Page 1

PIXMA MP180 / MP460

SERVICE REFERENCE MANUAL

(Differences from the base models, PIXMA MP170 / MP450, only)

Part 1: MAINTENANCE

1. Maintenance

2. Error Display

3. Repair

Part 3: APPENDIX

2. Connector Location and Pin Layout

3. Specifications

Attachment 1: PARTS LIST (for Asia)

QY8-13AX-010

First Edition: June 16, 2006

Second Edition: June 23, 2006

Canon Inc.

(1/1)

Page 2

Part 1: MAINTENANCE

1. Maintenance

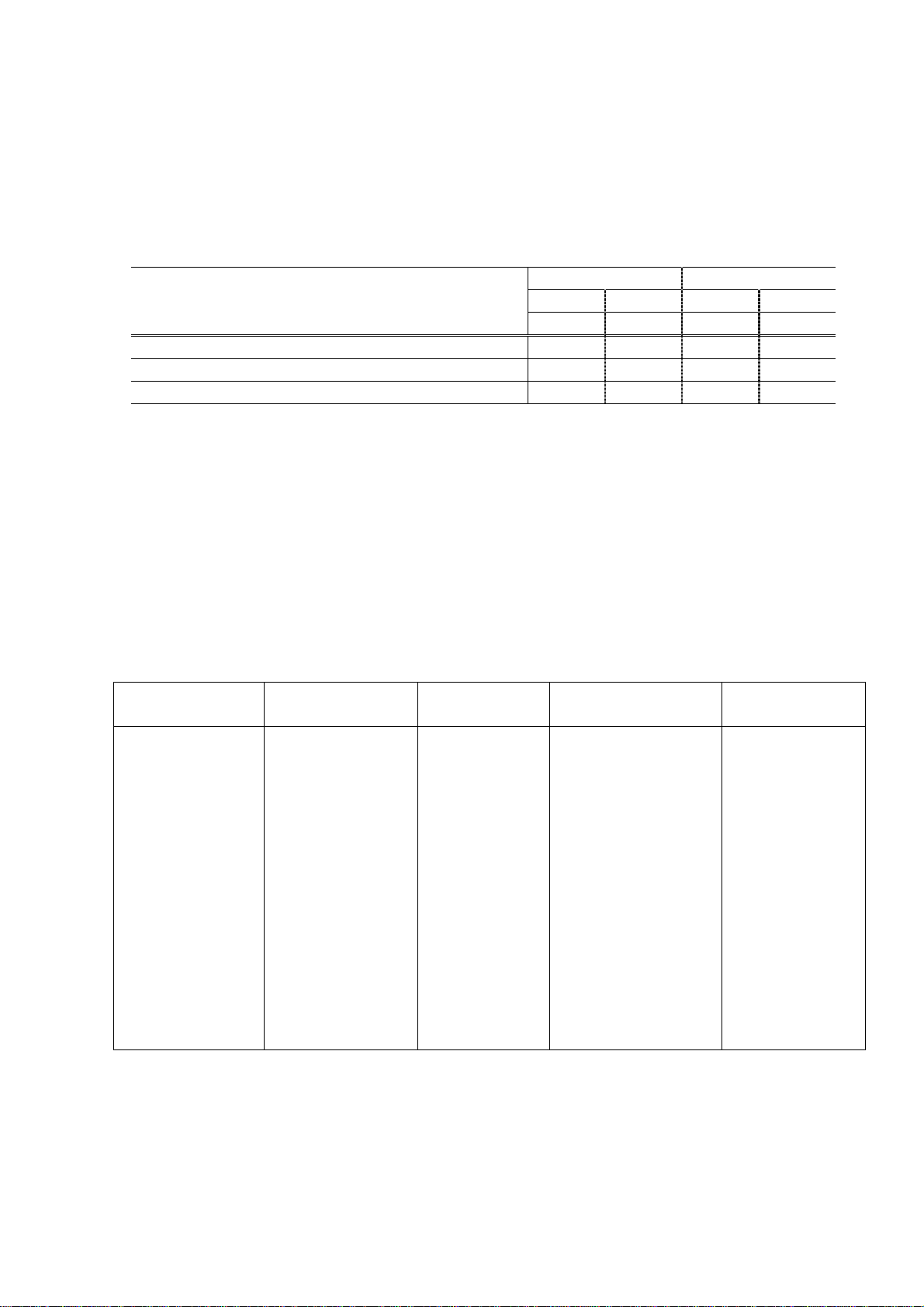

1-3. Product Life

(1) Machine

Same as the MP170 and MP450.

(2) Ink cartridge

Units: pages

Standard High capacity

BK CL BK CL

PG-40 CL-40 PG-50 CL-51

Black document (ISO/IEC 19752)*1 348 (3,350) 510 (5,590)

Color document (ISO/IEC FCD24712)*1 355 308 547 560

Photo (4" x 6")*2 (2,165) 120 (3,275) 198

Note: ( ): Estimated supplemental yield

*1: Black/Color document: Declared yield value in accordance with ISO/IEC FCD24711. Values obtained by

continuous printing.

*2: Photo (4" x 6"): When printing Canon standard patterns on 4" x 6" Photo Paper Plus Glossy continuously

with the default settings of Photo Paper Plus Glossy using Windows XP printer driver in borderless

printing mode and Windows XP Photo Printing Wizard.

Declared yield value determined based on Canon standard method referring to ISO/IEC FCD24712.

2. Error Display

2-1. Operator Call Errors

- The error, "WASTE INK NEAR FULL" (MP170) or "The waste ink absorber is almost full" (MP450),

deleted.

- The error U161, "CHECK INK" (MP170) or "The following ink may have run out" (MP450), deleted.

- Add the following error.

MP460 LCD MP180 LCD Error [Error

Solution Remarks

code]

The ink absorber is

almost full.

Press [OK] to

continue printing.

Contact the service

center.

REQ. SEVICE SOON Warning: The ink

absorber becomes

almost full.

[1700 for the main

ink absorber, 1710

for the platen ink

absorber]

Pressing the OK button

will clear the error, and

enable printing.

At repair:

For main ink absorber

replacement, replace

- the bottom case unit

(MP180: QM3-1362

MP460: QM3-1364),

or

- the ink absorber kit

(MP180: QY5-0149

MP460: QY5-0151)

For platen ink absorber

replacement, replace

- the platen ink absorber

(QC1-6014), and

- the ink absorber kit

(MP180: QY5-0149

MP460: QY5-0151)

The service call

error, indicating the

ink absorber is full,

is likely to occur

soon.

(2/2)

Page 3

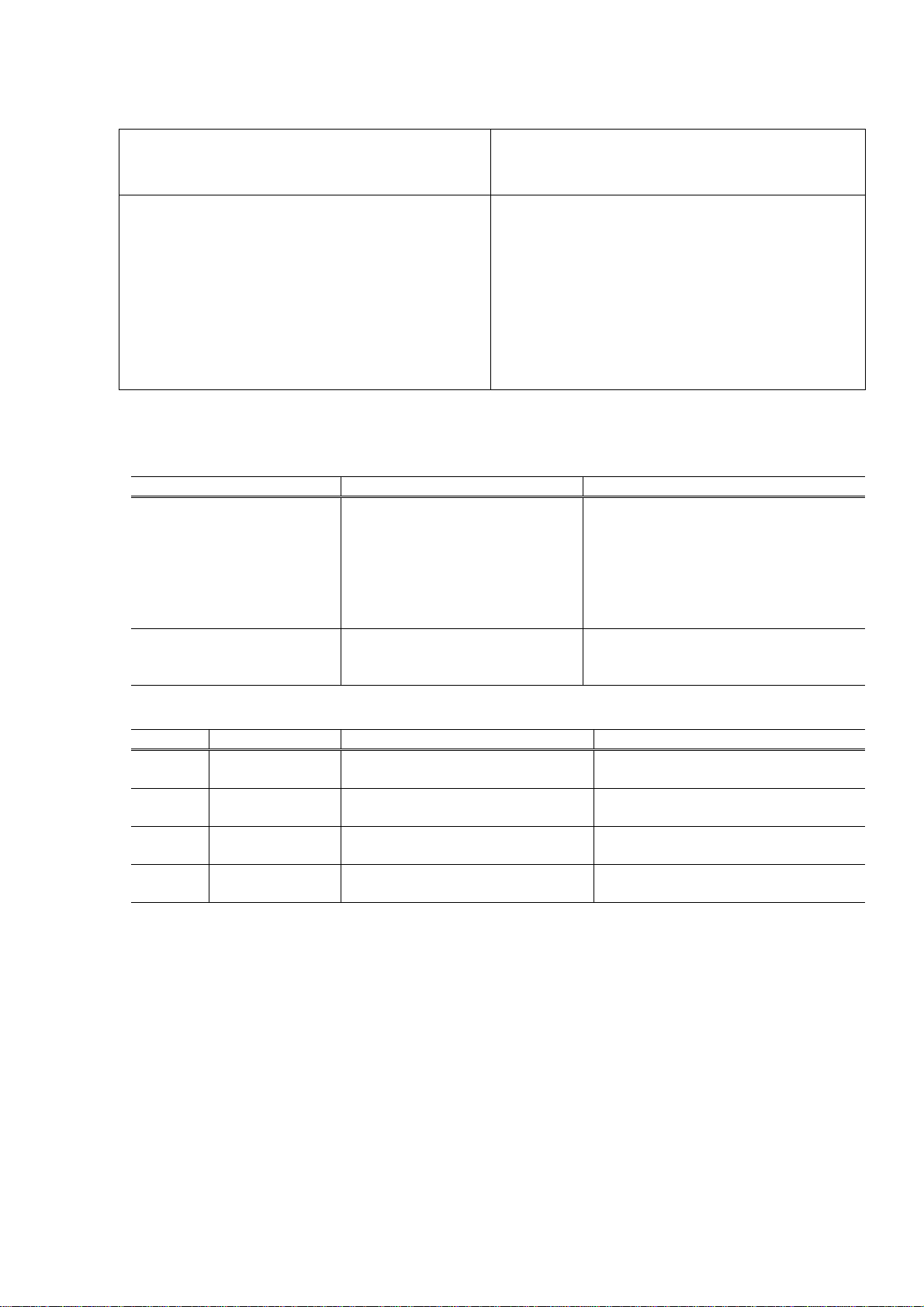

2-1. Operator Call Errors

Error [Error code] Solution

Main ink absorber full [5B00]

Platen ink absorber full [5B10]

3. Repair

3-3. Adjustment / Settings

(7) Service mode

Function Procedures Remarks

Ink absorber counter reset See "Service mode operation

Ink absorber counter value

setting

<Service mode operation procedures>

Time(s) LED indication Function Remarks

4 times Green

(ON/OFF)

12 times Green

(ON/OFF)

13 times Orange (Alarm) Ink absorber counter value setting See "Ink absorber counter value

14 times

Return to the menu selection.

or more

(Replacement of listed parts, which are likely to

Main ink absorber:

- Bottom case unit

MP180: QM3-1362

MP460: QM3-1364

- Ink absorber kit

MP180: QY5-0149

MP460: QY5-0151

Platen ink absorber:

- Platen ink absorber (QC1-6014)

- Ink absorber kit

MP180: QY5-0149

MP460: QY5-0151

The main ink absorber counter and

procedures" below.

the platen ink absorber counter can be

reset separately.

If the value of the main ink absorber

counter is 7% or more, replace the

bottom case unit or ink absorber

(inside the bottom case unit).

See "Service mode operation

procedures" below.

The value can be set for the main ink

absorber counter and the platen ink

absorber counter separately.

Ink absorber counter reset

Button and LCD test

be faulty)

setting procedures" below.

(3/3)

Page 4

<Ink absorber counter resetting procedures>

1) In the ink absorber counter resetting mode, press the Stop/Reset button the specified number of

time(s) according to the ink absorber whose counter should be reset to 0%.

Time(s) LED indication Ink absorber

0 times Green

(ON/OFF)

1 time Orange (Alarm) Platen ink absorber

2 times Green

(ON/OFF)

Main ink absorber

Both the main and platen ink absorbers

<Ink absorber counter value setting procedures>

1) In the ink absorber counter value setting mode, press the Stop/Reset button the specified number

of time(s) according to the ink absorber whose value should be transferred to the EEPROM.

Time(s) LED indication Ink absorber

0 times Green

(ON/OFF)

1 time Orange (Alarm) Platen ink absorber

2 times Green

(ON/OFF)

3 times

or more

Orange (Alarm) Return to the ink absorber counter value setting mode

Main ink absorber

Both the main and platen ink absorbers

2) Press the ON/OFF button to proceed to the next step.

3) The ink absorber counter value can be set in 10% increments by pressing the Stop/Reset button.

Press the Stop/Reset button the appropriate number of time(s) to select the value which is

closest to the actual ink amount in the ink absorber.

Time(s) Ink absorber counter value to be set (%)

0 times 0%

1 time 10%

2 times 20%

3 times 30%

4 times 40%

5 times 50%

6 times 60%

7 times 70%

8 times 80%

9 times 90%

10 times

or more

Not valid.

Press the ON/OFF button to return to the ink absorber counter value setting mode.

4) Press the ON/OFF button to set the selected value to the EEPROM

3-4. Verification Items

(1) Service test print

<EEPROM information contents>

On the service test print (sample below), confirm the EEPROM information as shown below. (The

information is given in the upper portion of the printout.)

MPxxx M=Vxxx D=xxx.x USB(xxxxxx)

JPN JPN JPN JPN JPN JPN JPN

JPN JPN JPN JPN JPN JPN JPN

MPxxx: Model name

M=Vxxx: ROM version

D=xxx.x: Ink amount in the main ink absorber (%)

(4/4)

Page 5

USB(xxxxxx): USB serial number

JPN: Destination

<Print check items>

On the service test print (sample below), confirm the following items:

- Check 1, nozzle check pattern: Ink shall be ejected from all nozzles.

- Check 2, top of form accuracy: The lines shall not extend off the paper.

- Check 3, vertical straight line accuracy: The lines shall not be broken.

<Service test print sample>

Check 2: Top of form

Check 1: Nozzle check pattern

Check 3: Vertical straight line accuracy

(5/5)

Page 6

(2) EEPROM information print

<How to read EEPROM information print>

Print sample:

MP460 JPN V1.00 ST=2006/05/30-16:41 LPT=2006/07/04-10:25

ER(ER0=1000 ER1=5100) P_ON(S=00001) MSD(000)

IF(USB1=1) PC(M=000 R=000 T=011 D=000 C=000)

D=008.0 Ps 000.0

TPAGE(TTL=00022 COPY=00005)

CLT(2006/06/02-11:34)

CT(BK_ST=002 BK_HC=002 CL_ST=000 CL_HC=000)

IS(BK=0 M=0 C=0 Y=0)

IC(BK=02150 M=02435 C=02001 Y=02081)

A_REG=0 M_REG=1

CDIN(PB=000 OPB=000) BTIN=0

PAGE(All=00145 PP=00112 HR+MP=00000 PR+SP+SG=00033 GP=00000 PC=00000 EV=00000)

CDPAGE(All=00000)

EDGE=00000 L=00031 BTPAGE=00000

<Direct>

LG=01 Japanese CDI=000 CDP=000

CDD-PR (L=00020 2L=00000 PC=00000 A4=00000)

CDD-SP (L=00020 2L=00000 PC=00000 A4=00000)

CDD-MP (L=00020 2L=00000 PC=00000 A4=00000)

DCD-PP (L=00020 2L=00000 PC=00000 A4=00000)

DCD-FPP (L=00020 2L=00000 PC=00000 A4=00000)

DCD-MPP (L=00020 2L=00000 PC=00000 A4=00000)

PrnB=00000 SC=00000 Seal=00000

<Scanner>

SC=00000 SCAN_ER(ER0=0000 ER1=0000)

SC-dpi(75=00000 150=00000 300=00000 600=00000 1200=00000 2400=00000)

SG(GY=00000 CL=00000)

<Copy>

MCASF(PP=00000 SP+PR+GP=00000 OTH=00000)

CCASF(PP=00000 HR+MP=00000 PR+SP+SG=00000 GP=00000 PC=00000)

- EEPROM Information <Hex.> -

Printed items:

1: Model name (Destination)

2: ROM version

3: Installation date

4: Last printing time

5: Operator call / service call error record

6: Power-on count (soft-power-on)

7: Longest period of non-printing

8: I/F connection (USB1)

9: Purging count (M = manual cleaning, R = deep cleaning, T = timer cleaning, D = cleaning by dot

count, C = cleaning at ink cartridge replacement)

10: Ink amount in the ink absorber (D = main, Ps = platen)

11: Total print pages (TTL = total, COPY = number of copying sheets)

12: Last cleaning time

13: Ink cartridge replacement count (Black standard, black high capacity, color standard, color high

capacity)

14: Ink status (BK/M/C/Y)

(6/6)

Page 7

15: Total ink consumpt ion amount (BK/M/C/Y)

16: Half-automatic print head alignment on the machine

17: Manual print head alignment via the MP driver

18: Camera Direct print-supported device connection record (Canon PictBridge, other PictBridge)

19: Bluetooth-supported device connection record

20: Number of pages fed from ASF (total, plain paper, High Resolution Paper & Matte Photo Paper,

Photo Paper Pro & Photo Paper Plus Glossy & Photo Paper Plus Semi-gloss, Glossy Photo

Paper, Postcard, Envelope)

21: Camera Direct print pages in total

22: Borderless print pages

23: L & 4x6 print pages

24: Print pages via Bluetooth connection

<Direct>

25: Language setting

26: Number of times a memory card is inserted

27: Total Card Direct print pages

28: Memory Card Direct print pages: Photo Paper Pro (4x6, 5x7, postcard, A4/LTR)

29: Memory Card Direct print pages: Photo Paper Plus Glossy (4x6, 5x7, postcard, A4/LTR)

30: Memory Card Direct print pages: Matte Photo Paper (4x6, 5x7, postcard, A4/LTR)

31: Camera Direct print pages: Photo Paper (4x6, 5x7, postcard, A4/LTR)

32: Camera Direct print pages: Fast Photo Paper (4x6, 5x7, postcard, A4/LTR)

33: Camera Direct print pages: Matte Paper (4x6, 5x7, postcard, A4/LTR)

34: Print Beam pages fed

35: Business Card / Credit Card size paper pages fed

36: Sticker pages fed

<Scanner>

37: Total number of scanning

38: Scanning error status history

39: Number of scanning by the scanning resolution (75/150/300/600/1200/2400 dpi)

40: Number of scanning by the scanning tone (grayscale/color)

<Copy>

41: Number of monochrome copy pages fed from ASF (plain paper, Photo Paper Plus Glossy &

Photo Paper Pro & Photo Paper Plus Semi-gloss & Glossy Photo Paper, other paper)

42: Number of color copy pages fed from ASF (plain paper, High Resolution Paper & Matte Photo

Paper, Photo Paper Pro & Photo Paper Plus Glossy & Photo Paper Plus Semi-gloss, Glossy

Photo Paper, postcard)

- Printer EEPROM information dump in hex (Address 00h to FFh) –

(7/7)

Page 8

Part 3: APPENDIX

2. Connector Location and Pin Layout

2-1. Main Board

CN201 (IrDA) (MP460 only)

No. Signal name Function

1 S-GN Ground

2 IR RXD Receiving data signal

3 IR TXD Sending data signal

4 to 8 +3.3V Power supply

CN405 (Remote debugger)

No. Signal name Function

1 TXD Sending data signal

2 RXD Receiving data signal

3 GND Ground

4 +3.3V Power supply

(8/8)

Page 9

2-6. Carriage Board (Print Head Connector)

[Color print head]

No. Signal name Function

1 HENB2 Heat enable

2 HCLK Print head clock

3 B_HLAT Latch signal

4 B_DATA_C C serial data

5 B_DIA Diode sensor anode

6 to 11 GND Ground

12 to 15 --- Not used

16 ID4 Print head ID

17 to 22 VH Print head drive 24V

23 --- Not used

24 SGND Ground

25 DATA_M M serial data

26 VHT Power supply for power transistor inside the print head

27 VID Power supply for ID reading

28 B_HVDD Print head logic power supply

29 DATA_Y Y serial data

30 B_CNO Print head contact detection signal

31 B_HE1 Heat enable

[Black print head]

No. Signal name Function

1 SGND Ground

2 A_HCLK Print head clock

3 A_HLAT Latch signal

4 A_DATA_EVEN Even nozzle data

5 A_DIA Diode sensor anode

6 to 11 GND Ground

12 to 15 --- Not used

16 ID2 Print head ID

17 to 22 VH Print head drive 24V

23 --- Not used

24 SGND Ground

25 SGND Ground

26 A_VHT Power supply for power transistor inside the print head

27 A_VID Power supply for ID reading

28 A_HVDD Print head logic power supply

29 A_DATA_ODD Odd nozzle data

30 A_CNO Print head contact detection signal

31 A_HENB0 Heat enable

(9/9)

Page 10

3. Specifications

r

<Machine >

Throughput Approx. 52 sec. (PP-101 4x6, borderless printing, default settings)

For reference:

Custom 5 Standard

Black 22 ppm 13.7 ppm

Color 17 ppm 9.0 ppm

Print media

specifications

Acoustic noise level

(highest print quality)

Transparency CF-102 deleted.

- Printing from a computer: Approx. 44.5 dB

- Copying: Approx. 48.0 dB

<Copy>

Copy speed *1

Approx. 53 sec.

<Card Direct Printing>

Memory card drive Supported

memory card

Compact Flash TYPE I/II, Microdrive, SmartMedia Card,

Memory Stick, Memory Stick PRO, SD card, MultiMedia

Card (ver. 3.31), xD-Picture Card*, miniSD card*, Memory

Stick Duo*, Memory Stick PRO Duo*

Throughput *2 Approx. 67 sec. (MP460)

Approx. 66 sec. (MP180)

<Camera Direct Printing>

Supported digital

cameras

Digital cameras and digital video cameras supporting PictBridge

Throughput *3 Approx. 66 sec.

*1: Document copy speed is based on copying the manuscript "ISO/IEC FCD24712: Newsletter" (digital data printed

by offset) using default settings on plain paper.

Copy speed may vary depending on document complexity, copy mode, page coverage, type of paper used, etc.

and does not take into account warming up time.

*2: When printing a 6 megapixel image taken by certain Canon digital camera from a memory card on default

settings using Photo Paper Plus Glossy without border.

Actual print speed may vary depending on image data, print mode, type of paper and type of memory card

used.

*3: When printing a 6 megapixel image taken by certain Canon digital camera from PictBridge on default settings

using Photo Paper Plus Glossy without border.

Actual print speed may vary depending on image data, print mode, type of paper used and device that the printer

is connected to.

* Adapte

(10/10)

Loading...

Loading...