Canon LBP 5000 Service Manual. Parts Catalog

Service Manual

LBP5000 Series

LBP5000

Jan 19 2006

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features ..................................................................................................................................................... 1- 1

1.1.1 Feature ....................................................................................................................................................................1- 1

1.2 System construction ................................................................................................................................... 1- 1

1.2.1 System Construction ...............................................................................................................................................1- 1

1.3 Product Specifications ................................................................................................................................1- 1

1.3.1 Product Specifications .............................................................................................................................................1- 1

1.4 Name of Parts.............................................................................................................................................1- 3

1.4.1 External View...........................................................................................................................................................1- 3

1.4.2 Cross Section View .................................................................................................................................................1- 5

1.5 Using the Machine......................................................................................................................................1- 5

1.5.1 Control Panel...........................................................................................................................................................1- 5

1.6 Safety ......................................................................................................................................................... 1- 6

1.6.1 Safety of the Laser Light..........................................................................................................................................1- 6

1.6.2 Regulations Under the Center for Devices and Radiological Health (CDRH) .........................................................1- 6

1.6.3 Handling the Laser Unit ...........................................................................................................................................1- 6

1.6.4 Safety of Toner........................................................................................................................................................1- 6

Chapter 2 TECHNICAL REFERENCE

2.1 Functional Configuration............................................................................................................................. 2- 1

2.1.1 Outline .....................................................................................................................................................................2- 1

2.2 Basic Sequense..........................................................................................................................................2- 1

2.2.1 Basic Sequence of Operation..................................................................................................................................2- 1

2.2.2 Power-On Sequence ...............................................................................................................................................2- 1

2.3 LASER EXPOSURE SYSTEM ...................................................................................................................2- 2

2.3.1 Overview/Configuration ...........................................................................................................................................2- 2

2.3.1.1 Outline...................................................................................................................................................................................... 2- 2

2.3.2 Laser Control ...........................................................................................................................................................2- 4

2.3.2.1 Outline...................................................................................................................................................................................... 2- 4

2.3.2.2 Laser Emission Control ............................................................................................................................................................ 2- 4

2.3.2.3 Automatic power control (APC)................................................................................................................................................ 2- 4

2.3.2.4 Horizontal synchronous control................................................................................................................................................ 2- 5

2.3.2.5 Image Mask Control ................................................................................................................................................................. 2- 5

2.3.2.6 Fault Detection ......................................................................................................................................................................... 2- 5

2.3.3 Laser Scanner Motor Control ..................................................................................................................................2- 5

2.3.3.1 Outline...................................................................................................................................................................................... 2- 5

2.3.3.2 Speed Control .......................................................................................................................................................................... 2- 6

2.3.3.3 Phase Control .......................................................................................................................................................................... 2- 6

2.3.3.4 Fault Detection ......................................................................................................................................................................... 2- 6

2.4 IMAGE FORMATION SYSTEM.................................................................................................................. 2- 7

2.4.1 Overview/Configuration ...........................................................................................................................................2- 7

2.4.1.1 Outline...................................................................................................................................................................................... 2- 7

2.4.1.2 Image Formation Process ........................................................................................................................................................ 2- 7

2.4.1.3 Electrostatic latent image formation block ............................................................................................................................... 2- 8

2.4.1.4 Developing block...................................................................................................................................................................... 2- 9

2.4.1.5 Transfer block ........................................................................................................................................................................ 2- 10

2.4.1.6 Fixing block ............................................................................................................................................................................ 2- 11

2.4.1.7 Drum cleaning block .............................................................................................................................................................. 2- 11

2.4.2 High-Voltage Control .............................................................................................................................................2- 11

2.4.2.1 Outline.................................................................................................................................................................................... 2- 11

2.4.2.2 Generation of the Primary Charging Bias .............................................................................................................................. 2- 12

Contents

2.4.2.3 Generation of the Developing Bias ........................................................................................................................................ 2- 12

2.4.2.4 Generation of the Transfer Bias ............................................................................................................................................. 2- 12

2.4.2.5 Generation of the Fixing Bias................................................................................................................................................. 2- 13

2.4.3 Image Stabilizaton Control.....................................................................................................................................2- 13

2.4.3.1 Overview of the Image Stabilization Control Mechanism....................................................................................................... 2- 13

2.4.3.2 Environment corrective control .............................................................................................................................................. 2- 13

2.4.3.3 Image density corrective control (D-max control) .................................................................................................................. 2- 13

2.4.3.4 Image halftone corrective control (D-half control) .................................................................................................................. 2- 13

2.4.3.5 Image density detection control ............................................................................................................................................. 2- 13

2.4.3.6 Overview of Color Misregistration Corrective Control ........................................................................................................... 2- 14

2.4.3.7 Color misregistration detection .............................................................................................................................................. 2- 14

2.4.4 Toner Cartridge......................................................................................................................................................2- 15

2.4.4.1 Outline.................................................................................................................................................................................... 2- 15

2.4.4.2 Memory Tag Control .............................................................................................................................................................. 2- 16

2.4.4.3 Detection of Toner cartridge presence/absence .................................................................................................................... 2- 16

2.4.4.4 Detecting the End of Life of the Cartridge .............................................................................................................................. 2- 16

2.4.4.5 Detecting the Level of Toner .................................................................................................................................................. 2- 16

2.4.5 Transfer Unit ..........................................................................................................................................................2- 16

2.4.5.1 ETB Unit................................................................................................................................................................................. 2- 16

2.4.5.2 ETB Cleaning ......................................................................................................................................................................... 2- 17

2.5 Pickup/Feeding/Delivery System.............................................................................................................. 2- 18

2.5.1 Overview/Configuration..........................................................................................................................................2- 18

2.5.1.1 Outline.................................................................................................................................................................................... 2- 18

2.5.2 Other Control .........................................................................................................................................................2- 20

2.5.2.1 outline .................................................................................................................................................................................... 2- 20

2.5.2.2 Picking Up Paper from the Cassette ...................................................................................................................................... 2- 21

2.5.2.3 Picking Up Paper from the Manual Feeder ............................................................................................................................ 2- 21

2.5.2.4 Moving the Print Paper .......................................................................................................................................................... 2- 21

2.5.2.5 Transport Speed Control........................................................................................................................................................ 2- 22

2.5.2.6 Paper loop control .................................................................................................................................................................. 2- 22

2.5.2.7 Automatic release of fixing pressure mechanism .................................................................................................................. 2- 23

2.5.3 Detecting Jams ......................................................................................................................................................2- 23

2.5.3.1 Jam Detection Outline............................................................................................................................................................ 2- 23

2.5.3.2 Delay Jams ............................................................................................................................................................................ 2- 24

2.5.3.3 Stationary Jams ..................................................................................................................................................................... 2- 24

2.5.3.4 Other Jams ............................................................................................................................................................................ 2- 24

2.6 FIXING UNIT SYSTEM ............................................................................................................................ 2- 24

2.6.1 Overview/Configuration..........................................................................................................................................2- 24

2.6.1.1 Outline.................................................................................................................................................................................... 2- 24

2.6.2 Various Control Mechanisms.................................................................................................................................2- 25

2.6.2.1 Fixing Temperature Control ................................................................................................................................................... 2- 25

2.6.3 Protective Functions ..............................................................................................................................................2- 27

2.6.3.1 Outline.................................................................................................................................................................................... 2- 27

2.6.3.2 Fault Detection ....................................................................................................................................................................... 2- 27

2.7 EXTERNAL AND CONTROLS SYSTEM ................................................................................................. 2- 27

2.7.1 Power Supply.........................................................................................................................................................2- 27

2.7.1.1 Power Supply ......................................................................................................................................................................... 2- 27

2.7.1.2 Other Function ....................................................................................................................................................................... 2- 28

2.8 ENGINE CONTROL SYSTEM ................................................................................................................. 2- 29

2.8.1 Construction...........................................................................................................................................................2- 29

2.8.1.1 Outline.................................................................................................................................................................................... 2- 29

2.8.2 DC Controller .........................................................................................................................................................2- 29

2.8.2.1 Outline.................................................................................................................................................................................... 2- 29

2.8.2.2 Operation of Individual Blocks ............................................................................................................................................... 2- 30

2.8.2.3 Fan/Motor Control .................................................................................................................................................................. 2- 31

2.8.2.4 Main Motor Fault Detection .................................................................................................................................................... 2- 31

2.8.2.5 Fan Motor Fault Detection ..................................................................................................................................................... 2- 31

2.8.3 Video Controller PCB.............................................................................................................................................2- 31

2.8.3.1 Outline.................................................................................................................................................................................... 2- 31

2.8.3.2 Overview of the Block ............................................................................................................................................................ 2- 32

Contents

Chapter 3 DISASSEMBLY AND ASSEMBLY

3.1 Before Parts Replacement .........................................................................................................................3- 1

3.1.1 Outline .....................................................................................................................................................................3- 1

3.2 EXTERNAL AND CONTROLS SYSTEM ...................................................................................................3- 2

3.2.1 Rear Cover ..............................................................................................................................................................3- 2

3.2.1.1 Removing the Rear Cover ....................................................................................................................................................... 3- 2

3.2.2 Right Cover..............................................................................................................................................................3- 2

3.2.2.1 Removing the Right Cover/Right Cassette Cover.................................................................................................................... 3- 2

3.2.3 Left Cover ................................................................................................................................................................3- 3

3.2.3.1 The former procedure of removing the Left Cover/Left Cassette Cover .................................................................................. 3- 3

3.2.3.2 Removing the Left Cover/Left Cassette Cover ........................................................................................................................ 3- 3

3.2.4 Upper Cover ............................................................................................................................................................ 3- 3

3.2.4.1 The former procedure of removing the Upper Cover .............................................................................................................. 3- 3

3.2.4.2 Removing the Upper Cover ..................................................................................................................................................... 3- 3

3.2.5 Front Cover..............................................................................................................................................................3- 3

3.2.5.1 The former procedure of removing the Front Cover ............................................................................................................... 3- 3

3.2.5.2 Removing the Front Cover ....................................................................................................................................................... 3- 3

3.2.6 Delivery Tray ...........................................................................................................................................................3- 4

3.2.6.1 Removing the Delivery Tray..................................................................................................................................................... 3- 4

3.2.7 Face-down Cover ....................................................................................................................................................3- 4

3.2.7.1 The former procedure of removing the Face-Down Cover ...................................................................................................... 3- 4

3.2.7.2 Removing the Face-Down Cover ............................................................................................................................................. 3- 4

3.2.8 Main Drive Unit ........................................................................................................................................................ 3- 4

3.2.8.1 The former procedure of removing the Main Drive Assembly.................................................................................................. 3- 4

3.2.8.2 Removing the Main Drive Assembly ........................................................................................................................................ 3- 5

3.2.9 Main Motor...............................................................................................................................................................3- 6

3.2.9.1 The former procedure of removing the Main Motor ................................................................................................................. 3- 6

3.2.9.2 Removing the Main Motor ........................................................................................................................................................ 3- 6

3.2.10 DC Controller PCB.................................................................................................................................................3- 7

3.2.10.1 The former procedure of removing the DC Controller PCB ................................................................................................... 3- 7

3.2.10.2 Removing the DC Controller PCB .......................................................................................................................................... 3- 7

3.2.11 Video Controller PCB.............................................................................................................................................3- 7

3.2.11.1 The former procedure of removing the Video Controller PCB ............................................................................................... 3- 7

3.2.11.2 Removing the Video Controller .............................................................................................................................................. 3- 7

3.2.12 Memory Controller PCB.........................................................................................................................................3- 8

3.2.12.1 The former procedure of Removing the Memory Controller PCB .......................................................................................... 3- 8

3.2.12.2 Removing the Memory Controller PCB .................................................................................................................................. 3- 8

3.2.13 Low-Voltage Power Supply Assembly ...................................................................................................................3- 8

3.2.13.1 The former procedure of Removing the Low-Voltage Power Supply PCB............................................................................. 3- 8

3.2.13.2 Removing the Low-Voltage Power Supply PCB .................................................................................................................... 3- 8

3.2.14 High-voltage PCB ..................................................................................................................................................3- 9

3.2.14.1 The former procedure of Removing the High-Voltage Power Supply PCB ............................................................................ 3- 9

3.2.14.2 Removing the High-Voltage Power Supply PCB.................................................................................................................... 3- 9

3.2.15 Machine Outside Environment Sensor ................................................................................................................3- 10

3.2.15.1 The former procedure of removing the Site Environment Sensor ....................................................................................... 3- 10

3.2.15.2 Removing the Site Environment Sensor .............................................................................................................................. 3- 10

3.2.16 Cartridge Fan.......................................................................................................................................................3- 11

3.2.16.1 The former procedure of removing Removing the Cartridge Fan ....................................................................................... 3- 11

3.2.16.2 Removing the Cartridge Fan ................................................................................................................................................ 3- 11

3.3 LASER EXPOSURE SYSTEM .................................................................................................................3- 11

3.3.1 Laser Scanner Unit................................................................................................................................................3- 11

3.3.1.1 The former procedure of removing the Laser Scanner Unit.................................................................................................. 3- 11

3.3.1.2 Removing the Laser Scanner Unit ......................................................................................................................................... 3- 11

3.4 IMAGE FORMATION SYSTEM................................................................................................................ 3- 12

3.4.1 MCY Developing Cylinder Drive Solenoid .............................................................................................................3- 12

3.4.1.1 The former procedure of removing the MCY Developing Cylinder Drive Solenoid ............................................................... 3- 12

3.4.1.2 Removing the MCY Developing Cylinder Drive Solenoid ...................................................................................................... 3- 12

3.4.2 Bk Developing Cylinder Drive Solenoid.................................................................................................................3- 12

Contents

3.4.2.1 The former procedure of removing the Bk Developing Cylinder Drive Solenoid................................................................... 3- 12

3.4.2.2 Removing the Bk Developing Cylinder Drive Solenoid .......................................................................................................... 3- 12

3.4.3 ETB Unit.................................................................................................................................................................3- 12

3.4.3.1 The former procedure of removing the ETB Unit .................................................................................................................. 3- 12

3.4.3.2 Removing the ETB Unit ......................................................................................................................................................... 3- 13

3.5 PICKUP/FEEDING/DELIVERY SYSTEM................................................................................................. 3- 13

3.5.1 Paper Pick-up Feeder Unit.....................................................................................................................................3- 13

3.5.1.1 The former procedure of removing the Pickup/Transport Assembly..................................................................................... 3- 13

3.5.1.2 Removing the Pickup/Transport Assembly ............................................................................................................................ 3- 13

3.5.2 Pickup Motor..........................................................................................................................................................3- 14

3.5.2.1 The former procedure of removing the Pickup Motor ........................................................................................................... 3- 14

3.5.2.2 Removing the Pickup Motor .................................................................................................................................................. 3- 14

3.5.3 Cassette Pickup Roller...........................................................................................................................................3- 15

3.5.3.1 Removing the Pickup Roller................................................................................................................................................... 3- 15

3.5.4 Cassette Pick-up Solenoid.....................................................................................................................................3- 15

3.5.4.1 The former procedure of removing the Cassette Pickup Solenoid ........................................................................................ 3- 15

3.5.4.2 Removing the Cassette Pickup Solenoid ............................................................................................................................... 3- 15

3.5.5 Cassette Separation Pad.......................................................................................................................................3- 15

3.5.5.1 Removing the Separation Pad ............................................................................................................................................... 3- 15

3.5.6 Manual Paper Sensor ............................................................................................................................................3- 15

3.5.6.1 The former procedure of removing the Manual Feeder Paper Sensor .................................................................................. 3- 15

3.5.6.2 Removing the Manual Feeder Paper Sensor......................................................................................................................... 3- 15

3.5.7 Registration Before Sensor....................................................................................................................................3- 16

3.5.7.1 The former procedure of removing the Registration Sensor .................................................................................................. 3- 16

3.5.7.2 Removing the Registration Sensor ........................................................................................................................................ 3- 16

3.6 FIXING SYSTEM...................................................................................................................................... 3- 16

3.6.1 Fixing Assembly.....................................................................................................................................................3- 16

3.6.1.1 The former procedure of removing the Fixing Assembly ....................................................................................................... 3- 16

3.6.1.2 Removing the Fixing Assembly.............................................................................................................................................. 3- 16

3.6.2 Fixing Film Unit ......................................................................................................................................................3- 17

3.6.2.1 The former procedure of removing the Fixing Film ................................................................................................................ 3- 17

3.6.2.2 Removing the Fixing Film ...................................................................................................................................................... 3- 17

3.6.3 Fixing Pressure Roller............................................................................................................................................3- 19

3.6.3.1 The former procedure of removing the Fixing Pressure Roller .............................................................................................. 3- 19

3.6.3.2 Removing the Fixing Pressure Roller .................................................................................................................................... 3- 19

3.6.4 Fixing Motor ...........................................................................................................................................................3- 19

3.6.4.1 The former procedure of removing the Fixing/Delivery Motor................................................................................................ 3- 19

3.6.4.2 Removing the Fixing/Delivery Motor ...................................................................................................................................... 3- 19

Chapter 4 MAINTENANCE AND INSPECTION

4.1 Periodically Replaced Parts ....................................................................................................................... 4- 1

4.1.1 Periodically Replaced Parts.....................................................................................................................................4- 1

4.2 Consumables ............................................................................................................................................. 4- 1

4.2.1 Durables Replaced by the User...............................................................................................................................4- 1

4.2.2 Durables Replaced by the Service Person ..............................................................................................................4- 1

4.3 Periodical Service....................................................................................................................................... 4- 1

4.3.1 Periodic Service.......................................................................................................................................................4- 1

4.4 Cleaning ..................................................................................................................................................... 4- 1

4.4.1 Pickup Roller............................................................................................................................................................4- 1

4.4.2 Separation Pad ........................................................................................................................................................4- 1

4.4.3 Registration Roller ...................................................................................................................................................4- 1

4.4.4 Registration Sub Roller............................................................................................................................................4- 1

4.4.5 Registration Shutter .................................................................................................................................................4- 1

4.4.6 Transport Guide.......................................................................................................................................................4- 1

4.4.7 Delivery Roller..........................................................................................................................................................4- 1

4.4.8 Fixing Inlet Guide.....................................................................................................................................................4- 1

4.4.9 Fixing Pressure Roller..............................................................................................................................................4- 1

Contents

4.5 User Maintenance ......................................................................................................................................4- 2

4.5.1 Outline .....................................................................................................................................................................4- 2

4.5.2 List Of Special Print Mode.......................................................................................................................................4- 3

Chapter 5 TROUBLESHOOTING

5.1 Countermeasures .......................................................................................................................................5- 1

5.1.1 Image Faults............................................................................................................................................................5- 1

5.1.1.1 Out of Focus ............................................................................................................................................................................ 5- 1

5.2 MEASUREMENT AND ADJUSTMENT ......................................................................................................5- 1

5.2.1 Test Print .................................................................................................................................................................5- 1

5.2.1.1 Test Print.................................................................................................................................................................................. 5- 1

5.2.2 Adjustment of Fixing System ..................................................................................................................................5- 2

5.2.2.1 Checking the Nip Width (fixing pressure roller)........................................................................................................................ 5- 2

5.3 SERVICE TOOLS.......................................................................................................................................5- 2

5.3.1 Standard Tools ........................................................................................................................................................5- 2

5.3.2 Solvent/Oil List.........................................................................................................................................................5- 3

5.4 Location of Convectors ............................................................................................................................... 5- 3

5.4.1 Connectors ..............................................................................................................................................................5- 3

5.5 ERROR CODE ........................................................................................................................................... 5- 5

5.5.1 Error Code ...............................................................................................................................................................5- 5

5.6 Sevice Mode...............................................................................................................................................5- 7

5.6.1 Outline .....................................................................................................................................................................5- 7

5.6.1.1 Outline...................................................................................................................................................................................... 5- 7

5.6.2 Service Mode Table.................................................................................................................................................5- 7

5.6.2.1 Service Mode Items ................................................................................................................................................................. 5- 7

Chapter 6 APPENDIX

6.1 OUTLINE OF ELECTRICAL COMPONENTS ............................................................................................ 6- 1

6.1.1 Clutch/Solenoid .......................................................................................................................................................6- 1

6.1.1.1 Solenoids ................................................................................................................................................................................. 6- 1

6.1.2 Motor/Fan ................................................................................................................................................................6- 2

6.1.2.1 Motors and Fans ...................................................................................................................................................................... 6- 2

6.1.3 Sensor .....................................................................................................................................................................6- 3

6.1.3.1 Sensors.................................................................................................................................................................................... 6- 3

6.1.4 PCBs .......................................................................................................................................................................6- 4

6.1.4.1 PCBs........................................................................................................................................................................................ 6- 4

Contents

Chapter 1 PRODUCT DESCRIPTION

Contents

Contents

1.1 Features ..........................................................................................................................................................................1-1

1.1.1 Feature.......................................................................................................................................................................................... 1-1

1.2 System construction .......................................................................................................................................................1-1

1.2.1 System Construction .................................................................................................................................................................... 1-1

1.3 Product Specifications....................................................................................................................................................1-1

1.3.1 Product Specifications ................................................................................................................................................................. 1-1

1.4 Name of Parts.................................................................................................................................................................1-3

1.4.1 External View .............................................................................................................................................................................. 1-3

1.4.2 Cross Section View...................................................................................................................................................................... 1-5

1.5 Using the Machine .........................................................................................................................................................1-5

1.5.1 Control Panel ............................................................................................................................................................................... 1-5

1.6 Safety .............................................................................................................................................................................1-6

1.6.1 Safety of the Laser Light.............................................................................................................................................................. 1-6

1.6.2 Regulations Under the Center for Devices and Radiological Health (CDRH)............................................................................ 1-6

1.6.3 Handling the Laser Unit............................................................................................................................................................... 1-6

1.6.4 Safety of Toner ............................................................................................................................................................................ 1-6

1.1 Features

Chapter 1

1.1.1 Feature

1. Smallest Color LBP

The machine has the smallest body of all Canon color LBPs.

2. Electrostatic Transportation Belt (ETB)

The machine uses an ETB for movement of media and transfer of images. The direct transfer of color images from the photosensitive drum to media has enable

a significant increase in printing speed.

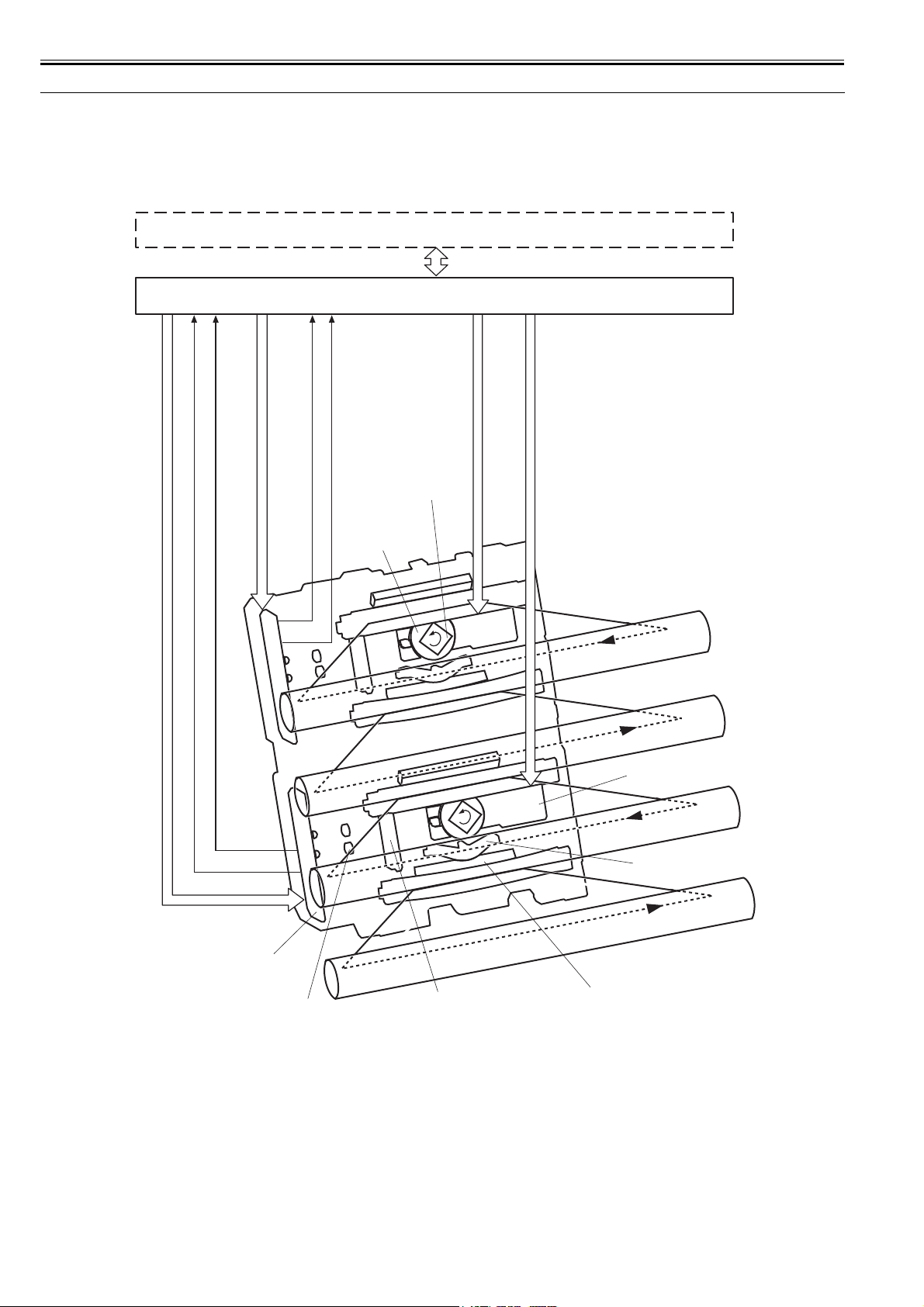

3. Four consecutive drum method (Inline method)

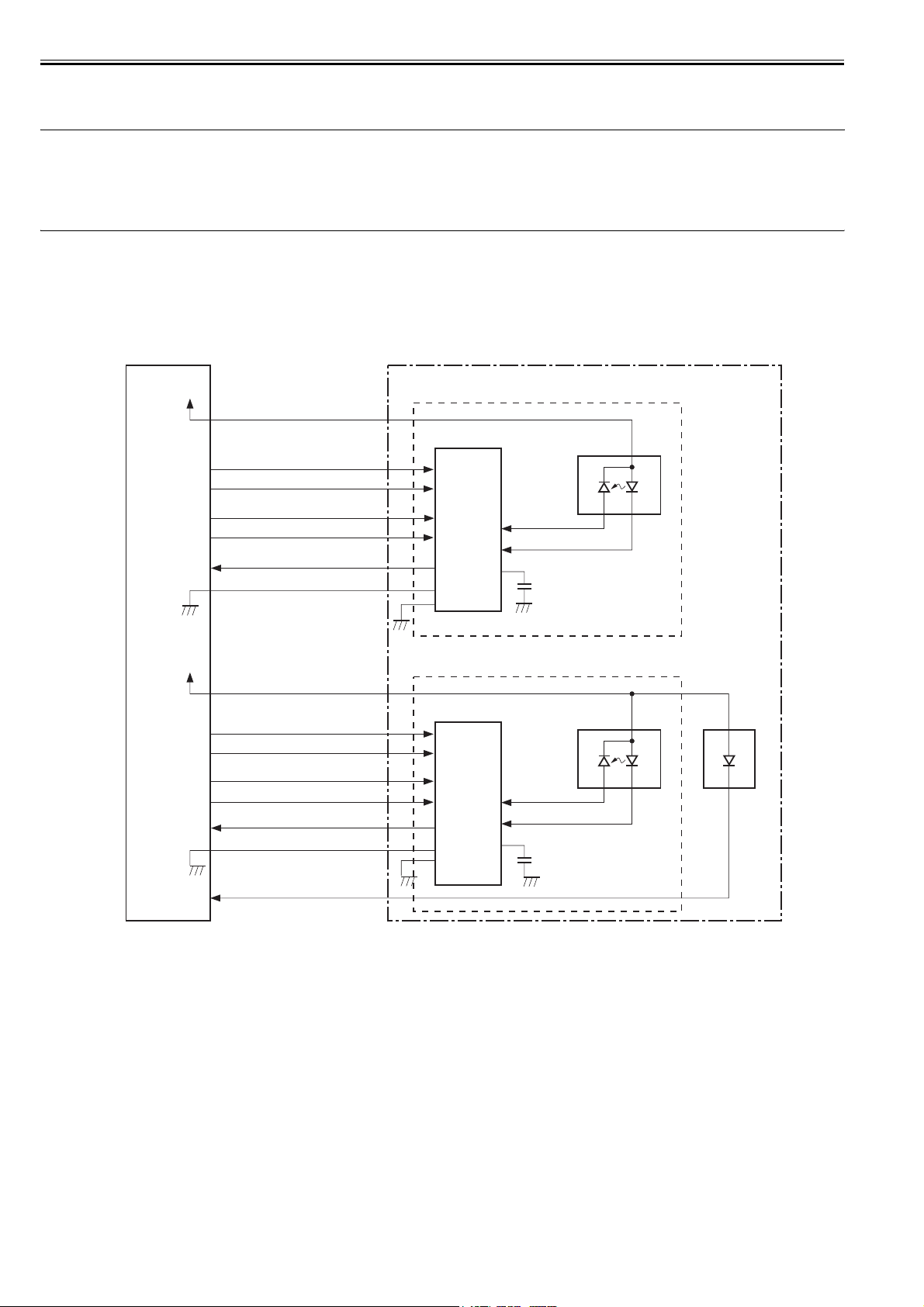

The machine uses a 4-drum construction, in which 4 toner cartridges are arranged in a straight line for one-shot transfer of 4 colors. Compared with the

conventional rotary construction, it brings about a bigger reduction in transfer time and a bigger increase in printing speed (full color).

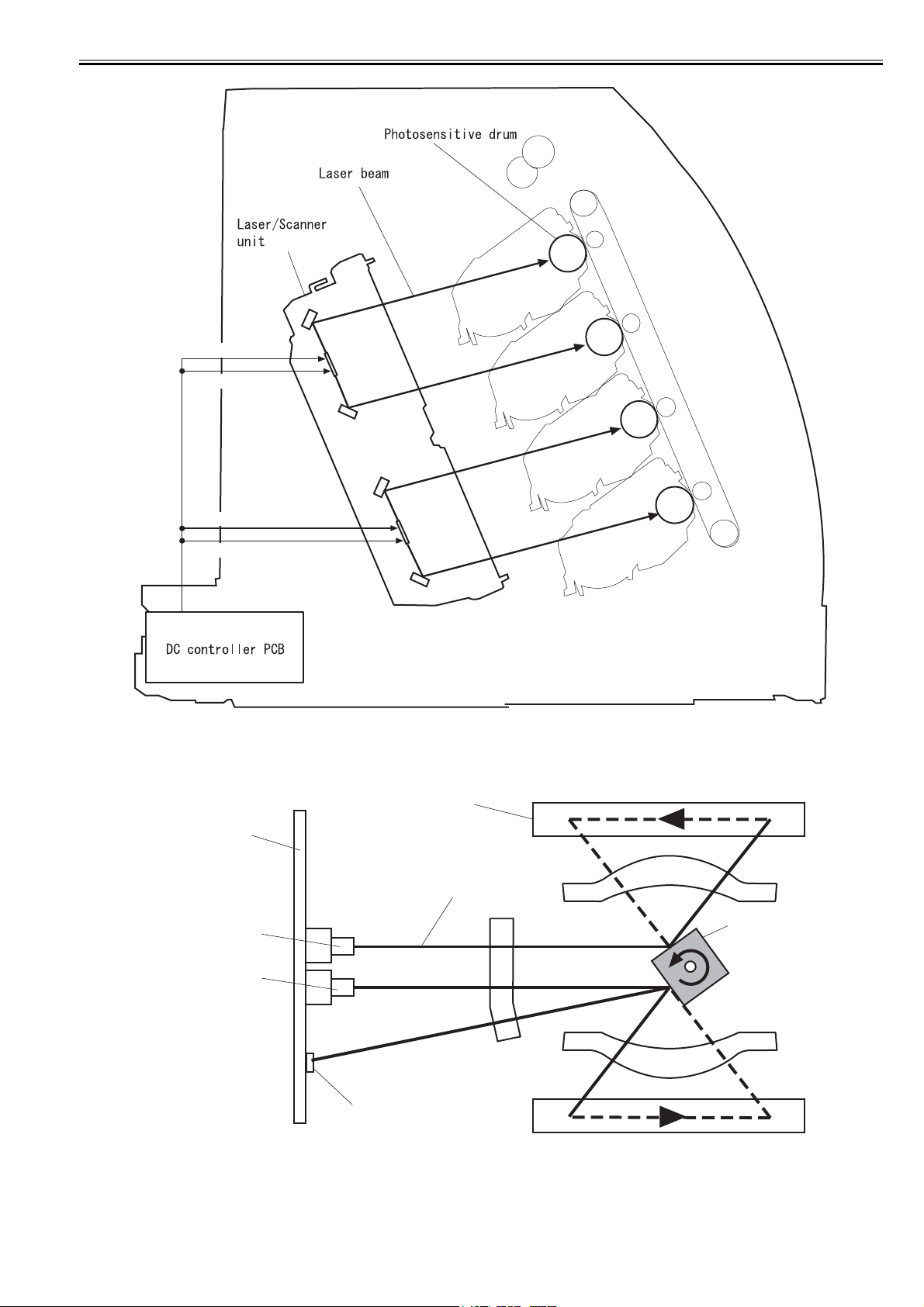

4. Integrated Laser Scanner Unit

The machine uses a 4-beam/2-mirror mechanism in which 2 laser beams (colors) are directed to each polygon mirror. Thanks to the elimination of the need for

separate laser scanner units commonly found in a 4-drum construction, the machine is less subject to color displacement and has a smaller laser unit.

5. On-Demand Fixing

The machine uses an on-demand fixing method combined with a ceramic heater so far mostly used in a mono-color printer. The fact has led to a shorter warmup period and lower energy consumption.

6. Support of Various Media Types

The machine permits the use of transparencies (mono-color prints only), label sheets, envelopes, and postcard-size sheets through both its cassette and manual

feeder.

Moreover, it also permits the use of heavy paper (163 g/m2 max.) in its cassette.

7. High-Performance Printing System (CAPT)

The machine draws on the latest developments in CAPT (Canon Advanced Printing Technology), which promises high performance in a Windows operating

system. Thanks to the technology, data processing usually assigned to the printer is now fully undertaken by a PC to take full advantage of the use of a PC for

higher printing speed. Its added benefits include the ability to process a large volume of data without adding memory to the printer.

8. Ease of Maintenance

The toner cartridges (cyan, magenta, yellow, black) each consist of a toner casing and a drum constructed as a single entity. This way, there is no need for toner

replenishment or drum replacement, which could well soil the hands of the user or take up his/her time. Mere replacement of the appropriate toner cartridge is

enough to keep the machine in good working condition.

The access cover is found at the front of the machine so that both cartridge replacement and jam removal are easy. In terms of printing processes, all (pickup,

development, transfer, fixing) take place at the front of the machine, resulting in a highly simple paper path.

1.2 System construction

0010-5849

1.2.1 System Construction

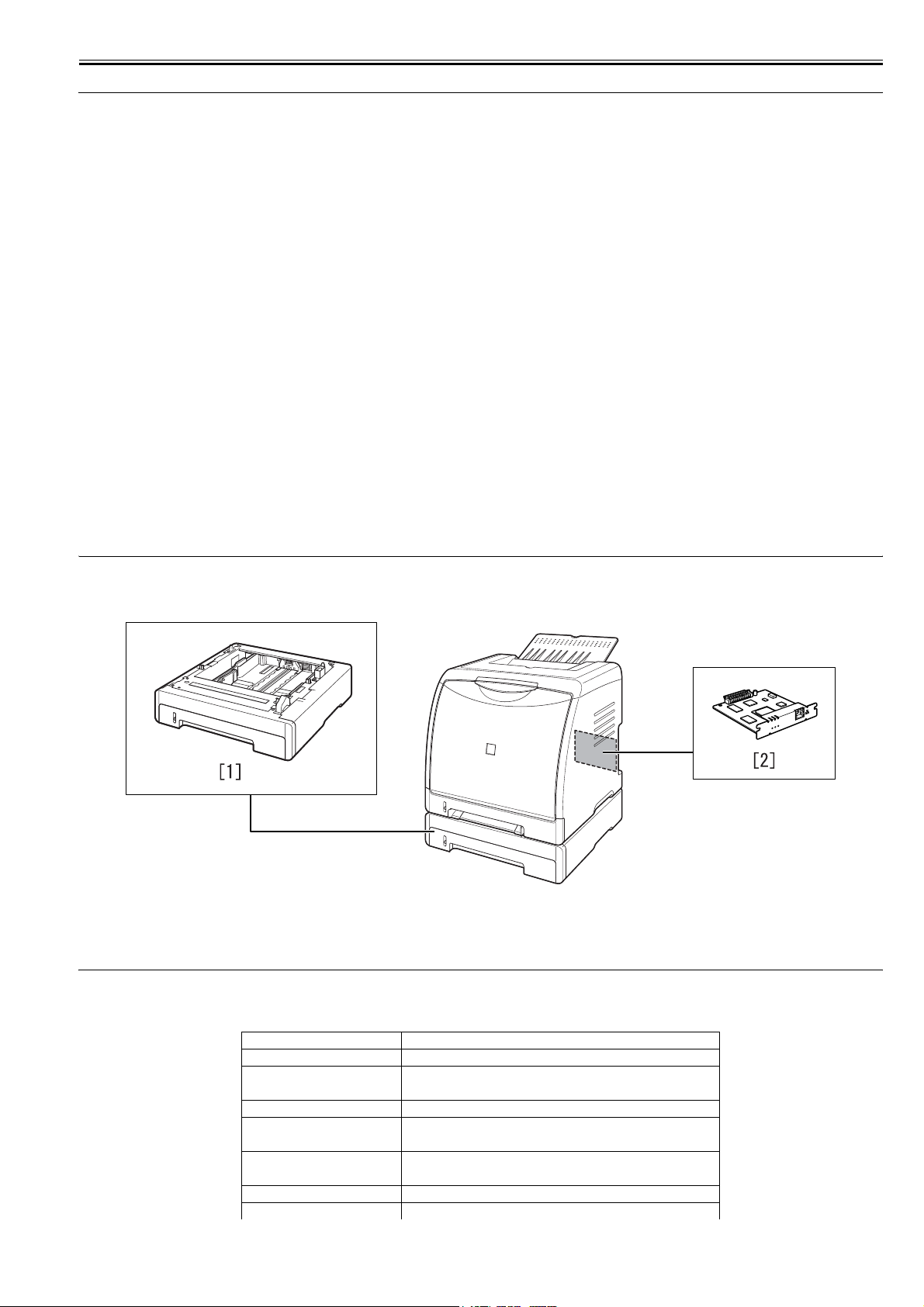

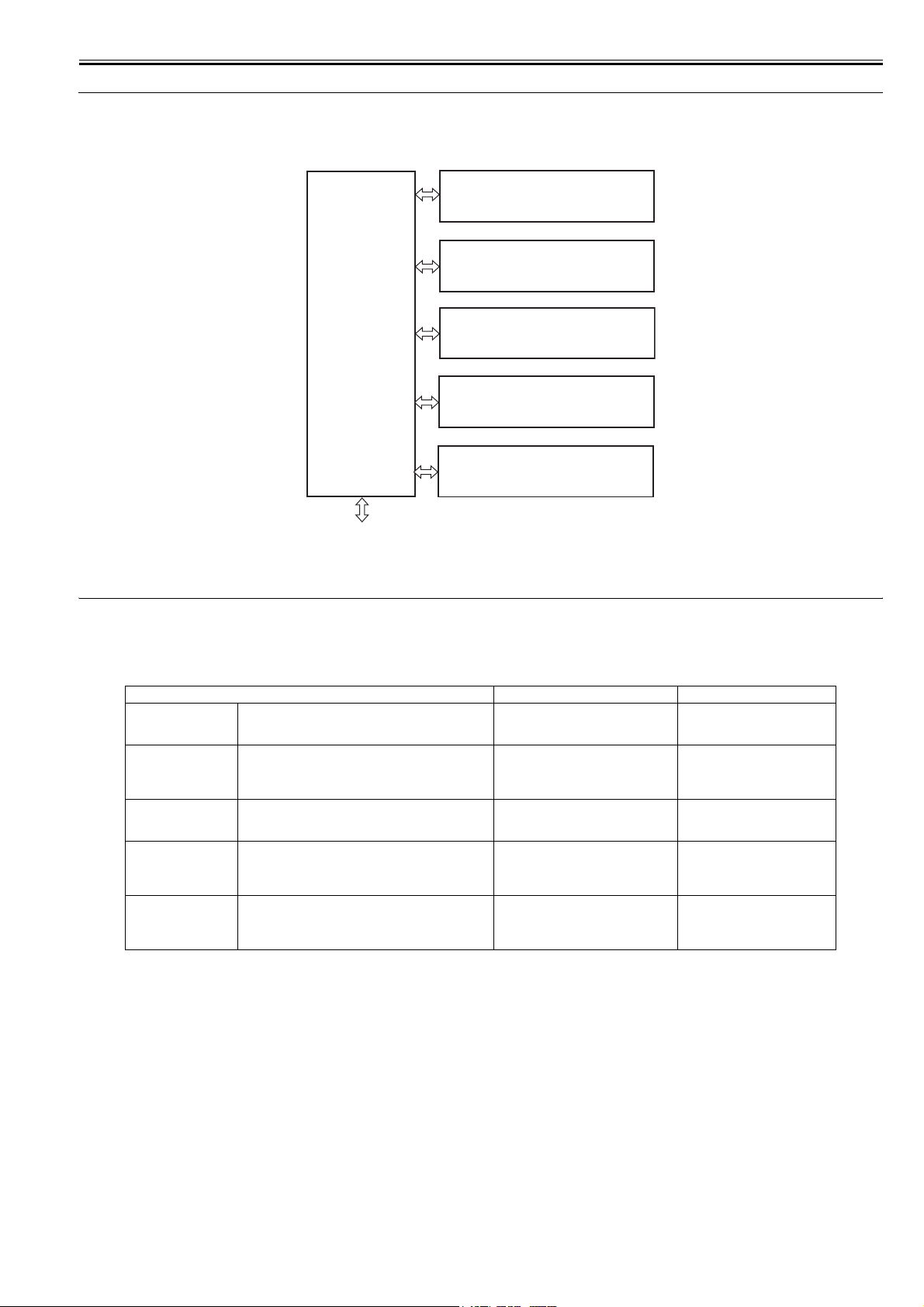

The following shows the machine's system construction:

[1] Paper Feeder PF-92

[2] Network Board NB-C1

1.3 Product Specifications

1.3.1 Product Specifications

F-1-1

0010-9607

100

K

LN

R

ER

1

-C

B

N

0010-6376

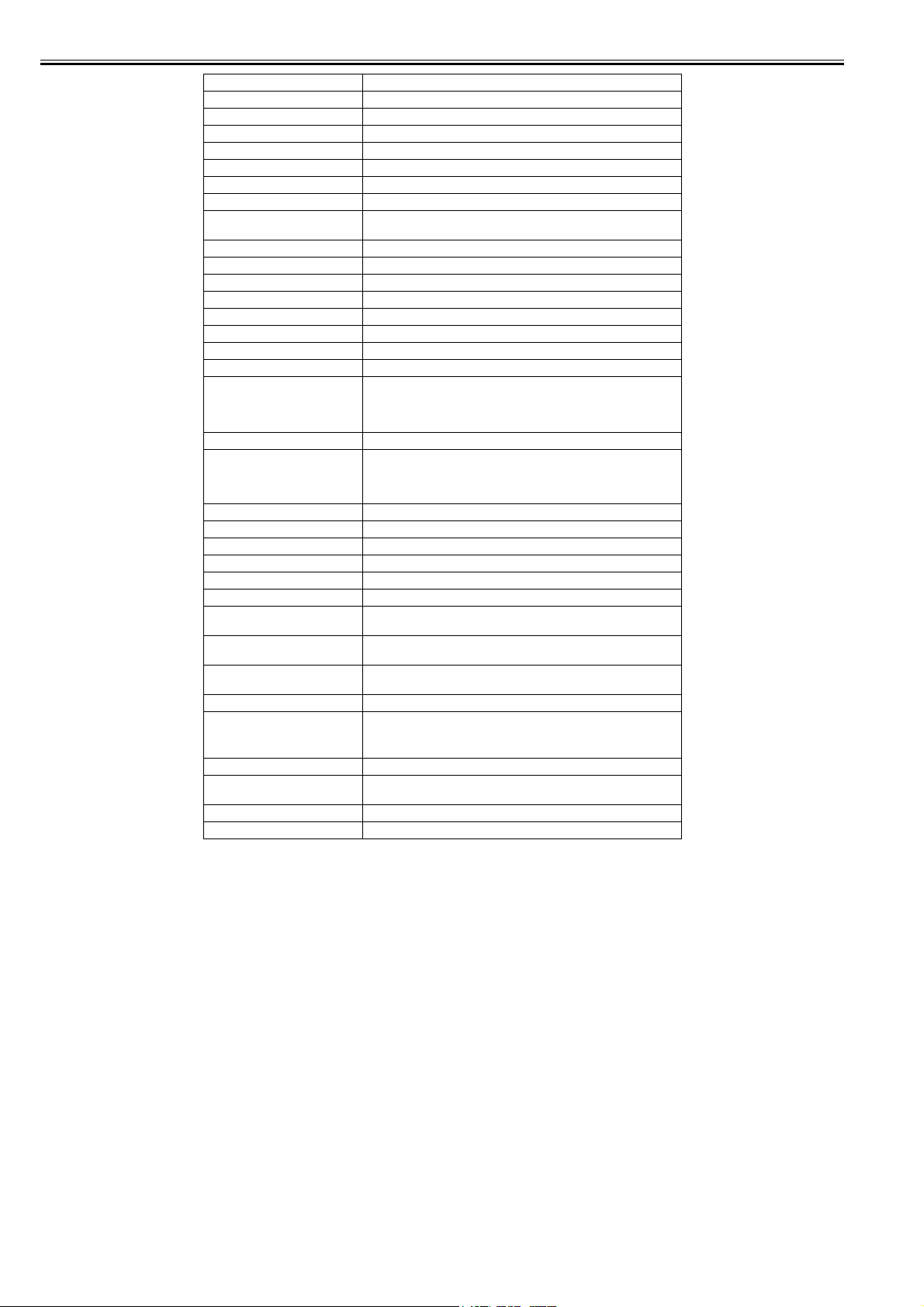

Body installation method Desktop page printer

Photosensitive medium OPC drum

Charging method Roller charging

Exposure method Laser scanning

Development method Toner projection development

Transfer method By Electrostatic Transportation Belt

Separation method Curvature

Pickup method By cassette/manual feeder

1-1

Chapter 1

Cassette pickup method By separation pad

Drum cleaning method By blade

Trasnsfer cleaning method Drum static collection

Fixing method On-demand

Delivery method Face-down

Contrast adjustment function Auto

Toner level detection function Available

Toner type non-magnetic, 1-component dry toner

Toner supply type By EP cartridge (for A4/LTR, about 2500 impressions of Bk; about 2000

Warm-up time 195 sec or less (approx.; at power-on, at 20 deg C)

Image margin (Leading edge) 5.0+1.5/-1.5mm

Image margin (Trailing edge) 5.0+1.5/-1.5mm

Image margin (Left/right) 5.0+1.0/-1.0mm

Number of gradations 16 gradations

Printing resolution 600dpi×600dpi

First print time 20 sec or less (approx.; both mono- and full-color)

Print speed (A4) 8 impressions/min (approx.; both mono- and full color)

Cassette paper size A4, B5, LGL, LTR, Executive, Index Card, envelope, user-defined sheet

Multifeeder paper size Same as for cassette

Cassette paper type Plain paper (60 to 90 g/m2), heavy paper (91 to 163 g/m2), envelope

Multifeeder tray paper type Same as for cassette

Cassette capacity 250 sheets (64 g/m2)

Multifeeder tray capacity 1 sheet

Delivery tray stack 125 sheets (plain paper, 64 g/m2)

Memory 8 MB (addition not possible)

Auto gradation correction Available

Operating environment

(Temperature range)

Operating environment

(Humidity range)

Operating environment

(Atmospheric pressure)

Noise 25 dB or less (standby); 50 dB or less (print)

Power supply rating 110 - 127 V (±10 %) 50/60 Hz (±2 Hz)

impressions of M, C, and Y)

(762 to 215.9 mm in length, 127.0 to 355.6 mm in width)

(Envelope DL, Envelope COM10, Envelope C5, Envelope

Monarch, Envelope B5), label sheet, transparency ((Black and white

printing only)

10Å` 30Åé

10 Å` 80%RH

l810.6 to 1013.3 hpa (0.8 to 1.0 atm)

220 - 240 V (±10 %) 50/60 Hz (±2 Hz)

Power consumption (Maximum) ñÒ638W or less (approx.)

Power consumption 18W or less (approx., operating; reference only); 220W or less (approx.,

Dimensions 407mm(W) x 367mm(D) x 376mm(H)

Weight 15.7 kg (approx.; excluding cartridges)

operating; reference only)

1-2

1.4 Name of Parts

Chapter 1

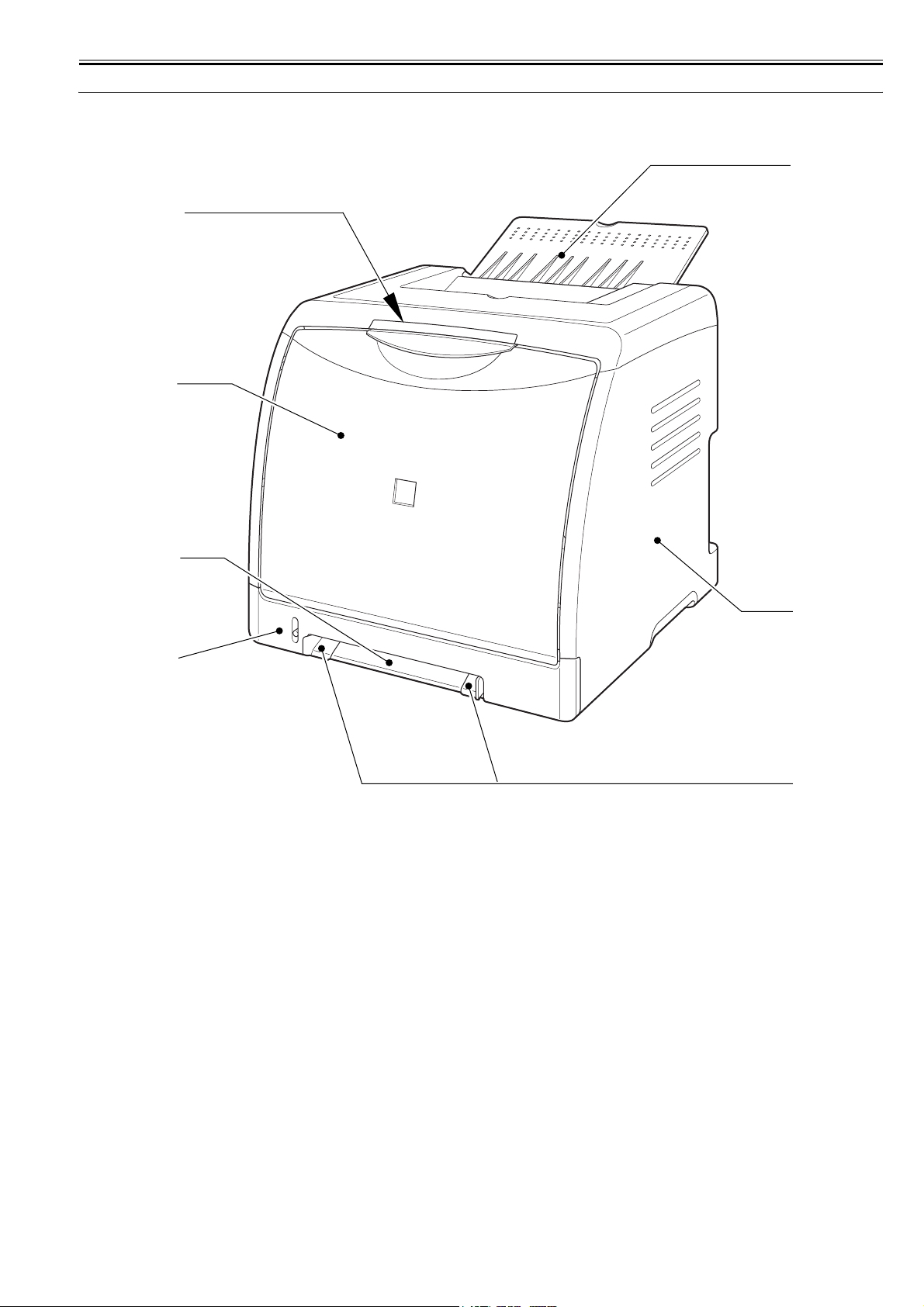

1.4.1 External View

[7]

[6]

[5]

0010-7392

[1]

[4]

[2]

[3]

F-1-2

[1] Delivery tray [2] Right cover

[3] Paper guide [4] Cassette

[5] Manual feeder slot [6] Front cover

[7] Lamp unit

1-3

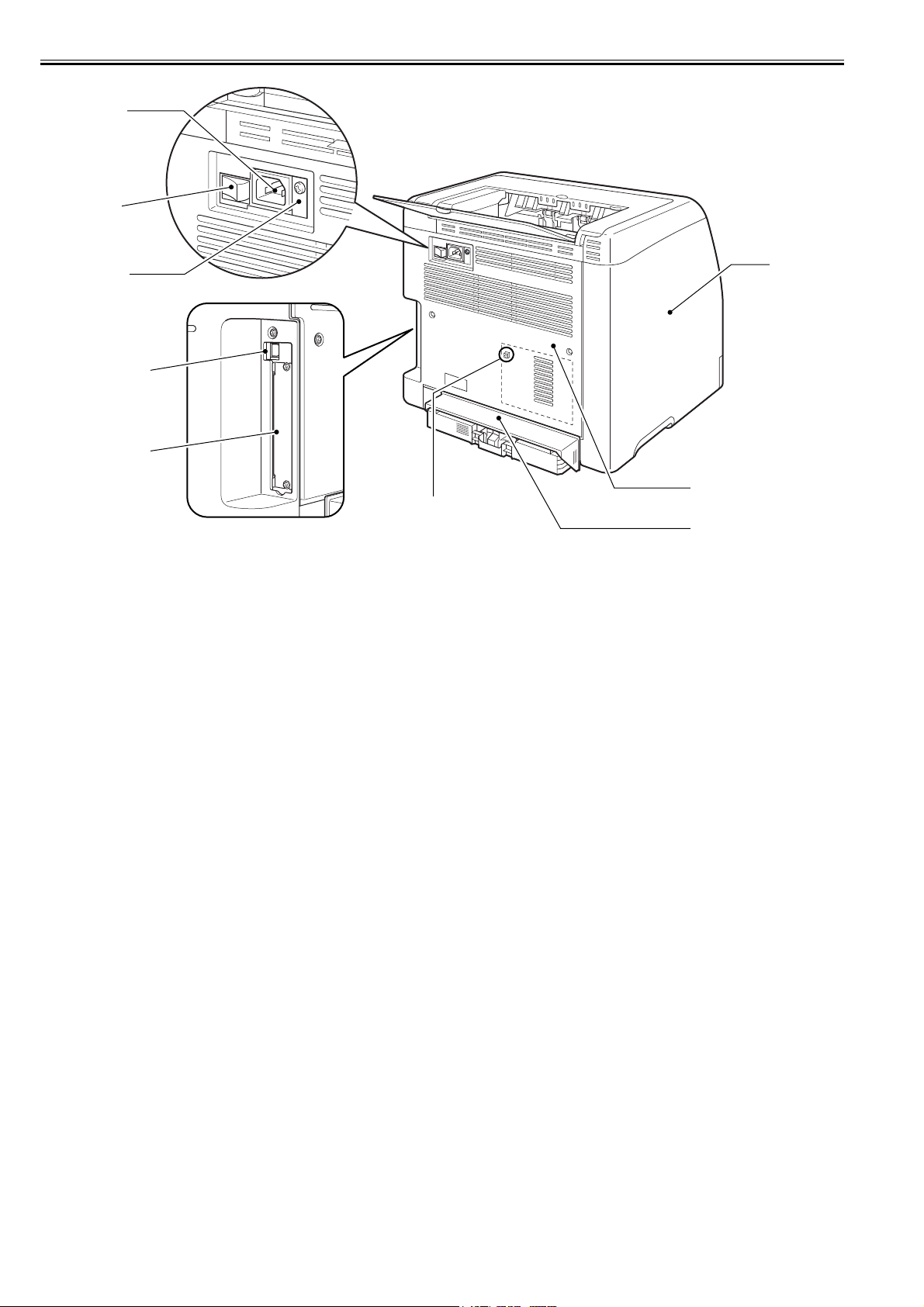

Chapter 1

[8]

[7]

[6]

[5]

[4]

[9]

F-1-3

[1] Left cover [2] Rear cover

[3] Cassette protective cover [4] Expansion board slot

[5] USB port [6] Grounding wire terminal

[7] Power supply switch [8] Power supply receptacle

[9] Test Print Switch

(On the DC controller PCB)

[1]

[2]

[3]

1-4

Chapter 1

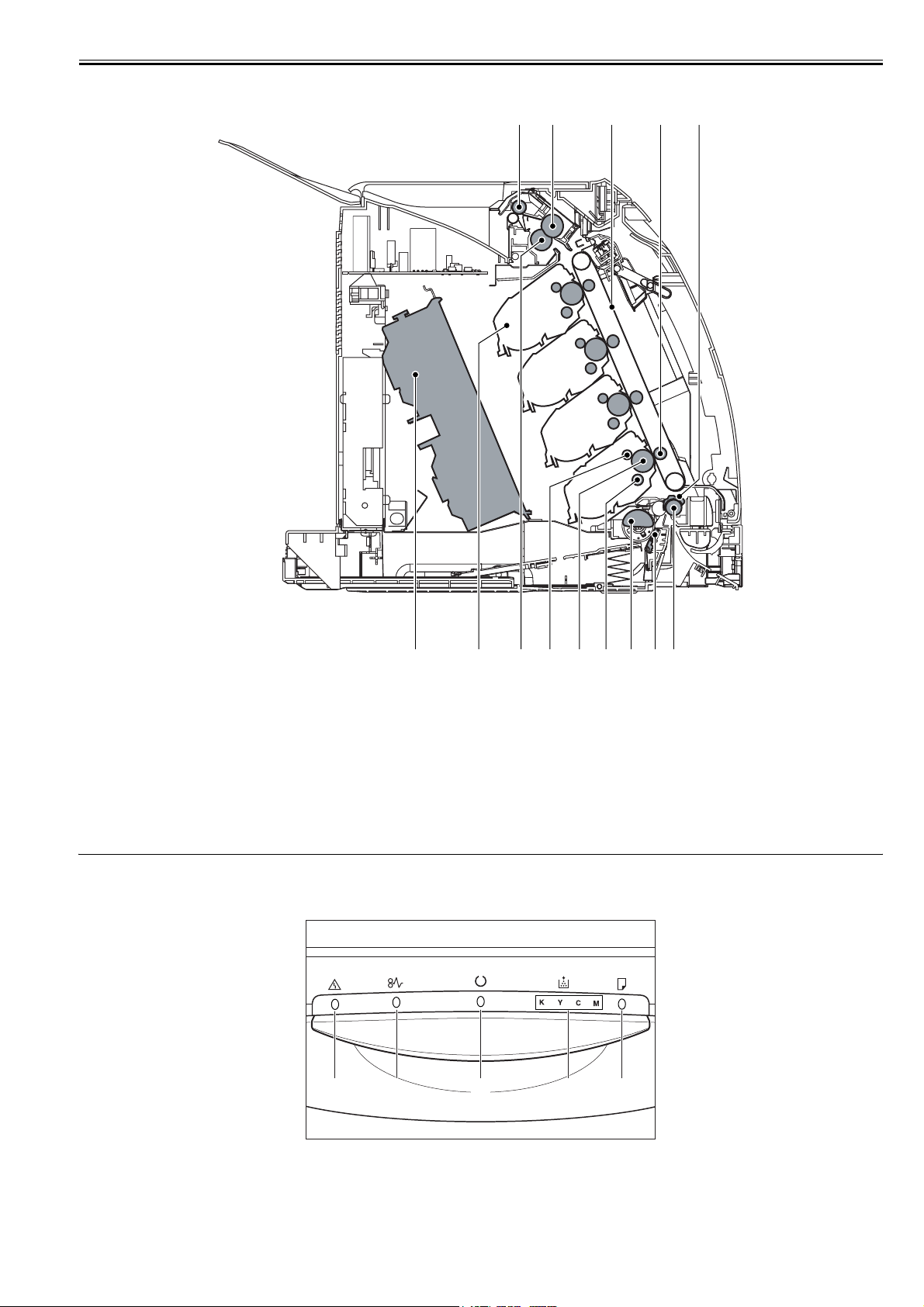

1.4.2 Cross Section View

0010-7393

[1] [2] [3] [4] [5]

[10][11][12][13][14]

F-1-4

[1] Delivery roller [2] Fixing pressure roller

[3] ETB [4] Transfer roller

[5] Registration shutter [6] Registration roller

[7] Separation pad [8] Pickup roller

[9] Developing cylinder [10] Photosensitive roller

[11] Primary charging roller [12] Fixing film unit

[13] Toner cartridge [14] Laser/scanner block

1.5 Using the Machine

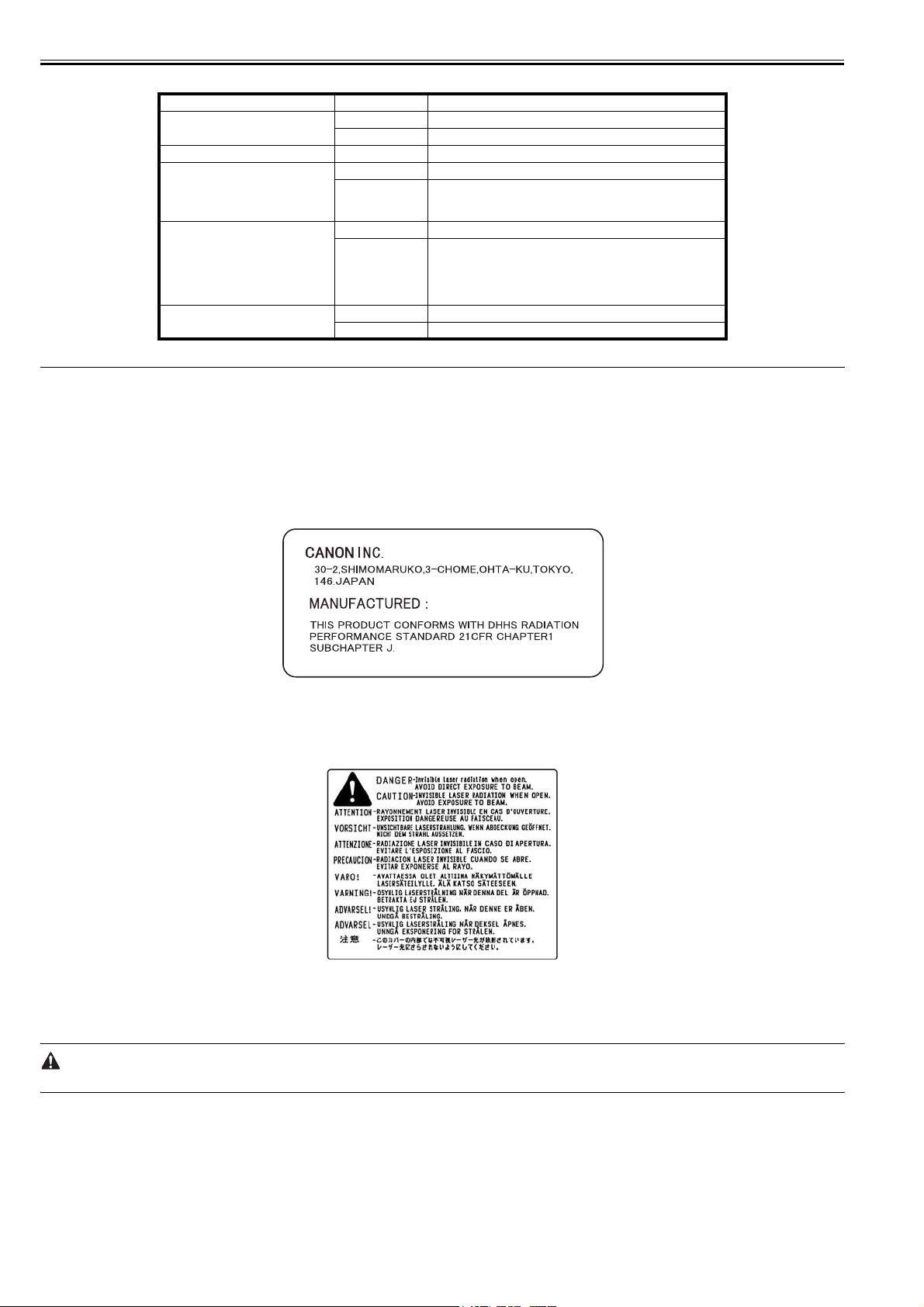

1.5.1 Control Panel

The lamp unit used to indicate the state of the printer consists of multiple LEDs that go on or flash as follows:

[1]

[2] [3] [4] [5]

[6][7][8][9]

0010-7869

F-1-5

1-5

Chapter 1

1.6 Safety

T-1-1

LED On/Flash Description

Alarm Indicator [1]

Paper Jam Indicator [2] flash A paper jam is occurring, disabling printing.

Ready Indicator [3]

Toner Indicator [4]

Load Paper Indicator [5]

on Service call is occurring.

flash An error is occurring, disabling printing.

on The printer is in the sleep mode and ready to print.

flash

on Toner cartridge replacement is required.

flash

on There is no paper in any paper source.

flash No paper or paper of an inappropriate size is loaded.

engine in operation, printing The printer is busy performing some

kind of processing or operation, such as printing, warming up,

calibrating, or pausing a job.

Cannot print because toner cartridge replacement is required or any

toner cartridge is not installed properly.

Indicator of the color that requires toner cartridge replacement

comes on or blinks. "K", "Y", "C", and "M" indicate black, yellow,

cyan, and magenta respectively.

1.6.1 Safety of the Laser Light

Laser light can prove to be hazardous to the human body. The machine's laser unit is fully enclosed in a protective housing and external covers so that its light will

not escape outside as long as the machine is used normally.

1.6.2 Regulations Under the Center for Devices and Radiological Health (CDRH)

The CDRH of the US Food and Drug Administration put into effect regulations governing the sale of laser products in the US on August 2, 1976. These regulations

apply to all laser products produced on and after August 1, 1976, and a laser product cannot be sold unless it has been certified to comply with the regulations. The

following is the label used to indicate that the product has been certified under the regulations, and all laser products sold in the US must bear the label.

F-1-6

1.6.3 Handling the Laser Unit

The laser/scanner unit emits invisible laser beam. DO NOT disassemble the unit as the laser beam can possibly damage your eyes. The unit cannot be adjusted in

0010-5913

0010-5915

0010-5916

the field. The following label is attached to the cover of the unit:

F-1-7

1.6.4 Safety of Toner

The machine's toner is a non-toxic material composed of plastic, iron, and small amounts of dye.

Do not put the toner into fire. It may explode.

Toner on the Skin or Clothes

1. If your skin or clothes came into contact with toner, use dry tissue to remove the toner, and then wash with water.

2. Do not use warm or hot water, which will cause the toner to jell, permanently fusing it with the fibers of the clothes.

3. Do not bring toner into contact with vinyl material. They are likely to react with each other.

1-6

0010-5919

Chapter 2 TECHNICAL REFERENCE

Contents

Contents

2.1 Functional Configuration ...............................................................................................................................................2-1

2.1.1 Outline.......................................................................................................................................................................................... 2-1

2.2 Basic Sequense...............................................................................................................................................................2-1

2.2.1 Basic Sequence of Operation ....................................................................................................................................................... 2-1

2.2.2 Power-On Sequence..................................................................................................................................................................... 2-1

2.3 LASER EXPOSURE SYSTEM.....................................................................................................................................2-2

2.3.1 Overview/Configuration .............................................................................................................................................................. 2-2

2.3.1.1 Outline.............................................................................................................................................................................................................2-2

2.3.2 Laser Control ............................................................................................................................................................................... 2-4

2.3.2.1 Outline.............................................................................................................................................................................................................2-4

2.3.2.2 Laser Emission Control...................................................................................................................................................................................2-4

2.3.2.3 Automatic power control (APC) .....................................................................................................................................................................2-4

2.3.2.4 Horizontal synchronous control ......................................................................................................................................................................2-5

2.3.2.5 Image Mask Control........................................................................................................................................................................................2-5

2.3.2.6 Fault Detection ................................................................................................................................................................................................2-5

2.3.3 Laser Scanner Motor Control....................................................................................................................................................... 2-5

2.3.3.1 Outline.............................................................................................................................................................................................................2-5

2.3.3.2 Speed Control..................................................................................................................................................................................................2-6

2.3.3.3 Phase Control ..................................................................................................................................................................................................2-6

2.3.3.4 Fault Detection ................................................................................................................................................................................................2-6

2.4 IMAGE FORMATION SYSTEM.................................................................................................................................2-7

2.4.1 Overview/Configuration .............................................................................................................................................................. 2-7

2.4.1.1 Outline.............................................................................................................................................................................................................2-7

2.4.1.2 Image Formation Process ................................................................................................................................................................................2-7

2.4.1.3 Electrostatic latent image formation block .....................................................................................................................................................2-8

2.4.1.4 Developing block ............................................................................................................................................................................................2-9

2.4.1.5 Transfer block ...............................................................................................................................................................................................2-10

2.4.1.6 Fixing block ..................................................................................................................................................................................................2-11

2.4.1.7 Drum cleaning block .....................................................................................................................................................................................2-11

2.4.2 High-Voltage Control ................................................................................................................................................................ 2-11

2.4.2.1 Outline...........................................................................................................................................................................................................2-11

2.4.2.2 Generation of the Primary Charging Bias.....................................................................................................................................................2-12

2.4.2.3 Generation of the Developing Bias ...............................................................................................................................................................2-12

2.4.2.4 Generation of the Transfer Bias ....................................................................................................................................................................2-12

2.4.2.5 Generation of the Fixing Bias .......................................................................................................................................................................2-13

2.4.3 Image Stabilizaton Control ........................................................................................................................................................ 2-13

2.4.3.1 Overview of the Image Stabilization Control Mechanism............................................................................................................................2-13

2.4.3.2 Environment corrective control.....................................................................................................................................................................2-13

2.4.3.3 Image density corrective control (D-max control)........................................................................................................................................2-13

2.4.3.4 Image halftone corrective control (D-half control).......................................................................................................................................2-13

2.4.3.5 Image density detection control ....................................................................................................................................................................2-13

2.4.3.6 Overview of Color Misregistration Corrective Control ...............................................................................................................................2-14

2.4.3.7 Color misregistration detection .....................................................................................................................................................................2-14

2.4.4 Toner Cartridge.......................................................................................................................................................................... 2-15

2.4.4.1 Outline...........................................................................................................................................................................................................2-15

2.4.4.2 Memory Tag Control.....................................................................................................................................................................................2-16

2.4.4.3 Detection of Toner cartridge presence/absence ............................................................................................................................................2-16

2.4.4.4 Detecting the End of Life of the Cartridge....................................................................................................................................................2-16

2.4.4.5 Detecting the Level of Toner ........................................................................................................................................................................2-16

2.4.5 Transfer Unit .............................................................................................................................................................................. 2-16

2.4.5.1 ETB Unit .......................................................................................................................................................................................................2-16

2.4.5.2 ETB Cleaning................................................................................................................................................................................................2-17

2.5 Pickup/Feeding/Delivery System.................................................................................................................................2-18

Contents

2.5.1 Overview/Configuration ............................................................................................................................................................ 2-18

2.5.1.1 Outline .......................................................................................................................................................................................................... 2-18

2.5.2 Other Control ............................................................................................................................................................................. 2-20

2.5.2.1 outline ........................................................................................................................................................................................................... 2-20

2.5.2.2 Picking Up Paper from the Cassette ............................................................................................................................................................. 2-21

2.5.2.3 Picking Up Paper from the Manual Feeder .................................................................................................................................................. 2-21

2.5.2.4 Moving the Print Paper ................................................................................................................................................................................. 2-21

2.5.2.5 Transport Speed Control ............................................................................................................................................................................... 2-22

2.5.2.6 Paper loop control ......................................................................................................................................................................................... 2-22

2.5.2.7 Automatic release of fixing pressure mechanism ......................................................................................................................................... 2-23

2.5.3 Detecting Jams ........................................................................................................................................................................... 2-23

2.5.3.1 Jam Detection Outline ..................................................................................................................................................................................2-23

2.5.3.1.1 Outline .................................................................................................................................................................................................. 2-23

2.5.3.2 Delay Jams .................................................................................................................................................................................................... 2-24

2.5.3.2.1 Pick-up delay jam ................................................................................................................................................................................. 2-24

2.5.3.2.2 Delivery delay jam ................................................................................................................................................................................ 2-24

2.5.3.3 Stationary Jams ............................................................................................................................................................................................. 2-24

2.5.3.3.1 Pickup Stationary Jam .......................................................................................................................................................................... 2-24

2.5.3.3.2 Delivery Stationary Jam........................................................................................................................................................................ 2-24

2.5.3.4 Other Jams .................................................................................................................................................................................................... 2-24