected and

when the dot count number

exceeds the threshold of

complete exhaustion of ink.

7

3-2. Service Call Error (by Cyclic Blinking in Orange (Alarm LED) and Green (Power LED), or Alarm

LED Lit in Orange)

Cycles of blinking in

orange and green

Error Corrective Action

2 times Carriage error [5100] - Carriage unit (QM3-2264)

- Timing slit strip film (QC1-6526)

- Logic board ass'y (QM3-2738)

*1

- Carriage motor (QK1-1500)

3 times Line feed error [6000] - Timing sensor unit (QM3-2464)

- Timing slit disk film (QC2-4598)

- Feed roller ass'y (QL2-1490)

- Logic board ass'y (QM3-2738)

*1

- Paper feed motor (QK1-3849)

4 times Purge cam sensor error [5C00] - Purge unit (QM3-0007)

- Logic board ass'y (QM3-2738)

*1

5 times Rear tray (cam) sensor error [5700] - Sheet feed unit (QM3-2723)

6 times Internal temperature error [5400] - Logic board ass'y (QM3-2738)*1

- Carriage unit (QM3-2264)

7 times Ink absorber full [5B00/5B01] - Ink absorber kit (QY5-0190)

8 times Print head temperature rise error [5200] - Print head (QY6-0067)

*1

9 times EEPROM / NVRAM error [6800]

- Logic board ass’y (QM3-2738)

- Logic board ass'y (QM3-2738)*1

NVRAM time out error [6801]

10 times VH monitor error [B200] - Logic board ass'y (QM3-2738)*1

- Print head (QY6-0067)

11 times Carriage lift mechanism error [5110] - PR lift shaft ass'y (QL2-1450)

- Sheet feed unit (QM3-2723)

- Logic board ass'y (QM3-2738)

*1

- Carriage lift sensor unit (QM3-1273)

12 times AP position error [6A00]

PG position error [5C10]

- Sheet feed unit (QM3-2723)

- Logic board ass'y (QM3-2738)

*1

- Purge unit (QM2-0007)

13 times Paper feed position error [6B00] - Sheet feed unit (QM3-2723)

- Logic board ass'y (QM3-2738)

*1

14 times Paper feed cam sensor error [6B10] - Sheet feed unit (QM3-2723)

- Logic board ass'y (QM3-2738)

*1

15 times USB Host VBUS overcurrent [9000] - Logic board ass'y (QM3-2738)*1

16 times Pump roller sensor error [5C20] - Logic board ass'y (QM3-2738)*1

- Purge unit (QM3-0007)

17 times Paper eject encoder error [6010] - Timing sensor unit (QM3-2464)

- Timing slit disk eject film (QC2-4599)

- Logic board ass'y (QM3-2738)

*1

- Paper feed motor (QK1-3849)

- Platen unit (QM3-2725)

19 times Ink tank position sensor error [6502] - Platen unit (QM3-0001)

*1

Power LED turned

- Logic board ass'y (QM3-2738)

ROM / RAM error - Logic board ass'y (QM3-2738)*1

off, and Alarm LED lit

*1: Before replacement of the logic board ass'y, check the ink absorber counter value (by service test print or EEPROM

information print). If the counter value is 7% or more, also replace the Ink absorber kit (QY5-0190) when replacing

the logic board ass'y.

8

3-3. Warnings

(1) Printer (No LED indication)

Displayed warning Remarks

Ink low Status indication only.

Print head temperature rise If the print head temperature is high when the top cover

is opened, the warning is displayed

*1

.

When the print head temperature falls, the warning is

released.

Protection of excess rise of the print head

temperature

*1: If the warning is displayed, the carriage does not move to the ink tank replacement position when the top cover is

opened.

If the print head temperature exceeds the specified limit,

a Wait is inserted during printing,

9

4. REPAIR

4-1. Notes on Service Part Replacement (and Disassembling / Reassembling)

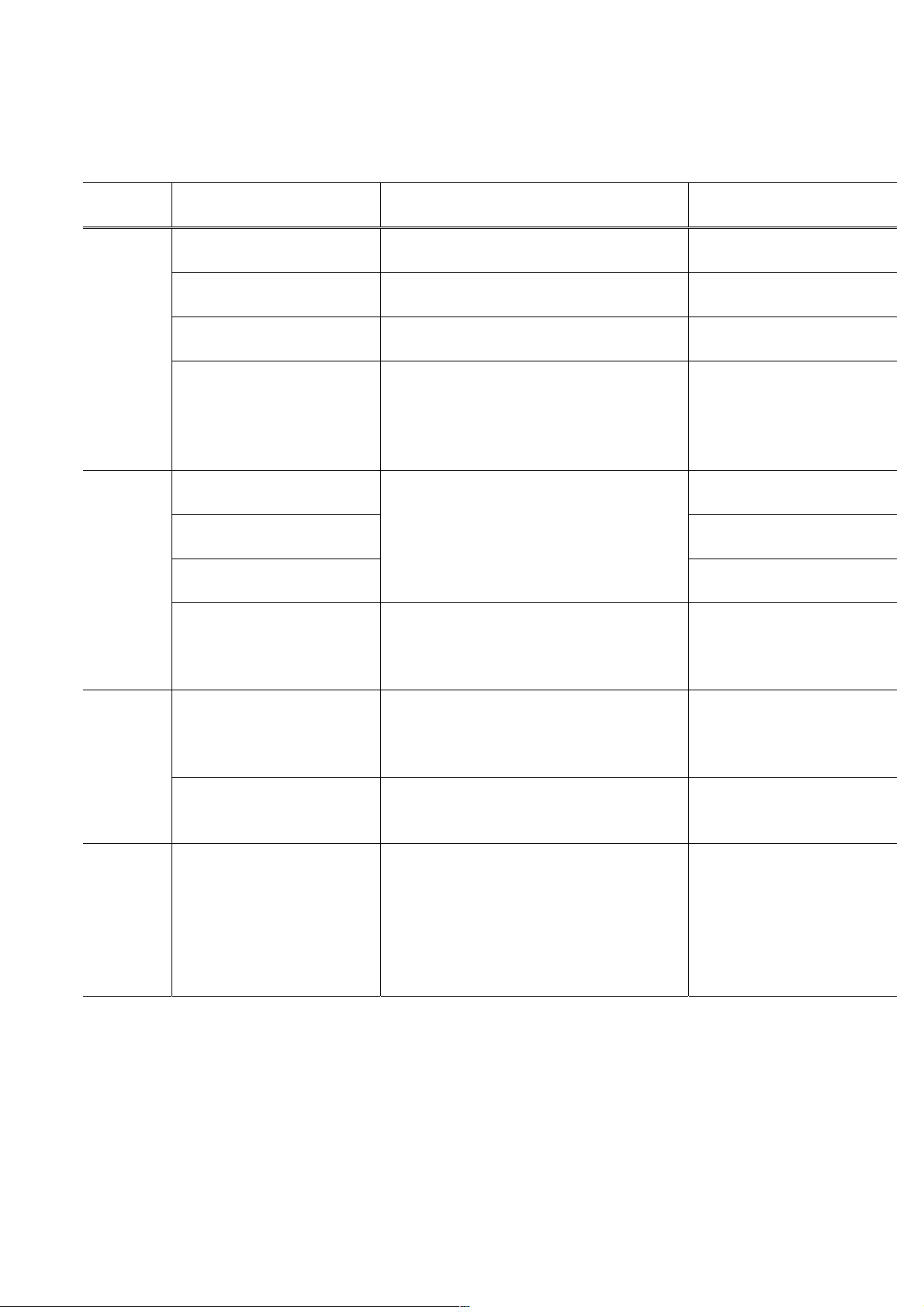

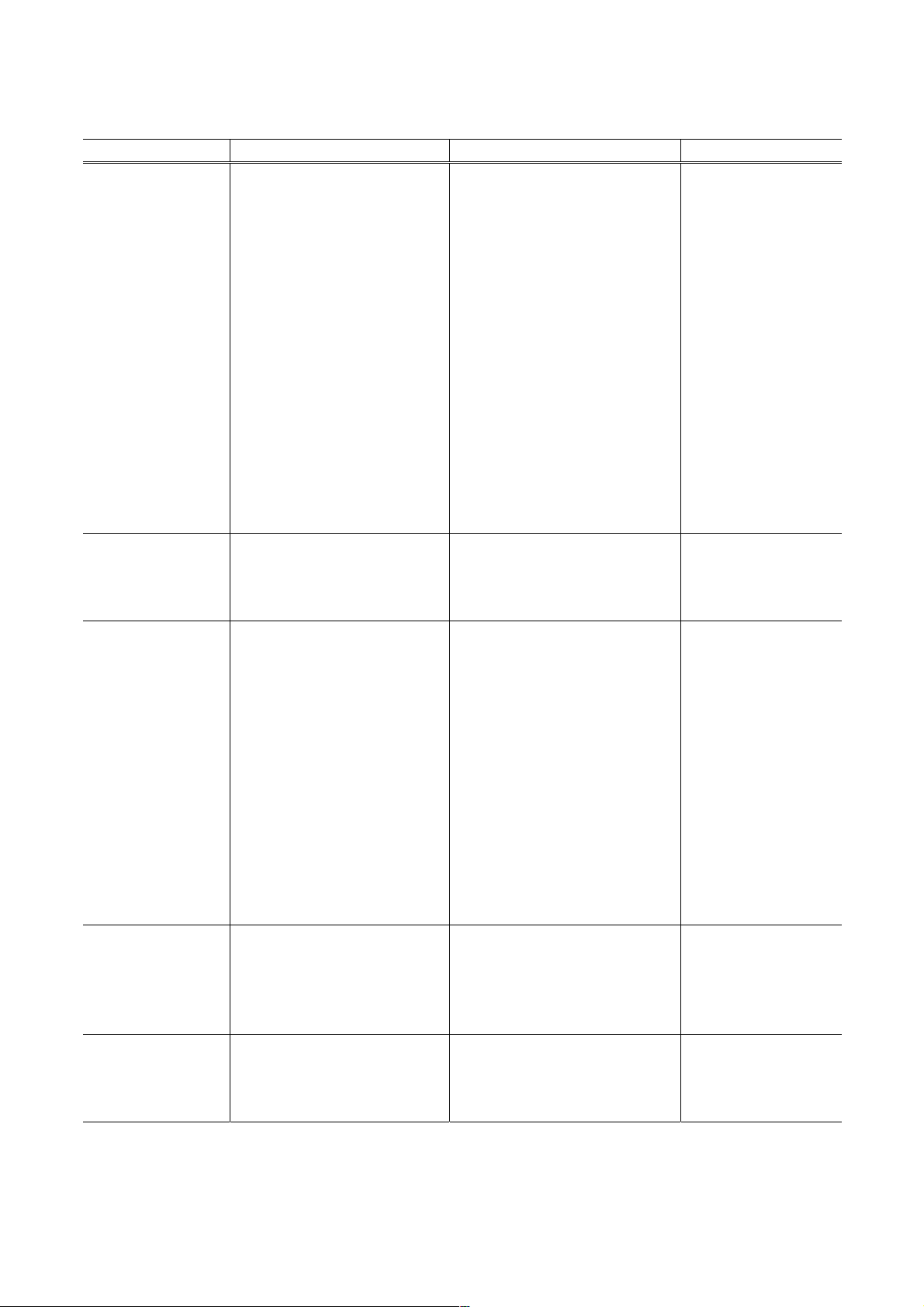

Service part Notes on replacement*1 Adjustment / settings Operation check

Logic board ass'y

QM3-2738

- Before removal of the logic

board ass'y, remove the

power cord, and allow for

approx. 1 minute (for

discharge of capacitor's

accumulated charges), to

prevent damages to the

logic board ass'y.

- Before replacement, check

the ink absorber counter

value (by service test print

or EEPROM information

print). If the value is 7% or

more, also replace the ink

absorber kit when replacing

the logic board ass'y.

After replacement:

1. Initialize the EEPROM.

2. Reset the ink absorber

counter.

3. Set the destination in the

EEPROM.

4. Correct the CD / DVD and

automatic print head

alignment sensors.

5. Check the ink system

function.

See 5. SERVICE MODE for

details of 1 to 5.

6. Perform LF / Eject correction.

7. Perform the print head

alignment in the user mode

*1

- EEPROM

information print

- Service test print

- Printing via USB

connection

- Direct printing from a

digital camera

.

See 5. SERVICE MODE.

Ink absorber kit

QY5-0190

Carriage unit

QM3-2264

After replacement:

Reset the ink absorber

counter.

See 5. SERVICE MODE.

At replacement:

1. Apply grease to the sliding

portions.

See 5. SERVICE MODE.

After replacement:

1. Correct the CD / DVD and

automatic print head

- Service test print

- EEPROM

information print

- Service test print

(Confirm CD / DVD

and automatic print

head alignment

sensor correction,

and ink system

function.)

alignment sensors.

See 5. SERVICE MODE.

2. Check the ink system

function.

See 5. SERVICE MODE.

3. Perform the print head

*1

.

- Service test print

Paper feed motor

QK1-3849

Platen unit

QM3-2725

- The red screws securing the

paper feed motor are

allowed to be loosened. (DO

NOT loosen any other red

screws.)

alignment in the user mode

At replacement:

1. Adjust the paper feed motor.

See 4-3. Adjustment /

Settings, (1) Paper Feed

Motor Adjustment

After replacement:

Check the ink system

function.

See 5. SERVICE MODE.

10

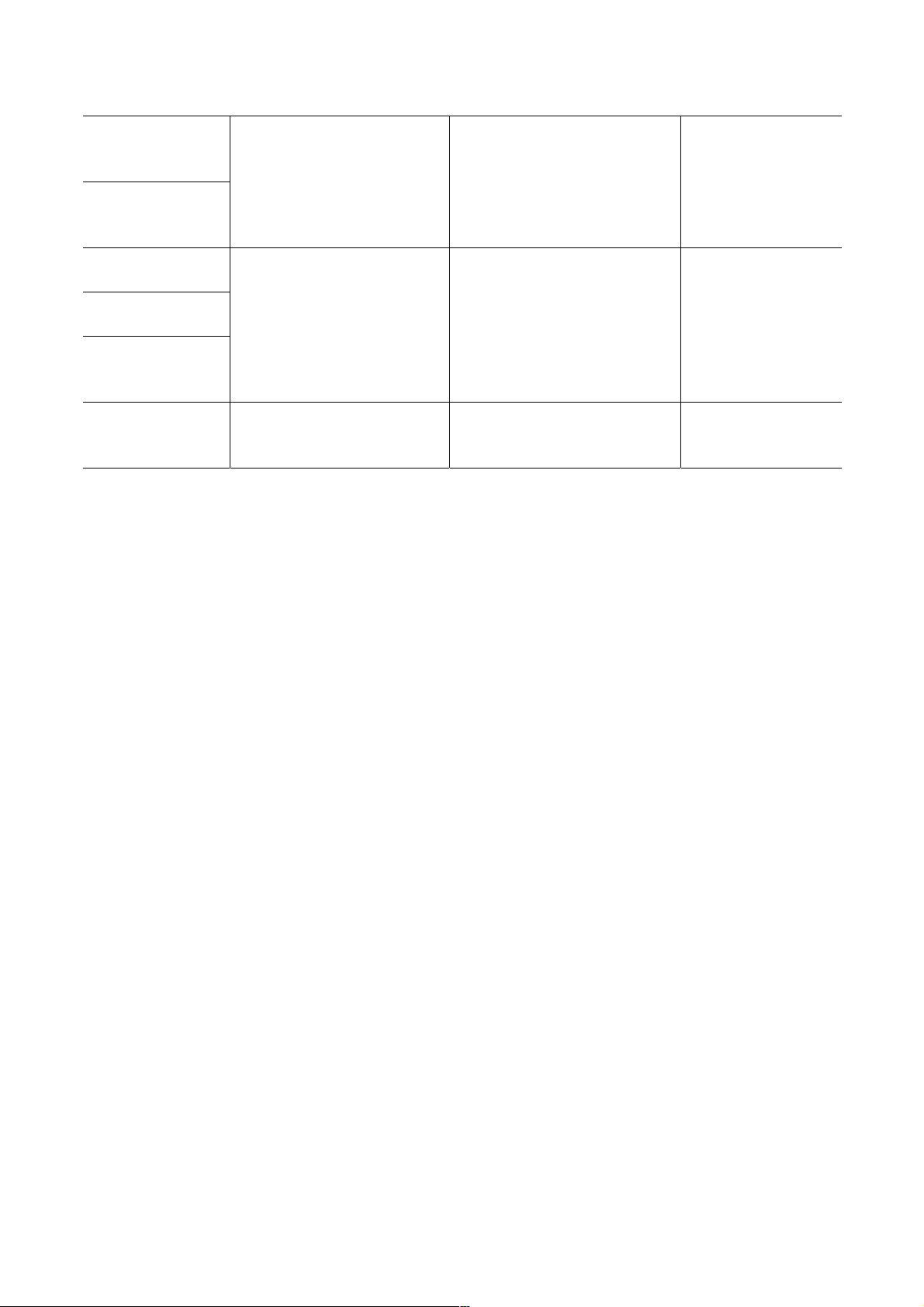

PR lift shaft ass'y

QL2-1450

Input carriage lift

At replacement:

Apply grease to the

sliding portions.

See 4-2. Grease Application

- Service test print

gear

QC2-1873

Timing slit strip film

QC1-6526

Timing slit disk film

QC2-0475

Timing slit disk

eject film

- Wipe off any grease from

the film with ethanol.

- Confirm no grease is on the

film. (Wipe off any grease

thoroughly with ethanol.)

- Do not bend the film

After replacement:

1. Perform the print head

alignment in the user mode

- Service test print

*1

.

QC2-0476

Print head

QY6-0067

*1: For automatic print head alignment, use Matte Photo Paper (MP-101). For manual print head alignment, plain paper

can be used.

After replacement:

- Service test print

1. Perform the print head

alignment in the user mode

*1

.

General notes:

- Make sure that the flexible cables and wires in the harness are in the proper position and connected

correctly

- Do not drop the ferrite core, which may cause damage.

- Protect electrical parts from damage due to static electricity.

- Before removing a unit, after removing the power cord, allow the printer to sit for approx. 1 minute

(for capacitor discharging to protect the logic board ass'y from damages).

- Do not touch the timing slit strip film, timing slit disk film, and timing slit disk eject film. No grease or

abrasion is allowed.

- Protect the units from soiled with ink.

- Protect the housing from scratches.

- Exercise caution with the red screws, as follows:

i. The red screws of the paper feed motor may be loosened only at replacement of the paper

feed motor unit (DO NOT loosen them in other cases).

ii. DO NOT loosen the red screws on both sides of the main chassis, securing the carriage shaft

positioning (they are not adjustable in servicing)

11

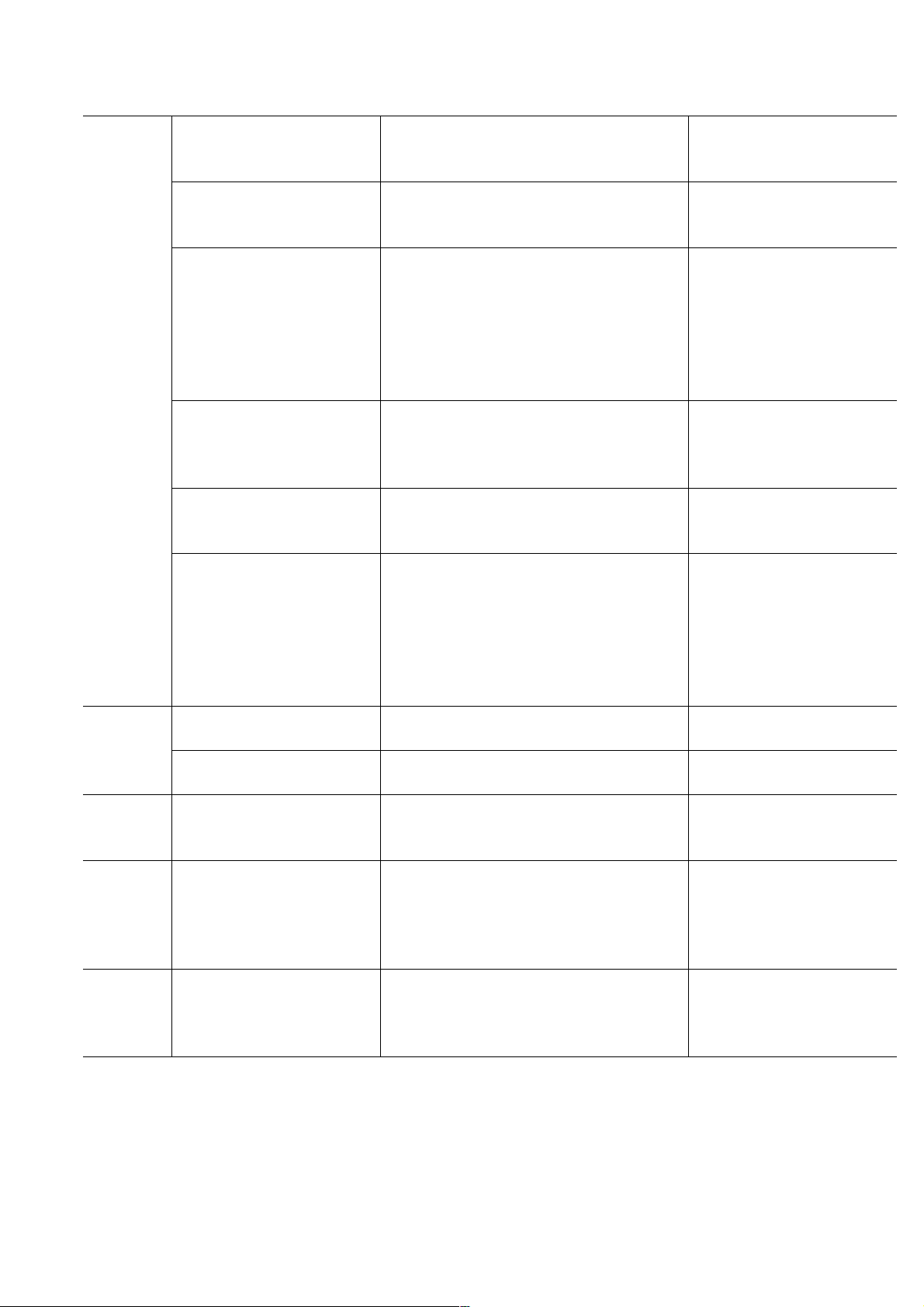

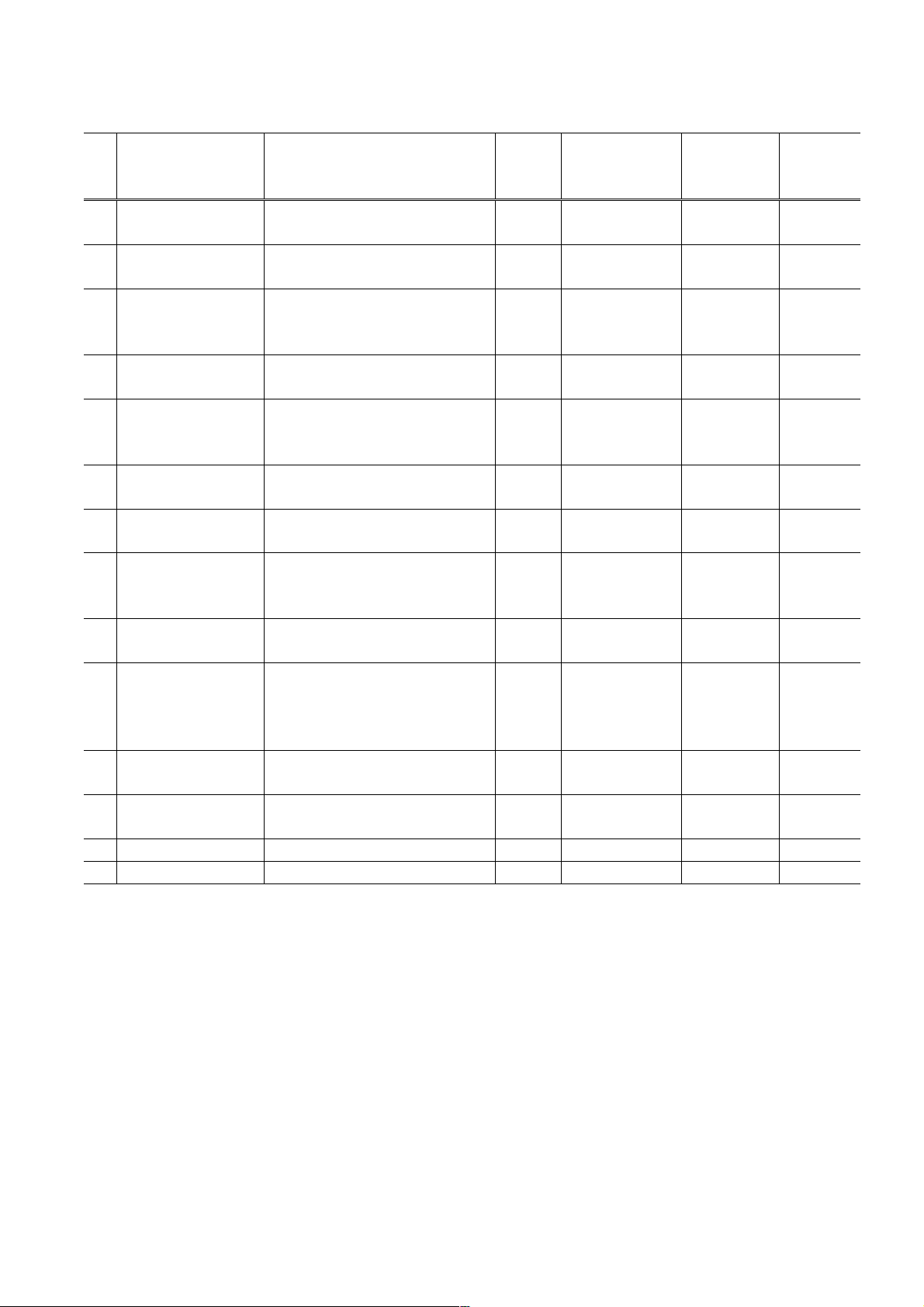

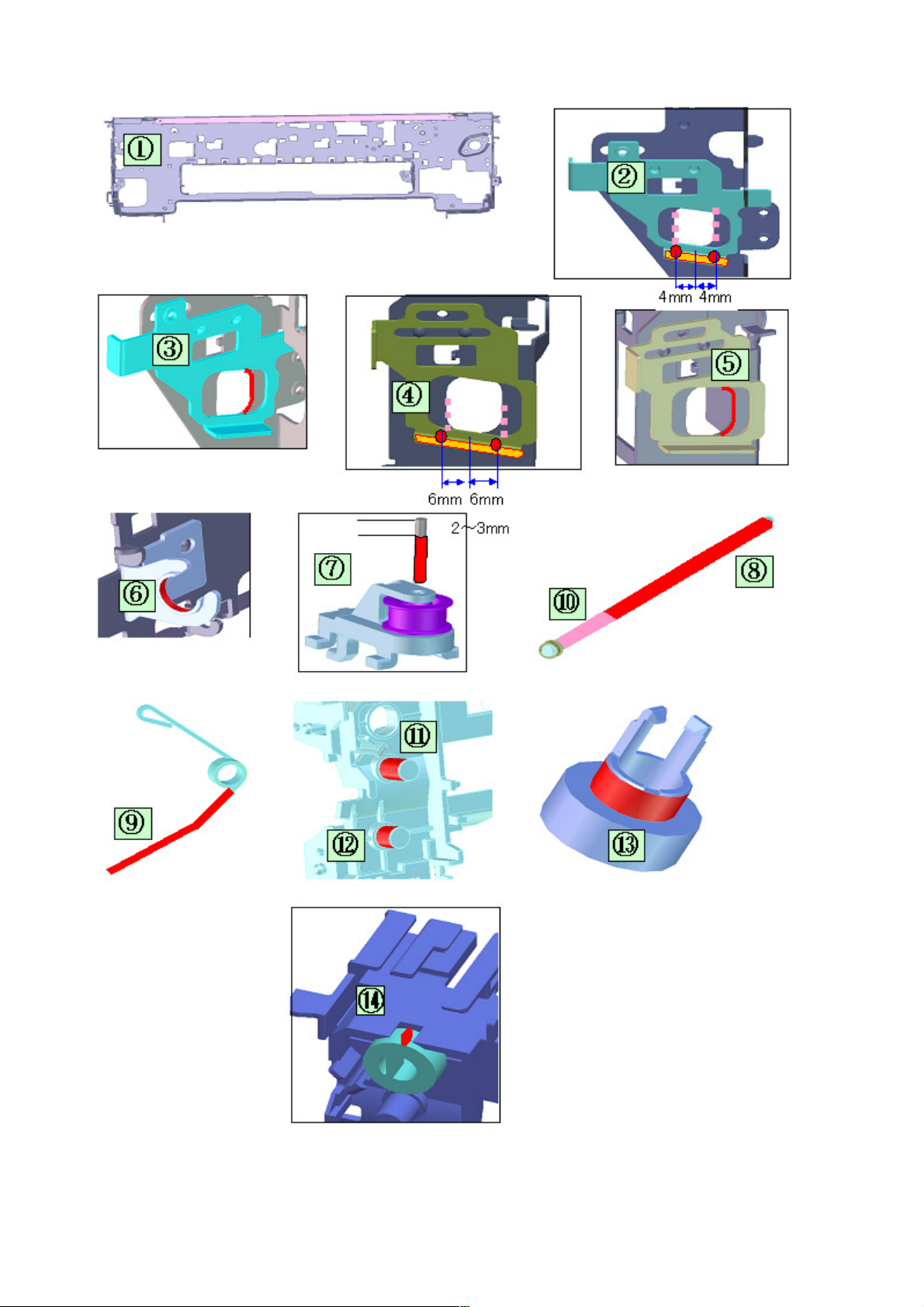

4-2. Grease Application

(1) Printer Unit

No Part name Where to apply grease / oil

1 Chassis ass'y

2 Adjust plate L

3 Chassis ass'y

4 Adjust plate R

5 Chassis ass'y

6 Chassis ass'y

7 Idler pulley

8 Carriage shaft

Carriage shaft

9

spring L

10 Carriage shaft

11 CL gear base

12 CL gear base

13 CL input gear Joint of the CL gear base (13) Floil KG107A 9 to 18 1 x 1

14 CL input gear CL input gear teeth (14) Floil KG107A 9 to 18 1 x 1

* 1 drop = 9 to 18 mg

Entire surface the carriage slider

contacts

Carriage shaft cam L sliding

portion

Carriage shaft sliding portion on

the left side of the chassis

(1 location)

Carriage shaft cam R sliding

portion

Carriage shaft sliding portion on

the right side of the chassis

(1 location)

PR lift shaft cam contact portion

(3 locations)

The shaft surface which

contacts the idler pulley hole

Entire surface of the carriage

shaft where the carriage unit

slides

Carriage shaft sliding portion (to

the end of the spring)

Carriage shaft surface where

the carriage unit slides (and

where the machine-application

of the grease is not feasible)

Outer surface of the CL idle

gear R cylinder

Outer surface of the CL output

gear cylinder

Drawing

No.

(1) Floil KG107A 27 to 54 3 x 1

(2) Floil KG107A 18 to 36 2 x 1

(3) Floil KG107A 9 to 18 1 x 1

(4) Floil KG107A 18 to 36 2 x 1

(5) Floil KG107A 9 to 18 1 x 1

(6) Floil KG107A 18 to 27 1.5 x 3

(7) Floil KG107A 9 to 18 1 x 1

(8) Floil KG107A 200 to 400

(9) Floil KG107A 9 to 18 1 x 1

(10) Floil KG107A 9 to 18 1 x 1

(11) Floil KG107A 9 to 18 1 x 1

(12) Floil KG107A 9 to 18 1 x 1

Grease / oil

Grease / oil

amount (mg)

Number of

drops* x

locations

12

13

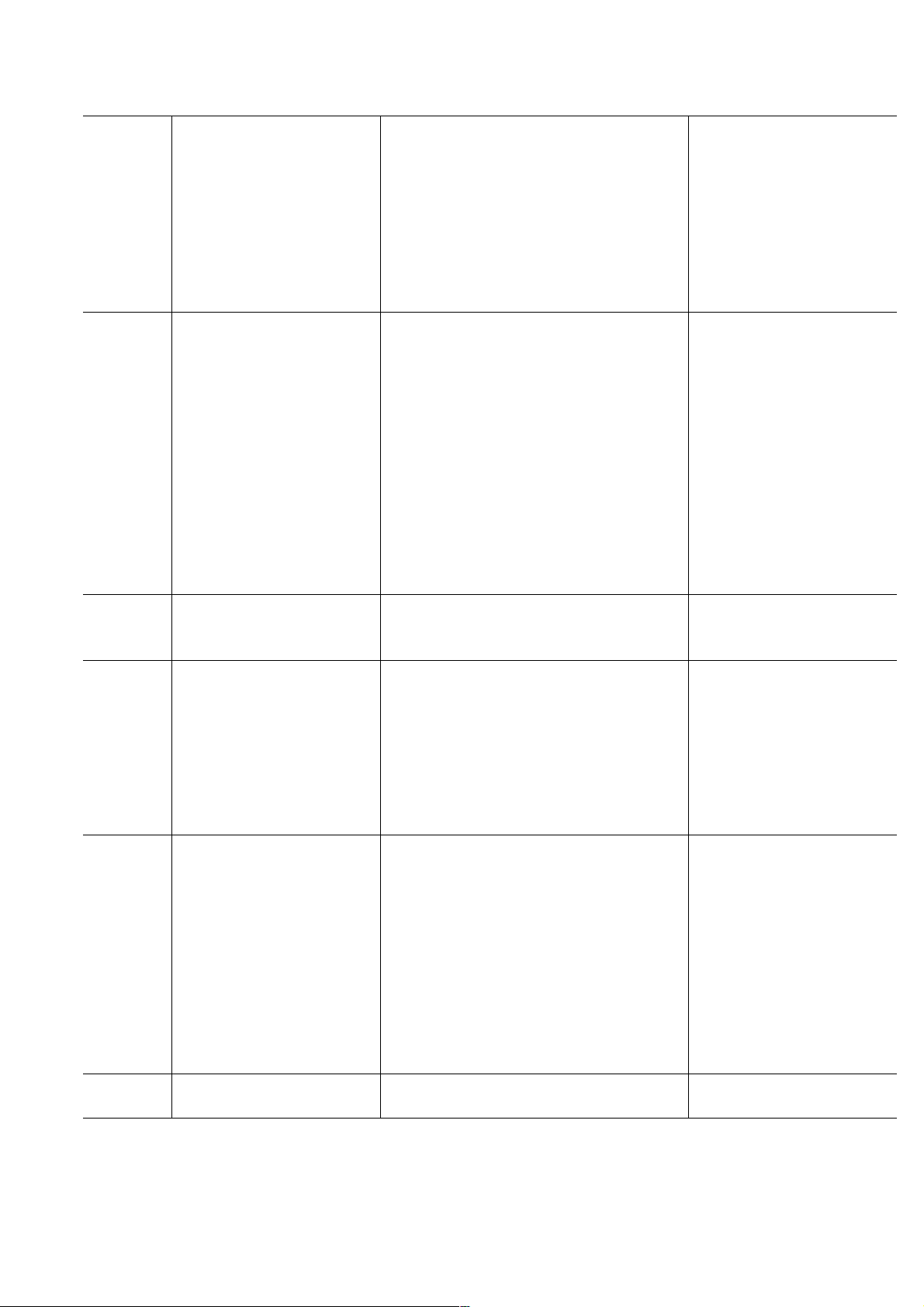

4-3. Adjustment / Settings

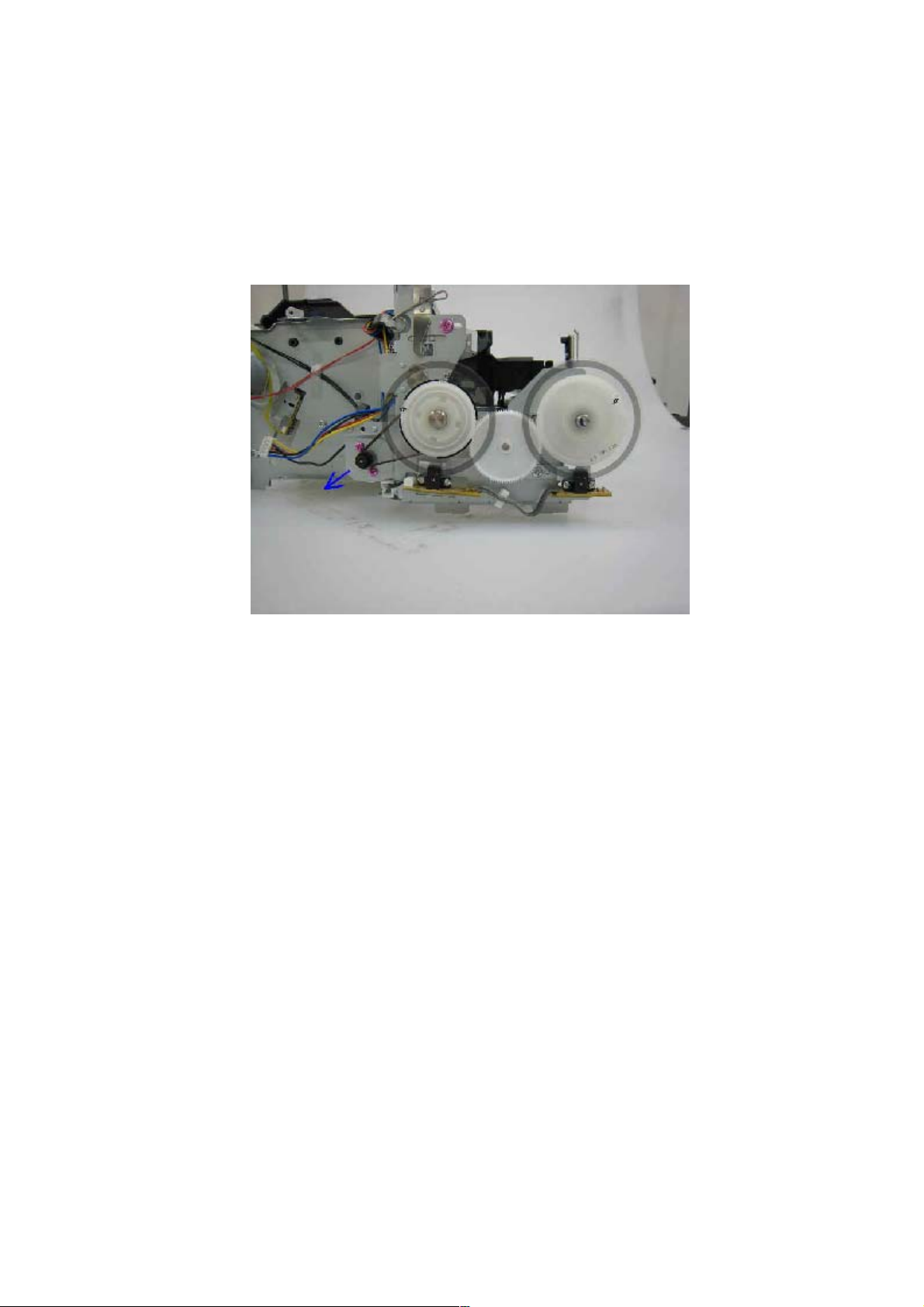

(1) Paper feed motor adjustment

Perform the following adjustments when the paper feed motor unit is replaced:

1) When attaching the motor, fasten the screws so that the belt is properly stretched (in the

direction indicated by the blue arrow in the figure below).

2) After replacement, be sure to perform the service test print, and confirm that no strange noise

or faulty print operation (due to dislocation of the belt or gear, or out-of-phase motor, etc.)

occurs.

Caution: The red screws securing the paper feed motor may be loosened only at replacement of the

paper feed motor unit. DO NOT loosen them in other cases.

14

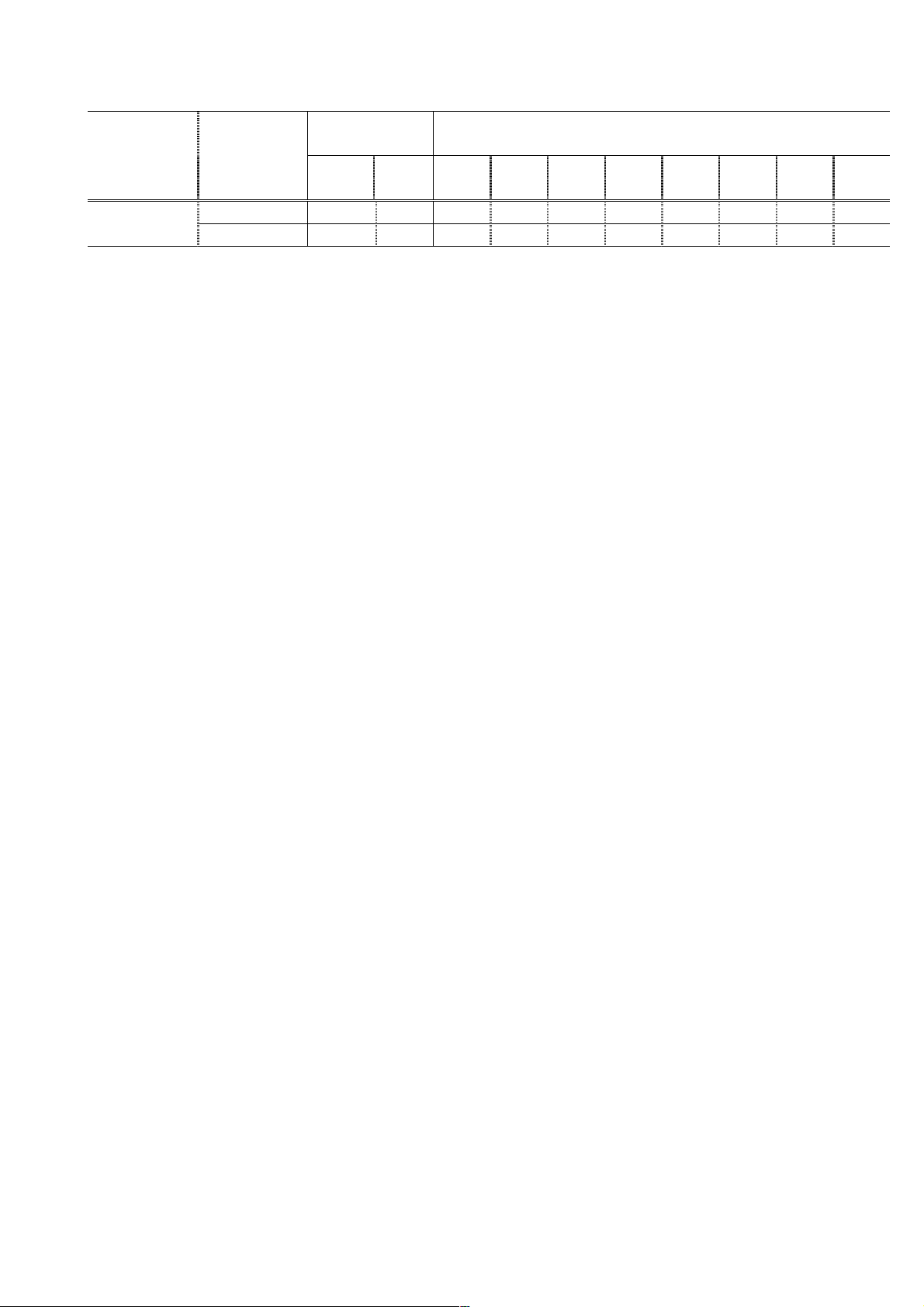

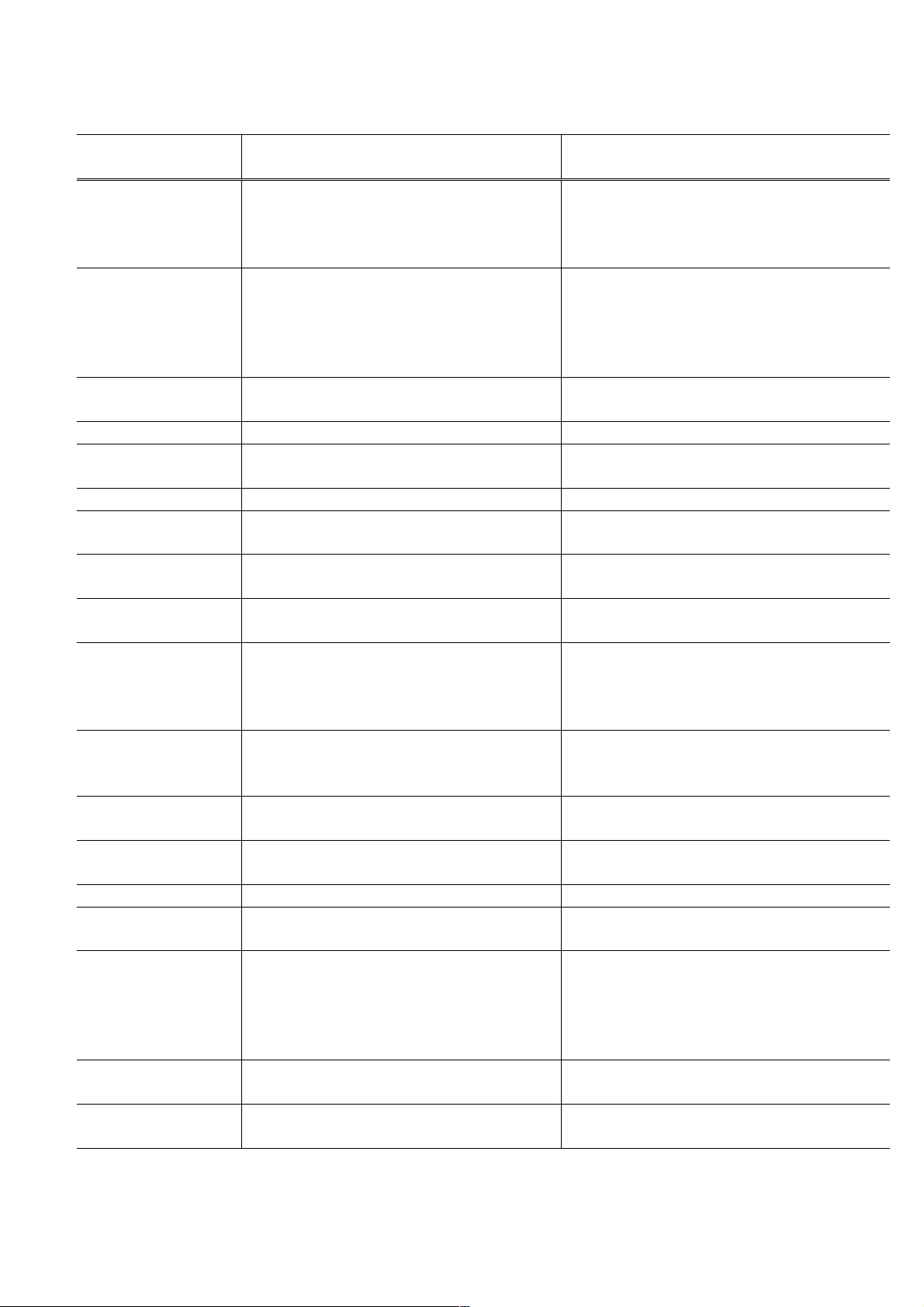

5. SERVICE MODE

Function Procedures Remarks

Service test print

- Model name

- Destination

- ROM version

- USB serial number

- Ink absorber counter value (ink

amount in the ink absorber)

- LF / Eject correction value

- CD / DVD sensor correction value

- Ink system function check result

- CD / DVD sensor correction result

EEPROM initialization See “Service mode

Ink absorber counter reset See “Service mode

LF / Eject correction See "Service mode

Left margin correction See "Service mode

Destination settings See "Service mode

See “Service mode

operation procedures”

below.

operation procedures”

below.

operation procedures”

below.

operation procedures"

below.

operation procedures"

below.

operation procedures"

below.

Set a sheet of A4 or Letter size paper

in the rear tray (cassette not usable).

The following items are NOT

initialized, and the shipment arrival

flag is not on:

- USB serial number

- Destination settings

- Ink absorber counter value (ink

amount in the ink absorber)

- CD / DVD correction value

- LF / Eject correction value

- Left margin correction value

- Record of disabling the function to

detect the remaining ink amount

If the ink absorber counter value is

7% or more, replace the ink absorber

kit.

Note: At the end of the service mode, press the Power button. The paper lifting plate of the sheet feed

unit will be raised.

<Service mode operation procedures>

1) With the printer power turned off, while pressing the Resume/Cancel button, press and hold the

Power button. (DO NOT release the buttons). The Power LED lights in green to indicate that a

function is selectable.

2) While holding the Power button, release the Resume/Cancel button. (DO NOT release the Power

button.)

3) While holding the Power button, press the Resume/Cancel button 2 times, and then release both

the Power and Resume/Cancel buttons. (Each time the Resume/Cancel button is pressed, the

Alarm and Power LEDs light alternately, Alarm in orange and Power in green, starting with Alarm

LED.)

4) When the Power LED lights in green, press the Resume/Cancel button the specified number of

15

time(s) according to the function listed in the table below. (Each time the Resume/Cancel button is

pressed, the Alarm and Power LEDs light alternately, Alarm in orange and Power in green, starting

with Alarm LED.)

Time(s) LED indication Function Remarks

0 times Green (Power) Power off When the print head is not

installed, the carriage

returns and locks in the

home position capped.

1 time Orange (Alarm) Service test print

2 times Green (Power) EEPROM information print

3 times Orange (Alarm) EEPROM initialization

4 times Green (Power) Ink absorber counter resetting Set a sheet of A4 or Letter sized plain

paper in the rear tray or cassette, and

reset the ink absorber counter. After

the ink absorber counter is reset, the

counter value is printed automatically.

See "Ink absorber counter resetting"

below.

5 times Orange (Alarm) Destination settings Press the Resume/Cancel

button the specified number

of time(s) according to the

destination.

6 times Green (Power) Print head deep cleaning Cleaning of both Black and Color

7 times Orange (Alarm) CD / DVD check pattern print Not used in servicing.

8 times Green (Power) CD / DVD print position

correction (horizontal: X direction)

9 times Orange (Alarm) CD / DVD print position

correction (vertical: Y direction)

10 times Green (Power) LF / Eject correction

11 times Orange (Alarm) Left margin correction

12 times Green (Power) Return to the menu selection

13 times Orange (Alarm) Register the ink amount in the ink

absorber

14 to 16

times

Green (Power) /

Orange (Alarm)

Return to the menu selection

Not used in servicing.

Not used in servicing.

Note: If the Resume/Cancel button is pressed 16 or more times, the Alarm LED (orange) lights

steadily without any changes.

<Destination settings>

In the destination settings mode, press the Resume/Cancel button the specified number of time(s)

according to the destination listed in the table below, and press the Power button.

Time(s) LED indication Destination CD / DVD print

0 times Green (Power) No change of the destination

1 time Orange (Alarm) Japan Supported

2 times Green (Power) Korea Not supported

3 times Orange (Alarm) US Not supported

4 times Green (Power) Europe Supported

5 times Orange (Alarm) Australia Supported

16

Loading...

Loading...