SERVICE

MANUAL

REVISION 0

COPYRIGHT 1999 CANON INC. CANON 2x500 sheet paper deck PD-82K REV. 0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

RY8-1392-000

JAN. 1999

2x500 sheet

PAPER DECK

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

PERIPHERAL PRODUCTS QUALITY PLANNING DIV.

PERIPHERAL PRODUCTS TECHNICAL DOCUMENTATION DEPT.

CANON INC.

5-1 Hakusan 7-chome, Toride-City, Ibaraki-Pref.,302-8501 Japan

PREFACE

This Service Manual contains basic information required for after-sales service of 2x500 sheet

paper deck PD-82K. This information is vital to the service technician in maintaining the high

print quality and performance of the paper deck.

This manual consists of the following chapters:

Chapter 1: Product information

Specifications, parts of the deck, and installation

Chapter 2: Operation and Timing

A description of the operating principles and timing sequences of the electrical and

mechanical systems.

Chapter 3: The Mechanical System

Explanation of mechanical operation, disassembly, reassembly, and adjustment

procedures

Chapter 4: Troubleshooting

Maintenance and servicing, reference values and adjustments, troubleshooting

procedures, lubricants, and solvents

Appendix: General circuit diagram, etc.

Information in this manual is subject to change as the product is improved or redesigned.

All relevant information in such cases will be supplied in Service Information Bulletins.

A thorough understanding of this paper deck, based on information in this Manual and Service

Information Bulletins is required for maintaining its performance and for locating and repairing

malfunctions.

DTP system

This manual was produced on an Apple PowerMacintosh 9500/233 personal computer and output by an

Apple LaserWriter 16/600 PS laser beam printer; final pages were printed on DAINIPPON SCREEN MFG

CO. LTD DT-R3100.

All graphics were produced with Macromedia FreeHand (J), and all documents and page layouts were

created with QuarkXPress (E).

The video images were captured with SONY degital video camcorder and Radius PhotoDV capture

board system, and modified with Adobe Photoshop (J).

CONTENTS

CHAPTER 1 PRODUCT INFORMATION

I. SPECIFICATIONS ................... 1-1

II. PARTS OF THE PAPER DECK . 1-2

A. External Views ................. 1-2

B. Cross Sectional Views ....... 1-3

III. INSTALLATION ...................... 1-4

A. Notes ................................ 1-4

B. Unpacking and Installation 1-4

CHAPTER 2 OPERATION AND TIMING

CHAPTER 3 THE MECHANICAL SYSTEM

I. BASIC OPERATION ................ 2-1

A. Outline ............................. 2-1

B. Input/Output of Paper Deck

Driver PCB ........................ 2-2

II. PICK-UP/FEED SYSTEM ........ 2-5

A. Outline ............................. 2-5

B. Paper Pick-up ................... 2-8

C. Paper Jam Detection ........ 2-19

III. POWER SUPPLIES ................. 2-20

A. Outline ............................. 2-20

B. Protective Function .......... 2-20

I. PREFACE .............................. 3-1

A. Outline ............................. 3-1

II. EXTERNALS .......................... 3-2

A. Locations ......................... 3-2

III. MAIN UNITS .......................... 3-5

A. Feed Unit ......................... 3-5

B. Pick-up Unit ..................... 3-5

IV. MAIN PARTS .......................... 3-8

A. Locations ......................... 3-8

B. Registration roller ............ 3-9

C. Pick-up roller /Feed roller 1/

Separation roller ............... 3-9

V. SENSORS .............................. 3-10

A. Locations ......................... 3-10

B. Paper feed unit sensor ...... 3-11

C. Upper cassette sensor /

Lower cassette sensor /

Upper cassette paper-level

sensor 1, 2 / Lower cassette

paper-level sensor 1, 2 /

Upper cassette paper-out

sensor / Lower cassette

paper-out sensor ............... 3-11

D. Registration paper sensor .. 3-12

E. Paper Jam sensor ............. 3-12

VI. SOLENOID/CLUTCH .............. 3-13

A. Locations ......................... 3-13

B. Pick-up solenoid ............... 3-14

C. Registration clutch ........... 3-14

VII. MOTORS ............................... 3-16

A. Locations ......................... 3-16

B. Paper feed motor .............. 3-17

C. Paper deck drive motor .... 3-17

D. Pick-up motor .................. 3-18

VIII.PCBs ..................................... 3-19

A. Locations ......................... 3-19

B. Paper deck driver PCB ...... 3-20

C. Pick-up PCB ...................... 3-20

D. Upper cassette paper-size

detection switch PCB ....... 3-21

E. Lower cassette paper-size

detection switch PCB ....... 3-21

F. Status LED PCB ................ 3-22

G. Power supply unit ............. 3-22

APPENDIX

I. GENERAL CIRCUIT DIAGRAM A-1 II. LIST OF SIGNALS .................. A-3

A. Input/Output signals to/from

Paper deck driver PCB ....... A-3

CHAPTER 4 TROUBLESHOOTING

I. PREFACE .............................. 4-1

A. Malfunction Diagnosis

Flowchart ......................... 4-1

B. Initial Checks ................... 4-3

C. Service Checkpoints ......... 4-4

D. Service Mode .................... 4-5

II. PAPER JAMS ......................... 4-9

III. PAPER FEEDING

TROUBLESHOOTING ............. 4-12

IV. MALFUNCTION

TROUBLESHOOTING ............. 4-13

V. MALFUNCTION STATUS

TROUBLESHOOTING ............. 4-15

VI. MEASUREMENT AND

ADJUSTMENT ....................... 4-16

A. Mechanical Adjustment .... 4-16

B. Electrical Adjustment ....... 4-18

C. LEDs, test pins, jumpers,

and switches on PCB ........ 4-18

VII. MAINTENANCE AND

SERVICING ............................ 4-20

A. Periodic Replacement

Parts ................................ 4-20

B. Expected Lives of

Consumable Parts ............. 4-20

C. Regular Servicing

Schedule .......................... 4-20

D. Standard Tools ................. 4-20

E. Special Tools .................... 4-20

F. List of Lubricants and

Cleaners ........................... 4-21

VIII.LOCATION OF CONNECTORS . 4-22

CHAPTER 1

PRODUCT INFORMATION

I. SPECIFICATIONS ................... 1-1

II. PARTS OF THE PAPER DECK .. 1-2

III. INSTALLATION ...................... 1-4

I. SPECIFICATIONS

1) Paper type Plain paper, colored paper, and thick paper

2) Paper size

Upper cassette B4, A4, Legal, and Letter sized plain paper (64g/m2to 105g/m

2

recommended paper)

Lower cassette A3, B4, A4, Ledger, Legal, and Letter sized plain paper (64g/m2to

105g/m2recommended paper)

3) Cassette type

Upper cassette Universal (accommodates B4, Legal, Letter, and A4 size)

Lower cassette Universal (accommodates Ledger, A3, B4, Legal, Letter, and A4

size)

4) Capacity Depth 50mm (About 500 sheets of paper (75g/m2) can be stacked.)

5) Environment

Temperature 10 to 32.5°C

Humidity 20 to 80%RH

Pressure 746 to 1013hPa (560 to 760mmHg)

6) Maximum power

consumption About 48.9W or less (Room temperature 20°C, Rated power sup-

ply voltage)

7) Dimensions 629 (width) x 520 (depth) x 651 (height) mm

8) Weight About 30kg

9) Line voltage 100-127V-10%, +6% (50/60Hz±2Hz)

requirements 220-240V-10%, +6% (50/60Hz±2Hz)

Specifications are subject to change with product modification.

1 - 1

CHAPTER 1

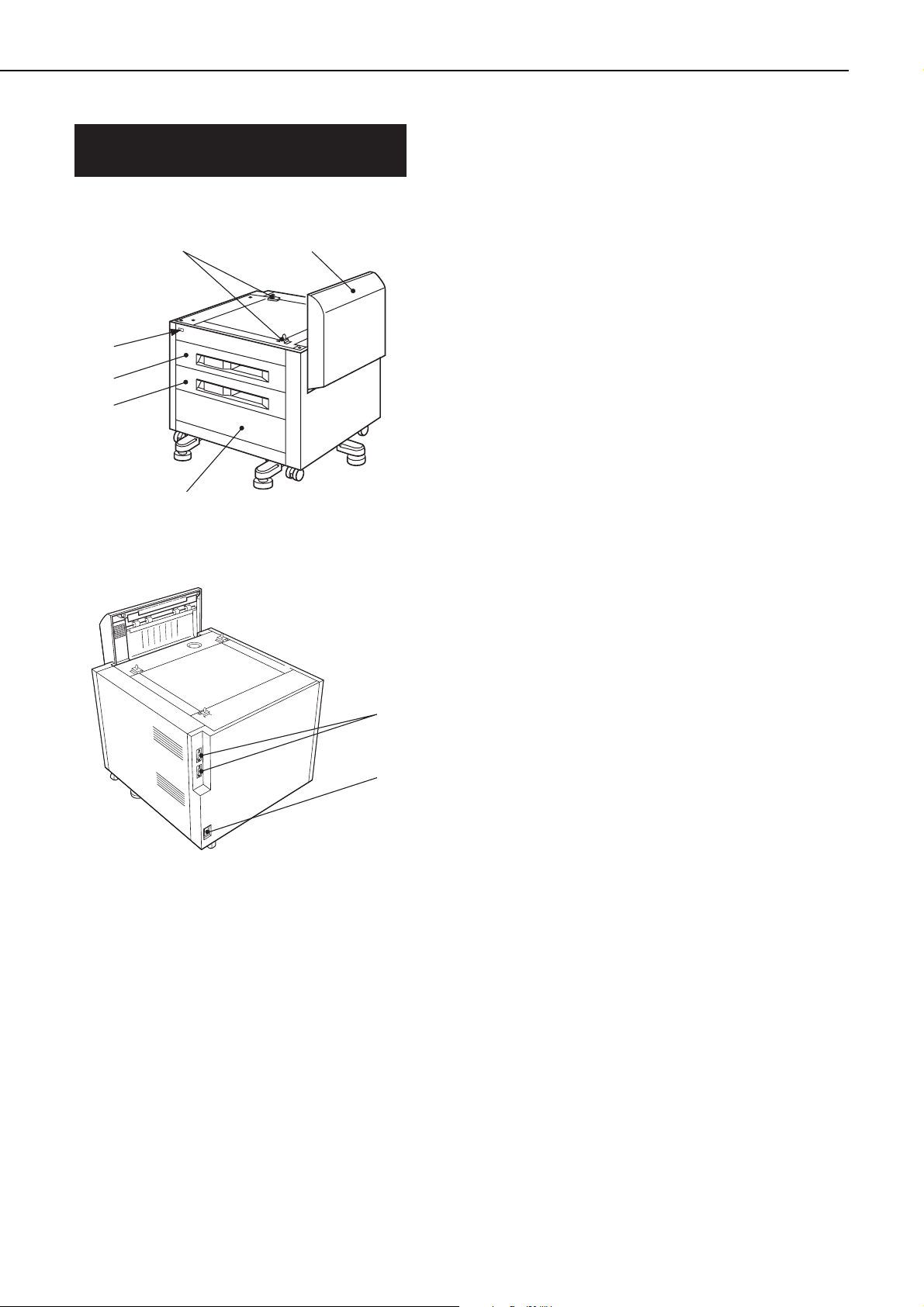

II. PARTS OF THE PAPER

DECK

A. External Views

Figure 1-2-1

Figure 1-2-2

1: Positioning pins

2: Paper feed unit

3: Housing unit

4: Lower cassette

5: Upper cassette

6: Status LED

7: Option interface connectors

8: Power receptacle

1 - 2

CHAPTER 1

➀➁

➅

➄

➃

➂

➆

➇

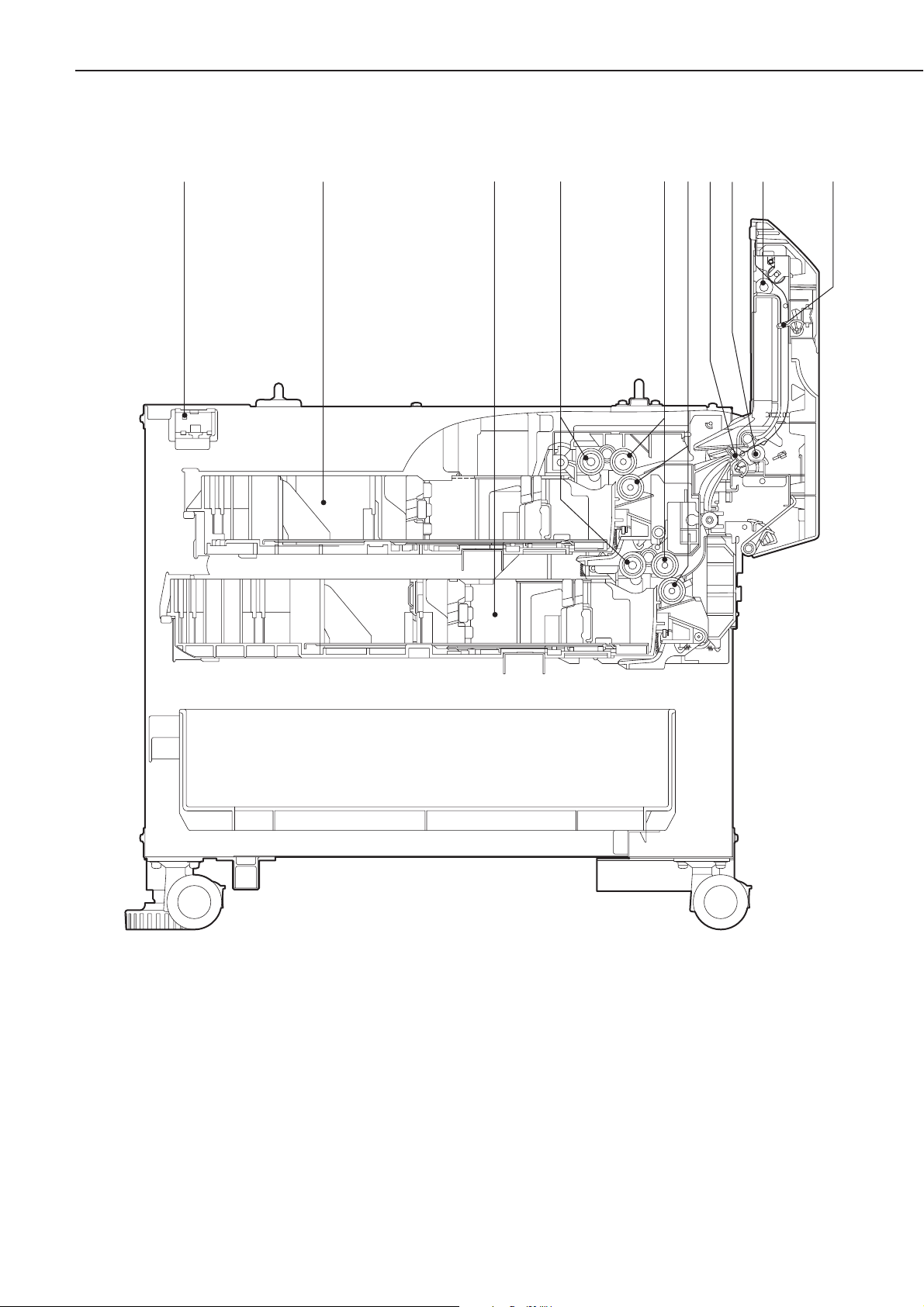

B. Cross Sectional Views

Figure 1-2-3

1 - 3

CHAPTER 1

1: Status LED

2: Upper cassette

3: Lower cassette

4: Pick-up roller

5: Feed roller 1

6: Separation roller

7: Registration paper sensor lever

8: Registration roller

9: Feed roller 2

10: Paper jam sensor lever

➀ ➁ ➂ ➃ ➄➅➆➇ ➈

➉

III. INSTALLATION

A. Notes

Use the following power supplies;

• Line voltage (AC): -10%, +6% rated voltage

• Power frequency: 50/60Hz ± 2Hz

B. Unpacking and Installation

Condensation will form on the metal surfaces when brought into a warm room from the cold.

Therefore, when moving the unit into a warm environment, leave it packed in its box for at least

an hour to acclimatize to room temperature.

1. Opening the paper deck packaging

1) Undo the paper deck packaging, and remove the box.

2) Take out the accessories. Confirm that the option interface cable and manual are included.

3) Remove the top pads (left/right) and remove the paper deck from the box.

4) Take the plastic bag off from around the deck and peel off the tape holding the various parts.

Check that none of the covers were scratched or deformed during shipment.

5) Open the feed unit and remove the spacer.

6) Pull out the cassettes and remove the spacer.

2. Connecting to the printer

1) Carry to the installation location and lock the casters.

2) Rotate the adjusters to install on the floor.

3) Open the feed unit.

4) Line up the printer and paper deck in the same direction, and have 4 people lift the printer.

Lower the printer onto the paper deck while aligning the 3 positioning pins on the paper

deck.

5) Close the feed unit.

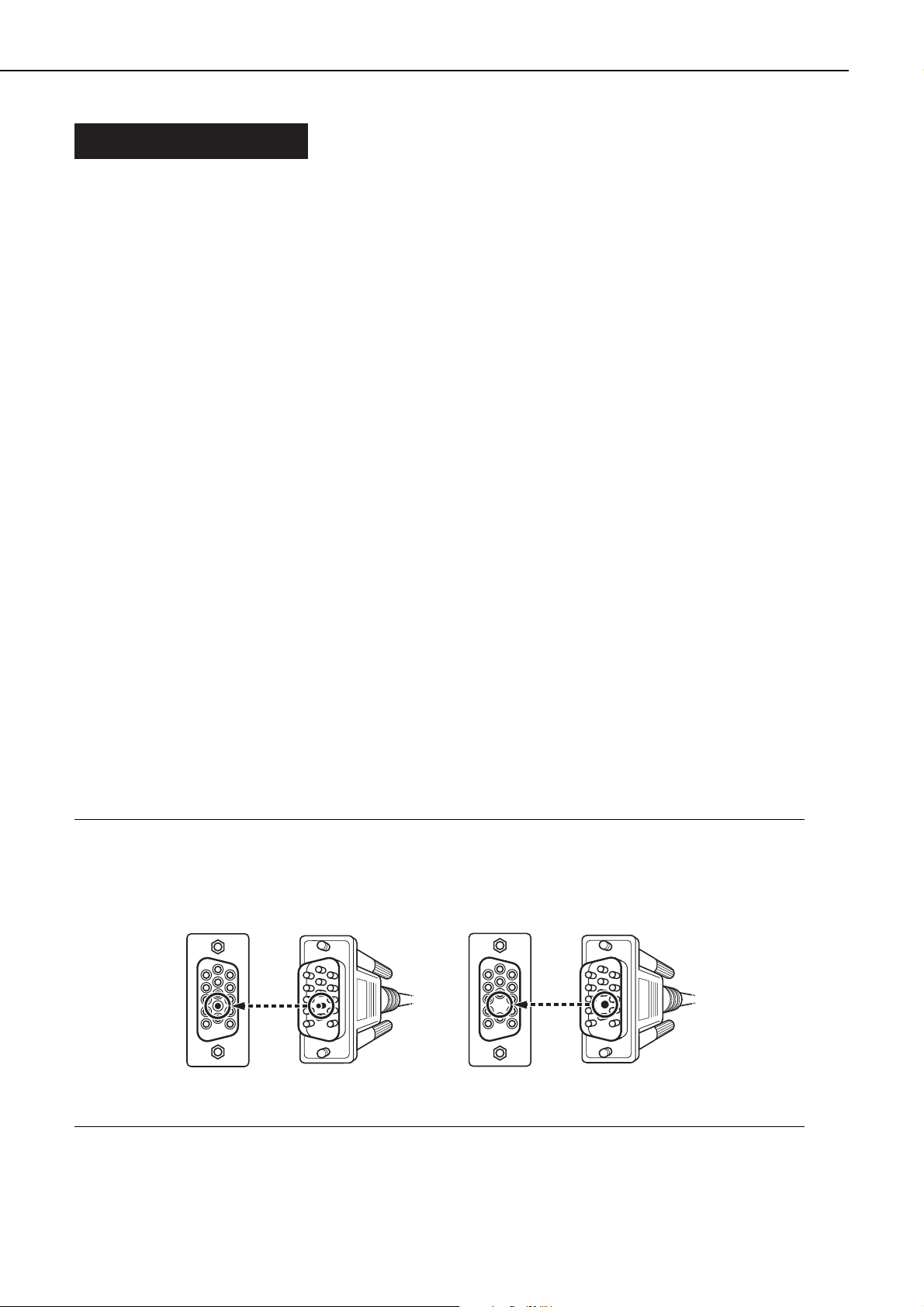

6) Connect the 15-pin-connector of the interface cable with the paper deck, and the 14-pinconnector with the printer.

7) Plug the power cord into the paper deck and the outlet.

Note: When connecting the interface cable with the printer and the paper deck, note that the

connectors at the ends of the interface cable contain different number of pin, 15 pins

and 14 pins.

Figure 1-3-1

1 - 4

CHAPTER 1

15-pins connector 14-pins connector

CHAPTER 2

OPERATION AND TIMING

1. This chapter describes the paper deck functions, the relationships between mechanisms

and circuits, and the timing of operations. Mechanical linkages are indicated by black and

white lines ( ), the flow of control signals by solid arrows ( ), and the flow of

groups of signals by outline arrows ( ).

2. An active-high signal is indicated by "H" or by a signal name without a slash in front of it,

such as "PSNS." An active-low signal is indicated by "L" or by a signal name with a slash in

front of, such as "/SCNON."

A signal that is "H" or has a name without a slash is active at the supply voltage level

(indicating that the signal is being output), and inactive at ground level (indicating that the

signal is not being output).

A signal that is "L" or has a slash in front of its name is active at ground level, and

inactive at the supply voltage level.

There is a microcomputer in this printer. But as the internal operation of the

microcomputer cannot be checked, an explanation of the operation of the microcomputer

has been left out.

As it is assumed that no repair will be made to customer circuit boards, the explanation

of board circuits is limited to an outline using block diagrams. So there are two types of

circuit explanations; (1) everything from the sensor to the input sections of the major circuit

boards, (2) everything from the output sections of the major circuit boards to the loads.

These are explained with block diagrams according to the function.

I. BASIC OPERATION ................ 2-1

II. PICK-UP/FEED SYSTEM ........ 2-5

III. POWER SUPPLIES ................. 2-20

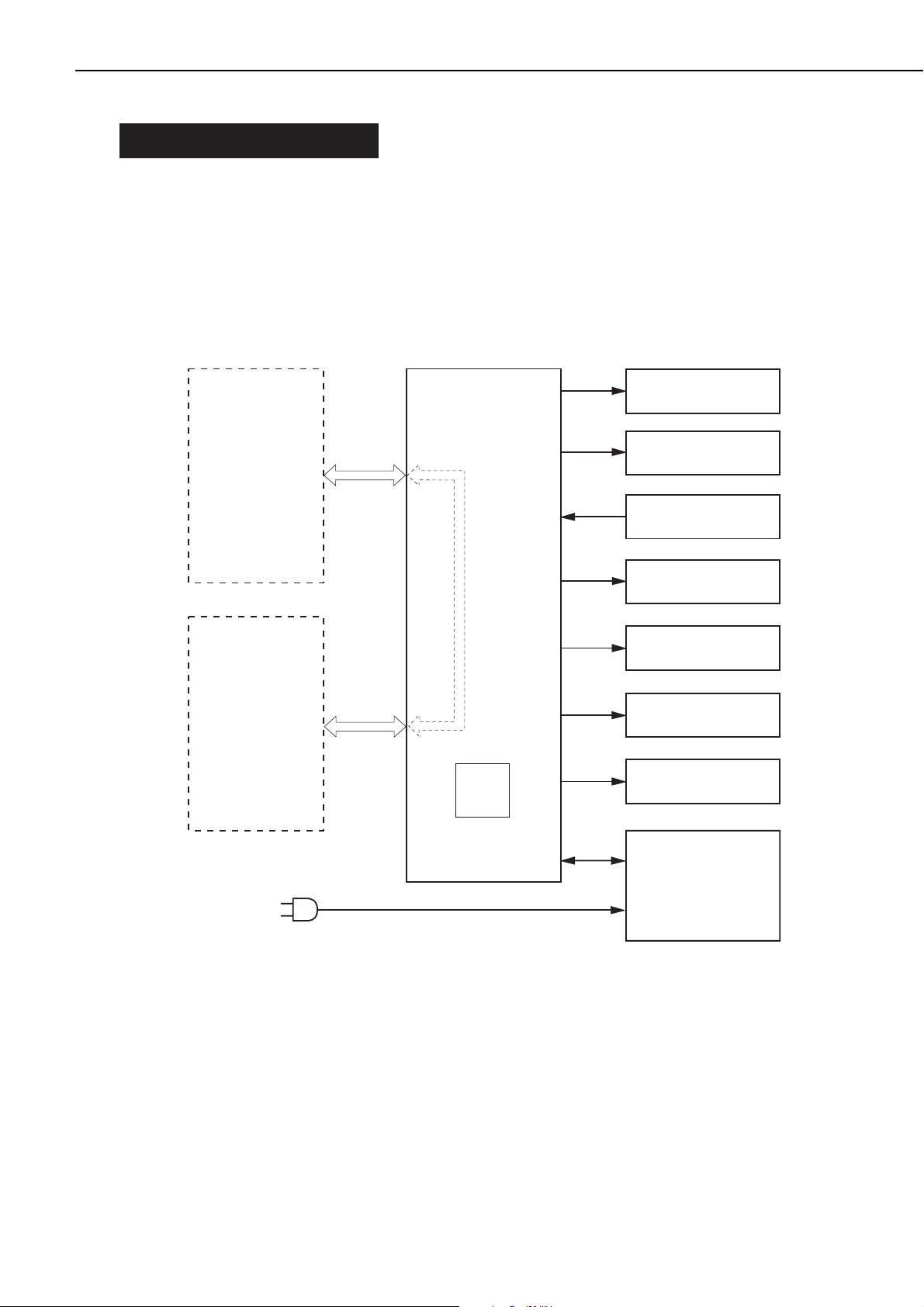

I. BASIC OPERATION

A. Outline

The paper deck feeds print paper to the printer.

The sequence of paper deck operations is controlled by the paper deck driver PCB. This PCB

contains an eight-bit microcomputer (IC201) to control the sequence of operations and serial

communication with the option controller PCB.

The paper deck driver drives the solenoids and motors according to various commands

coming from the option controller through the serial communication line. The paper deck

driver sends sensor and switch data to the option controller through the serial communication

line.

Figure 2-1-1

2 - 1

CHAPTER 2

Option

controller PCB

Optional driver

PCBs

Paper deck driver

PCB

IC 201

Registration clutch

Pick-up solenoid

Sensor / switch

Pick-up motor

Paper deck drive motor

Paper feed motor

Status LED PCB

Power supply

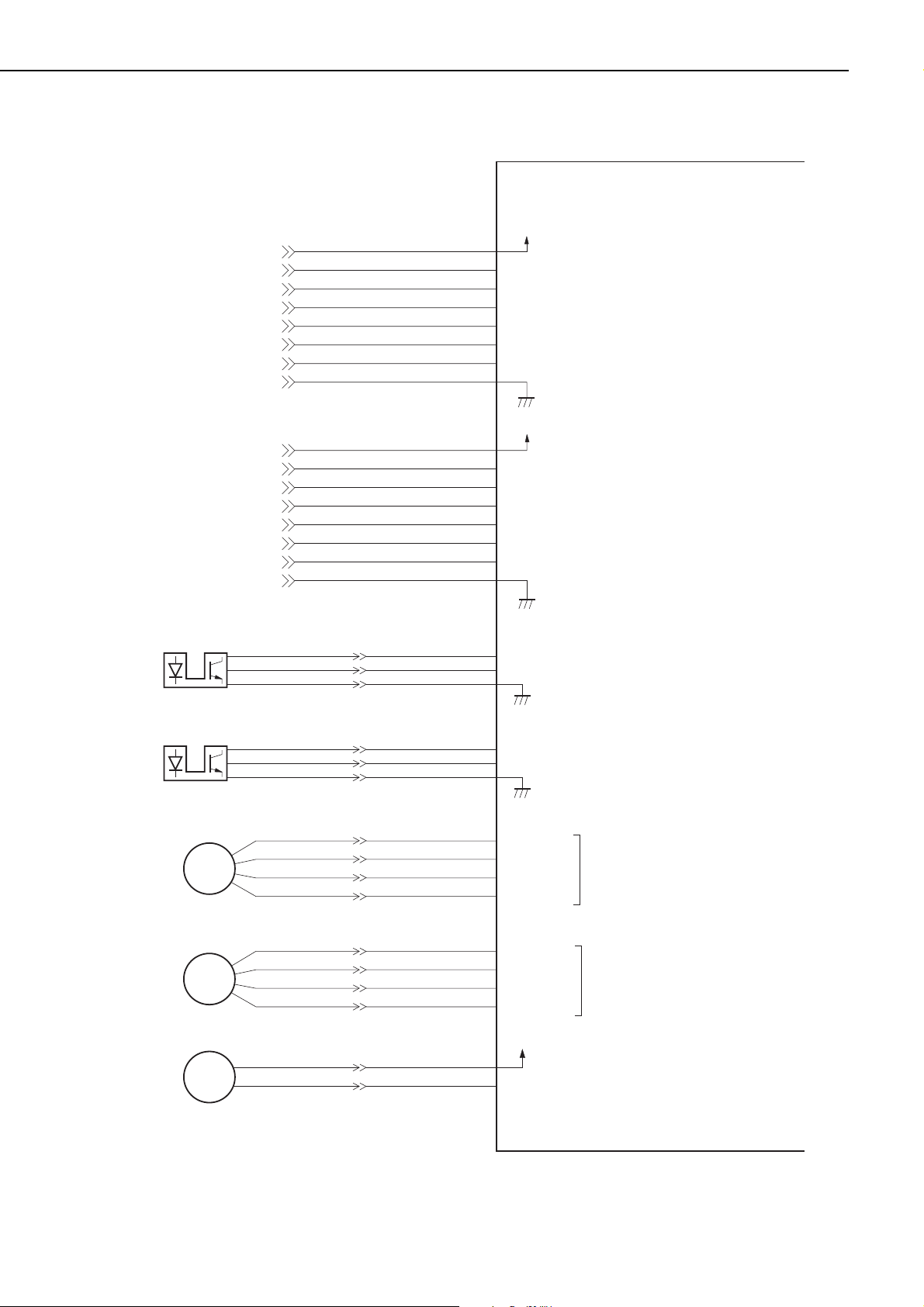

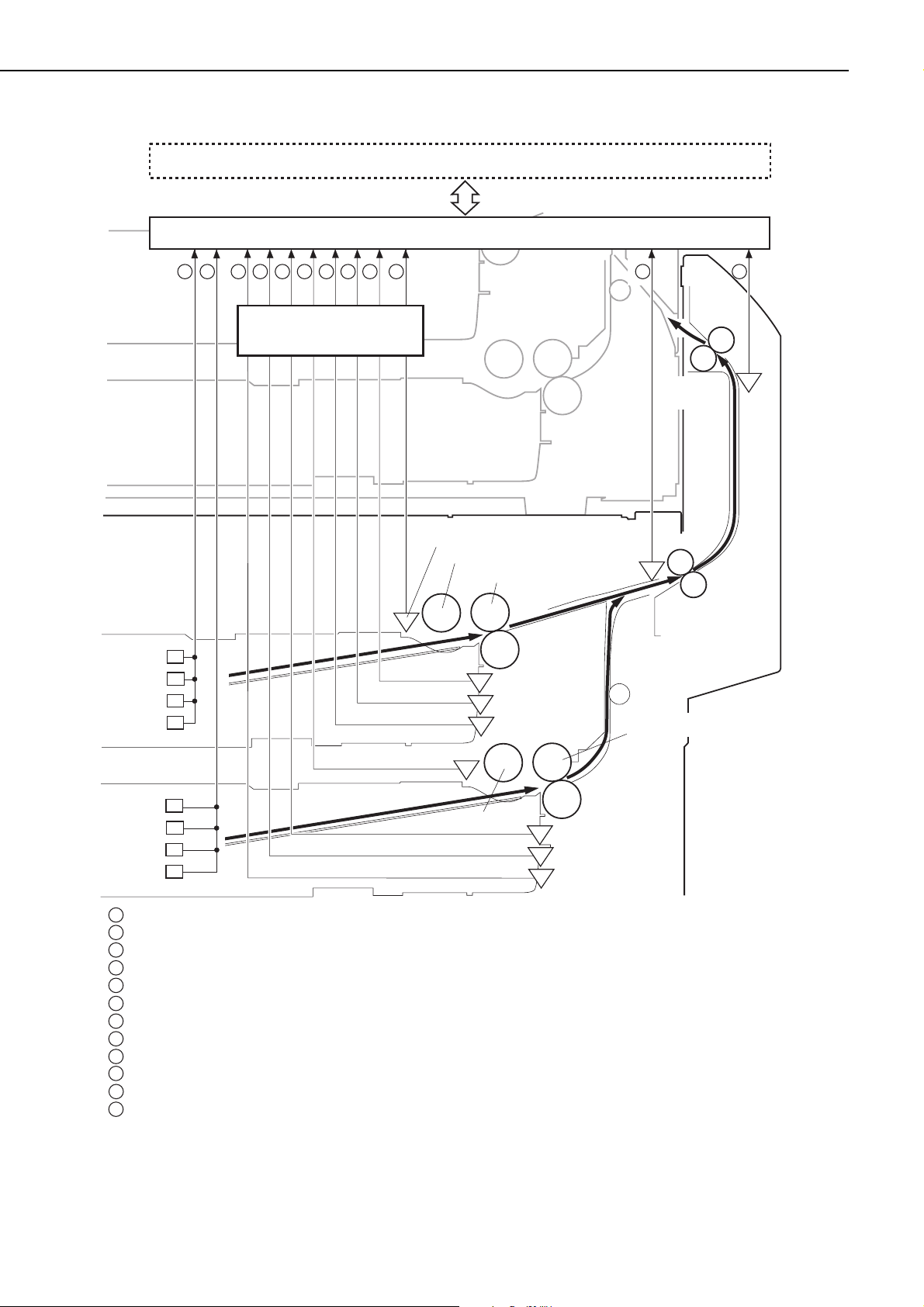

B. Input/Output of Paper Deck Driver PCB

Figure 2-1-2

2 - 2

CHAPTER 2

Paper deck Driver PCB

To option controller

To optional driver PCBs

Registration

paper sensor

PS1

J308-3

-1

-2

J305-4

-6

-5

J201-5/-10/-15

-2/-7/-8/-9/-11/-14

J202-5/-10/-15

-2/-7/-8/-9/-11/-14

J209-3

J207-4

-1

-2

-1

-3

-4

-6

-12

-13

-1

-3

-4

-6

-12

-13

-6

-5

+24V

TXI

RXO

CONTO

CKI

STRBI

PWRON-IN

+24V

TXO

RXI

CONTI

CKO

STRBO

PWRON-OUT

P5VB1

/REGS

SERIAL IN signal

SERIAL OUT signal

Communication ready signal

Serial clock signal

Strobe signal

Power on signal

SERIAL OUT signal

SERIAL IN signal

Communication ready signal

Serial clock signal

Strobe signal

Power on signal

"L" when the sensor detects paper.

Paper jam

sensor

Paper deck

drive motor

Paper feed

motor

Registration

clutch

PS2

SPM1

SPM2

CL1

J307-3

-1

-2

J305-1

-3

-2

Jxxx-1

-2

-3

-4

Jxxx-1

-2

-3

-4

J306-1

-2

J209-6

-4

-5

J301-4

-3

-2

-1

J302-4

-3

-2

-1

J210-2

-1

J207-1

-3

-2

J205-1

-2

-3

-4

J206-1

-2

-3

-4

J207-7

-8

P5VB2

/JAMS

DRVAD

DRVAND

DRVBD

DRVBND

FED1AD

FED1AND

FED1BD

FED1BND

+24V

/REGCLD

"L" when the sensor detects paper.

Paper deck drive motor

rotation control signal

Paper feed motor rotation

control signal

"L" to run the registration roller.

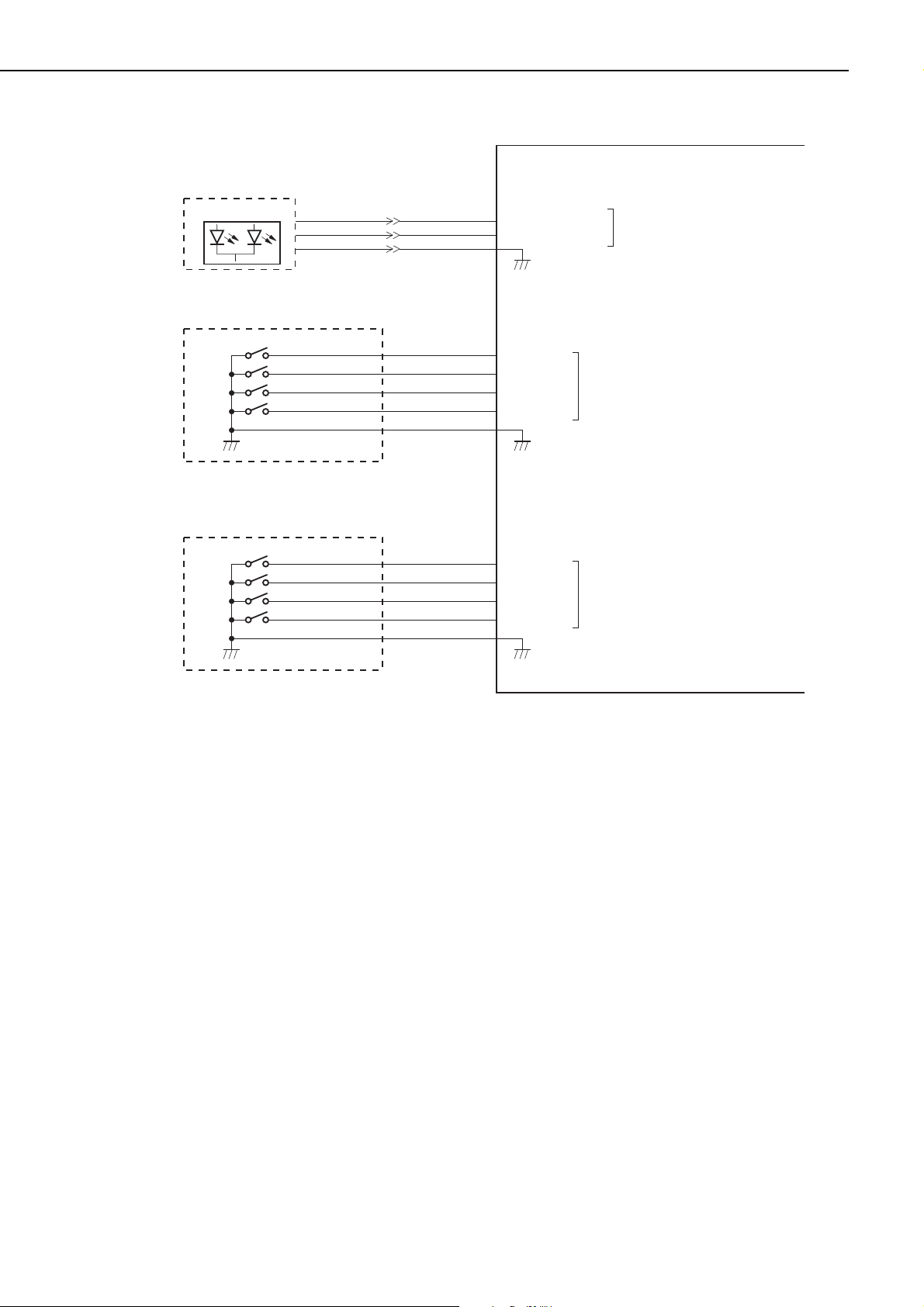

Figure 2-1-3

2 - 3

CHAPTER 2

Pick-up PCB

Paper deck driver PCB

Paper feed

unit sensor

Lower cassette

sensor

Upper cassette

sensor

Lower cassette

paper-level

sensor 1

Lower cassette

paper-level

sensor 2

Upper cassette

paper-level

sensor 1

Upper cassette

paper-level

sensor 2

Lower cassette

paper-out

sensor

Upper cassette

paper-out

sensor

PS3

J14-3

PS1201

PS1202

PS1203

PS1204

PS1205

PS1206

PS1207

PS1208

-2

-1

J1206-1

P5VBDOR

-2

GND

-3

/RDOORS

J1201-5

-12

-6

J208-18

-16

-10

-6-16

-12-10

-13-7

-14-8

-15-5

-11-9

-5-15

+5V

/RDOORS

/LDECKC

/UDECKC

LPVS2

LPVS1

UPVS2

UPVS1

/LDECKS

/UDECKS

"L" when the feed unit is open.

"L" when the sensor detects the

lower cassette.

"L" when the sensor detects the

upper cassette.

These sensors detect the amount

of paper remaining in the lower

cassette.

These sensors detect the amount

of paper remaining in the upper

cassette.

"L" when there is paper in the

lower cassette.

"L" when there is paper in the

upper cassette.

Pick-up motor

Cassette pick-up

solenoid

SPM3

SL1

J1202-1

J1203-2

-2

-3

-4

-1

J1201-20

-19

-18

-17

-4

-2

-1

-4

-3

-17

-9-11

FEDAD

FEDAND

FEDBD

FEDBND

+24V

/PUPSLD

Pick-up motor rotation control

signal

"L" to lower the arm.

Figure 2-1-4

2 - 4

CHAPTER 2

Status LED

Cassette paper-size detection switch PCB

Status LED PCB

LED1

J1-3

Paper deck driver PCB

J229-1

-2

-1

J219-3

-2

-3

J209-1

-2

-1

-2

-3

RED LED

GREEN LED

Status LED control signal

Lower cassette

paper-size

detection

switch

Cassette paper-size detection switch PCB

Upper cassett

paper-size

detection

switch

SW1601

SW1602

SW1603

SW1604

SW1601

SW1602

SW1603

SW1604

-2

-3

-4

-5

-2

-3

-4

-5

J204-10

e

J204-5

J1601B-1

J1601A-1

-9

-8

-7

-6

-4

-3

-2

-1

LSIZE1

LSIZE2

LSIZE3

LSIZE4

USIZE1

USIZE2

USIZE3

USIZE4

Detects the lower cassette

paper-size.

Detects the upper cassette

paper-size.

2 - 5

CHAPTER 2

II. PICK-UP/FEED SYSTEM

A. Outline

On receiving the pick-up command from the option controller, the paper deck driver starts

paper-pick up operation. The paper is picked up by the pick-up roller and fed into the feed

unit by the feed roller 1 and the separation roller. The paper stops after its skew is corrected

by the registration roller.

The paper deck driver runs the pick-up motor (SPM3). The pick-up roller, feed roller 1, and

separation roller are rotated by the rotational force of the pick-up motor.

At the same time, the paper deck driver runs the paper deck drive motor (SPM1) and turns

ON the pick-up solenoid (SL1). As a result, the pick-up roller is lowered to the paper level, and

the paper is sent to the feed unit by the rotating pick-up roller.

The paper sent to the feed unit is stopped when it reaches the registration roller after

passing through the registration paper sensor (PS1). On receiving the feed command, the

paper deck driver rotates the pick-up motor (SPM3) and the feed motor (SPM2). At the same

time, it turns ON the registration clutch (CL1). As a result, the feed roller 1, registration roller,

and feed roller 2 are rotated, and the paper is fed into the printer.

There are two photointerrupters (PS1 and PS2) in the paper path to detect arrival or passing

of the paper.

If the paper does not reach or pass each sensor within the specified period of time, the paper

deck driver assesses a paper jam, stops operation, and notifies the option controller of the jam.

Figure 2-2-1

2 - 6

CHAPTER 2

21

3 4 5 6 7 8

Pick-up PCB

Option controller PCB

Paper deck driver PCB

9

Serial line

11

1210

Feed

roller 2

PS2

PS1208

SW1601

SW1602

SW1603

SW1604

PS1207

SW1601

SW1602

SW1603

SW1604

: UPPER CASSETTE PAPER-SIZEDETECTION signal

1

: LOWER CASSETTE PAPER-SIZEDETECTION signal

2

: LOWER CASSETTE PAPER-LEVELDETECTION signal 1 (LPVS1)

3

: LOWER CASSETTE PAPER-LEVELDETECTION signal 2 (LPVS2)

4

: LOWER CASSETTE DETECTION signal (/LDECKC)

5

: LOWER CASSETTE PAPER-OUTDETECTION signal (/LDECKS)

6

: UPPER CASSETTE PAPER-LEVELDETECTION signal 1 (UPVS1)

7

: UPPER CASSETTE PAPER-LEVELDETECTION signal 2 (UPVS2)

8

: UPPER CASSETTE DETECTION signal (/UDECKC)

9

: UPPER CASSETTE PAPER-OUTDETECTION signal (/UDECKS)

10

: REGISTRATION PAPER DETECTION signal (/REGS)

11

: PAPER JAM DETECTION signal (/JAMS)

12

Pick-up roller

Feed roller 1

PS1202

PS1205

PS1206

Pick-up roller

PS1: Registration paper sensor

PS2: Paper jam sensor

PS1201: Lower cassette sensor

PS1202: Upper cassette sensor

PS1203: Lower cassette paper-level sensor 1

PS1204: Lower cassette paper-level sensor 2

PS1205: Upper cassette paper-level sensor 1

PS1206: Upper cassette paper-level sensor 2

PS1207: Lower cassette paper-out sensor

PS1208: Upper cassette paper-out sensor

SW1601: Cassette paper-size detection switch

SW1602: Cassette paper-size detection switch

SW1603: Cassette paper-size detection switch

SW1604: Cassette paper-size detection switch

PS1

Registration

roller

Separation

roller

Feed roller 1

Separation

roller

PS1201

PS1203

PS1204

Figure 2-2-2

2 - 7

CHAPTER 2

PAPERDECK DRIVE MOTOR

DRIVE signals

(/PUSLD)

PICK-UP MOTOR

PICK-UP SOLENOID

DRIVE signal

Pick-up PCB

Option controller PCB

Paper deck driver PCB

DRIVE signal

PAPERFEED MOTOR

DRIVE signals

Serial line

REGISTRATIONCLUTCH

DRIVE signal (REGICL)

Feed roller 2

SPM1

SL1

Upper cassette

SPM2

Rotation

SPM3

Lower cassette

Reverse rotation

Pick-up roller

Lifter

Pick-up roller

Registration

roller

CL1

Feed roller 1

P

Separation

roller

Feed roller 1

Separation roller

Lifter

Paper feed

unit

SPM1: Paper deck drive motor

SPM2: Paper feed motor

SPM3: Pick-up motor

SL1: Pick-up solenoid

CL1: Registration clutch

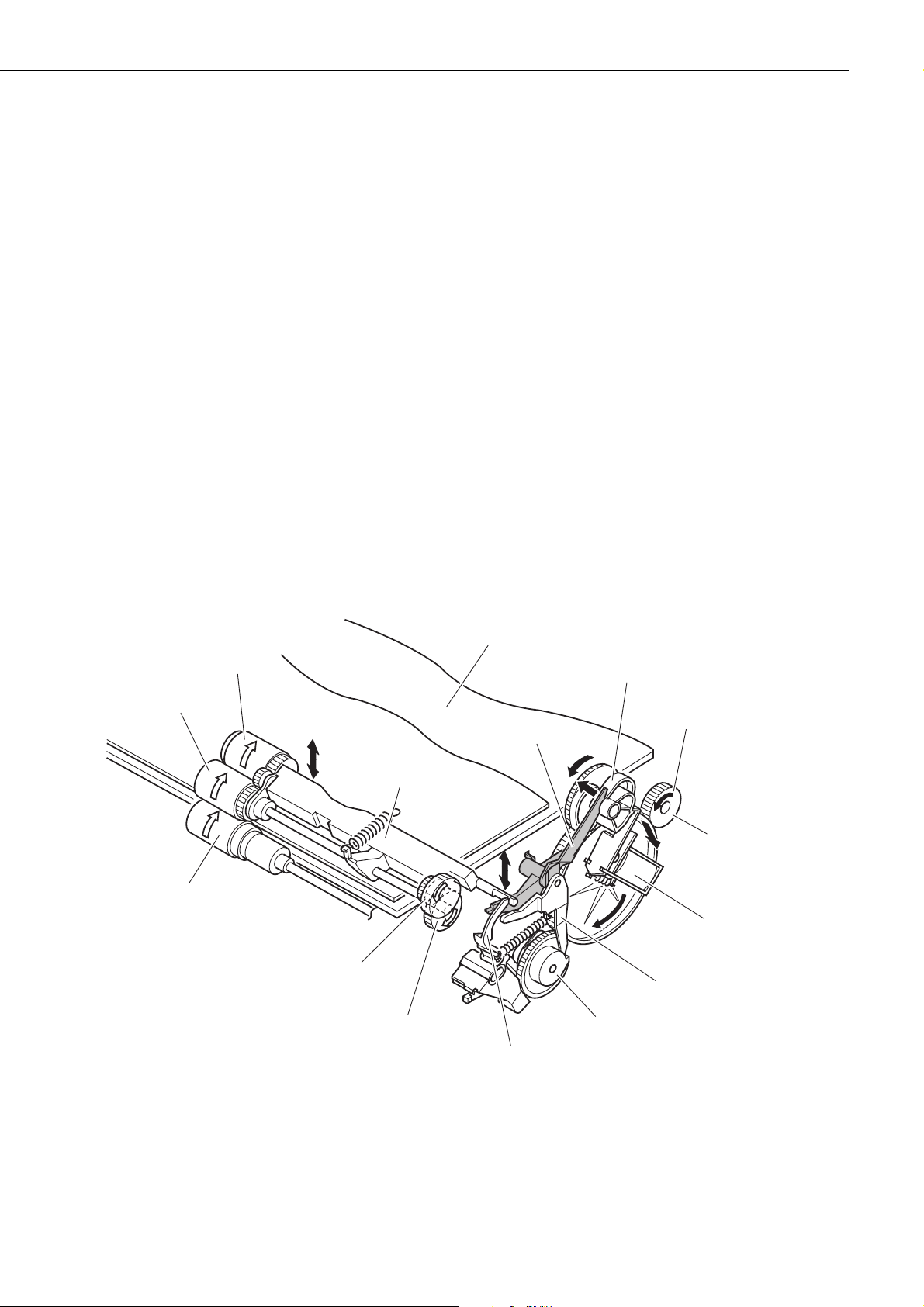

B. Paper pick-up

1. Pick-up operation

This paper deck conducts paper pick-up operation by lifting the paper to the paper pick-up

position with the lifter and lowering the rotating cassette pick-up roller to the paper level.

Paper pick-up operation is conducted only when the paper deck driver receives the pick-up

command from the option controller. The pick-up roller is lowered to the paper level by the

rotational force of the paper deck drive motor (SPM1). At the same time, the pick-up roller is

rotated by the rotational force of the pick-up motor.

Paper pick-up operation is conducted as follows.

On receiving the pick-up command from the option controller, the paper deck driver runs

the paper deck drive motor (SPM1) and the pick-up motor (SPM3). When the cassette pick-up

solenoid (SL1) is turned ON, the paper deck drive motor rotates the cassette pick-up cam via

the gear to drive the shaft drive arm.

At the same time, the rotational force of the pick-up motor is transmitted to the cassette

pick-up roller via the feed roller gear. As a result, the rotating cassette pick-up roller goes

down to the paper level, picks up a sheet of paper, goes up to the paper pick-up standby

position, and stops rotation.

When the pick-up motor rotates clockwise, the paper is picked up from the upper cassette

by rotating the cassette pick-up roller, feed roller 1 and separation roller of the upper cassette.

When the pick-up motor rotates counterclockwise, the paper is picked up from the lower

cassette by driving the cassette pick-up roller, feed roller 1 and separation roller of the lower

cassette.

Figure 2-2-3

2 - 8

CHAPTER 2

Pick-up roller

Feed roller 1

Separation roller

Print paper

Pick-up roller shaft

Pick-up motor drive

Feed roller gear

Paper lifting plate

Cassette pick-up cam

Paper deck

motor drive

Shaft drive arm

Gear

Cassettte pick-up

solenoid

Lift-up release arm

Lift-up cam

Pick-up roller shaft fixing arm

Figure 2-2-4

2 - 9

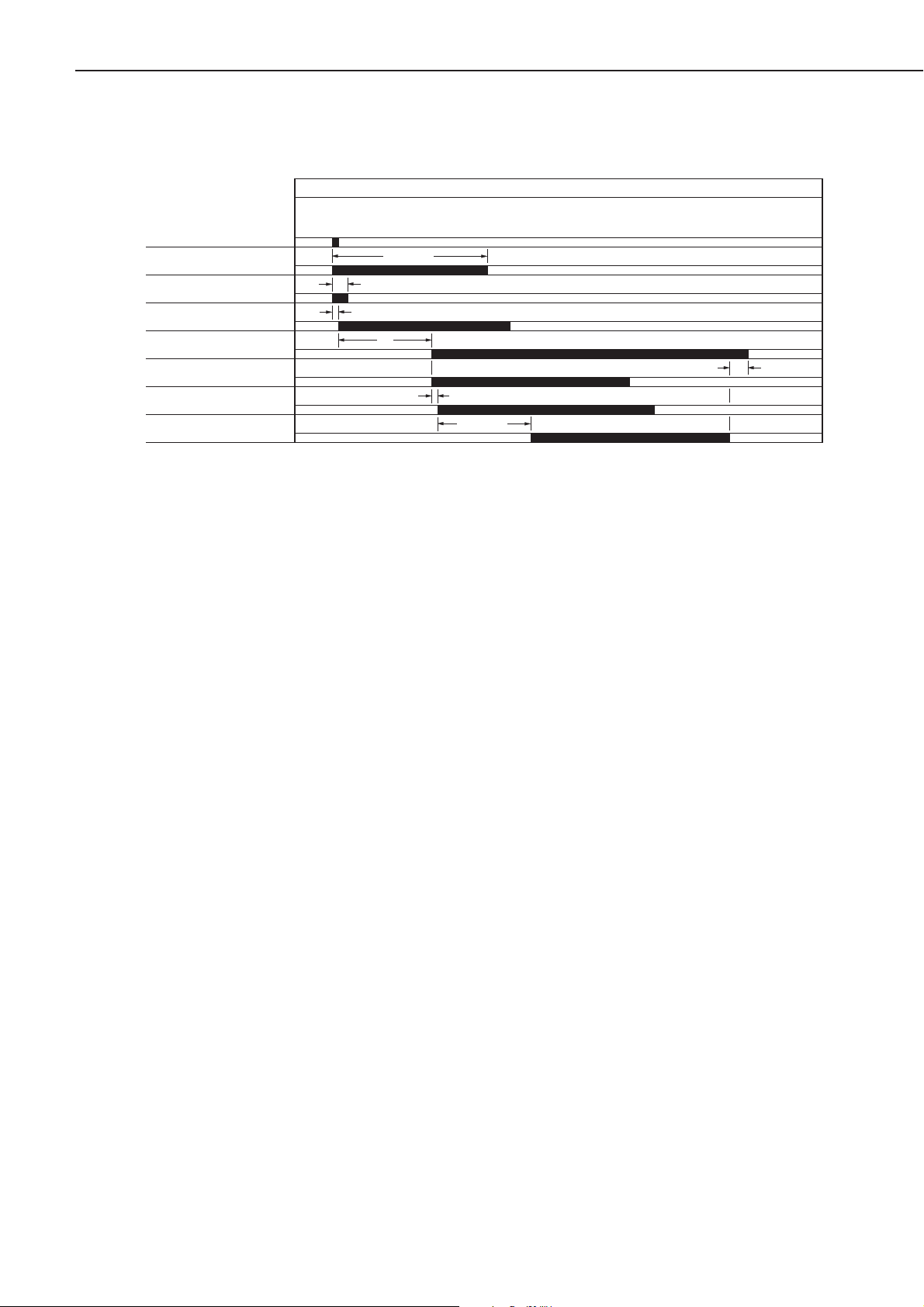

CHAPTER 2

Pick-up command

Drive motor (SPM1)

Pick-up solenoid (SL1)

Pick-up motor (SPM3)

Paper feed motor (SPM2)

Registration sensor (PS1)

Registration clutch (CL1)

Paper jam sensor (PS2)

T=Upper cassette pick-up : 0.8

T=Lower cassette pick-up : 1.1

(Unit: Seconds)

PRINT

about 1.0

0.3

0.1

T

about 0.4

about 0.1

about 0.8

a. Cassette detection/cassette paper size detection/cassette paper level detection

The upper and lower cassettes detection is executed by the upper cassette sensor (PS1202) and

the lower cassette sensor (PS1201). The paper detection in the upper and lower cassettes is

executed by the upper cassette paper out sensor (PS1208) and the lower cassette paper out

sensor (PS1207). The paper size detection is executed by the upper and lower cassette paper

size detection switches (SW1601 to SW1604) installed to each cassette. Each cassette has the

four switches. The combinations of the cassette paper size detection switches are shown in

Table 2-2-1.

Table 2-2-1

The remaining paper level in the cassette is detected according to the lifter position. The lifter

contains a light blocking plate which blocks two sensors on the pick-up PCB. The lifter

position is detected by these sensors. And, as a result, the remaining paper level in the

cassette is detected.

The remaining paper level in the upper cassette is detected by the combination of outputs

from the upper cassette paper level sensor 1 (PS1205) and the upper cassette paper level

sensor 2 (PS1206). The paper level in the lower cassette is detected by the combination of

outputs from the lower cassette paper level sensor 1 (1203) and the lower cassette paper level

sensor 2 (PS1204). Figure 2-2-5 shows the combinations of PS1205/PS1203 and

PS1206/PS1204.

2 - 10

CHAPTER 2

Cassette paper size detection switches

Paper size

Ledger

A3

B4

Legal

Letter

A4

Executive

SW1601

OFF

OFF

ON

ON

OFF

OFF

OFF

SW1602

OFF

ON

OFF

ON

OFF

OFF

ON

SW1603

OFF

OFF

OFF

OFF

OFF

ON

ON

SW1604

OFF

OFF

OFF

OFF

ON

OFF

OFF

Figure 2-2-5

2 - 11

CHAPTER 2

Pick-up unit

Pick-up PCB

Paper level Paper amount (Note)

Light blocking

plate

PS1204/PS1206

PS1203/PS1205

1

2

3

4

Note: In case of plain paper (75g/m

Full

About 430 sheets or more

High

Middle

Low empty

recommended paper)

1

2

3

About 210 - 490

About 60 -270

About 120 or less

2

Lifter

4

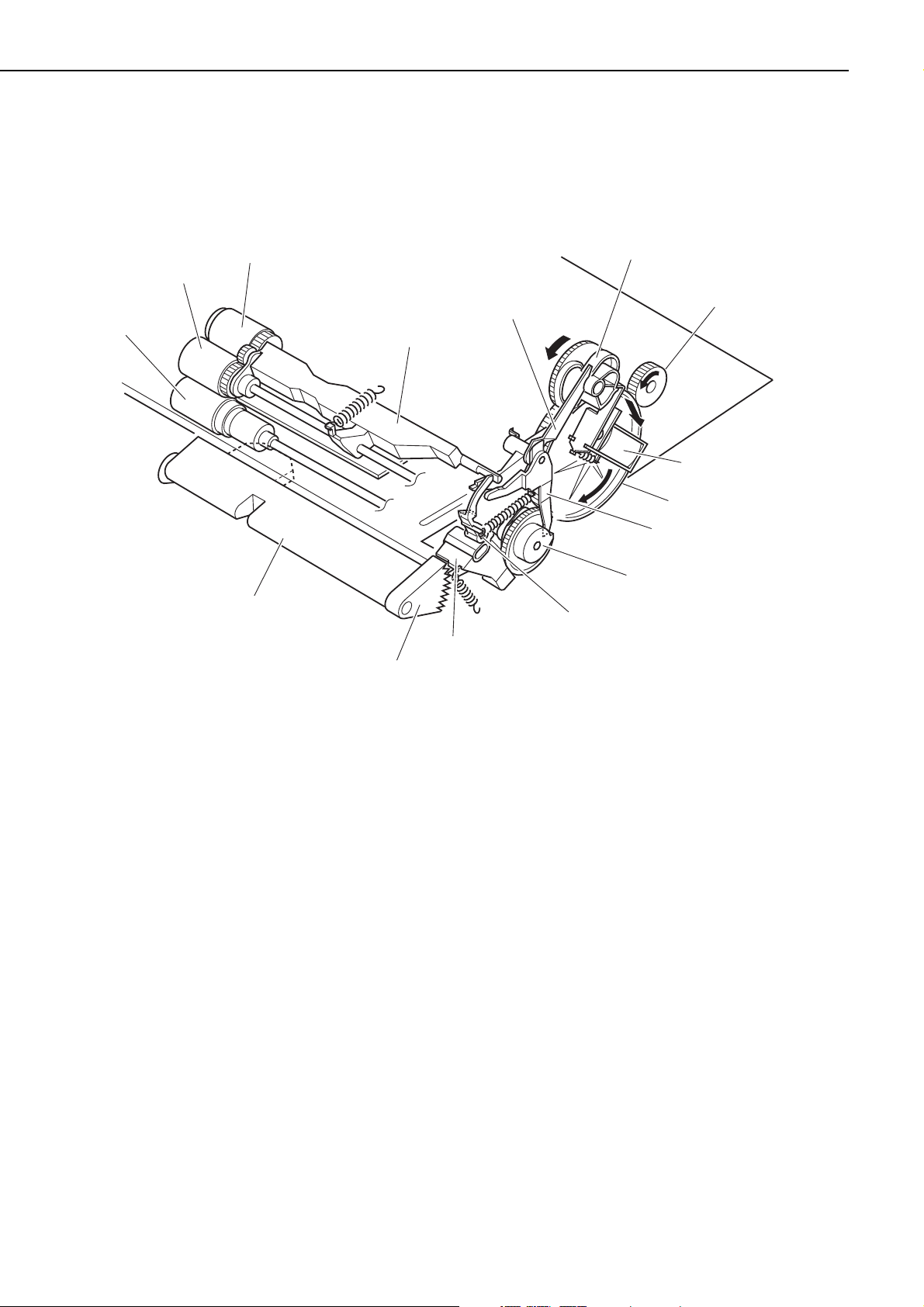

b. Lift-up operation

The lift-up operation is executed by the paper deck drive motor when a cassette is installed or

the pick-up roller shaft is set lower than certain level due to the paper reduce.

The two cases for the lift-up operation are as follows.

Figure 2-2-6

2 - 12

CHAPTER 2

Feed roller 1

Separation

roller

Pick-up roller

Lifter

Pick-up roller shaft

Lift-up arm

Lifter gear

Shaft drive arm

Pick-up roller shaft fixing arm

Cassette pick-up cam

Paper deck drive

motor drive

Cassette

pick-up solenoid

Gear

Lift-up release arm

Lift-up cam

1) Cassette is installed

➀ When a cassette is installed, the paper deck drive motor rotates, and the cassette paper

pick-up solenoid (SL3) is turned ON. Then, the shaft drive arm is driven by the cassette

paper pick-up cam rotation through the gear.

Figure 2-2-7

2 - 13

CHAPTER 2

Cassette pick-up cam

Shaft drive arm

Paper deck drive motor drive

Pick-up roller shaft

Pick-up roller shaft fixing arm

Lifter gear

Cassette pick-up solenoid

Lift-up cam

Loading...

Loading...